Page 1

CYS25G0101DX-ATC Evaluation Board

User’s Guide

Cypress Semiconductor Corporation • 3901 North First Street • San Jose • CA 95134 • 408-943-2600

March 19, 2002

[+] Feedback

Page 2

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table of Contents

1. Introduction ....................................................................................................................................... 4

2. Features ............................................................................................................................................. 4

3. Kit Contents ...................................................................................................................................... 4

4. Functional Description ..................................................................................................................... 4

5. Diagnostic Modes ........................................................................................................................... 12

5.1 Diagnostic Loopback Mode ..................................................................................................... 12

5.2 Line Loopback ........................................................................................................................... 13

5.3 Analog Line Loopback .............................................................................................................. 14

5.4 “Parallel Line Loopback” (TEST0) Mode ................................................................................ 15

5.4.1 Test the Internal RX CDR PLL Only ................................................................................ 15

5.4.2 Test the Internal RX CDR PLL and TX PLL .................................................................... 15

6. Testing Hookup ............................................................................................................................... 16

6.1 Set-up for BERT Test ................................................................................................................ 16

6.2 Set-up for Eye Diagram Test .................................................................................................... 17

6.3 SONET Jitter Transfer and Jitter Tolerance Test ................................................................... 18

6.4 Set-up for Testing the TX PLL in Parallel Line Loopback Mode ........................................... 19

7. Eye Diagram Testing Result .......................................................................................................... 20

8. Jitter Transfer Testing Result ........................................................................................................ 21

9. Jitter Tolerance Testing Result ..................................................................................................... 22

10. Schematic Diagram, PCB Layout and BOM (Bill of Material) ................................................... 23

Appendix A: Schematic Diagrams of the CYS25G0101DX Evaluation Board ............................... 24

Appendix B: PCB Layout Diagrams of the CYS25G0101DX Evaluation Board ............................ 32

Appendix C: CYS25G0101DX Evaluation Board LVPECL BOM (Bill of Material) ......................... 42

Appendix D: CYS25G0101DX Evaluation Board HSTL BOM (Bill of Material) .............................. 47

List of Figures

Figure 1. The Block Diagram of the CYS25G0101DX ......................................................................... 5

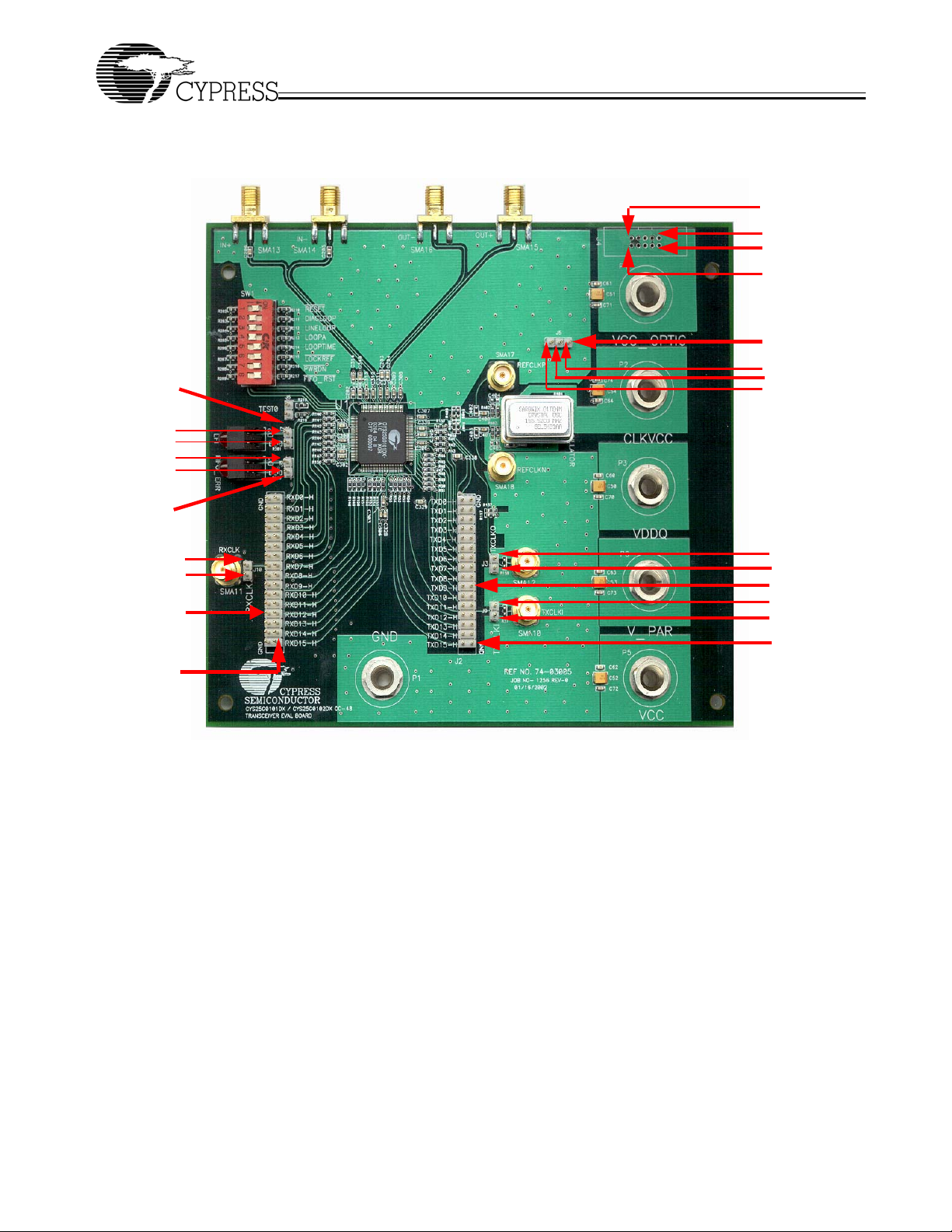

Figure 2. The CYS25G0101DX Evaluation Board ................................................................................ 6

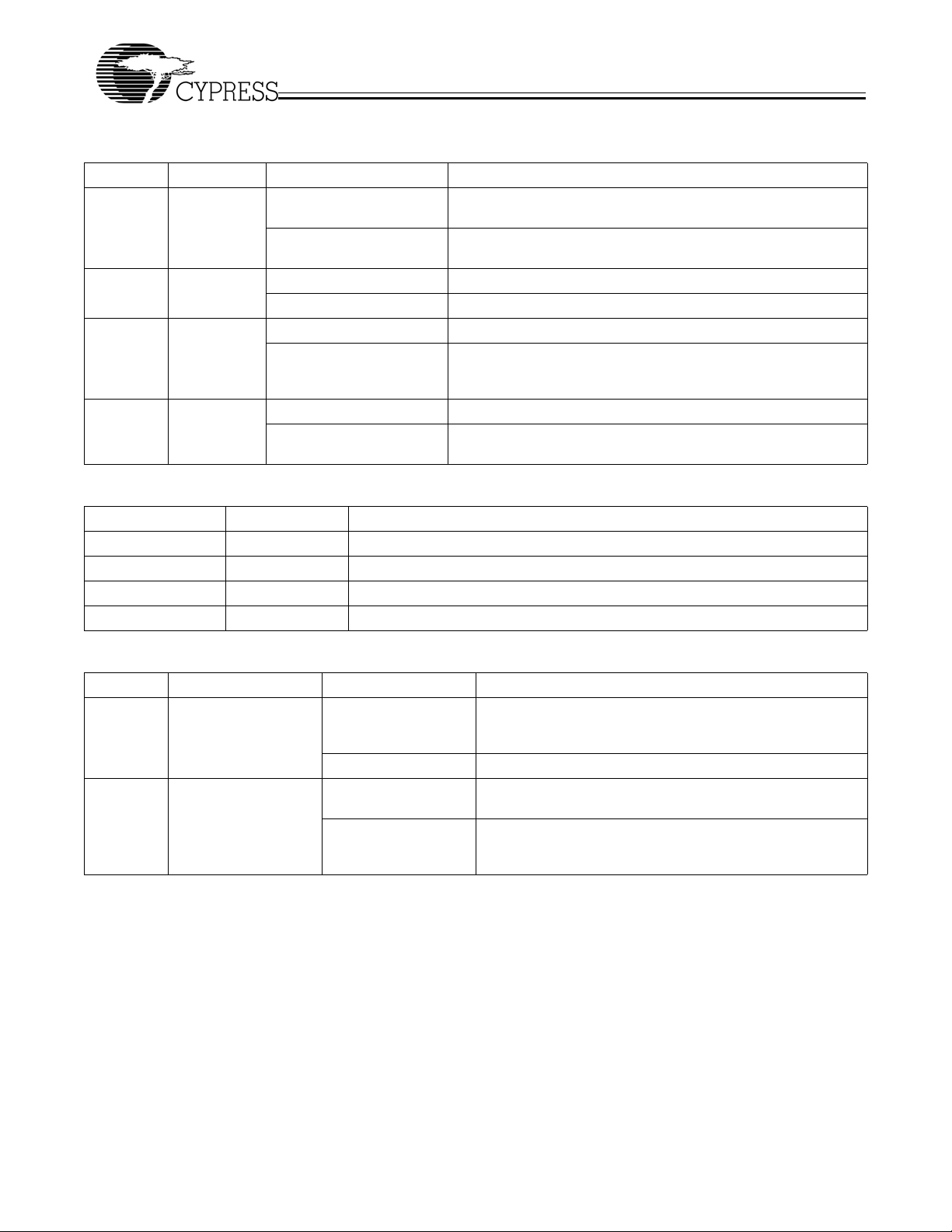

Figure 3. The Jumper Orientations of the CYS25G0101DX ............................................................. 11

Figure 4. Diagnostic Loopback Mode Data Path .............................................................................. 12

Figure 5. Line Loopback Mode Data Path .........................................................................................13

Figure 6. Analog Line Loopback Mode Data Path ............................................................................ 14

Figure 7. Parallel Loopback (TEST0) Mode Data Path ..................................................................... 15

Figure 8. Equipment Set-up for BERT Test .......................................................................................16

Figure 9. Equipment Set-up For Eye Diagram Test .......................................................................... 17

Figure 10. Equipment Set-up For Jitter Test ..................................................................................... 18

Figure 11. Equipment Set-up For Testing the TX PLL in Parallel Line Loopback Mode ............... 19

Figure 12. CYS25G0101DX Evaluation Board Eye Diagram ............................................................ 20

Figure 13. CYS25G0101DX Evaluation Board GR-253 Jitter Transfer Testing Result .................. 21

Figure 14. CYS25G0101DX Evaluation Board G958 Jitter Transfer Testing Result ...................... 21

Figure 15. CYS25G0101DX Evaluation Board GR-253 JitterTolerance Testing Result ................. 22

Figure 16. CYS25G0101DX Evaluation Board G825 Jitter Tolerance Testing Result .................... 22

Figure 17. Top Level of CYS25G0101DX Evaluation Board Schematic Diagram ......................... 25

Figure 18. Parallel Output Block Schematic Diagram ...................................................................... 26

Figure 19. Parallel Input Block Schematic Diagram ......................................................................... 27

Figure 20. Signals Block Schematic Diagram ................................................................................... 28

Figure 21. Power Supply Block Schematic Diagram ........................................................................ 29

Figure 22. Control Block Schematic Diagram ................................................................................... 30

2

[+] Feedback

Page 3

CYS25G0101DX-ATC Evaluation Board User’s Guide

List of Figures (continued)

Figure 23. Reference Clock Block Schematic Diagram ................................................................... 31

Figure 24. CYS25G0101DX Evaluation Board PCB Mechanical Drawing ....................................... 33

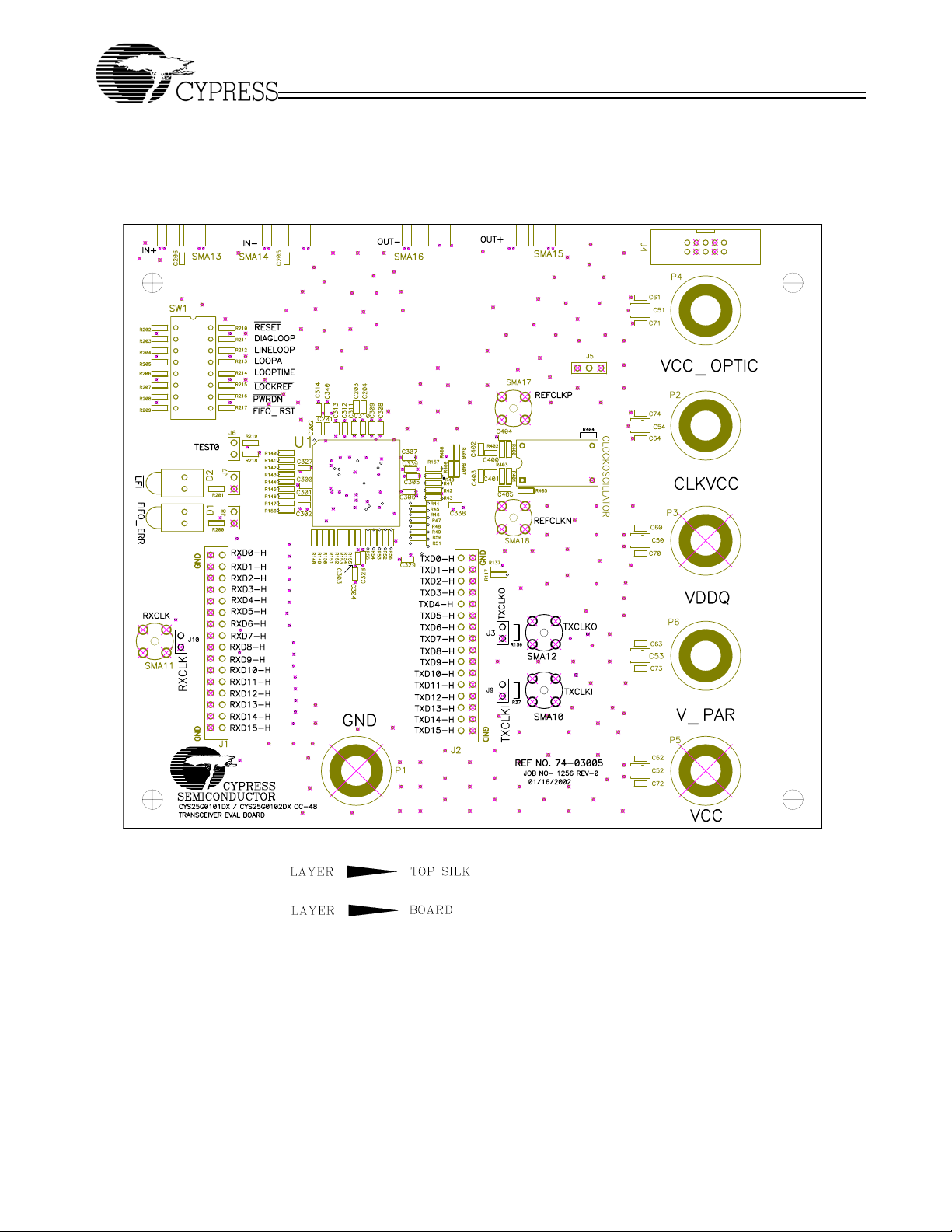

Figure 25. CYS25G0101DX Evaluation Board PCB Top Layer Silk Screen .................................... 34

