al

b

C

C

CY7C66013

CY7C66113

Full-Speed USB (12 Mbps) Peripher

Controller with Integrated Hu

Full-Spee d U SB (12 Mbps) Peripheral Controller with Integrated Hub

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 • 408-943-2600

Document #: 38-08024 Rev. *B Revised January 2, 2006

C

C

CY7C66013

CY7C66113

TABLE OF CONTENTS

1.0 FEATURES .............. ........................................................................................................................6

2.0 FUNCTIONAL OVERVIEW .............................................................................................................7

2.1 GPIO .............. ............................................................................................................................7

2.2 DAC ......... ...................................................................................................................................7

2.3 Clock ..........................................................................................................................................7

2.4 Memory .............. ........................................................................................................................7

2.5 Power-on Reset, Watchdog, and Free-running Timer ..... ..........................................................7

2.6 I2C and HAPI Interface ..............................................................................................................7

2.7 Timer ... .......................................................................................................................................7

2.8 Interrupts ....................................................................................................................................8

2.9 USB ............................................................................................................................................8

3.0 PIN CONFIGURATIONS ....... ........................................................................................................10

4.0 PRODUCT SUMMARY TABLES ..................................................................................................14

4.1 Pin Assignments ......................................................................................................................14

4.2 I/O Register Summary ..............................................................................................................14

4.3 Instruction Set Summary ..........................................................................................................16

5.0 PROGRAMMING MODEL .............................................................................................................17

5.1 14-bit Program Counter (PC) .............. .....................................................................................17

5.1.1 Program Memory Or gan i za tion .......................................................................................... ..........18

5.2 8-bit Accumulator (A) ...............................................................................................................19

5.3 8-bit Temporary Register (X) ....................................................................................................19

5.4 8-bit Program Stack Pointer (PSP) ..... .....................................................................................19

5.4.1 Data Memory Organization ............................................................................................. .. .............19

5.5 8-bit Data Stack Pointer (DSP) ................................................................................................19

5.6 Address Modes ........................................................................................................................20

5.6.1 Data (Immediate ) ............................................................................................................................20

5.6.2 Direct ...... ........................................................................................................................................20

5.6.3 Indexed ..........................................................................................................................................20

6.0 CLOCKING ....................................................................................................................................20

7.0 RESET .......... .................................................................................................................................21

7.1 Power-on Reset .......................................................................................................................21

7.2 Watchdog Reset .......................................................................................................................21

8.0 SUSPEND MODE ..........................................................................................................................22

9.0 GENERAL-PURPOSE I/O (GPIO) PORTS ...................................................................................22

9.1 GPIO Configuration Port ..........................................................................................................23

9.2 GPIO Interrupt Enable Ports ....................................................................................................24

10.0 DAC PORT ..................................................................................................................................25

10.1 DAC Isink Registers ...............................................................................................................26

10.2 DAC Port Interrupts ................................................................................................................26

11.0 12-BIT FREE-RUNNING TIMER .................................................................................................27

2

12.0 I

13.0 I

C AND HAPI CONFIGURATION REGISTER ...........................................................................27

2

C-COMPATIBLE CONTROLLER .............................................................................................28

14.0 HARDWARE ASSISTED PARALLEL INTERFACE (HAPI) ....................................................... 30

15.0 PROCESSOR STATUS AND CONTROL REGISTER ................................................................31

Document #: 38-08024 Rev. *B Page 2 of 61

C

C

CY7C66013

CY7C66113

16.0 INTERRUPTS ..............................................................................................................................31

16.1 Interrupt Vectors .....................................................................................................................33

16.2 Interrupt Latency ....................................................................................................................34

16.3 USB Bus Reset Interrupt ........................................................................................................34

16.4 Timer Interrupt ........................................................................................................................ 34

16.5 USB Endpoint Interrupts ........................................................................................................34

16.6 USB Hub Interrupt ..................................................................................................................35

16.7 DAC Interrupt .........................................................................................................................35

16.8 GPIO/HAPI Interrupt ..............................................................................................................35

16.9 I

17.0 USB OVERVIEW .........................................................................................................................36

17.1 USB Serial Interface Engine ..................................................................................................36

17.2 USB Enumeration ..................................................................................................................36

18.0 USB HUB .....................................................................................................................................37

18.1 Connecting/Disconnecting a USB Device ..............................................................................37

18.2 Enabling/Disabling a USB Device ..........................................................................................38

18.3 Hub Downstream Ports Status and Control ...........................................................................39

18.4 Downstream Port Suspend and Resume ...............................................................................40

18.5 USB Upstream Port Status and Control .................................................................................41

19.0 USB SIE OPERATION ................................................................................................................42

2

C Interrupt ............................................................................................................................36

19.1 USB Device Addresses ..........................................................................................................42

19.2 USB Device Endpoints ...........................................................................................................42

19.3 USB Control Endpoint Mode Registers ..................................................................................43

19.4 USB Non-Control Endpoint Mode Registers ..........................................................................44

19.5 USB Endpoint Counter Registers ...........................................................................................44

19.6 Endpoint Mode/Count Registers Update and Locking Mechanism ........................................44

20.0 USB MODE TABLES ..................................................................................................................47

21.0 REGISTER SUMMARY ...............................................................................................................51

22.0 SAMPLE SCHEMATIC ................................................................................................................53

23.0 ABSOLUTE MAXIMUM RATINGS ..............................................................................................54

24.0 ELECTRICAL CHARACTERISTICS ...........................................................................................54

25.0 SWITCHING CHARACTERISTICS

26.0 ORDERING INFORMATION .......................................................................................................57

27.0 PACKAGE DIAGRAMS ...............................................................................................................58

28.0 QUAD FLAT PACKAGE NO LEADS (QFN) PACKAGE DESIGN NOTES ................................59

.............................................................................................55

Document #: 38-08024 Rev. *B Page 3 of 61

C

C

CY7C66013

CY7C66113

LIST OF FIGURES

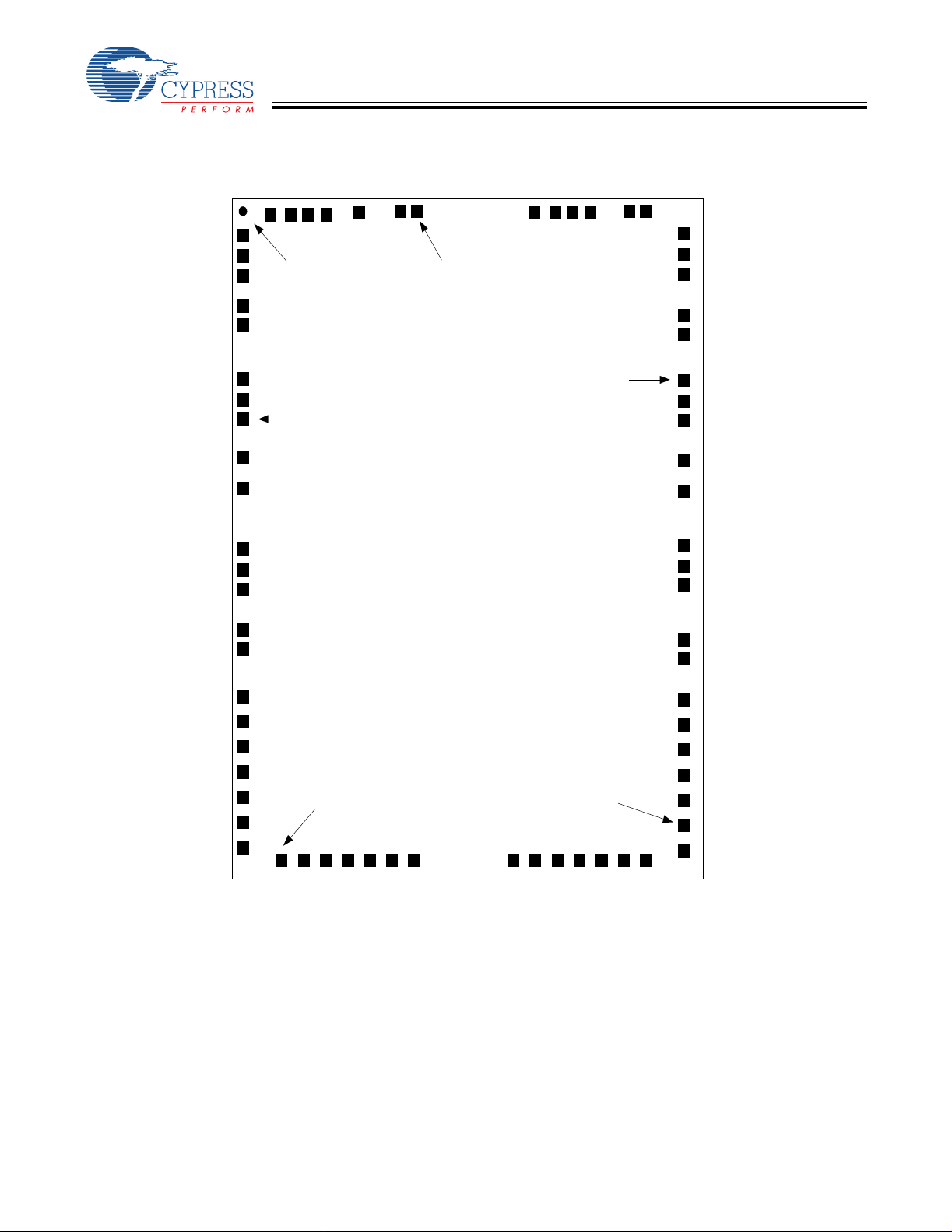

Figure 3-1. CY7C66113C 56-pin QFN Pin Assignment .......................................................................11

Figure 3-2. CY7C66113C DIE .............................................................................................................. 12

Figure 5-1. Program Memory Space with Interrupt Vector Table .........................................................18

Figure 6-1. Clock Oscillator On-Chip Circuit ........................................................................................20

Figure 7-1. Watchdog Reset ................................................................................................................ 21

Figure 9-1. Block Diagram of a GPIO Pin ............................................................................................22

Figure 9-2. Port 0 Data ........................................................................................................................23

Figure 9-3. Port1 Data .........................................................................................................................23

Figure 9-4. Port 2 Data ........................................................................................................................23

Figure 9-5. Port 3 Data ........................................................................................................................23

Figure 9-6. GPIO Configuration Register .............................................................................................23

Figure 9-7. Port 0 Interrupt Enable .......................................................................................................24

Figure 9-8. Port 1 Interrupt Enable .......................................................................................................25

Figure 9-9. Port 2 Interrupt Enable .......................................................................................................25

Figure 9-10. Port 3 Interrupt Enable .....................................................................................................25

Figure 10-1. Block Diagram of a DAC Pin ............................................................................................25

Figure 10-2. DAC Port Data .................................................................................................................26

Figure 10-3. DAC Sink Register ...........................................................................................................26

Figure 10-4. DAC Port Interrupt Enable ...............................................................................................26

Figure 10-5. DAC Port Interrupt Polarity ..............................................................................................26

Figure 11-3. Timer Block Diagram .......................................................................................................27

Figure 11-1. Timer LSB Register .........................................................................................................27

Figure 11-2. Timer MSB Register ........................................................................................................27

Figure 12-1. HAPI/I

Figure 13-1. I

Figure 13-2. I

Figure 15-1. Processor Status and Control Register ...........................................................................31

Figure 16-1. Global Interrupt Enable Register .....................................................................................32

Figure 16-2. USB Endpoint Interrupt Enable Register .........................................................................32

Figure 16-3. Interrupt Controller Function Diagram .............................................................................33

Figure 16-4. GPIO Interrupt Structure ..................................................................................................35

Figure 18-1. Hub Ports Connect Status ...............................................................................................38

Figure 18-2. Hub Ports Speed .............................................................................................................38

Figure 18-3. Hub Ports Enable Register ..............................................................................................38

Figure 18-4. Hub Downstream Ports Control Register .........................................................................39

Figure 18-5. Hub Ports Force Low Register .........................................................................................39

Figure 18-6. Hub Ports SE0 Status Register .......................................................................................39

Figure 18-7. Hub Ports Data Register ..................................................................................................40

Figure 18-8. Hub Ports Suspend Register ........................................................................................... 40

Figure 18-9. Hub Ports Resume Status Register .................................................................................40

Figure 18-10. USB Status and Control Register ..................................................................................41

Figure 19-1. USB Device Address Registers .......................................................................................42

Figure 19-2. USB Endpoint 0 Mode Registers .....................................................................................43

Figure 19-3. USB Non-Control Endpoint Mode Registers ....................................................................44

Figure 19-4. USB Endpoint Counter Registers ....................................................................................44

Figure 19-5. Token/Data Packet Flow Diagram ...................................................................................46

Figure 22-1. Sample Schematic ...........................................................................................................53

Figure 25-1. Clock Timing ....................................................................................................................56

Figure 25-2. USB Data Signal Timing ..................................................................................................56

Figure 25-3. HAPI Read by External Interface from USB Microcontroller ............................................56

Figure 25-4. HAPI Write by External Device to USB Microcontroller ...................................................57

Figure 28-1. Cross-section of the Area Underneath the QFN Package ...............................................60

Figure 28-2. Plot of the Solder Mask (White Area) ..............................................................................60

