Page 1

F2MC-8FX Family

MCU Board for MB95FV100D-102

MB2146-302A, Operation Manual

Doc. # 002-07488 Rev. *B

Cypress Semiconductor

198 Champion Court

San Jose, CA 95134-1709

Phone (USA): 800.858.1810

Phone (Intnl): +1.408.943.2600

www.cypress.com

Page 2

Copyrights

Copyrights

© Cypress Semiconductor Corporation, 2007-2017. This document is the property of Cypress Semiconductor Corporation

and its subsidiaries, including Spansion LLC ("Cypress"). This document, including any software or firmware included or referenced in this document ("Software"), is owned by Cypress under the intellectual property laws and treaties of the United

States and other countries worldwide. Cypress reserves all rights under such laws and treaties and does not, except as specifically stated in this paragraph, grant any license under its patents, copyrights, trademarks, or other intellectual property

rights. If the Software is not accompanied by a license agreement and you do not otherwise have a written agreement with

Cypress governing the use of the Software, then Cypress hereby grants you a personal, non-exclusive, nontransferable

license (without the right to sublicense) (1) under its copyright rights in the Software (a) for Software provided in source code

form, to modify and reproduce the Software solely for use with Cypress hardware products, only internally within your organization, and (b) to distribute the Software in binary code form externally to end users (either directly or indirectly through

resellers and distributors), solely for use on Cypress hardware product units, and (2) under those claims of Cypress's patents

that are infringed by the Software (as provided by Cypress, unmodified) to make, use, distribute, and import the Software

solely for use with Cypress hardware products. Any other use, reproduction, modification, translation, or compilation of the

Software is prohibited.

TO THE EXTENT PERMITTED BY APPLICABLE LAW, CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS OR

IMPLIED, WITH REGARD TO THIS DOCUMENT OR ANY SOFTWARE OR ACCOMPANYING HARDWARE, INCLUDING,

BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent permitted by applicable law, Cypress reserves the right to make changes to this document without further notice. Cypress does not assume any liability arising out of the application or use of any product or circuit described in

this document. Any information provided in this document, including any sample design information or programming code, is

provided only for reference purposes. It is the responsibility of the user of this document to properly design, program, and test

the functionality and safety of any application made of this information and any resulting product. Cypress products are not

designed, intended, or authorized for use as critical components in systems designed or intended for the operation of weapons, weapons systems, nuclear installations, life-support devices or systems, other medical devices or systems (including

resuscitation equipment and surgical implants), pollution control or hazardous substances management, or other uses where

the failure of the device or system could cause personal injury, death, or property damage ("Unintended Uses"). A critical

component is any component of a device or system whose failure to perform can be reasonably expected to cause the failure

of the device or system, or to affect its safety or effectiveness. Cypress is not liable, in whole or in part, and you shall and

hereby do release Cypress from any claim, damage, or other liability arising from or related to all Unintended Uses of Cypress

products. You shall indemnify and hold Cypress harmless from and against all claims, costs, damages, and other liabilities,

including claims for personal injury or death, arising from or related to any Unintended Uses of Cypress products.

Cypress, the Cypress logo, Spansion, the Spansion logo, and combinations thereof, WICED, PSoC, CapSense, EZ-USB, FRAM, and Traveo are trademarks or registered trademarks of Cypress in the United States and other countries. For a more

complete list of Cypress trademarks, visit cypress.com. Other names and brands may be claimed as property of their respective owners.

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 2

Page 3

Preface

Thank you for purchasing the MCU board for the F2MC*-8FX family MB95FV100D-102 (model number: MB2146-302A).

The MB2146-302A is a development support tool for developing and evaluating applied products

based on the F

This manual is intended for engineers who use the MB2146-302A (referred to below as the MCU

board) to develop applied products based on Cypress F

ual describes how to handle the MCU board and its functions as well as the setting procedures.

Be sure to read this manual before using the MCU board.

Be sure to read this manual before using the MCU board.

■ Using the product safely

This manual contains important information required for using the MB2146-302A safely. Be sure to

read through the manual before using the product and follow the instructions contained therein to

use it correctly.

In particular, carefully read the “Caution of the products described in this document” at the beginning

of this manual to understand the requirements for safe use of the product before using it.

After reading the manual, keep it handy for future reference.

■ Warranty and liability disclaimers

The specifications of the product are subject to change without notice.

In no event shall Cypress be liable for any loss or damages whatsoever directly or indirectly arising

out of the use of the product.

■ Product operating environment

2

MC-8FX family of microcontrollers manufactured by Cypress.

2

MC-8FX family microcontrollers. The man-

The operating temperature for the product ranges from 5 C to 35 C and the operating relative

humidity from 20% to 80%. Avoid using the product in hot or humid environment and prevent con

densation.

The product is a printed circuit board unit without a chassis such that all of the electronic components are exposed. Therefore, neither put anything on the product nor touch or let an electrically

charged material contact a metal part of it. Once the product has been powered, try to keep those

objects away from it which can short-circuit it or easily catch fire and burn. Use the product as hori

zontal as possible and avoid operating it at a place exposed to strong vibration, dust, or explosive

gas.

