Cypress Semiconductor CY37256P208-125NI, CY37256P208-125NC, CY37256P160-83AI, CY37256P160-83AC, CY37256P160-154AC Datasheet

...

5V, 3.3V, ISR™ High-Performance CPLD

s

Ultra37000 CPLD Fami

ly

Cypress Semiconductor Corporation • 3901 North First Street • San Jose, CA 95134 • 408-943-2600

Document #: 38-03007 Rev. *B Revised May 7, 2 003

Features

• In-System Reprogrammable™ (ISR™) CMOS CPLDs

—JT AG interface for reconfigu rabili ty

—Design changes do not cause pinout changes

—Design changes do not cause timing changes

• High density

—32 to 512 macrocells

—32 to 264 I/O pins

—Five dedicated inputs including four clock pins

• Simple timing model

—No fanout delays

—No expande r delays

—No dedicated vs. I/O pin delays

—No additional delay through PIM

—No penalty for using full 16 product terms

—No delay for steering or sharing product terms

• 3.3V and 5V versions

• PCI-compatible

[1]

• Programmable bus-hold capabilities on all I/Os

• Intelligent product term allocator provides:

—0 to 16 product terms to any macrocell

—Product term steering on an individual basis

—Product term sharing among local macrocells

• Flexible clocking

—Four synchronous clocks per device

—Product term clocking

—Clock polarity control per logic block

• Consistent packa ge/pinout offering across al l densities

—Simplifies design migration

—Same pinout for 3.3V and 5.0V devices

• Packages

—44 to 400 leads in PLCC, CLCC, PQFP, TQFP, CQFP,

BGA, and Fine-Pitch BGA packages

General Description

The Ultra37000™ fam ily of CMOS CPLDs pr ovides a range of

high-density programmable logic solutions with unparalleled

system performance. The Ultra37000 family is designed to

bring the flexibil ity , ease of use, and performance of th e 22V10

to high-density CP LDs. The arch itecture is based on a number

of logic bloc ks that are co nnected by a P rogrammab le Interconnect Matrix (PIM). Each logic block features its own

product term array, product term allocator, and 16 mac rocell s.

The PIM distributes signals from the logic block ou tputs and all

input pins to the logic block inputs.

All of the Ul t ra3 7 00 0 de vi ce s a re el ec t rically eras ab le a n d I n System Reprogrammable (ISR), which simplifies both design

and manufacturing flows, thereby reducing costs. The ISR

feature provides the ability to reconfigure the devices without

having design changes cause pinout or timing changes. The

Cypress ISR function is implemented through a JTAGcompliant serial interface. Data is shifted in and out through

the TDI and TDO pins, respectively. Because of the superior

routability an d simp le t iming model of the Ul tra370 00 devi ces,

ISR allows users to ch ange exis ting logic designs whi le simultaneously fixing pinout assignments and maintaining system

performance.

The entire family features JTAG for ISR and boundary scan,

and is compatible with the PCI Local Bus specification,

meeting the electrical and timing requirements. The

Ultra37000 family features user programmable bus-hold

capabilities on all I/Os.

Ultra37000 5.0V Devices

The Ultra37000 devices operate with a 5V supply and can

support 5V or 3.3V I/O levels. V

CCO

connections pr ovide th e

capability of interfacing to either a 5V or 3.3V bus. By

connecting the V

CCO

pins to 5V the user insures 5V TT L levels

on the outputs. If V

CCO

is connected to 3.3V the output levels

meet 3.3V JEDEC standard CMOS levels and are 5V tolerant.

These devices require 5V ISR programming.

Ultra37000V 3.3V Devices

Devices operating with a 3.3V suppl y require 3.3V o n all V

CCO

pins, reducing the device’s power consumption. These

devices support 3.3V JEDEC standard CMOS output levels,

and are 5V-tolerant. These devices allow 3.3V ISR

programming.

Note:

1. Due to the 5V-tolerant nature of 3.3V device I/Os, the I/Os are not clamped to V

CC

, PCI V

IH

= 2V.

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 2 of 63

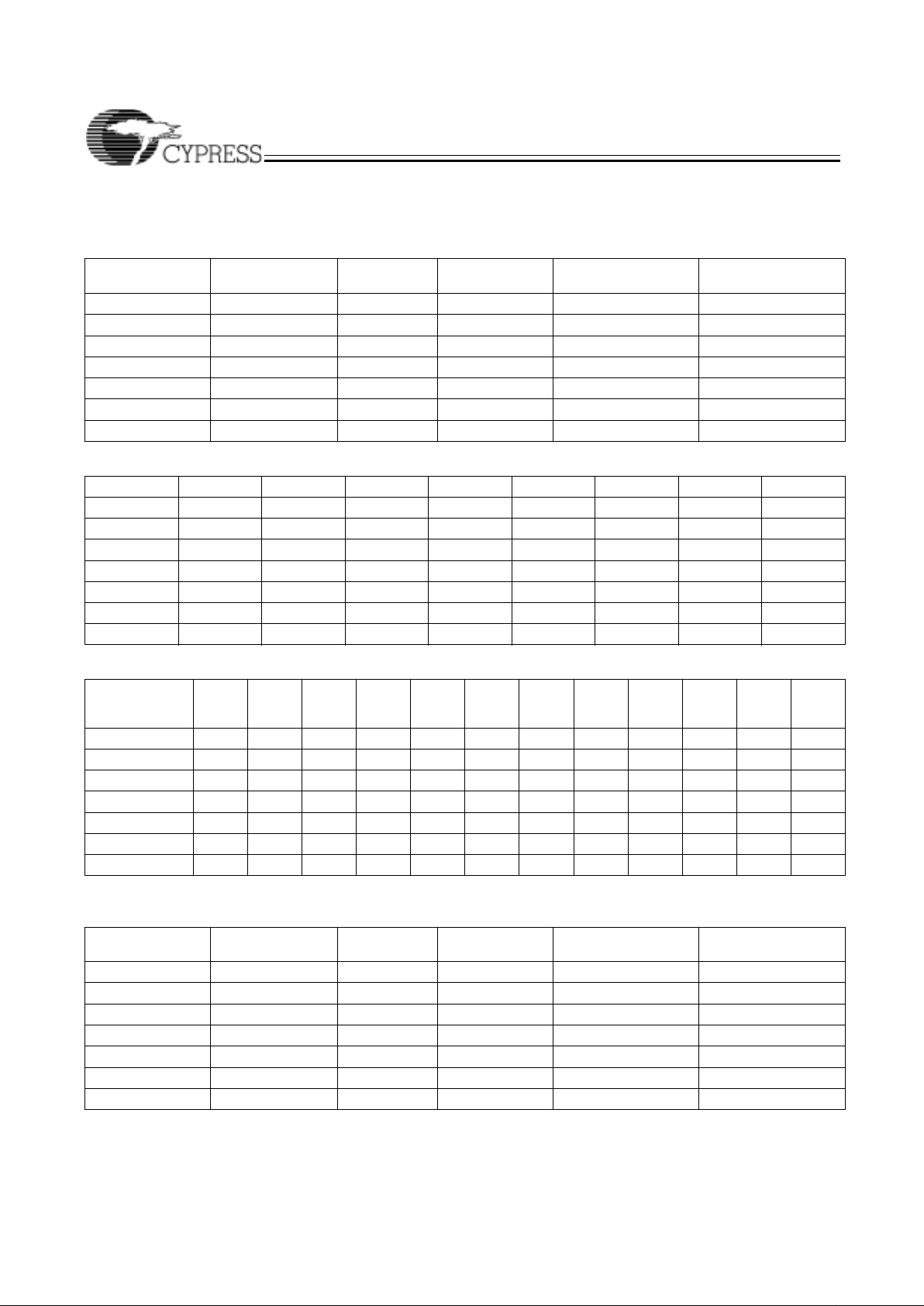

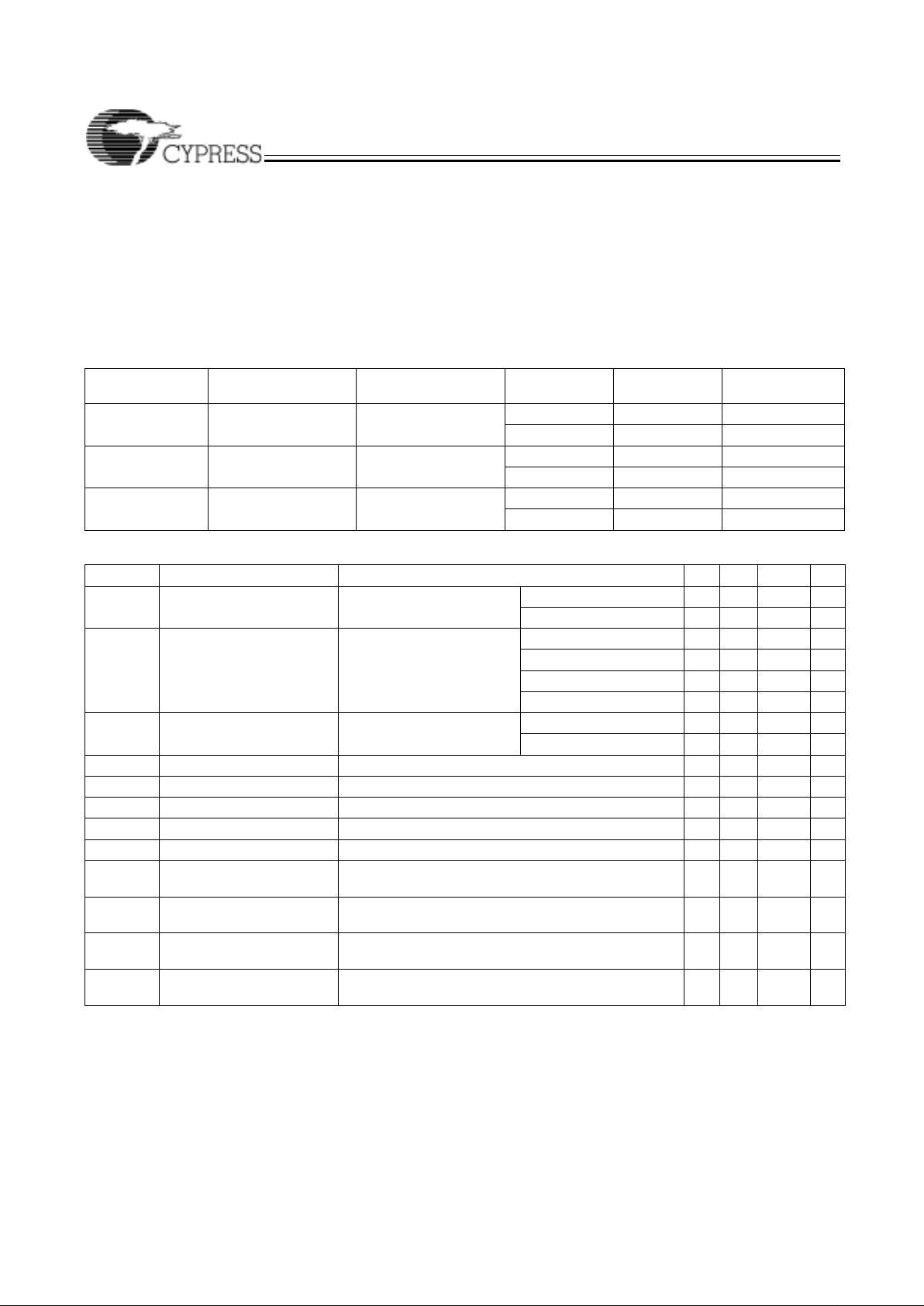

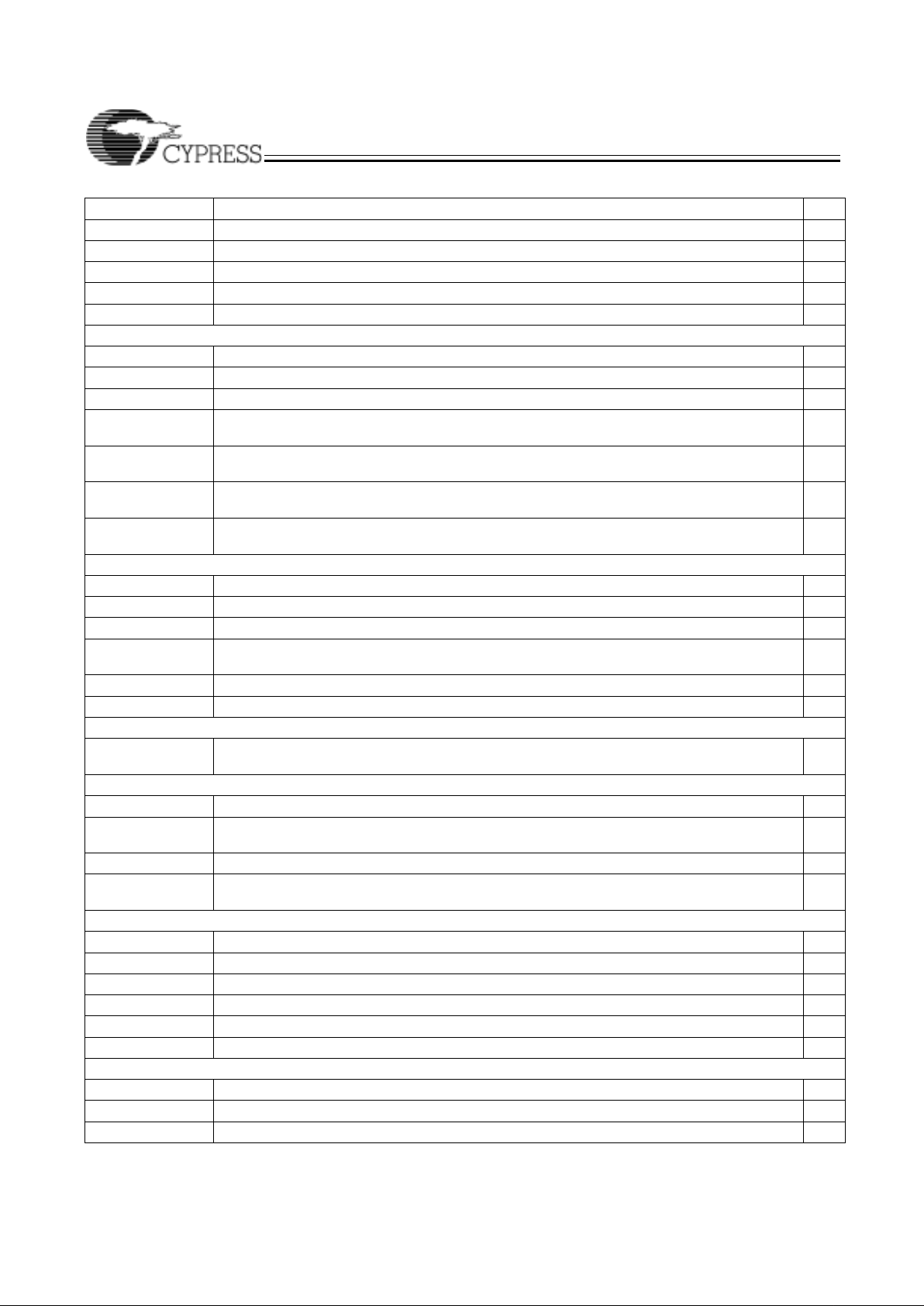

Selection Guide

5.0V Selection Guide

3.3V Selection Guide

General Information

Device Macrocells

Dedicated

Inputs I/O Pins Speed (t

PD

) Speed (f

MAX

)

