Cypress Semiconductor GVT71512D18TA-6.7, GVT71512D18TA-6, GVT71512D18TA-5, GVT71512D18TA-4.4, GVT71512D18T-6.7 Datasheet

...

256K x 36/512K x 18 Pipelined SRAM

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

Cypress Semiconductor Corporation • 3901 North First Street • San Jose • CA 95134 • 408-943-2600

May 9, 2001

1CY7C1329

Features

• Fast access times: 2.5 ns, 3.0 ns, and 3.5 ns

• Fast clock speed: 225, 200, 166, and 150 MHz

•Fast OE

access times: 2.5 ns, 3.0 ns, and 3.5 ns

• Optimal for depth expansion (one cycle chip deselect

to eliminate bus contention)

• 3.3V –5% and +10% power supply

• 3.3V or 2.5V I/O supply

• 5V tolerant inputs except I/Os

• Clamp diodes to V

SS

at all inputs and outputs

• Common data inputs and data outputs

• Byte Write Enable and Global Write contr ol

• Multiple chip enables for depth expansion:

three chip enables f or T A package ver sion and two chip

enables for B and T packa ge ver s ions

• Address pipeline capability

• Address, data, and control registers

• Internally self-timed Write Cycle

• Burst control pins (interleaved or linear burst sequence)

• Automatic po wer-down for portable applications

• JTAG boundary scan for B and T package version

• Low profile 11 9-bump, 14-mm x 22-mm PBGA (Ball Grid

Array) and 100-pin TQFP packages

Functional Description

The Cypress Synchronous Burst SRAM family employs

high-speed, low-power CMOS designs using advanced triple-layer polysilicon, double-layer metal technology. Each

memory cell consists of four transistors and two high-valued

resistors.

The CY7C1360A/GVT71256D36 and CY7C1362A/

GVT71512D18 SRAMs in tegrate 262 ,144x36 and 524,28 8x18

SRAM cells with advanced synchronous peripheral circuitry

and a 2-bit counter for inter nal burst operation. All synchronous inputs are gated by registers controlled by a positive-edge-triggered Clock Input (CLK). The synchronous inputs include all addresses, all data inputs, address-pipelining

Chip Enable (CE

), depth-expansion Chip Enables (CE2 and

CE2), burst control inpu ts (ADSC, ADSP, and ADV), Write Enables (BWa

, BWb, BWc, BWd , and BWE), and global write

(GW

). However, the CE2 chip enable input i s only available for

the TA package version.

Asynchronous inputs include the Output Enable (OE

) and

burst mode cont rol (MODE). Th e data outp uts (Q), enab led b y

OE

, are also asynchronous.

Addresses and chip enables are registered with either Address Status Processor (ADSP

) or Address Status Controller

(ADSC

) input pins. Subsequen t burst addresses can be inter-

nally generated as co ntrolled b y the Burst Advanc e Pin (AD V).

Address, data in puts, an d write contro ls are registere d on-chip

to initiate self-timed WRITE cycle. WRITE cycles can be one

to four bytes wide as controlled by the write control inputs.

Individual byte write allows individual byte to be written. BWa

controls DQa. BWb controls DQb. BWc controls DQc. BWd

controls DQd. BWa, BW b, BWc, and BWd can be active only

with BWE

being LOW. GW being LOW causes all bytes to be

written. The x18 v ersion on ly has 18 data inpu ts/outputs (DQa

and DQb) along with BW a

and BWb (no BWc, BWd, DQc , and

DQd).

For the B a nd T pac kage v ers ions, four pins are used to imple-

ment JTAG test capabilitie s: Test Mode Select (TM S), Test Data-In (TDI), Test Clock (TCK), and Test Data-Out (TDO). The

JTAG circuitry is used to serially shift data to and from the

device. JTAG inputs use LVTTL/LVCMOS levels to shift data

during this testing mo de of oper ation . The TA pac kage v ersio n

does not offer the JTAG capability.

The CY7C1360A/GVT71256D36 and CY7C1362A/

GVT71512D18 operate from a +3.3V power supply. All inputs

and outputs are LVTTL compatible.

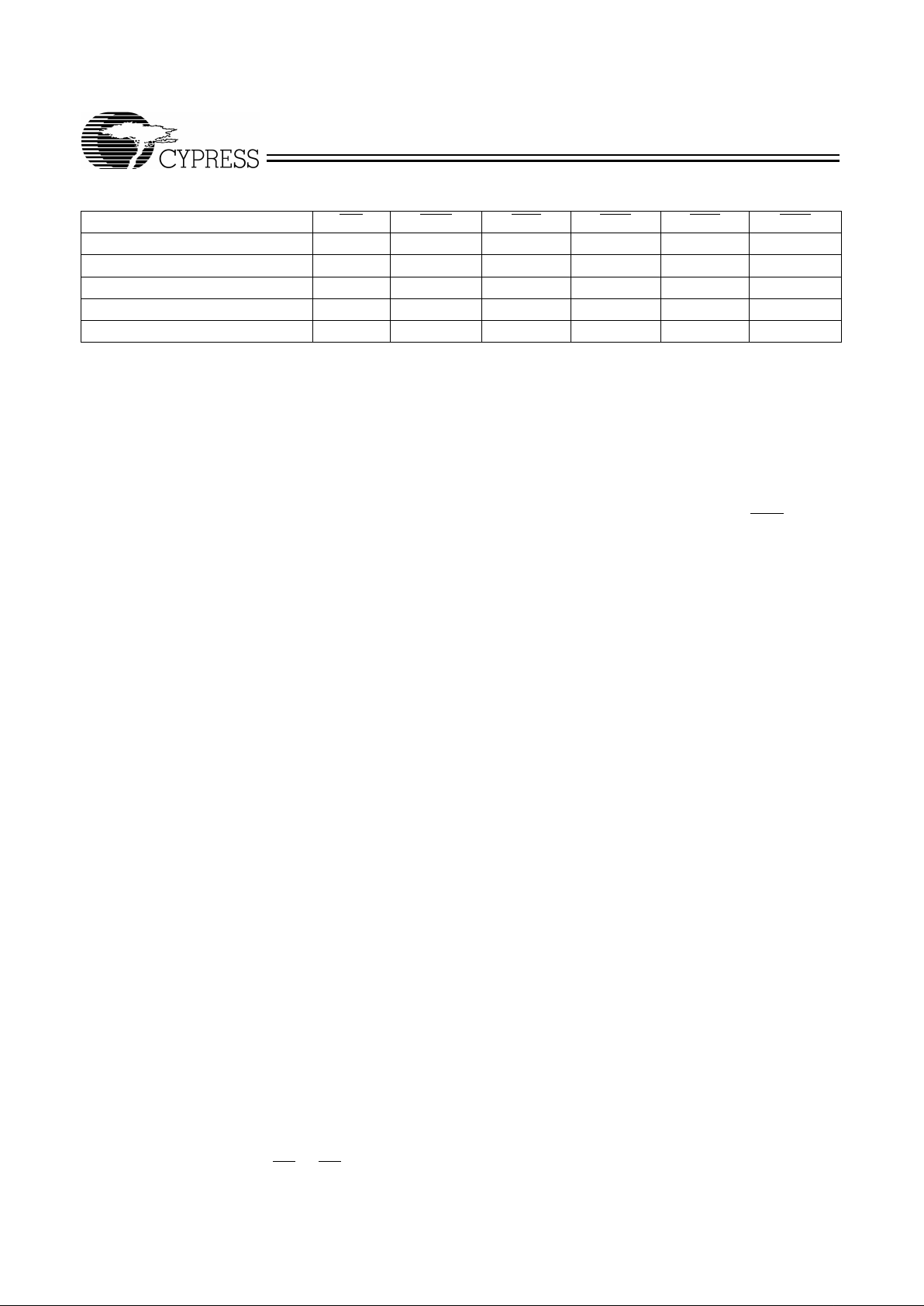

Selection Guide

7C1360A-225

71256D36-4.4

7C1362A-225

71512D18-4.4

7C1360A-200

71256D36-5

7C1362A-200

71512D18-5

7C1360A-166

71256D36-6

7C1362A-166

71512D18-6

7C1360A-150

71256D36-6.7

7C1362A-150

71512D18-6.7

Maximum Access Time (ns) 2.5 3.0 3.5 3.5

Maximum Operating Current (mA) Commercial 570 510 425 380

Maximum CMOS Standby Curren t (mA) 10 10 10 10

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

2

Notes:

