Page 1

PSoCEval User Guide

and Example Projects

Cypress MicroSystems, Inc.

2700 162nd Street SW, Building D

Lynnwood, WA 98037

Phone: 800.669.0557

Fax: 425.787.4641

1

Page 2

2

3

TABLE OF CONTENTS

INTRODUCTION TO PSOCEVAL

Introduction to the PsoCEval.....................................3

What Comes with my PSoCEval? .............................4

PSoCEval Power Supply Options..............................6

Introduction to MiniProg ...........................................7

Specications for MiniProg ....................................... 9

Operating Changes to the PsoCEval..........................9

Introduction to Example Projects.............................10

Example #1 ADC Conversion and LCD Display ......................11

Example #2 Blink an LED.........................................................16

Example #3 Output a SINE Wave..............................................19

Example #4 Dynamically Re-congure a PWM .......................24

Example #5 Combine PWMs using Output Logic ....................29

Cypress Support.......................................................32

Welcome to the new exciting world of the PSoCEval!

PSoCEval allows you to evaluate what PSoC has to offer. The

board includes an LCD module, potentiometer, LEDs, and plenty

of breadboard space. This user guide includes ve different

example projects that can be used with the PSoCEval board. The

MiniProg can program both the PSoC on your PSoCEval board or

on a proto board you might build using a ve-pin header.

The example projects can answer your questions. Want to see how

PSoC can talk with an LCD? Hook up the LCD module and output

your sensor’s data. Curious how PSoC’s dynamic re-conguration

is reshaping how designers do business? Switch back and forth

between different types of PWMs. Test both the digital and analog

resources of our system-on-a-chip in your application.

Use PSoCEval to gain insight into how the PSoC’s breadth of

exibility and functionality can work for you!

Page 3

4

5

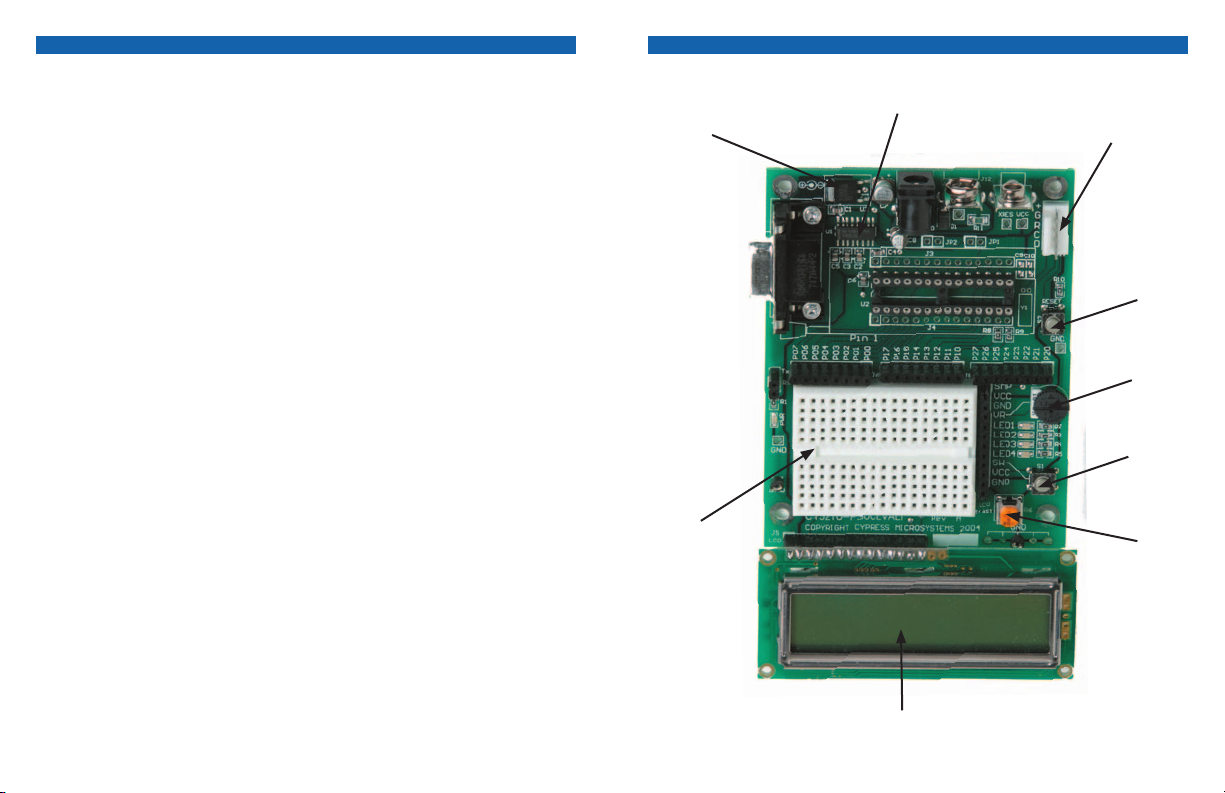

WHAT COMES WITH MY PSOCEVAL?

