Page 1

Service Manual

Car Audio

COMPACT DISC CHANGER

MODEL:AKD-80C

DAEWOO ELECTRONICS CO., LTD

Page 2

DAEWOO

CONTENTS

- 1 -

GENERAL SPECIFICATIONS......................................................2

GENERAL....................................................................................3

DISASSEMBLY............................................................................7

DIAGRAMS...................................................................................................10

PARTS LIST.................................................................................................26

1.IDENTIFICATION OF PARTS...........................................................................3

2.INSTALLATION PARTS AND SUPPLIED MOUNTING HARDWARE...........3~4

3.INSTALLATION METHOD (HOW TO INSTALL THE UNIT)...............................5

4.INSTALLATION METHOD (HOW TO INSTALL THE VEHICLE)........................6

5.PREPARATIONS............................................................................................6

1.DISASSEMBLY..............................................................................................7

2.PICK-UP/MECHANISM/MAGAZINE ASSEMBLY...............................................8

3.IDENTIFICATION OF MAGAZINE.....................................................................9

1.SCHEMATIC DIAGRAM.................................................................................10

2.ELECTRICAL SPECIFICATION........................................................................11

3.MICOM PIN CONFIGURATION & DESCRIPTIONS.................................12~14

4.IC BLOCK DIAGRAM & TERMINAL VOLTAGE........................................15~23

5.PRINTED CIRCUIT BOARDS...................................................................24~25

ELECTRICAL PARTS LIST.....................................................................26~27

Page 3

GENERAL SPECIFICATIONS

DAEWOO

Compact Disc Digital Audio System

Material : GAAIAS

Wavelength : 780nm

Emission Duration : Continuous

Laser Output Power : Less Than 44.6uW

5-20,000Hz + 1dB

Below Measurable Limit

90dB

Line Output (For changer Connector Only)

800mA (CD Play Back)

800mA (During Loading or Ejection a Disc)

-10oC to 55oC (14oF to 131oF)

Appro x 245 x 85 x174mm (W x H x D)

Not lncl. Projection Parts and Control

Approx. 2.3kg

12V DC Car Battery

(Negative Ground)

Disc Magazine (1)

Mounting Hardware(1Set)

Connecting Cable (1)

System

Laser Diode Properties

Frequency Response

Wow and Flutter

Signal-To Noise Ratio

Outputs

Current Drain

Operating Temperature

Dimensions

Weight

Power Requirement

Supplied Accessories

- 2 -

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK OR BASE UNIT

1. The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the

potential difference generated by the charged electrostatic load, etc. on clothing and the human

body.

2. During repair, pay attention to electrostatic breakdown and also use the procedure in the printed

matter which is included in the repair parts.

3. The flexible board is easily damaged and should be handled with care.

CAUTION :

USE OF CONTROLS, ADJUSTMENTS, OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE SPECIFIED

HEREIN, MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

THE COMPACT DISC PLAYER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE EXCEPT PROPERLY

QUALIFIED SERVICE PERSONNEL.

