Page 1

Installation Instructions

Distinctive® Wall Mount Range Hoods

DTHP30, DTHP36, DTHP48

APPROVED FOR USE WITH ALL DACOR® RANGES AND COOKTOPS.

TESTED IN ACCORDANCE WITH THE LATEST EDITION OF ANSI/UL 507

STANDARD FOR ELECTRIC FANS AND CAN/CSA-C22.2 NO. 115 STANDARD

FOR FANS AND VENTILATORS.

Part No. 109174 Rev. A

Page 2

Table of Contents

Important Safety Instructions .......................................... 1

Important Information About Safety Instructions .............. 1

General Safety Precautions ............................................. 2

Product Specifications .................................................... 3

General Specifications ..................................................... 3

Weight Specifications ....................................................... 3

Dimensions ...................................................................... 4

Preparation and Setup ...................................................... 6

Parts List .......................................................................... 6

Necessary Tools and Hardware ....................................... 6

Meeting Electrical Codes ................................................. 7

Installing the Electrical Source ......................................... 7

Meeting Installation Requirements ................................... 8

Planning the Ductwork ..................................................... 9

Preparing the Mounting Location ....................................11

Installation Instructions .................................................. 12

Marking the Centerlines ................................................ 12

Installing the Holding Brackets ....................................... 13

Rotating the Fan(s) for Rear Exhaust ............................ 14

Using the Dual to Single Transition Kit# AHT10 ............ 18

Hanging the Range Hood .............................................. 20

Hardwiring the Hood ...................................................... 21

Verifying the Setup ......................................................... 23

The Installation Checklist ............................................... 24

Wiring Diagrams .............................................................. 25

Before You Begin...

Important:

• Installer: In the interest of safety and to minimize problems, read these Installation Instructions completely and

carefully before you begin the installation process. Leave these installation instructions with the consumer.

Write the Data Plate Information in the Use and Care Manual before installing the unit.

• Customer: Keep these Installation Instructions for future reference and the local electrical inspector’s use.

If You Need Help...

If you have questions or problems with installation, contact your Dacor dealer or

the Dacor Customer Service Team. For repairs to Dacor appliances under warranty call the Dacor Distinctive Service line. Whenever you call, have the model

and serial number of the appliance ready. The model and serial number are

printed on the appliance data plate.

Dacor Customer Service Team

Phone: (800) 793-0093 ex. 2813 (U.S.A. and Canada)

Monday — Friday 6:00

Website: www.dacor.com

Dacor Distinctive Service (for repairs under warranty only)

Phone: (800) 793-0093 ex. 2822 (U.S.A. and Canada)

Monday — Friday 6:00

a.m. to 5:00 p.m. Pacific Time

a.m. to 5:00 p.m. Pacific Time

Appliance Data Plate

The appliance data plate is a label that:

• has the model and serial number information and electrical requirements.

• is located inside the hood, above the filters on the back wall of the chassis.

Remove the filters to view it.

All specifications subject to change without notice. Dacor assumes no liability for changes to specifications.

© 2008 Dacor, all rights reserved.

Page 3

Important Safety Instructions

Important Information About

Safety Instructions

• The Important Safety Instructions and warnings in

these instructions are not meant to cover all possible

problems and conditions that can occur. Use common

sense and caution when installing, maintaining or operating this or any other appliance.

• Always contact the Dacor Customer Service Team

about problems and conditions that you don’t understand.

Safety Symbols and Labels

DANGER

Immediate hazards that WILL result in severe personal

injury or death.

WARNING

Hazards or unsafe practices that COULD result in severe

personal injury or death.

CAUTION

Hazards or unsafe practices that MIGHT result in minor

personal injury or property damage.

DANGER

To avoid the possibility of explosion or fire, do not store or use combustible, flammable or explosive vapors and liquids

(such as gasoline) inside or in the vicinity of this or any other appliance. Also keep items that could explode, such as

aerosol cans away from cooktop burners, ovens and range hoods. Do not store flammable or explosive materials in

adjacent cabinets or areas.

WARNING

If the information in this manual is not followed exactly, a fire or explosion may result causing property damage, personal

injury or death.

WARNING

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

a) Use this unit only in the manner intended by the manufacturer. If you have questions, contact the manufacturer.

b) Before servicing or cleaning unit, switch power off at service panel and lock the service disconnecting means

to prevent power from being switched on accidentally. When the service disconnecting means cannot be

locked, securely fasten a prominent warning device, such as a tag, to the service panel.

WARNING

WARNING – TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

a) Installation work and electrical wiring must be done by qualified person(s) in accordance with all applicable

codes and standards, including fire-rated construction.

b) Sufficient air is needed for proper combustion and exhausting of gases through the flue(chimney) of fuel

burning equipment to prevent back drafting. Follow the heating equipment manufacturer’s guideline and safety

standards such as those published by the National Fire Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

c) When cutting or drilling into wall or ceiling, do not damage electrical wiring and other hidden utilities.

d) Ducted fans must always be vented to the outdoors.

READ AND SAVE THESE INSTRUCTIONS

1

Page 4

Important Safety Instructions

CAUTION

For general ventilating use only. Do not use to exhaust hazardous or explosive materials and vapors.

General Safety Precautions

To reduce the risk of fire, electric shock, serious injury or death when using your appliance, follow basic safety

precautions, including the following:

WARNING

• Do not install or operate this hood if it has been damaged, dropped, has damaged electrical wires or is not working

properly. If the product is damaged when received, immediately contact the dealer or builder.

• This range hood must be installed and grounded by a qualified installer according to these installation instructions.

• Install or locate this appliance only in accordance with these installation instructions and the requirements specified

by the manufacturer of the cooktop or range. Improper installation, adjustment, alteration, service, or maintenance

can cause serious personal injury or property damage.

• The user should not install, repair, or replace any part of the range hood unless specifically recommended in the

literature accompanying it. A qualified service technician should perform all other service. Contact the nearest Dacor

authorized service representative at (800) 793-0093, or at www.dacor.com for examination, repair or adjustment.

• Keep all packaging materials away from children. Plastic bags can cause suffocation.

• Do not use an extension cord or adapter plug with this appliance.

• The installer must show the user the fuse box or circuit breaker panel box and how to turn the power on/off.

• Before installing or servicing the range hood, switch the power OFF at the fuse box circuit breaker and lock the electrical panel door to prevent power from being switched on accidentally. When the electrical panel cannot be locked,

securely fasten a prominent warning device, such as a tag, to the electrical panel.

• Read the Use and Care Manual completely before using the appliance. Clean the appliance only as instructed in the

Use and Care Manual. Use only the cleaners specified.

• Do not tamper with the controls.

• Never allow the filters to become blocked or clogged. Do not allow foreign objects, such as cigarettes or napkins, to

be sucked into the hood.

• Clean the filters, channels, and all grease-laden surfaces often to prevent grease fires and to maintain performance.

• If the cooktop and range hood are near a window, use an appropriate window treatment; Avoid long drapes or window coverings that could blow over the cooktop and hood and create a fire hazard.

• Always run the fan(s) whenever the cooktop is operating.

• Never leave the range or cooktop unattended when a burner (or element) is in use. Boil-overs and greasy spills may

smoke and/or ignite.