Please conrm that your kit includes the following items:

• PSoCEval Evaluation Board

• MiniProg Programmer

• LCD Module

• CY8C29466-24PXI 28-Pin DIP Sample

• PSoC Designer CD

• USB Cable

• Wire Pack

• User Guide

For additional technical information a schematic is available online

at www.cypress.com/ >> Developer Kits.

Regulator

Breadboard

RS232

Transceiver

ISSP Header

Reset

Button

POT

Button

LCD

Contrast

LCD Module

Page 4

6

7

PSOCEVAL POWER SUPPLY OPTIONS

INTRODUCTION TO MINIPROG

The following are PSoCEval power supply options:

1. Powered by the MiniProg unit.

2. Powered by a 9-12V DC wall transformer with

positive tip barrel plug and a 100 mA or higher rating.

Recommended model is CUI Inc., EPAS-101W-12.

3. Powered by a 9V battery connected to battery terminals.

4. Powered from the ICE pod in socket.

Only one of the power supplies should be used at a time. Do not

use a power supply that is less than 9V or exceeds 12V.

The Cypress MicroSystems MiniProg gives you the ability to

program PSoC parts quickly and easily.

It is small and compact, and connects to your PC using the

provided USB 2.0 cable.

During prototyping, the MiniProg can be used as an in-system

serial programmer (ISSP) to program PSoC devices on your PCB.

(See Application Notes AN2014 and AN2026 available online at

www.cypress.com for more details.)

For production purposes, it is recommended that you use the

CY3207ISSP programmer or a third-party production programmer.

Once the MiniProg is connected, you can use PSoC Programmer

software to program. (This free software can either be launched

from within PSoC Designer or run as a stand alone program.)

Page 5

8

9

SPECIFICATIONS FOR MINIPROG

OPERATING CHANGES TO THE PSOCEVAL

The operating temperature of the MiniProg is from 0° C to 50° C.

Always plug the USB cable into the MiniProg before attaching it

to the ve-pin header on the board.

When using an ISSP adapter cable with MiniProg, keep the length

under six inches to avoid signal integrity issues.

When using MiniProg, the LEDs blink at a variable rate to track

connection status. The green LED near the USB connector turns

on after MiniProg is plugged into the computer and congured by

the OS. If MiniProg cannot nd the correct driver in the system,

this LED will not turn on. After the device has been congured,

the LED stays on at about a 4-Hz blink rate. This changes during

programming, where the blink duty cycle increases.

The red LED at the bottom turns on when the MiniProg powers the

part. The LED is off when power is provided by the target board.

To use an external 32 kHz crystal oscillator, R8 and R9 on the

PSoCEval board must be removed. C9 and C10 must be added,

with values determined by the type of feedback desired. It is

recommended that you use unbalanced feedback, with C9 at 12

pF and C10 at 100 pF. (See Application Note AN2027 online at

www.cypress.com for complete details.)

To use PSoCEval at 3.3V, two parts will need to be swapped on the

board: the regulator and the RS232 transceiver, shown in Figure 1.

Suitable replacements or their equivalents are as follows:

Regulator:

TI UA78M33CKTPR

(Digikey 296-13425-1-ND)

RS232 Transceiver:

Maxim MAC3232CSE

(Digikey MAX3232CSE-ND)

Page 6

10

11

INTRODUCTION TO EXAMPLE PROJECTS

Four Example Projects are described in the following sections.

Each section is organized as follows:

EXAMPLE PROJECT #1 ADC CONVERSION

AND LCD DISPLAY

Project Name: ASM_Example_ADC_UART_LCD

Project Name: PSoC Designer project name.

Purpose: Overview of the project.

Implementation: Describes the funtionality.

Connections: Pin connections to wire up the PSoCEval board.