Page 4

GENERAL

DAEWOO

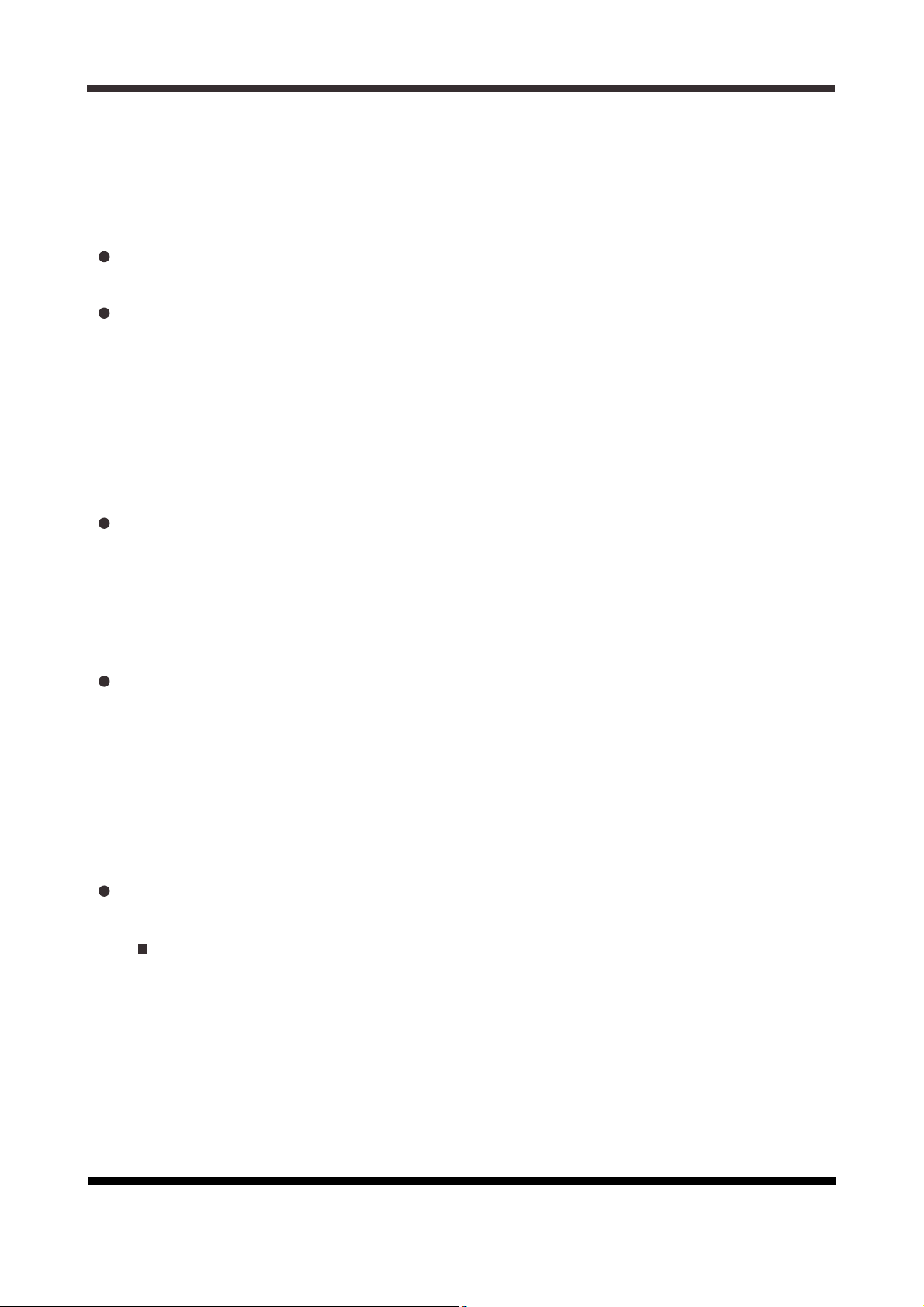

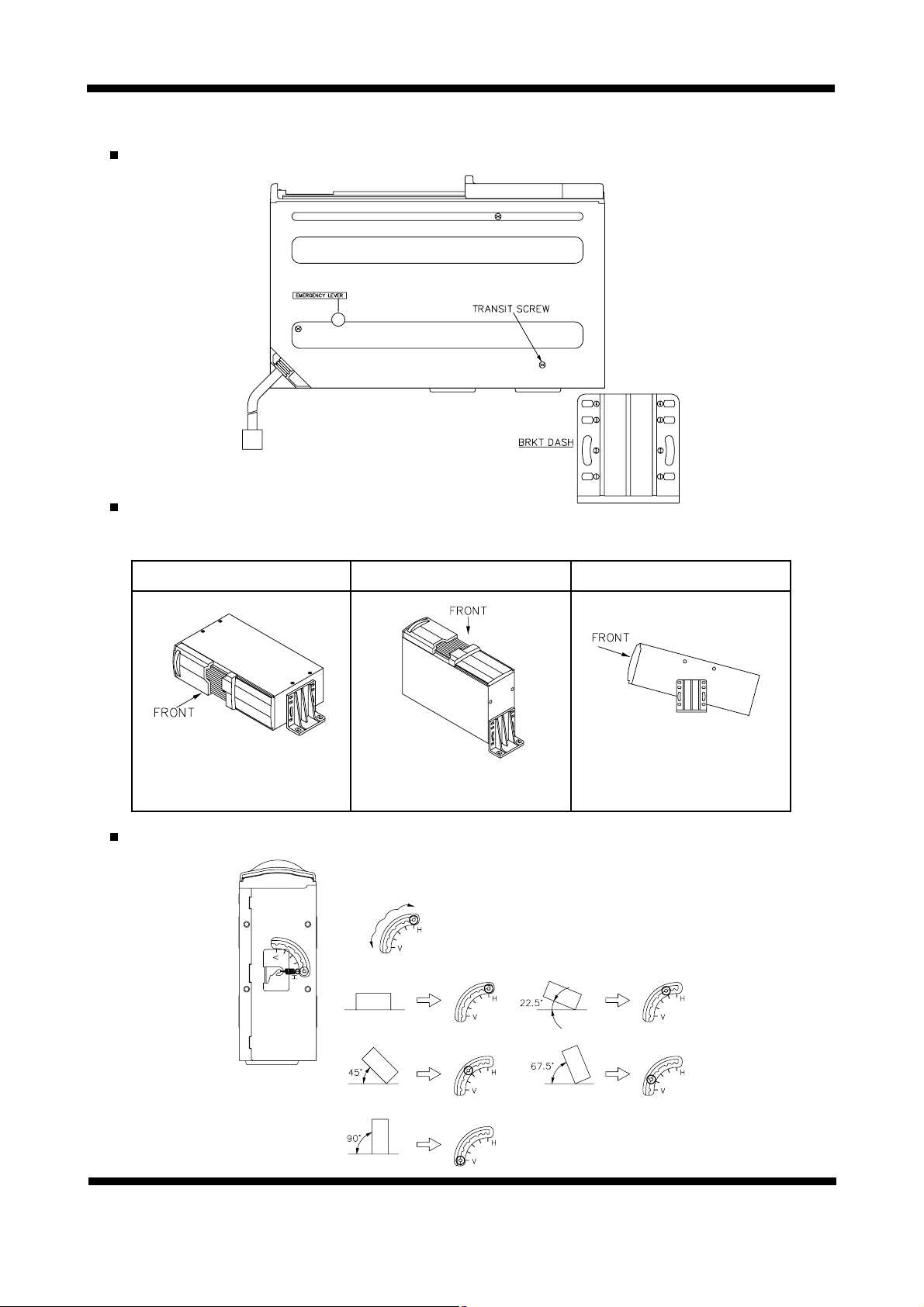

1.IDENTIFICATION OF PARTS

2. INSTALLATION PARTS AND SUPPLIED MOUNTING HARDWARE

- 3 -

Page 5

DAEWOO

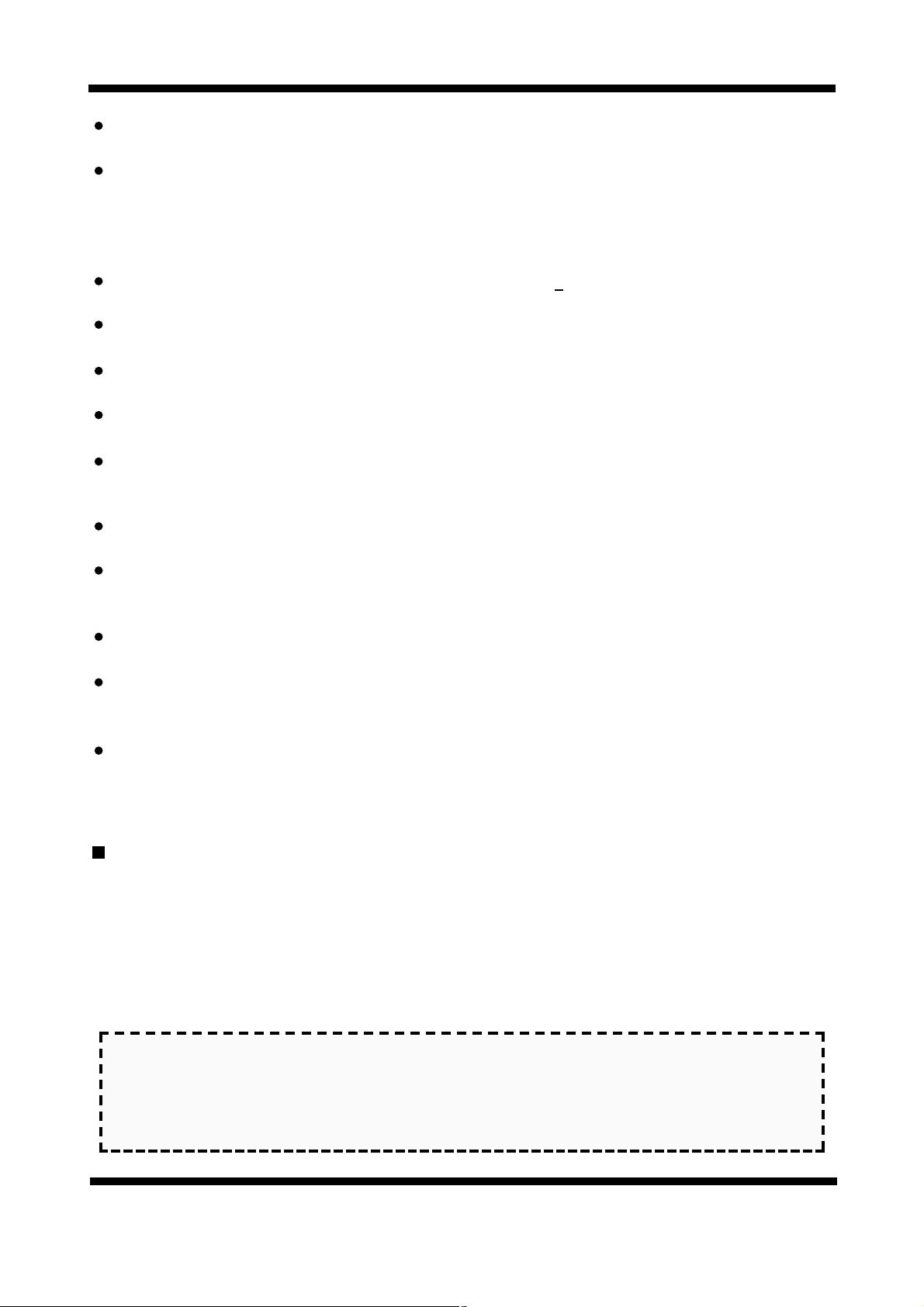

HORIZONTAL POSITION INSTALLATION (WITH BRACKET STUD)

VERTICAL POSITION INSTALLATION

(WITH BRACKET STUD)

HORIZONTAL POSITION INSTALLATION

(WITHOUT BRACKET STUD)

SUSPENDED POSITION INSTALLATION

(WITH BRACKET STUD)

VERTICAL POSITION INSTALLATION

(WITHOUT BRACKET STUD)

- 4 -

Use the wing nut to hold in place the

installation bracket with bolt(M6 x 25) to the

installation bracket, which is attached to the

unit. Then affix the cushion rubber.

