Page 1

r

CYV15G0404RB

Independent Clock Quad HOTLink II™

Deserializing Reclocke

Features

• Second-generation HOTLink® technology

• Compliant to SMPTE 292M and SMPTE 259M video

standards

• Quad channel video reclocking deserializer

— 195 to 1500 Mbps serial data signaling rate

— Simultaneous operation at different signaling rates

• Supports reception of either 1.485 or 1.485/1.001 Gbps data

rate with the same training clock

• Supports half-rate and full-rate clocking

• Internal phase-locked loops (PLLs) with no external PLL

components

• Selectable differential PECL-compatible serial inputs

— Internal DC restoration

• Synchronous LVTTL parallel interface

• JTAG boundary scan

• Built-In Self-Test (BIST) for at-speed link testing

• Link Quality Indicator

— Analog signal detect

— Digital signal detect

• Low-power: 3W @ 3.3V typical

• Single 3.3V supply

• Thermally enhanced BGA

• Pb-Free package option available

•0.25µ BiCMOS technology

Functional Description

The C YV15G0404RB Ind ependent Clock Quad HOT Link II™

Deserializing Reclocker is a point-to-point or point-to-multipoint communications building block enabling data transfer

over a variety of high speed se ri al li n ks i n cl ud i n g SMPTE 292

and SMPTE 259 video applications. It supports signaling rates

in the range of 195 to 1500 Mbps for each serial link. The four

channels are independent and can simultaneously operate at

different rates. Each receive channel accepts serial data and

converts it to 10-bit parallel characters and presents these

characters to an Output Register. The received serial data can

also be reclocked and retransmitted through the reclocker

serial outputs. Figure 1, "HOTLink II™ System Connections,"

on page 2 illustrates typical connections between independent

video coprocessors and corresponding CYV15G0404RB

Reclocking Deserializer and CYV15G0403TB Serializer chips.

The CYV15G0404RB is SMPTE-259M and SMPTE-292M

compliant according to SMPTE EG34-1999 Pathological Test

Requirements.

As a second generation HOTLink device, the

CYV15G0404RB extends the HOTLink family with enhanced

levels of integration and faster data rates, while maintaining

serial-link compatibility (data and BIST) with other HOTLink

devices.

Each channel of the CYV15G0404RB Quad HOTLink II device

accepts a serial bit-stream from one of two selectable

PECL-compatible differential line receivers, and using a

completely integrated Clock and Data Recovery PLL, recovers

the timing information necessary for data reconstruction. The

device reclocks and retransmits recovered bit-stream through

the reclocker serial outputs. It also deserializes the recovered

serial data and presents it to the destination host system.

Each channel contains an independent BIST pattern checker.

This BIST hardware enables at speed testing of the

high-speed serial data paths in each receive section of this

device, each transmit section of a connected HOTLink II

device, and across the interconnecting links.

The CYV15G0404RB is ideal for SMPTE applications where

different data rates and serial interface standards are

necessary for each channel. Some applications include

multi-format routers, switchers, format converters, SDI

monitors, and camera control units.

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 • 408-943-2600

Document #: 38-02102 Rev. *C Revised February 16, 2007

[+] Feedback

Page 2

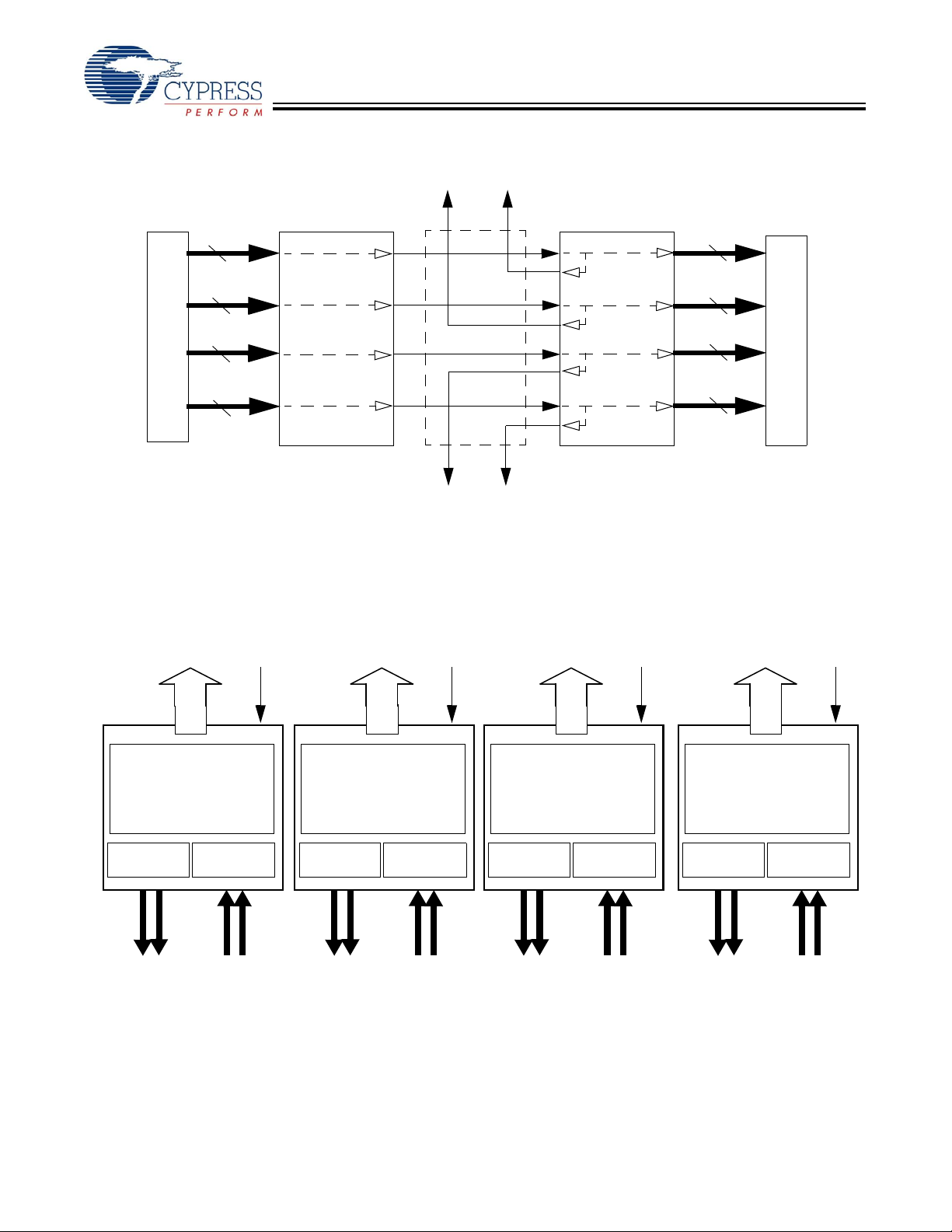

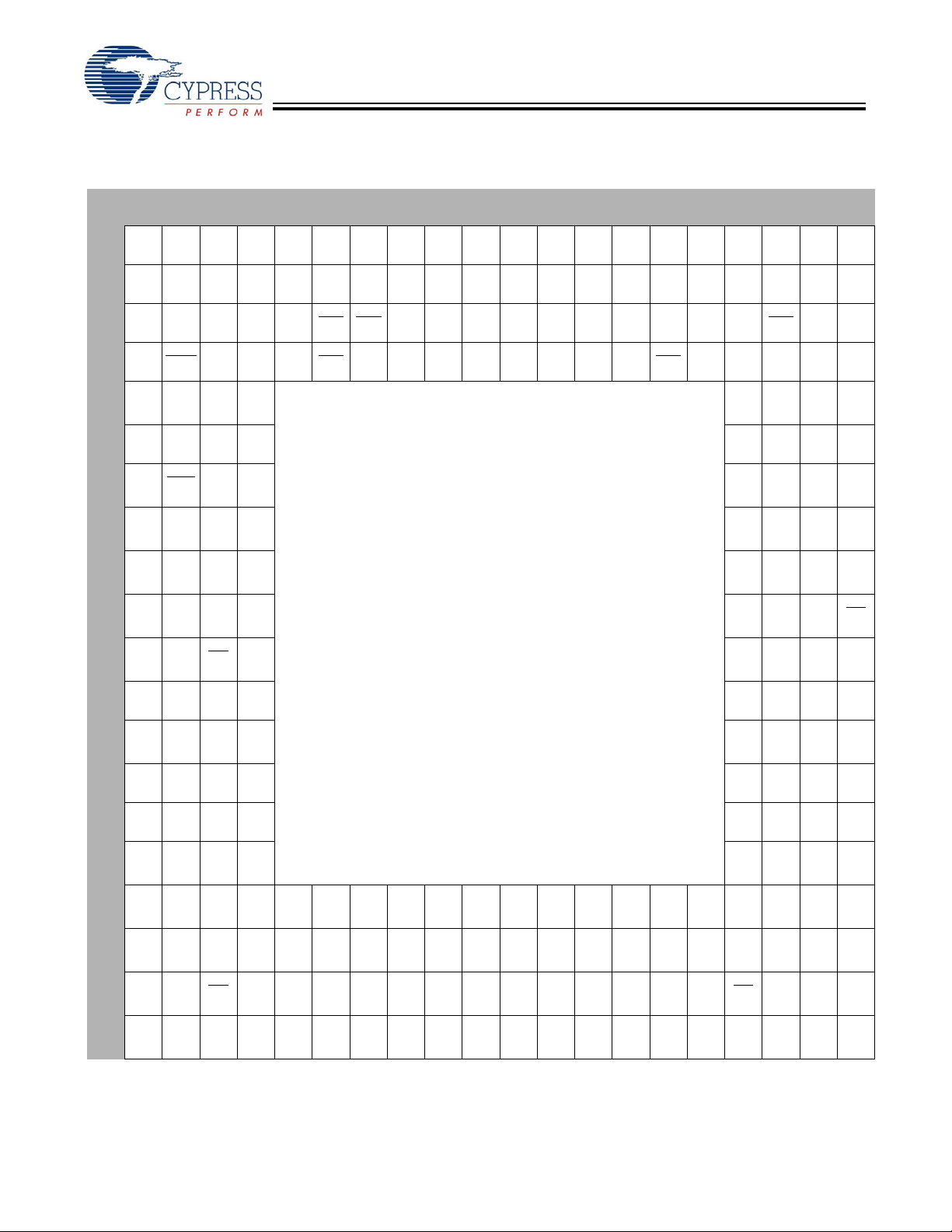

Figure 1. HOTLink II™ System Connections

Reclocked

Outputs

CYV15G0404RB

10

Video Coprocesso r

10

Independent

Channel

10

10

CYV15G0403TB

Serializer

Serial Links

Reclocked

Outputs

Reclocking Deserializer

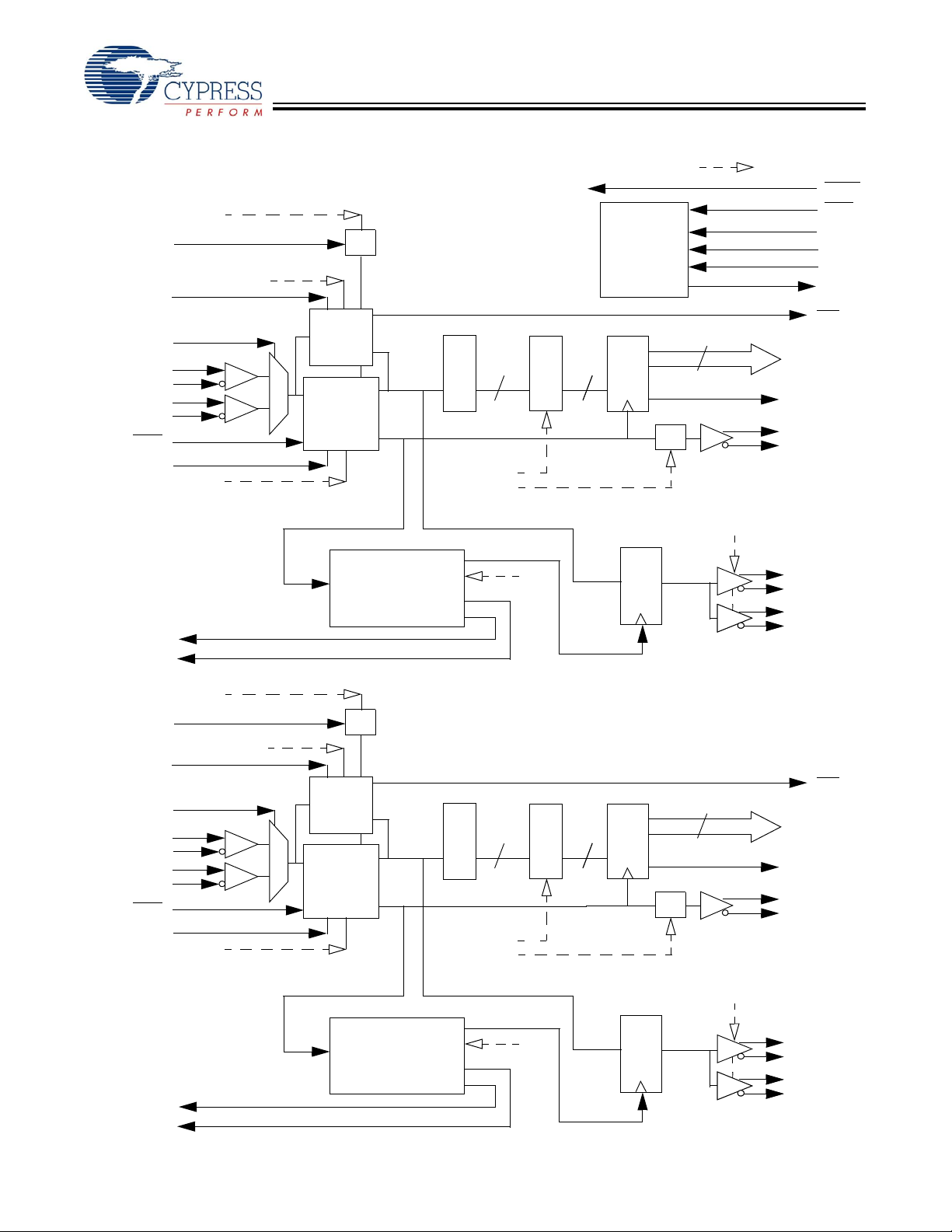

CYV15G0404RB Deserializing Reclocker Logic Block Diagram

RXDA[9:0]