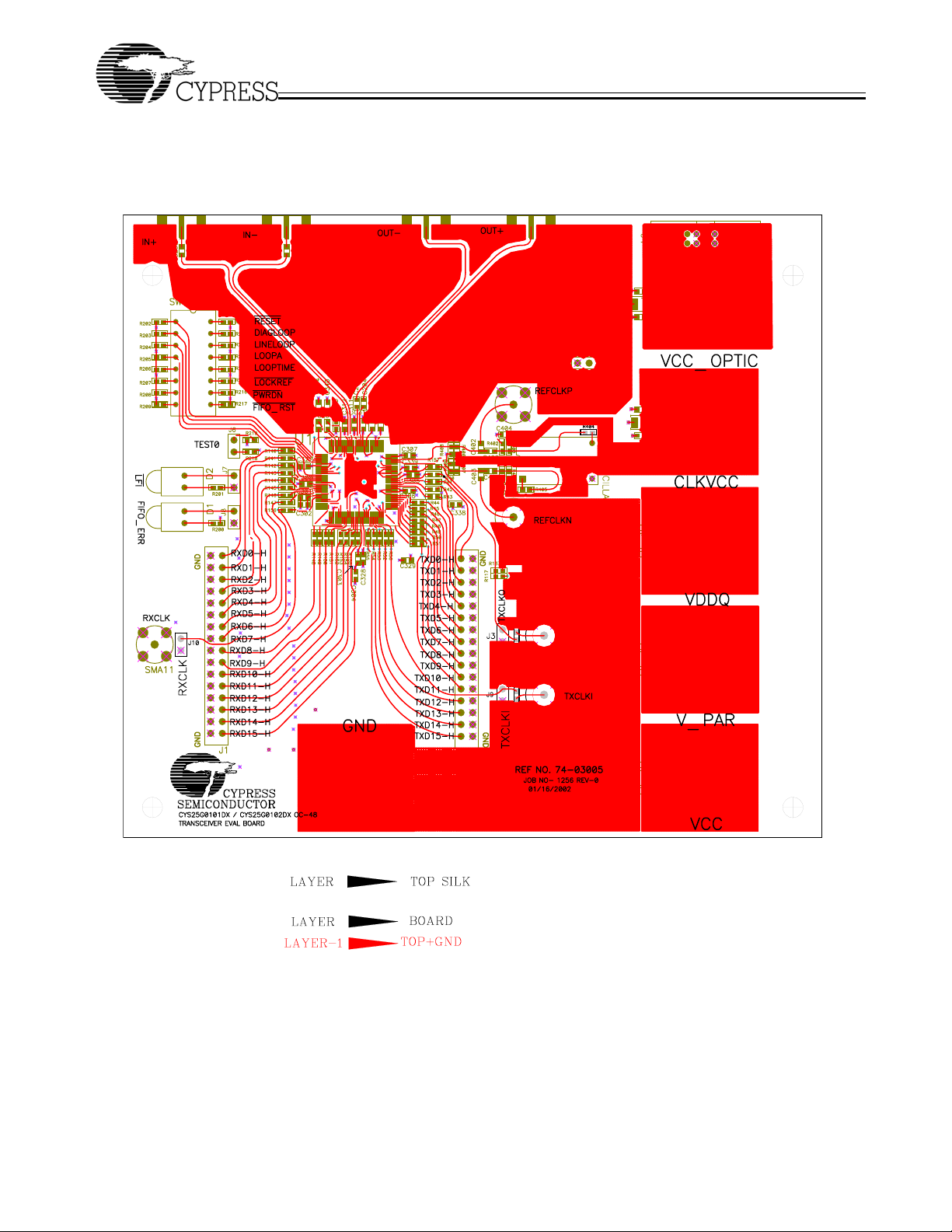

Figure 26. CYS25G0101DX Evaluation Board PCB Top Layer Layout ........................................... 35

Figure 27. CYS25G0101DX Evaluation Board PCB Top Layer Solder Mask .................................. 36

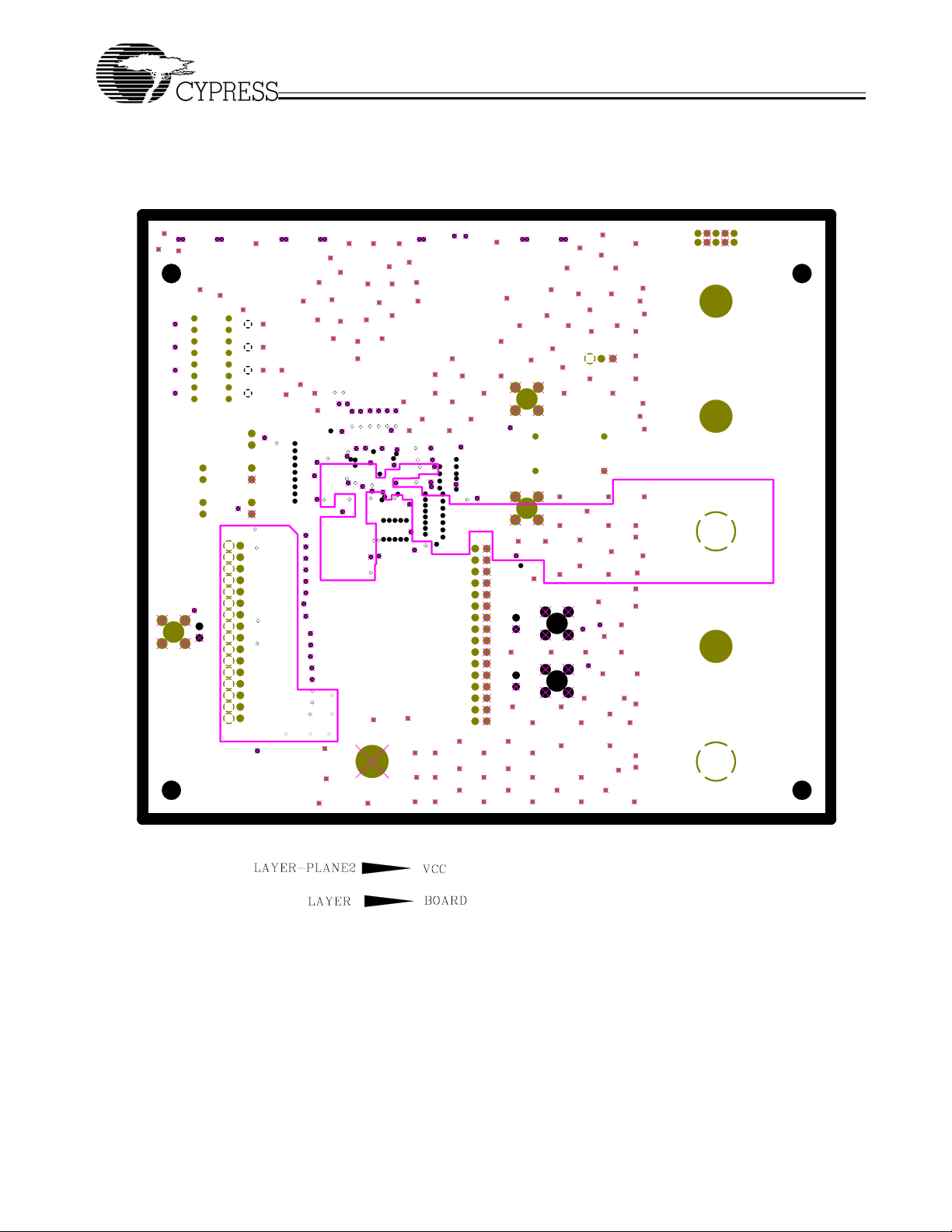

Figure 28. CYS25G0101DX Evaluation Board PCB Power Plane Layout ....................................... 37

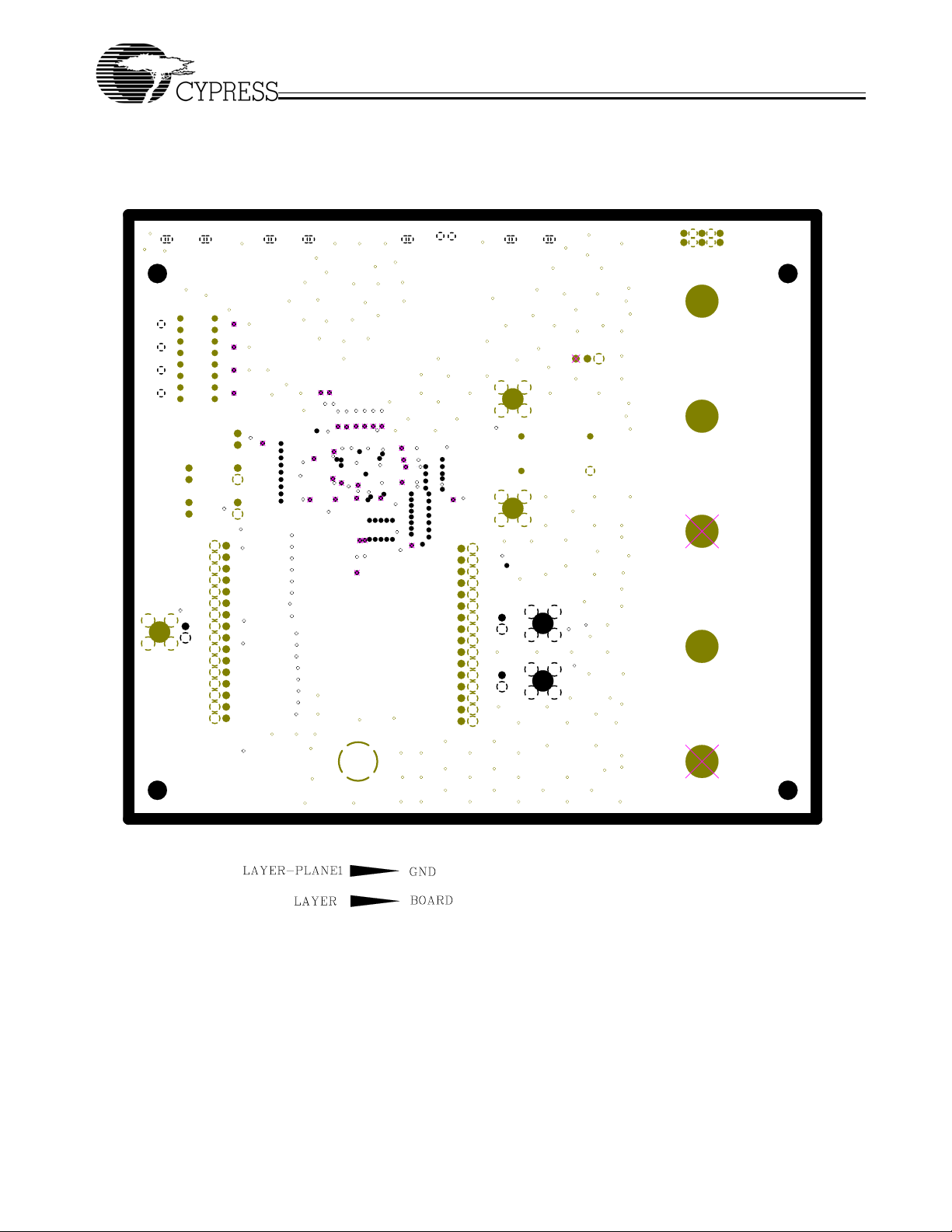

Figure 29. CYS25G0101DX Evaluation Board PCB Ground Plane Layout ..................................... 38

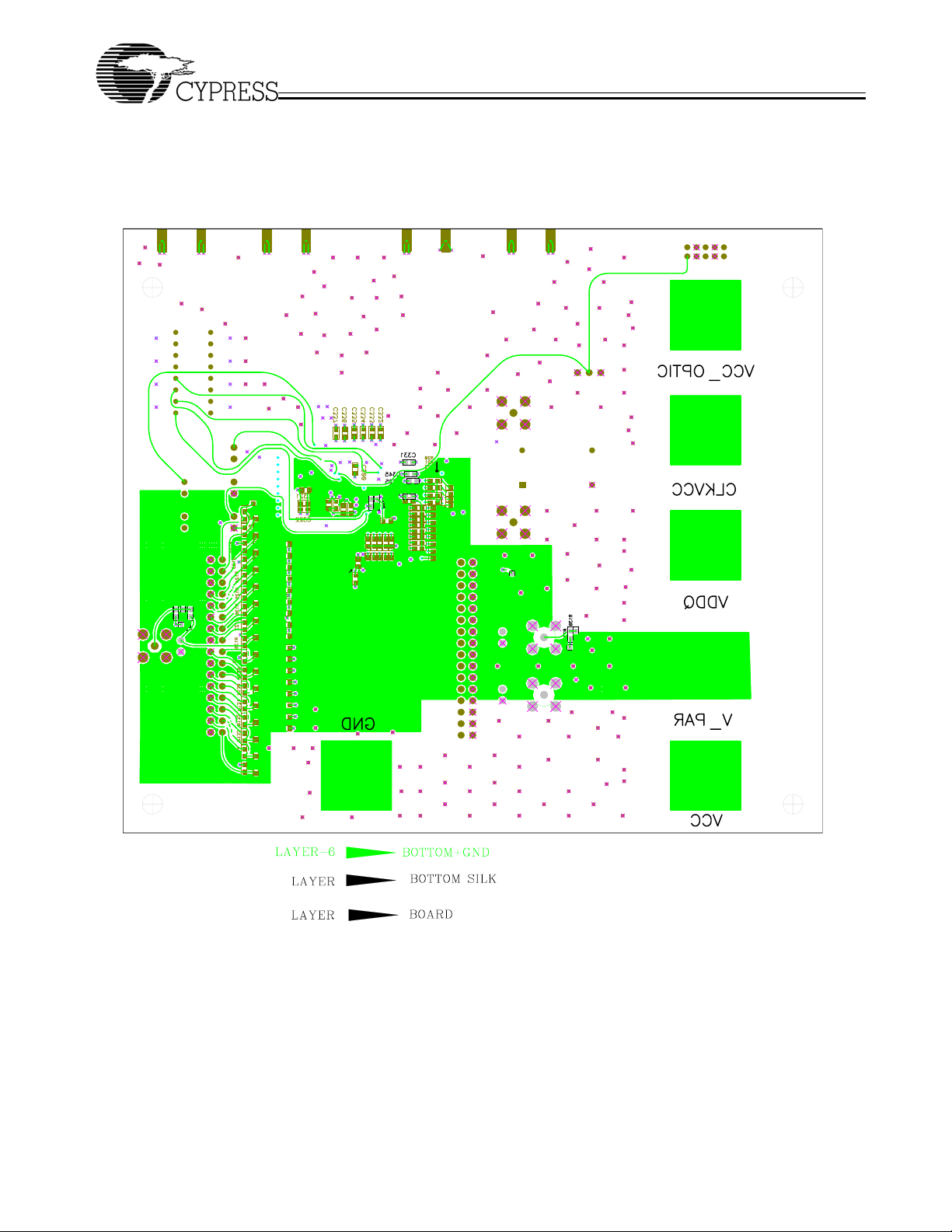

Figure 30. CYS25G0101DX Evaluation Board PCB Bottom Silk Screen ........................................ 39

