Dacor EF48, IF48, EF42, IF42 Service Manual

Service Manual

Built-in Refrigerator

Covers Models:

EF48

IF48

EF42

IF42

Please read all safety information before installing, operating, or repairing this appliance.

Table of ConTenTs

Section 1 - Product Familiarization .............................1-1

A Refrigerator for a Different Kind of Consumer ............1-1

A New Level of Performance for Fresh Food Storage ......1-2

Long Term Storage With a Higher Level of Performance .1-3

Cooling Performance that Matches the Needs .................1-4

Sound Performance Beyond Many Expectations .............1-4

Features Should be the Expectation not the Exception ....1-6

Meeting the Expectation of a Tall Cool Drink of Water .....1-6

Options that Meet the User’s Expectations ....................... 1-7

Features and Benefits are Not All you Should Expect ....1-12

Making Sure the Available Space is

as Useful as Possible ...................................................... 1-12

More Space up Front Where you Use It .........................1-12

Something this Special Needs Special Considerations ..1-13

Setting Aside the Space .................................................. 1-14

Dimension Specifications ................................................1-16

After All’s in Place ...........................................................1-17

After the Install, the Finishing Touches ........................... 1-19

Dacor Built-in Refrigerator Q & A....................................1-22

Installation Instructions ...................................................1-24

Tool Requirements ..........................................................1-24

Installation Checklist .......................................................1-24

Preparing the Space .......................................................1-24

Plumbing Connection ......................................................1-25

Reverse Osmosis ............................................................ 1-25

Uncrating the Unit ...........................................................1-26

Water Line Installation .....................................................1-26

Leveling ........................................................................... 1-27

90° Door Stop ................................................................. 1-27

Blocking the Unit .............................................................1-28

More than 1" Clearance ..................................................1-28

Installing Backer Panels .................................................. 1-29

Panel Installation for Dispenser Models.......................... 1-30

One-piece Overlay/Frame Panel Installation ..................1-31

Panel Details ...................................................................1-32

Installing Side Panels ...................................................... 1-34

Anchor the Unit (Optional) ..............................................1-35

Adjust Door Hinges .........................................................1-35

Section 2 - Technical Orientation ................................2-1

Dacor Built-in Refrigerator Technical Orientation ........... 2-1

System Overview ................................................................2-1

DC Power Supply .............................................................. 2-1

System Control ..................................................................2-3

Temperature Monitoring ....................................................2-4

Variable Capacity Compressor .......................................... 2-6

Sealed System .................................................................2-8

Cabinet Airflow ................................................................2-10

Defrost System ................................................................ 2-11

Water Dispenser System ................................................2-12

Cabinet ...............................................................................2-14

Leveling System .............................................................. 2-14

Door Assembly ................................................................ 2-15

Shelf Systems .................................................................2-16

FoodSaver™ Drawers .....................................................2-17

Cabinet Lighting ..............................................................2-19

User Interface (Controls) ................................................. 2-20

Section 3 - Service Diagnostics ..................................3-1

Service Test Mode ..............................................................3-1

Service Test 01 – Software Revision ................................3-2

Service Test 02 – High Ambient Override .........................3-2

Service Test 03 – Fresh Food Thermistor .........................3-3

Service Test 04 – Evaporator Thermistor .......................... 3-3

Service Test 05 – Freezer Thermistor ...............................3-3

Service Test 06 – Ambient Thermistor ..............................3-3

Service Test 07 – Fresh Food Fan ....................................3-4

Service Test 08 – Evaporator / Freezer Fan Test .............3-4

Service Test 09 – Open Damper .......................................3-4

Service Test 10 – Close Damper ......................................3-5

Service Test 11 – Defrost Heaters ....................................3-5

Service Test 12 – Condenser Fan ....................................3-5

Service Test 13 – Fresh Food Lights ................................3-6

Service Test 14 – Freezer Lights ......................................3-6

Service Test 15 – Fountain Lamp .....................................3-6

Service Test 16 – Compressor Maximum Speed ..............3-7

Service Test 17 – Compressor Minimum Speed ...............3-7

Service Test 18 – Fresh Food Fan Speed ........................3-8

Service Test 19 – Freezer Fan Speed ..............................3-8

Service Test 20 – Fresh Food Thermistor Value ............... 3-8

Service Test 21 – Freezer Thermistor Value .................... 3-9

Service Test 22 – Ambient Thermistor Value .................... 3-9

Service Test 23 – Evaporator Thermistor Value................3-9

Service Test 24 – Display Temperature Select ...............3-10

Service Test 25 – Fountain State .................................... 3-10

Service Test 26 – Bypass Valve Switch .......................... 3-11

Service Test 27 – Filter Valve Switch .............................. 3-11

Service Test 28 – Actuator Switch .................................. 3-11

Service Test 29 – Cube Solenoid ....................................3-12

Service Test 30 – Auger Motor ........................................3-12

Service Test 31 – Chute Solenoid ...................................3-12

Service Test 32 – Water Valve ........................................ 3-12

Service Test 33 – Force Defrost and Exit .......................3-12

Section 4 - FoodSaver™ TEST MODE ........................4-1

FoodSaver™ Test Mode ..................................................... 4-1

v

seCTion 1 - ProduCT familiarizaTion

Section 1 - Product Familiarization

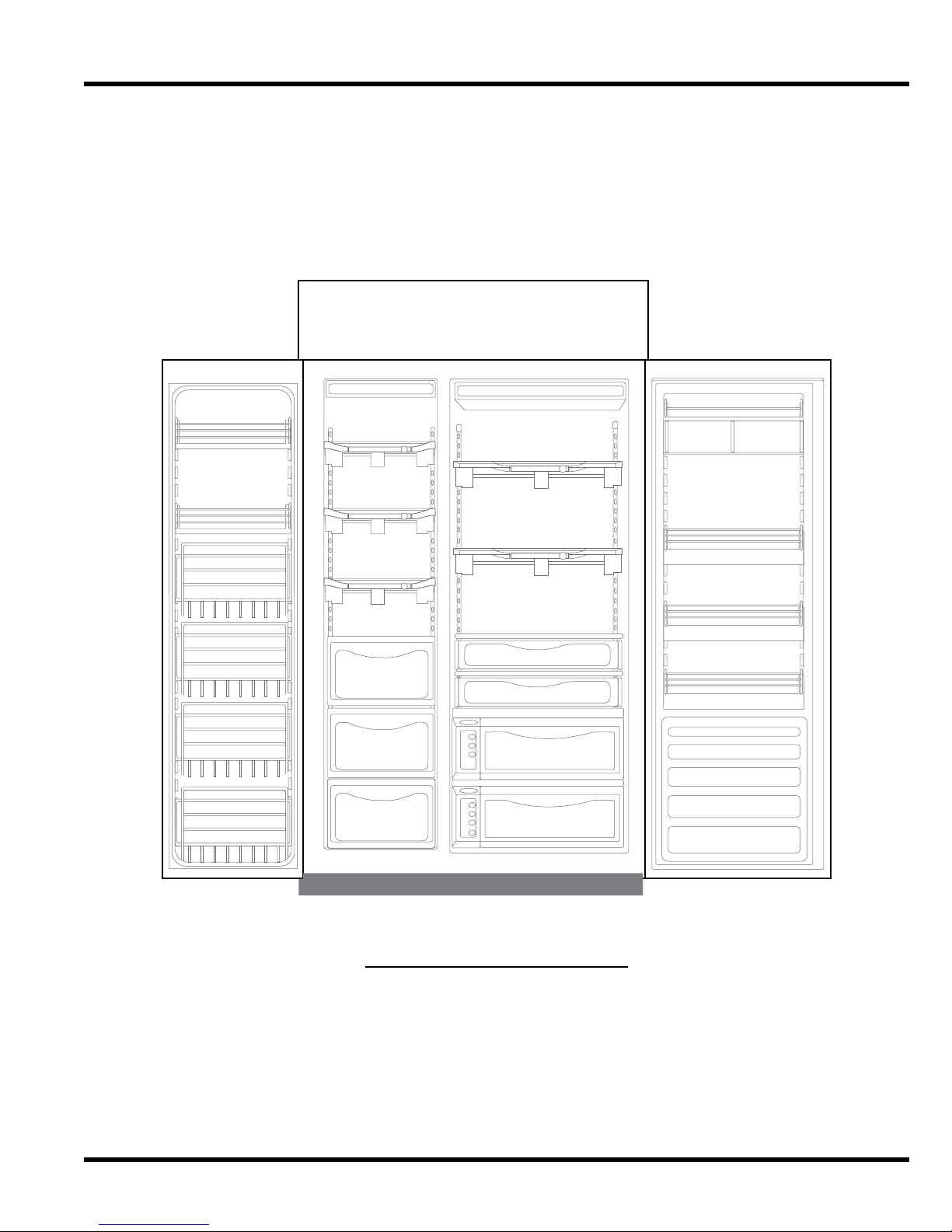

A Refrigerator for a Different Kind of Consumer

The new Dacor Built-in Refrigerators provide a new level of performance for a specialty market. This

line of refrigeration products is targeted to enter into a market with little competition.

This market is characterized by custom kitchens that are a gourmet’s dream. Imagine the kitchens

you see on the Cooking Channel installed in your home. Only without the audience. Countertops that

provide preparation space for serving dozens and cooktops that can cook for a crowd as well as a

family.

Big kitchens and big plans require a big refrigerator. Simply making a freestanding unit larger

introduces new problems. As a cabinet gets larger, temperature control and access to the contents

becomes a greater challenge.

Not only are the refrigeration needs different in these dream kitchens but the decorating demands are

greater. A refrigerator is either expected to stand out as a statement that the owners have arrived

at a particular level of success or blend into the background in a silent testimony to the fact that

success means that you no longer need to shout about it. A refrigerator with the ability to change in

appearance as the kitchen evolves to a new décor.

