Page 1

Installation Instructions

Built-In Refrigerator

42 and 48 Inch Models: EF42DBSS, EF42NBSS, EF48DBSS, EF48NBSS

IF42DBOL, IF42NBOL, IF48DBOL, IF48NBOL

Part No. 103675 Rev. E/W10159564E

Page 2

Table of Contents

Refrigerator Safety .......................................................................1

Model Identification ......................................................................2

Installation Requirements ......................................................3-12

Tools and Parts ...........................................................................3

Location Requirements ............................................................3-4

Electrical Requirements ..............................................................4

Water Supply Requirements .......................................................5

Tipping Radius ............................................................................5

Product Dimensions ....................................................................6

Door Swing Dimensions .............................................................7

Door Panels and Cabinetry Clearance ....................................8-9

Custom Panels and Handles ...............................................10-11

Custom Side Panels ............................................................12-13

Customer Service Information

If you have questions or problems with installation, contact your

®

Dacor

call, have the model and serial number of the appliance ready.

The model and serial number are printed on the appliance data

label. The label is located inside the refrigerator on the right.

dealer or the Dacor Customer Service Team. When you

Installation Instructions ........................................................14-21

Unpack Refrigerator ..................................................................14

Reduce Tipping Radius.............................................................14

Move Refrigerator into House ...................................................14

Install Anti-Tip Boards ...............................................................15

Connect Water Supply .........................................................15-16

Plug in Refrigerator ...................................................................16

Move to Final Location .............................................................16

Level and Align Refrigerator .....................................................17

Custom Panel and Handle Installation ....................................18

Adjust Doors .............................................................................19

Install Side Panel(s) ..................................................................20

Install Base Grille ......................................................................20

Complete Installation ................................................................21

Water System Preparation ........................................................21

Notes.........................................................................................22

Français ..................................................................................23-44

Dacor Customer Service

Phone: (800) 793-0093

Web site: www.Dacor.com

All specifications subject to change without notice.

Dacor assumes no liability for changes to specifications.

© 2008 Dacor, all rights reserved.

Page 3

Refrigerator Safety

WARNING

Tip Over Hazard

Refrigerator is top heavy and tips easily when not

completely installed.

Keep doors taped closed until refrigerator is

completely installed.

Use two or more people to move and install

refrigerator.

Failure to do so can result in death or serious injury.

You can be killed or seriously injured if you don't immediately

You

can be killed or seriously injured if you don't

follow

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

follow instructions.

instructions.

DANGER

WARNING

1

Page 4

Model Identification

Refrigerators With Ice and Water Dispensers

EF42DBSS and EF48DBSS:

42” and 48” dispensing models with all stainless steel finish

42” and 48” dispensing models designed for installation of custom

IF42DBOL and IF48DBOL:

panels and handles

Refrigerators Without Ice and Water Dispensers

EF42NBSS and EF48NBSS:

42” and 48” non-dispensing models

with all stainless steel finish

2

42” and 48” non- dispensing models designed for installation of

IF42NBOL and IF48NBOL:

custom panels and handles

Page 5

Installation Requirements

WARNING

Explosion Hazard

Keep flammable materials and vapors, such as

gasoline, away from refrigerator.

Failure to do so can result in death, explosion, or fire.

Tools and Parts

Tools needed:

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed

here.

Cordless drill

Drill bits

Two adjustable wrenches

Phillips screwdriver

Small level

Appliance dolly

®†

T27 screwdriver

Torx

¹¹⁄ 32” nut driver

³⁄ 8” and ¹⁄2” open-end wrenches

5

Allen wrench (

4” and

¹⁄

Tape measure

Parts Needed:

Six #8 x 3” (7.6 cm) wood screws (longer screws may be

needed)

One or two 2” x 4” x 32” (5 cm x 10 cm x 81 cm) wood

board(s)

IF Series Models: Make custom panels, or consult a

qualified cabinetmaker or carpenter to make the panels. See

“Installation Requirements” for more information.

EF Series Models: Comes with doors that have a stainless

steel finish and are shipped complete.

If you are connecting the water line directly to copper tubing

and not to a shutoff valve, you need a ferrule, a union, and a

4” (6.35 mm) compression fitting.

¹⁄

⁄32”)

5

/16” socket drivers

Location Requirements

Your Dacor refrigerator can be recessed in an opening between

cabinets or installed at the end of a cabinet run using a side panel

to enclose the refrigerator.

IMPORTANT:

Observe all governing codes and ordinances.

It is recommended that you do not install the refrigerator near

an oven, radiator, or other heat source.

Do not install in a location where the temperature will fall

below 55°F (13°C).

Floor must support the refrigerator weight, more than 600 lbs

(272 kg), door panels and contents of the refrigerator.

Ceiling height must allow for side tipping radius. See Tipping

Radius.

Location should permit doors to open fully. See Door Swing

Dimensions.

Location must permit top grille removal. See Opening

Dimensions.

Opening Dimensions

To avoid tipping during use, the solid soffit must be within 1”

(2.5 cm) maximum above the refrigerator. If the solid soffit

is higher than 1” (2.5 cm) or one is not available, then the

refrigerator must be braced.

If the anti-tip boards are needed, they must be attached to the

rear wall studs 80” to 90” (203 cm to 229 cm) above the floor.

See Install Anti-Tip Boards for more information.

NOTE: A clearance of ¹⁄2” (1.3 cm) must be maintained above

the top grille in order for the top grille to be removed.

† TORX is a registered trademark of Textron Innovations Inc.

1/2” (1.3 cm)