TRGCLKA±

RXDB[9:0]

TRGCLKB±

RXDC[9:0]

Independent

Channel

CYV15G0404RB

TRGCLKC±

10

10

10

Video Coprocessor

10

RXDD[9:0]

TRGCLKD±

Deserializer

Reclocker

ROUTA1±

ROUTA2±

x10

RX

INA1±

x10

Deserializer

Reclocker

INA2±

ROUTB1±

ROUTB2±

RX

INB1±

Reclocker

INB2±

x10

Deserializer

±

±

ROUTC1

ROUTC2

RX

±

INC1

x10

Deserializer

Reclocker

±

±

INC2

±

ROUTD1

ROUTD2

RX

±

IND1

±

IND2

Document #: 38-02102 Rev. *C Page 2 of 27

[+] Feedback

Page 3

CYV15G0404RB

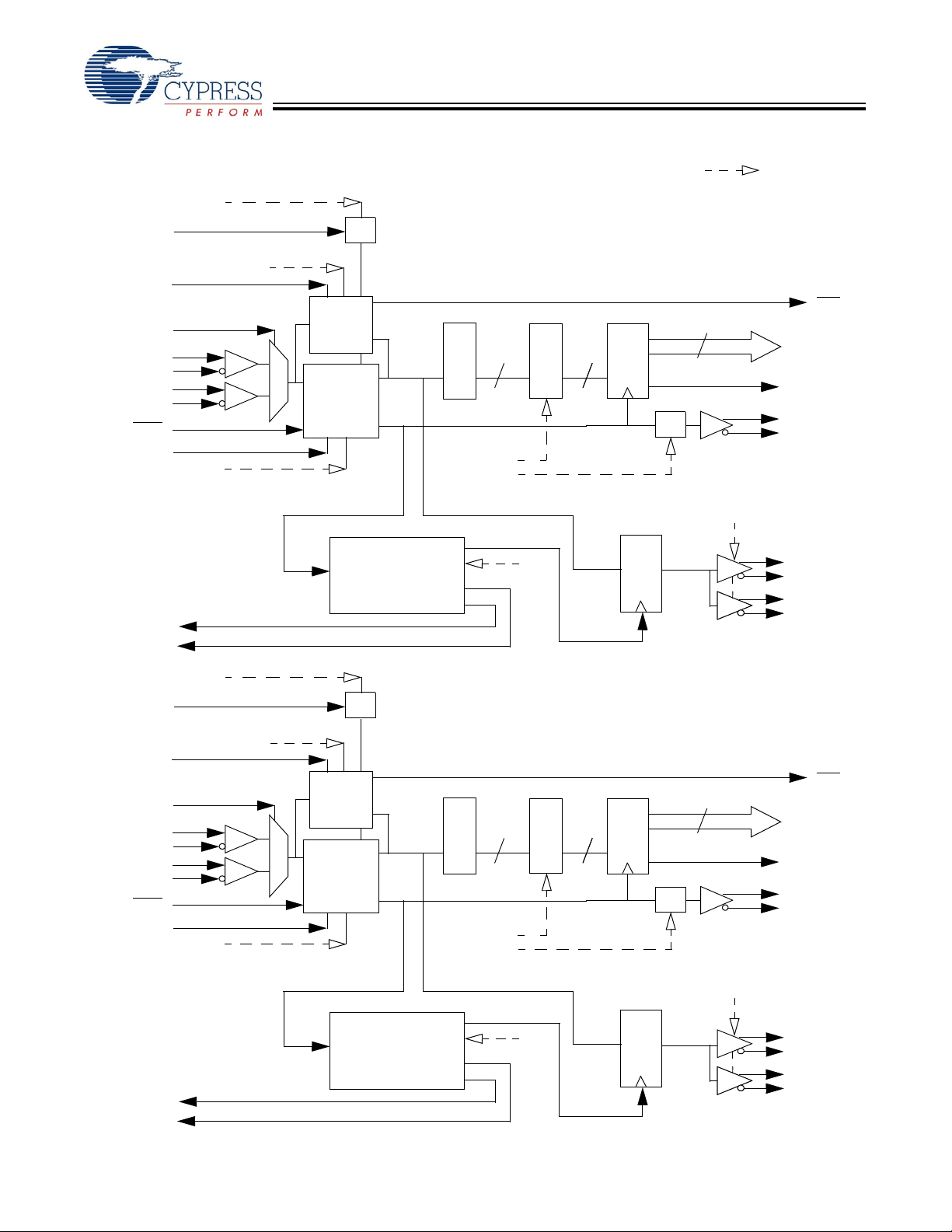

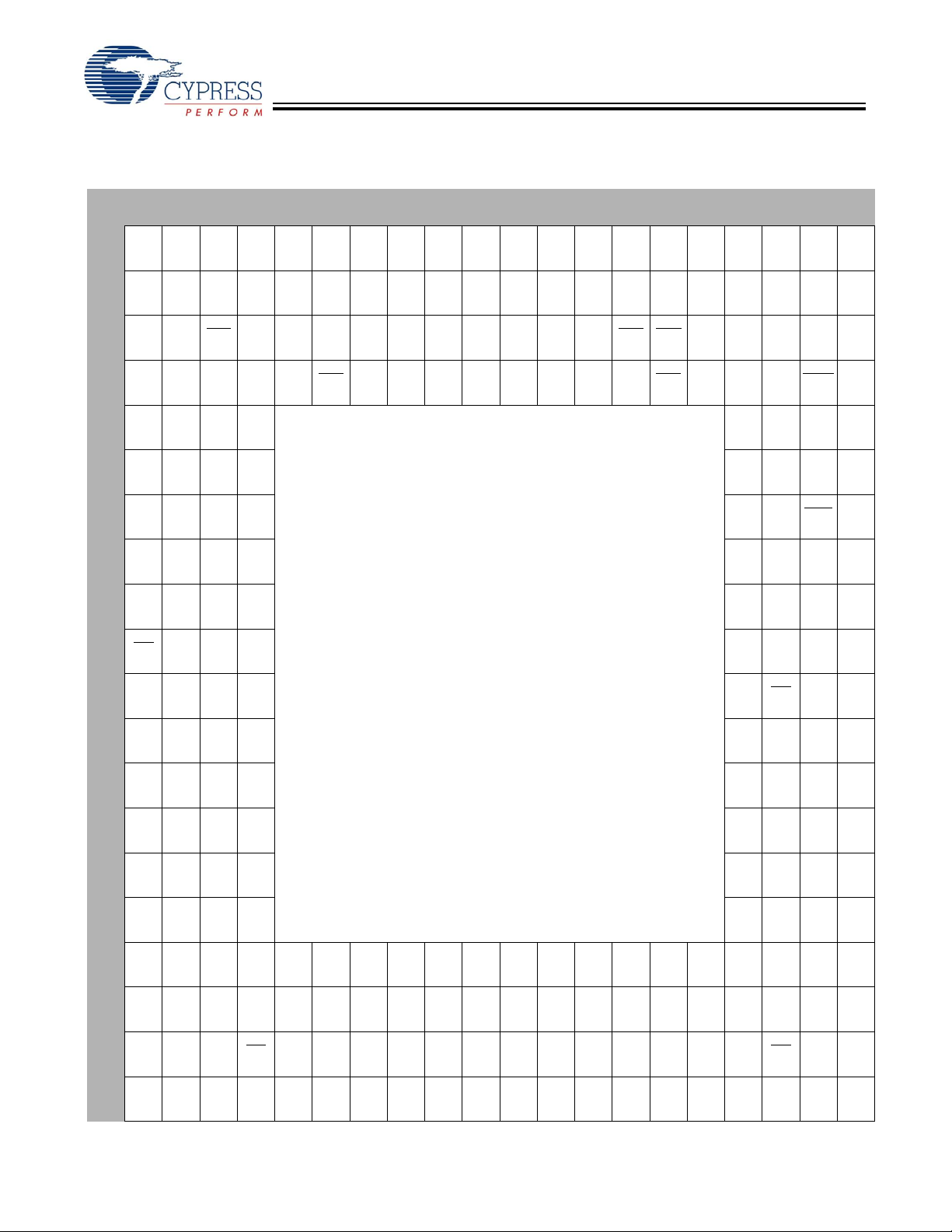

Reclocking Deserializer Path Block Diagram

TRGRATEA

TRGCLKA

SDASEL[2..1]A[1:0]

LDTDEN

INSELA

INA1+

INA1–

INA2+

INA2–

ULCA

SPDSELA

RXPLLPDA

Recovered Character Clock

RECLKOA

REPDOA

x2

Receive

Signal

Monitor

Clock &

Data

Recovery

PLL

Recovered Serial Data

Reclocker

Output PLL

Clock Multiplier A

Character-Rate Clock A

10

Shifter

RXBISTA[1:0]

RXRATEA

ROE[2..1]A

10

BIST LFSR

JTAG

Boundary

Scan

Controller

Output

Register

÷2

Register

10

ROE[2..1]A

= Internal Signal

RESET

TRST

TMS

TCLK

TDI

TDO

LFIA

RXDA[9:0]

BISTSTA

RXCLKA+

RXCLKA–

ROUTA1+

ROUTA1–

ROUTA2+

ROUTA2–

TRGCLKB

LDTDEN

INSELB

INB1+

INB1–

INB2+

INB2–

ULCB

SPDSELB

RECLKOB

REPDOB

TRGRATEB

SDASEL[2..1]B[1:0]

RXPLLPDB

x2

Receive

Signal

Monitor

Clock &

Data

Recovery

PLL

Recovered Character Clock

Reclocker

Output PLL

Clock Multiplier B

Character-Rate Clock B

10

Shifter

RXBISTB[1:0]

RXRATEB

Recovered Serial Data

ROE[2..1]B

10

BIST LFSR

Output

Register

Register

÷2

10

ROE[2..1]B

LFIB

RXDB[9:0]

BISTSTB

RXCLKB+

RXCLKB–

ROUTB1+

ROUTB1–

ROUTB2+

ROUTB2–

Document #: 38-02102 Rev. *C Page 3 of 27

[+] Feedback

Page 4

CYV15G0404RB

Reclocking Deserializer Path Block Diagram (continued)

TRGRATEC

TRGCLKC

SDASEL[2..1]C[1:0]

LDTDEN

INSELC

INC1+

INC1–

INC2+

INC2–

ULCC

SPDSELC

RXPLLPDC

Recovered Character Clock

RECLKOC

REPDOC

x2

Receive

Signal

Monitor

Clock &

Data

Recovery

PLL

Reclocker

Output PLL

Clock Multiplier C

Character-Rate Clock C

10

Shifter

RXBISTC[1:0]

RXRATEC

Recovered Serial Data

ROE[2..1]C

10

BIST LFSR

Output

Register

Register

÷2

10

ROE[2..1]C

= Internal Signal

LFIC

RXDC[9:0]

BISTSTC

RXCLKC+

RXCLKC–

ROUTC1+

ROUTC1–

ROUTC2+

ROUTC2–

TRGCLKD

LDTDEN

INSELD

IND1+

IND1–

IND2+

IND2–

ULCD

SPDSELD

RECLKOD

REPDOD

TRGRATED

SDASEL[2..1]D[1:0]

RXPLLPDD

x2

Receive

Signal

Monitor

Clock &

Data

Recovery

PLL

Recovered Character Clock

Reclocker

Output PLL

Clock Multiplier D

Character-Rate Clock D

10

Shifter

RXBISTD[1:0]

RXRATED

Recovered Serial Data

ROE[2..1]D

10

BIST LFSR

Output

Register

Register

÷2

10

ROE[2..1]D

LFID

RXDD[9:0]