The new Dacor Built-in Refrigerator meets these needs and will exceed the customer’s expectations for

years to come.

Product or Environment image

Page 1-1

daCor builT-in refrigeraTor serviCe manual

WARMER

COOLER

daCor builT-in refrigeraTor serviCe manual

A New Level of Performance for Fresh Food Storage

Warm air rises, cool air falls.

As a refrigerator cabinet increases in size, maintaining temperature control

becomes more challenging. As a cabinet becomes taller the air has a

greater ability to settle in layers. This is called stratification. The warmer air

rises to the top of the cabinet while the cooler air settles to the bottom.

If the temperature control is at the top of the refrigerator, cooling the

cabinet enough to satisfy the thermostat can result in the bottom of the

refrigerator being too cold for the contents. A common result is frozen

lettuce. If the temperature control is in the middle of the cabinet the top of

the cabinet may be too warm for optimum shelf life of dairy products.

Temperature stratification can have a major impact on the longevity of fresh

foods. To minimize this effect the Dacor Built-in Refrigerators keep the air

moving in the fresh food section even when the temperatures are already at

their optimum. This results in temperature differences of one degree or less

throughout the fresh food compartment.

Not all fresh foods are best kept at the same temperature. Fresh cuts

of meat will keep longer at a lower temperature (31˚F) than vegetables

(34˚F) and citrus (38˚F). If you set the fresh food section for the optimum

temperature for one of these product the others will not be at their best

storage temperature.

Produce crispers and meat drawers can help this situation but the Dacor

Built-in Refrigerator takes this concept a step further. Using a feature known as FoodSaver™Technology

the system allows three different temperatures to be maintained in the fresh food section. The main

section can be set for good storage of dairy and condiments as well as other foods. This temperature

can be set to whatever the customer wants, which could be approximately 37 degrees. One FoodSaver

module can be set to store the citrus at 38 degrees and the other can be set to store meats at 31

degrees. It is almost like getting three refrigerators in one cabinet. Fresh food will remain fresh longer

when stored at the right temperature.

The FoodSaver drawers each have a fan motor and temperature control incorporated into their

construction. The control can open a damper and allow the fan motor to draw cooler air from

the freezer section if needed. If the drawer needs to be warmer than the rest of the fresh food

compartment (fresh food 35 and citrus at 38) there is a small heating element that will maintain the

temperature selected by the owner.

Besides providing optimum storage temperature, the FoodSaver modules also provide better humidity

control. Conventional crisper drawers can often end up with condensation inside. This condensation

can result in excessive moisture settling on the produce and cause premature aging. The FoodSaver

modules use a space-age polymer to regulate the amount of moisture in the compartment. The pores

in this polymer increase in size when too much

moisture is present in the drawer and close

when the moisture is at the right level. This

allows excess moisture to leave the drawer and

the correct humidity level is maintained. This

eliminates the condensation problem found in

many crisper drawers.

These features and their interaction allow the

Dacor Built-in Refrigerator to keep contents

fresher for a longer period of time than

systems without these features. This allows the

customer to enjoy increased freshness in the

foods they store.

Page 1-2

Long Term Storage With a Higher Level of Performance

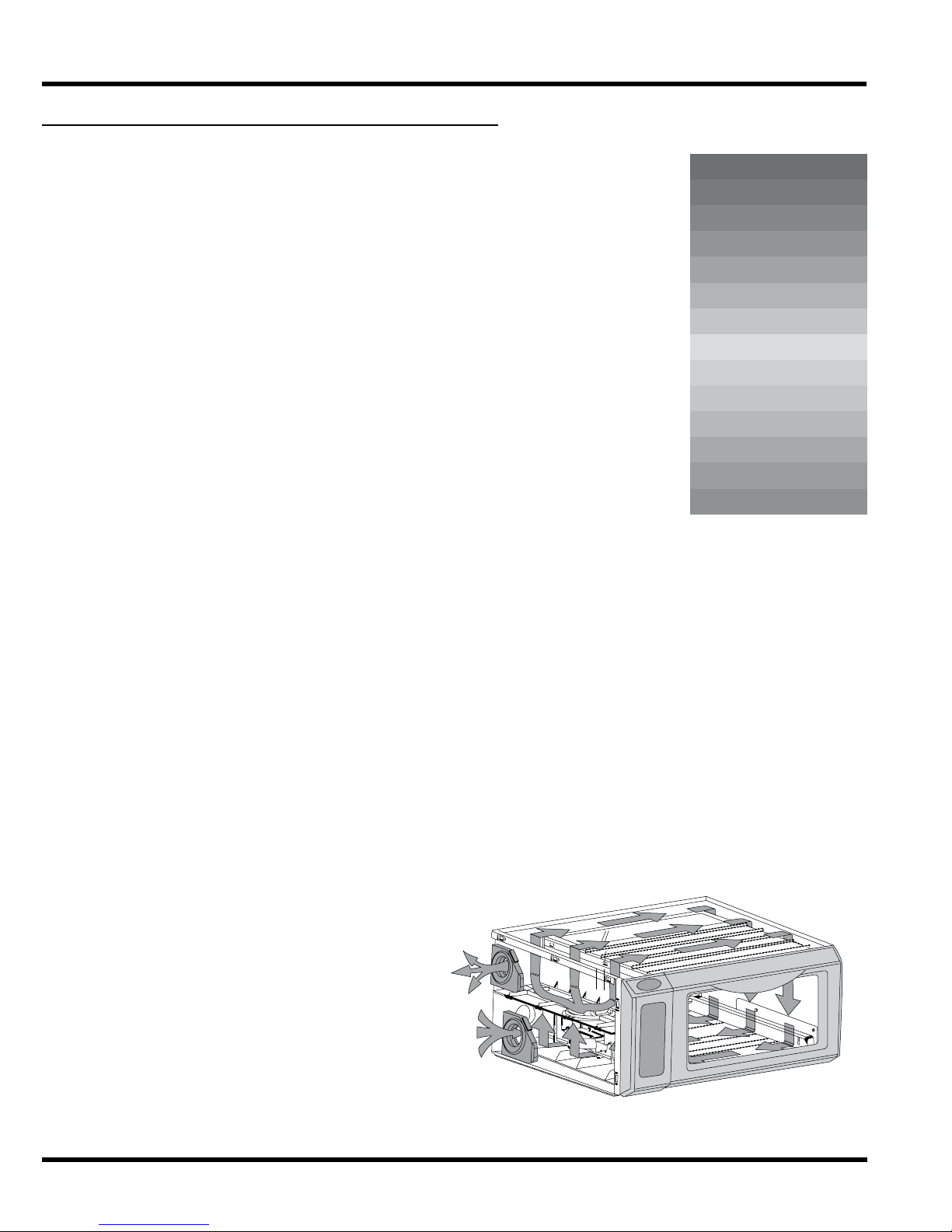

Cooling Coil (Evaporator)

Heating Element

Freezer Compartment

Heat

One of the most discouraging aspects of long term frozen food

storage is freezer burn. Freezer burn is most often the result of the

outer layers of the product thawing slightly and refreezing multiple

times. One of the most common causes of this thawing is the

defrost cycle needed for modern frost-free products.

When the system enters a defrost cycle, a heater is turned on to

warm the cooling coil in the freezer and melt any frost off from the

coil before it has the opportunity to affect the performance of the

system. While the coil is heating, it is not uncommon for the area

around the coil to heat enough to thaw the outer layer of product

and in-turn create freezer burn.

The Dacor Built-in Refrigerators minimize temperature swings

during defrost with two different features. One of the features is

Preemptive Adaptive Defrosting while the other is sub-cooling prior to

defrost.

Many manufacturers have added adaptive defrost to their product

lines. Adaptive defrost adapts to the use and environment of the

product and provides defrost cycles only when necessary. Not only

does this often result in fewer defrost cycles that could potentially

damage the freezer contents, it allows for energy saving.

Preemptive adaptive defrost takes this energy and food saving even

further by attempting to make sure that the defrost happens when

the refrigerator and freezer are not being used. In a normal adaptive

defrost, when it is time for a defrost, the defrost starts. This may

mean that a defrost cycle could start in the middle of preparing

dinner. At a time when refrigerator usage is at maximum, the system

is defrosting and cannot provide the cooling needed to maintain

optimum temperatures.

With a preemptive adaptive defrost, the system looks forward and

anticipates usage patterns to avoid defrosting at a time that may not

be best. The control tracks information about how the owners use

the refrigerator. The refrigerator has learned that between four and

seven in the afternoon there are a large number of door openings. A

large number of door openings translates to a high use period. If the

system identifies that a defrost is scheduled to happen around fivethirty, it must make a decision. Either perform the defrost at 3 PM,

before the high use period, or wait until 8 PM after the high use period. The decision is made by the

controller and will be based on the time elapsed since the last defrost, the measured temperatures and

the usage since the last defrost. The end result is a defrost cycle happening when it least likely to affect

the life of the freezer contents.

Another way to prevent damaging temperature swings is to lower the temperature of the freezer

contents below normal before a defrost cycle is started. If the contents are cooler than normal before

the defrost cycle begins, there is less chance that the outer layers will thaw during the defrost cycle.

The Dacor Built-in Refrigerators look ahead and before starting defrost provides maximum cooling to

the freezer compartment. The result of the maximum cooling period is lower freezer temperature. With

a lower starting temperature, the defrost can take place and overall freezer temperature may rise only

one degree above normal. This is in comparison to other refrigeration products that may rise ten or

more degrees during defrost.

