Page 1

r

CY7C63413C

CY7C63513C

CY7C63613C

Low-S peed High I/O, 1.5-Mbps USB Controlle

Features

• Low-cost solution for low-speed applications with high

I/O requirements such as keyboards, keyboards with

integrated pointing device, gamepads, and many

others

• USB Specification Compliance

— Conforms to USB Specification, V ersions 1.1 and 2.0

— Conforms to USB HID Specification, Version 1.1

— Supp orts 1 device address and 3 data endpoints

— Integrated USB transceiver

• 8-bit RISC microcontroller

— Harvard architecture

— 6-MHz external ceramic resonator

— 12-MHz internal CPU clock

• Internal memory

— 256 bytes of RAM

— 8 Kbytes of EPROM

• Interface can auto-configure to operate as PS2 or USB

•I/O port

— The CY7C63413C/513C have 24 General Purpose I/O

(GPIO) pins (Port 0 to 2) cap able of sinking 7 mA per

pin (typical)

— The CY7C63613C has 12 General Purpose I/O (GPIO)

pins (Port 0 to 2) capable of sinking 7 mA per pin

(typical)

— The CY7C63413C/513C have eight GPIO pins (Port

3) capable of sinking 12 mA per pin (typical) which

can drive LEDs

— The CY7C63613C has four GPIO pins (Port 3) capable

of sinking 12 mA per pin (typical) which can driv e

LEDs

— Higher current drive is available by connecting

multiple GPIO pins together to drive a common

output

— Each GPIO port can be configured as inputs with

internal pull-ups or open drain outputs or traditional

CMOS outputs

— The CY7C63513C has an additional eight I/O pins on

a DAC port which has programmable current sink

outputs

— Mask able interrupts on all I/O pins

• 12-bit free-running timer with one microsecond clock

ticks

• Watch Dog Timer (WDT)

• Internal Power-On Reset (POR)

• Improved output drivers to reduce EMI

• Operating voltage from 4.0V to 5.5V DC

• Operating temperature from 0 to 70 degrees Celsius

• CY7C63413C available in 40-pin PDIP , 48-pin SSOP, 48pin SSOP - Tape reel, all in Lead-Free versions for

production

• CY7C63513C available in 48-pin SSOP Lead-Free

packages for production

• CY7C63613C available in 24-pin SOIC Lead-Free

packages for production

• Industry-standard programmer support

Functional Overview

The CY7C63413C/513C/613C are 8-bit RISC One Time

Programmable (OTP) microcontrollers. The instruction set has

been optimized specifically for USB operations, although the

microcontrollers can be used for a variety of non-USB

embedded applications.

The CY7C63413C/513C features 32 General-Purpose I/O

(GPIO) pins to support USB and other applications. The I/O

pins are grouped into four ports (Port 0 to 3) where each port

can be configured as inputs with internal pull -ups, open drain

outputs, or traditional CMOS outputs. The CY7C63413C/513C

have 24 GPIO pins (Ports 0 to 2) that are rated at 7 mA typical

sink current. The CY7C63413C/513C has 8 GPIO pins (Port

3) that are rated at 12 mA typical sink current, which allows

these pins to drive LEDs.

The CY7C63613C features 16 General-Purpose I/O (GPIO)

pins to support USB and other applications. The I/O pins are

grouped into four ports (Port 0 to 3) where each port can be

configured as inputs with internal pull-ups, open drain outputs,

or traditional CMOS outputs. The CY7C63613C has 12 GPIO

pins (Ports 0 to 2) that are rated at 7 mA typical sink current.

The CY7C63613C has 4 GPIO pins (Port 3) that are rated at

12 mA typical sink current, which allows these pins to drive

LEDs.

Multiple GPIO pins can be connected together to drive a single

output for more dri ve current capacity. Additionally, each I/O

pin can be used to generate a GPIO interrupt to the microcontroller. Note the GPIO interrupts all share the same “GPIO”

interrupt vector.

The CY7C63513C features an additional 8 I/O pins in the DAC

port. Every DAC pin includes an integrated 14-Kohm pull-up

resistor. When a “1” is written to a DAC I/O pin, the output

current sink is disabled and the output pin is driven high by the

internal pull-up resistor. When a “0” is written to a DAC I/O pin,

the internal pull-up is disabled and the output pin provides the

programmed amount of sink

current. A DAC I/O pin can

be used as an input with an

internal pull-up by writing a

“1” to the pin.

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 • 408-943-2600

Document #: 38-08027 Rev. *B Revised January 6, 2006

[+] Feedback

Page 2

CY7C63413C

CY7C63513C

CY7C63613C

The sink current for each DAC I/O pin can be individually

programmed to one of sixteen values using dedicated Isink

registers. DAC bits [1:0] can be used as high current outputs

with a programmable sink current range of 3.2 to 16 mA

(typical). DAC bits [7:2] have a programmable current sink

range of 0.2 to 1.0 mA (typical). Again, multiple DAC pins can

be connected together to drive a single output that requires

more sink current capacity. Each I/O pin can be used to

generate a DAC interrupt to the microcontroller and the

interrupt polarity for each DAC I/O pin is individually programmable. The DAC port interrupts share a separate “DAC”

interrupt vector.

The Cypress microcontrollers use an external 6-MHz ceramic

resonator to provide a reference to an internal clock generator.

This clock generator reduces the clock-related noise

emissions (EMI). The clock generator provide s the 6 a nd 12MHz clocks that remain internal to the microcontroller.

The CY7C63413C/513C/613C are offered with single EPROM

options. The CY7C63413C, CY7C63513C and the

CY7C63613C have 8 Kbytes of EPROM.

These parts include Power-on Reset logic, a Watch Dog Timer ,

a vectored interrupt controller, and a 12-bit free-running timer.

The Power-On Reset (POR) logic detects when power is

applied to the device, resets the logic to a known state, and

begins executing instructions at EPROM address 0x0000. The

Watch Dog Timer can be used to ensure the firmware never

gets stalled for more than approximately 8 ms. The firmware

can get stalled for a variety of reasons, including errors in the

code or a hardware failure such as waiting for an interrupt that

never occurs. The firmware should clear the Watch Dog Timer

periodically. If the Watch Dog Timer is not cleared for approximately 8 ms, the microcontroller will generate a hardware

watch dog reset.

The microcontroller supports eight maskable interrupts in the

vectored interrupt controller. Interrupt sources include the USB

Bus-Reset, the 128-µs and 1.024-ms outputs from the freerunning timer, three USB endpoints, the DAC port, and the

GPIO ports. The timer bits cause an interrupt (if enabled) when

the bit toggles from LOW “0” to HIGH “1.” The USB endpoints

interrupt after either the USB host or the USB controller sends

a packet to the USB. The DAC ports have an additional level

of masking that allows the user to select which DAC inputs can

cause a DAC interrupt. The GPIO ports also have a level of

masking to select which GPIO inputs can cause a GPIO

interrupt. For additional flexibility, the input transition polarity

that causes an interrupt is programmable for each pin of the

DAC port. Input transition polarity can be programmed for

each GPIO port as part of the port configuration. The interrupt

polarity can be either rising edge (“0” to “1”) or falling edge (“1”

to “0”).

The free-running 12-bit timer clocked at 1 MHz provides two

interrupt sources as noted above (128-µs and 1.024-ms). The

timer can be used to measure the duration of an event under

firmware control by reading the timer twice: once at the start

of the event, and once after the event is complete. The

difference between the two readings indicates the durati on of

the event measured in microseconds. The upper four bits of

the timer are latched into an internal register when the

firmware reads the lower eight bits. A read from the upper four

bits actually reads data from the internal register, instead of the

timer. This feature eliminates the need for firmware to attempt

to compensate if the upper four bits happened to incre ment

right after the lower 8 bits are read.

The CY7C63413C/513C/613C include an integrated USB

serial interface engine (SIE) that supports the integrated

peripherals. The hardware supports one USB device address

with three endpoints. The SIE allows the USB host to communicate with the function integrated into the microcontroller.

Finally, the CY7C63413C/513C/613C support PS/2 operation.

With appropriate firmware the D+ and D– USB pins can also

be used as PS/2 clock and data signals. Products utilizing

these devices can be used for USB and/or PS/2 operation with

appropriate firmware.

Document #: 38-08027 Rev. *B Page 2 of 32

[+] Feedback

Page 3

CY7C63413C

CY7C63513C

CY7C63613C

.