2

2

2

C Configuration Register ......................................................................................27

C Data Register .............................................................................................................28

C Status and Control Register .......................................................................................28

Document #: 38-08024 Rev. *B Page 4 of 61

C

C

CY7C66013

CY7C66113

LIST OF TABLES

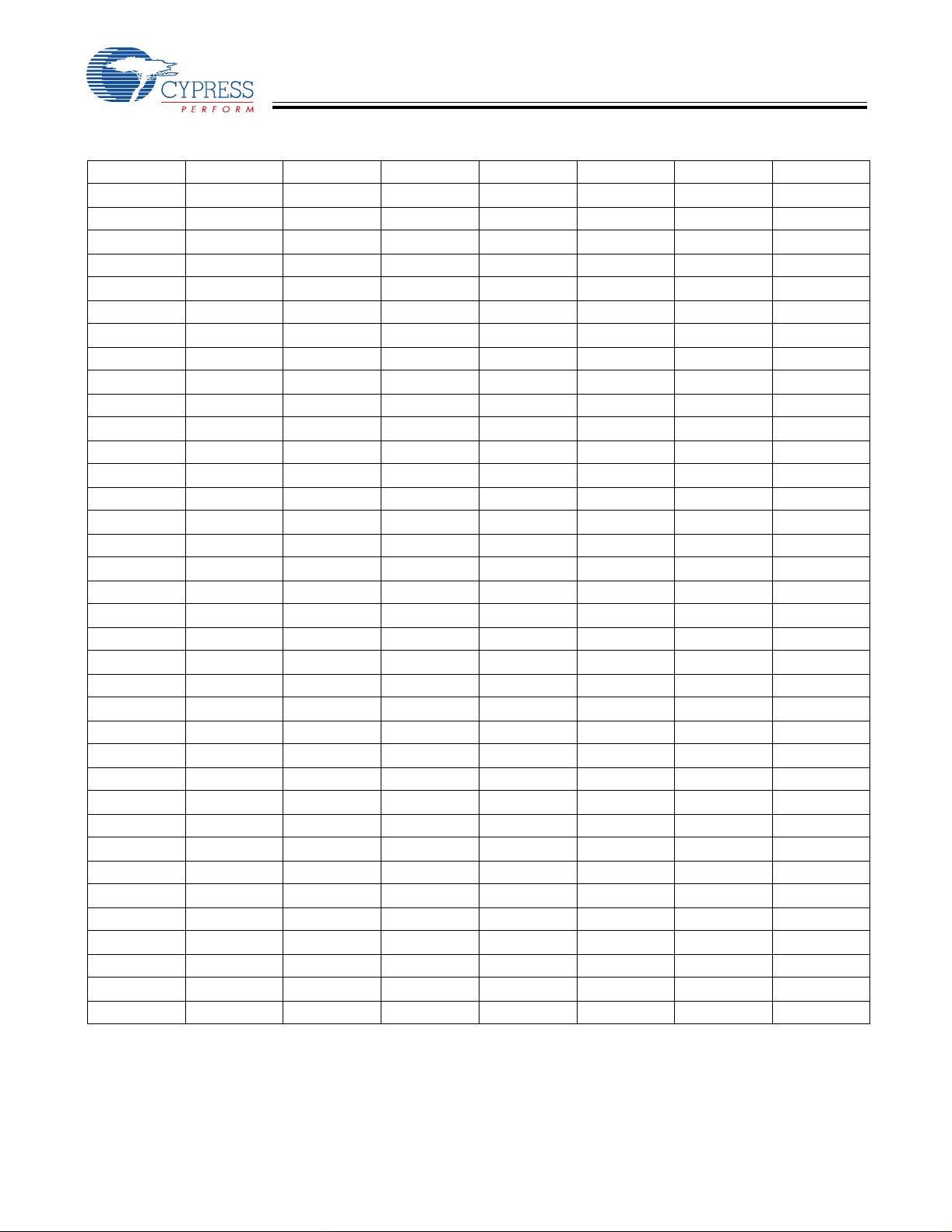

Table 3-1. Pad Coordinates in microns (0,0) to bond pad centers .......................................................13

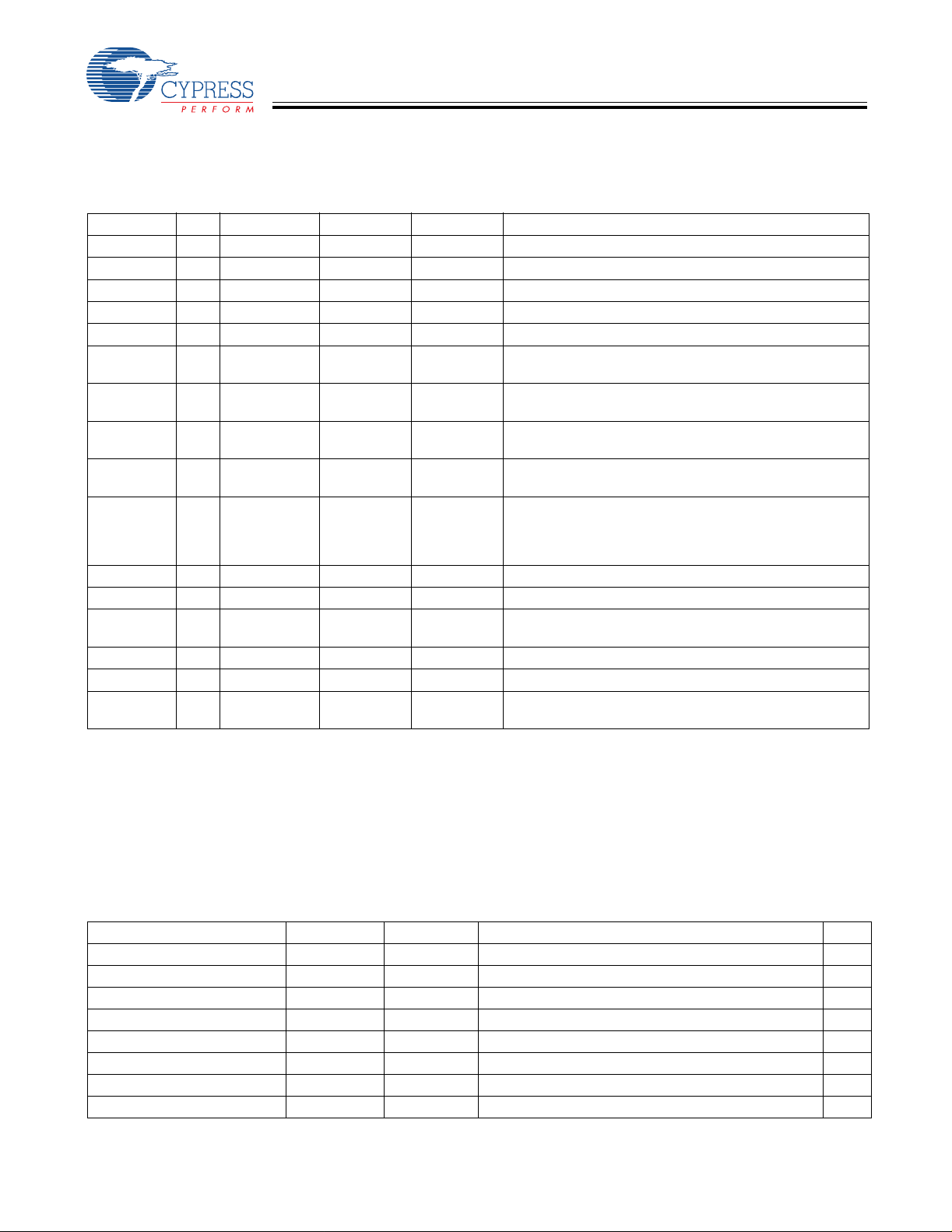

Table 4-1. Pin Assignments .................................................................................................................14

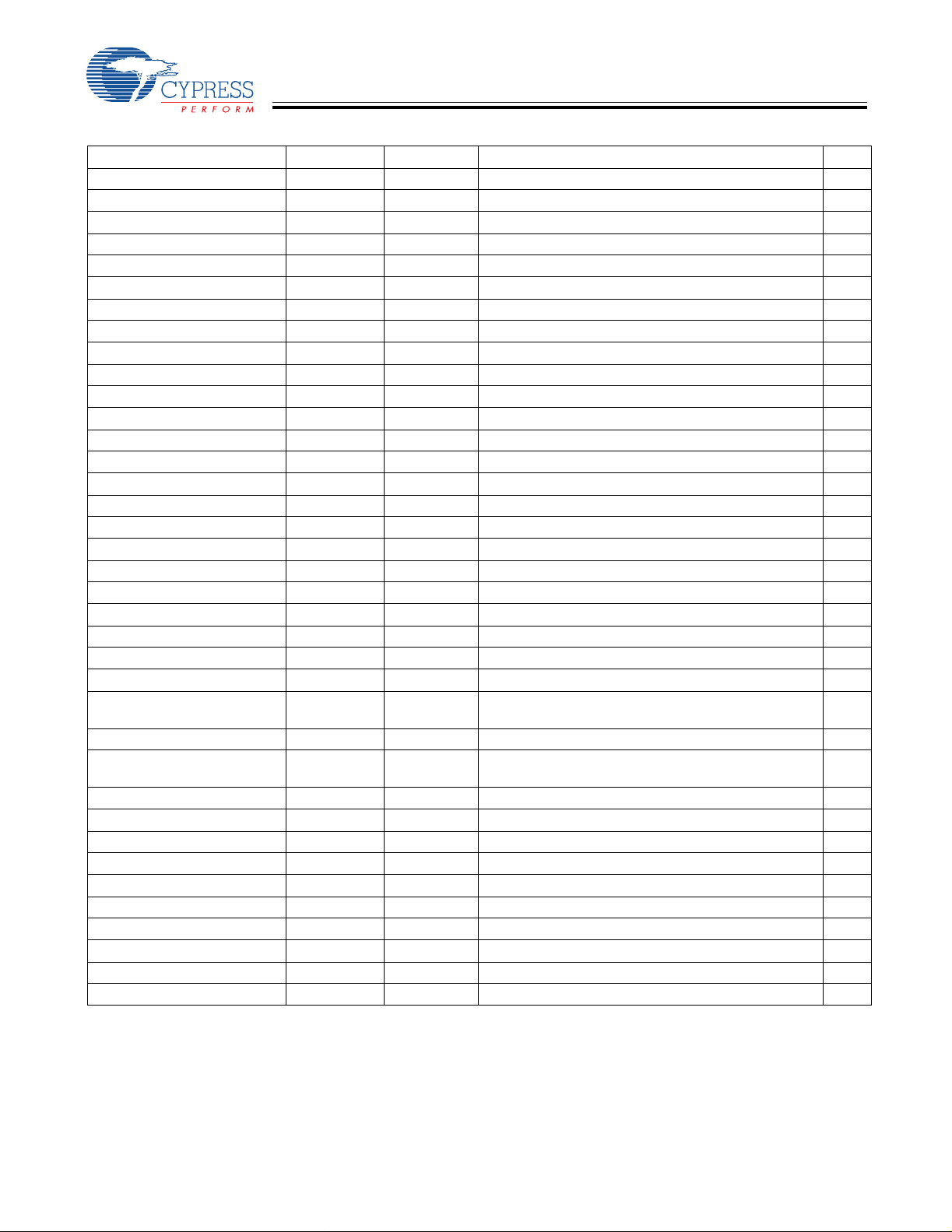

Table 4-2. I/O Register Summary ........................................................................................................14

Table 4-3. Instruction Set Summary .....................................................................................................16

Table 9-1. GPIO Port Output Control Truth Table and Interrupt Polarity .............................................24

Table 12-1. HAPI Port Configuration .......................................................................................... ..........28

Table 12-2. I

Table 13-1. I

Table 14-1. Port 2 Pin and HAPI Configuration Bit Definitions ............................................................30

Table 16-1. Interrupt Vector Assignments .......... ..................................................................................34

Table 18-1. Control Bit Definition for Downstream Ports ................. ............................. .... ...................39

Table 18-2. Control Bit Definition for Upstream Port ............................................................................41

Table 19-1. Memory Allocation for Endpoints ......................................................................................42

Table 20-1. USB Register Mode Encoding ..........................................................................................47

Table 20-2. Decode T able for Table 20-3: “Details of Modes for Differing Traffic Conditio ns” ........... .48

Table 20-3. Details of Modes for Differing Traffic Conditions

2

C Port Configuration .................. .....................................................................................28

2

C Status and Control Register Bit Definitions .................................................................29

...............................................................49

Document #: 38-08024 Rev. *B Page 5 of 61

C

C

CY7C66013

CY7C66113

1.0 Features

• Full-speed USB peripheral microcontroller with an integrated USB hub

—Well-suited for USB compound devices such as a keyboard hub functi on

• 8-bit USB optimized microcontroller

—Harvard architecture

—6-MHz external clock source

—12-MHz internal CPU clock

—48-MHz internal Hub clock

• Internal memory

—256 bytes of RAM

—8 KB of PROM

2

• Integrated Master/Slave I

• Hardware-assisted Parallel Interface (HAPI) for data transfer to external devices

•I/O ports

—Three GPIO ports (Port 0 to 2) capable of sinking 8 mA per pin (typical)

—An additional GPIO port (Port 3) capable of sinking 12 mA per pin (typical) for high current requirements: LEDs

—Higher current drive achievable by connectin g multiple GPIO pins together to drive a common output

—Each GPIO port can be configured as inputs with inter nal pull-ups or open drain output s or traditional CMOS output s

—A Digital-to-Analog Conversion (DAC) port with programmable current sink output s is available on the CY7C661 13C

device

—Maskable interrupts on all I/O pins

• 12-bit free-runni ng ti me r wit h one microsecond clock ticks

• Watchdog T imer (WDT)

• Internal Power-on Reset (POR)

• USB Specification compliance

—Conforms to USB Specification, Version 1.1

—Conforms to USB HID Specification, Version 1.1

—Supports one or two device addresses with up to five user-configured endpoints

• Up to two 8-byte control endpoi nts

• Up to four 8-byte data endpoints

• Up to two 32-byte data end points

—Integrated USB transceivers

—Supports four downstream USB ports

—GPIO pins can provide individual power control outputs for each downstream USB port

—GPIO pins can provide indivi dual port over current inputs for each downstream USB port

• Improved output drive rs to reduce electromagnetic inte rference (EMI)

• Operating voltage from 4.0V–5.5V DC

• Operating temperature from 0°–70°C

• CY7C66013C available in 48-pin SSOP (-PVC) packages

• CY7C66113C available in 56-pin QFN or 56-pin SSOP (-PVC) packages

• Industry-standard programmer support

C-compatible controller (100 kHz) enabled through General-purpose I/O (GPIO) pins

Document #: 38-08024 Rev. *B Page 6 of 61

C

C

CY7C66013

CY7C66113

2.0 Functional Overview

The CY7C66013C and CY7C66113C are compound devices with a full-speed USB microcontroller in combination with a USB

hub. Each device is well-suited for combination peripheral functions with hubs, such as a keyboard hub function. The eight-bit

one-time-programm able microcontroller with a 12-Mbps USB Hub supports as many as four downstream ports.

