Page 1

STK11C68-5 (SMD5962-92324)

64 Kbit (8K x 8) SoftStore nvSRAM

Features

STORE/

RECALL

CONTROL

POWER

CONTROL

SOFTWARE

DETECT

STATIC RAM

ARRAY

128 X 512

Quantum Trap

128 X 512

STORE

RECALL

COLUMN I/O

COLUMN DEC

ROW DECODER

INPUT BUFFERS

OE

CE

WE

HSB

V

CC

V

CAP

A

0

- A

12

A

0

A

1

A

2

A

3

A

4

A

10

A

5

A

6

A

7

A

8

A

9

A

11

A

12

DQ

0

DQ

1

DQ

2

DQ

3

DQ

4

DQ

5

DQ

6

DQ

7

Logic Block Diagram

Functional Description

■ 35 ns, 45 ns, and 55 ns access times

■ Pin compatible with industry standard SRAMs

■ Software initiated nonvolatile STORE

■ Unlimited Read and Write endurance

■ Automatic RECALL to SRAM on power up

■ Unlimited RECALL cycles

■ 1,000,000 STORE cycles

■ 100 year data retention

■ Single 5V ± 10% operation

■ Military temperature

■ 28-pin (300 mil) CDIP and 28-pad LCC packages

The Cypress STK11C68-5 is a 64 Kb fast static RAM with a

nonvolatile element in each memory cell. The embedded

nonvolatile elements incorporate QuantumTrap technology to

produce the world’s most reliable nonvolatile memory. The

SRAM provides unlimited read and write cycles, while

independent nonvolatile data resides in the highly reliable

QuantumTrap cell. Data transfers under software control from

SRAM to the nonvolatile elements (the STORE operation). On

power up, data is automatically restored to the SRAM (the

RECALL operation) from the nonvolatile memory. RECALL

operations are also available under software control.

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 • 408-943-2600

Document Number: 001-51001 Rev. *A Revised April 07, 2009

[+] Feedback

Page 2

STK11C68-5 (SMD5962-92324)

Pinouts

1&

$

$

$

$

$

$

$

$

'4

'4

'4

9

66

9

&&

1&

$

$

$

$

'4

'4

'4

'4

'4

$

:(

2(

&(

723

Figure 1. Pin Diagram - 28-Pin DIP

Figure 2. Pin Diagram - 28-Pin LLC

Pin Definitions

Pin Name Alt I/O Type Description

A

0–A12

DQ

-DQ

0

7

WE

CE

OE

V

SS

V

CC

Document Number: 001-51001 Rev. *A Page 2 of 15

W

E

G

Input Addre ss Inputs. Used to select one of the 8,192 bytes of the nvSRAM.

Input/Output Bidirectional Data I/O Lines. Used as input or output lines depending on operation.

Input

Write Enable Input, Active LOW . When the chip is enabled and WE is LOW, dat a on the I/O

pins is written to the specific address location.

Input Chip Enable Input, Active LOW. When LOW, selects the chip. When HIGH, deselects the

chip.

Input

Output Enable, Active LOW. The active LOW OE input enables the data output buffers during

read cycles. Deasserting OE

Ground Ground for the Device. The device is connected to ground of the system.

Power Supply Power Supply Inputs to the Device.

HIGH causes the I/O pins to tristate.

[+] Feedback

Page 3

STK11C68-5 (SMD5962-92324)

Device Operation

The STK11C68-5 is a versatile memory chip that provides

several modes of operation. The STK11C68-5 can operate as a

standard 8K x 8 SRAM. It has an 8K x 8 Nonvolatile Elements

shadow to which the SRAM information can be copied or fro m

which the SRAM can be updated in nonvolatile mode.

The software sequence is clocked with CE

controlled Reads.

When the sixth address in the sequence is entered, the STORE

cycle commences and the chip is disabled. It is important that

Read cycles and not Write cycles are used in the sequence. It is

not necessary that OE is LOW for a valid sequence. After the

t

cycle time is fulfilled, the SRAM is again activated for

STORE

Read and Write operation.

SRAM Read

The STK11C68-5 performs a Read cycle whenever CE and OE

are LOW while WE is HIGH. The address specified on pins A

0–12

determines the 8,192 data bytes accessed. When the Read is

initiated by an address transition, the outputs are valid after a

delay of t

the outputs are valid at t

(Read cycle 1). If the Read is initiated by CE or OE,

AA

ACE

or at t

, whichever is later (Read

DOE

cycle 2). The data outputs repeatedly respond to address

changes within the t

access time without the need for

AA

transitions on any control input pins. They remain valid until

another address change or until CE

or OE is brought HIGH, or

WE is brought LOW.

