Page 1

CY8CKIT-030 PSoC

®

3 Development

Kit Guide

Doc. # 001-61038 Rev. *A

Cypress Semiconductor

198 Champion Court

San Jose, CA 95134-1709

Phone (USA): 800.858.1810

Phone (Intnl): 408.943.2600

http://www.cypress.com

Page 2

Copyrights

Copyrights

© Cypress Semiconductor Corporation, 2011. The information contained herein is subject to change without notice. Cypress

Semiconductor Corporation assumes no responsibility for the use of any circuitry other than circuitry embodied in a Cypress

product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor

intended to be used for medical, life support, life saving, critical control or sa fety applica tions, unless pursu ant to an express

written agreement with Cypress. Furthermore, Cypress does not authorize its products for use as critical components in lifesupport systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The

inclusion of Cypress products in life-support systems application implies that the manufacturer assumes all risk of such use

and in doing so indemnifies Cypress against all charges.

Any Source Code (software and/or firmware) is owned by Cypress Semiconductor Corporation (Cypress) and is protected by

and subject to worldwide patent protection (United States and foreign), United States copyright laws and international treaty

provisions. Cypress hereby grants to licensee a personal, non-exclusive, non-transferable license to copy, use, modify, create

derivative works of, and compile the Cypress Source Code and derivative works for the sole purpose of creating custom software and or firmware in support of licensee product to be used only in conjunction with a Cypress integrated circuit as specified in the applicable agreement. Any reproduction, modification, transla tion, compilation, or representation of this Source

Code except as specified above is prohibited without the express written permission of Cypress.

Disclaimer: CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. Cypress reserves the right to make changes without further notice to the materials described

herein. Cypress does not assume any liability arising out of the applica tion or use of any product or circuit described herein.

Cypress does not authorize its products for use as critical components in life-support systems whe re a malfunction or failure

may reasonably be expected to result in significant injury to the user. The inclusion of Cypress’ product in a life-support systems application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress against all

charges.

Use may be limited by and subject to the applicable Cypress software license agreement.

®

Creator™ is a trademark and PSoC® is a registered trademark of Cypress Semiconductor Corp. All other trademarks

PSoC

or registered trademarks referenced herein are property of the respective corporations.

Flash Code Protection

Cypress products meet the specifications contained in their particular Cypress PSoC Data Sheets. Cypress believes that its

family of PSoC products is one of the most secure families of its kind on the market today, regardless of how they are used.

There may be methods, unknown to Cypress, that can breach the code protecti on features. Any of these methods, to our

knowledge, would be dishonest and possibly illegal. Neither Cypress nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not mean that we are guaranteeing the product as ‘unbreakable’.

Cypress is willing to work with the customer who is concerned about the inte grity of their code. Co de prot ection i s constantly

evolving. We at Cypress are committed to continuously improving the code protection features of our products.

2 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 3

Contents

1. Introduction 5

1.1 Kit Contents..................................... ... ... ....................................... ... ... ... .... ..................5

1.2 PSoC Creator ..............................................................................................................5

1.3 Additional Learning Resources..................... ... ... ... ... .... ... ... ... .... ... ...............................6

1.4 Document History ........................................................................................................6

1.5 Documentation Conventions .......................................................................................6

2. Getting Started 7

2.1 Introduction..................................................................................................................7

2.2 CD Installation .................................... ... ... .... ... ... ... ... .... ...................................... .... ... ..7

2.3 Install Hardware...........................................................................................................8

2.4 Install Software ............................................................................................................8

2.5 Uninstall Software........................................................................................................8

3. Kit Operation 9

3.1 Introduction..................................................................................................................9

3.2 Programming PSoC 3 Device......................................................................................9

4. Hardware 11

4.1 System Block Diagram ....................................... ....................................... ... ... ... .... ...11

4.2 Functional Description .................................. ......................................... .... ................12

4.2.1 Power Supply.................................................................................................12

4.2.1.1 Power Supply Jumper Settings........................................................14

4.2.1.2 Grounding Scheme..........................................................................14

4.2.1.3 Low Power Functionality. .... ... ... ... ... .... ... ... ... .... ... ... ... ... .... ... ... ... .......15

4.2.2 Programming Interface...................................................................................15

4.2.2.1 On-board Programming Interface....................................................15

4.2.2.2 JTAG/SWD Programming................................................................16

4.2.3 USB Communication..................... .... ... ... ... ... .... ... ... ... .... ... ... ..........................17

4.2.4 Boost Convertor.............................................................................................18

4.2.5 32-kHz and 24-MHz Crystal...........................................................................19

4.2.6 PSoC 3 Development Kit Expansion Ports....................................................19

4.2.6.1 Port D. ... ....................................... ... .... ... ... .......................................19

4.2.6.2 Port E........ ... ... ... ....................................... ... .... ... ... ..........................21

4.2.7 RS-232 Interface............................................................................................22

4.2.8 Prototyping Area ........... ... .... ... ... ... .... ... ... ....................................... ... ... ... .... ...22

4.2.9 Character LCD........................................... ... .... ... ... ... ....................................23

4.2.10 CapSense Sensors........................................................................................24

5. Example Projects 25

5.1 Voltage Display..........................................................................................................26

5.1.1 Project Description..................................... ... .... ... ... ... .... ... ... ... ... .... ... .............26

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 3

Page 4

Contents

5.1.2 Hardware Connections ..................................................................................26

5.1.3 Del-Sig ADC Configuration............................................................................26

5.1.4 Verify Output..................................................................................................27

5.2 Intensity LED...... ... ... ....................................... ... .... ...................................... ... .... ......27

5.2.1 Project Description .. ... ... .... ... ... ....................................... ... ... .... ... ...................27

5.2.2 Hardware Connections ..................................................................................27

5.2.3 Verify Output..................................................................................................28

5.3 Low Power Demonstration ........................................................... ... .... ......................28

5.3.1 Project Description .. ... ... .... ... ... ....................................... ... ... .... ... ...................28

5.3.2 Hardware Connections ..................................................................................28

5.3.3 Verify Output..................................................................................................28

5.4 CapSense Example...................................................................................................29

5.4.1 Project Description .. ... ... .... ... ... ....................................... ... ... .... ... ...................29

5.4.2 Hardware Connections ..................................................................................29

5.4.3 Verify Output..................................................................................................30

5.5 ADC and DMA-DAC Example...................................................................................31

5.5.1 Project Description .. ... ... .... ... ... ....................................... ... ... .... ... ...................31

5.5.2 Hardware Connections ..................................................................................31

5.5.3 Verify Output..................................................................................................31

A. Appendix 33

A.1 Schematic..................................................................................................................33

A.2 Board Layout......... ... .... ... ... ... ... ....................................... ... .... ... ... .............................38

A.2.1 PDC-09589 Top.............................................................................................38

A.2.2 PDC-09589 Power.........................................................................................39

A.2.3 PDC-09589 Ground.......................................................................................40

A.2.4 PDC-09589 Bottom........................................................................................41

A.3 BOM .........................................................................................................................42

4 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 5

1. Introduction

Thank you for your interest in the CY8CKIT-030 PSoC® 3 Development Kit. This kit allows you to

develop precision analog and low power designs using PSoC 3. You can design your own projects

with PSoC Creator™ or by altering sample projects prov ided with this kit.

The CY8CKIT-030 PSoC 3 Development Kit is based on the PSoC 3 family of dev ices. PSoC 3 is a

Programmable System-on-Chip™ platform for 8- and 16-bit applications. It combines precision

analog and digital logic with a high-performance CPU. With PSoC, you can create the exact

combination of peripherals and integrated proprietary IP to meet your application requirements.

1.1 Kit Contents

The PSoC 3 Development Kit contains:

■ Development board

■ Kit CD

■ Quick Start Guide

■ USB A to Mini B cable

■ 3.3 V LCD module

Inspect the contents of the kit; if you find any part missing, contact your n earest Cypress sales office

for help.

1.2 PSoC Creator

Cypress's PSoC Creator software is a state-of-the-art, easy-to-use integrated development

environment (IDE) that introduces a game-changing, hardware and software design environment

based on classic schematic entry and revolutionary embedded design methodology.

With PSoC Creator, you can:

■ Create and share user-defined, custom peripherals using hierarchical schematic design.

■ Automatically place and route select components and integrate simple glue logic, normally

located in discrete muxes.

■ Trade-off hardware and software design considerations allowing you to focus on what matters

and getting to market faster.

PSoC Creator also enables you to tap into an entire tools eco system with integrated compiler tool

chains, RTOS solutions, and prod uction programmers to support both PSoC 3 and PSoC 5.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 5

Page 6

Introduction

1.3 Additional Learning Resources

Visit www.cypress.com for additional learning resources in the form of data sheets, technical

reference manual, and application notes.

1.4 Document History

Revision

** 01/06/11 QVS Initial version of kit guide

*A 04/28/11 RKAD Updated Schematic

PDF Creation

Date

1.5 Documentation Conventions

Table 1-1. Document Conventions for Guides

Convention Usage

Courier New

Italics

[Bracketed, Bold]

File > Open

Bold

Times New Roman

Text in gray boxes Describes cautions or unique functionality of the product.

Displays file locations, user entered text, and source code:

C:\ ...cd\icc\

Displays file names and reference documentation:

Read about the sourcefile.hex file in the PSoC Designer User Guide.

Displays keyboard commands in procedures:

[Enter] or [Ctrl] [C]

Represents menu paths:

File > Open > New Project

Displays commands, menu paths, and icon names in procedures:

Click the File icon and then click Open.

Displays an equation:

2 + 2 = 4

Origin of

Change

Description of Change

6 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 7

2. Getting S tarted

2.1 Introduction

This chapter describes how to install and configure the PSoC 3 Development Kit. Chapter 3

describes the kit operation. It explains how to program a PSoC 3 device with PSoC Programmer and

use the kit with the help of an example project. To reprogram the PSoC device with PSoC Creator,

refer to the CD installation instructions for PSoC Creator. Chapter 4 details the hardware operation.

Chapter 5 provides instructions to create a simple example project. The Appendix section provides

the schematics and BOM associated with the PSoC 3 Development Kit.