2.1 GPIO

The CY7C66013C feat ures 29 G PIO pins t o support USB and other applic ations. The I /O pins are grouped into fo ur port s (P0[7:0 ],

P1[7:0], P2[7:0], P3[4:0]) where each port can be configured as inputs with internal pull-ups, open drain outputs, or traditional

CMOS outputs. Ports 0 to 2 are rated at 8 mA per pin (typical) sink current. Port 3 pins are rated at 12 mA per pin (typical) sink

current, which allows these pins to drive LEDs. Multiple GPIO pins can be connected together to drive a single output for more

drive curre nt capacity. Additional ly, each I/O pin can be used to generate a GPIO interrupt to the m icrocontroller. All of the GPIO

interrupts all share the same “GPIO” interrupt vector.

The CY7C66113C has 31 GPIO pins (P0[7:0], P1[7:0], P2[7:0], P3[6:0]).

2.2 DAC

The CY7C66113C has an additional port P4[7:0] that features an additional eight programmable sink current I/O pins (DAC).

Every DAC pin includes an integrated 14-kΩ pull-up resistor. When a ‘1’ is written to a DAC I/O pin, the output current sink is

disabled and the output pin is driven HIGH by the internal pull-up resistor. When a ‘0’ is written to a DAC I/O pin, the internal

pull-up is disabled and the output pin provides the programmed amount of sink current. A DAC I/O pin can be used as an input

with an internal pull- up by wri ting a ‘1’ to the pin.

The sink current for each DAC I/O pin can be individually programmed to one of sixteen values using dedicated Isink registers.

DAC bits DAC[1:0] can be used as high current outputs with a programmable sink current range of 3.2 to 16 mA (typical). DAC

bits DAC[7:2] have a programmable current sink range of 0.2 to 1.0 mA (typical). Multiple DAC pins can be connected together

to drive a single output that requires more sink current capacity. Each I/O pin can be used to generate a DAC interrupt to the

microcontroller. Also, the int errupt polarity for each DAC I/O pin is indi vidually programmable.

2.3 Clock

The microcontroller uses an external 6-MHz crystal and an internal oscillator to provide a reference to an internal PLL-based

clock generator. This technology all ows the customer application to use an inexpensive 6-MH z fundamental crystal that r educes

the clock-related noise emissions (EMI). A PLL clock generator provides the 6-, 12-, and 48-MHz clock signals for distribution

within the microcont roller.

2.4 Memory

The CY7C66013C and CY7C66113C have 8 KB of PROM.

2.5 Power-on Reset, Watchdog, and Free-running Timer

These parts include POR logic, a WDT, and a 12-bit free-running timer. The POR logic detects when power is applied to the

device, rese ts the l ogic to a known sta te, and begins exec uting in structions at PROM addre ss 0x0000 . The WDT is us ed to en sure

that the microco ntrolle r recover s aft er a period of inact ivit y. The firmware may become inactive for a vari ety of reas ons, inc luding

errors in the code or a hardwar e fai lure such as waiting for an interrupt that never occurs.

2.6 I2C and HAPI Interface

The microcontroller can communicate with external electronics through the GPIO pins. An I2C-compatible interface accommodates a 100-kHz serial link with an external device. There is also a Hardware-assisted Parallel Interface (HAPI) which can be

used to transfer data to an external device.

2.7 Timer

The free-running 12-bit timer clocked at 1 MHz provides two interrupt sources, 128-µs and 1.024-ms. The timer can be used to

measure the duration of an event under firmware control by reading the timer at the start of the event and after the event is

complete. The difference between the two readings indicates the duration of the event in microseconds. The upper four bits of

the timer are lat ched i nto an i nternal r egist er when th e fir mware reads the l ower ei ght bi t s. A read f rom the upper four bit s actually

reads data fr om the i nternal regi ster, instead of the timer. This feature eliminates t he need f or fir mware to try to compens ate if the

upper four bits increment immediately after the lower eight bits are read.

Document #: 38-08024 Rev. *B Page 7 of 61

C

C

CY7C66013

CY7C66113

2.8 Interrupts

The microcontrol ler support s eleven mask abl e inter rupt s in the vec tored i nterr upt contr oll er . Inter rupt sour ces incl ude the 128 -µs

(bit 6) and 1.024-ms (bit 9) outputs from the fr ee-running timer, five USB end points, the USB hub, the DAC port, the GPIO ports,

and the I

to HIGH ‘1.’ The USB endpoints interrupt after the USB host has written data to the endpoint FIFO or after the USB controller

sends a packet to the USB host. The DAC ports have an additional level of masking that allows the user to select which DAC

inputs can cause a DAC inte rr upt. The GPIO ports also have a level of mask ing to select which GPIO inputs can cause a GPI O

interrupt. For additional flexibility, the input transition polarity that causes an interrupt is programmable for each pin of the DAC

port. Input transition polarity can be programmed for each GPIO port as part of the port configuration. The interrupt polarity can

be rising edge (‘0’ to ‘1’ ) or falling edge (‘1’ to ‘0’).

2.9 USB

The CY7C66013C and CY7C66113C include an integrated USB Serial Interface Engine (SIE) that supports the integrated

peripherals and the hub cont roller func tion. The har dwar e support s up to t wo USB devi ce address es with one device addr ess for

the hub (two endpo int s) and a devi ce address f or a compound devi ce (thr ee endpo int s). The SI E allows the USB host t o communicate with the hub and func tions int egrate d into t he microco ntr olle r . The p art incl udes a 1:4 hub r epeater with one up st ream port

and four downstream ports. The USB Hub allows power-management control of the downstream ports by using GPIO pins

assigned by the user firmware. The user has the option of ganging the downstream ports together with a single pair of

power-management pins, or providing power management for each port with four pairs of power- m anagement pins.

2

C-compatible master mode interface. The timer bits cause an interrupt (if enabled) when the bit toggles from LOW ‘0’

Document #: 38-08024 Rev. *B Page 8 of 61

C

C

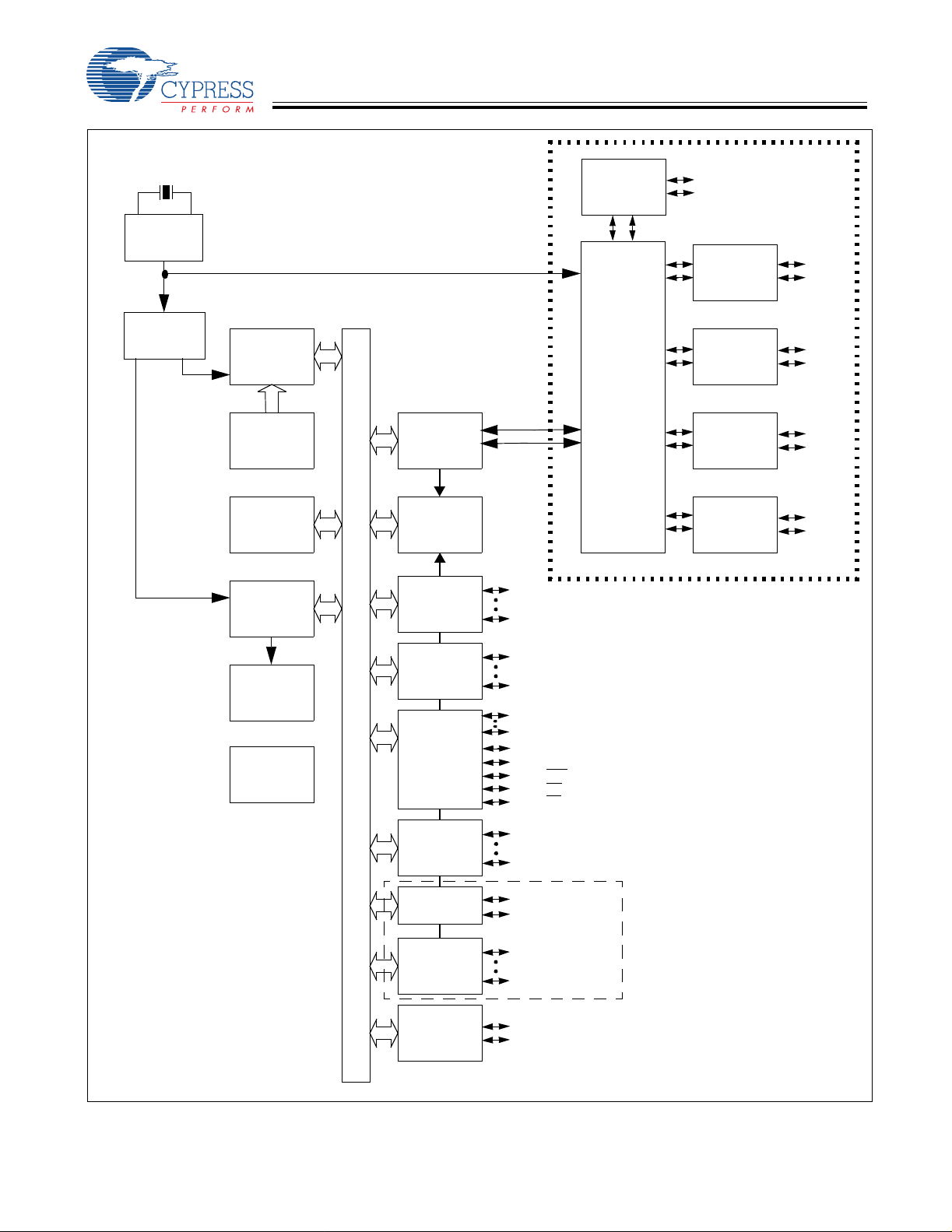

Logic Block Diagram

CY7C66013

CY7C66113

External 6-MHz crystal

PLL

48 MHz

Clock

Divider

6 MHz

12 MHz

12-MHz

8-bit

CPU

PROM

8 KB

RAM

256 byte

12-bit

Timer

8-bit Bus

USB

SIE

Interrupt

Controller

GPIO

PORT 0

P0[0]

P0[7]

USB

Transceiver

Repeater

Power management under firmware

D+[0]

Upstream

USB Port

D–[0]

USB

Transceiver

USB

Transceiver

USB

Transceiver

USB

Transceiver

Downstream USB Ports

control using GPIO pins

D+[1]

D–[1]

D+[2]

D–[2]

D+[3]

D–[3]

D+[4]

D–[4]

Watchdog

Timer

Power-On

Reset

GPIO

PORT 1

GPIO/

HAPI

PORT 2

GPIO

PORT 3

GPIO

PORT 3

DAC

PORT

I2C

Interface

*I2C-compatible interface enabled by firmware through

P2[1:0] or P1[1:0]

P1[0]

P1[7]

P2[0:1,7]

P2[2]; Latch_Empty

P2[3]; Data_Ready

P2[4]; STB

P2[5]; OE

P2[6]; CS

P3[0]

P3[4]

P3[5]

P3[6]

DAC[0]

DAC[7]