Note that using the product not in the above operating environment may unexpectedly cause personal injury to the user (or another person if present near the product) or physical damage to properties around the product.

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 3

-

-

Page 4

Preface

You should also keep the packaging materials used for shipping the product. They work well as they

are when you transport the product again, for example, if it becomes out of order and needs to be

repaired.

■ Related manuals

Refer to the following manuals for additional information:

■ Hardware Manual of the MCU used

■ Data Sheet of the MCU used

■ “MB2146-09 BGM Adapter Instruction Manual”

■ Related “Header Board Instruction Manuals”

■ ““SOFTUNE Workbench Operation Manual”

■ “SOFTUNE Workbench USER’S Manual”

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 4

Page 5

■ Caution of the products described in this document

The following precautions apply to the product described in this manual.

CAUTION

Cuts, Damage

Cuts

Damage

Preface

Indicates a potentially hazardous situation which, if not avoided appropriately, may

result in minor or moderate injury and/or damage to the product or the equipment

to which the product is connected, to software resources such as data, or to other

properties.

Before moving the product, be sure to turn off all the power supplies and unplug the

les. Watch your steps when carrying the product. Do not use the product in an

cab

unstable location such as a place exposed to strong vibration or a sloping surface.

Doing so may let the product fall, resulting in an injury or fault.

The product has some sharp-pointed or edged parts inevitably exposed, such as

jumper plugs. Use meticulous care in handling the product not to get injured with

such pointed parts.

Neither put anything on or apply shock to the product. Once the product has been

po

wered, do not carry it.

Doing either may cause a fault due to overloading or shock.

Damage

Damage

Damage

Damage

Damage

Damage

Since the product contains many electronic components, keep it away from direct

sun

light, high temperature, and high humidity to prevent condensation. Do not use

or store the product where it is exposed to much dust or a strong magnetic or electric field for an extended period of time.

An adverse operating or storage environment can cause a fault.

Use the product within the ranges of

its general specifications.

Operating it outside the range of any general specification may cause a fault.

To prevent electrostatic breakdown, do not let your finger or an object touch any

metal part of the connector. Before handling the product, touch a metal object (such

as a door knob) to discharge static electricity from your body.

Before turning the power on, in particular, be sure to finish making all the required

nections. To set up and use the product, follow the instructions given in this doc-

con

ument.

Using the product incorrectly or inappropriately may cause a fault.

Before plugging or unplugging any cable for this product, be sure to turn the power

ply off. When unplugging a cable, remove it while holding the connector without

sup

pulling the cable itself. Pulling the cable itself or bending it may expose or disconnect the cable core, resulting in a fault.

Because the product has no casing, it is recommended that it be stored in the original packaging. Re-transporting the product m

ay damage it to cause a fault. Keep

the packaging materials used for shipment of the product and use them when retransporting it.

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 5

Page 6

Contents

1. Product Outline 7

1.1 Product configuration...................................................................................................8

1.2 Appearance and part name .........................................................................................9

2. Checking the Delivered Product 10

3. Connections 11

3.1 Connecting the MCU board to the header board.......................................................11

3.2 Note on connection....................................................................................................12

3.3 Disconnection ............................................................................................................12

4. How to Setup 13

4.1 How to the switch and jumper plug on a MCU board setup.......................................13

4.2 How to oscillator mounting on a MCU board .............................................................14

4.3 Handling notes...........................................................................................................14

4.4 Setting of the switch and jumper plug........................................................................15

4.5 Setting of the clock input selector switch (SW2)........................................................17

4.6 Setting of the product selector switch (SW3).............................................................18

4.7 Setting of the sub clock selector jumper plug (S1) ....................................................19

4.8 Setting of the LVD2 detection voltage selector jumper plug (S2) ..............................20

5. Product Specifications 21

5.1 General specifications ...............................................................................................21

5.2 Functional explanation...............................................................................................21

5.3 Clock settings ............................................................................................................23

5.4 Header board specifications ......................................................................................24

5.5 Connector socket specifications ................................................................................24

5.6 Pin assignment of header board I/F connector..........................................................24

Revision History 29

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 6

Page 7

1. Product Outline

BGM adapter

MCU board

Header board

The MB2146-302A is the MCU board (model number: MB2146-302A) mounting an evaluation MCU

for the F

consists of a combination of three products: the header board, MCU board, and BGM adapter

(model number: MB2146-09) as shown in Figure 1-1.

Figure 1-1. System configuration

2

MC-8FX Family of Cypress 8-bit microcontrollers. The F2MC-8FX evaluation environment,

MB2146-09

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 7

Page 8

1.1 Product configuration

Ta bl e 1-1 lists the product configuration in the MCU board package. Table 1-2 lists optional parts for

the MCU board package that can be purchased separately.

Table 1-1. Product configuration

Name Model number Description

2

F

MC-8FX MCU board*

MB2146-302A

Product Outline

MCU board with built-in MB95FV100D10

2

* Neither the oscillator nor the capac

itor is bundled with the MB2146-302A. Therefore, prepare them

separately.

Table 1-2. Optional parts

Name Model number Description

BGM adapter*

Header board*

1

2

MB2146-09

MB2146-2xx

ICE unit for F

Connector/package conversion header

ard

bo

2

MC-8FX

*1: To use the BGM adapter, you need additional tools such as debugger software.

