Page 1

er

A

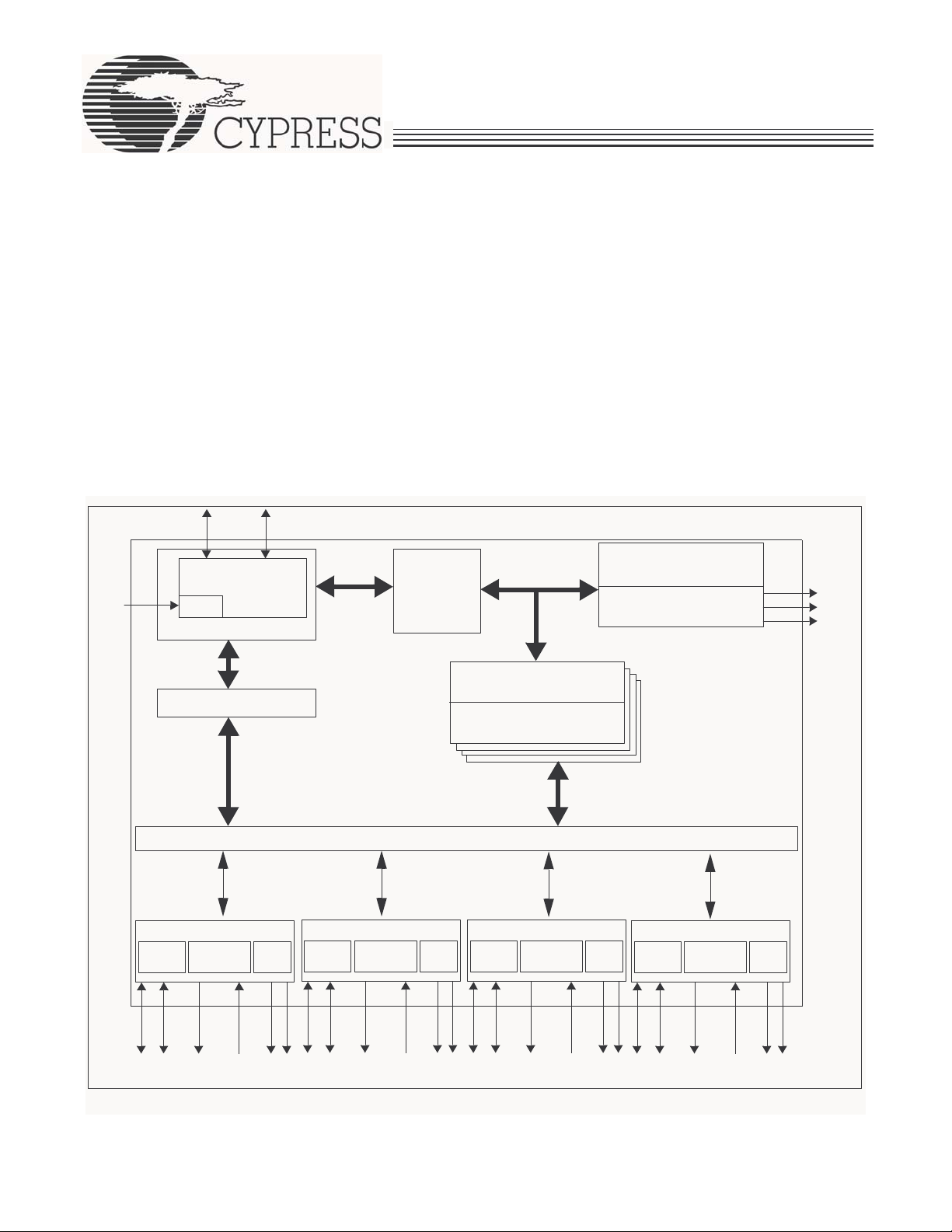

Figure 1-1. Blo ck Diagram

CY7C65640

TetraHub™ High-Speed USB Hub Controll

1.0 TetraHub™ Features

• USB 2.0 hub

• Four downstream port s

• Multiple transact ion translators— one per downstream

port for maximum performance

• VID, PID, and DID configured from external SPI

EEPROM

• 24-MHz external crystal

• Small package—Quad Flat Pack, no leads (QFN)

• Integrated up stream pull-up resist or

• Integrated downstream pull-down resistors for all

downstream ports

• Integrated up stream and downstream series termination resistors

.

D+ D–

Serial

Interface

Engine

24 MHz

Crystal

USB 2.0 PHY

PLL

USB Upstream Port

• Configurable with external SPI EEPROM

—N umb er of Active Ports

—N umb er of Removabl e Ports

—Maximum Power

—Hub Controller Power

—Power-On Timer

—Overcurrent Timer

—Disable Overcurrent Timer

—Enable Full-speed Only

—Disable P o rt Indicators

—Gang Power switching

—Enable Single TT Mode Only

—Enable NoEOPatEOF1

High-Speed

USB Control Logic

SPI Communication

Block

SPI_SCK

SPI_SD

SPI_CS

Hub Repeater

USB Downstream Port 1

PHY

D–

Port Power

Control

OVR#[1] LEDPWR#[1]

USB 2.0

D+

Port

Status

USB Downstream Port 2

PHY

D–

Port Power

Control

USB 2.0

D+

OVR#[2] LEDPWR#[2]

Routing Logic

Port

Status

USB 2.0

D+

Transaction Translator (X4)

TT RAM

USB Downstream Port 3

PHY

D–

Port Power

Control

Port

Status

OVR#[3] LEDPWR#[3]

USB Downstream Port 4

PHY

D–

Port Pow e r

Control

OVR#[4] LEDPWR#[4]

USB 2.0

D+

Port

Status

Cypress Semiconductor Corporation • 3901 North First Street • San Jose, CA 95134 • 408-943-2600

Document #: 38-08019 Rev. *H Revised August 2, 2005

Page 2

A

CY7C65640

2.0 Introduction

Cypress’s TetraHub is a high-performance self-powered

Universal Serial Bus (USB) 2.0 hub. The Tetra architecture

provides four downstream USB ports, with a Transaction

Translator (TT) for each port, making it the highest-performance hub possi ble. T his si ngle-c hip devi ce inco rporat es on e

upstream and four downstream USB transceivers, a Serial

Interface Engine (SIE), USB Hub Controller and Repeater , and

four TTs. It is suitable for standalone hubs, mot her board hu bs,

and monitor hub applications.

Being a fixed-function USB device, there is no risk or added

engineering effort required for firmware development. The

developer does not need to wri te any firmwar e for their d esign.

The CY4602 Tetrahub USB 2.0 4-port Hub Reference Design

Kit provides all materials and documents needed to move

rapidly into production. The reference design kit includes

board schematics, bill of materials, Gerber files, Orcad files,

key applicat ion notes, and product description.

CY7C65640A-LFXC is a functional and pin equivalent die

revision of Cypress's CY7C65640-LFXC. Changes were

made to improve device performance.

2.1 TetraHub Architecture

Figure 1-1 is a block diagram of the TetraHub Architecture.

2.2 USB Serial Interface Engine (SIE)

The SIE allows the CY7C65640A to communicate with the

USB host through the USB repeater component of the hub.

The SIE handles the fol lowing USB bus activ ity indepen dent ly

of the Hub Control Block:

• Bit stuffing/unstuffing

• Checksum generation/checking

• ACK/NAK/STALL

• TOKEN type identification

• Address checking.

2.3 Hub Controller

The Hub Control Block do es t he followi ng pr otocol handli ng at

a higher level:

• Coordinate enumeration by respondi ng to SETUP packets

• Fill and empty the FIFOs

• Suspend/Resume coordination

• Verify and select DATA toggle values

• Port power contr ol and over-current det ection.

The Hub Controller provides status and control and permits

host access to the hub.

2.4 Hub Repeater

The Hub Repeater manages the connectivity between

upstream and downstream facing ports that are operating at

the same speed. It supports full-/low-speed connectivity and

high-speed connectivity. Per the USB 2.0 specification, the

Hub Repeater provides the following functions:

• Sets up and tear s d own connect ivi ty on pack et boundari es

• Ensures orderly entry into and out of the Suspend state,

including proper handling of remote wakeups.

2.5 Transaction Translator

The TT basically trans lates data fr om one speed to another. A

TT takes high-speed split transactions and translates them to

full-/low-speed transactions when the hub is op erating at high

speed (the upstream port is connected to a high-speed host

controller) and has full-/low-speed devices attached. The

operating speed of a device attac hed on a downst ream faci ng

port determines whether the Routing Logic connects a port to

the Transaction Translator or Hub Repeater section. If a low/full-speed device is connected to the hub operating at high

speed, the data transfer route includes the transaction translator. If a high-speed device is connected to this high-speed

hub the route only includes the repeater and no transaction

translator since the device and the hub are in conformation

with respect to their data transfer speed. When the hub is

operating at full speed (the upstream port is connected to a

full-speed host controller), a high-speed peripheral will not

operate at its ful l ca pab ili ty. These devic es wil l o nly wor k at 1. 1

speed. Full- and low-speed devices connected to t his hub will

operate at their 1.1 speed.

