Page 1

STK17T88

32K x 8 AutoStore™ nvSRAM with

Real Time Clock

Features

■ nvSRAM Combined With Integrated Real-Time Clock

Functions (RTC, Watc hdog Timer, Clock Alarm, Power

Monitor)

■ Capacitor or Battery Backup for RTC

■ 25, 45 ns Read Access and R/W Cycle Time

■ Unlimited Read/Write Endurance

■ Automatic Nonvolatile STORE on Power Loss

■ Nonvolatile STORE Under Hardware or Software Control

■ Automatic RECALL to SRAM on Power Up

■ Unlimited RECALL Cycles

■ 200K STORE Cycles

■ 20-Year Nonvolatile Data Retention

■ Single 3V +20%, -10% Power Supply

■ Commercial and Industrial Temperatures

■ 48-pin 300-mil SSOP Package (RoHS-Compliant)

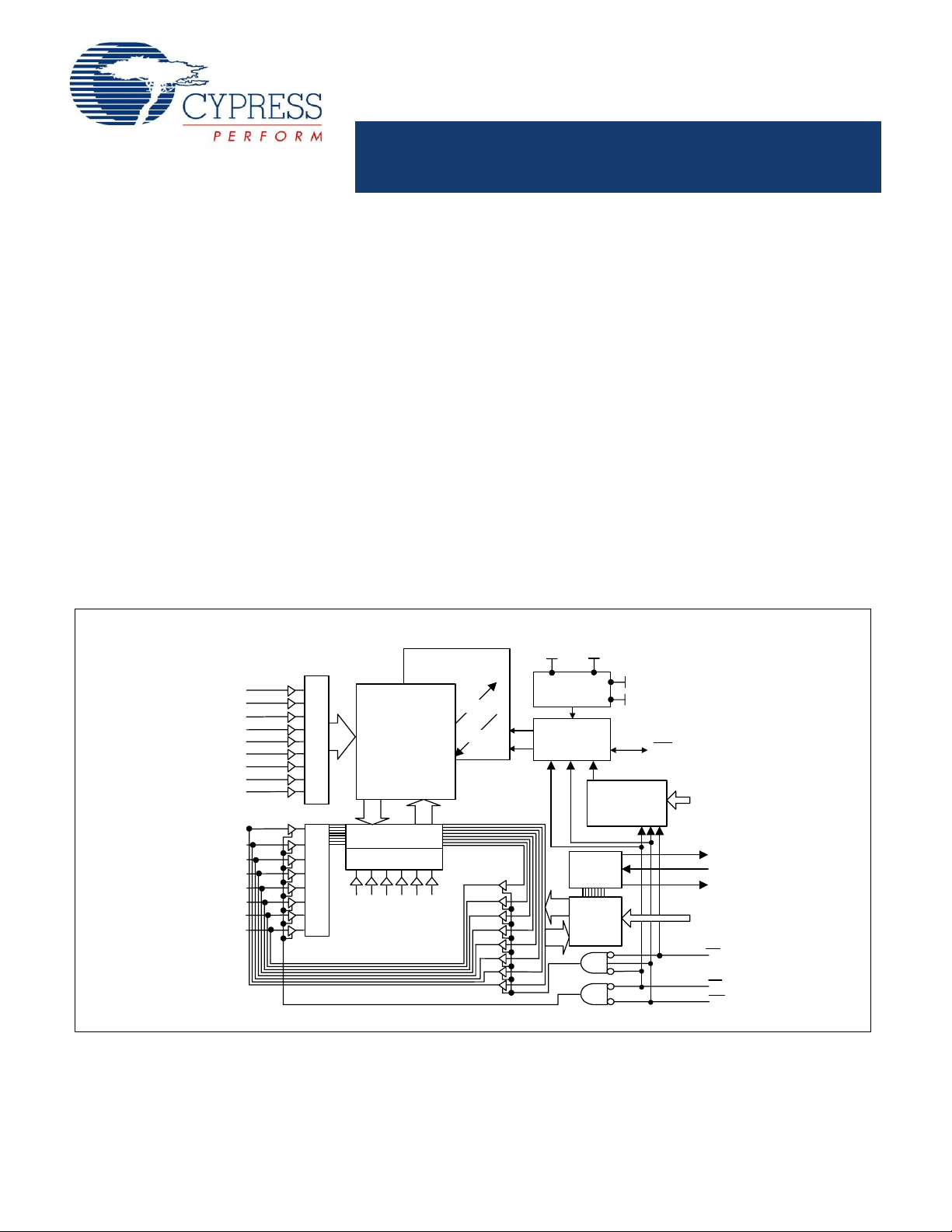

Logic Block Diagram

A

5

A

6

A

7

A

DQ

DQ

DQ

DQ

DQ

DQ

DQ

DQ

8

A

9

A

11

A

12

A

13

A

14

0

1

2

3

4

5

6

7

ROW DECODER INPUT BUFFERS

STATIC RAM

ARRAY

512 X 512

COLUMN I/O

COLUMN DEC

A0 A1 A2 A3 A4 A

Quantum Trap

512 X 512

STORE

RECALL

10

Description

The Cypress STK17T88 combines a 256 Kb nonvolatile static

RAM (nvSRAM) with a full-featured real-time clock in a reliable,

monolithic integrated circuit.

The 256 Kb nvSRAM is a fast static RAM with a nonvolatile

Quantum Trap storage element included with each memory cell.

The SRAM provides the fast access and cycle times, ease of use

and unlimited read and write endurance of a normal SRAM. Data

transfers automatically to the nonvolatile storage cells when

power loss is detected (the STORE operation). On power up,

data is automatically restored to the SRAM (the RECALL

operation). Both STORE and RECALL operations are also

available under software control.

The real time clock function provides an accurate clock with leap

year tracking and a programmable, high accuracy oscillator. The

Alarm function is programmable for one-ti me ala rms or peri odi c

minutes, hours, or days alarms. There is also a programmable

watchdog timer for processor control.

V

V

CC

POWER

CONTROL

STORE/

RECALL

CONTROL

RTC

MUX

CAP

V

V

SOFTWARE

DETECT

RTCbat

RTCcap

HSB

A13 – A

X

X

INT

A14 – A

G

0

1

2

0

E

W

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 •408-943-2600

Document Number: 001-52040 Rev. *A Revised March 17, 2009

[+] Feedback

Page 2

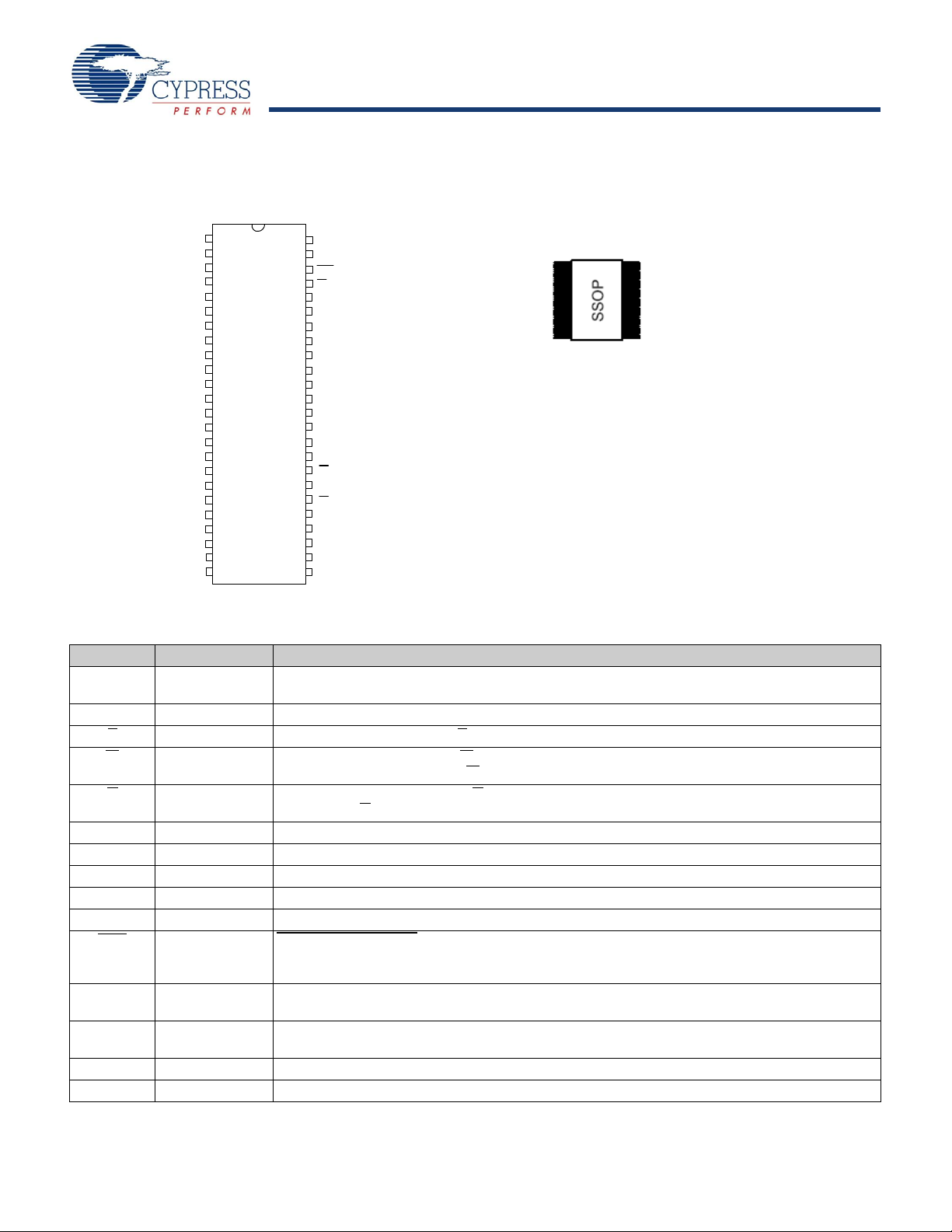

Pin Configurations

Figure 1. 48-Pin SSOP

V

CAP

1

2

A

14

3

A

4

12

A

7

5

A

6

6

A

5

7

INT

8

A

4

9

NC

10

NC

11

NC

12

V

SS

13

NC

14

V

RTCbat

15

DQ

0

16

A

3

17

A

2

18

A

1

19

A

20

0

DQ

1

21

DQ

2

22

X

23

1

X

2

24

(TOP)

STK17T88

Relative PCB Area Usage

V

48

CC

CNCN

47

46

HSB

45

W

A

44

13

A

6

43

A

9

42

NC

41

A

40

11

39

NC

38

NC

37

NC

36

V

SS

35

NC

V

34

RTCcap

DQ

33

6

G

32

A

31

10

30

E

DQ

29

7

DQ

28

5

DQ

27

4

DQ

3

26

V

CC

25

[1]

Pin Descriptions

Pin Name IO Type Description

A

14-A0

DQ

-DQ

7

0

E Input Chip Enable: The active low E input selects the device.