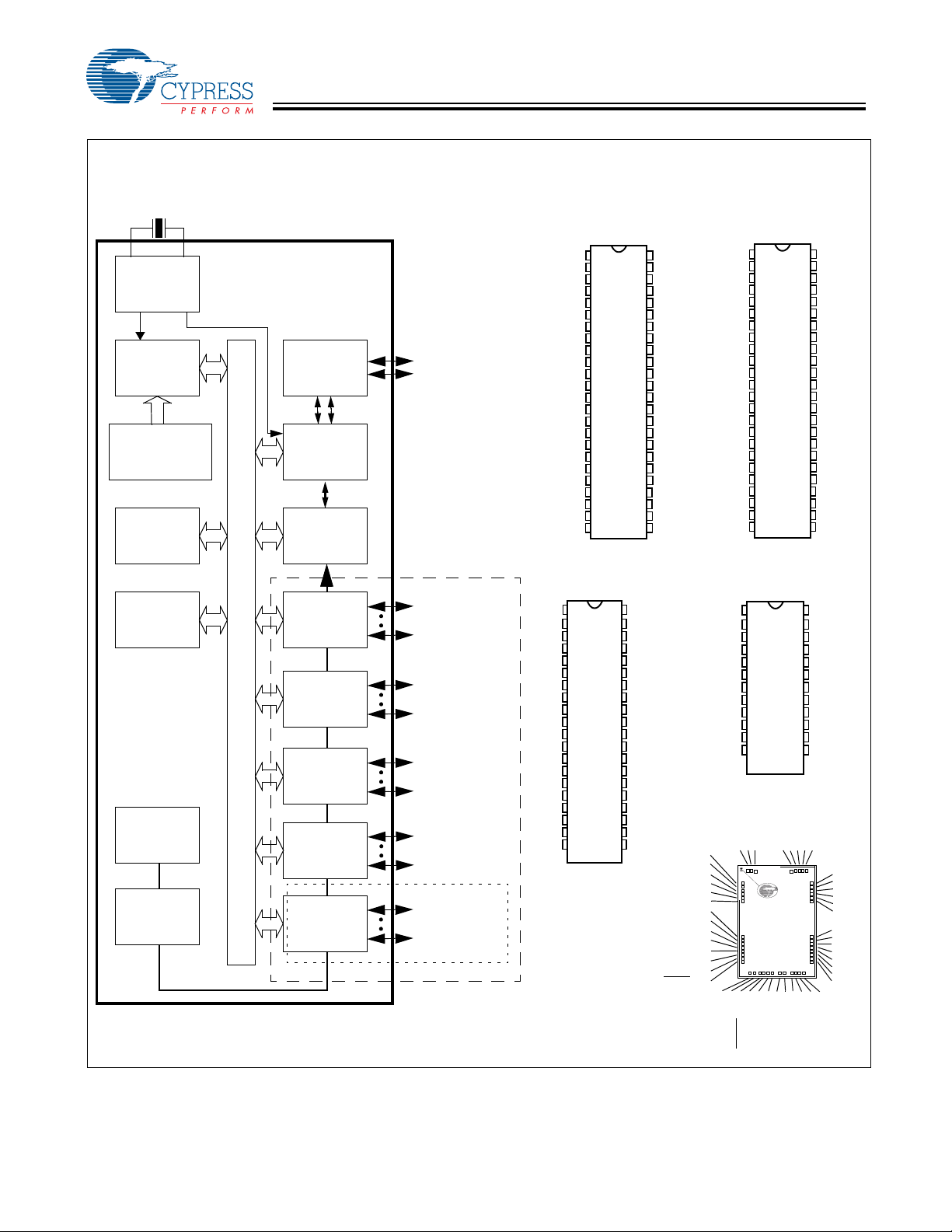

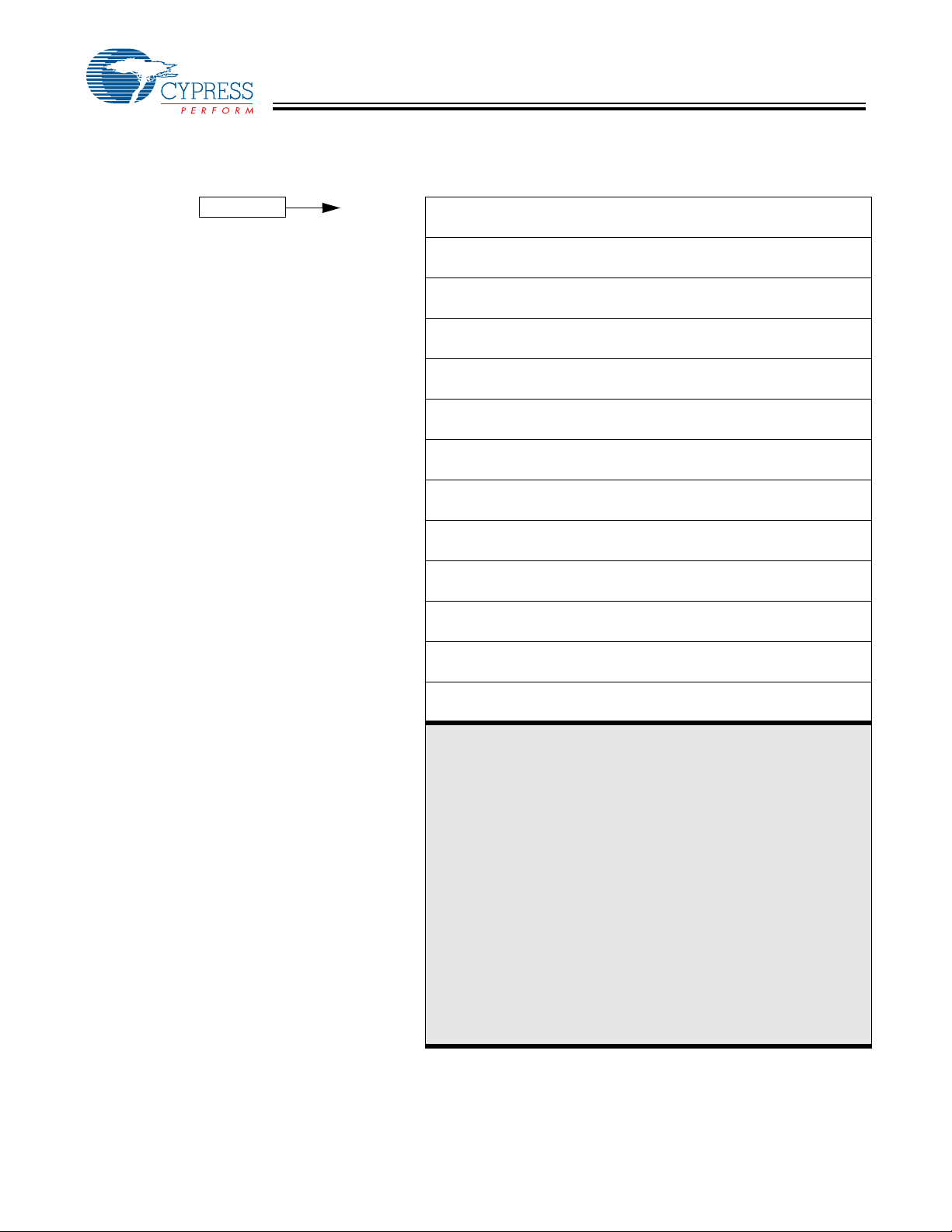

Logic Block Diagram

6-MHz ceramic resonator

OSC

12 MHz

4/6/8 Kbyte

6 MHz

12-MHz

8-bit

CPU

EPROM

RAM

256 byte

8-bit Bus

12-bit

Timer

Watch Dog

Timer

Power-on

Reset

USB

Transceiver

USB

SIE

Interrupt

Controller

GPIO

PORT 0

GPIO

PORT 1

GPIO

PORT 2

GPIO

PORT 3

DAC

PORT

USB

D+

PS/2

D–

PORT

See Note 1

P0[0]

P0[7]

P1[0]

P1[7]

P2[0]

P2[7]

P3[0]

High Current

Outputs

P3[7]

DAC[0]

CY7C63513C only

DAC[7]

Pin Configuration

CY7C63513C

48-pin SSOP

1

D+

D–

P3[7]

P3[5]

P3[3]

P3[1]

P2[7]

P2[5]

P2[3]

P2[1]

P1[7]

P1[5]

P1[3]

P1[1]

DAC[7]

DAC[5]

P0[7]

P0[5]

P0[3]

P0[1]

DAC[3]

DAC[1]

V

PP

Vss

CY7C63413C

40-pin PDIP

D+

1

D–

2

P3[7]

3

P3[5]

4

P3[3]

5

P3[1]

6

P2[7]

7

P2[5]

8

P2[3]

9

P2[1]

10

P1[7]

11

P1[5]

12

P1[3]

13

P1[1]

14

P0[7]

15

P0[5]

16

P0[3]

17

P0[1]

18

V

19

PP

20

Vss

48

2

47

46

3

4

45

5

44

43

6

7

42

8

41

9

40

39

10

11

38

12

37

13

36

35

14

15

34

16

33

17

32

18

31

19

30

20

29

21

28

22

27

23

26

24

25

40

V

39

V

38

P3[6]

37

P3[4]

36

P3[2]

35

P3[0]

34

P2[6]

33

P2[4]

32

P2[2]

31

P2[0]

30

P1[6]

29

P1[4]

28

P1[2]

27

P1[0]

26

P0[6]

25

P0[4]

24

P0[2]

23

P0[0]

22

XTAL

21

XTAL

CY7C63413C

48-pin SSOP

V

CC

Vss

P3[6]

P3[4]

P3[2]

P3[0]

P2[6]

P2[4]

P2[2]

P2[0]

P1[6]

P1[4]

P1[2]

P1[0]

DAC[6]

DAC[4]

P0[6]

P0[4]

P0[2]

P0[0]

DAC[2]

DAC[0]

XTAL

XTAL

OUT

IN

P3[7]

P3[5]

P3[3]

P3[1]

P2[7]

P2[5]

P2[3]

P2[1]

P1[7]

P1[5]

P1[3]

P1[1]

NC

NC

P0[7]

P0[5]

P0[3]

P0[1]

NC

NC

V

Vss

D+

D–

PP

48

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

V

CC

Vss

47

46

P3[6]

P3[4]

45

P3[2]

44

P3[0]

43

P2[6]

42

P2[4]

41

P2[2]

40

39

P2[0]

P1[6]

38

P1[4]

37

P1[2]

36

35

P1[0]

NC

34

NC

33

P0[6]

32

31

P0[4]

30

P0[2]

P0[0]

29

NC

28

NC

27

XTAL

26

25

XTAL

OUT

IN

CY7C63613C

24-pin SOIC

1

2

3

4

5

6

7

9

10815

11

12

24

V

CC

23

V

SS

22

P3[6]

21

P3[4]

20

P1[2]

19

P1[0]

18

P0[6]

17

P0[4]

16

P0[2]

P0[0]

14

XTAL

XTAL

OUT

IN

13

P3[7]

P3[5]

P1[3]

P1[1]

P0[7]

P0[5]

P0[3]

P0[1]

V

Vss

D+

D–

PP

CC

SS

CY7C63413C

48-Pad Die

OUT

IN

0

P3[3]

P3[1]

P2[7]

P2[5]

P2[3]

P2[1]

P1[7]

P1[5]

P1[3]

P1[1]

DAC[7]

DAC[5]

P0[7]

P0[5]

P3[5]

P0[3]

P0[1]

DAC[3]

CC

V

Vss

D+

P3[7]

D–

PP

V

DAC[1]

P3[4]

P3[6]

P3[2]

P3[0]

P2[6]

P2[4]

P2[2]

P2[0]

P1[6]

P1[4]

P1[2]

P1[0]

DAC[6]

DAC[4]

P0[6]

IN

OUT

Vss

XTAL

XTAL

P0[4]

P0[2]

P0[0]

DAC[0]

DAC[2]

0

Note:

1. CY7C63613C is not bonded out for all GPIO pins shown in Logic Block Diagram. Refer to pin configuration diagram for bonded out pins. See note on page 12

for firmware code needed for unused GPIO pins.

.