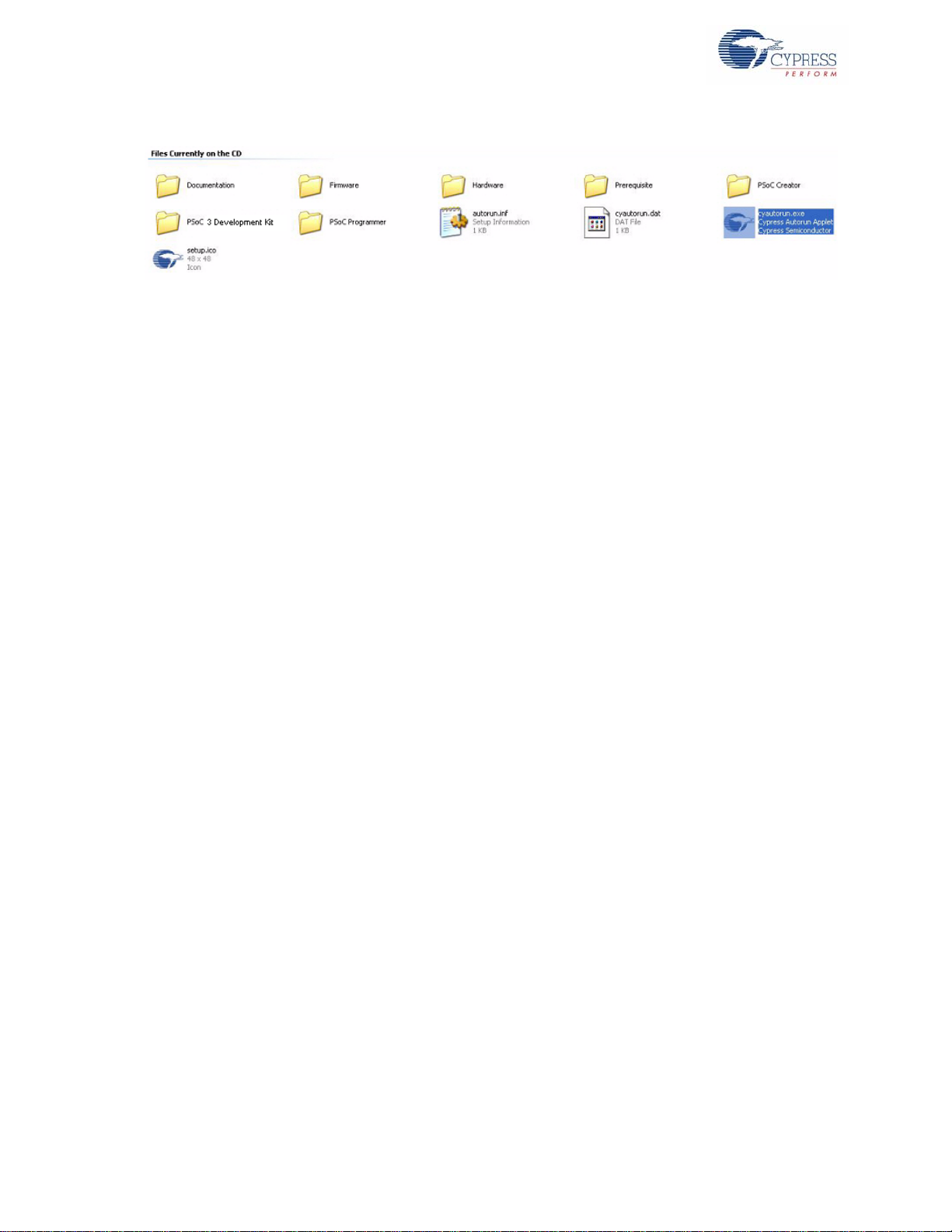

2.2 CD Installation

Follow these steps to install the PSoC 3 Development Kit software:

1. Insert the kit CD into the CD drive of your PC. The CD is designed to auto-run and the kit menu

appears.

Figure 2-1. Kit Menu

Note If auto-run does not execute, double-click AutoRun on the root directory of the CD.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 7

Page 8

Getting Started

After the installation is complete, the kit contents are available at the following location:

C:\Program Files\Cypress\PSoC 3 Development Kit\1.0

2.3 Install Hardware

No hardware installation is required for this kit.

2.4 Install Software

When installing the PSoC 3 Development Kit, the installer checks if your system has the required

software. These include PSoC Creator, PSoC Programmer, Windows Installer, .NET, Acrobat

Reader, and KEIL Complier. If these applications are not installed, then the installer prompts you to

download and install them.

Install the following software from the kit CD:

1. PSoC Creator

2. PSoC Programmer 3.12.3 or later

Note When installing PSoC Programmer, select Typical on the Installation Type page.

3. Example projects (provided in the Firmware folder)

2.5 Uninstall Software

The software can be uninstalled using one of the following methods:

■ Go to Start > Control Panel > Add or Remove Programs; select the Remove button.

■ Go to Start > All Programs > Cypress > Cypress Update Manager > Cypress Update Man-

ager; select the Uninstall button.

■ Insert the installation CD and click Install PSoC 3 Development Kit button. In the CyInstaller

for PSoC 3 Development Kit 1.0 window, select Remove from the Installation T ype drop-down

menu. Follow the instructions to uninstall.

8 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 9

3. Kit Operation

3.1 Introduction

The example projects in the PSoC 3 Development Kit help you develop precision analog

applications using the PSoC 3 family of devices. The board also has hooks to enable low power

measurements for low power application development and evaluation.

3.2 Programming PSoC 3 Device

The default programming interface for the board is a USB based on-board programming interface.

To program the device, plug the USB cable to the programming USB connector J1, as shown in the

following figure.

Figure 3-1. Connect USB Cable to J1

When plugged in, the board enumerates as DVKProg. After enumeration, initiate, build, and then

program using PSoC Creator.

When using on-board programming, it is not necessary to power the board from the 12-V or 9-V DC

supply or a battery. The USB power to the programming section can be used.

If the board is already powered from another source, plugging in the programming USB does not

damage the board.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 9

Page 10

Kit Operation

The PSoC 3 device on the board can also be programmed using a MiniProg3 (CY8CKIT-002). To

use MiniProg3 for programming, use the connector J3 on the board as shown in the following figure.

Note The MiniProg3 (CY8CKIT-002) is not part of the PSoC 3 Development Kit contents. It can be

purchased from the Cypress Online Store.

Figure 3-2. Connect MiniProg

With the MiniProg3, programming is similar to the on-board programmer; however, the setup

enumerates as a MiniProg3.

10 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 11

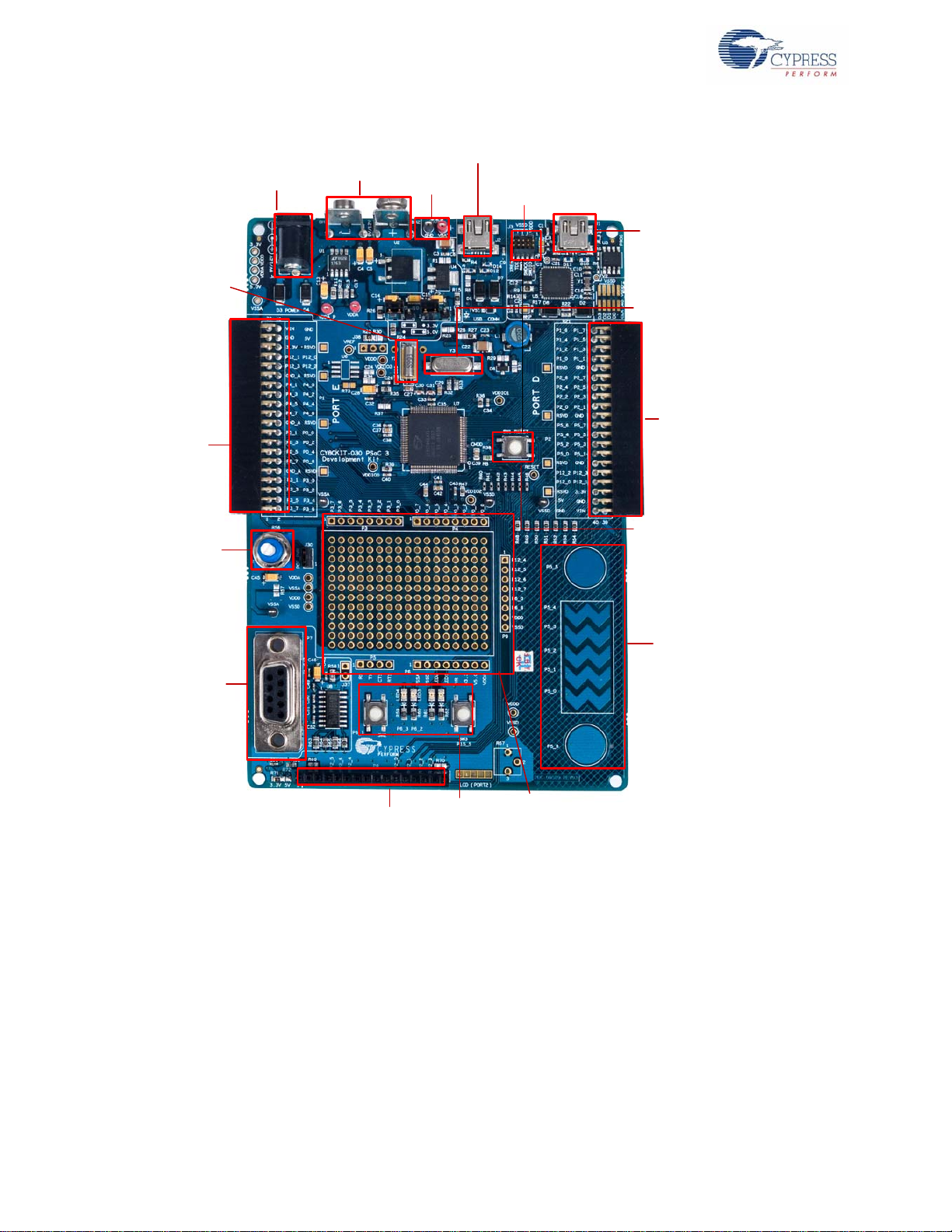

4. Hardware

4.1 System Block Diagram

The PSoC 3 Development Kit has the following sections:

■ Power supply system

■ Programming interface

■ USB communications

■ Boost convertor

■ PSoC 3 and related circuitry

■ 32-kHz crystal

■ 24-MHz crystal

■ Port E (analog performance port) and port D (CapSense

■ RS232 communications interface

■ Prototyping area

■ Character LCD interface

■ CapSense buttons and sliders

®

or generic port)

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 11

Page 12

Hardware

Power Adapter

9V Battery

Boost Converter

Input

Communication USB

10-Pin JTAG/SWD/SWO

Debug and Prog Header

On-Board

Programming

USB

24 MHz Crystal

Port D

(CapSense/

Miscellaneous

Port)

32 kHz Crystal

Port E

(Analog Port)

Variable

Resistor/

Potentiometer

RS-232

Interface

Character LCD Interface

Switches/LEDs

Prototyping Area

CapSense

RESET Button

Figure 4-1. PSoC 3 Development Kit Details

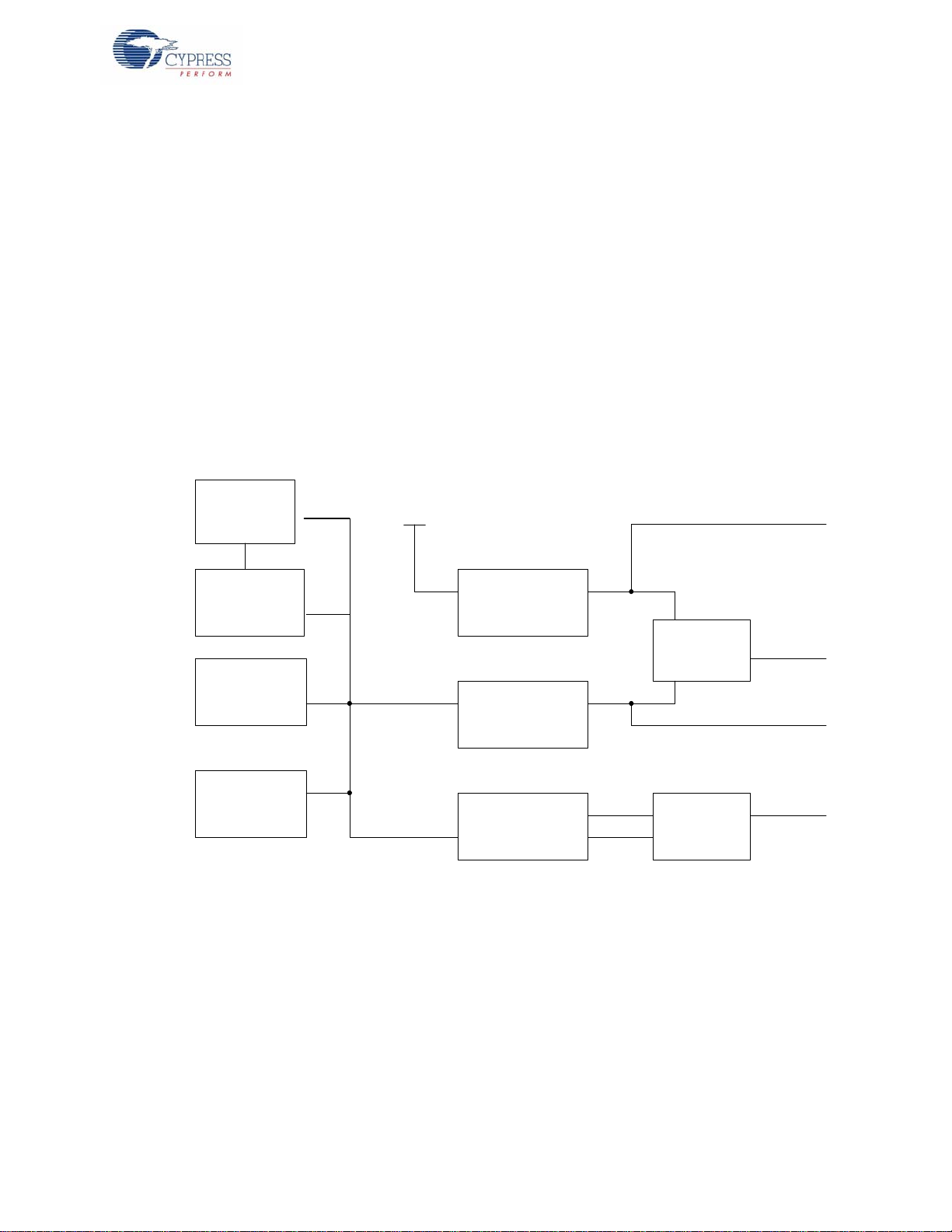

4.2 Functional Description

4.2.1 Power Supply

The power supply system on this board is versatile; input supply can be from the following sources:

■ 9-V or 12-V wall wart supply using connector J4

■ 9-V battery connector using connectors BH1 and BH2

■ USB power from communications section using connector J2

■ USB power from the on-board programming section using connector J1

■ Power from JTAG/SWD programming interface using connector J3

■ Power through boost convertor that uses the input test points VBAT and GND

12 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 13

Hardware

3.3-V Regulator

5-V Regulator

5-V/3.3-V Analog

Regulator

USB

Commu nication

Power

9-V Battery

12-V/9-V Wall

wart

Vin

Vddd

Selection

(J10)

Vdda

Selection

(J11)

3.3 V

Vddd

5 V

Vdda

USB

Programming

5 V

The board power domain has five rails:

■ Vin rail: This is where the input of the on-board regulators are connected. This domain is

powered through protection diodes.

■ 5-V rail: This is the output of the 5-V regulator U2. The rail is a fixed 5 V output regardless of

jumper settings. The voltage in this rail can be less than 5 V only when the board is powered by

the USB. This 5-V rail powers the circuits that require fixed 5 V supply.

■ 3.3-V rail: This is the output of the 3.3-V regulator U4. This rail remains 3.3 V regardless of

jumper settings or power source changes. It powe rs the circui t s requ iring fixed 3.3 V supply such

as the on-board programming section.

■ Vddd rail: This rail provides power to the digital supply for the PSoC device. It can be derived

from either the 5 V or 3.3 V rail. The selection is made using J10 (3-pin jumper).

■ Vdda rail: This rail provides power to the analog supply of the PSoC device. It is the output of a

low noise regulator U1. The regulator is a variable output voltage and can be either 3.3 V or 5 V.

This is done by changing the position on J11 (3-pin jumper).

The following block diagram shows the structure of the power system on the board.

Figure 4-2. Power System Structure

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 13

Page 14

Hardware

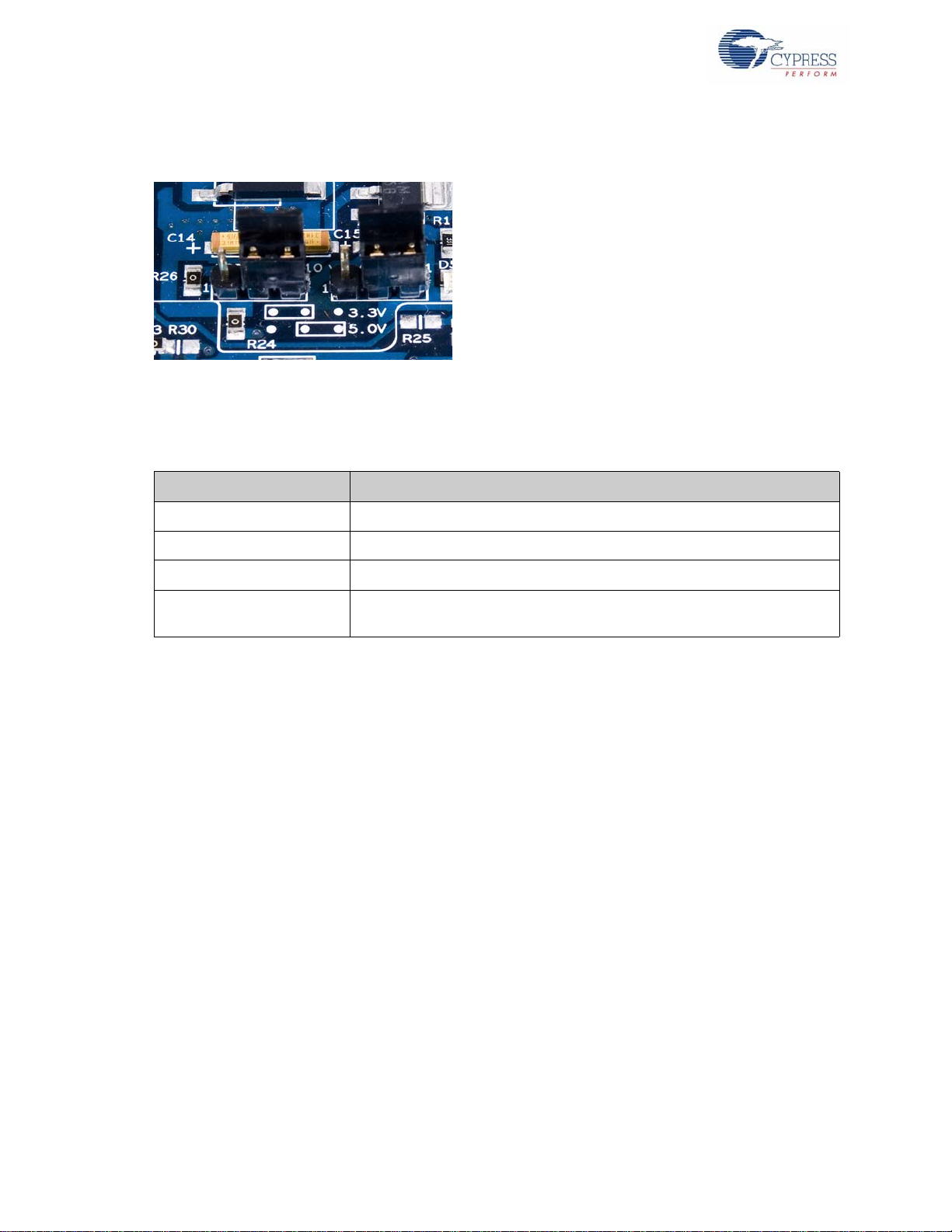

4.2.1.1 Power Supply Jumper Settings

Figure 4-3. Jumper Settings

Two jumpers govern the power rails on the board. J10 is responsible for the selection of Vddd (digital

power) and J11 selects Vdda (analog power).