3

Page 6

Installation Requirements

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

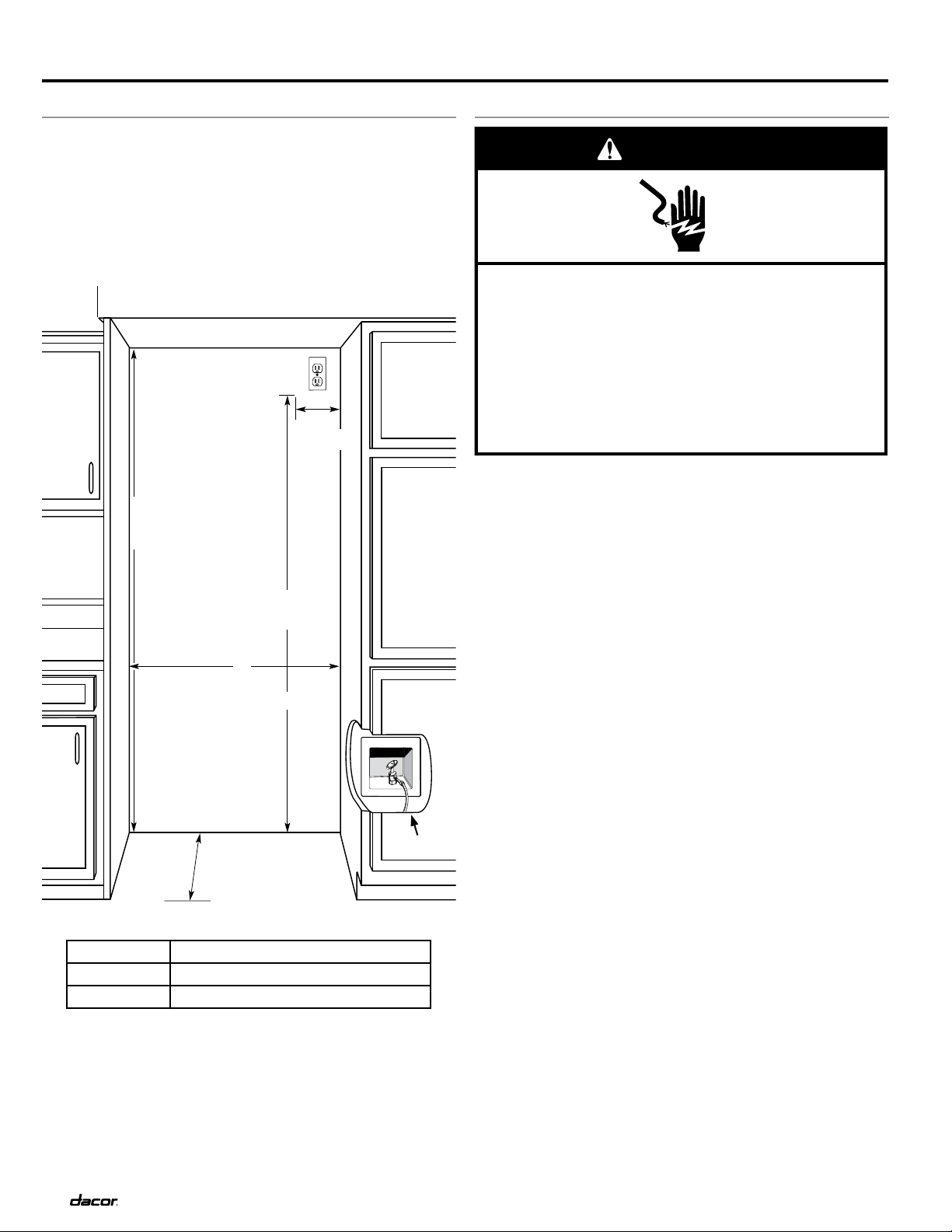

Location Requirements (continued)

A grounded 3 prong electrical outlet should be placed within

4” (10.2 cm) of the right side cabinets or end panel. See

Electrical Requirements for more information.

The water shutoff should be located in the base cabinet on

either side of the refrigerator or some other easily accessible

area. If the water shutoff valve is not in the cabinets, the

plumbing for the water line can come through the floor or

the back wall. See Water Supply Requirements for more

information.

4”

(10.2 cm)

83 1/2” (212.1 cm) min.

84 3/4” (215.2 cm)

to bottom of solid soffit

77”

(195.6 cm)

A

Width

(see chart following)

See page 5

Electrical Requirements

Before you move your refrigerator into its final location, it is

important to make sure you have the proper electrical connection.

Recommended Grounding Method

A 115 Volt, 60 Hz., AC only 15 or 20-amp fused, grounded

electrical supply is required. It is recommended that a separate

circuit serving only your refrigerator be provided. Use an outlet

that cannot be turned off by a switch. Do not use an extension

cord.

IMPORTANT: If this product is connected to a GFCI (Ground

Fault Circuit Interrupter) equipped outlet, nuisance tripping of the

power supply may occur, resulting in loss of cooling. Food quality

and flavor may be affected. If nuisance tripping has occurred, and

if the condition of the food appears poor, dispose of it.

NOTE: Before performing any type of installation, cleaning, or

removing a light bulb, remove the top grille and turn the master

power switch to OFF or disconnect power at the circuit breaker

box.

When you are finished, turn ON the main power switch or

reconnect power at the circuit breaker box. Then reset the control

to the desired setting.

24”

(61.0 cm) min.

Model Series Cutout Width A

EF42, IF42 41½” (105.4 cm) to 41¾” (106.1 cm)

EF48, IF48 47½” (120.7 cm) to 47¾” (121.3 cm)

NOTE: Flooring under refrigerator must be at same level as the

room. Face of cabinetry must be plumb.

4

Page 7

Installation Requirements

A

Water Supply Requirements

All installations must meet local plumbing code requirements.

The water shutoff should be located in the base cabinet on

either side of the refrigerator or some other easily accessible

area. The right-hand side is recommended. The access hole

through the cabinet must be within ½” (12.7 mm) of the rear

wall.

NOTE: If the water shut off valve is in the back wall behind the

refrigerator, it must be at an angle so that the tube is not kinked

when the refrigerator is pushed into its final position.

Access hole with 1/2” (1.3 cm) of

floor and rear wall

Possible water

line locations

1”

6”

(15.2 cm)

(2.5 cm)

6”

(15.2 cm)

If the water pressure to the reverse osmosis system is less than

40 to 60 psi (276 to 414 kPa):

Check to see whether the sediment filter in the reverse

osmosis system is blocked. Replace the filter if necessary.

Allow the storage tank on the reverse osmosis system to refill

after heavy usage.

If your refrigerator has a water filter cartridge, it may further

reduce the water pressure when used in conjunction with a

reverse osmosis system. Remove the water filter cartridge.

If you have questions about your water pressure, call a licensed,

qualified plumber.