W

G Input Output Enable: The active low G input enables the data output buffers during read cycles.

X

1

X

2

V

RTCcap

V

RTCbat

V

CC

HSB

INT Output Interrupt Control: Can be programmed to respond to the clock alarm, the watchdog timer and the

V

CAP

V

SS

NC No Connect Unlabeled pins have no internal connections.

Note

1. For detailed package size specifications, see Package Diagram on page 21.

Input Address: The 15 address inputs select one of 32,768 bytes in the nvSRAM array or one of 16 bytes

in the clock register map.

I/O Data: Bi-directional 8-bit data bus for accessing the nvSRAM and RTC.

Input Write Enable: The active low W enables data on the DQ pins to be written to the address location

selected on the falling edge of E.

De-asserting G

high caused the DQ pins to tri-state.

Output Crystal Connection, drives crystal on startup.

Input Crystal Connection for 32.768 kHz crystal.

Power Supply Capacitor supplied backup RTC supply voltage (Left unconnected if V

Power Supply Battery supplied backup RTC supply voltage (Left unconnected if V

RTCcap

RTCbat

is used).

is used).

Power Supply Power: 3.0V, +20%, -10%

I/O Hardware Store Busy: When low this output indicates a Store is in progress. When pulled low

external to the chip, it initiates a nonvolatile STORE operation. A weak pull up resistor keeps this

pin high if not connected. (Connection Optional).

power monitor. Programmable to either active high (push/pull) or active low (open-drain)

Power Supply Autostore™ Capacitor: Supplies power to nvSRAM during power loss to store data from SRAM

to nonvolatile storage elements.

Power Supply Ground

Document Number: 001-52040 Rev. *A Page 2 of 22

[+] Feedback

Page 3

Absolute Maximum Ratings

Voltage on Input Relative to Ground.................–0.5V to 4.1V

Voltage on Input Relative to V

Voltage on DQ

or HSB......................–0.5V to (VCC + 0.5V)

0-7

...........–0.5V to (VCC + 0.5V)

SS

Temperature under Bias...............................–55°C to 125°C

Junction Temperature................................... –55°C to 140°C

Storage Temperature.................................... –65°C to 150°C

Power Dissipation.............................................................1W

DC Output Current (1 output at a time, 1s duration)....15 mA

RF (SSOP-48) Package Thermal Characteristics

θ

6.2 C/W; θja 51.1 [0fpm], 44.7 [200fpm], 41.8 C/W [500fpm]

jc

DC Characteristics

(V

= 2.7V-3.6V)

CC

Symbol Parameter

I

CC

I

CC

I

CC

I

CC

Average VCC Current 65

1

Average VCC Current

2

during STORE

Average V

3

at t

3V, 25°C, Typical

Average V

4

Current during

AVAV

CC

= 200ns

CAP

AutoStore™ Cycle

I

SB

V

Standby Current

CC

(Standby, Stable

CMOS Levels)

I

ILK

Input Leakage

Current

Current

Commercial Industrial

Min Max Min Max

50

3 3 mA All Inputs Don’t Care, VCC = max

10 10 mA W

3 3 mA All Inputs Don’t Care

33mAE

±1 ±1 µAV

STK17T88

Note: Stresses greater than those listed under “Absolute

Maximum Ratings” may cause permanent damage to the device.

This is a stress rating only, and functional operation of the device

at conditions above those indicated in the operational section s

of this specification is not implied. Exposure to absolute

maximum rating conditions for extended periods may affect

reliability.

Units Notes

70

55

mAmAt

= 25 ns

AVAV

t

= 45 ns

AVAV

Dependent on output loading and cycle rate.

Values obtained without output loads.

Average current for duration of STORE

cycle (t

≥ (V

All Other Inputs Cycling at CMOS Levels

STORE

– 0.2V)

CC

)

Dependent on output loading and cycle rate.

Values obtained without output loads.

Average current for duration of STORE cycle

(t

STORE

)

≥ (VCC -0.2V)

All Others V

Standby current level after nonvolatile cycle

≤ 0.2V or ≥ (V

IN

CC

-0.2V)

complete

= max

CC

V

= VSS to V

IN

CC

I

OLK

V

IH

V

IL

Note:The HSB

Note:The INT is open-drain and does not source or sink high current when interrupt Register bit D3 is below.

Off-St ate Output

Leakage Current

Input Logic “1”

Voltage

Input Logic “0”

Voltage

pin has I

OUT

±1 ±1 µAV

= max

CC

V

= VSS to VCC, E or G ≥ VIH

IN

2.0 VCC + 0.5 2.0 VCC + 0.5 V All Inputs

VSS –0.5 0.8 VSS –0.5 0.8 V All Inputs

=-10uA for VOH of 2.4V, this parameter is characterized but not tested.

Document Number: 001-52040 Rev. *A Page 3 of 22

[+] Feedback

Page 4

DC Characteristics (continued)

(V

= 2.7V-3.6V)

CC

Symbol Parameter

V

OH

V

OL

T

A

V

CC

V

CAP

NV

C

DATA

Output Logic “1”

Voltage

Output Logic “0”

Voltage

Operating Temperature

Operating Voltage 2.7 3.6 2.7 3.6 V 3.0V +20%, -10%

Storage Capacitance 17 57 17 57 µFBetween V

Nonvolatile STORE

operations

Data Retention 20 20 Years At 55°C

R

Min Max Min Max

200 200 K

Commercial Industrial

Units Notes

2.4 2.4 V I

0.4 0.4 V I

0 70 –40 85 °C

OUT

OUT

= –2 mA

= 4 mA

CAP

STK17T88

pin and VSS, 5V rated.

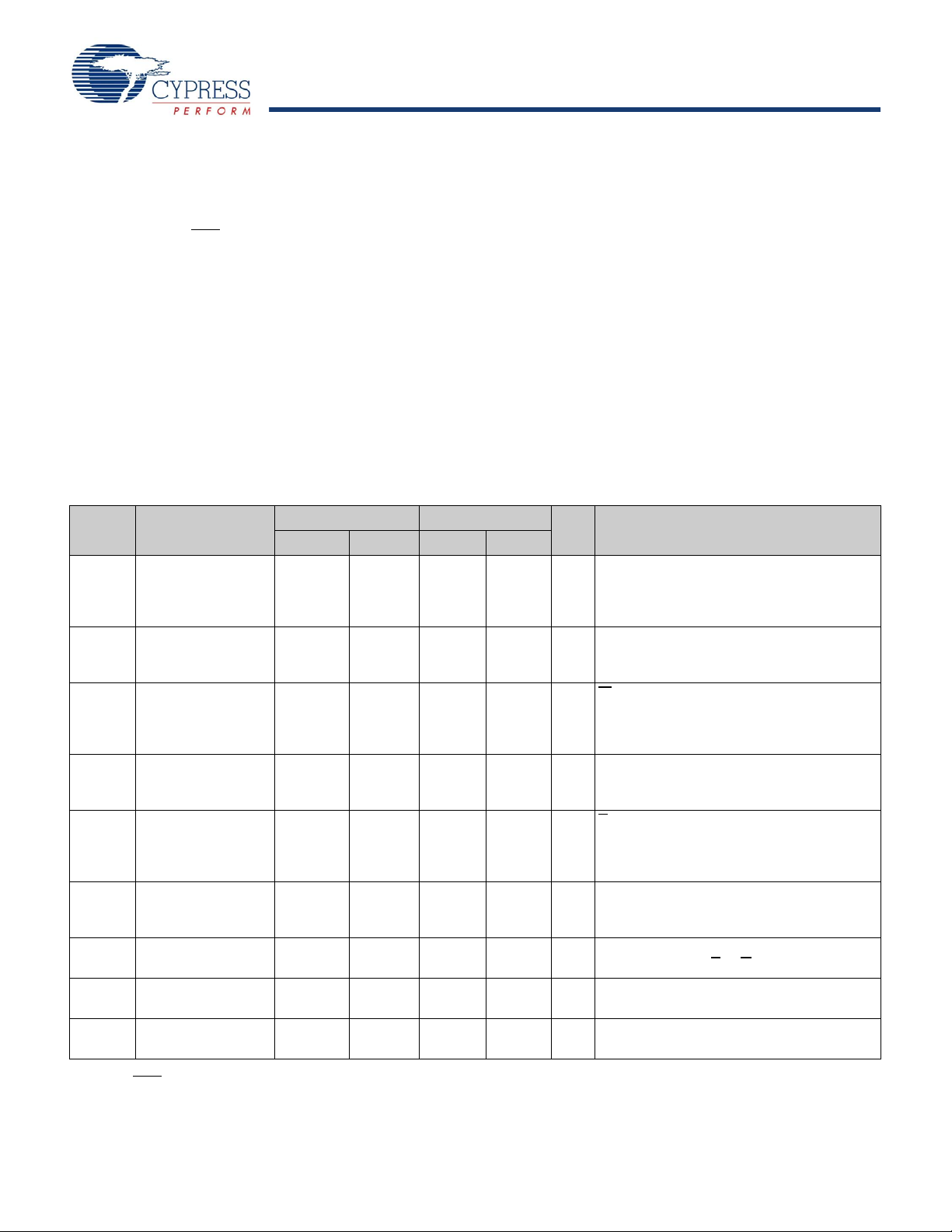

AC Test Conditions

Input Pulse Levels....................................................0V to 3V

Input Rise and Fall Times...................................................≤ 5ns

