CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

Low-speed USB Peripheral Controller

Cypress Semiconductor Corporation • 3901 North First Street • San Jose • CA 95134 • 408-943-2600

Document #: 38-08027 Rev. ** Revised June 4, 2002

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

TABLE OF CONTENTS

1.0 FEATURES .....................................................................................................................................5

2.0 FUNCTIONAL OVERVIEW ...... ...................... ........................ ..................... .. ..................................6

3.0 PIN ASSIGNMENTS .......................................................................................................................8

4.0 PROGRAMM I N G M OD E L ..... .. .. .............. .. ............. .. ............. ... ............. .. ............. ... ............. .. .........8

4.1 14-bit Program Counter (PC) ................. ..........................................................................................8

4.2 8-bit Accumulator (A) .......................................................................................................................8

4.3 8-bit Index Register (X) ................................................ .................... .................... ............................8

4.4 8-bit Program Stack Pointer (PSP) ..................................................................................................9

4.5 8-bit Data Stack Pointer (DSP) ........................................................................................................9

4.6 Address Modes ........................................................ ................................................... .....................9

4.6.1 Data ........................................................................................................................................................9

4.6.2 Direct ......................................................................................................................................................9

4.6.3 Indexed ...................................................................................................................................................9

5.0 INSTRUCTION SET SUMMARY ........................................................ .. .. ............................... .. .. .. ..11

6.0 MEMORY ORGANIZATION ..........................................................................................................12

6.1 Program Memory Organization ................................ ........................... .. .........................................12

6.2 Data Memor y O r ga n ization ............. .. .. ............. .............. .. ............. .. .............. .. ............. .. ................13

6.3 I/O Registe r S u m ma ry ........................ .. .............. .. ............. .. ............. ... ............. ............. ................14

7.0 CLOCKING ....................................................................................................................................15

8.0 RESET ................................................................. .............................. ............................................15

8.1 Power-On Reset (POR) .................................................................................................................15

8.2 Watch Dog Res e t (WDR) ........... .. .............. .. ............. .. .............. .. .. ............. ... ............. .. ..................16

9.0 GENERAL PURPOSE I/O PORTS ...............................................................................................16

9.1 GPIO Interrupt Enable Ports ..........................................................................................................17

9.2 GPIO Configuration Port ................................................................................................................18

10.0 DAC PORT ..................................................................................................................................19

10.1 DAC Port Int e rrupts ............... ............. ... ............. .. ............. .. .............. .. .. ............. ... ......................19

10.2 DAC Isink Re g i sters .. ............. .. .............. .. ............. .. ............. ... ............. .. ............. ... ......................20

11.0 USB SERIAL IN T E R F A CE ENGINE (SI E ) ................... .. ............. .. .............. .. ............. .. ..............20

11.1 USB Enum e ra tion ....... .. ............. ... ............. .. ............. .............. .. ............. .. .............. .. ....................20

11.2 PS/2 Opera t io n .... ... ............. .. ............. ... ............. .. ............. .. .............. .. ............. .. .........................20

11.3 USB Port Status and Control .......................................................................................................21

12.0 USB DEVICE ....... ... ............. .. ............. ... ............. .. ............. .. .............. .. ............. .. .........................21

12.1 USB Ports ............... .. ............. .. .............. .. .. ............. .. .............. .. ............. .. .............. ......................21

12.2 Device Endpoints (3) .................................................. ........................ .. ........................ ...............21

13.0 12-BIT FREE-RUNNING TIMER ............................................................ ............................. ........22

13.1 Timer (LSB) .................................................................................................................................22

13.2 Timer (MSB) ................................................................................................................................22

14.0 PROCESSOR STATUS AND CONTROL REGISTER ................................. .. ............................23

15.0 INTERRUPTS ..............................................................................................................................24

15.1 Interrupt Vectors ..........................................................................................................................24

Document #: 38-08027 Rev. ** Page 2 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

15.2 Interrupt Latency ..........................................................................................................................25

15.2.1 USB Bus Reset Interrupt ....................................................................................................................25

15.2.2 Timer Interrupt ................................. ...... ....... ...... ....... ...... ...... ....... ...... ................................................25

15.2.3 USB Endpoint Interrupts .....................................................................................................................25

15.2.4 DAC Interrupt ............... ....... ...... ....... ...... ....... ...... ....... ...... ...... .............................................................25

15.2.5 GPIO Interrupt ....................................................................................................................................25

16.0 TRUTH TABLES .........................................................................................................................26

17.0 ABSOLUTE M A X I M U M R A T INGS ......... ............. .. .. .............. .. ............. .. .............. .. ............. .. .....29

18.0 DC CHARACTERISTICS ............................................................................................................30

19.0 SWITCHING CHARACTERISTICS ............................................... .. ............................................31

20.0 ORDERIN G IN F O RMATION .............. ... ............. .. .. ............. ... ............. .. ............. ... ............. .. .......33

21.0 PACKAGE DIAGRAMS ................................. ................................. ............................................34

Document #: 38-08027 Rev. ** Page 3 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

LIST OF FIGURES

Figure 6-1. Pro g ra m M e mo ry Space with In te rrupt Vector T ab le ........... .............. .. ............. ............. ... . 12

Figure 7-1. Clo ck Oscillator On-c h i p Ci r cu i t ..... .. ............. .. .............. .. ............. .. .............. .. .....................15

Figure 8-1. Watch Dog Reset (W D R ) ... .. ............. .. .............. .. ............. .. .............. .. ............. .. .................16

Figure 9-1. Blo ck D ia g ra m of a GPIO Line .... .. ............. .. ............. ... ............. .. ............. ... .. ............. ........ 16

Figure 9-2. Por t 1 Data 0x01h (rea d/ w ri te ) .......................... .. ............. .. .............. .. .. ............. .. ...............17

Figure 9-3. Por t 2 Data 0x02h (rea d/ w ri te ) .......................... .. ............. .. .............. .. .. ............. .. ...............17

Figure 9-4. Por t 3 Data 0x03h (rea d/ w ri te ) .......................... .. ............. .. .............. .. .. ............. .. ...............17

Figure 9-5. DAC Port Data 0x30h (read/write) ........................................................... ........................... 17

Figure 9-6. Por t 0 Int e rr u p t E na b le 0x04h (writ e on ly ) ......... ............. .. ............. ... ............. .. ............. .. . ...17

Figure 9-7. Por t 1 Int e rr u p t E na b le 0x05h (writ e on ly ) ......... ............. .. ............. ... ............. .. ............. .. . ...17

Figure 9-8. Por t 2 Int e rr u p t E na b le 0x06h (writ e on ly ) ......... ............. .. ............. ... ............. .. ............. .. . ...17

Figure 9-9. Por t 3 Int e rr u p t E na b le 0x07h (writ e on ly ) ......... ............. .. ............. ... ............. .. ............. .. . ...17

Figure 10-1. Bl o ck D ia g ra m o f D A C P or t ......... .. ............. .. .............. .. ............. .. ... ............. .. ...................19

Figure 10-2. DAC Port Data 0x30h (read/write) ............................................................ .. ......................19

Figure 10-3. DAC Port Interrupt Enable 0x31h (write only) .......................................... ........................19

Figure 10-4. DAC Port Interrupt Polarity 0x32h (write o nly) .................................. ...................... .........19

Figure 10-5. DAC Port Isink 0x3 8 h to 0 x3 F h (write only) .......... ............. ... ............. .. ............. ... ............ 20

Figure 11-1. USB Status and Control Register 0x1Fh ..........................................................................21

Figure 12-1. USB Device Address Register 0x10h (read/write) ...........................................................21

Figure 12-2. USB Device Counter Registers 0x11h, 0x13h, 0x15h (read/write) ................ ..................22

Figure 13-1. Ti m e r B lo c k D ia g r a m .......... .. ............. ... ............. .. ............. .. .............. .. ............. .. ...............23

Figure 15-1. USB End Point Interrupt Enable Register 0x21h (read/write) ..........................................24

Figure 19-1. Cl o ck T im in g ................ .. .............. .. ............. .. .............. .. .. ............. ... ............. .. ................... 32

Figure 19-2. USB Data Signal Timing ...................................................................................................32

Figure 19-3. Rec e iver Jitter Tole ra n c e ..... .. .............. .. ............. .. .. .............. .. ............. .. .............. ............ 32

Figure 19-4. Di ff erential to EOP T ra n sition Skew and E O P Wid t h . ............. .. ............. ... ............. .. ........ 33

Figure 19-5. Differential Data Jitter ....................................................................................................... 33

LIST OF TABLES

Table 6-1. I/O Register Summary ........................................................................................................ 14

Table 15-1. Interrupt Vector Assignments ...........................................................................................24

Table 16-1. USB Register Mode Encoding ................................................. .. .......................... .............26

Table 16-2. Decode table forTable 16-3: “Details of Modes for Differing Traffic Conditions” ..............27

Table 16-3. Details of Modes for Differing Traffic Co nditions ..............................................................28

Document #: 38-08027 Rev. ** Page 4 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

1.0 Features

• Low-cost solution for low-speed applications such as mice, gamepads, keyboards, joystick and others

• USB Specification Compliance

—Conforms to USB Specification, Versions 1.1 and 2.0

—Conforms to USB HID Specification, Version 1.1

—Supports 1 device address and 3 data endpoints

—Integrated USB transceiver

• 8-bit RISC microcontroller

—Harvard architecture

—6-MHz external ceramic resonator

—12-MHz internal CPU clock

• Internal memory

—256 bytes of RAM

—4 Kbytes of EPROM (CY7C63411, CY7C63511)

—6 Kbytes of EPROM (CY7C63412, CY7C63512, CY7C63612)

—8 Kbytes of EPROM (CY7C63413, CY7C63513, CY7C63613)

• Interface can auto-configure to operate as PS2 or USB

•I/O port

—The CY7634XX/5XX have 24 General Purpose I/O (GPIO) pin s (Port 0 to 2) capable of sinki ng 7 mA per pin (typical)

—The CY7C636XX have 12 General-Purpose I/O (GPIO) pins (Port 0 to 2) capable of sinking 7 mA per pin (typical)