The jumper settings for each power scheme are as follows.

Powering Scheme Jumper Settings

Vdda = 5 V, Vddd = 5 V J10 in 5 V setting and J11 in 5 V setting.

Vdda = 3.3 V, Vddd = 3.3 V J10 in 3.3 V setting and J11 in 3.3 V setting.

Vdda = 5 V, Vddd = 3.3 V J10 in 3.3 V setting and J11 in 5 V setting.

Vdda = 3.3 V, Vddd = 5 V

Warning:

■ The PSoC device performance is guaranteed when Vdda is greater than or equal to Vddd. Fail-

ure to meet this condition can have implications on the silicon performance.

■ When USB power is used, ensure a 3.3 V setting on both analog and digital supplies. This is

because, the 5 V rail of the USB power is not accurate and is not recommended.

4.2.1.2 Grounding Scheme

The board is designed considering analog designs as major target applications. Therefore, the

grounding scheme in the board is unique to ensure precision analog performance.

There are three types of ground on this board:

■ GND - This is the universal ground where all the regulators are referred. Both Vssd and Vssa

connect to this ground through a star connection.

■ Vssd - This is the digital ground and covers the digital circuitry present on the board, such as

RS232 and LCD.

■ Vssa - This is the analog ground and covers the grounding for analog circuitry present on the

board, such as the reference block.

Can be achieved, but is an invalid condition because the PSoC 3 silicon

performance cannot be guaranteed.

When creating custom circuitry in the prototyping area provided on the board, remember to use the

Vssa for the sensitive analog circuits and Vssd for the digital ones.

Port E on the board is the designated analog expansion connector. This connector brings out

ports 0, 3, and 4, which are the best performing analog ports on PSoC 3 and PSoC 5 devices. The

expansion connector, port E, has two types of grounds. One is the analog ground (GND_A in silk

14 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 15

screen, Vssa in the schematic), which connects directly to the analog ground on the board. The

other ground known simply as GND, is used for the digital and high current circuitry on the

expansion board. This differentiation on the connector grounds helps the expansion board designer

to separate the analog and digital ground on any high precision analog boards being designed for

port E.

4.2.1.3 Low Power Functionality

The kit also facilitates application development, which requires low power consumption. Low power

functions require a power measurement capability, also available in this kit.

The analog supply is connected to the device through the zero-ohm resistor (R23). By removing this

resistor and connecting an ammeter in series using the test points, Vdda_p and Vdda, you can

measure the analog power used by the system.

The digital supply can be monitored by removing connection on the jumper J10 and connecting an

ammeter in place of the short. This allows to measure the digital power used by the system.

The board provides the ability to measure analog and digital power separately. T o measure power at

a single point, rather than at analog and di git al sep ar ately, remove the resistor R23 to disconnect the

analog regulator from powering the Vdda and short Vdda and Vddd through R30. Now, the net

power can be measured at the J10 jumper similar to the digital power measurement. To switch

repeatedly between R23 and R30, moving around the zero-ohm resistors can be discomforting.

Hence, a J38 (unpopulated) is provided to populate a male 3 -pi n he ader a nd h ave a shor tin g jum per

in the place of R23/R30.

Hardware

While measuring device power, make the following changes in the board to avoid leakage through

other components that are connected to th e device power rails.

■ Disconnect the RS232 power by disconnecting R58. An additional jumper capability is available

as J37 if you populate it with a 2-pin male header.

■ Disconnect the potentiometer by disconnecting J30.

■ Ground the boost pins if boost operation is not used by po pulating R1, R28, and R29. Also make

sure R25 and R31 are not populated.

4.2.2 Programming Interface

This kit allows programming in two modes:

■ Using the on-board programming interface

■ Using the JTAG/SWD programming interface that uses a MiniProg3

4.2.2.1 On-board Programming Interface

The on-board programmer interfaces with your PC through a USB connector marked as USB

programming.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 15

Page 16

Hardware

Figure 4-4. On-board Programming Interface

When the USB programming is plugged into the PC, it enumerates as DVKProg and you can use the

normal programming interface from PSoC Creator to program this board through the on-board

programmer.

A zero-ohm resistor R9 is provided on the board to disconnect power to the on-board programme r.

4.2.2.2 JTAG/SWD Programming

Apart from the on-board programming interface, the board also provides the option of using the

MiniProg3. This interface is much faster than the on-board program interface. The JTAG/SWD

programming is done through the 10-pin connector, J3.

16 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 17

Figure 4-5. JTAG/SWD Programming

Hardware

The JTAG/SWD programming using J3 requires the MiniProg3 programmer, which can be

purchased from http://www.cypress.com.

4.2.3 USB Communication

The board has a USB communications interface that uses the connector, as shown in Figure 4-6.

The USB connector connects to the D+ and D– lines on the PSoC to enable development of USB

applications using the board. This USB interface can also supply power to the board as di scussed in

Power Supply on page 12.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 17

Page 18

Hardware

Figure 4-6. USB Interface

4.2.4 Boost Convertor

The PSoC 3 device has a unique capability of working from a voltage supply as low as 0.5 V. This is

possible using the boost convertor. The boost convertor uses an external inductor and a diode.

These components are pre-populated on the board. Figure 4-7 shows the boost convertor.

To enable the boost convertor functionality, make the following hardware changes on the board.

■ Populate resistors R25, R27, R29, and R31

■ Ensure that R1 and R28 are not populated

After making these changes, you can make a boost convertor based design by making the

appropriate configurations in the project. The input power supply to the boost convertor must be

provided through the test points marked Vbat and GND.

18 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 19

Figure 4-7. Boost Converter

Hardware

4.2.5 32-kHz and 24-MHz Crystal

PSoC 3 has an on-chip Real Time Clock (RTC), which can function in sleep. This requires an

external 32-kHz crystal, which is provided on board to facilitate RTC based designs. The PSoC 3

also has an option for an external MHz crystal in applications where the IMO tolerance is not

satisfactory. In these applications, the board has a 24-MHz crystal to provide an accurate main

oscillator.

4.2.6 PSoC 3 Development Kit Expansion Ports

The PSoC 3 Development Kit has two expansion ports, Port D and Port E, each with their own

unique features.

4.2.6.1 Port D

This is the miscellaneous port on the board. It is designe d to handle CapSense based application

boards and digital application boards. The signal routing to this port adheres to the stringent

requirements posed to provide good performance CapSense. This port can also be used for other

functions and Expansion Board Kits (EBKs).

This port is not designed for precision analog performance. The pins on the port are functionally

compatible to port B of the PSoC Development Kit. So any project made to function on port B of the

PSoC Development Kit can be easily ported over to port D on this board. A caveat to this is that

there is no opamp available on this port; therefore, opamp based designs are not recommended for

use on this port.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 19

Page 20

Hardware

The following figure shows the pin mapping for the port.

Figure 4-8. Port D

20 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 21

4.2.6.2 Port E

This is the analog port on this kit and has special layout considerations. It also brings out all analog

resources such as dedicated opamps to a single connect. Therefore, this port is ideal for precision

analog design development. This port is functionally compatible to port A of the PSoC Development

Kit and it is easy to port application developed on port A.

There are two types of grounds on this port, CGND1 and CGND2. The two grounds are conne cted to

the GND on the board, but are provided for expansion boards desig ned for analog performance. The

expansion boards have an analog and digital ground. The two grounds on this port help to keep it

distinct even on this board until it reaches the GND plane.

Figure 4-9. Port E

Hardware

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 21

Page 22

Hardware

4.2.7 RS-232 Interface

The board has an RS-232 transceiver on board for designs using RS-232 (UART). The RS-232

section power can be disconnected through a single resistor R58. This is useful for low-power

designs.

Figure 4-10. RS-232 Interface

4.2.8 Prototyping Area

The prototyping area on the board has two complete ports of the device for simple custom circuit

development. The ports in the area are port 0 and port 3, which bring out the four dedicated opamp

pins on the device. Therefore, these ports can be used with the prototyping area to create simple yet

elegant analog designs. It also brings SIOs such as port 12[4], port 12[5], port 12[6], and port 12[7]

and GPIOs such as port P6[0] and port P6[6]. There is power and ground connections close to the

prototyping space for convenience.

The area also has four LEDs and two switches for applications development. The two switches on

the board are hard-wired to port 15[5] and port 6[1]. Two LEDs out of the four are hard-wired to port

6[2] and port 6[3] and the other two are brought out on pads closer to the prototyping area.

22 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 23

Figure 4-11. Prototyping Area

Hardware

This area also comprises of a potentiometer to be used for analog system development work. The

potentiometer connects from Vdda, whic h is a n o ise free supply and is hence capable of being used

for low noise analog applications. Potentiometer output is available on P6[5] and VR o n header P6 in

prototyping area.

4.2.9 Character LCD

The kit has a character LCD module, which goes into the character LCD header, P8. The LCD runs

on a 3.3-V supply and can function regardless of the voltage on which PSoC is powered. There is a

zero-ohm resistor setting available on the LCD section (R71/72), making it possible to convert it to a

3.3 V LCD.

CAUTION: When the resistor is shifted to support a 5 V LCD module, plugging in a 3.3 V LCD mod-

ule into the board can damage the LCD module.

Figure 4-12. Pin 1 Indication

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 23

Page 24

Hardware

Figure 4-13. LCD Connected on P8 Connector

4.2.10 CapSense Sensors

The board layout has considered the special requirements for CapSense. It has two CapSense

buttons and a 5-element CapSense slider. The CapSense buttons are connected to pins P5[6] and

P5[5]. The slider elements are connected to pins P5[0:4].

The Cmod (modulation capacitor) is connected to pin P6[4] and an optional Rb (bleeder resistor) is

available on P15[4].

Figure 4-14. CapSense Sensors

24 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 25

5. Example Projects

To access example projects described in this section, open the PSoC Creator start page. For

additional example projects, visit http://www.cypress.com.