*2: The header board is an interface board to conn

ect the MCU board to your user system. Choose

and purchase a type of header board which is applicable to the production MCU to be used.

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 8

Page 9

1.2 Appearance and part name

* Note used during debugging.

(1) LVD2 detection voltage selector jumper plug*

(2) Voltage selector switch

(3) Product selector switch

(4) LVD selector switch

(5) Clock selector switch (SW1-1: CLK)

Clock supervisor selector switch (SW1-2 : CLK S.V.)

APB8 bus output selector switch (SW1-3: APB8) (for extension) *

C-pin selector switch (SW1-4: C)

(6) Clock input selector switch (SW2-1: X0, SW2-2: X1, SW2-3: X0A, SW2-4: X1A)

(7) Sub clock crystal oscillator mounting socket

(8) Main clock crystal oscillator mounting socket

(9) Sub clock selector jumper plug

(10) BGM adapter connector

(11) Header board I/F connector A

(12) Header board I/F connector B

(13) Evaluation MCU (MB95FV100D-102)

(14) Incorrect insertion prevention guard

Top view Bottom view

(1)

(5)

(7)

(3)

(9)

(8)

(13)

(14)

(12)

(2)

(4)

(10)

(6)

(11)

The appearance of a MCU board and the part name are shown in Figure 2.

Product Outline

Figure 1-2.

GNDVCC

LVD4

LVD3

LVD2

LVD1

LVD0

8

9

7

A

6

B

5

C

4

D

3

E

2

F

1

0

PRODUCT SELECT

ADAPTER

MCU board appearance figure

3V5V

LVD2OFFLVD1

CLK

CLK S.V.

APB8CX0X1X0A

ON ON

1 2 3 4 1 2 3 4

C B A

SUB CLOCK

BGM

X1A

1

2

MAIN CLOCK

HEADER I/F CONNECTOR A

HEADER I/F CONNECTOR B

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 9

Page 10

2. Checking the Delivered Product

Before using the MCU board, confirm that the following components are included in the box:

■ MCU board: 1

■ Operation manual (English version, this manual) : 1

■ Operation manual (Japanese version) : 1

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 10

Page 11

3. Connections

MCU board

Incorrect insertion

prevention guard

Header board

MB2146-09

MCU board

Index mark LVD2 detection voltage

selector jumper plug (S2) *

BGM adapter

BGM adapter connector (CN3)

*: Be sure to connect the BGM adapter correctly to the BGM adapter connector (CN3) on the MCU board. I

can damage the MCU board if it is accidentally connected to the LVD2 detection voltage selector jumper

plug (S2).