Holes with the “H” marks are to be used for

horizontal or suspending and “V” for vertical

installation.

1.

Only the provided screws and brackets should be used during installation. Using

screws other than those specified will cause damage.

2. Before installation, check that there is no harness at the back when making a hole

on the dashboard.

Dangerous Installation

Page 6

DAEWOO

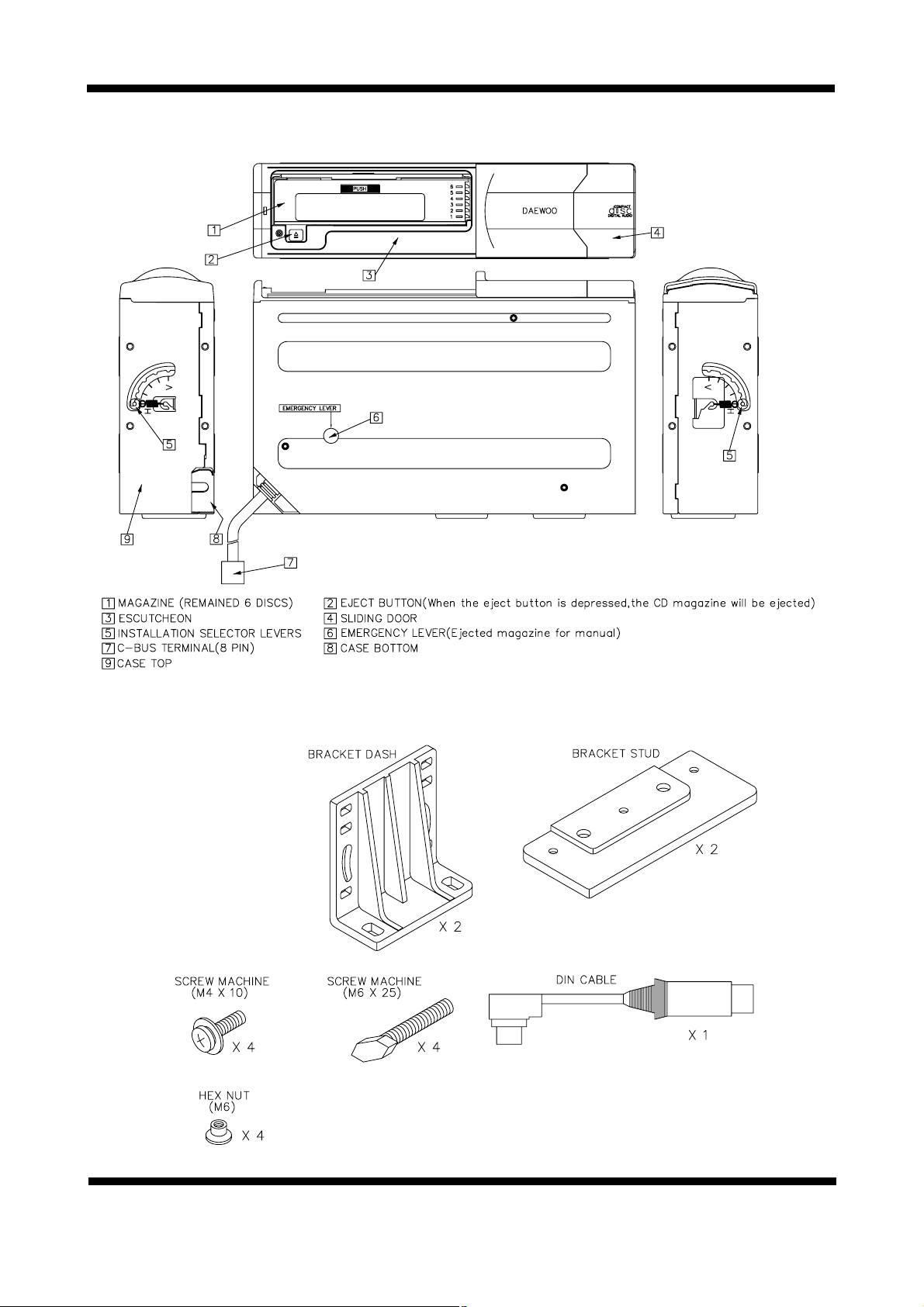

3. INSTALLATION METHOD

(HOW TO INSTALL THE UNIT)

- 5 -

REMOVE TRANSIT SCREW 3 EACH BEFORE INSTALLATION

PART BRACKET DASH(L TYPE) ADHERE TO THE UNIT

After Setting the installation selector levers both sides(left, right)

SETTING THE INSTALLATION SELECTOR LEVERS ADJUST FOR UNIT (PRIOR TO INSTALL)

HORIZONTAL VERTICAL DECLINING

After Select Mark Hole(1), (2), (3)

The unit fasten by the screw(M4 x 10)

After Select Mark Hole (4)

The unit fasten by the screw(M4 x10)

After Select Mark Hole (2)

The unit fasten by the screw(M4 x 10)