• Do not leave children alone or unattended in the area where the cooktop and range hood are in use. Never allow

children to sit or stand on an appliance. Do not let children play with a range, cooktop, or range hood. Do not store

items of interest to children above or around the cooktop, range, or range hood.

• The minimum vertical distance between the cooktop surface and the exterior part of the hood must be no less

than 30” (76.2 cm). The vertical distance may be longer for the range or cooktop being used. Consult the range or

cooktop Installation Instructions for the minimum and maximum vertical distance from the appliance being used.

• TO REDUCE THE RISK OF FIRE, USE ONLY METAL DUCTWORK.

• PROLONGED POWER FAILURE Do not attempt to use this appliance during a continuous power failure.

2

Page 5

Product Specifications

General Specifications

All Models

Features Description

Fan Speeds Adjustable

Filters Mesh style, dishwasher safe

Exhaust(s) 8-inch duct diameter

Total

Connected

Load

Lights

120V, 60 Hz, 9 Amp. Max.

(10.0 Amp Max. surge)

Halogen 120V, 75W

Size: PAR16 E26/27

(All Replacement Types:

Dimmable with 75W Max)

Individual Models

Model

Number

Lights 4 3 2

Filters 4 3 2

Fans 2 1 1

Exhaust

Vents

Fan Rating 1200 CFM 600 CFM 600 CFM

DTHP48 DTHP36 DTHP30

2 1 1

Individual Models

Model Weight

DTHP3010 51 lbs. (23 kg)

DTHP3018

DTHP3610

DTHP3618 57 lbs. (26 kg)

DTHP4810 70 lbs. (32 kg)

DTHP4818 77 lbs. (35 kg)

53 lbs. (24 kg)