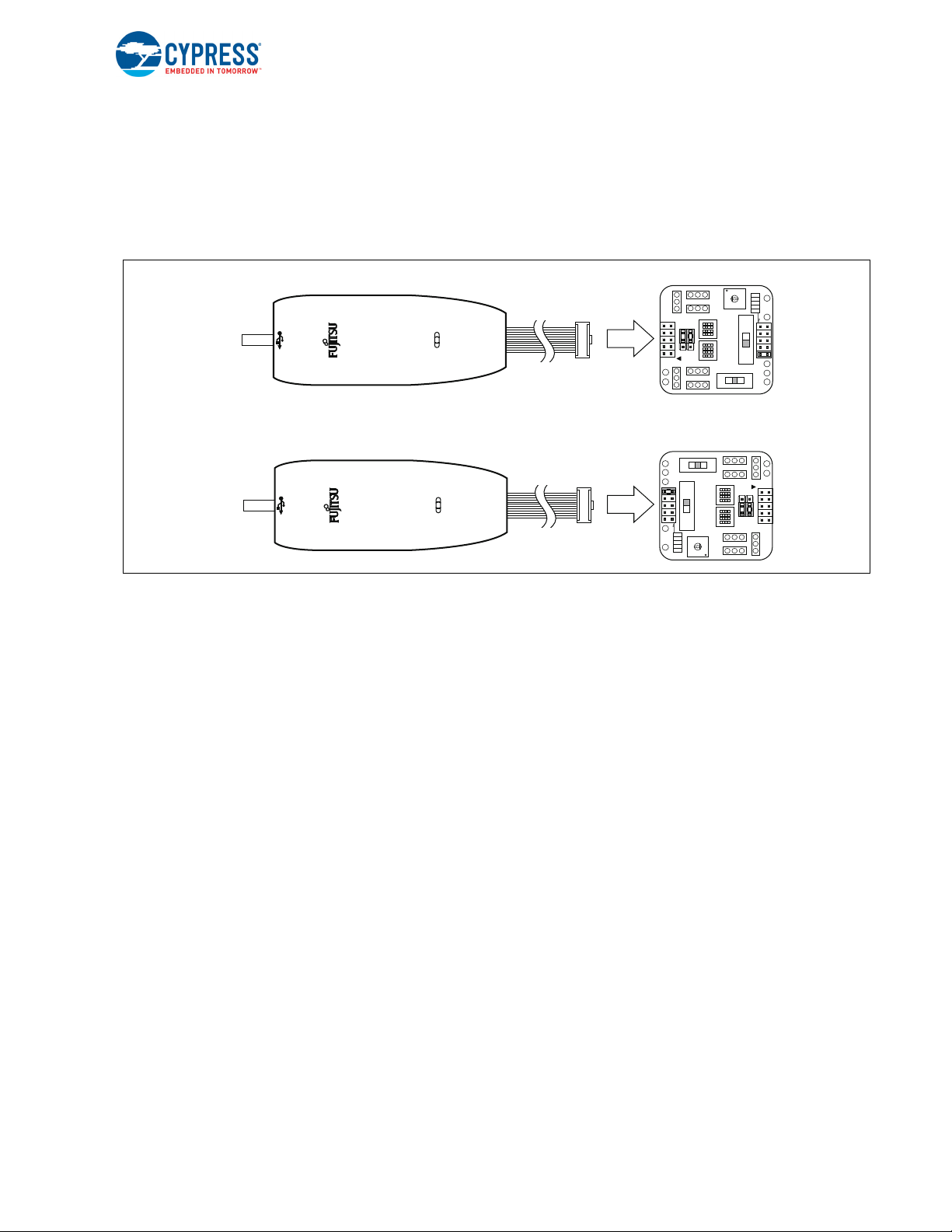

3.1 Connecting the MCU board to the header board

Align the MCU board the header board facing each other, then plug their mating connectors

together. Those connectors are provided with incorrect insertion prevention guards located diagonally. Position the two boards so that the incorrect in

each other and plug the connectors together completely (see “Figure 3-1”).

Figure 3-1.

Connection of MCU board and header board

sertion prevention guards do not interfere with

■ Connecting the MCU board to the BGM adapter

Connect the BGM adapter to the MCU board. Plu

pletely into the BGM adapter conn

ector on the MCU board such that the index marks (▼) aligned

g the BGM adapter's interface connector com-

(see “Figure 3-2”).

Figure 3-2.

Connection of MCU board and BGM adapter

ADAPTER

BGM

SUB CLOCK

C B A

2

MAIN CLOCK

PRODUCT SELECT

4

5

3

6

2

7

LVD4

1

8

0

9

LVD3

F

E

ON ON

1 2 3 4 1 2 3 4

CLK

CLK S.V.

APB8

C

X0

X1

1

X0A

X1A

GND

A

B

LVD2

D

C

VCC

LVD1

LVD0

3V5V

LVD2OFFLVD1

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 11

Page 12

3.2 Note on connection

1. Be sure to connect the BGM adapter connector (CN3). The BGM adapter connector and the

LVD2 detection voltage selector jumper plug have the same shape (see “Figure 3-3”). The MCU

board may break if the BGM adapter co

voltage selector jumper plug (S2) on the other side of the board.

Connections

nnector is accidentally plugged into the LVD2 detection

Figure 3-3.

Connection direction of BGM adapter

2. To supply a main clock signal and sub clock signa

circuit on the user system so that it supplies the clock signal to the MCU board via a buffer

circuit.

3.3 Disconnection

MB2146-09

MB2146-09

PRODUCT SELECT

4

5

3

6

7

2

LVD4

1

8

0

9

LVD3

F

GNDVCC

A

B

E

LVD2

D

OK

NG

ADAPTER

BGM

GNDVCC

SUB CLOCK

C B A

2

MAIN CLOCK

LVD2OFFLVD1

3V5V

LVD0

LVD1

LVD2

LVD3

LVD4

C

LVD1

LVD0

5V

ON ON

1 2 3 4 1 2 3 4

CLK

CLK S.V.

APB8

C

X0

X1

1

X0A

X1A

3V

LVD2OFFLVD1

1 2 3 4 1 2 3 4

ON ON

PRODUCT SELECT

MAIN CLOCK

1

2

C B A

SUB CLOCK

BGM

ADAPTER

X1A

X0A

X1

X0

C

APB8

CLK S.V.

CLK

C

D

B

E

A

F

9

0

8

1

7

2

6

3

5

4

l from the user system, provide an oscillation

a. Remove the BGM adapter from the MCU board. Holding the MCU board firmly, pull the BGM

adapter vertically from the BGM adapter connector on the MCU board.

b. Remove the header board from the MCU board. Remove it with uniform force without applying

force to only one point.

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 12

Page 13

4. How to Setup

4.1 How to the switch and jumper plug on a MCU board setup

Please set the following switches referring to “Figure 6 The switch and jumper plug on a MCU

board”.

1. Set the clock selector switch (SW1-1) to ON or

tively.

2. Set the clock supervisor select

or switch (SW1-2) to OFF.

3. Set the C-pin selector switch (SW1-4) to OFF.

4. Set the clock input selector switch (SW2).

Check that value with “Setting of the clock input

5. Set the product selector switch (SW3) to the valu

production MCU.

Check that value with “Setting of the product select

6. Set the LVD selector switch (SW4) to OFF.

7. Set the power supply selector switch (SW5) to 3V.

8. Set the sub clock selector jumper plug (S1).

OFF to disable or enable the sub clock, respec-

selector switch (SW2)”.

e corresponding to the number of pins on the

or switch (SW3)”.

Check that value with “Setting of the sub clock selector jumper plug (S1)”.

