Page 1

Service Manual

OPEN

OPEN

DISCS MAGAZINE

COMPACT DISC CHANGER SYSTEM

DISC AUTO CHANGER

DISCS MAGAZINE

COMPACT DISC CHANGER SYSTEM

DISC AUTO CHANGER

AKD-100C

DIGITAL AUDIO/COMPACT DISC CHANGER

AKD-105C

DIGITAL AUDIO/COMPACT DISC CHANGER

C

O

M

P

A

C

T

D

I

S

C

C

H

A

N

G

E

R

D

I

G

I

T

A

L

A

U

D

I

O

Car Audio

COMPACT DISC CHANGER

MODEL: AKD-100C

AKD-105C

DAEWOO ELECTRONICS CO., LTD

Page 2

CONTENTS

¡ GENERAL SPECIFICA TIONS....................................................................................................2

¡ GENERAL................................................................................................................................3

1. IDENTIFICATION OF PARTS.......................................................................................................................................3

2. INSTALLATION PARTS AND SUPPLIED MOUNTING HARDWARE ...............................................................3~4

3. INSTALLATION METHOD (HOW TO INSTALL THE UNIT)....................................................................................5

4. INSTALLATION METHOD (HOW TO INSTALL THE VECHICLE)...........................................................................6

5. PREPARATIONS...........................................................................................................................................................6

¡ DISASSEMBLY........................................................................................................................7

1. DISASSEMBLY.............................................................................................................................................................7

2. PICK UP ASSEMBLY....................................................................................................................................................8

3. MAGAZINE ASSEMBLY..............................................................................................................................................9

4. MECHANISM ASSEMBLY........................................................................................................................................10

¡ DIAGRAMS............................................................................................................................11

1. ELECTRICAL SPECIFICATION ..................................................................................................................................11

2. MICOM PIN CONFIGURATION & DESCRIPTIONS.........................................................................................12~14

3. IC BLOCK DIAGRAM & TERMINAL VOLTAGE ...............................................................................................15~26

4. PRINTED WIRING BOARDS...............................................................................................................................27~28

5. SCHEMATIC DIAGRAM.............................................................................................................................................29

¡ P AR TS LIST ...........................................................................................................................30

1. EXPLODED PARTS LIST............................................................................................................................................30

2. ELECTRIC PARTS LIST........................................................................................................................................31~32

DAEWOO

1

Page 3

GENERAL SPECIFICATIONS

¡ System Compact Disc Digital Audio System

¡ Laser Diode Properties Material : GAAIAS

Wavelength : 780nm

Emission Duration : Continuous

Laser Output Power : Less Than

44.6µW

¡ Frequency Response 5-20,000Hz ± 1dB

¡ Wow and Flutter Below Measurable Limit

¡ Signal-To Noise Ratio 90dB

¡ Outputs Line Output (For Changer Connector Only)

¡ Current Drain 800mA (CD Play Back)

800mA (During Loading or Ejection a Disc)

¡ Operating Temperature -10˚C to 55˚C (14˚F to 131˚F)

¡ Dimensions Approx 245 x 85 x 174 mm (WxHxD)

Not Incl. Projection Parts and Control

¡ Weight Approx. 2.3kg

¡ Power Requirment 12V DC Car Battery

(Negative Ground)

¡ Supplied Accessories Disc Magazine (1)

Mounting Hardware(1Set)

Connecting Cable (1)

§ NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic breakdown because of the potential difference

generated by the charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic breakdown and also use the procedure in the printed matter which is

included in the repair parts.

The flexible board is easily damaged and should be handled with care.

@@@@@@@@e?

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?

@@@@@@@@e?

@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?

@@h?

@@h?

@@h?

@@h?

@@h?

@@h?

@@

@@

@@

@@

@@

@@

@@

@@

CAUTION:

@@

@@

@@

@@

@@

@@

@@

@@

USE OF CONTROLS, ADJUSTMENTS, OR PERFORMANCE OF PROCEDURES OTHER THAN THOSE

@@

@@

@@

@@

@@

@@

@@

@@

SPECIFIED HEREIN, MAY RESULT IN HAZARDOUS RADIATION EXPOSURE.

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

THE COMPACT DISC PLAYER SHOULD NOT BE ADJUSTED OR REPAIRED BY ANYONE EXCEPT PROPERLY

@@

@@

@@

@@

@@

@@

@@

@@

QUALIFIED SERVICE PERSONNEL.

@@

@@

@@

@@

@@g

@@g

@@g

@@g

@@g

@@g

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@

@@@@@@@@

?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@?e@@@@@@@@e?@@@@@@@@

@@@@@@@@

?@@@@@@@@

?@@@@@@@@

@@@@@@@@

@@@@@@@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

@@

?@@

?@@

?@@

?@@

?@@

?@@

DAEWOO

2

Page 4

GENERAL

AKD-100C

DIGITAL AUDIO/COMPACT DISC CHANGER

OPEN

1. IDENTIFICA TION OF PARTS

¥BMAGAZINE (REMAINED 10 DISCS)

⁄BEJECT BUTTON (When the eject button is

depressed, the CD magazine will be ejected)