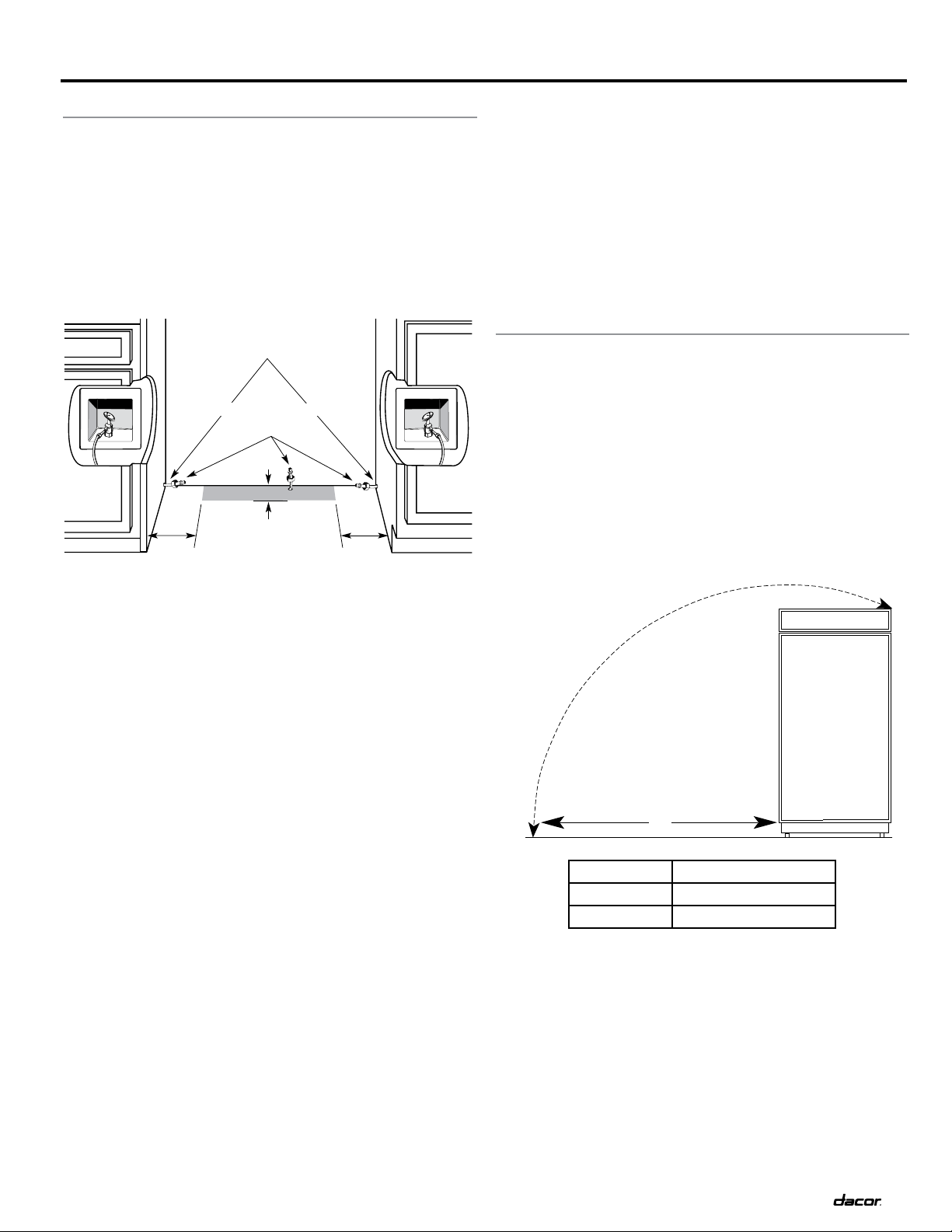

Tipping Radius

Be sure there is adequate ceiling height to stand the refrigerator

upright when it is moved into place.

The dolly wheel height must be added to the tipping radius

when a dolly is used.

If needed, the tipping radius can be reduced. See Reduce

Tipping Radius.

Side Tipping Radius

The side tipping radius varies depending upon the width of the

model. Use the chart provided to determine the side tipping

radius.

NOTE: Tip on side only.

If the water shutoff valve is not in the cabinets, the plumbing

for the water line can come through the floor. A ½” (12.7 mm)

hole for plumbing should be drilled at least 6” (15.2 cm) from

the right or left hand side cabinet or panel. On the floor, the

hole should be no more than 1” (2.54 cm) away from the back

wall. See Connect the Water Supply.

If additional tubing is needed, use copper tubing and check

for leaks. Install the copper tubing only in areas where the

household temperatures will remain above freezing.

Do not use a piercing-type or ³⁄

which reduces water flow and clogs more easily.

NOTE: Your refrigerator dealer has a kit available with a ¼” (6.35

mm) saddle-type shutoff valve, a union and copper tubing. Before

purchasing, make sure a saddle-type valve complies with your

local plumbing codes.

16” (4.76 mm) saddle valve

Water Pressure

A cold water supply with water pressure between 30 and 120 psi

(207 and 827 kPa) is required to operate the water dispenser and

ice maker. If you have questions about your water pressure, call a

licensed, qualified plumber.

Reverse Osmosis Water Supply

IMPORTANT: The pressure of the water supply coming out of

a reverse osmosis system going to the water inlet valve of the

refrigerator needs to be between 30 and 120 psi (207 and 827

kPa). If a reverse osmosis water filtration system is connected

to your cold water supply, the water pressure to the reverse

osmosis system needs to be a minimum of 40 to 60 psi (276 to

414 kPa).

A

Model Series Tipping Radius A

EF42, IF42 93” (236.2 cm)

EF48, IF48 96” (243.8 cm)

5

Page 8

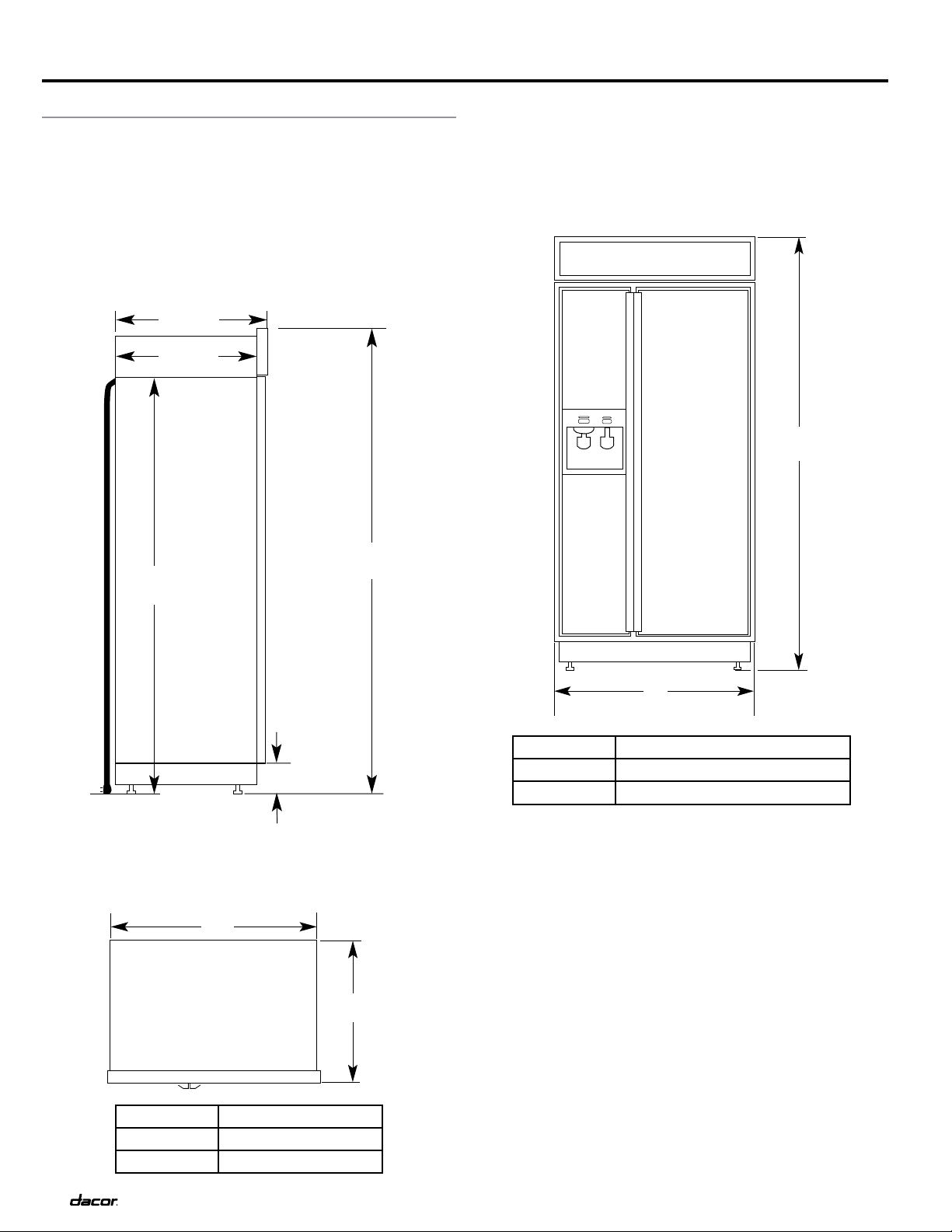

Product Dimensions

Installation Requirements

Side View:

The depth from the front of the top grille to the back of the

refrigerator cabinet is 25³⁄8” (64.5 cm).

