Page 1

CVX-1300

Operations Manual

DataBender™ Universal Format Converter

CVX-1300_MAN_112011

Page 2

Data I/O

Reader - Wiegand, Strobed (Clock & Data), F/2F

LED - 0 to 30v

Interface

+5vDC @ 100 ma

Output

95% (non-condensing)

Storage (-55°C to +150°C)

Operating (-40°C to +80°C*)

Power

Unreg Input 8 to 16VDC* @ 200ma Max

Input

Humidity

Aluminum enclosure

Size 3.5” x 2.75” x .75”

Temp

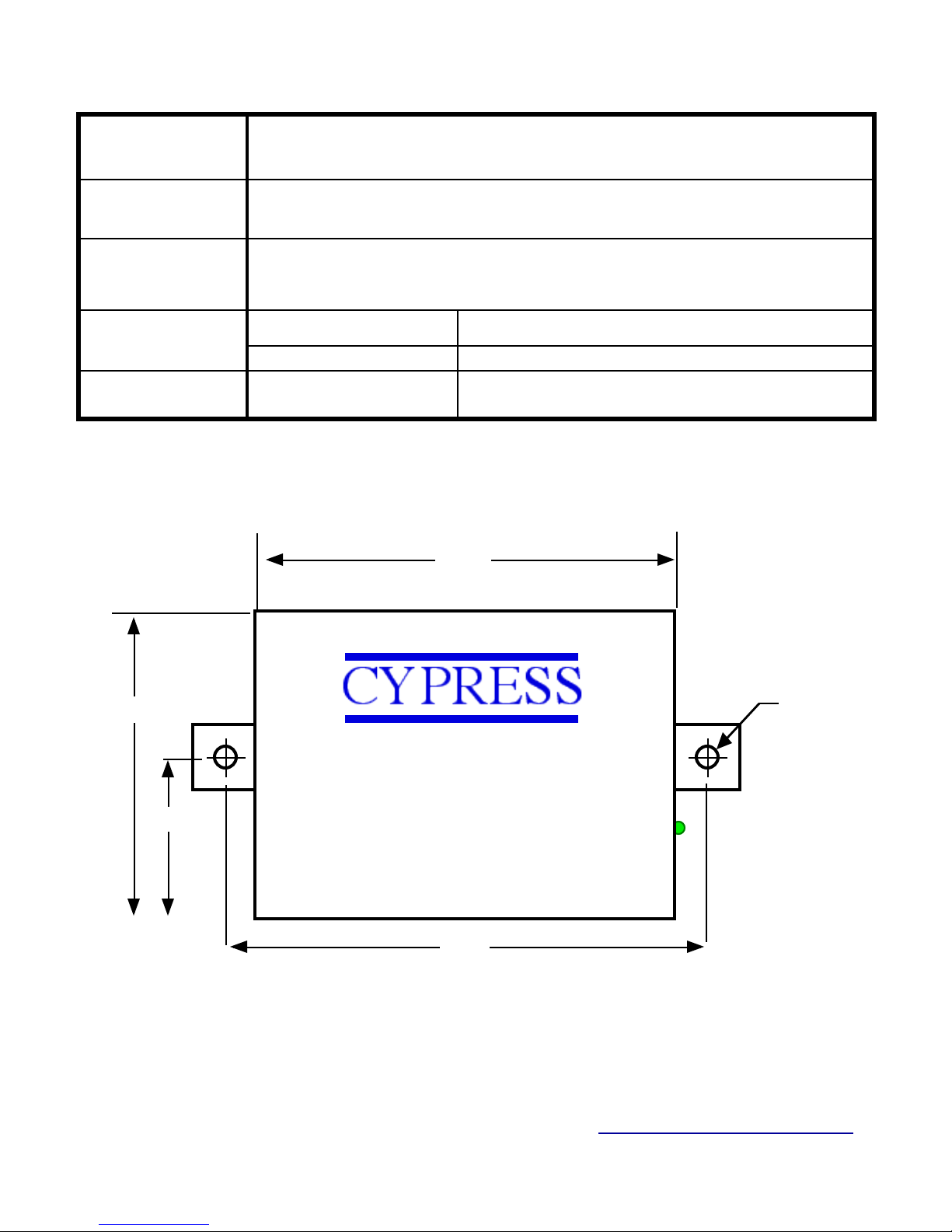

Physical

3.3”

DataBender CVX-1300

2.8”

1.4”

3.65”

ø 0.15”

External Dimensions and Mounting Holes

Unit Height = 0.75”

Electrical and Mechanical Specifications

* See notes on following page for temperature and power ratings

This complies with part 15 of the FCC rules

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired operation.

Cypress Computer Systems, Inc. ⌖ Lapeer, MI 48446 ⌖ www.cypresscomputer.com

© 2011 Cypress Computer Systems Inc.

Page 3

Initial Setup - CVX-1300 Converter

The CVX-1300 will support many different input and output formats.

The CVX-1300 replaces the CVX-1200 and many of the standard Cypress CVT series of

converters (e.g. CVT-2232 CVT-9102).

A DIP switch determines which conversion process will be used.

A “Legacy” cross reference chart is provided to quickly determine which settings to use for standard

Cypress converter numbers. In most cases several baud rate options are available to expand the

capabilities of existing converters. The Legacy cross reference chart will list the converter CVT

number and the CVX numbers and the DIP switch setting that will apply. Use the converter

numbers to find the DIP switch settings on the CVX-1300 application charts.

Setting up the CVX-1300 converter:

1. First determine which converter (conversion process) is required for the application. This may be

one of the standard Cypress converters or one of the new converters that are now part of the

CVX-1300 library. All of the different conversion processes are described in detail in this manual.

Each process will have a wiring diagram and specification sheet to describe the wiring connections

and operation.

2. Set the DIP switch to the setting called out in the CVX application chart.

3. Refer to the wiring diagram for the particular converter that is being used. The wiring diagrams

are different depending upon the type of conversion being performed.

4. Connect power to the CVX-1300 board.

5. If the diagnostic indicator LED flashes Green slowly, a valid converter number has been selected.

If the diagnostic indicator is illuminated a solid Red color, an invalid DIP switch

setting has been made.

6. Connect peripheral devices (Readers, Panel, Switches etc.) according to the appropriate wiring

diagram.

LEGACY CONVERTER EXAMPLE: You need a CVT-2232 that operates at 2400 Baud.

The Legacy Compatibility chart calls out CVX numbers 1,2, and 3.

Looking at the CVX application charts for #1,#2,and #3 lists 3 baud rates.

Selecting the 2400 Baud rate for CVX converter #2 would yield a DIP switch setting of:

1 OFF, 2 ON , 3 OFF, 4 OFF, 5 OFF, 6 OFF, 7 OFF, 8 OFF

The wiring diagram would reference the Wiegand to Serial connections.

NOTE: The CVX-1300 does not use an onboard DB type connector for RS-232 serial signals.