By providing defrost only when needed and sub-cooling before defrost, the Dacor Built-in Refrigerators

help protect the owner’s investment in fine groceries and allows them to make purchases at their

convenience instead of on demand.

seCTion 1 - ProduCT familiarizaTion

Page 1-3

daCor builT-in refrigeraTor serviCe manual

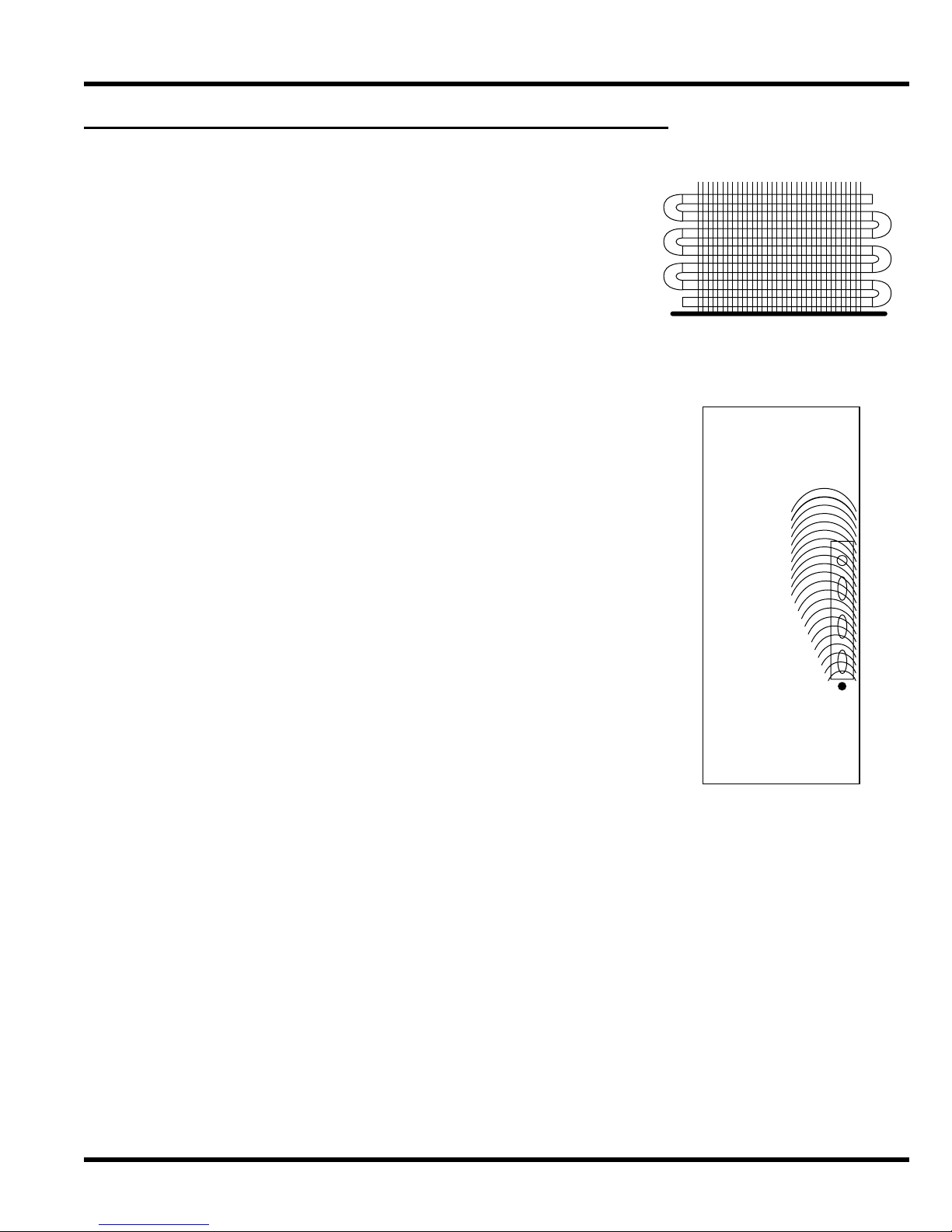

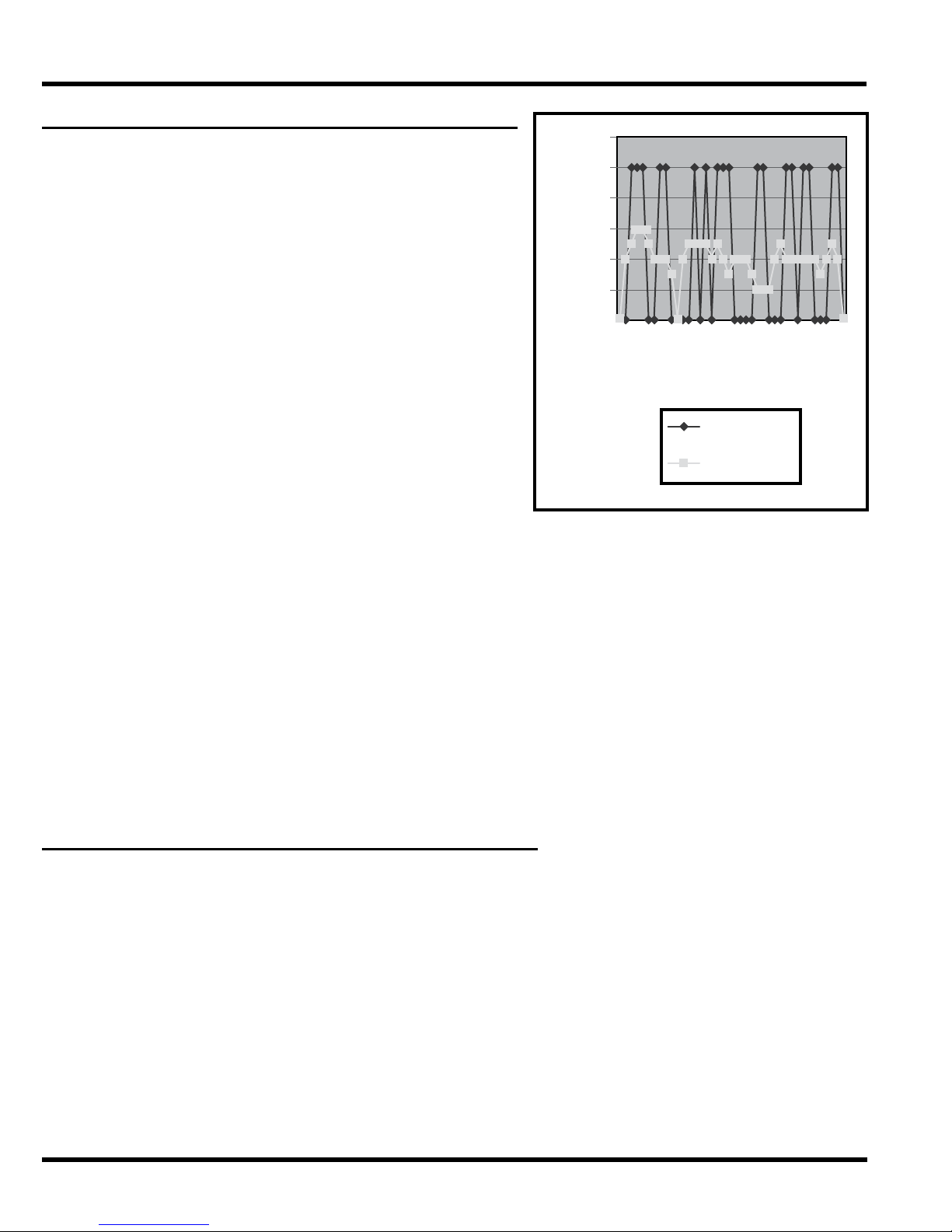

Conventional

Compressor

Variable Speed

120%

Capacity

Time (Minutes)

100%

80%

60%

40%

20%

0%

5

30

55

80

105

130

155

180

daCor builT-in refrigeraTor serviCe manual

Cooling Performance that Matches the Needs

Most refrigeration products run at two speeds. One of the

speeds is high and the other is off. While this has been a

suitable technology for many years, the need to conserve

energy has recently become more important.

One way to decrease operating costs is to operate the

system at a lower speed over a longer period of time. The

most efficient operation would occur if the system could

be fine tuned to run continuously at a level that constantly

matched the cooling requirements.

This is a lot like your car. In stop and go driving in a city

environment your mileage will be lower than when you set

the cruise control and are out on the open country roads.

The energy needed to start your car moving and get it up

to twenty-five miles per hour is greater than the energy

needed to keep it moving at fifty-five miles per hour. You

can always feel comfortable knowing the power is there to

quickly accelerate if needed but you can keep it in reserve

and save money until the need arises.

Dacor Built-in Refrigerators use variable capacity cooling

to match the needs of the user. Variable Capacity Cooling

is not brand new technology. It is a more expensive

technology. The demand in the US has not been strong enough to encourage refrigerator

manufacturers to include this technology in their standard product line. This technology has

been in use in Europe and Asia where the power infrastructure is not as well developed and

energy conservation is of higher concern. A true luxury product should include the newest

technology and features just as a true luxury car should have all the latest features and

options available.

By providing Variable Capacity the Dacor Built-in products provide high performance power

when needed and high efficiency all of the time.

While this product line is not currently Energy Star™ rated, the performance is just short of

the requirements. The testing procedures are very specific and the laboratory tests place this

product just under the threshold needed. In actual use, this product line could actually result

in lower energy bills than expected, depending on the use patterns.

In the long run, slow and steady will win the race and the customer who is interested in peak

performance will not be disappointed with the results of Variable Capacity Cooling.

Sound Performance Beyond Many Expectations

About the only time we become concerned with the noise our refrigerator makes is either

when the sound drastically changes and service is needed, or when it is loud enough to be

heard in a quiet house on a sleepless night.

Dacor Built-in Refrigerators were designed from the start to be some of the quietest on

the market. Special insulation is included to limit the noise heard outside of the cabinet.