Pictures are included to help you verify your wiring for each

project.

Example Code (main.asm): Code to run the project.

The example projects are available in PSoC Designer. To use

them, open PSoC Designer and browse to select the correct

le. The example projects are found in …\Program Files\Cypress

MicroSystems\ PSoC Designer\Examples. Choose the chip type you

desire and open the project’s .soc le (CY8C29x66 comes with the

PSoCEval board).

When using the MiniEval programmer, do not use the “Connect”

and “Download” buttons in PSoC Designer. Theys are for use with

an In-Circuit Emulator (ICE).

Purpose: To demonstrate the 12-bit incremental ADC by

measuring the voltage of the potentiometer, transmitting the

conversion result out the UART, and displaying it on the LCD.

Implementation: This project enables the LCD, UART and

ADCINC12, and then goes into an endless loop.

In the loop, the ADC status (as it monitors the potentiometer) is

checked. If the ADC has completed a conversion, the result is

placed in “iResult” and the HEX value is transmitted out the serial

port and displayed on the LCD as ASCII text.

The clock divider VC1 provides a sample clock of 3 MHz to the

ADCINC12, resulting in a sample rate of 180 samples per second.

The clock divider VC3 generates the baud clock for the UART by

dividing 24 MHz by 156.

The UART internally divides VC3 by 8, resulting in a baud rate of

19,200 bps.

Page 7

12

13

Connections:

P01 -> VR = ADC Input (0-Vdd)

P16 -> RX = Serial RX

P27 -> TX = Serial TX

Example Code (main.asm):

// include m8c specic declarations

include “m8c.inc”

// include User Module API specic declarations

include “psocapi.inc”

export _main:

// inform assembler that variables follow

area bss(RAM)

// ADC result variable

iResult: blk 2

// inform assembler that program code follows

area text(ROM,REL)

_main:

mov A, UART_PARITY_NONE

// Enable UART

lcall UART_1_Start

mov A, >sRomString1

mov X, <sRomString1

// Display example string

lcall UART_1_CPutString

lcall UART_1_PutCRLF

mov A, PGA_1_MEDPOWER

// Turn on PGA power

lcall PGA_1_Start

mov A, ADCINC12_1_MEDPOWER

// Turn on ADC power

lcall ADCINC12_1_Start

Page 8

14

15

mov A, 0

// Sample forever

lcall ADCINC12_1_GetSamples

// Init the LCD

lcall LCD_1_Start

// row

mov A, 0

// column

mov X, 0

lcall LCD_1_Position

mov A, >sRomString2

mov X, <sRomString2

// Display string

lcall LCD_1_PrCString

// Enable Global interrupts

M8C_EnableGInt

loop:

// If conversion complete....

lcall ADCINC12_1_fIsDataAvailable

jz loop

// Get result, convert to unsigned and clear ag

lcall ADCINC12_1_iGetData

mov [iResult+1], A

mov [iResult+0], X

// add 0x0800 to result

add [iResult+0], 0x08

lcall ADCINC12_1_ClearFlag

mov A, [iResult+1]

mov X, [iResult+0]

// Print result to UART

lcall UART_1_PutSHexInt

// Tack on a CR and LF

lcall UART_1_PutCRLF

// row

mov A, 1

// column

mov X, 0

// display result in hex

lcall LCD_1_Position

mov A, [iResult+1]

mov X, [iResult+0]

lcall LCD_1_PrHexInt

jmp loop

area lit

sRomString1:

DS “Example ADC_UART_LCD”

db 00h

sRomString2:

DS “PSoC LCD”

db 00h

area text

Page 9

16

17

EXAMPLE PROJECT #2 BLINK AN LED

Project Name: ASM_Example_Blink_LED

Purpose: To demonstrate blinking an LED at a varying duty cycle

using a hardware PWM.

Implementation: The clock dividers VC1, VC2, and VC3 are used

to divide the 24 MHz system clock by 16, 16 and 256, respectively.

The resulting 366 Hz clock is used as the input to an 8-bit PWM.

This in turn produces an LED blink period of 1.4 Hz.

Connections:

P20 -> LED1

Page 10

18

19

Example Code (main.asm):

EXAMPLE PROJECT #3 OUTPUT A SINE WAVE

// include m8c specic declarations

include “m8c.inc”

// include User Module API specic declarations

include “psocapi.inc”

export _main:

_main:

// Enable PWM

lcall PWM8_1_Start

lcall PWM8_1_EnableInt

// Enable Global interrupts

M8C_EnableGInt

loop:

jmp loop

Project Name: ASM_Example_DAC_ADC

Purpose: To demonstrate a PSoC project that outputs a SINE wave

using a 6-bit DAC. The SINE wave period is based on the current

ADC value of the potentiometer.