Serial connections can be made directly to the 12 position connector.

An optional patch cord is available with a Female DB-9 connector and flying leads.

The wiring diagrams indicate the equivalent DB-9 connections to the CVX-1300 J3 connector.

Page 4

Electrical and Environmental Specifications

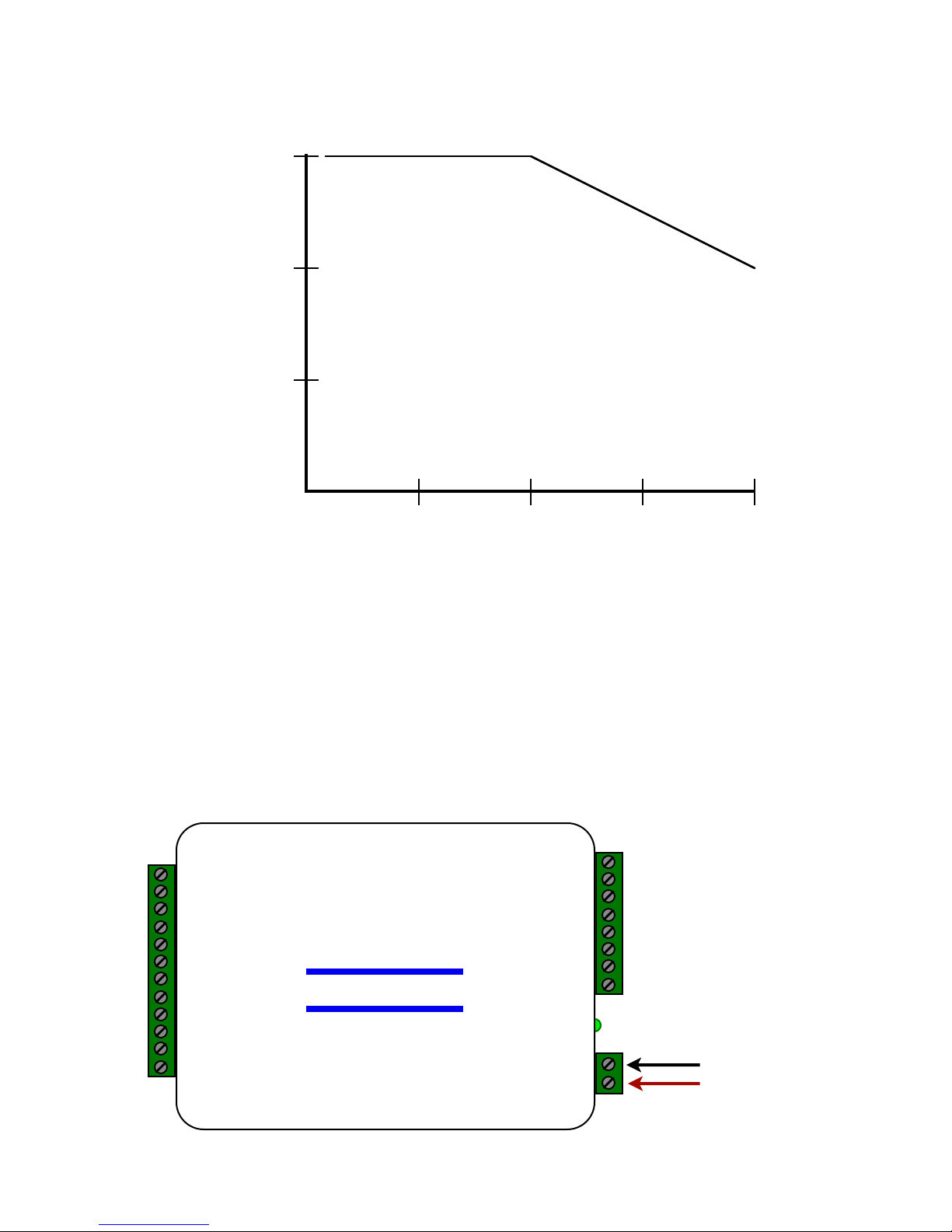

810121416805535-40

Ambient Temperature

(Degrees Celsius)

Supply Voltage

Temperature/Voltage de-rating curve

*

Converter CVX-1300

CYPRESS

The CVX-1300 units should be operated with a filtered 12 Volt nominal DC supply.

Any voltage between 8 and 16 volts can be utilized by following the temperature /voltage

derating curve. Voltage should not exceed 16 VDC under normal operating conditions.

1-D0/CLK Input

2-D1/Data Input

3-Aux2 LED Out

4-Ground

5-RS232 Input

6-RS232 Output

7-RLY1 N.C.

8-RLY1 Com

9-RLY1 N.O.

10-RLY2 N.C.

11-RLY2 Com

12-RLY2 N.O.

1-D0/CLK Output

2-D1/Data Output

3-Aux1 LED In

4-Analog In1

5-Analog In2

6-+5 VDC Out

7-RS485 (-)

8-RS485 (+)