Individual Models

Model

Number

DTHP3010 x

DTHP3018 x x x

DTHP3610 x

DTHP3618 x x x

DTHP4810 x

DTHP4818 x x x

Top Vent Rear Vent

Rotatable

Fan

3

Page 6

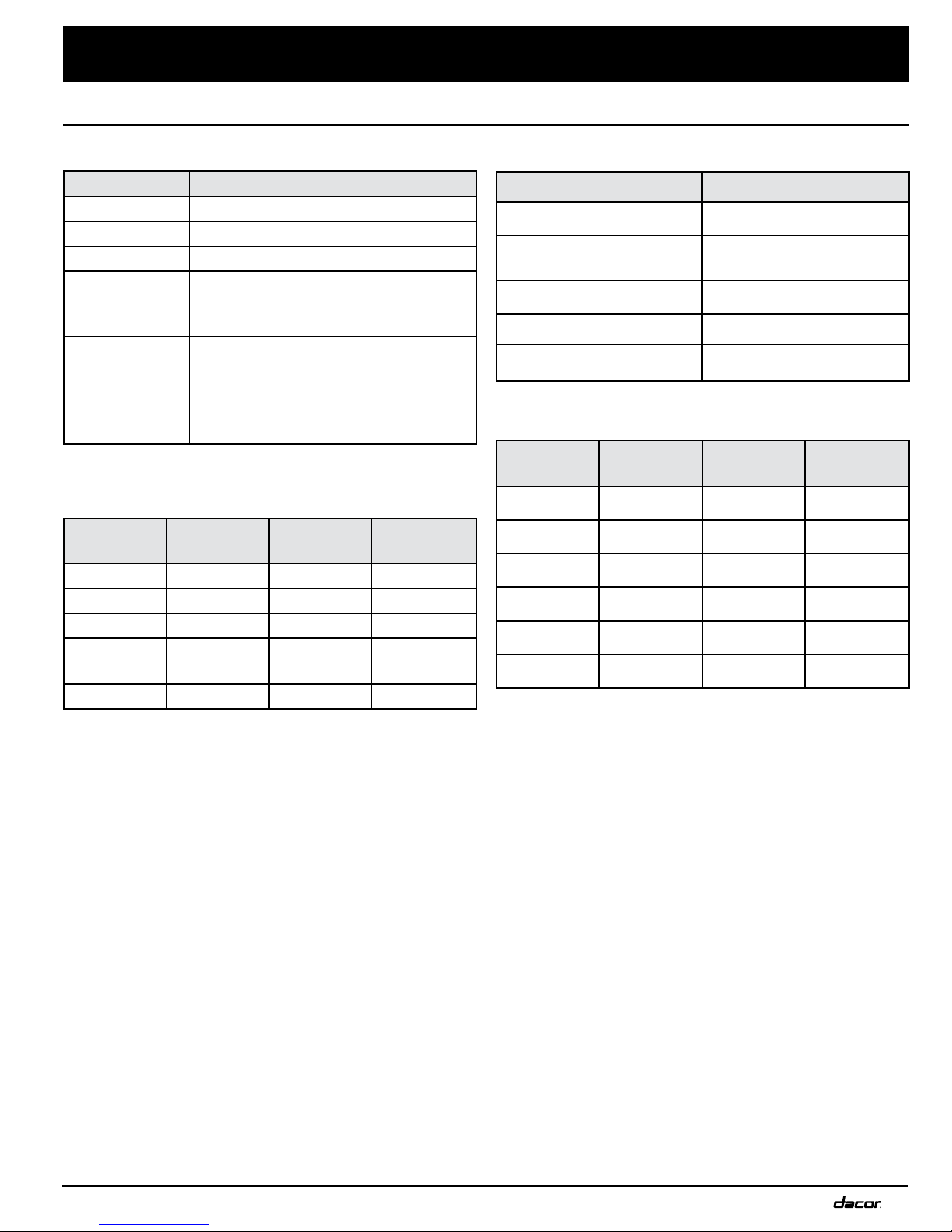

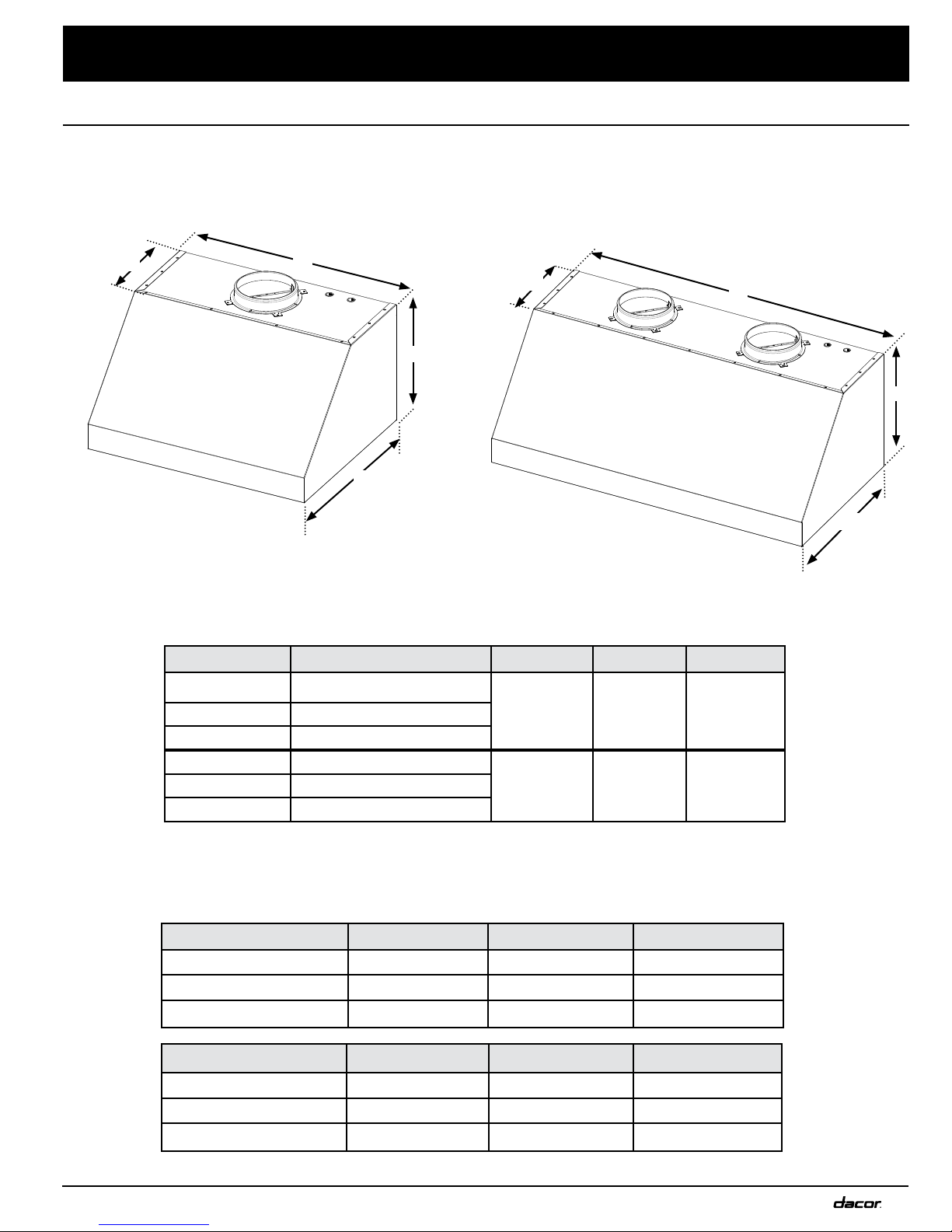

Dimensions

Product Specifications

Electrical and Ductwork Connections

Connect electrical wires and ductwork through the top or rear of the hood.

Top Connections: All Models

Single Exhaust Models**

Standard 8-inch duct

Electrical access holes

7/8 in dia. (5.1 cm)

C

A

B

See Top Access Holes table on

right page.

C

L

9 7/8 in

(25.1 cm)

19 3/4 in

(50.2 cm)

Tolerances: +1/16” -0”, unless otherwise stated.

Dual Exhaust Models*

Standard 8-inch duct

Back of

hood

5 3/4 in

(14.61 cm)

See Rear Access Holes table on

right page.

B

A

Electrical access holes

7/8 in (5.1 cm) (diameter)

Bottom of

hood

Rear Connections: DTHP3018, 3618, 4818

19 3/4 in

(50.2 cm)

C

9 7/8 in

(25.1 cm)

C

L

Dual Exhaust Models*

Standard 8-inch duct

Single Exhaust Models**

Standard 8-inch duct

5 3/4”

(14.61 cm)

Models DTHP48

*

Models DTHP36 &

**

DTHP30

4

Page 7

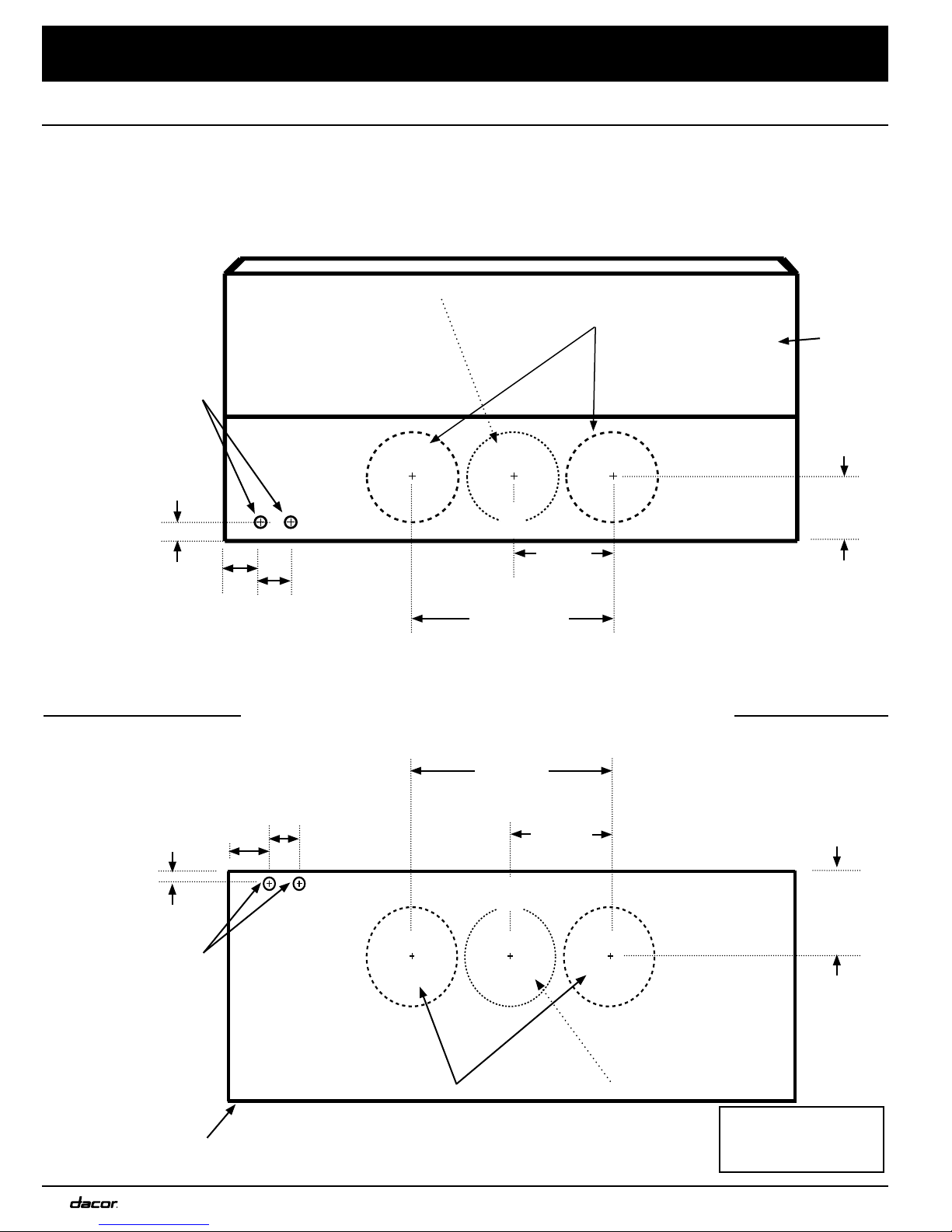

Product Specifications

Dimensions

Single Fan: DTHP30 & DTHP36 Series

D

A

Tolerances: +1/16” -0” unless otherwise stated.