Document #: 38-08027 Rev. *B Page 3 of 32

[+] Feedback

Page 4

CY7C63413C

CY7C63513C

CY7C63613C

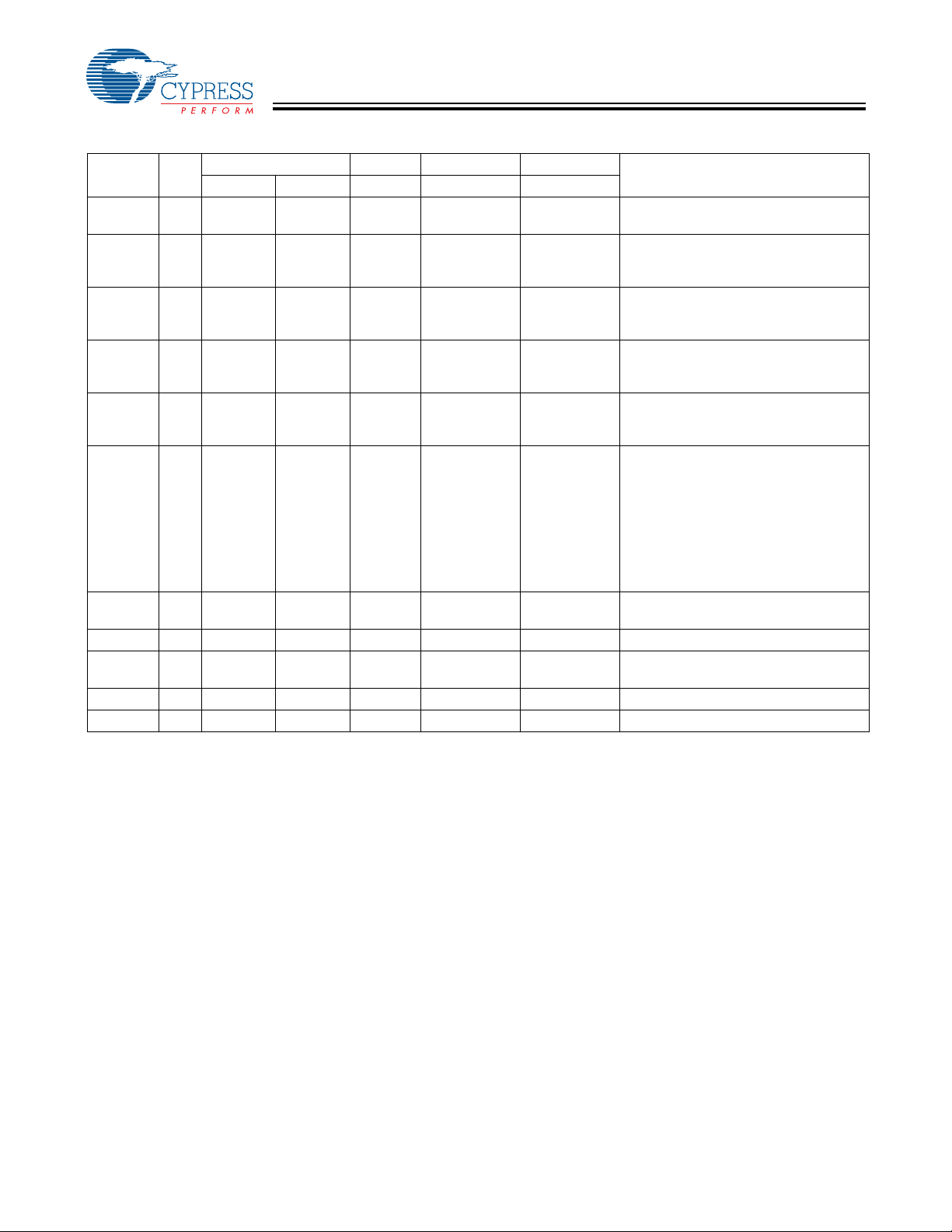

Pin Definitions

CY7C63413C CY7C63513C CY7C63613C

Name I/O

D+, D– I/O 1,2 1,2 1,2 1,2 1,2 USB differential data; PS/2 clock and

P0[7:0] I/O 15,26,16

25,17,24

18,23

P1[3:0] I/O 11,30,12,

P2 I/O 7,34,8,

P3[7:4] I/O 3,38,4,

DAC I/O n/a n/a 15,34,16,

XTAL

IN

XTAL

OUT

V

PP

V

CC

Vss 20,39 24,47 24,47 24,47 12, 23 Ground

29,13,28,

14,27

33,9,32,

10,31

37,5,36,

6,35

21 25 25 25 13 6-MHz ceramic resonator or external

IN

OUT 22 26 26 26 14 6-MHz ceramic resonator

19 23 23 23 11 Programming voltage supply, ground

40 48 48 48 24 Voltage supply

17,32,18

31,19,30

20,29

11,38,12,

37,13,36,

14,35

7,42,8,

41,9,40,

10,39

3,46,4,

45,5,44,

6,43

17,32,18,

31,19,30,

20,29

1 1,38,12,

37,13,36,

14,35

7,42,8,

41,9,40,

10,39

3,46,4,

45,5,44,

6,43

33,21,28,

22,27

17,32,18,31,

19,30,20,29

1 1,38,12,37,

13,36,14,35

7,42,8,41,9,

40,10,39

3,46,4,45,5,

44,6,43

15,34,16,33,

21,28,22,27

7, 18, 8, 17, 9,

16, 10, 15

5, 20, 6, 19 GPIO Port 1 capable of sinking 7 mA

n/a GPIO Port 2 capable of sinking 7 mA

3, 22, 4, 21 GPIO Port 3 capable of sinking 12 mA

n/a DAC I/O Port with programmable

Description40-Pin 48-Pin Die 48-Pin 24-Pin

data signals

GPIO port 0 capable of sinking 7 mA

(typical)

(typical).

(typical).

(typical).

current sink outputs. DAC[1:0] offer a

programmable range of 3.2 to 16 mA

typical. DAC[7:2] have a programmable sink current range of 0.2 to 1.0

mA typical. DAC I/O Port not bonded

out on CY7C63613C. See note on

page 12 for firmware code needed for

unused pins.

clock input

during operation

Programming Model

14-bit Program Counter (PC)

The 14-bit Program Counter (PC) allows access for up to 8

kilobytes of EPROM using the CY7C63413C/513C/613C

architecture. The program counter is cleared during reset,

such that the first instruction executed after a reset is at

address 0x0000. This is typically a jump instruction to a reset

handler that initializes the application.

The lower eight bits of the program counter are incremented

as instructions are loaded and executed. The upper six bits of

the program counter are incremented by executing an XPAGE

instruction. As a result, the last instruction executed within a

256-byte “page” of sequential code should be an XPAGE

instruction. The assembler directive “XPAGEON” will cause

the assembler to insert XPAGE instructions automatically. As

instructions can be either one or two bytes long, the assembler

may occasionally need to insert a NOP followed by an XPAGE

for correct execution.

The program counter of the next instruction to be executed,

carry flag, and zero flag are saved as two bytes on the program

stack during an interrupt acknowledge or a CALL instruction.

The program counter, carry flag, and zero flag are restored

from the program stack only during a RETI instruction.

Document #: 38-08027 Rev. *B Page 4 of 32

Please note the program counter cannot be accessed directly

by the firmware. The program stack can be examined by

reading SRAM from location 0x00 and up.

8-bit Accumulator (A)

The accumulator is the general purpose, do everything

register in the architecture where results are usually calculated.

8-bit Index Register (X)

The index register “X” is available to the firmware as an

auxiliary accumulator. The X register also allows the processor

to perform indexed operations by loading an index value into

X.

8-bit Program Stack Pointer (PSP)

During a reset, the Program Stack Pointer (PSP) is set to zero.

This means the program “stack” starts at RAM address 0x00

and “grows” upward from there. Note the program stack

pointer is directly addressable under firmware con trol, using

the MOV PSP,A instruction. The PSP supports interrupt

service under hardware control and CALL, RET, and RETI

instructions under firmware control.

[+] Feedback

Page 5

CY7C63413C

CY7C63513C

CY7C63613C

During an interrupt acknowledge, interrupts are disabled and

the 14-bit program counter, carry flag, and zero flag are written

as two bytes of data memory. The first byte is stored in the

memory addressed by the program stack pointer, then the

PSP is incremented. The second byte is stored in memory

addressed by the program stack pointer and the PSP is incremented again. The net effect is to store the program counter

and flags on the program “stack” and increment the program

stack pointer by two.

The Return From Interrupt (RETI) instruction decrements the

program stack pointer, then restores the second byte from

memory addressed by the PSP. The program stack pointer is

decremented again and the first byte is restored from memory

addressed by the PSP. After the program counter and flags

have been restored from stack, the interrupts are enabled. The

effect is to restore the program counter and flags from the

program stack, decrement the program stack pointer by two,

and re-enable interrupts.

The Call Subroutine (CALL) instruction stores the program

counter and flags on the program stack and increments the

PSP by two.

The Return From Subroutine (RET) instruction restores the

program counter, but not the flags, from program stack and

decrements the PSP by two.

8-bit Data Stack Pointer (DSP)

The Data Stack Pointer (DSP) supports PUSH and POP

instructions that use the data stack for temporary storage. A

PUSH instruction will pre-decrement the DSP, then write data

to the memory location addressed by the DSP. A POP

instruction will read data from the memory location addressed

by the DSP, then post-incre ment the DSP.

During a reset, the Data Stack Pointer will be set to zero. A

PUSH instruction when DSP equal zero will write data at the

top of the data RAM (address 0xFF). This would write data to

the memory area reserved for a FIFO for USB endpoint 0. In

non-USB applications, this works fine and is not a problem.

For USB applications, it is strongly recommended that the

DSP is loaded after reset just below the USB DMA buffers.

Address Modes

The CY7C63413C/513C/613C microcontrollers support three

addressing modes for instructions that require data operands:

data, direct, and indexed.

Data

The “Data” address mode refers to a data operand that is

actually a constant encoded in the instruction. As an example,

consider the instruction that loads A with the constant 0xE8:

• MOV A,0E8h

This instruction will require two bytes of code where the first

byte identifies the “MOV A” instruction with a data operand as

the second byte. The second byte of the ins truction will be the

constant “0xE8”. A constant may be referred to by name if a

prior “EQU” statement assigns the constant value to the name.

For example, the following code is equivalent to the example

shown above:

• DSPINIT: EQU 0E8h

• MOV A,DSPINIT

Direct

“Direct” address mode is used when the data operand is a

variable stored in SRAM. In that case, the one byte address of

the variable is encoded in the instruction. As an example,

consider an instruction that loads A with the contents of

memory address location 0x10:

• MOV A, [10h]

In normal usage, variable names are assigned to variable

addresses using “EQU” statements to improve the readability

of the assembler source code. As an example, the following

code is equivalent to the example shown above:

• buttons: EQU 10h

• MOV A,[buttons]

Indexed

“Indexed” address mode allows the firmware to manipulate

arrays of data stored in SRAM. The address of the data

operand is the sum of a constant encoded in the instruction

and the contents of the “X” register. In normal usage, the

constant will be the “base” address of an array of data and the

X register will contain an index that indicates which element of

the array is actually addressed:

• array: EQU 10h

•MOV X,3

• MOV A,[x+array]

This would have the effect of loading A with the fourth element

of the SRAM “array” that begins at address 0x10. The fourth

element would be at address 0x13.