⁄CESCUTCHEON

⁄DSLIDING DOOR

⁄EINSTALLATION SELECTOR LEVERS

⁄FDIN SOCKET

⁄GCASE TOP

⁄HCHASSIS MAIN

2. INST ALLATION PAR TS AND SUPPLIED MOUNTING HARDW ARE

DAEWOO

3

Page 5

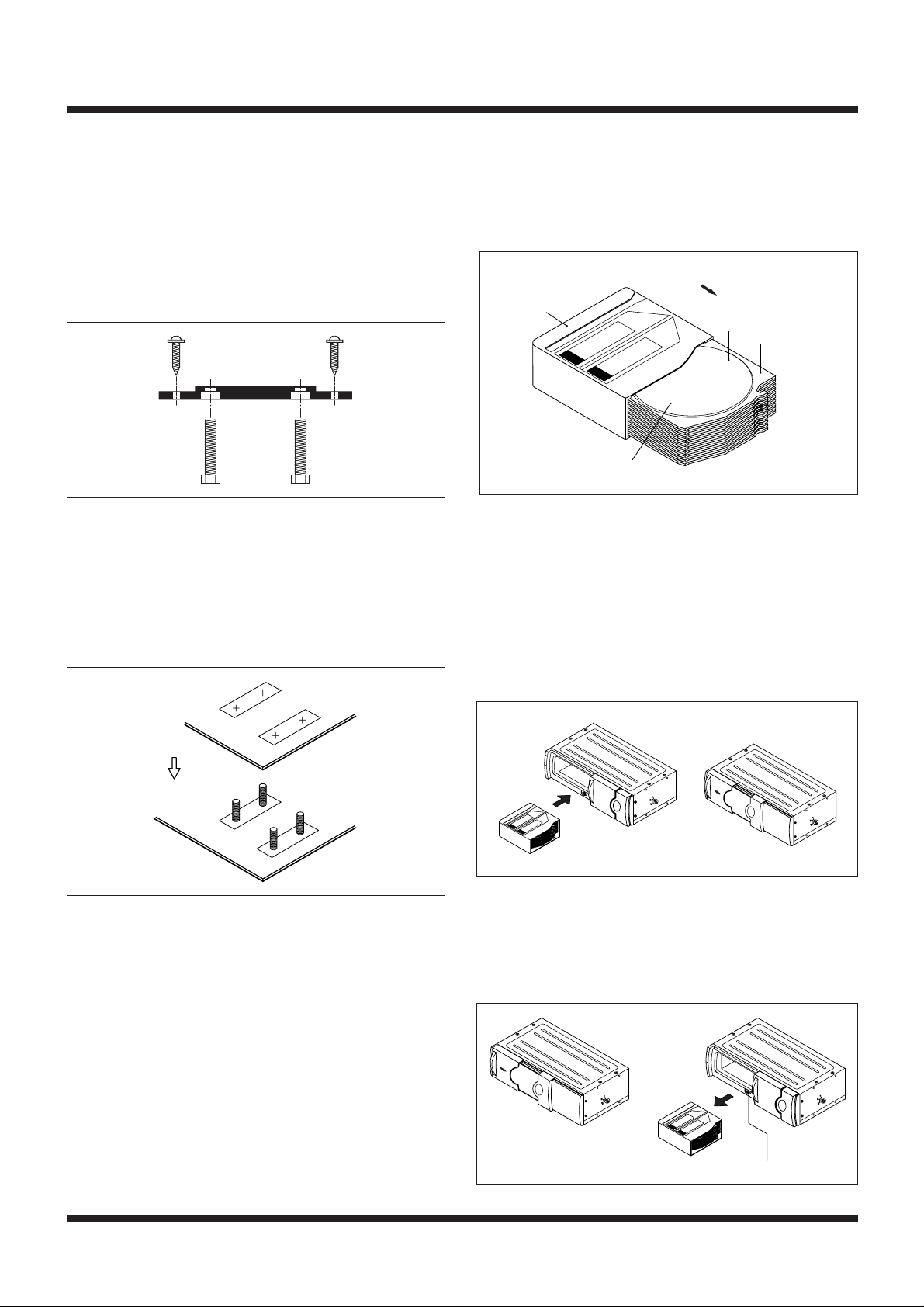

§ HORIZONTAL POSITION INSTALLATION (WITH BRKT STUD)

Casing

M4x10

Casing

Damage

Use the wing nut to hold in place the installation bracket with bolt

(M6x25) to the installation bracket, which is attached to the unit.

Then affix the cushion rubber. Holes with the “0” marks are to be

used for horizontal or suspending and “90” for vertical

installation.

§ VERTICAL POSITION INSTALLATION (WITH BRKT

STUD)

§ SUSPENDED POSITION INSTALLATION (WITH

BRKT STUD)

§ HORIZONTAL POSITION INSTALLATION

(WITHOUT BRKT STUD)

§ VERTICAL POSITION INSTALLATION (WITHOUT

BRKT STUD)

Dangerous Installation

1. Only the provided screws and brackets should be used during installation. Using screws other than those

specified will cause damage.

2. Before installation, check that there is no harness at the back when making a hole on the dashboard.

DAEWOO

4

Page 6

3. INST ALLATION METHOD (HOW TO INSTALL THE UNIT)

TRANSIT BOLT

BRACKET

MOUNTING

FRONT

FRONT

FRONT

HORIZONTAL VERTICAL DECLINING

After Select Mark Hole ,

The unit fasten by the screw

(M4x8)

After Select Mark Hole ,

The unit fasten by the screw

(M4x8)

After Select Mark Hole ,

The unit fasten by the screw

(M4x8)

§ REMOVE TRANSIT SCREW 3 EACH BEFORE INST ALLATION.

§ SETTING THE INST ALLATION SELECTOR LEVERS ADJUST FOR THE UNIT

(PRIOR TO INST ALL)

(VERTICAL)

DAEWOO

5

Page 7

4. INST ALLATION METHOD (HOW TO

INST ALL THE VECHICLE)

Should be determined before the unit install under

carpet.

5. PREP ARATIONS

§ USAGE OF MAGAZINE (To load the discs)

* Load the discs with the labels facing upwards, as

shown in the diagram.

Adjust the installation bracket with bolts to suit the

place of installation.

* Remove the floor carpet and decide on the place to

install.

* Remove the separator of the cushion rubber that is

attached to the installation bracket with bolt and

install accordingly.

* Align the unit with the bolts and secure it with the

wing nuts.

Tray extracted direction

Magazin

Label Side

Tray

Disc

§ TO LOAD THE MAGAZINE

* Slide the sliding door to the right until it is

completely latched on.

* Load the magazine in the direction as shown in

the diagram push it in until is locked into the unit.

* After the magazine has been loaded, close the

sliding door.

(If not close sliding door, Dirt or dust entering it

will cause damage)

§ TO REMOVE THE MAGAZINE

* Open the sliding door and depress the eject

button.

* Remove the magazine when it has been ejected.

* Close the sliding door.