Input and Output Timing Reference Levels....................1.5V

Output Load..................................See Figure 2 and Figure 3

Capacitance

Symbol Parameter

C

IN

C

OUT

Input Capacitance 7 pF ∆V = 0 to 3V

Output Capacitance 7 pF ∆V = 0 to 3V

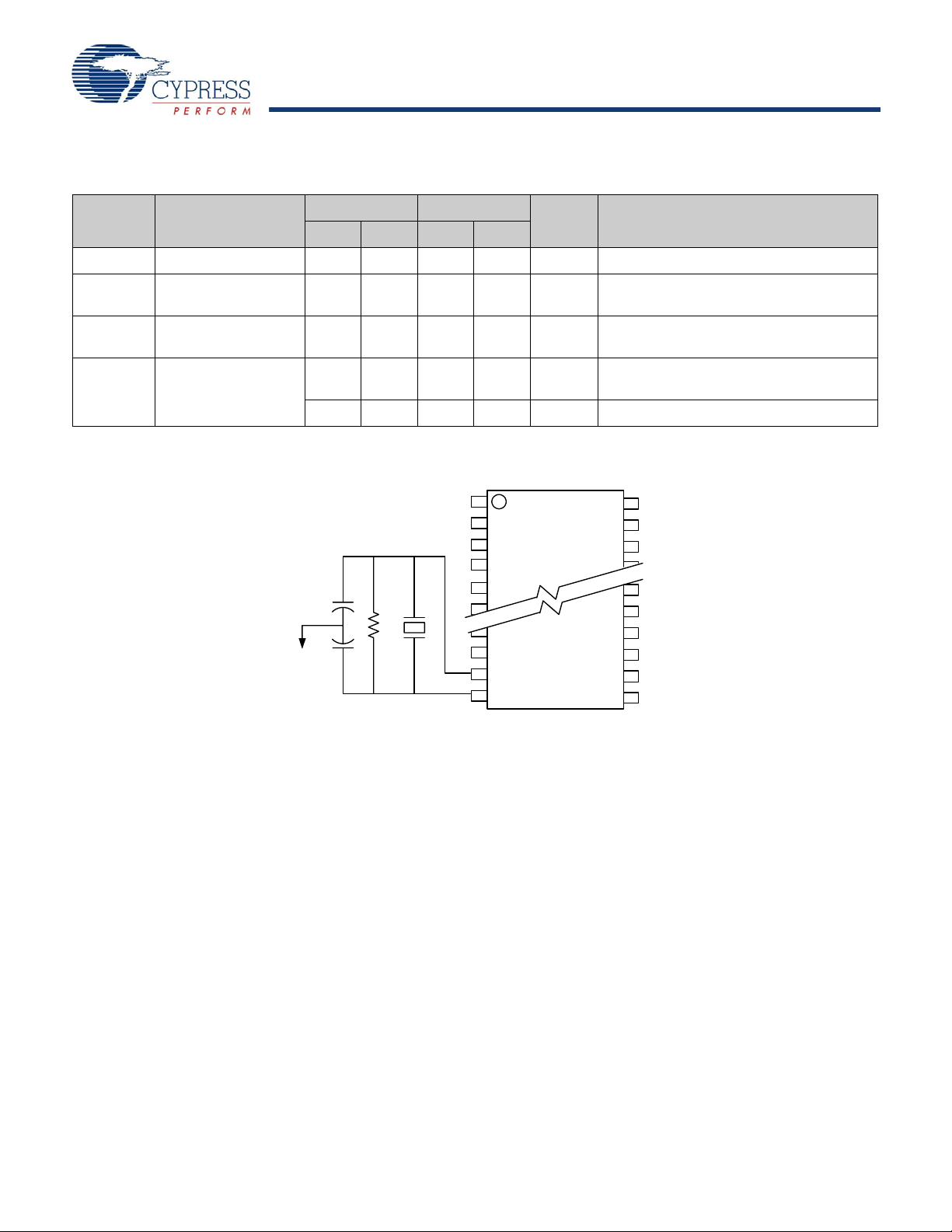

Figure 2. AC Output Loading Figure 3. AC Output Loading for Tristate Specs (THZ, tLZ,

[2]

Max Units Conditions

, t

, t

, t

t

WLQZ

WHQZ

GLQX

GHQZ

)

Note

2. These parameters are guaranteed but not tested.

Document Number: 001-52040 Rev. *A Page 4 of 22

[+] Feedback

Page 5

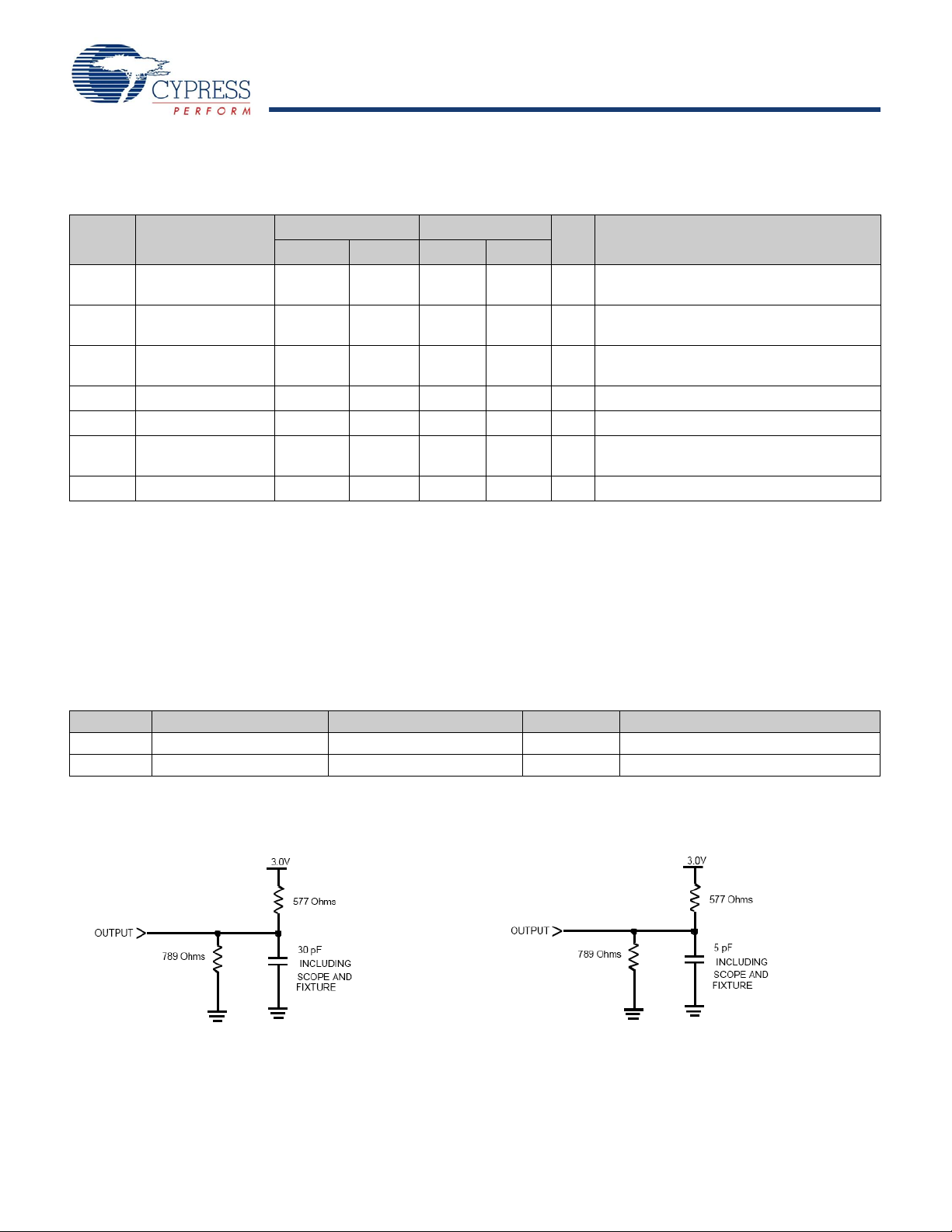

RTC DC Characteristics

STK17T88

Symbol Parameter

Units Notes

Min Max Min Max

IBAK RTC Backup Current — 300 — 350 nA From either VRTCcap or VRTCbat

Commercial Industrial

VRTCbat RTC Battery Pin

1.8 3.3 1.8 3.3 V Typical = 3.0 Volt s during normal operation

Voltage

VRTCcap RTC Capacitor Pin

1.2 2.7 1.2 2.7 V Typical = 2.4 Volt s during normal operation

Voltage

tOSCS RTC Oscillator time to

start

— 10 — 10 sec At Minimum T emperature from Power up or

Enable

—5—5secAt 25°C from Power up or Enable

Figure 4. RTC Component Configuration

1

C

2

C

RF

1

Y

X

1

X

2

Recommended Values

Y

= 32.768 KHz

1

RF

= 10M Ohm

= 0 (install cap footprint,

C

1

but leave unloaded)

C

= 56 pF ± 10% (do not vary from this value)