The power cord is 84” (213 cm) long.

The water line attached to the back of the refrigerator is 5 ft

(1.5 m) long.

Height dimensions are shown with leveling legs extended ¹⁄

(3 mm) below the rollers.

25 3/8”

(64.5 cm)

23 1/2”

(59.7 cm)

84” (213.4 cm)

Power Cord

Front View:

Width dimensions were measured from trim edge to trim edge.

Height dimensions are shown with leveling legs extended ¹⁄ 8”

(3 mm) below the rollers.

8”

*83 3/8”

(211.8 cm)

*83 3/8”

(211.8 cm)

*3 1/2” (8.9 cm)

* When leveling legs are fully extended to 1¼” (3.2 cm) below

rollers, add 1¹⁄

8” (2.9 cm) to the height dimensions.

Top View:

A

25 3/8”

(64.5 cm)

Model Width A

EF42, IF42 41 ¼” (104.8 cm)

EF48, IF48 47 ¼” (120.0 cm)

B

(see following chart)

Model Series Width B (Trim edge to trim edge)

EF42, IF42 42 ¼” (107.3 cm)

EF48, IF48 48 ¼” (122.6 cm)

*When leveling legs are fully extended to 1¼” (3.2 cm) below

rollers, add 1¹⁄

8” (2.9 cm) to the height dimensions.

6

Page 9

130˚

130˚

90˚

90˚

110˚

110˚

50¹⁄2

"

(128.3 cm)

45¹⁄4

"

(114.9 cm)

26

³⁄4

"

(68.0 cm)

19

³⁄4

"

(50.2 cm)

40"

(101.6 cm)

43

¹⁄2"

(110.5 cm)

Installation Requirements

130˚

130˚

90˚

90˚

110˚

110˚

47"

(119.4 cm)

42

9

⁄16"

(108.1 cm)

23

¹⁄4

"

(59.1 cm)

17

¹⁄2"

(44.5 cm)

38"

(96.5 cm)

41"

(104.1 cm)

Door Swing Dimensions

The location must permit both doors to open to a minimum of

90°. Allow 4½” (11.4 cm) minimum space between the side of the

refrigerator and a corner wall.

NOTE: More clearance may be required if you are using overlay

panels, custom handles or extended handles on a IF series

model.

To adjust the door swing, see Adjust Doors.

EF42 and IF42 Model Series

EF48 and IF48 Model Series

7

Page 10

Backer Panel

Overlay Panel

Spacer Panel

1

/4" (6.4 mm)

3

/4" (1.9 cm)

1" (2.5 cm)

1

/2" (1.3 cm)

1"

1

1

/4"

1

1

/2"

1"

(2.5 cm)

1

(3.2 cm)

1

/4"

1

(3.8 cm)

1

/2"

1

/2"

Refrigerator

Side Trim

Door

Hinge

(2.5 cm)

(3.2 cm)

(3.8 cm)

(1.3 cm)

Cabinetry

3

/4"

(1.9 cm)

110˚ Door

Stop Position

Installation Requirements

Door Panels and Cabinetry Clearance - IF42/IF48 Series Models

The custom door panels and adjacent cabinetry for models series IF42 and IF48 must be designed so that there is sufficient clearance

for the doors to swing open. If the refrigerator is to be installed close to the wall, see Door Swing 90° on facing page.

Door Swing 110°

Actual Size

Refrigerator to

Cabinetry Clearance

NOTE: For IF Series models, rout the

hinge side of the custom door panels

to a radius that is equal to at least half

the thickness of the panel if a 130°

door swing is desired. See Adjust

Doors.

When the doors are closed the refrigerator will extend beyond the face of the adjacent cabinetry to some degree.

8

Page 11

1

/4" (6.4 mm)

3

/4" (1.9 cm)

1" (2.5 cm)

1

/2" (1.3 cm)

3

/

4

"

1"

1

1

/

4

"

11/

2

"

1

/

2

"

Refrigerator

Side Trim

Hinge

90° Door

Stop Position

Backer Panel

Door

Overlay Panel

Door Swing 90

˚

Actual Size

Refrigerator to

Cabinetry Clearance

(1.9 cm)

(2.5 cm)

(3.8 cm)

(1.3 cm)

(3.2 cm)

Spacer Panel

Cabinetry

1

/

2

"

3

/

4

"

1"

(1.3 cm)

(1.9 cm)

(2.5 cm)

Door Swing 90°

Actual Size

Refrigerator to

Cabinetry Clearance

Installation Requirements

Allow a minimum of 4½” (11.4 cm) of space between the side of the refrigerator and a corner wall. More clearance may be needed if

thicker custom panels or custom handles are used. Do not overlook baseboards.

9

Page 12

Installation Requirements

Overlay Panel

Overlay Panel

Spacer Panel

Backer Panel

Backer Panel

Door

5

/8" to 3/4"

(1.6 to

1.9 cm)

1

/8"

(3.2 mm)

1

/4"

(6.4 mm)

1" minimum*

(2.5 cm)

Door/Grille Trim

Spacer Panel

Offset Dimension

1

/8"

(3.2 mm)

Overlay Panel

Backer Panel

Door

1" minimum*

(2.5 cm)

Door/Grille Trim

Spacer Panel

Offset Dimension

1

/8"

(3.2 mm)

Custom Panels and Handles - IF42/IF48 Series Models

Custom overlay panels used with models IF42 and IF48 allow you

to blend the exterior of your refrigerator into the overall kitchen

décor, and to use custom handles for additional design flexibility.

Panel Specifications

The custom panels must have backer panels attached in order •

to mount them to the refrigerator. It is most common to work

with three layers, as shown in the illustrations below. The three

layers consist of a decorative overlay panel, a ¹/

spacer panel or spacer strips and a ¼” (6.35 mm) backer panel.

In some cases, instead of constructing the panel using three •

layers, the cabinet manufacturer may choose to work with a

single piece routed for the different dimensions. Follow the

panel dimension and placement instructions on the facing page

to be sure that the custom overlay panels will fit properly.

To minimize panel weight, you may use 2” (5.08 cm) spacer •

strips around the perimeter in place of full-sheet solid spacer

panels. The spacer strips must be set in at least 1” (2.54 cm)

from the top, bottom and side edges of the backer panel. If you

use spacer strips, it is also recommended that you use two 2”

(5.08 cm) strips horizontally centered for added support.