3.0 Applications

• Standalone Hubs

• Motherboard Hubs

• Monitor Hub applications

• External Per sonal Stor age Dri ves

• Port Replicators

• Portable Drive

• Docking Stations

4.0 Functional Overview

The Cypress TetraHub USB 2.0 Hub is a high-performance,

low-system-cost solution fo r USB. Th e TetraHub USB 2.0 Hub

integrates 1.5k upstream pull-up resistors for full-speed

operation and all downstream 15k pull-down resistors as well

as series termination resistors on all upstream and

downstream D+ and D– pins. This results in optimization of

system costs by providing built-in support for the USB 2.0

specification.

4.1 System Initialization

On power-up, t he TetraHub will read an ex ternal SPI EE PROM

for configuration information. At the most basic level, this

EEPROM will have the Vendor ID (VID), Product ID (PID), and

Device ID (DID) for the customer's application. For more

specialized applications, other configuration options can be

specified. See section 8.0 for more detai ls.

After reading the EEPROM, if BUSPOWER (connected to upstream VBus) is HIGH, TetraHub will enable the pull-up

resistor on the D+ to indicate that it is connected to the

upstream hub, after which a USB Bus Reset is expected.

During this reset, TetraHub will initiate a chirp to indicate that

it is a high-speed peripheral. In a USB 2.0 system, the

upstream hub will respond with a chirp sequence, and

TetraHub will be in a high- speed mode, with the upstre am D+

Document #: 38-08019 Rev. *H Page 2 of 21

Page 3

A

CY7C65640

pull-up resistor turned off. In USB 1.x systems, no such chirp

sequence from the upstream hub will be seen, and TetraHub

will operate as a normal 1.x hub (operating at full speed).

4.2 Enumeration

After a USB Bus Reset, TetraHub is in an unaddressed, un configured stat e (configur ation value set to 0). During the enu meration process, the host will set the hub's address and configuration by sending a SetCongfiguration request. Changing the

hub address will restore it to an unconfigured state.

For high-speed multi-TT support, the host must also set the

alternate interface setti ng to 1 (the def ault mode i s singl e-TT).

Once the hub is configured, the full hub functionality is

available.

4.3 Multiple Transaction Translator Support

After TetraHub is configured in a high-speed system, it will be

in Single TT mode. The host may th en set the hub i nto Multipl e

TT mode by sending a SetInterface command. In Multiple TT

mode, each full -speed por t is han dled ind epende ntly an d thus

has a full 12-Mbp s ban dwidt h av ailab le. In Si ngle T T mode, all

traffic f rom the host desti ned for full - or low- spee d port s wil l be

forwarded to all of those ports. This means that the 12-Mbps

bandwidth is shared by all full- and low-speed ports.

4.4 Downstream Ports

T etraHub supp orts a maximum of four downstream port s, each

of which may be marked as usable or removable in the

extended configuration (0xD2 EEPROM load, see section

8.2). Downstream D+ and D– pull-down resistors are incorporated in TetraHub for each port. Prior to the hub being

configured, the ports are driven SE0 (Single Ended Zero,

where both D+ and D– are driven LOW) and are set to the

unpowered sta te. Once the hub is c onfigured, t he ports are not

driven, and the host may power the ports by sending a

SetPortPower command to each port. After a port is powered,

any connect or disconnect event is detected by the hub. Any

change in the port sta te is report ed by the hub back to the host

through the Status Change Endpoint (endpoint 1). Upon

receipt of SetPort R eset command from the host, the hub will

• Drive SE0 on the corresponding port

• Put the port in an enabled state

• Enable the green por t indicator for that port (i f not previously

overridden by t he host)

• Enable babble detection once the port is enabl ed.

Babble consists of either unterminated traffic from a

downstream port (o r loss of activi ty), or a non-idle condi tion on

the port after EOF2. If babble is detected on an enabled port,

that port will be disabl ed. A Cle arPort Enable comm and from

the host will also disable the specifie d port.

Downstream ports can be individually suspended by the host

with the SetPortSuspend command. If the hub is not

suspended, any res ume will be con fined t o that in divid ual port

and reflected to the host through a port change indication in

the Hub Status Change Endpoint. If the hub is suspended, a

resume on this port will be forwarded to the host, but other

resume events will not be seen on that port. The host may

resume the port by sendi ng a ClearPortSuspend com m and.

4.5 Upstream Port

The upstream port includes the transmitter and the receiver

state machine. The Transmitter and Receiver operate in highspeed and full-speed depending on the current hub configuration.

The transmitter state machine monitors the upstream facing

port while the Hub Repeater has connectivity in the upstream

direction. This monitoring activity prevents propagation of

erroneous indications in the upstream direction. In particular,

this machine prevents babble and disconnect events on the

downstream facing ports of this hub from propagating and

causing the hub to be disabled or disconnected by the hub to

which it is attached. This allows the Hub t o only disconnect t he

offensive port on detecting a babble from it.

4.6 Power Switching

TetraHub includes interface signals for external port power

switches. Both ganged and individ ual (per-p ort) configu rations

are supported, with individual switching being the default.

Initially all ports are unpowered. After enumerating, the host

may power each port by sending a SetPortPower command

for that port. The power switching and over-current detection

of downstream ports is m anaged by control pins connected to

an external power switch device. PWR [n]# output pins of the

CY7C65640A series ar e connected to t he respective e xternal

power switch's port power enable sign als. (Note that each port

power output pin of the external power switch must be

bypassed with a n electro lytic or t anta lum capaci tor as requ ired

by the USB specification. These capacitors supply the inrush

currents, which occur during downstream device hot-attach

events.)

4.7 Over-current Detection

Over-current detection includes timed detection of 8 ms by

default. This parameter is configured from the external

EEPROM in a range of 0 ms to 15 m s for both an enabled por t

and a disabled port individually. Detection of over-current on

downstream ports is managed by control pins conn ected to an

external power switch device.

The OVR[n]# pins of the CY7C65640A series are connected

to the respective external power switch's port over-current

indication (output) signals. Upon detecting an over-current

condition, the hub device r eports the over-current condition to

the host and disables the PWR# output to the external power

device.

4.8 Port I ndicators

The USB 2.0 port indicators are also supported directly by

TetraHub. As per the specification, each downstream port of

the hub supports an option al st atus indic ator . The pre sence of

indicators for downstream facing ports is specified by bit 7 of

the wHubCharacter istics field of the hub class d escriptor. The

default TeraHub descriptor specifies that port indicators are

supported (wHubChar acteri sti cs, bit 7 is set). If po rt indi cator s

are not included in the hub, this should be disabled by the

EEPROM.

Each port indicator is strategically located directly on the

opposite edge of the port which it is associated with. The

indicator provides two colors: green an d am ber. This is i m plemented as two separate LEDs, one amber and the other

green. A combi nation of hardware and soft ware contr ol is u sed

Document #: 38-08019 Rev. *H Page 3 of 21

Page 4

A

CY7C65640

to infor m the us er of th e cu rrent sta tus of t he port o r the devic e

attached to the port and to guide the user through problem

resoluti on. Col ors a nd b linking ar e used to pr ovide info rmatio n

to the user. The significance of the color of the LED depends

on the operational mode of the TetraHub. There are two

modes of operat ion f or t he TetraHub port i ndicat ors: automat ic

and manual.

On power-up the TeraHub defaults t o Automatic Mode, where

the color of the Port Indicato r (Green, Amber , Off) indicates the

functional status of the TetraHub port. In Automatic Mode,

TetraHub will turn on the green LED whenever the port is

enabled and the amber LED when it has had an over-current

condition detected. Th e color of the port indicator is set by th e

port state machine. Blinking of the LEDs is not supported in

T able 4-1. Automatic Port State to Port Indicat or Color Mapping

Downstream Facing Hub Port State

Port

Switching

With Off or Amber if due to an

Overcurrent Condition

Without Off Off or Amber if due to an

Table 4-2. Port Indicator Color Definitions in Manual Mode

Color Definition Port State

Off Not operational

Amber Error condition

Green Fully Operational

Blinking Off/Green Software Attention

Blinking Off/Amber Hardware Attention

Blinking Green/Amber Reserved

Powered Off

Disconnected, Disabled, Not

Configured, Reset ti ng, Testing

Off Green Off

Overcurrent Conditi on

Automatic Mode. Table 4- 1 below identifies the mapping of

color to port state in Automatic Mode.

In manual mode, the indicators are under the control of the

host, which can turn on one of the LEDs, or leave them off.