Bumpers have been added to prevent vibration. The Variable Capacity Compressor has a

lower volume at a lower speed. Even the control area is insulated so that the relays that

switch different circuits are barely audible.

The end result is a system that will only be heard when the user is trying to hear it. It will be

seldom that the users will even notice when the system is running.

There are some noises that are normal. The following page identifies some of the normal

noises and indicates what the source could be.

Page 1-4

seCTion 1 - ProduCT familiarizaTion

Sound Performance Beyond Many Expectations (continued)

Normal Operating Sound

Recent improvements in refrigeration design may introduce sounds in your new refrigerator that were

not noticed in earlier models. These improvements were made to create a refrigerator that will preserve

food better, run more energy efficient, and perform quieter overall. Because new unit designs run

quieter than past models you may start to detect sounds that were actually present in your older units

but were typically masked by the refrigerator’s higher sound levels. Many of these sounds are normal.

The following are some of the normal sounds your new refrigerator may make:

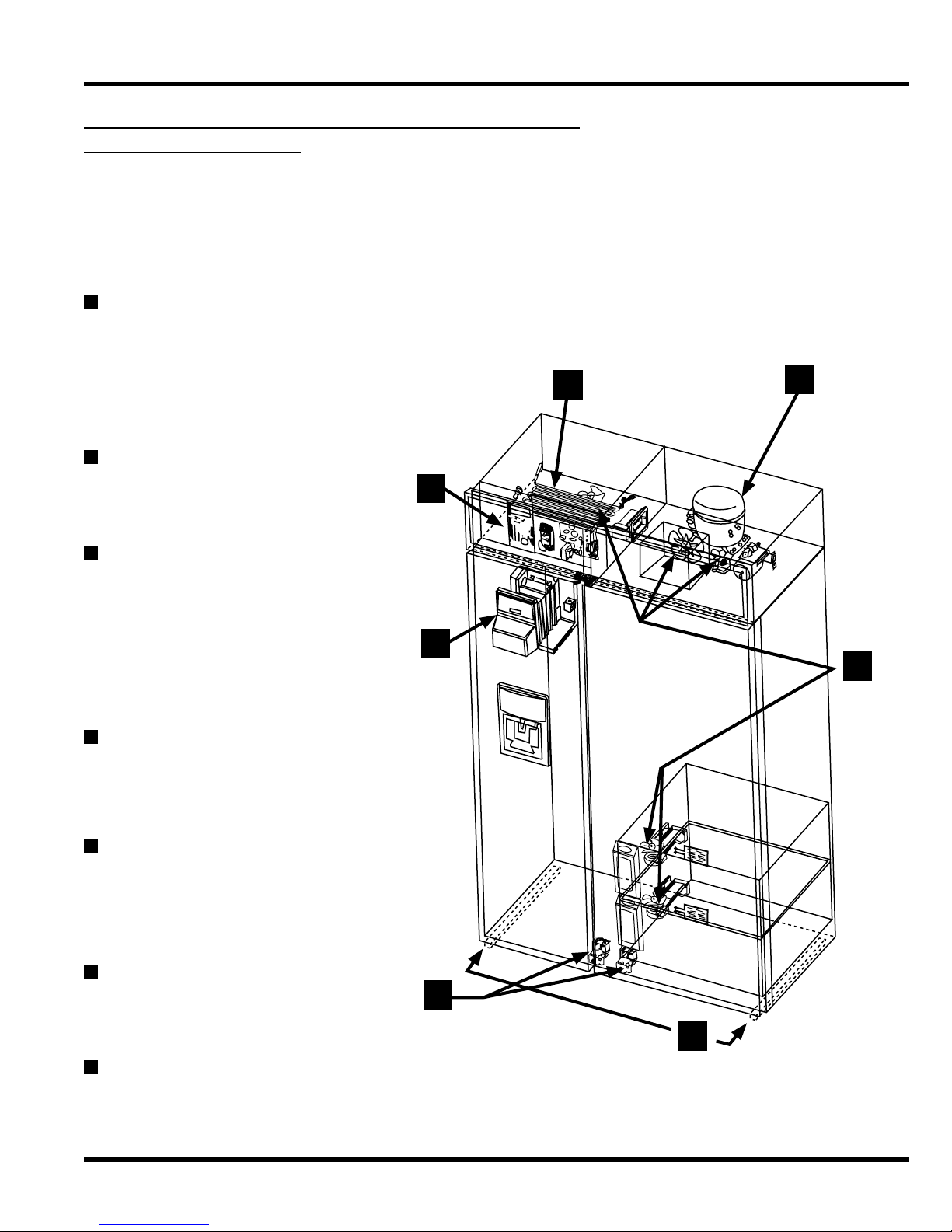

1

COMPRESSOR: The compressor on

1.

this unit has a variable speed motor.

This variability allows the system to

adjust to different usage needs and

thereby make your cabinet much more

energy efficient. This will introduce

speed change sounds and some higher

pitched humming sounds that are

normal for the operation of this type of

compressor.

2

CONTROL SWITCHES: In the

2.

electronics control area there are

numerous control switches that make

a quiet clicking sound when you use

your refrigerator or during some of the

normal system operations.

3

AIRFLOW SOUNDS: There are a

3.

number of fans in the unit that make

airflow sounds when in operation.

The freezer fan circulates cool air

throughout the refrigerator. The

refrigerator circulating fan helps keep

that compartment’s temperature more

uniform. The condenser fan on top of

your unit is utilized to remove the heat

generated by the system. Lastly, the

FoodSaver™ compartments circulate

air to maintain optimum temperatures.

4

WATER VALVES (if equipped): If

4.

your unit has an ice dispenser or

icemaker you may detect a slight

buzzing sound under the unit when

water is requested from the ice

dispenser or when the icemaker needs

water to make ice.

5

ICEMAKER: If equipped with an

5.

icemaker the cabinet will occasionally

generate a rattling sound when ice

cubes are ejected into the freezer ice

bin. You may also detect the motor

that is ejecting that ice. These are

normal sounds necessary for ice

making.

6

REFRIGERANT FLOW: The flow of

6.

the cooling fluid in your freezer area

may cause gurgling or quiet knocking

sounds when the unit cycles on or

when the unit cycles off. This is just

the shock of the system cycling.

7

CABINET LEVELING: An unleveled

7.

cabinet may cause rattles and vibration

noises. This can be corrected by

adjusting the leveling wheels properly.

6

2

5

4

7

1

3

Page 1-5

daCor builT-in refrigeraTor serviCe manual

daCor builT-in refrigeraTor serviCe manual

Features Should be the Expectation not the Exception

Many of the built-in refrigerators currently in homes across America were designed for

storage capacity more than they were designed for ease of use and functionality.

If you want a lot of room for storage, they may be the right choice for you. If you want the

same features that are available with even modestly priced refrigerators, you need to look

away from them and towards a built-in system designed by a company who understands

consumer expectations and convenience.

Some of the common expectations for a refrigerator include spill-proof shelves, adjustable

door storage and ample lighting. Some customers want through the door ice and water

dispensing.

These types of features are incorporated into the built-in refrigeration products as well as

some less common features.

Not only is illumination ample, it is exceptional. There are six lamps in the fresh food

compartment alone. Four at the top and one behind each FoodSaver™ drawer. This will put

an end to the search for something in the dark rear corners of a refrigerator compartment.

While not often thought of, it is not unreasonable to expect a crisper drawer to hold a head

of lettuce. While this may not be possible in some of the competition’s crisper drawers, most

average heads of lettuce will fit just fine in the FoodSaver drawers. In fact you should be

able to fit in three or four heads with a bag of carrots, radishes and some green onions. Who

needs salad in a bag when it all fits just fine in the FoodSaver drawer and with the superior

storage performance, it will still be fresh when you need it.

A deli tray that keeps a hold of the contents might seem like a prerequisite for a drawer. We

have come to expect that a deli drawer is made of plastic and will contain any minor leakage

that may occur. One of the last things someone wants is meat juices dripping from the deli

drawer onto other products in the cabinet.

Some manufacturers think that a wire basket will do the job just fine. In reality the contents

are exposed to too much air and the contents dry out. If something were to leak, the

leakage is destined to make a mess elsewhere. The Dacor Built-in Refrigerators include

plastic Food Storage drawers. Wide drawers with room for lots of deli products. Wide drawers

that allow you to easily see the contents. To top it off, if one Food Storage drawer isn’t

enough, you can get two.

Meeting the Expectation of a Tall Cool Drink of Water

A feature more commonly found on current refrigeration products is through the door ice and

water dispensing. The Dacor Built-in Refrigerators offer this feature. The user has the choice

of water, cubed ice or crushed ice.

All of the water is filtered before going to the dispenser or the icemaker. Like any type of

water filter, the filter cartridge needs to be replaced on a regular basis. The control system

monitors the amount of water flowing through the filter and recommends when it is time to

order a new cartridge on the control panel. The cartridge itself is mounted in the equipment

compartment on top. By placing the filter above the cabinet, valuable storage space isn’t

used in the fresh food compartment for the filter.

If a customer already has a reverse osmosis system for filtering their drinking water, the

lower pressure often present with this type of system could cause slow dispensing or hollow

ice cubes. Since the reverse osmosis system is a better filter than the cartridge filter, a

bypass cap is provided to eliminate the cartridge altogether. This bypass cap could improve

the dispensing speed and help to reduce the hollow ice cube complaint. For the customer

who wants to reduce the number of times the cabinet door is opened to retrieve chilled

water of ice cubes this dispenser will meet their expectations. For the customer with no

desire for a dispenser, the product is available without the dispenser and the customer can

choose whether they want a built-in icemaker by choosing the right combination of shelves

for their needs.