Page 7

DAEWOO

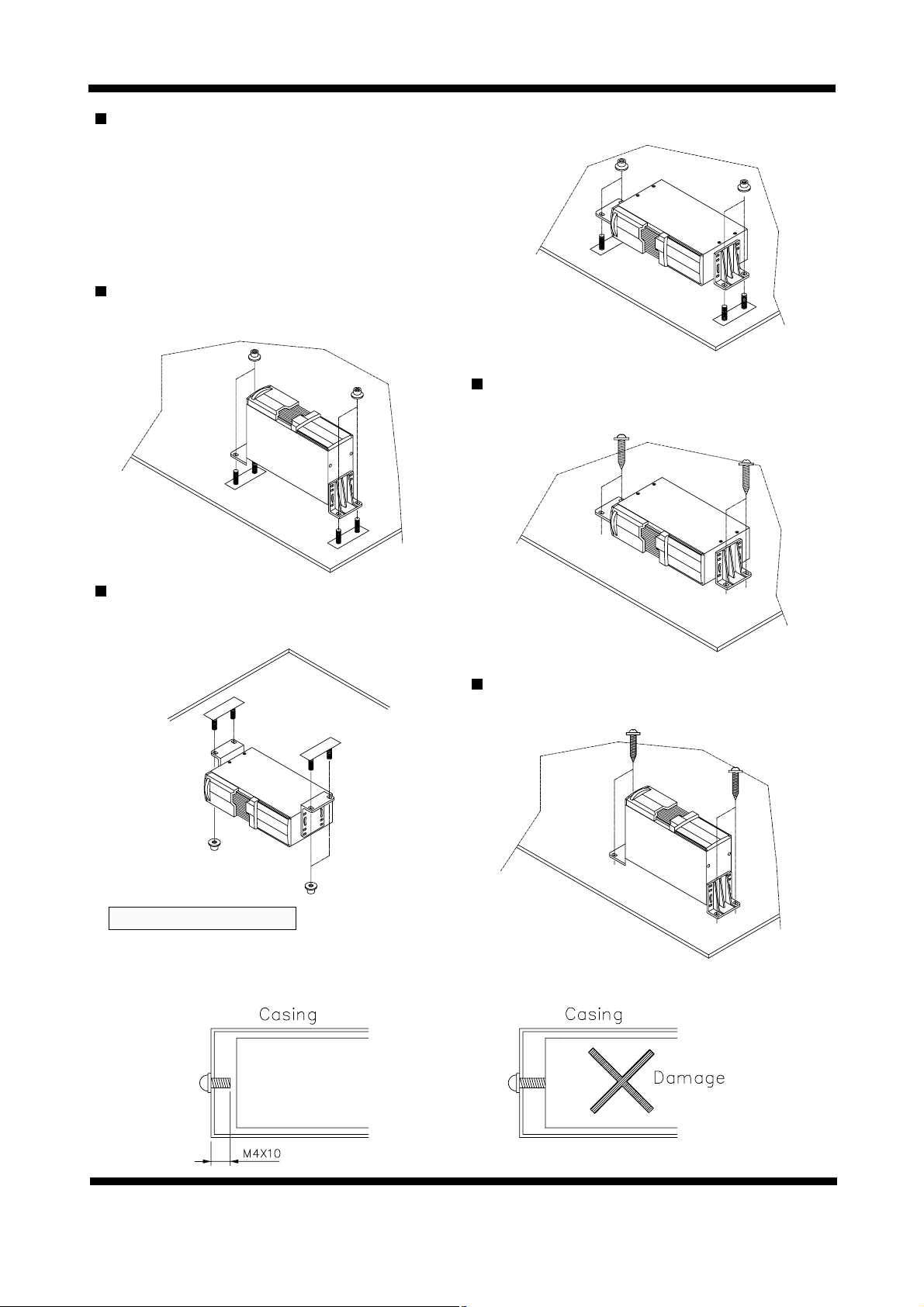

4.INSTALLATION METHOD

(HOW TO INSTALL THE VEHICLE)

5.PREPARATIONS

- 6 -

Should be determined before the unit install under

carpet.

Adjust the installation bracket with bolts to suit the place

of installation.

1.Remove the floor carpet and decide on the place to

install.

2.Remove the separator of the cushion rubber that is

attached to the installation bracket with bolt and install

accordingly.

3.Align the unit with the bolts and secure it with the wing

nuts.

1.USAGE OF MAGAZINE (To load the discs)

Load the discs with the labels facing upwards, as

shown in the diagram.

2.TO LOAD THE MAGAZINE

Slide the sliding door to the right until it is completely

latched on.

Load the magazine in the direction as shown in the

diagram. push it in until is locked into the unit.

After the magazine has been loaded, close the sliding

door.

(If not close sliding door, Dirt or dust entering it will

cause damage)

3.TO REMOVE THE MAGAZINE

Open the sliding door and depress the eject button.

Remove the magazine when it has been ejected.

Close the sliding door.

Notes on handling the optical pick-up block or base unit

1.The laser diode in the optical pick-up block may suffer

electrostatic breakdown because of the potential

difference generated by the charged electrostatic

load,etc. on clothing and the human body.

2.During repair, pay attention to electrostatic breakdown

and also use the procedure in the printed matter which

is included in the repair parts.

3.The flexible board is easily damaged and should be

handled with care.

CAUTION:

USE OF CONTROLS, ADJUSTMENTS, OR PERFORMANCE OF PROCEDURES OTHER THAN

THOSE SPECIFIED HEREIN, MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

THE COMPACT DISC PLAYER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE

EXCEPT PROPERLY QUALIFIED SERVICE PERSONNEL.