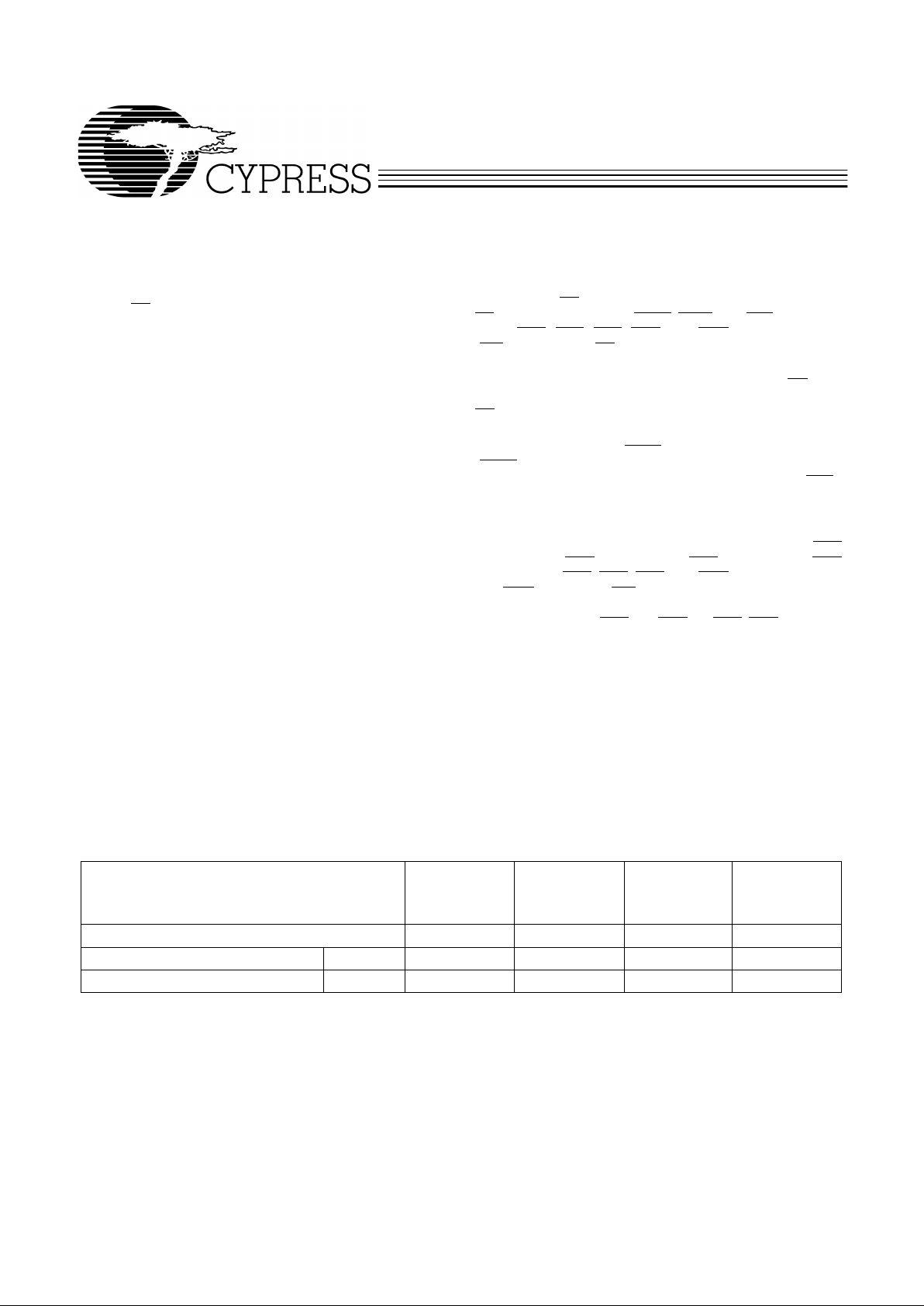

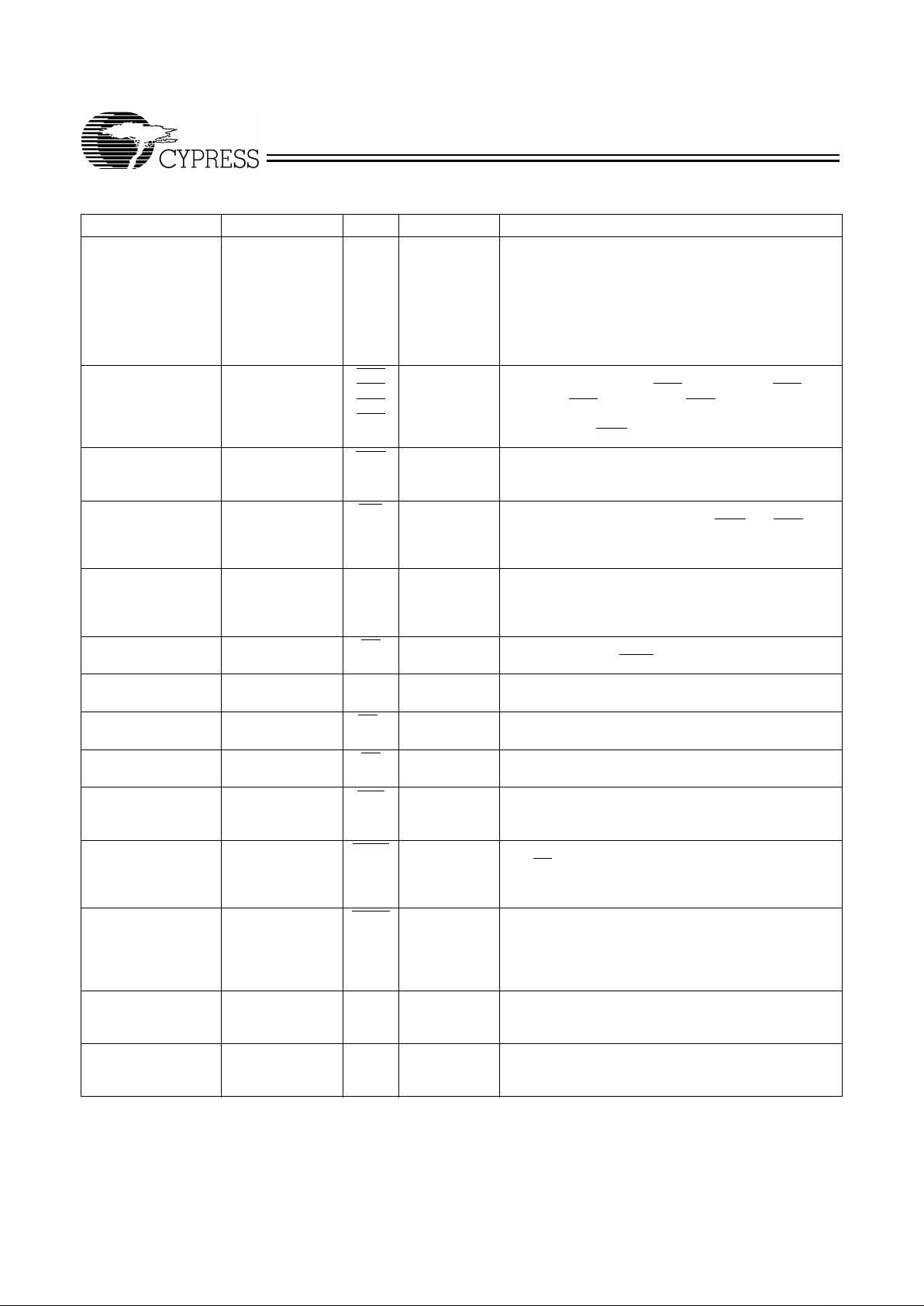

1. The Functional Block Diagram illustrates simplified device operation. See Truth Table, pin descriptions and timing diagrams for detailed information.

2. CE

2

is for TA version only.

DQ

DQ

BWb#

BWE#

BWa#

GW#

BYTE b

WRITE

BYTE a

WRITE

OUTPUT

REGISTER

OE#

byte b write

ADSP#

ADSC#

Address

Register

Binary

Counter

& Logic

CLR

A

A1-A0

ADV#

MODE

512K x 9 x 2

SRAM Array

Output Buffers

Input

Register

byte a write

DQa,DQb

DQ DQ

DQ

ENABLE

Power Down LogicZZ

17

CE#

CE2

CE2#

DQ

DQ

BWc#

BWE#

BWd#

BYTE c WRITE

BYTE d WRITE

OUTPUT

REGISTER

OE#

byte c write

ADSP#

ADSC#

Address

Register

Binary

Counter

& Logic

CLR

A

A1-A0

ADV#

MODE

256K x 9 x 4

SRAM Array

Output Buffers

Input

Register

byte d write

DQa,DQb

DQc,DQd

DQ

DQ

DQ

BWa#

BWb#

GW#

BYTE a WRITE

BYTE b WRITE

CLK

byte b write

byte a write

DQ

DQ

ENABLE

Power Down LogicZZ

16

CE#

CE2

CE2#

Functional Block Diagram—256K x 36

[1]

Functional Block Diagram—512K x 18

[1]

[2]

[2]