Please use with following settings, because

■ Set the APB8 bus output selector switch (SW1-3) to OFF.

■ Set the LVD2 detection voltage selector jumper plug (S2) to LVD0.

APB8 bus and LVD2 functions are not available.

Check that value with “Setting of the LVD2 detection voltage selector jumper plug (S2)”.

Figure 4-1.

The switch and jumper plug on a MCU board

S2

GND VCC

LVD4

LVD3

LVD2

8

9

7

A

6

B

5

C

4

D

3

E

2

F

1

0

PRODUCT SELECT

SC5 SC6

SC4

ADAPTER

5V

LVD1

LVD0

SW5

SW3

CLK

CLK S.V.

APB8CX0X1X0A

ON ON

1 2 3 4 1 2 3 4

SW1 SW2

S1

C B A

SUB CLOCK

BGM

3V

X1A

1

2

MAIN CLOCK

LVD2OFFLVD1

SW4

SC3 SC2

SC1

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 13

Page 14

4.2 How to oscillator mounting on a MCU board

Ceramic oscillator

Crystal oscillator

Capacitor mounting socket

Crystal oscillator

mounting socket

GND

Capacitor mounting socket

■ For information on the crystal oscillator such as its frequency, refer to the data-

sheet for the evaluation MCU.

■ For the capacitance of the capacitor, refer to the datasheet for the crystal oscilla-

tor, etc.

■ Neither the crystal oscillator nor the capacitor is bundled with this product.

Mount a crystal or ceramic oscillator in the crystal oscillator mounting sockets (for the main clock and

sub clock) on the MCU board.

How to Setup

The MCU board has one crystal oscillator mounting socket

for the main clock and the other for the

sub clock. To distinguish them from each other, the board has the “MAIN CLOCK” and “SUB

CLOCK” labels are printed on the board near the main clock socket and sub clock socket. Mount the

crystal or ceramic oscillator along with the capacitors on the MCU board (see “Figure 4-2”).

Figure 4-2.

The example of mount of crystal or ceramic oscillator

4.3 Handling notes

1. Data can not be written/erased to lower banks (1000H to 3FFFH) in the software development

2

support environment for the F

2. Do not perform a chip erase when using the so

2

MC-8FX (MB95FV100D and MB2146-09).

F

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 14

MC-8FX (MB95FV100D and MB2146-09).

ftware development support environment for the

Page 15

4.4 Setting of the switch and jumper plug

BGM

ADAPTER

SUB CLOCK

C B A

1

2

CLK

CLK S.V.

APB8CX0X1X0A

X1A

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

PRODUCT SELECT

LVD4

LVD3

LVD2

LVD1

LVD0

GNDVCC

3V5V

LVD2OFFLVD1

MAIN CLOCK

1 2 3 4 1 2 3 4

ON

ON

SW5

SW3

SW1 SW2

S1

SC5 SC6

SC4

SC3 SC2

SC1

S2

LVD4

LVD3

LVD2

LVD1

LVD0

SW4

The positions of the switch and jumper plug on the MCU board is shown in Figure 4-3, and specifications are shown in Ta bl e 4-1.

How to Setup

Figure 4-3.

Positions of switches and jumper plugs on the MCU board

Table 4-1. Switch and jumper plug settings

Switch/Jumper plug Settings

Clock selector switch SW1-1

Clock supervisor selector

SW1-2

switch

APB8 bus output se-

lector

SW1-3

switch

ON : Disable the sub clock

OFF : Enable the sub clock

ON : Enable the clock supervisor function

OFF : Disable the clock supe

ON : Enable the APB8 bus

OFF : Disable the APB8 bus

rvisor function

Shipment

setting

OFF

OFF

OFF

ON : Connect the C pin to the on-board

C-pin selector switch SW1-4

Clock input selector

switch

SW2

0.

OFF : Disconnect the C pin from the on-board

1F capacitor

0.

Select the main clock and

sub clock source

on the MCU board or on the user system

(See “Setting of the clock input selector

OFF

OFF

1F capacitor

switch (SW2)”).

Product selector

switch

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 15

SW3

Set this switch depending on the number of

s on the target MCU to be used (See “Set-

pin

ting of the product selector swit

ch (SW3)”).

0

Page 16

How to Setup

Switch/Jumper plug Settings

Select the low-voltage detection function.

LVD selector switch SW4

LVD1 : LVD1 enabled

OFF : LVD function disabled

LVD2 : LVD2 enabled

Select 5V or 3V supply for the operating volt-

Voltage selector switch SW5

age of the evaluation MCU.

5V : 5V supply

3V : 3V supply

Sub clock selector

jumper plug

LVD2 detection voltage selector jumper

plug

S1

S2

Select whether to use the sub clock.

(See Setting of the sub clock selector jumper

plug (S1)”).

Set the LVD2 detection voltage (See “Setting

of the LVD2 detection voltage selector jumper

plug (S2)”).

Shipment

setting

OFF

3V

Jumper of

B-C

LVD0

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 16

Page 17

4.5 Setting of the clock input selector switch (SW2)

Figure 4-4 shows the clock input selector switch. Ta bl e 4-2 lists switch positions for the main clock

supply source. Table 4-3 lists switch positions for the sub clock supply source.