CY37032 32 5 32 6 200

CY37064 64 5 32/64 6 200

CY37128 128 5 64/128 6.5 167

CY37192 192 5 120 7.5 154

CY37256 256 5 128/160/192 7.5 154

CY37384 384 5 160/192 10 118

CY37512 512 5 160/192/264 10 118

Speed Bins

Device 200 167 154 143 125 100 83 66

CY37032 X X X

CY37064 X X X

CY37128 X X X

CY37192 X X X

CY37256 X X X

CY37384 X X

CY37512 X X X

Device-Package Offering and I/O Count

Device

44-

Lead

TQFP

44-

Lead

PLCC

44-

Lead

CLCC

84-

Lead

PLCC

84-

Lead

CLCC

100-

Lead

TQFP

160-

Lead

TQFP

160-

Lead

CQFP

208-

Lead

PQFP

208-

Lead

CQFP

256Lead

BGA

352Lead

BGA

CY37032 37 37

CY37064 37 37 37 69 69

CY37128 69 69 69 133

CY37192 125

CY37256 133 133 165 197

CY37384 165 197

CY37512 165 165 197 269

General Information

Device Macrocells

Dedicated

Inputs I/O Pins Speed (t

PD

) Speed (f

MAX

)

CY37032V 32 5 32 8.5 143

CY37064V 64 5 32/64 8.5 143

CY37128V 128 5 64/80/128 10 125

CY37192V 192 5 120 12 100

CY37256V 256 5 128/160/192 12 100

CY37384V 384 5 160/192 15 83

CY37512V 512 5 160/192/264 15 83

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 3 of 63

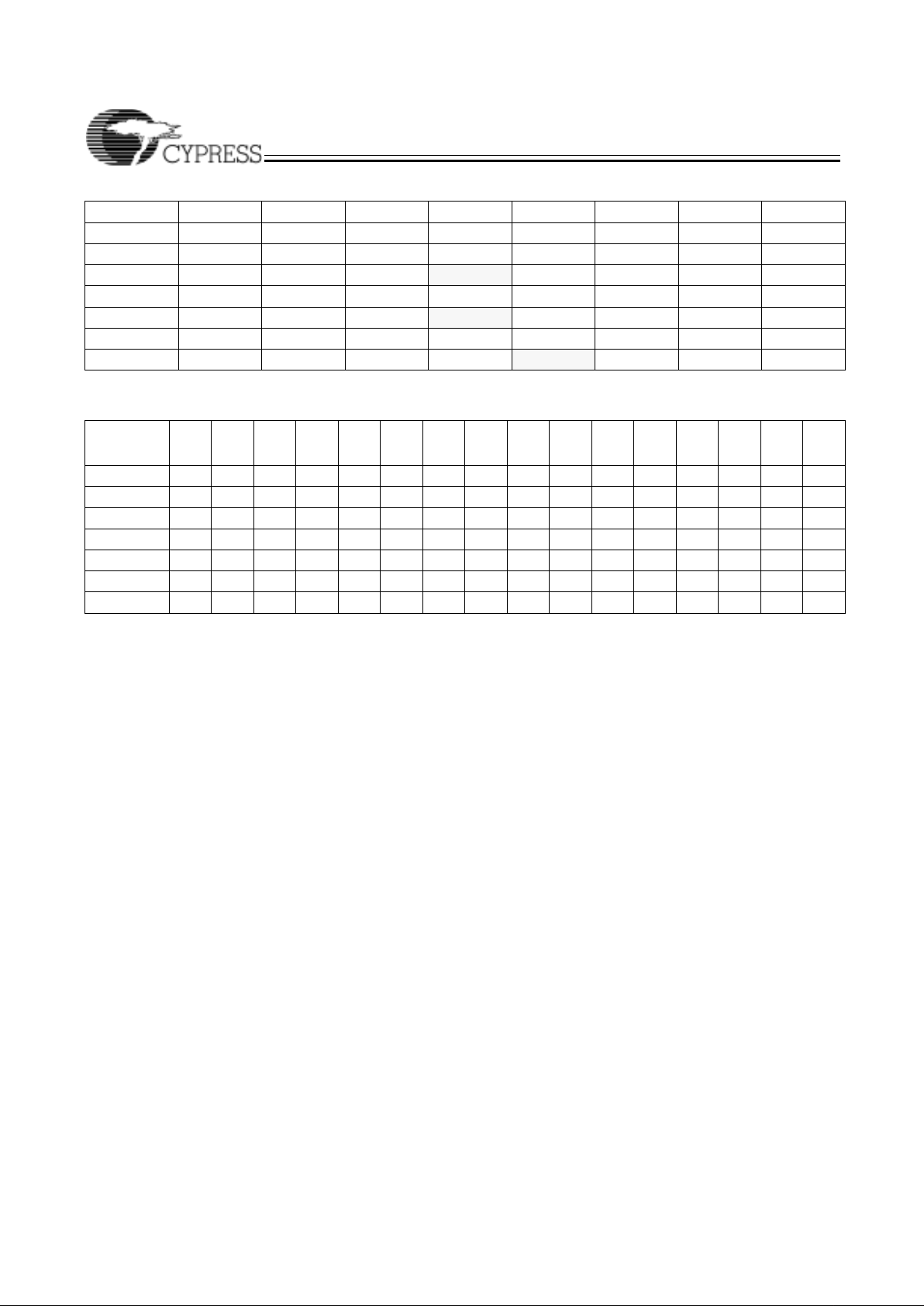

Architecture Overview of Ultra37000 Family

Programmable Interconnect Matrix

The Programmable Interconnect Matrix (PIM) consists of a

completely global routing matrix for signals from I/O pins and

feedbacks from the logic blocks. The PIM provides extremely

robust interconnection to avoid fitting and density limitations.

The inputs to the PIM consist of all I/O and dedicated input pins

and all mac r oc el l fe ed ba c ks fr om w i thi n t h e lo g ic b lo ck s. Th e

number of PIM input s increases with pin co unt and the number

of logic blocks. The outputs from the PIM are signals ro uted to

the appropriate logic blocks. Each logic block receives 36

inputs from the PIM and their compl ements, allow ing for 32-bit

operations to be implemented in a single pass through the

device. The wide number of inputs to the logic block also

improves the routing capacity of the Ultra37000 family.

An important feature of the PIM is its simple timing. The propagation delay through the PIM is accounted for in the timing

specifications fo r each devi ce. Th ere is no ad dition al del ay for

traveling through the PIM. In fact, all inputs travel through the

PIM. As a result, there are no route-dependent timing parameters on the Ultra37000 devices. The worst-case PIM delays

are incorporated in all appropriate Ultra37000 specifications.

Routing signals through the PIM is completely invisible to the

user . All routing is accomplished by software—no hand routing

is necessary. Warp™ and third- party dev elopm ent packag es

automatically route designs for the Ultra37000 family in a

matter of minutes. Finally, the rich routing resources of the

Ultra37000 family accommodate last minute logic changes

while maintaining fixed pin assignments.

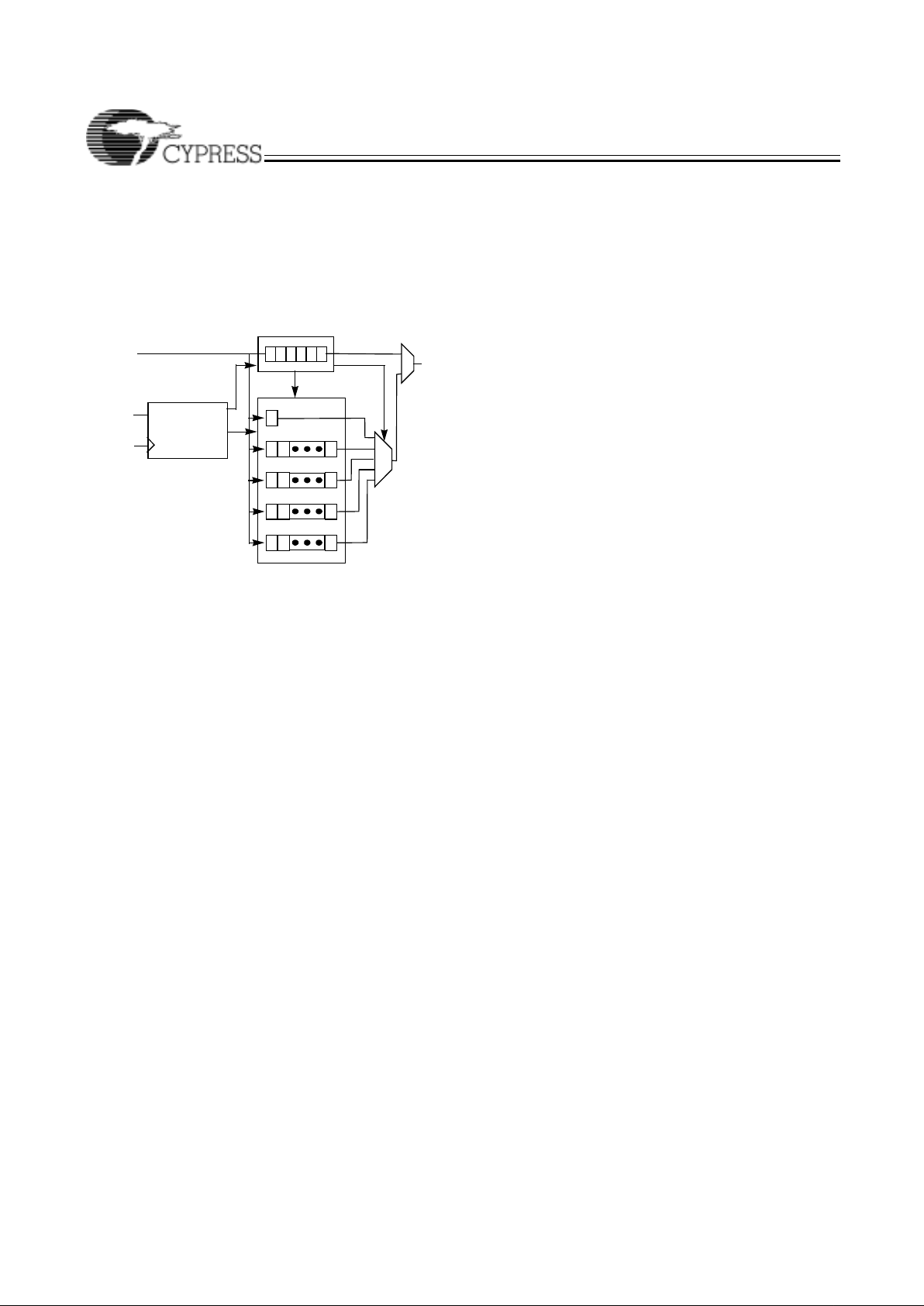

Logic Block

The logic block is the basic building block of the Ultra37000

architect ure. It consis ts of a prod uct te rm arra y, an intelligen t

product-term allocator, 16 macrocells, and a number of I/O

cells. The number of I/O cells varies depending on the device

used. Refe r to Figure 1 for the block diagram.

Product Term Array

Each logic block features a 72 x 87 programmable product

term array. This array accepts 36 inputs from the PIM, which

originate from macrocell feedbacks and device pins. Active

LOW and active HIGH versions of each of these inputs are

generated to create the full 72-input field. The 87 product

terms in the array can be created from any of the 72 inputs.

Of the 87 product terms, 80 are for general-purpose use for

the 16 macrocells in the logic block. Four of the remaining

seven product terms i n the logic block are ou tpu t en abl e (O E)

product terms. Each of the OE product terms controls up to

eight of the 16 macrocells and is selectable on an individual

macrocell basis. In other words, each I/O cell can select

between one of two OE product terms to control the output

buffer. The first two of these four OE product terms are

available to the upper half of the I/ O macrocells in a logic block.

The other two OE product te rms are a vailabl e to the lower half

of the I/O macrocells in a logic block.

The next two product terms in each logic block are dedicated

asynchronous set and asynchronous reset product terms. The

final product te rm is th e produ ct term clo ck. The set, r eset, OE

and product term clock have polarity control to realize OR

functions in a single pass through the array.