Ground

+8 to +16 VDC In

J2

DC Power IN

J3

J1

Page 5

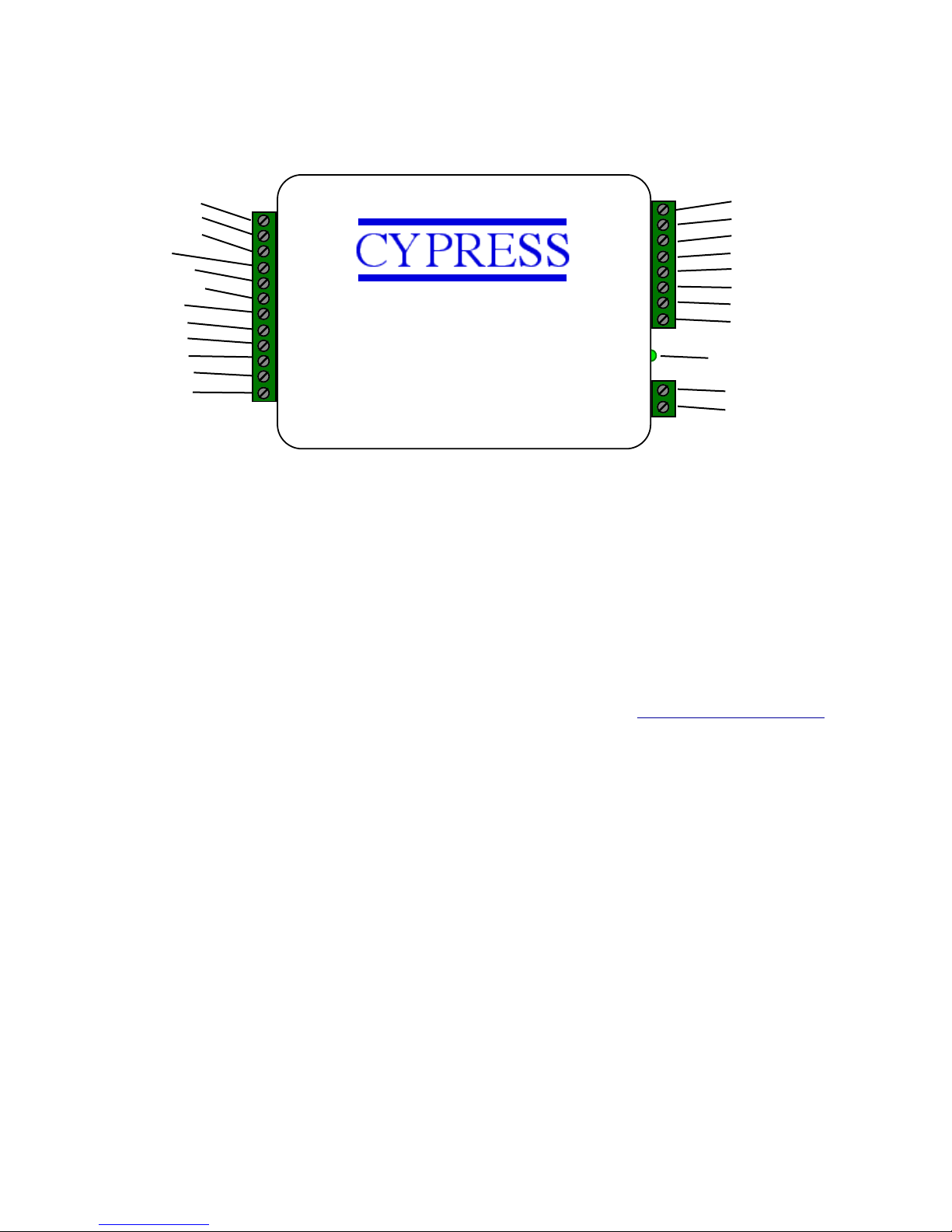

External connections and product description

Converter CVX-1300

1-D0/CLK Input

2-D1/Data/F2F Input

3-Aux2 LED Out

4-Ground

5-RS232 Input

6-RS232 Output

7-RLY1 N.C.

8-RLY1 Com

9-RLY1 N.O.

10-RLY2 N.C.

11-RLY2 Com

12-RLY2 N.O.

Note: F2F connections support

unsupervised mode

1-D0/CLK Output

2-D1/Data/F2F Output

3-Aux1 LED In

4-Analog In1

5-Analog In2

6-+5 VDC Out

7-RS485 (-)

8-RS485 (+)

Diagnostic LED

1-Ground

2-8 to 16 VDC In

Note: Terminals shown for reference.

Connections may or may not be utilized based on converter function.

The Cypress CVX-1300 is based on the CVX-1200 series converter. For most legacy converter

functions, the DIP switch settings will be set the same as with the Cypress CVX-1200.

This document provides detailed wiring information and a reference to DIP switch settings for the

converter. Detailed conversion descriptions are provided in chapters organized for each type of

conversion function. i.e. Wiegand to Serial functions will have a chapter, Serial to Strobed will have

a chapter etc. Each chapter is a separate document and is available at www.cypressoworld.com

A Diagnostic LED is provided to provide operational status of the converter:

Diagnostic LED OFF - No power

Diagnostic LED Blinking Green - Unit is operating

Diagnostic LED Red - Undefined DIP Switch Setting

Page 6

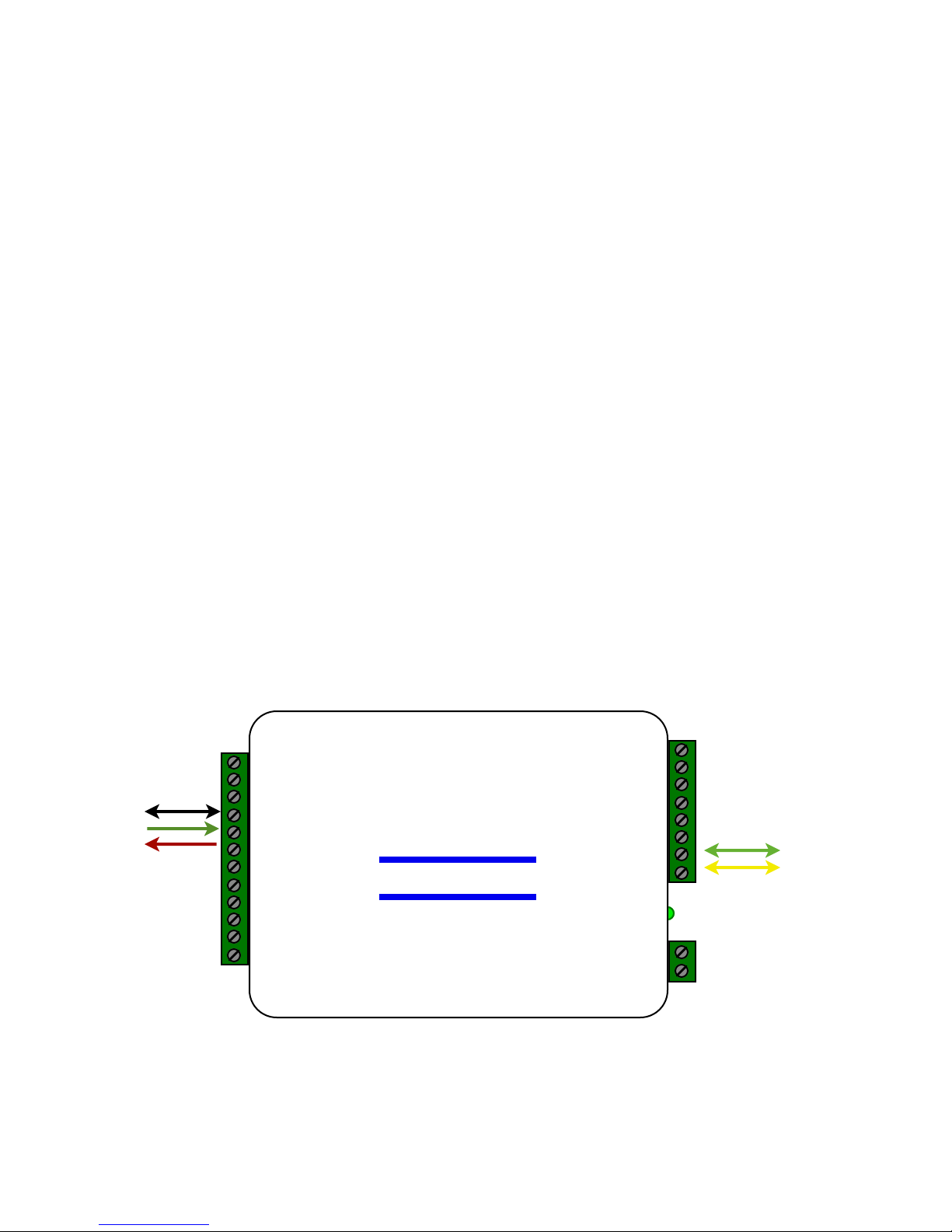

CVX-1300 Serial data and RS485

*

Converter CVX-1300

CYPRESS

The CVX-1300 can support both RS-232 and RS-485 signals for transmitting and receiving

serial data. For most converters utilizing serial data, both interfaces are always active and may

be used by making the appropriate connections to the converter. Either the RS-232 or RS-485

interface may be used, but a loss of data will occur if both interfaces have active data at the

same time.