For the grille and the door panels to be flush, the overlay door •

panel should be ¼” (6.35 mm) thicker than the overlay grille

panel.

IMPORTANT:

Install the custom panels only after moving the refrigerator into •

place (see page 16).

The weight of the overlay panels cannot exceed:•

50 lbs (23 kg) for the refrigerator door 30 lbs (13.5 kg) for the freezer door (total) 10 lbs (4.5 kg) for the top grille -

8” (3.18 mm)

Important Information About Freezer Door Overlay

Panels on Dispenser Models:

There are two basic methods for paneling the freezer door on •

dispenser models:

Frameless method Framed method -

The framless method involves fabricating two separate panels •

for above and below the dispenser that slide in from the handle

side of the door.

The framed method involves fabricating a single overlay panel •

and attaching two separate sets of spacer and backer panels

above and below the dispenser cutout (see facing page). The

completed panel slides into place as a single unit.

IMPORTANT: The dispenser is recessed behind the overlay

panel for the freezer door. The edges of the overlay panel around

the bottom of the dispenser may be exposed to water during

normal use. Seal the area around the dispenser to prevent water

seepage and damage. It is suggested that the edges of the

panel around the bottom the dispenser be covered by waterproof

material to prevent damage to the finish over time.

10

* The spacer panel offset must be a minimum

of 1” (2.5 cm) from all four edges of each

backer panel, including the edges next to the

dispenser (on dispenser models).

Page 13

Installation Requirements

Top Grille

C

73/8"

(18.7 cm)

81/2"

(21.6 cm)

Offset

Bottom

Backer

1" (2.5 cm)

F

70¹⁄2"

(179.1 cm)

70¹⁄2

"

(179.1 cm)

E

D

B

Refrigerator Panel for

Freezer Panel for

Non-Dispenser Models all Models

Handle-Side

Backer

Offset

¹⁄8" (3.2 mm)

A

¹⁄8

"

(3.2 mm)

Backer Bottom Offset

¹⁄8

"

(3.2 mm)

24 "

(61.1 cm)

35”

(88.9 cm)

Framed MethodFrameless Method

34³⁄8"

(87.3 cm)

34³⁄8

"

(87.3 cm)

23

3

⁄8

"

(59.4 cm)

D

D

D

A

A

D

Bottom Offset

¹⁄8

"

(3.2 mm)

7

⁄16

Freezer Panels for

Dispenser Models

A

11

15

⁄16

"

(30.5 cm)

35”

(88.9 cm)

11

"

(29.5 cm)

5

⁄8

Dispenser

cutout is

centered

left to right

Handle-Side

Offset

¹⁄8" (3.2 mm)

Handle-Side

Offset

¹⁄8

¹⁄8

" (3.2 mm)

Handle-Side

Offset

¹⁄8" (3.2 mm)

Backer

Backer

Bottom Offset

Backer

Backer

Backer

Backer

Top Freezer Panel

Bottom Freezer Panel

Top Offset

"

(1.1 cm)

23

3

⁄8

"

(59.4 cm)

¹⁄16 "

(180.5 cm)

71

Decorative Overlay Panels

Model

Series

IF42 17¹⁄

IF48 19

Model

Series

IF42 16

IF48 19

A B C

8” (43.5 cm) 23¹⁄8” (58.74 cm) 40½” (102.9 cm)

5

⁄8” (49.9 cm) 265⁄8” (67.6 cm) 46½” (118.1 cm)

D E F

7

⁄

” (42.9 cm) 22

8

3

⁄

” (49.2 cm) 26

8

Backer Panels

7

⁄

” (58.1 cm) 40½” (102.9 cm)

8

3

⁄

” (67.0 cm) 46½” (118.1 cm)

8

Custom Handles

Dacor recommends handles with larger D-style pulls. If using

screws with thick heads, they must be countersunk into the panel

before installing the handles.

Any handle designed for use with an appliance should produce

satisfactory results. Mounting screw length varies with the total

thickness of the panels.

IMPORTANT: Dacor does not advise the use of single pull knobs.

Trim frame

surrounding door

B

A

Door

A. Countersunk screw

B. Handle

C. Door panel assembly

Handle Detail

C

20” Typ.

(50.6 cm)

36” Max.

(91.4 cm)

11

Page 14

Installation Requirements

A

A

Custom Side Panels - IF42/IF48

Custom side panels may be needed when not enough space is

available to have cabinets on both sides of the refrigerator or

when the refrigerator is placed at the end of a cabinet run. You

may choose an Inset or Recessed Inset panel installation for

models IF42 and IF48.

Refrigerator and Side Trim Dimensions

The width and height of a side panel are determined by the type

of installation you are planning.

NOTES:

The dimensions shown are actual product dimensions and

may not reflect the needed installation dimensions.

The side panel should be a minimum of ½” (1.3 cm) thick to

avoid warping.

If the opening depth is 25” (63.5 cm) or more, you may want to

install a support board on the rear wall.

Refrigerator

23 1/2”

(59.7 cm)

Inset Installation Dimensions

Measure the distance from point 1. A (as shown) to the back

wall. Add ¹⁄32” (0.8 mm) to this measurement to allow the side

panel to fit into the trim.

If the panel is more than ³⁄2. 8” (9.5 mm) thick, rout the front edge

to allow the side panel to fit into the trim.

Back wall

A

Recessed Inset Installation Dimensions

Measure the distance from point 1. B (as shown) to back wall.

Route the front edge of the support board or attach a ³⁄2. 8” (9.5

mm) board to hold the panel in the cabinet side trim.

Side Trim

Back wall

B

3/16” (4.5 mm)

3/8” (9.7 mm)

1/16” (1.5 mm)

1/8” (3.2 mm)

12

Page 15

Installation Requirements

A

A

A

24¹⁄8

"

(61.3 cm)

23

½

"

(59.7 cm)

23¹¹⁄16

"

(60.3 cm)

Custom Side Panels - EF42/EF48

Custom side panels may be needed when not enough space is

available to have cabinets on both sides of the refrigerator or

when the refrigerator is placed at the end of a cabinet run. You

may choose an inset, flush or recessed inset panel installation for

models EF42 and EF48.

Refrigerator and Side Trim Dimensions

The width and height of a side panel are determined by the type

of installation you are planning.

NOTES:

The dimensions shown are actual product dimensions and

may not reflect the needed installation dimensions.

The side panel should be a minimum of ½” (1.3 cm) thick to

avoid warping.

If the opening depth is 25” (63.5 cm) or more, you may want to

install a support board on the rear wall.

Refrigerator

24 1/8”

(61.3 cm)

23 11/16”

(60.3 cm)

23 1/2”

(59.7 cm)

Inset Installation Dimensions

Measure the distance from point 1. A (as shown) to the back

wall. Add 7⁄32” (5.6 mm) to this measurement to allow the side

panel to fit into the trim.

If the panel is more than ¼” (6.4 mm) thick, route the front 2.

edge to allow the side panel to fit into the trim.

Back wall

A

Flush Installation Dimensions

Measure the distance from point 1. B (as shown) to the back

wall.

Attach the support board with a screw or adhesive that is 2.

compatible with aluminum and wood.