Figure 31. CYS25G0101DX Evaluation Board PCB Bottom Layer Layout ..................................... 40

Figure 32. CYS25G0101DX Evaluation Board PCB Bottom Solder Mask ....................................... 41

List of Tables

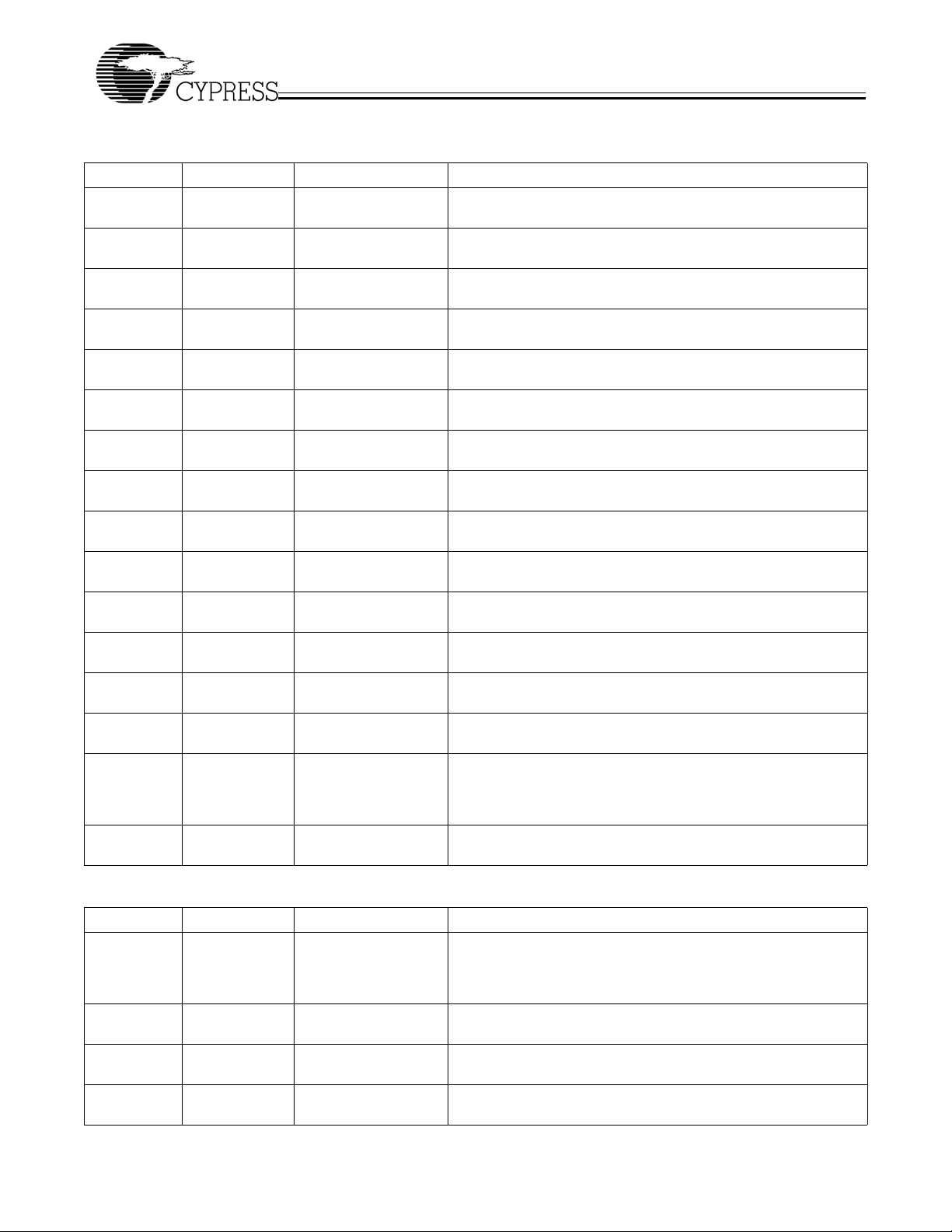

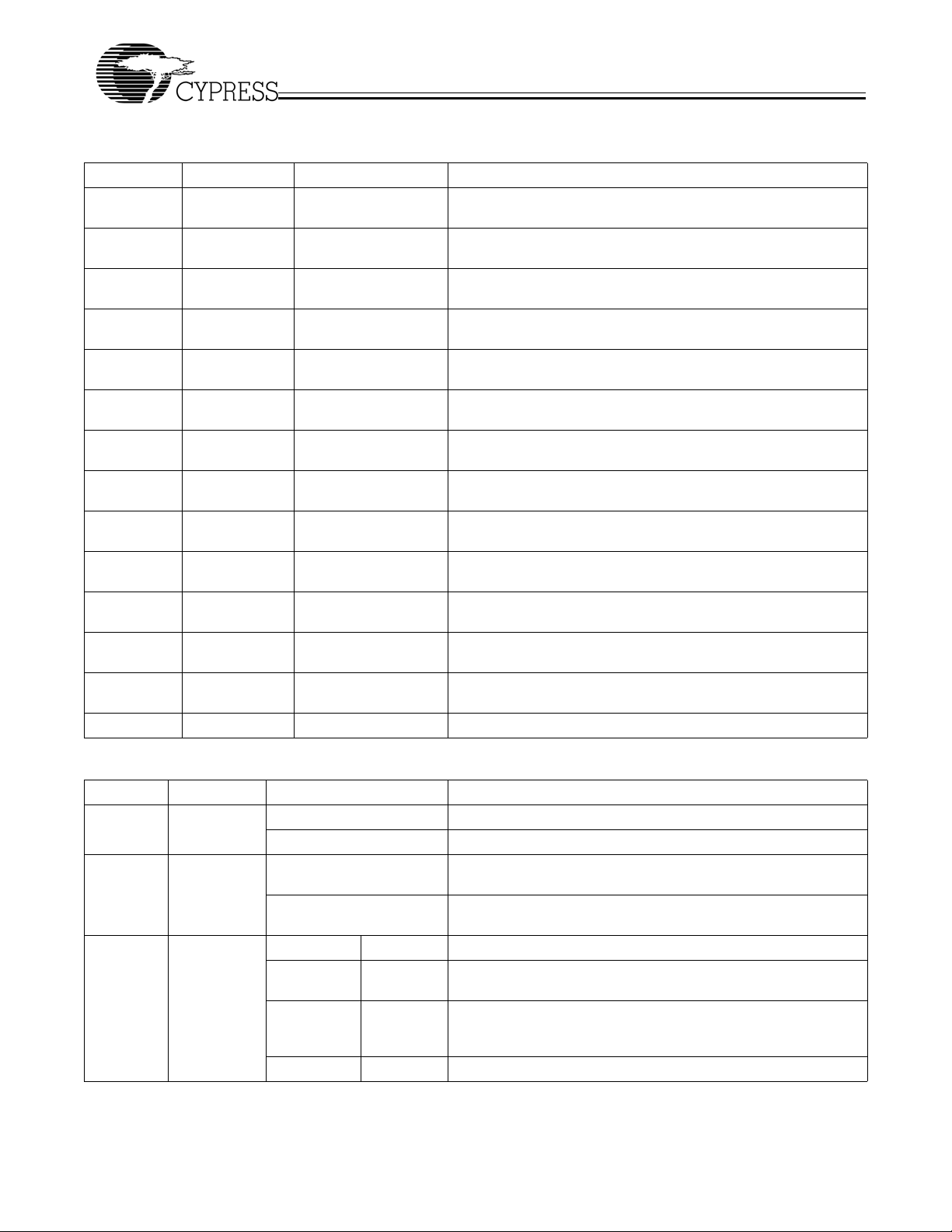

Table 1. Functional Description of the Connectors ............................................................................ 6

Table 2. Pin Assignment of J1 Header and Description of J10 Header ............................................ 7

Table 3. Pin Assignment of J2 Header and Description of J9 Header .............................................. 8

Table 4. Functional Description of DIP Switch 1 (SW1) ..................................................................... 9

Table 5. Functional Description of J4 Connector ............................................................................. 10

Table 6. Description of LED Indicators .............................................................................................. 10

Table 7. Operation Specification of CYS25G0101DX Evaluation Board ......................................... 23

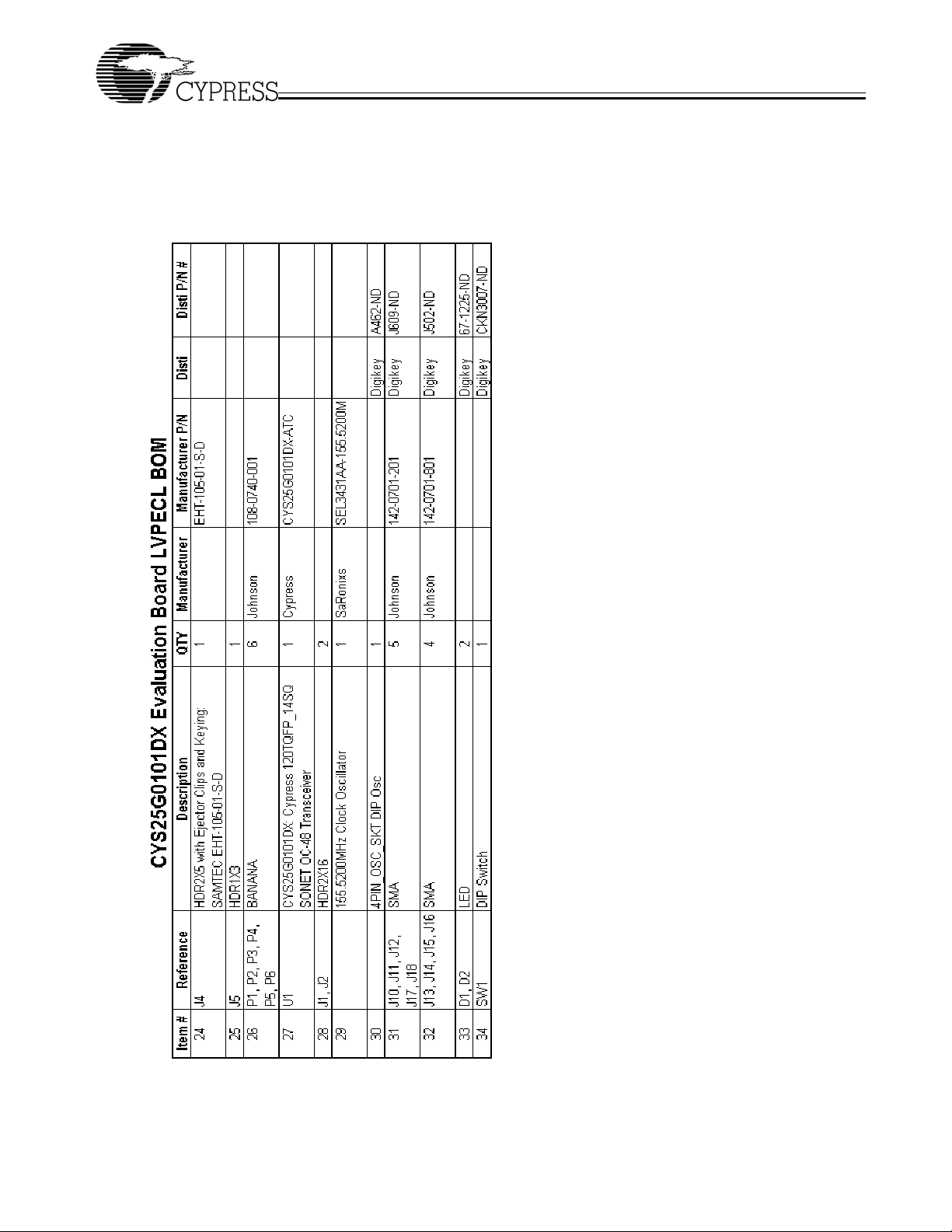

Table 8. CYS25G0101DX Evaluation Board LVPECL BOM - Page 1 of 4 ........................................ 43

Table 9. CYS25G0101DX Evaluation Board LVPECL BOM - Page 2 of 4 ........................................ 44

Table 10. CYS25G0101DX Evaluation Board LVPECL BOM - Page 3 of 4 ..................................... 45

Table 11. CYS25G0101DX Evaluation Board LVPECL BOM - Page 4 of 4 ..................................... 46

Table 12. CYS25G0101DX Evaluation Board HSTL BOM - Page 1 of 4 .......................................... 48

Table 13. CYS25G0101DX Evaluation Board HSTL BOM - Page 2 of 4 .......................................... 49

Table 14. CYS25G0101DX Evaluation Board HSTL BOM - Page 3 of 4 .......................................... 50

Table 15. CYS25G0101DX Evaluation Board HSTL BOM - Page 4 of 4 .......................................... 51

3

[+] Feedback

Page 4

CYS25G0101DX-ATC Evaluation Board User’s Guide

1. Introduction

Cypress's CYS25G0101DX SONET OC-48 Transceiver is a communications building block for high-speed SONET data communications. It provides complete parallel-to-serial and serial-to- parallel con versions, clock generation, and cl ock and data recover y operations in a single chip, optimized for full SONET/SDH compliance. The CYS25G0101DX Evaluation Board is designed for evaluating as

well as understanding the characteristics of the CYS25G0101DX SONET/SDH Transceiv er. The CYS25G0101DX SONET/SDH

Transceiver Evaluation Board provides the following advantages.

2. Features

• Flexible and easy to operate

• On-board Cypress 120-pin TQFP CYS25G0101DX SONET/SDH Transceiver

• Supports LVPECL and HSTL interfaces

• Dip switch for selecting different diagnostic modes

• Four diagnostic modes – Diagnostic Loopback mode, Line Loopback mode, Analog Line Loopback mode, and factory TEST0

(Parallel Line Loopback) mode

• LFI and FIFO_ERR LEDs

• Onboard oscillator for the REFCLK

• Supports external clock source for the REFCLK

• 16-bit RxD, 16-bit TxD bus, RXCLK, TXCLKI, TXCLKO interface

• SMA connectors for CML input and output buffers

• Separate Banana Jacks for all voltage sources for measuring current individually

3. Kit Contents

• CYS25G0101DX Evaluation Board

• Certificate of Compliance

• CYS25G0101DX Evaluation Kit CD

— Users Guide

— Application Notes

— Data Sheet

4. Functional Description

This board can be used to test the CYS25G0101DX in various modes, such as TEST0 (parallel line loopba ck mode), LINELOOP,

LOOPA and LOOPTIME. The REFCLK of the CYS25G0101DX is connected to the onbo ard 155.52-MHz oscillator. The on-board

REFCLK can be replaced by connecting the external reference clock source to J17 and J18. To use the external reference clock

source, the C400 and C401 (0.01-µF cap) have to be removed and placed on C402 and C403 position s . Also , the P2 , CLKVCC, has to

be disconnected from the power supply (or power down). The CYS25G0101DX Evaluation Board provides an optional optical module

interface for connecting to an optical module daughter card.