Dual Fan: Model DTHP48 Series

D

A

C

C

B

B

Hood Dimensions

Model A B C D

DTHP3010 29 7/8” (75.9 cm)

DTHP3610 35 7/8” (91.1 cm)

DTHP4810 47 7/8” (121.6 cm)

DTHP3018 29 7/8” (75.9 cm)

DTHP3618 35 7/8” (91.1 cm)

DTHP4818 47 7/8” (121.6 cm)

24”

(61 cm)

24”

(61 cm)

10”

(25.4 cm)

18”

(45.7 cm)

Page 4: Electical Access Dimensions

Top Access Holes A B C

DTHP48

DTHP36

DTHP30

1 1/2” (3.81 cm) 5” (12.7 cm) 3” (7.62 cm)

1 1/2” (3.81 cm) 4 1/2” (11.43 cm) 3” (7.62 cm)

1 1/2” (3.81 cm) 5 1/2” (13.97 cm) 3” (7.62 cm)

Rear Access Holes A B C

DTHP48

DTHP36

DTHP30

1” (2.54 cm) 5” (12.7 cm) 3” (7.62 cm)

1” (2.54 cm) 4 1/2” (11.43 cm) 3” (7.62 cm)

1” (2.54 cm) 5 1/2” (13.97 cm) 3” (7.62 cm)

11 7/8”

(30.2 cm)

11 7/8”

(30.2 cm)

5

Page 8

Preparation and Setup

Parts List

Hood (1)

A

Grease channel (1)

B

Mesh filter

C

Holding brackets and hardware (2)

D

Halogen light bulbs

E

F

Light replacement tool (1)

G

Literature (2)

I

Dacor Cleaning Creme (1)

E

A

Hood Model DTHP48 DTHP36 DTHP30

Mesh

C

Filters

Halogen

E

Lights

4 3 2

4 3 2

pictures vary by model

C

D

F

G

I

B

Necessary Tools and Hardware

Please make sure these tools and hardware are within

reach before beginning the installation.

Hood Installation

Phillips screwdriver Drill + bits Jigsaw

Flathead

screwdriver

Pencil or

marking tool

Wire connector caps Level

Wire stripper Junction box

Tape measure 8” Ducting

Stud finder Foil tape

Sheet metal

screws

18 AWG Wire

or 3-prong

power cord

STAINLESS

STEEL

CLEANER

Blower Rotation (optional)

Phillips screwdriver 5/16” Nut driver

Dual to Single Vent

Transition Kit (optional accessory)

Dacor Kit #AHT10 Drill Foil tape

10” Ducts and

ducting materials

Sheet metal

screws

6

Page 9

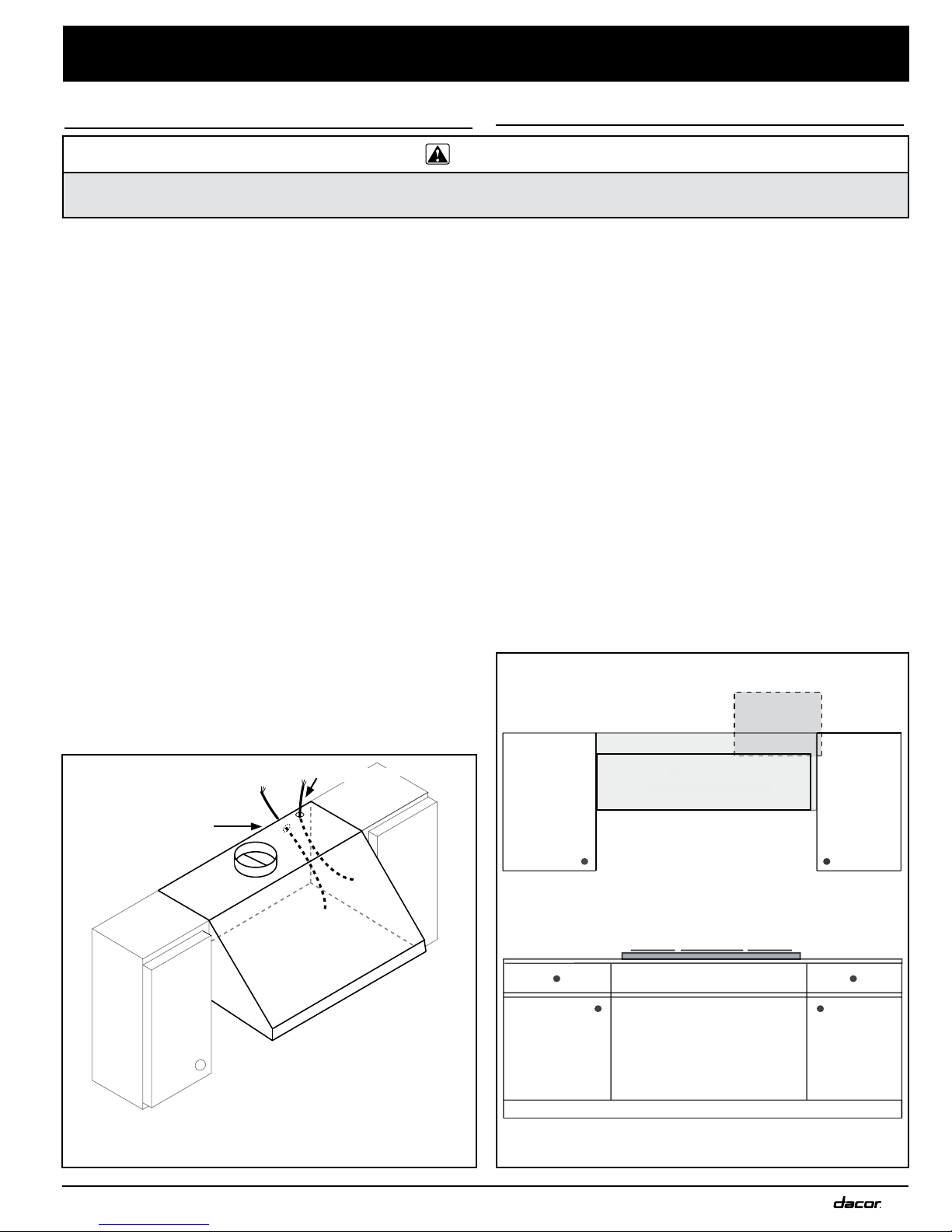

Preparation and Setup

Meeting Electrical Codes

Installing the Electrical Source

WARNING

Make sure electrical service to the range hood is installed by a licensed electrician.

It is the owner’s responsibility to confirm that all electrical

requirements are met by a qualified electrician who is is

servicing this appliance.

The electrical installation, including the minimum supplywire size and grounding, must be in accordance with the

National Electric code ANSI/NFPA* (or latest revision), local

codes, and ordinances.

*A copy of this standard can be obtained from:

National Fire Protection Association

1 Batterymarch Park

Quincy, Massachusetts 02269-9101

• The ground terminal on the hood must be connected

to a grounded, metallic, permanent wiring system, or a

grounding conductor installed by a licensed electrician.

• Do not ground the appliance or appliance wiring to a

gas pipeline or to the neutral (white) power supply wire.

• Do not install a fuse in the neutral or ground circuit.

• Connect the hood directly to an electrical junction

box. Hard-wire the hood according to local code direct-

ly to a dedicated three-wire grounded, single phase

circuit rated at 120 Vac 60 Hz, 15 Amp.