Examples:

The CVT-2232 function will provide a serial input and convert to a Wiegand output.

Serial data can be read from either the RS-232 or RS-485 interface. The baud rate will be

determined by the DIP switch setting.

The CVT-9110 function will provide a Wiegand input and a serial output. Serial data will be

output on the RS-232 and RS-485 interface.

NOTE: Some of the CVX-1300 converters may not support both RS-232 and RS-485

interfaces. Converters that do not support both interfaces will be noted in the specific converter

specification.

RS-232 Interface

1-D0/CLK Input

2-D1/Data Input

3-Aux2 LED Out

4-Ground

5-RS232 Input

6-RS232 Output

7-RLY1 N.C.

8-RLY1 Com

9-RLY1 N.O.

10-RLY2 N.C.

11-RLY2 Com

12-RLY2 N.O.

1-D0/CLK Output

2-D1/Data Output

3-Aux1 LED In

4-Analog In1

5-Analog In2

6-+5 VDC Out

7-RS485 (-)

8-RS485 (+)

1-Ground

2-8 to 16 VDC In

RS-485 Interface

Page 7

This Page left intentionally blank

Page 8

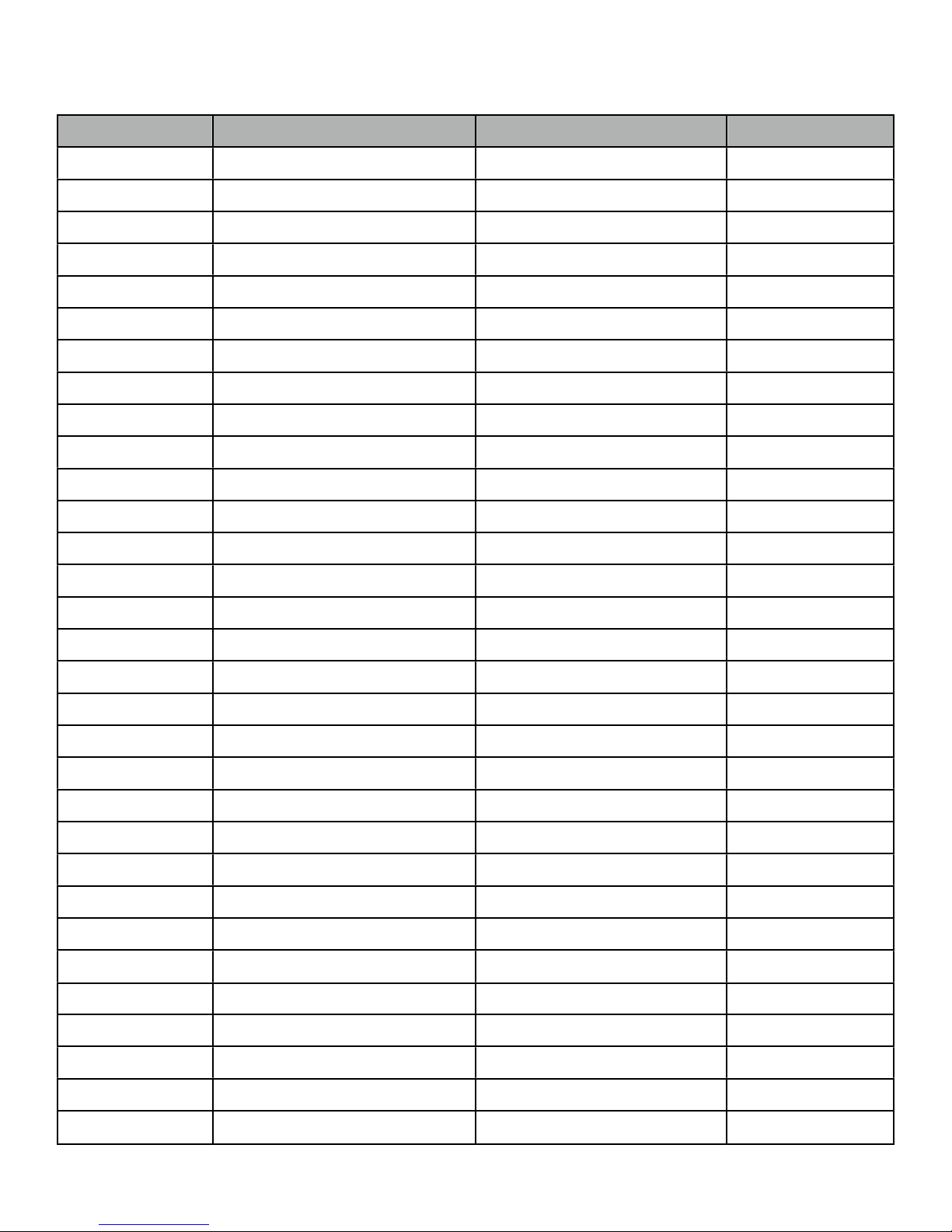

Converter

Input

Output

Settings(#)

CVT2232

Wiegand 24 to 40

Serial 13 Digits with <CR>

1 , 2 , 3

CVT-2111

Wiegand 1 to 40

Serial Dec/Hex Digits

7, 8, 9

CVT-2110

Wiegand 1 to 48

SerialHex Digits

10 , 11, 12

CVT-2144

Wiegand 44

Serial12 Digits

13 , 14 , 15

CVT-2145

Wiegand 44/32

Serial 12/10 Digits

16 , 17 , 18

CVT-2152

Wiegand 1 to 96

Serial 24 Hex Dec

19 , 20 , 21

CVT-2151

Wiegand 1 to 40

Serial HID Hex

22 , 23 , 24

CVT-2201

Strobed/ABA

Serial 24 Hex

25 , 26 , 27

CVT-2403

F/2F Raw

Serial ASCII Hex

28

CVT-2404

F/2F ABA

Serial ASCII Hex

29

CVT-2405

F/2F ABA

Wiegand 37 bit Custom

30

CVT-2406

F/2F ABA

Wiegand 37 bit Custom

33

CVT-9102

Serial 10 Dec

Wiegand 26

65 , 66 , 67

CVT-9110

Serial 12 Hex

Wiegand Variable

68 , 68 , 70

CVT-9109

Serial Transcore

Wiegand 26

71

CVT-9129

Serial Transcore

Xico 6

72

CVT-9132

Serial Transcore

Wiegand 37

73

CVT-9137

Serial Transcore

Wiegand 26

74

CVT-9117

Serial Transcore

Wiegand 26

75

CVT-9161

Serial Transcore

Wiegand 26

76

CVT-9162

Serial Transcore

Wiegand 37

77

CVT-9164

Serial Transcore

Wiegand 37

78

CVT-9201

Serial ASCII

Strobed / ABA

79,80,81,82

CVT-5932

Dallas iButton 1Wire

Wiegand 26

34

CVT-9165

Serial Transcore 26 bit

Wiegand 26

84

CVT-0026

Wiegand 24-40 bit

Wiegand 26

97

CVT-0026A

24-40 bit, spec 34 bit pr.