Document #: 38-08027 Rev. *B Page 5 of 32

[+] Feedback

Page 6

CY7C63413C

CY7C63513C

CY7C63613C

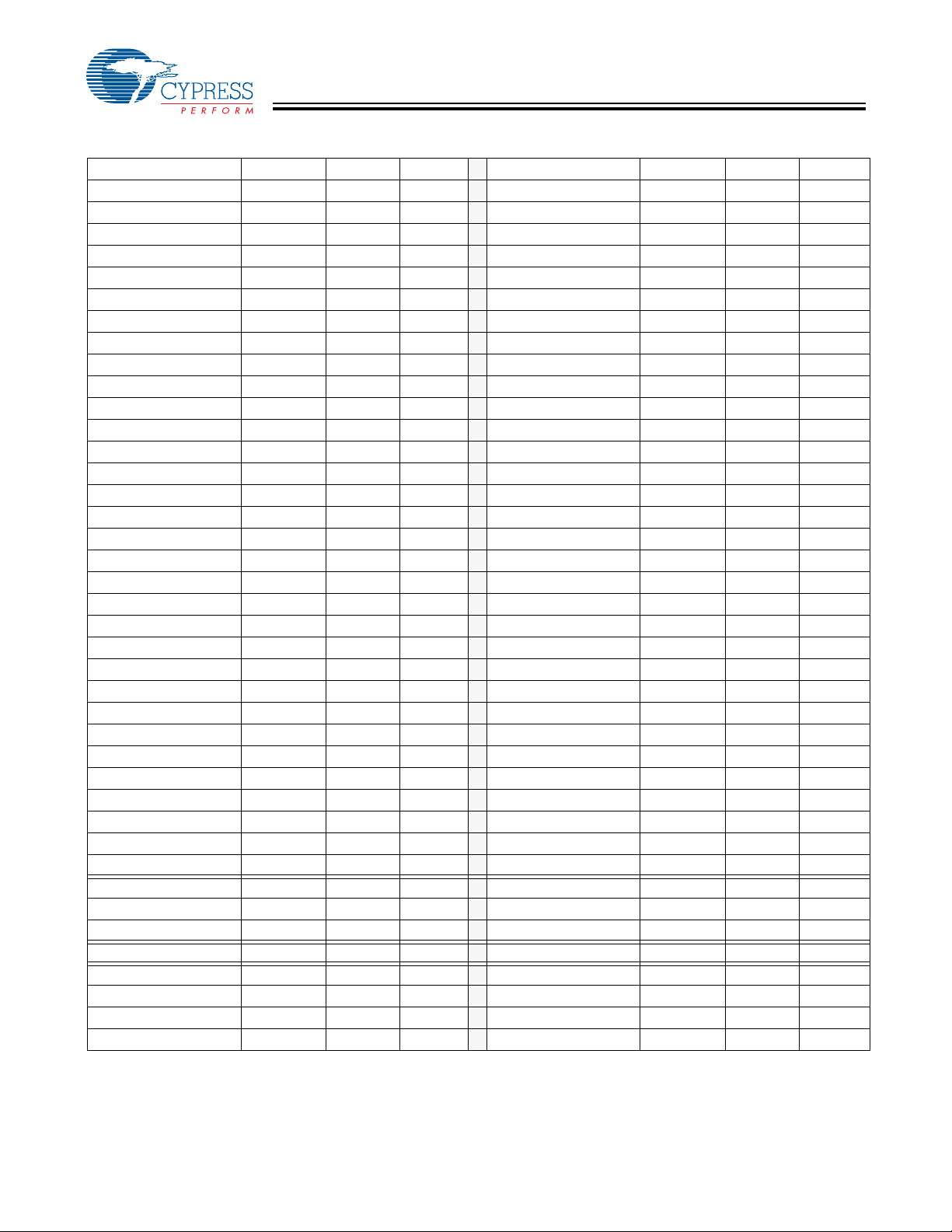

Instruction Set Summary

MNEMONIC operand opcode cycles MNEMONIC operand opcode cycles

HALT 00 7

ADD A,expr data 01 4 INC A acc 21 4

ADD A,[expr] direct 02 6

ADD A,[X+expr] index 03 7 INC [expr] direct 23 7

ADC A,expr data 04 4

ADC A,[expr] direct 05 6

ADC A,[X+expr] index 06 7 DEC X x 26 4

SUB A,expr data 07 4

SUB A,[expr] direct 08 6

SUB A,[X+expr] index 09 7 IORD expr address 29 5

SBB A,expr data 0A 4

SBB A,[expr] direct 0B 6

SBB A,[X+expr] index 0C 7

OR A,expr data 0D 4

OR A,[expr] direct 0E 6

OR A,[X+expr] index 0F 7 SWAP A,X 2F 5

AND A,expr data 10 4

AND A,[expr] direct 11 6

AND A,[X+expr] index 12 7 MOV [X+expr],A index 32 6

XOR A,expr data 13 4

XOR A,[expr] direct 14 6

XOR A,[X+expr] index 15 7 AND [expr],A direct 35 7

CMP A,expr data 16 5

CMP A,[expr] direct 17 7

CMP A,[X+expr] index 18 8 XOR [X+expr] ,A index 38 8

MOV A,expr data 19 4

MOV A,[expr] direct 1A 5

MOV A,[X+expr] index 1B 6 ASL 3B 4

MOV X,expr data 1C 4

MOV X,[expr] direct 1D 5

reserved 1E

XPAGE 1F 4

MOV A,X 40 4

MOV X,A 41 4

MOV PSP,A 60 4

CALL addr 50-5F 10

JMP addr 80-8F 5 JC addr C0-CF 5

CALL addr 90-9F 10

JZ addr A0-AF 5 JACC addr E0-EF 7

JNZ addr B0-BF 5

NOP 20 4

INC X x 22 4

INC [X+expr] index 24 8

DEC A acc 25 4

DEC [expr] direct 27 7

DEC [X+expr] index 28 8

IOWR expr address 2A 5

POP A 2B 4

POP X 2C 4

PUSH A 2D 5

PUSH X 2E 5

SWAP A,DSP 30 5

MOV [expr],A direct 31 5

OR [expr],A direct 33 7

OR [X+expr],A index 34 8

AND [X+expr],A index 36 8

XOR [expr],A direct 37 7

IOWX [X+expr] index 39 6

CPL 3A 4

ASR 3C 4

RLC 3D 4

RRC 3E 4

RET 3F 8

DI 70 4

EI 72 4

RETI 73 8

JNC addr D0-DF 5

INDEX addr F0-FF 14

Document #: 38-08027 Rev. *B Page 6 of 32

[+] Feedback

Page 7

Memory Organization

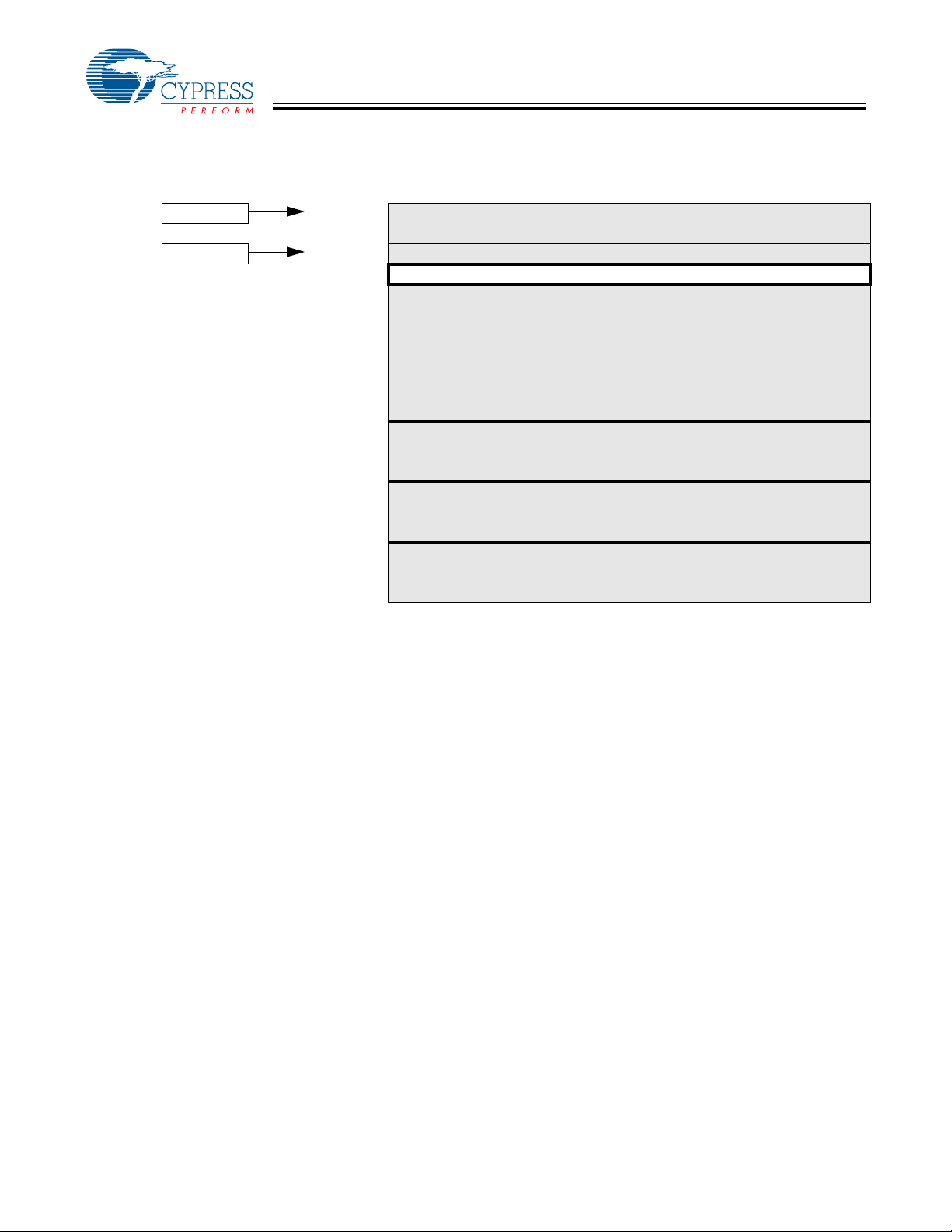

Program Memory Organization

after reset Address

14-bit PC 0x0000 Program execution begins here after a reset

0x0002 USB Bus Reset interrupt vector

0x0004 128-µs timer interrupt vector

0x0006 1.024-ms timer interrupt vector

0x0008 USB address A endpoint 0 interrupt vector

0x000A USB address A endpoint 1 interrupt vector

0x000C USB address A endpoint 2 interrupt vector

0x000E Reserved

CY7C63413C

CY7C63513C

CY7C63613C

0x0010 Reserved

0x0012 Reserved

0x0014 DAC interrupt vector

0x0016 GPIO interrupt vector

0x0018 Reserved

0x001A Program Memory begins here

(8K - 32 bytes)

0x1FDF 8-KB PROM ends here (CY7C63413C, CY7C63513C, CY7C63613C)

Figure 1. Program Memory Space with Interrupt Vector Table

Document #: 38-08027 Rev. *B Page 7 of 32

[+] Feedback

Page 8

CY7C63413C

CY7C63513C

CY7C63613C

Data Memory Organization

The CY7C63413C/513C/613C microcontrollers provide 256

bytes of data RAM. In normal usage, the SRAM is partitioned

after reset Address

8-bit PSP 0x00 Program Stack begins here and grows upward

8-bit DSP user Data Stack begins here and grows downward

The user determines the amount of memory required

User Variables

0xE8

USB FIFO for Address A endpoint 2

0xF0

USB FIFO for Address A endpoint 1

0xF8

USB FIFO for Address A endpoint 0

Top of RAM Memory 0xFF

into four areas: program stack, data stack, user variables and

USB endpoint FIFOs as shown below:

Document #: 38-08027 Rev. *B Page 8 of 32

[+] Feedback

Page 9

CY7C63413C

CY7C63513C

CY7C63613C

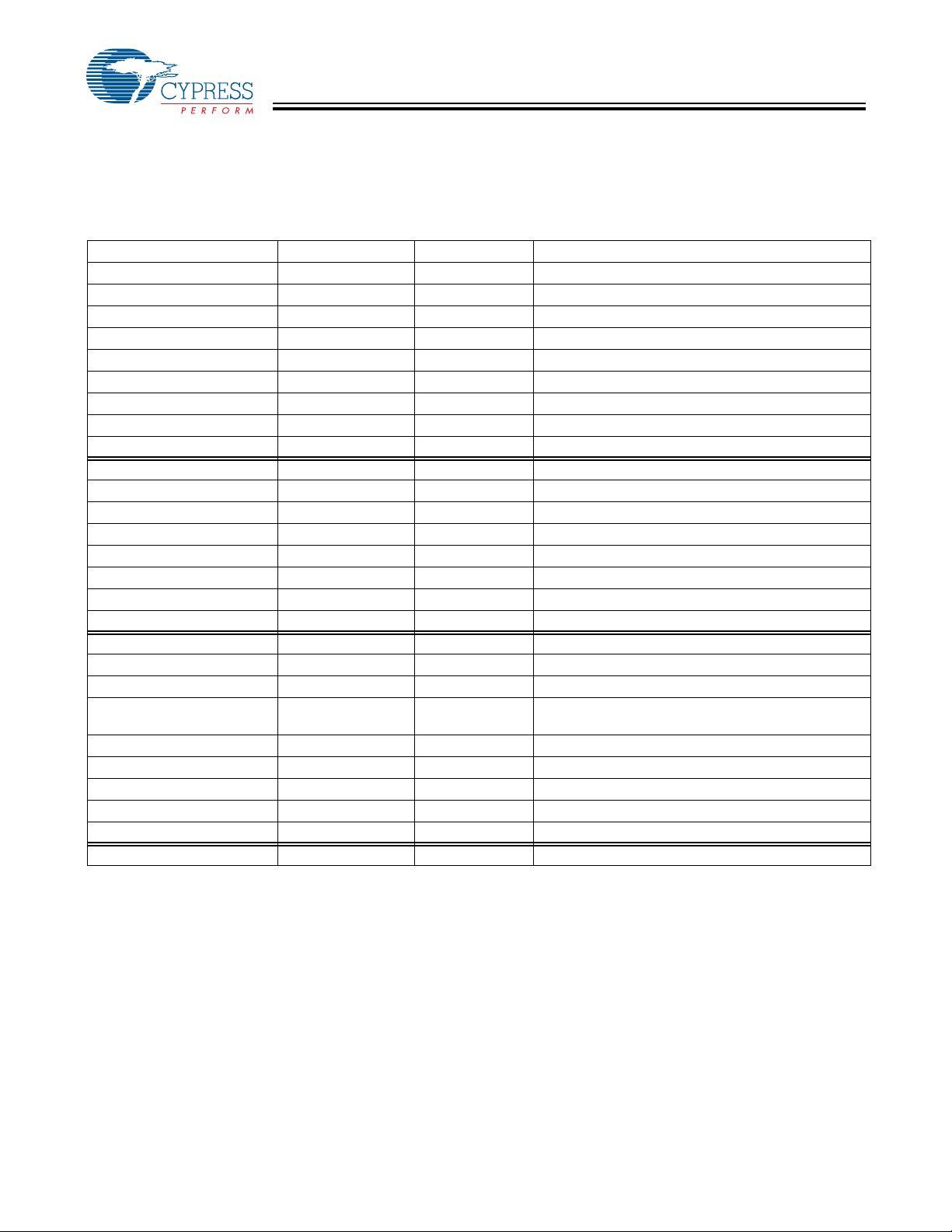

I/O Register Summary

I/O registers are accessed via the I/O Read (IORD) and I/O

Write (IOWR, IOWX) instructions. IORD reads the selected

port into the accumulator. IOWR writes data from the accumu-

Table 1. I/O Register Summary

Register Name I/O Address Read/Write Function

Port 0 Data 0x00 R/W GPIO Port 0

Port 1 Data 0x01 R/W GPIO Port 1

Port 2 Data 0x02 R/W GPIO Port 2

Port 3 Data 0x03 R/W GPIO Port 3

Port 0 Interrupt Enable 0x04 W Interrupt enable for pins in Port 0

Port 1 Interrupt Enable 0x05 W Interrupt enable for pins in Port 1

Port 2 Interrupt Enable 0x06 W Interrupt enable for pins in Port 2

Port 3 Interrupt Enable 0x07 W Interrupt enable for pins in Port 3

GPIO Configuration 0x08 R/W GPIO Ports Configurations

USB Device Address A 0x10 R/W USB Device Address A

EP A0 Counter Register 0x11 R/W USB Address A, Endpoint 0 counter register

EP A0 Mode Register 0x12 R/W USB Address A, Endpoint 0 configuration register

EP A1 Counter Register 0x13 R/W USB Address A, Endpoint 1 counter register

EP A1 Mode Register 0x14 R/C USB Address A, Endpoint 1 configuration register

EP A2 Counter Register 0x15 R/W USB Address A, Endpoint 2 counter register

EP A2 Mode Register 0x16 R/C USB Address A, Endpoint 2 configuration register

USB Status & Control 0x1F R/W USB upstream port traffic status and control register

Global Interrupt Enable 0x20 R/W Global interrupt enable register

Endpoint Interrupt Enable 0x21 R/W USB endpoint interrupt enables

Timer (LSB) 0x24 R Lower eight bits of free-running timer (1 MHz)

Timer (MSB) 0x25 R Upper four bits of free-running timer that are latched

WDR Clear 0x26 W Watch Dog Reset clear

DAC Data 0x30 R/W DAC I/O

DAC Interrupt Enable 0x31 W Interrupt enable for each DAC pin

DAC Interrupt Polarity 0x32 W Inte rrupt polari ty for each DAC pin

DAC Isink 0x38-0x3F W One four bit sink current register for each DAC pin

Processor Status & Control 0xFF R/W Microprocessor status and control

Note:

2. DAC I/O Port not bonded out on CY7C63613C. See note on page 12 for firmware code needed for unused GPIO pins.

lator to the selected port. Indexed I/O Write (IOWX) adds the

contents of X to the address in the instruction to form the port

address and writes data from the accumulator to the specified

port. Note that specifying address 0 (e.g., IOWX 0h) means

the I/O port is selected solely by the contents of X.

when the lower eight bits are read.