Figure 5-1. PSoC Creator Start Page

Follow these steps to open and program example projects:

1. Click on Example Projects from Kits and Solutions on the PSoC Creator Start page.

2. Create a folder in the desired location and click OK.

3. The project opens in PSoC Creator and is saved to that folder.

4. Build the example project to generate the .hex file.

5. To program the example projects, power the board us ing the instructions in On-board Program-

ming Interface on page 15.

6. Click the Program icon to program the board.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 25

Page 26

Example Projects

5.1 Voltage Display

5.1.1 Project Description

This example code measures a simple analog voltage controlled by the potentiometer. The code

uses the internal Delta-Sigma ADC configured for a 20-bit operation; the ADC range is 0 to Vdda.

The voltage measurement resolution is in microvolts. The results are displayed on the character

LCD module.

Note The PSoC 3 Development Kit is factory-programmed with the Voltage Display example

project.

5.1.2 Hardware Connections

The example requires the character LCD on P8. Because it uses the potentiometer, the jumper

POT_PWR should be in place. This connects the potentiometer to the Vdda.

5.1.3 Del-Sig ADC Configuration

Figure 5-2. Delta-Sigma ADC Configuration

The Del-Sig ADC is configured as follows:

■ Continuous mode of operation is selected because the ADC scans only one channel.

■ Conversion rate is set to 187 samples/sec, which is the maximum sample rate possible at 20-bit

resolution.

■ Range is set to Vssa to Vdda in single ended mode because the potentiometer ou tp ut is a single

ended signal that can go from 0 to Vdda. Therefore, at 20-bit resolution, the ADC will resolve in

steps of Vdda/2

26 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

20

.

Page 27

5.1.4 V erify Output

Build and program the example project and reset the device. The LCD shows the voltage reading

corresponding to the voltage on the potent iometer. Figure 5-3 demonstrates the functionality. When

you turn the potentiometer, the voltage value changes. You can also verify the voltage on the

potentiometer using a precision multimeter.

Note The potentiometer connects to a differential ADC, which works in single-ended mode. This

means the ADC input is measured against internal Vssa. Any offset in the measurement can be

positive or negative. This can result in a small offset voltage, even when the potentiometer is zero.

Figure 5-3. Voltage Display

Example Projects

5.2 Intensity LED

5.2.1 Project Description

This example code uses a pulse width modulator ( PWM) to illumin ate an LED. When the pul se wid th

of the PWM varies, the LED brightness changes. By continuously varying the pulse width of the

PWM, the example code makes an LED go from low brightness to a high brightness and back.

5.2.2 Hardware Connections

No hardware connections are required for this project, because all the connectio ns ar e ha rd wired to

specific pins on the board.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 27

Page 28

Example Projects

5.2.3 V erify Output

When the example code is built and programmed into the device, reset the device by pressing the

RESET button or power cycling the board.

The project output is LED3 glowing with a brightness control that changes with time (see Figure 5-4).

Figure 5-4. Verify Output - Example Project

5.3 Low Power Demonstration

5.3.1 Project Description

This example project demonstrates the low power functionality of PSoC 3. The project implements

an RTC based code, which goes to sleep and wakes up on the basis of switch input s.

The RTC uses an accurate 32-kHz clock generated using the external cryst al provid ed on the boar d.

When there is a key press, the device is put to sleep while the RTC is kept active.

5.3.2 Hardware Connections

The project requires a 3.3 V LCD to view the time display. No extra connections are required for

project functionality. To make low power measurements using this project, refer and implement the

changes proposed in Low Power Functionality on page 15.

5.3.3 V erify Output

In normal operation, the project displays the time star ting from 00:00:00. When you press the SW2

button, the device is put to sleep. If an ammeter is connected to measure the system current (refer

Low Power Functionality on page 15 for details), a system current of less than 2 µA is displayed.

The device wakes up when SW2 is pressed again and displays the time on the LCD. The following

figures show the output display.

28 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 29

Figure 5-5. PSoC 3 in Active Mode

Figure 5-6. PSoC 3 in Sleep Mode

Example Projects

5.4 CapSense Example

5.4.1 Project Description

This example project provides a platform to build CapSense based projects using PSoC 3. The

example uses two CapSense buttons and one 5-element slider provided on the board. Each

capacitive sensor on the board is scanned using the Cypress CSD algorithm. The buttons are pretuned in the example code to take care of factors such as board parasitic.

5.4.2 Hardware Connections

This project uses the LCD for display; therefore, ensure that it is plugged into the port. There ar e no

specific hardware connections required for this project because all connections are hard wired on

the board.

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 29

Page 30

Example Projects

5.4.3 V erify Output

Build and program the example project and reset the device. The LCD displays the status of the two

buttons as ON/OFF . The LCD also shows the slider touch position as a percentage. When you touch

either of the buttons, the corresponding button's state changes on the LCD. When the slider is

touched, the corresponding finger posit io n is displa ye d as a pe rc en tage on the LCD.

Figure 5-7. CapSense Slider

Figure 5-8. CapSense Button

30 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 31

5.5 ADC and DMA-DAC Example

5.5.1 Project Description

This project demonstrates sine wave generation by using an 8-bit DAC and DMA. The sine wave

period is based on the current value of the ADC value of the potentiometer.

The firmware reads the voltage output by the board potentiometer and displays the raw counts on

the board character LCD display. An 8-bit DAC outputs a table generated sine wave to an LED using

DMA at a frequency proportional to the ADC count.

5.5.2 Hardware Connections

For this example, the character LCD must be installed on P8. The example uses the potentiometer;

therefore, the jumper POT_PWR should also be in place. This jumper connects the potentiometer to

the Vdda.

5.5.3 V erify Output

Build, program the device, and press the Reset button on the PSoC 3 Development Kit to see the

ADC output displayed on the LCD. LED4 is an AC signal output whose period is based on the ADC.

Turning the potentiometer results in LCD value change. This also results in change in the period of

the sine wave fed into LED4, which can also be observed.

Example Projects

Figure 5-9. ADC Output

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 31

Page 32

Example Projects

32 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 33

A. Appendix

VSSA

VSSD

Note:

For 5V: J11-3 to J11-2, J10-3 to J10-2

For 3.3V: J11-2 to J11-1, J10-2 to J10-1

For 5V Analog,3.3V Digital: J11-3 to J11-2, J10-2 to J10-1

5.0V/1A LDO

3.3V/0.8A LDO

+9V/+12V, 1A

9V Battery

Terminals

VSSB

GND

Power Supply

VSSA

NO LOAD

VSSD

GND

GND

GND

GND

GND

5V/3.3V/0.5A LDO

GND

NO LOAD

GND

Note: Load R30 when either

Analog and Digital regulator required

VSSD

NO LOAD

VSSA

VDDA_P

RED

VSSD

NO LOAD

VSSA

VSSD

NO LOAD

GND GND

NO LOAD

VBAT

GND

Note: Load R25, R29 and R31 for operating the device on Boost

Note: Load R1,R28 and Un-Load R27 for low power application

NO LOAD

Internal Boost Regulator

NO LOAD

VSSB

NO LOAD

GND

SEL3V3

SENSE

SENSE

SEL3V3

VDDA_P

Ind

Vboost

VDDA

VDDD

V3.3

VDDD

V5.0

V5.0

VDDA

VIN

V3.3

V5.0

VDDD

VDDA

V5.0

VDDA

VBAT

VDDD

0805

R29

0805

R29

0805

R31

0805

R31

0805

R28

0805

R28

SOT23

D6

ZHCS

SOT23

D6

ZHCS

TO-252

U2

AP1117D50G

TO-252

U2

AP1117D50G

GND

1

VOUT

2

VIN

3

0402

C23

0.1 uFd

0402

C23

0.1 uFd

0805

R25

0805

R25

7032

L1

22 uH

7032

L1

22 uH

0805

R26

ZERO

0805

R26

ZERO

1 2

0805

D5

LED Green

0805

D5

LED Green

21

0603

R13

3.74K

0603

R13

3.74K

12

D-64

D4

SS12-E3/61T

D-64

D4

SS12-E3/61T

2 1

J11J11

11223

3

J4

POWER JACK P-5

J4

POWER JACK P-5

1

2

3

SOT-223

U4

LM1117MPX-3.3

SOT-223

U4

LM1117MPX-3.3

GND

1

VOUT

2

VIN

3

TAB

4

J33J33

1

1

9V

BH1

BAT 9V MALE

9V

BH1

BAT 9V MALE

NEG1

1

NEG2

2

NEG3

3

0805

R15

330 ohm

0805

R15

330 ohm

12

D-64

D3

SS12-E3/61T

D-64

D3

SS12-E3/61T

2 1

TP3

RED

TP3

RED

0805

R24

ZERO

0805

R24

ZERO

12

+

3216

C14

10 uFd 16v

+

3216

C14

10 uFd 16v

J38J38

1

1

2

2

3

3

+

3216

C2

10 uFd 16v

+

3216

C2

10 uFd 16v

0402

C3

0.1 uFd

0402

C3

0.1 uFd

1210

C6

22 uFd

10V

1210

C6

22 uFd

10V

BH2

BAT 9V FEMALE

BH2

BAT 9V FEMALE

POS1

1

POS2

2

POS3

3

0805

R23

ZERO

0805

R23

ZERO

1 2

+

3216

C15

10 uFd 16v

+

3216

C15

10 uFd 16v

1210

C22

22 uFd

10V

1210

C22

22 uFd

10V

TP1

BLACK

TP1

BLACK

0805

R57

ZERO

0805

R57

ZERO

12

+

3216

C13

10 uFd 16v

+

3216

C13

10 uFd 16v

0805

R11

1K

0805

R11

1K

12

TP2

RED

TP2

RED

0805

R30

ZERO

0805

R30

ZERO

12

TP4

RED

TP4

RED

+

3216

C4

10 uFd 16v

+

3216

C4

10 uFd 16v

J10J10

11223

3

0805

R27

ZERO

0805

R27

ZERO

1 2

0402

C17

0.1 uFd

0402

C17

0.1 uFd

0603

R12

3.16K

0603

R12

3.16K

12

+

3216

C5

10 uFd 16v

+

3216

C5

10 uFd 16v

U1

LT1763CS8

U1

LT1763CS8

IN

8

nSHDN

5

OUT

1

SENSE

2

Byp

4

GND3GND16GND2

7

0805R10805

R1

A.1 Schematic

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 33

Page 34

VSSD

NO LOAD

VSSB

NO LOAD

VSSD

VSSA

VSSD

VSSA

VSSA

PSoC 3 Section

VSSD

NO LOAD

VSSD

Rbleed

Cmod

NO LOAD NO LOAD

Note:

Place De-Caps near to the Chip

VSSD

VSSD

VSSD

NO LOAD

NO LOAD

VSSD

VSSA

NO LOAD

VSSA

VSSA

VSSA

NO LOAD

NO LOAD

P5[6]

P5[7]

P6[5]

P6[2]

P4[5]

P5[0]

P12[2]

P1[5]

P0[0]

P4[6]

P5[1]

P12[3]

/XRES

P5[2]

P4[7]

P5[3]

SWO

P4[1]

P4[2]

P6[3]

P4[3]

P4[4]

P3[1]

P0[1]

P6[4]

P15[5]

P3[2]

P0[2]

TDI

P2[0]

P2[1]

P2[2]

Ind

Vboost

VBAT

P2[3]

SWDCK

P2[4]

P2[5]

P4[0]

P2[6]

P6[0]

P2[7]

SWDIO

P0[5]

P0[4]

P12[0]

P0[7]

P1[7]

P3[3]

P6[1]

P0[3]

P12[1]

DP_P

P3[4]

DM_P

P3[0]

P0[6]

P15[4]

P3[6]

P3[7]

VBUS2

P1[6]

P12[4]

P6[7]

P15[4]

P12[5]

P12[6]

P12[7]

P1[2]

P5[4]

DM

DP

P3[5]

P5[5]

P6[6]

VCCa

VDDA

VDDA

VDDD

VDDD

VCCd

VCCd

VDDD

VDDD

VDDA

VDDD VDDA

0402

C36

0.1 uFd

0402

C36

0.1 uFd

21

Y3

24 MHz Crystal

21

Y3

24 MHz Crystal

0603

R38

2.2K

0603

R38

2.2K

J16

1 PIN HDR

J16

1 PIN HDR

1

1

0603

R35

ZERO

0603

R35

ZERO

0603

R36

ZERO

0603

R36

ZERO

0603

C27

22 pFd

0603

C27

22 pFd

12

Y2

32.768KHz XTAL

Y2

32.768KHz XTAL

1 2

345

0603

C37

1.0 uFd

0603

C37

1.0 uFd

J8

1 PIN HDR

J8

1 PIN HDR

1

1

J26

1 PIN HDR

J26

1 PIN HDR

1

1

R23KR2

3K

0402

C26

0.1 uFd

0402

C26

0.1 uFd

0603

R47

ZERO

0603

R47

ZERO

0402

C35

0.1 uFd

0402

C35

0.1 uFd

J12

1 PIN HDR

J12

1 PIN HDR

1

1

0402

C40

0.1 uFd

0402

C40

0.1 uFd

0402

C41

0.1 uFd

0402

C41

0.1 uFd

0402

C38

0.1 uFd

0402

C38

0.1 uFd

J25

1 PIN HDR

J25

1 PIN HDR

1

1

0402

C43

0.1 uFd

0402

C43

0.1 uFd

U7

CY8C3866AXI-040 TQFP100

U7

CY8C3866AXI-040 TQFP100

P2_5

1

P2_6

2

P2_7

3

P12_4 I2C0_SCL, SIO

4

P12_5 I2C0_SDA, SIO

5

P6_4

6

P6_5

7

P6_6

8

P6_7

9

VSSb

10

Ind

11

Vboost

12

Vbat

13

VSSd

14

XRES

15

P5_0

16

P5_1

17

P5_2

18

P5_3

19

P1_0

20

P1_1

21

P1_2

22

P1_3

23

P1_4

24

P1_5

25

VDDio126P1_627P1_728P12_6_SIO29P12_7_SIO30P5_431P5_532P5_633P5_734P15_6 DP35P15_7 DM36VDDd37VSSd38VCCd39NC140NC241P15_042P15_143P3_044P3_145P3_246P3_347P3_448P3_549VDDio3

50

VDDio0

75

P0_3

74

P0_2

73

P0_1

72

P0_0

71

P4_1

70

P4_0

69

SIO_P12_3

68

SIO_P12_2

67

VSSd

66

VDDa

65

VSSa

64

VCCa

63

NC8

62

NC7

61

NC6

60

NC5

59

NC4

58

NC3

57

P15_3

56

P15_2

55

SIO, I2C1_SDA P12_1

54

SIO, I2C1_SCL P12_0

53

P3_7

52

P3_6

51

P2_499P2_398P2_297P2_196P2_0

95

P15_594P15_4

93

P6_392P6_291P6_190P6_0

89

VDDd

88

VSSd

87

VCCd

86

P4_785P4_684P4_583P4_482P4_381P4_280P0_779P0_678P0_577P0_4

76

VDDio2

100

R8

1.5KR81.5K

0805

C39

2200 pFd

0805

C39

2200 pFd

12

0402

C30

22 pFd

0402

C30

22 pFd

0603

R33

22E

0603

R33

22E

1 2

0603

C44

1.0 uFd

0603

C44

1.0 uFd

0603

R39

ZERO

0603

R39

ZERO

TP5TP5

0603

C42

1.0 uFd

0603

C42

1.0 uFd

0402

C31

22 pFd

0402

C31

22 pFd

J18

1 PIN HDR

J18

1 PIN HDR

1

1

0603

R3222E

0603

R3222E

1 2

0402

C33

0.1 uFd

0402

C33

0.1 uFd

J22

1 PIN HDR

J22

1 PIN HDR

1

1

0402

C34

0.1 uFd

0402

C34

0.1 uFd

0603

C29

1.0 uFd

0603

C29

1.0 uFd

0603

C25

22 pFd

0603

C25

22 pFd

12

34 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 35

GND

PLACE ONE CAP PER EACH VCC ON U5.

PLACE C11 AND C16 CLOSE

CLOSE TO U5-3 AND U5-7.

TP2

GND

NO LOAD

GND

GND

FX2LP Programmer

GND

FIRMWARE UPDATE

REQUIRED FOR

GND

GND

GND

USB BACKVOLTAGE

COMPLIANCE.

GND

VSSD

VSSD

SWD/SWV/JTAG

VSSD

10-PIN TRACE HEADER

NO LOAD

SWDIO

SWDCK

3V3_FX12P

SWO

/XRES

D+

VBUS1

VBUS1

D-

3V3_FX12P

VBUS1

3V3_FX12P

VBUS1

SWO

/XRES

SWDCK

TDI

P2[5]

P2[7]

P2[4]

P2[6]

P2[3]

SWDIO

V3.3

VIN V5.0

VDDD

VDDD

0603

R21

39K

1%

0603

R21

39K

1%

1 2

0402

R5

2.2K

0402

R5

2.2K

Y1

24 MHzY124 MHz

13

2

0402

C11

2.2 uFd

6.3V

0402

C11

2.2 uFd

6.3V

0402

R17

10K

0402

R17

10K

0805

R9

ZERO

0805

R9

ZERO

12

0402

C8

0.01 uFd

0402

C8

0.01 uFd

1 2

8-SOIC

U3

24LC00/SN 8-SOIC

8-SOIC

U3

24LC00/SN 8-SOIC

SDA

5

NC11NC22NC3

3

VCC

8

SCL

6

NC4

7

GND

4

0402

C19

0.1 uFd

0402

C19

0.1 uFd

D-64

D8

SS12-E3/61T

D-64

D8

SS12-E3/61T

2 1

J3

50MIL KEYED SMD

J3

50MIL KEYED SMD

1

3

5

7

9

2

4

6

8

10

J40

50MIL KEYED SMD

J40

50MIL KEYED SMD

1

3

5

7

9

2

4

6

8

10

0402

C1

0.1 uFd

0402

C1

0.1 uFd

U5

CY7C68013A-56LTXC

U5

CY7C68013A-56LTXC

RESERVED

14

WAKEUP#

44

PA1/nINT1

34

SCL

15

VCC5

43

SDA

16

PA2/SLOE

35

VCC3

17

PA3/WU2

36

VCC4

27

PA4/FIFOADR0

37

PA5/FIFOADR1

38

AVCC1

3

PA6/PKTEND

39

GND3

26

PA7/FLAGD

40

GND4

28

PB0/FD0

18

GND6

56

AGND1

6

XTALIN

5

XTALOUT

4

PA0/nINT0

33

PB1/FD1

19

PB2/FD2

20

PB3/FD3

21

PB4/FD4

22

PB5/FD5

23

PB6/FD6

24

PB7/FD7

25

DPLUS

8

DMINUS

9

CLKOUT

54

RESET#

42

VCC6

55

RDY0/SLRD

1

RDY1/SLWR

2

CTL0/FLAGA

29

CTL1/FLAGB

30

CTL2/FLAGC

31

IFCLK

13

PD0/FD8

45

PD1/FD9

46

PD2/FD10

47

PD3/FD11

48

PD4/FD12

49

PD5/FD13

50

PD6/FD14

51

PD7/FD15

52

VCC111VCC2

32

GND112GND2

41

AGND2

10

AVCC2

7

GND553CP

57

0402

C10

0.1 uFd

0402

C10

0.1 uFd

0402

C18

0.1 uFd

0402

C18

0.1 uFd

D-64

D2

SS12-E3/61T

D-64

D2

SS12-E3/61T

2 1

0402

C21

0.1 uFd

0402

C21

0.1 uFd

0402

C16

0.1 uFd

0402

C16

0.1 uFd

TV1TV1

1

0402

R6

2.2K

0402

R6

2.2K

0402

C20

0.1 uFd

0402

C20

0.1 uFd

TV2

TV-20R

TV2

TV-20R

1

0603

R14

100K

1%

0603

R14

100K

1%

12

0402

R3

100K

0402

R3

100K

0603

R22

62K

1%

0603

R22

62K

1%

1 2

0402

C12

0.1 uFd

0402

C12

0.1 uFd

D-64

D11

D-64

D11

2 1

J1

USB MINI BJ1USB MINI B

VBUS

1

DM

2

DP

3

GND

5

ID

4

S16S2

7

S38S4

9

D-64

D10

D-64

D10

2 1

0402

C7

0.1 uFd

0402

C7

0.1 uFd

J9J9

1

1

D-64D9D-64

D9

2 1

NO LOAD

CapSense Button and Slider

NO LOAD

VSSA

NO LOAD

NO LOAD

VSSA

VSSD

NO LOAD

VSSA

NO LOAD

VSSD

NO LOAD

VSSA

NO LOAD

NO LOAD

VSSD

VSSD

VSSD

Prototype Area

VSSA

NO LOAD

Note: Load R56 for

high precision analog

Note: Un-Load R48 - R54 to disconnect Capacitive Sensors

VSSA

VSSD

VSSD

VSSD

VSSD

NO LOAD

NO LOAD

NO LOAD

NO LOAD

P0[2]