Page 8

DISASSEMBLY

DAEWOO

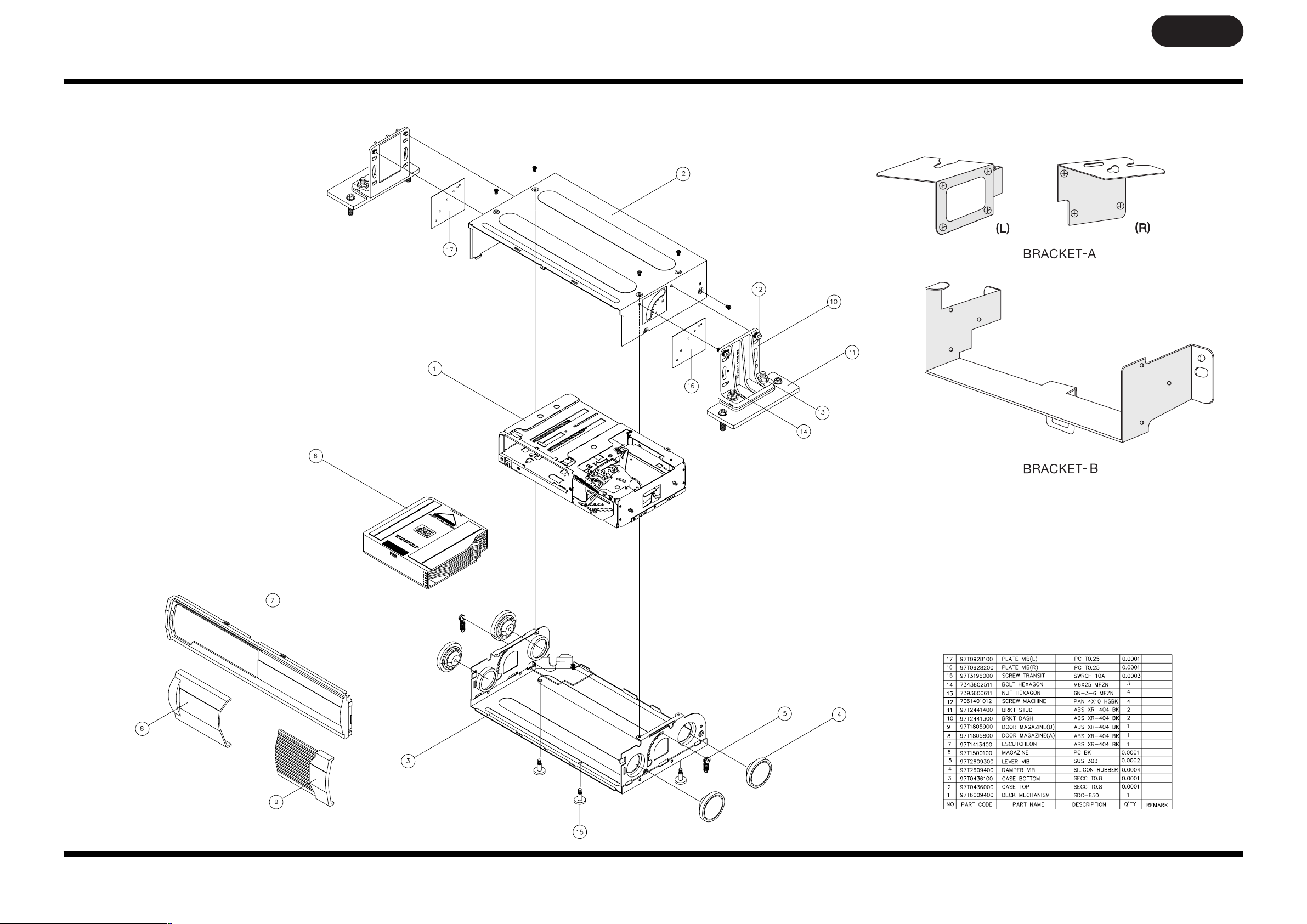

1. DISASSEMBLY

- 7 -

Size:A3

Page 9

DAEWOO

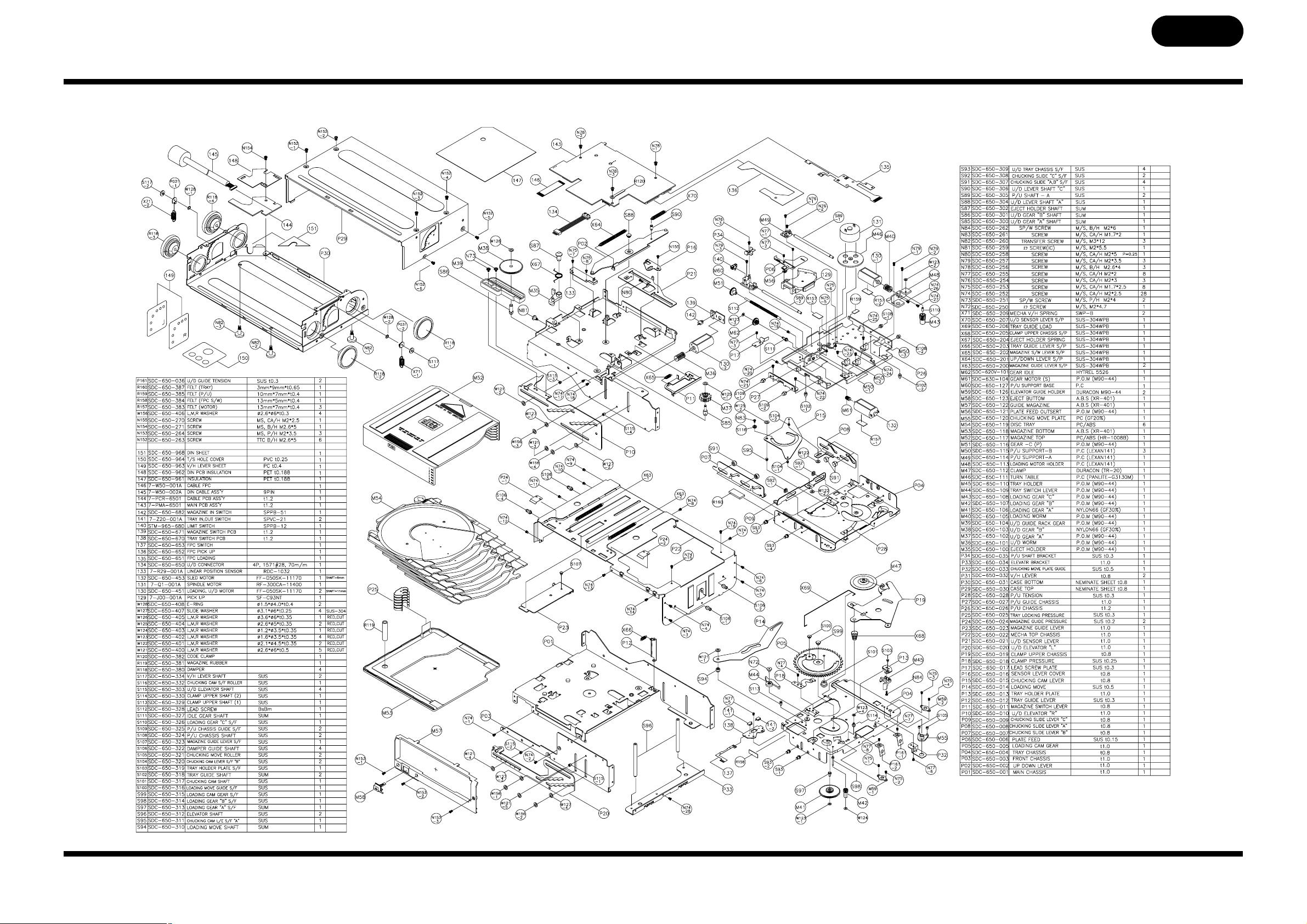

2. PICK-UP/MECHANISM/MAGAZINE ASSEMBLY

- 8 -

Size:A3

Page 10

DAEWOO

3. IDENTIFICATION OF MAGAZINE

- 9 -

Page 11

DIAGRAMS

DAEWOO

1. SCHEMATIC DIAGRAM

- 10 -

Size:A3

Page 12

DIAGRAMS

DAEWOO

2.ELECTRICAL SPECIFICATION

TEST DISC : SONY YEDS 18 TYPE 4 OR TCD-784

PLAY ABILITY TEST (25oC)

- 11 -

NO

ITEM

TEST

CONDITION

UNIT NOMINAL LIMIT 1 2 REMARK

1

2

3

4

5

6

7

8

20Hz

100Hz

dB

dB

dB

dB

dB

dB

V

mA

%

10KHz

20KHz

1KHz

-2.6

0.01

4dB

2dB

2dB

3dB

80dB

75dB

3dB

3dB

70dB

60dB

0.8 0.1

<5mA

0.3%

JIS A

FILTER

JIS A

FILTER

JIS A

FILTER

JIS A

FILTER

JIS A

FILTER

-0.3

-1.3

90

90

0.07

20dB

20dB

86

76

2.7

FREQUENCY RESPONSE

S/N RATIO

DYNAMIC RANGE

T.H.D

DE-EMPHASIS

CHANNEL SEPARATION

OUTPUT LEVEL (V)

BACK UP CURRENT(mA)

5KHz

16KHz

1KHz

10KHz

1KHz

L

R

L

R

ITEM

FINGER PRINTS

ECCENTRICITY DISC

VERTICAL DEVIATION DISC

SCRATCH DISC

INTERRUPTION DISC

TEST CONDITION

BLACK DOT

A-BEX TCD-721R

A-BEX TCD-725A

A-BEX TCD-725A

A-BEX TCD-725A

A-BEX TCD-713

A-BEX TCD-731R

LIMIT

600uM

700uM

600uM

65uM

210uM

1000uM

< +

< +

< +

< +

<

>

>

> +

> +

+

+

+

Page 13

3. MICOM PIN CONFIGURATION & DESCRIPTIONS

DAEWOO

PIN CONFIGURATIONS (LC865016B-XXXX)

