Page 1

CY7C68000A

MoBL-USB™ TX2 USB 2.0 UTMI

Transceiver

MoBL-USB™ TX2 Features

Tri_state

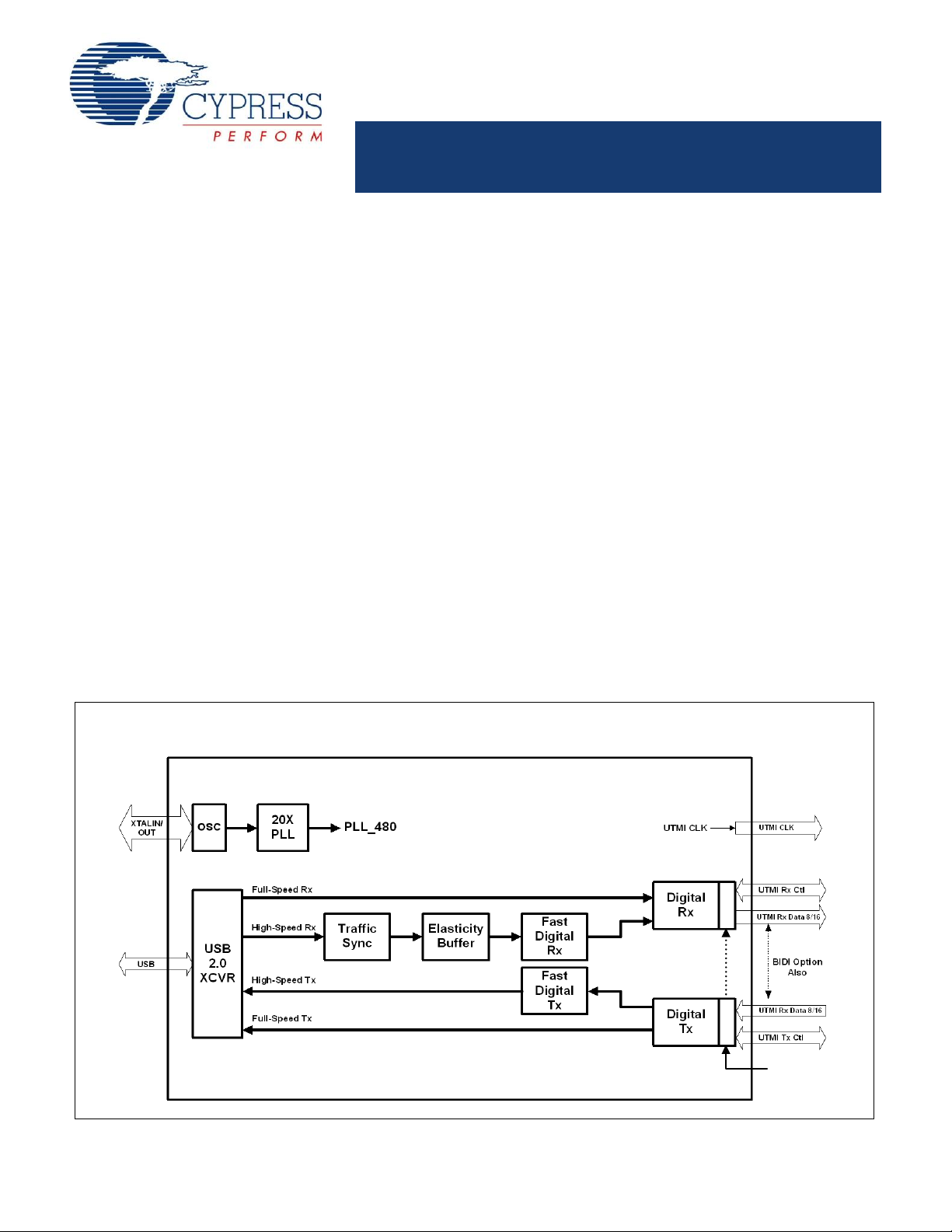

Logic Block Diagram

■ UTMI-compliant and USB 2.0 certified for device operation

■ Operates in both USB 2.0 High Speed (HS), 480 Mbits/second,

and Full Speed (FS), 12 Mbits/second

■ Optimized for Seamless Interface with Intel

cations Processors

■ Tri-state Mode enables sharing of UTMI Bus with other devices

■ Serial-to-Parallel and Parallel-to-Serial Conversions

■ 8-bit Unidirectional, 8-bit Bidirectional, or 16-bit Bidirectional

External Data Interface

■ Synchronous Field and EOP Detection on Receive Packets

■ Synchronous Field and EOP Generation on Transmit Packets

■ Data and Clock Recovery from the USB Serial Stream

■ Bit stuffing and unstuffing; Bit Stuff Error Detection

■ Staging Register to manage Data Rate variation due to Bit

stuffing and unstuffing

■ 16-bit 30 MHz and 8-bit 60 MHz Parallel Interface

■ Ability to switch between FS and HS terminations and signaling

■ Supports detection of USB Reset, Suspend, and Resume

■ Supports HS identification and detection as defined by the USB

2.0 Specification

®

Monahans Appli-

■ Supports transmission of Resume Signaling

■ 3.3V Operation

■ Two package options: 56-pin QFN and 56-pin VFBGA

■ All required terminations, including 1.5 Kohm pull up on

DPLUS, are internal to chip

■ Supports USB 2.0 Test Modes

The Cypress MoBL-USB TX2 is a Universal Serial Bus (USB)

specification revision 2.0 transceiver, serial and deserializer, to a

parallel interface of either 16 bits at 30 MHz or eight bits at 60

MHz. The MoBL-USB TX2 provides a high speed physical layer

interface that operates at the maximum allowable USB 2.0

bandwidth. This enables the system designer to keep the

complex high speed analog USB components external to the

digital ASIC. This decreases development time and associated

risk. A standard USB 2.0-certified interface is provided and is

compliant with Transceiver Macrocell Interface (UTMI) specification version 1.05 dated 3/29/2001.