Wiegand 26

98

CVT-3526

Wiegand 35 bit C1000

Wiegand 26

99

CVT-5100

12 digit Strobed ABA

Wiegand 26

100

CVT-5100A

Last 8 digit Strobed ABA

Wiegand 26

101

CVT-5200

Wiegand 26 and 35 bit

12 Digit Strobed/ABA

102

CVX-1300 Legacy Compatable formats

Page 9

Converter

Input

Output

Settings(#)

CVT-5201

Wiegand 26 bit

10 digit Strobed/ABA

103

CVT-2211

Wiegand ABA

Serial ASCII

35,36

CVT-0126

Wiegand 26 bit

Wiegand 26 bit fixed FC=215

104

CVT-9117A

Serial Transcore

Wiegand 26

85

CVT-3226

Wiegand 32 Bit Kastle

Wiegand 26 bit Standard

105

CVT-9133

Serial ASCII

Wiegand 36 bit Special

86

CVT-9501

Serial ASCII 1-12 digits

F/2F

83

CVT-2485

Wiegand 24-40

Serial ASCII RS-485

1,2,3

CVT-9485

Serial ASCII RS-485

Wiegand 24-40

65,66,67

CVT-2201F

Strobed/ABA Fall Edge

Serial 24 Hex

37

CVT-5100F

Strobed/ABA Fall Edge

Wiegand 26 bit

106

CVT-5100AF

Strobed/ABA Fall Edge

Wiegand 26 bit

107

CVX-2232-5

Wiegand 24-40

Serial- Last 5 digits

38

CVX-9174

Serial ASCII 1-10 Dec

Wiegand 37 Bit FC = 1

87

CVT-0126B

Wiegand 26 bit

Wiegand 26 bit fixed FC=0

108

CVT-5217

Wiegand 24-40

8 digit Strobed/ABA

112

CVX-1300 Legacy Compatable formats

Page 10

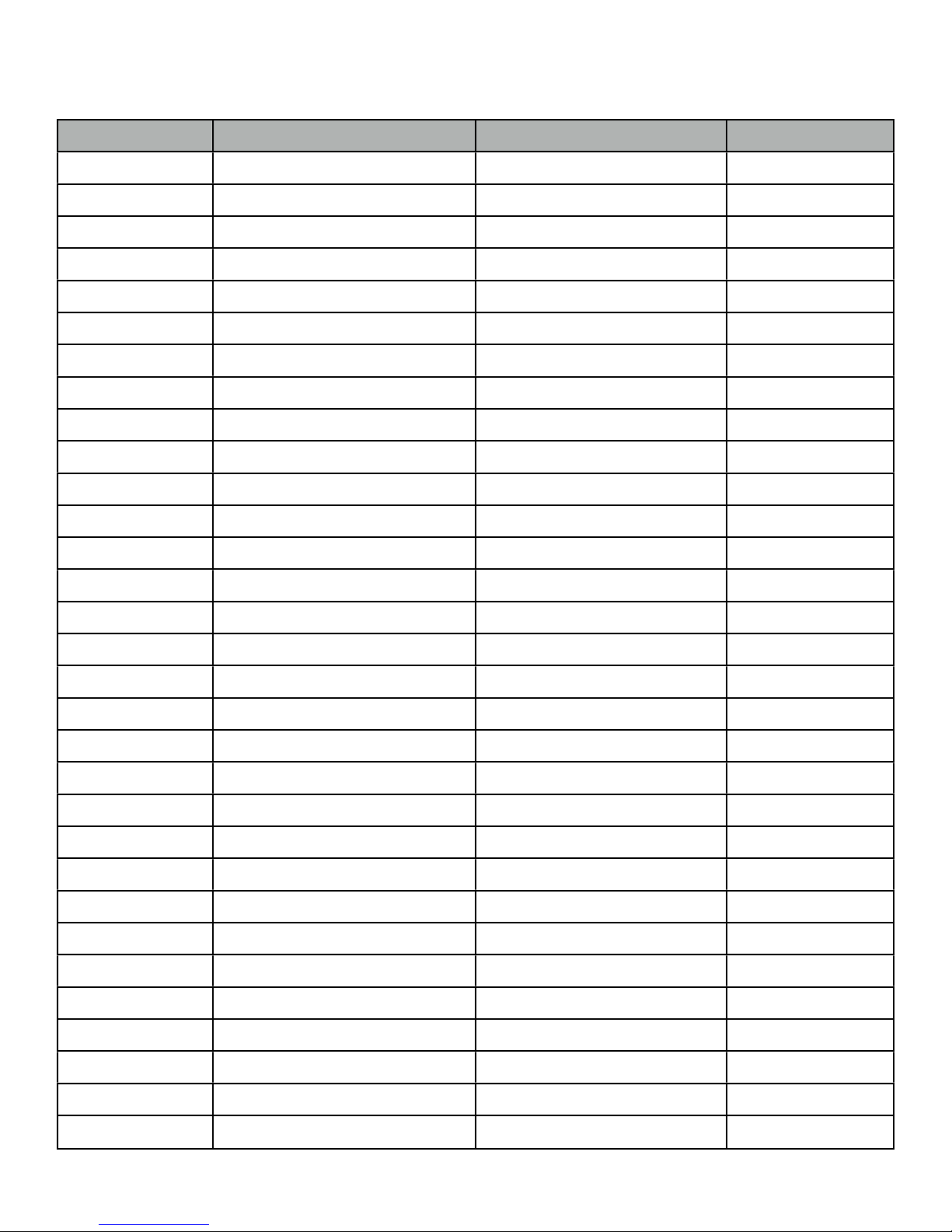

#

DIP SWITCH SETTING

INPUT

OUTPUT

#

12345678Interface

Format

Interface

Format

0

Test Mode

Test Mode

1

X

Wiegand

24 to 40 bits

RS-232 (9600)

13 Digits,CR

2

X

Wiegand

24 to 40 bits

RS-232 (2400)

13 Digits,CR

3XX

Wiegand

24 to 40 bits

RS-232 (1200)

13 Digits,CR

4

X

Wiegand

24 to 48 bits

RS-232 (9600)