- 12 -

Page 14

DAEWOO

PIN DESCRIPTION

- 13 -

PIN

No

FUNCTION

D-GND

DATA

DATA

EJECT

D-GND

D-GND

TEST

ACC

STBY

D-GND

D-GND

TEST

SL +

OPTION

SLED MOTOR Control Pulse

SLED MOTOR Control Pulse

1

2

3

4

5

6

7

8

9

10

11

12

13

PIN

NAME

P70

P71

P72

P73

P30

P31

P32

P33

P34

P35

P36

P37

P40

I/O

I/O

I

I

I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

SL -

14

P41

I/O

D-GND15

P42

I/O

PLAY MODE (L)

S-MUTE16

P43

I/O

A-MUTE17

P44

I/O

POWC18

P45

I/O

D-GND19

P46

I/O

D-GND20

P47

I/O

SUBQ DATA SYNC DETECTOR

FSEQ21

P50

I/O

FOCUS OK SIGNAL IN

DRF22

P51

I/O

VSS POWER PIN(-)

23

VSS

VDD/VPP POWER

PIN(+)

24

VDD/

VPP

IN SW

25

P20

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

PULL UP (22K)

PULL UP (22K)

PULL UP (22K)

PULL UP (22K)

PULL UP (47K)

PULL UP (47K)

PULL UP (47K)

LOAD SW

26

P21

HOME SW

27

P22

M SW

28

P23

P24

29

P24

DOK

30

P25

DISK P

31

P26

LOAD P

32

P27

Page 15

DAEWOO

- 14 -

PIN DESCRIPTION

PIN

No

FUNCTION

SK

COIN

SQOUT

CQCK

RWC

WRQ

TEST

DO

XT1

XT2

VSS POWER PIN (-)

OPTION

41

42

43

44

45

46

47

48

49

50

51

52

PIN

NAME

P11

P12

P13

P14

P15

P16

P17

TEST1

XT1/

P74

XT2

VSS

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

O

RES REST PINRES

I

I

O

CF1

53

CF1

I

CF2

54

CF2

O

CONNECT TO VS1(VDD)

VDD POWER PIN (+)

55

VDD

PULL-UP (10K)

56

P80

AD INPUT PORT

AD INPUT PORT

AD INPUT PORT

AD INPUT PORT

AD INPUT PORT

AD INPUT PORT

AD INPUT PORT

AD INPUT PORT

57

P81

58

P82

59

P83

60

P84

61

P85

62

P86

63

64

P87

I

I

I

I

I

I

I

I

PULL UP (10K)

I/O

DI

P10

I/O

LOAD

33

P00

I/O

E-UP

34

P01

I/O

E-DN

UNLOAD

35

P02

I/O

D-GND

36

P04

I/O

D-GND

37

P05

I/O

XRST

38

P06

I/O

CS

39

P07

40

Page 16

4. IC BLOCK DIAGRAM & TERMINAL VOLTAGE

DAEWOO

IC 101(LA9240M) -RF+ASSP+AUDIO FILTER

- 15 -

1. PIN CONFIGURATION

2. BLOCK DIAGRAM

Page 17

3. TERMINAL VOLTAGE & DESCRIPTION

DAEWOO

- 16 -

PIN

No

Pickup photodiode connection pin. Added to FIN1 pin to generate the RF signal, subtracted

from FIN1 pin to generate the FE signal.

1

FIN2

Pickup photodiode connection pin.2 FIN1

SYMBOL

CONTENTS

Pickup photodiode connection pin. Subtracted from F pin to generate the TE signal.3E

Pickup photodiode connection pin.4F

TE signal DC component input pin.5TB

Pin which connects the TE signal gain setting resistor between this pin and TE pin.6 TE

-

TE signal output pin.7TE

TES(Track Error Sense) comparator input pin. The TE signal is input through a band pass filter.

8 TESI

Shock detection input pin.9 SCI

Tracking gain time constant setting pin.10 TH

TA amplifier output pin.11 TA

Pin for configuring the tracking phase compensation constant between the TD and VR pins.

12 TD

-

Tracking phase compensation setting pin.13 TD

Tracking jump signal (kick pulse) amplitude setting pin.14 JP

Tracking control signal output pin.15 TO

Focusing control signal output pin.16 FD

Pin for configuring the focusing phase compensation constant between the FD and FA pin.

Pin for configuring the focusing phase compensation constant between the FD

-

and FA-pin.

Pin for configuring the focusing phase compensation constant between the FA and FE pin.

17 FD

-

18 FA

19 FA

-

FE signal output pin.20 FE

Pin which connects the FE signal gain setting resistor between this pin and FE pin.21 FE

-

Analog signal GND.22 AGND

CV+ and CV -pins input signal single-end output.23 SP

Spindle amplifier input.24 SPI

12-cm spindle mode gain setting resistor connection pin.25 SPG

Spindle phase compensation constant connection pin, along with the SPD pin.26 SP

Spindle control signal output pin.27 SPD

Sled phase compensation constant connection pin.28 SLEQ

Sled control signal output pin.29 SLD

Input pin for sled movement signal from microprocessor.30 SL

-

Input pin for sled movement signal from microprocessor.SL

+

31

Input pin for tracking jump signal from DSP.32 JP

Input pin for tracking jump signal from DSP.JP

+

33

Input pin for tracking gain control signal from DSP. Gain is low when TGL is high.

Input pin for tracking off control signal from DSP. Tracking servo is off when TOFF is high.

34 TGL

35 TOFF

Output pin for TES signal to DSP.36 TES

The High Frequency Level is used to determine whether the main beam is positioned over a

bit or over the mirrored surface.

37 HFL

Sled servo off control input pin.38 SLOF

Input pin for CLV error signal from DSP.

Input pin for CLV error signal from DSP.

39

CV

-

40

CV

+

Page 18

DAEWOO

- 17 -

PIN

No

RF output pin.

41

RFSM

RF gain setting and EFM signal 3T compensation constant setting pin, along with the RFSM pin.

42

RFS

-

Slice Level Control is an output pin that controls the data slice level used by the DSP for the

RF wave form.

43 SLC

SYMBOL

CONTENTS

Input pin used by DSP for controlling the data slice level.44 SLI

Digital system GND pin.45 DGND

Focus search smoothing capacitor output pin.46 FSC

Tracking balance control, EF balance adjustment variable range setting pin.47 TBC

No connection

48 NC

Disc defect detection output pin.49 DEF

Reference clock input pin. 4.23 MHz signal from the DSP is input.50 CLK

Microprocessor command clock input pin.51 CL

Microprocessor command data input pin.52 DAT

Microprocessor command chip enable input pin.53 CE

RF level detection output (Detect RF)54 DRF

Focus search select; focus search mode (+search/+search vs. the reference voltage)

switching pin

55 FSS

Servo system and digital system VCCpin.

By-pass capacitor connection pin for reference voltage.

Reference voltage output pin.

56 VCC2

VCC1

57

REFI

58 VR

Disc defect detection time constant setting pin.59 LF2

RF signal peak hold capacitor connection pin.

RF signal bottom hold capacitor connection pin.

60 PH1

61 BH1

APC circuit output pin.

APC circuit input pin.