This product is also optimized to seamlessly interface with

Monahans -P & -L applications processors. It has been characterized by Intel and is recommended as the USB 2.0 UTMI transceiver of choice for its Monahans processors. It is also capable

of tri-stating the UTMI bus, while suspended, to enable the bus

to be shared with other devices.

Two packages are defined for the family: 56-pin QFN and 56-pin

VFBGA.

The functional block diagram follows.

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 • 408-943-2600

Document #: 38-08052 Rev. *G Revised October 5, 2008

[+] Feedback

Page 2

CY7C68000A

Applications

Mobile Applications

■ Smart Phones

■ PDA Phones

■ Gaming Phones

■ MP3 players

■ Portable Media Players (PMP)

■ GPS Tracking Devices

Consumer Applications

■ Cameras

■ Scanners

■ DSL Modems

■ Memory Card Readers

Non-Consumer Applications

■ Networking

■ Wireless LAN

■ Home PNA

Functional Overview

The functionality of this chip is described in the following

sections:

USB Signaling Speed

The MoBL-USB TX2 operates at two of the rates defined in the

USB Specification 2.0, dated 4/27/2000.

■ Full speed, with a signaling bit rate of 12 Mbps

■ High speed, with a signaling bit rate of 480 Mbps

The MoBL-USB TX2 does not support the LS signaling rate of

1.5 Mbps.

Transceiver Clock Frequency

The MoBL-USB TX2 has an on-chip oscillator circuit that uses

an external 24 MHz (±100 ppm) crystal with the following characteristics:

■ Parallel resonant

■ Fundamental mode

■ 500 μW drive level

■ 27 to 33 pF (5% tolerance) load capacitors

An on-chip phase-locked loop (PLL) multiplies the 24 MHz oscillator up to 30 or 60 MHz, as required by the transceiver parallel

data bus. The default UTMI interface clock (CLK) frequency is

determined by the DataBus16_8 pin.

Buses

The two packages enable a 8- or 16-bit bidirectional data bus for

data transfers to a controlling unit.

Suspend and Tri-state Modes

When the MoBL-USB TX2 is not in use, the processor reduces

power consumption by putting it into Suspend mode using the

Suspend pin.

While in Suspend mode, Tri-state mode may be enabled, which

tri-states all outputs and IOs, enabling the UTMI interface pins to

be shared with other devices. This is valuable in mobile handset

applications, where GPIOs are at a premium. The outputs and

IOs are tri-stated ~50ns when Tri-state mode is enabled, and are

driven ~50ns when Tri-state mode is disabled. All inputs must not

be left floating while in Tri-state mode.

When resuming after a suspend, the PLL stabilizes approximately 200 μs after the suspend pin goes high.

Reset Pin

An input pin (Reset) resets the chip. This pin has hysteresis and

is active HIGH according to the UTMI specification. The internal

PLL stabilizes approximately 200 μs after V

has reached 3.3V.

CC

Line State

The Line State output pins LineState[1:0] are driven by combinational logic and may be toggling between the ‘J’ and the ‘K’

states. They are synchronized to the CLK signal for a valid

signal. On the CLK edge, the state of these lines reflect the state

of the USB data lines. Upon the clock edge the ‘0’ bit of the

LineState pins is the state of the DPLUS line and the ‘1’ bit of

LineState is the DMINUS line. When synchronized, the setup

and hold timing of the LineState is identical to the parallel data

bus.

Full-speed versus High-speed Select

The FS versus HS is done through the use of both XcvrSelect

and the TermSelect input signals. The TermSelect signal enables

the 1.5 Kohm pull up on to the DPLUS pin. When TermSelect is

driven LOW, a SE0 is asserted on the USB providing the HS

termination and generating the HS Idle state on the bus. The

XcvrSelect signal is the control that selects either the FS transceivers or the HS transceivers. By setting this pin to a ‘0’ the HS

transceivers are selected and by setting this bit to a’1’ the FS

transceivers are selected.

Document #: 38-08052 Rev. *G Page 2 of 15

[+] Feedback

Page 3

CY7C68000A

Operational Modes

The operational modes are controlled by the OpMode signals.

The OpMode signals are capable of inhibiting normal operation

of the transceiver and evoking special test

take effect immediately and take precedence over any pending

data operations. The transmission data rate when in OpMode

depends on the state of the XcvrSelect input.

OpMode[1:0] Mode Description

00 0 Normal operation

01 1 Non-driving

10 2 Disable Bit Stuffing and NRZI

encoding

11 3 Reserved

modes. These modes

Mode 0 enables the transceiver to operate with normal USB data

decoding and encoding.

Mode 1 enables the transceiver logic to support a soft disconnect

feature that tri-states both the HS and FS transmitters, and

removes any termination from the USB, making it appear to an

upstream port that the device is disconnected from the bus.

Mode 2 disables Bit Stuff and NRZI encoding logic so ‘1’s loaded

from the data bus becomes ‘J’s on the DPLUS/DMINUS lines

and ‘0’s become ‘K’s.