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

3

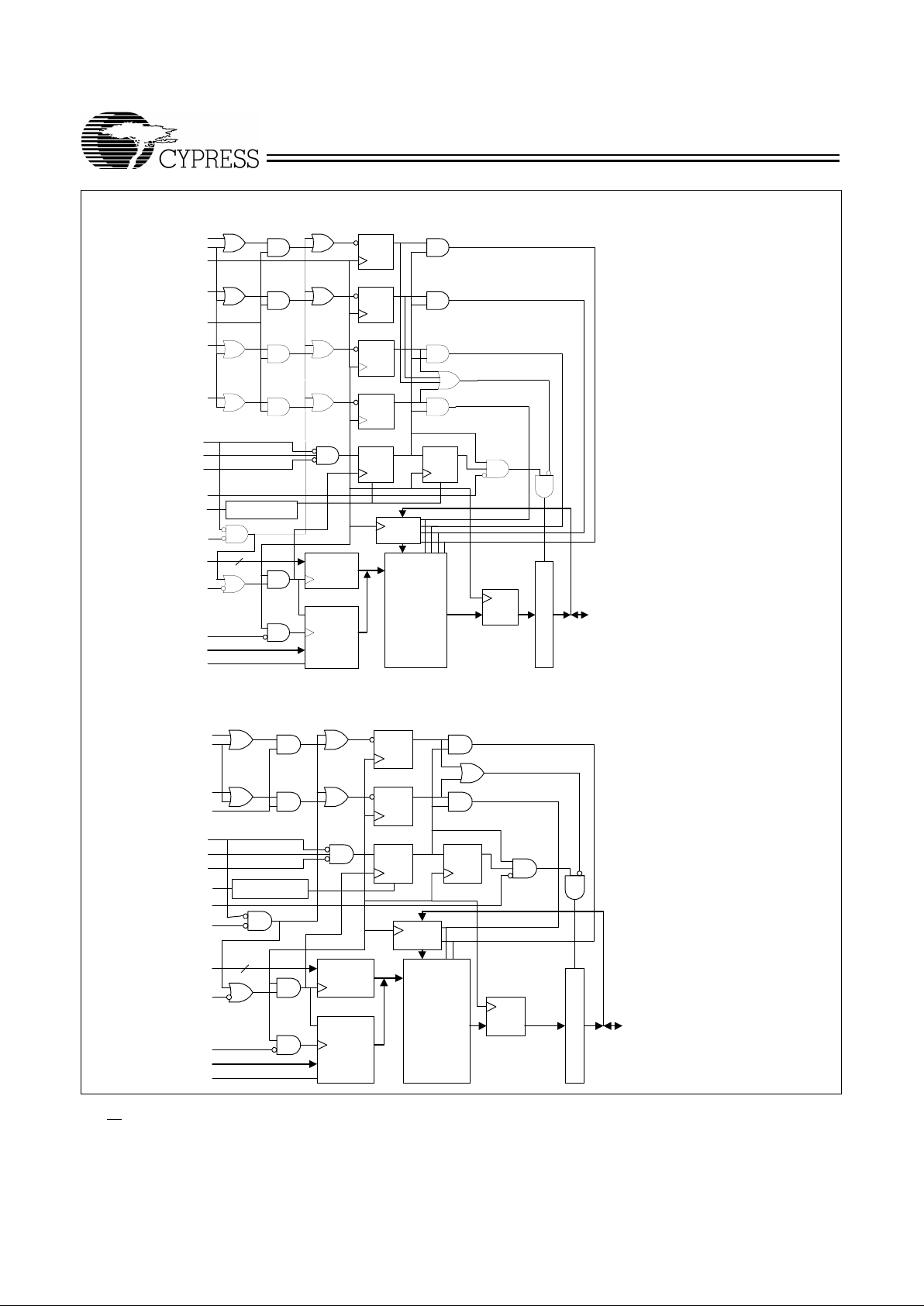

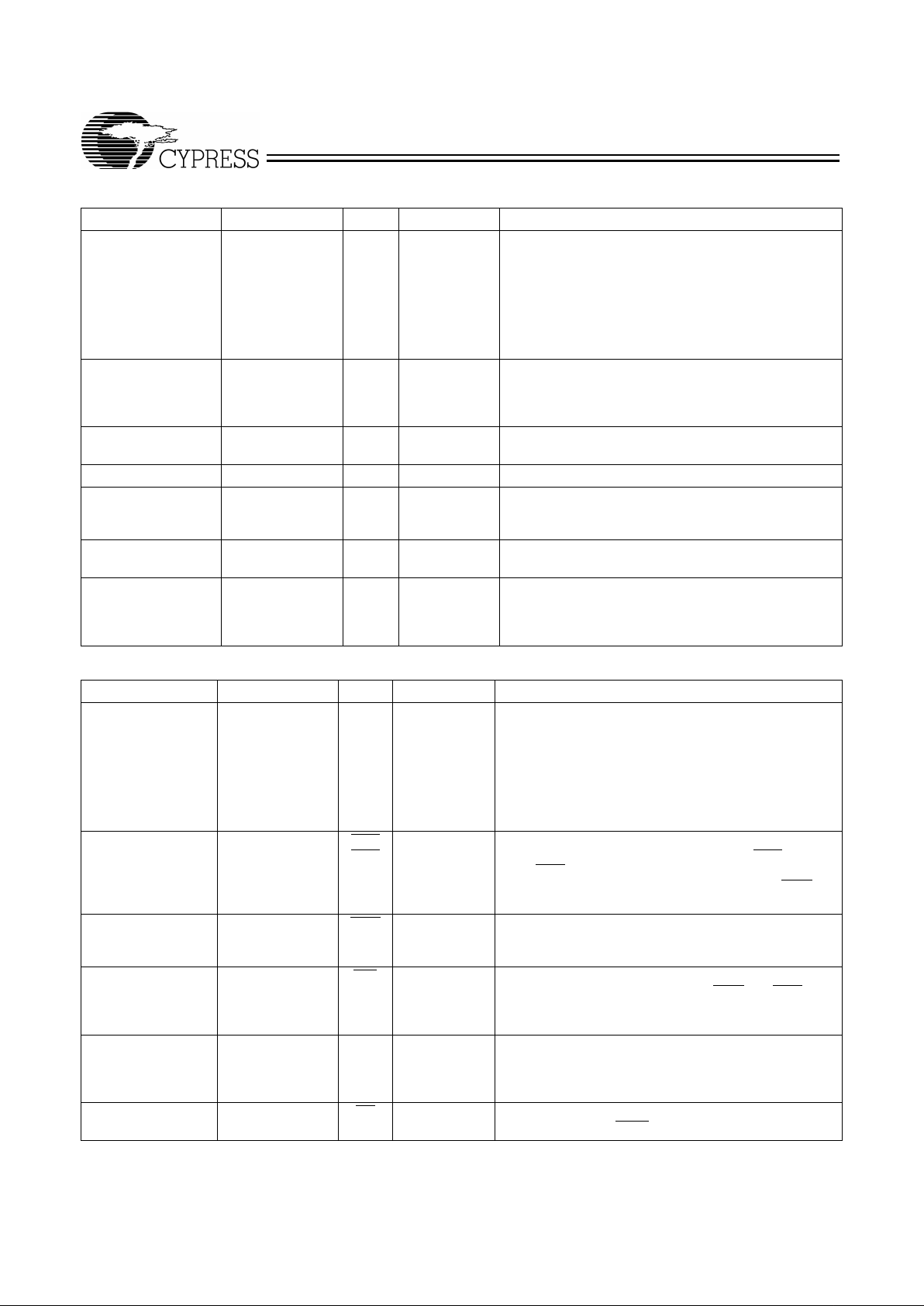

Pin Configurations

AAA

A

A1

A0

TMS

TDI

V

SS

V

CC

TDO

TCK

AAAAAAA

DQb

DQb

DQb

V

CCQ

V

SS

DQb

DQb

DQb

DQb

V

SS

V

CCQ

DQb

DQb

V

SS

NC

V

CC

ZZ

DQa

DQa

V

CCQ

V

SS

DQa

DQa

DQa

DQa

V

SS

V

CCQ

DQa

DQa

DQa

DQc

DQc

DQc

V

CCQ

V

SS

DQc

DQc

DQc

DQc

V

SS

V

CCQ

DQc

DQc

V

CC

NC

V

SS

DQd

DQd

V

CCQ

V

SS

DQd

DQd

DQd

DQd

V

SS

V

CCQ

DQd

DQd

DQd

A

A

CE

CE

2

BWd

BWc

BWb

BWa

A

VCCV

SS

CLKGWBWEOEADSC

ADSP

ADV

A

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31323334353637383940414243444546474849

50

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

100999897969594939291908988878685848382

81

MODE

CY7C1360A/GVT71256D36

(256K X 36)

NC

A

NC

NC

V

CCQ

V

SS

NC

DPa

DQa

DQa

V

SS

V

CCQ

DQa

DQa

V

SS

NC

V

CC

ZZ

DQa

DQa

V

CCQ

V

SS

DQa

DQa

NC

NC

V

SS

V

DDQ

NC

NC

NC

NC

NC

NC

V

CCQ

V

SS

NC

NC

DQb

DQb

V

SS

V

CCQ

DQb

DQb

V

CC

NC

V

SS

DQb

DQb

V

CCQ

V

SS

DQb

DQb

DQb

NC

V

SS

V

CCQ

NC

NC

NC

AACE

CE2NCNCBWb

BWaAVCCV

SS

CLKGWBWEOEADSC

ADSP

ADV

A

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31323334353637383940414243444546474849

50

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

100999897969594939291908988878685848382

81

CY7C1362A/GVT71512D18

(512K x 18)

NC

100-Pin TQFP

Top View

AAA

A

A1

A0

NC

NC

V

SS

V

CC

NC

AAAAAAA

A

DQb

DQb

DQb

V

CCQ

V

SS

DQb

DQb

DQb

DQb

V

SS

V

CCQ

DQb

DQb

V

SS

NC

V

CC

ZZ

DQa

DQa

V

CCQ

V

SS

DQa

DQa

DQa

DQa

V

SS

V

CCQ

DQa

DQa

DQa

DQc

DQc

DQc

V

CCQ

V

SS

DQc

DQc

DQc

DQc

V

SS

V

CCQ

DQc

DQc

V

CC

NC

V

SS

DQd

DQd

V

CCQ

V

SS

DQd

DQd

DQd

DQd

V

SS

V

CCQ

DQd

DQd

DQd

A

A

CE

CE

2

BWd

BWc

BWb

BWa

CE2VCCV

SS

CLKGWBWEOEADSC

ADSP

ADV

A

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31323334353637383940414243444546474849

50

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

100999897969594939291908988878685848382

81

MODE

CY7C1360A/GVT71256D36

(256K X 36)

NC

A

NC

NC

V

CCQ

V

SS

NC

DQa

DQa

DQa

V

SS

V

CCQ

DQa

DQa

V

SS

NC

V

CC

ZZ

DQa

DQa

V

CCQ

V

SS

DQa

DQa

NC

NC

V

SS

V

CCQ

NC

NC

NC

NC

NC

NC

V

CCQ

V

SS

NC

NC

DQb

DQb

V

SS

V

CCQ

DQb

DQb

V

CC

NC

V

SS

DQb

DQb

V

CCQ

V

SS

DQb

DQb

DQb

NC

V

SS

V

CCQ

NC

NC

NC

AACE

CE2NCNCBWb

BWa

CE2VCCV

SS

CLKGWBWEOEADSC

ADSP

ADV

A

A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31323334353637383940414243444546474849

50

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

100999897969594939291908988878685848382

81

CY7C1362A/GVT71512D18

(512K x 18)