10 Digits,CR

5XX

Wiegand

24 to 48 bits

RS-232 (2400)

10 Digits,CR

6XX

Wiegand

24 to 48 bits

RS-232 (1200)

10 Digits,CR

7XX

X

Wiegand

24 to 48 bits

RS-232 (9600)

Dec/Hex Digits

8

X

Wiegand

24 to 48 bits

RS-232 (2400)

Dec/Hex Digits

9XX

Wiegand

24 to 48 bits

RS-232 (1200)

Dec/Hex Digits

10XX

Wiegand

1 to 48 bits

RS-232 (9600)

Hex Digits

11XX

X

Wiegand

1 to 48 bits

RS-232 (2400)

Hex Digits

12XX

Wiegand

1 to 48 bits

RS-232 (1200)

Hex Digits

13XX

X

Wiegand

44 bits

RS-232 (9600)

12 Digits

14XX

X

Wiegand

44 bits

RS-232 (2400)

12 Digits

15XXXX

Wiegand

44 bits

RS-232 (1200)

12 Digits

16

X

Wiegand

44/32 bits

RS-232 (9600)

12/10 Digits

17XX

Wiegand

44/32 bits

RS-232 (2400)

12/10 Digits

18XX

Wiegand

44/32 bits

RS-232 (1200)

12/10 Digits

19XX

X

Wiegand

1 to 96 bits

RS-232 (9600)

24 Hex/Dec

20XX

Wiegand

1 to 96 bits

RS-232 (2400)

24 Hex/Dec

21XX

X

Wiegand

1 to 96 bits

RS-232 (1200)

24 Hex/Dec

22XX

X

Wiegand

1 to 40 bits

RS-232 (9600)

HID Hex

23XXXX

Wiegand

1 to 40 bits

RS-232 (2400)

HID Hex

24XX

Wiegand

1 to 40 bits

RS-232 (1200)

HID Hex

25XX

X

Strobed

ABA

RS-232 (9600)

24 Hex

26XX

X

Strobed

ABA

RS-232 (2400)

24 Hex

27XXXX

Strobed

ABA

RS-232 (1200)

24 Hex

28XX

X

F/2F

Raw-All bits

RS-232 (1200)

RS-232 (9600)

29XXXX

F/2F

ABA

RS-232 (9600)

ASCII Hex

30XXXX

F/2F

ABA

Wiegand

37 Bit Custom

31XXXX

X

TEST

MODE

RS-232 (9600)

Test String

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

DIP Switch Application Table

Page 11

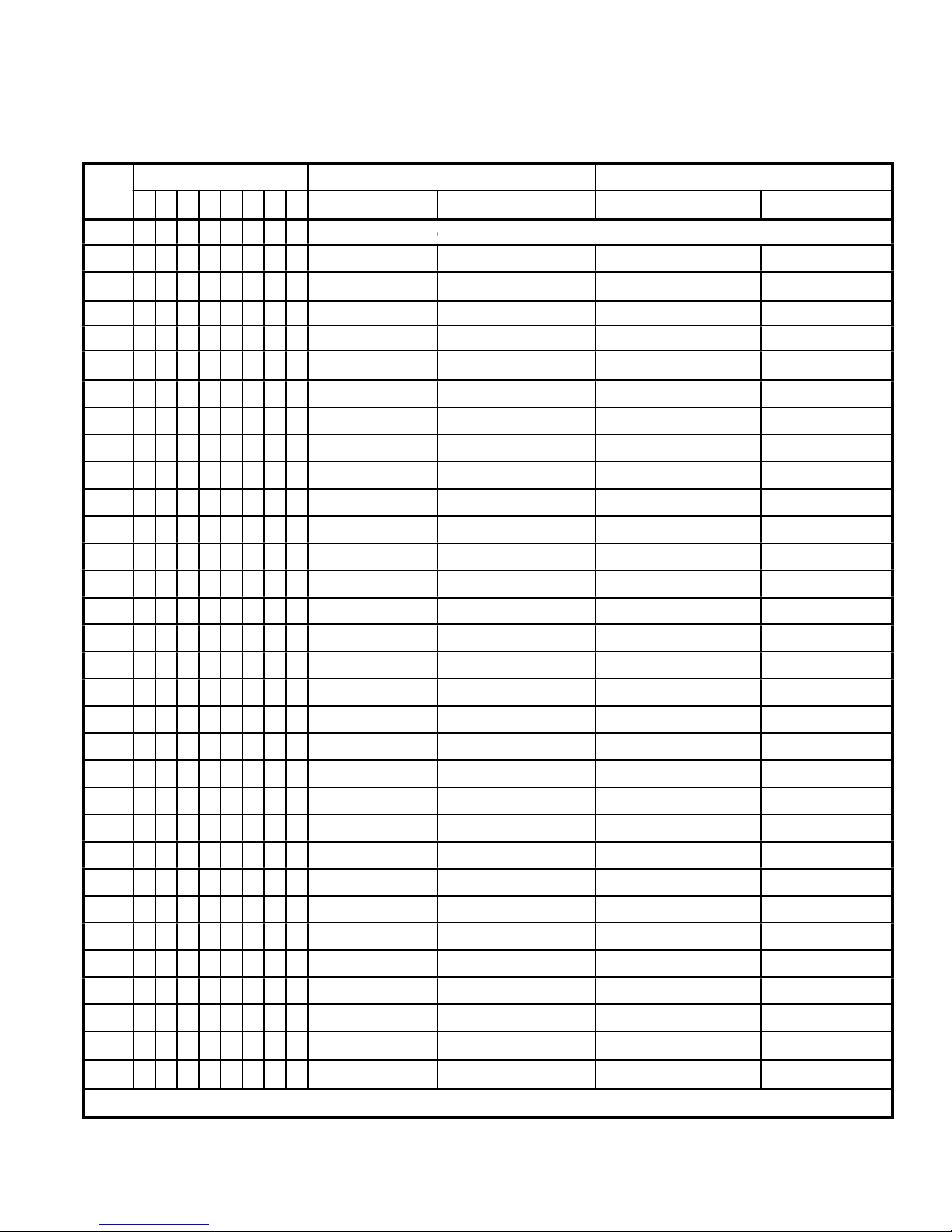

#

DIP SWITCH SETTING

INPUT

OUTPUT

#

12345678Interface

Format

Interface

Format

32

X

Wiegand Output TEST MODE- 26 Bit FC =123 Badge = 4567

33XX

F/2F

ABA

Wiegand

37 Bit Custom

34XX

Dallas iButton

64 Bit Binary

Wiegand

26 Bit

35XX

X

Wiegand

ABA

RS-232 (9600)

ASCII

36XX

Wiegand

ABA

RS-232 (2400)

ASCII

37XX

X

Strobed Fall

ABA

RS-232 (9600)

24 Hex ASCII

38XX

X

Wiegand

24 to 40 bits

RS-232 (9600)