DPLUS/DMINUS Impedance Termination

The CY7C68000A does not require external resistors for USB

data line impedance termination or an external pull up resistor on

the DPLUS line. These resistors are incorporated into the part.

They are factory trimmed to meet the requirements of USB 2.0.

Incorporating these resistors also reduces the pin count on the

part.

Document #: 38-08052 Rev. *G Page 3 of 15

[+] Feedback

Page 4

CY7C68000A

Pin Configurations

D4

D3

V

CC

D2

Reserved

D1

D0

CLK

DataBus16_8

Uni_bidi

GND

TXValid

V

CC

ValidH

28

27

26

25

24

23

22

21

20

19

18

17

16

15

43

44

45

46

47

48

49

50

51

52

53

54

55

56

1

2

3

4

5

6

7

8

9

10

11

12

13

14

42

41

40

39

38

37

36

35

34

33

32

31

30

29

GND

D5

Reserved

D6

D7

D8

D9

Reserved

D10

D11

V

CC

D12

GND

D13

TXReady

Suspend

Reset

AV

CC

XTALOUT

XTALIN

AGND

AV

CC

DPLUS

DMINUS

AGND

XcvrSelect

TermSelect

OpMode0

V

CC

D14

D15

Reserved

Tri_state

RXError

RXActive

RXValid

GND

LineState1

LineState0

V

CC

GND

OpMode1

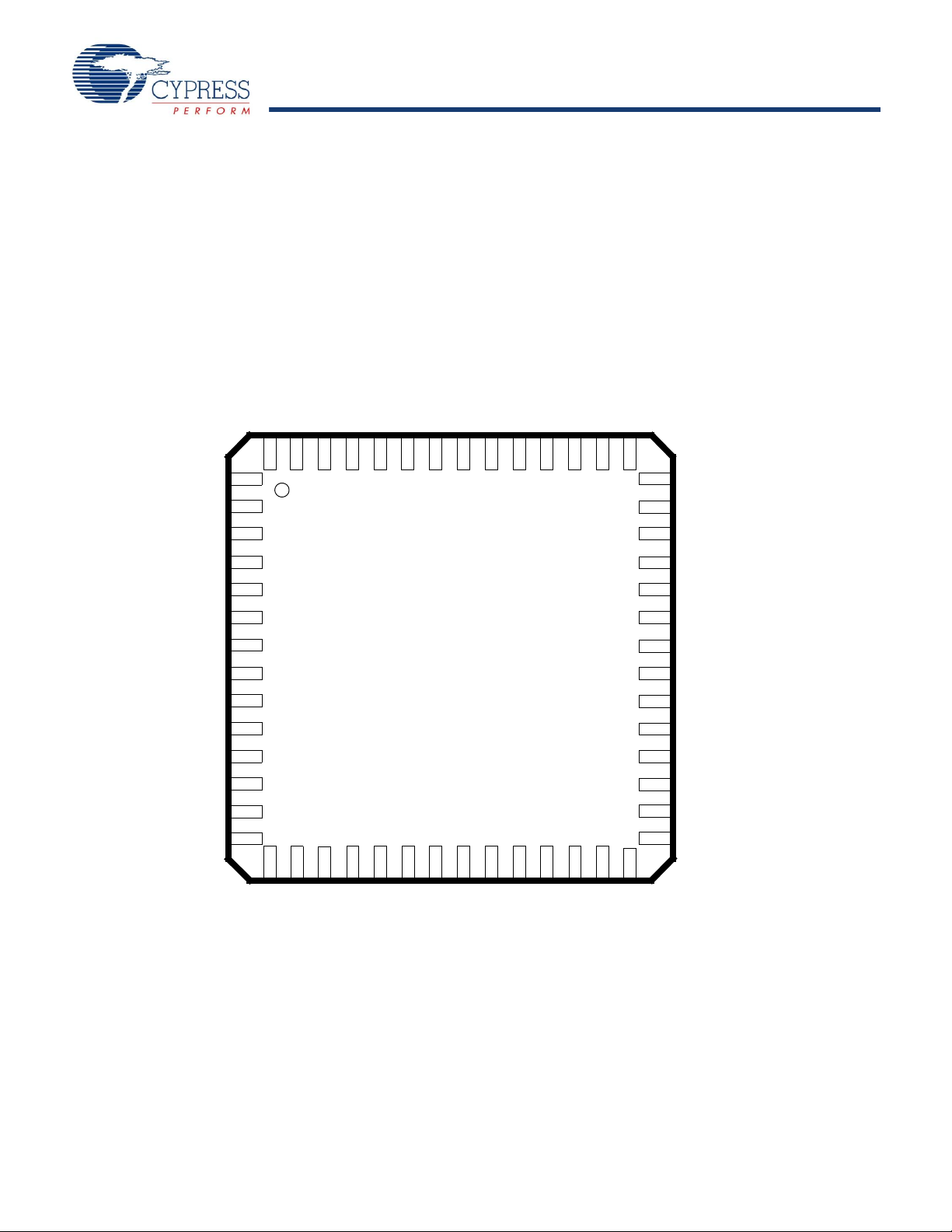

CY7C68000A

56-pin QFN

The following pages illustrate the individual pin diagrams that are available in the 56-pin QFN and 56-pin VFBGA packages.

The packages offered use either an 8-bit (60 MHz) or 16-bit (30 MHz) bus interface.

