e

CY7C6800

1

EZ-USB SX2™ High-Speed USB Interface Devic

1.0 EZ-USB SX2™ Features

• USB 2.0-certified compliant

—On the USB-IF Integrators List: T est I D Number

40000713

• Operates at high (480 Mbps) or full (12 Mbps) speed

• Supports Control Endpoint 0:

—Used for handling USB device requests

• Supports four configurable endpoints that share a 4-

KB FIFO space

—Endpoints 2, 4, 6, 8 for appl ication-specific control

and data

• Standard 8- or 16-bit external master interface

—Glueless interface to most standard microproces-

sors DSPs, ASICs, and FPGAs

—Synchronous or Asynchronous interface

• Integrated phase-locked loop (PLL)

• 3.3V operation, 5V tolerant I/Os

• 56-pin SSOP and QFN package

• Complies with most device class specificati ons

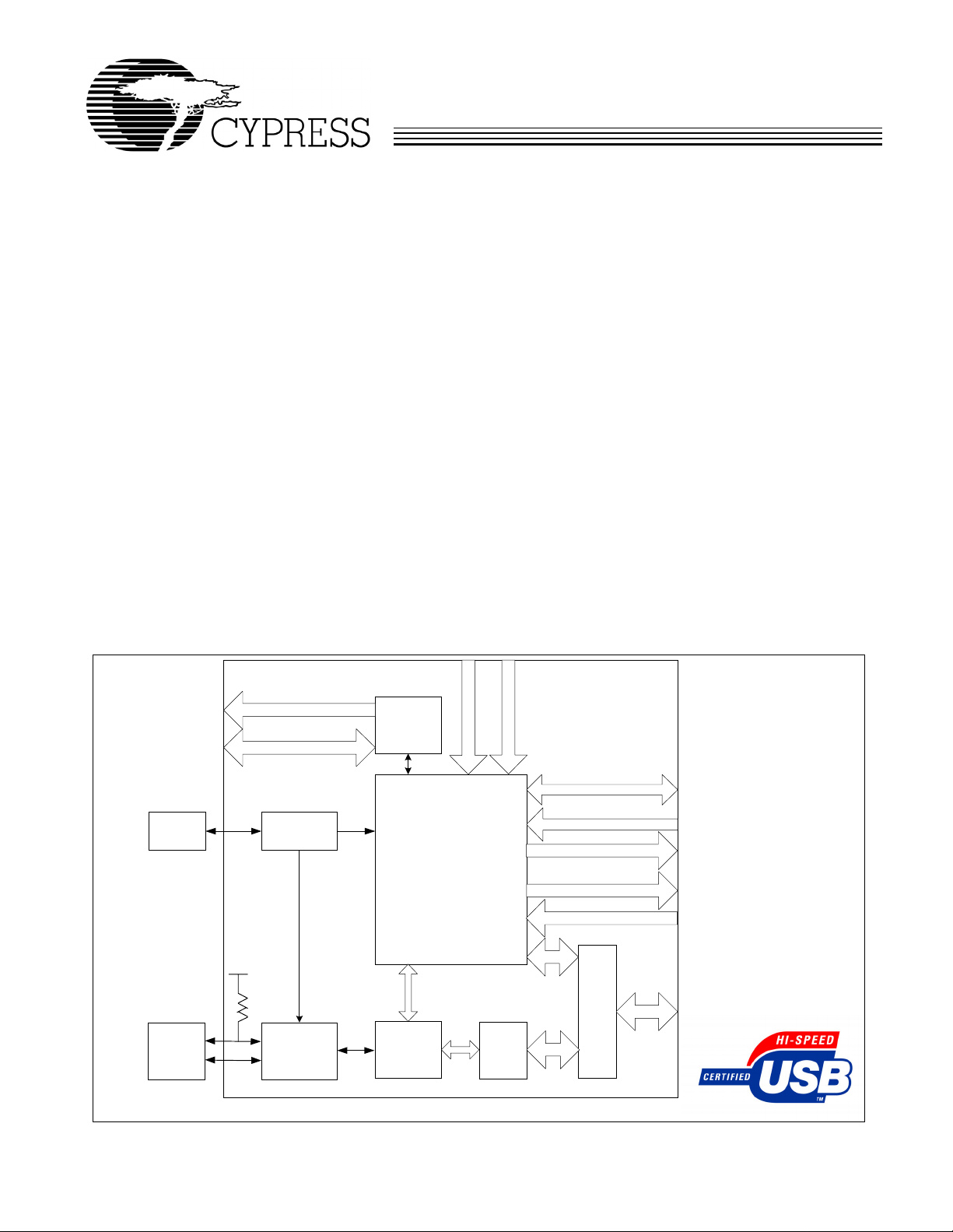

2.1 Block Diagram

2.0 Applications

• DSL modems

• AT A interface

• Memory card readers

• Legacy conversion devices

• Cameras

• Scanners

• Home PNA

• Wireless LAN

• MP3 players

•Networking

•Printers

The “Reference Designs” section of the Cypress web site

provides additional tools for typical USB applications. Each

reference design comes complete with firmware source code

and object code, schematic s, and documenta ti on. Please see

the Cypress web site at www.cypress. com .

24 MHz

XTAL

DPLUS

DMINUS

VCC

1.5K

USB 2.0 XCVR

SCL

SDA

PLL

I2C Bus

Controller

(Master On l y )

SX2 Internal Logic

CY Smart USB

FS/HS Engine

RESET#

WAKEUP*

4 KB

FIFO

Figure 2-1. Block Diagram

IFCLK*

Read*, Write*, OE*, PKTEND *, CS#

Interrupt#, Ready

Flags (3/4)

Address (3)

Control

FIFO

Data

8/16-Bit Data

Bus

Data

Cypress Semiconductor Corporation • 3901 North First Street • San Jose • CA 95134 • 408-943-2600

Document #: 38-08013 Rev. *E Revised July 13, 2004

1

FOR

FOR

CY7C6800

2.2 Introduction

The EZ-USB SX2™ USB interf ace device is designed to wo rk

with any external master, such as standard microprocessors,

DSPs, ASICs, and FPGAs to enable USB 2.0 support for any

peripheral design. SX2 has a built-in USB transceiver and

Serial Interface Engine (SIE), along with a command dec oder

for sending and receiving USB data. The controller has four

endpoints that share a 4-KB FIFO space for maximum flexibility and throughput, as well as Control Endpoint 0. SX2 has

three address pins and a selectable 8- or 16- bit data bus for

command and data input or out put.

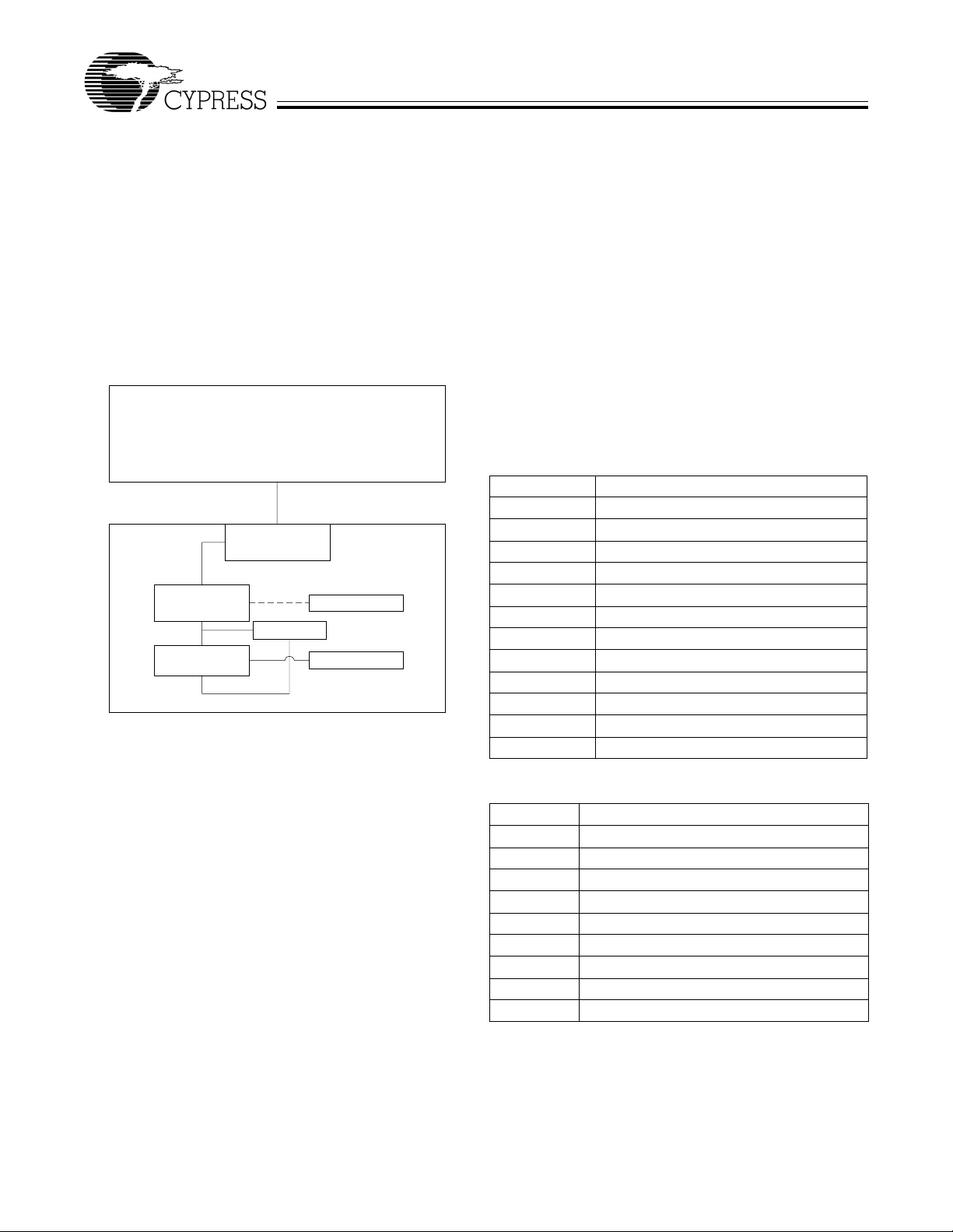

2.3 System Diagram

Windows/USB Capable Host

USB Cable

USB Connection

Cypress

SX2

RAM/ROM

Device CPU Application

Figure 2-2. Example USB System Diagram

EEPROM

3.3 Boot Methods

During the power-up sequence, internal logic of the SX2

checks for the presence of an I

EEPROM, it will boot off the EEPROM. When the presence of

an EEPROM is detected, the SX2 checks the value of first

byte. If the first byte is found to be a 0xC4, the SX2 loads the

next two bytes into the IFCONFIG and POLAR registers,

respectively. If the fourth byte is also 0xC4, the SX2

enumerates using t he descriptor i n the EEPROM, then signal s

to the external master when enumeration is complete via an

ENUMOK interrupt (Section 3.4). If no EEPROM is detected,

the SX2 relies o n the extern al master f or the descr iptors. Once

this descriptor infor mation i s recei ve from the exte rnal mast er,

the SX2 will connect to the USB bus and enumerate.

3.3.1 EEPROM Organization

The valid sequence of bytes in the EEPROM are displayed

below

T able 3-1. Descriptor Lengt h Set to 0x06:

Default Enumeration

Byte Index Description

00xC4

1 IFCONFIG

2POLAR

30xC4

4 Descriptor Length (LSB):0x06

5 Descriptor Length (MSB): 0x00

6 VID (LSB)

7 VID (MSB)

8 PID (LSB)

9 PID (MSB)

10 DID (LSB)

1 1 DID (MSB)

2

C EEPROM.

[1,2]

If it finds an

3.0 Functional Overview

T able 3-2. Descriptor Length Not Set to 0x06

3.1 USB Signaling Speed

SX2 operates at two of the three rates def ined in the Universal

Serial Bus Specification Revision 2.0, dated April 27, 2000:

• Full-speed, with a signaling bit rate of 12 Mbits/s

• High-speed, with a signal ing bit rate of 480 Mbits/s.

SX2 does not support the low-speed signaling rate of 1.5

Mbits/s.

3.2 Buses

SX2 features:

• A selectable 8- or 16-bit bidirectional data bus

• An address bus for selecting the FIFO or Command Interface.

Notes:

1. Because there is no direct way to detect which EEPROM type (single or double address) is connected, SX2 uses the EEPROM address pins A2, A1, and A0

to determine whether to send out one or two bytes of address. Single-byte address EEPROMs (24LC01, etc.) should be strapped to address 000 and doublebyte EEPROMs (24LC64, etc.) should be strapped to address 001.

2. The SCL and SDA pins must be pulled up for this detection method to work properly, even if an EEPROM is not connected. Typical pull-up values are 2.2K – 10K

Ohms.