CY7C66113C only

SCLK

SDATA

High Current

Outputs

Additional

High Current

Outputs

Document #: 38-08024 Rev. *B Page 9 of 61

C

C

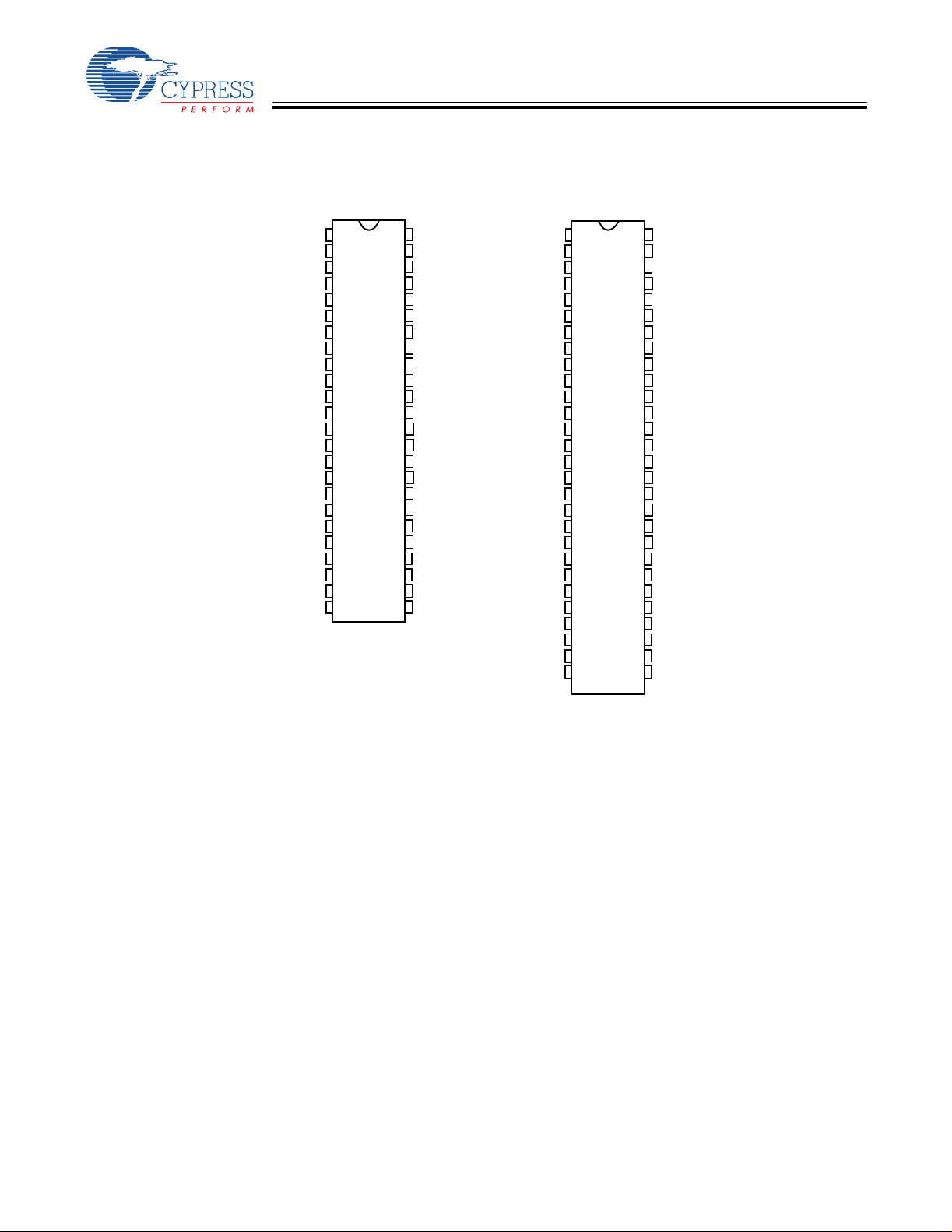

3.0 Pin Configurations

CY7C66013

CY7C66113

XTALOUT

XTALIN

V

REF

P1[3]

P1[5]

P1[7]

P3[1]

D+[0]

D–[0]

P3[3]

GND

D+[1]

D–[1]

P2[1]

D+[2]

D–[2]

P2[3]

P2[5]

P2[7]

GND

P0[7]

P0[5]

P0[3]

P0[1]

CY7C66013C

48-pin SSOP

1

48

2

47

3

46

4

45

5

44

43

6

7

42

8

41

9

40

10

39

11

38

12

37

13

36

14

35

15

34

16

33

17

32

18

31

19

30

29

20

21

28

22

27

23

26

24 25

TOP VIEW

V

CC

P1[1]

P1[0]

P1[2]

P1[4]

P1[6]

P3[0]

D–[3]

D+[3]

P3[2]

GND

P3[4]

D–[4]

D+[4]

P2[0]

P2[2]

GND

P2[4]

P2[6]

V

PP

P0[0]

P0[2]

P0[4]

P0[6]

XTALOUT

XTALIN

V

REF

P1[3]

P1[5]

P1[7]

P3[1]

D+[0]

D–[0]

P3[3]

GND

P3[5]

D+[1]

D–[1]

P2[1]

D+[2]

D–[2]

P2[3]

P2[5]

P2[7]

DAC[7]

P0[7]

P0[5]

P0[3]

P0[1]

DAC[5]

DAC[3]

DAC[1]

CY7C66113C

56-pin SSOP

1

56

2

55

54

3

4

53

5

52

6

51

7

50

8

49

9

48

10

47

11

46

12

45

13

44

43

14

15

42

16

41

17

40

18

39

19

38

20

37

21

36

22

35

23

34

24

33

25

32

26

31

27

30

28

29

V

CC

P1[1]

P1[0]

P1[2]

P1[4]

P1[6]

P3[0]

D–[3]

D+[3]

P3[2]

P3[4]

D–[4]

D+[4]

P3[6]

P2[0]

P2[2]

GND

P2[4]

P2[6]

DAC[0]

V

PP

P0[0]

P0[2]

P0[4]

P0[6]

DAC[2]

DAC[4]

DAC[6]

Document #: 38-08024 Rev. *B Page 10 of 61

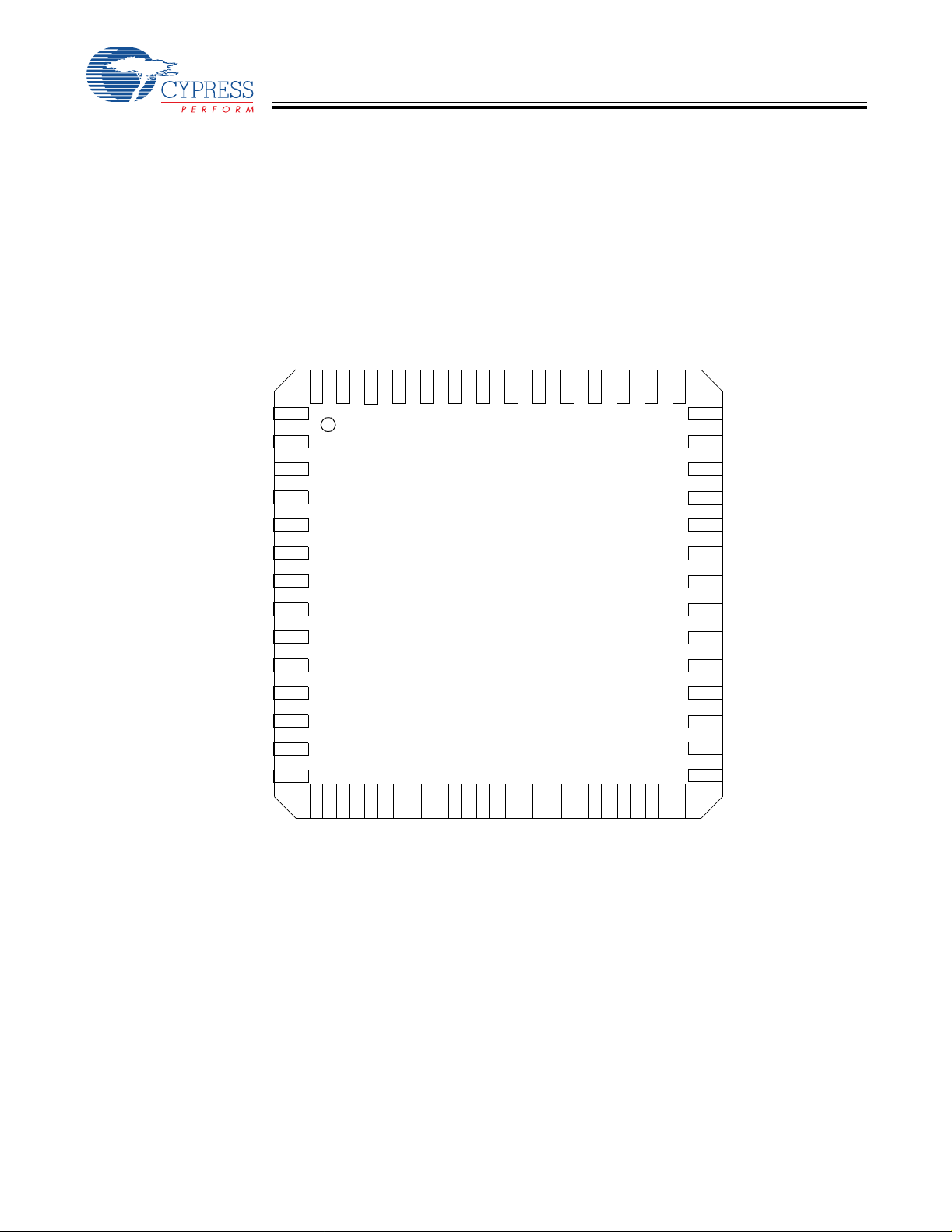

C

C

D+[0]

56

P3[1]

55

P1[7]

54

P1[5]

53

P1[3]

52

Vref

51

CY7C66013

CY7C66113

XTALOUT

XTALIN

P1[6]

P1[4]

P1[2]

P1[0]

P1[1]

Vcc

43

44

45

46

47

48

49

50

D-[0]

P3[3]

GND

P3[5]

D+[1]

D–[1]

P2[1]

D+[2]

D–[2]

P2[3]

P2[5]

P2[7]

DAC[7]

P0[7]

10

11

12

13

14

1

2

3

4

5

6

7

8

9

18

17

16

15

DAC[5]

P0[1]

P0[3]

P0[5]

CY7C66113C

56-pin QFN

21

20

19

DAC[6]

DAC[1]

DAC[3]

22

DAC[4]

23

DAC[2]

24

P0[6]

25

P0[4]

26

P0[2]

27

P0[0]

28

Vpp

42

41

40

39

38

37

36

35

34

33

32

31

30

29

P3[0]

D–[3]

D+[3]

P3[2]

P3[4]

D–[4]

D+[4]

P3[6]

P2[0]

P2[2]

GND

P2[4]

P2[6]

DAC[0]

Figure 3-1. CY7C66113C 56-pin QFN Pin Assignment

Document #: 38-08024 Rev. *B Page 1 1 of 61

C

C

(

4)

CY7C66013

CY7C66113

(3398, 419

Cypress Logo

Pin 15

Pin 1

Pin 60

Pin 30 Pin 45

0,0)

Document #: 38-08024 Rev. *B Page 12 of 61

DIE ST EP : 3398 x 4194 m icrons

Die Size: 3322 x 4129 m icrons

Die Thickness: 14 mils = 355.6 microns

Pad Size: 80 x 80 microns

Figure 3-2. CY7C66113C DIE

C

C

CY7C66013

CY7C66113

Table 3-1. Pad Coordinates in microns (0,0) to bond pad centers

Pad # Pin Name X Y Pad # Pin Name X Y

1 XtalOut 1274.2 3588.8 37 DAC6 2000.6 210.6

2 XtalIn 1132.8 3588.8 38 DAC4 2103.6 210.6

3 Vref 889.85 3588.8 39 DAC2 2206.6 210.6

4 Port11b 684.65 3588.8 40 Port06 2308.4 210.6

5 Port13 581.65 3588.8 41 Port04 2411.4 210.6

6 Port15 478.65 3588.8 42 Port02 2514.4 210.6

7 Vss 375.65 3588.8 43 Port00 2617.4 210.6

8 Port17 0 3408.35 44 Vpp 2992.4 25.4

9 Port31 0 3162.05 45 DAC0 2992.4 151.75

10 Du+ 0 3060.55 46 Port26 2992.4 306.15

11 Du– 0 2752.4 47 DD+6 2992.4 407.65

12 Port33 0 2650.95 48 DD–6 2992.4 715.75

13 Vss 0 2474.6 49 Port24 2992.4 817.25

14 Port35 0 2368.45 50 Vss 2992.4 923.4

15 DD+1 0 2266.95 51 Port22 2992.4 1086.75

16 DD–1 0 1958.85 52 DD+5 2992.4 1188.25

17 Port37 0 1857.35 53 DD–5 2992.4 1496.35

18 Vref 0 1680.4 54 Port20 2992.4 1597.85

19 Port21 0 1567.4 55 Vref 2992.4 1710.8

20 DD+2 0 1465.95 56 Port36 2992.4 1874.75

21 DD–2 0 1157.85 57 DD+4 2992.4 1976.25

22 Port23 0 1056.35 58 DD–4 2992.4 2284.35

23 Vss 0 880 59 Port34 2992.4 2385.85

24 Port25 0 773.85 60 Vss 2992.4 2492

25 DD+7 0 672.35 61 Port32 2992.4 2655.35

26 DD–7 0 364.25 62 DD+3 2992.4 2756.85

27 Port27 0 262.75 63 DD–3 2992.4 3064.95

28 DAC7 0 100.75 64 Port30 2992.4 3166.45

29 Vss 0 0 65 Port16 2992.4 3412.25

30 Port07 375.2 210.6 66 Port14 2634.2 3588.8

31 Port05 478.2 210.6 67 Port12 2531.2 3588.8

32 Port03 581.2 210.6 68 Port10 2428.2 3588.8

33 Port01 684.2 210.6 69 Port11 2325.2 3588.8

34 DAC5 788.4 210.6 70 VCC 2221.75 3588.8

35 DAC3 891.4 210.6 71 PadOpt 2121.75 3588.8

36 DAC1 994.4 210.6 72

Document #: 38-08024 Rev. *B Page 13 of 61

C

C

CY7C66013

CY7C66113

4.0 Product Summary Tables

4.1 Pin Assignments

Table 4-1. Pin Assignments

Name I/O 48-Pin 56-Pin QFN 5 6-Pi n SSO P Description

D+[0], D–[0] I/O 8, 9 56, 1 8, 9 Upstream port, USB differential data.