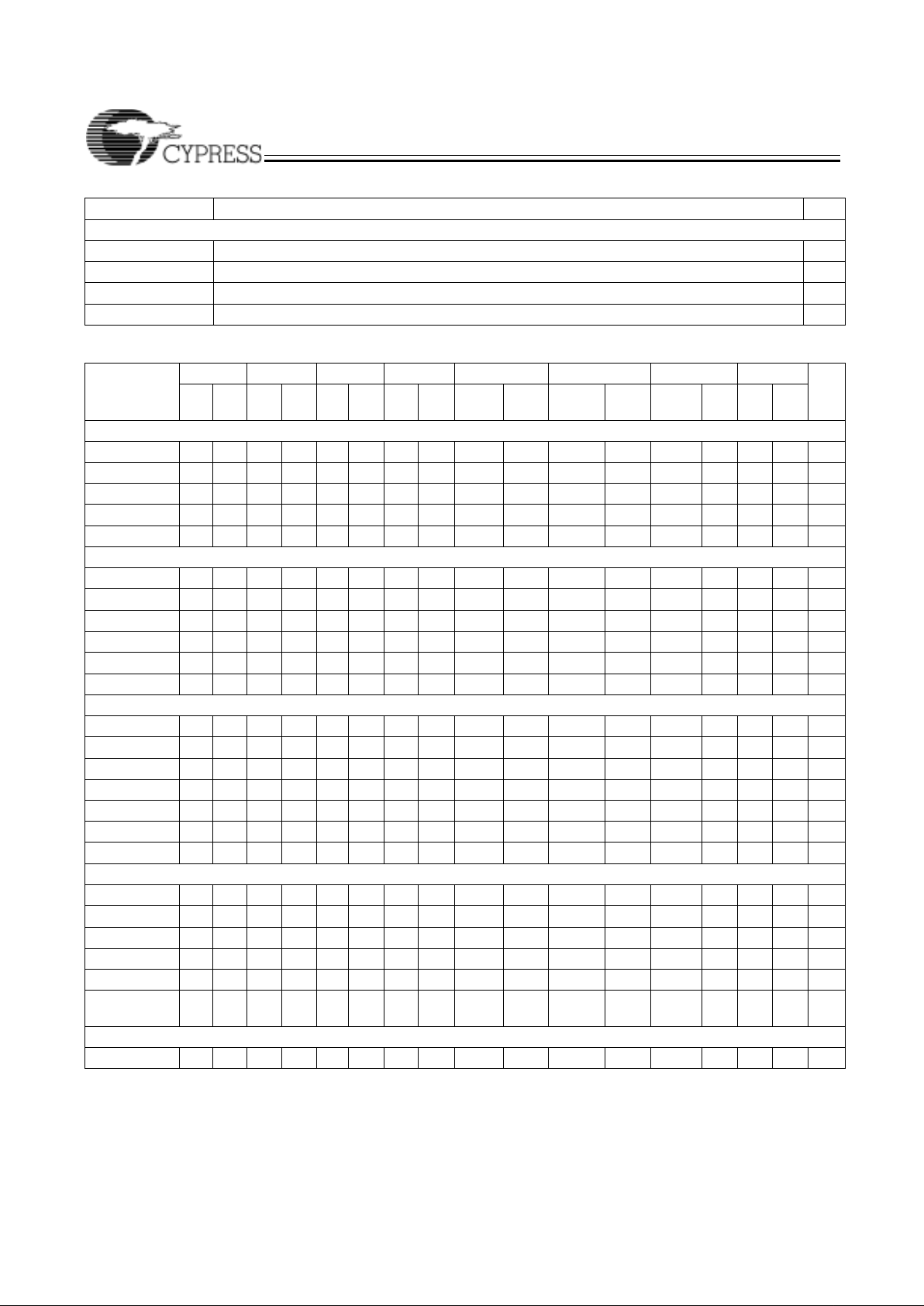

Speed Bins

Device 200 167 154 143 125 100 83 66

CY37032V X X

CY37064V X X

CY37128V

XX X

CY37192V XX

CY37256V XXX

CY37384V XX

CY37512V

XXX

Shaded areas indicate preliminary speed bins.

Device-Package Offering & I/O Count

Device

44-

Lead

TQFP

44-

Lead

PLCC

44-

Lead

CLCC

48-

Lead

FBGA

84-

Lead

PLCC

84-

Lead

CLCC

100-

Lead

TQFP

100-

Lead

FBGA

160-

Lead

TQFP

160-

Lead

CQFP

208-

Lead

PQFP

208-

Lead

CQFP

256-

Lead

BGA

256-

Lead

FBGA

352-

Lead

BGA

400-

Lead

FBGA

CY37032V 37 37 37

CY37064V 37 37 37 37 69 69 69

CY37128V 69 69 69 85 133

CY37192V 125

CY37256V 133 133 165 197 197

CY37384V 165 197

CY37512V 165 165 197 269 269

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 4 of 63

Low-Power Option

Each logic block can operate in high-speed mode for critical

path performance, or in low-power mode for power conservation. The logic bloc k mode is se t by the user on a l ogic block

by logic block basis.

Product Term Allocator

Through the product term allocator, software automatically

distributes product terms among the 16 macrocells in the logic

block as needed. A total of 80 p roduct terms are available from

the local product term array. The product term allocator

provides two important capabilities without affecting performance: product term steering and product term sharing.

Product Term Steering

Product term steering is the process of assigning product

terms to macrocell s as neede d. For e xamp le, if o ne ma croce ll

requires ten produc t terms whi le anot her need s just th ree, the

product term allocator will “steer” ten product terms to one

macrocell and three to the other. On Ultra37000 devices,

product terms are steere d on an ind ividu al bas is. Any n umber

between 0 and 16 product terms can be steered to any

macrocell. Note that 0 product terms is useful in cases where

a particular macrocell is unused or used as an input register.

Product Term Sharing

Product term sharing i s the process of using the same p roduct

term among multiple macrocells. For example, if more than

one output has one or more product terms in its equation that

are common to other outputs, those product terms are only

programmed once. The Ultra37000 product term allocator

allows sharing across groups of four output macrocells in a

variable fashion. The software automatically takes advantage

of this capability—the user does not have to intervene.

Note that neither product term sharing nor product term

steering have any effect on the speed of the product. All worstcase steering and sharing configurations have been incorporated in the timing specifications for the Ultra37000 devices.

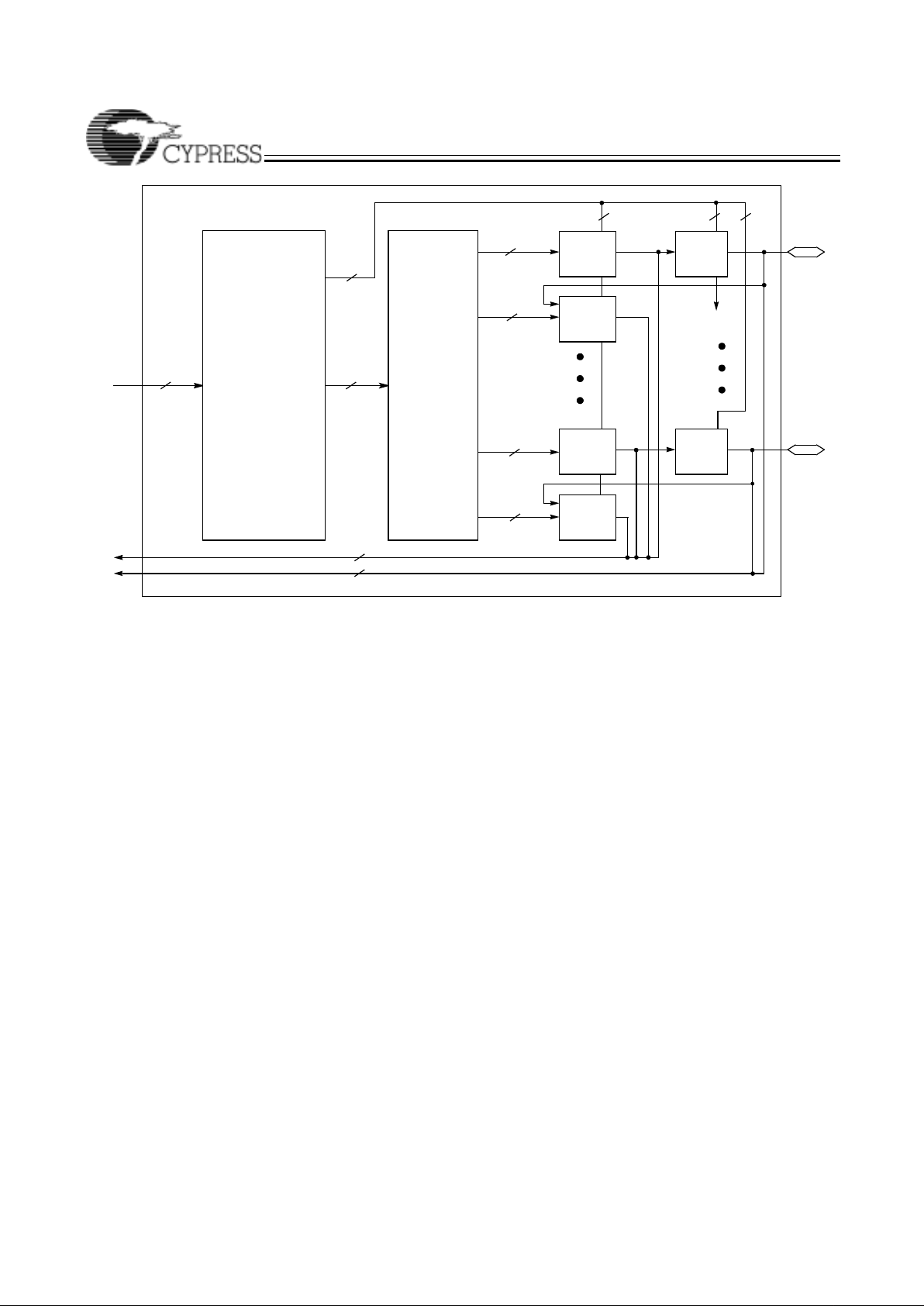

Ultra37000 Macrocell

Within each logic block there are 16 macrocells. Macrocells

can either be I/O Macrocells, which include an I/O Cell which

is associated with an I/O pin, or buried Macrocells, which do

not connect to an I/O. The combination of I/O Macrocells and

buried Macrocells varies from device to device.

Buried Macrocell

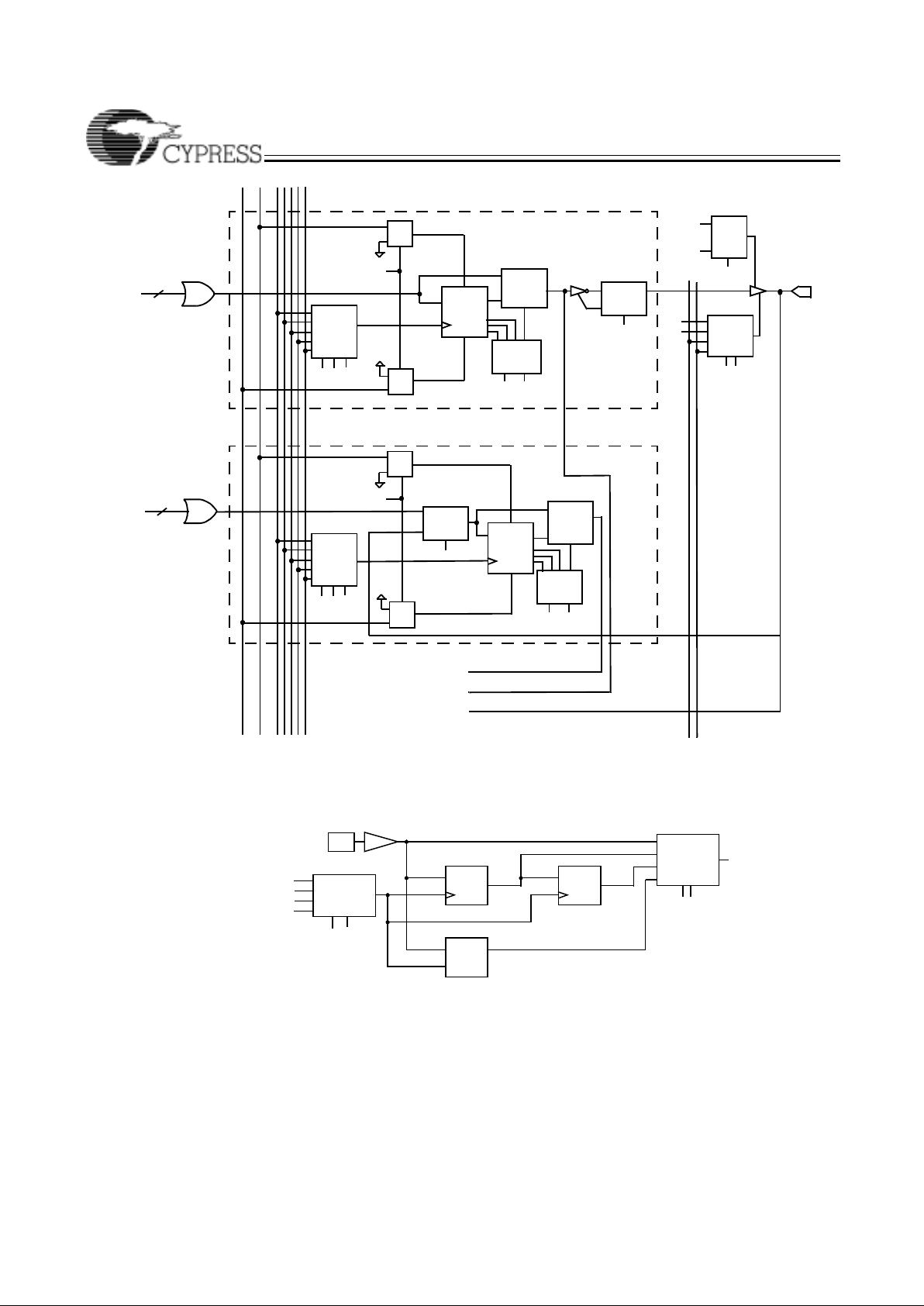

Figure 2 displays the architecture of buried macrocells. The

buried macrocell features a register tha t can be confi gured as

combinatorial, a D flip-flop, a T flip-flop, or a level-triggered

latch.

The register can be asynchronously set or asynchronously

reset at the logic block level with the separate set and reset

product terms. Each of these pro duct terms features programmable polarity. This allows the registers to be set or reset

based on an AND expression or an OR expression.

Clocking of the register is very flexible. Four global

synchronous clocks and a product term clock are available to

clock the register. Furthermore, each clock features programmable polarity so that registers can be triggered on falling as

well as rising edges (see the Clo cking sec tio n). Cloc k pol ari t y

is chosen at the logic block level.

The buried macrocell also supports input register capability.