BISTSTD

RXCLKD+

RXCLKD–

ROUTD1+

ROUTD1–

ROUTD2+

ROUTD2–

Document #: 38-02102 Rev. *C Page 4 of 27

[+] Feedback

Page 5

CYV15G0404RB

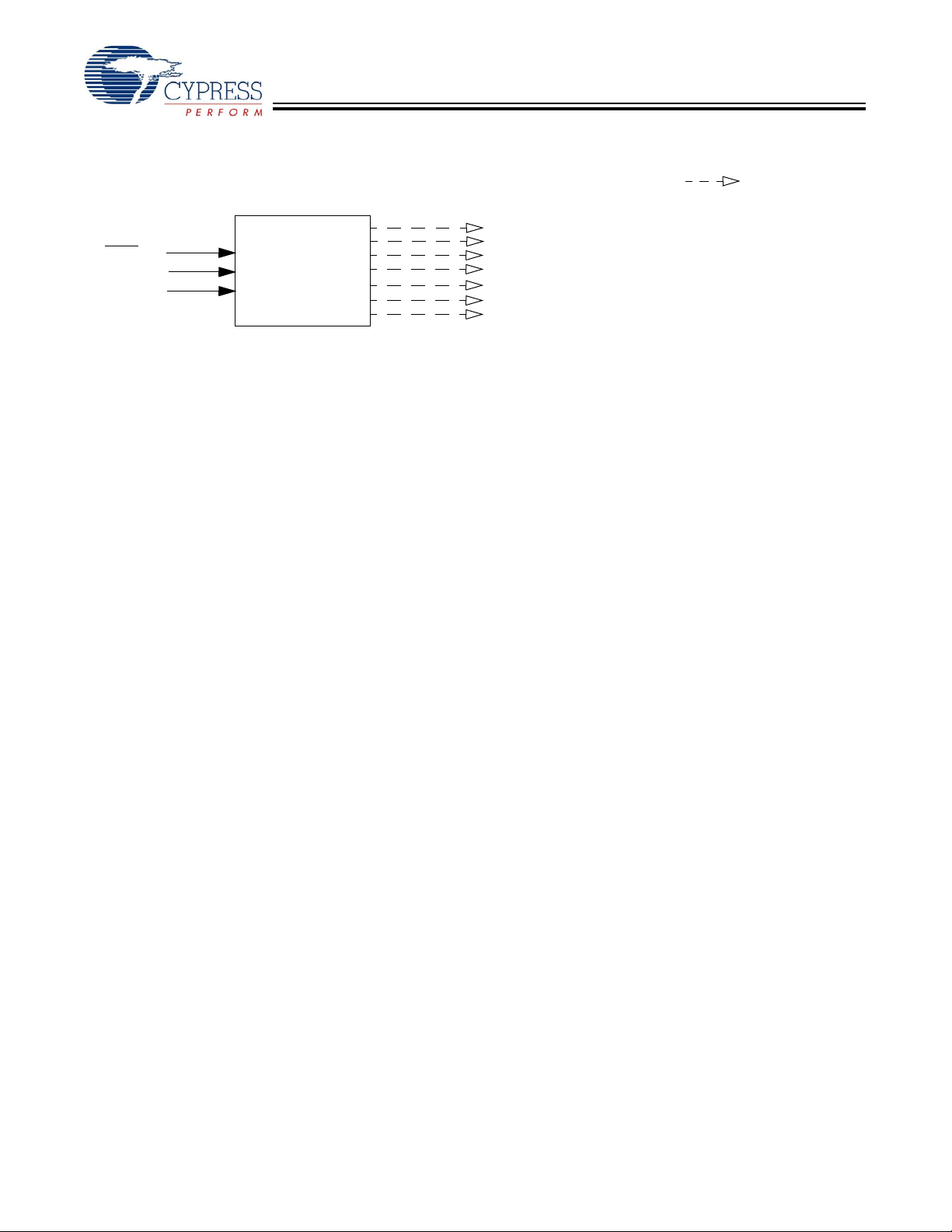

Device Configuration and Control Block Diagram

WREN

ADDR[3:0]

DATA[7:0]

Device Configuration

and Control Interface

= Internal Signal

RXBIST[A..D]

RXRATE[A..D]

SDASEL[A..D][1:0]

RXPLLPD[A..D]

ROE[2..1][A..D]

GLEN[11..0]

FGLEN[2..0]

Document #: 38-02102 Rev. *C Page 5 of 27

[+] Feedback

Page 6

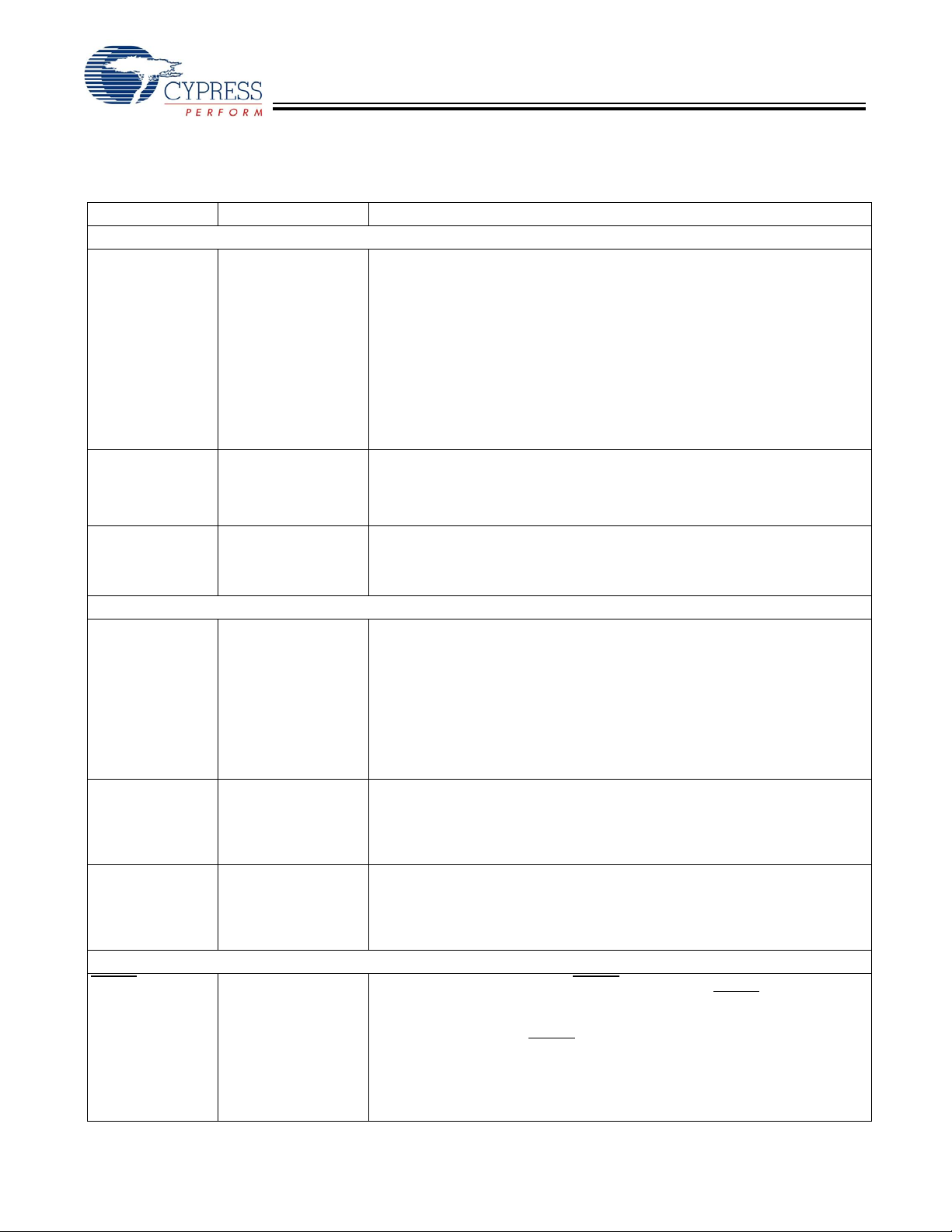

CYV15G0404RB

Pin Configuration (Top View)

[1]

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

A

IN

ROUT

C1–

C1–INC2–

B

IN

ROUT

C1+

C1+INC2+

C

TDI TMS INSELC INSELB

D

TCLK RESET INSELD INSELA

E

VCCVCCVCCV

F

RX

DC[8]RXDC[9]

G

H

J

K

L

M

N

WREN

GND

GND GND GND GND GND GND GND GND

GND GND GND GND

RX

TRG

DC[4]

CLKC–

RX

TRG

DC[5]

CLKC+

RX

DC[6]RXDC[7]

GND GND GND GND GND GND GND GND

ROUT

C2–

ROUT

C2+

CC

VCCV

CC

GND GND

GND GND

LFIC

GND

RE

V

CC

PDOC

V

CC

V

CC

V

CC

V

CC

IN

ROUT

D1–

D1–

IN

ROUT

D1+

D1+

ULCD ULCC

ULCA SPD

SELC

GND

GND

GND

GND

IN

D2–

IN

D2+

DATA

[7]

DATA

[6]

ROUT

D2–INA1–

ROUT

D2+INA1+

DATA

[5]

DATA

[4]

DATA

[3]

DATA

[2]

ROUT

A1–

ROUT

A1+

DATA

[1]

DATA

[0]

IN

GND

A2–

IN

GND

A2+

GND V

CC

GND GND

ROUT

A2–

ROUT

A2+

SPD

SELD

ULCB

IN

V

CC

B1–

IN

V

CC

B1+

LDTD ENTRST

V

CC

V

NC V

CC

VCCVCCVCCV

V

CC

SPD

SELB

BIST

STBRXDB[2]RXDB[7]RXDB[4]

RX

DB[5]RXDB[6]RXDB[9]

RX

DB[8]RXCLKB+RXCLKB–

TRG

CLKB+

CLKB–REPDOB

ROUT

B1–INB2–

ROUT

B1+INB2+

CC

RX

DB[0]RECLKOBRXDB[1]

NC

ROUT

B2–

ROUT

B2+

TDO

GND

SCAN

TMEN3

EN2

SPD

SELARXDB[3]

LFIB

GND

TRG

GND

CC

P

RX

DC[3]RXDC[2]RXDC[1]RXDC[0]

R

BIST

STCRECLKOCRXCLKC+RXCLKC–

T

VCCVCCVCCV

U

VCCVCCVCCVCCV

V

VCCVCCV

W

VCCV

CC

Y

VCCV

CC

Note

1. NC = Do not connect.

CC

DD[8]

LFID RX

CLKD–

RX

DD[9]

CLKD+

RX

RX

CC

CC

V

CC

V

CC

V

CC

RX

DD[4]RXDD[3]

RX

DD[5]RXDD[1]

RX

DD[6]RXDD[0]

RX

DD[7]RXDD[2]

GND GND

BIST

GND

STD

ADDR

GND

[3]

RE

GND

CLKOD

ADDR

TRG

[0]

CLKD–

ADDR

TRG

[2]

CLKD+RECLKOA

ADDR

[1]RXCLKA+REPDOA

NC

GND

CLKA–

GND GND GND VCCV

GND GND VCCV

GND GND VCCV

RX

GND GND VCCV

GND GND GND GND

VCCVCCVCCV

VCCVCCVCCV

RX

CC

CC

CC

CC

V

DA[4]

DA[9]RXDA[5]RXDA[2]RXDA[1]

PDOD

CC

RX

LFIA TRG

CLKA+RXDA[6]RXDA[3]

RE

TRG

CLKA–RXDA[8]RXDA[7]

BIST

STARXDA[0]