—The CY7C634XX/5XX have eight GPIO pi ns (Port 3) capable of sinkin g 12 mA per pin (typical) which can drive LEDs

—The CY7C636XX have four GPIO pins (Port 3) capable of sinking 12 mA per pin (typical) which can drive LEDs

—Higher current drive is available by connecting multiple GPIO pins together to drive a common output

—Each GPIO port can be configured as inputs w ith internal pull-ups or open drain outputs or traditional CMO S outputs

—The CY7C635XX has an additional eight I/O pins on a DAC port which has programmable current sink outputs

—Maskable interrupts on all I/O pins

• 12-bit free-running timer with one microsecond clock ticks

• Watch Dog Timer (WDT)

• Internal Power-On Reset (POR)

• Improved output drivers to reduce EMI

• Operating voltage from 4.0V to 5.5V DC

• Operating temperature from 0 to 70 degrees Celsius

• CY7C634XX available in 40-pin PDIP, 48-pin SSOP for production

• CY7C635XX available in 48-pin SSOP packages for production

• CY7C636XX available in 24-pin SOIC packages for production

• Industry-standard programmer support

Document #: 38-08027 Rev. ** Page 5 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

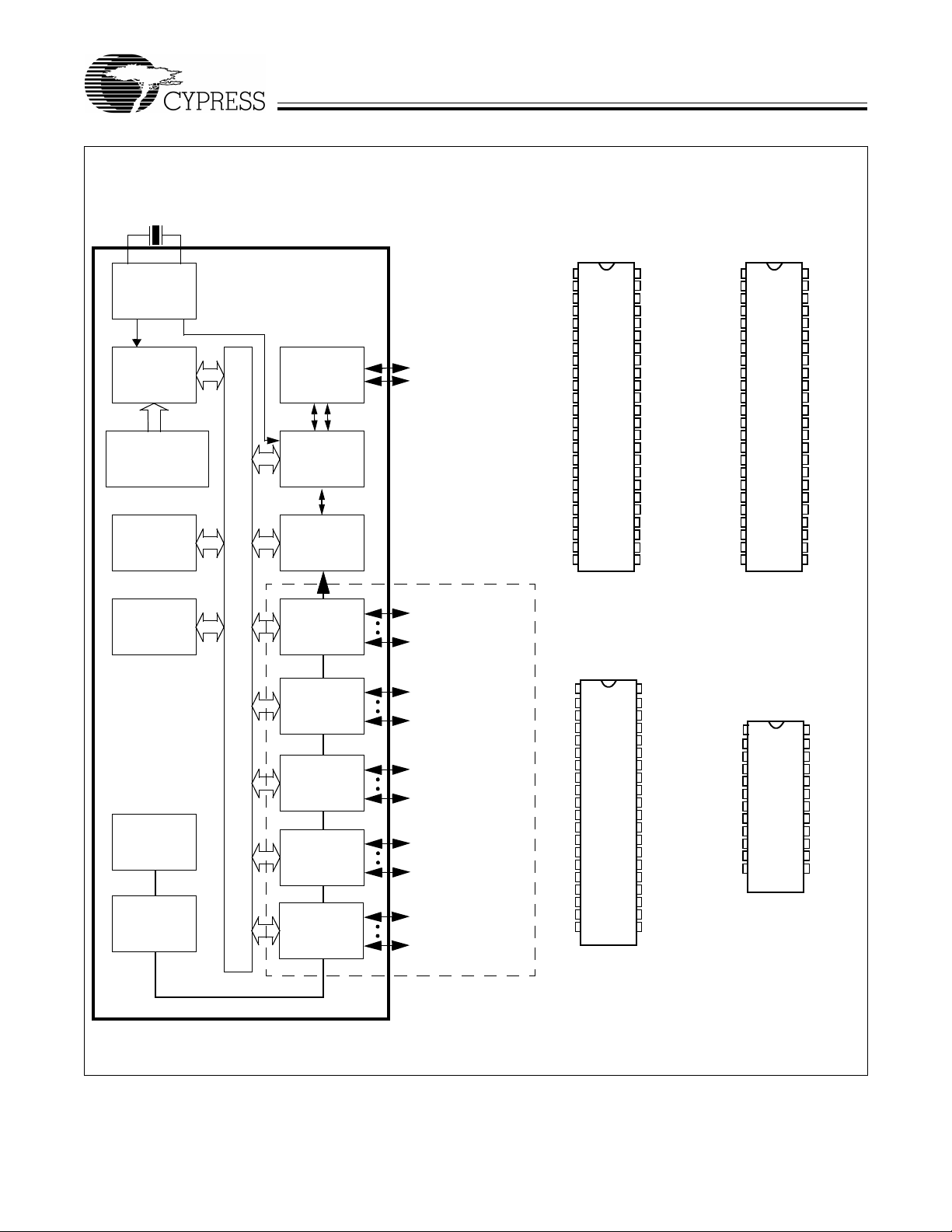

2.0 Functional Overview

The CY7C634XX/5XX/6XX are 8-bit RISC One Time Programmable (OTP) microcontrollers. The instruction set has been optimized specifical ly for USB operations alt hough, the microcon trollers can be used for a variety of non-USB emb edded applications.

The CY7C634XX/5XX feature 32 General-Purpose I/O (GPIO) pins and the CY7C636XX features 16 General-Purpose I/O

(GPIO) pins to sup port USB and o ther appli cations. Th e I/O pi ns ar e gr ouped into four po rts (Po rt 0, 1 , 2, a nd 3) where each po rt

can be configured as inputs with internal pull-ups, open drain outputs, or traditional CMOS outputs. The CYC634XX/5XX have

24 GPIO pins (Ports 0, 1, and 2) and th e CY7C636XX has 12 GPIO pins (Ports 0 and 1) that are rated at 7 mA ty pical sink current .

The CYC634XX/5XX has 8 GPIO pins (Port 3) and the CY7C636XX has 4 GPIO pins (Port 3) which are rated at 12 mA typical

sink current, which allows these pins to drive LEDs. Multiple GPIO pins can be connected together to drive a single output for

more drive current capacity. Additionally, each I/O pin can be used to generate a GPIO interrupt to the microcontroller. Note the

GPIO interrupts all share the same “GPIO” interrupt vector.

The CY7C635XX feat ures an additional 8 I/O pins in the DAC port. Every DA C pin includes an integrated 14-Koh m pull-up resisto r.

When a “1” is writte n t o a D AC I/O p in , th e o utpu t c urre nt sink is disabled and the ou tput pi n is driven high by the internal pull-up

resistor . When a “0” is writ ten to a DAC I/O pin, the i nternal pull-up is disab led and the output pin provides the prog rammed amount

of sink current. A DAC I/O pin can be used as an input with an internal pull-up by writing a “1” to the pin.

The sink current for each DAC I/O pin can be individually programmed to one of sixteen values using dedicated Isink registers.

DAC bits [1:0] can be used as high current outputs with a programmable sink current range of 3.2 to 16 mA (typical). DAC bits

[7:2] have a programmable current sink range of 0.2 to 1.0 mA (typical). Again, multiple DAC pins can be connected together to

drive a single output that requires more sink current capacity. Each I/O pin can be used to generate a DAC interrupt to the

microcontroller and the interrupt polarity for each DAC I/O pin is individually programmable. The DAC port interrupts share a

separate “DAC” interrupt vector.

The Cypress microc ontrollers use an extern al 6-MHz ceramic resonator to provide a reference to an internal cl ock generator . Thi s

clock generator reduces the clock-related noise emissions (EMI). The clock generator provides the 6- and 12-MHz clocks that

remain internal to the microcontroller.

The CY7C64XX/5XX/6XX are offered with multiple EPROM options to maximize flexibility and minimize cost. The CY7C63411

and the CY7C63511 have 4 Kilobytes of EPROM. The CY7C63412, CY7C63512, and CY7C63612 have 6 Kbytes of EPROM.

The CY7C63413, CY7C63513, and CY7C63613 have 8 Kbytes of EPROM.

These parts include Power-on Reset logic, a Watch Dog Timer, a vectored interrupt controller, and a 12-bit free-running timer.

The Power-On Reset (POR) logic detects when power is applied to the device, resets the logic to a known state, and begins

executing instruc tions at EPROM a ddress 0x0 000h. Th e W atch Dog T imer can be used t o ensure the firmw are neve r gets sta lled

for more than approximatel y 8 ms. The firmware can get stall ed for a variety of reasons , including errors in the co de or a hardware

failure such as waitin g for an interrupt that neve r occurs. The firmware sh ould clear the W atch Dog T imer periodically. If the Watch

Dog Timer is not cleared for approximately 8 ms, the microcontroller will generate a hardware watch dog reset.

The microcontroller su pports eight maskab le interrupts in the v ectored interrupt cont roller . Interrupt sour ces include the USB BusReset, th e 12 8-µs and 1.024-ms outputs from the free-running timer, three USB endpoints, the DAC port, and the GPIO ports.

The timer bits cause an interrupt (if enabled) when the bit toggles from LOW “0” to HIGH “1.” The USB endpoints interrupt after

either the USB host or the USB controller sends a packet to the USB. The DAC ports have an additional level of masking that

allows the user to select which DAC inputs can cause a DAC interrupt. The GPIO ports also have a level of masking to select

which GPIO inputs can cause a GPIO interrupt. For additional flexibility, the input transition polarity that causes an interrupt is

programmable for each pin of the DAC port. Input transition polarity can be programmed for each GPIO port as part of the port

configuration. The interrupt polarity can be either rising edge (“0” to “1”) or falling edge (“1” to “0”).

The free-running 12-b it time r cloc ked at 1 MHz pro vides two inter rupt sou rce s as n oted ab ove (12 8-µs a nd 1.02 4-ms). The timer

can be used to measure th e duration of a n event unde r firmware con trol by readi ng the timer twi ce: once at the st art of the eve nt,

and once after the event is complete. The difference between the two readings indicates the duration of the event measured in

microseconds. The upper four bits of the timer are latched into an internal register when the firmware reads the lower eight bits.

A read from the upper four bits actual ly reads data from the internal regist er , instead of the timer . This featur e eliminates th e need

for firmware to attempt to compensate if the upper four bits happened to increment right after the lower 8 bits are read.