• See the diagram below: Top or Rear Electrical

Access Holes for wire hole locations inside the hood.

• See Wiring Diagrams at the end of this document.

Install an electrical junction box near the hood’s electrical

access holes according to local codes.

See image below: Suggested Area of Junction Box.

1. Drill 7/8” holes in the wall or cabinet (as needed) to act

as a passageway for the electrical wiring.

2. See the last pages of this Installation Guide for wire

diagrams.

Junction Box

Area

Top Access

Rear Access

Hood

Suggested Area of Junction BoxTop or Rear Electrical Access Holes

7

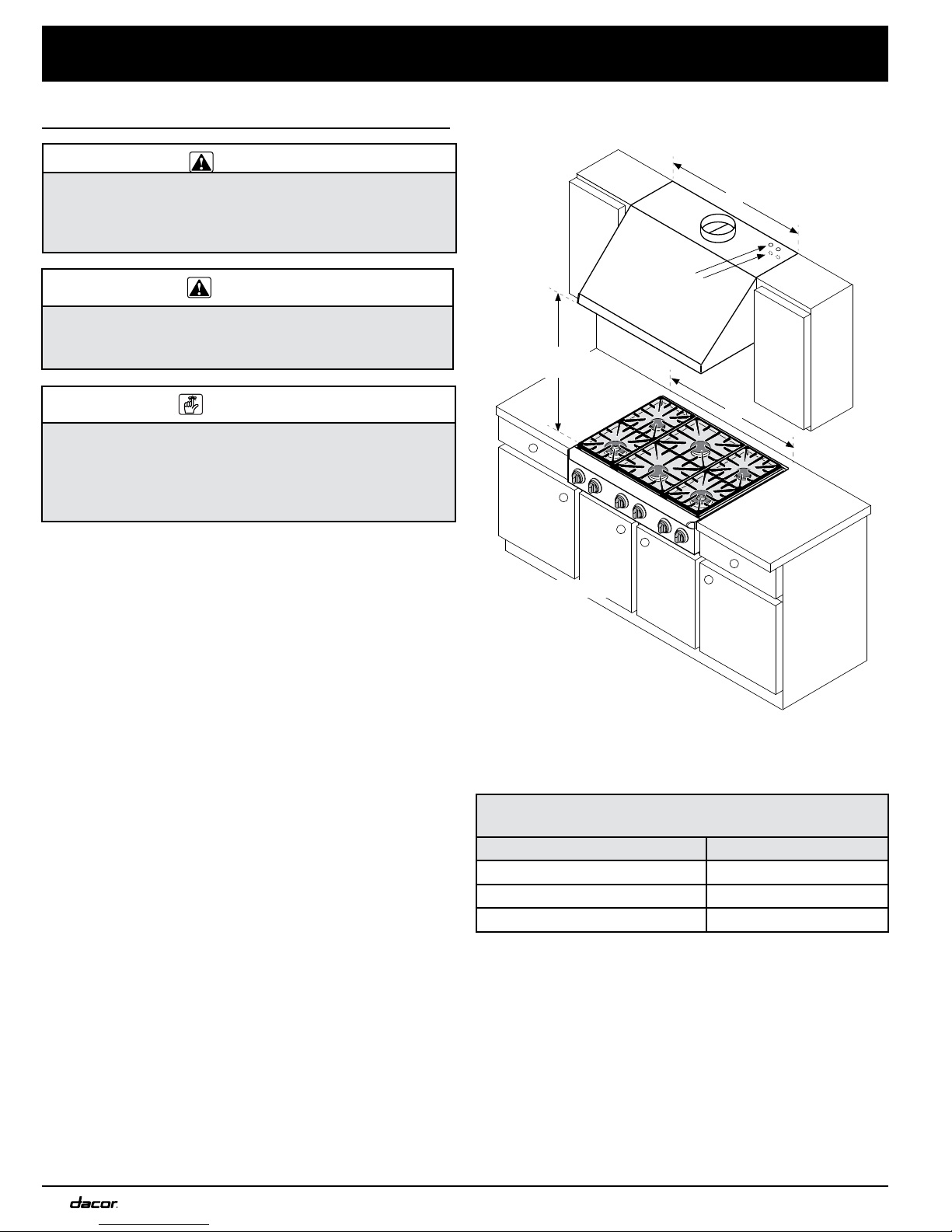

Page 10

E

30” min.*

(76.2 cm)

Electrical

access

* From cooking surface

top

rear

E

Preparation and Setup

Meeting Installation Requirements

WARNING

Observe all governing codes and ordinances during

planning and installation. Contact your local building

department for further information. Use only ductwork

deemed acceptable by state, municipal and local codes.

WARNING

To reduce the risk of personal injury caused by reaching

over a hot appliance, cabinet storage space located

directly above the range should be avoided.

IMPORTANT

See the diagram for minimum installed distance from

the hood to the cooktop surface. The minimum specified

distance may be higher for the particular range or

cooktop in use. Check the manufacturers specifications

for the cooktop or range.

• The hood must be as wide as the cooktop surface or

wider.

• Plan the installation so that all minimum dimensions

are met or exceeded.

• Dimensions given are minimum clearances, unless otherwise noted.

• All contact surfaces between the hood and any cabinetry or walls must be sturdy, solid, and at right angles.

• Install the hood and cooking appliance(s) so that they

can be removed if service is required.

Cabinet Layout Dimensions

8

Minimum Width of E:

Upper Cabinet Cutout & Appliance Width

Models E

DTHP3010, DTHP3018 30 inches (76.2 cm)

DTHP3610, DTHP3618 36 inches (91.5 cm)

DTHP4810, DTHP4818 48 inches (121.9 cm)

All tolerances: +1/16” -0”, unless otherwise stated.

Page 11

Preparation and Setup

Planning the Ductwork

WARNING

• To prevent combustion by-products, smoke or odors

from entering the home and to improve efficiency, tape

all duct joints securely.

• Range hoods may interrupt the proper flow of smoke

and combustion gases from furnaces, gas water heaters, and fireplaces. To avoid drawing lethal gases into

the home, follow the manufacturer’s recommendation

for these devices and consult NFPA and ASHRAE recommendations.

• Failure to install a remote blower or proper ductwork

may result in a backdraft and/or insufficient venting of

smoke and fumes.

• DO NOT install an additional in-line or external blower

to increase the length of the duct run. Even small differences between blower air flow rates can greatly

reduce the air draw by the hood.

CAUTION

To reduce the risk of fire and to properly exhaust air, be

sure to duct air outside the house or building. Do not vent

exhaust air into spaces within walls or ceilings or into

attics, crawl spaces or garages.

WARNING

During duct installation, make sure there are no

obstructions that keep the damper flaps on the top of the

hood from opening.

• Local building codes may require the use of makeup air

systems with ventilation systems that move air greater

than the specified movement rate (CFM).

The specified rate varies based on locale. Consult a

qualified HVAC specialist when designing the system

for the requirements in your area and to assure optimal

performance.

• All ductwork materials (including screws and foil tape)

must be purchased separately.

• Make sure ductwork does not interfere with floor joists

or wall studs.

• Fasten all joints with sheet metal screws and seal with

certified duct tape or foil tape.

• Two 8-inch exhausts may be merged into one 10-inch

duct using Dacor transition kit AHT10. See page 18

for details.