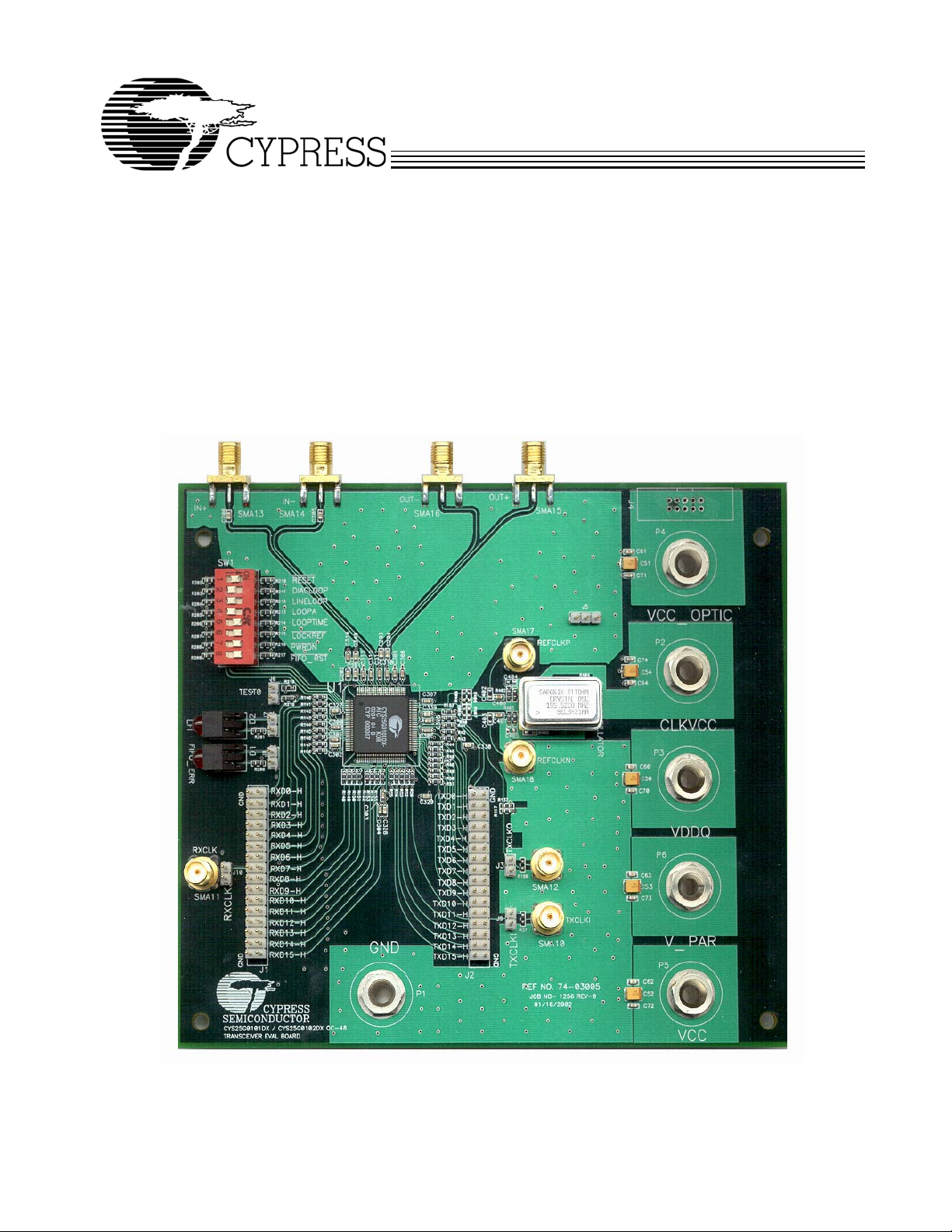

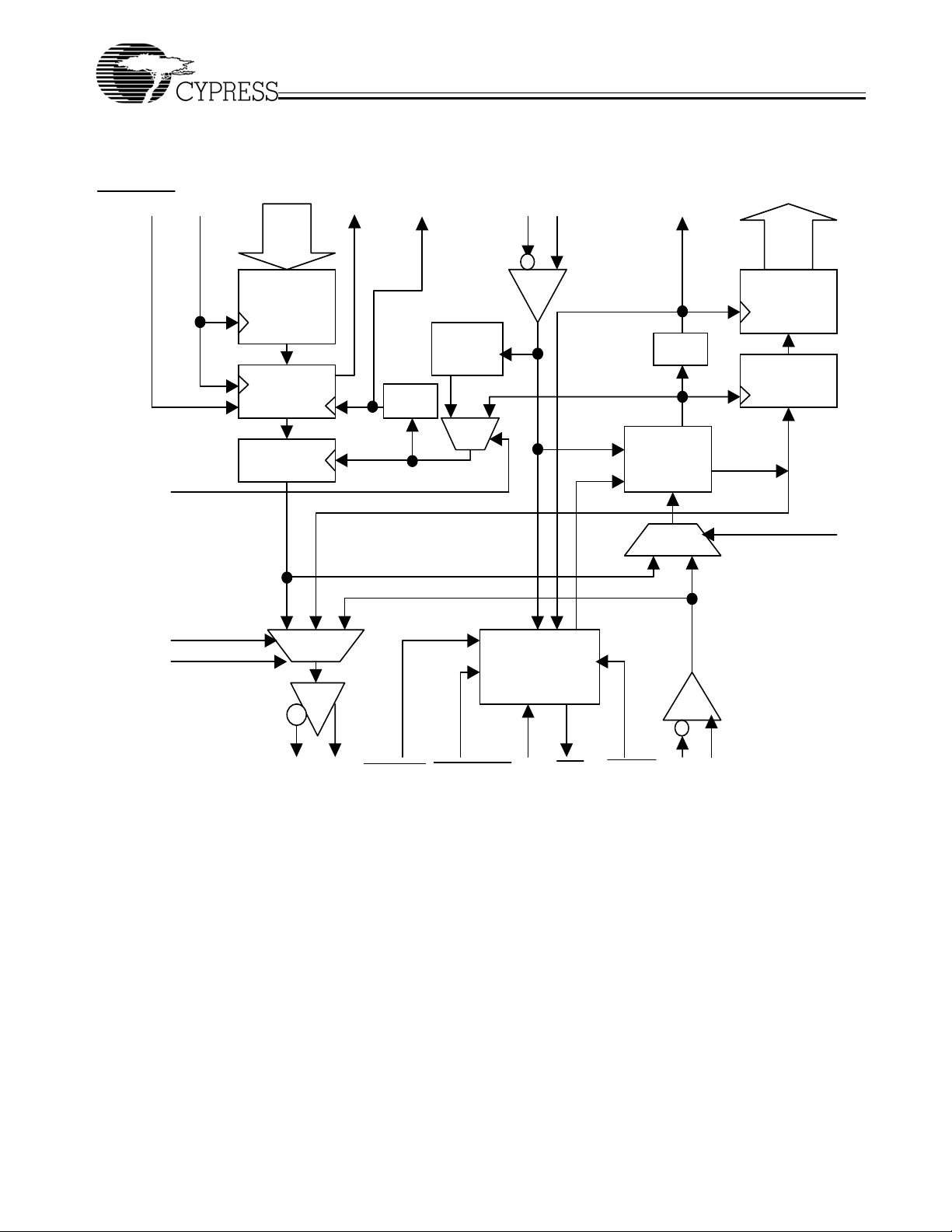

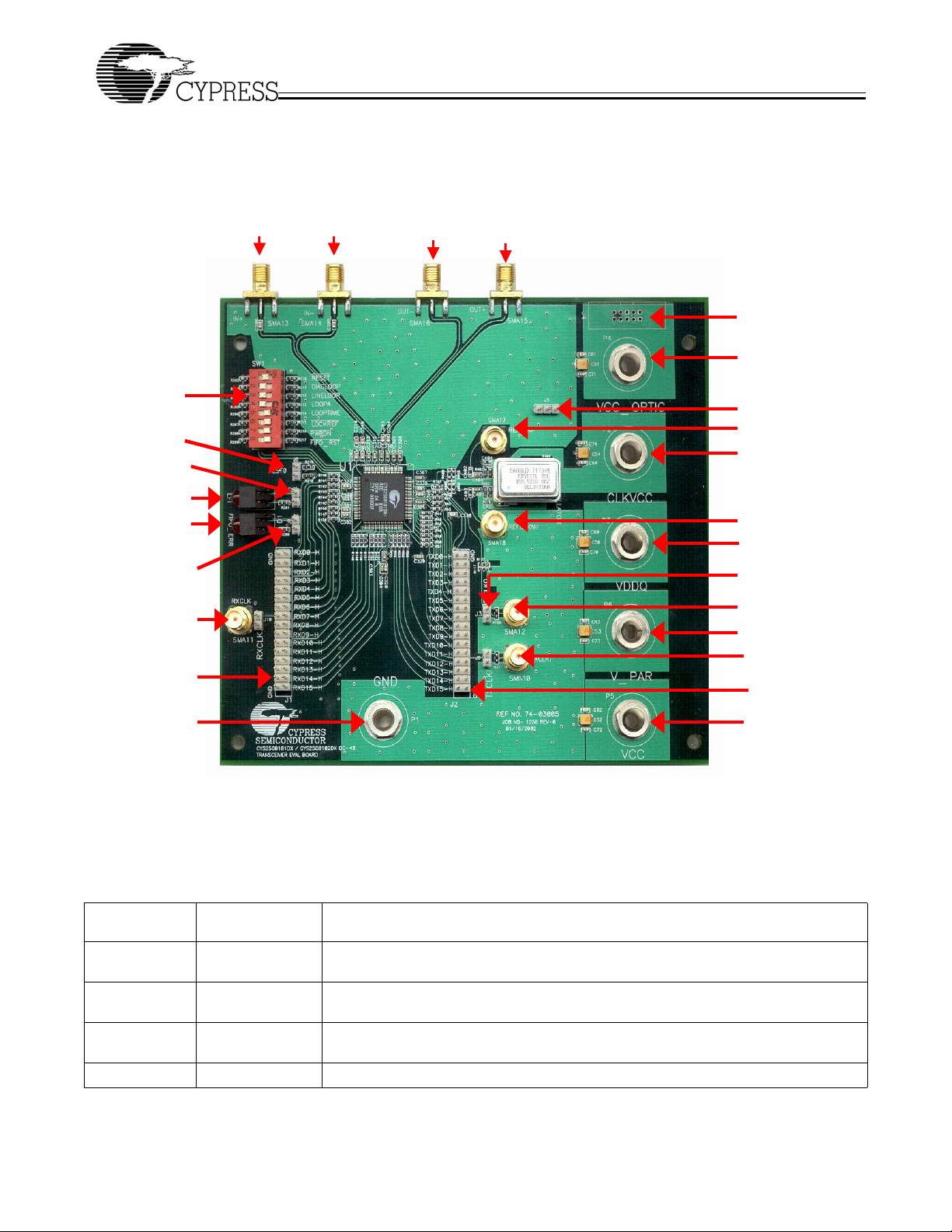

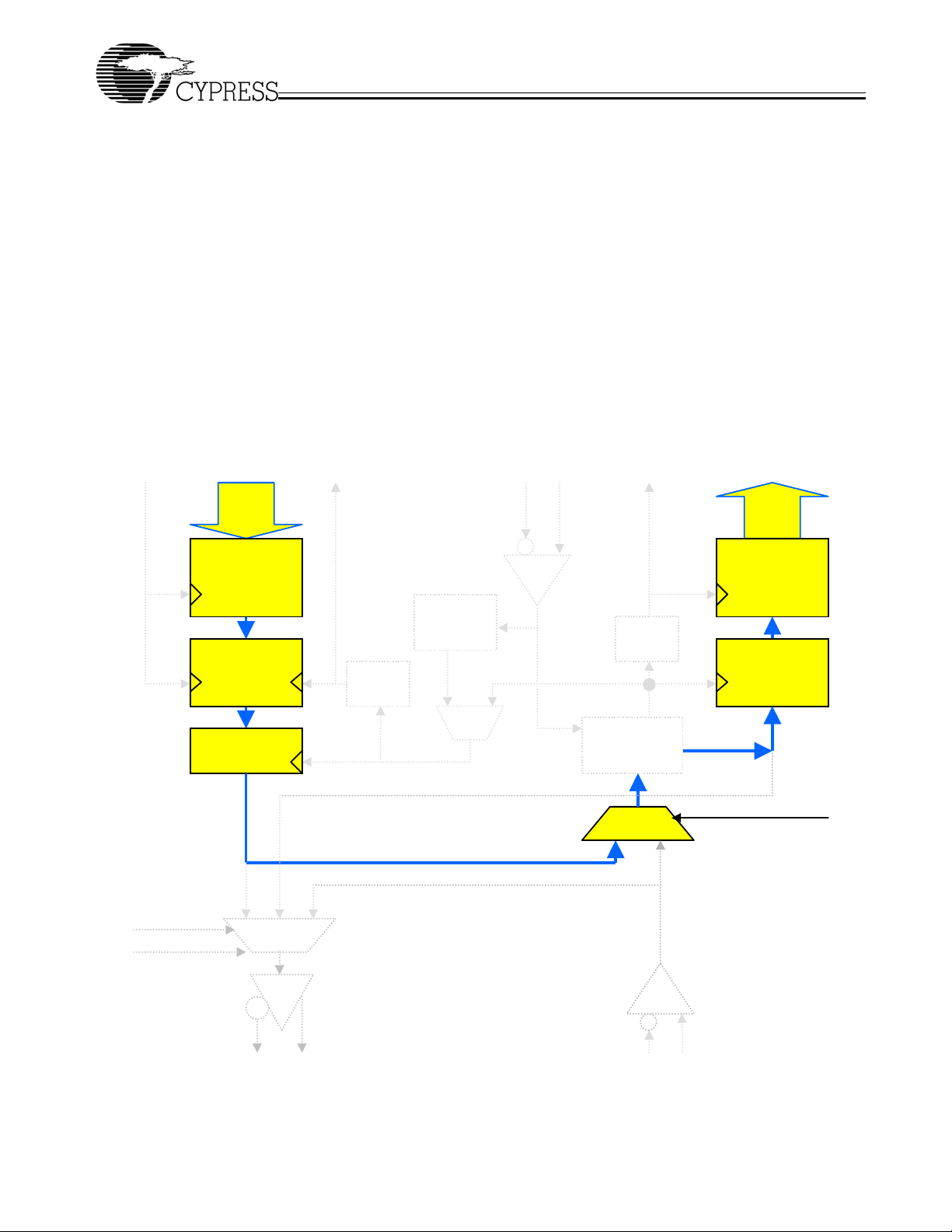

The block diagram of the CYS25G0101DX is shown in Figure 1. The detailed functional description can be found in the

CYS25G0101DX data sheet. Figure 2 shows the picture of the CYS25G0101DX Evaluation Board and the location of the jumpers.