CC

CC

Document #: 38-02102 Rev. *C Page 6 of 27

[+] Feedback

Page 7

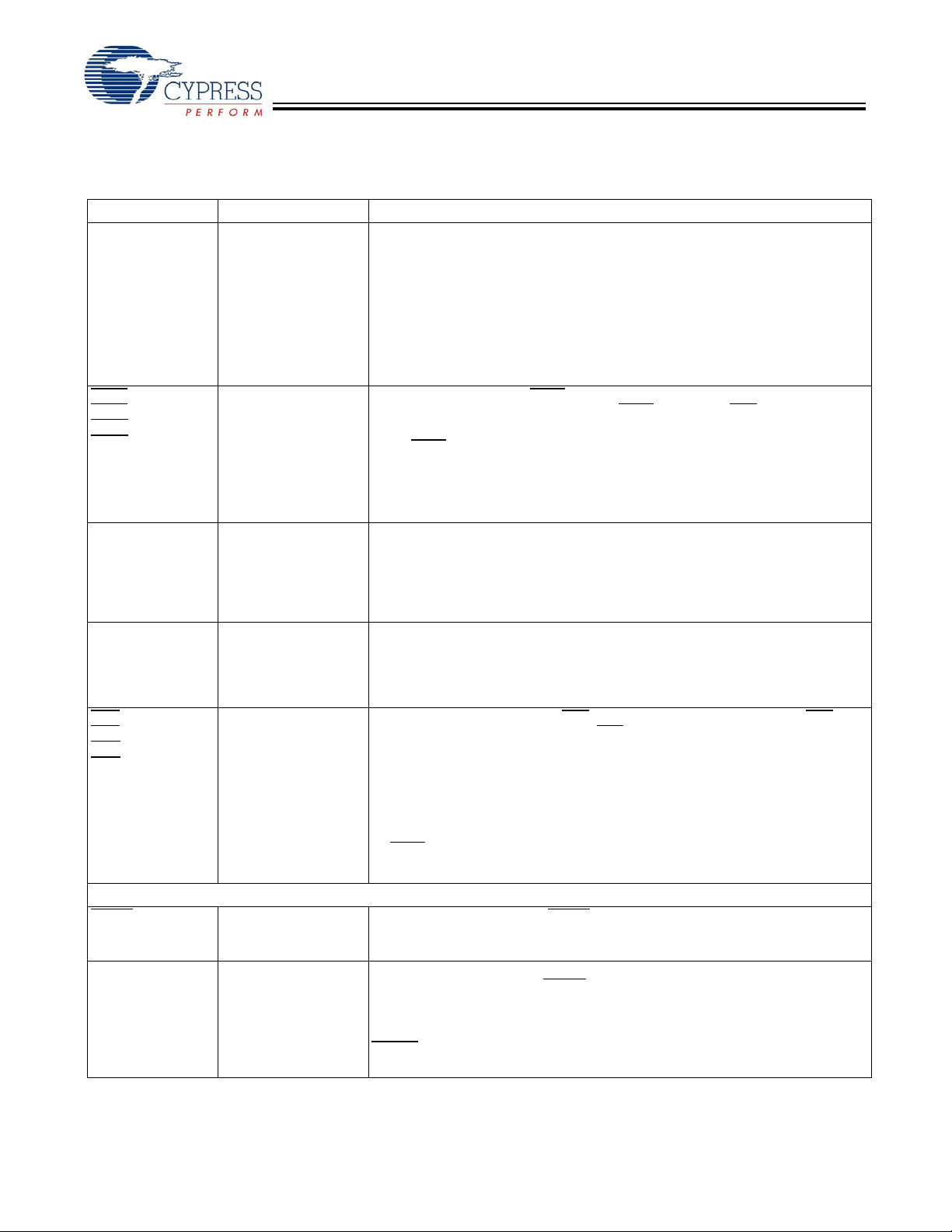

CYV15G0404RB

Pin Configuration (Bottom View)

[1]

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

ROUT

A

B2–INB2–

ROUT

B

B2+INB2+

TDO

C

TMEN3 SCAN

D

VCCVCCVCCV

E

RX

F

DB[1]RECLKOBRXDB[0]

RX

G

DB[3]

GND GND GND GND GND GND GND GND

H

RX

J

DB[4]RXDB[7]RXDB[2]

GND

EN2

SPD

SELA

ROUT

B1–INB1–

ROUT

B1+INB1+

TRST LDTD

EN

V

NC V

CC

CC

V

CC

SPD

NC

SELB

BIST

STB

V

V

V

CC

CC

CC

CC

ROUT

A2–INA2–

ROUT

A2+INA2+

SPD

SELD

ULCB

GND

GND

VCCGND

GND GND

ROUT

A1–INA1–

ROUT

A1+INA1+

DATA

[1]

DATA

[0]

DATA

[3]

DATA

[2]

ROUT

D2–IND2–

ROUT

D2+IND2+

DATA

[5]

DATA

[4]

DATA

[7]

DATA

[6]

GND

GND

GND

GND

ROUT

D1–IND1–

ROUT

D1+IND1+

ULCC ULCD

SPD

ULCA

SELC

ROUT

V

CC

C2–INC2–

ROUT

V

CC

C2+INC2+

INSELB INSELC TMS TDI

V

CC

INSELA INSELD RESET TCLK

V

CC

VCCVCCVCCV

VCCV

GND GND

GND GND GND GND

CC

ROUT

C1–INC1–

ROUT

C1+INC1+

RX

DC[9]RXDC[8]

WREN

GND

CC

LFIB RX

K

L

M

N

P

R

T

U

V

W

Y

DB[9]RXDB[6]RXDB[5]

RX

GND

CLKB–RXCLKB+RXDB[8]

RE

TRG

GND

PDOB

CLKB–

TRG

CLKB+

GND GND GND GND GND GND GND GND

GND GND GND GND

VCCVCCVCCV

VCCVCCVCCV

RX

BIST

DA[0]

STA

RX

DA[1]RXDA[2]RXDA[5]RXDA[9]

RX

DA[3]RXDA[6]

RX

DA[7]RXDA[8]

CLKA+

CLKA–REPDOD

V

CC

TRG

TRG

CC

CC

RX

VCCVCCGND GND GND

DA[4]

VCCVCCGND GND

LFIA

VCCVCCGND GND

VCCVCCGND GND

TRG

CLKD–

RE

TRG

CLKOA

CLKD+

RE

PDOARXCLKA+

RX

GND

CLKA–

ADDR

[0]

ADDR

[2]

ADDR

[1]

NC RE

GND GND

BIST

GND

STD

ADDR

GND

[3]

GND

CLKOD

RX

DD[3]RXDD[4]

RX

DD[1]RXDD[5]

RX

DD[0]RXDD[6]

RX

DD[2]RXDD[7]

GND GND

LFIC TRG

GND

RE

V

PDOC

DC[0]RXDC[1]RXDC[2]RXDC[3]

CLKC–RXCLKC+RECLKOC

CC

RX

RX

VCCVCCVCCV

VCCVCCVCCVCCV

RX

V

CC

V

CC

V

CC

VCCVCCV

DD[8]

RX

LFID

CLKD–

RX

CLKD+RXDD[9]

TRG

CLKC–RXDC[4]

CLKC+RXDC[5]

RX

DC[7]RXDC[6]

BIST

STC

CC

CC

CC

VCCV

CC

VCCV

CC

Document #: 38-02102 Rev. *C Page 7 of 27

[+] Feedback

Page 8

Pin Definitions

CYV15G0404RB Quad HOTLink II Deserializing Reclocker

Name IO Characteristics Signal Description

Receive Path Data and Status Signals

RXDA[9:0]

RXDB[9:0]

RXDC[9:0]

RXDD[9:0]

BISTSTA

BISTSTB

BISTSTC

BISTSTD

REPDOA

REPDOB

REPDOC

REPDOD

Receive Path Clock Signals

TRGCLKA±

TRGCLKB±

TRGCLKC±

TRGCLKD±

RXCLKA±

RXCLKB±

RXCLKC±

RXCLKD±

RECLKOA

RECLKOB

RECLKOC

RECLKOD

Device Control Signals

RESET

LVTTL Output,

synchronous to the

RXCLK± output

LVTTL Output,

synchronous to the

RXCLKx± output

Asynchronous to

reclocker output

channel

enable / disable

Differential LVPECL or

single-ended

LVTTL input clock

LVTTL Output Clock Receive Clock Output. RXCLKx± is the receive interface clock that controls

LVTTL Output Reclocker Clock Output

LVTTL Input,

asynchronous,

internal pull up

Parallel Data Output. RXDx[9:0] parallel data outputs change relative to the

receive interface clock. If RXCLKx± is a full-rate clock, the RXCLKx± clock outputs

are complementary clocks operating at the character rate. The RXDx[9:0] outputs

for the associated receive channels follow the rising edge of RXCLKx+ or the

falling edge of RXCLKx–. If RXCLKx± is a half-rate clock, the RXCLKx± clock

outputs are complementary clocks operating at half the character rate. The

RXDx[9:0] outputs for the associated receive channels follow both the falling and

rising edges of the associated RXCLKx± clock outputs.

When BIST is enabled on the receive channel, the RXDx[1:0] and BISTSTx

outputs present the BIST status. See Table 5, “Receive BIST Status Bits,” on

page 17 for each status that the BIST state machine reports. Also, while BIST is

enabled, ignore the RXDx[9:2] outputs.

BIST Status Outp ut. When RXBISTx[1:0] = 10, BISTSTx (along with RXDx[1:0])

displays the status of the BIST reception. See T able 5, “Receive BIST S tat us Bits,”

on page 17 for the BIST status for each combination of BISTSTx and RXDx[1:0].

When RXBISTx[1:0] ≠ 10, ignore BISTSTx.

Reclocker Powered Down Status Output. REPDOx asserts HIGH when the

associated channel’s reclocker output logic powers down. This occurs when

disabling ROE2x and ROE1x by setting ROE2x = 0 and ROE1x = 0.

CDR PLL Training Clock. The frequency detector (Range Controller) of the

associated receive PLL uses the TRGCLKx± clock inputs as the reference source

to reduce PLL acquisition time.

In the presence of valid serial data, the recovered clock output of the receive CDR

PLL (RXCLKx±) has no frequency or phase relationship with TRGCLKx±.

When a single-ended LVCMOS or LVTTL clock source drives the clock, connect

the clock source to either the true or complement TRGCLKx input, and leave the

alternate TRGCLKx input open (floating). When an LVPECL clock source drives

it, the clock must be a differential clock, using both inputs.

timing of the RXDx[9:0] parallel outputs. These true and complement clocks

control timing of data output transfers. These clocks output continuously at either

the half-character rate (1/20 the serial bit-rate) or character rate (1/1 0 the serial

bit-rate) of the data being received, as selected by RXRATEx.

. The associated reclocker output PLL synthesizes the

RECLKOx output clock, which operates synchronous to the internal recovered

character clock. RECLKOx operates at either the same frequency as RXCLKx±

(RXRATEx = 0), or at twice the frequency of RXCLKx± (RXRATEx = 1). The

reclocker clock outputs have no fixed phase relationship to RXCLKx±.

Asynchronous Device Reset. RESET initializes all state machines, counters,

and configuration latches in the device to a known state. RESET

for a minimum pulse width. When the reset is removed, all state machines,

counters and configuration latches are at an initial state. According to the JTAG

specifications, the device RESET

JTAG controller has to be reset separately. Refer to “JTAG Support” on page 17

for the methods to reset the JTAG state machine. See Table 3, “Device Configu-

ration and Control Latch Descriptions,” on page 14 for the in itialize values of the

device configuration latches.

CYV15G0404RB

must assert LOW

cannot reset the JTAG controller . Therefore, the

Document #: 38-02102 Rev. *C Page 8 of 27

[+] Feedback

Page 9

CYV15G0404RB

Pin Definitions (continued)

CYV15G0404RB Quad HOTLink II Deserializing Reclocker

Name IO Characteristics Signal Description

LDTDEN LVTTL Input,

internal pull up

ULCA

ULCB

LVTTL Input,

internal pull up

ULCC

ULCD

[2]

SPDSELA

SPDSELB

3-Level Select

static control input

SPDSELC

SPDSELD

INSELA

INSELB

LVTTL Input,

asynchronous

INSELC

INSELD

LFIA

LFIB

LVTTL Output,

asynchronous

LFIC

LFID

Device Configuration and Control Bus Signals

WREN

LV TTL input,

asynchronous,

internal pull up

ADDR[3:0] LVTTL input

asynchronous,

internal pull up

Notes

2. Use 3-Level Select inputs for static configuration. These are ternary input s th at use logic le vels of L OW, MID, and HIGH. To implement the LOW level, connect

directly to V

which allows it to self bias to the proper level.

3. See “Device Configuration and Control Interface” on page13 for detailed information about the operation of the Configuration Interface.

(ground). To implement the HIGH level, connect directly to VCC (power). To implement the MID level, do not connect the input (leave floating),

SS

Level Detect Transition Density Enable. When LDTDEN is HIGH, the Signal

Level Detector, Range Controller, and Transition Density Detector are all enabled

to determine if the RXPLL tracks TRGCLKx± or the selected input serial data

stream. If the Signal Level Detector, Range Controller, or Transition Density

Detector are out of their respective limits while LDTDEN is HIGH, the RXPLL locks

to TRGCLKx± until they become valid. The SDASEL[A..D][1:0] inputs configure

the trip level of the Signal Level Detector. The Transition Density Detector limit is

one transition in every 60 consecutive bits. When LDTDEN is LOW, only the

Range Controller determines if the RXPLL tracks TRGCLKx± or the selected input

serial data stream. Set LDTDEN = HIGH.

Use Local Clock. When ULCx is LOW, the RXPLL locks to TRGCLKx± instead

of the received serial data stream. While ULCx

is LOW, the LFIx for the associ ated

channel is LOW, indicating a link fault.

When ULCx

is HIGH, the RXPLL performs Clock and Data Recovery functions on

the input data streams. This function is used in applications that need a stable

RXCLKx±. When valid data transitions are absent for a long time, or the high-gain

differential serial inputs (INx±) are left floating, the RXCLKx± outputs may briefly

be different from TRGCLKx±.

Serial Rate Select. The SPDSELx inputs specify the operating signaling-rate

range of each channel’s receive PLL.

LOW = 195–400 MBd

MID = 400–800 MBd

HIGH = 800–1500 MBd.