[2]

Document #: 38-08027 Rev. *B Page 9 of 32

[+] Feedback

Page 10

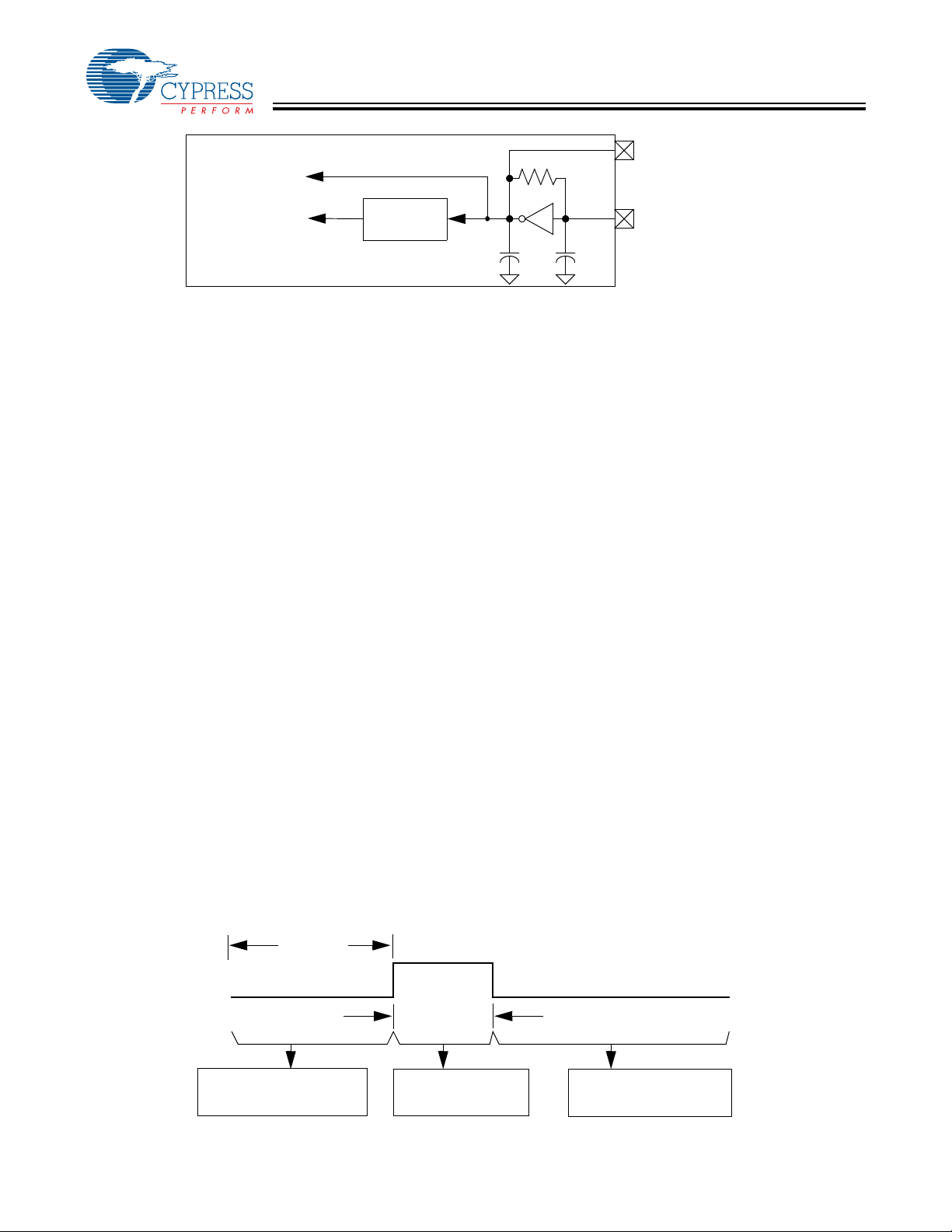

Clock Distribution

clk1x

(to USB SIE)

clk2x

(to Microcontroller)

Clock

Doubler

30 pF

Figure 2. Clock Oscillator On-chip Circuit

30 pF

CY7C63413C

CY7C63513C

CY7C63613C

XTALOUT

XTALIN

Clocking

The XTALIN and XTAL

troller. The user can connect a low-cost ceramic resonator or

an external oscillator can be connected to these pins to

provide a reference frequency for the internal clock distribution

and clock doubler.

An external 6-MHz clock can be applied to the XTAL

the XTAL

XTAL

tively shorted to ground.

pin is left open. Please note that grounding the

OUT

pin is not permissible as the internal clock is effec-

OUT

are the clock pins to the microcon-

OUT

IN

pin if

Reset

The USB Controller supports three types of resets. All

registers are restored to their default states during a reset. The

USB Device Addresses are set to 0 and all interrupts are

disabled. In addition, the Program Stack Pointer (PSP) and

Data Stack Pointer (DSP) are set to 0x00. For USB applications, the firmware should set the DSP below 0xE8 to avoid a

memory conflict with RAM dedicated to USB FIFOs. The

assembly instructions to do this are shown below:

Mov A, E8h ; Move 0xE8 hex into Accumulator

Swap A,dsp ; Swap accumulator value into dsp register

The three reset types are:

1. Power-On Reset (POR)

2. Watch Dog Reset (WDR)

3. USB Bus Reset (non hardware reset)

The occurrence of a reset is recorded in the Processor Status

and Control Register located at I/O address 0xFF. Bits 4, 5,

and 6 are used to record the occurrence of POR, USB Reset,

and WDR respectively. The firmware can interrogate these bits

to determine the cause of a reset.

The microcontroller begins execution from ROM address

0x0000 after a POR or WDR reset. Although this looks like

interrupt vector 0, there is an important difference. Reset

8.192 ms

to 14.336 ms

processing does NOT push the program counter, carry flag,

and zero flag onto program stack. That means the reset

handler in firmware should initialize the hardware and begin

executing the “main” loop of code. Attempting to execute either

a RET or RETI in the reset handler will cause unpredictable

execution results.

Power-On Reset (POR)

Power-On Reset (POR) occurs every time the V

the device ramps from 0V to an internally defined trip voltage

(Vrst) of approximately 1/2 full supply voltage. In addition to the

normal reset initialization noted under “Reset,” bit 4 (PORS) of

the Processor Status and Control Register is set to “1” to

indicate to the firmware that a Power-On Reset occurred. The

POR event forces the GPIO ports into input mode (high

impedance), and the state of Port 3 bit 7 is used to control how

the part will respond after the POR releases.

If Port 3 bit 7 is HIGH (pulled to V

the idle state (DM HIGH and DP LOW) the part will go into a

semi-permanent power down/suspend mode, waiting for the

USB IO to go to one of Bus Reset, K (resume) or SE0. If Port

3 bit 7 is still HIGH when the part comes out of suspend, then

a 128-µs timer starts, delaying CPU operation until the ceramic

resonator has stabilized.

If Port 3 bit 7 was LOW (pulled to V

ms timer, delaying CPU operation until V

then continuing to run as reset.

Firmware should clear the POR Status (PORS) bit in register

0xFF before going into suspend as this status bit selects the

128-µs or 96-ms start-up timer value as follows: IF Port 3 bit 7

is HIGH then 128-µs is always used; ELSE if PORS is HIGH

then 96-ms is used; ELSE 128-µs is used.

Watch Dog Reset (WDR)

The Watch Dog Timer Reset (WDR) occurs when the Most

Significant Bit (MSB) of the 2-bit Watch Dog Timer Register

transitions from LOW to HIGH. In addition to the normal reset

) and the USB IO are at

CC

) the part will start a 96-

SS

CC

voltage to

CC

has stabilized,

2.048 ms

At least 8.192 ms

since last write to WDT

Document #: 38-08027 Rev. *B Page 10 of 32

WDR goes high

for 2.048 ms

Figure 3. Watch Dog Reset (WDR)

Execution begins at

Reset Vector 0X00

[+] Feedback

Page 11

CY7C63413C

CY7C63513C

CY7C63613C

initialization noted under “Reset,” bit 6 of the Processor Status

and Control Register is set to “1” to indicate to the firmware

that a Watch Dog Reset occurred.

The Watch Dog Timer is a 2-bit timer clocked by a 4.096-ms

clock (bit 11) from the free-running timer. Writing any value to

the write-only Watch Dog Clear I/O port (0x26) will clear the

Wat ch Dog Timer.

In some applications, the Watch Dog Timer may be cleared in

the 1.024-ms timer interrupt service routine. If the 1.024-ms

timer interrupt service routine does not get executed for 8.192

ms or more, a Watch Dog Timer Reset will oc cur . A Watch Dog

Timer Reset lasts for 2.048 ms after which the microcontroller

begins execution at ROM address 0x0000. The USB transmitter is disabled by a Watch Dog Reset because the USB

Device Address Register is cleared. Otherwise, the USB

Controller would respond to all address 0 transactions. The

USB transmitter remains disabled until the MSB of the USB

address register is set.

GPIO

CFG

Internal

Data Bus

Data

Out

Latch

General Purpose I/O Ports

Ports 0 to 2 provide 24 GPIO pins that can be read or written.

Each port (8 bits) can be configured as inputs with internal pullups, open drain outputs, or traditional CMOS outputs. Please

note an open drain output is also a high-impedance (no pullup) input. All of the I/O pins within a given port have the same

configuration. Ports 0 to 2 are considered low current drive

with typical current sink capability of 7 mA.

The internal pull-up resistors are typically 7 kΩ. Two factors

govern the enabling and disabling of the internal pull-up

resistors: the port configuration selected in the GPIO Configuration register and the state of the output data bit. If the GPIO

Configuration selected is “Resistive” and the output data bit is

“1,” then the internal pull-up resistor is e nabled for that GPIO

pin. Otherwise, Q1 is turned off and the 7-kΩ pull-up is

disabled. Q2 is “ON” to sink current whenever the output data

bit is written as a “0.” Q3 provides “HIGH” source current when

the GPIO port is configured for CMOS outputs and the output

data bit is written as a “1”. Q2 and Q3 are sized to sink and

source, respectively, roughly the same amount of current to

support traditional CMOS outputs with symmetric drive.

V

CC

mode

2 bits

Q1

Q3

7 kΩ

Q2

to Interrupt

Controller

ESD

GPIO

Pin

Interrupt

Enable

Port Write

Internal

Buffer

Control

Port Read

Control

Figure 4. Block Diagram of a GPIO Line

.