Figure 1. CY7C68000A 56-pin QFN Pin Assignment

Document #: 38-08052 Rev. *G Page 4 of 15

[+] Feedback

Page 5

CY7C68000A

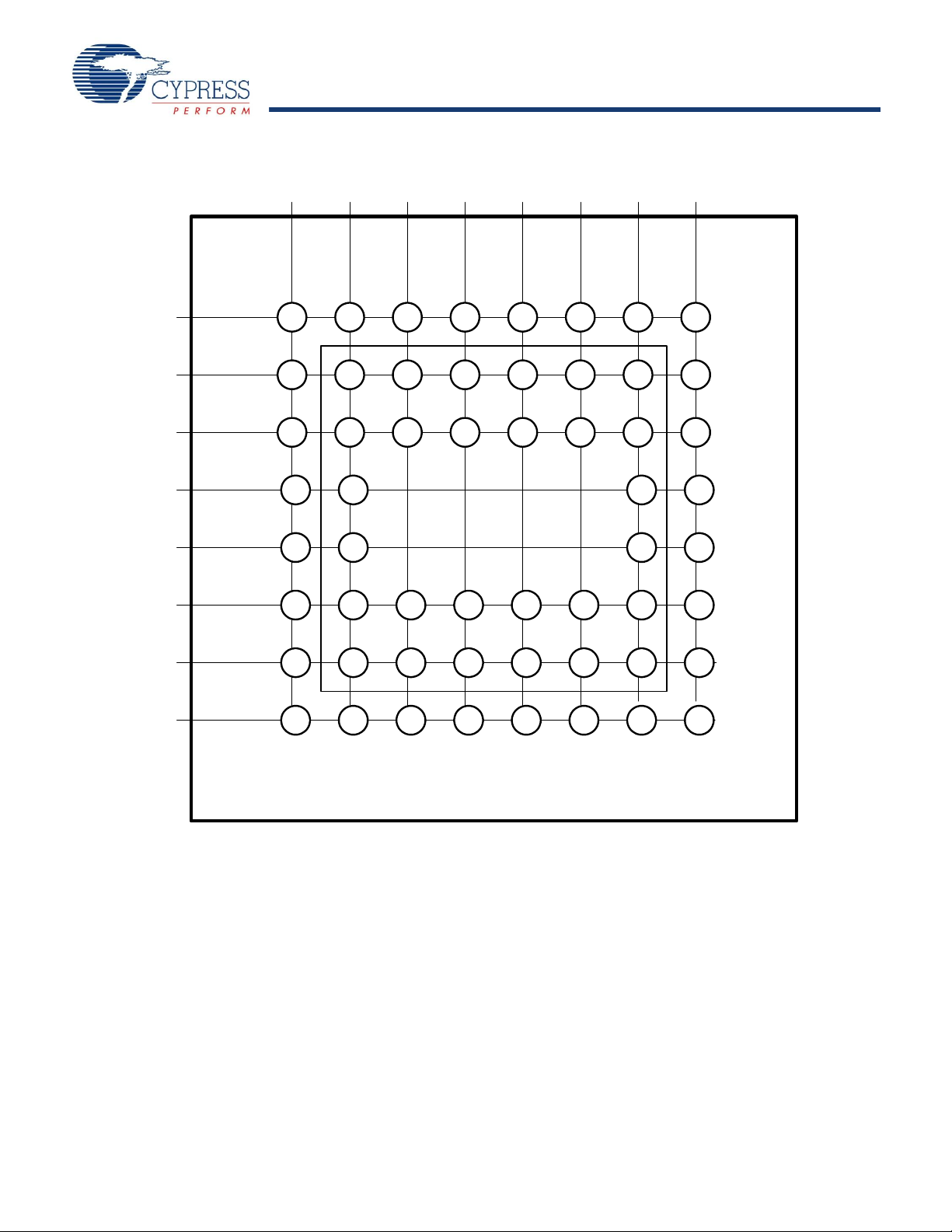

Figure 2. CY7C68000A 56-pin VFBGA Pin Assignment

12345678

A

B

C

D

E

F

G

H

1A 2A 3A 4A 5A 6A 7A 8A

1B 2B 3B 4B 5B 6B 7B 8B

1C 2C 3C 4C 5C 6C 7C 8C

1D 2D 7D 8D

1E 2E 7E 8E

1F 2F 3F 4F 5F 6F 7F 8F

1G 2G 3G 4G 5G 6G 7G 8G

1H 2H 3H 4H 5H 6H 7H 8H

Document #: 38-08052 Rev. *G Page 5 of 15

[+] Feedback

Page 6

CY7C68000A

Pin Descriptions

Note

1. Unused inputs should not be left floating. Tie either HIGH or LOW as appropriate. Outputs that are three-statable should only be pulled up or down to ensure

signals at power-up and in standby.

Table 1. Pin Descriptions

QFN VFBGA Name Type Default Description

4H1AVCC PowerN/AAnalog V

This signal provides power to the analog section of the chip.

CC

8H5AVCC PowerN/AAnalog VCC This signal provides power to the analog section of the chip.

7H4AGND PowerN/AAnalog Ground Connect to ground with as short a path as possible.

11 H8 AGND Power N/A Analog Ground Connect to ground with as short a path as possible.

9 H6 DPLUS I/O/Z Z USB DPLUS Signal Connect to the USB DPLUS signal.

10 H7 DMINUS I/O/Z Z USB DMINUS Signal Connect to the USB DMINUS signal.

49 G8 D0 I/O Bidirectional Data Bus This bidirectional bus is used as the entire data

48 G7 D1 I/O

46 G5 D2 I/O

bus in the 8-bit bidirectional mode or the least significant eight bits in the

16-bit mode. Under the 8-bit unidirectional mode, these bits are used as

inputs for data, selected by the RxValid signal.