Receive Input Selector. The INSELx input determines which external serial bit

stream passes to the receiver’s Clock and Data Recovery circuit. When INSELx

is HIGH, the Primary Differential Serial Data Input, INx1±, is the associated receive

channel. When INSELx is LOW, the Secondary Differential Serial Data Input,

INx2±, is the associated receive channel.

Link Fault Indication Output. LFIx is an output status indicator signal. LFIx is the

logical OR of six internal conditions. LFIx

asserts LOW when any of the following

conditions is true:

• Received serial data rate is outside expected range

• Analog amplitude is below expected levels

• Transition density is lower than expected

• Receive is channel disabled

is LOW

•ULCx

• TRGCLKx± is absent.

Control Write Enable. The WREN input writes the values of the DATA[7:0] bus

into the latch specified by the address location on the ADDR[3:0] bus.

[3]

Control Addressing Bus. The ADDR[3:0] bus is the input address bus that

configures the device. The WREN

into the latch specified by the address location on the ADDR[3:0] bus.

input writes the values of the DATA[7:0] bus

[3]

Table 3,

“Device Configuration and Control Latch Descriptions,” on page 14 lists the config-

uration latches within the device, and the initiali zation value of the latches when

RESET

is asserted. Table 4, “Device Control Latch Configuration Table,” on

page 16 shows how the latches are mapped in the device.

Document #: 38-02102 Rev. *C Page 9 of 27

[+] Feedback

Page 10

Pin Definitions (continued)

CYV15G0404RB Quad HOTLink II Deserializing Reclocker

Name IO Characteristics Signal Description

DATA[7:0] LVTTL input

asynchronous,

internal pull-up

Internal Device Configuration Latches

RXRATE[A..D] Internal Latch

SDASEL[2..1][A..D]

Internal Latch

[4]

[4]

[1:0]

RXPLLPD[A..D] Internal Latch

RXBIST[A..D][1:0] Internal Latch

ROE2[A..D] Internal Latch

ROE1[A..D] Internal Latch

GLEN[11..0] Internal Latch

FGLEN[2..0] Internal Latch

[4]

[4]

[4]

[4]

[4]

[4]

Factory Test Modes

SCANEN2 LVTTL input,

internal pull down

TMEN3 LVTTL input,

internal pull down

Analog I/O

ROUTA1±

ROUTB1±

CML Differential

Output

ROUTC1±

ROUTD1±

ROUTA2±

ROUTB2±

CML Differential

Output

ROUTC2±

ROUTD2±

INA1±

Differential Input Primary Differential Serial Data Input. The INx1± input accepts the serial data

INB1±

INC1±

IND1±

INA2±

Differential Input Secondary Differential Serial Data Input. The INx2± input accepts the serial

INB2±

INC2±

IND2±

JTAG Interface

TMS LVTTL Input,

internal pull up

TCLK LVTTL Input,

internal pull down

Note

4. See Device Configuration and Control Interface for detailed information on the internal latches.

Control Data Bus. The DATA[7:0] bus is the input data bus that configures the

device. The WREN

input writes the values of the DATA[7:0] bus into the latch

specified by address location on the ADDR[3:0] bus.

ration and Control Latch Descriptions,” on page 14 lists the configuration latches

within the device, and the initialization value of the latches when RESET is

asserted. Table 4, “Device Control Latch Configuration T able,” on page 16 shows

the way the latches are mapped in the device.

Receive Clock Rate Select.

Signal Detect Amplitude Select.

Receive Channel Power Control.

Receive BIST Disabled.

Reclocker Differential Serial Output Driver 2 Enable.

Reclocker Differential Serial Output Driver 1 Enable.

Global Latch Enable.

Force Global Latch Enable.

Factory Test 2. The SCANEN2 input is for factory testing only. Leave this input

as a NO CONNECT, or GND only.

Factory Test 3. The TMEN3 input is for factory testing only . Leave this input as a

NO CONNECT, or GND only.

Primary Differential Serial Data Output. The ROUTx1± PECL-compatible CML

outputs (+3.3V referenced) can drive terminated transmission lines or standard

fiber-optic transmitter modules, and must be AC-coupled for PECL-compatible

connections.

Secondary Differential Serial Data Output. The ROUTx2± PECL-compatible

CML outputs (+3.3V referenced) are capable of driving terminated transmi ssion

lines or standard fiber-optic transmitter modules, and must be AC coupled for

PECL-compatible connections.

stream for deserialization. The INx1± serial stream passes to the receive CDR

circuit to extract the data content when INSELx = HIGH.

data stream for deserialization. The INx2± serial stream passes to the receiver

CDR circuit to extract the data content when INSELx = LOW.

Test Mode Select. Controls access to the JTAG Test Modes. If TMS is HIGH for

5 TCLK cycles, the JTAG test controller resets.

>

JTAG Test Clock.

CYV15G0404RB

[3]

Table 3, “Device Configu-

Document #: 38-02102 Rev. *C Page 10 of 27

[+] Feedback

Page 11

CYV15G0404RB

Pin Definitions (continued)

CYV15G0404RB Quad HOTLink II Deserializing Reclocker

Name IO Characteristics Signal Description

TDO 3-State LVTTL Output Test Data Out. JTAG data output buffer. High-Z while JTAG test mode is not

selected.

TDI LVTTL Input,

internal pull up

TRST

Power

V

CC

GND Signal and Power Ground for all internal circuits.

LVTTL Input,

internal pull up

Test Data In. JTAG data input port.

JTAG reset signal. When asserted (LOW), this input asynchronously resets the

JTAG test access port controller.

+3.3V Power.

CYV15G0404RB HOTLink II Operation

The CYV15G0404RB is a highly configurable, independent

clocking, quad-channel reclocking deserializer that supports

reliable transfer of large quantities of digital video data, using

high-speed serial links from multiple sources to multiple destinations. This device supports four 10-bit channels.

CYV15G0404RB Receive Data Path

Serial Line Receivers

Two differential Line Receivers, INx1± and INx2±, are

available on each channel to accept serial data streams. The

associated INSELx input selects the active Serial Line

Receiver on a channel. The Serial Line Receiver inputs are

differential, and can accommodate wire interconnect and

filtering losses or transmission line attenuation greater than

16 dB. For normal operation, these inputs must receive a

signal of at least VI

differential. Each Line Receiver can be DC or AC coupled to

+3.3V powered fiber-optic interface modules (any ECL/PECL

family, not limited to 100K PECL) or AC coupled to +5V

powered optical modules. The common mode tolerance of

these line receivers accommodates a wide range of signal

termination voltages. Each receiver provides internal DC

restoration, to the center of the receiver’s common mode

range, for AC coupled signals.

Signal Detect/Link Fault

Each selected Line Receiver (that is, that routed to the clock

and data recovery PLL) is simultaneously monitored for

• Analog amplitude above amplitude level selected by

SDASELx

• Transition density above the specified limit

• Range controls reporting the received data stream inside

normal frequency range (±1500 ppm

• Receive channel enabled

• Reference clock present

not asserted.

•ULCx

> 100 mV, or 200 mV peak-to-peak

DIFF

[21]

)

All of these conditions must be valid for the Signal Detect block

to indicate a valid signal is present. This status is presented on

the LFIx

receive channel, which changes synchronous to the receive

interface clock.

Analog Amplitude

While most signal monitors are based on fixe d co nstants, the

analog amplitude level detection is adjustable to allow

operation with highly attenuated signals, or in high noise

environments. The SDASELx latch sets the analog amplitude

level detection via the device configuration interface. The

SDASELx latch sets the trip point for the detection of a valid

signal at one of three levels, as listed in Table 1. This control

input affects the analog monitors for all receive channels. The

Analog Signal Detect monitors are active for the Line Receiver,

as selected by the associated INSELx input.

Table 1. Analog Amplitude Detect Valid Signal Levels

SDASEL Typical Signal with Peak Amplitudes Above

Transition Density

The Transition Detection logic checks for the absence of

transitions spanning greater than six transmission characters

(60 bits). If there are no transitions in the data received, the

Detection logic for that channel asserts LFIx

Range Controls

The CDR circuit includes logic to monitor the frequency of the

PLL Voltage Controlled Oscillator (VCO) samples the

incoming data stream. This logic ensures that the VCO

(Link Fault Indicator) output associated with each

[5]

00 Analog Signal Detector is disabled

01 140 mV p-p differential

10 280 mV p-p differential

11 420 mV p-p differential

.

Note

5. The peak amplitudes listed in this table are for typical waveforms that generally have 3–4 transitions for every ten bit s. In a worst case environment the signals

may have a sine-wave appearance (highest transition density with repeating 0 101...). Signal peak amplitudes l evels within this environment type could increase

the values in the table above by approximately 100 mV.

Document #: 38-02102 Rev. *C Page 11 of 27

[+] Feedback

Page 12

CYV15G0404RB

operates at, or near the rate of the incoming data stream for

two primary cases:

• When the incoming data stream resumes after a time in

which it was “missing.”

• When the incoming data stream is outside the acceptable

signaling rate range.

T o perform this function, periodically compare the frequency of

the RXPLL VCO to the frequency of the TRGCLKx± input. If

the VCO is running at a frequency beyond ±1500 ppm

defined by the TRGCLKx± frequency, it is periodically forced

to the correct frequency (as defined by TRGCLKx±, SPDSELx,

and TRGRATEx) and then released in an attempt to lock to the

input data stream.

Calculate the sampling and relock period of the Range Control

as follows: RANGE_CONTROL_SAMPLING_PERIOD =

(RECOVERED BYTE CLOCK PERIOD) * (4096).

During the time that the Range Control forces the RXPLL VCO

to track TRGCLKx±, the LFIx

valid serial data stream is applied, it may take up to one

RANGE CONTROL SAMPLING PERIOD before the PLL

locks to the input data stream, after which LFIx

Table 2 lists the operating serial signaling rate and allowable

range of TRGCLK± frequencies.

Table 2. Operating Speed Settings

SPDSELx TRGRATEx

LOW

MID (Open) 1 20–40 400–800

HIGH 1 40–75 800–1500

Receive Channel Enabled

The CYV15G0404RB contains four receive channels that it

can independently enable and disable. Each channel are

enabled or disabled separately through the RXPLLPDx input

latch as controlled by the device configuration interface.

RXPLLPDx latch = 0 disables the associated PLL and analog

circuitry of the channel. Any disabled channel indicates a

constant link fault condition on the LFIx output. RXPLLPDx =

1 enables the associated PLL and receive channel to receive

a serial stream.

Note When a disabled receive channel is reenabled, the

status of the associated LFIx

outputs for the associated channel may be indetermin ate for

up to 2 ms.

Clock/Data Recovery

A separate CDR block within each receive channel performs

the extraction of a bit rate clock and recovery of bits from each

received serial stream. An integrated PLL that tracks the

frequency of the transitions in the incoming bit stream and

aligns the phase of the internal bit rate clock to the transitions

1 Reserved 195–400

0 19.5–40

0 40–80

0 80–150

output is asserted LOW. After a

is HIGH.

TRGCLKx±

Frequency

(MHz)

output and data on the parallel

Rate (Mbps)

[21]

Signaling

as

in the selected serial data stream performs the clock extraction

function.

Each CDR accepts a character-rate (bit-rate ÷ 10) or

half-character-rate (bit-rate ÷ 20) training clock from the

associated TRGCLKx± input. This TRGCLKx± input is used to

• Ensure that the VCO (within the CDR) is operating at the

correct frequency (rather than a harmonic of the bit rate)

• Reduce PLL acquisition time

• Limit unlocked frequency excursions of the CDR VCO when

there is no input data present at the selected Serial Line

Receiver.

Regardless of the type of signal present, the CDR attempts to

recover a data stream from it. If the signaling rate of the

recovered data stream is outside the limits set by the range

control monitors, the CDR tracks TRGCLKx± instead of the

data stream. Once the CDR output (RXCLK±) frequency

returns close to TRGCLKx± frequency, the CDR input

switches back to the input data stream. If no data is present at

the selected line receiver, this switching behavior may cause

brief RXCLK± frequency excursions from TRGCLKx±.

However, the LFIx

stream. The frequency of TRGCLKx± must be within ±1500

[21]

ppm

of the frequency of the clock that drives the reference

clock input of the remote transmitter, to ensure a lock to the

incoming data stream. This large ppm tolerance allows the

CDR PLL to reliably receive a 1.485 or 1.485/1.001 Gbps

SMPTE HD-SDI data stream with a constant TRGCLK

frequency.

For systems using multiple or redundant connections, use the

LFIx output to select an alternate data stream. When the

device detects an LFIx

selection of the associated INx1± and INx2± input through the

associated INSELx input. When a port switch takes place, the

receive PLL for that channel reacquires the new serial stream.

Reclocker

Each receive channel performs a reclocker function on the

incoming serial data. To do this, the Clock and Data Recovery

PLL first recovers the clock from the data. The recovered clock

retimes the data and then passes it to an output register. It also

passes the recovered character clock from the receive PLL to

the reclocker output PLL, which generates the bit clock that

clocks the retimed data into the output register. This data

stream is then transmitted through the differential serial

outputs.