5 Digits, CR

39XXXX

Radionics

Readykey

Wiegand

40 Bit

40XX

Radionics

Readykey

Wiegand

34 Bit

41XX

X

Radionics

Readykey

Wiegand

26 Bit

42XX

X

43XXXX44XXX45XXXX46XXXX47XXXXX48X

X

49XX

X

50XXX51XXXX52XXX53XXXX54XXXX55XXXXX56XXX57XXXX58XXXX59XXXXX60XXXX61XXXX

X

62XXXX

X

63XXXXXX

TEST

MODE

FC = 246

BADGE = ++

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

DIP Switch Application Table

Page 12

#

DIP SWITCH SETTING

INPUT

OUTPUT

#

12345678Interface

Format

Interface

Format

64

X

Strobed ABA Output TEST MODE Number = 123456789

65XX

RS-232 (9600)

10 Dec

Wiegand

26 bit

66XX

RS-232 (2400)

10 Dec

Wiegand

26 bit

67XX

X

RS-232 (1200)

10 Dec

Wiegand

26 bit

68XX

RS-232 (9600)

12 Hex

Wiegand

Variable

69XX

X

RS-232 (2400)

12 Hex

Wiegand

Variable

70XX

X

RS-232 (1200)

12 Hex

Wiegand

Variable

71XXXX

RS-232 (9600)

TransCore

Wiegand

26 bit

72XX

RS-232 (9600)

TransCore

Wiegand

Xico 6

73XX

X

RS-232 (9600)

TransCore

Wiegand

37

74XX

X

RS-232 (9600)

TransCore

Wiegand

26

75XXXX

RS-232 (9600)

TransCore

Wiegand

26 (9117)

76XX

X

RS-232 (9600)

TransCore

Wiegand

26 (9161)

77XXXX

RS-232 (9600)

TransCore

Wiegand

37

78XXXX

RS-232 (9600)

TransCore

Wiegand

37

79XXXX

X

RS-232 (9600)

ASCII

Strobed

ABA

80XX

RS-232 (2400)

ASCII

Strobed

ABA

81XX

X

RS-232 (1200)

ASCII

Strobed

ABA

82XX

X

RS-232 (9600)

ASCII

Strobed NoPU

ABA

83XXXX

RS-232 (9600)

ASCII Decimal

F/2F

12 digit ABA

84XX

X

RS-232 (9600)

TransCore 26b

Wiegand

26 bit

85XXXX

RS-232 (9600)

Transcore

Wiegand

26 bit

86XXXX

RS-232 (9600)

ASCII Decimal

Wiegand

36 bit

87XXXX

X

RS-232 (9600)

ASCII Decimal

Wiegand

37 bit

88XXX89XXXX

90XXXX

91XXXX

X

RS-232 (9600)

Mag-Tek Track 1

Wiegand

26 bit

92XXXX93XXXXX

94XXXX

X

RS-232 (9600)

12 digit ASCII

Wiegand

40 bit

95XXXXXX

RS-232 (9600)

16 digit ASCII

Wiegand

64 bit

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

Continued

DIP Switch Application Table

Page 13

#

DIP SWITCH SETTING

INPUT

OUTPUT

#

12345678Interface

Format

Interface

Format

96XX

Reserved

Reserved

97XX

X

Wiegand

24-40 bit

Wiegand

26 bit

98XX

X

Wiegand

24-40 bit

Wiegand

26 bit

99XXXX

Wiegand

35 bit

Wiegand

26 bit

100

XXX

Strobed

ABA/ 12 digits

Wiegand

26 bit

101

XXX

X

Strobed

ABA/Last 8 dig.

Wiegand

26 bit

102

XXX

X

Wiegand

26 bit

Strobed/ABA

12 digits

103

XXXXX

104

XXX

105

XXX

X

106

XXX

X

107

XXXXX

108

XXXX109

XXXXX

110XXXXX111XXXXXX

112XX

X

113XXXX

114XXXX

115XXXXX116XXXX

117XXXXX118XXXXX119XXXXXX

120

XXXX121

XXXXX

122

XXXXX

123

XXXXXX124

XXXXX

125

XXXXX

X

126

XXXXX

X

127

XXXXXXX

DIP Switch Application Table

Page 14

Standard Wiring Diagrams - CVX-1300 Converter

Wiring diagrams are referenced by function and number. The specific converter

descriptions will refer to these diagrams.

CVX-1300 Electrical Connections

1. Serial data and RS485

2. Standard power supply connections

LISTING OF STANDARD WIRING DIAGRAMS

1. Wiegand to Serial.

2. Serial to Wiegand

3. Wiegand to Wiegand

4. Strobed to Serial

5. Serial to Strobed

6. Strobed to Wiegand

7. Wiegand to Strobed

8. F/2F to Wiegand

9.Serial to F2F

10. Dallas iButton to Wiegand

11. Serial to Wiegand - Special Application

12 Radionics 1 Wire to Wiegand

FCC Part 15 COMPLIANCE

This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

Page 15

Wiring Diagram #1 Wiegand to Serial

CVX Terminal

DB9 Pin

Ground

5

RS232 Input

3

RS232 Output

2

Reader powered by external supply (8 to 16 VDC)

Card

Reader

Data0

Data1

LED

Ground

Connections

to Serial

Device

DB-9 Connections

Direct to PC Com Port

D0/Clock In

D1/Data In

LED Out

Ground

RS232 Input

RS232 Output

Data Bender®

+8 to +16 VDC In

Ground

(-)

(+)

DC

Power

Supply

The Wiegand to RS232 converters support incoming commands to

control the Reader LED and Converter Relay.

RX Data:

NOTE: Commands must be capitalized characters

Turn LED on................ @ L 1

Turn LED off............... @ L 0

Toggle LED................. @ L 2 (Bi-Color LED Turns Orange)

Turn Relay on.............. @ R 1

Turn Relay off............. @ R 0

Page 16

Wiring Diagram #1 Wiegand to Serial

CVX Terminal

DB9 Pin

Ground

5

RS232 Input

3

RS232 Output

2

Reader powered by converter +5 VDC

Card

Reader

Data0

Data1

LED

Ground

Connections

to Serial

DB-9 Connections

Direct to PC Com Port

Device

D0/Clock In

D1/Data In

LED Out

Ground

RS232 Input

RS232 Output

Data Bender®

+8 to +16 VDC In

+5VDC Out

Ground

(-)

(+)

DC

Power

Supply

The Wiegand to RS232 converters support incoming commands to

control the Reader LED and Converter Relay.