P6[5]

P0[3]

LED1

P0[4]

LED2

P0[5]

P0[6]

P0[7]

P6[5]

P6[1]

P6[2]

P3[0]

P3[1]

P3[2]

P15[5]

P3[3]

P3[4]

P3[5]

P3[6]

P3[7]

P6[3]

P12[7]

LED1

P0[0]

P12[4]

P5[0]

P5[5]

P5[1]

P5[2]

P5[6]

P5[3]

P5[4]

P6[0]

P6[5]

/XRES

P12[5]

P0[1]

P6[6]

P12[6]

LED2

VDDD

VDDA

VDDD

V3.3

V5.0

VDDD

VDDA

VDDA

VDDA

VDDD

P9

RECP 8X1P9RECP 8X1

112233445566778

8

J6

1 PIN HDRJ61 PIN HDR

1

1

0805

LED2

LED Red

0805

LED2

LED Red

2 1

0805

R61

330 ohm

0805

R61

330 ohm

1 2

+

3216

C45

10 uFd 16v

+

3216

C45

10 uFd 16v

0603

R51

ZERO

0603

R51

ZERO

J34J34

1

1

CSB2

CapSense

CSB2

CapSense

1

0603

R48

ZERO

0603

R48

ZERO

J50

Breadboard

J50

Breadboard

R56

POT 10K

R56

POT 10K

13

2

0603

R49

ZERO

0603

R49

ZERO

CSB1

CapSense

CSB1

CapSense

1

0805

R62

330 ohm

0805

R62

330 ohm

1 2

R55

10K

R55

10K

1 3

2

SW3

SW PUSHBUTTON

SW3

SW PUSHBUTTON

1A1B2A

2B

CSS1

CapSense Linear Slider 5 Seg

CSS1

CapSense Linear Slider 5 Seg

12345

J7

1 PIN HDRJ71 PIN HDR

1

1

J31J31

1

1

J5

1 PIN HDRJ51 PIN HDR

1

1

P4

RECP 8X1P4RECP 8X1

112233445566778

8

J32J32

1

1

0805

R60

330 ohm

0805

R60

330 ohm

1 2

0603

R52

ZERO

0603

R52

ZERO

J30J30

1

1

2

2

J35

1 PIN HDR

J35

1 PIN HDR

1

1

0603

R54

ZERO

0603

R54

ZERO

0805

LED4

LED Red

0805

LED4

LED Red

2 1

0603

R53

ZERO

0603

R53

ZERO

0805

R59

330 ohm

0805

R59

330 ohm

1 2

SW1

SW PUSHBUTTON

SW1

SW PUSHBUTTON

1A1B2A

2B

0805

LED1

LED Red

0805

LED1

LED Red

2 1

0805

LED3

LED Red

0805

LED3

LED Red

2 1

J14

1 PIN HDR

J14

1 PIN HDR

1

1

J28

1 PIN HDR

J28

1 PIN HDR

1

1

SW2

SW PUSHBUTTON

SW2

SW PUSHBUTTON

1A1B2A

2B

P6P6

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

J29J29

1

1

J36

1 PIN HDR

J36

1 PIN HDR

1

1

0603

R50

ZERO

0603

R50

ZERO

J27

1 PIN HDR

J27

1 PIN HDR

1

1

P3

RECP 8X1P3RECP 8X1

112233445566778

8

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 35

Page 36

VSSD

CGND1

VSSD

CGND1

SDA

SCL

CGND1

GND

NO LOAD

SDASCL

Port E (Analog EBK Connector) Port D (Misc Connector)

NO LOAD

NO LOAD

NO LOAD

NO LOAD

NO LOAD

Expansion Connectors

VSSA

NO LOAD

NO LOAD

Use Separate Track

for CGND1 to GND

NO LOAD

Voltage Reference

VSSA

VSSA

NO LOAD

NO LOAD

VSSA

NO LOAD

VREF

P2[4]

P2[2]

P2[0]

P2[6]

P5[6]

P5[0]

P5[2]

P5[4]

P1[2]

P1[6]

TDI

SWDIO

SWO

SWDCK

P12[1]

P12[3]

P1[7]

P1[5]

P12[0]

P12[2]

VIN

V3.3

V5.0

P3[2]

P3[6]

P3[4]

P3[0]

P3[3]

P3[1]

P12[1]

P0[7]

P0[5]

P4[3]

P4[1]

P12[3]

P3[7]

P3[5]

P0[6]

P0[3]

P0[1]

P4[7]

P4[5]P4[4]

P4[2]

P4[0]

P12[0]

P12[2]

P0[4]

P0[2]

P0[0]

P4[6]

VIN

V3.3

V5.0

P2[3]

P2[1]

P2[7]

P2[5]

P5[7]

P5[5]

P5[3]

P5[1]

P3[2]

P0[3]

VREF

VDDA

J13J13

1

1

U6

LM4140U6LM4140

VIN

2

EN

3

VREF

6

NC

5

GND1GND14GND27GND3

8

0805

R73

ZERO

0805

R73

ZERO

1 2

0805

R37

ZERO

0805

R37

ZERO

1 2

J39J39

1

1

0603

C24

1.0 uFd

0603

C24

1.0 uFd

J17J17

1

1

+

3216

C28

10 uFd 16v

+

3216

C28

10 uFd 16v

J15J15

1

1

J21J21

1

1

P2

20x2 RECP RA

P2

20x2 RECP RA

112

2

334

4

556

6

778

8

9910

10

111112

12

131314

14

151516

16

171718

18

191920

20

21

21

23

23

25

25

27

27

29

29

31

31

33

33

35

35

37

37

39

39

22

22

24

24

26

26

28

28

30

30

32

32

34

34

36

36

38

38

40

40

J24J24

1

1

J20J20

1

1

0402

C32

0.1 uFd

0402

C32

0.1 uFd

0805

R34

ZERO

0805

R34

ZERO

1 2

J19J19

1

1

P1

20x2 RECP RA

P1

20x2 RECP RA

112

2

334

4

556

6

778

8

9910

10

111112

12

131314

14

151516

16

171718

18

191920

20

21

21

23

23

25

25

27

27

29

29

31

31

33

33

35

35

37

37

39

39

22

22

24

24

26

26

28

28

30

30

32

32

34

34

36

36

38

38

40

40

J23J23

1

1

36 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 37

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 37

Page 38

A.2 Board Layout

A.2.1 PDC-09589 Top

38 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 39

A.2.2 PDC-09589 Power

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 39

Page 40

A.2.3 PDC-09589 Ground

40 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 41

A.2.4 PDC-09589 Bottom

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 41

Page 42

A.3 BOM

Item Qty Reference Value Description Manufacturer Mfr Part Number

PCB Cypress PDC-09589

1 1 BH1 BAT 9V MALE

2 1 BH2 BAT 9V FEMALE

39

4 2 C6,C22 22 uFd

529

6 2 C8,C9 0.01 uFd

7 1 C11 2.2 uFd

8 4 C29,C37,C42,C44 1.0 uFd

9 4 C30,C31,C25, C27 22pF

10 1 C39 2200 pFd

11 6 D1,D2,D3,D4, D7, D8 SS12-E3/61T

12 1 D5 LED Green

13 1 D6 ZHCS

14 2 J1,J2 USB MINI B

15 1 J3

16 1 J4

17 5

19 4

20 1 L1 22 uH

21 2 P1,P2 20x2 RECP RA

22 1 P7 DB9 FEMALE

23 1 P8

24 2 R3,R4 100K

C2,C4,C5,C13,C14,C1

5,C28,C45,C46

C7,C10,C12,C16,C17,

C18,C19,C20,C21,C2

6,C32,C33,C34,C35,C

36,C38,C40,C41,C43,

C47,C48,C49,C50,C5

1,C52, C53, C1, C3,

C23

TP1, J26, J27, J35,

J28

LED1,LED2,LED3,LE

D4

10 uFd 16v

0.1 uFd

50MIL KEYED

SMD

POWER JACK P-5CONN JACK POWER 2.1mm

BLACK TEST

POINT

LED Red LED RED CLEAR 0805 SMD Rohm Semiconductor SML-210LTT86

LCD HEADER W/

O BACKLIGHT

BATTERY HOLDER 9V Male

PC MT

BATTER Y HOLDER 9V Female

PC MT

CAP 10UF 16V TANTALUM

10% 3216

CAP CER 22UF 10V 10% X5R

1210

CAP .1UF 16V CERAMIC Y5V

0402

CAP 10000PF 16V CERAMIC

0402 SMD

CAP CER 2.2UF 6.3V 20%

X5R 0402

CAP CERAMIC 1.0UF 25V X5R

0603 10%

CAP, CER, 22 pF, 50V, 5%,

COG, 0603, SMD

SMD/SMT 0805 2200pF 50volts

C0G 5%

DIODE SCHOTTKY 20V 1A

SMA

LED GREEN CLEAR 0805

SMD

DIODE SCHOTTKY 40V 1.0A

SOT23-3

CONN USB MINI AB SMT

RIGHT ANGLE

CONN HEADER 10 PIN 50MIL

KEYED SMD

PCB RA

TEST POINT PC MINI .040"D

Black

INDUCTOR SHIELD PWR

22UH 7032

CONN FMALE 40POS DL .100

R/A GOLD

CONN DB9 FMALE VERT

PRESSFIT SLD

CONN RECEPT 16POS .100

VERT AU

RES 100K OHM 1/16W 5%

0402 SMD

Keystone Electronics 593

Keystone Electronics 594

AVX TAJA106K016R

Kemet C1210C226K8PACTU

Panasonic - ECG ECJ-0EF1C104Z

Panasonic - ECG ECJ-0EB1C103K

Panasonic - ECG ECJ-0EB0J225M

Taiyo Yuden TMK107BJ105KA-T

Panasonic - ECG ECJ-0EC1H220J

Murata

Vishay/General Semi-

conductor

Chicago Miniature CMD17-21VGC/TR8

Zetex ZHCS1000TA

TYCO 1734035-2

Samtec FTSH-105-01-L-DV-K

CUI PJ-102A

Keystone Electronics 5001

TDK Corporation

Sullins Electronics

Corp.