depress the eject button in here

6

DAEWOO

Page 8

DISASSEMBLY

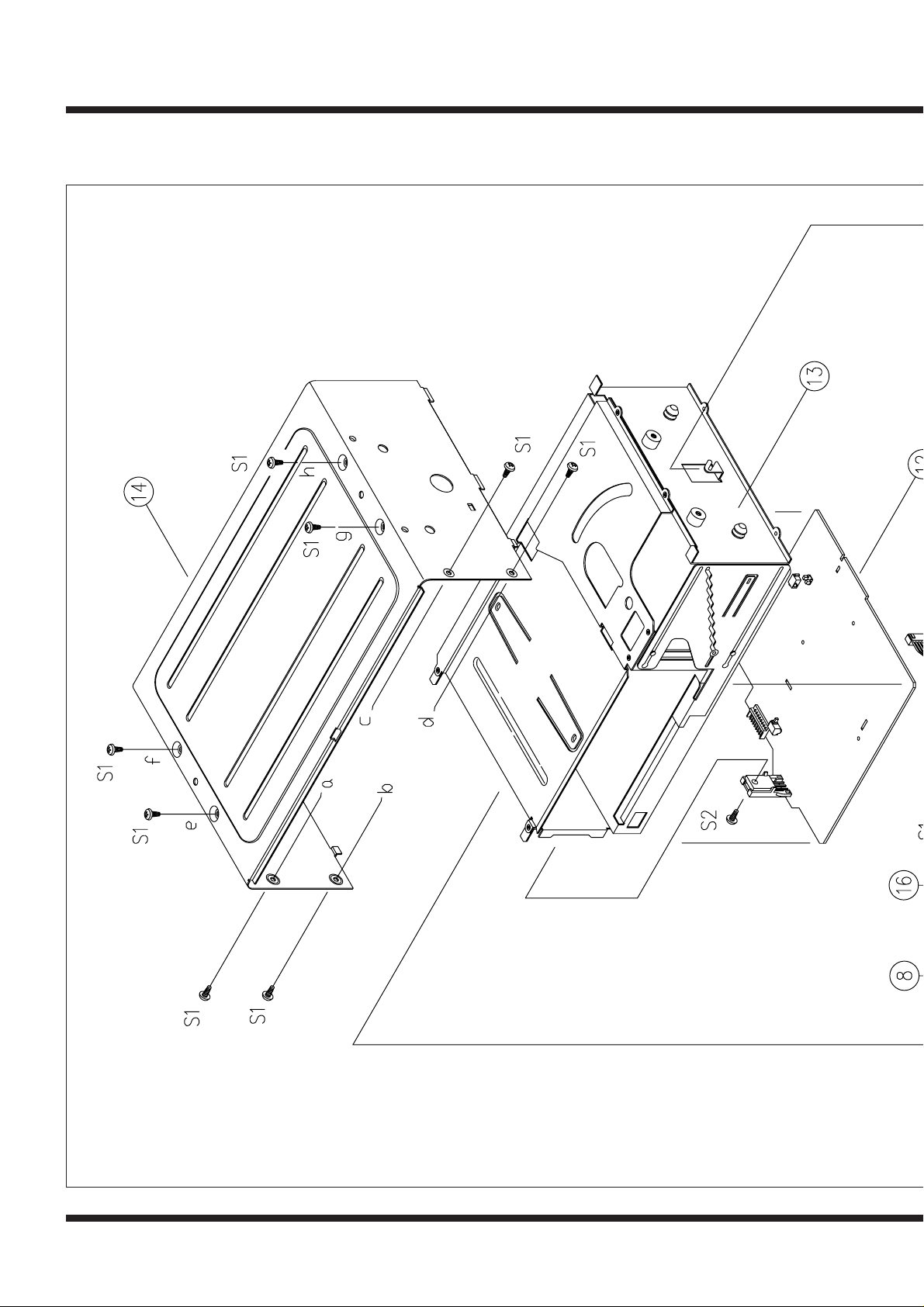

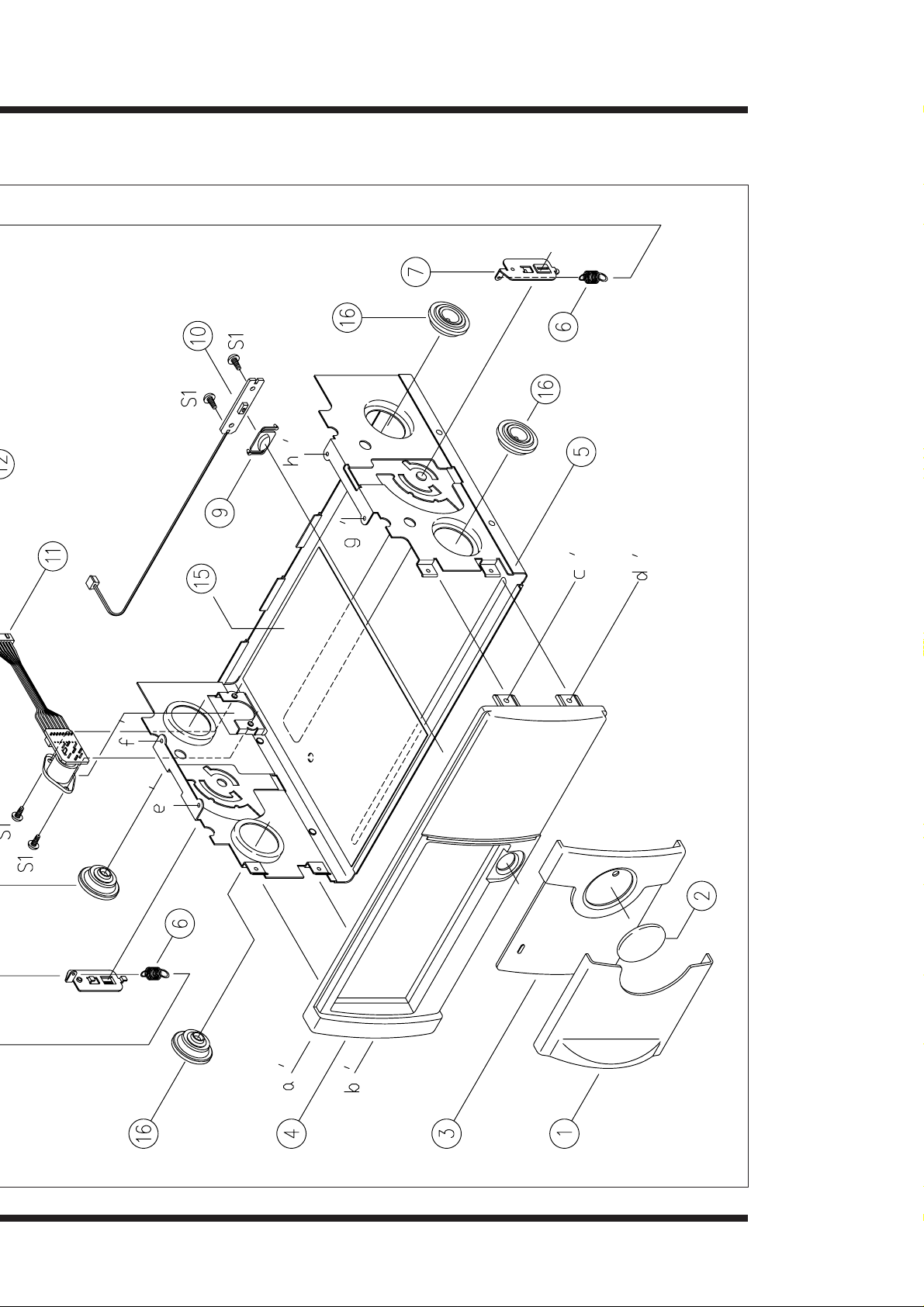

1. DISASSEMBLY

7

Page 9

DAEWOO

Page 10

2. PICK UP ASSEMBLY

DAEWOO

8

Page 11

3. MAGAZINE ASSEMBLY

DAEWOO

9

Page 12

4. MECHANISM ASSEMBLY

10

Page 13

MODEL: TN-CDC1010-102M

DAEWOO

Page 14

DIAGRAMS

1. ELECTRICAL SPECIFICA TION

§ TEST DISC: SONY YEDS 18 YTPE 4 OR TCD-784

TEST

NO ITEM UNIT NOMINAL LIMIT 1 2 REMARK

CONDITION

20Hz -2.6 ¡´±4dB

100Hz dB 0.01 ¡´±2dB

1 FREQUENCY RESPONSE

10KHz -0.3 ¡´±2dB

20KHz -1.3 ¡´±3dB

JIS A

2 S/N RATIO 1KHz dB 90 ¡ˆ±80dB

FILTER

JIS A

3 DYNAMIC RANGE dB 90 ¡ˆ±75dB

FILTER

4 T.H.D % 0.07 ¡´0.3%

5KHz dB 20dB ±3dB JIS A

5 DE-EMPHASIS

16KHz dB 20dB ±3dB FILTER

L

1KHz 86 ¡ˆ70dB

R JIS A

6 CHANNEL SEPARATION dB

L FILTER

10KHz 76 ¡ˆ60dB

R

7 OUTPUT LEVEL (V) 1KHz V 0.8±0.1

8 BACK UP CURRENT (mA) mA 2.7 ⁄ 5mA

§ PLAY ABILITY TEST (25˚C)

ITEM TEST CONDITION LIMIT

JIS A

FILTER

SCRATCH DISC A-BEX TCD-721R 600µM

INTERRUPTION DISC A-BEX TCD-725A 700µM

BLACK DOT A-BEX TCD-725A 600µM

FINGER PRINTS A-BEX TCD-725A 65µM

ECCENTRICITY DISC A-BEX TCD-713 210µM

VERTICAL DEVIATION DISC A-BEX TCD-731R 1000µM

DAEWOO

11

Page 15

2. MICOM PIN CONFIGURA TION & DESCRIPTIONS

KS57C0404/C0408

(44-QFP-1010B)