Document #: 38-08013 Rev. *E Page 2 of 42

Byte Index Description

00xC4

1IFCONFIG

2POLAR

30xC4

4 Descriptor Length (L SB)

5 Descriptor Length (MSB

6 Descriptor[0]

7 Descriptor[1]

8 Descriptor[2]

1

FOR

FOR

CY7C6800

• 0xC4: This initial byte tells the SX2 that this is a valid EEPROM with configuration information.

• IFCONFIG: The IFCONFIG byte contains the settings for

the IFCONFIG regi ster . The IFCONFI G register bi ts are defined in Section 7. 1. If the external master requires an interface configu ration different from the def ault, that interface

can be specified by this byte.

• POLAR: The Polar byte contains the polarity of the FIFO

flag pin signals. The POLAR register bits are defined in

Section 7.3. If th e external master requires signal polarity

differ ent from the default, the polari ty can be specified by

this byte.

• Descriptor: The Descriptor byte determines if the SX2

loads the desc riptor from the EEPROM. If this byt e = 0xC4,

the SX2 will l oad the descript or starting with the next byte.

If this byte does not equal 0xC4, the SX2 will wait for descriptor information from the external master.

• Descriptor Length: The Descriptor l ength is within the next

two bytes and i ndicate the length o f the descriptor con tained

within the EEPROM. The l ength is loaded least significant

byte (LSB) first, then most significant byte (MSB).

• Byte 7 Starts Descri ptor Inform ation: The descript or can

be a maximum of 500 bytes.

3.3.2 Default Enumeration

An optional d efault descr iptor can be used t o si mplif y enumeration. Onl y the V endor ID (VID), Product ID (PID), and Device

ID (DID) need t o b e loaded b y the SX2 f or i t to en umerate wi th

this default set-up. This information is either loaded from an

EEPROM in the case when the presence of an EEPROM

(Table 3-1) is detected, or the ext ernal master m ay simply l oad

a VID, PID, and DID when no EEPROM is present. In this

default enumeration, the SX2 uses the in-built default

descriptor (refer to Section 12.0).

If the descript or length loaded from the EEPROM is 6, SX2 will

load a VID, PID, and DID from the EEPROM and enumerate.

The VID, PID, and DID are loaded LSB, then MSB. For

example, if the VID, PID, and DID are 0x0547, 0x1002, and

0x0001, respectively, then the bytes should be stored as:

• 0x47, 0x05, 0x02, 0x10, 0x01, 0x00.

If there is no EEPROM, SX2 will wait for the external master

to provide the descriptor information. To use the default

descriptor, the external master must write to the appropriate

register (0x30) with descriptor length equal to 6 followed by the

VID, PID, and DID. Refer to Secti on 4.2 for fur ther info rmatio n

on how the external mast er may load the values.

The default descriptor enumerates four endpoints as listed in

the following page:

• Endpoint 2: Bulk out, 512 bytes in high-speed mode, 64

bytes in full-s peed m ode

• Endpoint 4: Bulk out, 512 bytes in high-speed mode, 64

bytes in full-s peed m ode

• Endpoint 6: Bulk in, 512 byt es in high-speed mode, 64 bytes

in full-speed mode

• Endpoint 8: Bulk in, 512 byt es in high-speed mode, 64 bytes

in full-speed mode.

The entire default descriptor is listed in Section 12.0 of this

data sheet.

3.4 Interrupt System

3.4.1 Architecture

The SX2 provides an output signal that indicates to the

external mast er t hat the SX2 has an inter rupt condi tion, or that

the data from a register re ad reques t is avail able. The SX2 has

six interrupt sources: SETUP, EP0BUF, FLAGS, ENUMOK,

BUSACTIVITY, and READY . Eac h interrup t can be enab led or

disabled by setting or clearing the corresponding bit in the

INTENABLE register.

When an interrupt occurs, the INT# pin will be asserted, and

the corresponding bit will be set in the Interrupt Status Byte.

The external master reads the Interrupt Status Byte by

strobing SLRD/SLOE. This presents the Interrupt Status Byte

on the lower portion of the data bus (FD[7:0]). Reading the

Interrupt Status Byte automatically clears the interrupt. Only

one interrupt request will occur at a time; the SX2 buffers

multiple pending interrupts.

If the ext ernal master has initiated a register read request, the

SX2 will buffer inte rrupts unt il the external master has read the

data. This insures that after a read sequence has begun, the

next interrupt that is received from the SX2 will indicate that

the corresponding data is available. Followi ng is a description

of this INTENABLE register.

3.4.2 INTENABLE Register Bit Definition

Bit 7: SETUP

If this interrupt is enabled, and the SX2 receives a set-up

packet from the USB host, the SX2 asserts the INT# pin and

sets bit 7 in the Int errupt St atus Byte. Th is inter rupt onl y occurs

if the set-up request is not one that the SX2 automatically

handles. For complete details on how to handle the SETUP

interr up t , re fe r to S ec ti o n 5 .0 of this data sheet .

Bit 6: EP0BUF

If this interrupt is enabl ed, and the Endpoi nt 0 buff er becomes

available to the external master for read or write operations,

the SX2 asserts the INT# pin and sets bit 6 in the Interrupt

Status Byte. This in terrupt i s used for handlin g the data ph ase

of a set-up req uest. Fo r comple te de tails on h ow to handle t he

EP0BUF interrupt, refer t o Secti on 5.0 of this data sheet.

Bit 5: FLAGS

If this int errupt is e nabled, and any O UT endpoi nt FIF O’ s stat e

changes from empty to not-empty, the SX2 asserts the INT#

pin and sets bit 5 in the Interrupt Status Byte. This is an

alternate way to monitor the status of OUT endpoint FIFOs

instead of using the FLAGA-FLAGD pins, and can be used to

indicate when an OUT packet has been received from the

host.

Bit 2: ENUMOK

If this interrupt is enabled and the SX2 receives a

SET_CONFIGURATION request from the USB host, the SX2

asserts the I NT# pin and sets bi t 2 i n the Int errup t Stat us Byte .

This event signals the completion of the SX2 enumeration

process.

Bit 1: BUSACTIVITY

If this interrupt is enabled, and the SX2 detects either an

absence or resumption of activity on the USB bus, the SX2

asserts the I NT# pin and sets bi t 1 i n the Int errup t Stat us Byte .

This usually indicates that the USB host is either suspending

Document #: 38-08013 Rev. *E Page 3 of 42

1

FOR

FOR

CY7C6800

or resuming or that a self-powered device has been plugged

in or unplugged. If the SX2 is bus-powered, the external

master must put the SX2 into a low-power mode after

detecting a USB suspend condition to be USB-compliant.

Bit 0: READY

If this interrupt is enabled, bit 0 in the Interrupt Status Byte is

set when the SX2 has powered up and performed a self-test.

The external master should always wait for this interrupt

before trying to read or write to the SX2, unless an external

EEPROM with a valid descriptor is present. If an external

EEPROM with a valid descriptor is present, the ENUMOK

interrupt will occur instead of the READY interrupt after power

up. A READY interrupt will also occur if the SX2 is awakened

from a low-power mode via the WAKEUP pin. This READY

interrupt i ndicates that the SX2 is ready for commands or data.

Although it is true that all interrupts will be buffered once a

command read request has been initiated, in very rare conditions, there might be a situation when there is a pending

interrupt already, when a read request is initiated by the

external master. In this case it is the interrupt status byte that

will be output when the external master asserts the SLRD. So,

a condition exists wher e the Int errup t Statu s Data Byt e can be

mistaken for t he resul t of a command re gister read requ est . In

order to get around this possible race condition, the first thing

that the external master must do on getting an interrupt from

the SX2 is check the status of the READY pin. If the READY

is low at the time the INT# was asserted, the data that will be

output when the external master strobes the SLRD is the

interrupt status byte (not the actual data requested). If the

READY pin is high at the time when the interrupt is asserted,

the data output on strobing the SLRD is the actual data byte

requested by the external master. So it is important that the

state of the READY pin be checked at the time the INT# is

asserted to ascertain the cause of the interrupt.

3.5 Resets and Wakeup

3.5.1 Reset

An input pi n (RESET#) reset s the chi p. The i nternal PLL s tabilizes af ter V

network (R = 100 K Ohms, C = 0.1 uf) is used to provide the

has reached 3.3V. Typically, an external RC

CC

RESET# signal. Th e Clock must be in a st able sta te for at l east

200 us before the RESET is released.

3.5.2 USB Reset When the SX2 detect s a USB Reset condi tion on the USB bus,

SX2 handles it like any other enumeration sequence. This

means that SX2 will enumerate again and assert the

ENUMOK interrupt to let the external master know that it has

enumerated. The external master will then be responsible for

configuring the SX2 for the application. The external master

should also check whether SX2 enumerated at High or Full

speed in order to adjust the EPxPKTLENH/L register values

accordingly. The last initialization task is for the external

master to flush all of the SX2 FIFOs .

3.5.3 Wakeup

The SX2 exits its low-power state when one of the following

events occur:

• USB bus signals a res um e. The SX2 will assert a BUSACTIVITY interrupt.

• The external master asserts the W AKEUP pin. The SX2 wi ll

assert a READY interrupt

[3]

.

3.6 Endpoint RAM

3.6.1 Size

• Control endpoint: 64 Bytes: 1 × 64 bytes (Endpoint 0).

• FIFO Endpoints: 409 6 Bytes: 8 × 51 2 by tes (E ndpoi nt 2, 4,

6, 8).

3.6.2 Organization

• EP0–Bidirectional Endpoint 0, 64-byte buff er.

• EP2, 4, 6, 8–Eight 512-byte buffers, bulk, interrupt, or isochronous. EP2 and EP6 can be either double-, triple-, or

quad-buffer ed. EP4 and EP8 c an only be do ubl e-buf fere d.

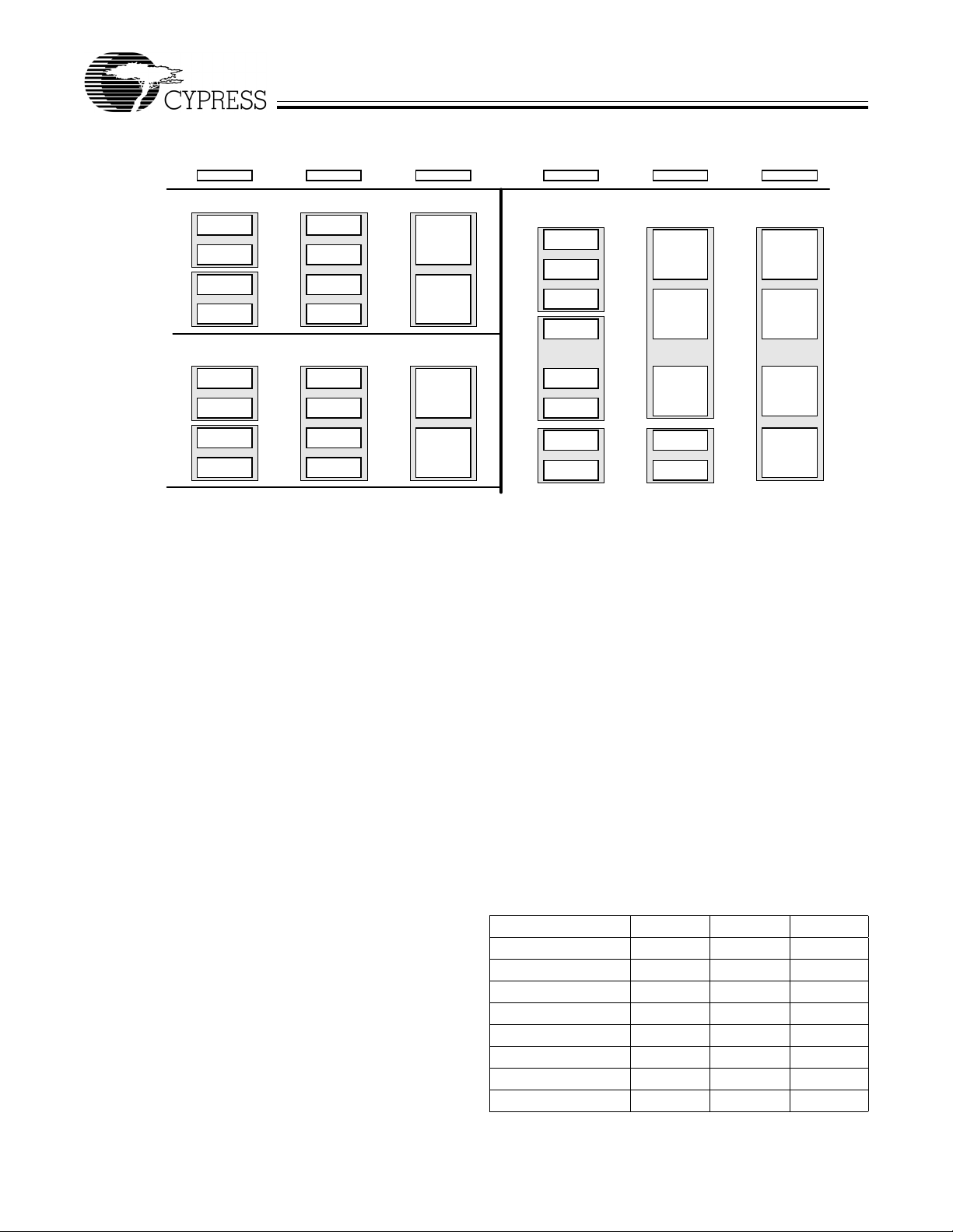

For high-speed endpoint configuration options, see

Figure 3-1.