A

B

Vent Direction Options

The fan factory default direction is through top A of the

hood. However, the fan can be rotated to vent through the

rear B of the hood.

When planning new ductwork, always find the shortest,

most direct route to the outside.

Duct Length Calculation Table

The maximum straight duct length for the hood is determined by the type of duct used. See the chart below.

Duct Size Maximum Duct Run

8-inch Round 60 feet

10-inch Round 50 feet

3 1/4-in x 10-in Rectangular 50 feet

For each elbow and transition added, a certain length must

be subtracted from the maximum duct run to compensate

for wind resistance.

To determine your maximum length:

1. Start with the total max. length of your duct run, then

2. Subtract all of the ductwork equivalent lengths (see

chart below).

Ductwork Equivalent Lengths

Piece Subtract Piece Subtract

8-inch

90° Elbow

8-inch

45° Elbow

3-in x 10-inch

to Round 90°

Transition

Roof Cap *

* The equivalent lengths of roof and wall caps vary with

model and configuration.

7 feet 10-inch 90° Elbow 5 feet

3 feet 10-inch 45° Elbow 2 feet

3¼ in x 10 in to 8

25 feet

in / 10 in Round

Transition

Wall Cap with

Damper

4 feet

*

9

Page 12

Preparation and Setup

Ductwork Tips

Wherever possible, reduce the number of transitions, turns,

and sharp angles. Two staggered 45° angles are better

than one sharp 90° angle.

Keep turns as far away from the hood exhaust as possible,

and keep as much space between any bends as possible.

For best performance: use round duct instead of rectangular, especially when elbows are required.

If multiple elbows are used, try to keep at least 24 inches of

straight duct between each elbow.

Avoid using “S” or back-to-back adjacent elbows.

In extremely cold weather regions, use thermal breaks, i.e.,

short sections of non-metallic duct, to avoid indoor heat

loss. Locate the break as close as possible to the outside

pass-through point.

Do not use flexible metal duct. Do not use ductwork that is

smaller than what is advised in the tables.

• The hood exhaust connects to an 8-inch round duct.

You can increase the duct size over the duct run if

desired.

• To prevent a backdraft, never decrease the duct size

over the run. If existing ductwork is smaller than 8

inches in diameter, remove it and replace it with 8-inch

ductwork.

• Do not rely on tape alone to seal duct joints. Fasten

all connections with sheet metal screws, and tape all

joints with certified duct tape or foil tape.

• Use sheet metal screws as needed to support the

weight of the ducting.

• To prevent backdrafts, a damper at the duct outlet may

also be required.

10

Page 13

Preparation and Setup

WARNING

• The electricity to the range hood should be installed

only by a licensed electrician.

• Observe all governing codes and ordinances during

site preparation and installation. Contact your local

building department for further information.

• Failure to properly anchor the hood to the wall may

result in personal injury due to the unit falling off the

wall.

• To avoid an electric shock hazard and property damage, locate electric wires and water pipes and avoid

drilling or cutting in the vicinity.

• Use the temporary holding brackets only to hold the

hood in place until permanent anchoring is secured.

Preparing the Mounting Location

Holding brackets and hardware are provided to temporarily

hold the hood in place while you permanently fasten the

hood to the wall.

The illustrations below show the purpose of the holding

brackets and the support behind the wall.

1. If mounting the hood to brick or masonry, select

anchors capable of holding the full weight of the hood.

2. Make sure the mounting surface is properly reinforced

to support the full weight of the unit.

• If mounting the unit to drywall or a plastered surface,

install a reinforced mounting block between the studs.

• Attach screws directly to the studs and cabinets if they

align with the mounting holes in the back and top of the

hood.

Model Weight

DTHP3010 51 lbs. (23 kg)

DTHP3018

DTHP3610

53 lbs. (24 kg)

Holding Brackets

(Enlarged for Detail)

DTHP3618 57 lbs. (26 kg)

DTHP4810 70 lbs. (32 kg)

DTHP4818 77 lbs. (35 kg)

Stud

Support Block

Holding Brackets

Stud

Support Structures Behind the Wall

11

Page 14

Installation Instructions

Marking the Centerlines

These measurements and marks are for centering and

leveling the hood, marking the duct cutouts, and installing

the holding brackets.

The holding brackets temporarily hold the hood while you

mount it permanently into place.

Have a marking tool, tape measure, and level ready.

1. Position the hood in the same orientation as it will be

when installed. (For example, if it is a top vent installation, set the hood with the vents on top.)

2. Measure the distance from the edge of the hood to the

center of the exhaust port.

3. Transfer that measurement to the wall (for a rear vent),

or overhead (for top vent). Measure the X and Y axis to

find the centerline.

4. Extend the line down 10 inches (25.4 cm).

5. Cut a hole that is 1 inch larger than the duct. Dual

exhaust models require two (2) holes.

Top Exhaust

C

L

48” (121.92 cm)

DTHP48 Top and Rear

Exhaust Centerline

C

L

9 7/8”

(25.08 cm)

14 1/8”

(35.88 cm)

Top Exhaust Centerline

Rear Exhaust

C

L

12

Rear Exhaust Centerline

Page 15

Installation Instructions

Installing the Holding Brackets

IMPORTANT: Placing the holding brackets above, below, or

off the centerline will cause alignment problems during final

installation.

1. Mark the holding bracket’s horizontal centerline 2 1/8

inches (54 cm) below the top of the hood.

2. Next, mark the holding bracket’s two vertical centerlines. Refer to the table and image on right.

3. Measure and mark the “F” distance.

4. Lay the bracket against the wall, and align the

screwholes with the horizontal centerline.

• Make sure the anchors and/or screws being used are

strong enough to support the hood.

• Make sure drywall installations are properly

reinforced.

5. Mark the two holes in the bracket.

6. Drill those two holes for screws or anchors.

7. Attach the brackets securely to the wall.

Holding Bracket Cenerline Distance

Models F

DTHP3010, DTHP3018 10 1/2 in (31.75 cm)

DTHP3610, DTHP3618 7 1/8 in (18.1 cm)

DTHP4810, DTHP4818 17 in (43.18 cm)

2 1/8”

Bracket

placement

Hood

C

L

F F

Bracket

placement

Marking the Centerlines and Brackets

Step 4

Mounting

block

C

L

location

Hood

C

L

Attaching the Brackets to the Wall

13

Page 16

Installation Instructions

Rotating the Fan(s) for Rear Exhaust

WARNING

• Do not install the range hood unless the electrical service provided meets the range hood specifications.

• Observe all governing codes and ordinances during installation. Contact your local building department for further

information.

• A qualified technician must complete the installation of this built-in appliance. More than one person is required to

raise the hood into place. The owner is responsible to make sure the hood is properly installed.

DTHP Models with Fan Rotation:

3018, 3618, 4818

Top Exhaust

A

Rear

Exhaust

B

5/16” Nut driver Phillips screwdriver

Cable ties

Tools and Hardware Needed

AHT10 Transition Kit

(optional) plus metal

screws and foil tape

10” Ducts and

ducting materials

8” Duct and

ducting materials

The 18-inch hoods have fan(s) that can be rotated so that

the air is vented out the back of the hood.

If the hood will be installed in a top exhaust A configuration your hood is already in the factory default, top exhaust

position.