2

Document Number: 001-52040 Rev. *A Page 5 of 22

[+] Feedback

Page 6

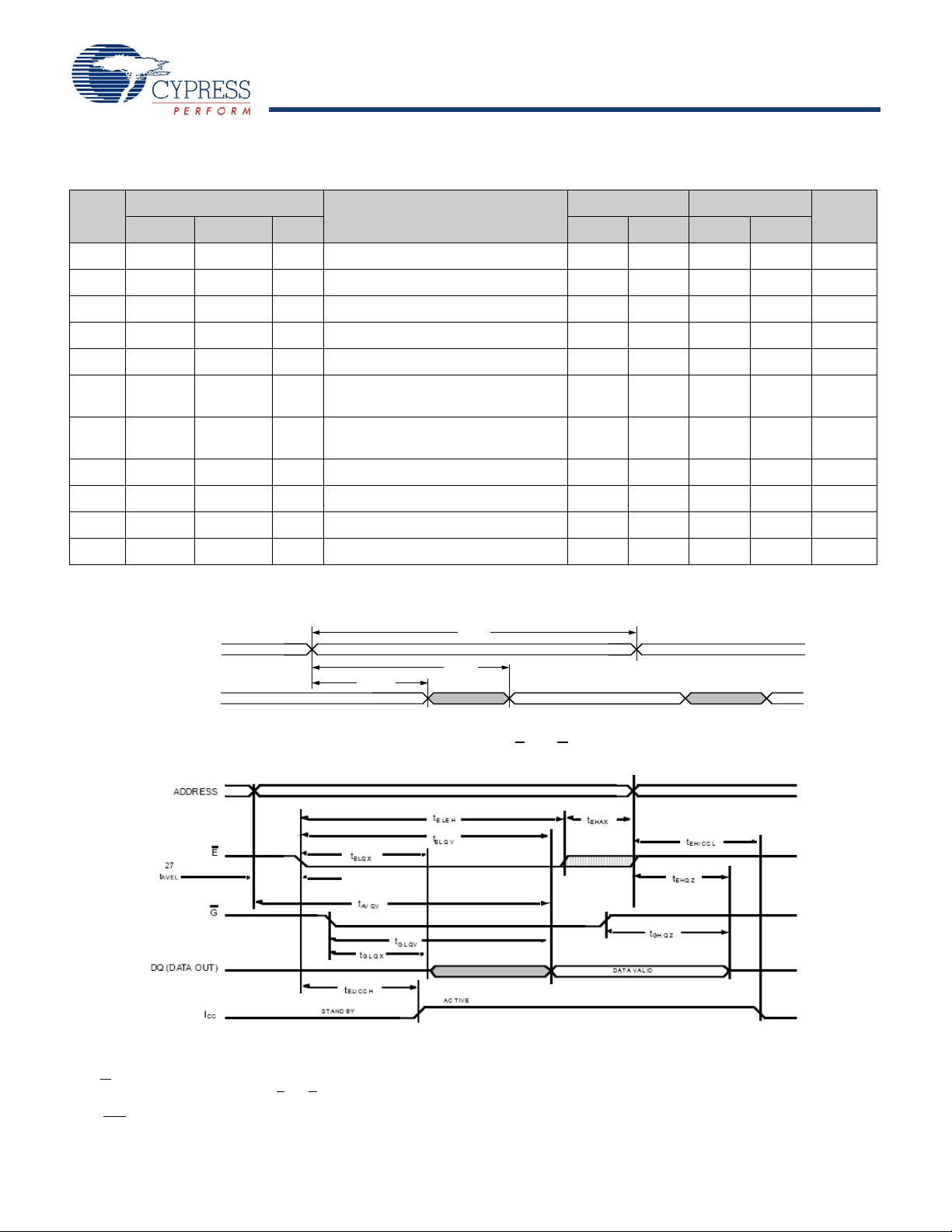

SRAM READ Cycles #1 and #2

STK17T88

NO.

Symbols

#1 #2 Alt. Min Max Min Max

1t

2t

AVAV

3t

AVQV

4t

5t

AXQX

6t

7t

8t

9t

10 t

11 t

DQ (DATA OUT)

[3]

[4]

[4]

ADDRESS

ELQV

t

ELEH

t

AVQV

GLQV

t

AXQX

ELQX

EHQZ

GLQX

GHQZ

ELICCL

EHICCH

[5]

[6]

[5]

[3]

[3]

Parameter

STK17T88-25 STK17T88-45

t

ACS

t

RC

t

AA

t

OE

t

OH

t

LZ

t

HZ

t

OLZ

t

OHZ

t

PA

t

PS

Chip Enable Access Time 25 45 ns

Read Cycle Time 25 45 ns

Address Access Time 25 45 ns

Output Enable to Data Valid 12 20 ns

Output Hold after Address Change 3 3 ns

Address Change or Chip Enable to

33ns

Output Active

Address Change or Chip Disable to

Output Inactive

Output Enable to Output Active 0 0 ns

Output Disable to Output Inactive 10 15 ns

Chip Enable to Power Active 0 0 ns

Chip Disable to Power Standby 25 45 ns

Figure 5. SRAM READ Cycle #1: Address Controlled

2

t

AVAV

3

t

t

AXQX

5

AVQV

DATA VALID

Units

10 15 ns

[3,4,6]

Figure 6. SRAM READ Cycle #2: E and G Controlled

Notes

must be high during SRAM READ cycles.

3. W

4. Device is continuously selected with E

5. Measured ± 200mV from steady state output voltage.

must remain high during READ and WRITE cycles.

6. HSB

and G both low

2

6

3

8

10

1

4

29

[6]

11

7

9

Document Number: 001-52040 Rev. *A Page 6 of 22

[+] Feedback

Page 7

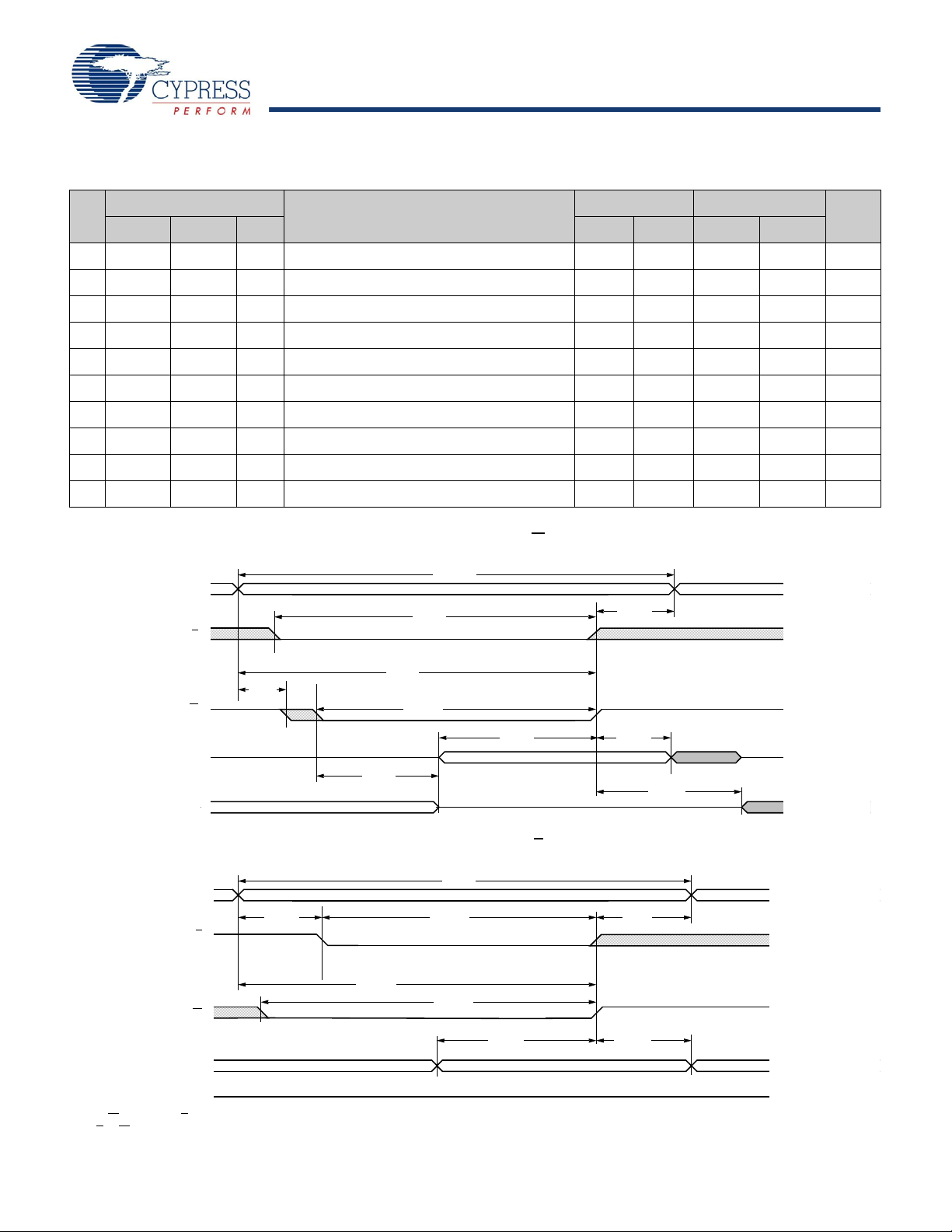

SRAM WRITE Cycles #1 and #2

STK17T88

NO.

12 t

AVAV

13 t

WLWHtWLEH

14 t

ELWH

15 t

DVWHtDVEH

16 t

WHDXtEHDX

17 t

AVWH

18 t

AVWL

19 t

WHAX

20 t

WLQZ

21 t

WHQX

Symbols

STK17T88-25 STK17T88-45

Parameter

#1 #2 Alt. Min Max Min Max

ADDRESS

t

AVAV

t

ELEH

t

AVEH

t

AVEL

t

EHAX

E

t

t

t

t

t

t

t

t

t

t

Write Cycle Time 25 45 ns

WC

Write Pulse Width 20 30 ns

WP

Chip Enable to End of Write 20 30 ns

CW

Data Set-up to End of Write 10 15 ns

DW

Data Hold after End of Write 0 0 ns

DH

Address Set-up to End of Write 20 30 ns

AW

Address Set-up to Start of Write 0 0 ns

AS

Address Hold after End of Write 0 0 ns

WR

Write Enable to Output Disable 10 15 ns

WZ

Output Active after End of Write 3 3 ns

OW

Figure 7. SRAM WRITE Cycle #1: W Controlled

12

t

AVAV

14

t

ELWH

[7, 8]

19

t

WHAX

Units

t

W

DATA IN

DATA IN

DATA OUT

ADDRESS

E

W

DATA IN

Notes

7. If W

or W must be ≥ V during address transitions.

8. E

DATA OUT

is low when E goes low, the outputs remain in the high-impedance state.

18

AVWL

17

t

AVWH

13

t

WLWH

15

t

DVWH

DATA VALID

HIGH IMPEDANCE

PREVIOUS DATA

20

t

WLQZ

Figure 8. SRAM WRITE Cycle #2: E Controlled

12

t

AVAV

t

AVEL

18

17

t

AVEH

14

t

ELEH

13

t

WLEH

HIGH IMPEDANCE

t

DVEH

15

DATA VALID

16

t

WHDX

[7, 8]

t

EHAX

16

t

EHDX

21

t

WHQX

19

Document Number: 001-52040 Rev. *A Page 7 of 22

[+] Feedback

Page 8

AutoStore/Power Up RECALL

STK17T88

NO.