The buried macrocell can be configured to act as an input

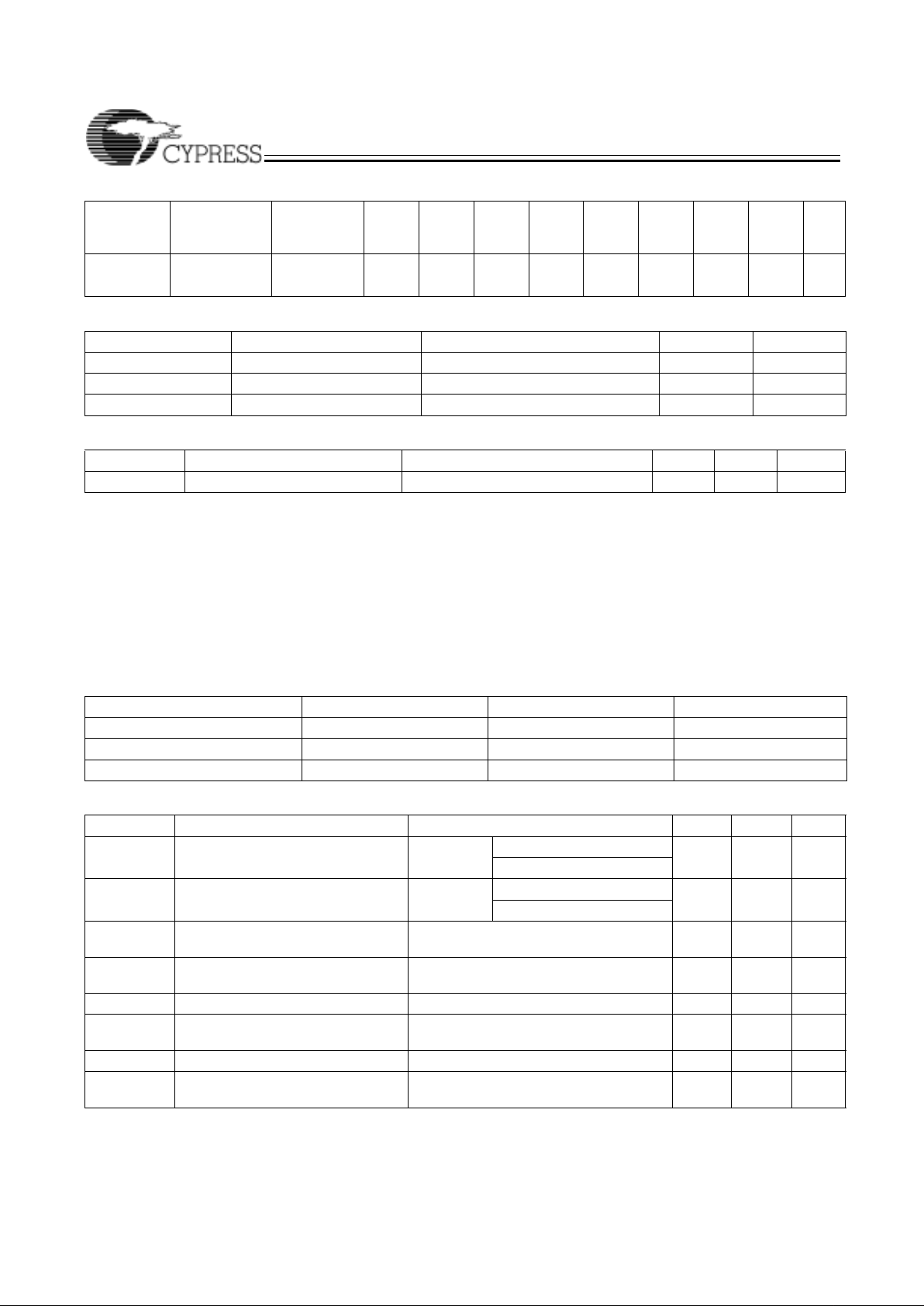

Figure 1. Logic Block with 50% Buried Macrocells

I/O

CELL

0

PRODUCT

TERM

ALLOCATOR

I/O

CELL

14

MACRO-

CELL

0

MACRO-

CELL

1

MACRO-

CELL

14

0−16

PRODUCT

TERMS

72 x 87

PRODUCT TERM

ARRAY

8036

8

16

TO

PIM

FROM

PIM

7

3

2

MACRO-

CELL

15

2

to cells

2, 4, 6 8, 10, 12

0−16

PRODUCT

TERMS

0−16

PRODUCT

TERMS

0−16

PRODUCT

TERMS

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 5 of 63

register (D-type or latch) whose input comes from the I/O pin

associated with the neighboring macrocell. The output of all

buried macrocells is sent directly to the PIM regardless of its

configuration.

I/O Macrocell

Figure 2 illustrates the architecture of the I/O macrocell. The

I/O macrocell supports the same functions as the buried

macrocell with the addi tion of I/O capabi lity . At the output of the

macrocell, a polarity control mux is available to select active

LOW or active HIGH signals. This has the added advantage

of allowing significant logic reduction to occur in many applications.

The Ultra37000 m acrocell featu res a feedba ck path to the PIM

separate from the I/O pin input path. This means that if the

macrocell is buried (fed back internally only), the associated

I/O pin can still be used as an input.

Bus Hold Capabilities on all I/Os

Bus-hold, which is an i mprov ed ver sion o f the p opula r intern al

pull-up resistor, is a weak latch connected to the pin that does

not degrade the device’s performance. As a latch, bus-hold

maintains the last state of a pin when the pin is placed in a

high-impedance state, thus reducing system noise in businterface applications. Bus-hold additionally allows unused

device pins to remain unconnected on the board, which is

particularly useful during prototyping as designers can route

new signals to the device without cutting trace connections to

V

CC

or GND. For more informati on, see th e applicati on note

“Understanding Bus-Hold - A Feature of Cypress CPLDs.”

Programmable Slew Rate Control

Each output has a pro grammable c onfiguratio n bit, which sets

the output slew rate t o fast or slow . For design s concerned with

meeting FCC emissi ons st and ards the slo w edge pro vides for

lower system noise. For designs requiring very high performance the fast edge rate provides maximum system performance.

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 6 of 63

f

Figure 2. I/O and Buried Macrocells

Figure 3. Input Macrocell

C2 C3

DECODE

C2 C3

DECODE

0

1

2

3

O

C6

C5

“0”

“1”

0

1

O

D/T/L

Q

R

P

0

1

2

3

O

C0

0

1

O

C4

FEEDBACK TO PIM

FEEDBACK TO PIM

BLOCK RESET

0−16

TERMS

I/O MACROCELL

I/O CELL

FROM PTM

0

1

O

D/T/L Q

R

P

FROM PTM

1

O

C7

FEEDBACK TO PIM

BURIED MACROCELL

0

ASYNCHRONOUS

PRODUCT

0−16

TERMS

PRODUCT

C1

4

0

1

2

3

Q

4

C24

C0C1

C24

C25

C25

4 SYNCHRONOUS CLOCKS (CLK0,CLK1,CLK2,CLK3)

1 ASYNCHRONOUS CLOCK(PTCLK)

BLOCK PRESET

ASYNCHRONOUS

FAST

SLOW

C26

SLEW

0

1

0

1

0

1

0

1

OE0

OE1

0

1

2

3

O

C12 C13

TO PIM

D

Q

D

Q

D

Q

LE

INPUT PIN

0

1

2

O

C10

FROM CLOCK

POLARITY MUXES

3

C11

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 7 of 63

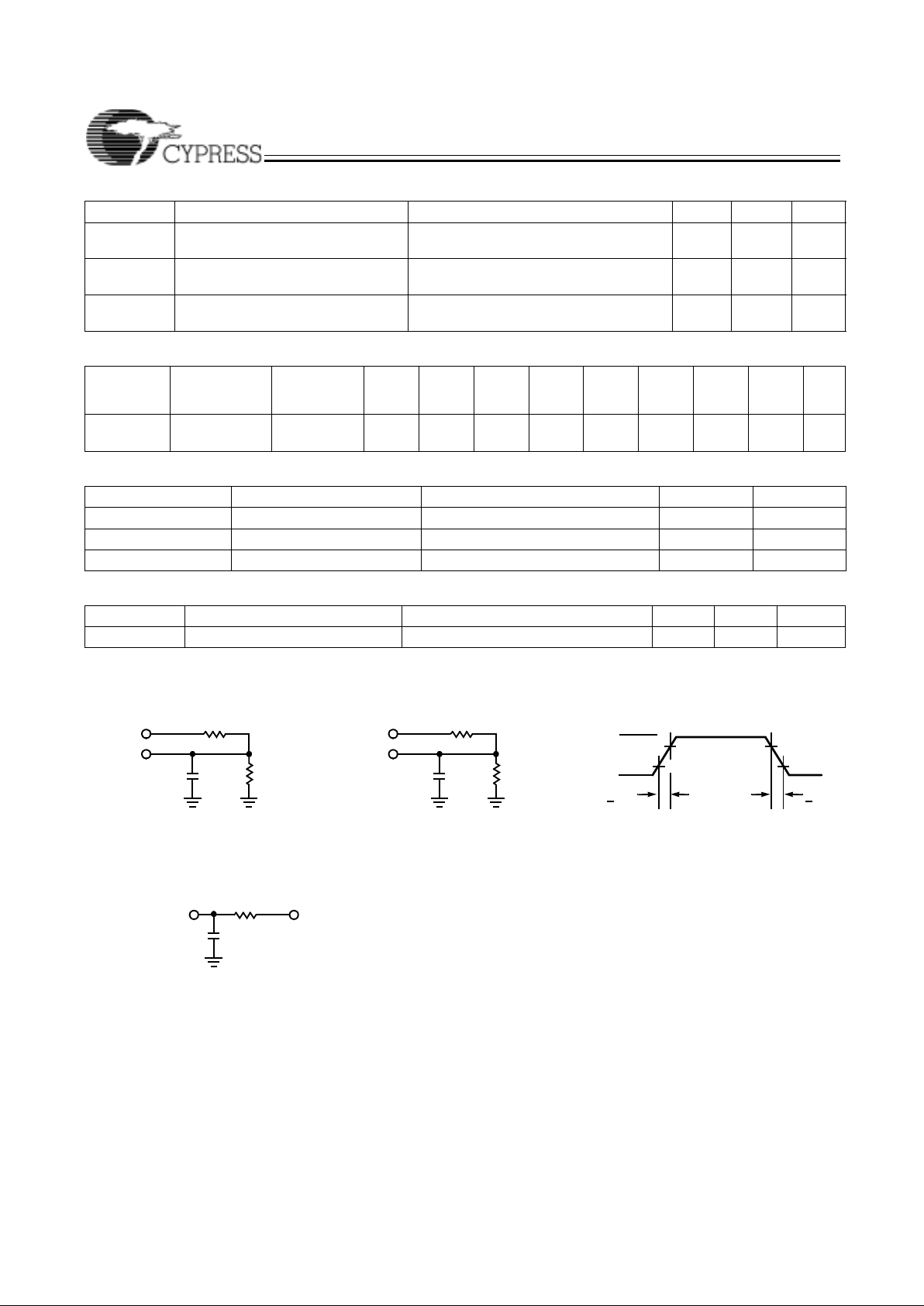

Clocking

Each I/O and buried macroc ell has access to four synchronou s

clocks (CLK0, CLK1, CLK2 and CLK3) as well as an

asynchronous product term clock PTCLK. Each input

macrocell has access to all four synchronous clocks.

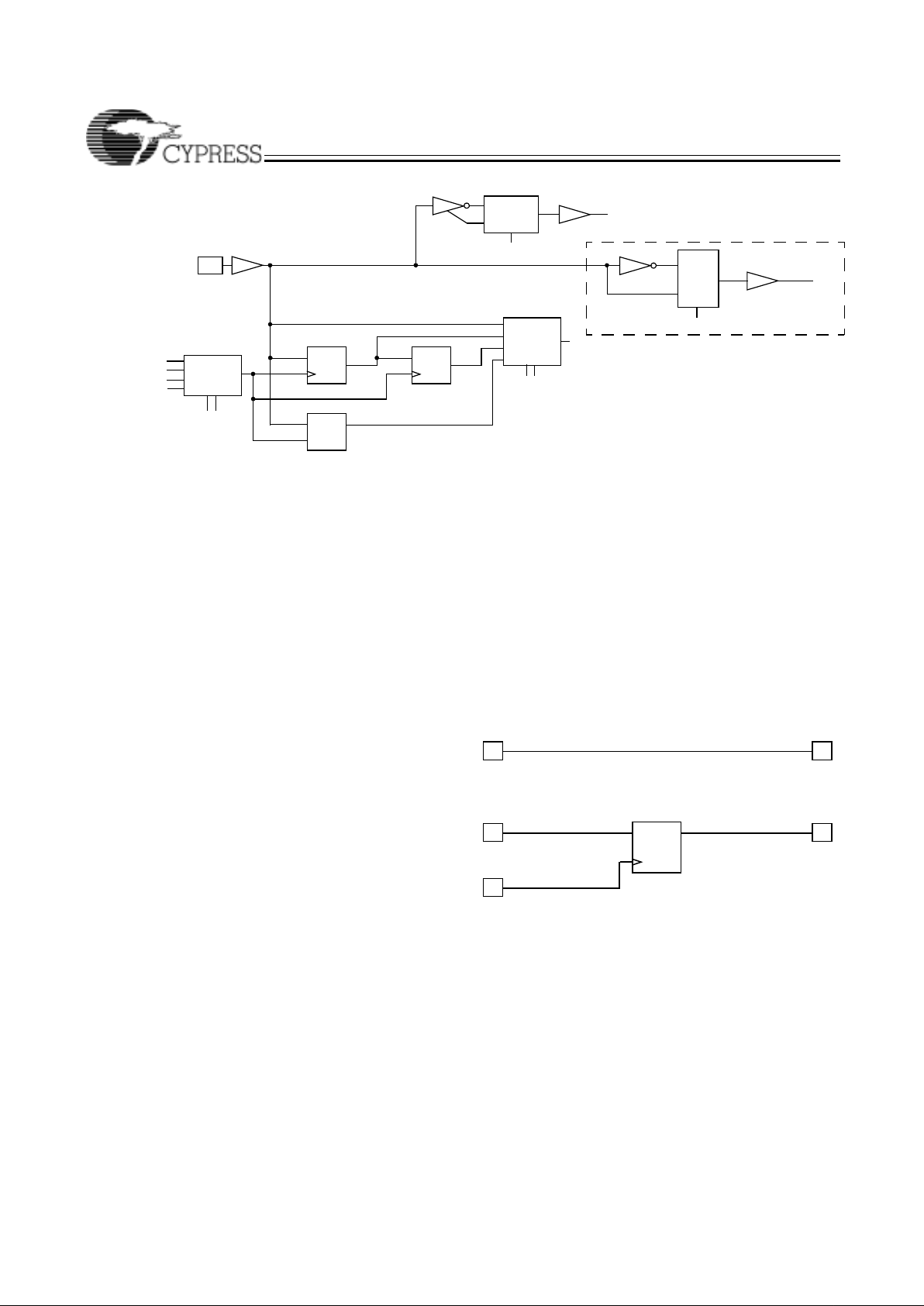

Dedicated Inputs/Clocks

Five pins on each member of the Ultra37000 family ar e designated as input-only. There are two types of dedicated inputs

on Ultra37000 devices: input pins and input/clock pins.

Figure 3 illustrates the architecture for input pins. Four input

options are available for the user: combinatorial, registered,

double-registered, or latched. If a registered or latched option

is selected, any one of the input clocks can be selected for

control.

Figure 4 illustrates the architecture for the input/clock pins.