Note:

3. if the descriptor loaded is set for remote wakeup enabled and the host does a set feature remote wakeup enabled, then the SX2 logic will perform RESUME

signalling after a WAKEUP interrupt.

Document #: 38-08013 Rev. *E Page 4 of 42

1

FOR

FOR

3.6.3 Endpoi nt Configurations (Hig h-speed Mode)

EP0 IN&OUT 64 64 64 64 64 64

CY7C6800

Group A

EP2

EP4

512

512

EP2

512

512

512

1024

512

EP2

512

1024

512

Group B

512

EP6

512

EP6

512

EP8

512

512

1024

512

EP6

512

1024

512

Figure 3-1. Endpoint Configuration

Endpoint 0 is the same for every configuration as it serves as

the CONTROL end point. For Endpoints 2, 4, 6, and 8, refer to

Figure 3-1. Endpoints 2, 4, 6, and 8 may be configured by

choosing eith er:

• One configuration from Group A and one from Group B

• One configuration from Group C.

Some example endpoi nt configurations are as foll ows.

• EP2: 1024 bytes double-buffered, EP6: 512 bytes quadbuffered.

• EP2: 512 bytes double-buffered, EP4: 512 bytes doublebuffered , EP6: 512 bytes doubl e-buf fere d, EP8: 512 bytes

double buffered.

• EP2: 1024 bytes quad-buf fered.

3.6.4 Default Endpoint Memory Configuration

At power-on-reset, the endpoint memories are configured as

follows:

• EP2: Bulk OUT, 512 bytes/packet, 2x buffered.

• EP4: Bulk OUT, 512 bytes/packet, 2x buffered.

• EP6: Bulk IN, 512 bytes/packet, 2x buffered.

• EP8: Bulk IN, 512 bytes/packet, 2x buffered.

3.7 External Interface

The SX2 presents two interfaces to the external master.

1. A FIFO interface thr ough which EP2, 4, 6, an d 8 data flows.

2. A command interf ace, which is used to set up the SX2, read

status, load descriptors, and access Endpoint 0.

Group C

EP2

EP6

EP8

512

512

512

EP2

512

512

512

512

EP8

512

1024

1024

1024

512

512

1024

1024

EP2

1024

1024

3.7.1 Architecture

The SX2 slave FIFO archit ecture has eight 512-byte blocks in

the endpoint RAM that directly serve as FIFO memories and

are controlled by FIFO control signals (IFCLK, CS#, SLRD,

SL WR, SLOE, PKTEND, and FIFOADR[2 :0]).

The SX2 command interface is used to set up the SX2, read

status, load descriptors, and access Endpoint 0. The

command interface has its own READY signal for gating

writes, and an INT# signa l to ind icate that the SX2 has data to

be read, or that an inter rupt event has occurred. The command

interface uses the same control signals (IFCLK, CS#, SLRD,

SLWR, SLOE, and FIFOADR[2:0]) as the FIFO interface,

except for PKTEND.

3.7.2 Control Signals

3.7.2.1 FIFOADDR Lines

The SX2 has three address pins that are used to select either

the FIFOs or the command interface. The addresses correspond to the following table.

Table 3-3. FIFO Address Lines Setting

Address/Selection FIFOADR2 FIFOADR1 FIFOADR0

FIFO2 0 0 0

FIFO4 0 0 1

FIFO6 0 1 0

FIFO8 0 1 1

COMMAND 1 0 0

RESERVED 1 0 1

RESERVED 1 1 0

RESERVED 1 1 1

Document #: 38-08013 Rev. *E Page 5 of 42

1

FOR

FOR

CY7C6800

The SX2 accepts either an internally derived clock (30 or 48

MHz) or externally supplied clock (IFCLK, 5-50 MHz), and

SLRD, SLWR, SLOE, PKTEND, CS#, FIFOADR[2:0] signals

from an external master. The interface can be selected for 8or 16- bit operation by an internal configuration bit, and an

Output Enable si gnal SLOE enabl es the dat a bus dr iver of th e

selected width. The external master must ensure that the

output enable signal is inactive when writing data to the SX2.

The interface can operate either asynchronously where the

SLRD and SLWR signals act directly as strobes, or synchronously where the SLRD and SL W R act as clock quali fiers. The

optional CS# sig nal wi ll trista te t he d ata bu s a nd ign ore SLRD,

SL W R, PKTEND.

The external master reads from OUT endpoints and writes to

IN endpoints, and reads from or writes to the command

interface.

3.7.2.2 Read: SLOE and SLRD

In synchronous mode, the FIFO pointer is incremented on

each rising edge of IFCLK while SLRD is asserted. In

asynchronous mo de, the FIFO pointer i s incremented on each

asserted-to-deasserted transit ion of SLRD.

SLOE is a d ata bus dr iver enable. When SLOE i s asserte d, the

data bus is driven by the SX2.

3.7.2.3 Write: SLWR

In synchronous mode, data on the FD bus is written to the

FIFO (and the FIFO pointer is incremented) on each rising

edge of IFCLK while SLWR is asserted. In asynchronous

mode, data on t he FD bus i s writ ten t o the F IFO (and th e FIFO

pointer is incremented) on each asserted-to-deasserted

transition of SLWR.

3.7.2.4 PKTEND

PKTEND commits the current buffer to USB. To send a short

IN packet (one which has not been filled to max packet size

determined by the value of PL[X:0] in EPxPKTLENH/L), the

external maste r st robes the PKTEND pin.

All these interface signals have a default polarity of low. In

order to change the polarity of PKTEND pin, the master may

write to the POLAR register anytime. In order to switch the

polarity of the SLWR/SLRD/SLOE, the master must set the

appropriate bit s 2, 3 and 4 respectively in th e FIFOPINPOLAR

register locat ed at XDATA space 0xE609. Please note that the

SX2 powers up with the polarities set to low. Section 7.3

provides further information on how to access this register

located at XDATA space.

3.7.3 IFCLK

The IFCLK pin can be c onfigured to be either an i nput (def ault)

or an output interface clock. Bits IFCONFIG[7:4] define the

behavior of the interface clock. To use the SX2’s intern allyderived 30- or 48-MHz clock, set IFCONFIG.7 to 1 and set

IFCONFIG.6 to 0 (30 MHz) or to 1 (48 MHz). T o use an externally supplied clock, set IFCONFIG.7=0 and drive the IFCLK

pin (5 MHz – 50 MHz). The input or output IFCLK signal can

be inverted by setting IFCONFIG.4=1.

3.7.4 FIFO Access

An external master can access the slave FIFOs either

asynchronously or synchronously :

• Asynchronous–SLRD, SLWR, and PKTEND pins are

strobes.

• Synchronous–SLRD, SLWR, and PKTEND pins are enables for the IFCLK clock pi n.

An external master accesses the FIFOs throu gh the data bus,

FD [15:0]. This bus can be either 8- or 16-bits wide; the width

is selected via the WORDWIDE bit in the EPxPKTLENH/L

registers. The data bus is bidirectional, with its output drivers

controlled by the SLOE pin. The FIFOADR[2:0] pins select

which of the four FIFOs is connected to the FD [15:0] bus, or

if the command interface is selected.

3.7.5 FIFO Flag Pins Configurat ion

The FIFO flags are FLAGA, FLAGB, FLAGC, and FLAGD.

These FLAGx pins report the status of the FIFO selected by

the FIFOADR[2:0] pins. At reset , the se pins are configured to

report the status of the following:

• FLAGA reports the stat us of the programmable flag.

• FLAGB reports the stat us of the full flag.

• FLAGC reports the status of the empty flag.

• FLAGD defaults to the CS# function.

The FIFO flags can either be indexed or fixed. Fixed flags

report the status of a particular FIFO regardless of the value

on the FIFOADR [2:0] pins. Indexed flags report the status of

the FIFO selected by the FIFOADR [2:0] pins.

[4]

3.7.6 Default FIFO Programmab le Fl ag Set- up

By default, FLAGA is the Programmable Flag (PF) for the

endpoint being pointed to by the FIFOADR[2:0] pins. For EP2

and EP4, the default endpoint configuration is BULK, OUT,

512, 2x, and the PF pin asserts when the entire FIFO has

greater than/equal to 512 b yte s. For EP6 a nd EP8, the defaul t

endpoint configuration is BULK, IN, 512, 2x, and the PF pin

asserts when t he entir e FIFO has less than /equal t o 512 by tes.

In other words, EP6/8 report a half-empty state, and EP2/4

report a half-full state. The polarity of the programmable flag

is set to active low and cannot be altered.

3.7.7 FIFO Programmable Flag (PF) Set-up

Each FIFO’s programmable-level flag (PF) asserts when the

FIFO reaches a user-defined fullness threshold. That

threshold is configured as follows:

1. For OUT packets: The thres hold i s sto red in PFC12 :0. Th e

PF is asserted when the number o f bytes i n the entire FI FO

is less than/equal to (DECIS = 0) or greater than/equal to

(DECIS = 1) the threshold.

2. For IN packets, with PKTSTAT = 1: The th reshol d is st ored

in PFC9:0. The PF is asserted when the number of bytes

written into the current packet in the FIFO i s less than/equa l

to (DECIS = 0) or greater than/equal to ( D ECIS = 1) the

threshold.

3. For IN packets, with PKTSTAT = 0: The th reshol d is st ored

in two parts: PKTS2:0 holds the numbe r of committed packets, and PFC9:0 holds the number of bytes in the current

packet. The PF is asserted when the FIFO is at or less full

than (DECIS = 0), or at or more full than (DE C IS = 1), the

threshold.

Document #: 38-08013 Rev. *E Page 6 of 42

1

FOR

FOR

CY7C6800

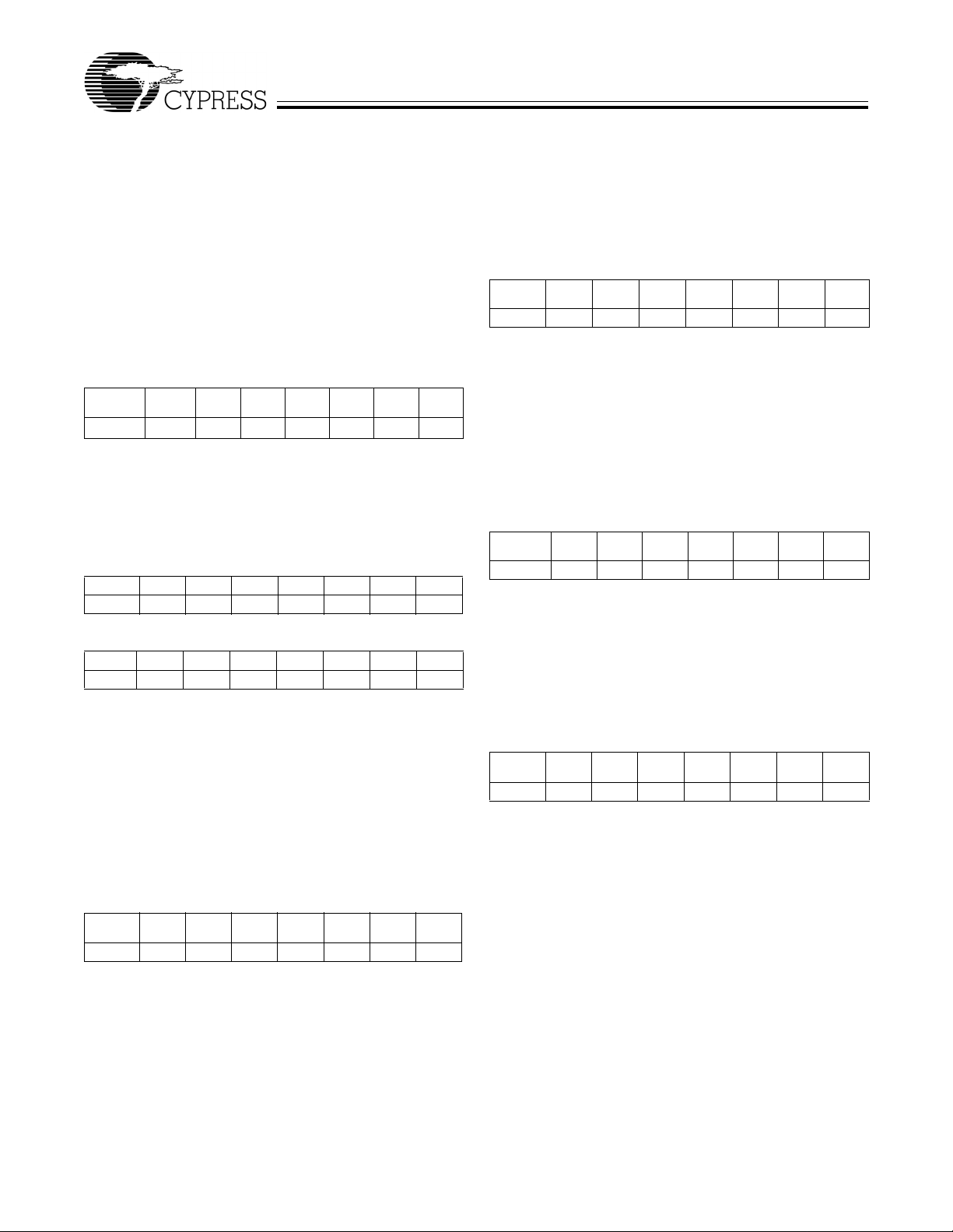

3.7.8 Command Protocol

An address of [1 0 0] on FIFOADR [2:0] will select the

command interface. The command interface is used to write

to and read from the SX2 registers and the Endpoint 0 buffer,

as well a s the des criptor RAM. Command read and write t ransactions occur over FD[7:0] only. Each byte written to the SX2

is either an address or a data byte, as determined by bit7. If

bit7 = 1, then the byte i s considered an address byte. If bit7 =

0, then the byte is considered a data byte. If bit7 = 1, then bit6

determines whether the address byte is a read request or a

write request. If bit6 = 1, then the byte is considered a read

request. If bit 6 = 0 then the byte is co nsider ed a write r equest.