SRAM Write

A Write cycle is performed whenever CE and WE are LOW . Th e

address inputs must be stable before entering the Write cycle

and must remain stable until either CE or WE goes HIGH at the

end of the cycle. The data on the common I/O pins DQ

written into the memory if it has valid t

end of a WE

controlled Write or before the end of an CE

. This is done before the

SD

0–7

are

controlled Write. Keep OE HIGH during the entire Write cycle to

avoid data bus contention on common I/O lines. If OE

internal circuitry turns off the output buffers t

LOW.

HZWE

is left LOW,

after WE goes

Software ST OR E

Data is transferred from the SRAM to the nonvolatile memory by

a software address sequence. The STK11C68-5 software

STORE cycle is initiated by executing sequential CE controlled

Read cycles from six specific address locations in exact order.

During the STORE cycle, an erase of the previous nonvolatile

data is first performed followed by a program of the nonvolatile

elements. When a STORE cycle is initiated, input and output are

disabled until the cycle is completed.

Because a sequence of Reads from specific addresses is used

for STORE initiation, it is important that no other Read or Write

accesses intervene in the sequence. If they intervene, the

sequence is aborted and no STORE or RECALL takes place.

To initiate the software STORE cycle, the following Read

sequence is performed:

1. Read address 0x0000, Valid READ

2. Read address 0x1555, Valid READ

3. Read address 0x0AAA, Valid READ

4. Read address 0x1FFF, Valid READ

5. Read address 0x10F0, Valid READ

6. Read address 0x0F0F, Initiate STORE cycle

Software RECALL

Data is transferred from the nonvolatile memory to the SRAM by

a software address sequence. A software RECALL cycle is

initiated with a sequence of Read operations in a manner similar

to the software STORE initiation. To initiate the RECALL cycle,

the following sequence of CE

controlled Read operations is

performed:

1. Read address 0x0000, Valid READ

2. Read address 0x1555, Valid READ

3. Read address 0x0AAA, Valid READ

4. Read address 0x1FFF, Valid READ

5. Read address 0x10F0, Valid READ

6. Read address 0x0F0E, Initiate RECALL cycle

Internally, RECALL is a two step procedure. First, the SRAM data

is cleared; then, the nonvolatile information is transferred into the

SRAM cells. After the t

ready for Read and Write operations. The RECALL operation

cycle time, the SRAM is again

RECALL

does not alter the data in the nonvolatile elements. The

nonvolatile data can be recalled an unlimited number of times.

Hardware RECALL (Power Up)

During power up or after any low power condition (VCC <

V

), an internal RECALL request is latched. When V

RESET

once again exceeds the sense voltage of V

cycle is automatically initiated and takes t

If the STK11C68-5 is in a Write

RECALL, the SRAM

data is corrupted. To help avoid this

state at the end of power up

HRECALL

SWITCH

, a RECALL

to complete.

CC

situation, a 10 Kohm resistor is connected either be tween WE

and system VCC or between CE and system VCC.

Hardware Protect

The STK11C68-5 of fers hardware protection against inadvertent

STORE operation and SRAM Writes during low voltage

conditions. When V

operations and SRAM Writes are inhibited.

CAP

< V

, all externally initiated STORE

SWITCH

Noise Considerations

The STK11C68-5 is a high speed memory. It must have a high

frequency bypass capacitor of approximately 0.1 µF connected

between V

as possible. As with all high speed CMOS ICs, careful routing of

power, ground, and signals reduce circuit noise.

CC

and V

using leads and traces that are as short

SS,

Document Number: 001-51001 Rev. *A Page 3 of 15

[+] Feedback

Page 4

STK11C68-5 (SMD5962-92324)

Low Average Active Power

Note

1. The six consecutive addresses must be in the order listed. WE

must be high during all six consecutive CE controlled cycles to enable a nonvolatile cycle.