This is done by a system software USB Hub class request.

Blinking of the LEDs is supported in Manual Mode. The port

indicators allow the user to intervene on any error detection.

For example, when babble is detected on plugging in a

defective de vice, or on occurr ence of an o vercurren t condit ion,

the port indicators corresponding to the downstream port will

blink green or only light the amber LED, respectively. Table 4-

2 below displays the color definition of the indicators when

TetraHub is in Manual Mode.

Enabled, T r ansmit,

or Tr ansm itR

Green Off

Suspended, Resuming,

SendEOR, Restart_E /S

Note. Informati on present ed in Table 4-1 and Table 4-2 is from

USB 2.0 specificati on Tables 11- 6 and 11-7, respectively.

Document #: 38-08019 Rev. *H Page 4 of 21

Page 5

A

5.0 Pin Configuration

CY7C65640

DD–[4]

DD+[4]

VCC

GND

DD–[3]

DD+[3]

VCC

GND

DD–[2]

DD+[2]

VCC

GND

PWR#[3]

VCC

545556

OVR#[3]

53 52

PWR#[4]

GND

OVR#[4]

51 50 49 48 47 46 45 44 43

SPI_SD

GND

SPI_SCK

RESET

1

2

3

4

5

6

7

8

9

10

11

AMBER#[4]

VCC

GREEN#[4]

AMBER#[3]

42

41

GREEN#[3]

40

GND

VCC

39

38

AMBER#[2]

GREEN#[2]

37

AMBER#[1]

36

GREEN#[1]

35

GND

34

33

VCC

32

OVR#[2]

GND

DD–[1]

DD+[1]

12

13

14

2827262524232221201918171615

D–

D+

GND

VCC

VCC

XIN

GND

VCC

XOUT

GND

SPI_CS

BUSPOWER

VCC

GND

31

30

29

PWR#[2]

OVR#[1]

PWR#[1]

Figure 5-1. 56-pin Quad Flat Pack No Leads (8 mm x 8 mm)

Document #: 38-08019 Rev. *H Page 5 of 21

Page 6

A

CY7C65640

6.0 Pin Description Table

Table 6-1 below displays the pin assignments for the

CY7C65640A.

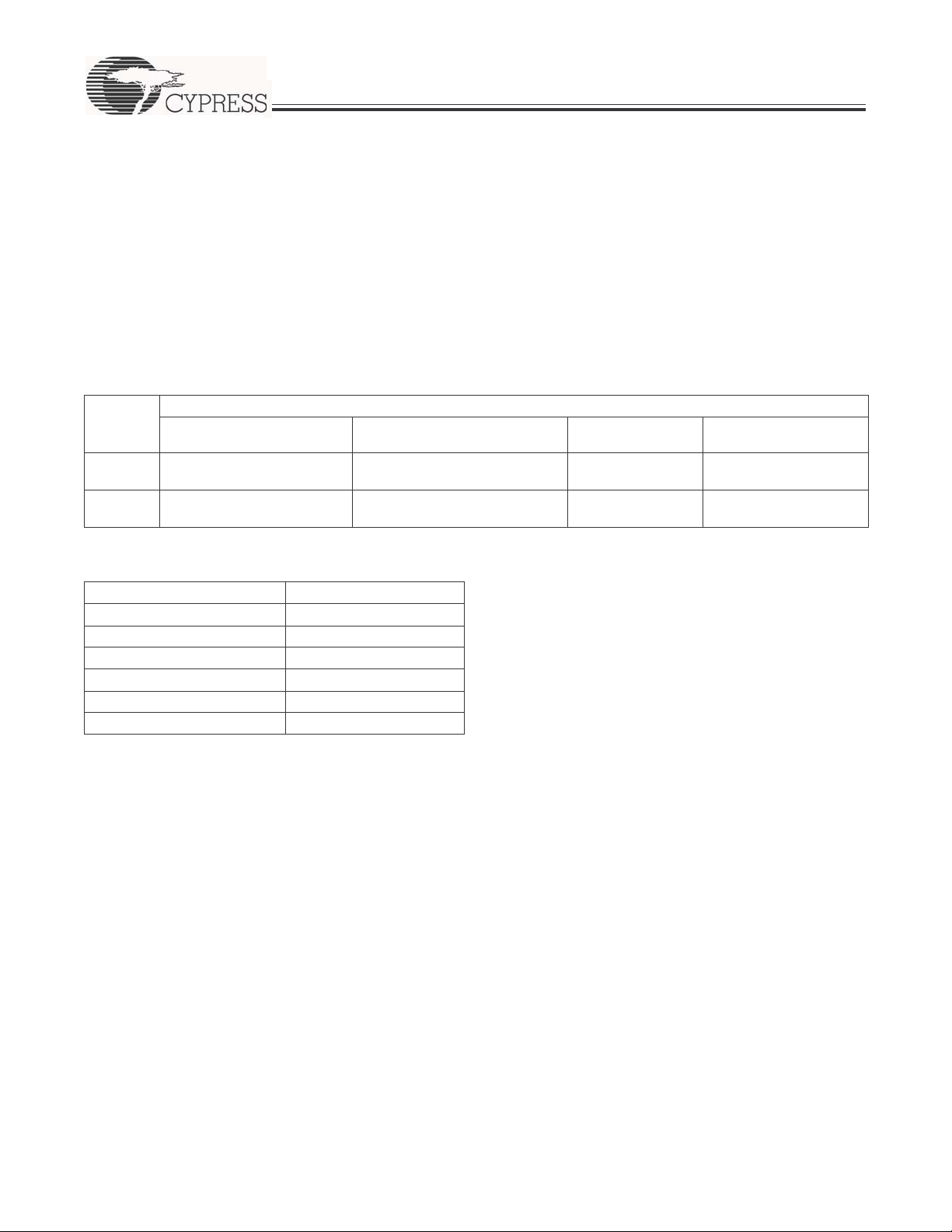

T able 6-1. Pin Assignments

Pin Name Type Default Description

3 VCC Power N/A V

7 VCC Power N/A V

11 VCC Power N/A V

15 VCC Power N/A V

19 VCC Power N/A V

23 VCC Power N/A V

27 VCC Power N/A V

33 VCC Power N/A V

39 VCC Power N/A V

45 VCC Power N/A V

55 VCC Power N/A V

4 GND Power N/A GND. Connect to Ground with as short a path as possible.

8 GND Power N/A GND. Connect to Ground with as short a path as possible.

12 GND Power N/A GND. Connect to Ground with as short a path as possible.

16 GND Power N/A GND. Connect to Ground with as short a path as possible.

20 GND Power N/A GND. Connect to Ground with as short a path as possible.

24 GND Power N/A GND. Connect to Ground with as short a path as possible.

28 GND Power N/A GND. Connect to Ground with as short a path as possible.

34 GND Power N/A GND. Connect to Ground with as short a path as possible.

40 GND Power N/A GND. Connect to Ground with as short a path as possible.

47 GND Power N/A GND. Connect to Ground with as short a path as possible.

50 GND Power N/A GND. Connect to Ground with as short a path as possible.

56 GND Power N/A GND. Connect to Ground with as short a path as possible.

21 XIN Input N/A 24-MHz Crystal IN or External Clock Input.

22 XOUT Output N/A 24-MHz Crystal OUT.

46 RESET# Input N/A Active LOW Reset. This pin resets the entire chip. It is normally tied to V

26 BUSPOWER Input N/A VBUS. Connect t o the VBUS pin of the up stream connecto r. Th is signal indicates

SPI INTERFACE

25 SPI_CS O O SPI Chip Select. Connect to CS pin of the EEPROM.

48 SPI_SCK O O SPI Clock. Connect to EEPROM SCK pin.

49 SPI_SD I/O/Z Z SPI Dataline Connect to GND with 15-KΩ

UPSTREAM PORT

17 D– I/O/Z Z Upstream D– Signal.

18 D+ I/O/Z Z Upstream D+ Signal.

DOWNSTREAM PORT 1

13 DD–[1] I/O/Z Z Downstream D– Signal.

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

. This signal provid es power to the chip.

CC

through a 100K resisto r , and t o GND through a 0.1-µF cap acitor. Other than this,

no other special power- up procedure is requir ed.

to the hub that it is in a powered st ate, and may enable the D+ pull-up resistor

to indicate a connec tion. (The hub wi ll do so af ter the exter nal EEPROM is read,

unless it is put i nto a high-speed mode by the upstream hub). The hub can not

be bus powered, and the VBUS signal must not be used as a power source.

resistor and to the Data I/O pins of

the EEPROM.