Bits [5:0] hold the register address of the request. The format

of the command addre ss byte is shown in Table 3-4.

T able 3-4. Command Address Byte

Address/

Data#

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

Read/

Write# A5 A4 A3 A2 A1 A0

Each Write request is followed by two or more data bytes. If

another address byte is received before both data bytes are

received, t he SX2 ignores the first addr ess and any incompl ete

data transfers. The format for the data bytes is shown in

Table 3-5 and Table 3-6. Some registers take a series of byt es.

Each byte is transferred using the same protocol.

T able 3-5. Command Data Byte One

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 X X X D7 D6 D5 D4

T able 3-6. Command Data Byte T wo

Bit 7 Bit 6 Bit 5 Bit 4 Bit 3 Bit 2 Bit 1 Bit 0

0 X X X D3 D2 D1 D0

The first com mand data byt e contain s the upper nibble of data,

and the second command byte contains the lower nibble of

data.

3.7.8.1 Write Reques t Example

Prior to writing to a register, two conditions must be met:

FIFOADR[2:0] must hold [1 0 0], and the Ready line must be

HIGH. The external master should not initiate a command if

the READY pin is not in a HIgh state.

Example: to write the byte <10110000> into the IFCONFIG

register (0x01) , first send a command address byte as fol lows.

T able 3-7. Command Address Write Byte

Address/

Data#

Read/

Write# A5 A4 A3 A2 A1 A0

1 0000001

• The next six bits represent the register address (000001

binary = 0x01 hex).

Once the byte has been received the SX2 pulls the REA DY

pin low to inform the external master not to send any more

information. When the SX2 is ready to receive the next byte,

the SX2 pulls the READY pin high again. This next byte, the

upper nibble o f the d ata byt e, is writ ten to the SX2 as follows.

Table 3-8. Command Data Write Byte One

Address/

Data#

Don’t

Don’t

Care

0 XXX1011

Don’t

Care

Care D7 D6 D5 D4

• The first bit signifies that this is a data trans fer.

• The next three are don’t care bits.

• The next four bits hold th e upper nibble of the transferred

byte.

Once the byte has been received the SX2 pulls the REA DY

pin low to inform the external master not to send any more

information. When the SX2 is ready to receive the next byte,

the SX2 pulls the READY pin high again. This next byte, the

lower nibble of the data byte is written to the SX2.

Table 3-9. Command Data Write Byte Two

Address/

Data#

Don’t

Don’t

Care

0 XXX0000

Don’t

Care

Care D3 D2 D1 D0

At this point the entire byte <101 10000> has been transferred

to register 0x01 and the write sequence is complete.

3.7.8.2 Read Request Example

The Read cycle is simpler t han the write cycle. Th e Read cycl e

consists of a read reques t from the external master to t he SX2.

For example, to read the contents of register 0x01, a

command address byte is written to the SX2 as follows.

Table 3-10. Command Address Read Byte

Address/

Data#

Read/

Write# A5 A4 A3 A2 A1 A0

1 1000001

When the data is ready to be read, the SX2 asserts the INT#

pin to tell the external master that the data it requested is

waiting on FD[7:0].

[5]

• The first bit signifies an address transfer.

• The second bit signifie s that this is a write command.

Note:

4. In indexed mode, the value of the FLAGx pins is indeterminate except when addressing a FIFO (FIFOADR[2:0]={000,001,010,011}).

5. An important note: Once the SX2 receives a Read request, the SX2 allocates the interrupt line solely for the read request. If one of the six interrupt sources

described in Section 3.4 is asserted, the SX2 will buffer that interrupt until the read request completes.

Document #: 38-08013 Rev. *E Page 7 of 42

1

FOR

FOR

CY7C6800

4.0 Enumeration

The SX2 has two modes of enumeration. The first mode is

automatic through EEPROM boot load, as described in

Section 3.3. The second method is a manual load of the

descriptor or VID, PID, and DID as described below.

4.1 Standard Enumeratio n

The SX2 has 500 bytes of descriptor RAM into which the

external master may write its descriptor. The descriptor RAM

is accessed through register 0x30. To load a descriptor, the

external maste r does the following:

• Initiate a Write Request to register 0x30.

• Write two bytes (four command data transf ers) that define

the length of the entire descriptor about to be transferred.

The LSB is written first , fo llowed by the MSB.

• Write the descriptor, one byte at a time until complete.

Note: the register address is only written once .

After the entire descriptor has been transferred, the SX2 will

float the pull-up resistor connected to D+, and parse through

the descriptor to locate the individual descriptors. After the

SX2 has parsed the e ntir e desc ript or , the SX2 wi ll con nect th e

pull-up resistor and enumerate automatically. When enumeration is complete, the SX2 will notify the external master with

an ENUMOK interrupt.

The format and order of the descriptor should be as follows

(see Section 12.0 for an example):

• Device.

• Device qualifier.

• High-speed configuration, high-speed interface, highspeed endpoints.

• Full-speed configuration, full-speed interface, full-speed

endpoints.

• String.

4.2 Default Enumeration

The external master may si mply l oad a VI D, PID, and DID an d

use the defau lt des cript or bui lt i nto t he SX2. To use the default

descriptor, the descriptor length described above must equal

6. After the external master has written the length, the VID,

PID, and DID must be written LSB, t hen MSB. For example, if

the VID, PID, and DID are 0x04B4, 0x1002, and 0x0001

respectively, then the external master does the following:

• Initiates a Writ e Request to register 0x30.

• Writes two byte s (four command d ata transf ers) that define

the length of the entire descriptor about to be transferred.

In this case, the length is always six.

• Writes the V ID, PID, and DID bytes: 0xB4, 0x04, 0x02, 0x10,

0x01, 0x00 (in nibble format per the command protocol).

The default descriptor is listed in Section 12.0. The default

descriptor can be used as a starting point for a custom

descriptor.

Note:

6. These and all other data bytes must conform to the command protocol.

[6]

[6]

5.0 Endpoint 0

The SX2 wi ll automatica lly respon d to USB chapter 9 request s

without any external master intervention. If the SX2 receives

a request to which it cannot respond automatically, the SX2

will notify the external master. The external master then has

the choice of respond ing to the request or stalling.

After the SX2 receives a set-up packet to which it cannot

respond automatically, the SX2 will assert a SETUP interrupt.

After the external master reads the Interrupt Status Byte to

determine that the interrupt source was the SETUP interrupt,

it can initiate a read request to the SETUP register, 0x32.

When the SX2 sees a read request for the SETUP register, it

will present the first byte of set- up data to the external mast er.

Each additional read request will present the next byte of setup data, until all eight bytes have been read.

The external master can stall this request at this or any other

time. To stall a request, the external master initiates a write

request for the SETUP regi ster , 0x32, an d writes any non-zer o

value to the register.

If this set-up request has a data phase, the SX2 will then

interrupt the external master with an EP0BUF interrupt when

the buffer becomes available. The SX2 determines the

direction of the set -up request and interrupts when either:

• IN: the Endpoint 0 buff er becomes available to write to, or

• OUT : the Endpoint 0 buf fer r eceives a pac ket from the USB

host.

For an IN set-u p transaction, the external master can write up

to 64 bytes at a time for the data phase. The steps to write a

packet are as follows:

1. Wait for a n EP0BUF inte rrupt , indicat ing t hat the b uff er is

available.

2. Initiate a write request for register 0x31.

3. Write one data byte .

4. Repeat steps 2 and 3 until either all the data or 64 bytes

have been written, whichever is less.

5. Write the numbe r of byt es i n thi s packet to the b yt e count

register, 0x33.

T o se nd more than 64 byt es, the pr ocess is rep eated. The SX2

internally stores the length of the data phase that was

specified in the wLength field (bytes 6,7) of the set-up packet .

To send less than the requested amount of data, the external

master writes a packet that is less than 64 bytes, or if a multi ple

of 64, the external master follows the data with a zero-length

packet. When the SX2 sees a short or zero-length packet, it

will complete the set-up transfer by automatically completing

the handshake phase. The SX2 will not allow more data than

the wLength field specified in the set-up packet. Note: the

PKTEND pin does not apply to Endpoint 0. The only way to

send a short or zero length packet is by writing to the byte

count register with the appropriate value.

Document #: 38-08013 Rev. *E Page 8 of 42

1

FOR

FOR

CY7C6800

For an OUT set-up transaction, the external master can read

each packet received from the USB host during the data

phase. The steps to re ad a packet are as follows:

1. Wait f or an EP0BUF inte rrupt, indicati ng that a pac ket was

received from the US B host i nto the buffer.

2. Initiate a read re quest for the byte count regis ter, 0x33.

This indicates the amount of data received from the host.

3. Initiate a read re quest for register 0x31.

4. Read one byte.

5. Repeat steps 3 and 4 until the number of b ytes specified

in the byte count register has been read.

To receive more than 64 bytes, the process is repeated. The

SX2 internally stores the length of the data phase that was

specified in the wLength field of the set-up packet (bytes 6,7 ).

When the SX2 sees that the specified number of bytes have

been received, it will complete the set-up transfer by automatically comple ting the handshake phase. If the external master

does not wish to receive the entire transfer, it can stall the

transfer.

If the SX2 receives another set-up packet before the current

transfer has complet ed, it will int errupt the external master wi th

another SETUP in te rrupt. If the SX2 receives a set-up packet

with no data phase, the externa l master can accept the packet

and complete the handshak e pha se b y writ ing z ero t o the b yt e

count register.

The SX2 auto maticall y responds to all USB standard requests

covered in chapter 9 of the

USB 2.0 specification except the

Set/Clear F eature Endpoint r equests. When the host issues a

Set Feature or a Clear feature request, the SX2 will trigger a

SETUP interrupt to the external master. The USB spec

requires that the device respond to the Set endpoint feature

request by doing the fol lowing:

• Set the STALL condition on that endpoin t.

The USB spec requires that the device respond to the Clear

endpoint feature request by doing the following:

• Reset the Data Toggle for that endpoint

• Clear the STALL condition of that end point.

The register that is used to reset the data toggle TOGCTL

(located at XDATA location 0xE683) is not an index register

that can be addressed by the command protocol presented in

Section 3.7.8. The following section provides further information on this register bits and how to reset the data toggle

accordingly using a different set of command protocol

sequence.

5.1 Resetting Data Toggle

Following is the bi t def inition of the TOGCTL regis ter:

TOGCTL

Bit #

Bit Name Q S R I/O EP3 EP2 EP1 EP0

Read/Write R W W R/W R/W R/W R/W R/W

Default 00110010

7 6 5 4 3 2 1 0

Bit 7: Q, Data Toggle Value

Q=0 indicates DATA0 and Q=1 indicates DATA1, for the

endpoint sele cted by the I/O and EP3:0 bit s. Write the endpoi nt

select bits (IO and EP3: 0), before reading this value.

0xE683

Bit 6: S, Set Data Toggle to DATA1

After selecting the desired endpoint by writing the endpoint

select bits (IO and EP3:0), set S=1 to set the data toggle to

DATA1. The endpoint selection bits should not be changed

while thi s bit is wr itt e n.

Bit 5: R, Set Data Toggle to DATA0

Set R=1 to set the data toggle to DATA0. The endpoint

selection bits should not be changed while this bit is written.

Bit 4: IO , Select IN or OUT Endpoint

Set this bit to sel ect an endpoint direction prior to sett ing its R

or S bit. IO=0 selects an OUT endpoint, IO = 1 selects an IN

endpoint.