The CY7C634XX/5XX/6XX in clude an integr ated USB seria l interfac e engi ne (S IE) that supp orts th e integ rated p eripher als. Th e

hardware supports one U SB device address with three endpoi nts. The SIE allows the USB host to commu nicate with the f unction

integrated into the microcontroller.

Finally, the CY7C634XX/5XX/6 XX supp ort PS/2 o perati on. Wit h appro priate firmware the D+ and D– USB pins can also be used

as PS/2 clock and data signals. Products utilizing these devices can be used for USB and/or PS/2 operation with appropriate

firmware.

Document #: 38-08027 Rev. ** Page 6 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

.

Logic Block Diagram

6-MHz ceramic resonator

OSC

12 MHz

4/6/8 Kbyte

6 MHz

12-MHz

8-bit

CPU

EPROM

RAM

256 byte

8-bit Bus

12-bit

Timer

Watch Dog

Timer

Power-on

Reset

USB

Transceiver

USB

SIE

Interrupt

Controller

GPIO

PORT 0

GPIO

PORT 1

GPIO

PORT 2

GPIO

PORT 3

DAC

PORT

D+

D–

TOP VIEW

P0[0]

P0[7]

P1[0]

P1[7]

P2[0]

P2[7]

P3[0]

P3[7]

DAC[0]

DAC[7]

USB

PS/2

PORT

See Note 1

High Current

Outputs

Pin Configuration

48-pin SSOP

1

D+

D–

P3[7]

P3[5]

P3[3]

P3[1]

P2[7]

P2[5]

P2[3]

P2[1]

P1[7]

P1[5]

P1[3]

P1[1]

DAC[7]

DAC[5]

P0[7]

P0[5]

P0[3]

P0[1]

DAC[3]

DAC[1]

V

PP

Vss

CY7C63411/12/13

40-pin PDIP

40-pin CerDIP

D+

D–

P3[7]

P3[5]

P3[3]

P3[1]

P2[7]

P2[5]

P2[3]

P2[1]

P1[7]

P1[5]

P1[3]

P1[1]

P0[7]

P0[5]

P0[3]

P0[1]

V

PP

Vss

48

2

47

3

46

4

45

5

44

43

6

7

42

8

41

9

40

10

39

11

38

12

37

13

36

35

14

15

34

16

33

17

32

18

31

19

30

20

29

21

28

22

27

23

26

24 25

40

1

39

2

38

3

37

4

36

5

35

6

34

7

33

8

32

9

31

10

30

11

29

12

28

13

27

14

26

15

25

16

24

17

23

18

19

22

20

21

TOP VIEW

V

CC

Vss

P3[6]

P3[4]

P3[2]

P3[0]

P2[6]

P2[4]

P2[2]

P2[0]

P1[6]

P1[4]

P1[2]

P1[0]

DAC[6]

DAC[4]

P0[6]

P0[4]

P0[2]

P0[0]

DAC[2]

DAC[0]

XTAL

XTAL

V

CC

V

SS

P3[6]

P3[4]

P3[2]

P3[0]

P2[6]

P2[4]

P2[2]

P2[0]

P1[6]

P1[4]

P1[2]

P1[0]

P0[6]

P0[4]

P0[2]

P0[0]

XTAL

XTAL

OUT

IN

OUT

IN

48-pin SSOP

48-pin SideBraze48-pin SideBraze

1

D+

2

D–

3

P3[7]

4

P3[5]

5

P3[3]

6

P3[1]

7

P2[7]

P2[5]

8

9

P2[3]

10

P2[1]

11

P1[7]

P1[5]

12

13

P1[3]

14

P1[1]

15

NC

16

NC

17

P0[7]

18

P0[5]

19

P0[3]

20

P0[1]

NC

21

NC

22

V

23

PP

Vss

24 25

CY7C63612/13

24-pin SOIC

1

D+

2

D–

3

P3[7]

4

P3[5]

5

P1[3]

6

P1[1]

7

P0[7]

P0[5]

9

P0[3]

10815

P0[1]

11

V

PP

12

Vss

TOP VIEW

48

V

CC

Vss

47

46

P3[6]

P3[4]

45

P3[2]

44

P3[0]

43

P2[6]

42

P2[4]

41

P2[2]

40

39

P2[0]

38

P1[6]

37

P1[4]

36

P1[2]

35

P1[0]

34

NC

33

NC

P0[6]

32

31

P0[4]

30

P0[2]

29

P0[0]

NC

28

NC

27

XTAL

26

24

23

22

21

20

19

18

17

16

14

13

XTAL

V

CC

V

SS

P3[6]

P3[4]

P1[2]

P1[0]

P0[6]

P0[4]

P0[2]

P0[0]

XTAL

XTAL

OUT

IN

OUT

IN

Note:

1. CY7C63612/13 is not bonded out for all GPIO pins shown in Logic Block Diagram. Refer to pin configuration diagram for bonded out pins. See note on page 17

for firmware code needed for unused GPIO pins.

Document #: 38-08027 Rev. ** Page 7 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

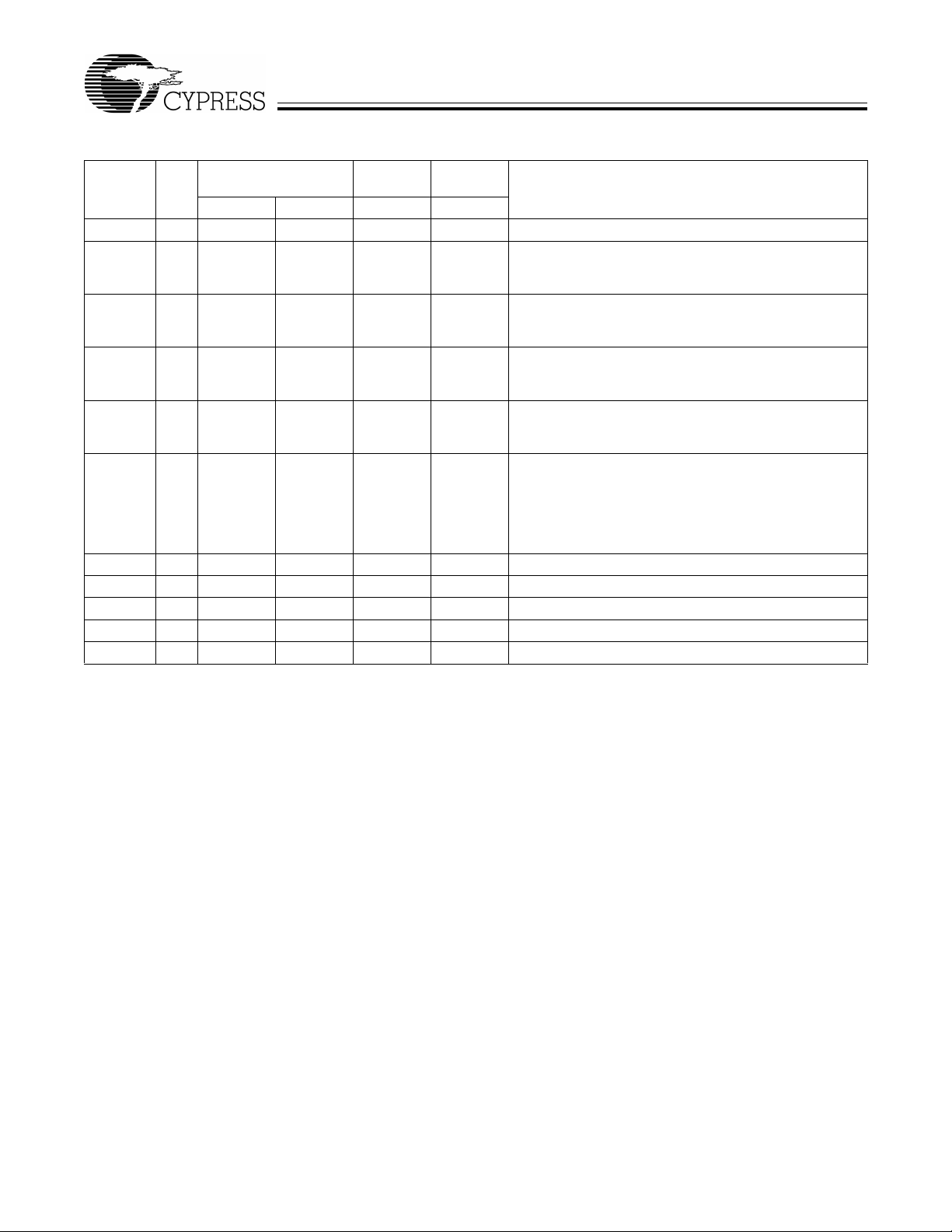

3.0 Pin Assignments

CY7C63411/12/13

Name I/O

D+, D– I/O 1,2 1,2 1,2 1,2 USB differential data; PS/2 clock and data signals

P0[7:0]

P1[3:0]

P2

P3[7:4]

DAC I/O n/a n/a 15,34,16,

XTAL

IN

XTAL

OUT

V

PP

V

CC

Vss 20,39 24,47 24,47 12,23 Ground

15,26,16,

25,17,24,

I/O

I/O

I/O

I/O

IN 21 25 25 13 6-MHz ceramic resonator or external clock input

OUT 22 26 26 14 6-MHz ceramic resonator

18,23

11,30,12,

29,13,28,

14,27

7,34,8,

33,9,32,

10,31

3,38,4,

37,5,36,

6,35

19 23 23 11 Programming voltage supply, ground during operation

40 48 48 24 Voltage supply

17,32,18,

31,19,30,

20,29

11,38,12,

37,13,36,

14,35

7,42,8,

41,9,40,

10,39

3,46,4,

45,5,44,

6,43

CY7C635

11/12/13

17,32,18,

31,19,30,

20,29

11,38,12,

37,13,36,

14,35

7,42,8,

41,9,40,

10,39

3,46,4,

45,5,44,

6,43

33,21,28,

22,27

CY7C636

12/13

Description40-Pin 48-Pin 48-Pin 24-Pin

7,18,8,

17,9,16,

10,15

5,20,6,19GPIO Port 1 capable of sink ing 7 mA (typical). P1[7:4] not

n/a GPIO Port 2 not bonded out on CY7C63612/13. See

3,22,4,21GPIO Port 3 capable of sinking 12 mA (typical). P3[3:0]

n/a DAC I/O Port with programmable current sink outputs.