Norcomp Inc. 191-009-223R001

Tyco Electronics 1-534237-4

Panasonic - ECG ERJ-2GEJ104X

GRM2165C1H222JA01

D

SS12-E3/61T

SLF7032T-220MR96-2PF

PPPC202LJBN-RC

42 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 43

Item Qty Reference Value Description Manufacturer Mfr Part Number

25 6

26 2 R5,R6 2.2K

27 1 R11 1K

28 1 R12 3.16K

29 1 R13 3.74K

30 1 R14 100K

31 5

32 8

33 13

34 2 R32,R33 22E

35 2 R63,R65 100 ohm

36 1 R56 POT 10K

37 1 R58 10E

38 1 R68 100 ohm

39 1 R69 10K

40 3 SW1,SW2,SW3

41 1 U1 LT1763CS8

42 1 U2 AP1117D50G IC REG LDO 1.0A 5.0V TO-252 Diodes Inc AP1117D50G-13

43 1 U3 24LC00/SN

44 1 U4 LM1117MPX-3.3

45 1 U5

46 1 U7

47 1 U8 MAX3232CDR

48 1 Y1 24 MHz

49 1 Y2 32.768KHz XTAL

50 1 Y3 24 MHz Crystal

R9,R23,R24,R26,R27,

R71

R15,R59,R60,R61,R6

2

R17,R40,R41,R42,R4

3,R44,R45,R46

R35,R36,R39,R47,R4

8,R49,R50,R51,R52,R

53,R54,R64,R66

ZERO

330 ohm

10K

ZERO

SW PUSHBUTTON

CY7C68013A56LTXC

CY8C3866AXI040 TQFP100

RES 0.0 OHM 1/10W 5% 0805

SMD

RES 2.2K OHM 1/16W 5%

0402 SMD

RES 1.0K OHM 1/8W 5% 0805

SMD

RES 3.16K OHM 1/10W .5%

0603 SMD

RES 3.74K OHM 1/10W 1%

0603 SMD

RES 100K OHM 1/10W 1%

0603 SMD

RES 330 OHM 1/10W 5% 0805

SMD

RES 10K OHM 1/16W 5% 0402

SMD

RES ZERO OHM 1/16W 5%

0603 SMD

RES 22 OHM 1/16W 1% 0603

SMD

RES 100 OHM 1/8W 5% 0805

SMD

POT 10K OHM 9MM SQ PLASTIC

RES 10 OHM 1/8W 5% 0805

SMD

RES 100 OHM 1/16W 5% 0603

SMD

RES 10K OHM 1/16W 5% 0603

SMD

LT SWITCH 6MM 160GF

H=2.5MM SMD

IC LDO REG LOW NOISE ADJ

8-SOIC

IC EEPROM 128BIT 400KHZ

8SOIC

IC REG 3.3V 800MA LDO SOT223

IC, FX2 HIGH-SPEED USB

PERIPHERAL CONTROLLER

QFN56

PSoC3 Mixed-Signal Array Cypress Semiconductor CY8C3866AXI-040

IC 3-5.5V LINE DRVR/RCVR

16-SOIC

RESONATOR, 24.000MHZ,

WITH CAPS, SMD

CRYSTAL 32.768 KHZ CYL

12.5PF CFS308

CRYSTAL 24.000MHZ 20PF

SMD

Panasonic-ECG ERJ-6GEY0R00V

Panasonic - ECG ERJ-2GEJ222X

Panasonic - ECG ERJ-6GEYJ102V

Yageo RT0603DRD073K16L

Panasonic - ECG ERJ-3EKF3741V

Yageo RC0603FR-07100KL

Panasonic - ECG ERJ-6GEYJ331V

Stackpole Electronics

Inc

Panasonic - ECG ERJ-3GEY0R00V

Panasonic - ECG ERJ-3EKF22R0V

Rohm MCR10EZHJ101

Bourns Inc. 3310Y-001-103L

Stackpole Electronics

Inc

Panasonic - ECG ERJ-3GEYJ101V

Panasonic - ECG ERJ-3GEYJ103V

Panasonic - ECG EVQ-Q2P02W

Linear Technology LT1763CS8#PBF

Microchip Technology 24LC00/SN

National Semiconductor LM1117IMP-3.3/NOPB

Cypress Semiconductor CY7C68013A-56LTXC

Texas Insturments MAX3232IDR

Murata

Citizen America Corpo-

ration

ECS Inc ECS-240-20-5PX-TR

RMCF 1/16S 10K 5% R

RMCF 1/10 10 5% R

CSTCE24M0XK2010R0

CFS308-32.768KDZFUB

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 43

Page 44

Item Qty Reference Value Description Manufacturer Mfr Part Number

51 3 J8,J33, TP2

52 1 R38 2.2K

53 2 J10,J11 3p_jumper

54 1 J30 2p_jumper

55 1 NA

56 1 NA 16 pin header

57 6

58 1 R21 39K

59 1 R22 62K

No Load Components

60 1 C24 1.0 uFd

61 13

62 4 J7,J32,J34,J36 BLACK

63 1 TP5 WHITE

64 1 J50 Breadboard BREADBOARD 17x5x2 3M 923273-I

65 4 P3,P4,P6,P9 RECP 8X1 CONN RECT 8POS .100 VERT 3M 929850-01-08-RA

66 1 R67 10K

67 10

68 1 R55 10K

69 2 R1,R28 ZERO

70 1 U6 LM4140

71 1 R8 1.5K

72 1 R2 3K

73 1 P5 4x1 RECP

74 1 J38 3p_jumper

75 1 J37 2p_jumper

76 1 J40

D9, D10, D11, D12,

D13, D14

J5,J6,J12,J14,J29,J31

,J18,J22,J25,TP3,TP4,

J16,J39

R30,R34,R57,R72,R2

5,R31,R70,R37,R29,

R73

RED TEST

POINT

3.3V LCD Module

16POS w/16 pin

header installed

ESD diode

RED

ZERO

50MIL KEYED

SMD

TEST POINT PC MINI .040"D

RED

RES 2.2KOHM 1/16W

2700PPM 5%0603

CONN HEADER VERT SGL

3POS GOLD

CONN HEADER VERT SGL

2POS GOLD

3.3V LCD Module 16POS w/16

pin header installed

CONN HEADER VERT SGL

16POS GOLD

SUPPRESSOR ESD 5VDC

0603 SMD

RES 39.0K OHM 1/10W 1%

0603 SMD

RES 62.0K OHM 1/10W 1%

0603 SMD

CAP CERAMIC 1.0UF 25V X5R

0603 10%

TEST POINT PC MINI .040"D

RED

TEST POINT PC MINI .040"D

Black

TEST POINT PC MINI .040"D

WHITE

POT 10K OHM 1/4" SQ CERM

SL ST

RES 0.0 OHM 1/10W 5% 0805

SMD

TRIMPOT 10K OHM 4MM TOP

ADJ SMD

RES ZERO OHM 1/10W 5%

0603 SMD

IC REF PREC VOLT

MICROPWR 8-SOIC

RES 1.5KOHM 1/10W

1500PPM 5%0805

RES 1/10W 3K OHM 0.1%

0805

CONN RECEPT 4POS .100

VERT GOLD

CONN HEADER VERT SGL

3POS GOLD

CONN HEADER VERT SGL

2POS GOLD

CONN HEADER 10 PIN 50MIL

KEYED SMD

Keystone Electronics 5000

Panasonic - ECG ERA-V27J222V

3M 961103-6404-AR

3M 961102-6404-AR

Lumex LCM-S01602DTR/A-3

3M 961116-6404-AR

Bourns Inc. CG0603MLC-05LE

Rohm Semiconductor MCR03EZPFX3902

Rohm Semiconductor MCR03EZPFX6202

Taiyo Yuden TMK107BJ105KA-T

Keystone Electronics 5000

Keystone Electronics 5001

Keystone Electronics 5002

Bourns Inc. 3362P-1-103LF

Panasonic-ECG ERJ-6GEY0R00V

Bourns Inc. 3214W-1-103E

Panasonic - ECG ERJ-3GEY0R00V

National Semiconductor LM4140ACM-1.0/NOPB

Panasonic - ECG ERA-S15J152V

Stackpole Electronics

Inc

3M 929850-01-04-RA

3M 961103-6404-AR

3M 961102-6404-AR

Samtec FTSH-105-01-L-DV-K

RNC 20 T9 3K 0.1% R

44 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Page 45

Item Qty Reference Value Description Manufacturer Mfr Part Number

77 2 CSB1,CSB2 CapSense CapSense Button Cypress

78 1 CSS1

79 9

80 2 TV1,TV2 PADS PADS

Install On Bottom of PCB As Close To Corners As Possible

81 5

Special Jumper Installation Instructions

82 1 J30

83 2 J10, J11

J9,J13,J15,J17,J19,J2

0,J21,J23,J24

CapSense Linear Slider 5 Seg

PADS PADS

Install jumper

across pins 1 and

2

Install jumper

across pins 1 and

2

CapSense Slider Cypress

BUMPER CLEAR .500X.23"

SQUARE

Rectangular Connectors MINI

JUMPER GF 13.5 CLOSE

TYPE BLACK

Rectangular Connectors MINI

JUMPER GF 13.5 CLOSE

TYPE BLACK

Richco Plastic Co RBS-3R

Kobiconn 151-8030-E

Kobiconn 151-8030-E

CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A 45

Page 46

46 CY8CKIT-030 PSoC 3 Development Kit Guide, Doc. # 001-61038 Rev. *A

Loading...

Loading...