Bit 3-0: EP3:0, Select Endpoint

Set these bits to select an endpoint prior to setting its R or S

bit. Valid values are 0, 1, 2, , 6, and 8.

A two-step process is employed to clear an endpoint data

toggle bit to 0. First, write to the TOGCTL register with an

endpoint address (EP3 :EP0) plus a dire ction bit (IO ). Keeping

the endpoint and direction bits the same, write a “1” to the R

(reset) bit. For example, to clear the data toggle for EP6

configured as an “IN” endpoint, write the following values

sequentially to TOGCTL:

00010110b

00110110b

Following is the sequence of events that the master should

perform to set this register to 0x16:

(1) Send Low Byte of the Register (0x83)

• Command address write of address 0x3A

• Command data writ e of upper nibble of the Low Byte of

Register Address (0x08)

• Command data writ e of l ower nibble of the Low Byte of

Register Address (0x03)

(2) Send High Byte of the Register (0xE6)

• Command address write of address 0x3B

• Command data writ e of upper nibble of the High Byte of

Register Address (0x0E)

• Command data write of l ower nibble of the High Byte of

Register Address (0x06)

(3) Send the actual value to write to the register Register (in

this case 0x16)

• Command address write of address0x3C

• Command data writ e of upper nibble of the High Byte of

Register Address (0x01)

• Command data writ e of l ower nibble of the High Byte of

Register Address (0x06)

The same command sequence needs to be followed to set

TOGCTL register to 0x36. The same command protocol

sequence can be used to reset the data toggle for the other

endpoints. In order to read the status of this register, the

external master must do the following sequence of event s:

(1) Send Low Byte of the Register (0x83)

• Command address write of 0x3A

Document #: 38-08013 Rev. *E Page 9 of 42

1

FOR

FOR

• Command data write of upper nibble of the Low Byte of

Register Address (0x08)

• Command data write of lower nibble of the Low Byte of

Register Address (0x03)

(2) Send High Byte of the Register (0xE6)

• Command address writ e of address 0x3B

• Command data write of upper nibble of the High Byte of

Register Address (0x0E)

• Command data write of lowe r ni bble of the High Byte of

Register Address (0x06)

(3) Get the actual value from the TOGCTL regist er (0x16)

• Command address READ of 0x3C

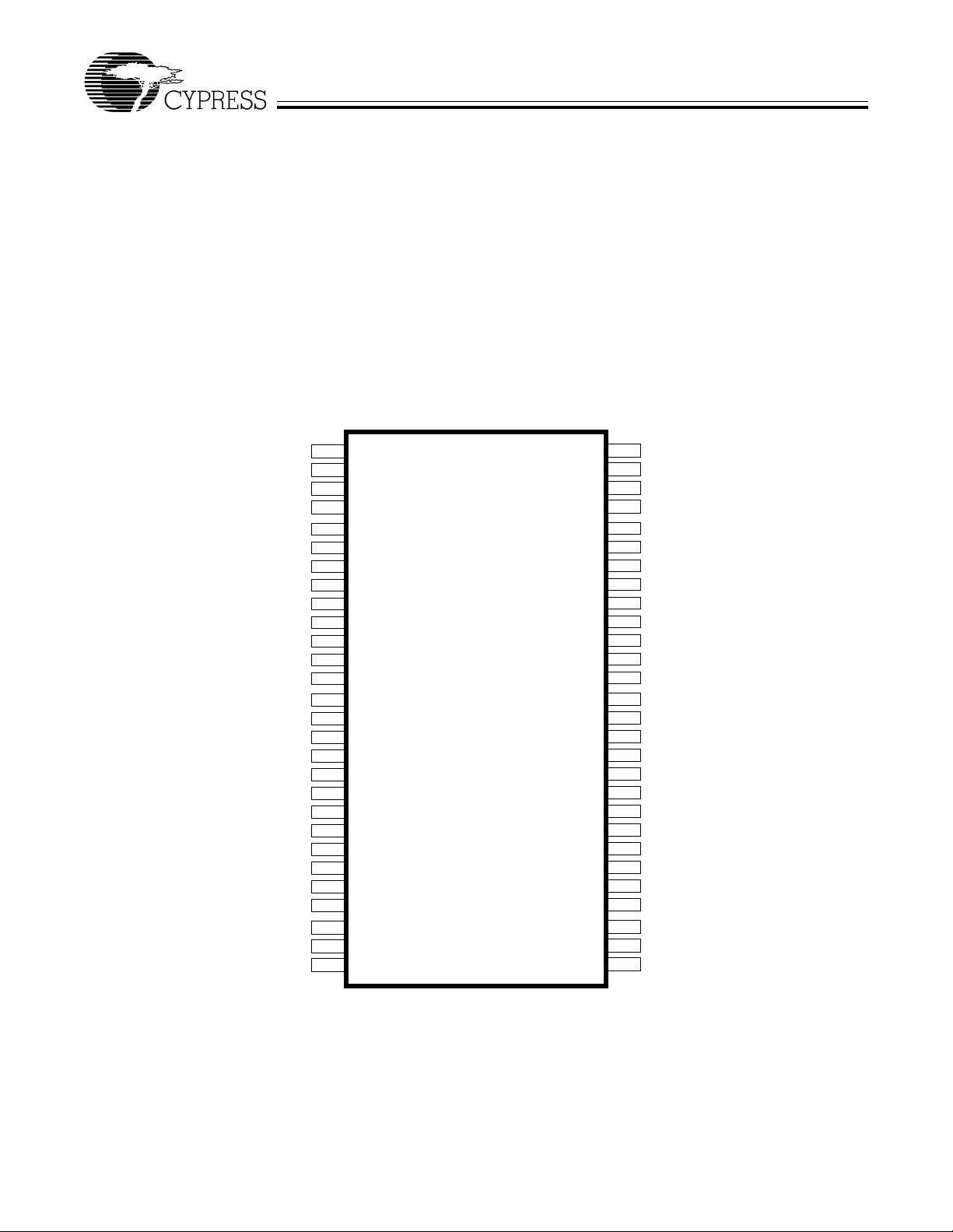

6.0 Pin Assignments

6.1 56-pin SSOP

CY7C6800

1

FD13

2

FD14

3

FD15

4

GND

5

NC

6

VCC

7

GND

8

*SLRD

9

*SLWR

10

AVCC

11

XTALOUT

12

XTALIN

13

AGND

14

VCC

15

DPLUS

16

DMINUS

17

GND

18

VCC

19

GND

20

*IFCLK

21

RESERVED

22

SCL

23

SDA

24

VCC

25

FD0

26

FD1

27

FD2

28

FD3

*WAKEUP

*FLAGD/CS#

FIFOADR1

FIFOADR0

FIFOADR2

CY7C68001

56-pin SSOP

FD12

FD11

FD10

FD9

FD8

VCC

RESET#

GND

*PKTEND

*SLOE

INT#

READY

VCC

*FLAGC

*FLAGB

*FLAGA

GND

VCC

GND

FD7

FD6

FD5

FD4

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

Figure 6-1. CY7C68001 56-pin SSOP Pin Assignment

Note:

7. A * denotes programmable polarity.

Document #: 38-08013 Rev. *E Page 10 of 42

[7]

1

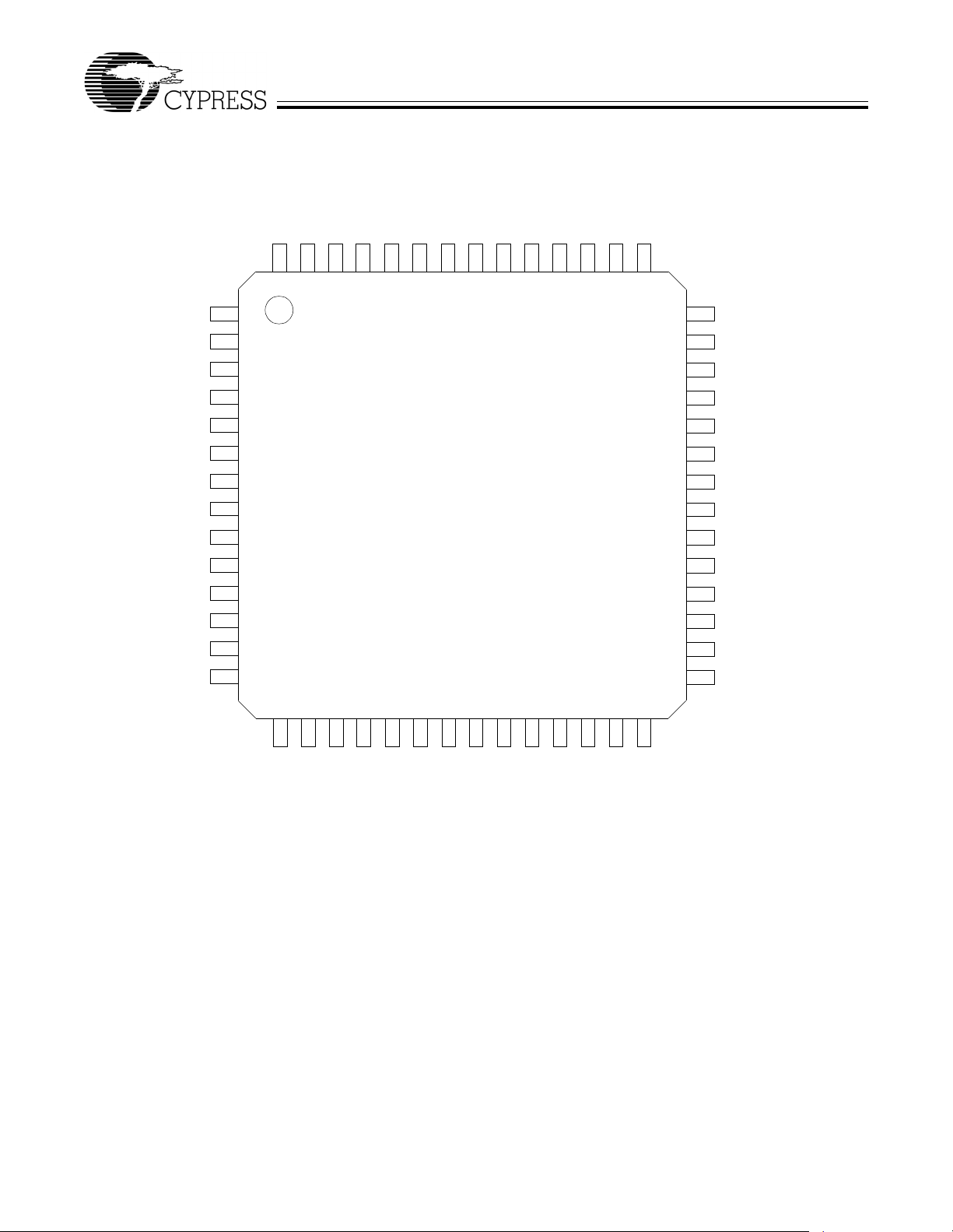

6.2 56-pin QFN

GND

56

VCC

55

FOR

FOR

CY7C6800

*

WAKEUP

FD15

FD14

FD13

FD12

FD11

NC

54

GND

53

52

51

50

49

FD10

484547

FD9

46

44

VCC

43

FD8

SLRD

*

SLW R

*

AVCC

XTAL O U T

XTAL IN

AGND

VCC

DPLUS

DMINUS

GND

VCC

GND

IFCLK

*

RESERVED

10

11

12

13

14

1

2

3

4

5

6

7

8

9

17

15

SCL

16

SDA

18

VCC

FD0

CY7C68001

56-pin Q FN

19

202721

FD1

FD2

FD3

22

FD4

23

FD5

24

FD6

25

FD7

26

GND

28

VCC

GND

42

41

40

39

38

37

36

35

34

33

32

31

30

29

RESET#

GND

FLAGD/CS#

*

PKTEND

*

FIFOAD R1

FIFOAD R0

FIFOAD R2

SLOE

*

INT#

READY

VCC

FLAGC

*

FLAGB

*

FLAGA

*

Figure 6-2. CY7C68001 56-pi n QF N Assignment

Document #: 38-08013 Rev. *E Page 11 of 42

[7]