Table 1 is the description of all jumpers and connectors. The bus connectors, J1 and J2, are used to connect to the 16-bit RxD and TxD

buses for transferring and receiving the parallel data. Table 2 and Tabl e 3 are the pin definitions of J1 and J2. A multi-function eight-position Dip switch provides the selection of the different diagnostic modes as well as the control functions. Ta b le 4 is the functional description of the Dip switch SW1. The TEST0 jumper, J6, when closed, is used to enable the factory TEST0 (Parallel Line Loop Back)

mode. In the “Parallel Line Loop Back” mode, parallel output buffers are internally jumped to the parallel input buffers. There is no need

to use external jumpers for the headers. J13, J14, J15, J16 and J4 are Differential CML input and output and power supply for the optional optical module daughter card. Ta b le 5 idescribes the optical modul e interface a nd Table 6 idescribes the LED. Figure 3 shows the

jumper orientations of the CYS25G0101DX Evaluation Board.

4

[+] Feedback

Page 5

CYS25G0101DX-ATC Evaluation Board User’s Guide

FIFO_RST

(155.52MHz)

TXCLKI

LOOPTIME

LINELOOP

LOOPA

FIFO_ERR

TXD

15:0

Input

Register

FIFO

(5byte)

SHIFTER

TXCLKO

/16

Tx Bit-Clock

TX PLL

x16

(155.52MHz)

REFCLK

Lock-to-Data /

Clock Control

Logic

(155.52MHz)

RXCLKOUT

Recovered

Bit-Clock

RX CDR

Lock-to-Ref

/16

PLL

RXD

15:0

Output

Register

SHIFTER

Retimed

Data

DIAGLOOP

OUT±

Figure 1. The Block Diagram of the CYS25G0101DX

5

RESETLFISDLOCKREFPWRDN

IN±

[+] Feedback

Page 6

CYS25G0101DX-ATC Evaluation Board User’s Guide

SW1

J6

J7

D2

D1

J8

SMA11

J1

SMA13 SMA14

SMA16

SMA15

J4

P4

J5

SMA17

P2

SMA18

P3

J3

SMA12

P5

SMA10

J2

P1

P5

Figure 2. The CYS25G0101DX Evaluation Board

Table 1. Functional Description of the Connectors

Jumpers and

Connectors Name Description

J1 RxD BUS 16-bit RxD Data Bus interface header (see Table 2 for details). Figure 3 shows the orienta-

tion of this header

J2 TxD BUS 16-bit TxD Data Bus interface header (see Tabl e 3 for details). Figure 3 shows the orienta-

tion of this header

J3 TxCLKO_H Header for CYS25G0101DX’s TXCLKO (pin 79) and GND. Figure 3 shows the orientation

of this jumper

J4 OPTIC POWER Power supply for external optical module (see Table 5 for details)

6

[+] Feedback

Page 7

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 1. Functional Description of the Connectors (continued)

Jumpers and

Connectors Name Description

J5 SD This jumper is used to set the SD signal. When open (default), SD signal will be driven by the

J6 TEST0 This jumper, when shorted, is to enable the Parallel Line Loopback mode.

J7 LFI Test Tap for CYS25G0101DX’s LFI (pin 1). Figure 3 shows the orientation of this jumper

J8 FIFO_ERR Test Tap for CYS25G0101DX’s LIFO (pin 51). Figure 3 shows the orientation of this jumper

SMA10 TXCLKI Optional SMA connector for CYS25G0101DX’s TXCLKI (pin 57). R37 need to be popu-

SMA11 RXCLK Optional SMA connector for CYS25G0101DX’s RXCLK (pin 24). C118, R118, R138 and

SMA12 TXCLKO Optional SMA connector for CYS25G0101DX’s TXCLKO (pin 79). C119, R119, R139 and

SMA13 IN+ SMA connector for CYS25G0101DX’s IN+ (pin 109). This connector is also for the optional

SMA14 IN- SMA connector for CYS25G0101DX’s IN– (pin 108). This connector is also for the optional

SMA15 OUT- SMA connector for CYS25G0101DX’s OUT– (pin 104). This connector is also for the option-

SMA16 OUT+ SMA connector for CYS25G0101DX’s OUT+ (pin 103). This connector is also for the option-

SMA17 REFCLKP Optional SMA connector for CYS25G0101DX’s REFCLK+ (pin 87). This connector is for us-

SMA18 REFCLKN Optional SMA connector for CYS25G0101DX’s REFCLK+ (pin 87). This connector is for us-

P1 GND Power Ground. For external power supply

P2 CLKVCC Power supply - +3.3V for the clock oscillator

P3 VDDQ Power supply - +3.3V for LVPECL output. +1.5V for HSTL outputs

P4 VCC_OPTIC Power supply - +3.3V for the optional optical module

P5 VCC Power supply - +3.3V for digital and low-speed I/O function

P6 V_Par Power supply - +3.3V for LVPECL output. +1.5V for HSTL outputs

optical module. When 1-2 are shorted, SD is forced to HIGH. When 2-3 are shorted, SD is

forced to LOW. Figure 3 shows the orientation of this jumper

lated, if this connector is used

R158 need to be populated and C116, R116, and R136 need to be unpopulated, if

this connector is used

R159 need to be populated and C117, R117, and R137 need to be unpopulated, if

this connector is used

optical module interface

optical module interface

al optical module interface

al optical module interface

ing the external reference clock instead of using the “on-board” oscillator (155.52MHz). To

use the external reference clock, C400 and C401 (0.01-µF cap) have to be removed

and placed on C402 and C403 positions. Also, The CLKVCC, P2, has to be disconnected from the power supply

ing the external reference clock instead of using the “on-board” oscillator (155.52MHz). To

use the external reference clock, C400 and C401 (0.01-µF cap) have to be removed

and placed on C402 and C403 positions. Also, The CLKVCC, P2, has to be disconnected from the power supply

Table 2. Pin Assignment of J1 Header and Description of J10 Header

Pin Number Name I/O Characteristics Description

1 RXD15 HSTL output Parallel receive data output RXD15. The outputs change following

RXCLK↓

3 RXD14 HSTL output Parallel receive data output RXD14. The outputs change following

RXCLK↓

7

[+] Feedback

Page 8

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 2. Pin Assignment of J1 Header and Description of J10 Header (continued)

Pin Number Name I/O Characteristics Description

5 RXD13 HSTL output Parallel receive data output RXD13. The outputs change following

7 RXD12 HSTL output Parallel receive data output RXD12. The outputs change following

9 RXD11 HSTL output Parallel receive data output RXD11. The outputs change following

11 RXD10 HSTL output Parallel receive data output RXD10. The outputs change following

13 RXD9 HSTL output Parallel receive data output RXD9. The outputs change following RX-

15 RXD8 HSTL output Parallel receive data output RXD8. The outputs change following RX-

17 RXD7 HSTL output Parallel receive data output RXD7. The outputs change following RX-

19 RXD6 HSTL output Parallel receive data output RXD6. The outputs change following RX-

21 RXD5 HSTL output Parallel receive data output RXD5. The outputs change following RX-

23 RXD4 HSTL output Parallel receive data output RXD4. The outputs change following RX-

25 RXD3 HSTL output Parallel receive data output RXD3. The outputs change following RX-

27 RXD2 HSTL output Parallel receive data output RXD2. The outputs change following RX-

29 RXD1 HSTL output Parallel receive data output RXD1. The outputs change following RX-

31 RXD0 HSTL output Parallel receive data output RXD0. The outputs change following RX-

2, 4, 6, 8, 10,

12, 14, 16, 18,

20, 22, 24, 26,

28, 30, 32

J10 RXCLK HSTL output Receive clock output. This clock is divided by 16 of the bit-rate clock

GND Ground Ground

RXCLK↓

RXCLK↓

RXCLK↓

RXCLK↓

CLK↓

CLK↓

CLK↓

CLK↓

CLK↓

CLK↓

CLK↓

CLK↓

CLK↓

CLK↓

extracted from the received serial stream

Table 3. Pin Assignment of J2 Header and Description of J9 Header

Pin Number Name I/O Characteristics Description

1, 3, 5, 7, 9, 11,

13, 15, 17, 19,

21, 23, 25, 27,

29, 31

2 TXD15 HSTL output Parallel transmit data input TXD15. The input data is sampled by TX-

4 TXD14 HSTL input Parallel transmit data input TXD14. The input data is sampled by TX-

6 TXD13 HSTL input Parallel transmit data input TXD13. The input data is sampled by TX-

GND Ground Ground

CLKI↑

CLKI↑

CLKI↑

8

[+] Feedback

Page 9

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 3. Pin Assignment of J2 Header and Description of J9 Header (continued)

Pin Number Name I/O Characteristics Description

8 TXD12 HSTL input Parallel transmit data input TXD12. The input data is sampled by TX-

10 TXD11 HSTL input Parallel transmit data input TXD10. The input data is sampled by TX-

12 TXD10 HSTL input Parallel transmit data input TXD9. The input data is sampled by TX-

14 TXD9 HSTL input Parallel transmit data input TXD8. The input data is sampled by TX-

16 TXD8 HSTL input Parallel transmit data input TXD8. The input data is sampled by TX-

18 TXD7 HSTL input Parallel transmit data input TXD7. The input data is sampled by TX-

20 TXD6 HSTL input Parallel transmit data input TXD6. The input data is sampled by TX-

22 TXD5 HSTL input Parallel transmit data ‘input TXD5. The input data is sampled by TX-

24 TXD4 HSTL input Parallel transmit data input TXD4. The input data is sampled by TX-

26 TXD3 HSTL input Parallel transmit data input TXD3. The input data is sampled by TX-

28 TXD2 HSTL input Parallel transmit data input TXD2. The input data is sampled by TX-

30 TXD1 HSTL input Parallel transmit data input TXD1. The input data is sampled by TX-

32 TXD0 HSTL input Parallel transmit data input TXD0. The input data is sampled by TX-

J9 TXCLKI HSTL input Parallel transmit data input clock

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

CLKI↑

Table 4. Functional Description of DIP Switch 1 (SW1)

Position Name State Description

1 RESET ON* Disable Reset - Normal operation

OFF Reset for all logic functions except the transmit FIFO

2 DIAGLOOP ON Transmit data (from TXD[15:0]) is routed through the receive clock

and data recovery and presented at RXD[15:0] output

OFF* Received serial data (from IN±) is routed through the receive clock and

data recovery and presented at RXD[15:0] output

3, 4 LINELOOP,

LOOPA

ON ON Invalid setting

ON OFF Received serial data is looped back from receive input (IN±) to trans-

mit output (OUT±) after being reclocked by the recovered clock

OFF ON Received serial data is looped back from receive input (IN±) to trans-

mit output (OUT±), but is not routed through the clock and data

recovery PLL

OFF* OFF* Disable serial data loop back.

9

[+] Feedback

Page 10

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 4. Functional Description of DIP Switch 1 (SW1) (continued)

Position Name State Description

5 LOOPTIME ON The transmission will be using the extracted receive bit-clock for the

OFF* The transmission will be using the REFCLK input (155.52 MHz), which

6 LOCKREF ON* The receive PLL locks to serial data stream

OFF The receive PLL locks to the REFCLK

7 PWRDN ON* Disable Power Down - Normal Operation

OFF Enable Device Power Down mode. All the logic and drivers are dis-

8 FIFO_RST ON* Disable FIFO reset - Normal Operation

OFF Reset the transmit FIFO pointers. The in and out pointers of the trans-

Table 5. Functional Description of J4 Connector

Pin Name Description

1A, 1B, 3A, 3B VCC_OPTIC Power supply for optical module

2A, 2B, 4A, 4B GND Power ground

5A NC No Connection

5B SD SD signal from optical module

transmitted bit clock

is multiplied by 16, to generate the transmitted bit clock

abled and placed into a standby condition where only minimal power is

dissipated

mit FIFO are reset to the maximum separation

Table 6. Description of LED Indicators

LED Name LED Status Description

D1 FIFO_ERR ON The transmit FIFO has either under or overflowed. The FIFO

OFF Indicates the FIFO has neither under or overflowed

D2 LFI ON Indicates no Line Fault. It will appear to be ON even when LFI is

OFF Indicates the selected receive data stream has been detected an

must be reset to clear the error (by switching the DIP switch

SW1-8 to OFF and then ON. See Table 4 for details)

toggling. In such a case observe LFI using a scope on J7

invalid either LOW input on SD or by the receive VCO being operated outside its specified limits

10

[+] Feedback

Page 11

J7

LFI

GND

FIFO_ERR

GND

J8

CYS25G0101DX-ATC Evaluation Board User’s Guide

5A

1A

1B

5B

J5

3

2

1

RXCLK

GND

J1

Pin 1

TXCLKO

GND

J2

TXCLKI

GND

Pin 1

Figure 3. The Jumper Orientations of the CYS25G0101DX

11

[+] Feedback

Page 12

CYS25G0101DX-ATC Evaluation Board User’s Guide

5. Diagnostic Modes

The CYS25G0101DX Evaluation Board provides four different diagnostic modes—Diagnostic Loopback mode, Line Loopback

mode, Analog Loopback mode and “Parallel Line Loopback” mode. Figure 4 to Figure 7 illustrate these diagnostic modes and Figure

8 to Figure 10 illustrate the testing equipment set-up for testing the characteristics of the CYS25G0101DX.