CMOS technology provides the STK11C68-5 the benefit of

drawing significantly less current when it is cycled at times longer

than 50 ns. Figure 3 and Figure 4 shows the relationship

between I

consumption is shown for both CMOS and TTL input levels

(commercial temperature range, VCC = 5.5V, 100% duty cycle

on chip enable). Only standby current is drawn when the chip is

disabled. The overall average current drawn by the STK11C68-5

depends on the following items:

■ Duty cycle of chip enable

■ Overall cycle rate for accesses

■ Ratio of Reads to Writes

■ CMOS versus TTL input levels

■ Operating temperature

■ V

CC

■ I/O loading

Figure 3. Current Versus Cy c le Time (Read)

and Read or Write cycle time. Worst case current

CC

level

Figure 4. Current Versus Cycle Time (Write)

Best Practices

Cypress nvSRAM products have been used effectively for over

15 years. While ease of use is one of the product’s main system

values, the experience gained from working with hundreds of

applications has resulted in the following suggestions as best

practices:

■ The nonvolatile cells in an nvSRAM are programmed on the

test floor during final test and quality assurance. Incoming

inspection routines at customer or contract manufacturer’s

sites sometimes reprograms these values. Final NV patterns

are typically repeating patterns of AA, 55, 00, FF, A5, or 5A.

The end product’s firmware must not assume that an NV array

is in a set programmed state. Routines that check memory

content values to determine first time system configuration.

■ Cold or warm boot status, and so on must always program a

unique NV pattern (for example, complex 4-byte pattern of 46

E6 49 53 hex or more random bytes) as part of the final system

manufacturing test. This is to ensure these system routines

work consistently.

Table 1. Hardware Mode Selection

CE WE A12–A0 Mode I/O Notes

L H 0x0000

0x1555

0x0AAA

0x1FFF

0x10F0

0x0F0F

L H 0x0000

0x1555

0x0AAA

0x1FFF

0x10F0

0x0F0E

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Nonvolatile STORE

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Nonvolatile RECALL

Output Data

Output Data

Output Data

Output Data

Output Data

Output High Z

Output Data

Output Data

Output Data

Output Data

Output Data

Output High Z

[1]

[1]

Document Number: 001-51001 Rev. *A Page 4 of 15

[+] Feedback

Page 5

STK11C68-5 (SMD5962-92324)

Maximum Ratings

Note

2. CE

> VIH does not produce standby current levels until any nonvolatile cycle in progress has timed out.

3. These parameters are guaranteed by design and are not tested.

Exceeding maximum ratings may shorten the useful life of the

device. These user guidelines are not tested.

Storage Tem perature ................................. –65°C to +150°C

Voltage on DQ

Power Dissipation .........................................................1.0W

DC Output Current (1 output at a time, 1s duration).... 15 mA

Operating Range

...................................–0.5V to Vcc + 0.5V

0-7

Temperature under bias..............................–55°C to +125°C

Supply Voltage on VCC Relative to GND..........–0.5V to 7.0V

Voltage on Input Relative to Vss............–0.6V to V

+ 0.5V

CC

Range

Military -55°C to +125°C 4.5V to 5.5V

Ambient

Temperature

V

CC

DC Electrical Characteristics

Over the operating range (VCC = 4.5V to 5.5V)

Parameter Description Test Conditions Min Max Unit

I

CC1

I

CC2

I

CC3

I

SB1

I

SB2

I

IX

I

OZ

V

V

V

V

IH

IL

OH

OL

Average VCC Current tRC = 35 ns

t

= 45 ns

RC

t

= 55 ns

RC

Dependent on output loading and cycle rate. Values obtained

without output loads. I

Average VCC Current

during STORE

Average VCC Current at

t

= 200 ns, 5V, 25°C

RC

Typical

[2]

VCC Standby Current

(Standby, Cycling TTL

Input Levels)

[2]

VCC Standby Current

All Inputs Do Not Care, VCC = Max

Average current for duration t

WE

> (VCC – 0.2V). All other inputs cycling.

Dependent on output loading and cycle rate. Values obtained

without output loads.

t

= 35 ns, CE > V

RC

tRC = 45 ns, CE > V

tRC = 55 ns, CE > V

CE > (VCC – 0.2V). All others V

Standby current level after nonvolatile cycle is complete.

IH

IH

IH

OUT

= 0 mA

STORE

IN

< 0.2V or > (VCC – 0.2V).