34

35

36

37

38

39

40

41

42

43

44

34

35

36

37

38

39

40

41

42

43

44

NC

UNLoad-SW

Load-SW

Rest-SW

MAGA-SW

VDD

GND

Load

UNLoad

E-UP

E-DOWN

34

35

36

37

38

39

40

41

42

43

44

NC

EJ-SWNCNC

TEST

SQCK

DMUTE

SQDT

SENSE

CLK

MDATA

34

35

36

37

38

39

40

41

42

43

44

BUS-OUT

PWR-ON

AMUTE

SMUTE

RESET

XOUT

XIN

NC

NC

FOK

GFS

XLT

XRST

BUS-IN

SCOR

CD-ON

DISC-P

VSS

TRCNT

NC

NC

NC

§ PIN CONFIGURA TIONS

12

DAEWOO

Page 16

PIN PIN NAME DESCRIPTION I/O ACTIVE

1 BUS-OUT MASTER MICOM DATA SIGNAL OUTPUT PIN. I/O H

2 PWR-ON THIS PIN IS USED FOR POWER CONTROL OUTPUT. O H

3 AMUTE AUDIO MUTE CONTROL PIN. O H

4 SMUTE MOTOR DRIVE IC MUTE CONTROL PIN. O L

5 RESET MICOM RESET INPUT PIN. I L

6 XOUT OSC OUTPUT PIN. O H

7 XIN OSC INPUT PIN. I H

8 NC NO CONNECTION. - -

9 NC NO CONNECTION. - 10 FOK THE INPUT PIN OF FOCUS OK SIGNAL (KB9223). I H

11 GFS THE LOCK STATUS INPUT OF FRAME SYNC (KS9286). I H

12 NC NO CONNECTION. - 13 NC NO CONNECTION. - 14 NC NO CONNECTION. - 15 TRCNT TRACK COUNT INPUT PIN (KB9223). I H

16 VSS GROUND PIN. - 17 DISC-P DISC POSITION INPUT PIN (FROM PHOTO INTERRUPTER) I H

18 CD-ON CDC MODE INPUT PIN (FROM MASTER MICOM). I H

19 SCOR SUB CODE FRAME SYNC INPUT PIN (KS9286). I 20 BUS-IN MASTER MICOM DATA SIGNAL INPUT PIN. I H

21 XRST SERVO/DSP IC RESET CONTROL PIN (KB9223, KS9286) O L

22 XLT SERVO/DSP IC DATA LATCH OUTPUT PIN. I/O 23 MDATA SERVO/DSP IC DATA OUTPUT PIN. I/O 24 CLK SERVO/DSP IC CLOCK OUTPUT PIN. I/O 25 SENSE KB9223, KS9286 INTERNAL STATUS INPUT PIN. I 26 SQDT SERIAL INPUT OF SUBCODE-Q DATA (KS9286) I 27 DMUTE SYSTEM MUTE CONTROL OUTPUT PIN. O H

28 SQCK SUBCODE-Q DATA CLOCK INPUT PIN. I 29 TEST SERVO/DSP IC TEST PIN. O H

30 NC NO CONNECTION. - -

DAEWOO

13

Page 17

PIN PIN NAME DESCRIPTION I/O ACTIVE

31 NC NO CONNECTION. - 32 EJ-SW EJECT KEY INPUT PIN. I H

33 NC IT MUST BE CONNECTED TO GROUND - 34 NC IT MUST BE CONNECTED TO GROUND - 35 UNLOAD-SW MECHA UNLOAD SWITCH INPUT PIN. I H

36 LOAD-SW MECHA LOAD SWITCH INPUT PIN. I H

37 RESET-SW MECHA RESET SWITCH INPUT PIN. I H

38 MAGA-SW MECHA MAGAZINE SWITCH INPUT PIN. I H

39 VDD DEVICE POWER SUPPLY PIN. - H

40 GND GROUND PIN. - 41 LOAD DISC LOAD OUTPUT PIN. O H

42 UNLOAD DISC UNLOAD OUTPUT PIN. O H

43 E-UP MECHA ELEVATOR UP CONTROL PIN. O H

44 E-DOWN MECHA ELEVATOR DOWN CONTROL PIN. O H

14

DAEWOO

Page 18

3. IC BLOCK DIAGRAM & TERMINAL VOLTAGE

646563

DVEE

PD1

66

PD2

67

F

68

E

69

PD

70

LD

71

VR

72

VCC

73

RF-

74

RFO

75

IRF

76

EQO

77

RFI

78

EQC

79

EI

80

GND

40

FOK

39

MIRROR

38

RESET

37

MLT

36

MDATA

35

MCK

34

VSSA

33

EFM

32

ASY

31

ISTAT

30

TRCNT

29

LOCK

28

FGD

27

FS3

26

FLB

25

SMEF

FEBIAS

62

TG2

61

TGU

60

FDFCT

59

FE158FE2

57

TDFCT

56

DVDD

55

LPFT

54

TE153TE2

52

TZC

51

ATSC

50

TEO

49

TE-

48

FEO

47

FE-

46

SPDLO

45

SPDL-

44

SL-

43

SLO

42

SL+

41

SSTOP

1 2

MCP

DCB3FRSH4DCC25DCC16FSET7VDDA8VCCP9GC2I10GC2O11CH2I12CH2O13CH1O14CH1I15GC1O16GC1I17RRC18VSSP19MUTEI20ISET21VREG22WDCK23SMDP24SMON

KB9223

§ IC 101 (KB9223) - RF + ASSP + AUDIO FILTER

DAEWOO

15

Page 19

§ BLOCK DIAGRAM

59

73

FE1

RF-

60

FDFCT

47

FE-

48

FEO

57

TDFCT

49

TE-

50

TEO

53

TE2

43

SLO

44

SL-

42

SL+

55

LPFT

46

SPDLO

45

SPDL-

25

SMEF

6

FSET

39

MRROR

1

MCP

40

FDK

23

SMDP

24

SMON

62

TG2

61

TGU

74

65

66

63

67

68

79

69

RFD

PD1

PD2

FEBIAS

F

E

EI

PD

70LD

71VR

78EQC

76EQO

75IRF

32ASY

33EFM

77RFI

2DCB

4DCC2

54

TE122WDCH30TRCNT29LOCK31ISTAT38RESET37MLT36MDATA35MCK51ATSC52TZC

15

GC1O

5

DCC1

16

GC11

13

CH1014CH11

19

MUTEI

17

RRC

12

CH2011CH21

9

GC2110CG20

58

FE226FLB28FGD27FS33FRSH

RF Amp

MICOM Data

Interface Logic

Built-in Post Filter Amp (L & R)

APC Amp

RF Level AGC

&

Equalizer

EFM

Comparator

Defect Detection

Circuit

Focus Error Amp

FE-BIAS Adjustment

Center Voltage Amp.

Tracking Error Amp

E/F Balance & Gain

Control

Focus Phase

Compensation

& Offset cancel circuit

Tracking Phase

Compensation Block

& Jump Pulse GEN.

Sled Servo Amplifier

& Sled Kick GEN.