5.1 Diagnostic Loopback Mode

In the Diagnostic Loopback mode, parallel data will loop through the input buffer, serializer, CDR block, deserializer and the output buffer. Figure 4 shows the data path (bold line) of the Diagnostic Loopback mode. To select the Diagnostic Loopback mode:

1. SW1-2 (DIAGLOOP) must be in ON position, SW1-3 (LINELOOP)

2. All other dip switches must be in their default positions as stated in Table 4

3. TEST0, jumper J6 must be opened

4. Apply the Testing Hookup illustrated in Figure 8 to Figure 10

TXCLKIN

Register

SHIFTER

LINELOOP

SW1-3 = OFF

TXD

15:0

Input

FIFO

(5byte)

TXCLK

/16

TX PLL

x16

REFCLK

RXCLKOUT

RXD

15:0

Output

Register

/16

SHIFTER

RX CDR

PLL

DIAGLOOP

(SW1-2) = ON

LOOPA

SW1-4 = OFF

OUT±

IN±

Figure 4. Diagnostic Loopback Mode Data Path

12

[+] Feedback

Page 13

CYS25G0101DX-ATC Evaluation Board User’s Guide

5.2 Line Loopback

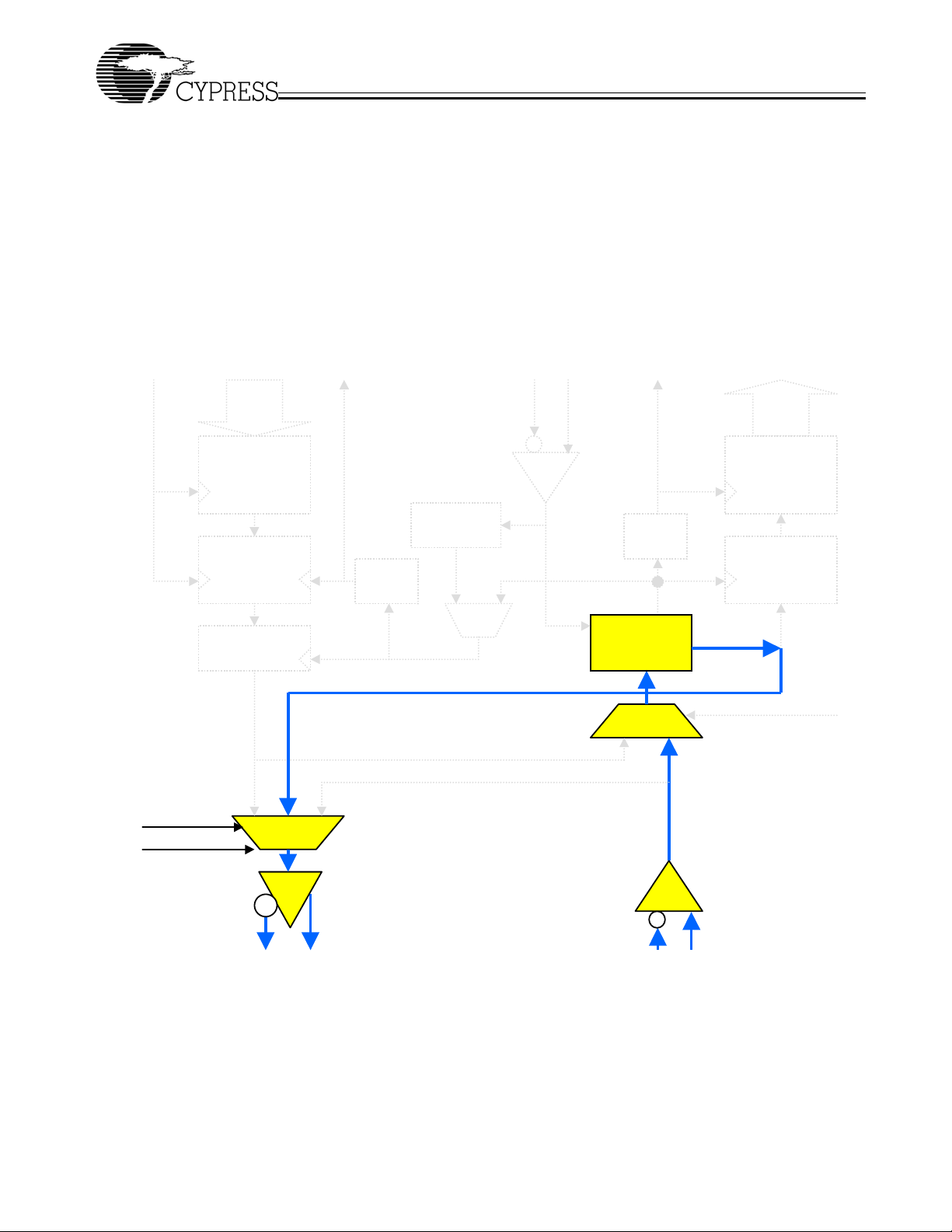

In the Line Loopback mode, serial data (from IN±) will loop through the serial input buffer and CDR block to the serial output buffer

(OUT±). Figure 5 shows the data path (bold line) of the Line Loopback mode. To select the Line Loopback mode:

1. SW1-3 (LINELOOP) must be in ON position

2. All other dip switch settings must be in their default positions as stated in Tab l e 4

3. TEST0, jumper J6 must be opened

4. Apply the Testing Hookup illustrated in Figure 8 to Figure 10

RXCLKOUTREFCLKTXCLKTXCLKIN

LINELOOP

SW1-3 = ON

TXD

15:0

Input

Register

FIFO

(5byte)

SHIFTER

/16

TX PLL

x16

RXD

15:0

Output

Register

/16

SHIFTER

RX CDR

PLL

DIAGLOOP

(SW1-2) = OFF

LOOPA

SW1-4 = OFF

OUT±

IN±

Figure 5. Line Loopback Mode Data Path

13

[+] Feedback

Page 14

CYS25G0101DX-ATC Evaluation Board User’s Guide

5.3 Analog Line Loopback

In the Analog Line Loopback mode, serial data (from IN±) will loop through directly from serial input buffer to the serial output buffer

(OUT±). Figure 6 shows the data path (bold line) of the Analog Line Loopback mode. To select the Analog Line Loopback mode:

1. SW1-4 (LOOPA) must be in ON position and SW1-3 (LINELOOP) must be in OFF position.

2. All other dip switches must be in their default positions as stated in Table 4

3. TEST0, jumper J6 must be opened

4. Apply the Testing Hookup illustrated in Figure 8 to Figure 10

RXCLKOUTREFCLKTXCLKTXCLKIN

Register

SHIFTER

LINELOOP

SW1-3 = OFF

TXD

15:0

Input

FIFO

(5byte)

/16

TX PLL

x16

RXD

15:0

Output

Register

/16

SHIFTER

RX CDR

PLL

DIAGLOOP

(SW1-2) = OFF

LOOPA

SW1-4 = ON

OUT±

Figure 6. Analog Line Loopback Mode Data Path

14

IN±

[+] Feedback

Page 15

CYS25G0101DX-ATC Evaluation Board User’s Guide

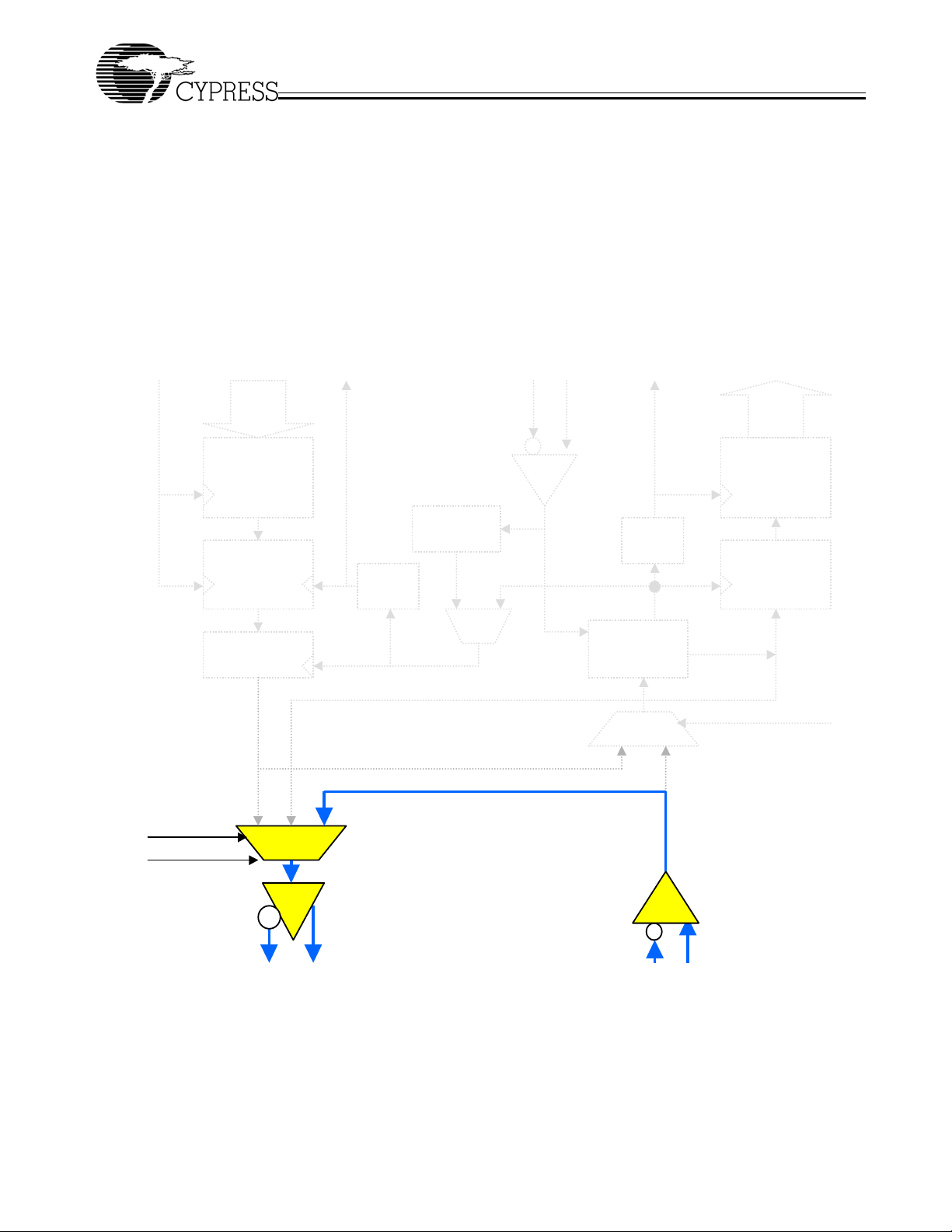

5.4 “Parallel Line Loopback” (TEST0) Mode

In Parallel Line Loopback mode, the parallel output buffe rs are internally linked to the parallel input buffers. Figure 7 shows the data

path (bold line) of the Parallel Line Loopback mode. In this test mode, the internal RX CDR PLL and TX PLL can b e tested by different

configurations.

5.4.1 Test the Internal RX CDR PLL Only

1. TEST0, jumper J6 must be shorted

2. SW1-5 (LOOPTIME) must be in ON position

3. All other dip switches must be in their default positions (see Table 4)

4. Apply the Testing Hookup illustrated in Figure 8 to Figure 10 for the measurement

5.4.2 Test the Internal RX CDR PLL and TX PLL

1. TEST0, jumper J6 must be shorted

2. All dip switches must be in their default positions (see Tabl e 4 )

3. Disconnect CLKVCC (P2), remove the 155.52-MHz oscillator, place C400 on C402 and C401 on C403 positions (see Table

1, jumpers J17 and J18 for details)

4. Apply the Testing Hookup illustrated in Figure 11 for the measurement

TXCLKIN

TXCLKIN

Register

Register

Register

SHIFTER

SHIFTER

LINELOOP

LINELOOP

SW1-3 = OFF

SW1-3 = OFF

LOOPA

LOOPA

SW1-4 = OFF

SW1-4 = OFF

TXD

TXD

15:0

15:0

Input

Input

Input

FIFO

FIFO

FIFO

(5byte)

(5byte)

(5byte)

REFCLK

TXCLK

TXCLK

TX PLL

TX PLL

x16

x16

/16

/16

JUMPER J6 (TEST0) = CLOSED

JUMPER J6 (TEST0) = CLOSED

REFCLK

RXCLKOUT

RXCLKOUT

/16

/16

RX CDR

RX CDR

PLL

PLL

RXD

RXD

15:0

15:0

Output

Output

Output

Register

Register

Register

SHIFTER

SHIFTER

DIAGLOOP

DIAGLOOP

(SW1-2) = OFF

(SW1-2) = OFF

OUT±

OUT±

Figure 7. Parallel Loopback (TEST0) Mode Data Path

15

IN±

IN±

[+] Feedback

Page 16

CYS25G0101DX-ATC Evaluation Board User’s Guide

6. Testing Hookup

6.1 Set-up for BERT Test

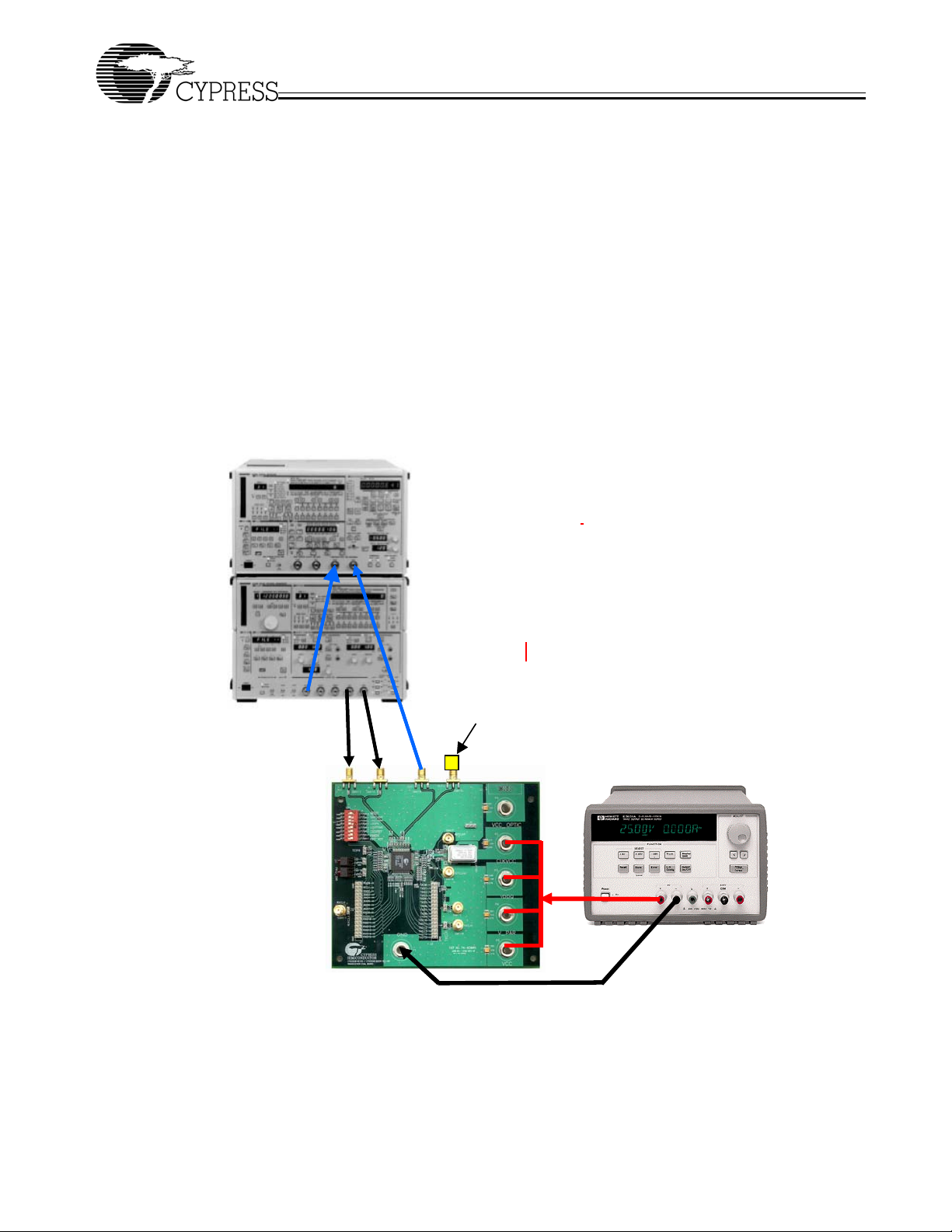

Figure 8 illustrates the set-up for the BERT test. The equipment list:

1. Evaluation Board – Cypress CYS25G0101DX Evaluation Board

2. Pattern Generator – Tektronix D3186 Pattern Generator

3. Error Detector– Tektronix D3286 Error Detector

4. Power Supply – HP E3631A DC Power Supply

* All equipment in the list is for reference only

Tektronix D3286

Pattern Analyzer

CLK2

Cypress CYS25G0101DX

Evaluation Board

Tektronix D3186

Pattern Generator

50ΩTerminator

For OUT-

IN+ IN-

Figure 8. Equipment Set-up for BERT Test

OUT-OUT+

HP E3631A

Power Supply

16

[+] Feedback

Page 17

CYS25G0101DX-ATC Evaluation Board User’s Guide

6.2 Set-up for Eye Diagram Test

Figure 9 illustrates the set-up for testing the Eye Diagram. The equipment list :

1. Evaluation Board – Cypress CYS25G0101DX Evaluation Board

2. Pattern Generator – Tektronix D3186 Pattern Generator

3. Oscilloscope – Agilent Infiniium DCA 86100A with 83484A Dual-Channel 50GHz Module

4. Power Supply – HP E3631A DC Power Supply

* All equipment in the list is for reference only

Tektronix D3186 Pattern Generator

Trigger Out

Cypress CYS25G0101DX

Evaluation Board

IN+ IN-

Agilent Infinium DAC 86100A Oscilloscope

with 8348A Dual-Channel 50GHz Module

Trigger

OUT-OUT+

HP E3631A

Power Supply

Figure 9. Equipment Set-up For Eye Diagram Test

17

[+] Feedback

Page 18

CYS25G0101DX-ATC Evaluation Board User’s Guide

6.3 SONET Jitter Transfer and Jitter Tolerance Test

Figure 10 illustrates the set-up for testing the jitter. The equipment list:

1. Evaluation Board – Cypress CYS25G0101DX Evaluation Board

2. SONET Tester – Agilent (HP) OmniBER 718 Communication Performance Analyzer

3. Optical Converters - Agilent (HP) 83446A Receiver and 83430A Transmitter

4. Power Supply – HP E3631A DC Power Supply

* All equipment in the list is for reference only

HP OmniBER 718

Communications

Performance Analyzer

Optical to Analog

Converter

(i.e. HP’s 83446A)

Cypress CYS25G0101DX

Evaluation Board

Figure 10. Equipment Set-up For Jitter Test

Analog to Optical

Converter (i.e. HP’s 83430A)

HP E3631A

Power Supply

18

[+] Feedback

Page 19

CYS25G0101DX-ATC Evaluation Board User’s Guide

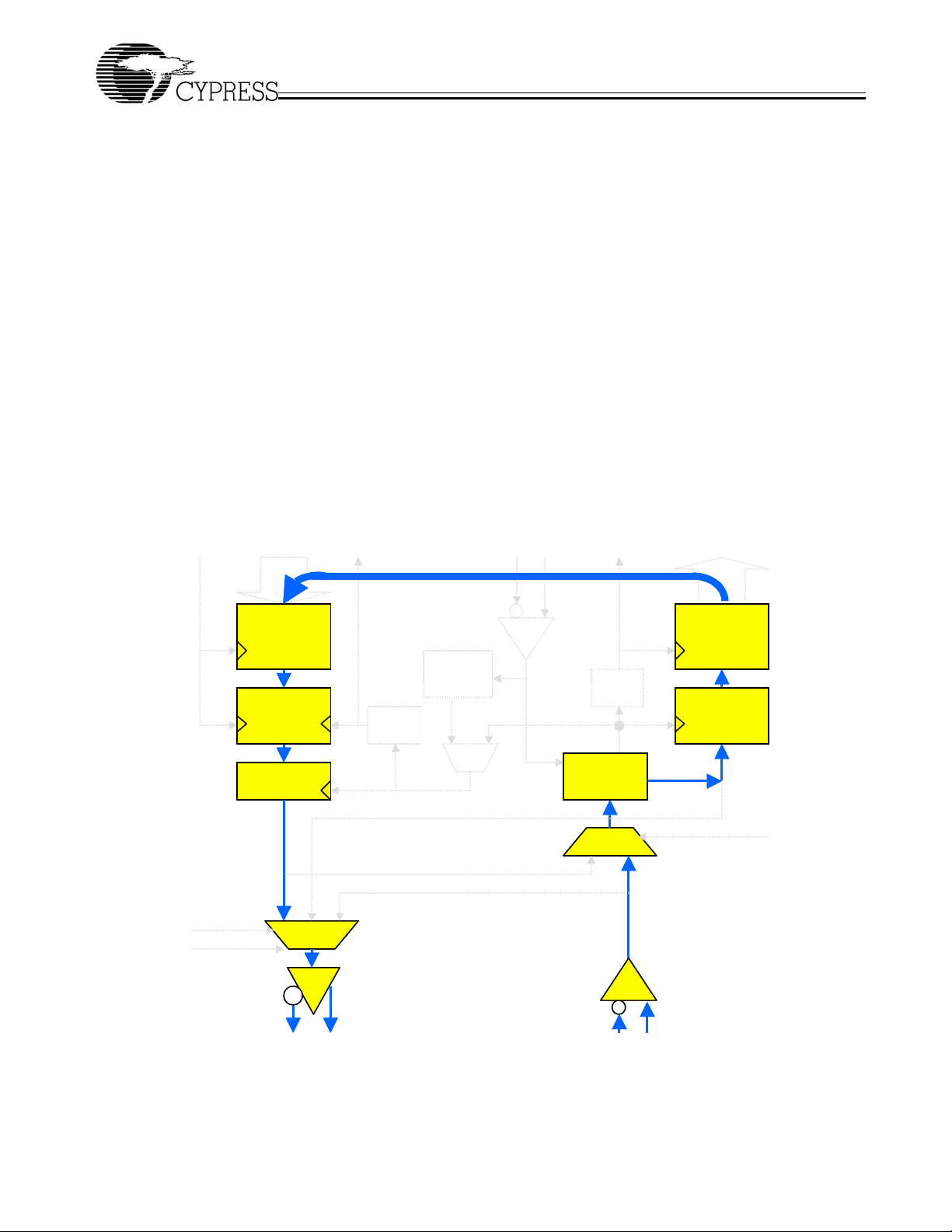

6.4 Set-up for Testing the TX PLL in Parallel Line Loopback Mode

Figure 11 illustrates the set-up for testing the TX PLL in Parallel Line Loopback Mode. The equipment list :

1. Evaluation Board – Cypress CYS25G0101DX Evaluation Board

2. Pattern Generator – Tektronix D3186 Pattern Generator

3. Error Detector– Tektronix D3286 Error Detector

4. Pulse Generator - HP 8133A Pulse Generator

5. Power Supply – HP E3631A DC Power Supply

* All equipment in the list is for reference only

Tektronix D3286

Pattern Analyzer

HP 8133A Pulse Generator

(configure to Output = Input Clock divided by 16)

CLK2

1. Disconnect CLKVCC

2. Remove the OSC

3. Place C400 on C402 and

C401 on C403 positions

Cypress CYS25G0101DX

Evaluation Board

Figure 11. Equipment Set-up For Testing the TX PLL in Parallel Line Loopback Mode

CLK1

IN+ IN-

Tektronix D3186

Pattern Generator

50ΩTerminator For OUT-

OUT-OUT+

External

External

Input

Input

Output+

Output-

HP E3631A

Power Supply

19

[+] Feedback

Page 20

CYS25G0101DX-ATC Evaluation Board User’s Guide

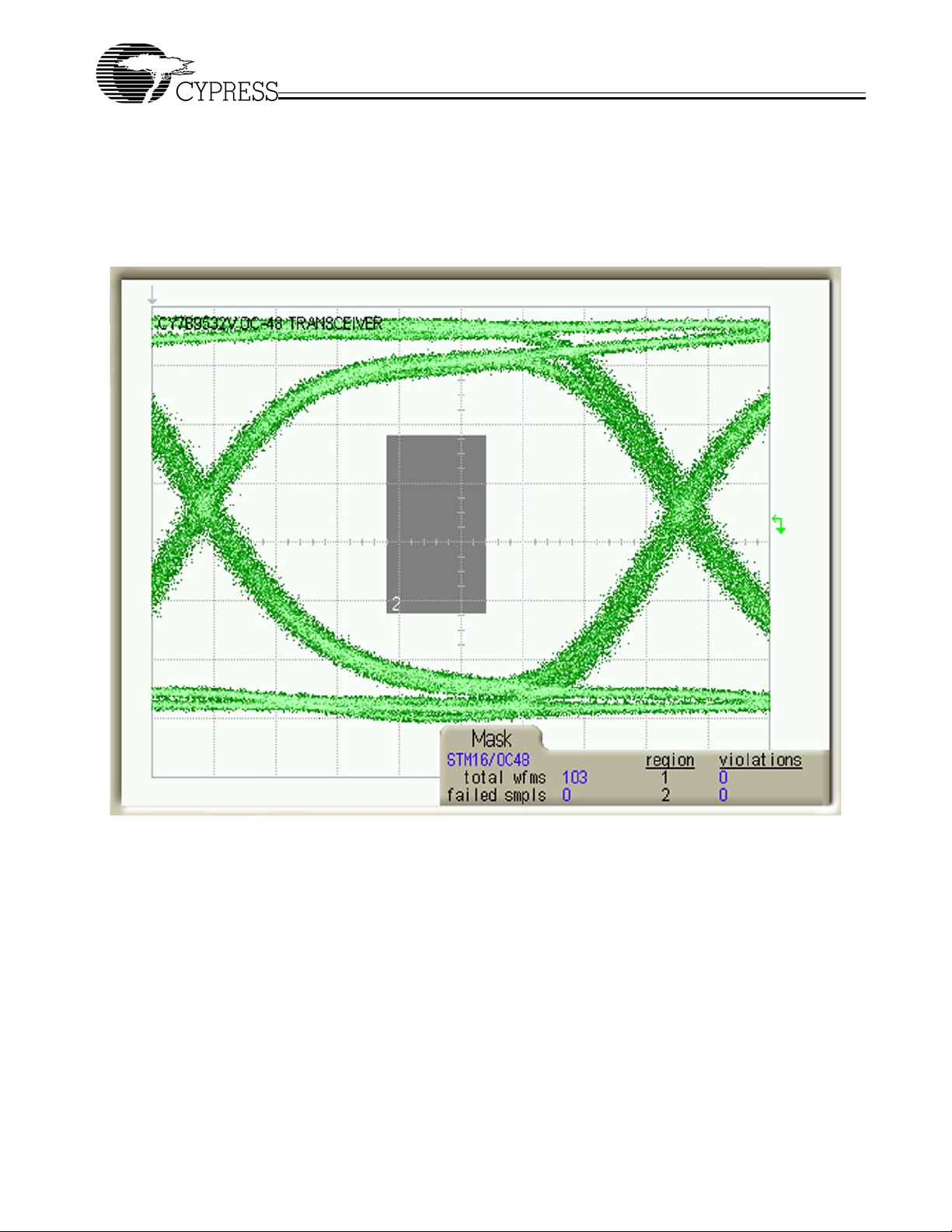

7. Eye Diagram Testing Result

Figure 12 is the Eye Diagram measurement from CYS25G0101DX Evaluati on Board by using the test set-up as in Figure 9. In this

measurement, the evaluation board is configured to parallel loop back mode (Figure 7) and with no SONET filter at the oscilloscope.

Figure 12. CYS25G0101DX Evaluation Board Eye Diagram

20

[+] Feedback

Page 21

CYS25G0101DX-ATC Evaluation Board User’s Guide

8. Jitter Transfer Testing Result

Figure 13 and Figure 14 show the Jitter Transfer measurement by using the test set-up as in Figure 10. Figure 13 is the measurement

result of the GR-253 (Bellcore) standard and Figure 14 is the measurement result of the G958 (ITU) standard. In this measurement, the

CYS25G0101DX evaluation board is configured to parallel loopback mode (Figure 7).

Figure 13. CYS25G0101DX Evaluation Board GR-253 Jitter Transfer Testing Result

Figure 14. CYS25G0101DX Evaluation Board G958 Jitter Transfer Testing Result

21

[+] Feedback

Page 22

CYS25G0101DX-ATC Evaluation Board User’s Guide

9. Jitter Tolerance Testing Result

Figure 15 and Figure 16 show the Jitter Tolerance measurement by using the test set-up as in Figure 10. Figure 15 is the measurement

result of the GR-253 (Bellcore) standard and Figure 16 is the measurement result of the G825 (ITU) standard. In this measurement, the

CYS25G0101DX evaluation board is configured to parallel loopback mode (Figure 7).

Figure 15. CYS25G0101DX Evaluation Board GR-253 JitterTolerance Testing Result

Figure 16. CYS25G0101DX Evaluation Board G825 Jitter Tolerance Testing Result

22

[+] Feedback

Page 23

CYS25G0101DX-ATC Evaluation Board User’s Guide

10. Schematic Diagram, PCB Layout and BOM (Bill of Material)

Figure 17 to Figure 23 in Appendix A shows the schematic diagram of the CYS25G0101DX evaluation board. Figure 17 is the top level

diagram for the schematic diagrams for Figure 18 to Figure 23. Figure 24 to Figure 32 in Appendix B show the PCB layout of each layer

of the CYS25G0101DX evaluation board. The Bill of Material (BOM) of the evaluation board is listed in Appendix C (for LVPECL Ta bl e

8 to Table 11) and Appendix D (for HSTL Table 12 to Table 15) respectively.