How to Setup

Figure 4-4.

Clock input selector switch (SW2)

X0

X1

X0A

ON

1 2 3 4

Table 4-2. Setting of main clock supply source

Main clock supply source

Clock area OFF OFF

User system ON ON

Table 4-3. Setting of the sub clock supply source

Sub clock supply source

Clock area OFF OFF

User system ON ON

Settings of the clock input selector switch

Settings of the clock input selector switch

X1A

SW2-1 SW2-2

SW2-3 SW2-4

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 17

Page 18

4.6 Setting of the product selector switch (SW3)

Ta bl e 4-4 lists the setting of product selector switch and product type.

Table 4-4. Setting of the product selector switch

Switch setting Product type

0 100-pin package type

1 80-pin package type

2 64-pin package type

3 48-pin, 52-pin package type

4 32-pin package type

5 28-pin package type

6 20-pin package type

7 Setting Prohibited

8 100-pin package, LCD function integrated type

9 80-pin package, LCD function integrated type

A 64-pin package, LCD function integrated type

B 48-pin, 52-pin package, LCD function integrated type

C

D

E

F

Setting Prohibited

How to Setup

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 18

Page 19

4.7 Setting of the sub clock selector jumper plug (S1)

C B A

1

2

C B A

1

2

Example 1 Example 2

Ta bl e 4-5 lists jumper plug positions and sub clock selection. Figure 4-5 shows examples of sub

clock selection.

Table 4-5. Setting of sub clock selector

Settings of the sub

- 1: C

A - 1: B

clock

(S1)

Jumper of

2: B - 2: C

Jumper of

2: A - 2: B

Sub clock

Used Supply source M1 correspondence pin X0A X1A

enable

disable

Clock area

User system*

X0A : R3 pin

X1A : V1 pin

selector jumper plug

Jumper of

1: B

Jumper of

1:

How to Setup

Example of

settings

Example 1

Example 2

* Oscillation is not guaranteed when the c

Figure 4-5.

The example of sub clock selection

rystal oscillator is mounted on the user system.

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 19

Page 20

How to Setup

LVD4

LVD3

LVD2

LVD1

LVD0

4.8 Setting of the LVD2 detection voltage selector jumper plug (S2)

Figure 4-6 shows the setting of the LVD2 detection voltage selector jumper plug (S2). Table 8 lists

jumper plug positions for detection voltages.

These settings cannot be used during debugging. Se

Figure 4-6.

Table 4-6. Setting of the LVD2 detection

The LVD2 detection voltage selector jumper plug (S2)

voltage selector jumper plug

Jumper plug position LVD2 setting value

LVD0 Å{4.17V

LVD1 Å{3.74V

LVD2 Å{3.3V

LVD3 Å{2.9V

LVD4 Å{2.6V

t the jumper to LVD0 to use the debugger.

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 20

Page 21

5. Product Specifications

5.1 General specifications

The general specifications of the MCU board are shown in Tab le 5-1.

Table 5-1. MCU board general specifications

Item Specification

Name

Model number MB2146-302A

Power supply

Frequency of

ration

ope

Operating tem-

perature

Operating humid-

ity

Dimensions 40.0mm (W) 40.0mm (

Weight 13g

MCU board for the F

E

valuation MCU (MB95FV100D-102) : Å{3.3V (UVcc)

MCU board power supply : Å{3.3V (supplied by the user system)

Max. 16.25MHz

5 C to 35 C

20Åì to 80Åì(No condensation is allowed.)

2

MC-8FX MB95FV100D-102

D) 14.6mm (H)

5.2 Functional explanation

The functional specifications of the MCU board are shown inTable 5-2, and a functional block dia-

gram is shown in Figure 5-1.

Table 5-2. MCU board functional specifications

Item Description

MCU board function

Switches

Jumper plugs

Clock mounting

socket

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 21

Serves as the adapter used in combination with the BGM adapter and header board to

e connection between the BGM adapter and

provid

evaluation MCU and between the evaluation MCU and user system.

Serve for clock selection, clock supervisor selection,

selection, C-pin setting, c

and voltage selection.

The jumper plugs on the MCU board can be used to make various

settings for low-voltage detection and clock selection.

The crystal oscillator mounted socket on the MCU b

to the main clock (X0/X1) and sub clock (X0A/X1A) pins on the evaluation MCU from the

MCU board.

lock selection, product selection, low-voltage detection setting,

APB8 bus output

oard is used to supply clock signals

Page 22

Figure 5-1. MCU board functional block diagram

AVcc

AVR

AVss

AVcc3

AVR3

Vcc

C

PG0

SEL4

SEL0

SEL1

SEL2

SEL3

LVR0

LVR1

LVR2

LVR3

LVR4

LVDIN

X0,X1,

X0A,X1A

LVDEN2

LVDEN

LVDREXT

APBEN

CSVEN

Vcc,GND,BRSTX,

BSIN,BSOUT,

BDBMX,BEXCK

0

0

0

0

0

0

0

0

1

2

1

1

1

1

1

1

1

1

4

2

3

1

2

3

4

5

0

1

Header board

I/F

connector

Header board

I/F

connector

Voltage

selector

switch

C-pin

selector

switch

Product

selector

switch

Clock selector

switch

MB95FV100D-102

(Evaluation MCU)

Other pins

LVD2 detection voltage

setting jumper plug

BGM

adapter

connector

Clock

selector

circuit

LVD

selector

switch

APB8 bus output

selector switch

Clock supervisor

selector switch

Product Specifications

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 22

Page 23

5.3 Clock settings

Clock input

selector switch

Crystal oscillator mounting

socket (main clock)

Sub clock selector

jumper plug

Crystal oscillator

mounting socket

(sub clock)

Figure 5-2 shows the clock-related circuit diagram.