1

FOR

FOR

CY7C6800

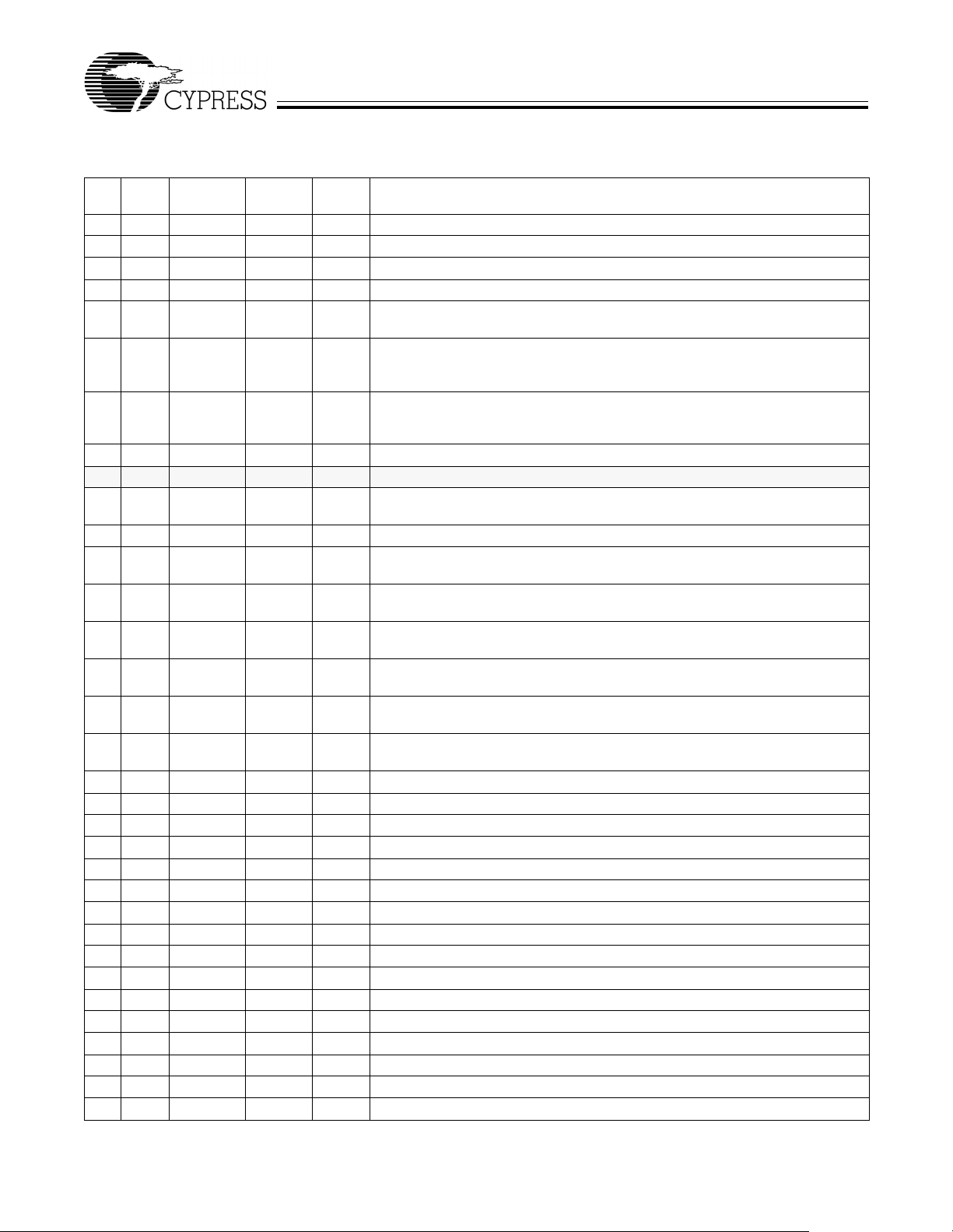

6.3 CY7C68001 Pin Definitions

T able 6-1. SX2 Pin Definitions

QFN

SSOP

Pin

Pin Name Type Default Description

3 10 AVCC Power N/A Analog V

6 13 AGND Power N/A Analog Ground. Connect to ground with as short a path as possible.

9 16 DMINUS I/O/Z Z USB D– Signal. Connect to the USB D– signal.

815DPLUSI/O/Z ZUSB D+ Signal. Connect to the USB D+ signal.

42 49 RESET# Input N/A Active LOW Reset. Rese ts the entire chip. This pin is normally tied to V

through a 100K resi stor, and to GND through a 0.1-µF capacitor.

5 12 XTALIN Input N/A Crystal Input. Connect this signal to a 24-MHz parallel-resonant, fundamental

mode crys tal and 20-pF capacitor to GND. It is also correct to drive XTALIN with

an external 24- MHz square wave derived from anothe r cl ock source.

4 11 XTALOUT Output N/A Crystal Output. Conn ect this signa l to a 24 -MHz parall el-reso nant , fun dament al

mode crystal and 20- pF capacitor to GND. If an external clock is used to drive

XTALIN, leave this pin open.

54 5 NC Output O No Connect. This pin must be left unconnected.

. This signal provi des power to the analog section of the chip.

CC

CC

33 40 READY Output L READY is an output-only ready that gates external command reads and writes.

Active High.

34 41 INT# Output H INT# is an output-only external interrupt signal. Active Low.

35 42 SLOE Input I SLOE is an input-onl y output enable with programmable polarity (POLAR.4) for

the slave FIFOs connected to FD[7:0] or FD[15:0].

36 43 FIFOADR2 Input I FIFOADR2 is an input-only address select for the slav e FIFOs connected to

FD[7:0] o r FD [ 1 5: 0 ].

37 44 FIFOADR0 Input I FIFOADR0 is an input-only address select for the slav e FIFOs connected to

FD[7:0] o r FD [ 1 5: 0 ].

38 45 FIFOADR1 Input I FIFOADR1 is an input-only address select for the slav e FIFOs connected to

FD[7:0] o r FD [ 1 5: 0 ].

39 46 PKTEND Input I PKTEND is an input-only packet end with programmable polari ty (POLAR.5) for

the slave FIFOs connected to FD[7:0] or FD[15:0].

40 47 FLAGD/CS#CS#:I

FLAGD:O

I FLAGD is a programmable slave- FIFO output status f lag signal. CS# is a mast er

chip select (default).

18 25 FD[0] I/O/Z I FD[0] is the bidirectional FIFO/Command data bus.

19 26 FD[1] I/O/Z I FD[1] is the bidirectional FIFO/Command data bus.

20 27 FD[2] I/O/Z I FD[2] is the bidirectional FIFO/Command data bus.

21 28 FD[3] I/O/Z I FD[3] is the bidirectional FIFO/Command data bus.

22 29 FD[4] I/O/Z I FD[4] is the bidirectional FIFO/Command data bus.

23 30 FD[5] I/O/Z I FD[5] is the bidirectional FIFO/Command data bus.

24 31 FD[6] I/O/Z I FD[6] is the bidirectional FIFO/Command data bus.

25 32 FD[7] I/O/Z I FD[7] is the bidirectional FIFO/Command data bus.

45 52 FD[8] I/O/Z I FD[8] is the bidirectional FIFO data bus.

46 53 FD[9] I/O/Z I FD[9] is the bidirectional FIFO data bus.

47 54 FD[10] I/O/Z I FD[10] is the bidir ectional FIFO data bus.

48 55 FD[11] I/O/Z I FD[11] is the bidirectional FIFO data bus.

49 56 FD[12] I/O/Z I FD[12] is the bidir ectional FIFO data bus.

50 1 FD[13] I/O/Z I FD[13] is the bidirectional FIFO data bus.

51 2 FD[14] I/O/Z I FD[14] is the bidirectional FIFO data bus.

52 3 FD[15] I/O/Z I FD[15] is the bidirectional FIFO data bus.

Document #: 38-08013 Rev. *E Page 12 of 42

1

FOR

FOR

CY7C6800

T able 6-1. SX2 Pin Definitions (continued)

QFN

SSOP

Pin

Pin Name Type Default Description

1 8 SLRD Input N/A SLRD is the input-only re ad strobe with programmable polari ty (POLAR.3) for the

slave FIFOs connected to FD[7:0] or FD[15:0].

2 9 SLWR Input N/A SLWR is the input-only write strobe with programmable polarity (POLAR.2) for

the slave FIFOs connected to FD[7:0] or FD[15:0].

29 36 FLAGA Output H FLAGA is a programmable slave-FIFO output status flag signal.

Defaults to PF for the FIFO se lected by th e FIFOADR [2:0] pins.

30 37 FLAGB Output H FLAGB is a programmable slave-FIFO output status flag signal.

Defaults to FULL for the FIFO selected by the FIFOADR[2:0] pins.

31 38 FLAGC Output H FLAGC is a programmable slave-FIFO output status flag signal.

Defaults to EMPTY for the FIFO selected by the FIFOADR[2:0] pins.

13 20 IFCLK I/O/Z Z Interface Clock, used for synchronously clocking data into or out of the slave

FIFOs. IFCLK al so serves as a tim ing referenc e for all slave FI FO control signals.

When using the internal clock reference (IFCONFIG.7=1) the IFCLK pin can be

configured to outp ut 30/48 MHz by setting bits IFCONFIG.5 and IFCONFIG.6.

IFCLK may be inver ted by se ttin g the bit IFCONFIG. 4=1. Pro grammable po lari ty.

14 21 Reserved Input N/A Reserved. Must be connected to ground.

44 51 WAKEUP Input N/A USB Wakeup. If th e SX2 is in suspend, asserting thi s pin starts up the oscill ator

15 22 SCL OD Z I

16 23 SDA OD Z I

and interrup ts t he SX2 to al low i t to exit the suspend mode. During normal

operation, ho lding W AKEUP asserted inhi bits the SX2 chip fro m suspending. This

pin has programmable polarity (POLAR.7).

2

C Clock. Connec t to V

EEPROM is attached.

2

C Data. Connect to V

is attached.

with a 2.2K-10 K Ohms resistor, even if no I2C

CC

with a 2. 2K-10 K Ohms res istor , even if no I2C EEPROM

CC

55 6 V

714 V

11 18 V

17 24 V

27 34 V

32 39 V

43 50 V

CC

CC

CC

CC

CC

CC

CC

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

53 4 GND Ground N/A Connect to ground.

56 7 GND Ground N/A Connect to ground.

10 17 GND Ground N/A Connect to ground.

12 19 GND Ground N/A Connect to ground.

26 33 GND Ground N/A Connect to ground.

28 35 GND Ground N/A Connect to ground.

41 48 GND Ground N/A Connect to ground.

Document #: 38-08013 Rev. *E Page 13 of 42

1

FOR

FOR

CY7C6800

7.0 Register Summary

T able 7-1. SX2 Register Summary

Hex Size Name Description D7 D6 D5 D4 D3 D2 D1 D0 Default Access

General Configuration

01 1 IFCONFIG Interface Configuration IFCLKSRC 3048MHZ IFCLKOE IFCLKPOL ASYNC STANDBY FLAGD/CS# DISCON 11001001 bbbbbbbb

02 1 FLAGSAB FIFO FLAGA and FLAGB Assign-

03 1 FLAGSCD FIFO FLAGC and FLAGD Assign04 1 POLAR FIFO polarities WUPOL 0 PKTEND SLOE SLRD SLWR EF FF 00000000 bbbrrrbb

05 1 REVID Chip Revision Major Major Major Major minor minor minor minor xxxxxxxx rrrrrrrr

Endpoint Configuration

06 1 EP2CFG Endpoint 2 Configuration VALID dir TYPE1 TYPE0 SIZE STALL BUF1 BUF0 10100010 bbbbbbbb

07 1 EP4CFG Endpoint 4 Configuration VALID dir TYPE1 TYPE0 0 STALL 0 0 10100000 bbbbrbrr

08 1 EP6CFG Endpoint 6 Configuration VALID dir TYPE1 TYPE0 SIZE STALL BUF1 BUF0 11100010 bbbbbbbb

09 1 EP8CFG Endpoint 8 Configuration VALID dir TYPE1 TYPE0 0 STALL 0 0 11100000 bbbbrbrr

0A 1 EP2PKTLENH E ndpoint 2 Packet Length H INFM1 OEP1 ZEROLEN WORD-

0B 1 EP2PKTLENL Endpoint 2 Packet Length L (IN only) PL7 PL6 PL5 PL4 PL3 PL2 PL1 PL0 00000000 bbbbbbbb

0C 1 EP4PKTLENH Endpoint 4 Packet Length H INFM1 OEP1 ZEROLEN WORD-

0D 1 EP4PKTLENL Endpoint 4 Packet Length L (IN only) PL7 PL6 PL5 PL4 PL3 PL2 PL1 PL0 00000000 bbbbbbbb

0E 1 EP6PKTLENH Endpoint 6 Packet Length H INFM1 OEP1 ZEROLEN WORD-

0F 1 EP6PKTLENL Endpoint 6 Packet Length L (IN only) PL7 PL6 PL5 PL4 PL3 PL2 PL1 PL0 00000000 bbbbbbbb

10 1 EP8PKTLENH Endpoint 8 Packet Length H INFM1 OEP1 ZEROLEN WORD-

11 1 EP8PKTLENL Endpoint 8 Packet Length L (IN only) PL7 PL6 PL5 PL4 PL3 PL2 PL1 PL0 00000000 bbbbbbbb

12 1 EP2PFH EP2 Programmable Flag H DECIS PKTSTAT IN: PKTS[2]

13 1 EP2PFL EP2 Programmable Flag L PFC7 PFC6 PFC5 PFC4 PFC3 PFC2 PFC1 PFC0 00000000 bbbbbbbb

14 1 EP4PFH EP4 Programmable Flag H DECIS PKTSTAT 0 IN: PKTS[1]