D+[1], D–[1] I/O 12, 13 5, 6 13, 14 Downstream port 1, USB differential data.

D+[2], D–[2] I/O 15, 16 8, 9 16, 17 Downstream port 2, USB differential data.

D+[3], D–[3] I/O 40, 41 40, 41 48, 49 Downstream port 3, USB differential data.

D+[4], D–[4] I/O 35, 36 36, 37 44, 45 Downstream port 4, USB differential data.

P0[7:0] I/O 21, 25, 22, 26,

23, 27, 24, 28

P1[7:0] I/O 6, 43, 5, 44, 4,

P2[7:0] I/O 19, 30, 18, 31,

P3[6:0] I/O 37, 10, 39, 7, 4255, 2, 4, 35,

DAC[7:0] I/O n/a 1 3, 18, 19, 20,

XTAL

IN

XTAL

OUT

V

PP

V

CC

GND 1 1, 20, 32, 38 3, 32 11, 40 Ground.

V

REF

45, 47, 46

17, 33, 14, 34

IN 2 50 2 6-MHz crystal or external clock input.

OUT 1 49 1 6-MHz crystal out.

29 28 36 Programming voltage supply, tie to ground during

48 48 56 Voltage supply.

IN 3 51 3 External 3.3V supply voltage for the differential data

14, 15, 16, 17,

24, 25, 26, 27

52, 53, 54, 43,

44, 45, 46, 47

7, 10, 11, 12,

30, 31, 33, 34

38, 39, 42,

21, 22, 23, 29

22, 32, 23, 33,

24, 34, 25, 35

6, 51, 5, 52, 4,

53, 55, 54

20, 38, 19, 39,

18, 41, 15, 42

43, 12, 46, 10,

47, 7, 50

21, 29, 26, 30,

27, 31, 28, 37

GPIO Port 0.

GPIO Port 1.

GPIO Port 2.

GPIO Port 3, capab le of sinking 12 mA (typical).

Digital to Analog Converter (DAC) Port with program-

mable current sink outputs. DAC[1 :0] offer a pro grammable

range of 3.2 to 16 mA typical. DAC[7:2] have a programmable sink current range of 0.2 to 1.0 mA typical.

norma l op e r at io n .

output buffers and the D+ pull-up.

4.2 I/O Register Summary

I/O registers ar e access ed via the I/O Rea d ( IORD) and I/O W rite ( I OWR, IOWX) inst ructi ons. I ORD reads dat a fr om t he sele cted

port into the accumul ator. IOWR performs the reverse; it writes dat a from the accumul ator to the sel ected port . Index ed I/O W rite

(IOWX) adds the contents of X to the address in the instruction to form the port address and writes dat a from the accumula tor to

the specified po rt . Specifying address 0 (e.g., IOWX 0h) means the I/ O regi ster is selected solely by the contents of X.

All undefined registers are reserved. It is important not to write to reserved registers as this may cause an undefined operation

or increased curre nt consumpti on dur in g operat ion. When writing to regi sters with res erved bi ts, the res erved b its must be wr it ten

with ‘0 .’

Table 4-2. I/O Register Summary

Register Name I/O Address Read/Write Function

Port 0 Data 0x00 R/W GPIO Port 0 Data 23 Port 1 Data 0x01 R/W GPIO Port 1 Data 23 Port 2 Data 0x02 R/W GPIO Port 2 Data 23 Port 3 Data 0x03 R/W GPIO Port 3 Data 23 Port 0 Interrupt Enable 0x04 W Interrupt Enable for Pins in Port 0 24 Port 1 Interrupt Enable 0x05 W Interrupt Enable for Pins in Port 1 25 Port 2 Interrupt Enable 0x06 W Interrupt Enable for Pins in Port 2 25 Port 3 Interrupt Enable 0x07 W Interrupt Enable for Pins in Port 3 25

Document #: 38-08024 Rev. *B Page 14 of 61

Page

C

C

CY7C66013

CY7C66113

Table 4-2. I/O Register Summary ( continued)

Register Name I/O Address Read/Write Function

GPIO Configuration 0x08 R/W G PIO Port Configurations 23

2

HAPI and I USB Device Address A 0x10 R/W USB Device Address A 42 EP A0 Counter Register 0x11 R/W USB Address A, Endpoint 0 Counter 44 EP A0 Mode Register 0x12 R/W USB Address A, Endpoint 0 Configuration 43 EP A1 Counter Register 0x13 R/W USB Address A, Endpoint 1 Counter 44 EP A1 Mode Register 0x14 R/W USB Address A, Endpoint 1 Configuration 44 EP A2 Counter Register 0x15 R/W USB Address A, Endpoint 2 Counter 44 EP A2 Mode Register 0x16 R/W USB Address A, Endpoint 2 Configuration 44 USB Status & Control 0x1F R/W USB Upstream Port Traffic Status and Control 41 Global Interrupt Enab le 0x20 R/W Global Interrupt Enab le 32 Endpoint Interru pt Enable 0x21 R/W USB Endpoint Interrupt Enables 32 Interrupt Vector 0x23 R Pending Interrupt Vector Read/Clear 34 Timer (LSB) 0x24 R Lower 8 Bits of Free-running Timer (1 MHz) 27 Timer (MSB) 0x25 R Upper 4 Bits of Free-running T imer 27 WDT Clear 0x26 W Watchdog Timer Clear 21

2

C Control & Status 0x28 R/W I2C Status and Control 28

I

2

C Data 0x29 R/W I2C Data 28

I DAC Data 0x30 R/W DAC Data 26 DAC Interrupt Enable 0x31 W Interrupt Enable for each DAC Pin 26 DAC Int er ru p t P o la rity 0x32 W Interr u pt Po la r ity fo r ea c h DAC P in 26 DAC Isink 0x38-0x3F W Input Sink Current Control for each DAC Pin 26 USB Device Address B 0x40 R/W USB Device Address B (not used in 5-endpoint mode) 42 EP B0 Counter Register 0x41 R/W USB Address B, Endpoint 0 Counter 44 EP B0 Mode Register 0x42 R/W USB Address B, Endpoint 0 Configuration, or

EP B1 Counter Register 0x43 R/W USB Address B, Endpoint 1 Counter 44 EP B1 Mode Register 0x44 R/W USB Address B, Endpoint 1 Configuration, or

Hub Port Connect Status 0x48 R/ W Hub Downstream Port Connect Status 38 Hub Port Enable 0x49 R/W Hub Downstream Ports Enable 38 Hub Port Speed 0x4A R/W Hub Downstream Ports Speed 38 Hub Port Control (Ports [4:1]) 0x4B R/W Hub Downstream Ports Control 39 Hub Port Suspend 0x4D R/W Hub Downstream Port Suspend Control 40 Hub Port Resume Status 0x4E R Hub Downstream Ports Resume Status 40 Hub Ports SE0 Status 0x4F R Hub Downstream Ports SE0 Status 39 Hub Ports Data 0x50 R Hub Downstream Ports Differential data 40 Hub Downstream Force Low 0x51 R/W Hub Downstream Ports Force LOW 39 Processor Status & Control 0xFF R/W Microprocessor Status and Control Register 31

C Configuration 0x09 R/W HAPI Width and I2C Position Configur ati on 27

USB Address A, Endpoint 3 in 5-endpoint mode

USB Address A, Endpoint 4 in 5-endpoint mode

Page

43

44

Document #: 38-08024 Rev. *B Page 15 of 61

C

C

CY7C66013

CY7C66113

4.3 Instruction Set Summary

Refer to the CYASM Assembler User’s Guide for more details.

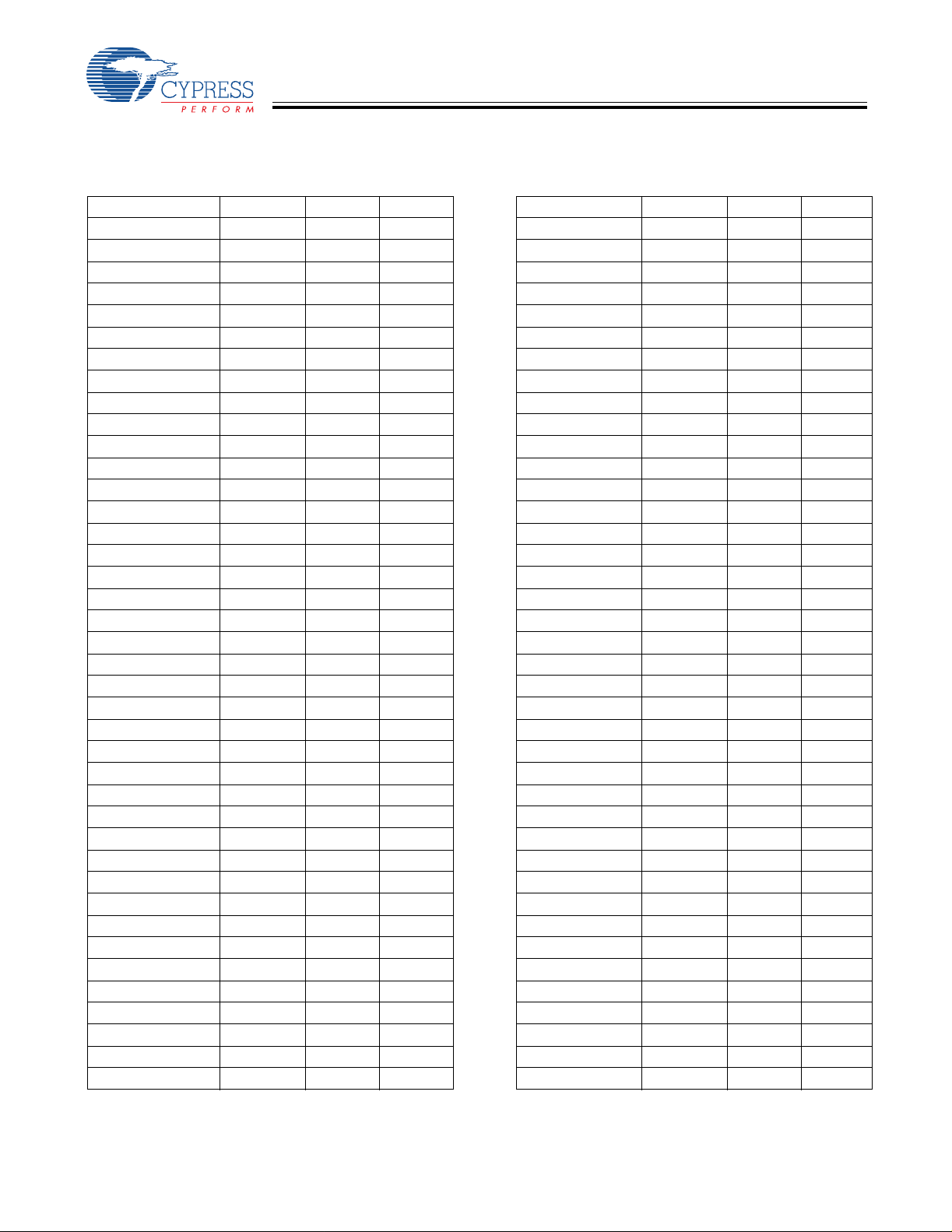

Table 4-3. Instruction Set Summary

MNEMONIC operand opcode cycles MNEMONIC operand opcode cycles

HALT 00 7 NOP 20 4

ADD A,expr data 01 4 INC A acc 21 4

ADD A,[expr] direct 02 6 INC X x 22 4

ADD A,[X+expr] index 03 7 INC [expr] direct 23 7

ADC A,expr data 04 4 INC [X+expr] index 24 8

ADC A,[expr] direct 05 6 DEC A acc 25 4

ADC A,[X+expr] index 06 7 DEC X x 26 4

SUB A,expr data 07 4 DEC [expr] direct 27 7

SUB A,[expr] direct 08 6 DEC [X+expr] index 28 8

SUB A,[X+expr] index 09 7 IORD expr address 29 5

SBB A,expr data 0A 4 IOWR expr address 2A 5

SBB A,[expr] direct 0B 6 POP A 2B 4

SBB A,[X+expr] index 0C 7 POP X 2C 4

OR A,expr data 0D 4 PUSH A 2D 5

OR A,[expr] direct 0E 6 PUSH X 2E 5

OR A,[X+expr] index 0F 7 SWAP A,X 2F 5

AND A,expr data 10 4 SWAP A,DSP 30 5

AND A,[ex p r] direct 1 1 6 MOV [expr],A direct 31 5

AND A,[X+expr] index 12 7 MOV [X+expr],A index 32 6

XOR A,expr data 13 4 O R [expr],A direct 33 7

XOR A,[expr] direct 14 6 OR [X+expr],A index 34 8

XOR A,[X+expr] index 15 7 AND [expr],A direct 35 7

CMP A,expr data 16 5 AND [X+expr],A i ndex 36 8

CMP A,[expr] direct 17 7 XOR [expr],A direct 37 7

CMP A,[X+expr] index 18 8 XOR [X+expr],A index 38 8

MOV A,expr data 19 4 IOWX [X+expr] index 39 6

MOV A,[expr] direct 1A 5 CPL 3A 4

MOV A,[X+expr] index 1B 6 ASL 3B 4

MOV X,expr data 1C 4 ASR 3C 4

MOV X,[expr] direct 1D 5 RLC 3D 4

reserved 1E RRC 3E 4

XPAGE 1F 4 RET 3F 8

MOV A,X 40 4 DI 70 4

MOV X,A 41 4 EI 72 4

MOV PSP,A 60 4 RETI 73 8

CALL addr 50 - 5F 10 JC addr C0-CF 5

JMP addr 80-8F 5 JNC addr D0-DF 5

CALL addr 90-9F 10 JACC addr E0-EF 7

JZ addr A0-AF 5 INDEX addr F0-FF 14

JNZ addr B0-BF 5

Document #: 38-08024 Rev. *B Page 16 of 61

C

C

CY7C66013

CY7C66113

5.0 Programming Model

5.1 14-bit Program Counter (PC)