Inputs are static. f = 0 MHz

Input Leakage Current VCC = Max, VSS < V

Off State Output

VCC = Max, VSS < V

Leakage Current

< V

IN

CC

< VCC, CE or OE > V

IN

or WE < V

IH

-1 +1 μA

IL

-5 +5 μA

Input HIGH Voltage 2.2 VCC + 0.5 V

Input LOW Voltage VSS – 0.5 0.8 V

Output HIGH Voltage I

Output LOW Voltage I

= –4 mA 2.4 V

OUT

= 8 mA 0.4 V

OUT

75

65

55

3mA

10 mA

24

21

20

1500 μA

mA

mA

mA

mA

mA

mA

Data Retention and Endurance

Parameter Description Min Unit

DATA

NV

C

R

Data Retention 100 Years

Nonvolatile STORE Operations 1,000 K

Capacitance

In this table, the capacitance parameters are listed.

Parameter Description Test Conditions Max Unit

C

C

IN

OUT

Input Capacitance TA = 25°C, f = 1 MHz,

V

= 0 to 3.0V

Output Capacitance 7pF

CC

Document Number: 001-51001 Rev. *A Page 5 of 15

[3]

8pF

[+] Feedback

Page 6

STK11C68-5 (SMD5962-92324)

Thermal Resistance

5.0V

Output

30 pF

R1 480Ω

R2

255Ω

Input Pulse Levels....................................................0V to 3V

Input Rise and Fall Times (10% to 90%)...................... <

5 ns

Input and Output Timing Reference Levels.................... 1.5V

In this table, the thermal resistance parameters are listed.

Parameter Description Test Conditions 28-CDIP 28-LCC Unit

Θ

Θ

Thermal Resistance

JA

(Junction to Ambient)

Thermal Resistance

JC

(Junction to Case)

Test conditions follow standard test methods and procedures for measuring thermal impedance, per EIA /

JESD51.

[3]

TBD TBD °C/W

TBD TBD °C/W

Figure 5. AC Test Loads

AC Test Conditions

Document Number: 001-51001 Rev. *A Page 6 of 15

[+] Feedback

Page 7

STK11C68-5 (SMD5962-92324)

AC Switching Characteristics

Notes

4. WE

must be High during SRAM Read cycles.

5. I/O state assumes CE

and OE < VIL and WE > VIH; device is continuously selected.

6. Measured ± 200 mV from steady state output voltage.

W

5&

W

$$

W

2+$

$''5(66

'4'$7$287

'$7$9$/,'

$''5(66

W

5&

&(

W

$&(

W

/=&(

W

3'

W

+=&(

2(

W

'2(

W

/=2(

W

+=2(

'$7$9$/,'

$&7,9(

67$1'%<

W

38

'4'$7$287

,&&

SRAM Read Cycle

Parameter

Cypress

Parameter

t

ACE

[4]

t

RC

[5]

t

AA

t

DOE

[5]

t

OHA

[6]

t

LZCE

[6]

t

HZCE

[6]

t

LZOE

[6]

t

HZOE

[3]

t

PU

[3]

t

PD

t

ELQV

t

AVAV,

t

ELEH

t

AVQV

t

GLQV

t

AXQX

t

ELQX

t

EHQZ

t

GLQX

t

GHQZ

t

ELICCH

t

EHICCL

Alt

Chip Enable Access Time 35 45 55 ns

Read Cycle Time 35 45 55 ns

Address Access Time 35 45 55 ns

Output Enable to Data Valid 15 20 35 ns

Output Hold After Address Change 5 5 5 ns

Chip Enable to Output Active 5 5 5 ns

Chip Disable to Output Inactive 13 15 25 ns

Output Enable to Output Active 0 0 0 ns

Output Disable to Output Inactive 13 15 25 ns

Chip Enable to Power Active 0 0 0 ns

Chip Disable to Power Standby 35 45 55 ns

Description

Switching Waveforms

Figure 6. SRAM Read Cycle 1: Address Controlled

35 ns 45 ns 55 ns

Min Max Min Max Min Max

[4, 5]

Unit

Figure 7. SRAM Read Cycle 2: CE and OE Controlled

Document Number: 001-51001 Rev. *A Page 7 of 15

[4]

[+] Feedback

Page 8

STK11C68-5 (SMD5962-92324)

SRAM Write Cycle

Notes

7. If WE

is Low when CE goes Low, the outputs remain in the high impedance state.

8.