CC

Document #: 38-08019 Rev. *H Page 6 of 21

Page 7

A

T able 6-1. Pin Assignments (continued)

Pin Name Type Default Description

14 DD+[1] I/O/Z Z Downstream D+ Signal.

36 AMBER#[1] O 1 LED. Driver output for Amber LED. Port Indicator Support. Activ e LOW.

35 GREEN#[1] O 1 LED. Driver output for Green LED. Port Indicator Support. Active LOW.

30 OVR#[1] Input 1 Overcurrent Condition Detection Input. Active LOW.

29 PWR#[1] O/Z Z Power Switch Driver Output . Active LOW.

DOWNSTREAM PORT 2

9 DD–[2] I/O/Z Z Downstream D– Signal.

10 DD+[2] I/O/Z Z Downstream D+ Signal.

38 AMBER#[2] O 1 LED. Driver output for Amber LED. Port Indicator Support. Activ e LOW.

37 GREEN#[2] O 1 LED. Driver output for Green LED. Port Indicator Support. Active LOW.

32 OVR#[2] Input 1 Overcurrent Condition Detection Input. Active LOW.

31 PWR#[2] O/Z Z Power Switch Driver Output . Active LOW.

DOWNSTREAM PORT 3

5 DD–[3] I/O/Z Z Downstream D– Signal.

6 DD+[3] I/O/Z Z Downstream D+ Signal.

42 AMBER#[3] O 1 LED. Driver output for Amber LED. Port Indicator Support. Activ e LOW.

41 GREEN#[3] O 1 LED. Driver output for Green LED. Port Indicator Support. Active LOW.

53 OVR#[3] Input 1 Overcurrent Condition Detection Input. Active LOW.

54 PWR#[3] O/Z Z Power Switch Driver Output . Active LOW.

DOWNSTREAM PORT 4

1 DD–[3] I/O/Z Z Downstream D– Signal.

2 DD+[3] I/O/Z Z Downstream D+ Signal.

44 AMBER#[3] O 1 LED. Driver output for Amber LED. Port Indicator Support. Activ e LOW.

43 GREEN#[3] O 1 LED. Driver output for Green LED. Port Indicator Support. Active LOW.

51 OVR#[3] Input 1 Overcurrent Condition Detection Input. Active LOW.

52 PWR#[3] O/Z Z Power Switch Driver Output . Active LOW.

CY7C65640

Unused port DD+/DD– lin es can be lef t floati ng. The po rt power, amber , and gr een LED pins should be l eft unco nnected, and the

overcurrent pin should be tied HIGH. The overc urrent pin is an input and it shou ld not be left floati ng.

7.0 Default Descriptors

7.1 Device Descriptor

The standard device descri ptor for TetraHub is based on the VID, PID, and DI D found in the SPI EEPROM. This VID/PID/DID in

the EEPROM will overwrite the default VID/PID/DID. If no EEPROM is used, the TetraHub will enumerate with the default

descriptor values as shown below.

Byte Full Speed High Speed Field Name Description

0 0x12 0x12 bLength 18 Bytes

1 0x01 0x01 bDescriptorType DEVICE_DESCRIPTOR

2,3 0 x0200 0x0200 bcdUSB USB specification 2.0

4 0x09 0x09 bDeviceClass HUB

5 0x00 0x00 bDeviceSubClass None

6 0x00 0x02 bDeviceProtocol None

7 0x40 0x40 bMaxPacketSize0 64 bytes

8,9 0x04B4 0xx04B4 wIdVendor VID (overwritten by what is defined in EEPROM)

10,11 0x6560 0x6560 wIdProduct PID (overwritten by what is defined in EEPROM)

Document #: 38-08019 Rev. *H Page 7 of 21

Page 8

A

Byte Full Speed High Speed Field Name Description

12, 13 0x000B 0x000B wbcdDevice DID (overwritten by what is defined in EEPROM)

14 0x00 0x00 iManufact urer No manufacturer string sup ported

15 0x00 0x00 iProduct No product stri ng supported

16 0x00 0x00 iSerialNumber No serial string supported

17 0x01 0x01 bNumConfigur ations One configuration supported

CY7C65640

7.2 Configuration Descriptor

Byte Full Speed High Speed Field Name Description

0 0x09 0x09 bLength 9 Bytes

1 0x02 0x02 bDescriptorType CONFIG_DESCRIPTOR

2 0x0019 0x0029

4 0x01 0x01 bNumInterfaces 1

5 0x01 0x01 bConfigurationValue The configuration to be used

6 0x00 0x00 iConfiguration

70xE0 0xE0bmAttributes

80x32 0x32

[1]

[2]

wTota lLength Length of all other des criptors

bMaxPower

7.3 Interface Descriptor

Byte Full Speed High Speed Field Name Description

0 0x09 0x09 bLength 9 Bytes

1 0x04 0x04 bDescriptorType INTERFACE_DESCRIPTOR

2 0x00 0x00 bInterfaceNumber

3 0x00 0x00 bAlternateSetting

4 0x01 0x01 bNumEndpoints

5 0x09 0x09 bInterfaceClass

6 0x00 0x00 bInterfaceSubClass

7 0x00 0x01 bInterfaceProtocol

80x00 0x00iInterface

7.4 Endpoint Descriptor

Byte Full Speed High Speed Field Name Description

0 0x07 0x07 bLength 7 Bytes

1 0x0 5 0x05 bDescriptorType ENDPOINT_DESCRIPTOR

2 0x81 0x81 bEndpointAddress IN Endpoint #1

3 0x03 0x03 bmAttributes Interrupt

4,5 0x0001 0x0001 wMaxPacketSize Maximum Packet Size

6 0xFF 0x0C bInterval Polling Rate

Notes:

1. This value is reported as 0x19 if the hub is configured in Single-TT mode.

2. This value is configured through the External EEPROM.

Document #: 38-08019 Rev. *H Page 8 of 21

Page 9

A

CY7C65640

7.5 Interface Descriptor

I

[3]

Byte Full Speed High Speed Field Name Description

0 N/A 0x09 bLength 9 Bytes

1 N/A 0x04 bDescriptorType INTERFACE_DESCRIPTOR

2 N/A 0x00 bInterfaceNumber Interface Desc ri ptor Index

3 N/A 0x01 bAlternateSetting Alternate Setting for th e Interface

4 N/A 0x01 bNumEndpoints Number of Endpoints Defined

5 N/A 0x09 bInterfaceClass Interface Class

6 N/A 0x00 bInterfaceSubClass Interface Sub-Class

7 N/A 0x02 bInterfaceProtocol Interface Protocol

8 N/A 0x00 bInterface Interface String Index

7.6 Endpoint Descriptor

[3]

Byte Full Speed High Speed Field Name Description

0 N/A 0x07 bLength 7 Bytes

1 N/A 0x05 bDescriptorType ENDPOINT_DESCRIPTOR

2 N/A 0x81 bEndpointAddress IN Endpoint #1

3 N/A 0x03 bmAttributes Interrupt

4,5 N/A 0x0001 w MaxPacketSize Maximum Packet Siz e

6 N/A 0x0C bInterval Polling Rate

7.7 Device Qualifier Descriptor

Byte Full Speed High Speed Field Name Description

0 0x0A 0x0A bLength 10 Bytes

1 0x06 0x06 bDescriptorType DEVICE_QUALIFIER

2,3 0x0200 0x0200 bcdUSB

4 0x09 0x09 bDeviceClass

5 0x00 0x00 bDeviceSubClass

6 0x02 0x00 bDeviceProtocol

7 0x40 0x40 bMaxPacketSize0

8 0x01 0x01 bNumConfigurations

9 0x00 0x00 bReserved

Note:

3. If TetraHub is configured for single-TT only (from the external EEPROM), this descriptor is not present.

Document #: 38-08019 Rev. *H Page 9 of 21

Page 10

A

7.8 Hub Descriptor

Byte All Speeds Field Name Description

0 0x09 bLength 9 Bytes

1 0x29 bDescriptorType HUB Descr iptor

[4]

20x04

3,4 0x0089

50x32

60x64

70x00

80xFF

bNbrPorts Number of ports supported

[4]

wHubCharacteristi cs b1, b0: Logical Power Switching Mode

00: Ganged power switch ing (all ports’ power at once)

01: Individual port power switching (Default in TetraHub)

b2: Identifies a Compou nd Device,

0: Hub is not part of a compound device (Default in TetraHub),

1: Hub is part of a compou nd device.

b4, b3: Over-current Protection Mode

00: Global Overcur rent Protection. The hub reports overcurr ent as a

summation o f all port s curr ent draw , without a br eakdown of individu al port

overcurrent status.

01: Individual Port Overcurr ent Protection. The h ub reports ov ercurrent on

a per-port basis. Each port has an over-curr ent status (Default in

TetraHub).

1X: No Overcurrent Protection. This option is allowed only for buspowered hubs that do not implement overcurrent protection.

b6, b5: TT Think Tim e

00: TT requires at most 8 FS bit times of inter transac tion gap on a

full-/low-speed downstream bus (Default in TetraHub).