62 LDD

63 LDS

RF system V

CC

pin.64

Page 19

DAEWOO

- 18 -

IC 501 (LB 1836) - 2CH. Bidirectional Motor Driver IC

1. PIN CONFIGURATION

2. BLOCK DIAGRAM

Page 20

DAEWOO

IC 201(LC 78626) - DSP for CDP

- 19 -

1. PIN CONFIGURATION

2. BLOCK DIAGRAM

Page 21

DAEWOO

3. TERMINAL VOLTAGE & DESCRIPTION

- 20 -

Defect detection signal(DEF)input. When not used,must be connected to 0V

For the PLL

Test input.Equipped with internal pull-down resistor.Must be connected to 0V

External VCO control phase comparator output

Internal VCO ground.Must be connected 0V

PDO output current adjustment resistor connection

Internal VCO power supply

VCO frequency range adjustment

Digital system ground. Must be connected to 0V

Test operation mode control input.Must be connected to VDD.

Test operation mode control input.Must be connected to VDD.

Test operation mode control input.Must be connected to VDD.

Test operation mode control input.Must be connected to VDD.

Test operation mode control input.Must be connected to VDD.

Test input.Equipped with internal pull-down resistor.Must be connected to 0V

Chip select input.Equipped with internal pull-down resistor.

When not controlled,must be connected to 0V

Test input. Must be connected to 0V

For slice

level control

EFM signal output

EFM signal input

Test input.Equipped with internal pull-down resistor.Must be connected to 0v

Disk motor control output.Can have a 3-state output depending on the

command

Rough servo/phase control automatic switching monitor output.If a high level then

rough servo mode.If a low level then phase control mode.

Track detect signal input.Schmidt input.

Tracking error signal input.Schmidt input.

Tracking off output.

Tracking gain switch output.Gain is increased with low level

Track jump control output.Can be 3-state output depending on the command.

EFM data playback clock monitor. 4.3218 MHz during phase lock.

Sync signal detect output.A high level when the sync signal detected from the EFM

signal matches the internally generated sync signal.

Digital system power supply.

Reset signal input for initializing only the anti-shock control part.(i.e. excluding the

DSP part.)Resets when this pin is low level,and release the reset when this pin is

high level.Tie this pin to the low level.(i.e.connected to 0V)if when using software

control on the anti-shock part alone through the anti-shock part only reset

disable/release command($f4) or the anti-shock only reset enable/inrush

command($f5).

Note:This pin is assigned as the least significant bit of the general I/O port however,

use as a general I/O pin is disabled.When the port I/O set command($DB) is

executed.The least significant bit is always “0”,and the output driver is not turned

ON.

1

2

3

4

5

6

7

8

9

10

11

12

13

I

O

P

AI

P

AI

P

I

I

I

I

I

I

I

I

O

I

I

O

O

O

I

I

O

O

O

O

O

O

P

I(I/O)

DEFI

TAI

PDO

VV

ss

ISET

VV

DD

FR

V

ss

TESCLK

TESA

TESB

TESC

TESGB

TEST5

CS

TEST1

EFMO

EFMI

TEST2

CLV

+

CLV

-

V/P

HFL

TES

TOFF

TGL

JP

+

JP

-

PCK

FSEQ

V

DD

ASRES

14

15

16

17

18

19

20

21

22

23

24

26

28

29

30

31

32

25

27

PIN

No

PIN

NAME

I/O FUNCTION

I

Page 22

DAEWOO

- 21 -

General I/O pin 2.This controls the commands from the microcontroller.When not

used,either set this as an input port and connect to 0V, or set this as an output port

and leave it open.

I/O

CONT2

33

PIN

No

General I/O pin4.This controls the commands from the microcontroller.This pin is

shared exclusively with the sub code frame sync signal output(SFSY).When not

used,either set this as an input port and connect to 0V,or set this as an output port

and leave it open.

General I/O pin4.This controls the commands from the microcontroller.This pin is

shared exclusively with the sub code P,Q,R,S,T,U,V,W output(PW).When not

used,either set this as an input port and connect to 0V,or set this as an output port

and leave it open.

General I/O pin3.this controls the commands from the microcontroller.This is

shared exclusively with the sub code read clock input(SBCK).When not

used,either set this as an input port and connect to 0V, or set this as an output port

and leave it open.

16.9344 MHz output

4.2336 MHz output

Digital output EIAJ format.

Test input.Equipped with internal pull-down resistor.Must be connected to 0v

G1,G2,one error, two error correction monitor output

7.35KHz sync signal output(frequency divided from the crystal oscillator)

Sub code block sync signal output

Test input.Equipped with internal pull-down resistor.Must be connected to 0v

Deemphasize monitor output.When high level, a deemphasize disc is being played back.

G2 flag output

Tracking error Test output.Under normal operation ,this should be left open.

DRAM switch:high: 1M, low:4M

Test input.Must be connected to 0V

Test input.Must be connected to 0V

L channel mute output

L channel power supply

L channel output

L channel ground.Must be connected to 0V

R channel output

R channel power supply

R channel mute output

Crystal oscillator power supply

16.9344 MHz crystal oscillator connection.

Crystal oscillator ground. Must be connected to 0V

Read/write control input.Schmidt input.

Microcontroller command input.

34

CONT3/

SBCK

I/O

35

36

37

PIN NAME I/O

I/O

I/O

O

I

O

I

O

O

O

O

O

O

O

I

I

I

O

P

AO

P

AO

P

O

P

O

I

P

I

I

FUNCTION

CONT4/

SFSY

CONT5/

PW

SBSY

TEST3

DOUT

TEST4

16M

4.2M

EFLG

FSX

EMPH

C2F

TOUT

MR1

TESE

TESD

MUTESL

LVdd

For the one-bit

D/A converter

LCHO

L/RVss

RCHO

RVdd

MUTER

XVDD

XOUT

XIN

XVSS

RWC

COIN

38

39

40

41

42

43

44

45

46

47

49

51

52

53

54

55

56

57

58

59

60

61

62

63

48

50

Page 23

DAEWOO

- 22 -

PIN

No

DRAM address bus

DRAM address bus

DRAM address bus

DRAM address bus

DRAM address bus

Remaining DRAM output

Remaining DRAM output

Remaining DRAM output

DRAM write terminated. (An RZP pulse is output when there is an overflow or a shock.))

Data contact point detection complete signal:low->high:detection complete(DRAM write start)

DRAN write enable signal input: high:write enable

Pause signal input : high :pause

C2F data contact point detection start signal : low -> high:detection start

Remaining DRAM alarm output: low : memory low

C2F shock detect pause signal input : low : pause shock detection

DRAM data bus

DRAM data bus

DRAM data bus

DRAM data bus

DRAM control signal

DRAM control signal

DRAM control signal

DRAM control signal

Digital system ground. Must be connected to 0V

DRAM address bus

DRAM address bus

DRAM address bus

DRAM address bus

DRAM address bus

Digital system power supply

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

PIN NAME I/O

O

O

O

I

I

O

O

I

I/O

I/O

I/O

I/O

O

O

O

O

O

O

O

O

O

P

O

O

O

O

O

P

FUNCTION

MMC1

MMC2

MMC3

OVF

CNTOK

WOK

PAUSE

NGJ

EMPN

SHOCK

DRAM3

DRAM2

DRAM1

DRAM0

OE

WE

CAS

RAS

AD9

AD8

AD7

AD6

AD5

Vss

AD4

AD3

AD2

AD1

AD0

Vdd

90

91

92

93

94

95

96

98

99

100

97

Sub code Q output standby output

Operating mode switch: high:shock proof, low:through

DRAM empty(an RZP pulse is output when the DRAM is empty.