GPIO port 0 capable of sinking 7 mA (typical)

bonded out on CY7C63612/13. See note on page 17

for firmware code needed for unused pins.

note on page 17 for firmware code needed for unused

pins.

not bonded out on CY7C63612/13. See note on

page 17 for firmware code needed for unused pins.

DAC[1:0] offer a programmable range of 3.2 to 16 mA

typical. DAC[7:2] have a programmable sink current

range of 0.2 to 1.0 mA ty pi ca l. D AC I/O Port not bonded

out on CY7C63612/13. See not e on page 17 for firmware

code needed for unused pins.

4.0 Programming Model

4.1 14-bit Program Counter (PC)

The 14-bit Program Counter (PC) allows access for up to 8 kilobytes of EPROM using the CY7C634XX/5XX/6XX architecture.

The program counter is cleared during reset, such that the first instruction executed after a reset is at address 0x0000h. This is

typically a jump instruction to a reset handler that initializes the application.

The lower eight bits of the program counter are incremented as instructions are loaded and executed. The upper six bits of the

program counter are increm ented by exe cuting an XPAGE instr uction . As a result, the la st instruc tion execu ted within a 256 -byte

“page” of sequential code should be an XPAGE instruction. The assembler directive “XPAGEON” will cause the assembler to

insert XPAGE instructions automatically. As instructions can be either one or two bytes long, the assembler may occasionally

need to insert a NOP followed by an XPAGE for correct execution.

The program counter of the next instructio n to be executed, ca rry flag, and zero fla g are saved as two bytes on the program sta ck

during an interrupt acknowledge or a CALL instruction. The program counter, carry flag, and zero flag are restored from the

program stack only during a RETI instruction.

Please note the program counter cannot be accessed directly by the firmware. The program stack can be examined by reading

SRAM from location 0x00 and up.

4.2 8-bit Accumulator (A)

The accumulator is the general purpose, do everything register in the architecture where results are usually calculated.

4.3 8-bit Index Register (X)

The index register “X” is available to the firmware as an auxiliary a ccumulator . The X regist er also allow s the processo r to perform

indexed operations by loading an index value into X.

Document #: 38-08027 Rev. ** Page 8 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

4.4 8-bit Program Stack Pointer (PSP)

During a reset, the Progra m Stac k Pointer (PSP) is s et to z ero. This mean s the program “stack” starts at RAM addre ss 0x 00 an d

“grows” upward from there. Note the program stack pointe r is directly addressable under firmware co ntrol, usin g the MOV PSP,A

instruction. The PSP supports interrupt service under hardware control and CALL, RET, and RETI instructions under firmware

control.

During an interrupt acknowledge, interrupts are disabled and the 14-bit program counter, carry flag, and zero flag are written as

two bytes of data memory. The first byte is stored in the memory addressed by the program stack pointer, then the PSP is

incremented. The second byte is stored in memory addressed by the program stack pointer and the PSP is incremented again.

The net effect i s t o s tore the prog ram co unt er an d fl ags on the program “stack” and increment the program stack pointer by two.

The Return From Interrupt (RETI) instruction dec rements th e program stack po inter , th en restores th e second byte from memory

addressed by the PSP. The program stack pointer is decremented again and the first byte is restored from memory addressed

by the PSP. After the program counter and flags have been restore d from stack, the interrupts are enabled. The ef fect is to restore

the program counter and flags from the program stack, decrement the program stack pointer by two, and re-enable interrupts.

The Call Subroutine (CALL) in struction stores the program counter and flags on the progra m stack and increments the PSP b y two.

The Return From Subroutine (RET) instruction restores the program counter, but not the flags, from program stack and decre-

ments the PSP by two.

4.5 8-bit Data Stack Pointer (DSP)

The Data Stack Pointer (DSP) supports PUSH and POP instructions that use the data stack for temporary storage. A PUSH

instruction will pre-decremen t the DSP, then wri te data to the memory locatio n address ed by the DSP. A POP instruction will rea d

data from the memory location addressed by the DSP, then post-increment the DSP.

During a reset, the Data Stack Pointer will be set to zero. A PUSH instruction when DSP equal zero will write data at the top of

the data RAM (address 0xFF). This would write data to the memory area reserved for a FIFO for USB endpoint 0. In non-USB

applications, this works fine and is not a proble m. For USB ap plicat ions, it is strong ly recomm ended th at the DSP is load ed aft er

reset just below the USB DMA buffers.

4.6 Address Modes

The CY7C63612/13 microcontrollers support three addressing modes for instructions that require data operands: data, direct,

and indexed.

4.6.1 Data

The “Data” addre ss mode refers to a data ope rand that is actual ly a constant encod ed in the instructi on. As an example, cons ider

the instruction that loads A with the constant 0xE8h:

• MOV A,0E8h

This instruction will require two bytes of code where the first byte identifies the “MOV A” instruction with a data operand as the

second byte. The second byte of the instruction will be the constant “0xE8h”. A constant may be referred to by name if a prior

“EQU” statement assigns the constant value to the name. For example, the following code is equivalent to the example shown

above:

• DSPINIT: EQU 0E8h

• MOV A,DSPINIT

4.6.2 Direct

“Direct” address mode is used when the data operand is a variable stored in SRAM. In that case, the one byte address of the

variable is encoded in the instruction. As an example, consider an instruction that loads A with the contents of memory address

location 0x10h:

• MOV A, [10h]

In normal usage, variable names are assigned to variable addresses using “EQU” statements to improve the readability of the

assembler source code. As an example, the following code is equivalent to the example shown above:

• buttons: EQU 10h

• MOV A,[buttons]

4.6.3 Indexed

“Indexed” address mode allows the firmware to manipulate arrays of data stored in SRAM. The address of the data operand is

the sum of a constant encoded in the instruction and the contents of the “X” register. In normal usage, the constant will be the

“base” address of an array of data and the X register will contain an index that indicates which element of the array is actually

addressed:

Document #: 38-08027 Rev. ** Page 9 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

• array: EQU 10h

• MOV X,3

• MOV A,[x+array]

This would have the effect of loading A with the fourth element of the SRAM “array” that begins at address 0x10h. The fourth

element would be at address 0x13h.

Document #: 38-08027 Rev. ** Page 10 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