Figure 5-2. Clock selector circuit

Product Specifications

(M1)

X0A

X1A

(R1)

X0

T4

X1

U2

R3

V1

GND

GND

CBA

1

2

3

4

1

2

X0

X1

X0A

X1A

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 23

Page 24

5.4 Header board specifications

MCU board I/F

connector B

MCU board I/F connector A

30mm

40mm

20mm

40mm

18mm

20mm

13mm

Incorrect insertion

prevention guard

Figure 5-3 shows recommended dimensions of the header board connected to the MCU board.

Ta bl e 5-3 lists the general specifica

Figure 5-3. Recommended dimensions of the header board (Top view)

tions of the header board.

Product Specifications

1212

119120119120

Table 5-3. General specifications of the header board.

Item Description

120 pin 0.5mm pitch 2 piece connector (Straight) 2

MCU board interface connector

Incorrect insertion prevention guard

Spacing between the MCU and header boards when

aged

eng

Model

number: WR-120SB-VF-N1(Japan Aviation

Electronics Industry, Limited)

2 pin SIP socket

Model number: PCW-3-1-1PW (MAC EIGHT)

Approx. 5.0mm

5.5 Connector socket specifications

The specifications of a connector and a socket is shown in Tab le 5-4

Table 5-4. Connector and socket specifications

Item Description

Header board interface connector Connects the MCU board to the header board.

BGM adapter connector Connects the MCU board to the BGM adapter.

Main clock mounting socket Mounts the main clock crystal oscillator.

Sub clock mounting socket Mounts the sub clock crystal oscillator.

5.6 Pin assignment of header board I/F connector

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 24

Ta bl e 5-5 and Table 5-6 lists the pin assignments of the header board interface connectors on the