Page 1-6

seCTion 1 - ProduCT familiarizaTion

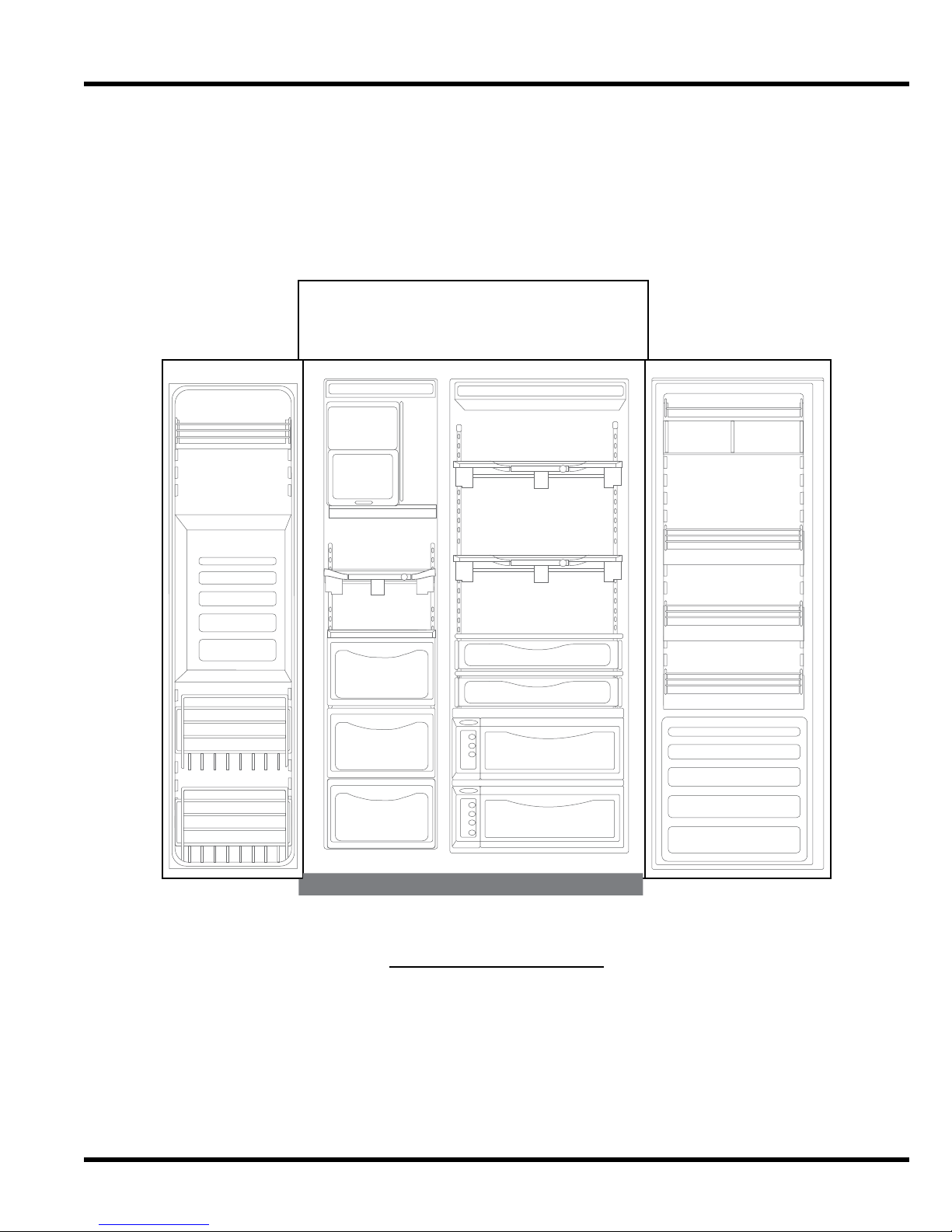

Options that Meet the User’s Expectations

When you go shopping for a new car you expect that you can select the options

that meet your needs. Often, though, the model that almost fits your desires is

on the lot and you choose it. Sometimes the dealer has to add a feature or two.

In short the right car for one person may not be the right car for another. The

Dacor Built-in Refrigerators allow the customer to get the refrigerator they want

and not another cookie-cutter appliance.

When it comes to refrigerators, the manufacturers have been providing different

packages for the different needs. The biggest option is usually color. From there

you can select feature levels ranging from entry level to deluxe. To truly meet

the customer’s desires a customizable product is the right option.

The Dacor Built-in Refrigerators can be configured in just about any way that will

meet the customer’s needs. While there are standard option packages available,

if a standard package doesn’t meet your needs, add the features you want. On

the freezer side, the icemaker and dispenser have specific locations that they

need to be installed. On the fresh food section the FoodSaver™drawers have to

be left where they are. Other than that, the consumer is free to configure their

appliance to their wishes.

If you want a refrigerator without a deli drawer but with two extra shelves, you

can get it. If you want three deli drawers and no icemaker, you can get it.

It is the customer’s decision as to what they want in a refrigerator.

Page 1-7

daCor builT-in refrigeraTor serviCe manual

daCor builT-in refrigeraTor serviCe manual

Page 1-8

48" DISPENSER MODEL

seCTion 1 - ProduCT familiarizaTion

48" DISPENSER MODEL

Page 1-9

daCor builT-in refrigeraTor serviCe manual

daCor builT-in refrigeraTor serviCe manual

Page 1-10

48" NON-DISPENSER MODEL

seCTion 1 - ProduCT familiarizaTion

48" NON-DISPENSER MODEL

Page 1-11

daCor builT-in refrigeraTor serviCe manual

daCor builT-in refrigeraTor serviCe manual

Features and Benefits are Not All you Should Expect

One of the sad realities of any machine is that it will need service. Just as regular oil changes

and tire rotations are needed to keep a car running smooth and efficiently, every appliance

deserves regular maintenance.

The biggest need of any refrigeration system is cleaning. The coil that transfers the heat to

the outside of the cabinet needs to be dusted out regularly to maintain peak efficiency. This

cleaning should be performed every three to six months.

From its inception, the Dacor Built-in Refrigerators were designed with service in mind. Since

the appliance is quite large and often built into the wall, it is best if service can be performed

where the unit sits.

The only components that cannot be reached from the front of the refrigerator are the water

tubes that supply the water filter and the icemaker.

Front serviceability is a key feature. Regular maintenance can be easily performed and

peak efficiency maintained. Things that are difficult to do seldom get done. The easy access

designed into the Dacor Built-in Refrigerators is important for long and efficient operation.

Progressive thinking will provide an appliance that not only has exceptional performance

when new, but will maintain that performance for years to come.

If the need should ever arise for repair, the Dacor Built-in Refrigerators come with one of the

best new product warranties available.

Making Sure the Available Space is as Useful as Possible

Most conventional refrigerators have the cooling system mounted in the bottom of the

cabinet. The interior space is shaped around the equipment and the end result is that usable

space is lost to equipment.

The Dacor Built-in Refrigerators place the cooling system at the top of the unit. This places

the equipment package up high and out of the way. This provides the most possible space

where people can use it.

The cabinet depth is considerably less than the cabinet depth of a large freestanding system.

By reducing the depth, almost every item in the refrigerator or freezer can be reached

without moving numerous other items.

Since more of the bottom space is available for storage, drawers are provided to bring the

contents out to where they can be easily viewed. Nobody wants to get on their knees to see

what is hiding in the back recesses of their refrigerator.

Both the fresh food and the freezer doors provide adjustable baskets for storage of items you

always want close at hand. Since the interior is completely customizable, if you want more

door shelves, just contact your Dacor retailer and have additional door baskets ordered.

More Space up Front Where you Use It

Most cooks place the things used most often in either the door storage or along the front of

the shelves. As new items are placed on the shelves the existing contents gradually move to

the rear of the cabinet. This usually means that sooner or later what you are looking for is at

the back of the refrigerator.

By increasing the width, the Dacor Built-in Refrigerators allow for more up front space. There

are more of the good seats available for the things you use most. Even if something is at the

back of the cabinet, the distance to it is less than with a large freestanding unit.

The actual capacity of the cabinet is not much different than the largest conventional

refrigerators available today. The space is easier to use and with proper planning, this

system fits into the kitchen with increased style and convenience.

Page 1-12

seCTion 1 - ProduCT familiarizaTion

Something this Special Needs Special Considerations

Not every kitchen in America has the right location for a refrigerator like they

use in a restaurant but if there is enough space, a Dacor Built-in Refrigerators fill

the spot beautifully.

There are two cabinet widths. The larger of the two is approximately 48 inches

wide. The smaller cabinet is 42 inches wide. Both units stand almost seven feet

tall. The cabinet is about two feet deep. This is the same depth as standard base

cabinets so the system can be installed right in line with the countertops and

cabinets.

Proper preparation is essential before the system is brought into the kitchen.

Location is always important for a refrigerator. The best designs for most

kitchens place the cooking area, the cleaning area and the refrigeration system

on the points of a triangle. The closer the triangle is to equal on each side,

the better. The space between all three points should be free from obstruction

with enough room for at least two people to work within the triangle without

getting in each other’s way. If the kitchen will only be occupied by one person a

smaller triangle will work. If a complete cook staff is used or caterers brought in

regularly, a larger triangle will be needed, if not two triangles.

Since many kitchens will be in the design stage when an appliance such as

the Dacor Built-in Refrigerator is considered, many customers will be able to

plan properly. Space can be allocated for as many refrigeration systems as the

customer feels is right for their needs.

Because of the forethought invested in design, this product line can be

completely enclosed in cabinetry. All airflow is through the front of the unit.

Cabinets can be built on either side as well as above the unit.

The location for installation should include an outlet on a dedicated circuit. This

outlet should be 75½" above the floor and 2" from the right side of the opening.