Reclocker Serial Output Drivers

The serial output interface drivers use differential Current

Mode Logic (CML) drivers to provide source-matched drivers

for 50Ω transmission lines. These drivers accept data from the

reclocker output register in the reclocker channel. These

drivers have signal swings equivalent to that of standard PECL

drivers, and can drive AC coupled optical modules or transmission lines.

Reclocker Output Channels Enabled

Each driver can be enabled or disabled separately via the

device configuration interface.

When a driver is disabled using the configu ration interface, it

internally powers down to reduce device power. If both

output indicates the validity of the input data

indication, external logic toggles

Document #: 38-02102 Rev. *C Page 12 of 27

[+] Feedback

Page 13

CYV15G0404RB

reclocker serial drivers for a channel are in this disabled state,

the associated internal reclocker logic also powers down. The

deserialization logic and parallel outputs remain enabled. A

device reset (RESET sampled LOW) disables all output

drivers.

Note When the disabled reclocker function (that is, both

outputs disabled) is reenabled, the data on the reclocker serial

outputs may not meet all timing specifications for up to 250 µs.

Output Bus

Each receive channel presents a 10-bit data signal (and a

BIST status signal when RXBISTx[1:0] = 10).

Receive BIST Operation

Each receiver channel contains an internal pattern checker

that is used to validate both device and link operation. These

pattern checkers are enabled by the associated RXBISTx[1:0]

latch through the device configuration interface. When

enabled, a register in the associated receive channel becomes

a signature pattern generator and checker by logically

converting to a Linear Feedback Shift Register (LFSR). This

LFSR generates a 511-character sequence. This provides a

predictable, yet pseudorandom, sequence that can be

matched to an identical LFSR in the attached Transmitter(s).

When synchronized with the received data stream, the

associated Receiver checks each character from the deserializer with each character generated by the LFSR and

indicates compare errors and BIST status at the RXDx[1:0]

and BISTSTx bits of the Output Register.

The BIST status bus {BISTSTx, RXDx[0], RXDx[1]} indicates

010b or 100b for one character period per BIST loop to

indicate loop completion. Use this status to check test pattern

progress.

Table 5, “Receive BIST Status Bits,” on page 17 lists the

specific status reported by the BIST state machine. The

receive status outputs report these same codes.

If the number of invalid characters received exceeds the

number of valid characters by 16, the receive BIST state

machine aborts the compare operations and resets the LFSR

to look for the start of the BIST sequence again.

A device reset (RESET

Enable Latches to disable BIST on all channels.

BIST Status State Machine

When a receive path is enabled to look for and compare the

received data stream with the BIST pattern, the {BISTSTx,

RXDx[0], RXDx[1]} bits identify the present state of the BIST

compare operation.

The BIST state machine has multiple states, as shown in

Figure 2, "Receive BIST State Machine," on page 18 and

Table 5, “Receive BIST Status Bits,” on page 17. When the

receive PLL detects an out-of-lock condition, it forces the BIST

state to the St art-of-BIST state, regardless of the present state

of the BIST state machine. If the number of detected errors

ever exceeds the number of valid matches by greater than 16,

the state machine is forced to the WAIT_FOR_BIST state,

where it monitors the receive path for the first character of the

next BIST sequence.

sampled LOW) presets the BIST

Power Control

The CYV15G0404RB supports user control of the powered up

or down state of each transmit and receive channel. The

RXPLLPDx latch controls the receive channels through the

device configuration interface. RXPLLPDx = 0 disables the

associated PLL and analog circuitry of the channel. The OE1x

and the OE2x latches control the transmit channels via the

device configuration interface. The ROE1x and the ROE2x

latches control the reclocker function through the device

configuration interface. When the configuration interface

disables a driver, the driver internally powers down to reduce

device power. If both serial drivers for a channel are in this

disabled state, the associated internal logic for that channel

also powers down. The reclocker serial drivers being disabled

in turn disables the reclocker function, but the deserialization

logic and parallel outputs remain enabled.

Device Reset State

Assertion of RESET

configuration latches in the device to a reset state.

Additionally, the JTAG controller must be reset for valid

operation (even if not performing JTAG testing). See “JTAG

Support” on page 17 for JTAG st ate machine initialization. See

Table 3, “Device Configuration and Control Latch Descriptions,” on page 14 for the initi alize values of th e configuration

latches.

Following a device reset, enable the receive channels used for

normal operation. Do this by sequencing the appropriate

values on the device configuration interface.

resets all state machines, counters, and

[3]

Device Configuration and Control Interface

Configure the CYV15G0404RB through the configuration

interface. The configuration interface enables the device to be

configured globally or enables each channel to be configured

independently. Table 3, “Device Configuration and Control

Latch Descriptions,” on p age 14 lists the configuration latches

within the device, including the initialization value of the

latches on the assertion of RESET

Latch Configuration T able,” on page 16 shows how the latches

are mapped in the device. Each row in Table 4 maps to an 8-bit

latch bank. There are 16 such write only latch banks. When

= 0, the logic value in the DAT A[7:0] latches to the latch

WREN

bank specified by the values in ADDR[3:0]. The second

column of Table 4 specifies the channels associated with the

corresponding latch bank. For example, the first three latch

banks (0, 1, and 2) consist of configuration bits for channel A.

Latch banks 12, 13, and 14 consist of Global configuration bits,

and the last latch bank (15) is the Mask latch bank, which can

be configured to perform bit-by-bit configuration.

Global Enable Function

The global enable function, controlled by the GLENx bits, is a

feature that can reduce the number of write operations needed

to set up the latch banks. This function is beneficial in systems

that use a common configuration in multiple channels. The

GLENx bit is present in bit 0 of latch banks 0 through 11 only.

Its default value (1) enables the global update of the latch

bank's contents. Setting the GLENx bit to 0 disables this

functionality.

. Table 4, “Device Control

Document #: 38-02102 Rev. *C Page 13 of 27

[+] Feedback

Page 14

CYV15G0404RB

Latch Banks 12, 13, and 14 load values in the related latch

banks in globally. A write operation to latch bank 12 performs

a global write to latch banks 0, 3, 6, and 9, depending on the

value of GLENx in these latch banks; latch bank 13 performs

a global write to latch banks 1, 4, 7, and 10; and latch bank 14

performs a global write to latch banks 2, 5, 8, and 11. The

GLENx bit cannot be modified by a global write operation.

Force Global Enable Function

FGLENx forces the global update of the target latch banks, but

does not change the contents of the GLENx bits. If FGLENx =

1 for the associated global channel, FGLENx forces the global

update of the target latch banks.

Mask Function

An additional latch bank (15) is a global mask vector that

controls the update of the configuration latch banks on a

bit-by-bit basis. A logic 1 in a bit location enables the update

of that same location of the target latch bank(s), whereas a

logic 0 disables it. The reset value of this latch bank is FFh,

thereby making its use optional by default. Th e mask latch

bank is not maskable. The bit 0 value of the mask latch bank

does not affect the FGLEN functionality.

Latch Types

There are two types of latch banks: static (S) and dynamic (D).

Each channel is configured by two static and one dynamic

Table 3. Device Configuration and Control Latch Descriptions

Name Signal Description

RXRATEA

RXRATEB

RXRATEC

RXRATED

SDASEL1A[1:0]

SDASEL1B[1:0]

SDASEL1C[1:0]

SDASEL1D[1:0]

SDASEL2A[1:0]

SDASEL2B[1:0]

SDASEL2C[1:0]

SDASEL2D[1:0]

TRGRATEA

TRGRATEB

TRGRATEC

TRGRATED

Receive Clock Rate Select. The initialization value of the RXRATEx latch = 1. RXRA TEx selects the rate

of the RXCLKx± clock output.

When RXRATEx = 1, the RXCLKx± clock outputs are complementary clocks that follow the recovered

clock operating at half the character rate. Data for the associated receive channels must latch alternately

on the rising edge of RXCLKx+ and RXCLKx–.

When RXRATEx = 0, the RXCLKx± clock outputs are complementary clocks that follow the recovered

clock operating at the character rate. Data for the associated receive channels must latch on the rising

edge of RXCLKx+ or falling edge of RXCLKx–.

Primary Serial Data Input Signal Detector Amplitude Select. The initialization value of the

SDASEL1x[1:0] latch = 10. SDASEL1x[1:0] selects the trip point for the detection of a valid signal for the

INx1± Primary Differential Serial Data Inputs.

When SDASEL1x[1:0] = 00, the Analog Signal Detector is disabled.

When SDASEL1x[1:0] = 01, the typical p-p differential voltage threshold level is 140 mV.

When SDASEL1x[1:0] = 10, the typical p-p differential voltage threshold level is 280 mV.

When SDASEL1x[1:0] = 11, the typical p-p differential voltage threshold level is 420 mV.

Secondary Serial Data Input Signal Detector Amplitude Select. The initialization value of the

SDASEL2x[1:0] latch = 10. SDASEL2x[1:0] selects the trip point for the detection of a valid signal for the

INx2± Secondary Differential Serial Data Inputs.

When SDASEL2x[1:0] = 00, the Analog Signal Detector is disabled

When SDASEL2x[1:0] = 01, the typical p-p differential voltage threshold level is 140 mV.

When SDASEL2x[1:0] = 10, the typical p-p differential voltage threshold level is 280 mV.

When SDASEL2x[1:0] = 11, the typical p-p differential voltage threshold level is 420 mV.

Traini ng Clock Rate Select. The initialization value of the TRGRA TEx latch = 0. TRGRATEx selects the

clock multiplier for the training clock input to the associated CDR PLL. When TRGRATEx = 0, the

associated TRGCLKx± input is not multiplied before it is passed to the CDR PLL. When TRGRATEx = 1,

the TRGCLKx± input is multiplied by 2 before it is passed to the CDR PLL. TRGRATEx = 1 and SPDSELx

= LOW is an invalid state and this combination is reserved.

latch banks. The S type contains those settings that normally

do not change for a given application, whereas the D type

controls the settings that might change during the application's

lifetime. The first and second rows of each channel (address

numbers 0, 1, 3, 4, 6, 7, 9, and 10) are the static control

latches. The third row of latches for each channel (address

numbers 2, 5, 8, and 11) are the dynamic control latches that

are associated with enabling dynamic functions within the

device.

Latch Bank 14 is also useful for those users that do not need

the latch based programmable feature of the device. This latch

bank is used in those applications that do not need to modify

the default value of the static latch banks, and that can afford

global (that is, not independent) control of the dynamic signals.

In this case, this feature becomes available when ADDR[3:0]

is unchanged with a value of “1110” and WREN

The signals present in DATA[7:0] effectively become global

control pins, and for the latch banks 2, 5, 8, and 11.

Static Latch Values

There are some latches in the table that have a static value

(that is, 1, 0, or X). The latches that have a ‘1’ or ‘0’ must be

configured with their corresponding value each time that their

associated latch bank is configured. The latches that have an

‘X’ are don’t cares and can be configured with any value

is asserted.

Document #: 38-02102 Rev. *C Page 14 of 27

[+] Feedback

Page 15

CYV15G0404RB

Table 3. Device Configuration and Control Latch Descriptions (continued)

Name Signal Description

RXPLLPDA

RXPLLPDB

RXPLLPDC

RXPLLPDD

RXBISTA[1:0]

RXBISTB[1:0]

RXBISTC[1:0]

RXBISTD[1:0]

ROE2A

ROE2B

ROE2C

ROE2D

ROE1A

ROE1B

ROE1C

ROE1D

GLEN[11..0] Global Enable. The initialization value of the GLENx latch = 1. The GLENx reconfigures several channels

FGLEN[2..0] Force Glob al Enable. The initialization value of the FGLENx latch is NA. The FGLENx latch forces a

Receive Channel Enable. The initialization value of the RXPLLPDx latch = 0. RXPLLPDx selects whether

the associated receive channel is enabled or powered down. RXPLLPDx = 0 powers down the associated

receive PLL and analog circuitry. RXPLLPDx = 1 enables the associated receive PLL and analog circuitry.

Receive Bist Disable / SMPTE Receive Enable. The initialization value of the RXBISTx[1:0] latch = 11.

For SMPTE data reception, RXBISTx[1:0] should not remain in this initialization state (1 1). RXBISTx[1:0]

selects whether receive BIST is disabled or enabled and sets the associated channel for SMPTE data

reception. RXBISTx[1:0] = 01 disables the receiver BIST function and sets the associated channel to

receive SMPTE data. RXBISTx[1:0] = 10 enables the receive BIST function and sets the associated

channel to receive BIST data. RXBISTx[1:0] = 00 and RXBISTx[1:0] = 11 are invalid states.

Reclocker Secondary Differential Serial Data Output Driver Enable. The initialization value of the

ROE2x latch = 0. ROE2x selects whether the ROUT2± secondary differential output drivers are enabled

or disabled. ROE2x = 1 enables the associated serial data output driver, allowing data to be transmitted

from the transmit shifter. ROE2x = 0 disables the associated serial data output driver. When the configuration interface disables a driver, the driver internally powers down to reduce device power. If both serial

drivers for a channel are in this disabled state, the associated internal logic for that channel also powers

down. A device reset (RESET sampled LOW) disables all output drivers.