Side Trim

1/4” (6.35 mm)

3/16” (4.7 mm)

7/32” (5.5 mm)

13/32” (10 mm)

11/64”

(4.5 mm)

5/8”

(15.7 mm)

Back wall

B

Recessed Inset Installation Dimensions

Measure the distance from point 1. C (as shown) to the back

wall.

Route the front edge of the support board or attach a 2.

¼” (6.4 mm) board to hold the panel in the cabinet side trim.

Back wall

C

13

Page 16

Installation Instructions

WARNING

Tip Over Hazard

Refrigerator is top heavy and tips easily when not

completely installed.

Keep doors taped closed until refrigerator is

completely installed.

Use two or more people to move and install

refrigerator.

Failure to do so can result in death or serious injury.

WARNING

Tip Over Hazard

Refrigerator is top heavy and tips easily when not

completely installed.

Keep doors taped closed until refrigerator is

completely installed.

Use two or more people to move and install

refrigerator.

Failure to do so can result in death or serious injury.

Unpack Refrigerator

IMPORTANT:

If you receive a damaged product, immediately contact your

dealer or builder. Do not install or use a damaged appliance.

Do not remove the film on the outside until the refrigerator is in

its operating position.

All four leveling legs must contact the floor to support and

stabilize the full weight of the refrigerator.

Keep the cardboard shipping piece or plywood under the

refrigerator until it is installed in the operating position.

Remove and save the literature package bag taped to the side 1.

of the refrigerator and the parts bag behind the grille. Remove

the four brackets (two on each side) that attach the shipping

base to the refrigerator bottom.

NOTE: Do not remove tape and door bracing until the refrigerator

is in its final position.

If necessary, reduce the tipping radius. See 2. Tipping Radius

(page 5) for ceiling height requirements or Reduce Tipping

Radius for step-by-step instructions. If you do not need to

reduce the tipping radius, proceed to Move the Refrigerator

into House.

Reduce Tipping Radius

(if required)

Before bringing the refrigerator into the home, be sure there is

adequate ceiling height to stand the refrigerator upright. See

Tipping Radius (page 5).

If you do not have adequate ceiling height to stand the refrigerator

upright, the tipping radius can be reduced by removing the top

grille and side trims (see the following chart).

14

Model Reduced Tipping Radius

EF42, IF42 88½” (224.8 cm)

EF48, IF48 89¼” (226.7 cm)

Grasp both ends of the top grille.1.

Push the top grille straight up, then pull straight out. Lay the 2.

grille on a soft surface.

B B

A. Top grille

B. Cabinet side trim

Remove the six screws attaching each cabinet side trim to the 3.

refrigerator and remove the side trims.

A

Move Refrigerator into House

Place an appliance dolly under the left side of the refrigerator 1.

as shown. Be sure to avoid damaging the side trims and

handles. Place the corner posts from the packing materials

over the trims and handles as appropriate. Slowly tighten the

strap.

NOTE: Pass the

dolly strap under

the handles

for EF series

models.

Place pieces 2.

of the shipping

carton on the

floor when rolling

the dolly and

refrigerator into the house. Move the refrigerator close to the

built-in opening.

Place top of cardboard carton or plywood under refrigerator.3.

Stand the refrigerator up. First, place the left bottom edge of 4.

the refrigerator on the floor, stand the refrigerator upright and

then lower the right-hand side of the refrigerator to the floor.

Do not remove the film on the outside. 5.

Reassemble the trim and top grille after the dolly has been 6.

removed from the refrigerator.

Page 17

Installation Instructions

Install Anti-Tip Boards

IMPORTANT:

To avoid tipping during use, the solid soffit must be within 1”

(2.5 cm) maximum above the refrigerator. If the solid soffit

is higher than 1” (2.5 cm) or one is not available, then the

refrigerator must be braced.

It is recommended that board(s) be installed before the

refrigerator is installed.

Board(s) must be long enough to fully cover the width of the

compressor cover.

Locate the board(s) so the bottom surface(s) of the board(s) is

(are) 84” (213 cm) from the floor.

During installation, raise the refrigerator up so there is ¼” (6.35

mm) maximum between the top of the refrigerator and the

bottom of the anti-tip board(s). Do not crush the compressor

cover when raising the rear leveling legs.

To Install Anti-tip Boards

Mark the stud locations on rear wall 80” to 90” (203 cm to 229 1.

cm) above floor.

Securely attach one or two 2” x 4” x 32” (5 cm x 10 cm x 81 2.

cm) boards to wall studs behind refrigerator. Use six #8 x 3”

(7.6 cm) (or longer) wood screws. The wood screws must be

screwed into the studs at least 1½” (3.8 cm). The board(s)

must overlap the compressor cover.

A

B

C

Connect Water Supply

Read all directions before you begin.

IMPORTANT: If you turn the refrigerator on before the water line

is connected, turn the ice maker OFF.

Style 1 - Shutoff Valve Connection

NOTE: If your water line connection does not look like Style 1,

see Style 2 - Copper Line Connection.

Unplug refrigerator or disconnect power supply.1.

IMPORTANT: Before attaching the tubing to shutoff valve, flush

the main water supply line to remove particles and air in the water

line. Allow enough flow so that water becomes clear. Flushing

the water line may help avoid filters and/or water valves from

becoming clogged.

Remove the shipping tape from the gray, coiled water tubing 2.

on the rear of the refrigerator.

Thread the provided 3.

nut onto the shutoff

valve as shown.

Turn shutoff valve 4.

ON.

Check for leaks. 5.

Tighten any nuts

or connections

(including

connections at the

valve) that leak.

Plug in the refrigerator or reconnect power.6.

Flush the water system. See 7. Water System Preparation.

NOTE: Allow 24 hours to produce the first batch of ice. Discard

the first three batches of ice produced. Allow 3 days to completely

fill ice container.

A. Bulb

B. Nut

C. Water tubing

A

B

C

2” (5 cm)

D

A. Center board 1/4” (6.4 mm) max. above refrigerator

B. Two 2” x 4” x 32” (5 cm x 10 cm x 81 cm) boards

C. Attach to studs with six #8 x 3” (7.6 cm) screws

D. Compressor cover

Style 2 - Copper Line Connection

Connecting to Water Line

NOTE: If existing water line meets the Water System

Requirements, see Connecting to Refrigerator.

Unplug refrigerator or disconnect power.1.

Turn OFF main water supply. Turn ON nearest faucet long 2.

enough to clear line of water.

Locate a ½” to 1¼” (1.25 cm to 3.18 cm) vertical cold water 3.

pipe near the refrigerator.

IMPORTANT:

Make sure it is a cold water pipe.

Horizontal pipe will work, but drill on the top side of the pipe,

not the bottom. Doing so will help keep water away from the

drill and normal sediment from collecting in the valve.

Determine the length of copper tubing you need. Measure 4.

from the connection on the lower left rear of refrigerator to

the water pipe. Add 7 ft. (2.1 m) to allow for cleaning. Use ¼”

(6.35 mm) O.D. (outside diameter) copper tubing. Be sure both

ends of copper tubing are cut square.