44 G3 D3 I/O

43 G2 D4 I/O

41 F8 D5 I/O

39 F6 D6 I/O

38 F5 D7 I/O

37 F4 D8 I/O Bidirectional Data Bus This bidirectional bus is used as the upper eight

36 F3 D9 I/O

34 F1 D10 I/O

bits of the data bus when in the 16-bit mode, and not used when in the

8-bit bidirectional mode. Under the 8-bit unidirectional mode these bits

are used as outputs for data, selected by the TxValid signal.

33 G4 D11 I/O

31 E1 D12 I/O

29 D8 D13 I/O

27 G1 D14 I/O

26 E2 D15 I/O

50 A1 CLK Output Clock This output is used for clocking the receive and transmit parallel

data on the D[15:0] bus.

3 B2 Reset Input N/A Active HIGH Reset Resets the entire chip. This pin can be tied to V

through a 0.1-μF capacitor and to GND through a 100 K resistor for a

10-ms RC time constant.

12 B3 XcvrSelect Input N/A Transceiver Select This signal selects between the Full Speed (FS) and

the High Speed (HS) transceivers:

0: HS transceiver enabled

1: FS transceiver enabled

13 B4 TermSelect Input N/A Termination Select This signal selects between the Full Speed (FS) and

the High Speed (HS) terminations:

0: HS termination

1: FS termination

2 B1 Suspend Input N/A Suspend Places the CY7C68000A in a mode that draws minimal power

from supplies. Shuts down all blocks not necessary for Suspend/Resume

operations. While suspended, TermSelect must always be in FS mode

to ensure that the 1.5 Kohm pull up on DPLUS remains powered.

0: CY7C68000A circuitry drawing suspend current

1: CY7C68000A circuitry drawing normal current

[1]

CC

Document #: 38-08052 Rev. *G Page 6 of 15

[+] Feedback

Page 7

CY7C68000A

Table 1. Pin Descriptions (continued)

QFN VFBGA Name Type Default Description

24 B8 Tri_state Input Tri-state Mode Enable Places the CY7C68000A into Tri-state mode

which tri-states all outputs and IOs. Tri-state Mode can only be enabled

while suspended.

0: Disables Tri-state Mode

1: Enables Tri-state Mode

19 C2 LineState1 Output Line State These signals reflect the current state of the single-ended

receivers. They are combinatorial until a “usable” CLK is available then

they are synchronized to CLK. They directly reflect the current state of the

DPLUS (LineState0) and DMINUS (LineState1).

D– D+ Description

0 0 0: SE0

0 1 1: ‘J’ State

1 0 2: ‘K’ State

1 1 3: SE1

18 C1 LineState0 Output Line State These signals reflect the current state of the single-ended

receivers. They are combinatorial until a ‘usable’ CLK is available then

they are synchronized to CLK. They directly reflect the current state of the

DPLUS (LineState0) and DMINUS (LineState1).

D– D+ Description

00–0: SE0

01–1: ‘J’ State

10–2: ‘K’ State

11–3: SE1

15 B6 OpMode1 Input Operational Mode These signals select among various operational

modes.

10 Description

00–0: Normal Operation

01–1: Non-driving

10–2: Disable Bit Stuffing and NRZI encoding

11–3: Reserved

14 B5 OpMode0 Input Operational Mode These signals select among various operational

modes.

10 Description

00–0: Normal Operation

01–1: Non-driving

10–2: Disable Bit Stuffing and NRZI encoding

11–3: Reserved

54 A5 TXValid Input Transmit Valid This signal indicates that the data bus is valid. The asser-

tion of Transmit Valid initiates SYNC on the USB. The negation of Transmit Valid initiates EOP on the USB. The start of SYNC must be initiated

on the USB no less than one or no more that two CLKs after the assertion

of TXValid.

In HS (XcvrSelect = 0) mode, the SYNC pattern must be asserted on the

USB between 8- and 16-bit times after the assertion of TXValid is detected

by the Transmit State Machine.

In FS (Xcvr = 1), the SYNC pattern must be asserted on the USB no less

than one or more than two CLKs after the assertion of TXValid is detected

by the Transmit State Machine.

1 A8 TXReady Output Transmit Data Ready If TXValid is asserted, the SIE must always have

data available for clocking in to the TX Holding Register on the rising edge

of CLK. If TXValid is TRUE and TXReady is asserted at the rising edge

of CLK, the CY7C68000A loads the data on the data bus into the TX

Holding Register on the next rising edge of CLK. At that time, the SIE

should immediately present the data for the next transfer on the data bus

[1]

(continued)

.

Document #: 38-08052 Rev. *G Page 7 of 15

[+] Feedback

Page 8

CY7C68000A

Table 1. Pin Descriptions (continued)

QFN VFBGA Name Type Default Description

[1]

(continued)

21 A4 RXValid Output Receive Data Valid This signal indicates that the DataOut bus has valid

data. The Receive Data Holding Register is full and ready to be unloaded.

The SIE is expected to latch the DataOut bus on the clock edge.

22 B7 RXActive Output Receive Active This signal indicates that the receive state machine has

detected SYNC and is active.