22 t

23 t

24 V

25 V

Symbols

STK17T88

Parameter

Standard Alternate Min Max

HRECALL

STORE

SWITCH

CCRISE

t

HLHZ

Power up RECALL Duration 40 ms 9

STORE Cycle Duration 12.5 ms 10, 11

Low Voltage Trigger Level 2.65 V

V

Rise Time 150 µS

CC

Figure 9. AutoStore Power Up RECALL

25

Units Notes

23 23

22

22

NOTE: Read and Write cycles will be ignored during STORE, RECALL and while VCC is below V

Notes

9. t

10. If an SRAM WRITE has not taken place since the last nonvolatile cycle, no STORE will take place

11. Industrial Grade Devices require 15 ms Max.

starts from the time VCC rises above V

HRECALL

SWITCH

SWITCH

Document Number: 001-52040 Rev. *A Page 8 of 22

[+] Feedback

Page 9

Software-Controlled STORE/RECALL Cycle

In the following table, the software controlled STORE and RECALL cycle parameters are listed.

STK17T88

[12, 13]

NO.

Symbols

Parameter

STK17T88-35 STK17T88-45

E Cont Alternate Min Max Min Max

26 t

27 t

28 t

29 t

30 t

AVAV

AVEL

ELEH

EHAX

RECALL

t

t

t

RC

AS

CW

STORE / RECALL Initiation Cycle Time 25 45 ns 13

Address Set-up Time 0 0 ns

Clock Pulse Width 20 30 ns

Address Hold Time 1 1 ns

RECALL Duration 100 100 ms

Figure 10. Software Store/Recall Cycle: E CONTROLLED

26

27

28

29

26

23 30

Units Notes

[13]

Notes

12.The software sequence is clocked on the falling edge of E

13.The six consecutive addresses must be read in the order listed in the Software STORE/RECALL Mode Selection Table . W must be high during all six consecutive cycles.

controlled READs

Document Number: 001-52040 Rev. *A Page 9 of 22

[+] Feedback

Page 10

Hardware STORE Cycle

STK17T88

NO.

Symbols

Standard Alternate Min Max

31 t

32 t

DELAY

HLHX

t

HLQZ

Hardware STORE to SRAM Disabled 1 70 µs14

Hardware STORE Pulse Width 15 ns

Soft Sequence Commands

Parameter

Units Notes

Figure 11. Hardware STORE Cycle

32

23

31

STK17T88

NO.

Symbols Parameter STK17T88 Units Notes

Standard Min Max

33 t

SS

Soft Sequence Processing Time 70 µs 15, 16

Figure 12. Soft Sequence Command

33 33

Notes

14.On a hardware STORE initiation, SRAM operation continues to be enabled for time tDELAY to allow read/write cycles to complete

15.This is the amount of time that it takes to take action on a soft sequence command. Vcc power must remain high to effectively register command.

16.Commands like Store and Recall lock out I/O until operation is complete which further increases this time. See specific command

Document Number: 001-52040 Rev. *A Page 10 of 22

[+] Feedback

Page 11

MODE Selection

STK17T88

E W G A14-A

0

Mode I/O Power Notes

H X X X Not Selected Output High Z S tandby

L H L X Read SRAM Output Data Active

L L X X Write SRAM Input Data Active

LH L0x0E38

0x31C7

0x03E0

0x3C1F

0x303F

0x0FC0 Nonvolatile Store Output High Z I

LH L0x0E38

0x31C7

0x03E0

0x3C1F

0x303F

0x0C63

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Nonvolatile Recall

Output Data

Output Data

Output Data

Output Data

Output Data

Output Data

Output Data

Output Data

Output Data

Output Data

Output High Z

Active 17,18, 19

CC2

Active

17,18, 19

Notes

17.The six consecutive addresses must be in the order listed. W

18.While there are 15 addresses on the STK17T88, only the lower 13 are used to control software modes.

19.I/O state depends on the state of G

. The I/O table shown assumes G low.

must be high during all six consecutive cycles to enable a nonvolatile cycle.

Document Number: 001-52040 Rev. *A Page 11 of 22

[+] Feedback

Page 12

STK17T88

nvSRAM Operation

The STK17T88 nvSRAM is made up of two functional components paired in the same physical cell. These are the SRAM

memory cell and a nonvolatile QuantumTrap™ cell. The SRAM

memory cell operates like a standard fast static RAM. Data in the

SRAM can be transferred to the nonvolatile cell (the STORE

operation), or from the nonvolatile cell t o SRAM (the RECALL

operation). This unique architecture allows all cells to be stored

and recalled in parallel. During the STORE and RECALL operations SRAM READ and WRITE operations are inhibited. The

STK17T88 supports unlimited read and writes like a typical

SRAM. In addition, it provides unlimited RECALL operations

from the nonvolatile cells and up to 200K STORE operations.

SRAM READ

The STK17T88 performs a READ cycle whenever E and G are

low while W

A

0-14

When the READ is initiated by an address transition, the outputs

are valid after a delay of t

initiated by E

whichever is later (READ cycle #2). The data outputs repeatedly

respond to address changes within the t

without the need for transitions on any cont rol input pins, and

remain valid until another address change or until E

brought high, or W

Figure 13. AutoStore Mode

SRAM WRITE

A WRITE cycle is performed whenever E and W are low and HSB

is high. The address inputs must be stable prior to entering the

WRITE cycle and must remain stable until either E

high at the end of the cycle. The data on the common I/O pins

DQ0-7 are written into memory if it is valid t

of a W

controlled WRITE.

It is recommended that G

cycle to avoid data bus contention on common I/O lines. If G

left low, internal circuitry turns off the output buffers t

goes low.

W

AutoStore Operation

The STK17T88 stores data to nvSRAM using one of three

storage operations. These three operations are Hardware Store

and HSB are high. The address specified on pins

determine which of the 32,768 data bytes are accessed.

(READ cycle #1). If the READ is

and G, the outputs are valid at t

CAP

V

AVQV

and HSB is brought low.

V

CAP

V

CC

W

ELQV

AVQV

V

10k Ohm

or at t

GLQV

access time

or G is

CC

0.1µF

or W goes

before the end

controlled WRITE or t

DVEH

DVWH

before the end of an E

be kept high during the entire WRITE

is

after

WLQZ

(activated by HSB

), Software Store (activated by an address

sequence), and AutoStore (on power down).

AutoStore operation, a unique feature of Cypress QuanumTrap

technology that is a standard feature on the STK17T88.

During normal operation, the device draws current from V

charge a capacitor connected to the V

charge is used by the chip to perform a single

If the voltage on the V

automatically disconnects the V

operation is initiated with power provided by the V

pin drops below V

CC

pin from VCC. A STORE

CAP

pin. This stored

CAP

STORE operation.

SWITCH

CAP

Figure 5 shows the proper connection of the storage capacitor

(V

) for automatic store operation. Refer to the DC Character-

CAP

istics table for the size of the capacitor . The volt age on the V

pin is driven to 5V by a charge pump internal to the chip. A pull

up should be placed on W

to hold it inactive during power up.

To reduce unneeded nonvolatile stores, AutoStore and

Hardware Store operations are ignored unless at least one

WRITE operation has taken place since the most recent

or RECALL cycle. Software initiated STORE cycles are

performed regardless of whether a WRITE operation has taken

,

place. The HSB

signal can be monitored by the system to detect

an AutoStore cycle is in progress.

Hardware STORE (HSB) Operation

The STK17T88 provides the HSB pin for controlling and

acknowledging the

used to request a hardware

STORE operations. The HSB pin can be

STORE cycle. When the HSB pin is

driven low, the STK17T88 conditionally initiates a

operation after t

WRITE to the SRAM took place since the last STORE or

. An actual STORE cycle only begins if a

DELAY

RECALL cycle. The HSB pin has a very resistive pull up and is

internally driven low to indicate a busy condition while the

STORE (initiated by any means) is in progress. This pin should

be externally pulled up if it is used to drive other inputs.

SRAM READ and WRITE operations that are in progress when

is driven low by any means are given time to complete

HSB

before the STORE operation is initiated. After HSB

goes low, the

STK17T88 continues to allow SRAM operations for t

During t

If a WRITE is in progress when HSB

time, t

requested after HSB

, multiple SRAM READ operations may take place.

DELAY

, to complete. However, any SRAM WRITE cycles

DELAY

goes low will be inhibited until HSB returns

is pulled low, it is allowed a

high.

During any

the STK17T88 will continue to drive the HSB

it only when the

STORE operation, regardless of how it was initiated,

pin low, releasing

STORE is complete. Upon completion of the

STORE operation, the STK17T88 will remain disabled until the

HSB

pin returns high.

If HSB

is not used, it should be left unconnected.

Hardware Recall (POWER UP)

During power up or after any low-power condition

(V

CC<VSWITCH

When V

RECALL cycle is automatically initiated and takes t

complete.

), an internal RECALL request will be latched.

once again exceeds the sense voltage of V

CC

CC

, the part

capacitor.

CAP

STORE

STORE

DELAY

SWITCH

HRECALL

to

.

, a

to

Document Number: 001-52040 Rev. *A Page 12 of 22

[+] Feedback

Page 13

STK17T88

Software STORE

Data can be transferred from the SRAM to the nonvolatile

memory by a software address sequence. The STK17T88

software

STORE cycle is initiated by executing sequential E

controlled READ cycles from six specific address locations in

exact order. During the

STORE cycle, previous data is erased

and then the new data is programmed into the nonvolatile

elements. Once a

STORE cycle is initiated, further memory

inputs and outputs are disabled until the cycle is completed.

To initiate the software

STORE cycle, the following READ

sequence must be performed:

1. Read address 0x0E38, Valid READ

2. Read address 0x31C7, Valid READ

3. Read address 0x03E0, Valid READ

4. Read address 0x3C1F, Valid READ

5. Read address 0x303F, Valid READ

6. Read address 0x0FC0, Initiate STORE cycle

Once the sixth address in the sequence has been entered, the

STORE cycle commences and the chip is disabled. It is

important that READ cycles and not WRITE cycles be used in

the sequence. After the t

SRAM is again activated for READ and WRITE operation.

cycle time has been fulfilled, the

STORE

Software RECALL

Data can be transferred from the nonvolatile memory to the

SRAM by a software address sequence. A software

RECALL

cycle is initiated with a sequence of READ operations in a manner similar to the software

STORE initiation. To initiate the

RECALL cycle, the following sequence of E controlled READ

operations must be performed:

1. Read address 0x0E38, Valid READ

2. Read address 0x31C7, Valid READ

3. Read address 0x03E0, Valid READ

4. Read address 0x3C1F, Valid READ

5. Read address 0x303F, Valid READ

6. Read address 0x0C63, Initiate RECALL cycle

Internally,

RECALL is a two-step procedure. First, the SRAM

data is cleared, and second, the nonvolatile information is transferred into the SRAM cells. After the t

cycle time, the

RECALL

SRAM is again ready for READ or WRITE operations. The

RECALL operation in no way alters the data in the nonvolatile

storage elements.