15

Page 18

Installation Instructions

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death,

fire, or electrical shock.

WARNING

WARNING

Tip Over Hazard

Refrigerator is top heavy and tips easily when not

completely installed.

Keep doors taped closed until refrigerator is

completely installed.

Use two or more people to move and install

refrigerator.

Failure to do so can result in death or serious injury.

Using a cordless drill, drill a ¼” (6.35 mm) hole in the cold 5.

water pipe you have selected.

Fasten the shutoff valve to the cold water pipe with the pipe 6.

clamp. Be sure the outlet end is solidly in the ¼” (6.35 mm)

drilled hole in the water pipe and that the washer is under the

pipe clamp. Tighten the packing nut. Tighten the pipe clamp

screws slowly and evenly so the washer makes a watertight

seal. Do not overtighten.

A

G

F

E

A. Cold water pipe

B. Pipe clamp

C. Copper tubing

D. Compression nut

Slip the compression sleeve and compression nut on the 7.

copper tubing as shown. Insert the end of the tubing into the

outlet end squarely as far as it will go. Screw compression nut

onto outlet end with adjustable wrench. Do not overtighten the

nut or the sleeve. Doing so will crush the copper tubing.

IMPORTANT: Before attaching the tubing to shutoff valve,

flush the main water supply line to remove particles and air in

the water line. Allow enough flow so that water becomes clear.

Flushing the water line may help avoid filters and/or water

valves from becoming clogged.

Turn off the shutoff valve on the water pipe. Coil the copper 8.

tubing.

Check for leaks around the saddle valve.9.

B

C

D

E. Compression sleeve

F. Shutoff valve

G. Packing nut

Connecting to Refrigerator

Unplug the refrigerator or disconnect power.1.

Remove the shipping tape from the gray, coiled water tubing 2.

on the rear of the refrigerator.

Measure the distance from the shutoff valve to the opening in 3.

which the refrigerator will be located. Tubing must be extended

from the shutoff valve into the refrigerator opening following

specific guidelines. See Water Supply Requirements.

A ¼” x ¼” (6.4 mm x 6.4 mm) coupling is needed in order to 4.

connect the water tubing to an existing household water line.

Thread the provided nut onto the coupling on the end of the

copper tubing.

Check for leaks. Tighten any nuts or connections (including 6.

connections at the valve) that leak.

Plug in the refrigerator or reconnect power.7.

Flush the water system. See 8. Water System Preparation.

NOTE: Allow 24 hours to produce the first batch of ice. Discard

the first three batches of ice produced. Allow 3 days to completely

fill ice container.

Plug in Refrigerator

Set control switch at top of cabinet to the 1. OFF position.

Plug into a grounded 3 prong outlet.2.

Move to Final Location

A

A. Water tubing

B. Nut

C. Bulb

D. Coupling (purchased)

Turn shutoff valve ON.5.

16

B

E. Ferrule (purchased)

F. Nut (purchased)

G. Household water line (as

connected in previous section)

ECF

D

G

IMPORTANT: To avoid floor damage, make sure levelers are

raised (not touching floor) and refrigerator is on rollers before

moving.

Place top of cardboard carton or plywood under refrigerator. 1.

Remove dolly.

Do not remove the film on the outside.2.

Move the refrigerator straight back and evenly into the 3.

opening. Be sure the refrigerator side trims do not interfere

with the door opening. Also, be sure that the water tubing is

not kinked and the power cord is on top of the refrigerator.

Page 19

WARNING

Tip Over Hazard

Refrigerator is top heavy and tips easily when not

completely installed.

Keep doors taped closed until refrigerator is

completely installed.

Use two or more people to move and install

refrigerator.

Failure to do so can result in death or serious injury.

Installation Instructions

Level and Align Refrigerator

IMPORTANT: All four leveling legs must contact the floor to

support and stabilize the full weight of refrigerator. Rollers are for

moving refrigerator and not for permanent support.

B

A

A. Rear leveling bolt

B. Front leveling bolt

After moving the refrigerator to its final location:

5

⁄16” socket driver to turn the leveling bolts clockwise to

Use a 1.

extend the legs to the floor as shown. The rollers should be off

the floor.

Adjust the leveling legs to level and align the refrigerator from 2.

left to right and front to back so that the refrigerator is level

and aligned with the cabinetry. The cabinetry surface must be

plumb for the ideal fit of the refrigerator side trim.

A

B

Continue adjusting all of the leveling legs to raise the 3.

refrigerator until the top is within at least 1” (2.5 cm) of the top

soffit.

NOTE: If an anti-tip board has been used, adjust the leveling

legs until the top of the refrigerator is within ¼” (6.4 mm) of

the bottom of the anti-tip board as shown. Do not crush the

compressor cover.

A

2” (5 cm)

D

A. Center board 1/4” (6.4 mm) max. above refrigerator

B. Two 2” x 4” x 32” (5.\ cm x 10 cm x 81 cm) boards

C. Attach to studs with six #8 x 3” (7.6 cm) screws

D. Compressor cover

IMPORTANT: Adjust in small increments to keep from

damaging the cabinet trim and causing problems with the

door alignment or top grille fit. To avoid damage to the cabinet

or leveling legs, do not apply more than 50 inch-pounds (5.7

Nm) of torque to the leveling bolts. The leveling legs can be

extended to a maximum of 1¼” (3.2 cm) below the rollers.

For IF series models, additional adjustments may be needed 4.

after the custom panels are installed.

B

C

17

Page 20

Installation Instructions

Front View

Custom Panel and Handle Installation - IF42/IF48 Series Models

IMPORTANT:

Install the custom handles prior to installing the panels on the

refrigerator.

Create custom door overlay panels according to the

specifications in the Custom Panels and Handles section.

Dacor is not responsible for customer installed molding or

decorative panels that need to be removed or replaced to

service the refrigerator.

Handle Installation

Before installing a custom panel assembly, install the custom

handle hardware.

Counter-sink the screw head into the back of the panel to allow

the panel to slide into place smoothly and for proper fit.

B

A

A. Countersunk screw

B. Handle

C. Door panel assembly

C

Slide the panel into the top grille 3.

channel and reattach the end

cap.

Replace the top grille in the 4.

cabinet side trims and pull the

panel down slightly to lock it into

place.

Door Panel Installation

Remove all tape and door bracing from the refrigerator and 1.

freezer doors.

Open the refrigerator and freezer compartment doors.2.

Remove the handle side and top trims.3.

A

G. Panel

G

A

Side View

Front View

Top Grille Panel Installation

Grasp both ends of the top grille. Push straight up, then pull 1.

straight out. Place the top grille panel-side down on a soft

working surface.

Remove one end cap by loosening the nuts and sliding off the 2.

end cap.

C. Bottom rail

D. Nuts

E. End cap

F. Top rail

B B

A. Top grille

B. Cabinet side trim

E

F

A

C

D

A. Trims

Slide the custom panels into the bottom and hinge side trims 4.

on the refrigerator compartment and freezer compartment

doors, making sure that the backer panel fits into the hinge

side trims.

B

B. Panels

Reinstall the handle-side and 5.

top trims.