Like the input pins, input/clock pins can be combinatorial,

registered, double-registered, or latched. In addition, these

pins feed the clocking structures throughout the device. The

clock path at the input has user-configurable polarity.

Product Term Clocking

In addition to the four synchronous clocks, the Ultra37000

family also has a product term clock for asynchronous

clocking. Each logic block has an independent product term

clock which is available to a ll 16 macrocells . Each product te rm

clock also supports user configurable polarity selection.

Timing Model

One of the most impo rtan t feature s of the U ltra3 7000 fa mily is

the simplicity of its timing. All delays are worst case and

system performance is unaf fected by the features use d. Figure

5 illustrates the true timing model for the 167-MHz devices in

high speed mode. For combinatorial paths, any input to any

output incurs a 6.5-ns worst-case delay regardless of the

amount of logic used. For synch ronous syst ems, the inp ut setup time to the outpu t macroc ells for a ny input is 3.5 ns a nd the

clock to output time is also 4.0 ns. These measurements are

for any output and synchronous clock, regardless of the logic

used.

The Ultra37000 features:

• No fanout delays

• No expander delays

• No dedicated vs. I/O pin delays

• No additional delay through PIM

• No penalty for using 0–16 product terms

• No added delay for steering product terms

• No added delay for sharing product terms

• No routing delays

• No output bypass delays

The simple timing model of the Ultra37000 family eliminates

unexpected performance penalties.

JTAG and PCI Standards

PCI Compliance

5V operation of the Ultra37000 is fully compliant with the PCI

Local Bus Specification published by the PCI Special Interest

Group. The 3.3V products meet all PCI requirements except

for the output 3.3V clamp, which is in direct conflict with 5V

tolerance. The Ultra37000 family’s simple and predictable

timing model ensures compliance with the PCI AC specifications independent of the design.

Figure 4. Input/Clock Macrocell

0

1

2

3

O

C10C11

TO PIM

D

Q

D

Q

D

Q

LE

INPUT/CLOCK PIN

0

1

2

O

FROM CLOCK

CLOCK PINS

0

1

O

C12

TO CLOCK MUX ON

ALL INPUT MACROCELLS

TO CLOCK MUX

IN EACH

3

0

1

CLOCK POLARITY MUX

ONE PER LOGIC BLOCK

FOR EACH CLOCK INPUT

POLARITY INPUT

LOGIC BLOCK

C8

C9

C13, C14, C15 OR C16

O

Figure 5. Timing Model for CY37128

COMBINATORIAL SIGNAL

REGISTERED SIGNAL

D,T,L O

CLOCK

INPUT

INPUT

OUTPUT

OUTPUT

tS = 3.5 ns

t

CO

= 4.5 ns

t

PD

= 6.5 ns

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 8 of 63

IEEE 1149.1-compliant JTAG

The Ultra37000 family has an IEEE 1149.1 JTAG interface for

both Boundary Scan and ISR.

Boundary Scan

The Ultra37000 family supports Bypass, Sample/Preload,

Extest, Idcode, and Usercode boundary sc an instructions. The

JTAG interface is shown in Figure 6.

In-System Reprogramming (ISR)

In-System Reprogram ming is the comb ination of the capability

to program or reprogram a device on-board, and the ability to

support design changes without changing the system timing

or device pinout. This combination means design changes

during debug or field upgrades do not cause board respins.

The Ultra37000 family implements ISR by providing a JTAG

compliant interface for on-board programming, robust routing

resources for pinout flexibility, and a simple timing model for

consistent system performance.

Development Software Support

Warp

Warp is a st ate-of-the-art compil er and complete CPLD de sign

tool. For design entry , Warp provides an IEEE-STD-1076/1164

VHDL text editor , an IEEE-STD-1364 V erilo g text editor, and a

graphical finite state machine editor. It provides optimized

synthesis and fitting by replacing basic circuits with ones preoptimized for the target device, by implementing logic in

unused memory an d by perfect comm unication betwee n fitting

and synthesis. To facilitate design and debugging, Warp

provides graphical timing simulation and analysis.

Warp Professional

™

Warp Professional contains several additional features. It

provides an extra method of design entry with its graphical

block diagram ed itor. It allows up to 5 ms timin g simulation

instead of only 2 ms. It allows comp arison of waveforms before

and after design changes.

Warp Enterprise

™

Warp Enterprise provides even more features. It provides

unlimited timing simulation and source-level behavioral

simulation as well as a debug ger. It has the ability to generate

graphical HDL blocks from HDL text. It can even generate

testbenches.

Warp is available for PC and UNIX platforms. Some features

are not avai lable i n the U NIX ve rsion. For fur ther infor matio n

see the Warp for PC, W arp for UNIX, Warp Profession al and

Warp Enterprise data sheets on Cypress’s web site

(www.cypress.com).

Third-Party Software

Although Warp is a complete CP LD developm ent tool o n its

own, it interfaces with nearly every third party EDA tool. All

major third-party software vendors provide support for the

Ultra37000 family o f de vi ce s. Refe r to the th ird-party software

data sheet or contact your local sales office for a list of

currently supported third-p a rty vendors.

Programming

There are four programming options available for Ultra37000

devices. The first method is to use a PC with the 37000

UltraISR programming cable and software. With this method,

the ISR pins of the Ultra37000 devices are routed to a

connector at the edge of the printed circuit board. The 37000

UltraISR programming cable is then connected between the

parallel port of the PC and this connector. A simple configuration file instructs the ISR software of the programming

operations to be perform ed on each of the Ultra 37000 device s

in the system. The ISR s oftware then automatic ally co mpletes

all of the necessary dat a manipulatio ns required to accomplis h

the programming, reading, verifying, and other ISR functions.

For more information on the Cypress ISR Interface, see the

ISR Programming Kit data sheet (CY3700i).

The second meth od for programming U ltra37000 device s is on

automatic test equip ment (A TE). This i s accomplished throu gh

a file created by the ISR sof tware. Check th e Cypress web site

for the latest ISR software download information.

The third programming option for Ultra37000 devices is to

utilize the embedded controller or processor that already

exists in the s ystem. T he Ultr a37000 ISR softw are assi sts in

this method by converting the device JEDEC maps into the

ISR serial stream that c ont ains the ISR ins tructi on inf ormati on

and the addresses and data of locations to be programmed.

The embedded controller then simply directs this ISR stream

to the chain of Ultra37000 devices to complete the desired

reconfiguring or diagnostic operations. Contact your local

sales office for information on availability of this option.

The fourth method for programming Ultra37000 devices is to

use the same programmer that is currently being used to

program F

LASH370i devices.

For all pinout, electrical, and timing requirements, refer to

device data shee ts. For ISR cable an d software speci fications,

refer to the UltraISR kit data sheet (CY3700i).

Third-Party Programmers

As with development software, Cypress support is available

on a wide va riety of thi rd-par ty prog rammer s. All majo r thir dparty programmers (including BP Micro, Data I/O, and SMS)

support the Ultra37000 family.

Figure 6. JTAG Interface

Instruction Register

Boundary Scan

idcode

Usercode

ISR Prog .

Bypass Reg.

Data Registers

JTAG

TAP

CONTROLLER

TDO

TDI

TMS

TCK

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 9 of 63

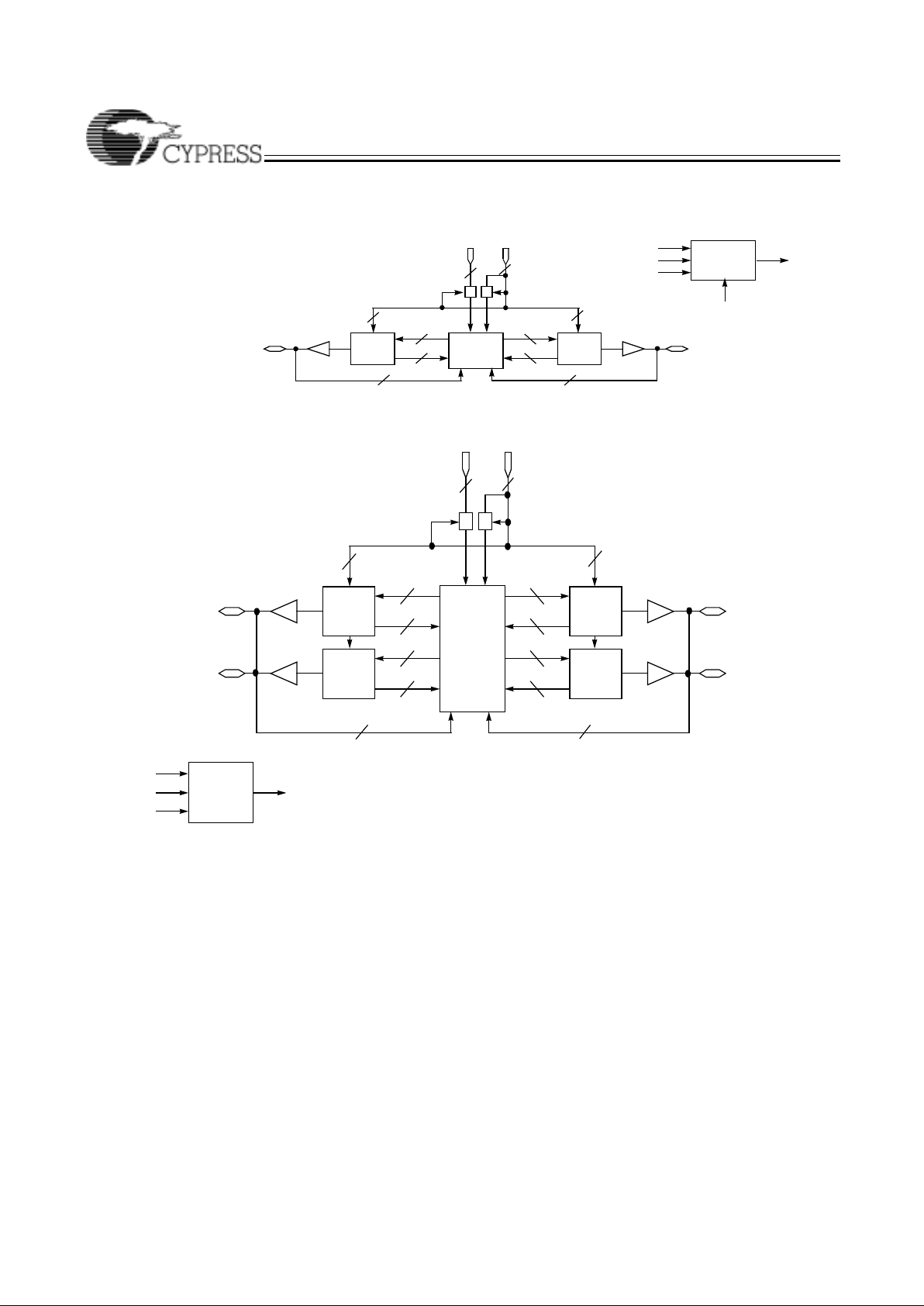

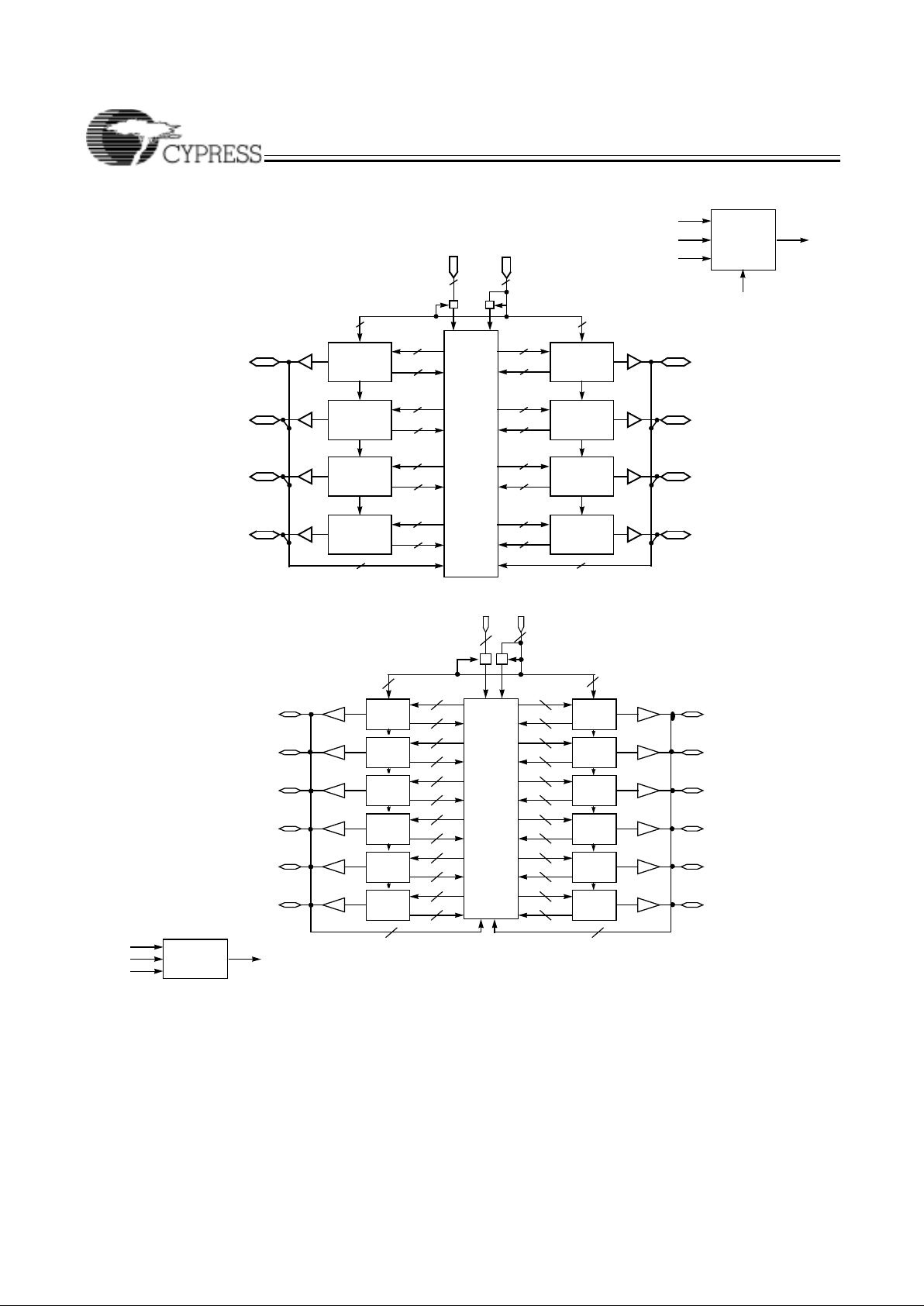

Logic Block Diagrams

CY37032/CY37032V

LOGIC

BLOCK

B

LOGIC

BLOCK

A

36

16

36

16

Input

Clock/

Input

16 I/Os

16 I/Os

I/O

0

−I/O

15

I/O16−I/O

31

4

4

4

16

16

TDI

TCK

TMS

TDO

JTAG Tap

Controller

1

PIM

JTAG

EN

LOGIC

BLOCK

D

LOGIC

BLOCK

C

LOGIC

BLOCK

A

LOGIC

BLOCK

B

36

16

36

16

36

16

36

16

Input

Clock/

Input

16 I/Os

16 I/Os

16 I/Os

16 I/Os

I/O

0

-I/O

15

I/O16-I/O

31

I/O48-I/O

63

I/O32-I/O

47

4

4

4

32

32

TDI

TCK

TMS

TDO

JTAG Tap

Controller

1

PIM

CY37064/CY37064V (100-Lead TQFP)