01: TT requires at most 16 FS bit ti me s.

10: TT requires at most 24 FS bit ti me s.

11: TT requires at most 32 FS bit times.

b7: Port Indicator s Supported,

0: Port Indicators are not supported on its downstream facing ports and

the PORT_INDICATOR request has no effect .

1: Port Indicators are supported on its downstream facing ports and the

PORT_INDICAT O R request controls the indicat ors. See Section 4 and 9

(Default in TetraHub).

b15...b8: Reserved

[4]

bPwrOn2PwrGood Time from when the port is power ed to when the power is good on that port

[4]

bHubContrCurrent Maximum current requirement for the Hub Controller

[4]

bDeviceRemovable Indicates if the port has a removable device attached

[4]

bPortPwrCtrlMask Required for compatibility with soft w are written for 1.0 compliant devices

CY7C65640

Note:

4. This value is configured through the External EEPROM.

Document #: 38-08019 Rev. *H Page 10 of 21

Page 11

A

CY7C65640

8.0 Configuration Options

Systems using TetraHub must have an external EEPROM in

order for the device to have a unique VID, PID, and DID. The

TetraHub can talk to SPI EEPROM that are double byte

addressable only. Tet raHub uses the command format from

the '040 parts. The TetraHub cannot talk to ‘080 EEPROM

parts, as the read command format used for talking to ‘080 is

not the same as ‘040. The '010s and '020s uses the same

command format as used t o inter face with th e ‘040 and henc e

these can also be used to interface with the TetraHub.

8.1 Default – 0xD0 Load

When used in default mod e, onl y a unique VID, PID, and DID

must be present in the external SPI EEPROM. The contents

of the EEPROM must contain this information in the following

format:

Byte Value

00xD0

1 VID (LSB)

2 VID (MSB)

3 PID (LSB)

4 PID (MSB)

5 DID (LSB)

6 DID (MSB)

8.2 Configured – 0xD2 Load

Byte Value (MSB->LSB)

00xD2

1VID (LSB)

2 VID (MSB)

3PID (LSB)

4 PID (MSB)

5 DID (LSB)

6 DID (MSB)

7 EnableOverCurrentTimer[3:0] , Di sableOvercurr ent-

Timer[3:0]

8 ActivePo rts[3:0], Rem o v ableP o rts[3:0]

9MaxPower

10 HubControllerPower

11 PowerOnTimer

12 IllegalHubDescriptor, Unused, FullspeedOnly ,

NoPortIndicators , Reserved, Gan gPowered, SingleT-

TOnly, NoEOPatEOF1

Byte 0: 0xD2

Needs to be programmed with 0x D2

Byte 1: VID (LSB)

Least Significant Byte of Vendor ID

Byte 2: VID (MSB)

Most Significant Byte of Vendor ID

Byte 3: PID (LSB)

Least Significant Byte of Product ID

Byte 4: PID (MSB)]

Most Significant Byte of Product ID

Byte 5: DID (LSB)

Least Significant Byte of Device ID

Byte 6: DID (MSB)]

Most Significant Byte of Device ID

Byte 7: EnableOvercurrentTimer[3:0], DisabledOvercurrentTimer[3:0]

Count time in ms fo r filtering o vercurrent detection. Bits 7–4

are for an enabled port, and bits 3–0 are for a disabled por t.

Both range from 0 ms t o 15 ms. See section 4 .8. Default: 8

ms = 0x88.

Byte 8 : ActivePo rts [3 :0 ], Remo va b le P o r ts[3 : 0 ]

Bits 7–4 are the ActivePorts[3:0] bits that indicates if the

corresponding port is usable. For example, a two-port hub

that uses port s 1 and 4 wou ld set th is field t o 0x09. The t otal

number of ports reported in the Hub Descriptor: bNbrPorts

field is calculated from this. Bits 3–0 are the RemovablePorts[3:0] bits that indicates whether the corresponding

port is removable (set to HIGH). This bit’s values are recorded appropriately in the

HubDescriptor:DeviceRemovable fiel d. Default: 0xFF.

Byte 9: MaximumPower

This value i s reported in the Confi gurationDes criptor:bMax Power field and is the current in 2-mA intervals that is required from the upstream hub. Default: 0x32 = 100 mA

Byte 10: HubControllerPower

This value is re ported in t he HubDescri ptor:bHub Contr Current field and is th e curr ent in milliamper es required by the

hub controller. Default: 0x64 = 100 mA.

Byte 11: PowerOnTimer

This value is reported in the HubDescriptor:bPwrOn2PwrGood f ield and is t he time in 2-ms interval s

from the SetPortPower command until the power on the

corresponding downstream port is good. Default: 0x32 =

100 ms.

Byte 12: IllegalHubDescriptor, Unused, FullspeedOnly,

NoPortIndicators, Reserved, GangPowered, SingleTTOnly, NoEOPatEOF1

Bit 7: Illeg alHubDescriptor: For GetHubDesc ri ptor request,

some USB hosts use a DescriptorTypeof 0x00 instead of

HUB_DESCRIPTOR, 0x29. According to the USB 2.0 st andard, a hub must treat thi s as a Request Error, and STALL

the transaction accordingly (USB 2.0, 11.24.2.5). For systems that do not accept this, the IllegalHubDescriptor configuration bit may be set to allow TetraHub to accept a DescriptorType of 0x00 for this command. Default is 0,

recommended setting is 1.

Bit 6: Unused: This bit is an unused, don’t care bit and can

be set to anything.

Bit 5: Fullspeed: Only configures t he hub to be a full -speed

only device. Default set to 0.

Document #: 38-08019 Rev. *H Page 1 1 of 21

Page 12

A

CY7C65640

Bit 4: NoPortIndicators: Turns off the port indicators and

does not report them as present in the HubDescriptor,

wHubCharacteristics b7 field. Default set to 0.

Bit 3: Reserved: This bit is reserved and should not be set

to 1. Must be set to 0.

Bit 2: GangPowered: Indicates whether the port power

switching is ganged (set to 1) or per-port (set to 0). This is

reported in the HubDescriptor, wHubCharacteristics field,

b4, b3, b1, and b0. Default set to 0.

Bit 1: SingleTT Only: Indi cates that the hub shoul d only support single T ransact ion Tran slator mode. This changes var ious descriptor values. Default set to 0.

Bit 0: NoEOPatEOF1 tur ns of f the EOP gener ation at EOF1

in full-spee d mode. Note that s everal USB 1.1 h osts can not

handle EOPatEOF1 properly. Cypress recommends that

this option be turned off for general-purpose hubs. Default

is 0, recommended setting is 1.