NC

TA Package Version

TA Package Version

T Package Version

T Package Version

AAA

A

A1

A0

TMS

TDI

V

SS

V

CC

TDO

TCK

AAAAAAA

MODE

AAA

A

A1

A0

NC

NC

V

SS

V

CC

NC

AAAAAAA

A

MODE

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

4

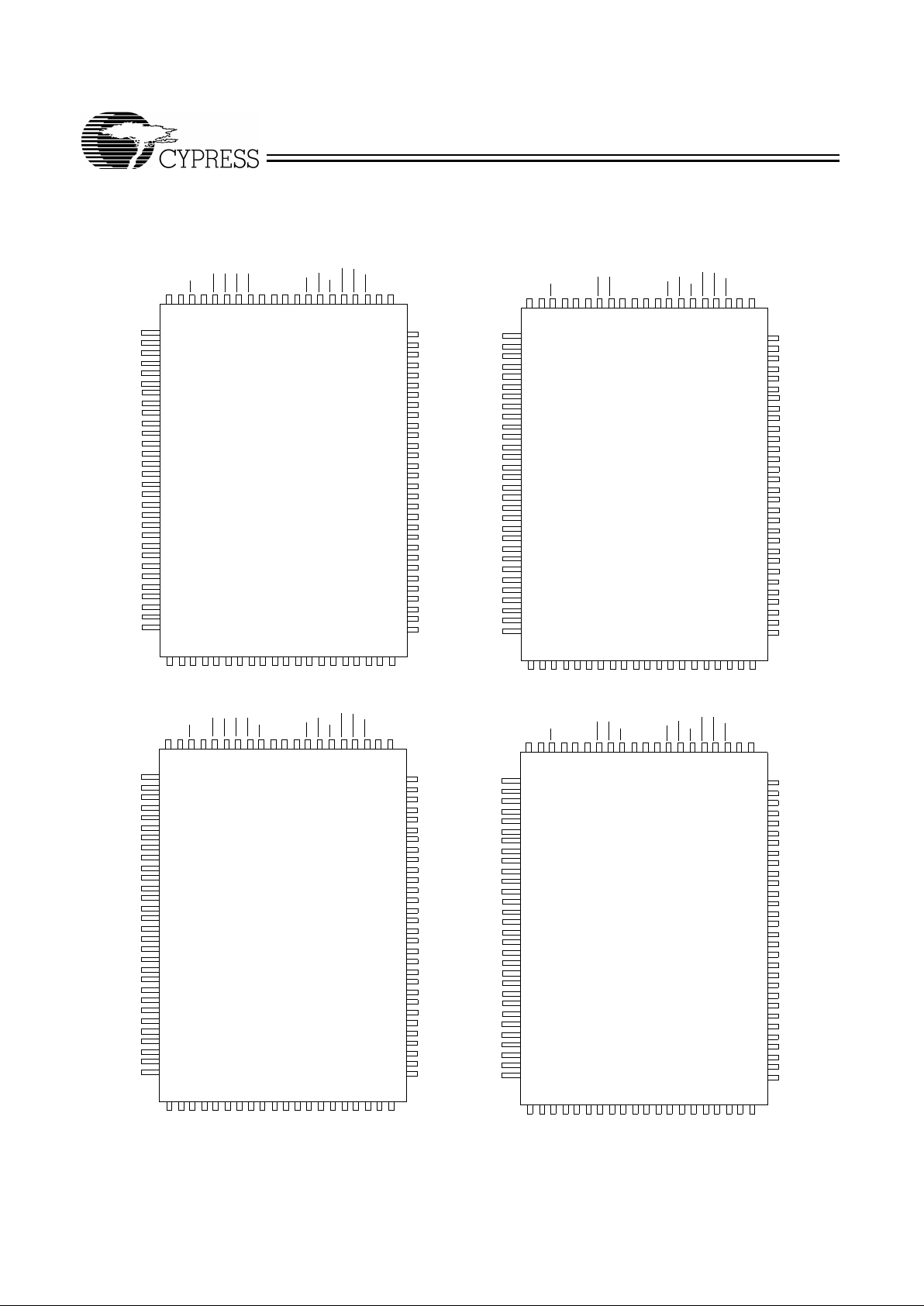

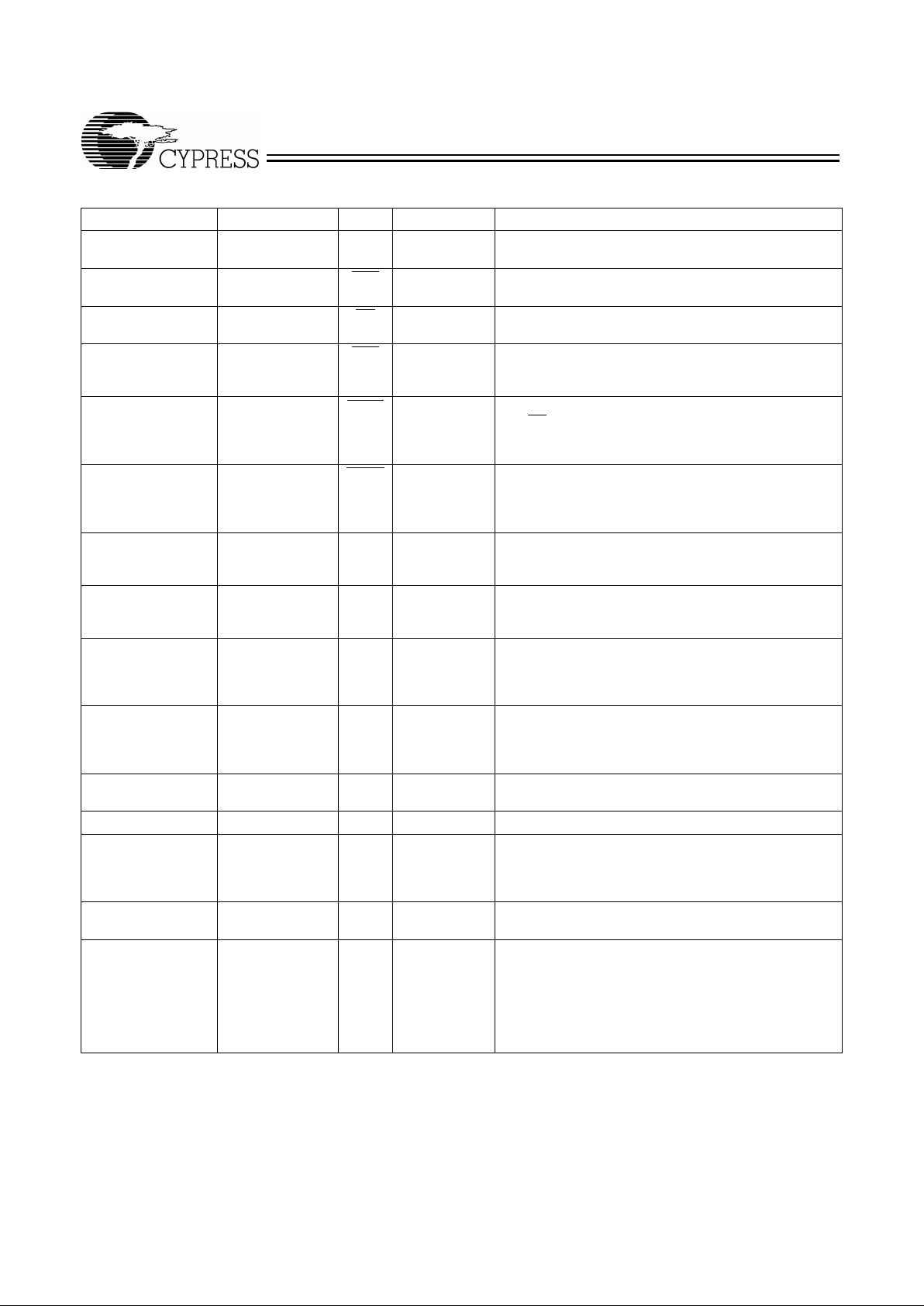

Pin Configurations

(continued)

119-Ball BGA

1234567

A V

CCQ

A A ADSP AAV

CCQ

B NC CE

2

AADSCAANC

C NC A A V

CC

AANC

D DQc DQc V

SS

NC V

SS

DQb DQb

E DQc DQc V

SS

CE V

SS

DQb DQb

F V

CCQ

DQc V

SS

OE V

SS

DQb V

CCQ

G DQc DQc BWc

ADV BWb DQb DQb

H DQc DQc V

SS

GW V

SS

DQb DQb

J V

CCQ

V

CC

NC V

CC

NC V

CC

V

CCQ

K DQd DQd V

SS

CLK V

SS

DQa DQa

L DQd DQd BWd

NC BWa DQa DQa

M V

CCQ

DQd V

SS

BWE V

SS

DQa V

CCQ

N DQd DQd V

SS

A1 V

SS

DQa DQa

P DQd DQd V

SS

A0 V

SS

DQa DQa

R NC A MODE V

CC

NC A NC

T NC NC A A A NC ZZ

U V

CCQ

TMS TDI TCK TDO NC V

CCQ

Top View

1234567

A V

CCQ

A A ADSP AAV

CCQ

B NC CE

2

AADSCACE2NC

C NC A A V

CC

AANC

D DQb NC V

SS

NC V

SS

DQa NC

E NC DQb V

SS

CE V

SS

NC DQa

F V

CCQ

NC V

SS

OE V

SS

DQa V

CCQ

G NC DQb BWb

ADV V

SS

NC DQa

H DQb NC V

SS

GW V

SS

DQa NC

J V

CCQ

V

CC

NC V

CC

NC V

CC

V

CCQ

K NC DQb V

SS

CLK V

SS

NC DQa

L DQb NC V

SS

NC BWa DQa NC

M V

CCQ

DQb V

SS

BWE V

SS

NC V

CCQ

N DQb NC V

SS

A1 V

SS

DQa NC

P NC DQb V

SS

A0 V

SS

NC DQa

R NC A MODE V

CC

NC A NC

T NC A A NC A A ZZ

U V

CCQ

TMS TDI TCK TDO NC V

CCQ

256Kx36

512Kx18

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

5

256K X 36 Pin Descriptions

X36 PBGA Pins X36 QFP Pins Name Type Description

4P

4N

2A, 3A, 5A, 6A, 3B,

5B, 6B, 2C, 3C, 5C,

6C, 2R, 6R, 3T, 4T, 5T

37

36

35, 34, 33, 32,

100, 99, 82, 81,

44, 45, 46, 47, 48,

49, 50

92 (T Version)

43 (TA Version)

A0

A1

A

Input-

Synchronous

Addresses: These inpu ts a re regis tered a nd m ust me et

the set-up and hold times arou nd the rising edge of CLK.

The burst counter generates internal addresses associated with A0 and A1, during burst cycle and wait cycle.

5L

5G

3G

3L

93

94

95

96

BWa

BWb

BWc

BWd

Input-

Synchronous

Byte Write: A byte write is LOW for a WRITE cycle and

HIGH for a READ cycle. BWa

controls DQa. BWb controls DQb. BWc c ontrols D Qc. BW d controls DQd. Data

I/O are high impedanc e if either of these in puts are LOW ,

conditioned by BWE

being LOW.

4M 87 BWE

Input-

Synchronous

Write Enable: This active LOW input gates byte write

operations and must meet the set-up and hold times

around the rising edge of CLK.

4H 88 GW

Input-

Synchronous

Global Write: This active LOW input allows a full 36-bit

WRITE to occur independ ent of the BWE

and BWn lines

and must meet the set-up and hold times around the

rising edge of CLK.

4K 89 CLK Input-

Synchronous

Clock: This signal registers the addresses, data, chip

enables , write control, and burst c ontrol inputs on its rising edge. All synchron ous inp uts m ust m eet set-u p and

hold times around the clock’s rising edge.

4E 98 CE

Input-

Synchronous

Chip Enable: Th is active LO W input is used to enable the

device and to gate ADSP

.

2B 97 CE

2

Input-

Synchronous

Chip Enable: This active HIGH input is used to enable

the device.

- (not availab le for

PBGA)

92 (for TA Version

only)

CE

2

Input-

Synchronous

Chip Enable: Th is active LO W input is used to enable the

device. Not available for B and T package versions.

4F 86 OE

Input Output Enable: This a ctive LO W asynch ronous input en-

ables the data output drivers.

4G 83 ADV

Input-

Synchronous

Address Advance : This activ e LO W input is us ed to control the internal burst co unter. A HIGH on this pin generates wait cycle (no address advance).

4A 84 ADSP

Input-

Synchronous

Address Status Processo r: This active LO W input, along

with CE

being LOW, causes a new external address to

be registered and a READ cycle i s initiated using the new

address.

4B 85 ADSC

Input-

Synchronous

Address Status Controller: This active LOW input causes the device to be deselected or selected along with

new external address to be registered. A READ or

WRITE cycle is initiated depending upon write control

inputs.

3R 31 MODE Input-

Static

Mode: This input sele cts the b urst seq uence. A L OW on

this pin selects Linear Burst. A NC or HIGH on this pin

selects Interleaved Burst.

7T 64 ZZ Input-

Asynchronous

Snooze: This active HIGH input puts the device in low

power consumption standby mode. For normal operation, this input has to be e ither LOW or NC (N o Connect).

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

6

(a) 6P, 7P, 7N, 6N,

6M, 6L, 7L, 6K, 7K,

(b) 7H, 6H, 7G, 6G,

6F, 6E, 7E, 7D, 6D,

(c) 2D , 1D, 1E, 2E, 2F,

1G, 2G, 1H, 2H,

(d) 1K, 2K, 1L, 2L,

2M, 1N, 2N, 1P, 2P

(a) 51, 52, 53, 56,

57, 58, 59, 62, 63

(b) 68, 69, 72, 73,

74, 75, 78, 79, 80

(c) 1, 2, 3, 6, 7, 8,

9, 12, 13

(d) 18, 19, 22, 23,

24, 25, 28, 29, 30

DQa

DQb

DQc

DQd

Input/

Output

Data Inputs/Outputs: First By te i s DQa. Se co nd By te i s

DQb. Third Byt e is DQc. F ourth Byte is DQd. Input data

must meet set-up and hol d times around the rising edge

of CLK.

2U

3U

4U

38

39

43

for B and T v ersion

TMS

TDI

TCK

Input IEEE 1149.1 test inputs. LVTTL-level inputs. Not avail-

able for TA package version.

5U 42

for B and T v ersion

TDO Output IEEE 1149.1 test output. LVTTL-level output. Not avail-

able for TA package version.

4C, 2J, 4J, 6J, 4R 15, 41, 65, 91 V

CC

Supply Core power Supply: +3.3V –5% and +10%

3D , 5D, 3E, 5E, 3F , 5F,

3H, 5H, 3K, 5K, 3M,

5M, 3N, 5N, 3P, 5P

5, 10, 17, 21, 26,

40, 55, 60, 67, 71,

76, 90

V

SS

Ground Ground: GND.

1A, 7A, 1F, 7F , 1J , 7J,

1M, 7M, 1U, 7U

4, 11, 20, 27, 54,

61, 70, 77

V

CCQ

I/O Supply Output Buffer Supply: +2.5V or +3.3V.

1B, 7B, 1C, 7C, 4D,

3J, 5J, 4L, 1R, 5R,

7R, 1T, 2T, 6T, 6U

14, 16, 66

38, 39, 42 for TA

Version

NC - No Connect: These sig nals are not internally conne cted.

User can leave it floating or connect it to V

CC

or VSS.

256K X 36 Pin Descriptions

(continued)

X36 PBGA Pins X36 QFP Pins Name Type Description

512K X 18 Pin Descriptions

X18 PBGA Pins X18 QFP Pins Name Type Description

4P

4N

2A, 3A, 5A, 6A, 3B,

5B, 6B, 2C, 3C, 5C,

6C, 2R, 6R, 2T, 3T,

5T, 6T

37

36

35, 34, 33, 32,

100, 99, 82, 81,

80, 48, 47, 46, 45,

44, 49, 50

92 (T Version)

43 (TA Version)

A0

A1

A

Input-

Synchronous

Addresses: These inputs are registered and must meet

the set up and hold t imes ar ound the rising ed ge of C LK.

The burst counter generates internal addresses associated with A0 and A1, during burst cycle and wait cycle.

5L

3G

93

94

BWa

BWb

Input-

Synchronous

Byte Write Enables: A byte write enable is LOW for a

WRITE cycle and HIGH for a READ cycle. BW a

controls

DQa. BWb controls DQb . Data I/O ar e high impedanc e if

either of these inputs are LOW, conditioned by BWE

be-

ing LOW.

4M 87 BWE

Input-

Synchronous

Write Enable: This active LOW input gates byte write operations and mus t meet the set-up and hold times aro und

the rising edge of CLK.

4H 88 GW

Input-

Synchronous

Global Write: This active LOW input allows a full 18-bit

WRITE to occur inde pendent o f the BWE

and WEn lines

and must meet the set-up and hold times around the rising edge of CLK.

4K 89 CLK Input-

Synchronous

Clock: This signa l registers the addres ses, data, ch ip enables, write control and burst control inputs on its rising

edge. All sync hronous inputs m ust mee t set- up and h old

times around the clock’s rising edge.

4E 98 CE

Input-

Synchronous

Chip Enable: This active LOW input is used to enable the

device and to gate ADSP

.

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

7

2B 97 CE2 Input-

Synchronous

Chip Enable: This active HIGH input is use d to enable the

device.