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 10 of 63

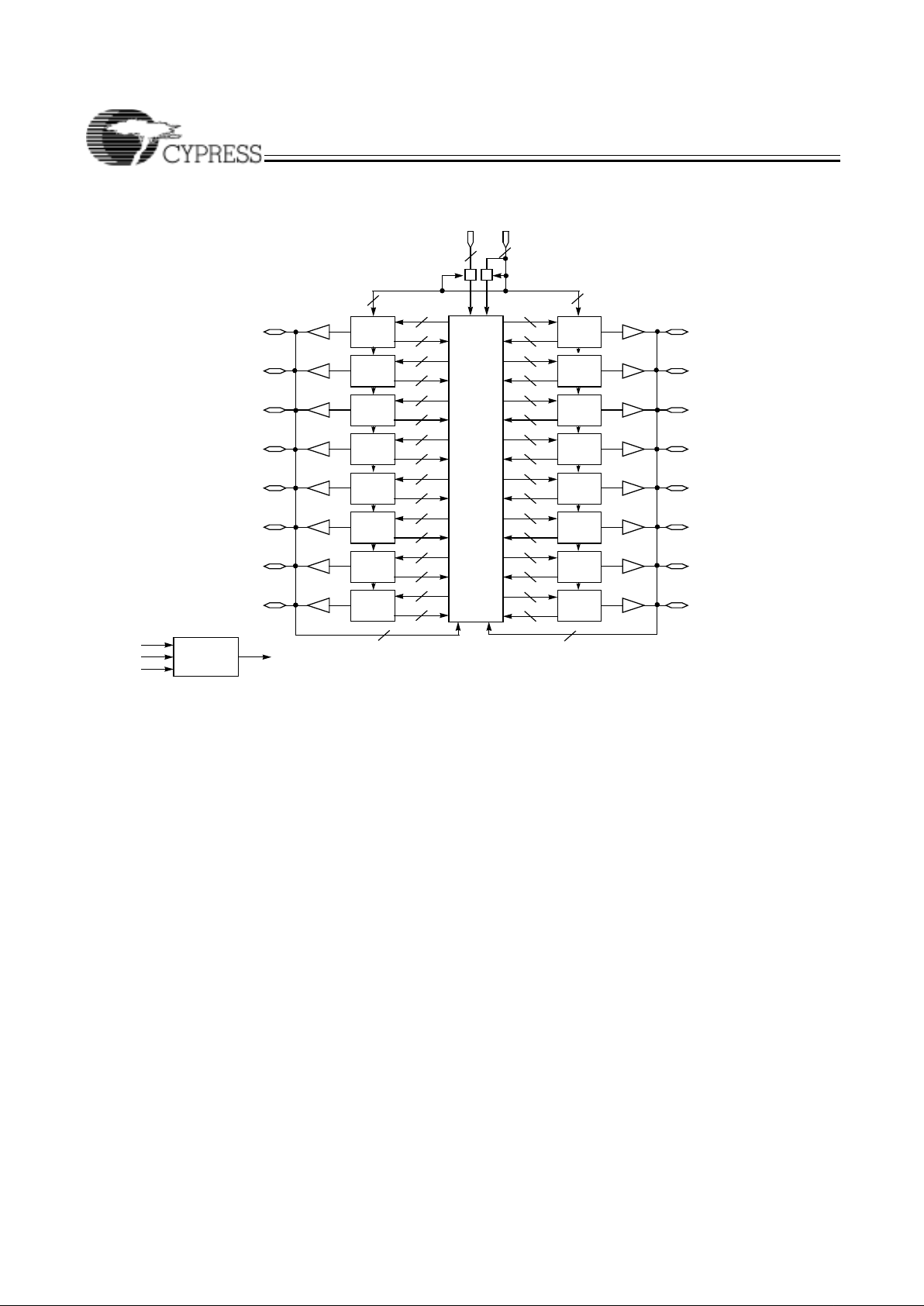

Logic Block Diagrams (continued)

TDI

TCK

TMS

TDO

JTAG Tap

Controller

CY37128/CY37128V (160-lead TQFP)

PIM

INPUT

MACROCELL

CLOCK

INPUTS

4 4

36

16

16

36

LOGIC

BLOCK

36

16

16

36

16 I/Os

36 36

36

16

16

36

16

16

64

64

41

INPUT/CLOCK

MACROCELLS

I/O

0

–I/O

15

A

INPUTS

LOGIC

BLOCK

C

LOGIC

BLOCK

B

LOGIC

BLOCK

D

LOGIC

BLOCK

H

LOGIC

BLOCK

G

LOGIC

BLOCK

F

LOGIC

BLOCK

E

I/O16–I/O

31

I/O32–I/O

47

I/O28–I/O

63

I/O

112

–I/O

127

I/O96–I/O

111

I/O80–I/O

95

I/O64–I/O

79

16 I/Os

16 I/Os

16 I/Os

16 I/Os

16 I/Os

16 I/Os

16 I/Os

JTAG

EN

LOGIC

BLOCK

H

LOGIC

BLOCK

L

LOGIC

BLOCK

I

LOGIC

BLOCK

J

LOGIC

BLOCK

K

LOGIC

BLOCK

A

LOGIC

BLOCK

B

LOGIC

BLOCK

C

LOGIC

BLOCK

D

LOGIC

BLOCK

E

LOGIC

BLOCK

G

LOGIC

BLOCK

F

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

PIM

Input

Clock/

Input

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

10 I/Os

I/O

0

–I/O

9

I/O10–I/O

19

I/O20–I/O

29

I/O30–I/O

39

I/O40–I/O

49

I/O50–I/O

59

I/O

110

–I/O

119

I/O

100

–I/O

109

I/O90–I/O

99

I/O80–I/O

89

I/O70–I/O

79

I/O60–I/O

69

4

4

4

6060

TDI

TCK

TMS

TDO

JTAG Tap

Controller

1

CY37192/CY37192V (160-lead TQFP)

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 11 of 63

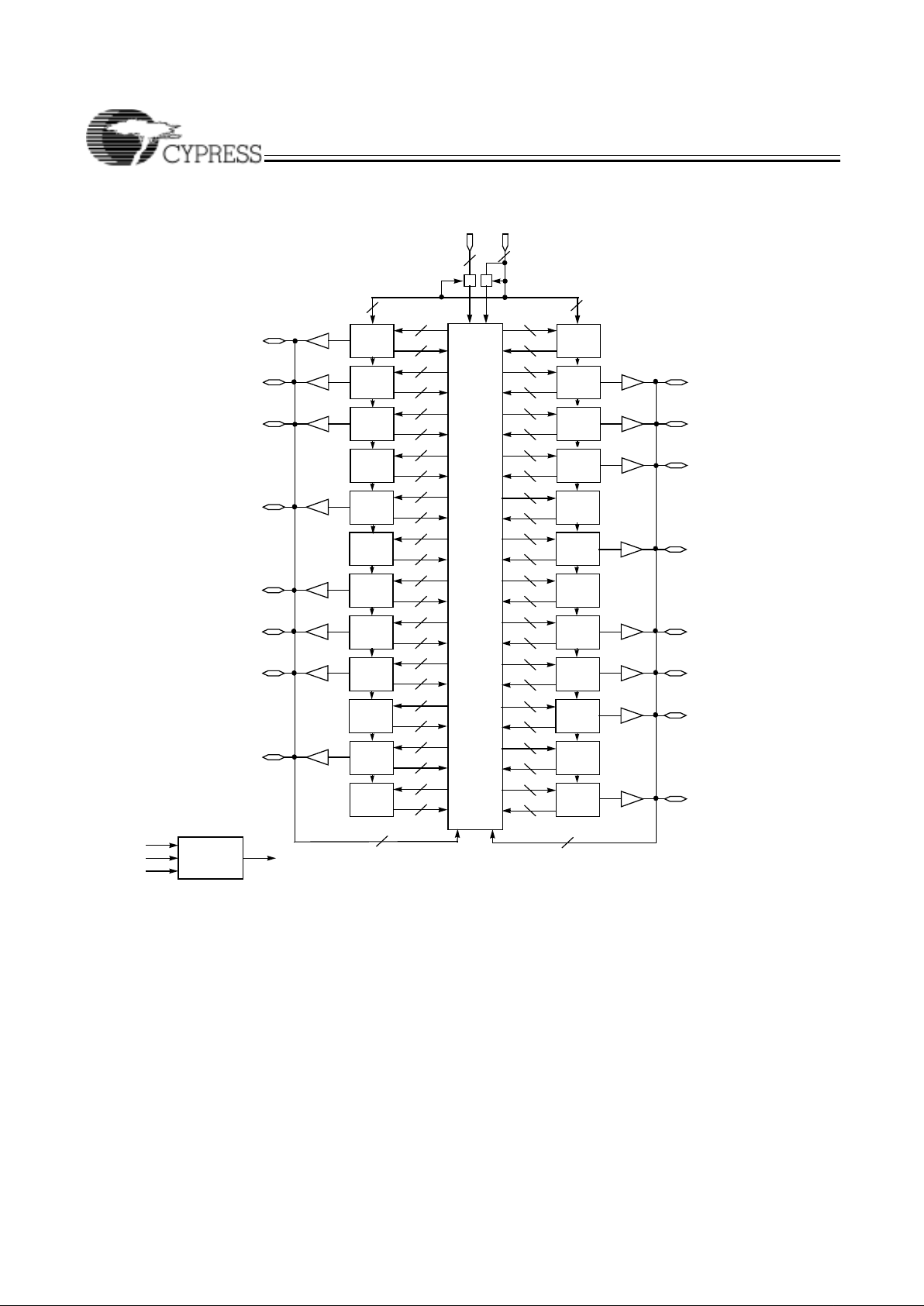

Logic Block Diagrams (continued)

CY37256/CY37256V (256-lead BGA)

LOGIC

BLOCK

G

LOGIC

BLOCK

H

LOGIC

BLOCK

I

LOGIC

BLOCK

J

LOGIC

BLOCK

L

LOGIC

BLOCK

P

LOGIC

BLOCK

M

LOGIC

BLOCK

N

LOGIC

BLOCK

O

LOGIC

BLOCK

A

LOGIC

BLOCK

B

LOGIC

BLOCK

C

LOGIC

BLOCK

D

LOGIC

BLOCK

E

LOGIC

BLOCK

K

LOGIC

BLOCK

F

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

PIM

Input

Clock/

Input

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

I/O

0

−I/O

11

I/O12−I/O

23

I/O24−I/O

35

I/O36−I/O

47

I/O48−I/O

59

I/O60−I/O

71

I/O72−I/O

83

I/O84−I/O

95

I/O

180

−I/O

191

I/O

168

−I/O

179

I/O

156

−I/O

167

I/O

144

−I/O

155

I/O

132

−I/O

143

I/O

120

−I/O

131

I/O

108

−I/O

119

I/O96−I/O

107

4

4

4

96

96

TDI

TCK

TMS

TDO

JTAG Tap

Controller

1

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 12 of 63

Logic Block Diagrams (continued)

CY37384/CY37384V (256-Lead BGA)