MCU board

Page 25

Table 5-5. Pin assignment of header board I/F connector A

Product Specifications

Connector

Pin

Number

1

2 B9 PC1 42 E1 LVSS * 82 P4 BDBMX

3 C9 PC2 43 F4

4 D9 PC3 44 F3

5 A8 PC0 45 F2

6 B8 PB4 46 F1 P22A 86 R4 RSTX

7 C8 PB5 47 GND * 87 T1 ROMS1

8 D8 PB6 48 GND * 88 T2 BSIN

9 A7 PB7 49 G4 P20A 89 T3 Vss *

10 B7 PB2 50 G3 NC1 90 T4 X0

11 C7 PB0 51 G2 P21A 91 U1 BEXCK

12 D7 PB1 52 G1 P23A 92 U2 X1

13 A6 PB3 53 H4 P24A 93 U3 MOD

14 B6 PA 2 54 H3 P25A 94 U4 PF2

15 C6 P95 55 H2 P26A 95 V1 X1A

16 D6 PA0 56 H1 P27A 96 V2 Vcc53 *

17 A5 PA 3 57 J4 P24B 97 GND *

18 B5 P94 58 J3 P50 98 GND *

19 C5 P90 59 J2 P23B 99 V3 PINT0

20 D5 P91 60 J1 P51 100 V4

21 A4 PA 1 61 K1 P52 101 R5 PF1

22 A3 P93 62 K2 P55 102 T5 PF0

23 GND * 63 K3 P54 103 U5 NC2

24 GND * 64 K4 P53 104 V5

25 A2 CSVENX 65 L1 P70 105 R6 APBENX

26 A1 Vss * 66 L2 P74 106 T6 PINT1

27 B4 P92 67 L3 P73 107 U6 PCLK

28 B3 TCLK 68 L4 P72 108 V6 PADDR0

29 B2 LVCC * 69 M1 P71 109 R7

30 B1 LV DIN 70 M2 P76 11 0 T7 PLOCK

31 C4 Cpin 71 M3 P80 111 U7 PWRITE

32 C3 Vcc51 * 72 M4 P77 112 V7 PADDR1

33 C2 LVDENX2 73 GND * 113 R8 PADDR2

34 C1 LVR4 74 GND * 114 T8 PADDR3

35 D4 TESTO 75 N1 P75 11 5 U8 PADDR4

36 D3 LVD OUT 76 N2 P82 116 V8 PADDR5

Evaluation

MCU Pin

Number

A9 PC4 41 E2 LV R3 81 P3 BSOUT

Signal

line

name

Connector

Pin

Number

Evaluation

MCU Pin

Number

Signal

line

name

LVDRE

XT

LVD BGR

LVD EN

X

Connector

Pin

Number

83 R1 P83

84 R2 BRSTX

85 R3 X0A

Evaluation

MCU Pin

Number

Signal

line

name

PSEL_E

XT

PENABLE

PAC -

TIVE

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 25

Page 26

Product Specifications

Connector

Pin

Number

37 D2 LVR2 77 N3 PG0 11 7 R9 PADDR7

38 D1 BGOENX 78 N4 P84 118 T9

39 E4 LV R1 79 P1 P81 119 U9 PADDR6

40 E3 LV R0 80 P2 ROMS0 120 V9

Evaluation

MCU Pin

Number

Signal

line

name

Connector

Pin

Number

Evaluation

MCU Pin

Number

Signal

line

name

Connector

Pin

Number

Evaluation

MCU Pin

Number

Signal

line

name

PRDA-

TA0

PRDA-

TA1

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 26

Page 27

Table 5-6. Pin assignment of header board I/F connector B

Product Specifications

Connector

Pin

Number

1 A10 PC5 41 E17 NC4 81 P16 P34

2 B10 PD0 42 E18 SEL0 82 P15 P35

3 C10 PC6 43 F15 SEL3 83 R18 P44

4 D10 PC7 44 F16 SEL4 84 R17 P36

5 A11 PD1 45 F17 SEL1 85 R16 P31

6 B11 PD2 46 F18 P04C 86 R15 AV cc3

7 C11 PD3 47 GND * 87 T18 P40

8 D11 PD4 48 GND * 88 T17 P32

9 A12 PD5 49 G15 P06C 89 T16 AVs s

10 B12 PD7 50 G16 P07C 90 T15 AV R

11 C12 P61 51 G17 P05C 91 U18 P33

12 D12 P60 52 G18 P00C 92 U17 P30

13 A13 PD6 53 H15 P01C 93 U16 AV R3

14 B13 P64 54 H16 P02C 94 U15 P15

15 C13 P66 55 H17 P03C 95 V18 AVcc

16 D13 P65 56 H18 P07A 96 V17 DA0

17 A14 P62 57 J15 P04A 97 GND *

18 B14 PE0A 58 J16 P05A 98 GND *

19 C14 PE3A 59 J17 P06A 99 V16 P14

20 D14 PE2A 60 J18 P03A 100 V15 P10

21 A15 P63 61 K18 P02A 101 R14 P16

22 A16 P67 62 K17 P07B 102 T14 DA1

23 GND * 63 K16 P01A 103 U14 P13

24 GND * 64 K15 P00A 104 V14

25 A17 PE4A 65 L18 P06B 105 R13 P11

26 A18 Vcc54 * 66 L17 P05B 106 T13 P12

27 B15 PE1A 67 L16 P04B 107 U13 NC3

28 B16 PE5A 68 L15 P03B 108 V13

29 B17 PE7A 69 M18 P02B 109 R12

30 B18 PE3B 70 M17 P00B 110 T12

31 C15 PE6A 71 M16 P46 111 U12

32 C16 Vss * 72 M15 P47 11 2 V12

33 C17 PE2B 73 GND * 113 R11

34 C18 PE7B 74 GND * 114 T11

35 D15 PE1B 75 N18 P01B 11 5 U11

Evaluation

MCU Pin

Number

Signal

line

name

Connector

Pin

Number

Evaluation

MCU Pin

Number

Signal

line

name

Connector

Pin

Number

Evaluation

MCU Pin

Number

Signal

line

name

PWDA-

TA7

PWDA-

TA3

PWDA-

TA5

PWDA-

TA6

PWDA-

TA4

PRDA-

TA7

PWDA-

TA0

PWDA-

TA1

PWDA-

TA2

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 27

Page 28

Product Specifications

Connector

Pin

Number

36 D16 PE0B 76 N17 P43 116 V11

37 D17 PE6B 77 N16 P41 117 R10

38 D18 SEL2 78 N15 P42 118 T10

39 E15 PE5B 79 P18 P45 119 U10

40 E16 PE4B 80 P17 P37 120 V10

Evaluation

MCU Pin

Number

Signal

line

name

Connector

Pin

Number

Evaluation

MCU Pin

Number

Signal

line

name

Connector

Pin

Number

*: About power supply pins (common to connectors A and B)

Connect the Vcc51, Vcc53 and Vcc54 pins to

Connect the Vss pin to GND. Disco

nnect the LVSS pin from GND.

Vcc. Disconnect the LVCC pin from Vcc.

: 3.3V power supply pins

: GND power supply pins

Evaluation

MCU Pin

Number

Signal

line

name

PRDA-

TA6

PRDA-

TA3

PRDA-

TA4

PRDA-

TA5

PRDA-

TA2

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 28

Page 29

Revision History

Document Revision History

Document Title: F2MC-8FX Family, MCU Board for MB95FV100D-102 MB2146-302A, Operation Manual

Document Number: 002-07488

Revision ECN# Issue Date

**

*A 5299269 06/13/2016 HUAL Migrated to Cypress format

*B 5774833 06/15/2017 NIBK Updated Cypress Logo and Copyright.

03/13/2007 HUAL Initial release

Origin of

Change

Description of Change

F2MC-8FX Family, MCU BOARD for MB95FV100D-102 MB2146-302A, Operation Manual, Doc. # 002-07488 Rev. *B 29

Loading...

Loading...