RXActive is negated after a bit stuff error or an EOP is detected.

23 A6 RXError Output Receive Error

0 Indicates no error.

1 Indicates that a receive error has been detected.

56 A7 ValidH I/O ValidH This signal indicates that the high-order eight bits of a 16-bit data

word presented on the Data bus are valid. When DataBus16_8 = 1 and

TXValid = 0, Valid H is an output, indicating that the high-order receive

data byte on the Data bus is valid. When DataBus16_8 = 1 and TXValid

= 1, ValidH is an input and indicates that the high-order transmit data byte,

presented on the Data bus by the transceiver, is valid. When

DataBus16_8 = 0, ValidH is undefined. The status of the receive

low-order data byte is determined by RXValid and are present on D0–D7.

51 A2 DataBus16_8 Input Data Bus 16_8 This signal selects between 8- and 16-bit data transfers.

1–16-bit data path operation enabled. CLK = 30 MHz.

0–8-bit data path operation enabled. When Uni_Bidi = 0, D[8:15] are undefined. When Uni_Bidi =1, D[0:7] are valid on TxValid and D[8:15] are

valid on RxValid. CLK = 60 MHz

Note: DataBus16_8 is static after Power-on Reset (POR) and is only

sampled at the end of Reset.

6 H3 XTALIN Input N/A Crystal Input Connect this signal to a 24 MHz parallel-resonant, funda-

mental mode crystal and 30 pF capacitor to GND.

It is also correct to drive XTALIN with an external 24 MHz square wave

derived from another clock source.

5 H2 XTALOUT Output N/A Crystal Output Connect this signal to a 24 MHz parallel-resonant, funda-

mental mode crystal and 30 pF (nominal) capacitor to GND. If an external

clock is used to drive XTALIN, leave this pin open.

52 A3 Uni_Bidi Input Driving this pin HIGH enables the unidirectional mode when the 8-bit

interface is selected. Uni_Bidi is static after power-on reset (POR).

55 C6 V

17 C7 V

28 D7 V

32 E7 V

45 E8 V

CC

CC

CC

CC

CC

Power VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

Power N/A VCC. Connect to 3.3V power source.

53 C4 GND Ground N/A Ground.

16 C5 GND Ground N/A Ground.

20 C3 GND Ground N/A Ground.

30 D1 GND Ground N/A Ground.

42 D2 GND Ground N/A Ground.

47 G6 Reserved INPUT Connect pin to Ground.

40 F7 Reserved INPUT Connect pin to Ground.

35 F2 Reserved INPUT Connect pin to Ground.

25 C8 Reserved INPUT Connect pin to Ground.

Document #: 38-08052 Rev. *G Page 8 of 15

[+] Feedback

Page 9

CY7C68000A

Absolute Maximum Ratings

Note

2. Connected to the USB includes 1.5 Kohm internal pull up. Disconnected has the 1.5 Kohm internal pull up excluded.

Operating Conditions

Storage Temperature ................................. –65°C to +150°C

Ambient Temperature with Power Supplied ..... 0°C to +70°C

Supply Voltage to Ground Potential ...............–0.5V to +4.0V

DC Input Voltage to Any Input Pin ............................. 5.25 V

DC Voltage Applied to Outputs

in High-Z State ..................................... –0.5V to V

CC

+ 0.5V

TA (Ambient Temperature Under Bias) ............ 0°C to +70°C

Supply Voltage ...............................................+3.0V to +3.6V

Ground Voltage .................................................................0V

F

(Oscillator or Crystal Frequency) ... 24 MHz ± 100 ppm

OSC

...................................................................Parallel Resonant

Power Dissipation ....................................................630 mW

Static Discharge Voltage .......................................... > 2000V

Max Output Current, per IO pin ................................... 4 mA

Max Output Current, all 21–IO pins ............................84 mA

DC Characteristics

Table 2. DC Characteristics

Parameter Description Conditions Min Ty p Max Unit

V

CC

V

IH

V

IL

I

I

V

OH

V

OL

I

OH

I

OL

C

IN

C

LOAD

I

SUSP

I

CC

I

CC

t

RESET

Supply Voltage 3.0 3.3 3.6 V

Input High Voltage 2 5.25 V

Input Low Voltage –0.5 0.8 V

Input Leakage Current 0< VIN < V

Output Voltage High I

Output Low Voltage I

= 4 mA 2.4 V

OUT

= –4 mA 0.4 V

OUT

CC

±10 μA

Output Current High 4mA

Output Current Low 4mA

Input Pin Capacitance Except DPLUS/DMINUS/CLK 10 pF

DPLUS/DMINUS/CLK 15 pF

Maximum Output Capacitance Output pins 30 pF

Suspend Current Connected

Disconnected

[2]

[2]

228 273 μA

835μA

Supply Current HS Mode Normal operation OPMOD[1:0] = 00 175 mA

Supply Current FS Mode Normal operation OPMOD[1:0] = 00 90 mA

Minimum Reset time 1.9 ms

Document #: 38-08052 Rev. *G Page 9 of 15

[+] Feedback

Page 10

CY7C68000A

AC Electrical Characteristics

TCSU_MIN

TCH_MIN

TDSU_MIN

TDH_MIN

TCDO

TCCO

DataIn

DataOut

Control_Out

Control_In

CLK

USB 2.0 Transceiver

USB 2.0-compliant in FS and HS modes.