- (not available for

PBGA)

92 (for TA Versio n

only)

CE2 Input-

Synchronous

Chip Enable: This active LOW input is used to enable the

device. Not available for B and T package versions.

4F 86 OE

Input Output Enable: Thi s activ e LOW asynchronous input en-

ables the data output drivers.

4G 83 ADV

Input-

Synchronous

Address Adva nc e: T his ac tive LOW input is used to c ontrol the internal burst counter. A HIGH on this pin generates wait cycle (no address advance).

4A 84 ADSP

Input-

Synchronous

Address Status Processor: This act ive LO W in put, along

with CE

being LOW , ca uses a new ex ternal address to be

registered and a READ cycle is initiated using the new

address.

4B 85 ADSC

Input-

Synchronous

Address Status Cont roller: This activ e LOW input causes

device to be de selected or se lected along with ne w e xternal address to be registere d. A READ or WRI TE cycle i s

initiated depending upon write control inputs.

3R 31 MODE Input-

Static

Mode: This inpu t se lec ts th e burst sequence. A LOW on

this pin selects Linear Burst. An NC or HIGH on this pi n

selects Interleaved Burst.

7T 64 ZZ Input-

Asynchronous

Snooze: This active HIGH input puts the device in low

power consump tion standby mode. F or normal operation,

this input has to be either LOW or NC (No Connect).

(a) 6D, 7E, 6F, 7G,

6H, 7K, 6L, 6N, 7P

(b) 1D, 2E, 2G, 1H,

2K, 1L, 2M, 1N, 2P

(a) 58, 59, 62, 63,

68, 69, 72, 73, 74

(b) 8, 9, 12, 13, 18,

19, 22, 23, 24

DQa

DQb

Input/

Output

Data Inputs/Outputs: Lo w Byte is DQa. High Byte is DQb.

Input data must meet set up and hold times around the

rising edge of CLK.

2U

3U

4U

38

39

43

for B and T v ersion

TMS

TDI

TCK

Input IEEE 1149.1 test inputs. LVTTL-level inputs . Not available

for TA package version.

5U 42

for B and T v ersion

TDO Output IEEE 1149.1 test output. LVTTL-level output. Not avail-

able for TA package version.

4C, 2J, 4J, 6J, 4R 15, 41,65, 91 V

CC

Supply Core power Supply: +3.3V –5% and +10%

3D, 5D, 3E, 5E, 3F,

5F, 5G, 3H, 5H, 3K,

5K, 3L, 3M, 5M, 3N,

5N, 3P, 5P

5, 10, 17, 21, 26,

40, 55, 60, 67, 71,

76, 90

V

SS

Ground Ground: GND.

1A, 7A, 1F , 7 F , 1J, 7J ,

1M, 7M, 1U, 7U

4, 11, 20, 27, 54,

61, 70, 77

V

CCQ

I/O Supply Output Buffer Supply: +2.5V or +3.3V.

1B, 7B, 1C, 7C, 2D,

4D, 7D, 1E, 6E, 2F,

1G, 6G, 2H, 7H, 3J,

5J, 1K, 6K, 2L, 4L,

7L, 6M, 2N, 7N, 1P,

6P, 1R, 5R, 7R, 1T,

4T, 6U

1–3, 6, 7, 14, 16,

25, 28–30, 51–53,

56, 57, 66, 75, 78,

79, 80, 95, 96

38, 39, 42 for TA

Version

NC - No Connect: These signals are not internally connected.

User can leave it floating or connect it to V

CC

or VSS.

512K X 18 Pin Descriptions

(continued)

X18 PBGA Pins X18 QFP Pins Name Type Description

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

8

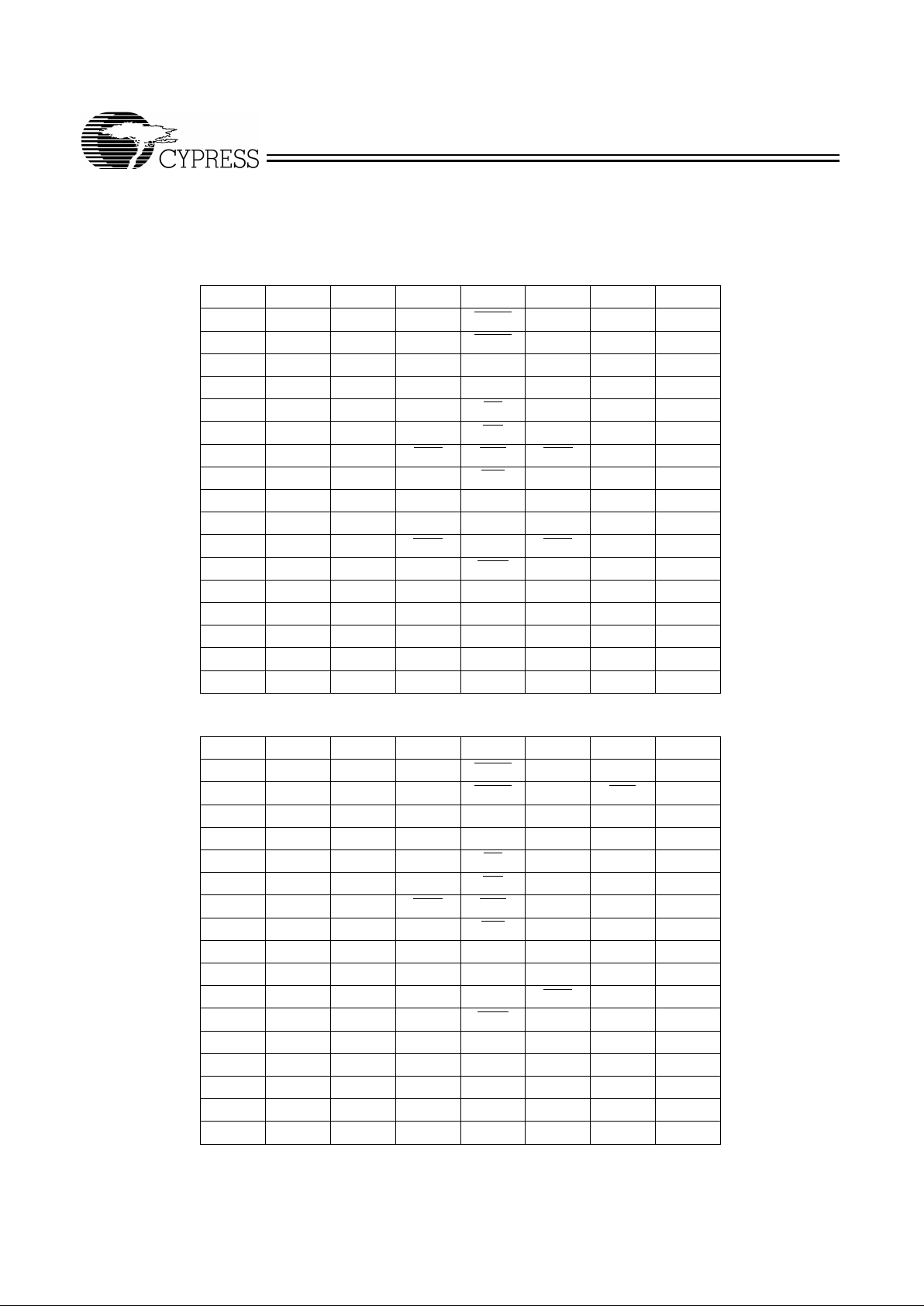

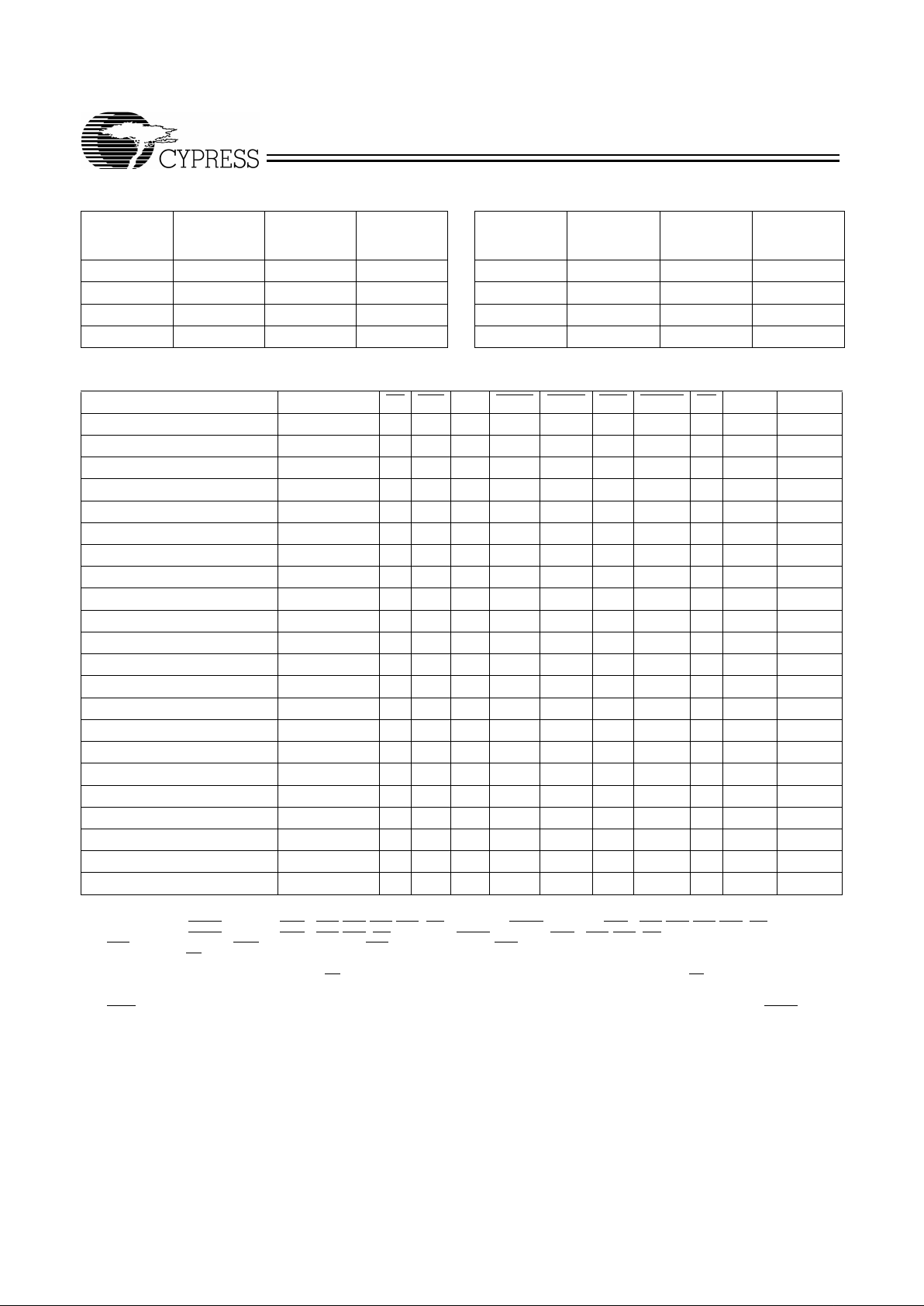

Notes:

3. X = “Don’t Care.” H = logic HIGH. L = logic LOW.

For X36 product, WRITE

= L means [BWE + BWa*BWb*BWc*BWd]*GW equals LOW. WRITE = H means [BWE + BWa*BWb*BWc*BWd]*GW equals HIGH.

For X18 product, WRITE = L means [BWE + BWa*BWb]*GW equals LOW. WRITE = H means [BWE + BWa*BWb]*GW equals HIGH.