Table 2. Port 0 Data

Addr: 0x00 Port 0 Data

P0[7] P0[6] P0[5] P0[4] P0[3] P0[2] P0[1] P0[0]

R/W R/W R/W R/W R/W R/W R/W R/W

Table 3. Port 1 Data

Addr: 0x01 Port 1 Data

P1[7] P1[6] P1[5] P1[4] P1[3] P1[2] P1[1] P1[0]

R/W R/W R/W R/W R/W R/W R/W R/W

Table 4. Port 2 Data

Addr: 0x02 Port 2 Data

P2[7] P2[6] P2[5] P2[4] P2[3] P2[2] P2[1] P2[0]

R/W R/W R/W R/W R/W R/W R/W R/W

Document #: 38-08027 Rev. *B Page 11 of 32

[+] Feedback

Page 12

CY7C63413C

CY7C63513C

CY7C63613C

Table 5. Port 3 Data

Addr: 0x03 Port 3 Data

P3[7] P3[6] P3[5] P3[4] P3[3] P3[2] P3[1] P3[0]

R/W R/W R/W R/W R/W R/W R/W R/W

Table 6. DAC Port Data

Addr: 0x30 DAC Port Data

Low current outputs

0.2 mA to 1.0 mA typical

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

R/W R/W R/W R/W R/W R/W R/W R/W

High current outputs

3.2 mA to 16 mA typical

Port 3 has eight GPIO pins. Port 3 (8 bits) can be configured

as inputs with internal pull-ups, open drain outputs, or traditional CMOS outputs. An open drain output is also a highimpedance input. Port 3 offers high current drive with a typical

current sink capability of 12 mA. The internal pull-up resistors

are typically 7 kΩ.

Note: Special care should be exercised with any unused GPIO

data bits. An unused GPIO data bit, either a pin on the chip or

a port bit that is not bonded on a particular package, must not

be left floating when the device enters the suspend state. If a

GPIO data bit is left floating, the leakage current caused by the

floating bit may violate the suspend current limitation specified

by the USB Specification. If a ‘1’ is written to the unused data

bit and the port is configured with open drain outputs, the

unused data bit will be in an indeterminate state. Therefore, if

an unused port bit is programmed in open-drain mode, it must

be written with a ‘0.’ Notice that the CY7C63613C will always

require that data bits P1[7:4], P2[7:0], P3[3:0] and DAC[7:0] be

written with a ‘0’.

Table 7. Port 0 Interrupt Enable

Addr: 0x04 Port 0 Interrupt Enable

P0[7] P0[6] P0[5] P0[4] P0[3] P0[2] P0[1] P0[0]

W W W W W W W W

Table 8. Port 1 Interrupt Enable

Addr: 0x05 Port 1 Interrupt Enable

P1[7] P1[6] P1[5] P1[4] P1[3] P1[2] P1[1] P1[0]

W W W W W W W W

During reset, all of the bits in the GPIO to a default configuration of Open Drain output, positive interrupt polarity for all

GPIO ports.

GPIO Interrupt Enable Ports

During a reset, GPIO interrupts are disabled by clearing all of

the GPIO interrupt enable ports. Writing a “1” to a GPIO

Interrupt Enable bit enables GPIO interrupts from the corresponding input pin.

GPIO Configuration Port

Every GPIO port can be programmed as inputs with internal

pull-ups, open drain outputs, and traditional CMOS outputs. In

addition, the interrupt polarity for each port can be programmed. With positive interrupt polarity, a rising edge (“0” to

“1”) on an input pin causes an interrupt. With negative polarity,

a falling edge (“1” to “0”) on an input pin causes an interrupt.

As shown in the table below, when a GPIO port is configured

with CMOS outputs, interrupts from that port are disabled. The

GPIO Configuration Port register provides two bits per port to

program these features. The possible port configurations are

as shown in Table 11.

Table 9. Port 2 Interrupt Enable

Addr: 0x06 Port 2 Interrupt Enable

P2[7] P2[6] P2[5] P2[4] P2[3] P2[2] P2[1] P2[0]

W W W W W W W W

Table 10.Port 3 Interrupt Enable

Addr: 0x07 Port 3 Interrupt Enable

P3[7] P3[6] P3[5] P3[4] P3[3] P3[2] P3[1] P3[0]

W W W W W W W W

Document #: 38-08027 Rev. *B Page 12 of 32

[+] Feedback

Page 13

CY7C63413C

CY7C63513C

CY7C63613C

Table 11.Possible Port Configurations

Port Configuration bits Pin Interrupt Bit Driver Mode Interrupt Polarity

11 X Resistive 10 0 CMOS Output disabled

10 1 Open Drain disabled

01 X Open Drain 00 X Open Drain + (default)

In “Resistive” mode, a 7-kΩ pull-up resistor is conditionally

enabled for all pins of a GPIO port. The resistor is enabled for

any pin that has been written as a “1.” The resistor is disabled

on any pin that has been written as a “0.” An I/O pin will be

driven high through a 7-kΩ pull-up resistor when a “1” has

been written to the pin. Or the output pin will be driven LOW,

with the pull-up disabled, when a “0” has been written to the

pin. An I/O pin that has been written as a “1” can be used as

an input pin with an integrated 7-kΩ pull-up resistor. Resistive

mode selects a negative (falling edge) interrupt polarity on all

pins that have the GPIO interrupt enabled.

In “CMOS” mode, all pins of the GPIO port are outputs that are

actively driven. The current source and sink capacity are

roughly the same (symmetric output drive). A CMOS port is not

a possible source for interrupts.

A port configured in CMOS mode has interrupt generation

direction. If a port’s associated Interrupt Mask bits are cleared,

those port bits are strictly outputs. If the Interrupt Mask bits are

set then those bits will be open drain inputs. As open drain

inputs, if their data output values are ‘1’ those port pins will be

CMOS inputs (HIGH Z output).

In “Open Drain” mode the internal pull-up resistor and CMOS

driver (HIGH) are both disabled. An I/O pin that has been

written as a “1” can be used as either a high-impedance input

or a three-state output. An I/O pin that has been written as a

“0” will drive the output LOW. The interrupt polarity for an open

drain GPIO port can be selected as either positive (rising

edge) or negative (falling edge).

During reset, all of the bits in the GPIO Configuration Register

are written with “0.” This selects the default configuration:

Open Drain output, positive interrupt polarity for all GPIO

ports.

disabled, yet the interrupt mask bits serve to control port

Addr: 0x08 GPIO Configuration Register

7 6 5 4 3 2 1 0

Port 3

Config Bit 1

Port 3

Config Bit 0

Port 2

Config Bit 1

Port 2

Config Bit 0

Port 1

Config Bit 1

Port 1

Config Bit 0

Port 0

Config Bit 1

W W W W W W W W

Table 12.GPIO Configuration Register

DAC Port

Port 0

Config Bit 0

V

CC

Internal

Data Bus

Interrupt

Enable

Interrupt

Polarity

DAC Write

Internal

Buffer

Data

Out

Latch

DAC Read

Isink

Register

Interrupt Logic

4 bits

Isink

DAC

to Interrupt

Controller

Q1

14 KΩ

DAC

I/O Pin

ESD

Figure 5. Block Diagram of DAC Port

Document #: 38-08027 Rev. *B Page 13 of 32

[+] Feedback

Page 14

CY7C63413C

CY7C63513C

CY7C63613C

Table 13.DAC Port Data

Addr: 0x30 DAC Port Data

Low current outputs

0.2 mA to 1.0 mA typical

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

R/W R/W R/W R/W R/W R/W R/W R/W

The DAC port provides the CY7C63513C with 8 programmable current sink I/O pins. Writing a “1” to a DAC I/O pin

disables the output current sink (Isink DAC) and drives the I/O

pin HIGH through an integrated 14 Kohm resistor. When a “0”

is written to a DAC I/O pin, the Isink DAC is enabled and the

pull-up resistor is disabled. A “0” output will cause the Isink

DAC to sink current to drive the output LOW. The amount of

sink current for the DAC I/O pin is programmable over 16

values based on the content s of the DAC Isink Register f or that

output pin. DAC[1:0] are the two high current outputs that are

programmable from a minimum of 3.2 mA to a maximum of 16

mA (typical). DAC[7:2] are low current outputs that are

programmable from a minimum of 0.2 mA to a maximum of 1.0

mA (typical).

When a DAC I/O bit is written as a “1,” the I/O pin is either an

output pulled high through the 14 Kohm resistor or an input

with an internal 14 Kohm pull-up resistor. All DAC port data bits

are set to “1” during reset.

DAC Port Interrupts

A DAC port interrupt can be enabled/disabled for each pin

individually. The DAC Port Interrupt Enable register provides

this feature with an interrupt mask bit for each DAC I/O pin.

Writing a “1” to a bit in this register enables interrupts from the

corresponding bit position. Writing a “0” to a bit in the DAC Port

Interrupt Enable register disables interrupts from the corresponding bit position. All of the DAC Port Interrupt Enable

register bits are cleared to “0” during a reset.

As an additional benefit, the interrupt polarity for each DAC pin

is programmable with the DAC Port Interrupt Polarity register.

Writing a “0” to a bit selects negative polarity (falling edge) that

will cause an interrupt (if enabled) if a falling edge tra nsition

occurs on the corresponding input pin. Writing a “1” to a bit in

this register selects positive polarity (rising edge) that will

cause an interrupt (if enabled) if a rising edge transition occurs

on the corresponding input pin. All of the DAC Port Interrupt

Polarity register bits are cleared during a reset.

DAC Isink Registers

Each DAC I/O pin has an associated DAC Isink register to

program the output sink current when the output is driven

LOW. The first Isink register (0x38) controls the current for

DAC[0], the second (0x39) for DAC[1], and so on until the Isink

register at 0x3F controls the current to DAC[7].

High current outputs

3.2 mA to 16 mA typical

Table 14.DAC Port Interrupt Enable

Addr: 0x31 DAC Port Interrupt Enable

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

W W W W W W W W

Table 15.DAC Port Interrupt Polarity

Addr: 0x32 DAC Port Interrupt Polarity

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

W W W W W W W W

Table 16.DAC Port Isink

Addr: 0x38-0x3F DAC Port Interrupt Polarity

Reserved Isink Value

Isink[3] Isink[2] Isink[1] Isink[0]

W W W W

Document #: 38-08027 Rev. *B Page 14 of 32

[+] Feedback

Page 15

CY7C63413C

CY7C63513C

CY7C63613C

USB Serial Interface Engine (SIE)

The SIE allows the microcontroller to communicate with the

USB host. The SIE simplifies the interface between the microcontroller and USB by incorporating hardware that handles the

following USB bus activity independently of the microcontroller:

• Bit stuffing/unstuffing

• Checksum generation/checking

•ACK/NAK

• Token type identification

• Address checking

Firmware is required to handle the rest of the USB interface

with the following tasks:

• Coordinate enumeration by responding to set-up packets

• Fill and empty the FIFOs

• Suspend/Resume coordination

• Verify and select Data toggle values

USB Enumeration

The enumeration sequence is shown below:

1. The host computer sends a Setup packet followed by a

Data packet to USB address 0 requesting the Device descriptor.

2. The USB Controller decodes the request and retrieves its

Device descriptor from the program memory space.

3. The host computer performs a control read sequence and

the USB Controller responds by sending the Device

descriptor over the USB bus.

4. After receiving the descriptor, the host computer sends a

Setup packet followed by a Data packet to address 0

assigning a new USB address to the device.

5. The USB Controller stores the new address in its USB

Device Address Register after the no-data control

sequence is complete.

6. The host sends a request for the Device descriptor using

the new USB address.

Table 17.USB Status and Control Register

Addr:0x1F USB Status and Control Register

7 6 5 4 3 2 1 0

Reserved Reserved D+ D– Bus Activity Control

R R R/W R/W R/W R/W

7. The USB Controller decodes the request and retrieves the

Device descriptor from the program memory .

8. The host performs a control read sequence and the USB

Controller responds by sending its Device descriptor over

the USB bus.

9. The host generates control reads to the USB Controller to

request the Configuration and Report descriptors.

10.The USB Controller retrieves the descriptors from its

program space and returns the data to the host over the

USB.

PS/2 Operation

PS/2 operation is possible with the CY7C63413C/513C/613C

series through the use of firmware and several operating

modes. The first enabling feature:

1. USB Bus reset on D+ and D− is an interrupt that can be

disabled;

2. USB traffic can be disabled via bit 7 of the USB register;

3. D+ and D− can be monitored and driven via firmware as

independent port bits.