Spindle Servo LPF

(Double Speed)

Mirror Detection

Circuit

FOK Detection

Circuit

MICOM TO SERVO CONTROL

AUTO SEQUENCER

ADJUSTMENT-FREE CONTROL

LDON

16

DAEWOO

Page 20

PIN PIN NAME DESCRIPTION VOLTAGE

1 MCP Capacitor connection pin for mirror hold 3.0V

2 DCB Capacitor connection pin for defect Botton hold 2.0V

3 FRSH Capacitor connection pin for time constant to generate focus search waveform 2.6V

4 DCC2 The input pin through capacitor of defect bottom hold output 0.9V

5 DCC1 The output pin of defect bottom hold 1.1V

6 FSET

7 VDD Analog VCC for servo part 4.9V

8 VCCP VCC for post filter 4.9V

9 GC2I Amplifier negative input pin for gain and low pass filtering of DAC output CH2 2.5V

10 GC2O Amplifier output pin for gain and low pass filtering of DAC output CH2 2.5V

11 CH2I The input pin for post filer channel 2 2.5V

12 CH2O The output pin for post filter channel 2 2.5V

13 CH1O The output pin for post filter channel 1 2.5V

14 CH1I The input pin for post filter channel 1 2.5V

15 GC1O Amplifier negative input pin for gain and low pass filtering of DAC output CH1 2.5V

16 GC1I Amplifier negative input pin for gain and low pass filtering of DAC output CH1 2.5V

17 RRC The pin for noise reduction of post filter bias 2.5V

18 VSSP VSS for post filter 19 MUTEI The input pin for post filter muting control 20 ISET The input pin for current setting of focus search, track jump and sled kick voltage 2.0V

21 VREG The output pin of regulator 3.4V

22 WDCK The clock input pin for auto sequence 2.5V

23 SMDP The input pin of CLV control output pin SMDP of DSP 2.8V

24 SMON The input pin for spindle servo ON through SMON of DSP 4.9V

25 SMEF The input pin of provide for an external LPF time constant 2.5V

26 FLB Capacitor connection pin to perform rising low bandwidth of focus loop 2.5V

27 FS3 The pin for high frequency gain change of focus loop with internal FS3 switch 2.4V

28 FGD Reducing high frequency gain with capacitor between FS3 pin 2.5V

29 LOCK Sled runaway prevention pin 4.9V

30 TRCNT Track count output pin 31 ISTAT Internal status output pin 4.9V

32 ASY The input pin for asymmetry control 2.5V

33 EFM EFM comparator output pin 2.5V

34 VSSA Analog VSS for servo part 35 MCK MICOM clock input pin 4.9V

36 MDATA MICOM data input pin 4.9V

37 MLT MICOM data latch input pin 4.9V

38 RESET Reset input pin 4.9V

39 MIRROR The mirror output for test 40 FOK The output pin of focus KO comparator 4.9V

The peak frequency setting pin for focus, tracking servo and cut off frequency of CLV LPF

0.8V

DAEWOO

17

Page 21

PIN PIN NAME DESCRIPTION VOLTAGE

41 SSTOP The pin detection whether pick up position is innermost or not 4.9V

42 SL+ The moninverting input pin of sled servo amplifier 2.5V

43 SLO The output pin of sled servo amplifier 2.5V

44 SL- The inverting input pin of sled servo amplifier 2.5V

45 SPDL- The noninverting input pin of spindle servo amplifier 2.5V

46 SPDLO The output pin of spindle servo amplifier 2.7V

47 FE- The inverting input pin of focus servo amplifier 2.5V

48 FEO The output pin of focus servo amplifier 2.3V

49 TE- The inverting input pin of tracking servo amplifier 2.5V

50 TEO The output pin of tracking servo amplifier 2.5V

51 ATSC The input pin for Anti-shock detection 2.5V

52 TZC The comparator input pin for tracking zero crossing detection 2.5V

53 TE2 Tracking servo input pin 2.5V

54 TE1 Tracking error amplifier output pin

55 LPFT The input pin of tracking error low pass filtering signal 2.5V

56 DVDD The power supply pin for logic circuit 4.9V

57 TDFCT The capacitor connection pin for tracking defect compensation 2.4V

58 FE2 Focus servo input pin 2.5V

59 FE1 Focus error amplifier output pin 2.4V

60 FDFCT The capacitor connection pin for focus defect compensation 2.4V

61 TGU The capacitor connection pin for focus defect compensation 2.4V

62 TG2

63 FEBIAS Focus error bias voltage control pin 64 DVEE The DVEE pin for logic circuit 65 PD1 The negative input pin of RF I/V amplifier 1 (A+C signal) 2.5V

66 PD2 The negative input pin of RF I/V amplifier 2 (B+D signal) 2.5V

67 F The negative input pin of F I/V amplifier (F signal) 2.5V

68 E The negative input pin E I/V amplifier (E signal) 2.5V

69 PD The input pin for APC 70 LD The output pin for APC 4.0V

71 VR The output pin of (AVEE+AVCC)/2 voltage 2.5V

72 VCC VCC for RF part 4.9V

73 RF- RF summing amplifier inverting input pin 2.5V

74 RFO RF summing amplifier output pin 3.3V

75 IRF The input pin for AGC 2.5V

76 ARF The output pin for AGC 2.5V

77 RFI The input pin for EFM comparating 2.5V

78 CAGC The capacitor connection pin for AGC 4.1V

79 EI Feedback input pin of E I/V amplifier for EF Balance control 80 GND GND for RF part 0V

The pin for high frequency gain change of tracking servo loop with internal TG2 switch