There is a recessed area in the cabinet to allow the unit to be pushed up against

the wall with the plug installed in this location.

A dedicated outlet is a good practice for any refrigerator and is required by the

electrical code of many areas of the country. The outlet should be mounted in

the back wall of the final location. The space should always leave enough room

for both the appliance and the plug in the outlet.

A water supply for the installed icemaker or water dispenser is essential. The

water line should come up through the floor or through the lower wall in the rear

center of the opening. Since all components were designed to be serviced from

the front, the ice and water hook-up is in the front behind the air grill.

The system is pushed into place and then the water line is connected. This is

opposite of the connection sequence for a standard refrigerator. Typically the

water line would be connected and then the system pushed the last few feet into

place. By placing the refrigerator before connecting the water line, there is less

flexing of the connection and a reduced chance for a water leak.

Page 1-13

daCor builT-in refrigeraTor serviCe manual

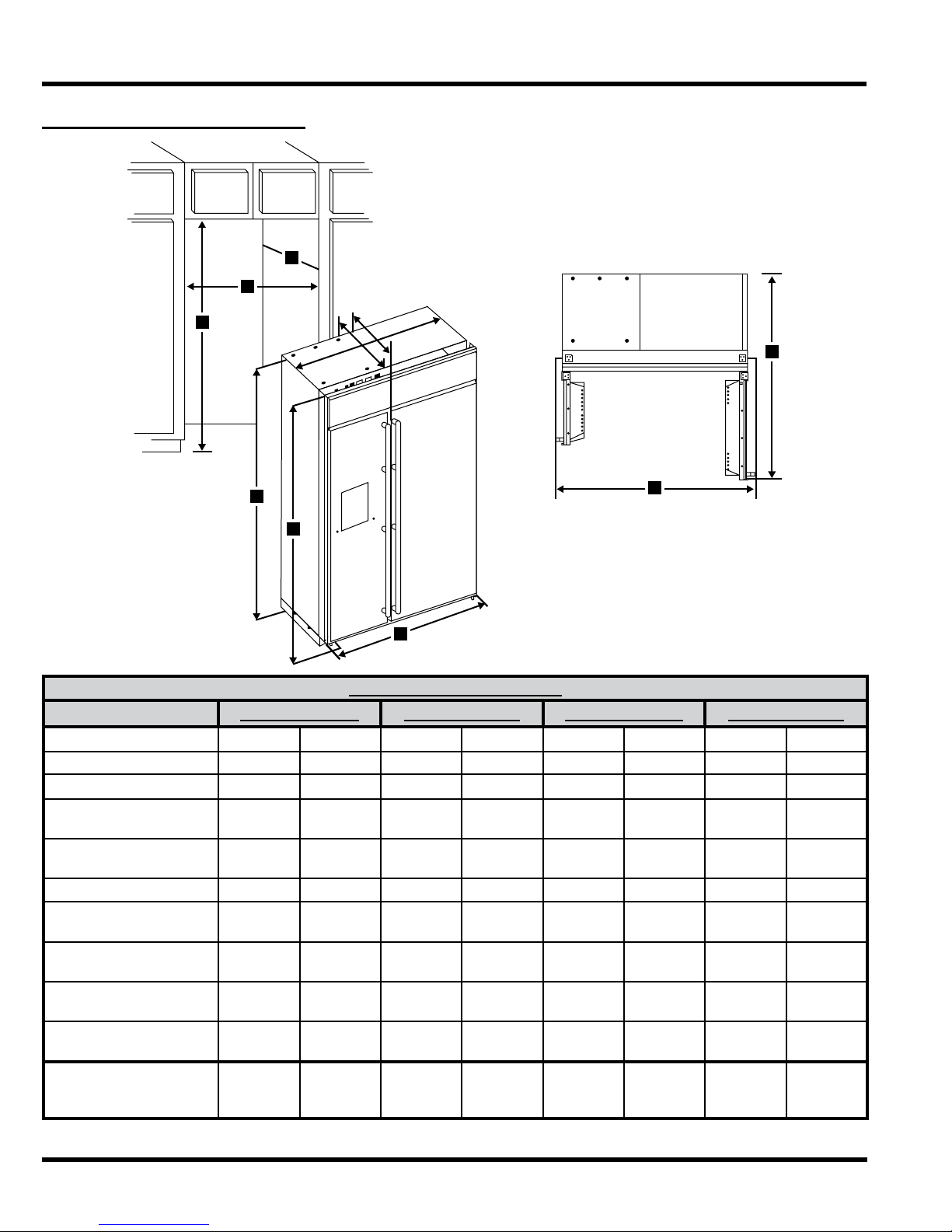

48" Cutout

47-1/2

Top View

24

47-1/4

48" Top View

43-11/16

52-9/16

50-3/4

47-1/2

Front View

83-3/4

daCor builT-in refrigeraTor serviCe manual

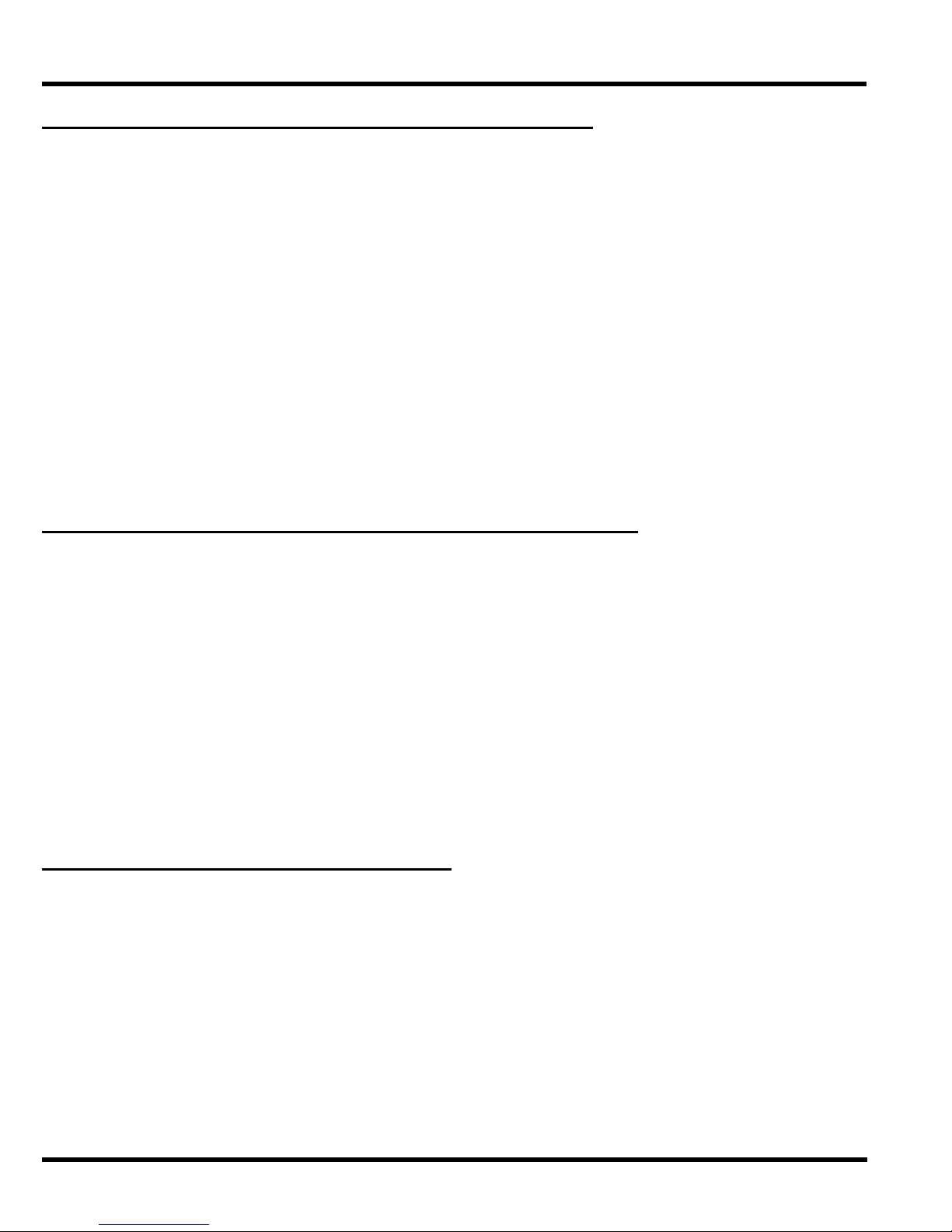

Setting Aside the Space

Just as with any refrigerator, it is always important that you have enough space to work

around the unit. The cabinet depth alone doesn’t tell the entire story. You need to consider

the length of the open doors to determine the total space you need for use of the appliance.

The 48" product requires an area that is 47½ inches wide and 52½ inches deep. Two feet of

the cabinet will be flush with the cabinets or built into the wall. This means that you need at

least two feet four and one half inches clear in front of the system. If you want to be able to

get past an open refrigerator, you will need even more space.

The 48" cutout needs to be at least 83¾", 47½" wide and at least 24" deep. A little extra

depth would allow for some adjustment room. Too much extra depth would make the

installation of the anti-tip device difficult.