9.0 Supported USB Requests

9.1 Device Class Commands

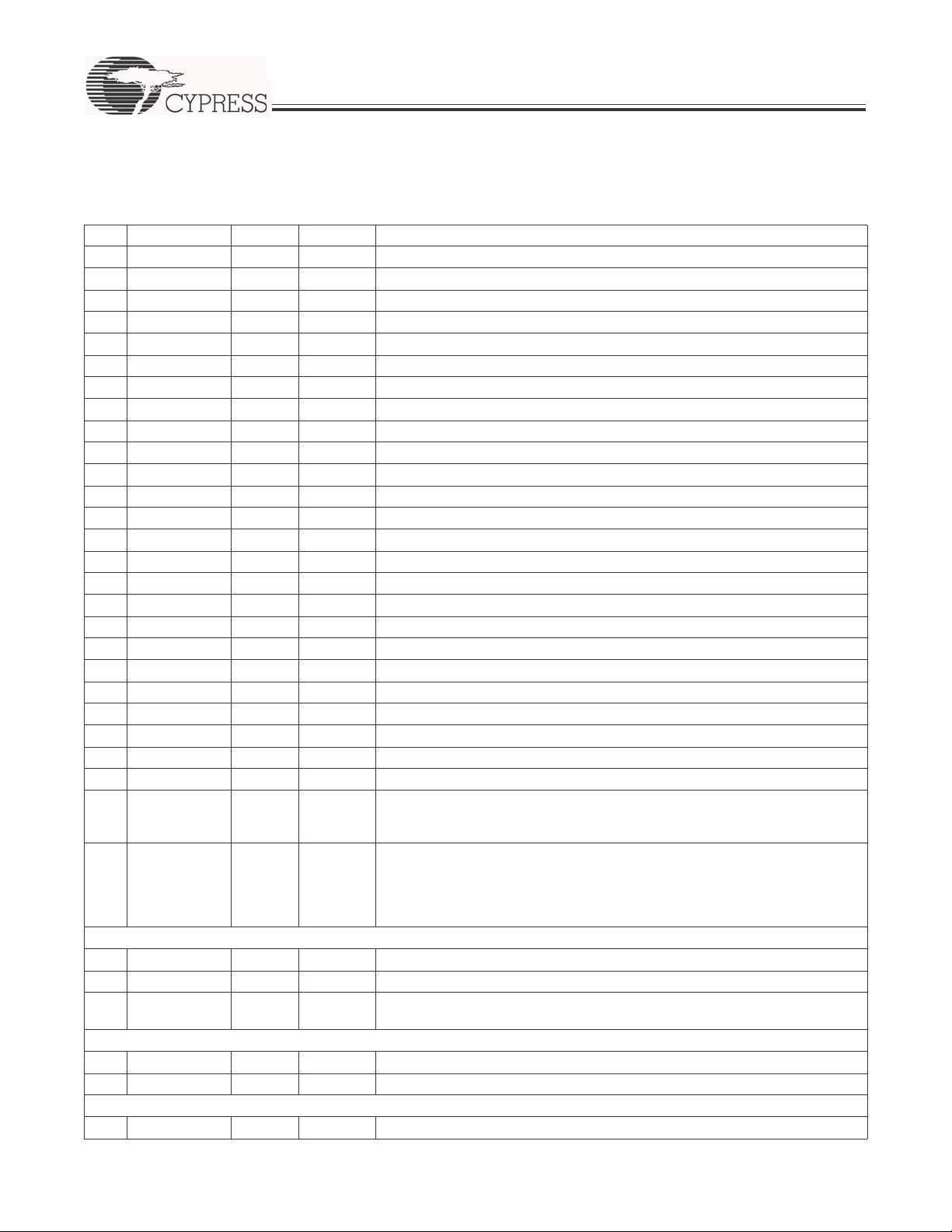

Table 9-1. Device Class Requests

Request bmRequestType bRequest wValue wIndex wLength Data

GetDev iceStatus 10000000B 0x00 0x0000 0x0000 0x0002 2 Byte Devi ce Status

GetInterfaceStatus 10000001B 0x00 0x0000 0x0000 0x0002 2 Byte Endpoint

GetEndpointStatus 10000010B 0x00 0x0000 0x0000 0x0002 2 Byte Endpoint

GetDev iceDescriptor 10000000B 0x06 0x0001 Zero or

GetConfigDescriptor 10000000B 0x06 0x0002 Zero or

GetDeviceQualifierDescriptor

GetOtherSpeedConfigurationDescriptor

GetConfiguration

SetCongfiguration

GetInterface 100000 01B 0xA 0x0000 0x0000 0x0001 Interface Number

SetInterface 00000001B 0x0B Alternate

SetAdd ress 00000000B 0x05 Device Address 0x0000 0x0000 None

SetDeviceRemoteWakeup 00000000B 0x03 0x01 0x0000 0x0000 None

SetDeviceTest_J 00000000B 0x03 0x02 0x0100 0x0000 None

SetDeviceTest_K 00000000B 0x03 0x02 0x0200 0x0000 None

SetDeviceTest_SE0_NAK 00000000B 0x03 0x02 0x0300 0x0000 None

SetDeviceTest_Packet 00000000B 0x03 0x02 0x0400 0x0000 None

SetEndpointHalt 00000000B 0x03 0x00 0x0000 0x0000 None

ClearDeviceRe-

moteWakeup

ClearEndpointHalt 00000000B 0x01 0x00 0x0000 0x0000 None

Note:

5. Only one configuration is supported in TetraHub.

[5]

[5]

100000 00B 0x06 0x0006 Zero or

100000 00B 0x06 0x0007 Zero or

10000000B 0x08 0x0000 0x0000 0x0001 Configuration value

00000000B 0x09 Configuration

Value

Setting

00000000B 0x01 0x01 0x0000 0x0000 None

Language ID

Language ID

Language ID

Language ID

0x0000 0x0000 None

Interface

Number

Descriptor

Length

Descriptor

Length

Descriptor

Length

Descriptor

Length

0x0000 None

Status

Status

Descriptor

Descriptor

Descriptor

Descriptor

Document #: 38-08019 Rev. *H Page 12 of 21

Page 13

A

CY7C65640

9.2 Hub Class Commands

T able 9-2. Hub Class Requests

Request bmRequestType bRequest wValue wIndex wLength Data

GetHubS tatus 10100000B 0x00 0x0000 0x0000 0x000 4 Hub Status (See Table 11-19

of Spec) Ch ange St atus (See

Table 11-20 of Spec)

GetPortStatus 10100011B 0x00 0x0000 Byte 0: 0x00

Byte 1: Port

ClearHubFeatur e 00100000B 0x01 Feature Selectors

[6]

0x0000 0x0000 None

0 or 1

[6]

ClearPortFeature 00100011B 0x01 Feature Selectors

1, 2, 8, 16, 17 , 18, 19,

Byte 0: 0x00

Byte 1: Port

or 20

ClearPortFeature 00100011B 0x01 Feature

Selectors

(PORT_INDICATOR)

[6]

22

Byte 0:

Selectors

0, 1, 2, or 3

Byte 1: Port

SetHubFeature 00100000B 0x03 Feature

Selector

SetPortFeature 00100011B 0x03 Feature

Selectors

[6]

[6]

0x0000 0x0000 TetraHub STALLs this

Port 0x0000 None

2, 4 or 8

SetPortFeature 00100011B 0x03 Feature

Selector

(PORT_TEST)

[6]

21

Byte 0:

Selectors

1,2, 3, 4 or 5

Byte 1: Port

SetPortFeature 00100011B 0x03 Feature

Selector

(PORT_INDICATOR)

[6]

22

Byte 0:

Selectors

0, 1, 2, or 3

Byte 1: Port

GetHubDescriptor 10100000B 0x06 Descriptor Type and

Descriptor Index

ClearTTBuffer 00100011B 0x08 Dev_Addr, EP_Num TT_Port 0x000 0 None

ResetTT 00100000B 0x09 0x0000 Byte 0: 0x00

Byte 1: Port

GetTTS tate 10100011B 0X0A TT_Flags Byte 0: 0x00

Byte 1: Port

Stop TT 00100011B 0x0B 0x0000 Byte 0: 0x00

Byte 1: Port

Notes:

6. Feature selector values for different features are presented in Table 9-3.

7. Selector values for different features are presented in Table 9-5.

8. Selector values for different features are presented in Table 9-4.

0x0004 Port Status (See Table 11- 21

of Spec) Ch ange St atus (See

Table 11-20 of Spec)

0x0000 None

0x0000 None

[7]

request

0x0000 None

[8]

0x0000 None

[7]