15 1 EP4PFL EP4 Programmable Flag L PFC7 PFC6 PFC5 PFC4 PFC3 PFC2 PFC1 PFC0 00000000 bbbbbbbb

16 1 EP6PFH EP6 Programmable Flag H DECIS PKTSTAT IN: PKTS[2]

17 1 EP6PFL EP6 Programmable Flag L PFC7 PFC6 PFC5 PFC4 PFC3 PFC2 PFC1 PFC0 00000000 bbbbbbbb

18 1 EP8PFH EP8 Programmable Flag H DECIS PKTSTAT 0 IN: PKTS[1]

19 1 EP8PFL EP8 Programmable Flag L PFC7 PFC6 PFC5 PFC4 PFC3 PFC2 PFC1 PFC0 00000000 bbbbbbbb

1A 1 EP2ISOINPKTS EP2 (if ISO) IN P ackets per frame (1-3) 0 0 0 0 0 0 INPPF1 INPPF0 00000001 bbbbbbb b

1B 1 EP4ISOINPKTS EP4 (if ISO) IN P ackets per frame (1-3) 0 0 0 0 0 0 INPPF1 INPPF0 00000001 bbbbbbb b

1C 1 EP6ISOINPKTS EP6 (if ISO) IN Packets per frame (1-3) 0 0 0 0 0 0 INPPF1 INPPF0 00000001 bbbbbbb b

1D 1 EP8ISOINPKTS EP8 (if ISO) IN Packets per frame (1-3) 0 0 0 0 0 0 INPPF1 INPPF0 00000001 bbbbbbb b

FLAGS

1E 1 EP24FLAGS Endpoints 2,4 FIFO Flags 0 EP4PF EP4EF EP4FF 0 EP2PF EP2EF EP2FF 00100010 rrrrrrrr

1F 1 EP68FLAGS Endpoints 6,8 FIFO Flags 0 EP8PF EP8EF EP8FF 0 EP6PF EP6EF EP6FF 01100110 rrrrrrrr

INPKTEND/FLUSH

20 1 INPK-

TEND/FLUSH

USB Configuration

2A 1 USBFRAMEH USB Frame count H 0 0 0 0 0 FC10 FC9 FC8 xxxxxxxx rrrrrrrr

2B 1 USBFRAMEL USB Frame count L FC7 FC6 FC5 FC4 FC3 FC2 FC1 FC0 xxxxxxxx rrrrrrrr

2C 1 MICROFRAME Microframe count, 0-7 0 0 0 0 0 MF2 MF1 MF0 xxxxxxxx rrrrrrrr

2D 1 FNADDR USB Function address HSGRANT FA6 FA5 FA4 FA3 FA2 FA1 FA0 00000000 rrrrrrrr

Interrupts

2E 1 INTENABLE Interrupt Enable SETUP EP0BUF FLAGS 1 1 ENUMOK BUSACTIVITY READY 11111111 bbbbbbbb

Descriptor

30 500 DESC Descriptor RAM d7 d6 d5 d4 d3 d2 d1 d0 xxxxxxxx wwwwww-

Endpoint 0

31 64 EP0BUF Endpoint 0 Buffer d7 d6 d5 d4 d3 d2 d1 d0 xxxxxxxx bbbbbbbb

32 8/1 SETUP Endpoint 0 Set-up Data / Stall d7 d6 d5 d4 d3 d2 d1 d0 xxxxxxxx bbbbbbbb

33 1 EP0BC Endpoint 0 Byte Count d7 d6 d5 d4 d3 d2 d1 d0 xxxxxxxx bbbbbbbb

Un-Indexed Register control

3A 1 Un-Indexed Register Low Byte pointer a7 a6 a5 a4 a3 a2 a1 a0

3B 1 Un-Indexed Register High Byte point-era7 a6 a5 a4 a3 a2 a1 a0

3C 1 Un-Indexed Register Data d7 d6 d5 d4 d3 d2 d1 d0

Address Un-I ndexed Registers in XDATA Space

0xE609 FIFOPINPOLAR FIFO Interface Pins Polarity 0 0 PKTEND SLOE SLRD SLWR EF FF 00000000 rrbbbbbb

0xE683 TOGCTL Data Toggle Control Q S R IO EP3 EP2 EP1 EP0 xxxxxxxx rbbbbbbb

ments

ments

[8]

[9]

Force Packet End / Flush FIFOs FIFO8 FIFO6 FIFO4 FIFO2 EP3 EP2 EP1 EP0 00000000 wwwwww-

Notes:

8. Please note that the SX2 was not designed to support dynamic modification of these endpoint configuration registers. If your applications need the ability to

change endpoint configurations after the device has already enumerated with a specific configuration, please expect some delay in being able to access the

FIFOs after changing the configuration. For example, after writing to EP2PKTLENH, you must wait for at least 35 us measured from the time the READY signal

is asserted before writing to the FIFO. This delay time varies for different registers and is not characterized, because the SX2 was not designed for this dynamic

change of endpoint configuration registers.

9. Please note that the SX2 was not designed to support dynamic modification of the INPKTEND/FLUSH register. If your applications need the ability to

endpoint configurations or access the INPKTEND register after the device has already enumerated with a specific configuration, please expect some delay in

being able to access the FIFOs after changing this register. After writing to INPKTEND/FLUSH, you must wait for at least 85 us measured from the time the

READY signal is asserted before writing to the FIFO. This delay time varies for different registers and is not characterized, because the SX2 was not designed

for this dynamic change of endpoint configuration registers

FLAGB3 FLAGB2 FLAGB1 FLAGB0 FLAGA3 FLAGA2 FLAGA1 FLAGA0 00000000 bbbbbbbb

FLAGD3 FLAGD2 FLAGD1 FLAGD0 FLAGC3 FLAGC2 FLAGC1 FLAGC0 00000000 bbbbbbbb

0 PL10 PL9 PL8 00110010 bbbbbbbb

0 0 PL9 PL8 00110010 bbbbbbbb

0 PL10 PL9 PL8 00110010 bbbbbbbb

0 0 PL9 PL8 00110010 bbbbbbbb

IN: PKTS[0]

OUT:PFC10

IN: PKTS[0]

OUT:PFC9

IN: PKTS[0]

OUT:PFC10

IN: PKTS[0]

OUT:PFC9

0 PFC9 PFC8 10001000 bbbbbbbb

0 0 PFC8 10001000 bbbbbbbb

0 PFC9 PFC8 00001000 bbbbbbbb

0 0 PFC8 00001000 bbbbbbbb

ww

ww

change

OUT:PFC12

OUT:PFC12

WIDE

WIDE

WIDE

WIDE

IN: PKTS[ 1]

OUT:PFC11

OUT:PFC10

IN: PKTS[ 1]

OUT:PFC11

OUT:PFC10

Document #: 38-08013 Rev. *E Page 14 of 42

1

7.1 IFCONFIG Register 0x01

FOR

FOR

CY7C6800

IFCONFIG

Bit #

Bit Name IFCLKSRC 3048MHZ IFCLKOE IFCLKPOL ASYNC STANDBY FLAGD/CS# DISCON

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 11001001

7.1.1 Bit 7: IFCLKSRC

This bit selects the clock source for the FIFOs. If IFCLKSRC

= 0, the external clock on the IFCLK pin is selected. If

IFCL KSRC = 1 (def ault), an internal 30 or 48 MH z clock is

used.

7.1.2 Bit 6: 3048MHZ

This bit select s the int ernal FIFO clock frequenc y. If 3048MHZ

= 0, the internal clock frequency is 30 MHz. If 3048MHZ = 1

(default), the internal clock frequency is 48 MHz.

7.1.3 Bit 5: IFCLKOE

This bit selects if the IFCLK pin is driven. If IFCLKOE = 0

(default), t he IFCLK pi n is floated. If IFCLKOE = 1, the IFCLK

7 6 5 4 3 2 1 0

When ASYNC = 1 (default), the FIFOs operate asynchronously. No clock signal input to IFCLK is required, and the

FIFO control signals function directly as read and write

strobes.

7.1.6 Bit 2: ST ANDBY

This bit instructs the SX2 to enter a low-power mode. When

ST ANDBY=1, the SX2 will enter a low-power m ode by turning

off its oscillator. The external master shou ld wr it e this bit after

it receives a bus activity interrupt (indicating that the host has

signaled a USB suspend condition). If SX2 is disconnected

from the USB bus, the e xternal master can writ e this bit at any

time to save power. Once suspended, the SX2 is awakened

either by resumption of USB bus activity or by assertion of its

WAKEUP pin.

0x01

pin is driven.

7.1.7 Bit 1: FLAGD/CS#

7.1.4 Bit 4: IFCLKPOL

This bit control s the polarity of the IFCLK signal.

• When IFCLKPOL=0, the clock has the polari ty shown in all

This bit controls the function of the FLAGD/CS# pin. When

FLAGD/CS# = 0 (default), the pin operates as a slave chip

select. If FLAGD/CS# = 1, the pin oper ates as FLAGD.

the timing diagrams in this data sheet (rising edge is the

activating edge).

• When IFCLKPOL=1, the clock is inverted (in some cases

may help w ith sati s fying data set-up times).

7.1.5 Bit 3: ASYNC

This bit control s whether the FIFO int erface i s synchro nous or

asynchronous. When ASYNC = 0, the FIFOs ope rate synchr onously. In synchronous mode, a clock is supplied either internally or externally on the IFCLK pin, and the FIFO control

signals fu nction as read and write enable signal s for the clock

7.1.8 Bit 0: DISCON

This bit controls whether the internal pull-up resistor

connected to D+ is pu ll ed high or floating. Whe n DISCON = 1

(default), the pull-up resistor is floating simulating a USB

unplug. When DISCON=0, the pull-up resistor is pulled high

signaling a USB connection.

7.2 FLAGSA B/FLAG SCD Register s 0x02/0x03

The SX2 has four FIFO flags output pins: FLAGA, FLAGB,

FLAGC, FLAGD.

signal.

FLAGSAB

Bit #

Bit Name FLAGB3 FLAGB2 FLAGB1 FLAGB0 FLAGA3 FLAGA2 FLAGA1 FLAGA0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 00000000

7 6 5 4 3 2 1 0

0x02

FLAGSCD

Bit #

Bit Name FLAGD3 FLAGD2 FLAGD1 FLAGD0 FLAGC3 FLAGC2 FLAGC1 FLAGC0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 00000000

Document #: 38-08013 Rev. *E Page 15 of 42

7 6 5 4 3 2 1 0

0x03

1

FOR

FOR

CY7C6800

These flags can be programmed to represent various FIFO

flags using four select bits for each FIFO. The 4-bit codi ng for

all four flags is the same, as shown in the following table

.

T able 7-2. FIFO Flag 4-bit Coding

FLAGx3 FLAGx2 FLAGx1 FLAGx0 Pin Function

0 0 0 0 FLAGA = PF ,

FLAGB = FF,

FLAGC = EF,

FLAGD = CS#

(actual FIFO is

selected by

FIFOADR[2:0]

pins)

0001Reserved

0010Reserved

0011Reserved

0 1 0 0 EP2 PF

0 1 0 1 EP4 PF

0 1 1 0 EP6 PF

0 1 1 1 EP8 PF

1 0 0 0 EP2 EF

1 0 0 1 EP4 EF

1 0 1 0 EP6 EF

1 0 1 1 EP8 EF

1100EP2 FF

1101EP4 FF

1110EP6 FF

1111EP8 FF

For the default (0000) selection, the four FIFO flags are fixedfunction as shown in the first table entry; the input pins

FIFOADR[2:0] select to which of the four FIFOs the flags

correspond. These pins are decoded as shown in Table 3-3.

The other (non- zero) values of FLAGx[3:0] allow the designer

to independently configure the four flag outputs FLAGAFLAGD to correspond to any flag-Programmable, Full, or

Empty-from any of the four endpoint FIFOs. This allows each

flag to be assigned to any of the four FIFOs, including those

not currently selected by the FIFOADR [2:0] pins. For

example, the external master could be filling the EP2IN FIFO

with data while also checking the empty flag for the EP4OUT

FIFO.

7.3 POLAR Register 0x04

This register cont rols the polariti es of FIFO pin signals and the

WAKEUP pin.

POLAR

Bit #

Bit

Name

Read/W

rite

Default 0 0 0 0 0 000

7 6 5 4 3 2 1 0

WUPOL 0 PKTEND SLOE SLRD SLWR EF FF

R/W R/W R/W R R R R/W R/W

0x04

7.3.1 Bit 7: WUPOL

This flag sets the polarity of the WAKEUP pin. If WUPOL = 0

(default), t he polarity is acti ve LOW. If WUPOL=1, the polar it y

is active HIGH.

7.3.2 Bit 5: PKTEND

This flag selects the pol arit y of the PKTEND pin. If PKTEND =

0 (default), the polarity is active LOW. If PKTEND = 1, the

polarity is active HIGH.