The 14-bit Program Counter (PC) allows access to up to 8 KB of PROM available with the CY7C66x13C architecture. The top

32 bytes of the ROM in the 8K part are reserved for testi ng purposes. The program count er is cleared duri ng reset, such that th e

first instr uction executed after a reset is at a ddress 0x0000h. Typically, this is a jump instruction t o a reset handler that initializes

the application (see Section 16.1, Interru pt Vectors, on page 33).

The lower eight bits of the program counter are incremented as instructions are loaded and executed. The upper six bits of the

program counter ar e incr emented by exe cut ing an XPAGE instruction. As a result , the la st inst ruct ion execu ted within a 256- byt e

“page” of sequen tial code should be an XPAGE instructi on. T he assembler direct ive “XPAGEON” causes the assembler to insert

XPAGE instructions automatically. Because instructions can be either one or two bytes long, the assembler may occasionally

need to insert a NOP followed by an XPAGE to execute corr ectly.

The address of the next instr ucti on to be execute d, the carr y flag, and the zer o flag ar e saved as two bytes on the program st ack

during an interrupt acknowledge or a CALL instruction. The program counter, carry flag, and zero flag are restored from the

program stack during a RETI instruction. Onl y the pr ogram counter is restored during a RET instruction.

The program counter cannot be accessed directly by the firmware. The program stack can be ex am ined by reading SRAM from

location 0x00 and up.

Document #: 38-08024 Rev. *B Page 17 of 61

C

C

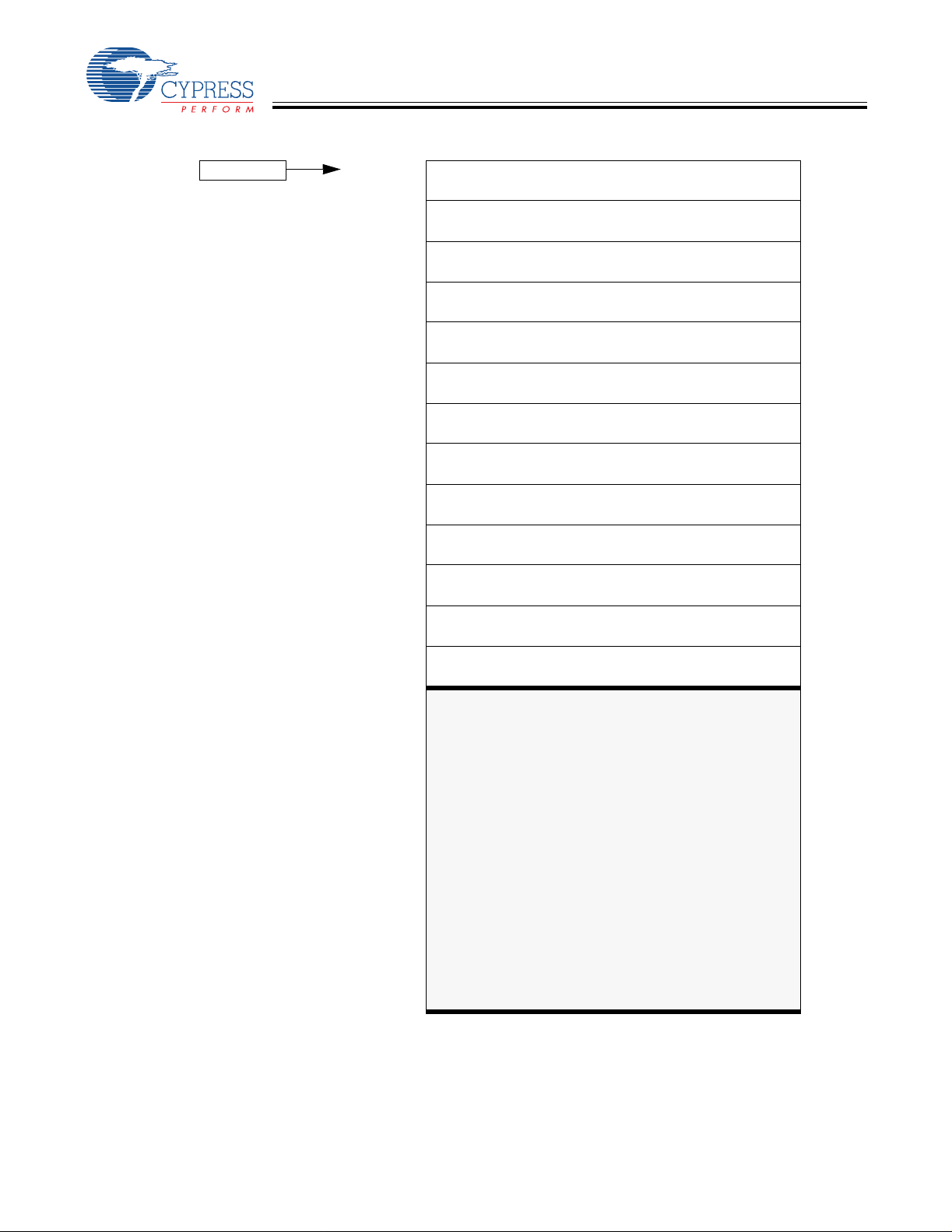

5.1.1 Program Memory Organization

after reset Address 14-bit PC 0x0000

Program execution begins here after a reset

CY7C66013

CY7C66113

0x0002

0x0004

0x0006

0x0008

0x000A

0x000C

0x000E

0x0010

0x0012

0x0014

0x0016

0x0018

USB Bus Reset interrupt vector

128-µs timer interrupt vector

1.024-ms timer i nterrupt vector

USB address A endpoint 0 interrupt vector

USB address A endpoint 1 interrupt vector

USB address A endpoint 2 interrupt vector

USB address B endpoint 0 interrupt vector

USB address B endpoint 1 interrupt vector

Hub interrupt vector

DAC interrupt vector

GPIO/HAPI interrupt vector

I2C interrupt vector

0x001A

0x1FDF

Figure 5-1. Progra m Memory Space with Interr upt Vector Table

Program Memory begins here

8 KB (-32) PROM ends here.

Document #: 38-08024 Rev. *B Page 18 of 61

C

C

CY7C66013

CY7C66113

5.2 8-bit Accumulator (A)

The accumulator is the general-purpose register for the microcontroller.

5.3 8-bit Temporary Register (X)

The “X” regi ster i s avail able to the firmwar e for t emporary storage of int ermediate results. The mi crocontro ller ca n perform indexed

operations based on the value in X. Refer to Section 5.6.3 for addi ti onal information.

5.4 8-bit Progr a m Stack Pointer (PSP)

During a reset, the Program Stack Pointer (PSP) is set to 0x00 and “grows” upward from this address. The PSP may be set by

firmware, using the MOV PSP,A instruction. The PSP supports interrupt service under hardware control and CALL, RET, and

RETI instructions under firmware control. The PSP is not readable by the firmware.

During an interrupt acknowledge, interrupts are disabled and the 14-bit progr am counter, carry flag, and zero flag are written as

two bytes of dat a memory . The f irst byte i s stored in the m emory address ed by the PSP, then the PSP is incre mented. The secon d

byte is stored in memory addressed by the PSP, and the PSP is incremented again. The overall effect is to store the program

counter and flags on the pro gram “stack” and increment th e PSP by two.

The Return From I nterr upt (RETI ) ins truct ion dec remen ts t he PSP, then rest ores t he second b yte from mem ory addr essed by th e

PSP. The PSP is decremente d ag ain and the f irst byte is r estor ed f rom m emory add ressed by t he PSP. After the pro gram count er

and flags hav e be en rest ored f r om sta ck, the i nter rupt s ar e enabl ed. Th e ov erall ef fec t is to r estor e t he prog ram c ounter and flags

from the program stack, decrement the PSP by two, and re-enable interrupts.

The Call Subroutine (CALL) instruction stores the program counter and flags on the program stack and increments the PSP by

two.

The Return From Subroutine (RET) instruction restores the program counter but not the flags from the program stack and

decrements the PSP by two.

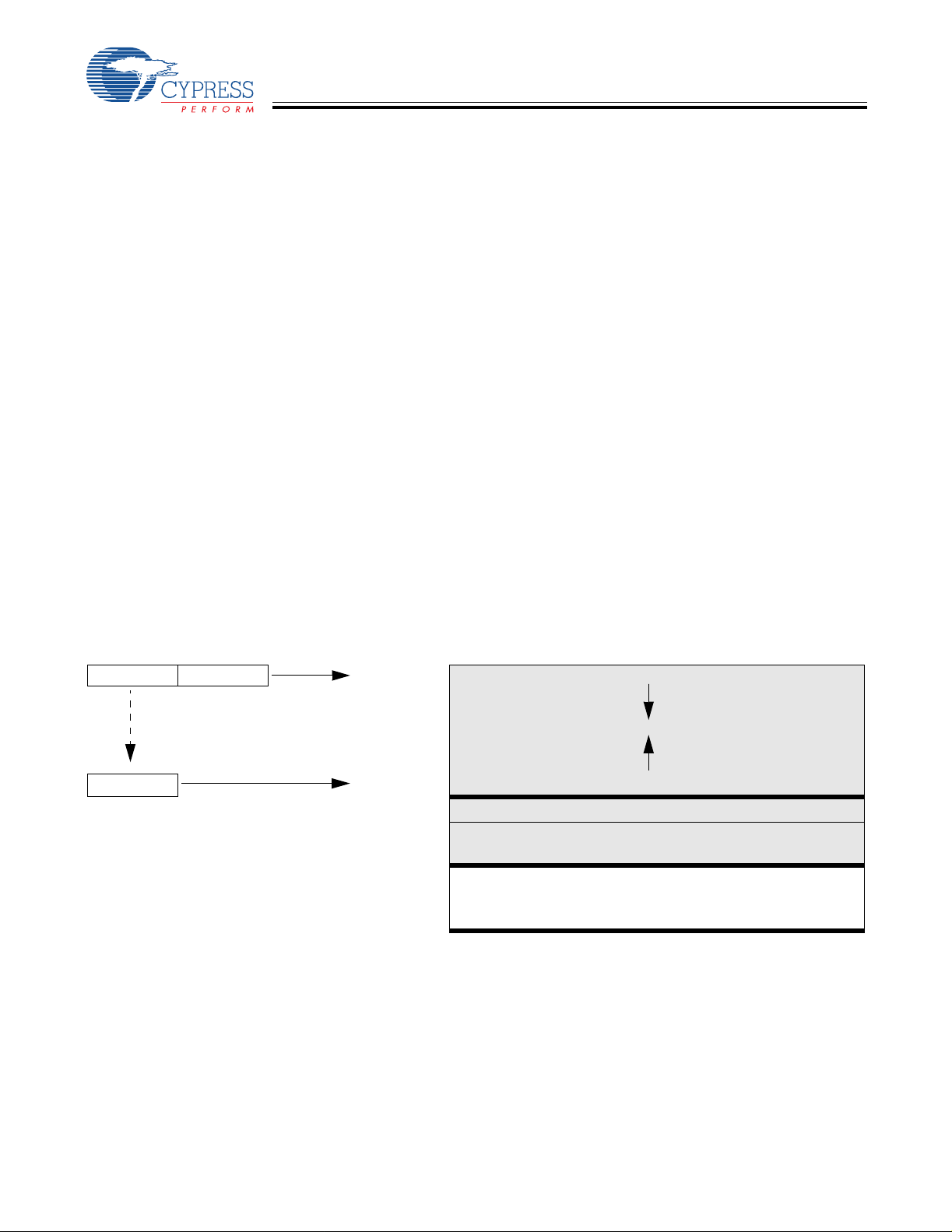

5.4.1 Data Memory Organization

The CY7C66x13C microcontrollers provide 256 bytes of data RAM. Normally, the SRAM is partitioned into four areas: program

stack, us er varia bles, data st ack, an d USB endpoi nt FI FOs. The f ol lowing is o ne e xample o f where t he program st ack, dat a st a ck,

and user variable s areas could be located.