Page 1-14

seCTion 1 - ProduCT familiarizaTion

42" Cutout

41-1/2

Top View

24

41-1/4

42" Top View

41-7/16

48-11/16

44-3/4

41-1/2

Front View

83-3/4

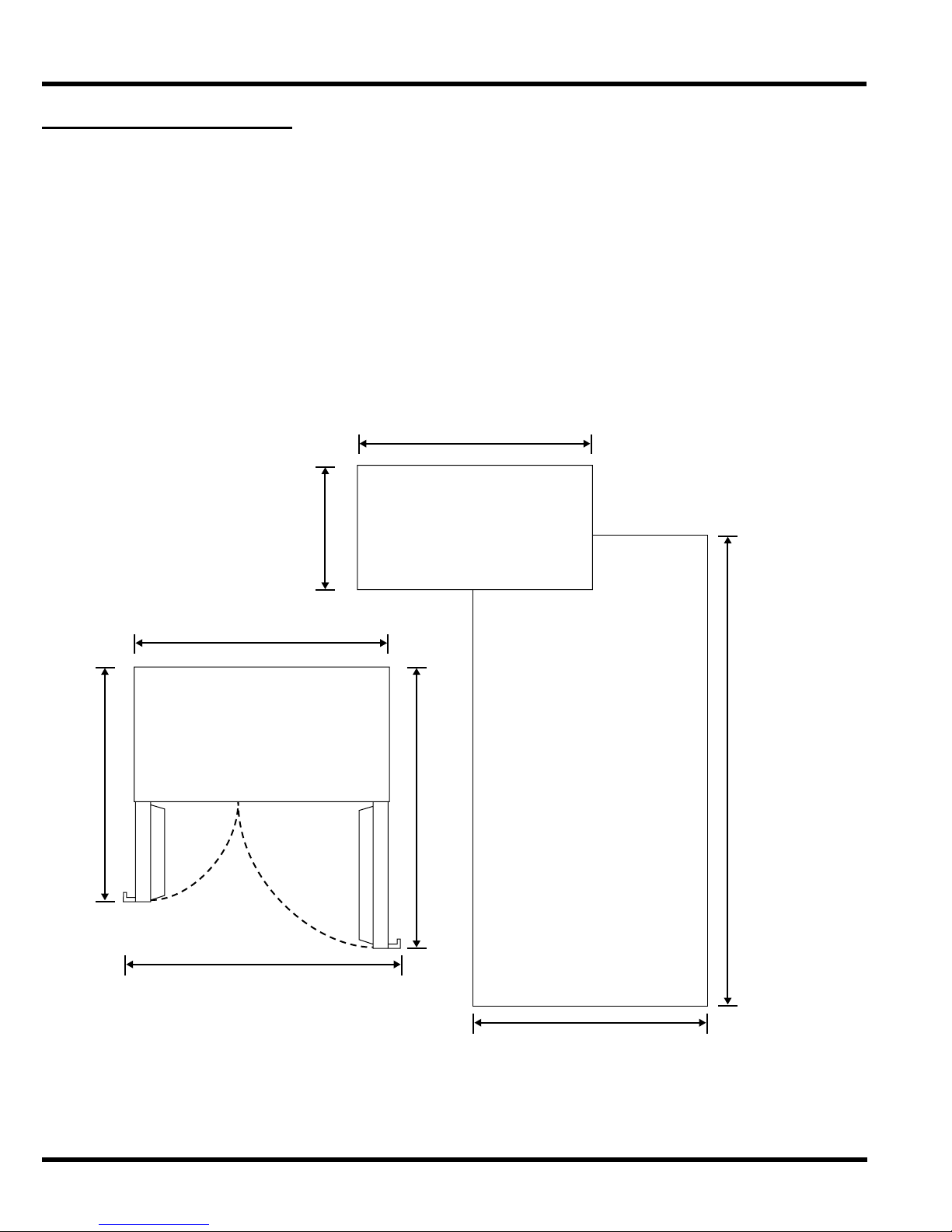

Setting Aside the Space (continued)

The 42" product requires an area that is 41½ inches wide and 48 11/16 inches deep. Two

feet of the cabinet will be flush with the cabinets or built into the wall. This means that you

need at least 24 11/16 inches clear in front of the system. If you want to be able to get

past an open refrigerator, you will need even more space.

The 42" cutout needs to be at least 83¾", 41½" wide and at least 24" deep. A little extra

depth would allow for some adjustment room. Too much extra depth would make the

installation of the anti-tip device difficult

Page 1-15

daCor builT-in refrigeraTor serviCe manual

A

B

C

D

E

G

J

K

TOP VIEW

daCor builT-in refrigeraTor serviCe manual

Dimension Specifications

EXTERIOR DIMENSIONS

Specifications

A. Cutout Height*

B. Cutout Width**

C. Cutout Depth

D

. Height to Top of

Cabinet

E. Height

Grille

F. Width (cabinet) 47 1/4 120.0 47 1/4 120.0 41 1/4 104.8 41 1/4 104.8

G. Width

closed)

Depth Excl. handles

H.

(closed)

Depth Incl. Handles

I.

(closed)

. Depth (fresh food

J

door open 90˚)

K. Width

90˚ including

handles)

*A. Add 1" (2.5 cm) for extended handle kit. **B. Add 2" (5.08 cm) for extended handle kit.

to Top of

(doors

(doors open

EF48 (in/cm) IF48 (in/cm) EF42 (in/cm) IF42 (in/cm)

83 3/4 212.7 83 3/4 212.7 83 3/4 212.7 83 3/4 212.7

47 1/2 120.7 47 1/2 120.7 41 1/2 105.4 41 1/2 105.4

24 61 24 61 24 61 24 61

83 1/16 210.9 83 1/16 210.9 83 1/16 210.9 83 1/16 210.9

83 3/8 211.8 83 3/8 211.8 83 3/8 211.8 83 3/8 211.8

48 1/16 122.1 48 1/16 122.1 42 1/16 106.8 42 1/16 106.8

25 1/4 64.1 25 1/4 64.1 25 1/4 64.1 25 1/4 64.1

26 5/8 67.6 N/A N/A 26 5/8 67.6 N/A N/A

52 1/2 133.3 52 9/16 133.5 48 11/16 123.7 48 3/4 123.8

50 3/4 128.9 N/A N/A 44 3/4 113.7 N/A N/A

Page 1-16

seCTion 1 - ProduCT familiarizaTion

1

2

3

Wall Studs

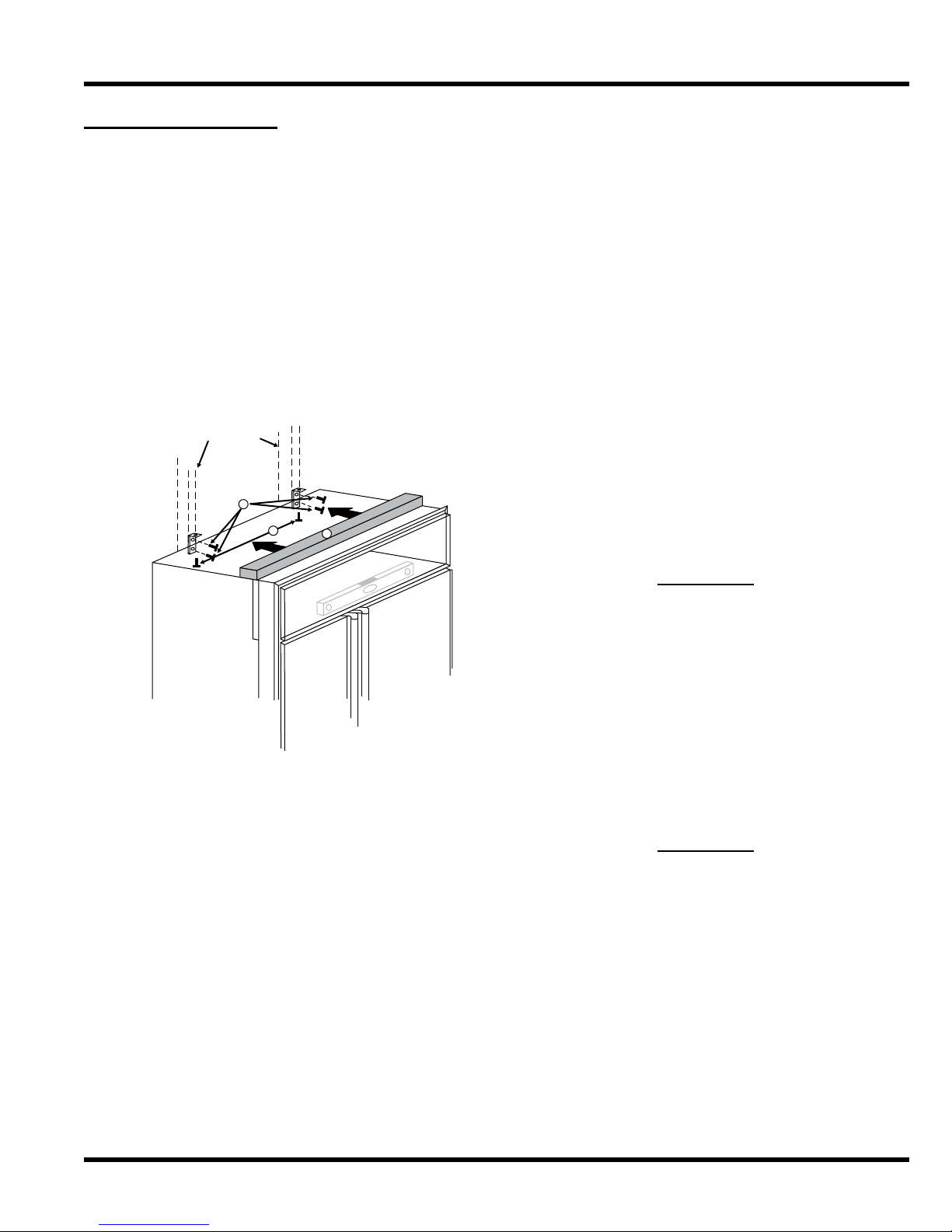

After All’s in Place

Once the unit is in place it must be leveled and secured to prevent any out of balance

possibilities.

A very important part of the installation process is installation of an anti-tip device. Anti-tip

devices have been around for a long time on ranges. The length of the door in relation to the

body of range makes it easy for an individual to tip the unit over if excess weight is applied to

the open door.