2.5V

18

DAEWOO

Page 22

§ IC 501 (KS9286) - DSP + DAC

AVDD1

KS9286

1

DPDO

2

DPFIN

3

DPFOUT

4

CNTVOL

5

ASS1

6

DATX

7

XIN

8

XOUT

9

WDCHO

10

LRCHO

11

ADATAO

12

DVSS1

13

BCKO

14

C2PO

15

VREFL2

16

TEST1

65

EFMI

66

ADATAI

67

/ISTAT

68

TRCNT

69

LOCK

70

PBFR

71

SMEF

72

SMON

73

DVDD2

74

SMDP

75

SMSD

76

BCKI

77

TESTV

78

DSPEED

79

LRCHI

80

DB7

40

DB8

39

MCK

38

MDAT

37

MLT

36

MUTE

35

DVDD1

34

SDAT

33

SBCK

32

SQOK

31

30

SQDT

29

SQCK

28

/ESP

27

RESET

26

S0S1

LKFS

25

VREFL1

17

AVDD2

18

RCHOUT

19

LCHOUT

20

AVSS2

21

VREFH1

22

VREFH2

23

EMPH

24

SRAM

64

CDROM

63

TEST0

62

XTALSEL

61

/CS

60

/WE

59

C16M

58

C4M

57

/JIT

56

ULKFS

55

FSDW

54

DVSS2

53

/PBCK

52

C2FL

51

C2F2

50

C2F1

49

C1F2

48

C1F1

47

DB1

46

DB2

45

DB3

44

DB4

43

DB5

42

DB6

41

PIN CONFIGURATION

DAEWOO

19

Page 23

§ BLOCK DIAGRAM

S0S1

26

EFMI

66

CNTVOL

5

DPFIN

3

SQDT

30

SQCK

29

LRCHO

11

ADATAO

12

BCKO

14

BCKI

77

ADATAI

67

LRCHI

80

EMPH

24

VREFL1

17

VREFH1

22

DPFIN

4

DPDO

2

SMEF

72

SMON

73

SMDP

75

MDAT

37

MCK

38

TRCNT

69

/ISTAT

68

MLT

36

SMSD

76

LOCK

70

XOUT

9

XIN

8

SBCK32SDAT

33

RCHOUT

19

LCHOUT

20

DATX

7

TEST1

65

CDROM

63

TEST0

62

XTALSEL

61

EFM

PHASE

DETECTOR

SUBCODE

SYNC

DETECTOR

SUBCODE

OUTPUT

EFM

DEMODULATOR

ADDRESS

GENERATOR

16K

SRAM

ECC

INTERPOLATOR

SUBCODE-Q

REGISTER

23B/T

SHIFT

REGISTER

X-TAL

TIMING

GENERATOR

DIGITAL

FILTER

& DE-EMPH

FRAME SYNC

DETECTOR

ROTECTOR

INSERTOR

DIGITAL

CLV

SERVO

DIGITAL

PLL

CPU

INTERFACE

TRACK

COUNTER

MODE

SELECTOR

DIGITAL

OUTPUT

D/A

CONVERTER

8 BIT DATA BUS

20

DAEWOO

Page 24

§ PIN DESCRIPTION

PIN PIN NAME IO DESCRIPTION VOLTAGE

1 AVDD1 - Analog VCC1 4.9V

2 DPDO O Charge pump output for Digital PLL 2.4V

3 DPFIN I Filter input for Digital PLL 2.4V

4 DPFOUT O Filter output for digital PLL 3.0V

5 CNTVOL I VCO control voltage for digital PLL 3.0V

6 AVSS1 - Analog Ground1 7 DATX O Digital Audio output data 8 XIN I X’tal oscillator input 2.1V

9 XOUT O X’tal oscillator output 2.3V

10 WDCHO O Word clock output of 48bit/Slot (88.2KHz) 2.5V

11 LRCHO O Channel clock output of 48bit/Slot (44.1KHz), 88.2KHz when ESP ON 12 ADATAO O

13 DVSS1 - Digital Ground1 14 BCKO O

15 C2PO O C2 Pointer for output audio data 16 VREFL2 I Input terminal2 of reference voltage “L” (Floating) 17 VREFL1 I Input terminal1 of reference voltage “L” (GND connection) 1.2V

18 AVDD2 - Analog VCC2 4.9V

19 RCHOUT O Right-Channel audio output through D/A converter 2.5V

20 LCHOUT O Left-Channel audio output through D/A converter 2.5V

21 AVSS2 - Analog ground2 22 VREFH1 I Input terminal1 of reference voltage “H” (VDD connection) 3.8V

23 VREFH2 I Input terminal2 of reference voltage “H” (Floating) 24 EMPH O Emphasis/Non-Emphasis output, H: Emphasis ON, L: Emphasis OFF 25 LKFS O The Lock Status output of frame sync 4.9V

26 S0S1 O Output of subcode sync signal (S0+S1) -

Serial audio data output of 48bit/Slot (MSB first), double speed output when ESP ON

Audio data bit clock output of 48 bit/Slot (2.1168MHz), 4.2336MHz when ESP ON

-

-

27 RESET I System reset at “L” 4.9V

28 /ESP I

29 SQCK I Clock for output Subcode-Q data 4.9V

30 SQDT O Serial output of Subcode-Q data -

ESP function ON/OFF control (“L”: ESP function ON, “H”: ESP function OFF)

DAEWOO

21

4.9V

Page 25

PIN PIN NAME IO DESCRIPTION VOLTAGE

31 SQOK O

32 SBCK I Clock for output subcode data 33 SDAT O Subcode serial data output 34 DVDD1 - Digital VDD1 4.9V

35 MUTE I Mute control input (“H”: Mute ON) 0V

36 MLT I Latch Signal Input from Micom (Schmit Trigger) 4.9V

37 MDAT I Serial data input from Micom (Schmit Trigger) 4.9V

38 MCK I Serial clock input from Micom (Schmit Trigger) 4.9V

39 DB8 I/O SRAM data I/O port 8 (MSB) 0V

40 DB7 I/O SRAM data I/O port 7 0V

41 DB6 I/O SRAM data I/O port 6 0V

42 DB5 I/O SRAM data I/O port 5 0V

43 DB4 I/O SRAM data I/O port 4 0V

44 DB3 I/O SRAM data I/O port 3 0V

45 DB2 I/O SRAM data I/O port 2 0V

The CRC (Cycle Redundancy Check) check result signal output of Subcode-Q

-

46 DB1 I/O SRAM data I/O port 1 (LSB) 0V

47 C1F1 I/O Monitoring output for C1 error correction (RA1) 48 C1F2 I/O Monitoring output for C1 error correction (RA2) 49 C2F1 I/O Monitoring output for C2 error correction (RA3) 50 C2F2 I/O Monitoring output for C2 error correction (RA4) -

51 C2FL I/O -

52 /PBCK I/O Output of VCO/2 (4.3218MHz) (RA6) 53 DVSS2 I/O Digital ground2 0V

54 FSDW I/O Windown or unprotected frame sync (RA7) 55 ULKFS I/O Frame sync protection state (RA8) 56 /JIT I/O

57 C4M I/O Only monitoring signal (4.2336MHz) (RA10) 58 C16 I/O 16.9344MHz signal output (RA11) 59 /WE I/O Terminal for test -

C2 decoder flag (RA5, “H”: When the processing C2 code is

impossible correction status.)

Display of either RAM overflow or underflow for ±4 frame jitter margin (RA9)

-

60 /CS I/O Terminal for test 61 XTALSEL I Mode Selection1 (H: 33.8688MHz, L: 16.9344MHz) 0V

DAEWOO

22

Page 26

PIN PIN NAME IO DESCRIPTION VOLTAGE

62 TESTO I TEST input terminal (GND connection) 0V

63 CDROM I Mode Selection 2 (H: CD-ROM, L; CDP) 0V

64 SRAM I TEST input terminal (GND connection) 0V

65 TEST1 I TEST input terminal (GND connection) 0V

66 EFMI I EFM signal input 2.5V

67 ADATAI I Serial audio data input of 48 bit/Slot (MSB first) 0V

68 /ISTAT O The internal status output 4.9V

68 /ISTAT O The internal status output 4.9V

69 TRCNT I Tracing counter input signal -

70 LOCK O 4.9V

71 PBFR O Write frame clock (Lock: 7.35Khz) 72 SMEF O LPF time constant control of the spindle servo error signal 2.5V

73 SMON O ON/OFF control signal for spindle servo 4.9V

74 DVDD2 - Digital VDD2 4.9V

75 SMDP O 2.8V

76 SMSD O Spindle Motor drive (Velocity control in the PHASE mode) 2.5V

77 BCKI I Audio data bit clock input of 48 bit/Slot (2.1168MHz) 0V

78 TESTV I TEST input terminal (GND connection) 79 DSPEED I TEST input terminal (VDD connection) 4.9V

80 LRCHI I Channel clock input of 48bit/Slot (44.1KHz) 0V

Output signal of LKFS condigiton sampled PBFR/16 (if LKFS is “H”, LOCK is “H

if LKFS is sampled “L” at least 8 times by PBFR/16, LOCK is “L”.)