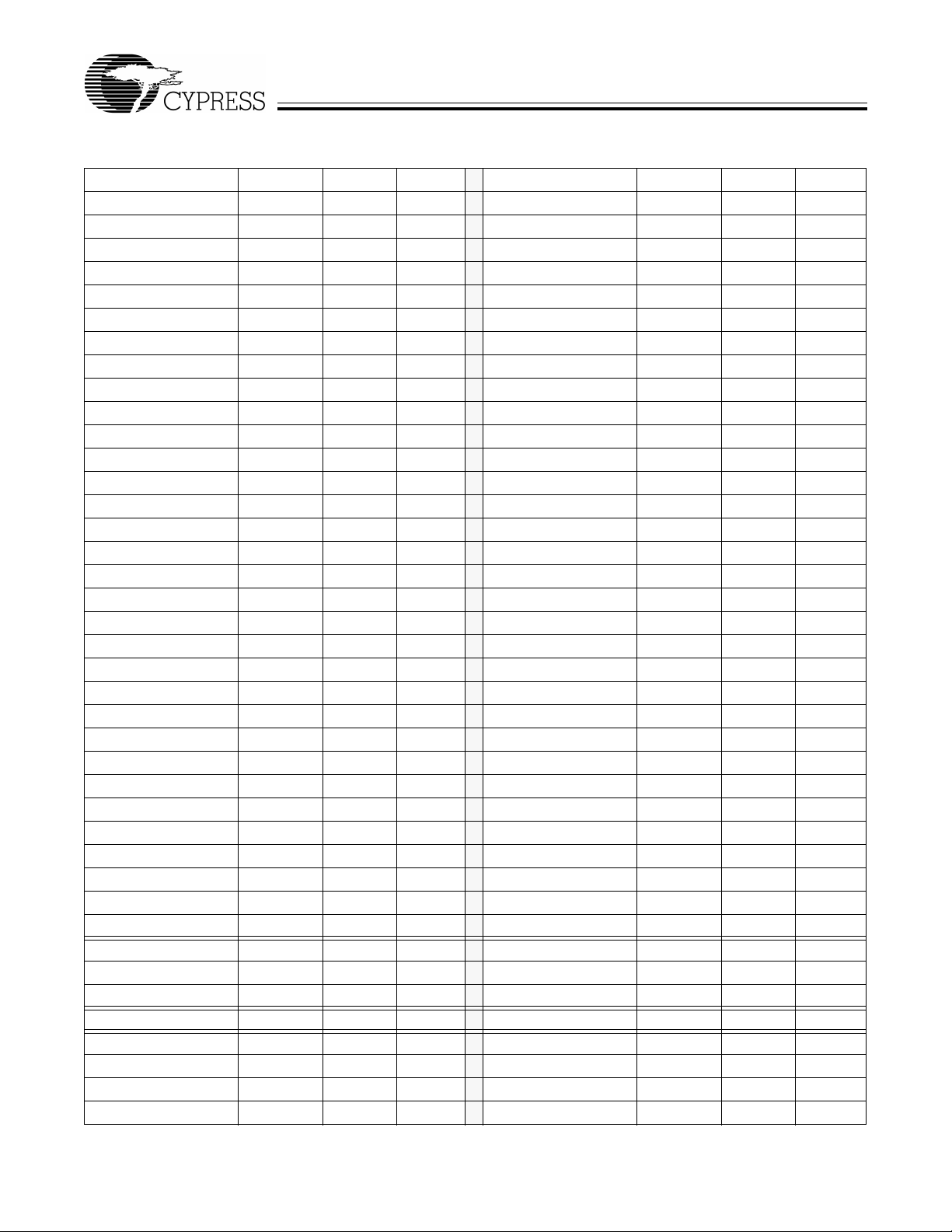

5.0 Instruction Set Summary

MNEMONIC operand opcode cycles MNEMONIC operand opcode cycles

HAL T 00 7 NOP 20 4

ADD A,expr data 01 4 INC A acc 21 4

ADD A,[expr] direct 02 6 INC X x 22 4

ADD A,[X+expr] index 03 7 INC [expr] direct 23 7

ADC A,expr data 04 4 INC [X+expr] index 24 8

ADC A,[expr] direct 05 6 DEC A acc 25 4

ADC A,[X+expr] index 06 7 DEC X x 26 4

SUB A,expr data 07 4 DEC [expr] direct 27 7

SUB A,[expr] direct 08 6 DEC [X+expr] index 28 8

SUB A,[X+expr] index 09 7 IORD expr address 29 5

SBB A,expr data 0A 4 IOWR expr address 2A 5

SBB A,[expr] direct 0B 6 POP A 2B 4

SBB A,[X+expr] index 0C 7 POP X 2C 4

OR A,expr data 0D 4 PUSH A 2D 5

OR A,[expr] direct 0E 6 PUSH X 2E 5

OR A,[X+expr] index 0F 7 SWAP A,X 2F 5

AND A,expr data 10 4 SWAP A,DSP 30 5

AND A,[expr] direct 11 6 MOV [expr],A direct 31 5

AND A,[X+expr] index 12 7 MOV [X+expr],A index 32 6

XOR A,expr data 13 4 OR [expr],A direct 33 7

XOR A,[expr] direct 14 6 OR [X+expr],A index 34 8

XOR A,[X+expr] index 15 7 AND [expr],A direct 35 7

CMP A,expr data 16 5 AND [X+expr],A index 36 8

CMP A,[expr] direct 17 7 XOR [expr],A direct 37 7

CMP A,[X+expr] index 18 8 XOR [X+expr],A index 38 8

MOV A,expr data 19 4 IOWX [X+expr] index 39 6

MOV A,[expr] direct 1A 5 CPL 3A 4

MOV A,[X+expr] index 1B 6 ASL 3B 4

MOV X,expr data 1C 4 ASR 3C 4

MOV X,[expr] direct 1D 5 RLC 3D 4

reserved 1E RRC 3E 4

XPAGE 1F 4 RET 3F 8

MOV A,X 40 4 DI 70 4

MOV X,A 41 4 EI 72 4

MOV PSP,A 60 4 RETI 73 8

CALL addr 50-5F 10

JMP addr 80-8F 5 JC addr C0-CF 5

CALL addr 90-9F 10 JNC addr D0-DF 5

JZ addr A0-AF 5 JACC addr E0-EF 7

JNZ addr B0-BF 5 INDEX addr F0-FF 14

Document #: 38-08027 Rev. ** P age 11 of 36

FOR

FOR

6.0 Memory Organization

6.1 Program Memory Organization

after reset Address

14-bit PC 0x0000 Program execution begins here after a reset

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

0x0002 USB Bus Reset interrupt vector

0x0004 128-µs timer interrupt vector

0x0006 1.024-ms timer interrupt vector

0x0008 USB address A endpoint 0 interrupt vector

0x000A USB address A endpoint 1 interrupt vector

0x000C USB address A endpoint 2 interrupt vector

0x000E Reserved

0x0010 Reserved

0x0012 Reserved

0x0014 DAC interrupt vector

0x0016 GPIO interrupt vector

0x0018 Reserved

0x001A Program Memory begins here

0x0FFF

0x17FF 6-KB PROM ends here (CY7C63612)

(8K - 32 bytes)

0x1FDF 8-KB PROM ends here (CY7C63613)

Figure 6-1. Program Memory Space with Interrupt Vector Table

Document #: 38-08027 Rev. ** Page 12 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

6.2 Data Memory Organization

The CY7C63612/13 microcontrollers provide 256 bytes of data RAM. In normal usage, the SRAM is partitioned into four areas:

program stack, data stack, user var iab les and USB end poi nt FIFO s as sho w n belo w:

after reset Address

8-bit PSP 0x00 Program Stack begins here and grows upward

8-bit DSP user Data Stack begins here and grows downward

The user determines the amount of memory required

User Variables

0xE8

USB FIFO for Address A endpoint 2

0xF0

0xF8

To p of RAM Memory 0xFF

USB FIFO for Address A endpoint 1

USB FIFO for Address A endpoint 0

Document #: 38-08027 Rev. ** Page 13 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

6.3 I/O Register Summary

I/O registers are accessed via the I/O Read (IO RD) and I/O W ri te (IOWR, IOW X) instru ction s. IORD reads the selecte d port into

the accumulator. IOWR writes data from the accumulator to the selected port. Indexed I/O Write (IOWX) adds the contents of X

to the address in the instruction to form the port address and writes data from the accumulator to the specified port. Note that

specifying address 0 (e.g., IOWX 0h) means the I/O port is selected solely by the contents of X.

Table 6-1. I/O Register Summary

Register Name I/O Address Read/Write Function

Port 0 Data 0x00 R/W GPIO Port 0

Port 1 Data 0x01 R/W GPIO Port 1

Port 2 Data 0x02 R/W GPIO Port 2

Port 3 Data 0x03 R/W GPIO Port 3

Port 0 Interrupt Enable 0x04 W Interrupt enable for pins in Port 0

Port 1 Interrupt Enable 0x05 W Interrupt enable for pins in Port 1

Port 2 Interrupt Enable 0x06 W Interrupt enable for pins in Port 2

Port 3 Interrupt Enable 0x07 W Interrupt enable for pins in Port 3

GPIO Configuration 0x08 R/W GPIO Ports Configurations

USB Device Address A 0x10 R/W USB Device Address A

EP A0 Counter Register 0x11 R/W USB Address A, Endpoint 0 counter register

EP A0 Mode Register 0x12 R/W USB Address A, Endpoint 0 configuration register

EP A1 Counter Register 0x13 R/W USB Address A, Endpoint 1 counter register

EP A1 Mode Register 0x14 R/C USB Address A, Endpoint 1 configuration register

EP A2 Counter Register 0x15 R/W USB Address A, Endpoint 2 counter register

EP A2 Mode Register 0x16 R/C USB Address A, Endpoint 2 configuration register

USB Status & Control 0x1F R/W USB upstream port traffic status and control register

Global Interrupt Enable 0x20 R/W Global interrupt enable register

Endpoint Interrupt Enable 0x21 R/W USB endpoint interrupt enables

Timer (LSB) 0x24 R Lower eight bits of free-running timer (1 MHz)

Timer (MSB) 0x25 R Upper four bits of free-runn ing time r tha t are la tch ed

WDR Clear 0x26 W Watch Dog Reset clear

DAC Data 0x30 R/W DAC I/O

DAC Interrupt Enable 0x31 W Interrupt enable for each DAC pin

DAC Interrupt Polarity 0x32 W Interrupt polarity for each DAC pin

DAC Isink 0x38-0x3F W One four bit sink current register for each DAC pin

Processor Status & Control 0xFF R/W Microprocessor status and control

Note:

2. DAC I/O Port not bonded out on CY7C63612/13. See note on page 17 for firmware code needed for unused GPIO pins.

when the lower eight bits are read.

[2]

[2]

[2]

[2]

Document #: 38-08027 Rev. ** Page 14 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

7.0 Clocking

Clock Distribution

clk1x

(to USB SIE)

clk2x

(to Microcontroller)

Clock

Doubler

30 pF

30 pF

Figure 7-1. Clock Oscillator On-chip Circuit

The XTALIN and XTAL

external oscillator can be connected to these pins to provide a reference frequency for the internal clock distribution and clock

are the clock pins to the microcontroller. The user can connect a low-cost ceramic resonator or an

OUT

doubler.

An external 6 MHz clock can be applied to th e XT AL

pin is not permissible as the internal clock is effectively shorted to ground.

pin if the XTAL

IN

pin is left open. Please note that grounding the XT AL

OUT

XTALOUT

XTALIN

OUT

8.0 Reset

The USB Controller supp orts three types of re sets. All registe rs are restored to t heir default state s during a reset. The USB Device

Addresses are set to 0 and all inte rrupts are disabled. In ad dition, the Program Stack Po inter (PSP) and Data Stack Pointer (DSP)

are set to 0x00. For USB applications, the firmware should set the DSP below 0xE8h to avoid a memory conflict with RAM

dedicated to USB FIFOs. The assembly instructions to do this are shown below:

Mov A, E8h ; Move 0xE8 hex into Accumulator

Swap A,dsp ; Swap accumulator value int o dsp register

The three reset types are:

1. Power-On Reset (POR)

2. Watch Dog Reset (WDR)

3. USB Bus Reset (non hardware reset)

The occurrence of a res et is rec orde d i n t he Proc es sor Stat us and Control Register l ocate d a t I/O a ddre ss 0 xFF. Bits 4, 5, and 6

are used to record the occurrence of POR, USB Reset, and WDR respectively. The firmware can interrogate these bits to

determine the cause of a reset.

The microcontroller begins execution from ROM address 0x0000h after a POR or WDR reset. Although this looks like interrupt

vector 0, there is an important difference. Reset processing does NOT push the program counter, carry flag, and zero flag onto

program stack. That means the reset handler in firmware should initialize the hardware and begin executing the “main” loop of

code. Attempting to execute either a RET or RETI in the reset handler will cause unpredictable execution results.

8.1 Power-On Reset (POR)

Power-On Reset (POR) occurs every time the VCC voltage to the device ramps from 0V to an internal ly define d trip volta ge (V rst)

of approximately 1/2 full supply voltage. In addition to the normal reset initialization noted under “Reset,” bit 4 (PORS) of the

Processor Status and Control Register is set to “1” to indicate to the firmware that a Power-On Reset occurred. The POR event

forces the GPIO p orts i nto i npu t m od e (hig h im ped anc e), an d the s tate o f Po rt 3 b it 7 is us ed to c on trol ho w the part will respond

after the POR releases.

If Port 3 bit 7 is HIGH (pulled to V

permanent power down/suspend mode, waiting for the USB IO to go to one of Bus Reset, K (resume) or SE0. If Port 3 bit 7 is

still HIGH when the part comes out of suspend, then a 128-µs timer starts, delaying CPU operation until the ceramic resonator

has stabilized.