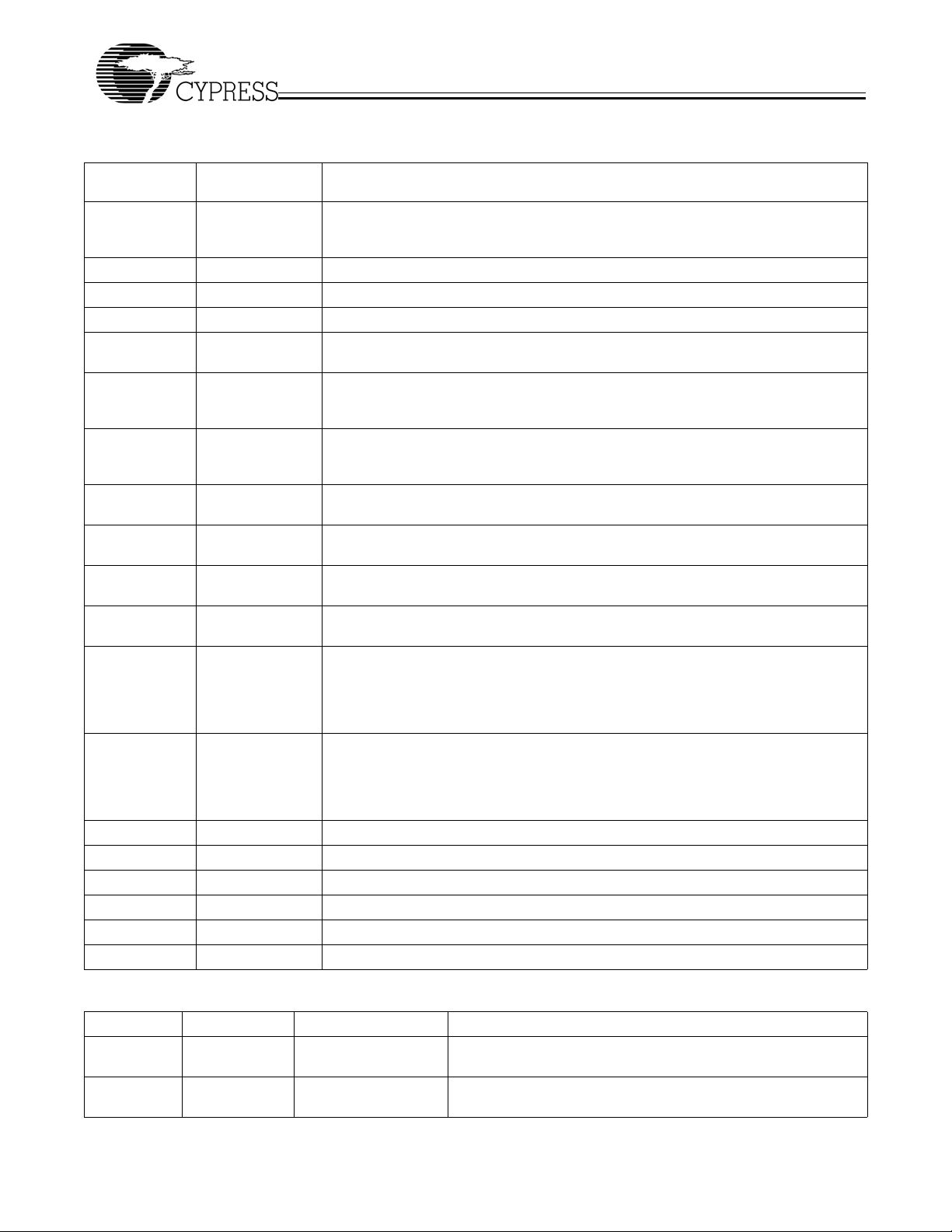

Table 7. Operation Specification of CYS25G0101DX Evaluation Board

Description Min. Max. Unit Notes

Power Supply VCC 3.135 3.465 V 1

Current I

VCC

Clock Power Supply CLKVCC 3.135 3.465 V

Current I

Notes:

1. The operation voltage VCC for the device at the power supply nodes.

2. The operation current drawn by supply VCC at room temperature.

3. Assumes onboard clock option. If external clock (SMA option) is used the current drawn will depend on the termination resistors required for

CLKVCC

the external clock.

280 320 mA 2

75 90 mA 3

23

[+] Feedback

Page 24

CYS25G0101DX-ATC Evaluation Board User’s Guide

Appendix A: Schematic Diagrams of the

CYS25G0101DX Evaluation Board

24

[+] Feedback

Page 25

CYS25G0101DX-ATC Evaluation Board User’s Guide

Power

Supply Block

Power

Supply Block

Signals Block

o

Signals Block

o

Parallel

Output Block

Parallel

Output Block

Parallel Input

Block

Parallel Input

Block

Figure 17. Top Level of CYS25G0101DX Evaluation Board Schematic Diagram

Reference

Clock Block

Reference

Clock Block

Control

Block

Control

Block

25

[+] Feedback

Page 26

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 18. Parallel Output Block Schematic Diagram

26

[+] Feedback

Page 27

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 19. Parallel Input Block Schematic Diagram

27

[+] Feedback

Page 28

CYS25G0101DX-ATC Evaluation Board User’s Guide

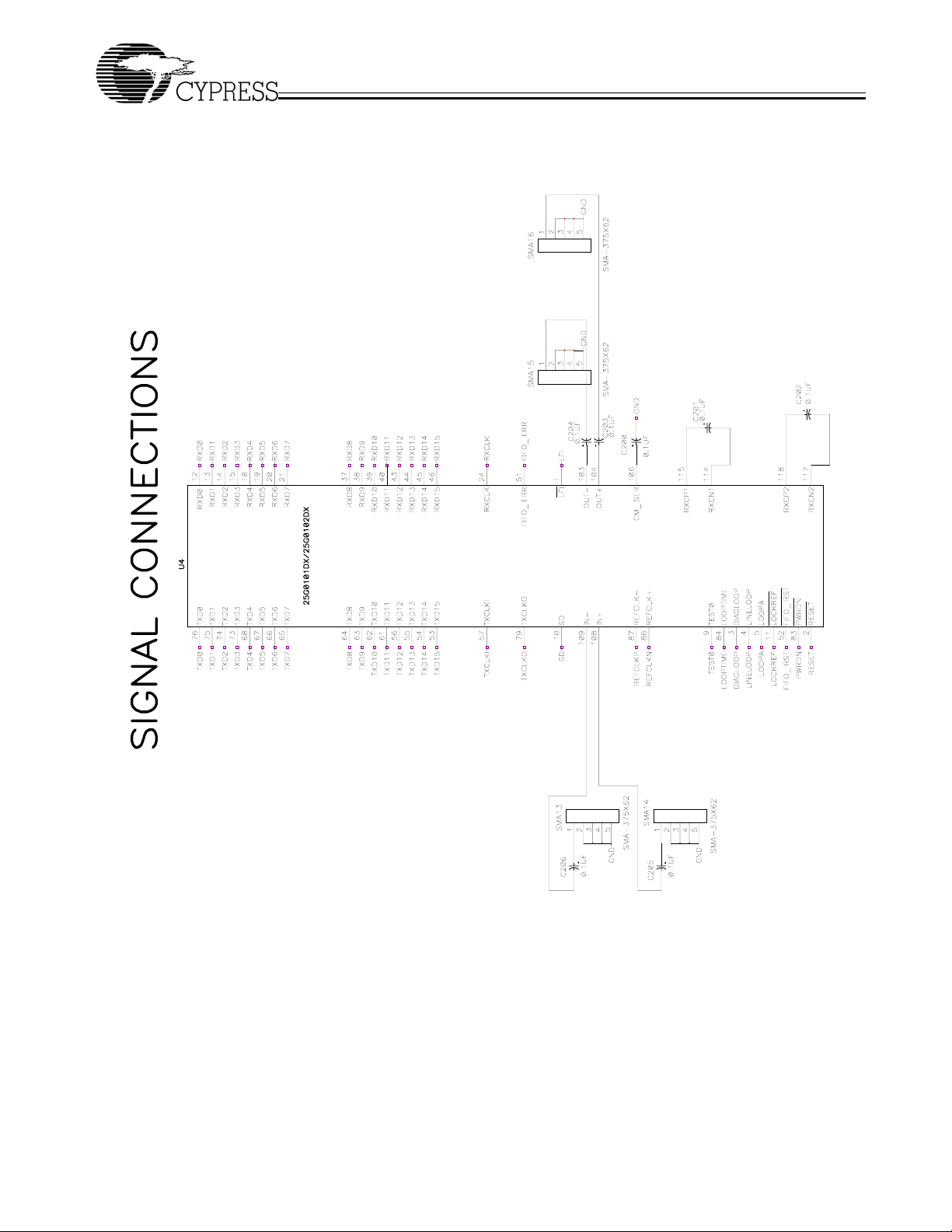

Figure 20. Signals Block Schematic Diagram

28

[+] Feedback

Page 29

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 21. Power Supply Block Schematic Diagram

29

[+] Feedback

Page 30

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 22. Control Block Schematic Diagram

30

[+] Feedback

Page 31

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 23. Reference Clock Block Schematic Diagram

31

[+] Feedback

Page 32

CYS25G0101DX-ATC Evaluation Board User’s Guide

Appendix B: PCB Layout Diagrams of the

CYS25G0101DX Evaluation Board

32

[+] Feedback

Page 33

CYS25G0101DX-ATC Evaluation Board User’s Guide

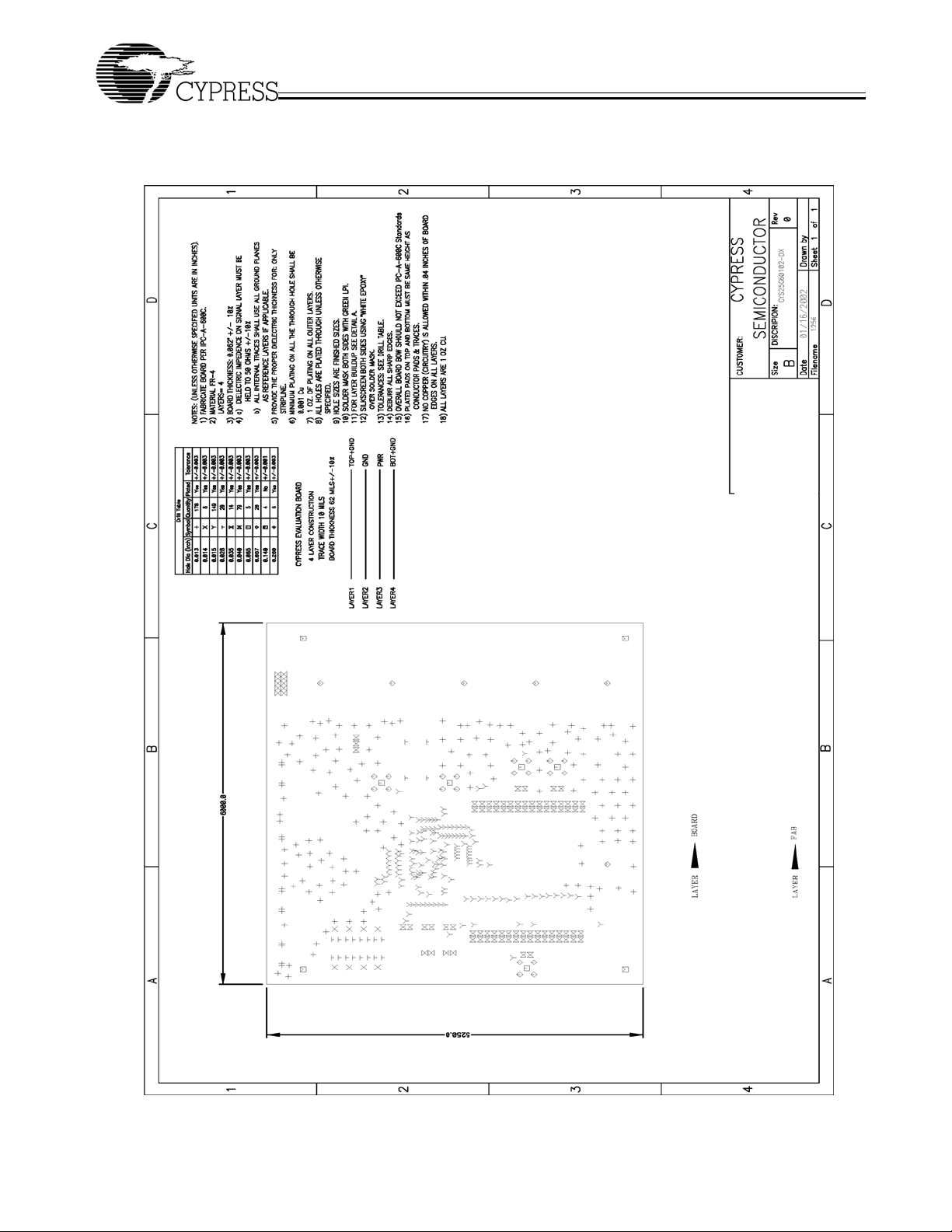

Figure 24. CYS25G0101DX Evaluation Board PCB Mechanical Drawing

33

[+] Feedback

Page 34

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 25. CYS25G0101DX Evaluation Board PCB Top Layer Silk Screen

34

[+] Feedback

Page 35

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 26. CYS25G0101DX Evaluation Board PCB Top Layer Layout

35

[+] Feedback

Page 36

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 27. CYS25G0101DX Evaluation Board PCB Top Layer Solder Mask

36

[+] Feedback

Page 37

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 28. CYS25G0101DX Evaluation Board PCB Power Plane Layout

37

[+] Feedback

Page 38

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 29. CYS25G0101DX Evaluation Board PCB Ground Plane Layout

38

[+] Feedback

Page 39

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 30. CYS25G0101DX Evaluation Board PCB Bottom Silk Screen

39

[+] Feedback

Page 40

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 31. CYS25G0101DX Evaluation Board PCB Bottom Layer Layout

40

[+] Feedback

Page 41

CYS25G0101DX-ATC Evaluation Board User’s Guide

Figure 32. CYS25G0101DX Evaluation Board PCB Bottom Solder Mask

41

[+] Feedback

Page 42

CYS25G0101DX-ATC Evaluation Board User’s Guide

Appendix C: CYS25G0101DX Evaluation

Board LVPECL BOM (Bill of Material)

42

[+] Feedback

Page 43

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 8. CYS25G0101DX Evaluation Board LVPECL BOM - Page 1 of 4

43

[+] Feedback

Page 44

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 9. CYS25G0101DX Evaluation Board LVPECL BOM - Page 2 of 4

44

[+] Feedback

Page 45

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 10. CYS25G0101DX Evaluation Board LVPECL BOM - Page 3 of 4

45

[+] Feedback

Page 46

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 11. CYS25G0101DX Evaluation Board LVPECL BOM - Page 4 of 4

46

[+] Feedback

Page 47

CYS25G0101DX-ATC Evaluation Board User’s Guide

Appendix D: CYS25G0101DX Evaluation

Board HSTL BOM (Bill of Material)

47

[+] Feedback

Page 48

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 12. CYS25G0101DX Evaluation Board HSTL BOM - Page 1 of 4

48

[+] Feedback

Page 49

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 13. CYS25G0101DX Evaluation Board HSTL BOM - Page 2 of 4

49

[+] Feedback

Page 50

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 14. CYS25G0101DX Evaluation Board HSTL BOM - Page 3 of 4

50

[+] Feedback

Page 51

CYS25G0101DX-ATC Evaluation Board User’s Guide

Table 15. CYS25G0101DX Evaluation Board HSTL BOM - Page 4 of 4

© Cypress Semiconductor Corporation, 2002. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use

of any circuitry other than circuitry embodied in a Cypress Semiconductor product. Nor does it convey or imply any license under patent or other rights. Cypress Semiconductor does not authorize

its products for use as critical components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress

Semiconductor products in life-support systems application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress Semiconductor against all charges.

[+] Feedback

Loading...

Loading...