Remove the film from the screw 6.

covers C. Slide or snap the

screw covers into the handle

trim section.

Check refrigerator level and 7.

alignment. Adjust if needed.

C

B

18

Page 21

Installation Instructions

Adjust Doors

Door Height Adjustment

Use the following steps to adjust the door height, up or 1.

down, after the doors have been leveled. Open the freezer

or refrigerator door. Locate the bottom hinge and remove the

door stop screw.

EF Series Models

Remove the door stop screw from the bottom side of the hinge

with a ³⁄8” open end wrench.

B C

A

A. Bushing

B. Door stop screw

C. Locking plate

After adjusting, check the doors to make sure they are even at 4.

the top and bottom. If the doors are not even, continue to turn

the bushing to adjust the door height.

Replace the locking plate.5.

Turn the bushing slightly to align the hinge and locking plate 6.

screw holes.

Replace the door stop screw or screws and tighten.7.

IMPORTANT: Do not place the door stop screw in the 130°

position on Overlay Series models unless the custom panels

have been routed on the hinge side. See Door Panels and

Cabinetry Clearance.

Make final recheck to make sure the doors are aligned and 8.

even.

Door Swing Adjustment

Check that the refrigerator door can open freely. If the door 1.

opens too wide, remove the door stop screw or screws

(depending on your model) from the bottom hinge. See Door

Height Adjustment earlier in this section.

Hold the door open to a position that is less than 90°.2.

Replace the door stop screw or screws in the bottom hinge 3.

and tighten.

Overlay Models

Remove the two door stop screws: one from the bottom side

using a ³⁄8” open end wrench and one from the top side using

a 3⁄32” Allen wrench.

A

B

A. Door stop screw from bottom

B. Door stop screw from top (110°)

Remove the locking plate as shown.2.

B

A

A. 130°

B. 110° (IF series refrigerators)

C. 90°

C

Door-to-Door or Door-to-Refrigerator Trim

Adjustment

Loosen, but do not remove, the four Torx 27 flat-head 1.

mounting screws and the two ¼” hex head mounting screws.

Adjust the top hinge of either door to align it with the other 2.

door or the refrigerator trim.

Tighten the four Torx 27 flat-head mounting screws to a torque 3.

of approximately 100 inch-pounds (11.3 Nm) and tighten the

two ¼” hex head mounting screws.

A

Turn the bushing located underneath the bottom of the hinge 3.

using a ½” open end wrench. Turning the bushing to the left

(counterclockwise) will raise the door. Turning the bushing

right (clockwise) will lower the door.

B

A. Torx 27 flat-head mounting screws

B. 1/4” hex-head mounting screws

19

Page 22

Installation Instructions

Install Side Panel(s)

If the built-in area depth is 25” (63.5 cm) or more, the side panels

can be installed inside the side trim or attached to the outside of

the side trim.

IMPORTANT: Dacor is not responsible for customer installed

molding or decorative panels that need to be removed or replaced

to service the refrigerator.

For the inside side trim piece, slide the front edge of the 1.

routed side panel into the trim piece.

Nail the rear edge of the panel to the support board.2.

A

Snap the skirt onto the base grille.3.

A

B

A. Base grille

B. Skirt

Trim the skirt by scoring the 4.

proper “V” groove with a utility

knife. Break the skirt at the

score line.

C

C. “V” groove

B

A. Support board (mounted to back wall)

B. Cab side trim

Install Base Grille

There are two pieces to the base grille to allow for a custom fit:

the base grille itself and the skirt. The skirt can be added to the

base grille in order to extend it all the way to the floor.

To see if the skirt is needed, place the base grille into position. 1.

Do not attach the base grille to the refrigerator. Measure the

distance between the bottom of the base grille and the floor.

The gap must be a minimum of ½” (1.27 cm) in order to add

the skirt.

NOTE: If the gap measures less than ½” (1.27 cm), skip steps 3

and 4 of the instructions, and install the base grille only.

Remove the film from the base grille.2.

Using the two screws, attach the base grille assembly to the 5.

refrigerator as shown.

D

D. Screws (2)

Install the water filter and rotate it one-quarter turn to the right. 6.

It may be hard to turn. The cap should be in the horizontal

position.

20

Page 23

Installation Instructions

Ice Maker

Complete Installation

Turn the water supply line valve to the “Open” position.1.

Turn the refrigerator switch to the ON position. See 2. Power On/

Off Switch in the use and care manual for instructions. Wait a

few minutes. Check the water line connections for leaks.

Remove all boxes, parts packages and packing materials from 3.

the interior of the refrigerator. See the Care and Cleaning

section in the use and care manual for instructions. Remove

the film and cardboard from the grille and doors or door frame,

depending on your model.

Install the shelves and bins in the refrigerator and freezer 4.

compartments.

The controls are preset at the factory to the midpoint setting. 5.

Check that the compressor is operating properly and that all

the lights are working.

Flush the water system before use. See 6. Water System

Preparation.

To get the most efficient use from your new built-in refrigerator,

read your use and care manual. Keep Installation Instructions and

the use and care manual near the refrigerator for easy reference.

Water System Preparation

Please read before using the water system.

Immediately after installation, follow the steps below to make sure

that the water system is properly cleaned.

NOTE: If your model has a base grille filter system, make sure

the base grille filter is properly installed and the cap is in the

horizontal position.

Use a sturdy container to depress the water dispenser bar 2.

until the water begins to flow. Flush the water system by

dispensing and discarding 6 qt. (5.7 L) of water. Cleaning the

system will take approximately 3 to 4 minutes and will help

clear air from the line. Additional flushing may be required in

some households.

NOTE: As air is cleared from the system, water may spurt out of

the dispenser.

Open the freezer door and turn on the ice maker. For non-3.

dispenser models, lower the wire shutoff arm. For dispenser

models, move the switch to the ON (left) position.

Allow 24 hours to produce the first batch of ice.

Discard the first three batches of ice produced.

Depending on your model, you may want to select the

maximum ice feature to increase the production of ice.

Any questions or problems with this installation should be directed

to your Dacor dealer or the Dacor Customer Service Team at

(800) 793-0093 or visit our web site at www.Dacor.com.

If you need service, be sure to have the model and serial

numbers when you call. You’ll find these numbers on the serial

number plate, located on the right hand side of the fresh food

compartment.

Do not use with water that is microbiologically unsafe or

of unknown quality without adequate disinfection before

or after the system. Systems certified for cyst reduction

may be used on disinfected waters that may contain

filterable cysts.

Open the freezer door and turn off the ice maker. 1.

For non-dispenser models, lift up the ice maker cover, then, lift

up the wire shutoff arm as shown.

Ice maker cover

Non-Dispenser Models

For dispenser models, move the switch to the OFF (right)

setting as shown. The On/Off switch is located on the top right

side of the freezer compartment.

Dispenser Models

21

Page 24

Dacor ● 1440 Bridge Gate Drive, Diamond Bar, CA 91765 ● Tel: (800) 793-0093 ● FAX: (626) 403-3130 ● www.Dacor.com

Loading...

Loading...