If Port 3 bit 7 was LOW (pulled to V

continuing to run as reset.

Firmware should clear the POR Status (PORS) bit in register FFh before going into suspend as this status bit selects the 128-µs

or 96-ms start-up timer value as follows: IF Port 3 bit 7 is HIGH then 128-µs is always used; ELSE if PORS is HIGH then 128-ms

is used; ELSE 128-µs is used.

) and the USB IO are at the idle state (DM HIGH and DP LOW) the part will go into a semi-

CC

) the part will start a 96-ms timer, delaying CPU operation until VCC has stabili zed, th en

SS

Document #: 38-08027 Rev. ** Page 15 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

8.2 Watch Dog Reset (WDR)

The Watc h Dog T imer Reset (WDR) occur s when the Most Signific ant Bit (MSB) o f the 2-bit W atch Dog T imer Regist er transition s

from LOW to HIGH. In addition to the normal reset initialization noted under “Reset,” bit 6 of the Processor Status and Control

Register is set to “1” to indicate to the firmware that a Watch Dog Reset occurred.

8.192 ms

to 14.336 ms

2.048 ms

At least 8.192 ms

since last write to WDT

WDR goes high

for 2.048 ms

Execution begins at

Reset Vector 0X00

Figure 8-1. Watch Dog Reset (WDR)

The Watch Dog Timer is a 2-bit timer clocked by a 4.096-ms clock (bit 11) from the free-running timer. Writing any value to the

write-only Watch Dog Clear I/O port (0x26h) will clear the Wa tch Dog Timer.

In some applications , th e Watch Dog Timer may be cleared in the 1 .02 4-m s ti me r inte rrup t service routine. If the 1.024-m s tim er

interrupt se r vi ce ro ut i n e do es not ge t ex ec u ted f o r 8. 1 9 2 ms or m o re , a Watch D o g Timer R es et w i l l oc cu r. A Watch Dog Timer

Reset lasts for 2.048 ms after which the microcontroller begins execution at ROM address 0x0000h. The USB transmitter is

disabled by a Watch Dog Reset because the USB Device Address Register is cleared. Otherwise, the USB Controller would

respond to all address 0 transactions. The USB transmitter remains disabled until the MSB of the USB address register is set.

9.0 General Purpose I/O Ports

V

Internal

Data Bus

GPIO

CFG

Port Write

Internal

Buffer

Data

Out

Latch

mode

2 bits

Control

Q1

7 kΩ

Q2

CC

Q3

ESD

GPIO

Pin

Port Read

Interrupt

Enable

Control

to Interrupt

Controller

Figure 9-1. Block Diagram of a GPIO Line

Ports 0 to 2 provide 24 GPIO pins that can be read or written. Each port (8 bits) can be configured as inputs with internal pullups, open drain outputs, or traditional CMOS outputs. Please note an open drain output is also a high-impedance (no pull-up)

input. All of the I/O pins within a gi ven port have the same conf iguration. Ports 0 to 2 are con sidered low curren t drive with typical

current sink capability of 7 mA.

The internal pull-up resis tors are typically 7 kΩ. Two fac tors gov ern the enablin g and d isabling of the internal pull-up resisto rs: the

port configuration selected in the GPIO Configuration register and the state of the output data bit. If the GPIO Configuration

selected is “Resistive” and the output data bit is “1,” then the internal p ull-up re sisto r is ena bled for t hat GPIO pin. O therwis e, Q1

is turned off and the 7-kΩ pull-up is disabled. Q2 is “ON” to sink current whenever the output data bit is written as a “0.” Q3

Document #: 38-08027 Rev. ** Page 16 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

provides “HIGH” source current when the GPIO port is configured for CMOS outputs and the output data bit is written as a “1”.

Q2 and Q3 are sized to sink and source, respectively, roughly the same amount of current to support traditional CMOS outputs

with symmetric drive.

P0[7] P0[6] P0[5] P0[4] P0[3] P0[2] P0[1] P0[0]

P1[7] P1[6] P1[5] P1[4] P1[3] P1[2] P1[1] P1[0]

Figure 9-2. Port 1 Data 0x01h (read/write)

P2[7] P2[6] P2[5] P2[4] P2[3] P2[2] P2[1] P2[0]

Figure 9-3. Port 2 Data 0x02h (read/write)

P3[7] P3[6] P3[5] P3[4] P3[3] P3[2] P3[1] P3[0]

Figure 9-4. Port 3 Data 0x03h (read/write)

Low current outputs

0.2 mA to 1.0 mA typical

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

Figure 9-5. DAC Port Data 0x30h (read/write)

Port 3 has eight GPIO pins. Port 3 (8 bits) can be configured as inputs with internal pull-ups, open drain outputs, or traditional

CMOS outputs. An open drain output is also a high-impedance input. Port 3 offers high current drive with a typical current sink

capability of 12 mA. The internal pull-up resistors are typically 7 kΩ.

Note: Special care should be exercised with any unused GPIO data bits. An unused GPIO data bit, either a pin on the chip or a

port bit that is not bonded on a particular package, must no t be l eft fl oa ting when the d ev ic e en ters the s us pe nd s tate . If a G PIO

data bit is left floating, the leakage current caused by the floating bit may violate the suspend current limitation specified by the

USB Specification. I f a ‘1’ is wr itten to the unus ed data bit and the port is confi gur ed with ope n drain ou tputs, the un used d ata bit

will be in an indeterminate state. Therefore, if an unused port bit is programmed in open-drain mode, it must be written with a ‘0.’

Notice that the CY7C63612/13 will always require that data bits P1[7:4], P2[7:0], P3[3:0] and DAC[7:0] be written with a ‘0.’

During reset, all of the GPIO pins are set to output “1” (input) with the internal pull-up enabled. In this state, a “1” will always be

read on that GPIO pin unless an external current sink drives the output to a “0” state. Writ ing a “0” to a GPIO pin enables the

output current sink to ground (LOW) and disables the internal pull-up for that pin.

High current outputs

3.2 mA to 16 mA typical

9.1 GPIO Interrupt Enable Ports

During a reset, GPIO interrupts are disabled by clearing all of the GPIO interrupt enable ports. Writing a “1” to a GPIO Interrupt

Enable bit enables GPIO interrupts from the corresponding input pin.

P0[7] P0[6] P0[5] P0[4] P0[3] P0[2] P0[1] P0[0]

Figure 9-6. Port 0 Interrupt Enable 0x04h (write only)

P1[7] P1[6] P1[5] P1[4] P1[3] P1[2] P1[1] P1[0]

Figure 9-7. Port 1 Interrupt Enable 0x05h (write only)

P2[7] P2[6] P2[5] P2[4] P2[3] P2[2] P2[1] P2[0]

Figure 9-8. Port 2 Interrupt Enable 0x06h (write only)

P3[7] P3[6] P3[5] P3[4] P3[3] P3[2] P3[1] P3[0]

Figure 9-9. Port 3 Interrupt Enable 0x07h (write only)

Document #: 38-08027 Rev. ** Page 17 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

9.2 GPIO Configuration Port

Every GPIO port can be programmed as inputs with internal pull-ups, open drain outputs, and traditional CMOS outputs. In addition, the interrupt polarity for each port can be prog rammed. With pos itive inter rupt polarity, a rising edge (“0” to “1”) on an input

pin causes an interrupt. With neg ative polarity, a falling edge (“1” to “0”) on an input p in caus es an in terrupt. As shown in the tabl e

below, when a GPIO port is configured with CMOS outputs, interrupts from that port are disabled. The GPIO Configuration Port

register provides two bits per port to program these features. The possible port configurations are:

Port Configuration bits Pin Interrupt Bit Driver Mode Interrupt Polarity

11 X Resistive 10 0 CMOS Output disabled

10 1 Open Drain disabled

01 X Open Drain 00 X Open Drain + (default)

In “Resistive” mode, a 7-kΩ pull-up resistor is conditionally enabled for al l pins of a GPIO port . The resistor is enabled for any pin

that has been written as a “1.” The resistor is disabled on any pin that has been written as a “0.” An I/O pin w ill b e d riv en h igh

through a 7-kΩ pull-up res ist or w hen a “1” ha s b een wri tte n to th e pi n. O r the output pin will be driven LOW, wi th the pull-up disabled, when a “0” has been written to the pin. An I/O pin that has been written as a “1” can be used as an input pin with an integrated 7-kΩ pull-up resistor. Resistive mode selects a negative (falling edge) interrupt polarity on all pins that have the GPIO

interrupt enabled.

In “CMOS” mode, all pins of the GPIO port ar e outputs that are ac tivel y driven. The current s ource an d sink capa city a re roug hly

the same (symmetric output drive). A CMOS port is not a possible source for interrupts.

A port configured in CMOS mode has interrupt generation disabled, yet the interrupt mask bits serve to control port direction. If

a port’s associated Interrupt Ma sk bits a re cleared, those port b its are str ictly outp uts. If the I nterrupt Mask bit s are set then tho se

bits will be open drain input s. As op en dra in in puts, if their data output values are ‘1’ those port pins will be CMOS inputs (HIGH

Z output).

In “Open Drain” mode the internal pull-up resistor and CMOS driver (HIGH) are both disabled. An I/O pin that has been written

as a “1” can be used as either a hig h-im pe dan ce inp ut o r a th ree-s tat e ou tpu t. An I/O pin that has been wri tten as a “0” will drive

the output LOW. The interrupt polarity for an open drain GPIO port can be selected as either positive (rising edge) or negative

(falling edge).

During reset, all of the bits in the GPIO Configuration Register are written with “0.” This selects the default configuration: Open

Drain output, positive interrupt polarity for all GPIO ports.