RX Data:

NOTE: Commands must be capitalized characters

Turn LED on................ @ L 1

Turn LED off............... @ L 0

Toggle LED................. @ L 2 (Bi-Color LED Turns Orange)

Turn Relay on.............. @ R 1

Turn Relay off............. @ R 0

Page 17

Data0 Out

Data1 Out

DB9-5

Ground

DB9-2

DB9-3

DB9-6

Wiring Diagram #2 Serial to Wiegand

Data0

Data1

Ground

RS232 Input

RS232 Output

Data Bender®

+5VDC Out

Access

Control

Panel

Connections

to Serial

Device

Ground

+8 to +16 VDC In

(-)

(+)

DC

Power

Supply

Page 18

Wiring Diagram #3 Wiegand to Wiegand

Ground

Ground

Reader powered by external supply (8 to 16 VDC)

Card

Reader

Data0

Data1

Ground

D0 Output

D0 Input

D1 Output

D1 Input

Ground

Data Bender®

Ground

+8 to +16 VDC In

Reader powered by 5 Volt Supply

Data 0

Data 1

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Card

Reader

Data0

Data1

Ground

D0 Input

D1 Input

Ground

Data Bender®

D0 Output

D1 Output

+5 VDC Out

Ground

+8 to +16 VDC In

Data 0

Data 1

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Page 19

Wiring Diagram #4 Strobed to Serial

CVX Terminal

DB9 Pin

Ground

5

RS232 Input

3

RS232 Output

2

Reader powered by external supply (8 to 16 VDC)

Clock

Strobe

LED

Ground

Card

Reader

Connections

to Serial

Device

DB-9 Connections

Direct to PC Com Port

D0/Clock In

D1/Data In

LED Out

Ground

RS232 Input

RS232 Output

Data Bender®

+8 to +16 VDC In

Ground

(-)

(+)

DC

Power

Supply

The Strobed to RS232 converters support incoming commands to

control the Reader LED and Converter Relay.

RX Data:

NOTE: Commands must be capitalized characters

Turn LED on................ @ L 1

Turn LED off............... @ L 0

Toggle LED................. @ L 2 (Bi-Color LED Turns Orange)

Turn Relay on.............. @ R 1

Turn Relay off............. @ R 0

Page 20

Wiring Diagram #4 Strobed to Serial

CVX Terminal

DB9 Pin

Ground

5

RS232 Input

3

RS232 Output

2

Reader powered by converter +5 VDC

Clock

Strobe

LED

Ground

Card

Reader

Connections

to Serial

Device

DB-9 Connections

Direct to PC Com Port

D0/Clock In

D1/Data In

LED Out

Ground

RS232 Input

RS232 Output

Data Bender®

+8 to +16 VDC In

+5VDC Out

Ground

(-)

(+)

DC

Power

Supply

The Strobed to RS232 converters support incoming commands to

control the Reader LED and Converter Relay.

RX Data:

NOTE: Commands must be capitalized characters

Turn LED on................ @ L 1

Turn LED off............... @ L 0

Toggle LED................. @ L 2 (Bi-Color LED Turns Orange)

Turn Relay on.............. @ R 1

Turn Relay off............. @ R 0

Page 21

Ground

Clock Out

Data Out

DB9-5

DB9-2

DB9-3

DB9-6

5 Volts

(If Used)

Connections

to Serial

Device

Wiring Diagram #5 Serial to Strobed

Clock

Data

Ground

RS232 Input

RS232 Output

Data Bender®

+5VDC Out

Ground

+8 to +16 VDC In

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Page 22

Wiring Diagram #6 Strobed to Wiegand

Ground

Ground

Reader powered by external supply (8 to 16 VDC)

Card

Reader

Clock

Strobe

LED

Ground

Connections

to Serial

Device

D0/Clock In

D1/Data In

LED Out

Ground

RS232 Input

RS232 Output

Data Bender®

Ground

+8 to +16 VDC In

Reader powered by converter +5 VDC

Data 0

Data 1

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Card

Reader

Connections

Clock

Strobe

LED

Ground

to Serial

Device

D0/Clock In

D1/Data In

LED Out

Ground

RS232 Input

RS232 Output

Data Bender®

+8 to +16 VDC In

+5VDC Out

Ground

Data 0

Data 1

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Page 23

Wiring Diagram #7 Wiegand to Strobed

Ground

Ground

Reader powered by external supply (8 to 16 VDC)

Card

Reader

Data0

Data1

Ground

Clock Out

D0/Clock In

Data Out

D1/Data In

Ground

Data Bender®

Ground

+8 to +16 VDC In

Reader powered by 5 Volt Supply

Clock

Data

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Card

Reader

Data0

Data1

Ground

D0/Clock In

D1/Data In

Ground

Data Bender®

+8 to +16 VDC In

Clock Out

Data Out

+5VDC Out

Ground

Clock

Data

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Page 24

Wiring Diagram #8 F2F to Wiegand

Ground

Ground

Reader powered by external supply (8 to 16 VDC)

Card

Reader

F2F

Ground

D0 Output

D1 Output

F2F Input

Ground

Data Bender®

Ground

+8 to +16 VDC In

Reader powered by 5 Volt Supply

Data 0

Data 1

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Card

Reader

F2F

Ground

F2F Input

Ground

Data Bender®

D0 Output

D1 Output

+5 VDC Out

Ground

+8 to +16 VDC In

Data 0

Data 1

(-)

(+)

Access

Control

Panel

DC

Power

Supply

Page 25

F2F Output

DB9-5

Ground

DB9-2

DB9-3

DB9-6

Wiring Diagram #9 Serial to F2F

Ground

RS232 Input

RS232 Output

Data Bender®

+5VDC Out

F2F

Access

Control

Panel

Connections

to Serial

Device

Ground

+8 to +16 VDC In

(-)

(+)

DC

Power

Supply

Page 26

Ground

IButton®

Reader

Wiring Diagram #10 IButton® to Wiegand

4.7 k Pullup

Resistor

IButton Center Contact

Ground

Data In

Data In

Ground

Data Bender®

Data 0

Data 1

Access

Control

Panel

+5VDC Out

Ground

+8 to +16 VDC In

(-)

(+)

DC

Power

Supply

Page 27

Data0 Out

Data1 Out

DB9-5

Ground

DB9-2

DB9-3

DB9-4

Wiring Diagram #11 Serial to Wiegand

Special Application

Data0

Data1

Ground

RS232 Input

RS232 Output

Data Bender®

+5VDC Out

Access

Control

Panel

Connections

to Serial

Device

Ground

+8 to +16 VDC In

(-)

(+)

DC

Power

Supply

Page 28

Ground

Wiring Diagram #12 Radionics to Wiegand

Data Out (SIG)

Reader powered by external supply (8 to 16 VDC)

D0 Output

D1 Output

Data Bender®

Ground

+8 to +16 VDC In

+5VDC

485(-)

485(+)

Data 0

Data 1

(-)

(+)

2.7 k Pullup Resistors

Must be installed as shown.

Resistor values between 1k and 10k

should work. Both resistors should be the

same value

DC

Power

Supply

Ground (-V)

+VDC (+V)

Access

Control

Panel

Card

Reader

Loading...

Loading...