Reclocker Primary Differential Serial Data Output Driver Enable. The initialization value of the ROE1x

latch = 0. ROE1x selects whether the ROUT1± primary differential output drivers are enabled or disabled.

ROE1x = 1 enables the associated serial data output driver, allowing data to be transmitted from the

transmit shifter. ROE1x = 0 disables the associated serial data output driver. When the configuration

interface disables a driver, the driver internally powers down to reduce device power. If both serial drivers

for a channel are in this disabled state, the associated internal logic for that channel also powers down.

A device reset (RESET sampled LOW) disables all output drivers.

simultaneously in applications where several channels may have the same configuration. When GLENx

= 1 for a given address, that address can participate in a global configuration. When GLENx = 0 for a

given address, that address cannot participate in a global configuration.

GLobal ENable no matter what the setting is on the GLENx latch. If FGLENx = 1 for the associated Global

channel, FGLEN forces the global update of the target latch banks.

Device Configuration Strategy

Follow these steps to load the configuration latches on each

channel:

1. Pulse RESET

resets all four channels. Initialize the JTAG state machine

to its reset state, as detailed in “JT AG Support” on page 17.

2. Set the static latch banks for the target channel. You can

perform this step using a global operation, if the application

Document #: 38-02102 Rev. *C Page 15 of 27

Low after device power up. This operation

permits it. [This is an optional step if the default settings

match the desired configuration.]

3. Set the dynamic bank of latches for the target channel.

Enable the Receive PLLs and set each channel for SMPTE

data reception (RXBISTx[1:0] = 01) or BIST data reception

(RXBISTx[1:0] = 10). You can perform this step using a

global operation, if the application permits it. [Required

step.]

[+] Feedback

Page 16

CYV15G0404RB

Table 4. Device Control Latch Configuration Table

ADDR Channel Type DATA7 DATA6 DATA5 DATA4 DATA3 DATA2 DATA1 DATA0

0

(0000b)

1

(0001b)

2

(0010b)

3

(0011b)

4

(0100b)

5

(0101b)

6

(0110b)

7

(0111b)

8

(1000b)

9

(1001b)

10

(1010b)

11

(1011b)

12

(1100b)

13

(1101b)

14

(1110b)

15

(1111b)

A S 1 0 X X 0 0 RXRATEA GLEN0 10111111

A S SDASEL2A[1] SDASEL2A[0] SDASEL1A[1] SDASEL1A[0] X X TRGRATEA GLEN1 10101101

A D RXBISTA[1] RXPLLPDA RXBISTA[0] X ROE2A ROE1A X GLEN2 10110011

B S 1 0 X X 0 0 RXRATEB GLEN3 10111111

B S SDASEL2B[1] SDASEL2B[0] SDASEL1B[1] SDASEL1B[0] X X TRGRATEB GLEN4 10101101

B D RXBISTB[1] RXPLLPDB RXBISTB[0] X ROE2B ROE1B X GLEN5 10110011

C S 1 0 X X 0 0 RXRATEC GLEN6 10111111

C S SDASEL2C[1] SDASEL2C[0] SDASEL1C[1] SDASEL1C[0] X X TRGRATEC GLEN7 10101101

C D RXBISTC[1] RXPLLPDC RXBISTC[0] X ROE2C ROE1C X GLEN8 10110011

D S 1 0 X X 0 0 RXRATED GLEN9 10111111

D S SDASEL2D[1] SDASEL2D[0] SDASEL1D[1] SDASEL1D[0] X X TRGRATED GLEN10 10101101

D D RXBISTD[1] RXPLLPDD RXBISTD[0] X ROE2D ROE1D X GLEN11 10110011

GLOBAL S 1 0 X X 0 0 RXRATEGL FGLEN0 N/A

GLOBAL S SDASEL2GL[1] SDASEL2GL[0] SDASEL1GL[1] SDASEL1GL[0] X X TRGRATEGL FGLEN1 N/A

GLOBAL D RXBISTGL[1] RXPLLPDGL RXBISTGL[0] X ROE2GL ROE1GL X FGLEN2 N/A

MASK D D7 D6 D5 D4 D3 D2 D1 D0 11111111

Reset

Value

Document #: 38-02102 Rev. *C Page 16 of 27

[+] Feedback

Page 17

CYV15G0404RB

JTAG Support

The CYV15G0404RB contains a JTAG port to allow system

level diagnosis of device interconnect. Of the avai lable JTAG

modes, boundary scan and bypass are supported. This

capability is present only on the LVTTL inputs and outputs and

the TRGCLKx± clock input. The high-speed serial inputs and

outputs are not part of the JTAG test chain.

To ensure valid device operation after power-up (including

non-JTAG operation), the JTAG state machine must also be

initialized to a reset state. This must be done in addition to the

device reset (using RESET

using TRST

asserted), or by asserting TMS HIGH for at least 5 consecutive

TCLK cycles. This is necessary in order to ensure that the

Table 5. Receive BIST Status Bits

{BISTSTx, RXDx[0],

(assert it LOW and deassert it or leave it

RXDx[1]}

000, 001 BIST Data Compare. Character compared correctly.

010 BIST Last Go od. Last Character of BIST sequence detected and valid.

01 1 Reserved.

100 BIST Last Bad. Last Character of BIST sequence detected invalid.

101 BIST Start. Receive BIST is enabled on this channel, but character compares have not yet

110 BIST Error. While comparing characters, a mismatch was found in one or more of the character bits.

111 BIST Wait. The receiver is comparing characters, but has not yet found the start of BIST character to

). Initialize the JTAG st ate machine

commenced. This also indicates a PLL Out of Lock condition.

enable the LFSR.

JTAG controller does not enter any of the test modes after

device power-up. In this JTAG reset state, the rest of the

device will operate normally.

Note The order of device reset (using RESET

initialization does not matter.

3-Level Select Inputs

Each 3-Level select input reports as two bits in the scan

register. These bits report the LOW, MID, and HIGH state of

the associated input as 00, 10, and 11 respectively

JTAG ID

The JTAG device ID for the CYV15G0404RB is ‘0C811069’x.

Description

Receive BIST Status

(Receive BIST = Enabled)

) and JTAG

Document #: 38-02102 Rev. *C Page 17 of 27

[+] Feedback

Page 18

Figure 2. Receive BIST State Machine

CYV15G0404RB

{BISTSTx, RXDx[0], RXDx[1]} =

BIST_WAIT (111)

No

Yes, {BISTSTx, RXDx[0], RXDx[1]} =

BIST_DATA_COMPARE (000, 001)

Mismatch

Start of

BIST Detected

Compare

Next Character

Monitor Data

Received

{BISTSTx, RXDx[0],

RXDx[1]} =

BIST_START (101)

Receive BIST

Detected LOW

RX PLL

Out of Lock

Yes

Yes, {BISTSTx, RXDx[0], RXDx[1]} =

Auto-Abort

Condition

No

End-of-BIST

State

BIST_LAST_BAD (100)

No, {BISTSTx, RXDx[0], RXDx[1]} =

BIST_ERROR (110)

Match

End-of-BIST

State

Yes, {BISTSTx, RXDx[0], RXDx[1]} =

BIST_LAST_GOOD (010)

{BISTSTx, RXDx[0], RXDx[1]} =

BIST_DATA_COMPARE (000, 001)

No

Document #: 38-02102 Rev. *C Page 18 of 27

[+] Feedback

Page 19

CYV15G0404RB

Maximum Ratings

Static Discharge Voltage..........................................> 2000 V

(MIL-STD-883, Method 3015)

Excedding maximum ratings may shorten the device life. User

guidelines are not tested

Storage Temperature ..................................–65°C to +150°C

Ambient Temperature with

Power Applied.............................................–55°C to +125°C

Supply Voltage to Ground Potential...............–0.5V to +3.8V

DC Voltage Applied to LVTTL Outputs

in High-Z State.......................................–0.5V to V

CC

+ 0.5V

Output Current into LVTTL Outputs (LOW)..................60 mA

DC Input Voltage....................................–0.5V to V

CC

+ 0.5V

Latch Up Current....................................................> 200 mA

Power Up Requirements

The CYV15G0404RB requires one power supply. The voltage

on any input or I/O pin cannot exceed the power pin during

power up.

Operating Range

Range Ambient Temperature V

Commercial 0°C to +70°C +3.3V ±5%

CC

CYV15G0404RB DC Electrical Characteristics

Parameter Description Test Conditions Min Max Unit

LVTTL-compatible Outputs

V

OHT

V

OLT

I

OST

I

OZL

LVTTL-compatible Inputs

V

IHT

V

ILT

I

IHT

I

ILT

I

IHPDT

I

ILPUT

LVDIFF Inputs: TRGCLKx±

[7]

V

DIFF

V

IHHP

V

ILLP

V

COMREF

3-Level Inputs

V

IHH

V

IMM

V

ILL

I

IHH

I

IMM

I

ILL

Output HIGH Voltage IOH = −4 mA, VCC = Min. 2.4 V

Output LOW Voltage IOL = 4 mA, VCC = Min. 0.4 V

Output Short Circuit Current V

High-Z Output Leakage Current V

OUT

OUT

[6]

= 0V

, VCC = 3.3V –20 –100 mA

= 0V, V

CC

–20 20 µA

Input HIGH Voltage 2.0 VCC + 0.3 V

Input LOW Voltage –0.5 0.8 V

Input HIGH Current TRGCLKx Input, VIN = V

Other Inputs, V

IN

= V

CC

CC

1.5 mA

+40 µA

Input LOW Current TRGCLKx Input, VIN = 0.0V –1.5 mA

Other Inputs, V

Input HIGH Current with Internal Pull Down VIN = V

CC

= 0.0V –40 µA

IN

+200 µA

Input LOW Current with Internal Pull Up VIN = 0.0V –200 µA

Input Differential Voltage 400 V

Highest Input HIGH Voltage 1.2 V

CC

CC

Lowest Input LOW voltage 0.0 VCC/2 V

[8]

Common Mode Range 1.0 VCC – 1.2V V

Three-Level Input HIGH Voltage Min. ≤ VCC ≤ Max. 0.87 * V

Three-Level Input MID Voltage Min. ≤ VCC ≤ Max. 0.47 * V

CC

CC

V

CC

0.53 * V

Three-Level Input LOW Voltage Min. ≤ VCC ≤ Max. 0.0 0.13 * V

Input HIGH Current VIN = V

CC

200 µA

Input MID current VIN = VCC/2 –50 50 µA

Input LOW current VIN = GND –200 µA

CC

CC

mV

V

V

V

V

Notes

6. Teste d one output at a time, output shorted for less than one second, less than 10% duty cycle.

7. This is the minimum difference in voltage between the true and complement inputs required t o ensure detection of a logic-1 or logic-0. A logi c-1 exists whe n the

true (+) input is more positive than the complement (−) input. A logic-0 exists when the complement (−) input is more positive than true (+) input.

8. The common mode range defines the allowable range of TRGCLKx+ and TRGCLKx− when TRGCLKx+ = TRGCLKx−. This marks the zero-crossing between

the true and complement inputs as the signal switches between a logic-1 and a logic-0.

Document #: 38-02102 Rev. *C Page 19 of 27

[+] Feedback

Page 20

CYV15G0404RB

CYV15G0404RB DC Electrical Characteristics (continued)

Parameter Description Test Conditions Min Max Unit

Differential CML Serial Outputs: ROUT A1±, ROUT A2±, ROUTB1±, ROUTB2±, ROUTC1±, ROUTC2±, ROUTD1 ±, ROUTD2±

V

V

V

OHC

OLC

ODIF

Output HIGH Voltage

Referenced)

(V

CC

Output LOW Voltage

Referenced)

(V

CC

Output Differential Voltage

|(OUT+) − (OUT−)|

Differential Serial Line Receiver Inputs: INA1±, INA2±, INB1±, INB2±, INC1±, INC2±, IND1±, IND2±

V

V

V

I

I

VI

IHE

ILE

DIFFs

IHE

ILE

COM

[7]

[9]

Input Differential Voltage |(IN+) − (IN−)| 100 1200 mV

Highest Input HIGH Voltage V

Lowest Input LOW Voltage VCC – 2.0 V

Input HIGH Current VIN = V

Input LOW Current VIN = V

Common Mode input range ((VCC – 2.0V)+0.5)min,

Power Supply Typ Max

[10,11]

I

CC

[10,11]

I

CC

AC Test Loads and Waveforms

Max Power Supply Current TRGCLKx =

Typical Power Supply Current TRGCLKx =

100Ω differential load V

150Ω differential load V

100Ω differential load V

150Ω differential load V

– 0.5 V

CC

– 0.5 VCC – 0.2 V

CC

– 1.4 VCC – 0.7 V

CC

– 1.4 VCC – 0.7 V

CC

– 0.2 V

CC

100Ω differential load 450 900 mV

150Ω differential load 560 1000 m V

CC

Max. 1350 µA

IHE

Min. –700 µA

ILE

+1.25 +3.1 V

– 0.5V) max.