7 6 5 4 3 2 1 0

Port 3

Config Bit 1

Document #: 38-08027 Rev. ** Page 18 of 36

Port 3

Config Bit 0

Port 2

Config Bit 1

Port 2

Config Bit 0

Port 1

Config Bit 1

Port 1

Config Bit 0

Port 0

Config Bit 1

Port 0

Config Bit 0

10.0 DAC Port

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

V

CC

Internal

Data Bus

Interrupt

Enable

Interrupt

Polarity

DAC Write

Internal

Buffer

Data

Out

Latch

DAC Read

Isink

Register

4 bits

Isink

DAC

to Interrupt

Controller

Interrupt Logic

Q1

14 KΩ

DAC

I/O Pin

ESD

Figure 10-1. Block Diagram of DAC Port

The DAC port provides th e CY7C6 3511/12/13 with 8 programmable curren t sink I/O pins . W riting a “1” to a DAC I/O pin di sable s

the output current sink (Isi nk DAC) an d dri ve s the I/O p in H IGH throu gh an int egra t ed 14 Koh m resis tor. When a “0” is written to

a DAC I/O pin, th e Isink DAC is enabled and the pull-up resisto r i s d is abl ed . A “0” output will cause the Isink DAC to sink curre nt

to drive the output LOW. The amount of sink current for the DA C I/O pin is p r og ram mable over 16 values based on t he c ontents

of the DAC Isink Register for that output pin. DAC[1:0] are the two high current outputs that are programmable from a minimum

of 3.2 mA to a maxim um of 16 m A (ty pi ca l). DA C[7 :2] are low current outputs that are p rog ram ma ble from a m in im um of 0 .2 m A

to a maximum of 1.0 mA (typical).

When a DAC I/O bit i s wri tten as a “1,” t he I/O pin is either an outp ut p ulled high th rough t he 14 Ko hm resis tor or an inp ut with a n

internal 14 Kohm pull-up resistor. All DAC port data bits are set to “1” during reset.

Low current outputs

0.2 mA to 1.0 mA typical

High current outputs

3.2 mA to 16 mA typical

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

Figure 10-2. DAC Port Data 0x30h (read/write)

10.1 DAC Port Interrupts

A DAC port interrupt can be en abled/disabled for each pin individually . The DAC Port Interrupt Ena ble register provides this feature

with an interrupt mask bit for eac h DAC I/O pi n. Wr itin g a “1” to a bit in this register enables interrupts from the corresponding bit

position. Writing a “0” to a bit in the DAC Port Interrupt Enab le regi ster di sable s inte rrupts fr om the cor respon ding bi t posi tion. Al l

of the DAC Port Interrupt Enable register bits are cleared to “0” during a reset.

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

Figure 10-3. DAC Port Interrupt Enable 0x31h (write only)

As an additional benefit, the interrupt polarity for each DAC pin is programmable with the DAC Port Interrupt Polarity register.

Writing a “0” to a bit selects negative polarity (fall ing edge) that will caus e an interrupt (if enable d) if a falling edge transi tion occurs

on the corresponding input pin. Writing a “1” to a bit in this register selects positive po larity (rising edge ) that will cause an in terrupt

(if enabled) if a rising edge tran sition occurs on the correspond ing input pin . All of the DAC Port Inte rrupt Polarity regis ter bits are

cleared during a reset.

DAC[7] DAC[6] DAC[5] DAC[4] DAC[3] DAC[2] DAC[1] DAC[0]

Figure 10-4. DAC Port Interrupt Polarity 0x32h (write only)

Document #: 38-08027 Rev. ** Page 19 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

10.2 DAC Isink Registers

Each DAC I/O pin has an associated DAC Isink register to program the output sink current when the output is driven LOW. The

first Isink register (0x38h) controls the current for DAC[0], the second (0x39h) for DAC[1], and so on until the Isink register at

0x3Fh controls the current to DAC[7].

Reserved Isink Value

Isink[3] Isink[2] Isink[1] Isink[0]

Figure 10-5. DAC Port Isink 0x38h to 0x3Fh (write only)

11.0 USB Serial In t e rface Engine (S IE)

The SIE allows the microcontro ller to communicate with the USB hos t. The SIE simplifies the interface be tween the microcontroller

and USB by incorporating hardware that handles the following USB bus activity independently of the microcontroller:

• Bit stuffing/unstuffing

• Checksum generation/checking

• ACK/NAK

• Token type identification

• Address checking

Firmware is required to handle the rest of the USB interface with the following tasks:

• Coordinate enumeration by responding to set-up packets

• Fill and empty the FIFOs

• Suspend/Resume coordination

• Verify and select Data toggle values

11.1 USB Enumeration

The enumeration sequence is shown below:

1. The host computer sends a Setup packet followed by a Data packet to USB address 0 requesting the Device descriptor.

2. The USB Controller decodes the request and retrieves its Device descriptor from the program memory space.

3. The host computer performs a control read sequenc e and the USB Controller responds by sending th e Device de scriptor ove r

the USB bus.

4. After receiving the descriptor, the host computer sends a Setup packet followed by a Data packet to address 0 assigning a

new USB address to the device.

5. The USB Controller stores the new address in its USB Device Address Regis ter after the no-data control sequen ce is complete.

6. The host sends a request for the Device descriptor using the new USB address.

7. The USB Controller decodes the request and retrieves the Device descriptor from the program memory.

8. The host performs a control read sequence and the USB Controller respon ds by sending its Device descriptor over the USB bus .

9. The host generates control reads to the USB Controller to request the Configuration and Report descriptors.

10.The USB Controller retrieves the descriptors from its program space and returns the data to the host over the USB.

11.2 PS/2 Operation

PS/2 operation is possible with the CY7 C634XX/5XX /6XX se ries thro ugh the us e of firmwa re and sev eral operati ng mode s. The

first enabling feature:

1. USB Bus rese t on D+ and D− is an interrupt that can be disabled;

2. USB traffic can be disabled via bit 7 of the USB register;

3. D+ and D− can be monitored and driven via firmware as independent port bits.

Bits 5 and 4 of the Upstream Status and Contro l regi ste r are di rec tly connec ted to the D + an d D− USB pin s of the CY7 C634 XX/

5XX/6XX. These pins constantly monitor the levels of th es e si gna ls with C M OS inpu t thresholds. Firmware can pol l and decode

these signals as PS/2 clock and data.

Bits [2:0] defaults to ‘000’ at res et w hi ch allows the USB SIE to c ontr ol output on D+ and D−. Firmware can override the SIE and

directly control the stat e of the se pins vi a these 3 control b its. Sinc e PS/2 is an open drai n signa ling pro tocol, these mo des allow

all 4 PS/2 states to be generated on the D+ and D− pins

Document #: 38-08027 Rev. ** Page 20 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

11.3 USB Port Status and Control

USB status and control is regulated by the USB Status and Control Register located at I/O address 0x1Fh as shown in

Figure 11-1. This is a read/write register. All reserved bits must be written to zero. All bi ts in the re gister ar e cleare d during reset.

7 6 5 4 3 2 1 0

R R R/W R/W R/W R/W

Reserved Reserved D+ D– Bus Activity Control

Bit 2

Figure 11-1. USB Status and Control Register 0x1Fh

The Bus Activity bit is a “sticky” bit that indicates if any non-idle USB event has occurred on the USB bus. The user firmware

should check and clear this bit periodically to detect any loss of bus activity. Writing a “0” to the Bus Activity bit clears it while

writing a “1” preserves the current value. In other words, the firmware can clear the Bus Activity bit, but only the SIE can set it.

The 1.024-ms timer interrupt service routine is normally used to check and clear the Bus Activity bit. The following table shows

how the control bits are encoded for this register.

Control Bits Control action

000 Not forcing (SIE controls driver)

001 Force K (D+ HIGH, D– LOW)

010 Force J (D+ LOW, D– HIGH)

011 Force SE0 (D+ LOW, D– LOW)

100 Force SE0 (D− LOW, D+ LOW)

101 Force D− LOW, D+ HiZ

110 Force D− HiZ, D+ LOW

111 Force D− HiZ, D+ HiZ

Control

Bit 1

Control

Bit 0

12.0 USB Device

USB Device Address A inclu des three end points: EPA0, EPA1, and EP A2 . End Point 0 (EPA0) allows the USB host to recogniz e,

set up, and control the device. In particular, EPA0 is used to receive and transmit control (including set-up) packets.

12.1 USB Ports

The USB Controller provides one USB device address with three endpoints. The USB Device Address Register contents are

cleared during a reset, setting the USB device address to zero and marking this address as disabled. Figure 12-1 shows the

format of the USB Address Register.

Device

Address

Enable

Bit 7 (Device Address Enable) in the USB Device Address Register must be set by firmware before the serial interface engine

(SIE) will respond to USB traffic to this address. The Device Address in bits [6:0] must be set by firmware during the USB enumeration process to an add ress assi gned by the USB host th at do es not equ al zero. This regist er is cle ared by a hardw are res et

or the USB bus reset.

12.2 Device Endpoints (3)

The USB controller communicates with the host using dedicated FIFOs, one per endpoint. Each endpoint FIFO is implemented

as 8 bytes of dedicated SRAM. There are three endpoints defined for Device “A” that are labeled “EPA0,” “EPA1,” and EPA2.”

All USB devices are require d to have an endpoint numb er 0 (EP A0) that is used to initiali ze and control the USB devic e. End Point

0 provides access to the device configuration information and allows generic USB status and control accesses. End Point 0 is

bidirectional as the USB controller can both receive and transmit data.

The endpoint mode registers are cleared during reset. The EPA0 endpoint mode register uses the format shown below:

Device

Address

Bit 6

Device

Address

Bit 5

Figure 12-1. USB Device Address Register 0x10h (read/write)

Device

Address

Bit 4

Device

Address

Bit 3

Device

Address

Bit 2

Device

Address

Bit 1

Device

Address

Bit 0

Document #: 38-08027 Rev. ** Page 21 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

Endpoint 0

Set-up

Received

Bits[7:5] in the endpoint 0 mode registers (EPA0) are “sticky” status bits that are set by the SIE to report the type of token that

was most recently received. The sticky bits must be cleared by firmware as part of the USB processing.

The endpoint mode registers for EPA1 and EPA2 do not use bits [7:5] as shown below:

Reserved Reserved Reserved Acknowledge Mode

The ‘Acknowledge’ bit is set whenever the SIE engages in a transaction that completes with an ‘ACK’ packet.