If the hood will be installed in a rear exhaust B configuration, the fans must be rotated so the exhaust vents through

the rear of the hood and to the outside.

This must be done before hanging the hood.

14

Page 17

Installation Instructions

Rotating the Fans(s) for Rear Exhaust

Various models illustrate these instructions, so the images

presented might not be an exact replication of the hood

being installed.

However, the best illustrations were chosen to help

communicate the intended information.

Instructions:

Disassembling Parts

1. Unhook and remove the grease channel.

2. Place the hood assembly on a large, flat surface.

Take special care not to scratch the hood.

3. Remove the duct collar from the top of the unit.

Save the collar and screws.

Removing the Fan(s)

4. Tip the hood up, so that it lays on its back.

You are now facing inside the hood.

5. Find the end of the cable assembly, squeeze the

connector, and unplug it.

Do not pull directly on the cable assembly.

Doing so will damage the contacts and wires; always

pull from the connectors.

7. Unscrew the cable clamp(s) and remove the

hardware that holds the fan and L-bracket.

8. Detach the fan and plate, and place them nearby.

Step 1

Back of Hood

Grease Channel

Steps 2-3

Duct Collar

Back of Hood

continued...

Steps 4-8

fan

Front of Hood

L-Bracket

plate

15

Page 18

Installation Instructions

Rotating the Fans(s) for Rear Exhaust

Orientating the Blower/Vent L-Brackets

9. Unscrew and remove the L-bracket that is in the default

top-venting orientation.

10. Turn and align the L-bracket so the hole is in back of

the hood, allowing a rear-venting configuration.

continued...

Step 9

Top of

Hood

Back of

Hood

Default Orientation:

L-Bracket

Step 10

Top Vent Open

Rear Vent Closed

Top of

Hood

Back of

Hood

16

Blower/Vent

L-Bracket

Rotated Blower

Orientation:

Top Vent Closed

Rear Vent Open

Page 19

Installation Instructions

Rotating the Fan(s) for Rear Exhaust

Orientating the Blower(s)

It is imperative that the fan(s) are installed in the correct

orientation.

To do this, make sure the cable I/O port is against the

back of the hood. Confirm the orientation is correct by

comparing it with the figures on the right.

11. Lay the fan over the exit vent with this specific

placement:

When facing the inside of the hood,

• The cable I/O port must be on the right, and

• The cable I/O port must be against the back of

the hood.

Finalizing the Rear Vent Setup

Steps 11-13

Detail: Location of Cable I/O Port

Cable Clamp

Cable I/O port

Top of Hood

12. Refasten the cable clamps and cable assembly to the

hood.

13. Connect the cable assembly to the I/O port.

14. Attach the duct collars to the back of the hood.

15. Place the hood in a safe, upright position.

Back of Hood

Step 14

17

Page 20

Installation Instructions

32”

(81.3 cm)

13 3/4”

(34.9 cm)

3/4”

(1.9 cm)

9”

(22.9 cm)

2” (5.1 cm)

Using the Dual to Single

Transition Kit# AHT10

On dual exhaust models, the two 8-inch duct exhausts can

be transitioned into one 10-inch duct.

Assemble the Dacor transition kit # AHT10 before hanging

the hood. This transition kit fits over the top or rear ventilation exits.

IMPORTANT:

DTHP3010, 3610, 4810 models

CANNOT vent through the rear ducts.

Preparing the AHT10

1. Create a lip around the transition kit by bending the

bottom edges backward at right angles to create a 3/4”

flange around the base.

Bending the Flange for:

• Rear Vent Configuration

On models 3018, 3618, 4818

• Notes: 18” hood height requirement

DTHP3010, 3610, 4810

X

Four (4) corners are bent backward 90 degrees.

Bending the Flange for:

• Top Vent Configuration

On models 3010, 3610, 4810

3018, 3618, 4818

18

Four (4) corners are bent backward 90 degrees.

Page 21

Installation Instructions

Installing the AHT10

Top Vent: 3010, 3610, 4810

3018, 3618, 4818

1. Center the AHT10 transition kit over the duct collars.

2. Drill holes for screws in the flanges. Make sure the

holes pierce the top of the hood (see right).

3. Fasten the AHT10 into place using sheet metal screws

(not included).

4. Seal the base of the AHT10 with foil or duct tape.

Rear Vent: 3018, 3618, 4818

(18-inch height requirement)

Top Vent: 3010, 3610, 4810

3018, 3618, 4818

Dual vent model is

shown

Rear Vent: 3018, 3618, 4818

1. Center the AHT10 transition kit over the duct collars.

2. Drill holes for screws in the flanges. Make sure the

holes pierce the rear of the hood (see right).

3. Fasten the AHT10 into place using sheet metal screws

(not included).

4. Seal the base of the AHT10 with foil or duct tape.

19

Page 22

Installation Instructions

Hanging the Range Hood

WARNING

Hanging the range hood requires two people. Do not attempt to lift the hood without assistance.

When hanging the hood, be careful not to scratch or damage the hood.

1. Remove the plastic film from the hood.

There are hanging slots in the back of the hood a few

inches from the top. The holding brackets on the wall

engage here and temporarily hold the hood in place.

2. Lift the hood up and catch holding brackets in the

hanging slots in the back of the hood (see figure

Hanging the Hood).

3. Adjust the hood into its final position.

4. Mark the spot by drawing in a mounting hole in the

back of the hood (see figure Hanging and Mounting

Slots ). This is where a screw will hold the hood to the

wall stud or (concrete) anchor.

5. Mark the top of the hood if the configuration calls for

the hood to be secured at the top.

6. Remove the hood from the wall.

7. Drill the pilot or anchor holes. If using anchors, insert

them into the anchor holes.

8. Reattach the hood to the holding brackets.

9. Adjust the hood into its final position and fasten it into

place:

Insert the fasteners through the mounting slots in the

back and top of the hood and into the studs, mounting

blocks, or anchors.

Hanging the Hood

Holding brackets

Hanging slots in the

back of the hood

20

Mounting slots

Hanging and Mounting Slots

Page 23

Installation Instructions

Hardwiring the Hood

WARNING

• To avoid electric shock or fire hazard, make sure that

power to the hood power supply line is turned OFF at

the fuse box or circuit breaker before connecting the

electrical wiring.

• Miswiring the hood electrical wiring can create an

electric shock or fire hazard and could damage the

hood’s electrical system. See page 25.

• Do not ground the wires to the neutral (white) wire.

Connect the ground wire to a separate, properly

grounded ground-wire installed by a licensed electrician.

• Make sure that all wire used is the correct gauge and

capable of handling the total connected loads and

meeting all codes.

1. Shut the power OFF at the circuit breaker or fuse box.

2. Feed the cable assembly through the hood.

3. Connect the cable assembly to the fan.

4. Connect the hood wiring to an electrical junction box

on a dedicated circuit.

5. See next page for instructions on how to ground the

hood to a cold water pipe.

• Refer to Wire Diagrams on page 25.