Bits 5 and 4 of the Upstream Status and Control register are

directly connected to the D+ and D− USB pins of the

CY7C63413C/513C/613C. These pins constantly monitor the

levels of these signals with CMOS input thresholds. Firmware

can poll and decode these signals as PS/2 clock and data.

Bits [2:0] defaults to ‘000’ at reset which allows the USB SIE

to control output on D+ and D−. Firmware can override the SIE

and directly control the state of these pins via these 3 control

bits. Since PS/2 is an open drain signaling protocol, these

modes allow all 4 PS/2 states to be generated on the D+ and

D− pins

USB Port Status and Control

USB status and control is regulated by the USB Status and

Control Register located at I/O address 0x1F as shown in

Figure 17. This is a read/write register. All reserved bits must

be written to zero. All bits in the register are cleared during

reset.

Control

Bit 2

Bit 1

Control

Bit 0

Document #: 38-08027 Rev. *B Page 15 of 32

[+] Feedback

Page 16

CY7C63413C

CY7C63513C

CY7C63613C

The Bus Activity bit is a “sticky” bit that indicates if any non-idle

USB event has occurred on the USB bus. The user firmware

should check and clear this bit periodically to detect any loss

of bus activity . Writing a “ 0” to the Bus Activity bit clears it while

writing a “1” preserves the current value. In other words, the

firmware can clear the Bus Activity bit, but only the SIE can set

it. The 1.024-ms timer interrupt service routine is normally

used to check and clear the Bus Activity bit. The following table

shows how the control bits are encoded for this register.

Control

Bits Control Action

000 Not forcing (SIE controls driver)

001 Force K (D+ HIGH, D– LOW)

010 Force J (D+ LOW, D– HIGH)

011 Force SE0 (D+ LOW, D– LOW)

100 Force SE0 (D− LOW, D+ LOW)

101 Force D− LOW, D+ HiZ

110 Force D− HiZ, D+ LOW

111 Force D− HiZ, D+ HiZ

USB Device

USB Device Address A includes three endpoints: EPA0, EP A1,

and EPA2. End Point 0 (EPA0) allows the USB host to

recognize, set up, and control the device. In particular, EPA0

is used to receive and transmit control (including set-up)

packets.

USB Ports

The USB Controller provides one USB device address with

three endpoints. The USB Device Address Register contents

are cleared during a reset, setting the USB device address to

zero and marking this address as disabled. Figure 18 shows

the format of the USB Address Register.

Bit 7 (Device Address Enable) in the USB Device Address

Register must be set by firmware before the serial interface

engine (SIE) will respond to USB traffic to this address. The

Device Address in bits [6:0] must be set by firmware during the

USB enumeration process to an address assigned by the USB

host that does not equal zero. This register is cleare d by a

hardware reset or the USB bus reset.

Device Endpoints (3)

The USB controller communicates with the host using

dedicated FIFOs, one per endpoint. Each endpoint FIFO is

implemented as 8 bytes of dedicated SRAM. There are three

endpoints defined for Device “A” that are labeled “EPA0,”

“EPA1,” and EPA2.”

All USB devices are required to have an endpoint number 0

(EPA0) that is used to initialize and control the USB device.

End Point 0 provides access to the device configuration information and allows generic USB status and control accesses.

End Point 0 is bidirectional as the USB controller can both

receive and transmit data.

The endpoint mode registers are cleared during reset. The

EPA0 endpoint mode register uses the format shown in T able

19.

Bits[7:5] in the endpoint 0 mode registers (EPA0) are “sticky”

status bits that are set by the SIE to report the type of token

that was most recently received. The sticky bits must be

cleared by firmware as part of the USB processing.

The endpoint mode registers for EPA1 and EPA2 do not use

bits [7:5] as shown in Table 20.

Table 18.USB Device Address Register

Addr:0x10 USB Device Address Register

Device

Address

Enable

R/W R/W R/W R/W R/W R/W R/W R/W

Table 19.USB Device EPA0, Mode Register

Addr:0x12 USB Device EPA0, Mode Register

Endpoint 0

Set-up

Received

R/W R/W R/W R/W R/W R/W R/W R/W

Table 20.USB Device Endpoint Mode Register

Addr: 0x14, 0x16 USB Device Endpoint Mode Register

Reserved Reserved Reserved Acknowledge Mode

R/W R/W R/W R/W R/W R/W R/W R/W

Device

Address

Bit 6

Endpoint 0

In

Received

Device

Address

Bit 5

Endpoint 0

Out

Received

Device

Address

Bit 4

Acknowledge Mode

Device

Address

Bit 3

Bit 3

Bit 3

Device

Address

Bit 2

Mode

Bit 2

Mode

Bit 2

Device

Address

Bit 1

Mode

Bit 1

Mode

Bit 1

Device

Address

Bit 0

Mode

Bit 0

Mode

Bit 0

Document #: 38-08027 Rev. *B Page 16 of 32

[+] Feedback

Page 17

CY7C63413C

CY7C63513C

CY7C63613C

The ‘Acknowledge’ bit is set whenever the SIE engages in a

transaction that completes with an ‘ACK’ packet.

The ‘set-up’ PID status (bit[7]) is forced HIGH from the start of

the data packet phase of the set-up transaction, until the start

of the ACK packet returned by the SIE. The CPU is prevented

from clearing this bit during this interval, and subsequently

until the CPU first does an IORD to this endpoint 0 mode

register.

Bits[6:0] of the endpoint 0 mode register are locked from CPU

IOWR operations only if the SIE has updated one of these bits,

which the SIE does only at the end of a packet transaction (setup... Data... ACK, or Out... Data... ACK, or In... Data... ACK).

The CPU can unlock these bits by doing a subsequent I/O read

of this register.

Firmware must do an IORD after an IOWR to an endpoint 0

register to verify that the contents have changed and that the

SIE has not updated these values.

Table 21.USB Device Counter Registers

Addr: 0x11, 0x13, 0x15 USB Device Counter Registers

Data 0/1

Toggle

R/W R/W R/W R/W R/W R/W R/W R/W

Data Valid Reserved Reserved Byte count

While the ‘set-up’ bit is set, the CPU cannot write to the DMA

buffers at memory locations 0xE0 through 0xE7 and 0xF8

through 0xFF. This prevents an incoming set-up transaction

from conflicting with a previous In data buffer filling operation

by firmware.

The mode bits (bits [3:0]) in an Endpoint Mode Register control

how the endpoint responds to USB bus traffic. The mode bit

encoding is shown in Section .

The format of the endpoint Device counter registers is shown

in Table 21.

Bits 0 to 3 indicate the number of data bytes to be transmitted

during an IN packet, valid values are 0 to 8 inclusive. Data

Valid bit 6 is used for OUT and set-up tokens only. Data 0/1

Toggle bit 7 selects the DATA packet’s toggle state: 0 for

DATA0, 1 for DATA1.

Bit 3

Byte count

Bit 2

Byte count

Bit 1

Byte count

Bit 0

Document #: 38-08027 Rev. *B Page 17 of 32

[+] Feedback

Page 18

CY7C63413C

CY7C63513C

CY7C63613C

12-bit Free-running Timer

The 12-bit timer provides two interrupts (128 µs and 1.024 ms)

and allows the firmware to directly time events that are up to

4 ms in duration. The lower 8 bits of the timer can be read

directly by the firmware. Reading the lower 8 bits latches the

Timer (LSB)

Table 22.Timer Register

Addr: 0x24 Timer Register (LSB)

Timer

Bit 7

R R R R R R R R

Timer (MSB)

Table 23.Timer Register

Addr: 0x25 Timer Register (MSB)

Reserved Reserved Reserved Reserved Timer

Timer

Bit 6

Timer

Bit 5

Timer

Bit 4

upper 4 bits into a temporary register. When the firmware

reads the upper 4 bits of the timer, it is actually reading the

count stored in the temporary register. The effect of this logic

is to ensure a stable 12-bit timer value can be read, even when

the two reads are separated in time.

Timer

Bit 3

Bit 11

R R R R

Timer

Bit 2

Timer

Bit 10

Timer

Bit 1

Timer

Bit 9

1.024-ms interrupt

128-

µs interrupt

Timer

Bit 0

Timer

Bit 8

10 9 78

L1 L0L2L3

D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

6432

5

1 011

1-MHz clock

To Timer Register

8

Figure 6. Timer Block Diagram

Processor Status and Control Register

Table 24.Processor St atus and Control Register

Addr: 0xFF Processor Status and Control Register POR Default: 0x0101

7 6 5 4 3 2 1 0

IRQ

Pending

R R/W R/W R/W R/W R R/W R/W

The “Run” (bit 0) is manipulated by the HALT instruction. When

Halt is executed, the processor clears the run bit and halts at

the end of the current instruction. The processor remains

Watch Dog

Reset

USB Bus

Reset

Power-on

Reset

Suspend, Wait

for Interrupt

halted until a reset (Power On or Watch Dog). Notice, when

writing to the processor status and control register, the run bit

should always be written as a “1.”

Interrupt

Mask

WDC Reset: 0x41

Single Step Run

Document #: 38-08027 Rev. *B Page 18 of 32

[+] Feedback

Page 19

CY7C63413C

CY7C63513C

CY7C63613C

The “Single Step” (bit 1) is provided to support a hardware

debugger. When single step is set, the processor will execute

one instruction and halt (clear the run bit). This bit must be

cleared for normal operation.

The “Interrupt Mask” (bit 2) shows whether interrupts are

enabled or disabled. The firmware has no direct control over

this bit as writing a zero or one to this bit position will have no

effect on interrupts. Instructions DI, EI, and RETI manipulate

the internal hardware that controls the state of the interrupt

mask bit in the Processor Status and Control Register.

Writing a “1” to “Suspend, Wait for Interrupts” (bit 3) will halt

the processor and cause the microcontroller to enter the

“suspend” mode that significantly reduces power

consumption. A pending interrupt or bus activity will cause the

device to come out of suspend. After coming out of suspend,

the device will resume firmware execution at the instruction

following the IOWR which put the part into suspend. An IOWR

that attempts to put the part into suspend will be ignored if

either bus activity or an interrupt is pending.

The “Power-on Reset” (bit 4) is only set to “1” during a powe r

on reset. The firmware can check bits 4 and 6 in the reset

handler to determine whether a reset was caused by a Power

On condition or a Watch Dog Timeout. PORS is used to

determine suspend start-up timer value of 128 µs or 96 ms.

The “USB Bus Reset” (bit 5) will occur when a USB bus reset

is received. The USB Bus Reset is a singled-ended zero (SE0)

that lasts more than 8 microseconds. An SE0 is defined as the

condition in which both the D+ line and the D– line are LOW

at the same time. When the SIE detects this condition, the

USB Bus Reset bit is set in the Processor Status and Control

register and an USB Bus Reset interrupt is generated. Please

note this is an interrupt to the microcontroller and does n ot

actually reset the processor.

The “Watch Dog Reset” (bit 6) is set during a reset initiated by

the Watch Dog Timer. This indicates the Watch Dog Timer

went for more than 8 ms between watch dog clears.

The “IRQ Pending” (bit 7) indicates one or more of the interrupts has been recognized as active. The interrupt

acknowledge sequence should clear this bit until the next

interrupt is detected.

During Power-on Reset, the Processor Status and Control

Register is set to 00010001, which indicates a Power-on Reset

(bit 4 set) has occurred and no interrupts are pending (bit 7

clear) yet.

During a Watch Dog Reset, the Processor St atus and Control

Register is set to 01000001, which indicates a Watch Dog

Reset (bit 6 set) has occurred and no interrupts are pending

(bit 7 clear) yet.

Interrupts

All interrupts are maskable by the Global Interrupt Enable

Register and the USB End Point Interrupt Enable Register.

Writing a “1” to a bit position enables the interrupt associated

with that bit position. During a reset, the contents the Global

Interrupt Enable Register and USB End Point Interrupt Enable

Register are cleared, effectively disabling all interrupts.