Timing Diagram

HS/FS Interface Timing - 60 MHz

Figure 3. 60 MHz Interface Timing Constraints

Table 3. 60 MHz Interface Timing Constraints Parameters

Parameter Description Min Typ Max Unit Notes

T

CSU_MIN

T

CH_MIN

T

DSU_MIN

T

DH_MIN

T

CCO

T

CDO

Minimum setup time for TXValid 4 ns

Minimum hold time for TXValid 1 ns

Minimum setup time for Data (transmit direction) 4 ns

Minimum hold time for Data (transmit direction) 1 ns

Clock to Control out time for TXReady, RXValid,

18ns

RXActive and RXError

Clock to Data out time (Receive direction) 1 8 ns

Document #: 38-08052 Rev. *G Page 10 of 15

[+] Feedback

Page 11

CY7C68000A

HS/FS Interface Timing - 30 MHz

TCSU_MIN

TCH_MIN

TDSU_MIN

TDH_MIN

TCVO

TCCO

DataIn

DataOut

Control_Out

Control_In

CLK

TCDO

TVSU_MIN

TVH_MIN

Ttssu Ttspd

Ttspd

Suspend

Tri-state

Output / IO XXXX Hi-Z

Figure 4. 30 MHz Timing Interface Timing Constraints

Table 4. 30 MHz Timing Interface Timing Constraints Parameters

Parameter Description Min Typ Max Unit Notes

T

CSU_MIN

T

CH_MIN

T

DSU_MIN

T

DH_MIN

T

CCO

T

CDO

T

VSU_MIN

T

VH_MIN

T

CVO

Minimum setup time for TXValid 16 ns

Minimum hold time for TXValid 1 ns

Minimum setup time for Data (Transmit direction) 16 ns

Minimum hold time for Data (Transmit direction) 1 ns

Clock to Control Out time for TXReady, RXValid,

120ns

RXActive and RXError

Clock to Data out time (Receive direction) 1 20 ns

Minimum setup time for ValidH (transmit Direction) 16 ns

Minimum hold time for ValidH (Transmit direction) 1 ns

Clock to ValidH out time (Receive direction) 1 20 ns

Figure 5. Tri-state Mode Timing Constraints

Table 5. Tri-state Mode Timing Constraints Parameters

Parameter Description Min Typ Max Unit Notes

T

tssu

T

tspd

Document #: 38-08052 Rev. *G Page 11 of 15

Minimum setup time for Tri-state 0 ns

Propagation Delay for Tri-State mode 50 ns

[+] Feedback

Page 12

CY7C68000A

Ordering Information

51-85187 *C

Ordering Code Package Type

CY7C68000A-56LFXC 56 QFN

CY7C68000A-56BAXC 56 VFBGA

CY3683 MoBL-USB TX2 Development Board

Package Diagrams

The MoBL-USB TX2 is available in two packages:

■ 56-pin QFN

■ 56-pin VFBGA

Figure 6. 56-Pin Quad Flatpack No Lead Package 8 x 8 mm (Sawn Version) LS56B

Document #: 38-08052 Rev. *G Page 12 of 15

[+] Feedback

Page 13

CY7C68000A

Package Diagrams (continued)

TOP VIEW

PIN A1 CORNER

0.50

3.50

5.00±0.10

BOTTOM VIEW

0.10(4X)

3.50

5.00±0.10

0.50

Ø0.15 M C A B

Ø0.05 M C

Ø0.30±0.05(56X)

A1 CORNER

-B-

-A-

1.0 max

0.160 ~0.260

0.080 C

0.45

SEATING PLANE

0.21

0.10 C

-C-

SIDE VIEW

5.00±0.10

5.00±0.10

REFERENCE JEDEC: MO-195C

PACKAGE WEIGHT: 0.02 grams

E

G

H

F

D

C

B

A

13265486

7856 2341

E

G

H

F

D

C

B

A

001-03901-*B

Note

3. Source for recommendations: EZ-USB FX2™ PCB Design Recommendations, http:///www.cypress.com/cfuploads/support/app_notes/FX2_PCB.pdf

High-Speed USB Platform Design Guidelines, http://www.usb.org/developers/docs/hs_usb_pdg_r1_0.pdf.

Figure 7. 56 VFBGA (5 x 5 x 1.0 mm) 0.50 Pitch, 0.30 Ball BZ56

PCB Layout Recommendations

Follow these recommendations to ensure reliable, high-performance operation

■ A four-layer impedance controlled board is required to maintain

[3]

.

signal quality

■ Specify impedance targets (ask your board vendor what they

can achieve)

■ To control impedance, maintain trace widths and trace spacing

to within written specifications

■ Minimize stubs to minimize reflected signals

■ Connections between the USB connector shell and signal

ground must be done near the USB connector

■ Bypass and flyback capacitors on VBus, near the connector,

are recommended

■ Keep DPLUS and DMINUS trace lengths within 2 mm of each

other in length, with preferred length of 20 to 30 mm

■ Maintain a solid ground plane under the DPLUS and DMINUS

traces. Do not split the plane under these traces

■ Do not place vias on the DPLUS or DMINUS trace routing

■ Isolate the DPLUS and DMINUS traces from all other signal

traces by no less than 10 mm

Document #: 38-08052 Rev. *G Page 13 of 15

[+] Feedback

Page 14

CY7C68000A

Quad Flat Package No Leads (QFN) Package

0.017” dia

Solder Mask

Cu Fill

Cu Fill

PCB Material

PCB Material

0.013” dia

Via hole for thermally connecting the

QFN to the circuit board ground plane.