Implementation: This project uses a 64-entry SINE look-up table

to generate values used to update a 6-bit DAC. An 8-bit counter is

utilized to generate an interrupt at the DAC update rate (1/64 SINE

wave period). By adjusting the counter period, the DAC frequency

and the resulting SINE frequency may be modied. The counter

period is reloaded with the current ADC conversion value. The

ADC input voltage may be between 0 and Vdd volts depending on

the potentiometer. At higher frequencies, SINE wave jitter may be

observed due to the large timing impact of a one-count change in

the ADC conversion.

Page 11

20

21

Connections:

P01 -> VR = ADC Input (0-Vdd)

P05 -> LED1 -> Scope = DAC Output (0-Vdd)

Example Code (main.asm):

// include m8c specic declarations

include “m8c.inc”

// include User Module API specic declarations

include “psocapi.inc”

export _main

export bADCvalue

export bTablePos

export SINtable

// inform assembler that variables follow

area bss(RAM)

// Store ADC value for debug watch variable

bADCvalue: blk 1

// Stores last table position index

bTablePos: blk 1

// inform assembler that program code follows

area text(ROM,REL)

_main:

// starts DAC value update counter

lcall Counter8_1_Start

lcall Counter8_1_EnableInt

// Turn on PGA power

mov A, PGA_1_MEDPOWER

lcall PGA_1_Start

// Turn on DAC power

mov A, DAC6_1_HIGHPOWER

Page 12

22

23

lcall DAC6_1_Start

// Turn on ADC power

mov A, DELSIG8_1_HIGHPOWER

lcall DELSIG8_1_Start

lcall DELSIG8_1_StartAD

// Enable Global interrupts

M8C_EnableGInt

loop:

// if ADC conversion complete then.....

lcall DELSIG8_1_fIsDataAvailable

jz loop

// get ADC result and convert to offset binary

lcall DELSIG8_1_cGetDataClearFlag

add A, 0x80

// store value for debug watch variable

mov [bADCvalue], A

// counter period less then 0x03 is invalid

cmp A, 0x03

// excessive interrupt servicing

jnc LoadCounter

mov A, 0x03

LoadCounter:

// update DAC update rate

lcall Counter8_1_WritePeriod

jmp loop

area lit

// 64 entry SINE look-up table

SINEtable:

db 31, 33, 36, 39, 41, 44, 46, 49, 51, 53, 55, 56, 58,

59, 59

db 60, 60, 60, 59, 59, 58, 56, 55, 53, 51, 49, 47, 44,

42, 39

db 36, 33, 31, 28, 25, 22, 19, 16, 13, 11, 9, 7, 5, 3,

2, 1, 0

db 0, 0, 0, 1, 2, 3, 4, 6, 7, 10, 12, 14, 17, 20, 23,

26, 29

area text

Page 13

24

25

EXAMPLE PROJECT #4 DYNAMICALLY

RE-CONFIGURE A PWM

The PRS conguration contains a PRS with pulse density

(analogous to pulse width) and shifted bit stream output on LEDs.

Project Name: ASM_Example_Dynamic_PWM_PRS

Purpose: To demonstrate PSoC’s dynamic re-conguration

capability by switching a digital block between a PWM8 and a

PRS8 (Pseudo Random Sequence). This example project also

demonstrates the advantages of using a PRS to generate a pulse

width. A benet of the PRS is that it does not generate the strong

frequency harmonics of an equivalent PWM.

Implementation: The clock dividers VC1, VC2, and VC3 are

used to divide the 24 MHz system clock by 16, 16, and 128,

respectively. The resulting 732 Hz clock becomes the input to an 8bit Counter User Module in the base conguration (this is the rst

conguration in PSoC Designer).

If the SW button connected on the PSoCEval board is released,

conguration PWM_cong is loaded and a period of two is loaded

into the counter.

If the button is pressed and held, conguration PRS_cong is

loaded and a period of 128 is loaded into the counter.

The PWM conguration contains a standard 8-bit PWM with

a duty cycle of 50%. Both the pulse width and terminal count

outputs are displayed on LEDs.