7.3.3 Bit 4: SLOE

This flag selects the polarity of the SLOE pin. If SLOE = 0

(default), the polarity is active LOW. If SLOE = 1, the polarity

is active HIGH. This bit can only be changed by using the

EEPROM configuration load.

7.3.4 Bit 3: SLRD

This flag selects the polarity of the SLRD pin. If SLRD = 0

(default), the polarity is active LOW. If SLRD = 1, the polarity

is active HIGH. This bit can only be changed by using the

EEPROM configuration load.

7.3.5 S LWR Bit 2

This flag selects the polarity of the SLWR pin. If SLWR = 0

(default), the polarity is active LOW. If SLWR = 1, the polarity

is active HIGH. This bit can only be changed by using the

EEPROM configuration load.

7.3.6 EF Bit 1

This flag selects the polarity of the EF pin (FLAGA/B/C/D). If

EF = 0 (default), the EF pin is pulled low when the FIFO is

empty. If EF = 1, the EF pin is pulled HIGH when the FIFO is

empty.

7.3.7 FF Bit 0

This flag selects the polarity of the FF pin (FLAGA/B/C/D). If

FF = 0 (default), the FF pin is pulled low when the FIFO is full.

If FF = 1, the FF pin is pulled HIGH when the FIFO is full.

Note that bits 2(SLWR), 3(SLRD) and 4 (SLOE) are READ

only bits and cannot be set by the external master or the

EEPROM. On power-up, these bits are set to active low

polarity. In order to change the polarity after the device is

powered-up, the external master must access the previously

undocumented (un-indexed) SX2 register located at XDATA

space at 0xE609. This register has exact same bit definition

as the POLAR register except that bits 2, 3 and 4 defined as

SLWR, SLRD and SLOE respectively are Read/Write bits.

Following is the sequence of events that the master should

perform for s etting thi s register to 0x1C (set ting bi ts 4,3,and 2) :

1) Send Low Byte of the Register (0x09)

• Command address write of address 0x3A

• Command data write of upper nibble of the Low Byte of

Register Address (0x00)

• Command data write of lower nibble of the Low Byte of

Register Address (0x09)

Document #: 38-08013 Rev. *E Page 16 of 42

1

FOR

FOR

CY7C6800

(2) Send High Byte of the Register (0xE6)

• Command address write of address 0x3B

• Command data write of upper nibble of the High Byt e of

Register Address (0x0E)

• Command data write of lower nibble of th e High Byt e of

Register Address (0x06)

(3) Send the actual value to write to the register Register (in

this case 0x1C)

• Command address write of address 0x3C

• Command data write of upper nibble of the High Byt e of

Register Address (0x01)

• Command data write of lower nibble of th e High Byt e of

Register Address (0x0C)

In order t o avoid alter ing any other b its o f the F IFOPINPOLAR

register (0xE6 09) i nadver tentl y, the external m aster must do a

read (from POLAR register), modify the value to set/clear

appropriate bits and write the modified value to FIFOPINPOLAR register. The external master may read from the

POLAR register using the command read protocol as stated in

Section 3.7.8. Modify the value with the appropriate bit set to

change the polar ity as needed and wr i te this modi fied value t o

the FIFOPINPOLAR register.

7.4 REVID Register 0x05

These register bit s define the silicon revision.

REVID

Bit #

Bit

Name

Read/

Write

Default XXXXXXXX

7 6 5 4 3 2 1 0

Major Major Major Major Minor Minor Minor Minor

R/W R/W R/W R/W R/W R/W R/W R/W

0x05

The upper nibble is the maj or revision. The lower nibble is the

minor revision. For example: if REVID = 0x1 1, then the sili con

revision i s 1.1.

7.5 EPxCFG Register 0x06–0x09

These registers configure the large, data-handling SX2

endpoints, EP2, 4, 6, and 8. Figure 3-1 shows the configuration choices for these endpoints. Shaded blocks group

endpoint buffers for double-, triple-, or quad-buffering. The

endpoint direction is set independently—any shaded block

can have any direction.

EPxCFG

Bit #

Bit

Name

Read/

Write

Default 10100010

7 6 5 4 3 2 1 0

VALID DIR TYPE1 TYPE0 SIZE STALL BUF1 BUF0

R/W R/W R/W R/W R/W R/W R/W R/W

0x06, 0x08

.

EPxCFG

Bit #

Bit

Name

Read/W

rite

Default 10100010

7 6 5 4 3 2 1 0

VALID DIR TYPE1 TYPE0 SIZE STALL BUF1 BUF0

R/W R/W R/W R/W R R/W R R

0x07, 0x09

7.5.1 Bit 7: VALI D

The external master sets VALI D = 1 to activate an endpoint,

and VALID = 0 to deactivate it. All SX2 endpoints default to

valid. An endpoint whose VALID bit is 0 does not respond to

any USB traffic.

7.5.2 Bit 6: DIR

0 = OUT, 1 = IN. Defaults for EP2/4 a re DI R = 0, OUT, and fo r

EP6/8 are DIR = 1, IN.

7.5.3 Bit [5,4]: TYPE1, TYPE0

These bits define the endpoint type, as shown in Table 7-3.

The TYPE bits apply to all of the endpoint configuration

regist ers . A ll SX2 endpoints except EP0 default to BULK.

Table 7-3. Endpoint Type

TYPE1 TYPE0 Endpoint Type

00 Invalid

0 1 Isochronous

1 0 Bulk (Default)

1 1 Interrupt

7.5.4 Bit 3: SIZE

0 = 512 bytes (default), 1 = 1024 bytes.

Endpoints 4 and 8 can only be 512 bytes and is a read only

bit. The size of endpoin ts 2 and 6 is selectable.

7.5.5 Bit 2: STALL

Each bulk endpoint (IN or OUT) has a STALL bit (bit 2). If the

external master sets this bit, any requests to the endpoint

return a ST ALL handshake rather than ACK or NAK. The Get

Status-Endpoint Request returns the STALL state for the

endpoint indicated in byte 4 of the request. Note that bit 7 of

the endpoint number EP (byte 4) specifies directi on.

7.5.6 Bit [1,0]: BUF1, BUF0

For EP2 and EP6 the depth of endpoint buf fering is selected

via BUF1:0, as shown in Table 7-4. For EP4 and EP8 the

buffer is inter nally set to double buff ered and are read only bits .

Table 7-4. Endpoint Buffering

BUF1 BUF0 Buffering

00 Quad

01Invalid

[10]

1 0 Double

1 1 Triple

Notes:

10. Setting the endpoint buffering to invalid causes improper buffer allocation

Document #: 38-08013 Rev. *E Page 17 of 42

1

FOR

FOR

CY7C6800

7.6 EPxPKTLENH/L Registers 0x0A–0x11

The external master can use these registers to set smaller

packet sizes than the physical buffer size (refer to the previously de scrib ed EPxC FG regi st ers). T he defa ult packe t si ze is

512 bytes for all endpoints. Note that EP2 and EP6 can have

maximum sizes of 1024 bytes, and EP4 and EP8 can have

maximum sizes of 512 bytes, to be consistent with the

endpoint structure.

In addition, the EPxPKT LENH r egist er has four ot her e ndpoint

configuration bits.

EPxPKTLENL

Bit #

Bit Name PL7 PL6 PL5 PL4 PL3 PL2 PL1 PL0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 00000000

EP2PKTLENH,

EP6PKTLENH

Bit #

Bit Name INFM1 OEP1 ZERO

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 0011 0010

EP4PKTLENH,

EP8PKTLENH

Bit #

Bit Name INFM1 OEP1 ZERO

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 00110010

7 6 5 4 3 2 1 0

7 6 5 4 3 2 1 0

WORD

LEN

WIDE

7 6 5 4 3 2 1 0

WORD

LEN

WIDE

0 PL10 PL9 PL8

00 PL9PL8

7.6.1 Bit 7: INFM1 EPxPKTLENH.7

When the ext ernal mast er sets I NFM = 1 in an e ndpoint co nfiguration re gister, the FIFO flags for that endpoint become valid

one sample e arl ier than when the full condition occurs. These

bits take effect only when the FIFOs are operating synchronously according to an internally or externally supplied clock.

Having the FIFO flag indications one sample early simplifies

some synchronous interfaces. This applies only to IN

endpoints. Default is INFM1 = 0.

7.6.2 Bit 6: OEP1 EPxPKTLENH.6

When the external master sets an OEP = 1 in an endpoint

configuratio n register , t he FIFO flags for that endpoint become

valid one sample earlier than when the empty condition

occurs. These bits take effect only when the FIFOs are

operating synchronously according to an internally or externally supplied clock. Having the FIFO flag indications one

sample early simplifies some synchronous interfaces. This

applies only to OUT endpoints. Default is OEP1 = 0.

7.6.3 Bit 5: ZEROLEN EPxPKTLENH.5

When ZEROLEN = 1 (default), a zero length packet will be

sent when th e PKTEND pin i s asser ted an d t here ar e n o bytes

in the current packet. If ZEROLEN = 0, then a zero length

packet will not be sent under these conditions.

0x0B, 0x0D,

0x0F, 0x11

0x0A, 0x0E

0x0C, 0x10

7.6.4 Bit 4: WORDWIDE EPxPKTLENH.4

This bit controls whether the data interfa ce is 8 or 16 bits wide.

If WORDWIDE = 0, the data interface is eight bits wide, and

FD[15:8] have no function. If WORDWIDE = 1 (default), the

data interface is 16 bits wide.

7.6.5 Bit [2..0]: PL[X:0] Packet Length Bits

The default packet size is 512 bytes for all endpoints.

7.7 EPxPFH/L Register s 0x12–0x1 9

The Programmable Flag registers control when the PF goes

active for each of the four endpoint FIFOs: EP2, EP4, EP6,

and EP8. The EPxPFH/L fields are interpreted differently for

the high speed o peration and full speed operat ion and for OUT

and IN endpoints.

Following is the register bit definition f or high speed operation

and for full speed operation (when endpoint is configured as

an isochronous endpoi nt).

Full Speed ISO and High Speed Mode: EP2PFL,

EP4PFL, EP6PFL, EP8PFL

Bit #

Bit Name PFC7 PFC6 PFC5 PFC4 PFC3 PFC2 PFC1 PFC0

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 00000000

Full Speed ISO and Hi gh Speed Mode:

EP4PFH, EP8PFH

Bit #

Bit Name DECIS PKTSTAT 0 IN:

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 00001000

Full Speed ISO and High Speed Mode:

EP2PFH, EP6PFH

Bit #

Bit Name DECIS PKTSTAT IN:

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 10001000

7 6 5 4 3 2 1 0

7 6 5 4 3 2 1 0

IN:

OUT:

IN:

PKTS[0]

OUT:

PFC9

IN:

PKTS[0]

OUT:

PFC10

PKTS[1]

OUT:

PFC10

7 6 5 4 3 2 1 0

PKTS[2]

PKTS[1]

OUT:

PFC12

PFC11

Following is the bit definition for the same register when the

device is operating at full speed and the endpoint is not

configured as isochronous endpoint.

Full Speed Non-ISO Mode: EP2PFL,

EP4PFL, EP6PFL, EP8PFL

Bit #

Bit Name IN:

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 0 0 000000

7 6 5 4 3 2 1 0

IN:

PKTS[1]

OUT:

PFC7

PKTS[0]

PFC5 PFC4 PFC3 PFC2 PFC1 PFC0

OUT:

PFC6

0x13, 0x15,

0x17, 0x19

0x14, 0x18

0 0PFC8

0x12, 0x16

0 PFC9 PFC8

0x13, 0x15,

0x17, 0x19

Document #: 38-08013 Rev. *E Page 18 of 42

1

FOR

FOR

CY7C6800

Full Speed Non-ISO Mode:

EP2PFH, EP6PFH

Bit # 7 6 5 4 3 2 1 0

Bit Name DECIS PKTSTAT OUT:

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 1 0 00100 0

Full Speed Non-ISO Mode:

EP4PFH, EP8PFH

Bit #

Bit Name DECIS PKT-

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 0 0 0 0 1000

7 6 5 4 3 2 1 0

STAT

OUT:

PFC12

PFC11

0OUT:

PFC10

OUT:

PFC10

OUT:

PFC9

0x12, 0x16

0PFC9 IN:

PKTS[2]

OUT:

PFC8

0x14, 0x18

0 0PFC8

7.7.1 DECIS: EPxPFH.7

If DECIS = 0, t hen PF g oes hi gh whe n the b yte co unt i i s equal

to or less than what is defined in the PF registers. If DECIS =

1 (default), t hen PF goes high when the byte co unt equal to or

greater t han wh at i s set in th e PF regis ter. For OUT e ndpoi nts,

the byte count is the total number of b ytes i n the FIFO t hat ar e

available to the external master. For IN endpoints, the byte

count is determined by the PKSTAT bit.

7.7.2 PKSTAT: EPxPFH.6

For IN endpoints, the PF can apply to either the entire FIFO,

comprising multiple packets, or only to the current packet

being filled. If PKTST AT = 0 (def ault), the PF refers t o the entire