(V

CC

Commercial 910 1270 mA

MAX

Industrial 1320 mA

Commercial 900 1270 mA

125 MHz

Industrial 1320 mA

V

3.3V

R1

R1 = 590Ω

R2 = 435Ω

≤ 7 pF

C

L

(Includes fixture and

probe capacitance)

(a) LVTTL Output Test Load

Vth=1.4V

GND

≤ 1ns

2.0V

0.8V

(c) LVTTL Input Test Waveform

Notes

9. The common mode range defines the allowable range of INPUT+ and INPUT− when INPUT+ = INPUT−. This marks the zero crossing between the true and

complement inputs as the signal switches between a logic-1 and a logic-0.

10.Maximum I

outputs unloaded.

11. Typical I

channel sending a continuous alternating 01 pattern. The redundant outputs on each channel are powered down and the parallel output s are unloaded.

12.Cypress uses constant current (ATE) load configurations and forcing functions. This figure is for reference only.

13.The LVTTL switching threshold is 1.4V. All timing references are made relative to where the signal edges cross the threshold voltage.

is measured with VCC = MAX, TA = 25°C, with all channels and Serial Line Drivers enabled, sending a continuous alternating 01 pattern, and

CC

is measured under similar conditions except with VCC = 3.3V, TA = 25°C, with all channels enabled and one Serial Line Driver for each transmit

CC

C

3.0V

L

2.0V

0.8V

R2

[12]

Vth=1.4V

≤ 1 ns

[13]

V

IHE

V

ILE

≤ 270 ps

20%

RL= 100Ω

(Includes fixture and

probe capacitance)

(b) CML Output Test Load

V

80%

V

(d) CML/LVPECL Input Test Waveform

IHE

ILE

R

80%

L

[12]

20%

≤ 270 ps

Document #: 38-02102 Rev. *C Page 20 of 27

[+] Feedback

Page 21

CYV15G0404RB

CYV15G0404RB AC Electrical Characteristics

Parameter Description Min Max Unit

CYV15G0404RB Receiver LVTTL Switching Characteristics Over the Operating Range

f

RS

t

RXCLKP

t

RXCLKD

RXCLKR

[14]

RXCLKF

[18]

RXDv–

[18]

RXDv+

ROS

RECLKO

RECLKOD

[14]

t

t

t

t

f

t

t

CYV15G0404RB TRGCLKx Switching Characteristics Over the Operating Range

f

TRG

TRGCLK

t

TRGH

t

TRGL

[20]

t

TRGD

[14, 15, 16, 17]

t

TRGR

[14, 15, 16, 17]

t

TRGF

[21]

t

TRGRX

CYV15G0404RB Bus Configuration Write Timing Characteristics Over th e Operating Range

t

DATAH

t

DATAS

t

WRENP

CYV15G0404RB JTAG Test Clock Characteristics Over the Operating Range

f

TCLK

t

TCLK

RXCLKx± Clock Output Frequency 9.75 150 MHz

RXCLKx± Period = 1/f

RS

6.66 102.56 ns

RXCLKx± Duty Cycle Centered at 50% (Full Rate and Half Rate) –1.0 +1.0 ns

RXCLKx± Rise Time 0.3 1.2 ns

RXCLKx± Fall Time 0.3 1.2 ns

Status and Data Valid Time to RXCLKx± (RXRATEx = 0) (Full Rate) 5UI–2.0

Status and Data Valid Time to RXCLKx± (RXRATEx = 1) (Half Rate) 5UI–1.3

Status and Data Valid Time to RXCLKx± (RXRATEx = 0) 5UI–1.8

Status and Data Valid Time to RXCLKx± (RXRATEx = 1) 5UI–2.6

[19]

[19]

[19]

[19]

RECLKOx Clock Frequency 19.5 150 MHz

RECLKOx Period = 1/f

ROS

6.66 51.28 ns

RECLKOx Duty Cycle centered at 60% HIGH time –1.9 0 ns

TRGCLKx Clock Frequency 19.5 150 MHz

TRGCLKx Period = 1/f

REF

6.6 51.28 ns

TRGCLKx HIGH Time (TRGRATEx = 1)(Half Rate) 5.9 ns

TRGCLKx HIGH Time (TRGRATEx = 0)(Full Rate) 2.9

[14]

TRGCLKx LOW Time (TRGRATEx = 1)(Half Rate) 5.9 ns

TRGCLKx LOW Time (TRGRATEx = 0)(Full Rate) 2.9

[14]

TRGCLKx Duty Cycle 30 70 %

TRGCLKx Rise Time (20%–80%) 2 ns

TRGCLKx Fall Time (20%–80%) 2 ns

TRGCLKx Frequency Referenced to Received Clock Frequency –0.15 +0.15 %

Bus Configuration Data Hold 0 ns

Bus Configuration Data Setup 10 ns

Bus Configuration WREN Pulse Width 10 ns

JTAG Test Clock Frequency 20 MHz

JTAG Test Clock Period 50 ns

ns

ns

ns

ns

ns

ns

Notes

14.Tested initially and after any design or process changes that may affect these parameters, but not 100% tested.

15.The ratio of rise time to falling time must not vary by greater than 2:1.

16.For a given operating frequency, neither rise nor fall specification can be greater than 20% of the clock cycle period or th e data sheet maximum time.

17.All transmit AC timing parameters measured with 1ns typical rise time and fall time.

18. Parallel data output specifications are only valid if all outputs are loaded with similar DC and AC loads.

19.Receiver UI (Unit Interval) is c a l c u l a t e d a s 1 / (f

20.The duty cycle specification is a simultaneous condition with the t

cycle cannot be as large as 30%–70%.

21.TRGCLKx± has no phase or frequency relationship with the recovered clock(s) and only acts as a centering reference to reduce clock synchronization time.

TRGCLKx± must be within ±1500 PPM (±0.15%) of the tra nsmitter PLL reference (REFCLKx±) frequency. Although transmitting to a HOTLink II receiver channel

necessitates the frequency difference between the transmitter and receiver reference clocks to be within ±1500-PPM, the stability of the crystal needs to be

within the limits specified by the appropriate standard when transmitting to a remote receiver that is compliant to that standard.

* 20) (when TRGRATEx = 1) or 1/(f

TRG

REFH

and t

* 10) (when TRGRATEx = 0). In an operating link this is equivalent to tB.

TRG

parameters. This means that at faster character rates the TRGCLKx± duty

REFL

Document #: 38-02102 Rev. *C Page 21 of 27

[+] Feedback

Page 22

CYV15G0404RB

CYV15G0404RB AC Electrical Characteristics (continued)

Parameter Description Min Max Unit

CYV15G0404RB Device RESET Characteristics Over the Operating Range

t

RST

CYV15G0404RB Reclocker Serial Output Characteristics Over the Operating Range

Parameter Description Condition Min. Max. Unit

t

B

[14]

t

RISE

[14]

t

FALL

PLL Characteristics

Device RESET Pulse Width 30 ns

Bit Time 5128 660 ps

CML Output Rise Time 20−80% (CML Test Load) SPDSELx = HIGH 50 270 ps

SPDSELx = MID 100 500 ps

SPDSELx =LOW 180 1000 ps

CML Output Fall Time 80−20% (CML Test Load) SPDSELx = HIGH 50 27 0 ps

SPDSELx = MID 100 500 ps

SPDSELx =LOW 180 1000 ps

Parameter Description Condition Min Typ Max Unit

CYV15G0404RB Reclocker Output PLL Characteristics

t

JRGENSD

t

JRGENHD

[14, 22]

[14, 22]

Reclocker Jitter Generation - SD Data Rate TRGCLKx = 27 MHz 133 ps

Reclocker Jitter Generation - HD Data Rate TRGCLKx = 148.5 MHz 107 ps

CYV15G0404RB Receive PLL Characteristics Over the Operating Range

t

RXLOCK

Receive PLL Lock to Input Data Stream (cold start) 376k UI

Receive PLL Lock to Input Data Stream 376k UI

t

RXUNLOCK

Capacitance

Receive PLL Unlock Rate 46 UI

[14]

Parameter Description T est Conditions Max Unit

C

INTTL

C

INPECL

TTL Input Capacitance TA = 25°C, f0 = 1 MHz, VCC = 3.3V 7 pF

PECL input Capacitance TA = 25°C, f0 = 1 MHz, VCC = 3.3V 4 pF

Note

22.Receiver input stream is BIST data from the transmit channel. This data is reclocked and output to a wide bandwidth digit al sampling oscilloscope. The

measurement was recorded after 10,000 histogram hits , time referenced to REFCLKx± of the transmit channel.

Document #: 38-02102 Rev. *C Page 22 of 27

[+] Feedback

Page 23

Switching Waveforms for the CYV15G0404RB HOTLink II Receiver

CYV15G0404RB

Receive Interface

Read Timing

RXRATEx = 0

RXCLKx+

RXCLKx–

RXDx[9:0]

Receive Interface

Read Timing

RXRATEx = 1

RXCLKx+

RXCLKx–

t

RXCLKP

t

RXDV

–

t

RXDV+

t

RXCLKP

t

RXDV

–

RXDx[9:0]

t

RXDV+

CYV15G0404RB HOTLink II Bus Configuration Switching Waveforms

Bus Configuration

Write Timing

ADDR[3:0]

DATA[7:0]

t

WRENP

t

WREN

DATAS

t

DATAH

Document #: 38-02102 Rev. *C Page 23 of 27

[+] Feedback

Page 24

CYV15G0404RB

Table 6. Package Coordinate Signal Allocation

Ball

Signal Name Signal Type

ID

A01 INC1– CML IN C07 ULCC

A02 ROUTC1– CML OUT C08 GND GROUND F18 RXDB[0] LVTTL OUT

A03 INC2– CML IN C09 DATA[7] LVTTL IN PU F19 RECLKOB LVTTL OUT

A04 ROUTC2– CML OUT C10 DATA[ 5] LVTTL IN PU F20 RXDB[1] LVTTL OUT

A05 VCC POWER C11 DATA[3] LVTTL IN PU G01 GND GROUND

A06 IND1– CML IN C12 DATA[1] LVTTL IN PU G02 WREN

A07 ROUTD1– CML OUT C13 GND GROUND G03 GND GROUND

A08 GND GROUND C14 VCC POWER G04 GND GROUND

A09 IND2– CML IN C15 SPDSELD 3-LEVEL SEL G17 SPDSELB 3-LEVEL SEL

A10 ROUTD2– CML OUT C16 VCC POWER G18 NC NO CONNECT

A1 1 INA1– CML IN C17 LDTDEN LVTTL IN PU G19 SPDSELA 3-LEVEL SEL

A12 ROUTA1– CML OUT C18 TRST

A13 GND GROUND C19 GND GROUND H01 GND GROUND

A14 INA2– CML IN C20 TDO LVTTL 3-S OUT H02 GND GROUND

A15 ROUTA2– CML OUT D01 TCLK LVTTL IN PD H03 GND GROUND

A16 VCC POWER D02 RESET

A17 INB1– CML IN D03 INSELD LVTTL IN H17 GND GROUND

A18 ROUTB1– CML OUT D04 INSELA LVTTL IN H18 GND GROUND

A19 INB2– CML IN D05 VCC POWER H19 GND GROUND

A20 ROUTB2– CML OUT D06 ULCA

B01 INC1+ CML IN D07 SPDSELC 3-LEVEL SEL J01 GND GROUND

B02 ROUTC1+ CML OUT D08 GND GROUND J02 GND GROUND

B03 INC2+ CML IN D09 DATA[6] LVTTL IN PU J03 GND GROUND

B04 ROUTC2+ CML OUT D10 DATA[4] LVTTL IN PU J04 GND GROUND

B05 VCC POWER D11 DATA[2] LVTTL IN PU J17 BISTSTB LVTTL OUT

B06 IND1+ CML IN D12 DATA[0] LVTTL IN PU J18 RXDB[2] LVTTL OUT

B07 ROUTD1+ CML OUT D13 GND GROUND J19 RXDB[7] LVTTL OUT

B08 GND GROUND D14 GND GROUND J20 RXDB[4] LVTTL OUT

B09 IND2+ CML IN D15 ULCB

B10 ROUTD2+ CML OUT D16 VCC POWER K02 TRGCLKC– PECL IN

B1 1 INA1+ CML IN D17 NC NO CONNECT K03 GND GROUND

B12 ROUTA1+ CML OUT D18 VCC POWER K04 GND GROUND

B13 GND GROUND D19 SCANEN2 LVTTL IN PD K17 RXDB[5] LVTTL OUT

B14 INA2+ CML IN D20 TMEN3 L VTTL IN PD K18 RXDB[6] L VTTL OUT

B15 ROUTA2+ CML OUT E01 VCC POWER K19 RXDB[9] LVTTL OUT

B16 VCC POWER E02 VCC POWER K20 LFIB

B17 INB1+ CML IN E03 VCC POWER L01 RXDC[5] LVTTL OUT

B18 ROUTB1+ CML OUT E04 VCC POWER L02 TRGCLKC+ PECL IN