Wire nut,

3 places

UL/CSA approved

NEMA strain relief

GREEN

GREEN

To the house

circuit breaker

Junction box

WHITE

WHITE

BLACK

BLACK

To Junction

Box

Control Panel Wire Diagram

Neutral (white)

Ground (green)

Hot (black)

To Range Hood

Junction Box Wire Diagram

Not used

N1

Gnd

L1

Power

Terminals

inside Hood

21

Page 24

Installation Instructions

WARNING

• Do not ground the circuit to a gas line.

• Do not ground the circuit to a hot water pipe.

• Water lines that are insulated must be jumped to assure continuity to ground. See below.

To house circuit breaker

panel or fuse box

Wire nut,

3 places

GREEN

GREEN

UL/CSA approved

NEMA strain relief

WHITE

WHITE

BLACK

BLACK

To Range Hood

Grounding by External Cold Water Pipe

Separate No. 10 (minimum)

copper ground wire

Fasten clamp tightly

on metal pipe

Junction box

Meter

No. 4 copper

wire

Clamps

Bare metal

Insulated Pipe Jumper

(if necessary)

Inserting Light Bulbs

Make sure dimmable bulbs are used. The electronic board

was designed for dimmable lights and using non-dimmable

types will cause damage and faulty performance.

Shut the main circuit breaker OFF while inserting new or

while changing bulbs. If an electrical short occurs while the

main power circuit is ON, significant damage can occur.

Follow the diagram to the right for instructions.

1. Attach the suction cup to the lens of a dimmable light

bulb. (Both are supplied parts.)

Make sure the bulb faces are clean so the suction cup

can stick.

2. Insert the bulb into one of the light fixtures.

3. Screw it into place and remove the suction cup.

3

2

1

4. Repeat for the remaining light fixtures.

5. Switch the main circuit power ON.

Inserting Light Bulbs with the Suction Cup Tool

Replacement Part Number Replacement Part Description

700975 Halogen Bulb Replacement Kit (1 bulb + 1 suction cup tool)

22

Page 25

Verifying the Setup

Installation Instructions

FRONT

Control Panel

FAN

button

Verify the setup to ensure everything functions correctly.

1. Turn the power ON at the circuit panel or fuse box.

2. Assemble the filters if not already done so.

3. Insert the filters gently:

Be careful not to scratch the back of the grease

channel!

• Raise the front edge into the filter clip, and press

forward.

• Lift the rear edge up and above the grease channel.

Use caution not to scratch the filter against the grease

channel or scratch other parts of the hood or filters.

• Set the rear edge onto the grease channel.

4. Turn the LIGHTS knob. Twist the knob half-way around

for the lights to illuminate.

5. Turn the LIGHTS knob in the opposite direction to turn

the lights off.

6. Turn the FAN knob. The fan(s) will start at maximum

speed and decrease as you continue.

7. Turn the FAN knob in the opposite direction to turn the

fan(s) off.

Control Panel

LIGHTS

button

Grease channel

Filter

Detail of

filter clip

FRONT

If the Hood Fails to Function Correctly:

1. Verify that power is supplied to the hood via the outlet,

circuit breaker, or another main power source.

2. Make sure the electrical supply has not been disrupted

by a blown fuse or problems in the outlet or service.

3. Check the electrical connections to ensure that the

wiring installation has been completed correctly.

4. Repeat the above steps.

• If the hood still does not work, contact Dacor Distinctive

Service at (800) 793-0093 ex. 2822.

• Do not attempt to repair the appliance yourself.

• Dacor is not responsible for service required to correct

a faulty installation.

Replacement Part Number Replacement Part Description

702586 Mesh Style Filter (1 fully assembled filter)

REAR

FRONT

Location of Filter Clips

23

Page 26

Installation Instructions

The Installation Checklist

WARNING

• To ensure a safe and correct installation, the following checklist should be completed by the installer to

ensure that no part of the installation has been overlooked.

• Proper installation is the responsibility of the homeowner. The importance of proper installation of your

Dacor range hood cannot be overemphasized.

□ Is the hood properly attached to the wall according to

the instructions on pages 13 and 20?

□ Is the ductwork completely installed? Are all joints

attached with sheet metal screws and wrapped with foil

tape? See page 19.

□ Is the range hood wired and grounded according to

these instructions and in accordance with all applicable

electric codes? See pages 7 and 21.

□ Has the setup been verified? See page 23.

□ Have any problems been noted on the warranty card or

during the on-line warranty activation?

□ Has the warranty been activated on-line or the warranty

card filled out completely and mailed?

24

Page 27

Wiring Diagrams

DTHP3010, DTHP3018

CONNECT TO

120V 60Hz 15A

POWER SUPPLY

G

W

B

W

LAMP

DIMMER

FAN

SWITCH

HOOD

LIGHT 75W

HOOD

LIGHT 75W

B

G

W

WIRING DIAGRAM

DTHP3010, 3018

B

LIGHT

B

LIGHT

B

FAN

B

FAN

FAN MOTOR

FOR

CONNECTION

TO ARLC/ARSC

/ARSLC

CAUTION:

DISCONNECT POWER SUPPLY AT THE

FUSE BOX BEFORE SERVICING THIS EQUIPMENT.

Wiring Diagram: 1-Fan, 2-Light Models

W

B

G

FOR

CONNECTION

TO REMOTE

BLOWER

ILHSF -8/10 OR

REMP -3/16

25

Page 28

Wiring Diagrams

DTHP3610, DTHP3618

CONNECT TO

120V 60Hz 15A

POWER SUPPLY

G

W

B

W

LAMP

DIMMER

FAN

SWITCH

HOOD

LIGHT

75W

HOOD

LIGHT

75W

HOOD

LIGHT

75W

B

G

W

WIRING DIAGRAM

DTHP3610, DTHP3618

B

LIGHT

B

LIGHT

B

FAN

B

FAN

FAN MOTOR

FOR

CONNECTION

TO ARLC/ARSC

/ARSLC

CAUTION:

DISCONNECT POWER SUPPLY AT THE

FUSE BOX BEFORE SERVICING THIS EQUIPMENT.

Wiring Diagram: 1-Fan, 3-Light Models

W

B

G

FOR

CONNECTION

TO REMOTE

BLOWER

ILHSF -8/10 OR

REMP -3/16

26

Page 29

Wiring Diagrams

DTHP4810, DTHP4818

CONNECT TO

120V 60Hz 15A

POWER SUPPLY

G

W

B

W

LAMP

DIMMER

FAN

SWITCH

HOOD

LIGHT

75W

HOOD

LIGHT

75W

B

G

W

HOOD

LIGHT

75W

HOOD

LIGHT

75W

FAN MOTOR

WIRING DIAGRAM

DTHP4810, DTHP4818

B

B

B

B

LIGHT

LIGHT

FAN

FAN

FOR

CONNECTION

TO ARLC/ARSC

/ARSLC

B

G

FAN MOTOR

W

CAUTION:

DISCONNECT POWER SUPPLY AT THE

FUSE BOX BEFORE SERVICING THIS EQUIPMENT.

Wiring Diagram: 2-Blower, 4-Light Models

W

B

G

FOR

CONNECTION

TO REMOTE

BLOWER

ILHSF -8/10 OR

REMP -3/16

27

Page 30

Notes

28

Page 31

Page 32

Dacor ● 14425 Clark Avenue, City of Industry, CA 91745 ● Phone: (800) 793-0093 ● Fax: (626) 403-3130 ● www.dacor.com

Loading...

Loading...