4. BWa

enables write to DQa. BWb enables write to DQb. BWc enables write to DQ c. BWd ena bles wri te to DQd.

5. All inputs except OE must meet set up and hold times around the rising edge (LOW to HIGH) of CLK.

6. Suspending burst generates wait cycle.l

7. For a write operation following a read operation, OE

must be HI GH befo re the in put data re quired set -up time plus High- Z time f or OE and staying HIGH throughout

the input data hold time.

8. This device contains circuitry that will ensure the outputs will be in High-Z during power-up.

9. ADSP

LOW along with chip being selected always initiates a READ cycle at the L-H edge of CLK. A WRITE cycle can be performed by setting WRITE LOW for

the CLK L-H edge of the subsequent wait cycle. Refer to WRITE timing diagram for clarification.

Burst Address Table (MODE = NC/VCC)

First

Address

(external)

Second

Address

(internal)

Third

Address

(internal)

Fourth

Address

(internal)

A...A00 A...A01 A...A10 A...A11

A...A01 A...A00 A...A11 A...A10

A...A10 A...A11 A...A00 A...A01

A...A11 A...A10 A...A01 A...A00

Burst Address Table (MODE = GND)

First

Address

(external)

Second

Address

(internal)

Third

Address

(internal)

Fourth

Address

(internal)

A...A00 A...A01 A...A10 A...A11

A...A01 A...A10 A...A11 A...A00

A...A10 A...A11 A...A00 A...A01

A...A11 A...A00 A...A01 A...A10

Truth Table

[3, 4, 5, 6, 7, 8, 9]

Operation Address Used CE CE2 CE2 ADSP ADSC ADV WRITE OE CLK DQ

Deselected Cycle, Power Down None H X X X L X X X L-H High-Z

Deselected Cycle, Power Down None L X L L X X X X L-H High-Z

Deselected Cycle, Power Down None L H X L X X X X L-H High-Z

Deselected Cycle, Power Down None L X L H L X X X L-H High-Z

Deselected Cycle, Power Down None L H X H L X X X L-H High-Z

READ Cycle, Begin Burst External L L H L X X X L L-H Q

READ Cycle, Begin Burst External L L H L X X X H L-H High-Z

WRITE Cycle, Begin Burst External L L H H L X L X L-H D

READ Cycle, Begin Burst External L L H H L X H L L-H Q

READ Cycle, Begin Burst External L L H H L X H H L-H High-Z

READ Cycle, Continue Burst Next X X X H H L H L L-H Q

READ Cycle, Continue Burst Next X X X H H L H H L-H High-Z

READ Cycle, Continue Burst Next H X X X H L H L L-H Q

READ Cycle, Continue Burst Next H X X X H L H H L-H High-Z

WRITE Cycle, Continue Burst Next X X X H H L L X L-H D

WRITE Cycle, Continue Burst Next H X X X H L L X L-H D

READ Cycle, Suspend Burst Current X X X H H H H L L-H Q

READ Cycle, Suspend Burst Current X X X H H H H H L-H High-Z

READ Cycle, Suspend Burst Current H X X X H H H L L-H Q

READ Cycle, Suspend Burst Current H X X X H H H H L-H High-Z

WRITE Cycle, Suspend Burst Current X X X H H H L X L-H D

WRITE Cycle, Suspend Burst Current H X X X H H L X L-H D

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

9

IEEE 1149.1 Serial Boundary Scan (JTAG)

Overview

This device incorporates a serial boundary scan access port

(TAP). This port is designed to operate in a man ner consi stent

with IEEE Standard 1149.1-1990 (commonly referred to as

JTAG), but d oes not im plement al l of th e func tions re quired for

IEEE 1149.1 compliance. Certain functions have been modified or eliminated because their implementation places extra

delays in the critical speed path of the device. Nevertheless,

the device supports the standard TAP controller architecture

(the TAP controller is the state m achin e tha t cont rols t he TAPs

operation) and can be expected to function in a manner that

does not conflict with the o pera tion of de vice s with IEEE Standard 1149.1 compliant TAPs. The TAP operates using LVTTL/

LVCMOS logic level signaling.

Disabling the JTAG Feature

It is possib le to use this de v ice witho ut using the JTAG feature .

To disable t he TAP contro ller without i nterfering with no rmal

operation of the de vice , TCK shou ld be tied LO W (V

SS

) to prevent cloc king the d e vice . TDI and TMS ar e internally pulled up

and may be unconnected. They may alternately be pulled up

to V

CC

through a resistor. TDO should be left unconnected.

Upon power-up the device will come up in a reset state which

will not interfere w ith the ope r ati on of the device.

Test Access Port (TAP)

TCK - Test Clock (INPUT)

Clocks all TAP events. All inputs are captured on the rising

edge of TCK and all outp uts propagate fr om the f alling edge of

TCK.

TMS - Test Mode Select (INPUT)

The TMS input is sampled on the rising edge of TCK. This is

the command input for the TAP controller state machine. It is

allowab le to lea ve this pin unconnected if the TAP is not used.

The pin is pulled up internally, resulting in a logic HIGH level.

TDI - Test Data In (INPUT)

The TDI input is samp led on the rising edge o f TCK. This is the

input side of the se rial registers pl aced betwe en TDI and TDO .

The register placed between TDI and TDO is determined by

the state of the TAP controller state machine and the instruction that is currentl y loaded in the TAP instruction register (ref er

to Figure 1, TAP Controller State Diagram). It is allowable to

leave this pin unconnected if it is not used in an application.

The pin is pulled up inter nally, resulting in a logic HIGH level.

TDI is connected to th e M ost Si gn ific an t Bi t (M SB) o f a n y re gister. (See Figure 2.)

TDO - Test Data Out (OUTPUT)

The TDO output pin i s use d to seri all y clo ck data-out from the

registers. The output that is active depending on the state of

the TAP state machine (ref er to Figure 1, TAP Controller State

Diagram). Output changes in response to the falling edge of

TCK. This is the output side of the serial regi sters placed between TDI and TDO . TDO is conne cted to the Least Significa nt

Bit (LSB) of any register. (See Figure 2.)

Performing a TAP Reset

The TAP circuitry does not have a reset pin (TRST

, which is

optional in the IEEE 1149.1 specification). A RESET can be

performed for the TAP controller by forcing TMS HIGH (V

CC

)

for five rising edges of TCK and pre-loads the instruction register with the IDCODE command. This type of reset does not

affect the operation of the system logic. The reset affects test

logic only.

At power-up, the TAP is reset internally to ensure that TDO is

in a High-Z state.

Test Access Port (TAP) Registers

Overview

The various TAP registers are selected (one at a time) via the

sequences of ones and z eros inpu t to the TMS pin a s the TC K

is strobed. Each of the TAPs registers are serial shift register s

that capture serial input data on the rising edge of TCK and

push serial data out on subseque nt f alling edge of TCK. Whe n

a register is selected, it is connected between the TDI and

TDO pins.

Instruction Register

The instruction register holds the instructions that are executed by the TAP controller when it is moved into the run test/idl e

or the various data register states. The instructions are three

bits long. The register c an be loaded when it is placed between

the TDI and TDO pins. The parallel outputs of the instruction

register are automaticall y preloaded with th e IDCODE instruction upon powe r-up or whenever the controller is placed in th e

test-logic reset state. When the TAP controller is in the Capture-IR state, the two least si gnifican t bits of the serial instruction register are loaded with a binary “01” pattern to allow for

fault isolation of the board-level serial test data path.

Bypass Register

The bypass register is a single-bit register that can be placed

between TDI and TDO. It allows serial test data to be passed

through the device TAP to another device in the scan chain

with minimum del ay. The bypass register is set LOW (V

SS

)

when the BYPASS instruction is executed.

Note:

10. For the X18 product, there are only BWa

and BWb.

Partial Truth Table for READ/WRITE

[10]

Function GW BWE BWa BWb BWc BWd

READ H H X X X X

READ H L H H H H

WRITE one byte H L L H H H

WRITE all bytes H L L L L L

WRITE all bytes L X X X X X

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

10

Boundary Scan Register

The Boundary Scan register is connected to all the input and

bidirectional I/O pins (not counting the TAP pins) on the device.

This also incl udes a number of NC pins th at are r eser ved for

future needs. Ther e are a total of 70 bits f or the x36 de vice and

51 bits for the x18 device. The boundary scan register, under

the control of the TAP controller, is loaded with the conten ts of

the device I/O ring when the controller is in Capture-DR state

and then is placed between the TDI and TDO pins when the

controller is moved to Shift-DR state. The EXTEST, SAMPLE/PRELOAD and SAMPLE-Z instructions can be used to

capture the contents of the I/O ring.

The Boundary Scan Order table describes the order in which

the bits are connecte d. Th e fir st c olu mn defi nes the bit’s position in the boundary scan register. The MSB of the register is

connected to TDI, and LSB is connected to TDO. The second

column is the signal name, the third column is the TQFP pin

number, and the fourth column is the BGA bump number.

Identification (ID) Register

The ID Register is a 32-bi t register that is loaded with a de vice

and vendor specific 32-bit code when the controller is put in

Capture-DR state with the IDCODE command loaded in the

instruction register. The register is then placed between the

TDI and TDO pins when the controller is moved into Shift-DR

state. Bit 0 in the r egister i s the LSB an d the fi rst to rea ch TDO

when shifting b egins . The c ode is loaded from a 32-b it on- chip

ROM. It desc ribes various att ributes of the de vice as desc ribed

in the Identification Register Definitions table.

TAP Controller Instruction Set

Overview

There are two clas ses of instructions defined in the I EEE Standard 1149.1 -1990; the standard ( public) ins tructio ns and device specific (private) instructions. Some public instructions

are mandatory for IEEE 1149.1 compliance. Optional public

instructions must be implemented in prescribed ways.

Although the TAP controller in this device follows the IEEE

1149.1 conventions, it is not IEEE 1149.1 compliant because

some of the manda tory instructions are no t fully im plemente d.

The TAP on this device may be used to monitor all input and

I/O pads, b u t can not b e us ed to load addres s , data, or co ntrol

signals into the device or to preload the I/O buffers. In other

words, the device will not perform IEEE 1149.1 EXTEST, INTEST, or the preload portion of the SAMPLE/PRELOAD command.

When the TAP controller is place d in Capture-IR state, the two

least significant bits of the instruction register are loaded with

01. When the controller is moved to the Shift-IR state the instruction is serially loaded through the TDI input (while the

previous c ontents are shifted out at TDO). F or a ll ins tructions,

the T AP e xecutes ne wly loaded instruction s only when the controller is moved to Update-IR state. The TAP instruction sets

for this device are listed in the following tables.

EXTEST

EXTEST is an IEEE 1149.1 mandatory public instruction. It is

to be ex ecuted w hene ver th e instruction register is lo aded with

all 0s. EXTEST is not implemented in this device.

The TAP controller does recognize an all-0 instruction. When

an EXTEST instruction is loaded into the instruction register,

the device responds as if a SAMPLE/PRELOAD instruction

has been loaded. There is one diff erence between tw o instructions. Unlike SAMPLE/PRELO AD instruction, EXTEST places

the device outputs in a High-Z state.

IDCODE

The IDCODE instruction c auses a vend or-specific , 32-bit code

to be loaded into th e ID re gis ter when the controller is in Ca pture-DR mode and places the ID register betw een the TDI and

TDO pins in Shift-DR mode. The IDCODE instruction is the

default in struction loaded in the instruction upon po wer-up and

at any time the TAP controller is placed in the test-logic reset

state.

SAMPLE-Z

If the High-Z instructio n is l oaded in th e inst ruction reg ister, all

output pins are f orced to a High-Z state a nd the boundary scan

register is connected between TDI and TDO pins when the

TAP controller is in a Shift-DR state.