CE

or WE must be greater than VIH during address transitions.

t

WC

t

SCE

t

HA

t

AW

t

SA

t

PWE

t

SD

t

HD

t

HZWE

t

LZWE

ADDRESS

CE

WE

DATA IN

DATA OUT

DATA VALID

HIGH IMPEDANCE

PREVIOUS DATA

t

WC

ADDRESS

t

SA

t

SCE

t

HA

t

AW

t

PWE

t

SD

t

HD

CE

WE

DATA IN

DATA OUT

HIGH IMPEDANCE

DATA VALID

Parameter

Cypress

Parameter

t

WC

t

PWE

t

SCE

t

SD

t

HD

t

AW

t

SA

t

HA

[6,7]

t

HZWE

[6]

t

LZWE

Alt

t

AVAV

t

WLWH, tWLEH

t

ELWH, tELEH

t

DVWH, tDVEH

t

WHDX, tEHDX

t

AVWH, tAVEH

t

AVWL, tAVEL

t

WHAX, tEHAX

t

WLQZ

t

WHQX

35 ns 45 ns 55 ns

Description

Min Max Min Max Min Max

Unit

Write Cycle Time 35 45 55 ns

Write Pulse Width 25 30 45 ns

Chip Enable To End of Write 25 30 45 ns

Data Setup to End of Write 12 15 30 ns

Data Hold After End of Write 0 0 0 ns

Address Setup to End of Write 25 30 45 ns

Address Setup to Start of Write 0 0 0 ns

Address Hold After End of Write 0 0 0 ns

Write Enable to Output Disable 13 15 35 ns

Output Active After End of Write 5 5 5 ns

Switching Waveforms

Figure 8. SRAM Write Cycle 1: WE Controlled

Figure 9. SRAM Write Cycle 2: CE

and OE Controlled

[7, 8]

[7, 8]

Document Number: 001-51001 Rev. *A Page 8 of 15

[+] Feedback

Page 9

STK11C68-5 (SMD5962-92324)

AutoStore INHIBIT or Power Up RECALL

V

CC

V

SWITCH

V

RESET

POWER-UP RECALL

DQ (DATA OUT)

STORE INHIBIT

5V

t

HRECALL

POWER-UP

RECALL

BROWN OUT

STORE INHIBIT

NO RECALL

(V

CC

DID NOT GO

BELOW V

RESET

)

BROWN OUT

STORE INHIBIT

NO RECALL

(V

CC

DID NOT GO

BELOW V

RESET

)

BROWN OUT

STORE INHIBIT

RECALL WHEN

V

CC

RETURNS

ABOVE V

SWITCH

Notes

9. t

HRECALL

starts from the time VCC rises above V

SWITCH

.

Parameter Alt Description

[9]

t

HRECALL

t

STORE

V

SWITCH

V

RESET

t

RESTORE

t

HLHZ

Power up RECALL Duration 550 μs

STORE Cycle Duration 10 ms

Low Voltage T rigger Level 4.0 4.5 V

Low Voltage Reset Level 3.6 V

Figure 10. AutoStore INHIBIT/Power Up RECALL

STK11C68-5

Min Max

Unit

Document Number: 001-51001 Rev. *A Page 9 of 15

[+] Feedback

Page 10

STK11C68-5 (SMD5962-92324)

Software Controlled ST ORE/RECALL Cycle

Notes

10.The software sequence is clocked on the falling edge of CE

without involving OE (double clocking aborts the sequence).

11.The six consecutive addresses must be read in the order listed in Table 1 on page 4. WE

must be HIGH during all six consecutive cycles.

t

RC

t

RC

t

SA

t

SCE

t

HACE

t

STORE

/ t

RECALL

DATA VALID

DATA VALID

6#SSERDDA1#SSERDDA

HIGH IMPEDANCE

ADDRESS

CE

OE

DQ (DATA)

The software controlled STORE/RECALL cycle follows.

Parameter Alt Description

t

RC

[10]

t

SA

[10]

t

CW

t

HACE

t

RECALL

[10]

[10]

t

AVAV

t

AVEL

t

ELEH

t

ELAX

STORE/RECALL Initiation Cycle Time 35 45 55 ns

Address Setup Time 0 0 0 ns

Clock Pulse Width 25 30 35 ns

Address Hold Time 20 20 20 ns

RECALL Duration 20 20 20 μs

[10, 11]

35 ns 45 ns 55 ns

Min Max Min Max Min Max

Unit

Switching Waveform

Figure 11. CE Controlled Sof tware STORE/RECALL Cycle

[10]

Document Number: 001-51001 Rev. *A Page 10 of 15

[+] Feedback

Page 11

STK11C68-5 (SMD5962-92324)

Speed:

35 - 35 ns

45 - 45 ns

Package:

C = Ceramic 28-pin 300 mil DIP (gold lead finish)

Part Numbering Nomenclature

STK11C68 - 5 C 45 M

Temperature Range:

M - Military (-55 to 125°C)

K

L = Ceramic 28-pin LLC

= Ceramic 28-pin 300 mil DIP (Solder dip finish)

Retention / Endurance

5 = Military (10 years or 10

5

cycles)

55 - 55 ns

Case Outline

X = Ceramic 28-pin 300 mil DIP

Y = Ceramic 28-pin LLC

Device Class Indicator - Class M

SMD5962-92324 04 MX X

Lead Finish

A = Solder DIP lead finish

Device Type:

04 = 55 ns

05 = 45 ns

C = Gold lead DIP finish

X = Lead finish “A” or “C” is acceptable

06 = 35 ns

Document Number: 001-51001 Rev. *A Page 11 of 15

[+] Feedback

Page 12

STK11C68-5 (SMD5962-92324)

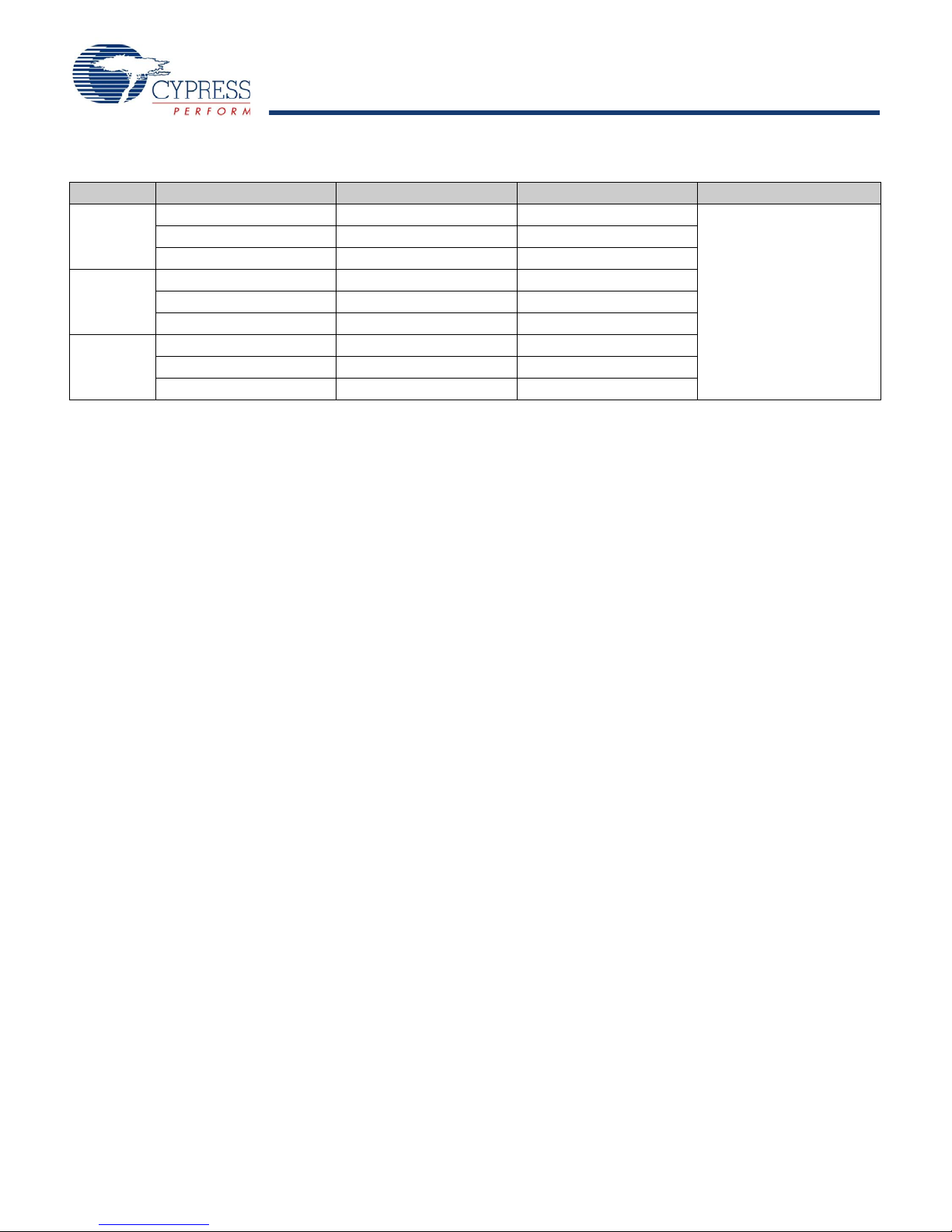

Ordering Information

Speed (ns) Ordering Code Package Diagram Pac kage Type Operating Range

35 STK11C68-5C35M 001-51695 28-Pin CDIP (300 mil) Military

STK11C68-5K35M 001-51695 28-Pin CDIP (300 mil)