External reset input: low reset(all internal blocks are reinitialized)

Remaining DRAM

O

I

O

I

O

WRQ

FMT

EMPP

RES

MMC0

66

67

68

69

70

Input pin for the command input latch clock and the sub code readout clock.Schmidt

input.

Sub code Q output

I

O

CQCK

SQOUT

64

65

Page 24

DAEWOO

IC 401 (BA6790FP) - 4CH. BTL driver for CDP

1. PIN CONFIGURATION

- 23 -

2. BLOCK DIAGRAM

PIN

No

FUNCTION

Driver channel 1 negative output

Driver channel 1 positive output

Driver channel 1 input

Driver channel 1 input,gain adjustment pin

Connect external transistor base

constant voltage output,connects to

external transistor collector

Mute control pin

Ground

Driver channel 2 input,gain adjustment pin

Driver channel 2 input

Driver channel 2 positive output

Driver channel 2 negative output

Substrate ground

Operational amplifier output

15 OP IN(-)

OP IN(+)

VO3(-)

VO3(+)

VIN3

VIN3

+

Vcc

Vcc

BIAS IN

VIN4

+

VIN4

VO4(+)

VO4(-)

GND

16

17

18

19

20

21

22

23

24

25

26

27

28

1

2

3

4

5

6

7

8

9

10

11

12

PIN

NAME

VO1(

-

)

PIN

No

FUNCTION

PIN

NAME

VO1(+)

VIN1

VIN1

+

REG-B

REG

OUT

MUTE

GND

VIN2

+

VIN2

VO2(+)

VO2(-)

GND

OP OUT

13

14

Operational amplifier input,negative

Operational

amplifier input,positive

Driver channel 3 negative output

Driver channel 3 positive output

Driver channel 3 input

Driver channel 3 gain adjustment pin

Power supply

Power supply

Bias amplifier input

Driver channel 4 gain adjustment pin

Driver channel 4 input

Driver channel 4 positive output

Driver channel 4 negative output

Substrate ground

Page 25

DAEWOO

5. PRINTED CIRCUIT BOARDS

TOP VIEW

- 24 -

Page 26

DAEWOO

BOTTOM VIEW

- 25 -

Page 27

DAEWOO

ELECTRICAL PARTS LIST

- 26 -

IC LC865016B-XXXX

IC LC78626E

IC LA9240M

TR DTC114YK

TR DTA123YK

TR DTC323TK

TR 2SB1238

TR KSD1691Y

CHARGE 0.047F/5.5V

ELEC 100/10V

ELEC 220/10V

ELEC 10/16V

ELEC 47/16V

ELEC 1000/16V

ELEC 4.7/16V

ELEC 0.22/50V

ELEC 0.33/50V

ELEC 0.47/50V

ELEC 1/50V

ELEC 2.2/50V

CHIP C5R0(2012)

CHIP C120(2012)

CHIP C100(2012)

CHIP C300(2012)

CHIP C101(2012)

CHIP C151(2012)

CHIP C331(2012)

CHIP C102(2012)

CHIP C332(2012)

IC301

IC201

IC101

IC LB1836M

IC501

IC BA6790FP

IC401

IC KIA7025F IC302

IC BA178M05FP IC701

TR 2SA1037K

Q101

Q705

TR DTC143EK

Q302, Q703

Q303, Q702

TR DTC143TK Q603

Q601, Q602

Q401, Q704

Q701

C137, C209, C308, C402

C713

C709

C206, C401, C706

C126, C127, C133, C619

C620

ELEC 22/16V C705

C119, C135, C707

C703

C125

C115

C131

C130

C301, C305

C118, C302, C613, C614

C122, C211

C121

C210

C205

C116

C110, C204

C105

C123, C136, C304, C621

C622, C623, C624, C712

C102, C106, C117

DESCRIPTION

REF - NO

DESCRIPTION

CHIP C333(2012)

CHIP C473(2012)

CHIP C104(2012)

C124

C107, C108

C101, C103, C104, C109

C111, C128, C132, C134

C201, C202, C203, C207

C208, C212, C303, C306

C307, C403, C501, C502

C618, C701, C702, C801

C625, C404

CHIP C103(2012)

CHIP C223(2012)

C113, C114, C120, C129

C138

C112, C704, C710, C711

[CAPACITOR]

DESCRIPTION REF - NO

PAST LIST

REF - NO

[I C]

DESCRIPTION

[TRANSISTOR]

Page 28

[DIODE]

[OTHERS]

[RESISTOR]

DAEWOO

- 27 -

DESCRIPTION

CHOKE TRANS EX-19/3mH

WAFER 18P

CONNECTOR 9P

CONNECTOR 4P

8P DIN PLUG(250

mm

)

PCB-MAIN / FR-4 135 x 111

mm

T=1.2

PCB-CONTROL / FR-4 50 x 39

mm

T=1.2

FFC 11P / 11P x 120mm(UL20696) CARD CABLE

REF - NO

CRYSTAL 16.9344

MHz

C-RESONATOR CST 12.0MTW XT301

XT201

L701

SWITCH EJECT (SKQNAB) SW301

JN101

WAFER 11P JN102, JN104, CON101

CON102

JN103

CHIP R=220 (2012)

CHIP R=1 (2012)

CHIP R=270 (3216)

ZENER DIODE 8.2V-C

CHIP DIODE DAN202K

RECT DIODE 1N4004A

DESCRIPTION

REF - NO

R102, R123, R124

R206

R705, R709

D301

CHIP DIODE DA204K D701

ZENER DIODE 5.6V-C ZD703

ZD702

ZENER DIODE 5.1V-B ZD701

CHIP DIODE DAP202K D303

D702, D703

DESCRIPTION

REF - NO

CHIP R=10 (2012)

CHIP R=100 (2012)

CHIP R=330 (2012)

CHIP R=220 (2012)

CHIP R=680 (2012)

CHIP R=1.8 (2012)

CHIP R=2.2 (2012)

CHIP R=3.9 (2012)

CHIP R=4.7 (2012)

CHIP R=5.6 (2012)

CHIP R=6.8 (2012)

CHIP R=8.2 (2012)

CHIP R=10 (2012)

CHIP R=12 (2012)

CHIP R=15 (2012)

CHIP R=18 (2012)

CHIP R=20 (2012)

CHIP R=22 (2012)

CHIP R=33 (2012)

CHIP R=39 (2012)

CHIP R=47 (2012)

CHIP R=56 (2012)

CHIP R=68 (2012)

CHIP R=100 (2012)

R133, R134

CHIP R=0 (2012) R117, R315

CHIP R=47 (2012) R708

R706

R107, R119, R125

R132

R201

CHIP R=1 (2012) R311, R703

CHIP R=1.2 (2012) R122

R619, R620

R110, R115, R704

R104

R105, R205

CHIP R=5.1 (2012) R202

R131

R707

R103, R404

R126, R128, R621

R116

R112, R401, R402, R405

R109, R121

R127

R106, R113, R129, R301

R304, R702

R204, R305

R111

R114, R306, R308, R309

R310, R313, 403

R118, R120, R130

R203

R101, R108, R307, R622

R623

Page 29

DAEWOO ELECTRONICS CO., LTD

99120

Loading...

Loading...