The Dacor Built-in Refrigerators have a similar problem, the refrigerator door is longer than the

cabinet is deep. If excess weight is applied on the door, the unit could tip forward.

FIGURE 18

FIGURE 19

If the cutout height is very close to the recommended height of 83¾", the cutout itself will

prevent any possible forward tipping. If there is more than one inch clear above the cabinet, a

section of 2x4 lumber must be mounted to the wall above the cabinet. This 2x4 will keep the

back of the cabinet from leaning away from the wall and will help prevent the possibility of

injury or damage from a mishap. The 2x4 is even included with the product.

It is also possible to prevent tipping using a section of pipe strap. Attach the pipe strap to the

wall and the cabinet. This strap will prevent the unit from tipping away from the wall.

Page 1-17

daCor builT-in refrigeraTor serviCe manual

daCor builT-in refrigeraTor serviCe manual

After All’s in Place (continued)

The Dacor Built-in Refrigerators include heavy-duty leveling legs at all four

corners. These leveling legs are adjusted from the front of the cabinet just as

any other service would be performed. Even with new construction there may

be slight unevenness to the flooring the system is installed upon. By including

four way leveling it is possible to level the refrigerator regardless of the

condition of the floor.

FIGURE 22

Page 1-18

seCTion 1 - ProduCT familiarizaTion

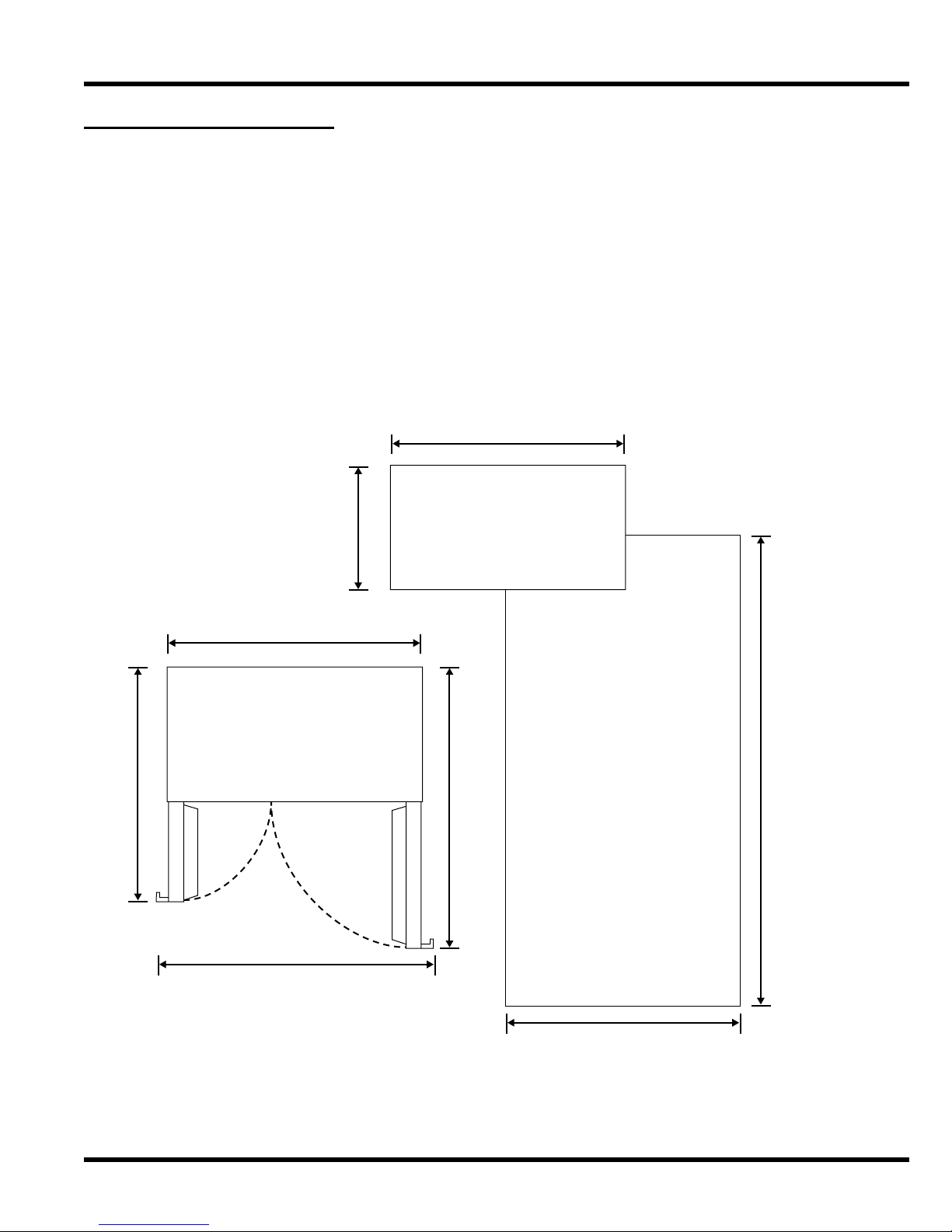

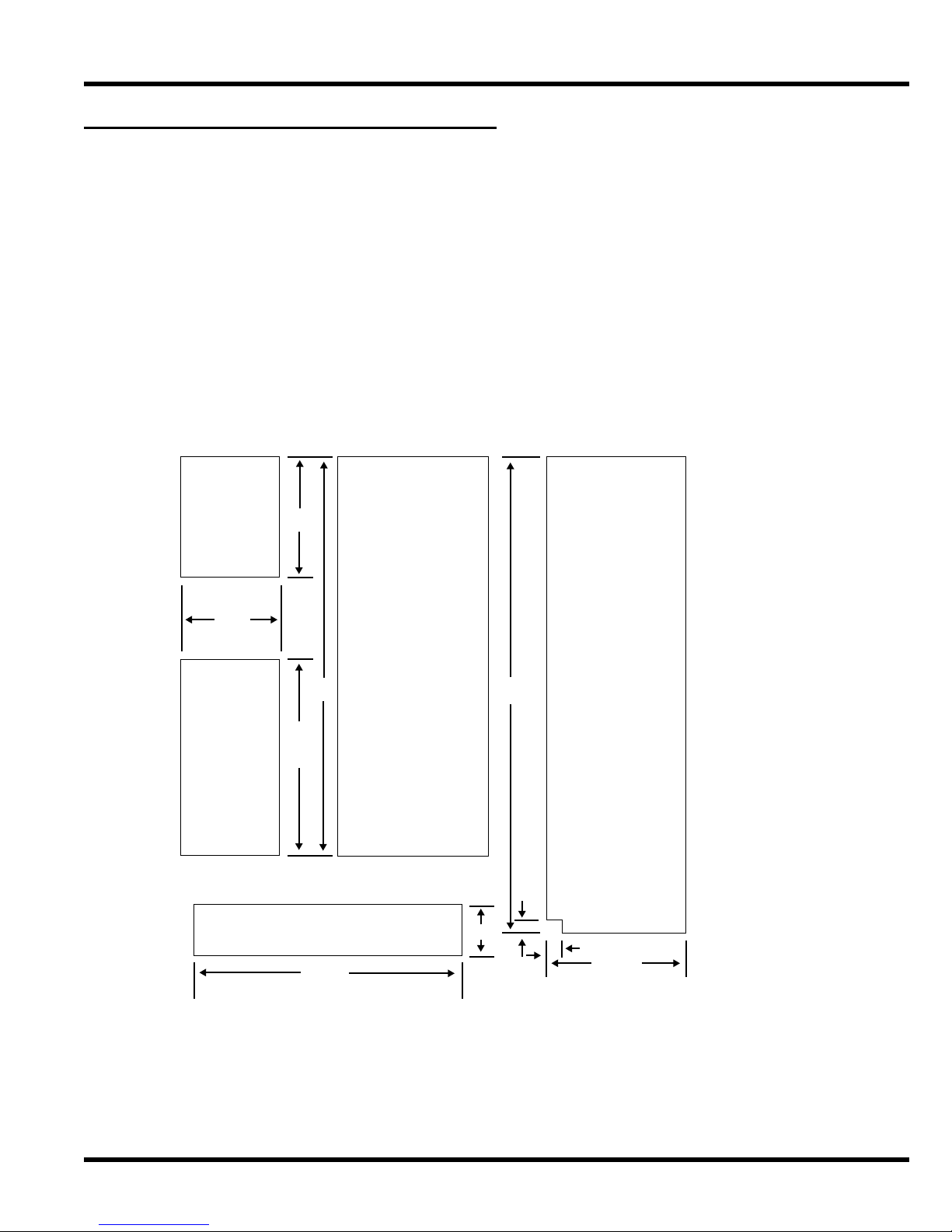

17.28"

20.92"

69.12"

34.00"

26.05"

82.79"

2.40"

2.50"

24.00"

8.80"

46.41"

Upper Frz.

Door Panel

Lower Frz.

Door Panel

Fresh Food

Door Panel

Side Panel

Machine Compartment Panel

After the Install, the Finishing Touches

As stated previously, the exterior of the Dacor Built-in Refrigerators is completely

customizable.

The stainless steel version of the refrigerator comes ready for use. The exterior is

suited for use in any kitchen with the space.

Panels can be manufactured for installation on the doors and sides of both the panel

and the overlay version. The panel version comes with full-length extruded handles.

The overlay version comes without a handle, allowing the customer to have any type of

handle manufactured to match their décor.

From glossy acrylic to rich mahogany, the exterior can be designed to either place the

system in the limelight or camouflage this workhorse to blend into its surroundings.

Instructions for the creation of the panels and the necessary dimensions are included

with the refrigeration system.

Page 1-19

Loading...

Loading...