STK11C68-5L35M 001-51696 28-Pin LCC (350 mil)

45 STK11C68-5C45M 001-51695 28-Pin CDIP (300 mil)

STK11C68-5K45M 001-51695 28-Pin CDIP (300 mil)

STK11C68-5L45M 001-51696 28-Pin LCC (350 mil)

55 STK11C68-5C55M 001-51695 28-Pin CDIP (300 mil)

STK11C68-5K55M 001-51695 28-Pin CDIP (300 mil)

STK11C68-5L55M 001-51696 28-Pin LCC (350 mil)

This table contains Final information. Contact your local Cypress sales representative for availability of these par ts.

Document Number: 001-51001 Rev. *A Page 12 of 15

[+] Feedback

Page 13

STK11C68-5 (SMD5962-92324)

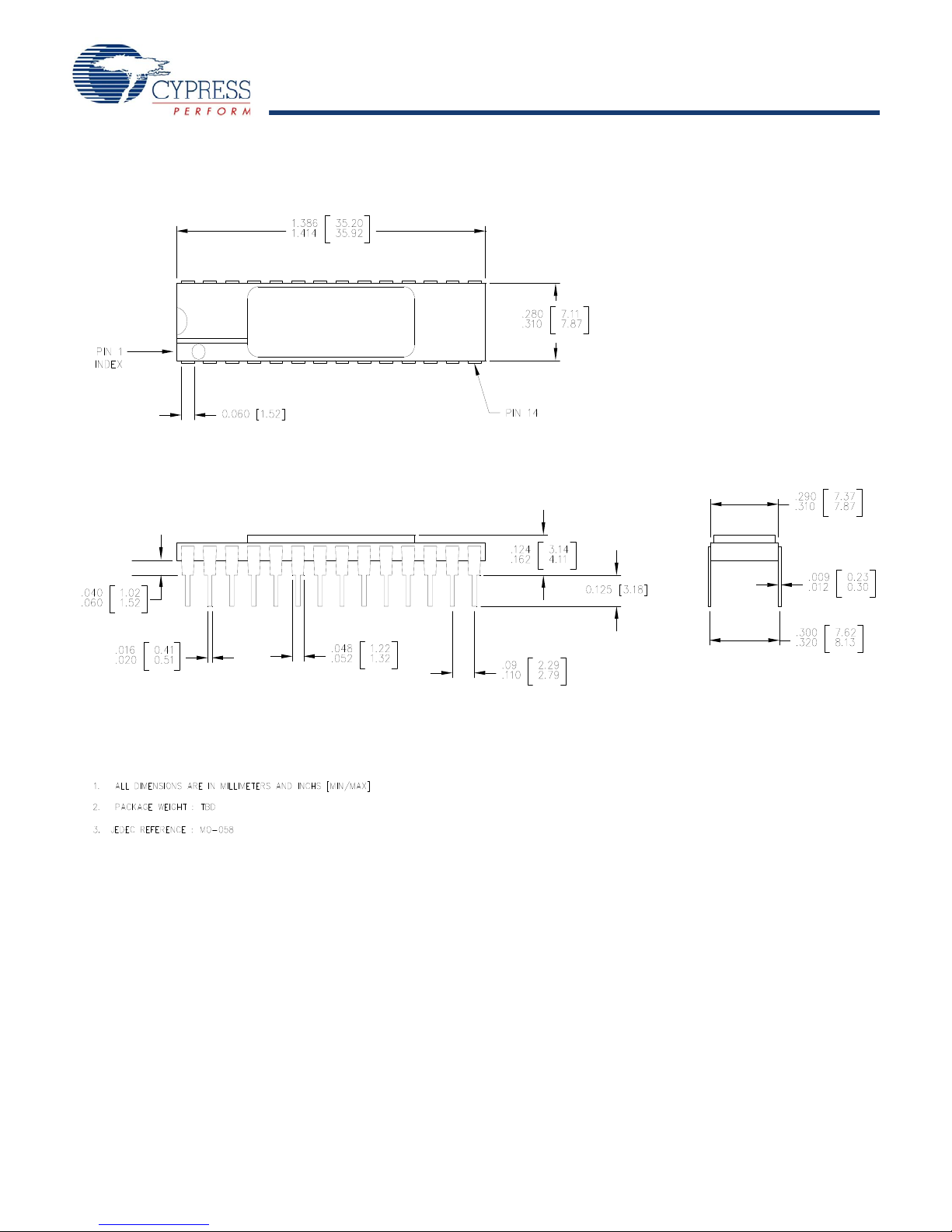

Package Diagrams

001-51695 **

Figure 12. 28-Pin (300-Mil) Side Braze DIL (001-51695)