Data Protection

The STK17T88 protects data from corruption during low-voltage

conditions by inhibiting all externally initiated STORE and

WRITE operations. The low-voltage condition is detected when

V

CC<VSWITCH

.

If the STK17T88 is in a WRITE mode (both E

power up, after a

RECALL, or after a STORE, the WRITE is

inhibited until a negative transition on E

and W low) at

or W is detected. This

protects against inadvertent writes during power up or brown out

conditions.

Noise Considerations

The STK17T88 is a high-speed memory and so must have a

high-frequency bypass capacitor of 0.1 µF connected between

both V

V

SS

all high-speed CMOS ICs, careful routing of power, ground, and

pins and VSS ground plane with no plane break to chip

CC

. Use leads and traces that are as short as possible. As with

signals reduce circuit noise.

Preventing AutoStore

Because of the use of nvSRAM to store critical RTC data, the

AutoStore function can not be disabled on the STK17T88.

Best Practices

nvSRAM products have been used effectively for over 15 years.

While ease-of-use is one of the product’s main system values,

experience gained working with hundreds of applications has

resulted in the following suggestions as best practices:

■ The nonvolatile cells in an nvSRAM are programmed on the

test floor during final test and quality assurance. Incoming

inspection routines at customer or contract manufacturer’s

sites sometimes reprograms these values. Final NV patterns

are typically repeating patterns of AA, 55, 00, FF, A5, or 5A.

End product’s firmware should not assume an NV array is in a

set programmed state. Routines that check memory content

values to determine first time system configuration, cold or

warm boot status, etc. should always program a unique NV

pattern (e.g., complex 4-byte pattern of 46 E6 49 53 hex or

more random bytes) as part of the final system manufacturing

test to ensure these system routines work consistently.

■ Power up boot firmware routines should rewrite the nvSRAM

into the desired state (autostore enabled, etc.). While the

nvSRAM is shipped in a preset state, best practice is to again

rewrite the nvSRAM into the desired state as a safeguard

against events that might flip the bit inadvertently (program

bugs, incoming inspection routines, etc.).

■ The OSCEN bit in the Calibration register at 0x7FF8 should be

set to 1 to preserve battery life when the system is in storage

(see Stopping and Starting the RTC Oscillator on page 14.

■ The V

and a maximum value size. Best practice is to meet this

requirement and not exceed the max V

nvSRAM internal algorithm calculates V

on this max Vcap value. Customers that want to use a larger

V

CAP

time should discuss their V

understand any impact on the V

a t

value specified in this datasheet includes a minimum

CAP

value because the

CAP

charge time based

CAP

value to make sure there is extra store charge and store

size selection with Cypress to

RECALL

cap

period.

voltage level at the end of

CAP

Document Number: 001-52040 Rev. *A Page 13 of 22

[+] Feedback

Page 14

STK17T88

Real Time Clock

The clock registers maintain time up to 9,999 years in

one-second increments. The user can set the time to any

calendar time and the clock automatically keeps track of days of

the week and month, leap years, and century transitions. There

are eight registers dedicated to the clock functions which are

used to set time with a write cycle and to read time during a read

cycle. These registers contain the Time of Day in BCD format.

Bits defined as “0” are currently not used and are reserved for

future use by Cypress.

Reading the Clock

The user should halt internal updates to the real time clock

registers before reading clock data to prevent reading of data in

transition. Stopping the internal register updates does not affect

clock accuracy.

Write a “1” to the read bit “R” (in the Flags register at 0x7FF0) to

capture the current time in holding registers. Clock updates do

not restart until a “0” is written to the read bit. The RTC registers

can now be read while the internal clock continues to run.

Within 20ms after a “0” is written to the read bit, all real time clock

registers are simultaneously updated.

Setting the Clock

Set the write bit “W” (in the Flags register at 0x7FF0) to a “1”

enable the time to be set. The correct day, date and time can then

be written into the real time clock registers in 24-hour BCD

format. The time written is referred to as the “Base Time.” This

value is stored in nonvolatile registers and used in calculation of

the current time. Reset the write bit to “0” to transfer the time to

the actual clock counters, The clock starts counting at the new

base time.

Backup Power

The RTC is intended to keep time even when system power is

lost. When primary power, V

time clock switches to the backup power supply connected to

either the V

RTCcap

or V

RTCbat

, drops below V

CC

pin.

The clock oscillator uses a maximum of 300 nanoamps at 2 volts

to maximize the backup time available from the backup source.

You can power the real time clock with either a capacitor or a

battery. Factors to be considered when choosing a backup

power source include the expected duration of power outages

and the cost and reliability trade-off of using a batte ry versus a

capacitor.

If you select a capacitor power source, connect the capacitor to

the V

Capacitor backup time values based on maximum current specs

pin and leave the V

RTCcap

pin unconnected.

RTCbat

are shown below. Nominal times are approximately 3 times

longer.

Capacitor Value Backup Time

0.1 F 72 hours

0.47 F 14 days

1.0 F 30 days

SWITCH

, the real

A capacitor has the obvious advantage of being more reliable

and not containing hazardous materials. The capacitor is

recharged every time the power is turned on so that the real time

clock continues to have the same backup time over years of

operation

If you select a battery power source, connect the battery to the

V

is recommended for this application. The battery capacity should

pin and leave the V

RTCbat

pin unconnected. A 3V lithium

RTCcap

be chosen for the total anticipated cumulative down-time

required over the life of the system.

The real time clock is designed with a diode internally connected

to the V

charged by the circuit.

pin. This prevents the battery from ever being

RTCbat

Stopping and Starting the RTC Oscillator

The OSCEN bit in Calibration register at 0x7FF8 enables RTC

oscillator operation. This bit is nonvolatile and shipped to

customers in the “enabled” state (set to 0). OSCEN should be set

to a 1 to preserve battery life while the system is in storage. This

turns off the oscillator circuit extending the battery life. If the

OSCEN bit goes from disabled to enabled, it typically takes 5

seconds (10 seconds max) for the oscillator to start.

The STK17T88 has the ability to detect oscillator failure due to

loss of backup power. The failure is recorded by the OSCF

(Oscillator Failed bit) of the Flags register (at address 0x7FF0).

When the device is powered on (V

OSCEN bit is checked for “enabled” status. If the OSCEN bit is

goes above V

CC

SWITCH

) the

enabled and the oscillator is not active within 5 ms, the OSCF bit

is set. The user should check for this condit ion and then writ e a

0 to clear the flag. When the OSCF flag bit, the real time clock

registers are reset to the “Base Time” (see the section Setting

the Clock on page 14, the value last written to the real time clock

registers.

The value of OSCF should be reset to 0 when the real time clock

registers are written for the first time. This initializes th e state of

this bit since it may have become set when the system was first

powered on.

To reset OSCF, set the write bit “W” (in the Flags register at

0x7FF0) to a “1” to enable writes to the Flags register. Write a “0”

to the OSCF bit and then reset the write bit to “0” to disable

writes.

Calibrating The Clock

The RTC is driven by a quartz controlled oscillator with a nominal

frequency of 32.768 KHz. Clock accuracy depends on the quality

of the crystal specified (usually 35 ppm at 25 C). This error could

equate to 1.53 minutes gain or loss per month. The STK17T88

employs a calibration circuit that can improve the accuracy to

+1/-2 ppm at 25 C. The calibration circuit adds or subtracts

counts from the oscillator divider circuit.

The number of time pulses added or subt racted depends upon

the value loaded into the five calibration bits found in Calibration

register (at 0x7FF8). Adding counts speeds the clock up;

subtracting counts slows the clock down. The Calibration bits

occupy the five lower order bits of the register. These bits can be

set to represent any value between 0 and 31 in binary form. Bit

D5 is a Sign bit, where a “1” indicates positive calib ration a nd a

“0” indicates negative calibration. Calibration occurs during a 64

minute period. The first 62 minutes in the cycle may, once per

Document Number: 001-52040 Rev. *A Page 14 of 22

[+] Feedback

Page 15

STK17T88

minute, have one second either shortened by 128 or lengthened

by 256 oscillator cycles.

If a binary “1” is loaded into the register, only the first 2 minutes

of the 64 minute cycle is modified; if a binary 6 is loaded, the first

12 are affected, and so on. Therefore each calibration step has

the effect of adding 512 or subtracting 256 oscillator cycles for

every 125,829,120 actual oscillator cycles. That is +4.068 or

-2.034 ppm of adjustment per calibration step in the Calibration

register.

The calibration register value is determined during system test

by setting the CAL bit in the Flags register (at 0x7FF0) to 1. This

causes the INT pin to toggle at a nominal 512 Hz. This frequency

can be measured with a frequency counter. Any deviation

measured from the 512 Hz indicates the degree and direction of

the required correction. For example, a reading of 512.01024 Hz

would indicate a +20 ppm error, requiring a -10 (001010) to be

loaded into the Calibration register. Note that setting or changing

the calibration register does not affect the frequency test ou tp ut

frequency.

To set or clear CAL, set the write bit “W” (in the Flags register at

0x7FF0) to a “1” to enable writes to the Flags register. Write a

value to CAL and then reset the write bit to “0” to disable writes.

The default Calibration register value from the factory is 00h. The

user calibration value loaded is retained during a power loss.

Alarm

The alarm function compares a user-programmed alarm

time/date (stored in registers 0x7FF1-5) with the real time clock

time-of-day/date values. When a match occu rs, the alarm flag

(AF) is set and an interrupt is generated if the alarm interrupt is

enabled. The alarm flag is automatica lly reset when the Flags

register is read.

Each of the alarm registers has a match bit as its MSB. Setting

the match bit to a 1 disables this alarm register from the alarm

comparison. When the match bit is 0, the alarm register is

compared with the equivalent real time clock register. Using the

match bits, an alarm can occur as specifically as one particular

second on one day of the month or as freque ntly as once per

minute.

Note The product requires the match bit for seconds (0x7FF2,

bit D7) be set to 0 for proper operation of the Alarm Flag and

Interrupt.