SAMPLE/PRELOAD

SAMPLE/PRELOAD is an IEEE 1149.1 man datory instruction.

The PRELOAD portion of the command is not imple mented in

this device, so the device TAP controller is not fully IEEE

1149.1-compliant.

When the SAMPLE/PRELOAD instruction is loaded in the in-

struction register and the TAP controller is in the Capture-DR

state, a snap shot of the data in the device’s input and I/O

buff ers is loa ded into the boundary scan reg ister. Because the

device system clock(s) are independent from the TAP clock

(TCK), it is possib le for the TAP to attempt to capture the inp ut

and I/O ring contents while the buffers are in trans ition (i.e., in

a metastable state). Although allowing the TAP to sample

metastable inputs will not harm the device, repeatable results

can not be expected. To guarantee that the boundary scan

register will capture the correct value of a signal, the device

input signals must be stabilized long enough to meet the TAP

controller’s capture set up plus hold time (t

CS

plus tCH). The

device clock input(s) need not be paused for any other TAP

operation e xcept c apturing the input and I/O ring content s into

the boundary scan register.

Moving the controller to Shift-DR state then places the boundary scan register betwee n the TDI and TDO pins . Because th e

PRELOAD portion of the command i s n ot i mp lemen ted in thi s

device, moving the controller to the Update-DR state with the

SAMPLE/PRELOAD instruction loaded in the instruction register has the same effect as the Pause-DR command.

BYPASS

When the BYPASS instruction is loaded in the instruction register and the TAP controller is in the Shift-D R state, the b ypass

register is placed betwe en TDI and TDO . This allows the boa rd

level scan path to be shortened to facilitate testing of other

devices in the scan pat h.

Reserved

Do not use these instructions. They are reserved for future

use.

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

11

Note:

11. The 0/1 next to each state represents the value at TMS at the rising edge of TCK.

Figure 1. TAP Controller State Diagram

[11]

TEST-LOGIC

RESET

REUN-TEST/

IDLE

SELECT

DR-SCAN

CAPTURE-DR

SHIFT-DR

EXIT1-DR

PAUSE-DR

EXIT2-DR

UPDATE-DR

SELECT

IR-SCAN

CAPTURE-IR

SHIFT-IR

EXIT1-IR

PAUSE-IR

EXIT2-IR

UPDATE-IR

1

0

1

1

0

1

0

1

0

0

0

1

1

1

0

1

0

1

0

0

0

1

0

1

1

0

1

0

0

1

1

0

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

12

Figure 2. TAP Controller Block Diagram

0

012..

29

3031

Boundary Scan Register

Identification Register

012..

.

.x

012

Instruction Register

Bypass Register

Selection

Circuitry

Selection

Circuitry

TAP Controller

TDI

TDO

TDI

TDI

[12]

TAP Electrical Characteristics (20°C < T

j

< 110°C; VCC = 3.3V –0.2V and +0.3V unless otherwise noted)

Parameter Description Test Conditions Min. Max. Unit

V

IH

Input High (Logic 1) Voltage

[13, 14]

2.0 VCC + 0.3 V

V

Il

Input Low (Logic 0) Voltage

[13, 14]

–0.3 0.8 V

IL

I

Input Leakage Current 0V < VIN < VCC –5.0 5.0 µA

IL

I

TMS and TDI Input Leakage Current 0V < VIN < VCC –30 30 µA

IL

O

Output Leakage Current Output disabled,

0V < VIN < V

CCQ

–5.0 5.0 µA

V

OLC

LVCMOS Output Low Voltage

[13, 15]

I

OLC

= 100 µA 0.2 V

V

OHC

LVCMOS Output High Voltage

[13, 15]

I

OHC

= 100 µA VCC – 0.2 V

V

OLT

LVTTL Output Low Voltage

[13]

I

OLT

= 8.0 mA 0.4 V

V

OHT

LVTTL Output High Voltage

[13]

I

OHT

= 8.0 mA 2.4 V

Notes:

12. X = 69 for the x36 configuration;

X = 50 for the x18 configuration.

13. All Voltage referenced to V

SS

(GND).

14. Overshoot: V

IH

(AC)<V

CC

+1.5V for t<

t

KHKH

/2, Undershoot: VIL(AC)<–0.5V for t<t

KHKH

/2, Power-up: VIH<3.6V and VCC<3.135V and V

CCQ

<1.4V for t<200 ms.

During normal operation, V

CCQ

must not exceed VCC. Control input signals (such as R/W, ADV/LD, etc.) may not have pulse widths less than t

KHKL

(min.).

15. This parameter is sampled.

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

13

TAP AC Switching Characteristics

Over the Oper at ing Rang e

[16, 17]

Parameter Description Min. Max Unit

Clock

t

THTH

Clock Cycle Time 20 ns

f

TF

Clock Frequency 50 MHz

t

THTL

Clock HIGH Time 8 ns

t

TLTH

Clock LOW Time 8 ns

Output Times

t

TLQX

TCK LOW to TDO Unknown 0 ns

t

TLQV

TCK LOW to TDO Valid 10 ns

t

DVTH

TDI Valid to TCK HIGH 5 ns

t

THDX

TCK HIGH to TDI Invalid 5 ns

Set-up Times

t

MVTH

TMS Set-up 5 ns

t

CS

Capture Set-up 5 ns

Hold Times

t

THMX

TMS Hold 5 ns

t

CH

Capture Hold 5 ns

Notes:

16. t

CS

and tCH refer to the set-up and hold time requirements of latching data from the boundary scan register.

17. Test conditions are specified using the load in TAP A C test conditions.

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

14

TAP Timing and Test Conditions

(a)

3.0V

V

SS

ALL INPUT PULSES

1.5V

(b)

1.5 ns

1.5 ns

TEST CLOCK

(TCK)

t

THTH

t

THTL

t

TLTH

TEST MODE SELECT

(TMS)

TEST DATA IN

(TDI)

TEST DATA OUT

(TDO)

t

MVTHtTHMX

t

DVTH

t

THDX

t

TLQX

t

TLQV

Vt = 1.5V

TDO

Z

0

= 50

Ω

50

Ω

20 pF

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

15

Identification Register Definiti ons

Instruction Field 256K x 36 512K x 18 Description

REVISION NUMBER

(31:28)

XXXX XXXX Reserved for revision number.

DEVICE DEPTH

(27:23)

00110 00111 Defines depth of 256K or 512K words.

DEVICE WIDTH

(22:18)

00100 00011 Defines width of x36 or x18 bits.

RESERVED

(17:12)

XXXXXX XXXXXX Reserved for future use.

CYPRESS JEDEC ID

CODE (11:1)

00011100100 00011100100 Allows unique identification of DEVICE vendor.

ID Register Presence

Indicator (0)

1 1 Indicates the presence of an ID register.

Scan Register Sizes

Register Name Bit Size (x36) Bit Size (x18)

Instruction 3 3

Bypass 1 1

ID 32 32

Boundary Scan 70 51

Instruction Codes

Instruction Code Description

EXTEST 000 Captures I/O ring contents. Place s the bounda ry scan register betw een TDI

and TDO. Forces all device outputs to High-Z state. This instruction is not

IEEE 1149.1-compliant.

IDCODE 001 Preloads ID register with vendor ID code and places it between TDI and

TDO. This instruction does not affect device operations.

SAMPLE-Z 010 Captures I/O ring contents. Place s the bounda ry scan register betw een TDI

and TDO. Forces all device outputs to High-Z state.

RESERVED 011 Do not use these instructions; they are reserved for future use.

SAMPLE/PRELOAD 100 Captures I/O ring contents. Place s the bounda ry scan register betw een TDI

and TDO. This instruction do es not aff ect de vice oper ations. Thi s instruction

does not implement IEEE 1149.1 PRELOAD function and is therefore not

1149.1-compliant.

RESERVED 101 Do not use these instructions; they are reserved for future use.

RESERVED 110 Do not use these instructions; they are reserved for future use.

BYPASS 111 Places the by pass registe r between TDI and TDO . Thi s instruction doe s not

affect device operations.

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

16

Boundary Scan Order (256K x 36)

Bit#

Signal

Name TQFP Bump ID

1 A 44 2R

2 A 45 3T

3 A 46 4T

4 A 47 5T

5 A 48 6R

6 A 49 3B

7 A 50 5B

8 DQa 51 6P

9 DQa 52 7N

10DQa536M

11 DQa 56 7L

12 DQa 57 6K

13 DQa 58 7P

14 DQa 59 6N

15 DQa 62 6L

16 DQa 63 7K

17 ZZ 64 7T

18 DQb 68 6H

19 DQb 69 7G

20 DQb 72 6F

21 DQb 73 7E

22 DQb 74 6D

23 DQb 75 7H

24 DQb 78 6G

25 DQb 79 6E

26 DQb 80 7D

27 A 81 6A

28 A 82 5A

29 ADV

83 4G

30 ADSP

84 4A

31 ADSC

85 4B

32 OE

86 4F

33 BWE

87 4M

34 GW

88 4H

35 CLK 89 4K

36 A 92 6B

37 BWa

93 5L

38 BWb

94 5G

39 BWc

95 3G

40 BWd

96 3L

41 CE

2

97 2B

42 CE

98 4E

43 A 99 3A

44 A 100 2A

45 DQc 1 2D

46 DQc 2 1E

47 DQc 3 2F

48 DQc 6 1G

49 DQc 7 2H

50 DQc 8 1D

51 DQc 9 2E

52 DQc 12 2G

53 DQc 13 1H

54 NC 14 5R

55 DQd 18 2K

56 DQd 19 1L

57DQd222M

58 DQd 23 1N

59 DQd 24 2P

60 DQd 25 1K

61 DQd 28 2L

62 DQd 29 2N

63 DQd 30 1P

64 MODE 31 3R

65 A 32 2C

66 A 33 3C

67 A 34 5C

68 A 35 6C

69 A1 36 4N

70 A0 37 4P

Boundary Scan Order (256K x 36)

(continued)

Bit#

Signal

Name TQFP Bump ID

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

17

Boundary Scan Order (512K x 18)

Bit#

Signal

Name TQFP Bump ID

1 A 44 2R

2 A 45 2T

3 A 46 3T

4 A 47 5T

5 A 48 6R

6 A 49 3B

7 A 50 5B

8 DQa 58 7P

9 DQa 59 6N

10 DQa 62 6L

11 DQa 63 7K

12 ZZ 64 7T

13 DQa 68 6H

14 DQa 69 7G

15 DQa 72 6F

16 DQa 73 7E

17 DQa 74 6D

18 A 80 6T

19 A 81 6A

20 A 82 5A

21 ADV

83 4G

22 ADSP

84 4A

23 ADSC

85 4B

24 OE

86 4F

25 BWE

87 4M

26 GW

88 4H

27 CLK 89 4K

28 A 92 6B

29 BWa

93 5L

30 BWb

94 3G

31 CE

2

97 2B

32 CE

98 4E

33 A 99 3A

34 A 100 2A

35 DQb 8 1D

36 DQb 9 2E

37 DQb 12 2G

38 DQb 13 1H

39 NC 14 5R

40 DQb 18 2K

41 DQb 19 1L

42DQb222M

43 DQb 23 1N

44 DQb 24 2P

45 MODE 31 3R

46 A 32 2C

47 A 33 3C

48 A 34 5C

49 A 35 6C

50 A1 36 4N

51 A0 37 4P

Boundary Scan Order (512K x 18)

(continued)

Bit#

Signal

Name TQFP Bump ID

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

18

Maximum Ratings

(Above which the useful life may be impaired. For user guidelines, not tested.)