Hub

Descriptor

Length

0x0000 None

TT State

TT State

Length

0x0000 None

Document #: 38-08019 Rev. *H Page 13 of 21

Page 14

A

CY7C65640

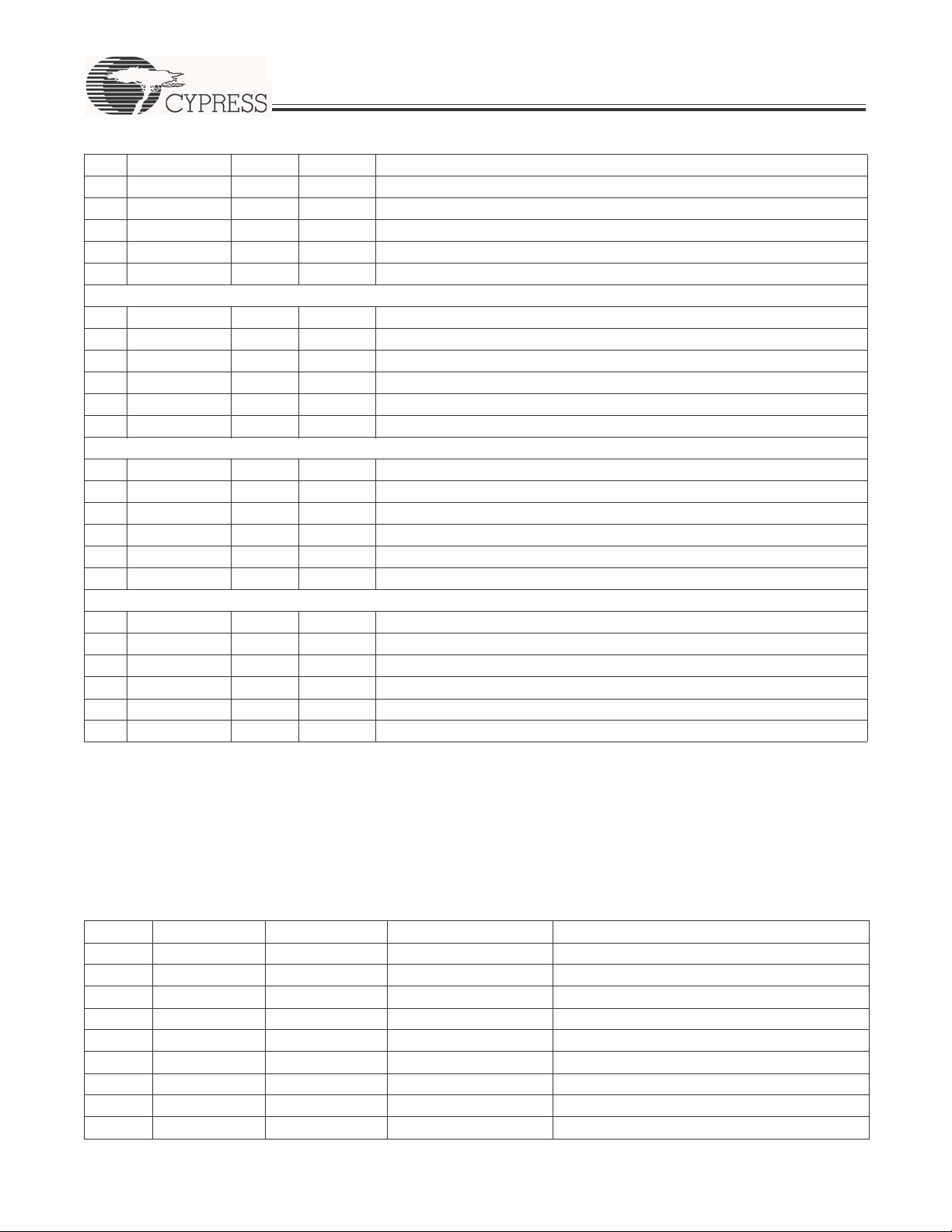

T able 9-3. Hub Class Feature Selector

Feature Selector Recipient Value

C_HUB_LOCAL_POWER Hub 0

C_HUB_OVER_CURRENT Hub 1

PORT_CONNECTION Port 0

PORT_ENABLE Port 1

PORT_SUSPEND Port 2

PORT_RESET Port 4

PORT_POWER Port 8

PORT_LOW_SPEED Port 9

C_PORT_CONNECTION Port 16

C_PORT_ENABLE Port 17

C_PORT_SUSPEND Port 18

C_PORT_OVER_CURRENT Port 19

C_PORT_RESET Port 20

PORT_TEST Port 21

PORT_INDICATOR Port 22

10.0 Upstream USB Connection

The following is a schemat ic of the USB upstream connector.

T able 9-4. Test Mode Selector for Feature Selector

PORT_TEST (0x21)

PORT_TEST Mode Description Selector Value

Test_J 1

Test_K 2

Test_SE0_NAK 3

Test_Packet 4

Test_Force_Enable 5

T able 9-5. Port Indicator Selector for Feature Selector

PORT_INDICATOR (0x22)

Port Indicator Color

Color Set Aut o matically as

shown in Table4-1

Selector

Value

Port Indicator

Mode

0 Automatic

Mode

Amber 1 Manual Mode

Green 2 Manual Mode

Off 3 Manual Mode

VCC

D–

D+

GND

SHELL

D–

D+

4.7 nF 250V

1 MΩ

Figure 10-1. USB Upstrea m Port Connect ion

11 .0 Downstream USB Connections

The following is a schematic of the USB downstream conn ector.

PWRx

150 µF

10V

0.01 µF

DD–[X]

DD+[X]

2.2 µF

10V

BUSPOWER

100 kΩ

VCC

D–

D+

GND

SHELL

Figure 11- 1. USB Downstream Port Connecti on

Document #: 38-08019 Rev. *H Page 14 of 21

Page 15

A

12.0 LED Connections

3.3V

The following is a schematic of the LED circuitr y.

GREEN#[x]

680Ω

CY7C65640

AMBER#[x]

Figure 12-1. USB Downstream Port Connection

680Ω

Document #: 38-08019 Rev. *H Page 15 of 21

Page 16

A

13.0 Sample Schemat i c

VCC

D–

D+

GND

SHELL

BUSPOWER

D–

D+

4.7 nF 250V

1 MΩ

2.2 µF

10V

100 kΩ

0.01 µF

680Ω

680Ω

CY7C65640

DD–[1]

DD+[1]

VCC

D–

D+

GND

SHELL

3.3V

5V

PWR1

OVR1

PWR2

OVR2

PWR3

OVR3

PWR4

OVR4

Power

Management

PWR4

PWR3

PWR2

PWR1

PWR1

150 µF

10V

GREEN#[1]

AMBER#[1]

BUSPOWER

3.3V

100K

0.1µF

D–

D+

DD–[1]

DD+[1]

DD–[2]

DD+[2]

DD–[3]

DD+[3]

DD–[4]

DD+[4]

3V

VCC1

VCC2

VCC3

VCC4

BUSPOWER

RESET

DD+

CY7C65640A-QFN

DD-[1]

DD+[1]

DD-[2]

DD+[2]

DD-[3]

DD+[3]

DD-[4]

DD+[4]

VCC5

VCC6

VCC7

VCC8

VCC9

SPI_SD

SPI_SCK

SPI_CS

SPI

EEPROM

SPI_SD

PWR2

150 µF

10V

0.01 µF

DD–[2]

DD+[2]

VCC

D–

D+

GND

SHELL

24 MHz

2 7pF

XIN

VCC10

VCC11

27 pF

XOUT

GREEN[1]

AMBER[1]

GREEN[2]

AMBER[2]

GREEN[3]

AMBER[3]

GREEN[4]

AMBER[4]

PWR1

PWR2

PWR3

PWR4

SPI_CS

SPI_SCK

SPI_SD

OVR1

OVR2

OVR3

OVR4

GREEN[1]

AMBER[1]

GREEN[2]

AMBER[2]

GREEN[3]

AMBER[3]

GREEN[4]

AMBER[4]

PWR1

OVR1

PWR2

OVR2

PWR3

OVR3

PWR4

OVR4

SPI_CS

SPI_SCK

SPI_SD

GREEN#[2]

AMBER#[2]

PWR3

150 µF

10V

GREEN#[3]

AMBER#[3]

PWR4

150 µF

10V

GREEN#[4]

680Ω

680Ω

680Ω

680Ω

680Ω

0.01 µF

0.01 µF

DD-[3]

DD+[3]

DD-[4]

DD+[4]

3.3V

VCC

D–

D+

GND

SHELL

3.3 V

VCC

D–

D+

GND

SHELL

3.3 V

GND1

GND2

GND3

GND4

GND5

GND6

GND7

GND8

GND9

GND10

GND11

GND12

AMBER#[4]

680Ω

Figure 13-1. Sample Schematic

Document #: 38-08019 Rev. *H Page 16 of 21

Page 17

A

CY7C65640

14.0 Electrical Characteristics

St ati c Discharge Voltage.. .......... .. .......... .. .......... .. .....> 2000V

Max. Ou tp u t S in k Cu rr e nt pe r I/ O........ ........................ 10 mA

14.1 Absolute Maximum Ratings

St orage Temperature ............... .. .......... .. ...–65°C to +150 °C

Ambient Temperature

with Pow er Ap p li ed ................. ..........................0°C to +7 0 °C

Supply Voltage to Ground Potential .............. –0.5V to +4.0V

DC Voltage Applied to Output s

in High Z State .......................................–0.5V to V

CC

+ 0.5V

Power Dissipation (4 HS ports)......................................1.6W

14.2 Oper ating Conditions

TA (Ambient Temperature Under Bias)............. 0°C to +70°C

Supply Voltage ................ .......... .. .......... .. ...+3.15V to +3.45V

Grou nd Voltage ............. ................................ .................... 0V

FOSC (Oscillator or Crystal Frequency).....24 MHz ± 0.05%,

parallel resonant, fundamental mode

14.3 DC Electrical Characteristics

Parameter Description Conditions Min. Typ. Max. Unit

V

CC

V

IH

V

IL

I

l

V

OH

V

OL

I

OH

I

OL

C

IN

I

SUSP

I

CC

USB Transceiver

Z

HSDRV

I

i

I

OZ

V

HSRS

T

rfi

Thermal Resistance

T

JA

Supp ly Voltage 3.15 3.3 3.45 V

Input High Voltage 2 5.25 V

Input Low Voltage –0.5 0.8 V

Input Leakage Current 0 < V

Output Voltage High I

Output Low Voltage I

< V

IN

CC

= 4 mA 2.4 V

OUT

= –4 mA 0.4 V

OUT

±10 µA

Output Current High 4mA

Output Current Low 4mA

Input Pin Capacitance 10 pF

Suspend Current 100 µA

Supply Current

4 Active port s Full-speed Host, Full-speed Devices 255 mA

High-speed Host, High-speed Devices 460 mA

High-speed Host, Full-speed Devices 395 mA

2 Active Ports Full-speed Host, Full-speed Devices 255 mA

High-speed Host, High-speed Devices 415 mA

High-speed Host, Full-speed Devices 380 mA

No Active Ports Full-speed Host 255 mA

High-speed Host 370 mA

Driver Output Resistance 41 45 49 Ω

Input Leakage Current ±0.1 ±5 µA

Three-stat e O utput OFF-State Current ±10 µA

High-speed Receiver Sensitivity Level 210 mV

Full-speed Fram e Jit ter 133 ns

Theta Thermal Coefficient Junction to

Ambient

E-Pad configura ti on in section 16.1

at zero airflow

23.27 °C/W

Document #: 38-08019 Rev. *H Page 17 of 21

Page 18

A

CY7C65640

14.4 AC Electrical Characteristics

Both the upstream USB transceiver and all four downstream

transceive rs have passed the USB-IF USB 2.0 Electrical Certificatio n Testing.