The alarm value should be initialized on power up by so ftware

since the alarm registers are not nonvolatile.

To set or clear the Alarm registers, set the write bit “W” (in the

Flags register at 0x7FF0) to a “1” to enabl e writes to the Ala rm

registers. Write an alarmvalue to the alarm registers and then

reset the write bit to “0” to disable writes.

Watchdog Timer

The watchdog timer is designed to interrupt or reset the

processor should its program get hung in a loop and not respond

in a timely manner. The software must reload the watchdog timer

before it counts down to zero to prevent this interrupt or reset.

The watchdog timer is a free-running-down counter that uses the

32Hz clock (31.25 ms) derived from the crystal oscillator. The

watchdog timer function does not operate unless the oscillator is

running.

The watchdog counter is loaded with a starting value from the

load register and then counts down to zero, setting the watchdog

flag (WDF) and generating an interrupt if the watchdog interrupt

is enabled. The watchdog flag bit is reset when the Flags register

is read. The operating software would normally reload the

counter by setting the watchdog strobe bit (WDS) to 1 within the

timing interval programmed into the load register.

T o use the watchdog timer to reset the processor on timeout, the

INT is tied to processor master reset and Interrupt register is

programmed to 24h to enable interrupts to pulse the reset pin on

timeout.

T o load the watchdog timer, set a new value into the load register

by writing a “0” to the wa tchdog wr ite bit (WDW) o f the watchd og

register (at 0x7FF7). Then load a new value into the load register.

Once the new value is loaded, the watchdog write bit is then set

to 1 to disable watchdog writes. The watchdog strobe bit (WDS)

is set to 1 to load this value into the watchdog timer. Note: Setting

the load register to zero disables the watchdog timer function.

The system software should initialize the watchdog load register

on power up to the desired value since the register is not nonvolatile.

Power Monitor

The STK17T88 provides a power monitor function. The power

monitor is based on an internal band-gap reference circui t that

compares the V

When the power supply drops below V

circuit is switched to the backup supply (battery or capacitor).

When operating from the backup source, no data may be read

or written and the clock functions are no t available to the user.

The clock continues to operate in the background. Updated clock

data is available to the user t

restored to the device.

When the power is lost, the PF flag in the Flags register is set to

indicate the power failure and an interru pt is generated if the

power fail interrupt is enabled (interrupt register=20h). The INT

line would normally be tied to the processor master reset input

to perform power-off reset.

voltage to V

CC

SWITCH

HRECALL

.

, the real time clock

SWITCH

delay after VCC has been

Interrupts

The STK17T88 has a Flags register, Interrupt register, and

interrupt logic that can interrupt the micro controll er or general a

power up master reset signal. There are three potential interrupt

sources: the watchdog timer, the power monitor, and the clock

alarm. Each can be individually enabled to d rive the INT pi n by

setting the appropriate bit in the Interrupt register. In addition,

each has an associated flag bit in the Flags register that the host

processor can read to determine the interrupt source. Two bits in

the interrupt register determine the operation of the INT pin

driver.

Document Number: 001-52040 Rev. *A Page 15 of 22

[+] Feedback

Page 16

STK17T88

Figure 15 is a functional diagram of the interrupt logic.

Figure 15. Interrupt Block Diagram

Watchdog

Timer

Power

Monitor

VINT

Clock

Alarm

WDF

WIE

PF

PFE

AF

AIE

P/L

Pin

Driver

H/L

V

CC

INT

V

SS

Interrupt Register

Watchdog Interrupt Enable (WIE). When set to 1, the watchdog

timer drives the INT pin when a watchdog time-out occurs. When

WIE is set to 0, the watchdog time-out only sets the WDF flag bit.

Alarm Interrupt Enable (AIE). When set to 1, the INT pin is driven

when an alarm match occurs. When set to 0, the alarm match

only sets the AF flag bit.

Power Fail Interrupt Enable (PFE). When set to 1, the INT pin is

driven by a power fail signal from the power monitor. When set

to 0, only the PF flag is set.

High/Low (H/L). When set to a 1, the I NT pin is active high and

the driver mode is push-pull. The INT pin can drive high only

when V

and the drive mode is open-drain. The active low (open drain)

CC>VSWITCH

. When set to a 0, the INT pin is active low

output is maintained even when power is lost.

Pulse/Level (P/L). When set to a 1, the INT pin is driven for

approximately 200 ms when the interrupt occurs. The p ulse is

reset when the Flags register is read. When P/L is set to a 0, the

INT pin is driven high or low (determined by H/L) until the Flags

register is read.

The Interrupt register is loaded with the default value 00h at the

factory. The user should configure the Interrupt register to the

value desired for their desired mode of operation. Once

configured, the value is retained during power failures.

Flags Register

The Flags register has three flag bits: WDF, AF, and PF. These

flags are set by the watchdog time-out, alarm match, or power

fail monitor respectively. The processor can either poll this

register or enable the interrupts to be informed when a flag is set.

The flags are automatically reset once the register is read.

The Flags register is automatically loaded with the value 00h on

power up (with the exception of the OSCF bit).

Document Number: 001-52040 Rev. *A Page 16 of 22

[+] Feedback

Page 17

RTC Register Map

STK17T88

Register

0x7FFF 10s Years Years Years: 00-99

0x7FFE 0 0 0 10s

0x7FFD 0 0 10s Day of Month Day of Month Day of Month: 01-31

0x7FFC 0 0 0 0 0 Day of Week Day of week: 01-07

0x7FFB 0 0 10s Hours Hours Hours: 00-23

0x7FFA 0 10s Minutes Minutes Minutes: 00-59

0x7FF9 0 10s Seconds Seconds Seconds: 00-59

0x7FF8 OSCEN

0x7FF7 WDS WDW WDT Watchdog*

0x7FF6 WIE[0] AIE[0] PFE[0] 0 H/L [1] P/L [0] 0 0 Interrupts*

0x7FF5 M 0 10s Alarm Date Alarm Day Alarm, Day of Month: 01-31

0x7FF4 M 0 10s Alarm Hours Alarm Hours Alarm, hours: 00-23

0x7FF3 M 10 Alarm Minutes Alarm Minutes Alarm, minutes: 00-59

0x7FF2 M 10 Alarm Seconds Alarm Seconds Alarm, seconds: 00-59

0x7FF1 10s Centuries Centuries Centuries: 00-99

0x7FF0 WDF AF PF OSCF 0 CAL[0] W[0] R[0] Flags*

*A binary value, not a BCD value.

0 - Not implemented, reserved for future use.

Default Settings of nonvolatile Calibration and Interrupt registers from factory

Calibration Register=00h

Interrupt Register=00h

The User should configure to the desired value at startup or during operation and the value is then retained during a power failure.

[ ] designates values shipped from the factory. See Stopping and Starting the RTC Oscillator on page 14.

D7 D6 D5 D4 D3 D2 D1 D0

0Cal

[0]

BCD Format Data

Months

Sign

Function / Range

Months Months: 01-12

Calibration [00000] Calibration values*

Document Number: 001-52040 Rev. *A Page 17 of 22

[+] Feedback

Page 18

STK17T88

Register Map Detail

0x7FFF

0x7FFE

0x7FFD

0x7FFC

0x7FFB

0x7FFA

0x7FF9

0x7FF8

OSCEN Oscillator Enable. When set to 1, the oscillator is disabled. When set to 0, the oscillator is enabled.

Calibration Sign Determines if the calibration adjustment is applied as an addition to or as a subtraction from the time-base.

Calibration These five bits control the calibration of the clock.

0x7FF7

WDS Watchdog S trobe. Setting this bit to 1 reloads and restarts the watchdog timer. The bit is cleared automat-

D7 D6 D5 D4 D3 D2 D1 D0

10s Years Years

Contains the lower two BCD digits of the year. Lower nibble contains the value for years; upper nibble

contains the value for 10s of years. Each nibble operates from 0 to 9. The range for the register is 0-99.

D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 10s

Contains the BCD digits of the month. Lower nibble contains the lower digit and operates from 0 to 9; upper

nibble (one bit) contains the upper digit and operates from 0 to 1. The range for the register is 1-12.

D7 D6 D5 D4 D3 D2 D1 D0

0 0 10s Day of month Day of month

Contains the BCD digits for the date of the month. Lower nibble contains the lower digit and operates from

0 to 9; upper nibble contains the upper digit and operates from 0 to 3. The range for the register is 1-31.

Leap years are automatically adjusted for.

D7 D6 D5 D4 D3 D2 D1 D0

00000 Day of week

Lower nibble contains a value that correlates to day of the week. Day of the wee k is a ring counter that

counts from 1 to 7 then returns to 1. The user must assign meaning to the day value, as t he day is not

integrated with the date.

D7 D6 D5 D4 D3 D2 D1 D0

0 0 10s Hours Hours

Contains the BCD value of hours in 24 hour format. Lower nibble contains the lower digit and ope rates

from 0 to 9; upper nibble (two b its) contains the upper digit and operates from 0 to 2. The range for the

register is 0-23.

D7 D6 D5 D4 D3 D2 D1 D0

0 10s Minutes Minutes

Contains the BCD value of minutes. Lower nibble contains the lower digit and operates from 0 to 9; upper

nibble contains the upper minutes digit and operates from 0 to 5. The range for the register is 0-59.

D7 D6 D5 D4 D3 D2 D1 D0

0 10s Seconds Seconds

Contains the BCD value of seconds. Lower nibble contains the lower digit and operates from 0 to 9; upper

nibble contains the upper digit and operates from 0 to 5. The range for the register is 0-59.

D7 D6 D5 D4 D3 D2 D1 D0

OSCEN 0 Calibratio

n Sign

Disabling the oscillator saves battery/capacitor power during storage.

D7 D6 D5 D4 D3 D2 D1 D0

WDS WDW WDT

ically once the watchdog timer is reset. The WDS bit is write only. Reading it always will return a 0.

Real Time Clock – Years

Real Time Clock – Months

Months

Month

Real Time Clock – Date

Real Time Clock – Day

Real Time Clock – Hours

Real Time Clock – Minutes

Real Time Clock – Seconds

Calibration

Calibration

Watchdog Timer

Document Number: 001-52040 Rev. *A Page 18 of 22

[+] Feedback

Page 19

Register Map Detail (continued)

WDW W atchdog Write Enable. Set this bit to 1 to disable writing of the watchdog time-out value (WDT5-WDT0).