After reset Address 8-bit DSP 8-bit PSP 0x00

(Move DSP

8-bit DSP

[1]

)

user selected

0xFF

User variables

USB FIFO sp ace for up to two Addresses and five endpoints

Program Stack Growth

Data Stack Growth

[2]

5.5 8-bit Data Stack Pointer (DSP)

The Data Stack Pointer (DSP) supports PUSH and POP instructions that use the data stack for temporary storage. A PUSH

instruction pre-decrements the DSP, then writes data to the memory location addressed by the DSP. A POP instruction reads

data from the memory lo cation addressed by the DSP, then post-increment s the DSP.

During a reset, the DSP is reset to 0x00. A PUSH instruction when DSP equals 0x00 writes data at the top of the data RAM

(address 0xFF). This writes data to the memory area reserved for USB endpoint FIFOs. Therefore, the DSP should be indexed

at an appropriate memory location that does not compromise the Program Stack, user-defined memory (variables), or the USB

endpoint FIFOs.

Notes:

1. Refer to Section 5.5 for a description of DSP.

2. Endpoint sizes are fixed by the Endpoint Size Bit (I/O register 0x1F, Bit 7), see

Table 19-1.

Document #: 38-08024 Rev. *B Page 19 of 61

C

C

CY7C66013

CY7C66113

For USB applicati ons, t he f irmware should set the DSP to an a ppro priate l ocati on t o avoid a memor y confl ict wit h RAM de dicate d

to USB FIFOs. The memory requirements for the USB endpoints are described in Section 19.2. Example assembly inst ructions

to do this with two device addresses (FIFOs begin at 0xD8) are shown below:

MOV A,20h; Move 20 hex into Accumulator (must be D8h or less)

SWAP A,DSP; swap accumulator value into DSP register.

5.6 Address Mode s

The CY7C66013C and CY7C66113C microcontrollers support three addressing modes for instructions that require data

operands: data, direct, and indexed.

5.6.1 Data (Immediate)

“Data” address mode refers to a data oper and that i s actual ly a const ant encod ed in t he instruct ion. As an example , consid er the

instruction th at loads A with the constant 0xD8:

• MOV A , 0D8h.

This instruction requires two bytes of code where the first byte identifies the “MOV A” instruction with a data operand as the

second byte. The second byte of the instruction is the constant “0xD8”. A constant may be referred to by name if a prior “EQU”

statement assigns the constant value to the name. For example, the following code is equivalent to the example shown above:

• DSPINIT: EQU 0D8h

• MOV A, DSPINIT.

5.6.2 Direct

“Direct” address mode is used when the data operand is a variable stored in SRAM. In that case, the one byte address of the

variable is encoded in the instruction. As an example, consider an instruction that loads A with the contents of memory add ress

loca t ion 0x1 0:

• MOV A, [10h].

Normally , vari able names are assi gned to vari able addresses using “EQU” st atements to improve the reada bility of th e assembler

source code. As an example, the following code is equiva lent to the example shown above:

• buttons: EQU 10h

• MOV A, [buttons].

5.6.3 Indexed

“Indexed” address mode allows the firmware to manipulate arrays of data stored in SRAM. The address of the data operand is

the sum of a const ant encoded i n the ins truct ion and t he con tent s of the “X” regi ster. Normally, the constant is the “base” address

of an array of data and the X regi ster contains an index tha t i ndicates which element of the array is actually addressed:

• array: EQU 10h

•MOV X, 3

• MOV A, [X+array].

This would have the effect of loading A with the fourth element of the SRAM “array” that begins at address 0x10. The fourth

element would be at address 0x13.

6.0 Clocking

XTALOUT

(pin 1)

XTALIN

(pin 2)

30 pF

Figure 6-1. Clock Oscillator On-Chip Circuit

The XTALIN and XTALOUT are the clock pins to the microcontroller. The user can connect an external oscillator or a crystal to

these pins. When using an external crystal, keep PCB traces between the chip leads and crystal as short as possible (less than

To Interna l PLL

30 pF

Document #: 38-08024 Rev. *B Page 20 of 61

C

C

CY7C66013

CY7C66113

2 cm). A 6-MHz fundamental frequ ency parall el resonant cryst al can be connect ed to these pins to provid e a reference frequenc y

for the i nternal PLL. The two internal 30- pF load caps appear in series to the externa l crystal and would be equiva lent to a 15-pF

load. Therefore, the crystal must have a required load capacitance of about 15–18 pF. A ceramic resonator does not allow the

microcontroller to meet the timing specifications of full speed USB and therefore a ceramic resonator is not recommended with

these parts.

An external 6-MHz clock can be applied to the XTALIN pin if the XTALOUT pin is left open. Grounding the XTALOUT pin when

driving XTALIN with an oscillator does not work because the internal clock is effectively shorted to ground.

7.0 Reset

The CY7C66x13C supports t w o resets: POR and a Watchdog Reset (WDR). Each of these resets causes:

• all registe rs to be restored to their defaul t states

• the USB device addresses to be set to 0

• all interr upts to be disabled

• the PSP and DSP to be set to memory address 0x00.

The occurrence of a reset is recorded in the Processor Status and Control Register, as described in Section 15.0. Bits 4 and 6

are used to record the occurrence of POR and WDR, respectively. Firmware can interrogate these bits to determine the cause

of a reset.

Program execution st arts at ROM address 0x0000 after a reset. Although this looks like interrupt vector 0, there is an important

difference. Reset processing does NOT push the program counter, carry flag, and zero flag onto program stack. The firmware

reset handle r shoul d conf ig ure th e hardwar e b efore the “ main” l oop of co de. Att emptin g to e xecut e a RET or RETI in the f irmwar e

reset handler causes unpredictable execution results.

7.1 Power-on Reset

When VCC is first applied to the chip, the POR signal is asserted and the CY7C66x13C enters a “semi-suspend” state. During

the semi-suspend state, which is different from the suspend state defined in the USB specification, the oscillator and all other

blocks of t he part are functi onal, except for t he CPU. This semi-suspend time ensures that both a valid V

that the internal PLL has time to stabilize before full operation begins. When the V

the oscillator is stable, the POR is deasserted and the on-chip timer starts counting. The first 1 ms of suspend time is not

interruptible, and the semi-suspend state continues for an additional 95 ms unless the count is bypassed by a USB Bus Reset

on the upstream port . The 95 ms provides time for V

If a USB Bus Reset occurs on the upstream port during the 95 ms semi-suspend time, the semi-suspend state is aborted and

program execution begins immediately from address 0x0000. In this case, the Bus Reset interrupt is pending but not serviced

until firmware sets the USB Bus Reset Interrupt Enable bit (bit 0 of register 0x20) and enables interrupts with the EI command.

The POR signal is asse rted whenever V

again. Behavior is the same as described above.

drops below appr oximately 2.5V , and remains asser ted until VCC rises above thi s level

CC

to stabilize at a valid operating volt age before the chip executes code.

CC

has risen above approximately 2.5V, and

CC

level is reached and

CC

7.2 Watchdog Reset

The WDR occurs when the internal WDT rolls over. Writing any value to the write-only Watchdog Restart Register at address

0x26 clears the timer. The timer rolls over and WDR occurs if it is not c leared within t

6 of the Processor S tatus and Cont rol Register is set to record t his event (the registe r contents ar e set to 010X0001 by the WDR).

A WDT Reset lasts for 2 ms, after which the microcontroller begins execution at ROM address 0x0000.

t

WATCH

2 ms

(8 ms minimum) of the last clear. Bit

WATCH

Last write to

WDT

Register

Document #: 38-08024 Rev. *B Page 21 of 61

No write to WDT

register, so WDR

goes HIGH

Figure 7-1. Watchdog Reset

Execution begins at

Reset Vector 0x0000

C

C

V

CY7C66013

CY7C66113

The USB transmitter is disabled by a WDR because the USB Device Address Registers are cleared (see Section 19.1).

Otherwise, the USB Control ler would respond to all address 0 transactions.

It is possible for the WDR bit of the Processor Status and Control Register (0xFF) to be set fol lowing a POR event. If a firmware

interrogates the Processor Status and Control Register for a set condition on the WDR bit, the WDR bit should be ignored i f the

POR (bit 3 of register 0xFF) bit is set.

8.0 Suspend Mode

The CY7C66x13C can be placed into a low-power state by setting the Su spend bit of the Processo r Status and Control register.

All logic blocks in the device are turned off except the GPIO interrupt logic and the USB receiver. The clock oscillator and PLL,

as well as the free-running and WDTs, are shut down. Only the occurrence of an enabled G PIO interrupt or non-idle bus activity

at a USB upstream or downst ream port wakes the part from suspend. The Run bit in the Processor Status and Control Register

must be set to resume a part out of suspend.

The clock oscillator restarts immediately after exiting suspend mode. The microcontroller returns to a fully functional state 1 ms

after the oscill ator is stable. The microco ntroller execu tes the instruction fol lowing the I/O write that placed the devic e into suspend

mode before servicing any interrupt requests.

The GPIO interrupt allows the controller to wake- up periodically and poll system component s while maintaini ng a very low average

power consumpti on. To achieve t he lowes t possibl e current duri ng susp end mod e, all I/O sho ul d be hel d a t V

applies to internal port pins that may not be bonded in a par ticular package.

Typical code for entering suspend is shown below:

... ; All GPIO set to low-power state (no floating pins)

... ; Enable GPIO interrupts if desired for wake-up

mov a, 09h ; Set suspend and run bits

iowr FFh ; Write t o Status and Control Regi ster – Enter suspend, wait for USB activity (or GPIO Interrupt)

nop ; This executes before any ISR

... ; Remaining code for exiting suspend routine.

or Gnd. This also

CC

9.0 General-purpose I/O (GPIO) Ports

GPIO

CFG

OE

Internal

Data Bus

Port Write

Port Read

Reg_Bit

STRB

(Latch is Transparent

except in HAPI mode)

Interrupt

Enable

Interrupt

Controller

Data

Out

Latch

Data

In

Latch

Data

Interrupt

Latch

mode

2-bits

Control

Control

Q1

14 kΩ

Q3*

CC

Q2

GPIO

PIN

*Port 0,1,2: Low I

Port 3: High I

sink

sink

Figure 9-1. Block Diagram of a GPIO Pin

Document #: 38-08024 Rev. *B Page 22 of 61

C

C

CY7C66013

CY7C66113

There are up to 31 GPIO pins (P0[7:0], P1[7:0], P2[7:0], and P3[6:0]) for the hardware interface. The number of GPIO pins

changes based on the pa ckag e type of t he chip. Each port c an be conf igur ed as input s wit h inter nal pul l-up s, open dr ain outp uts,

or traditional CMOS outputs. Port 3 offers a higher current drive, with typical current sink capability of 12 mA. The data for each

GPIO port is accessible through the data registers. Port data registers are shown in Figure 9-2 through Figure 9-5, and are set

to 1 on reset.

Port 0 Data ADDRESS 0x00

Bit #76543210 Bit Name P0.7 P0.6 P0.5 P0.4 P0.3 P0.2 P0.1 P0.0 Read/Write R/W R/W R/W R/W R/W R/W R/W R/W Reset11111111

Figure 9-2. Port 0 Data

Port 1 Data ADDRESS 0x01

Bit #76543210 Bit Name P1.7 P1.6 P1.5 P1.4 P1.3 P1.2 P1.1 P1.0 Read/Write R/W R/W R/W R/W R/W R/W R/W R/W Reset11111111

Figure 9-3. Port1 Data

Port 2 Data ADDRESS 0x02

Bit #76543210 Bit Name P2.7 P2.6 P2.5 P2.4 P2.3 P2.2 P2.1 P2.0 Read/Write R/W R/W R/W R/W R/W R/W R/W R/W Reset11111111

Figure 9-4. Port 2 Data

Port 3 Data ADDRESS 0x03

Bit #76 5 43210 Bit Name Reserved P3.6

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W Reset- 1 1 11111

CY7C66113C only

Special care should be taken with any unused GPI O data bits. An unused GPIO data bit, eit her a pin on the chip or a port bit that

is not bonded on a particular package, must not be left floating when the device enters the suspend state. If a GPIO data bit is

left floating, the leakage current caused by the floating bit may violate the suspend current limitation specified by the USB

specifications. If a ‘1’ is written to the unused data bit and the port is configured with open drain outputs, the unused data bit

remains in an indeterminate state. Therefore, if an unused port bit is programmed in open-drain mode, it must be written with a

‘0.’ Notice that the CY7C66013C always requires that P3[7:5] be written with a ‘0.’ When the CY7C66113C is used the P3[7]

should be written with a ‘0.’