LOGIC

BLOCK

AH

LOGIC

BLOCK

AI

LOGIC

BLOCK

BD

LOGIC

BLOCK

BE

LOGIC

BLOCK

BG

LOGIC

BLOCK

BL

LOGIC

BLOCK

BI

LOGIC

BLOCK

BJ

LOGIC

BLOCK

BK

LOGIC

BLOCK

AA

LOGIC

BLOCK

AB

LOGIC

BLOCK

AC

LOGIC

BLOCK

AD

LOGIC

BLOCK

AF

LOGIC

BLOCK

BF

LOGIC

BLOCK

AG

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

PIM

Input

Clock/

Input

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

I/O

0

−I/O

11

I/O12−I/O

23

I/O24−I/O

35

I/O48−I/O

59

I/O60−I/O

71

I/O72−I/O

83

I/O

168

−I/O

191

I/O

156

−I/O

179

I/O

144

−I/O

167

I/O

120

−I/O

143

I/O

108

−I/O

131

4

4

4

96

96

TDI

TCK

TMS

TDO

JTAG Tap

Controller

1

LOGIC

BLOCK

AJ

LOGIC

BLOCK

BC

16

16

12 I/Os

I/O

96

−I/O

119

LOGIC

BLOCK

AK

LOGIC

BLOCK

BB

16

16

12 I/Os

I/O

84

−I/O

95

LOGIC

BLOCK

AL

LOGIC

BLOCK

BA

16

16

12 I/Os

I/O

96

−I/O

107

LOGIC

BLOCK

AE

LOGIC

BLOCK

BH

16

16

12 I/Os

12 I/Os

I/O

36

−I/O

47

I/O

132

−I/O

155

36

36

36

36

36

36

36

36

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 13 of 63

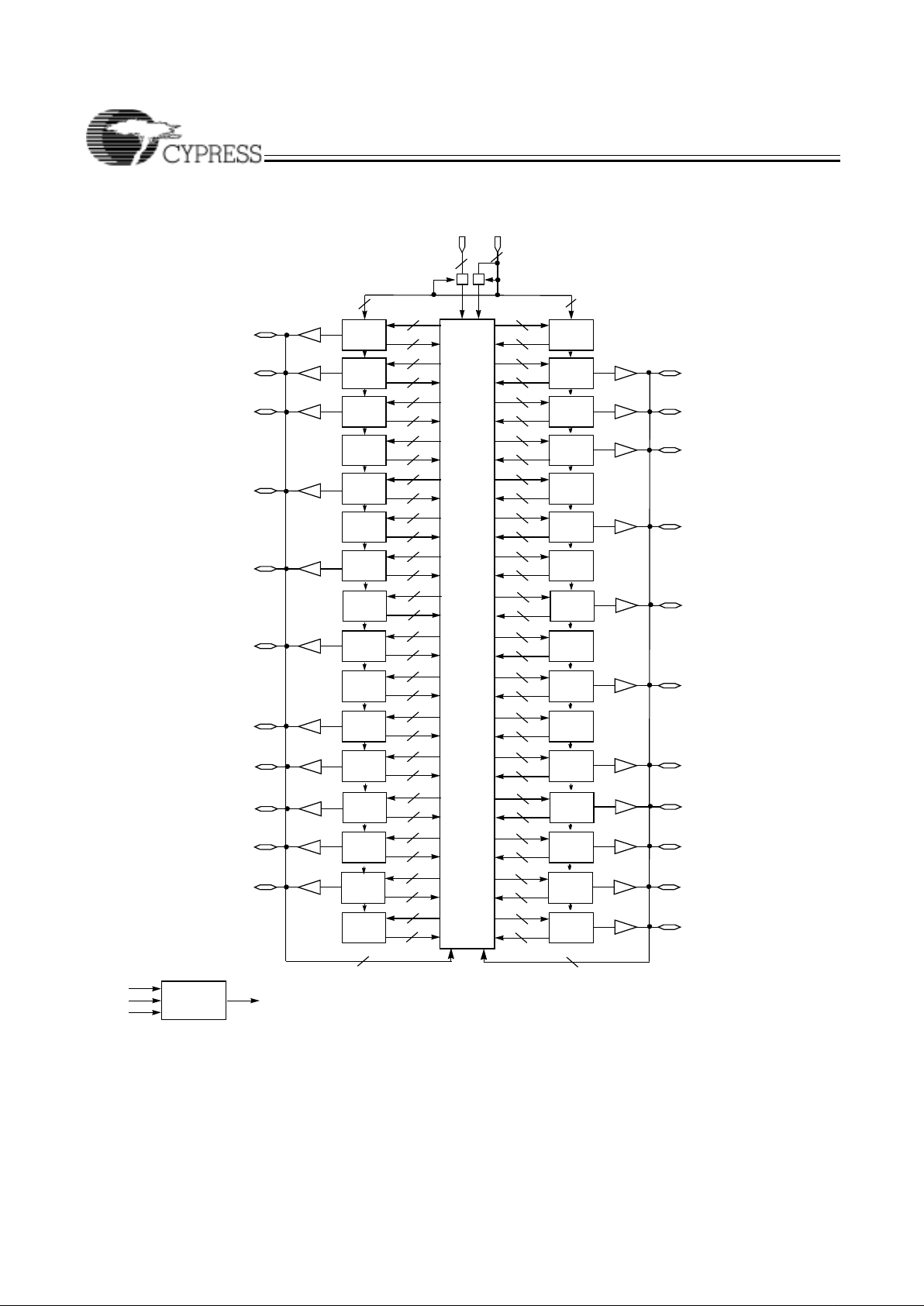

Logic Block Diagrams (continued)

CY37512/CY37512V (352-Lead BGA)

LOGIC

BLOCK

AG

LOGIC

BLOCK

AH

LOGIC

BLOCK

BI

LOGIC

BLOCK

BJ

LOGIC

BLOCK

BL

LOGIC

BLOCK

BP

LOGIC

BLOCK

BM

LOGIC

BLOCK

BN

LOGIC

BLOCK

BO

LOGIC

BLOCK

AA

LOGIC

BLOCK

AB

LOGIC

BLOCK

AC

LOGIC

BLOCK

AD

LOGIC

BLOCK

AE

LOGIC

BLOCK

BK

LOGIC

BLOCK

AF

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

36

36

16

36

16

36

16

36

16

36

16

36

16

36

16

Input

Clock/

Input

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

I/O

0

−

I/O

11

I/O12−

I/O

23

I/O24−

I/O

35

I/O36−

I/O

47

I/O48−

I/O

59

I/O60−

I/O

71

I/O72−

I/O

83

I/O84−

I/O

95

I/O

252

−

I/O

263

I/O

240

−

I/O

251

I/O

228

−

I/O

239

I/O

216

−

I/O

227

I/O

204

−

I/O

215

4

4

4

TDI

TCK

TMS

TDO

JTAG Tap

Controller

1

PIM

16

36

36

16

LOGIC

BLOCK

AI

LOGIC

BLOCK

BH

12 I/Os

I/O

96

−

I/O

107

16

36

36

16

LOGIC

BLOCK

AJ

LOGIC

BLOCK

BG

12 I/Os

12 I/Os

I/O

108

−

I/O

119

I/O

192

−

I/O

203

16

36

36

16

LOGIC

BLOCK

AK

LOGIC

BLOCK

BF

12 I/Os

I/O

120

−

I/O

131

16

36

36

16

LOGIC

BLOCK

AL

LOGIC

BLOCK

BE

12 I/Os

I/O

180

−

I/O

191

16

36

36

16

LOGIC

BLOCK

AM

LOGIC

BLOCK

BD

12 I/Os

I/O

168

−

I/O

179

16

36

36

16

LOGIC

BLOCK

AN

LOGIC

BLOCK

BC

12 I/Os

I/O

156

−

I/O

167

16

36

36

16

LOGIC

BLOCK

AO

LOGIC

BLOCK

BB

12 I/Os

I/O

144

−

I/O

155

16

36

36

16

LOGIC

BLOCK

AP

LOGIC

BLOCK

BA

12 I/Os

I/O

132

−

I/O

143

16

132132

16

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 14 of 63

5.0V Device Characteristics

Maximum Ratings

(Above which the us efu l l ife ma y be impaired. For us er gui delines, not tested.)

Storage Temperature .................................–65°C to +150°C

Ambient Temperature with

Power Applied.............................................–55°C to +125°C

Supply Voltage to Ground Potential...............–0.5V to +7.0V

DC Voltage Applied to Outputs

in High-Z State................................................–0.5V to +7.0V

DC Input Voltage............................................–0.5V to +7.0V

DC Program Voltage.............................................4.5 to 5.5V

Current into Outputs....................................................16 mA

Static Discharge Voltage...........................................> 2001V

(per MIL-STD-883, Method 3015)

Latch-up Current.....................................................> 200 mA

Operating Range

[2]

Range

Ambient

Temperature

[2]

Junction

Temperature

Output

Condition V

CC

V

CCO

Commercial 0°C to +70°C 0°C to +90°C 5V 5V ± 0.25V 5V ± 0.25V

3.3V 5V ± 0.25V 3.3V ± 0.3V

Industrial –40°C to +85°C –40°C to +105°C 5V 5V ± 0.5V 5V ± 0.5V

3.3V 5V ± 0.5V 3.3V ± 0.3V

Military

[3]

–55°C to +125°C –55°C to +130°C 5V 5V ± 0.5V 5V ± 0.5V

3.3V 5V ± 0.5V 3.3V ± 0.3V

5.0V Device Electrical Characteristics Over the Operating Range

Parameter Description T est Conditi ons Min. Typ. Max. Unit

V

OH

Output HIGH Voltage VCC = Min. IOH = –3.2 mA (Com’l/Ind)

[4]

2.4 V

IOH = –2.0 mA (Mil)

[4]

2.4 V

V

OHZ

Output HIGH Voltage with

Output Disabled

[5]

VCC = Max. IOH = 0 µA (Com’l)

[6]

4.2 V

IOH = 0 µA (Ind/Mil)

[6]

4.5 V

IOH = –100 µA (Com’l)

[6]

3.6 V

IOH = –150 µA (Ind/Mil)

[6]

3.6 V

V

OL

Output LOW Voltage VCC = Min. IOL = 16 mA (Com’l/Ind)

[4]

0.5 V

IOL = 12 mA (Mil)

[4]

0.5 V

V

IH

Input HIGH Voltage Guaranteed Input Logical HIGH Voltage for all Inputs

[7]

2.0 V

CCmax

V

V

IL

Input LOW Voltage Guaranteed Input Logical LOW Voltage for all Inputs

[7]

–0.5 0.8 V

I

IX

Input Load Current VI = GND OR VCC, Bus-Hold Disabled –10 10 µA

I

OZ

Output Leakage Current VO = GND or VCC, Output Disabled, Bus-Hold Disabled –50 50 µA

I

OS

Output Short Circuit Current

[8, 5]

VCC = Max., V

OUT

= 0.5V –30 –160 mA

I

BHL

Input Bus-Hold LOW

Sustaining Current

VCC = Min., VIL = 0.8V +75 µA

I

BHH

Input Bus-Hold HIGH

Sustaining Current

VCC = Min., VIH = 2.0V –75 µA

I

BHLO

Input Bus-Hold LOW

Overdrive Current

VCC = Max. +500 µA

I

BHHO

Input Bus-Hold HIGH

Overdrive Current

VCC = Max. –500 µA

Notes:

2. Normal Programming Conditions apply across Ambient Temperature Range for specified programming methods. For more information on programming the

Ultra37000 Family devices, please refer to the Application Note titled “An Introduction to In System Reprogramming with the Ultra37000.”

3. T

A

is the “Instant On” case temperature.

4. IOH = –2 mA, IOL = 2 mA for TDO.

5. Tested initially and after any design or process changes that may affect these parameters.

6. When the I/O is output disabled, the bus-hold circuit can weakly pull the I/O to above 3.6V if no leakage current is allowed. Note that all I/Os are output disabled

during ISR programming. Refer to the application note “Understanding Bus-Hold” for additional information.

7. These are absolute values with respect to device ground. All overshoots due to system or tester noise are included.

8. Not more than one output should be tested at a time. Duration of the short circuit should not exceed 1 second. V

OUT

= 0.5V has been chosen to avoid test

problems caused by tester ground degradation.

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 15 of 63

3.3V Device Characteristics

Maximum Ratings

(Above which the us efu l l ife ma y be impaired. For us er gui delines, not tested.)

Storage Temperature .................................–65°C to +150°C

Ambient Temperature with

Power Applied.............................................–55°C to +125°C

Supply Voltage to Ground Potential...............–0.5V to +4.6V

DC Voltage Applied to Outputs

in High-Z State................................................–0.5V to +7.0V

DC Input Voltage............................................–0.5V to +7.0V

DC Program Voltage.............................................3.0 to 3.6V

Current into Outputs......................................................8 mA

Static Discharge Voltage............................................>2001V

(per MIL-STD-883, Method 3015)

Latch-up Current......................................................>200 mA

Inductance

[5]

Parameter Description

Test

Conditions

44-

Lead

TQFP

44-

Lead

PLCC

44-

Lead

CLCC

84-

Lead

PLCC

84-

Lead

CLCC

100-

Lead

TQFP

160-

Lead

TQFP

208-

Lead

PQFP Unit

L Maximum Pin

Inductance

VIN = 5.0V

at f = 1 MHz

2 5 2 8 5 8 9 11 nH

Capacitance

[5]

Parameter Description Test Conditions Max. Unit

C

I/O

Input/Output Capacitance VIN = 5.0V at f = 1 MHz at TA = 25°C 10 pF

C

CLK

Clock Signal Capacitance VIN = 5.0V at f = 1 MHz at TA = 25°C 12 pF

C

DP

Dual Function Pins

[9]

VIN = 5.0V at f = 1 MHz at TA = 25°C 16 pF

Endurance Characteristics

[5]

Parameter Description T est Condit ions Min. Typ. Unit

N Minimum Reprogramming Cycles Normal Programming Conditions

[2]

1,000 10,000 Cycles

Operating Range

[2]

Range Ambient Temperature

[2]

Junction Te mperature V

CC

[10]

Commercial 0°C to +70°C 0°C to +90°C 3.3V ± 0.3V

Industrial –40°C to +85°C –40°C to +105°C

3.3V ± 0.3V

Military

[3]

–55°C to +125°C –55°C to +130°C 3.3V ± 0.3V

3.3V Device Electrical Characteristics Over the Operating Range

Parameter Description Test Conditions Min. Max. Unit

V

OH

Output HIGH Voltage VCC = Min. IOH = –4 mA (Com’l)

[4]

2.4 V

IOH = –3 mA (Mil)

[4]

V

OL

Output LOW Voltage VCC = Min. IOL = 8 mA (Com’l)

[4]

0.5 V

IOL = 6 mA (Mil)

[4]

V

IH

Input HIGH Voltage Guaranteed In put Logical HIGH V oltage for

all Inputs

[7]

2.0 5.5 V

V

IL

Input LOW Voltage Guaranteed Inpu t Lo gic al LO W Voltage for

all Inputs

[7]

–0.5 0.8 V

I

IX

Input Load Current VI = GND OR VCC, Bus-Hold Disabled –10 10 µA

I

OZ

Output Leakage Current VO = GND or VCC, Output Disabled, Bus-

Hold Disabled

–50 50 µA

I

OS

Output Short Circuit Current

[8, 5]

VCC = Max., V

OUT

= 0.5V –30 –160 mA

I

BHL

Input Bus-Hold LOW Sustaining

Current

VCC = Min., VIL = 0.8V +75 µA

Notes:

9. Dual pins are I/O with JTAG pins.

10. For CY37064VP100-143AC, CY37064VP100-143BBC, CY37064VP44-143AC, CY37064VP48-143BAC; Operating Range: V

CC

is 3.3V± 0.16V.