Pending interrupt requests are recognized during the last clock

cycle of the current instruction. When servicing an interrupt,

the hardware will first disable all interrupts by clearing the

Interrupt Enable bit in the Processor Status and Control

Register. Next, the interrupt latch of the current interrupt is

cleared. This is followed by a CALL instruction to the ROM

address associated with the interrupt being serviced (i.e., the

Interrupt Vector). The instruction in the interrupt table is

typically a JMP instruction to the address of the Interrupt

Service Routine (ISR). The user can re-enable interrupts in the

interrupt service routine by executing an EI instruction. Interrupts can be nested to a level limited only by the available

stack space.

The Program Counter value as well as the Carry and Zero

flags (CF , ZF) are automatically stored onto the Program Stack

by the CALL instruction as part of the interrupt acknowledge

process. The user firmware is responsible for insuring that the

processor state is preserved and restored during an interrupt.

The PUSH A instruction should be used as the first command

in the ISR to save the accumulator value and the POP A

instruction should be used just before the RETI instruction to

restore the accumulator value. The program counter CF and

ZF are restored and interrupts are enabled when the R ETI

instruction is executed.

Table 25.Global Interrupt Enable Register

Addr: 0x20 Global Interrupt Enable Register

7 6 5 4 3 2 1 0

Reserved Reserved GPIO

Interrupt

Enable

R/W R/W R/W R/W R/W

Table 26.USB End Point Interrupt Enable Register

Addr: 0x21 USB End Point Interrupt Enable Register

7 6 5 4 3 2 1 0

Reserved Reserved Reserved Reserved Reserved EPA2

Document #: 38-08027 Rev. *B Page 19 of 32

DAC

Interrupt

Enable

Reserved 1.024-ms

Interrupt

Enable

Interrupt

Enable

R/W R/W R/W

128-µsec

Interrupt

Enable

EPA1

Interrupt

Enable

USB Bus RST

Interrupt

Enable

EPA0

Interrupt

Enable

[+] Feedback

Page 20

CY7C63413C

CY7C63513C

CY7C63613C

Interrupt Vectors

The Interrupt Vectors supported by the USB Controller are

listed in Table 27. Although Reset is not an interrupt, per se,

the first instruction executed after a reset is at PROM address

Table 27.Interrupt Vector Assignments

Interrupt Vector Number ROM Address Function

not applicable 0x0000 Execution after Reset begins here

1 0x0002 USB Bus Reset interrupt

2 0x0004 128-µs timer interrupt

3 0x0006 1.024-ms timer interrupt

4 0x0008 USB Address A Endpoint 0 interrupt

5 0x000A USB Address A Endpoint 1 interrupt

6 0x000C USB Address A Endpoint 2 interrupt

7 0x000E Reserved

8 0x0010 Reserved

9 0x0012 Reserved

10 0x0014 DAC interrupt

11 0x0016 GPIO interrupt

12 0x0018 Reserved

Interrupt Latency

Interrupt latency can be calculated from the following

equation:

Interrupt Latency =(Number of clock cycles remaining in the

current instruction)

+ (10 clock cycles for the CALL instruction)

+ (5 clock cycles for the JMP instruction)

For example, if a 5 clock cycle instruction such as JC is being

executed when an interrupt occurs, the first instruction of the

Interrupt Service Routine will execute a min. of 16 clocks

(1+10+5) or a max. of 20 clocks (5+10+5) after the interrupt is

issued. Remember that the interrupt latches are sampled at

the rising edge of the last clock cycle in the current instruction.

USB Bus Reset Interrupt

The USB Bus Reset interrupt is asserted when a USB bus

reset condition is detected. A USB bus reset is indicated by a

single ended zero (SE0) on the upstream port for more than 8

microseconds.

Timer Interrupt

There are two timer interrupts: the 128-µs interrupt and the

1.024-ms interrupt. The user should disable both timer interrupts before going into the suspend mode to avoid possible

conflicts between servicing the interrupts first or the suspend

request first.

USB Endpoint Interrupts

There are three USB endpoint interrupts, one per endpoint.

The USB endpoints interrupt after the either the USB host or

the USB controller sends a packet to the USB.

0x0000—which corresponds to the first entry in the Interrupt

Vector Table. Because the JMP instruction is 2 bytes long, the

interrupt vectors occupy 2 bytes.

DAC Interrupt

Each DAC I/O pin can generate an interrupt, if enabled.The

interrupt polarity for each DAC I/O pin is programmable. A

positive polarity is a rising edge input while a negative polarity

is a falling edge input. All of the DAC pins share a single

interrupt vector, which means the firmware will need to read

the DAC port to determine which pin or pins caused an

interrupt.

Please note that if one DAC pin triggered an interrupt, no other

DAC pins can cause a DAC interrupt until that pin has returned

to its inactive (non-trigger) state or the corresponding interrupt

enable bit is cleared. The USB Controller does not assign

interrupt priority to different DAC pins and the DAC Interrupt

Enable Register is not cleared during the interrupt

acknowledge process.

GPIO Interrupt

Each of the 32 GPIO pins can generate an interrupt, if enabled.

The interrupt polarity can be programmed for each GPIO port

as part of the GPIO configuration. All of the GPIO pins share

a single interrupt vector, which means the firmware will need

to read the GPIO ports with enabled interrupts to determine

which pin or pins caused an interrupt.

Please note that if one port pin triggered an interrupt, no other

port pins can cause a GPIO interrupt until that port pin has

returned to its inactive (non-trigger) state or its corresponding

port interrupt enable bit is cleared. The USB Controller does

not assign interrupt priority to different port pins and the Port

Interrupt Enable Registers are not cleared during the interrupt

acknowledge process.

Document #: 38-08027 Rev. *B Page 20 of 32

[+] Feedback

Page 21

CY7C63413C

CY7C63513C

CY7C63613C

Truth Tables

Table 28.USB Register Mode Encoding

Mode Encoding Setup In Out Comments

Disable 0000 ignore ignore ignore Ignore all USB traffic to this endpoint

Nak In/Out

0001

Status Out Only 0010 accept stall check For Control endpoints

Stall In/Out 0011 accept stall stall For Control endpoints

Ignore In/Out 0100 accept ignore ignore For Control endpoints

Isochronous Out

0101

Status In Only 0110 accept TX 0 stall For Control Endpoints

Isochronous In

0111

Nak Out 1000 ignore ignore NAK An ACK from mode 1001 --> 1000

Ack Out 1001 ignore ignore ACK This mode is changed by SIE on issuance of ACK --> 1000

Nak Out - Status In 1010 accept TX 0 NAK An ACK from mode 1011 --> 1010

Ack Out - Status In 1011 accept TX 0 ACK This mode is changed by SIE on issuance of ACK --> 1010

Nak In 1100 ignore NAK ignore An ACK from mode 1101 --> 1100

Ack In 1101 ignore TX cnt ignore This mode is changed by SIE on issuance of ACK --> 1100

Nak In - Status Out 1110 accept NAK check An ACK from mode 1111 --> 1110 NAck In - Status Out

Ack In - Stat us Out 1111 accept TX cnt Check This mode is changed by SIE on issuance of ACK -->1110

accept NAK NAK Forced from Set-up on Control endpoint, from modes other

than 0000

ignore ignore always Available to low speed devices, future USB spec

enhancements

ignore TX cnt ignore Available to low speed devices, future USB spec

enhancements

The ‘In’ column represents the SIE’s response to the token

type.

A disabled endpoint will remain such until firmware changes it,

and all endpoints reset to disabled.

Any Setup packet to an enabled and accepting endpoint will

be changed by the SIE to 0001 (NAKing). Any mode which

indicates the acceptance of a Setup will acknowledge it.

Most modes that control transactions involving an ending ACK

will be changed by the SIE to a corresponding mode which

NAKs follow on packets.

A Control endpoint has three extra status bits for PID (Setup,

In and Out), but must be placed in the correct mode to function

as such. Also a non-Control endpoint can be made to act as a

Control endpoint if it is placed in a non appropriate mode.

A ‘check’ on an Out token during a Status transaction checks

to see that the Out is of zero length and has a Data Toggle

(DTOG) of 1.

Document #: 38-08027 Rev. *B Page 21 of 32

[+] Feedback

Page 22

CY7C63413C

CY7C63513C

CY7C63613C

Figure 7. Decode table forTable 29: “Details of Modes for Differing Traffic Conditions”

Properties of incoming packet

Encoding Status bits What the SIE does to Mode bits

PID Status bits Interrupt?

End Point

Mode

3

2 1 0 Token count buffer dval DTOG DVAL COUNT

Setup

In

Out

The validity of the received data

The quality status of the DMA buffer

The number of received bytes

Setup

In Out ACK 3 210

Acknowledge phase completed

End Point

Mode

ResponseInt

Legend:

UC: unchanged TX: transmit

x: don’t care RX: receive

available for Control endpoint only

The response of the SIE can be summarized as follows:

1. the SIE will only respond to valid transactions, and will ignore non-valid ones;

2. the SIE will generate IRQ when a valid transaction is

completed or when the DMA buffer is corrupted

3. an incoming Data packet is valid if the count is <= 10 (CRC

inclusive) and passes all error checking;

4. a Setup will be ignored by all non-Control endpoints (in

appropriate modes);

5. an In will be ignored by an Out configured endpoint and vice

versa.

The In and Out PID status is updated at the end of a tran saction.

TX0: transmit 0-length packet

The Setup PID status is updated at the beginning of the Data

packet phase.

The entire EndPoint 0 mode and the Count register are locked

to CPU writes at the end of any transaction in which an ACK

is transferred. These registers are only unlocked upon a CPU

read of these registers, and only if that read happens after the

transaction completes. This represents about a 1-µs window

to which to the CPU is locked from register writes to these USB

registers. Normally the firmware does a register read at the

beginning of the ISR to unlock and get the mode register information. The interlock on the Mode and Count registers

ensures that the firmware recognizes the changes that the SIE

might have made during the previous transaction.

Document #: 38-08027 Rev. *B Page 22 of 32

[+] Feedback

Page 23

CY7C63413C

CY7C63513C

CY7C63613C

Table 29.Details of Modes for Differing Traffic Conditions

End Point Mode PID Set End Point Mode

3 2 1 0 token count buffer dval DTOG DVAL COUNT Setup In Out ACK 3 2 1 0 response int

Setup Packet (if accepting)

See Table 28 Setup <= 10 data valid updates 1 updates 1 UC UC 1 0 0 0 1 ACK yes

See Table 28 Setup > 10 junk x updates updates updates 1 UC UC UC NoChange ignore yes

See Table 28 Setup x junk invalid updates 0 updates 1 UC UC UC NoChange ignore yes

Disabled

0 0 0 0 x x UC x UC UC UC UC UC UC UC NoChange ignore no

Nak In/Out

0 0 0 1 Out x UC x UC UC UC UC UC 1 UC NoChange NAK yes

0 0 0 1 In x UC x UC UC UC UC 1 UC UC NoChange NAK yes

Ignore In/Out

0 1 0 0 Out x UC x UC UC UC UC UC UC UC NoChange ignore no

0 1 0 0 In x UC x UC UC UC UC UC UC UC NoChange ignore no

Stall In/Out

0 0 1 1 Out x UC x UC UC UC UC UC 1 UC NoChange Stall yes

0 0 1 1 In x UC x UC UC UC UC 1 UC UC NoChange Stall yes

Control Write

Normal Out/premature status In

1 0 1 1 Out <= 10 data valid updates 1 updates UC UC 1 1 1 0 1 0 ACK yes

1 0 1 1 Out > 10 junk x updates updates updates UC UC 1 UC NoChange ignore yes

1 0 1 1 Out x junk invalid updates 0 updates UC UC 1 UC NoChange ignore yes

1 0 1 1 In x UC x UC UC UC UC 1 UC 1 NoChange TX 0 yes

NAK Out/premature status In

1 0 1 0 Out <= 10 UC valid UC UC UC UC UC 1 UC NoChange NAK yes

1 0 1 0 Out > 10 UC x UC UC UC UC UC UC UC NoChange ignore no

1 0 1 0 Out x UC invalid UC UC UC UC UC UC UC NoChange ignore no

1 0 1 0 In x UC x UC UC UC UC 1 UC 1 NoChange TX 0 yes

Status In/extra Out

0 1 1 0 Out <= 10 UC valid UC UC UC UC UC 1 UC 0 0 1 1 Stall yes