In normal non-HAPI mode, reads from a GPIO port always return the present state of the voltage at the pin, independent of the

settings in the Por t Dat a Regist ers. I f HAPI mode is activa ted for a port, reads of that por t return l atched da t a as contr olled by the

HAPI signals (see Section 14.0). During reset, all of the GPIO pins are set to a high impedance input state (‘1’ in open drain

mode). Writi ng a ‘0’ to a GPIO pin drives the pi n LOW . In this st ate, a ‘0’ is always read on t hat GPIO pin unl ess an ext ernal source

overdrives th e int ernal pull-down device.

P3.5

CY7C66113C

only

P3.4 P3.3 P3.2 P3.1 P3.0

Figure 9-5. Port 3 Data

9.1 GPIO Configuration Port

Every GPIO port can be programmed as in puts with internal pull-up s, outputs LOW or HIGH, or Hi-Z (fl oating, the pin i s not driven

internally). In addition, the interrupt polarity for each port can be programmed. The Port Configuration bits (Figure 9-6) and the

Interrupt Enable b it (Figure 9-7 through Figure 9-10) determine the interrupt polarity of the port pins.

GPIO Configuration ADDRESS 0x08

Bit #76543210 Bit Name Port 3

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W Reset00000000

Config Bit 1

Port 3

Config Bit 0

Port 2

Config Bit 1

Port 2

Config Bit 0

Port 1

Config Bit 1

Port 1

Config Bit 0

Port 0

Config Bit 1

Port 0

Config Bit 0

Figure 9-6. GPIO Configuration Register

Document #: 38-08024 Rev. *B Page 23 of 61

C

C

CY7C66013

CY7C66113

As shown in Table 9-1 below, a posi tive po lari ty on an i npu t pin r epresent s a r is ing edge i nter rupt ( LOW to HIGH) , and a n egativ e

polarity on an input pin represents a falling edge interrupt (HIGH to LOW).

The GPIO interrupt is generated when all of the following conditions are met: the Interrupt Enable bit of the associated Port

Interrupt Enable Register is enabled, the GPIO Interrupt Enable bit of the Global Interrupt Enable Register (Figure16-1) is

enabled, th e Interrupt Enabl e Sense (bit 2, Figure 15-1) is set, and the GPIO pin of the port sees an event matchi ng the interr upt

polarity.

The driving state of each GPIO pin is determined by the value written to the pin’s Data Register (Figure 9-2 through Figure 9-5)

and by its associated Port Configuration bits as shown in the GPIO Configuration Register (Figure9-6). These ports are

configured on a per-port basis, so all pins in a given port are configured together. The possible port configurations are detailed

in Table 9-1. As shown in this table below, when a GPIO port is configured with CMOS outputs, interrupts from that port are

disabled.

During reset, all of the bits in the GPIO Configuration Register are written with ‘0’ to select Hi-Z mode for all GPIO ports as the

default configuration.

T able 9-1. GPIO Port Output Control Truth Table and Interrupt Polarity

Port Config Bit 1 Port Con fi g Bit 0 Data Register Output Drive S trength Interrupt Enable Bit Interrupt Polarity

1 1 0 Output LOW 0 Disabled

1 Resistive 1 – (Falling Edge)

1 0 0 Output LOW 0 Disabled

1 Output HIGH 1 Disabled

0 1 0 Output LOW 0 Disabled

1 Hi-Z 1 – (Falling Edge)

0 0 0 Output LOW 0 Disabled

1 Hi-Z 1 + (Rising Edge)

Q1, Q2, and Q3 discussed be low ar e the t ransistors referenced in Figure 9-1. The available GPIO drive strength are:

• Output LOW Mode: The pin’ s Data Register is set to ‘0’

Writing ‘0’ to the pin’s Data Register puts the pin in output LOW mode, regardless of the contents of the Port Configuration

Bits[1:0]. In this mode, Q1 and Q2 are OFF. Q3 is ON. The GPIO pin is driven LOW through Q3.

• Output HIGH Mode: The pin’s Data Register is set to 1 and the Port Conf iguration Bits[1:0] is set to ‘10’

In this mode, Q1 and Q3 are OFF. Q2 is ON. The GPIO is pulled up through Q2. The GPIO pin is capable of sourcing ... of

current.

• Resistive Mode: The pin’s Data Register is set to 1 and the Port Configuration Bits[1:0] is set to ‘11’

Q2 and Q3 are OFF. Q1 is ON. Th e G PIO pin is pulled up wit h an internal 14kΩ resistor. In resi stive mode, the pin may serve

as an input. Reading the pin’s Data Register returns a logic HIGH if the pin is not driven LOW by an external source.

• Hi-Z Mode: The pin’s Data Register is set to1 and Port Configuration Bits[1:0] is set either ‘00’ or ‘01’

Q1, Q2, and Q3 are all OFF. The GPIO pin is not driven internally. In this mode, the pin may serve as an input. Reading the

Port Data Register returns the actual logic value on the port pins.

9.2 GPIO Interru pt Enabl e P orts

Each GPIO pin can be individually enabled or disabled as an interrupt source. The Port 0–3 Interrupt Enable registers provide

this feature with an interrupt enable bit for each GPIO pin. When HAPI mode (Section 14.0) is enabled the GPIO interrupts are

blocked, including ports not used by HAPI, so GPIO pins cannot be used as interrupt sources.

During a reset, GPIO interrupts are disabled by clearing all of the GPIO interrupt enable ports. Writing a ‘1’ to a GPIO Interrupt

Enable bit enables GPIO interrupts from the corresponding input pin. All GPIO pins share a common interrupt, as discussed in

Section 16.8.

Port 0 Interrupt Enable ADDRESS 0x04

Bit #76543210

Bit Name P0.7 Intr

Read/WriteWWWWWWWW

Reset00000000

Enable

P0.6 Intr Enable

P0.5 Intr Enable

P0.4 Intr Enable

P0.3 Intr Enable

Figure 9-7. Port 0 Interrupt Enable

P0.2 Intr Enable

P0.1 Intr Enable

P0.0 Intr Enable

Document #: 38-08024 Rev. *B Page 24 of 61

C

C

CY7C66013

CY7C66113

Port 1 Interrupt Enable ADDRESS 0x05

Bit #76543210

Bit Name P1.7 Intr

Read/WriteWWWWWWWW

Reset00000000

Port 2 Interrupt Enable ADDRESS 0x06

Bit #76543210

Bit Name P2.7 Intr

Read/WriteWWWWWWWW

Reset00000000

Port 3 Interrupt Enable ADDRESS 0x07

Bit #76 5 43210 Bit Name Reserved P3.6 Intr Enable

Read/WriteWW W WWWWW

Reset00 0 00000

Enable

Enable

P1.6 Intr Enable

P2.6 Intr Enable

CY7C66113C

only

P1.5 Intr Enable

P1.4 Intr Enable

P1.3 Intr

Enable

Figure 9-8. Port 1 Interrupt Enable

P2.5 Intr Enable

P2.4 Intr Enable

P2.3 Intr Enable

Figure 9-9. Port 2 Interrupt Enable

P3.5 Intr Enable CY7C66113C only

P3.4 Intr Enable

P3.3 Intr Enable

Figure 9-10. Port 3 Interrupt Enable

P1.2 Intr Enable

P2.2 Intr

Enable

P3.2 Intr Enable

P1.1 Intr Enable

P2.1 Intr Enable

P3.1 Intr Enable

P1.0 Intr Enable

P2.0 Intr Enable

P3.0 Intr Enable

10.0 DAC Port

The CY7C661 13CC fe atures a p rogrammabl e s ink cu rrent 8 bit port which is al so known as DAC por t. Ea ch o f thes e port I/O p ins

have a programmable current sink. Writing a ‘1’ to a DAC I/O pin disables the output current sink (I

pin HIGH through an integrated 14-kΩ resistor. When a ‘0’ is written to a DAC I/O pin, the I

resistor is disabled. This causes the I

DAC port pi n.

Internal

Data Bus

Interrupt

Enable

Interrupt

Polarity

DAC to sink current to drive t he output LOW. Figure 10-1 shows a block diagram of the

sink

V

CC

Q1

14 kΩ

DAC Write

Internal

Buffer

DAC Read

Data

Out

Latch

Suspend

(Bit 3 of Register 0xFF)

Isink

Register

4 bits

Isink

DAC

to Interrupt

Controller

Interrupt Logic

sink

Figure 10-1. Block Diagram of a DAC Pin

DAC) and drives the I/O

sink

DAC is enabled and the pull-up

DAC

I/O Pin

The amount of sink current for the DAC I/O pin is programmabl e over 16 val ues bas ed on the cont ents of the DAC Isink Regist er

(Figure 10-3) for that output pin. DAC[1:0] are high current outputs that are programmable from 3.2 mA to 16 mA (typical).

DAC[7:2] are low current outputs, programmable from 0.2 mA to 1.0 mA (typical).

When the suspend bit in Processor Status and Control Register (Figure 15-1) is set, the Isink DAC block of the DAC circuitry is

disabled. Special care should be taken when the CY7C66113C device is placed in the suspend. The DAC Port Data

Register(Figure 10-2) should normally be loaded with all ‘1’s (Figure 15-1) before setting the suspend bit. If any of the DAC bits

Document #: 38-08024 Rev. *B Page 25 of 61

C

C

CY7C66013

CY7C66113

are set t o ‘0’ when the de vice is suspen ded, that DAC input will float. T he float ing pin could r esult i n excessi ve cur rent co nsumption

by the device, unle ss an external load places the pin in a det erministic state.

DAC Port Data ADDRESS 0x30

Bit #76543210 Bit Name DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0] Read/Write R/W R/W R/W R/W R/W R/W R/W R/W Reset11111111

Figure 10-2. DAC Port Data

Bit [1..0]: High Current Outp ut 3.2 mA to 16 mA typical

1= I/O pin is an output pulled HGH through the 14-kΩ resistor. 0 = I/O pin is an input with an internal 14-kΩ pull-up resistor.

Bit [7..2]: Low Current Output 0.2 mA to 1 mA typical

1= I/O pin is an output pulled HGH through the 14-kΩ resistor. 0 = I/O pin is an input with an internal 14-kΩ pull-up resistor.

10.1 DAC Isink Registers

Each DAC I/O pin has an associated DAC Isink register to program the output sink current when the output is driven LOW. The

first Isink register (0x38) co ntrols the current for DAC[0], the secon d (0x39) for DAC[1], and so on until the Is ink register at 0x3F,

controls the curre nt to DAC[7].

DAC Sink Register ADDRESS 0x38 –0x3F

Bit #76543210 Bit Name Reserved Reserved Reserved Reserved Isink[3] Isink[2] Isink[1] Isink[0] Read/Write WWWW Reset - - - - 0 0 0 0

Figure 10-3. DAC Sink Register

Bit [3.. 0] : Is in k [x ] (x = 0..3)

Writing all ‘0’s to the Isink register causes 1/5 of the max current to flow through the DAC I/O pin. Writing all ‘1’s to the Isink

register provides the maximum current flow through the pin. The other 14 states of the DAC sink current are evenly spaced

between these two valu es.

Bit [7..4]: Reserved

10.2 DAC Port Interrupts

A DAC port interrupt can be enabled/disabled for each pin individually. The DAC Port Interrupt Enable register provides this

feature with an in terrupt enable b it f or each DAC I/ O pin. All o f the DAC Port I nterrupt Enab le reg ister bi t s are clear ed to ‘ 0’ dur in g

a reset. All DAC pins share a common in terrupt, as explained in Section 16.7.

DAC Port Interrupt ADDRESS 0x31

Bit #76543210 Bit Name Enable Bit 7 Enable Bit 6 Enable Bit 5 Enable Bit 4 Enable Bit 3 Enable Bit 2 Enable Bit 1 Enable Bit 0 Read/WriteWWWWWWWW Reset00000000

Figure 10-4. DAC Port Interrupt Enable

Bit [7..0]: Enable bit x (x= 0..7)

1 = Enables interrupts from the corresponding bit position; 0= Disables interrupts from the corresponding bit position

As an additional benefit, the interrupt polarity for each DAC pin is programmable with the DAC Port Interrupt Polarity register.

Writing a ‘0’ to a bit selects negative polar it y (falling edge) that causes an interrupt (if enabled) if a fall ing edge transition occurs

on the corresponding input pin. Writing a ‘1’ to a bit in this register selects positive polarity (rising edge) that causes an interrupt

(if enabled) if a rising edge transi tion occurs on t he cor respondi ng input pin. All of the DAC Port Interrup t Polar ity re giste r bit s are

cleared during a reset.

DAC IO Interrupt Polarity ADDRESS 0x32

Bit #76543210 Bit Name Polarity Bit 7 Polarity Bit 6 Polarity Bit 5 Polarity Bit 4 Polarity Bit 3 Polarity Bit 2 Polarity Bit 1 Polarity Bit 0 Read/WriteWWWWWWWW Reset00000000

Figure 10-5. DAC Port Interrupt Polarity

Document #: 38-08024 Rev. *B Page 26 of 61

C

C

1.024-ms interrupt

N

CY7C66013

CY7C66113

Bit [7.. 0] : P o la rity bit x (x= 0. .7 )

1= Selects positive polarity (rising edge) that causes an interrupt (if enabled);

0 = Selects negative polarity (falling edge ) tha t causes an interrupt (if enabled).

11.0 12-bit Free-running Timer