Voltage on VCC Supply Relative to VSS.........–0.5V to +4.6V

V

IN

...........................................................–0.5V to VCC+0.5V

Storage Temperature (plastic) .......................–55°C to +150°

Junction Temperature ...................................................+150°

Po w er Di ssip ati on ..................................................... ....1.0W

Short Circuit Output Current........................................ 50 mA

Operating Range

Range

Ambient

Temperature

[18]

V

CC

Com’l 0°C to +70°C 3.3V –5% / +10%

Electrical Characteristics

Over the Operating Range

Parameter Description Test Conditions Min. Max. Unit

V

IHD

Input High (Logic 1) Voltage

[13, 19]

Data Inputs (DQx) 2.0 VCC+0.3 V

V

IH

All Other Inputs 2.0 4.6 V

V

Il

Input Low (Logic 0) Voltage

[13, 19]

–0.5 0.8 V

IL

I

Input Leakage Current 0V < VIN < V

CC

–5 5 µA

IL

I

MODE and ZZ Inpu t Leak age Cu rrent

[20]

0V < VIN < V

CC

–30 30 µA

IL

O

Output Leakage Current Output(s) disabled,

0V <

V

OUT

< V

CC

–5 5 µA

V

OH

Output High Voltage

[13]

IOH = –5.0 mA 2.4 V

V

OL

Output Low Voltage

[13]

IOL = 8.0 mA 0.4 V

V

CC

Supply Voltage

[13]

3.135 3.6 V

V

CCQ

I/O Supply Voltage (3.3V)

[13]

3.135 V

CC

V

V

CCQ

I/O Supply Voltage (2.5V)

[13]

2.375 V

CC

V

Parameter Description Conditions Typ. -4.4 -5 -6 -6.7 Unit

I

CC

Power Supply Current:

Operating

[21, 22, 23]

Device selected; all inputs < VILor >

V

IH

; cycle time > tKC min.; VCC = Max.;

outputs open

150 570 510 425 380 mA

I

SB2

CMOS Standby

[22, 23]

Device deselected; VCC = Max.;

all inputs <

VSS + 0.2 or > VCC – 0.2;

all inputs static; CLK freq uency = 0

5 10101010mA

I

SB3

TTL Standby

[22, 23]

Device deselected; all inputs < VIL

or > VIH; all inputs static;

V

CC

= Max. CLK frequency = 0

15 30 30 30 30 mA

I

SB4

Clock Running

[22, 23]

Device deselected;

all inputs <

VIL or > VIH; VCC = Max.;

CLK cycle time > tKC Min.

40 125 110 90 80 mA

Capacitance

[15]

Parameter Description Test Conditions Typ. Max. Unit

C

I

Input Capacitance TA = 25°C, f = 1 MHz,

V

CC

= 3.3V

5 7 pF

C

O

Input/Output Capacitance (DQ) 7 8 pF

Notes:

18. T

A

is the case temperature.

19. Overshoot: V

IH

< +6.0V for t < tKC /2

Undershoot:V

IL

< –2.0V for t < tKC /2.

20. Output loading is specified with C

L

=5 pF as in AC Test Loads.

21. I

CC

is given with no output current. ICC increases with greater output loading and faster cycle times.

22. “Device Deselected” means the device is in Power-Down mode as defined in the truth table. “Device Selected” means the device is active.

23. Typical values are measured at 3.3V, 25°C, and 20 ns cycle time.

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

19

Thermal Resistance

Description Test Conditions Symbol TQFP Typ. Units

Thermal Resistance (Junction to Ambient) Still Air, soldered on a 4.25 x 1.125 inch,

4-layer PCB

Θ

JA

25 °C/W

Thermal Resistance (Junction to Case) Θ

JC

9 °C/W

DQ

317

Ω

351

Ω

5pF

(a) (b)

DQ

50

Ω

Z

0

=50

Ω

V

t

= 1.5V

3.3V

ALL INPUT PULSES

3.0V

0V

90%

10%

90%

10%

≤

1.0 ns

≤

1.0 ns

(c)

AC Test Loads and Waveforms for 3.3V I/O

(a)

DQ

50

Ω

Z

0

=50

Ω

V

t

= 1.25V

ALL INPUT PULSES

2.5V

0V

90%

10%

90%

10%

≤

1.0 ns

≤

1.0 ns

(c)

AC Test Loads and Waveforms for 2.5V I/O

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

20

Switching Characteristics

Over the Operat ing Range

[24]

Description

-4.4

225 MHz

-5

200 MHz

-6

166 MHz

-6.7

150 MHz

Parameter Min. Max. Min. Max. Min. Max. Min. Max. Unit

Clock

t

KC

Clock Cycle Time 4.4 5.0 6.0 6.7 ns

t

KH

Clock HIGH Time 1.7 2.0 2.4 2.6 ns

t

KL

Clock LOW Time 1.7 2.0 2.4 2.6 ns

Output Times

t

KQ

Clock to Output Valid V

CCQ

= 3.3V 2.5 3.0 3.5 3.5 ns

V

CCQ

= 2.5V 3.0 3.5 4.0 4.5

t

KQX

Clock to Output Invalid 1.25 1.25 1.25 1.25 ns

t

KQLZ

Clock to Output in Low-Z

[15, 25, 26]

0 0 0 0 ns

t

KQHZ

Clock to Output in High-Z

[15, 25, 26]

1.25 3.0 1.25 3.0 1.25 4.0 1.25 4.0 ns

t

OEQ

OE to Output Valid

[27]

V

CCQ

= 3.3V 2.5 3.0 3.5 3.5 ns

V

CCQ

= 2.5V 3.0 3.5 4.0 4.5

t

OELZ

OE to Output in Low-Z

[15, 25, 26]

0 0 0 0 ns

t

OEHZ

OE to Output in High-Z

[15, 25, 26]

2.5 2.5 3.5 3.5 ns

Set-up Times

t

S

Address, Controls, and Data In

[28]

1.5 1.5 1.5 2.0 ns

Hold Times

t

H

Address, Controls, and Data In

[28]

0.5 0.5 0.5 0.5 ns

Typical Output Buffer Characteristics

Output High Voltage Pull-Up Current Output Low Voltage Pull-Down Current

V

OH

(V) IOH (mA) Min. I

OH

(mA) Max. VOL (V) IOL (mA) Min. I

OL

(mA) Max.

–0.5 –38 –105 –0.5 0 0

0 –38 –105 0 0 0

0.8 –38 –105 0.4 10 20

1.25 –26 –83 0.8 20 40

1.5 –20 –70 1.25 31 63

2.3 0 –30 1.6 40 80

2.7 0 –10 2.8 40 80

2.9 0 0 3.2 40 80

3.4 0 0 3.4 40 80

Notes:

24. Test conditions as specified with the output loading as shown in part (a) of AC Test Loads unless otherwise noted.

25. Output loading is specified with C

L

=5 pF as in part (a) of AC Test Loads.

26. At any given temperature and voltage condition, t

KQHZ

is less than t

KQLZ

and t

OEHZ

is less than t

OELZ

.

27. OE

is a “Don’t Care” when a byte write enable is sampled LOW.

28. This is a synchronous device. All synchronous inputs must meet specified set up and hold time, except for “Don’t Care” as defined in the truth table.

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

21

Switching Waveforms

Read Timing

[29, 30]

Notes:

29. CE

active in this timing diagram means that all chip enables CE, CE2, and CE2 are active. CE2 is only available for TA package version.

30. For the X18 product, there are only BWa

and BWb for byte write control.

CLK

ADSP#

ADSC#

ADDRESS

BWa#, BWb#,

BWc#, BWd#

BWE#, GW#

CE#

ADV#

OE#

DQ

A1 A2

Q(A1) Q(A2) Q(A2+1) Q(A2+2) Q(A2+3) Q(A2) Q(A2+1)

t

KQ

t

KQLZ

t

OELZ

t

KQ

t

S

t

H

t

KH

t

KL

t

KC

t

OEQ

SINGLE READ BURST READ

t

H

t

H

t

S

t

S

t

S

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

22

Write Timing

[29, 30]

Switching Waveforms

(continued)

CLK

ADSP#

ADSC#

ADDRESS

CE#

ADV#

OE#

DQ

A1 A2

D(A2) D(A2+2) D(A2+3) D(A3) D(A3+1) D(A3+2)

t

S

t

H

GW#

A3

D(A1) D(A2+1)

t

KQX

t

OEHZ

Q D(A2+1)

SINGLE WRITE

BURST WRITE

BURST WRITE

t

H

t

H

t

S

t

S

BWa#, BWb#,

BWc#, BWd#,

BWE#

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

23

Read/Write Timing

[29, 30]

Switching Waveforms

(continued)

CLK

ADSP#

ADSC#

ADDRESS

CE#

ADV#

OE#

DQ

A1

A2 A3

Q(A1) Q(A2)

t

S

t

H

t

S

t

H

A4

D(A3) Q(A4) Q(A4+1) Q(A4+2) D(A5) D(A5+1)

Single Write Burst Read Burst WriteSingle Reads

A5

BWa#, BWb#,

BWc#, BWd#,

BWE#, GW#

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

24

Ordering Information

Speed

(MHz) Ordering C ode

Package

Name Package Type

Operating

Range

225 CY7C1360A-225AJC/

GVT71256D36T-4.4

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k Commercial

CY7C1360A-225AC/

GVT71256D36TA-4.4

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1360A-225BGC/

GVT71256D36B-4.4

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

200 CY7C1360A-200AJC/

GVT71256D36T-5

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1360A-200AC/

GVT71256D36TA-5

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1360A-200BGC/

GVT71256D36B-5

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

166 CY7C1360A-166AJC/

GVT71256D36T-6

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1360A-166AC/

GVT71256D36TA-6

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1360A-166BGC/

GVT71256D36B-6

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

150 CY7C1360A-150AJC/

GVT71256D36T-6.7

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1360A-150AC/

GVT71256D36TA-6.7

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1360A-150BGC/

GVT71256D36B-6.7

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

25

225 CY7C1362A-225AJC/

GVT71512D18T-4.4

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k Commercial

CY7C1362A-225AC/

GVT71512D18TA-4.4

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1362A-225BGC/

GVT71512D18B-4.4

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

200 CY7C1362A-200AJC/

GVT71512D18T-5

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1362A-200AC/

GVT71512D18TA-5

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1362A-200BGC/

GVT71512D18B-5

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

166 CY7C1362A-166AJC/

GVT71512D18T-6

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1362A-166AC/

GVT71512D18TA-6

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1362A-166BGC/

GVT71512D18B-6

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

150 CY7C1362A-150AJC/

GVT71512D18T-6.7

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1362A-150AC/

GVT71512D18TA-6.7

A101 100-Lead 1 4 x 20 x 1.4 mm Th in Quad Flat P ac k

CY7C1362A-150BGC/

GVT71512D18B-6.7

BG119 119-Lead FBGA (14 x 22 x 2.4 mm)

Document #: 38-00990-*A

Ordering Information

(continued )

Speed

(MHz) Ordering C ode

Package

Name Package Type

Operating

Range

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

26

Package Diagram s

100-Pin Thin Plastic Quad Flatpack (14 x 20 x 1.4 mm) A101

51-85050-A

CY7C1360A/GVT71256D36

CY7C1362A/GVT71512D18

PRELIMINARY

© Cypress Semiconductor Corporation, 2001. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use

of any circuitry other than circui try embodied in a Cypress S emiconductor p roduct. Nor does i t conv ey or imply an y license under pa tent or other rights. Cypress S emiconductor doe s not authorize

its products for use as critical components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress

Semiconductor products in life-support systems application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress Semiconductor against all charges.

Package Diagram s

(continued)

119-Lead FBGA (14 x 22 x 2.4 mm) BG119

51-85115

Loading...

Loading...