The ‘set-up’ PID status (bit[7]) is forced HIGH from the start of the data packet phase of the set-up transaction, until the start of

the ACK packet returned by the SIE. The CPU is prevented from clearing this bit during this interval, and subsequently until the

CPU first does an IORD to this endpoint 0 mode register.

Bits[6:0] of the endpoint 0 mode register are locked from CPU IOWR operations only if the SIE has updated one of these bits,

which the SIE does onl y at the end of a packet transac ti on (set-up ... Data ... ACK, or Out ... Data ... ACK, or In ... Data ... ACK).

The CPU can unlock these bits by doing a subsequent I/O read of this register.

Firmware must do an IORD after an IOWR to an endpoint 0 register to verify that the contents have changed and that the SIE

has not updated these values.

While the ‘set-up’ bit is set, the CPU cannot write to the DMA buffers at memory locatio ns 0 xE0 thro ug h 0x E7 a nd 0 xF 8 th roug h

0xFF. This prevents an incoming set-up transaction from conflicting with a previous In data buffer filling operation by firmware.

The mode bits (bits [3:0]) in an Endpoint Mode Register control how the endpoint responds to USB bus traffic. The mode bit

encoding is shown in Section 16.0.

The format of the endpoint Device counter registers is shown below:

Endpoint 0

In

Received

Endpoint 0

Out

Received

Acknowledge Mode

Bit 3

Bit 3

Mode

Bit 2

Mode

Bit 2

Mode

Bit 1

Mode

Bit 1

Mode

Bit 0

Mode

Bit 0

Data 0/1

Toggle

Bits 0 to 3 indicate the number of data bytes to be transmitted during an IN packet, valid values are 0 to 8 inclusive. Data Valid

bit 6 is used for OUT and set-up tok ens only . Data 0/1 T oggle bit 7 selects the DAT A packet’s toggle state: 0 for DA TA0, 1 for DAT A1.

Data Valid Reserved Reserved Byte count

Bit 3

Figure 12-2. USB Device Counter Registers 0x11h, 0x13h, 0x15h (read/write)

Byte count

Bit 2

Byte count

Bit 1

Byte count

Bit 0

13.0 12-bit Free-running Timer

The 12-bit timer provides two interrupts (128 µs and 1.024 ms) and allows the firmware to directly time events that are up to

4 ms in duration. The lower 8 bits of the timer can be read directly by the firmware. Reading the lower 8 bits latches the upper

4 bits into a temporary register. When the firmware reads the upper 4 bits of the timer, it is actually reading the count stored in

the temporary register. The effect of this logic is to ensure a stable 12-bit timer value can be read, even when the two reads are

separated in time.

13.1 Timer (LSB)

Timer

Bit 7

13.2 Timer (MSB)

Reserved Reserved Reserved Reserved Timer

Timer

Bit 6

Timer

Bit 5

Timer

Bit 4

Timer

Bit 3

Bit 11

Timer

Bit 2

Timer

Bit 10

Timer

Bit 1

Timer

Bit 9

Timer

Bit 0

Timer

Bit 8

Document #: 38-08027 Rev. ** Page 22 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

1.024-ms interrupt

µs interrupt

128-

10 9 7856432

1 011

1-MHz clock

L1 L0L2L3

D3 D2 D1 D0 D7 D6 D5 D4 D3 D2 D1 D0

To Timer Register

8

Figure 13-1. Timer Block Diagram

14.0 Processor Status and Control Register

7 6 5 4 3 2 1 0

R R/W R/W R/W R/W R R/W R/W

IRQ

Pending

Watch Dog

Reset

USB Bus

Reset

Power-on

Reset

Suspend, Wait

for Interrupt

Interrupt

Mask

Single Step Run

The “Run” (bit 0) is m anipulate d by the HALT instruction. When Halt is execut ed, the p roces sor cle ars the run bi t and ha lts at th e

end of the current instruction. The processor remains halted until a reset (Power On or Watch Dog). Notice, when writing to the

processor status and control register, the run bit should always be written as a “1.”

The “Single Step” (bit 1) is provided to support a hardware debugger. When single step is set, the processor will execute one

instruction and halt (clear the run bit). This bit must be cleared for normal operation.

The “Interrupt Mas k” (bit 2) sh ows whet her interrup ts are enabl ed or disabled . The firmw are has no dire ct contro l over this bit as

writing a zero or one to this bit position will have no effect on interrupts. Instructions DI, EI, and RETI manipulate the internal

hardware that controls the state of the interrupt mask bit in the Processor Status and Control Register.

Writing a “1” to “Suspend, Wait for Interrupts” (bit 3) will halt the processor and cause the microcontroller to enter the “suspend”

mode that significantly reduces power consumption. A pending interrupt or bus activity will cause the device to come out of

suspend. After coming out of suspen d, the d evice wil l resume firmwa re execut ion at the in struction followi ng the IOWR which put

the part into suspend. An IOWR that attempts to put the part into suspend will be ignored if either bus activity or an interrupt is

pending.

The “Power-on Reset” (bit 4) is only set to “1” during a power on reset. The firmware can check bi ts 4 and 6 in the reset handler

to determine whether a reset was caused by a Power On condi tion or a W atch D og Ti meout. PORS is used to determ ine suspen d

start-up timer value of 128 µs or 128 ms.

The “USB Bus Rese t” (bit 5) will occu r when a USB bus reset is rec eived. Th e USB Bus Reset is a sing led-ended ze ro (SE0) that

lasts more than 8 microseconds. An SE0 is defined as the condition in which both the D+ line and the D– line are LOW at the

same time. W hen t h e SI E de te c ts t his co nd i ti o n, t h e US B B us Re se t bit i s s et i n th e P roc es so r St a tus an d C ont r ol re gi ste r a nd

an USB Bus Reset interrupt is generated. Please note this is an interrupt to the microcontroller and does not actually reset the

processor.

The “Watch Dog Reset” (bit 6) is set during a reset initiated by the Watch Dog Timer. This indicates the Watch Dog Timer went

for more than 8 ms between watch dog clears.

The “IRQ Pending” (bit 7) indicates one or more of the interrupts has been recognized as active. The interrupt acknowledge

sequence should clear this bit until the next interrupt is detected.

During Power-on Reset, the Proc es so r Statu s a nd C on trol Regi ste r is s et to 000 100 01, which indicates a Power-on Res et (bi t 4

set) has occurred and no interrupts are pending (bit 7 clear) yet.

During a Watch Dog Reset, the Processor Status and Control Register is set to 01000001, which indicates a Watch Dog Reset

(bit 6 set) has occurred and no interrupts are pending (bit 7 clear) yet.

Document #: 38-08027 Rev. ** Page 23 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

15.0 Interrupts

All interrupts are maskable by the Global Interrupt Enable Register and the USB End Point Interrupt Enable Register. Writing a

“1” to a bit position enables the interrupt associated wi th that bit pos ition. During a reset, the co ntents the Glo bal Interrupt E nable

Register and USB End Point Interrupt Enable Register are cleared, effectively disabling all interrupts.

7 6 5 4 3 2 1 0

R/W R/W R/W R/W R/W

Reserved Reserved GPIO

Interrupt

Enable

7 6 5 4 3 2 1 0

Reserved Reserved Reserved Reserved Reserved EPA2

Figure 15-1. USB End Point Interrupt Enable Register 0x21h (read/write)

DAC

Interrupt

Enable

Reserved 1.024-ms

Interrupt

Enable

R/W R/W R/W

Interrupt

Enable

128-µsec

Interrupt

Enable

EPA1

Interrupt

Enable

USB Bus RST

Interrupt

Enable

EPA0

Interrupt

Enable

Pending interrupt requests are recognized during the last clock cycle of the current instruction. When servicing an interrupt, the

hardware will first disable all interrupts by clearing the Interrupt Enable bit in the Processor Status and Control Register. Next, the

interrupt latch of the current interrupt is cleared. This is followed by a CALL instruction to the ROM address associated with the

interrupt being servic ed (i.e., the Interrupt V ector). The instructio n in the interrupt tab le is typically a J MP instruction to the address

of the Interrupt Service Routine (ISR). The user can re-enable interrupts in the interrupt service routine by executing an EI

instruction. Interrupts can be nested to a level limited only by the available stack space.

The Program Counter v alue as well as the C arry and Zer o flags (C F, ZF) are automatically stored o nto the Program Stack by the

CALL instruction as part of the interrupt acknowledge process. The user firmware is responsible for insuring that the processor

state is preserved and restored during an interrupt. The PUSH A instruction should be used as the first command in the ISR to

save the accumul ator valu e and the POP A instruc tion sho uld be us ed just before the RETI ins truction to restore the accu mulator

value. The program counter CF and ZF are restored and interrupts are enabled when the RETI instruction is executed.

15.1 Interrupt Vectors

The Interrupt V ec tors supported by the U SB Controller a re listed in Table 15-1. Although Reset is not an interr upt, per se, the first

instruction execut ed after a reset is at PROM address 0x0000 h—which corre sponds to t he first entry in the Interrupt V ector Table.

Because the JMP instruction is 2 bytes long, the interrupt vectors occupy 2 bytes.

Table 15-1. Interrupt Vector Assignments

Interrupt V ecto r Number ROM Address Function

not applicable 0x0000h Execution after Reset begins here

1 0x0002h USB Bus Reset interrupt

2 0x0004h 128-µs timer interrupt

3 0x0006h 1.024-ms timer interrupt

4 0x0008h USB Address A Endpoint 0 interrupt

5 0x000Ah USB Address A Endpoint 1 interrupt

6 0x000Ch USB Address A Endpoint 2 interrupt

7 0x000Eh Reserved

8 0x0010h Reserved

9 0x0012h Reserved

10 0x0014h DAC interrupt

11 0x0016h GPIO interrupt

12 0x0018h Reserved

Document #: 38-08027 Rev. ** Page 24 of 36

FOR

FOR

CY7C63411/12/13

CY7C63511/12/13

CY7C63612/13

15.2 Interrupt Latency

Interrupt latency can be calculated from the following equation:

Interrupt Latency = (Number of clock cycles re ma ini ng in the current instruction) + (10 clock cycles for th e C ALL in stru cti on) +