14.4.1 Serial Peripheral Interface

Parameter Description Conditions Min. Typ. Max. Unit

Clock Rise/Fall Time 500 ns

Clock Frequency 250 kHz

Data Set- up Time 50 ns

Hold Time 100 ns

Reset period 1.9 ms

14.4.2 Eye Diagram

15.0 Ordering Information

Ordering Code Package Type

CY7C65640A-LFXC 56-pin QFN Lead-free Package

CY4602 TetraHub USB 2.0 4 port Hub Refere nce Design Kit

Document #: 38-08019 Rev. *H Page 18 of 21

Page 19

A

16.0 Package Diagrams

The TetraHub is available in a space-saving 56-pin QFN

(8 × 8 mm)

.

56-Lead QFN 8 x 8 MM LF56A

CY7C65640

TOP VIEW

7.90[0.311]

8.10[0.319]

7.70[0.303]

7.80[0.307]

N

0.80[0.031]

A

1

2

DIA.

Dimensions are in millimeters

MIN

MAX

7.80[0.307]

7.70[0.303]

1.00[0.039] MAX.

0.80[0.031] MAX.

8.10[0.319]

7.90[0.311]

SIDE VIEW

0°-12°

Note. The bottom metal pad size varies by product due to die

size varia ble. I f met al pad desi gn or di mension a re c ritica l wit h

your board designs, please contact a Cypress Sales office to

get the specific out line option.

16.1 Quad Flat Package No Leads (QFN) Package Design Notes

The QFN (Quad Flatpack No Leads), being a lead free

package, t he electri cal c ont act o f the p art t o the Pr inted Circuit

Board (PCB) is made by soldering the lands on the bottom

surface of the package to t he PCB. Hence specia l at tention is

required to the heat transfer area bel ow the package to prov ide

a good thermal bond to the circuit board. A Copper (Cu) fill

should be designed into the PCB as a thermal pad under the

package. Heat is transferred from the TetraHub through the

device’s metal paddl e on the bottom side of the package. Heat

from here is conducted t o the PCB at the thermal pad. I t is the n

conducted from the thermal pad to the PCB inner ground plan e

by a 5 x 5 arra y of via. A via is a plated throug h-hole in the PCB

with a finis hed d iameter of 13 mil. The QFN’ s met al d ie paddl e

must be soldered to the PCB’s thermal pad. Solder mask is

placed on the board to p side over each via to res ist solder flow

BOTTOM VIEW

0.08[0.003]

C

0.05[0.002] MAX.

0.18[0.007]

E-PAD

(PAD SIZE VARY

BY DEVICE TYPE)

6.45[0.254]

6.55[0.258]

0.28[0.011]

0.50[0.020]

PIN1 ID

N

0.20[0.008] R.

1

2

0.45[0.018]

6.55[0.258]

6.45[0.254]

0.24[0.009]

(4X)

0.60[0.024]

51-85144-*D

0.20[0.008] REF.

0.30[0.012]

0.50[0.020]

C

SEATING

PLANE

into the via. The mask on the top side also minimizes

outgassing during the solder reflow process.

Please follow the layout guidel ines p rov ided i n the PCB l ayout

files accompanied with the CY4602 TetraHub Reference

Design Kit. The information in this section was derived from

the origin al applicat ion note by the p ackage vendor . For furthe r

information on this package design please refer to the application note “Surface Mount Assembly of AMKOR’s

MicroLeadFrame (MLF) Technology”. This application note

can be downloaded f rom AMKOR’s webs ite f rom the fo llowing

URL

http://www.amkor.com/products/notes_papers/MLF_AppNote

_0301.pdf.

This application note provides detailed information on board

mounting guidelines, soldering flow, rework process, etc.

Figure 16-1 below displ ays a cross- sec tiona l area underneat h

the package. The cross section is of only one via. The solder

Paste template needs to be designed to allow at least 50%

solder coverage. The thickness of the solder paste template

should be 5 mil. It is recommended that “No Clean”, type 3

solder paste is used for mounting the part. Nitrogen purge is

recommended during ref low.

Document #: 38-08019 Rev. *H Page 19 of 21

Page 20

A

Cu Fill

CY7C65640

0.017” dia

Solder Mask

Cu Fill

PCB Material

Via hole for thermally connecting the

QFN to the circuit board ground plane.

0.013” dia

This figure only shows the top three layers of the

circuit board: Top Solder, PCB Dielectric, and

the Ground Plane.

PCB Material

Figure 16-1. Cross-sect ion of the Area Underneat h the QFN Package

Figure 16-2a is a plot of the solder mask pattern and Figure 16-2b displays an X-Ray image of the ass embly (darker areas indicate

solder).

Figure 16-2a. Plot of the Solder Mas k (White Area)

Figure 16-2b. X-Ray Image of the Assembly

TetraHub is a trademark of Cypress Semiconductor Corporation. All product and company names mentioned in this document

may be the trademarks of their respective holders.

Document #: 38-08019 Rev. *H Page 20 of 21

© Cypress Semiconductor Corporation, 2005. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use

of any circuitry other than circuitry embodied in a Cypress product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor intended to be

used for medical, life support, life saving, critical control or safety applications, unless pursuant to an express written agreement with Cypress. Furthermore, Cypress does not authorize its

products for use as critical components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress

Page 21

A

CY7C65640

Document History Page

Document Title: CY7C65640A TetraHub™ High-Speed USB Hub Controller

Document Number: 38-08019

REV. ECN NO. Issue Date

** 113506 04/25/02 BHA New Data Sheet (prelim inary)

*A 116812 08/15/02 MON Supply voltage range changed from 3.3V–3.6V to 3.15V–3.45

*B 118518 10/31/02 MON Fixed the Spec field in the Defau lt Device Descriptor section 7.1

*C 121793 12/09/02 MON Fixed the SPI clock Frequen cy to 250 KHz, section 14.4.1

*D 125275 04/02/03 MON Changed the name o f Bit 3 of Byte 12 of EEPROM f or a 0xD2 lo ad (section 8.2)

*E 234272 see ECN MON Added part number for the lead free package (CY7C65640-LFXC), section 15.0

*F 285171 see ECN KKU Changed CY7C65640 to CY7C65640A and reformatted to new format

*G 308296 see ECN KKU Added reset period under AC characteristics.

*H 390258 see ECN KKU added theta thermal coefficient junction to ambient (T

Orig. of

Change Descri ption of Change

Added EPROM types that can be used with HX2 (p. 14)

Added description of bit 7 of Byte 12 (Illegal Hub Descriptor) D2 Load (p. 15)

Added high speed sensit ivity level of receiver (p. 20)

Added QFN package desi gn notes (section 16.1)

Fixed Interface Protocol field of the i nterface descript or, section 7.3

Fixed Device Protocol field of the interface descriptor, section 7.7

Modified table 9-2, section 9.2

Added table 9-4, 9-5, section 9.2

Added table 4-1, 4-2, section 4.8

Added information on bits in wHubCharacterestics, section 7.8

Modified figure 16-1 in QFN package design n otes, section 16.1

Included the eye di agram, section 14.4.2

Preliminary to Final

Added information on the configuration of unused port pins, section 6.0

Added statement t hat no special power-up proc edure is required, sec ti on 6.0

from BusPowered to Reserved.

Removed all in dicat ion to the m isconc eption that the hub can suppo rt bus power.

Added information as to which ni bble of byt e 8 in the EEPROM defi nes the acti ve

ports and which nibble defines the removable ports, section 8.2.

Added further informati on on the BUSPOWER pin ( pin 26) functiona lity in section

6.0.

Changed the name of Bit 6 of Byte 12 of EEPROM for a 0xD2 load from

CompoundDevice to Unused, section 8.2.

Removed compound device from features list.

Update section 7.1 DID from 0x 0007 to 0x000B for rev E silicon.

) to section 14.3

JA

Document #: 38-08019 Rev. *H Page 21 of 21

Loading...

Loading...