Spindle Motor drive (Rough control in the PSEED mode,

Phase control in the PHASE mode)

DAEWOO

23

Page 27

§ IC 201 (KA3030D) - 6CH MOTOR DRIVE

28

GND27DO4B26DO4A25DI424CTL1

23

REFIN22VCC1

21

CTL2

20

LI2B19LI2A18DI317D03B16DO3A15GND

1

DO1A2DO1B

3

LO1A4LO1B

5

D11

6

LIA17LI1B

8

GND

9

VCC2

10

DI2

11

L02A12L02B

13

DO2A14DO2B

KA3030D

FIN

(GND)

FIN

(GND)

28 27 26 25 24 23 22 21 20 19 18 17 16 15

1 2 3 4 5 6 7 8 910 11 12 13

14

LEVEL SHIFT

SW

MUTE

–+

+–

LEVEL SHIFT

–+

LEVEL SHIFT

–+

LEVEL SHIFT

–+

H.V.P

T.S.D

U.V.P

BANGAP

REFERENCE

BIAS

SPEED CTL

LEVEL SHIFT

SPEED CTL

LEVEL SHIFTLOGIC LOGIC

+–

+–

+–

+–

DDD D D

DD

D

D

D

D

D

IN

ININ

IN

PIN CONFIGURATION

BLOCK DIAGRAM

24

DAEWOO

Page 28

PIN PIN NAME DESCRIPTION I/O VOLTAGE

1 FO- FOCUS SERVO DRIVE OUTPUT (-) O 3.9V

2 FO+ FOCUS SERVO DRIVE OUTPUT (+) O 3.3V

3 EO- ELEVATOR DOWN OUTPUT O 3.6V

4 EO+ ELEVATOR UP OUTUT O 3.6V

5 FOIN FOCUS SERVO DRIVE INPUT I 2.3V

6 EI- ELEVATOR DOWN INPUT I 0V

7 EI+ ELEVATOR UP INPUT I 0V

8 GND GROUND - 0V

9 VCC1 MECHANISM OPERATION SUPPLY VOLTAGE - 7.8V

10 SPIN SPINDLE MOTOR DRIVE INPUT I 2.7V

11 LO- LOADING MOTOR DRIVE OUTPUT (-) O 0V

12 LO+ LOADING MOTOR DRIVE OUTPUT (+) O 0V

13 SP+ SPINDLE MOTOR DRIVE OUTPUT (+0 O 3.9V

14 SP- SPINDLE MOTOR DRIVE OUTPUT (1) O 3.4V

15 GND GROUND - 0V

16 SL- SLED MOTOR DRIVE OUTPUT (-) O 3.9V

17 SL+ SLED MOTOR DRIVE OUTPUT (+) O 3.4V

18 SLIN SLED MOTOR DRIVE INPUT I 2.7V

19 LI+ LOADING MOTOR DRIVE INPUT (+) I 0V

20 LI- LOADING MOTOR DRIVE INPUT (-) I 0V

21 L-CNT LOADING MOTOR SPEED CONTROL I 5.7V

22 VCC2 SERVO MOTOR OPERATION SUPPLY VOLTAGE - 7.8V

23 VREF/MUTE REFERENCE & MUTE INPUT I 2.5V

24 E-CNT ELEVATOR MOTOR SPEED CONTROL I 5.7V

25 TOIN TRACKING SERVO DRIVE INPUT I 2.5V

26 TO+ TRACKING SERVO DRIVE OUTPUT (+) O 3.7V

27 TO- TRACKING SERVO DRIVE OUTPUT (-) O 3.5V

28 GND GROUND - 0V

DAEWOO

25

Page 29

§ IC 602 (KIA7027AP) - RESET IC

1

2

3

VCC

VREF

GND

OUT

+

–

BLOCK DIAGRAM

PIN PIN NAME DESCRIPTION I/O VOLTAGE

1 INPUT SUPPLY VOLTAGE INPUT I 4.9V

2 GND GROUND - 0V

3 OUTPUT VOLTAGE OUTPUT O 4.9V

§ IC 102 (BA4560F) - OP AMP

OUT1

-IN1

+IN

VEE

1

2

1ch

+–

1

3

2ch

+–

4

VCC

8

OUT2

7

+IN2

6

-IN2

5

PIN PIN NAME DESCRIPTION I/O VOLTAGE

1 OUT1 NB SIGNAL AMP OUTPUT O 2.5V

2 IN1 (-) NB SIGNAL INPUT I 2.5V

3 IN1 (+) REFERENCE VOLTAGE INPUT I 2.5V

4 GND GROUND - 0V

5 IN2 (+) REFERENCE VOLTAGE INPUT I 2.5V

6 IN2 (-) NA SIGNAL INPUT I 2.5V

7 OUT2 NA SIGNAL AMP OUTPUT O 2.5V

8 VCC SUPPLY VOLTAGE - 4.9V

DAEWOO

26

Page 30

4. PRINTED WIRING BOARDS

§ Top Side

DAEWOO

27

Page 31

§ Bottom Side

28

DAEWOO

Page 32

Page 33

6. MECHANISM ASSEMBLY

NO. PART NAME PARTS No DESCRIPTION Q’TY

1 MAIN CHASSIS ASS’Y 3008 01 504 1

2 SIDE PLATE ASS’Y 3008 01 502 1

3

4 EL PLATE A ASS’Y 3008 02 502 1

5 MAIN FRAME ASS’Y 3008 03 501 1

6 SUB FRAME ASS’Y 3008 04 501 1

7 P CHASSIS ASS’Y 3008 05 501 1

8 MAGAZINE ASS’Y 3008 06 302 1

9

10

11

12 EL MOTOR ASS’Y 3008 02 301 1

13 SW PWB ASS’Y 3008 03 303 1

14 L MOTOR ASS’Y 3008 03 302 1

15 LOCK PLATE A ASS’Y 3008 03 304 1

16 LOCK PLATE B ASS’Y 3008 03 305 1

17 CLAMP PLATE ASS’Y 3008 04 301 1

18 TURN TABLE ASS’Y 3008 05 301 1

19 21P PWB ASS’Y 3008 05 302 1

20 FEED MOTOR ASS’Y 3008 05 303 1

21 HOOK LEVER P ASS’Y 3008 04 502 1

22

23 FEED SCREW (M) ASS’Y 3031 05 304 1

24

25

26 EL GEAR B 3008 02 02 1

27 EL GEAR C 3008 02 17 1

28 EL GEAR D 3008 02 04 3

29 EL PLATE B 3008 02 06 1

30

31 MLA SPRING 3008 02 11 1

32 ML AR 3008 02 10 1

33

34 ER PLATE 3008 02 12 1

35

36

37 MOTOR BRACKET L 3008 03 07 1

38 TRAY GEAR 3008 03 28 1

39 MAIN GEAR 3008 03 31 1

40 LOADING GEAR 3008 03 10 1

41 LIFT GEAR 3008 03 33 1

42 TRAY GUIDE A 3008 03 13 1

43 TRAY GUIDE B 3008 03 14 1

44 CHAKING ARM 3008 03 30 1

45 LIFT PLATE A 3008 03 16 1

46 LIFT PLATE B 3008 03 17 1

47 LIFT SPRING 3008 03 18 2

48 CLUTCH SPRING 3008 03 27 1

49 LOCK PLATE C 3008 02 29 1

50 TRIG PLATE SPRING 3031 01 15 1

DAEWOO

30

Page 34

(MODEL TN-CDC1010-102M)