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 16 of 63

I

BHH

Input Bus-Hold HIGH Sustaining

Current

VCC = Min., VIH = 2.0V –75 µA

I

BHLO

Input Bus-Hold LOW Overdrive

Current

VCC = Max. +500 µA

I

BHHO

Input Bus-Hold HIGH Overdrive

Current

VCC = Max. –500 µA

Inductance

[5]

Parameter Description

Test

Conditions

44-

Lead

TQFP

44-

Lead

PLCC

44-

Lead

CLCC

84-

Lead

PLCC

84-

Lead

CLCC

100-

Lead

TQFP

160-

Lead

TQFP

208-

Lead

PQFP Unit

L Maximum Pin

Inductance

VIN = 3.3V

at f = 1 MHz

2 5 2 8 5 8 9 11 nH

Capacitance

[5]

Parameter Description Test Conditions Max. Unit

C

I/O

Input/Output Capacitance VIN = 3.3V at f = 1 MHz at TA = 25°C 8 pF

C

CLK

Clock Signal Capacitance VIN = 3.3V at f = 1 MHz at TA = 25°C 12 pF

C

DP

Dual Functional Pins

[9]

VIN = 3.3V at f = 1 MHz at TA = 25°C 16 pF

Endurance Characteristics

[5]

Parameter Description T est Condit ions Min. Typ. Unit

N Minimum Reprogramming Cycles Normal Programming Conditions

[2]

1,000 10,000 Cycles

3.3V Device Electrical Characteristics Over the Operating Range (continued)

Parameter Description Test Conditions Min. Max. Unit

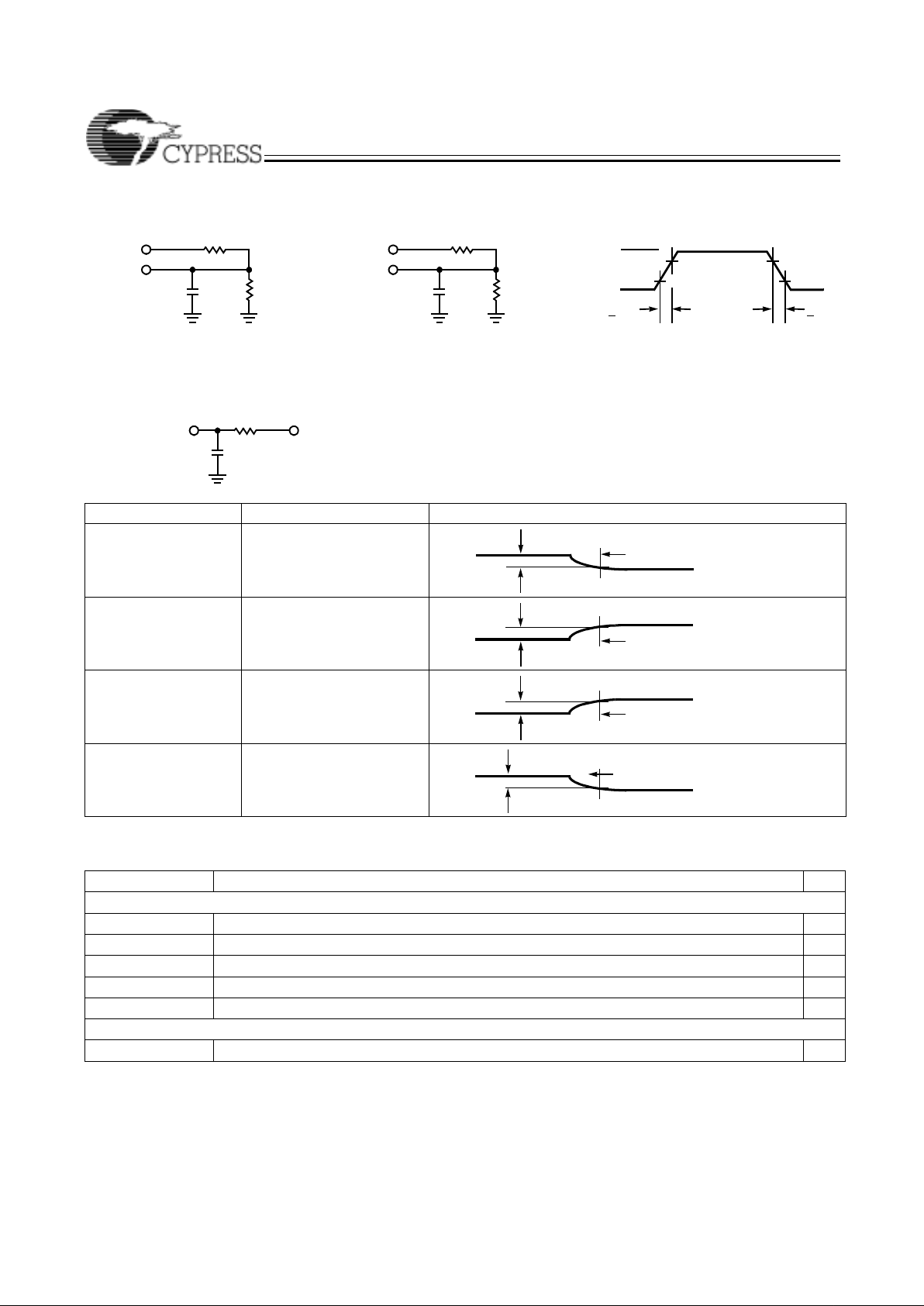

AC Characteristics

5.0V AC Test Loads and Waveforms

90%

10%

3.0V

GND

90%

10%

ALL INPUT PULSES

5V

OUTPUT

35 pF

INCLUDING

JIG AND

SCOPE

5V

OUTPUT

5 pF

INCLUDING

JIG AND

SCOPE

(a) (b)

<2 ns

OUTPUT

238Ω (COM’L)

319Ω(MIL)

170Ω (COM’L)

236Ω(MIL)

99Ω (COM’L)

136Ω (MIL)

Equivalent to: THÉVENIN EQUIVALENT

2.08V (COM'L)

2.13V (MIL)

238Ω (COM'L)

319Ω(MIL)

170Ω (COM'L)

236Ω(MIL)

<2 ns

(c)

5 OR 35 pF

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 17 of 63

3.3V AC Test Loads and Waveforms

AC Characteristics

90%

10%

3.0V

GND

90%

10%

ALL INPUT PULSES

3.3V

OUTPUT

35 pF

INCLUDING

JIG AND

SCOPE

3.3V

OUTPUT

5 pF

INCLUDING

JIG AND

SCOPE

(a) (b)

<2 ns

OUTPUT

295Ω (COM’L)

393Ω(MIL)

340Ω (COM’L)

453Ω(MIL)

Equivalent to: THÉVENIN EQUIVALENT

1.77V (COM'L)

1.77V (MIL)

295Ω (COM'L)

393Ω(MIL)

340Ω (COM'L)

453Ω(MIL)

<2 ns

(c)

270Ω (MIL)

158Ω(COM’L)

5 OR 35 pF

Parameter

[11]

V

X

Output Waveform—Measurement Level

t

ER(–)

1.5V

t

ER(+)

2.6V

t

EA(+)

1.5V

t

EA(–)

V

the

(d) Test Waveforms

V

OH

V

X

0.5V

V

OL

V

X

0.5V

V

X

V

O

H

0.5V

V

X

V

OL

0.5V

Switching Characteristics Over the Operating Range

[12]

Parameter Description Unit

Combinatorial Mode Parameters

t

PD

[13, 14, 15]

Input to Combinatorial Output ns

t

PDL

[13, 14, 15]

Input to Output Through Transparent Input or Output Latch ns

t

PDLL

[13, 14, 15]

Input to Output Through Transparent Input and Output Latches ns

t

EA

[13, 14, 15]

Input to Output Enable ns

t

ER

[11, 13 ]

Input to Output Disable ns

Input Register Parameters

t

WL

Clock or Latch Enable Input LOW Time

[8]

ns

Notes:

11. t

ER

measured with 5-pF AC Test Load and tEA measured with 35-pF AC Test Load.

12. All AC parameters are measured with two outputs switching and 35-pF AC Test Load.

13. Logic Blocks operating in Low-Power Mode, add t

LP

to this spec.

14. Outputs using Slow Output Slew Rate, add t

SLEW

to this spec.

15. When V

CCO

= 3.3V, add t

3.3IO

to this spec.

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 18 of 63

t

WH

Clock or Latch Enable Input HIGH Time

[8]

ns

t

IS

Input Register or Latch Set-up Time ns

t

IH

Input Register or Latch Hold Time ns

t

ICO

[13, 14, 15]

Input Register Clock or Latch Enable to Combinatorial Output ns

t

ICOL

[13, 14, 15]

Input Register Clock or Latch Enable to Output Through Transparent Output Latch ns

Synchronous Clocking Parameters

t

CO

[14, 15]

Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) or Latch Enable to Output ns

t

S

[13]

Set-Up Time from Input to Sync. Clk (CLK0, CLK1, CLK2, or CLK3) or Latch Enable ns

t

H

Register or Latch Data Ho ld Time ns

t

CO2

[13, 14, 15]

Output Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) or Latch Enable to Com binatoria l Output

Delay (Through Logic Array)

ns

t

SCS

[13]

Output Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) or Latch Enable to Outpu t Sy nc hro nou s

Clock (CLK

0

, CLK1, CLK2, or CLK3) or Latch Enable (Through Logic Array)

ns

t

SL

[13]

Set-Up Time from Inp ut T hrou gh Transparent Latch to Output Regist er Sy nc hron ou s C l ock (CL K0

CLK

1

, CLK2, or CLK3) or Latch Enable

ns

t

HL

Hold Time for Input Through Transparent Latch from Output Register Synchronous Clock (CLK0,

CLK

1

, CLK2, or CLK3) or Latch Enable

ns

Product Term Clock ing Param eters

t

COPT

[13, 14, 15]

Product Term Clock or Latch Enable (PTCLK) to Output ns

t

SPT

Set-Up Time from Input to Product Term Clock or Latch Enable (PTCLK) ns

t

HPT

Register or Latch Data Ho ld Time ns

t

ISPT

[13]

Set-Up Time for Buried Register used as an Input Register from Input to Product Term Clock or

Latch Enable (PTCLK)

ns

t

IHPT

Buried Reg ister Used as an Input Register or Lat ch Data Hold Time ns

t

CO2PT

[13, 14, 15]

Product Term Clock or Latch Enable (PTCLK) to Output Delay (Through Logic Array) ns

Pipelined Mode Parameters

t

ICS

[13]

Input Register Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) to Output Register S ync hro nou s

Clock (CLK0, CLK1, CLK2, or CLK3)

ns

Operating Frequency Parameters

f

MAX1

Maximum Frequency with Internal Feedback (Lesser of 1/t

SCS

, 1/(tS + tH), or 1/tCO)

[5]

MHz

f

MAX2

Maximum Frequency Data Path in Output Registered/Latched Mode (Lesser of 1/(tWL + tWH),

1/(t

S+tH

), or 1/tCO)

[5]

MHz

f

MAX3

Maximum Frequency with External Feedback (Lesser of 1/(tCO + tS) or 1/(tWL + tWH)

[5]

MHz

f

MAX4

Maximum Frequency in Pipelined Mode (Lesser of 1/(tCO + tIS), 1/t

ICS

, 1/(tWL + tWH), 1/(tIS + tIH),

or 1/t

SCS

)

[5]

MHz

Reset/Preset Parameters

t

RW

Asynchronous Re se t Width

[5]

ns

t

RR

[13]

Asynchronous Reset Recovery Time

[5]

ns

t

RO

[13, 14, 15]

Asynchronous Reset to Output ns

t

PW

Asynchronous Preset Widt h

[5]

ns

t

PR

[13]

Asynchronous Preset Recovery Time

[5]

ns

t

PO

[13, 14, 15]

Asynchronous Preset to Output ns

User Option Parameters

t

LP

Low Power Adder ns

t

SLEW

Slow Output Slew Rate Adder ns

t

3.3IO

3.3V I/O Mode Timing Adder

[5]

ns

Switching Characteristics Over the Operating Range

[12]

(continued)

Parameter Description Unit

Ultra37000 CPLD Fami

ly

Document #: 38-03007 Rev. *B Page 19 of 63

JTAG Timing Parameters

t

S JTAG

Set-up Time from TDI and TMS to TCK

[5]

ns

t

H JTAG

Hold Time on TDI and TMS

[5]

ns

t

CO JTAG

Falling Edge of TCK to TDO

[5]

ns

f

JTAG

Maximum JTAG Tap Controller Frequency

[5]

ns

Switching Characteristics Over the Operating Range

[12]

(continued)

Parameter Description Unit

Switching Characteristics Over the Operating Range

[12]

Parameter

200 MHz 167 MHz

154 MHz 143 MHz 125 MHz 100 MHz 83 MHz 66 MHz

Unit

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Min.

Max.

Combinatorial Mode Parameters

t

PD

[13, 14, 15]

6 6.5 7.5 8.5 10 12 15 20 ns

t

PDL

[13, 14, 15]

11 12.5 14.5 16 16.5 17 19 22 ns

t

PDLL

[13, 14, 15]

12 13.5 15.5 17 17.5 18 20 24 ns

t

EA

[13, 14, 15]

8 8.5 11 13 14 16 19 24 ns

t

ER

[11, 13 ]

8 8.5 11 13 14 16 19 24 ns

Input Register Parameters

t

WL

2.5 2.5 2.5 2.5 3 3 4 5 ns

t

WH

2.5 2.5 2.5 2.5 3 3 4 5 ns

t

IS

2 222 2 2.5 3 4ns

t

IH

2 222 2 2.5 3 4ns

t

ICO

[13, 14, 15]

11 11 11 12.5 12.5 16 19 24 ns

t

ICOL

[13, 14, 15]

12 12 12 14 16 18 21 26 ns

Synchronous Clocking Parameters

t

CO

[14, 15]

444.56 6.5

[16]

6.5

[17]

8

[18]

10 ns

t

S

[13]

44555.5

[16]

6

[17]

8

[18]

10 ns

t

H

0000 0 0 0 0ns

t

CO2

[13, 14, 15]

9.5 10 11 12 14 16 19 24 ns

t

SCS

[13]

5 66.57 8

[16]

10 12 15 ns

t

SL

[13]

7.5 7.5 8.5 9 10 12 15 15 ns

t

HL

0 000 0 0 0 0ns

Product Term Clock ing Param eters

t

COPT

[13, 14, 15]

7101013 13 13 1520ns

t

SPT

2.5 2.5 2.5 3 5 5.5 6 7 ns

t

HPT

2.5 2.5 2.5 3 5 5.5 6 7 ns

t

ISPT

[13]

0000 0000ns

t

IHPT

6 6.5 6.5 7.5 9 11 14 19 ns

t

CO2PT

[13, 14,

15]

12 14 15 19 19 21 24 30 ns

Pipelined Mode Parameters

t

ICS

[13]

56678

[16]

10 12 15 ns

Notes:

16. The following values correspond to the CY37512 and CY37384 devices: t

CO

= 5 ns, tS = 6.5 ns, t

SCS

= 8.5 ns, t

ICS

= 8.5 ns, f

MAX1

= 118 MHz.

17. The following values correspond to the CY37192V and CY37256V devices: t

CO

= 6 ns, tS = 7 ns, f

MAX2

= 143 MHz, f

MAX3

= 77 MHz, and f

MAX4

= 100 MHz;

and for the CY37512 devices: t

S

= 7 ns.

18. The following values correspond to the CY37512V and CY37384V devices: t

CO

= 6.5 ns, tS = 9.5 ns, and f

MAX2

= 105 MHz.

Loading...

Loading...