Connections:

P14 -> SW = User Button

P20 -> LED1 = PWM Pulse Width or PRS Pulse Density

P22 -> LED2 = PWM Terminal Count

P23 -> LED3 = PRS Bit Stream

Page 14

26

27

Example Code (main.asm):

// include m8c specic declarations

include “m8c.inc”

// include User Module API specic declarations

include “psocapi.inc”

export _main:

_main:

// congure port pins

and reg[PRT1DR], ~0x10

mov reg[PRT2DR], 0x00

// start clock generator

lcall Counter8_1_Start

// load PRS conguration

lcall LoadCong_PRS_Cong

jmp PWM

PRS:

// stop and unload PWM conguration

lcall PWM8_1_Stop

lcall UnloadCong_PWM_Cong

// then load PRS cong

lcall LoadCong_PRS_Cong

// update clock divider, don’t wait for period

reload

lcall Counter8_1_Stop

mov A, 0x7F

lcall Counter8_1_WritePeriod

lcall Counter8_1_Start

// congure and start PRS

mov A, 0x01

lcall PRS8_1_WriteSeed

mov A, 0xB8

lcall PRS8_1_WritePolynomial

lcall PRS8_1_Start

// load compare value, must be loaded after PRS is

started

mov reg[PRS8_1_SEED_REG], 0x7F

PRSloop:

// wait for button release

tst reg[PRT1DR], 0x10

jnz PRSloop

// simple debounce

tst reg[PRT1DR], 0x10

jnz PRSloop

jmp PWM

PWM:

// stop and unload PRS conguration

lcall PRS8_1_Stop

lcall UnloadCong_PRS_Cong

// then load PWM cong

lcall LoadCong_PWM_Cong

// update clock divider, don’t wait for period

reload

lcall Counter8_1_Stop

Page 15

28

29

mov A, 0x01

lcall Counter8_1_WritePeriod

lcall Counter8_1_Start

// congure and start PWM

mov A, 0xFF

lcall PWM8_1_WritePeriod

mov A, 0x7F

lcall PWM8_1_WritePulseWidth

// enable PWM

lcall PWM8_1_Start

EXAMPLE PROJECT #5 COMBINING PWMS

USING OUTPUT LOGIC

Project Name: ASM_Example_LED_Logic

Purpose: To demonstrate a PSoC project designed to blink an LED

using the output of two PWMs. The outputs are combined using an

AND gate in an output bus logic block. This logical combination

results in a beat frequency of 1.4 Hz.

PWMloop:

// wait for button release

tst reg[PRT1DR], 0x10

jz PWMloop

// simple debounce

tst reg[PRT1DR], 0x10

jz PWMloop

jmp PRS

Implementation: The clock dividers VC1 and VC2 are used to

divide the 24 MHz system clock by 16 and 16, respectively. The

resulting 93.37 kHz clock becomes the input to the two 8-bit

PWM User Modules with respective periods of 256 and 255. This

produces the LED beat frequency of 1.4 Hz.

Page 16

30

31

Connections:

P20 -> LED1

Example Code (main.asm):

// include m8c specic declarations

include “m8c.inc”

// include User Module API specic declarations

include “psocapi.inc”

export _main:

_main:

// Enable PWM1

lcall PWM8_1_Start

// Enable PWM2

lcall PWM8_2_Start

loop:

jmp loop

Page 17

CYPRESS CUSTOMER SUPPORT

We are committed to meeting your every need.

For more information about PSoC, check us out on the web at

www.cypress.com/psoc. There you will nd data sheets, hundreds

of application notes, contact information for local PSoC certied

consultants, and recorded tele-training modules for newcomers to

the PSoC world.

We offer live tele-training sessions regularly. Check online at

www.cypress.com/support/training.ctm for the next scheduled

time.

For application support please contact us online or call between 8

am – 6 pm PST at 1.800.669.0557 ext. 4814. We offer a four-hour

response time at our call center during normal business hours.

http://www.cypress.com/ http://www.cypress.com/support/

Copyright © 2004 Cypress MicroSystems, Inc. All rights reserved.

PSoC™, Programmable System-on-Chip™, and PSoC Designer™

are trademarks of Cypress MicroSystems, Inc. All other trademarks

or registered trademarks referenced herein are the property of their

respective owners. The information contained herein is subject to

change without notice. Made in the U.S.A.

32

mysupport.cfm

Loading...

Loading...