NO. PART NAME PARTS No DESCRIPTION Q’TY

51

52 HOOK LEVER M 3008 04 06 1

53 TRAY ARM 3008 04 11 1

54

55

56 P BASE A 3008 05 02 1

57 P BASE B 3008 05 03 1

58

59 EJECT LEVER 3008 02 20 1

60 TOP COVER 3008 01 14 1

61 E SPRING (10) 3008 02 25 1

62 PU GEAR (B) 3030 05 10 1

63 NUT PUSH SPR PLATE (M) 3031 05 30 1

64 FD GR BLK (M) 3031 05 28 1

65 PU M NUT (M) 3031 05 29 1

66 THRUST SPR 3031 05 10 1

67 PU SHAFT (M) 3031 05 32 1

68

69 PICK UP VED0375-TN 6904 16 01 1

70

71 HOLD PLATE 3008 01 13 1

72

73 ROTARY DAMPER 6502 01 01 1

74 GEAR SHEET 3008 02 18 1

75

76

77

78

79

80

81 CAMERA SCREW 1.7x2.2 9C01 17 223 2

82

83 CAMERA S TAPPING SCREW (G) 2x2.5 9C04 20 253 3

84 CAMERA B TAPPING 2x3.5 9C06 20 353 3

85 CAMERA B TAPPING SCREW 2x5 9C06 20 503 9

86 TS. SG2x3 9C20 20 301 18

87 TS.S TAMS 2x15 9C39 20 051 1

88 CAMERA TAPPING SCREW B (3) 2x5 9C44 20 503 2

89 CAMERA TAPPING SCREW P (3) 1.7x5 9C45 17 503 1

90

91 TAMS SCREW 2x3 9P02 20 031 2

92

93 TS. SG2x4 9C20 20 401 2

94

95 E RING S2.3 9E01 00 231 1

96

97 P WASHER CUT 1.55x5x0.5 9W02 50 060 6

98

99

100

31

DAEWOO

Page 35

PART LIST

1. EXPLODED P AR TS LIST

NO. PART CODE PART NAME DESCRIPTION Q’TY

1 97T1806200 DOOR L ABS XR-404 SPRAY/SILK 1

2 97T1001500 DECORATION URETAN PRINT 1

3 97T1806300 DOOR R ABS XR-404 SPRAY/SILK 1

4 97T1414900 ESCUTCHEON ABS XR-404 SPRAY/SILK 1

5 97T0663030 CHASSIS MAIN SECC1 0.8T PAINT 1

6 97T3013900 SPRING MTG STS-304 0.7PI 2

7 97T2609200 LEVER MTG SECC1 0.8T PAINT 2

8 97T13C4500 KNOB EJECT ABS XR-404 SILK 1

9 PNSWMBKC00 PCB SW AS AKD-100C 1

10 PNDJMBKC00 PCB CONN AS AKD-100C 1

11 PNMAMBKC00 PCB MAIN AS AKD-100C 1

12 97T6009300 DECK MECHANISM TN-CDC1010-102M 1

13 97T0436200 COVER TOP SECC1 0.8T PAINT/SILK 1

14 97T5602500 INSULATION PET 0.25T 1

15 97T2609900 DAMPER TN-CDC1010 4

S1 7173260611 SCREW TAPTITE TT2 BIN 2.6x6 MFZN 12

S2 7173260811 SCREW TAPTITE TT2 BIN 2.6x8 MFZN 1

§ OTHER

NO. PART CODE PART NAME DESCRIPTION Q’TY

1 97T1500200 MAGAZINE ASS’Y TN-CDC1010 IN/BAG 1

§ MOUNTING ACCESSORIES

NO. PART CODE PART NAME DESCRIPTION Q’TY

97T2444400 BRACKET MTG SCP-1 BK PAINT 2

97T2441400 BRACKET STUD ABS XR-404 BK 2

7343601511 BOLT HEXAGON 6B-3-6x15 MFZN 4

7393600611 NUT HEXAGON 6N-3-6 MFZN 4

7061401012 SCREW MACHINE PAN 4x10 HSBK 4

DAEWOO

32

Page 36

2. ELECTRIC P AR TS LIST

§ IC

REF PART NO. DESCRIPTION

IC101 1KB9223--- IC CHIP RF KB9223 RF+SSP+AF

IC102 1BA4560F-- IC AMP BA4560F

IC201 1KA3030D-- IC CHIP DRIVE KA3030D

IC501 1KS9286--- IC CHIP DSP KS9286 DSP+DAC

IC601 19920408H0 IC CHIP CUSTOM KS57C0408

IC602 1K1A7027P- IC RESET KIA7027AP

IC603 1SP123519- IC PHOTO SPI-235-19 SANYO

IC701 IZ1A78S05P IC REGULATOR KIA78S05P (AUTO)

§ TRANSISTER

REF PART NO. DESCRIPTION

HQ101 TKTA1663Y- TR CHIP KTA1663Y

HQ102 TKSR1110-Y TR CHIP KSR1110 (R10)

HQ103 TKSR1110-Y TR CHIP KSR1110 (R10)

HQ601 TKSC2859-Y TR CHIP KSC2859-Y (EIY)

Q701 TKTD2058Y- TR KTD2058-Y

Q702 TZSC945YC- TR KSC945YC

HQ703 TKSR1101-Y TR CHIP KSR1101-Y (R01)

HQ704 TKSR2113-Y TR CHIP KSR2113-Y (R63)

§ DIODE

REF PART NO. DESCRIPTION

HD101 DKDS226--B DIODE CHIP KDS226 SOT-23 C3

HD501 DKDS226-B DIODE CHIP KDS226 SOT-23 C3

HD502 DKDS226-BB DIODE CHIP KDS226 SOT-23 C3

HD601 DKDS184--B DIODE CHIP KDS-184 SOT-23 B3

HD603 DKDS184--B DIODE CHIP KDS-184 SOT-23 B3

HD604 DKDS184--B DIODE CHIP KDS-184 SOT-23 B3

D701 DKN4004A-- DIODE KN4004A AUTO 26MM

HD702 DKDS193--B DIODE CHIP KDS-193 SOT-23 F3

33

DAEWOO

Page 37

§ OTHERS

REF PART NO. DESCRIPTION

CH701 5LC0000308 COIL CHOKE EI-14MM PCB TYPE

CN101 97T8859400 CONN AS 21P 22x160 (FFC)

CN401 97T8859300 CONN AS 5P 6x120 (FFC)

CW101 97T6220800 CONNECTOR WAFER 6232-121-102-800 ELCO

CW201 97T6220600 CONNECTOR WAFER S2B-ZR-SM2-TF

CW301 97T62E7202 WAFER CN-W 00-8283-0211-000

CW401 97T6220700 CONNECTOR WAFER 6232-105-102-800 ELCO

CW501 97T62E7208 WAFER CN-W 00-8283-0811-000

CN501 97TH82406D CONN AS 8P #28 UL 1007 60MM

J501 97T6367600 SOCKET DIN LN-0505B-008 8P PCB TY

CN301 97TH294158 CONN AS 2P #28 UL 1007 150MM

SW601 5S50101Z02 SW TACT 1C-1P SKQC10918B 260G

SW602 5S50101113 SW TACT SPPB61180A ALPS

SW603 5S40201A30 SW PUSH MPU1130MLB0 MIC

XT501 5XJY16R93E CRYSTAL QUARTZ HC-49/S 16.9344MHz 30PF

XT601 5PT4R19MGW RESONATOR CERA CST4.19MGW

DAEWOO

34

Loading...

Loading...