This figure only shows the top three layers of the

circuit board: Top Solder, PCB Dielectric, and

the Ground Plane

Design Notes

Electrical contact of the part to the Printed Circuit Board (PCB)

is made by soldering the leads on the bottom surface of the

package to the PCB. Hence, special attention is required to the

heat transfer area below the package to provide a good thermal

bond to the circuit board. A Copper (Cu) fill is to be designed into

the PCB as a thermal pad under the package. Heat is transferred

from the MoBL-USB TX2 through the device’s metal paddle on

the package bottom. From here, heat is conducted to the PCB at

the thermal pad. It is then conducted from the thermal pad to the

PCB inner ground plane by an array of via. A via is a plated

through-hole in the PCB with a finished diameter of 13 mil. The

QFN’s metal die paddle must be soldered to the PCB’s thermal

pad. Solder mask is placed on the board top, over each via, to

resist solder flow into the via. The mask on the top side also

minimizes outgassing during the solder reflow process.

Figure 8. Cross section of the Area Underneath the QFN Package

For further information on this package design, refer to the application note “Surface Mount Assembly of AMKOR’s MicroLeadFrame (MLF) Technology.” Download this application note from

AMKOR’s website, by following this link:

http://www.amkor.com/products/notes_papers/MLFApp

Note.pdf. The application note provides detailed information on

board mounting guidelines, soldering flow, and rework process.

Figure 8 displays a cross-sectional area under the package. The

cross section is of only one via. The solder paste template needs

to be designed to enable at least 50 percent solder coverage.

The thickness of the solder paste template should be 5 mil. It is

recommended that ‘No Clean’, type 3 solder paste be used for

mounting the part. Nitrogen purge is recommended during

reflow.

Figure 9 is a plot of the solder mask pattern image of the

assembly (darker areas indicate solder).

Figure 9. Plot of the Solder Mask (White Area)

Document #: 38-08052 Rev. *G Page 14 of 15

[+] Feedback

Page 15

CY7C68000A

Document History Page

Document Title: CY7C68000A MoBL-USB™ TX2 USB 2.0 UTMI Transceiver

Document Number: 38-08052

REV. ECN NO.

Orig. of

Change

Submission

Date

Description of Change

** 285592 KKU See ECN New data sheet

*A 427959 TEH See ECN Addition of VFBGA Package information and Pinout, Removal of SSOP

Package. Edited text and moved figure titles to the top per new template

*B 470121 TEH See ECN Change from preliminary to final data sheet. Grammatical and formatting

changes

*C 476107 TEH See ECN This data sheet needs to be posted to the web site under NDA

*D 491668 TEH See ECN Addition of Tri-state Mode

*E 498415 TEH See ECN Update power consumption numbers

*F 567869 TEH See ECN Remove NDA requirement

*G 2587010 KKU/PYRS 10/13/08 Update Pin 6 description on Page 8

Update template

Sales, Solutions, and Legal Information

Worldwide Sales and Design Support

Cypress maintains a worldwide network of offices, solution centers, manufacturer’s representatives, and distributors. To find the office

closest to you, visit us at cypress.com/sales.

Products

PSoC psoc.cypress.com

Clocks & Buffers clocks.cypress.com

Wireless wireless.cypress.com

Memories memory.cypress.com

Image Sensors image.cypress.com

PSoC Solutions

General psoc.cypress.com/solutions

Low Power/Low Voltage psoc.cypress.com/low-power

Precision Analog psoc.cypress.com/precision-analog

LCD Drive psoc.cypress.com/lcd-drive

CAN 2.0b psoc.cypress.com/can

USB psoc.cypress.com/usb

© Cypress Semiconductor Corporation, 2004-2008. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use of

any circuitry other than circuitry embodied in a Cypress product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor intended to be used for

medical, life support, life saving, critical control or safety applications, unless pursuant to an express written agreement with Cypress. Furthermore, Cypress does not authorize its products for use as

critical components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress products in life-support systems

application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress against all charges.

Any Source Code (software and/or firmware) is owned by Cypress Semiconductor Corporation (Cypress) and is protected by and subject to worldwide patent protection (United States and foreign),

United States copyright laws and international treaty provisions. Cypress hereby grants to licensee a personal, non-exclusive, non-transferable license to copy, use, modify, create derivative works of,

and compile the Cypress Sou rce Code and derivative works for the sole purpose of cr eating custom software and or firmware in support of licensee product to be used only in conjunction with a Cypress

integrated circuit as specified in the applicable agreement. Any reproduction, modification, translation, compilation, or representation of this Source Code except as specified above is prohibited without

the express written permission of Cypress.

Disclaimer: CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH REGARD TO THIS MATERIAL, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. Cypress reserves the right to make changes without further notice to the materials described herein. Cypress does not

assume any liability arising out of the application or use of any product or circuit described herein. Cypress does not authorize its products for use as critical components in life-support systems where

a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress’ product in a life-support systems application implies that the manufacturer

assumes all risk of such use and in doing so indemnifies Cypress against all charges.

Use may be limited by and subject to the applicable Cypress software license agreement.

Document #: 38-08052 Rev. *G Revised October 5, 2008 Page 15 of 15

MoBL-USB TX2 is a trademark of Cypress Semiconductor Corporation. Intel is a registered trademark of Intel Corporation. All product and company names mentioned in

this document are the trademarks of their respective holders.

All products and company names mentioned in this document may be the trademarks of their respective holders.

[+] Feedback

Loading...

Loading...