WDT Watchdog time-out selection. The watchdog ti me r int erval i s select ed b y the 6-bit valu e in t hi s regist er. It

0x7FF6

WIE Watchdog Interrupt Enable. When set to 1 and a watchdog time-out occurs, the watchdog timer drives the

AIE Alarm Interrupt Enable. When set to 1, the alarm match drives the INT pin and sets the AF flag. When set

PFIE Power-Fail Enable. When set to 1, a power failure drives the INT pin and sets the PF flag. When set to 0,

0 Reserved for Future Use

H/L High/Low. When set to a 1, the INT pin is driven active high. When set to 0, t he INT pin is open drain,

P/L Pulse/Level. Wh en set to a 1, the INT p in is driven active (determin ed by H/L) by an interrupt source for

0x7FF5

M Match. Setting this bit to 0 causes the date value to be used in the alarm match. Setting this bit to 1 causes

0x7FF4

M Match. Setting this bit to 0 causes the hours value to be used in the alarm match. Setting this bit to 1

0x7FF3

M Match. Setting this bit to 0 causes the minutes value to be used in the alarm match. Setti ng this bit to 1

0x7FF2

M Match. Setting this bit to 0 causes the seconds’ value to be used in th e alarm match. Se ttin g this bit to 1

0x7FF1 Real Time Clock – Centuries

This allows the user to strobe the watchdog without disturbing the time-out value. Setting this bit to 0 allows

bits 5-0 to be written.

represents a multiplier of the 32 Hz count (31.25 ms). The range or time-out values is 31.25 ms (a setting

of 1) to 2 seconds (setting of 3Fh). Setting the watchdog timer register to 0 disables the timer. These bits

can be written only if the WDW bit was cleared to 0 on a previous cycle.

Interrupt

D7 D6 D5 D4 D3 D2 D1 D0

WIE AIE PFIE ABE H/L P/L 0 0

INT pin and sets the WDF flag. When set to 0, the watchdog time-out only sets the WDF flag.

to 0, the alarm match only sets the AF flag.

a power failure only sets the PF flag.

active low.

approximately 200 ms. When set to a 0, the INT pin is driven to an act ive level (as set by H/L) until t he

Flags register is read.

Alarm – Day

D7 D6 D5 D4 D3 D2 D1 D0

M 0 10s Alarm Date Alarm Date

Contains the alarm value for the date of the month and the mask bit to select or deselect the date value.

the match circuit to ignore the date value.

Alarm – Hours

D7 D6 D5 D4 D3 D2 D1 D0

M 0 10s Alarm Hours Alarm Hours

Contains the alarm value for the hours and the mask bit to select or deselect the hours value.

causes the match circuit to ignore the hours value.

Alarm – Minutes

D7 D6 D5 D4 D3 D2 D1 D0

M 10s Alarm Minutes Alarm Minutes

Contains the alarm value for the minutes and the mask bit to select or deselect the minutes value.

causes the match circuit to ignore the minutes value.

Alarm – Seconds

D7 D6 D5 D4 D3 D2 D1 D0

M 10s Alarm Seconds Alarm Seconds

Contains the alarm value for the seconds and the mask bit to select or deselect the seconds’ value.

causes the match circuit to ignore the seconds value.

10s Centuries Centuries

Contains the BCD value of Centuries. Lower nibble contains the lower digit and operates from 0 to 9; upper

nibble contains the upper centuries digit and operates from 0 to 9. The rang e for the register is 0-99

centuries.

STK17T88

Document Number: 001-52040 Rev. *A Page 19 of 22

[+] Feedback

Page 20

Register Map Detail (continued)

0x7FF0

WDF Watchdog Timer Flag. This read-only bit is set to 1 when the watchdog timer is allowed to reach 0 without

AF Alarm Flag. This read-only bit is set to 1 when the time and date match the value s stored in the alarm

PF Power-fail Flag. This read-only bit is set to 1 when power falls below the power-fail threshold V

OSCF Oscillator Fail Flag. Set to 1 on power up only if the oscillat or is enable d and not runn ing in the f irst 5ms

CAL Calibration Mode. When set t o 1, a 512Hz squa re wave is output on t he INT pin . When set to 0, the INT

W Write Time. Setting the W bit to 1 freezes updates of the RTC registers. The user ca n then write to the

R Rea d Time. Setting the R bit to 1 captures the current t ime in ho lding regist ers so th at clock updates are

D7 D6 D5 D4 D3 D2 D1 D0

WDF AF PF OSCF 0 CAL W R

being reset by the user. It is cleared to 0 when the Flags register is read or on power up

registers with the match bits = 0. It is cleared when the Flags register is read or on power up

is cleared to 0 when the Flags register is read or on power up.

of operation. This indicates that the RTC backup power failed and the clock value is no longer valid. The

user must reset this bit to 0 to clear this condition.

pin resumes normal operation. This bit defaults to 0 (disabled) on power up.

RTC registers, Alarm registers, Calibration register, Interrupt register and Flags register. Setting the W bit

to 0 disables writes to the registers and causes the contents of the real time clock registers to be transferred

to the timekeeping counters if the time has changed (a new base time is loaded). The bit defaults to 0 on

power up.

not during the reading process. Set the R bit to 0 to enable the holding register to resume clock updates.

The bit defaults to 0 on power up.

Flags

STK17T88

. It

SWITCH

Commercial and Industrial Ordering Information

STK17T88 - R F 45 I TR

Packaging Option:

TR = Tape and Reel

Blank = Tube

Temperature Range:

C - Commercial (0 to 70°C)

I - Industrial (-40 to 85°C)

Lead Finish

F = 100% Sn (Matte Tin) RoHS Compliant

Package:

R = Plastic 48-pin 330 mil SSOP

Speed:

25 - 25 ns

45 - 45 ns

Ordering Codes

Ordering Code Description Access Times (ns) Temperature

STK17T88-RF25 3.3V 32Kx8 AutoStore nvSRAM+RTC SSOP48-300 25 Commercial

STK17T88-RF45 3.3V 32Kx8 AutoStore nvSRAM+RTC SSOP48-300 45 Commercial

STK17T88-RF25TR 3.3 V 32 Kx8 AutoStore nvSRAM+RTC SSOP48-300 25 Commercial

STK17T88-RF45TR 3.3 V 32 Kx8 AutoStore nvSRAM+RTC SSOP48-300 45 Commercial

STK17T88-RF25I 3.3V 32Kx8 AutoStore nvSRAM+RTC SSOP48-300 25 Industrial

STK17T88-RF45I 3.3V 32Kx8 AutoStore nvSRAM+RTC SSOP48-300 45 Industrial

STK17T88-RF25ITR 3.3V 32Kx8 AutoStore nvSRAM+RTC SSOP48-300 25 Industrial

STK17T88-RF45ITR 3.3V 32Kx8 AutoStore nvSRAM+RTC SSOP48-300 45 Industrial

Document Number: 001-52040 Rev. *A Page 20 of 22

[+] Feedback

Page 21

Package Diagram

STK17T88

Figure 16. 48-Pin SSOP (51-85061)

51-85061-*C

Document Number: 001-52040 Rev. *A Page 21 of 22

[+] Feedback

Page 22

STK17T88

Document History Page

Document Title: STK17T88 32K x 8 AutoStore™ nvSRAM with Real-Time Clock

Document Number: 001- 52040

Rev ECN No.

** 2668660 GVCH/PYRS 03/04/2009 New data sheet

*A 2675319 GVCH 03/17/2009 Corrected typo on page 1 in ‘Description’

Sales, Solutions, and Legal Information

Worldwide Sales and Design Support

Cypress maintains a worldwide network of offices, solution centers, manufacturer’s representatives, and distributors. To find the office

closest to you, visit us at cypress.com/sales.

Orig. of

Change

Submission Date Description of change

section: changed 256KB to 256Kb.

Products

PSoC psoc.cypress.com

Clocks & Buffers clocks.cypress.com

Wireless wireless.cypress.com

Memories memory.cypress.com

Image Sensors image.cypress.com

PSoC Solutions

General psoc.cypress.com/solutions

Low Power/Low Voltage psoc.cypress.com/low-power

Precision Analog psoc.cypress.com/precision-analog

LCD Drive psoc.cypress.com/lcd-drive

CAN 2.0b psoc.cypress.com/can

USB psoc.cypress.com/usb

© Cypress Semiconductor Corporation, 2009. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use of any

circuitry other than circuitry embodied in a Cypress product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor intended to be used for medical,

life support, life saving, critical control or safety applications, unless pursuant to an express written agreement with Cypress. Furthermore, Cypress does not authorize its products for use as critical

components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress products in life-support systems

application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress against all charges.

Any Source Code (software and/or firmware) is owned by Cypress Semiconductor Corporation (Cypress) and is protected by and subject to worldwide patent protection (United States and foreign),

United States copyright laws and international treaty provisions. Cypress hereby gr ant s to l icense e a pers onal, no n-exclu sive , non-tr ansfer able license to copy, use, modify, create derivative works of,

and compile the Cypress Source Code and derivative works for the sole purpose of creating custom software and or firmware in support of licensee product to be used only in conjunctio n with a Cypress

integrated circuit as specified in the ap plicable agreem ent. Any reprod uction, modificatio n, translation, co mpilation, or repr esentation of this Source Code except as specifi ed above is prohib ited without

the express written permission of Cypress.

Disclaimer: CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Cypress reserves the right to make changes without further notice to the materials described herein. Cyp ress does not

assume any liability arising out of the app licati on or use o f any pr oduct or circ uit de scribed herein . Cypr ess does n ot auth orize its p roducts fo r use as critical compon ents in life-su pport systems whe re

a malfunction or failure may reason ably be expected to result in significant injury to the user. The inclusion of Cypress’ product in a life-support systems application implies that the manufacturer

assumes all risk of such use and in doing so indemnifies Cypress against all charges.

Use may be limited by and subject to the applicable Cypress software license agreement.

Document Number: 001-52040 Rev. *A Revised March 17, 2009 Page 22 of 22

AutoStore and Quant umTrap are registered trad emarks of Cypress Semico nductor Corporat ion. All product s and company n ames mentioned in this document may be th e trademarks of their re spective

holders.

[+] Feedback

Loading...

Loading...