Document Number: 001-51001 Rev. *A Page 13 of 15

[+] Feedback

Page 14

STK11C68-5 (SMD5962-92324)

Package Diagrams (continued)

1. ALL DIME NSIO N AR E IN IN CHE S AND M ILLIM ETER S [MIN/M AX]

2. JEDEC 95 OUTLINE# MO-041

3. PACKAGE WEIGHT : TBD

001-51696 **

Figure 13. 28-Pad (350-Mil) LCC (001-51696)

Document Number: 001-51001 Rev. *A Page 14 of 15

[+] Feedback

Page 15

STK11C68-5 (SMD5962-92324)

Document History Page

Document Title: STK11C68-5 (SMD5962-92324) 64 Kbit (8K x 8) SoftStore nvSRAM

Document Number: 001-51001

Rev. ECN No. Orig. of Change

Submission

Date

Description of Change

** 2666844 GVCH/PYRS 03/02/09 New data sheet

*A 2685053 GVCH 04/07/2009 Added part numbers: STK11C68-5K45M and STK11C68-5K55M

Sales, Solutions, and Legal Information

Worldwide Sales and Design Support

Cypress maintains a worldwide network of offices, solution centers, manufacturer’s representatives, and distributors. T o find the office

closest to you, visit us at cypress.com/sales.

Products

PSoC psoc.cypress.com

Clocks & Buffers clocks.cypress.com

Wireless wireless.cypress.com

Memories memory.cypress.com

Image Sensors image.cypress.com

PSoC Solutions

General psoc.cypress.com/solutions

Low Power/Low Voltage psoc.cypress.com/low-power

Precision Analog psoc.cypress.com/precision-analog

LCD Drive psoc.cypress.com/lcd-drive

CAN 2.0b psoc.cypress.com/can

USB psoc.cypress.com/usb

© Cypress Semiconductor Corporation, 2009. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use of any

circuitry other than circuitry embodied in a Cypress product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor intended to be used for medical,

life support, life saving, critical control or safety applications, unless pursuant to an express written agreement with Cypress. Furthermore, Cypress does not author ize its produc ts for use as critic al

components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress products in life-support systems

application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress against all charges.

Any Source Code (software and/or firmware) is owned by Cypress Semiconductor Corporation (Cypress) and is protected by and subject to worldwide patent protection (United States and foreign),

United States copyright laws and international treaty provisions. Cypress hereby gr ant s to l icense e a pers onal, no n-exclu sive , non-tr ansfer able license to copy, use, modify, create derivative works of,

and compile the Cypress Source Code and derivative works for the sole purpose of creating custom software and or firmware in support of licensee product to be used only in conjunction with a Cyp ress

integrated circuit as specified in the ap plicable agreem ent. Any reprod uction, modificatio n, translation, co mpilation, or repr esentation of this Source Co de except as speci fied above is pro hibited with out

the express written permission of Cypress.

Disclaimer: CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Cypress reserves the right to make changes without further notice to the materials described herein. Cypress d oes not

assume any liability arising out of the applic ation or use o f any pr oduct or circ uit de scribed herein . Cypr ess does n ot author ize its p roducts fo r use as critical compon ents in life-su pport systems whe re

a malfunction or failure may reason ably be expected to result in significant injury to the user. The inclusion of Cypress’ product in a life-support systems application implies that the manufacturer

assumes all risk of such use and in doing so indemnifies Cypress against all charges.

Use may be limited by and subject to the applicable Cypress software license agreement.

Document Number: 001-51001 Rev. *A Revised April 07, 2009 Page 15 of 15

AutoStore and Quant umTrap are registered trad emarks of Cypress Semico nductor Corporat ion. All product s and company n ames mentioned in this document may be th e trademarks of their re spective

holders.

[+] Feedback

Loading...

Loading...