Page 1

CY7C63310, CY7C638xx

enCoRe™ II

Low Speed USB Peripheral Controller

1. Features

■

USB 2.0-USB-IF certified (TID # 40000085)

■

enCoRe™ II USB - “enhanced Component Reduction”

❐

Crystalless oscillator with support for an external clock. The

internal oscillator eliminates the need for an external crystal

or resonator.

❐

Two internal 3.3V regulators and an internal USB pull up

resistor

❐

Configurable IO for real world interface without external components

■

USB Specification compliance

❐

Conforms to USB Specification, Version 2.0

❐

Conforms to USB HID Specification, Version 1.1

❐

Supports one low speed USB device address

❐

Supports one control endpoint and two data endpoints

❐

Integrated USB transceiver with dedicated 3.3V regulator for

USB signalling and D– pull up.

■

Enhanced 8-bit microcontroller

❐

Harvard architecture

❐

M8C CPU speed is up to 24 MHz or sourced by an external

clock signal

■

Internal memory

❐

Up to 256 bytes of RAM

❐

Up to eight Kbytes of Flash including EEROM emulation

■

Interface can auto configure to operate as PS/2 or USB

❐

No external components for switching between PS/2 and

USB modes

❐

No General Purpose IO (GPIO) pins required to manage dual

mode capability

■

Low power consumption

❐

Typically 10 mA at 6 MHz

❐

10 μA sleep

■

In system reprogrammability:

❐

Allows easy firmware update

■

GPIO ports

❐

Up to 20 GPIO pins

❐

2 mA source current on all GPIO pins. Configurable 8 or

50 mA/pin current sink on designated pins.

❐

Each GPIO port supports high impedance inputs, configurable pull up, open drain output, CMOS/TTL inputs, and

CMOS output

❐

Maskable interrupts on all IO pins

■

A dedicated 3.3V regulator for the USB PHY. Aids in signalling

and D– line pull up

■

125 mA 3.3V voltage regulator powers external 3.3V devices

■

3.3V IO pins

❐

4 IO pins with 3.3V logic levels

❐

Each 3.3V pin supports high impedance input, internal pull

up, open drain output or traditional CMOS output

■

SPI serial communication

❐

Master or slave operation

❐

Configurable up to 4 Mbit/second transfers in the master

mode

❐

Supports half duplex single data line mode for optical sensors

■

2-channel 8-bit or 1-channel 16-bit capture timer registers.

Capture timer registers store both rising and falling edge times.

❐

Two registers each for two input pins

❐

Separate registers for rising and falling edge capture

❐

Simplifies the interface to RF inputs for wireless applications

■

Internal low power wakeup timer during suspend mode:

❐

Periodic wakeup with no external components

■

12-bit Programmable Interval Timer with interrupts

■

Advanced development tools based on Cypress PSoC® tools

■

Watchdog timer (WDT)

■

Low voltage detection with user configurable threshold

voltages

■

Operating voltage from 4.0V to 5.5V DC

■

Operating temperature from 0–70°C

■

Available in 16 and 18-pin PDIP; 16, 18, and 24-pin SOIC;

24-pin QSOP, and 32-pin QFN packages

■

Industry standard programmer support

1.1 Applications

The CY7C63310/CY7C638xx is targeted for the following

applications:

■

PC HID devices

❐

Mice (optomechanical, optical, trackball)

■

Gaming

❐

Joysticks

❐

Game pad

■

General purpose

❐

Barcode scanners

❐

POS terminal

❐

Consumer electronics

❐

To ys

❐

Remote controls

❐

Security dongles

Cypress Semiconductor Corporation • 198 Champion Court • San Jose

Document 38-08035 Rev. *K Revised December 08 2008

,

CA 95134-1709 • 408-943-2600

[+] Feedback [+] Feedback

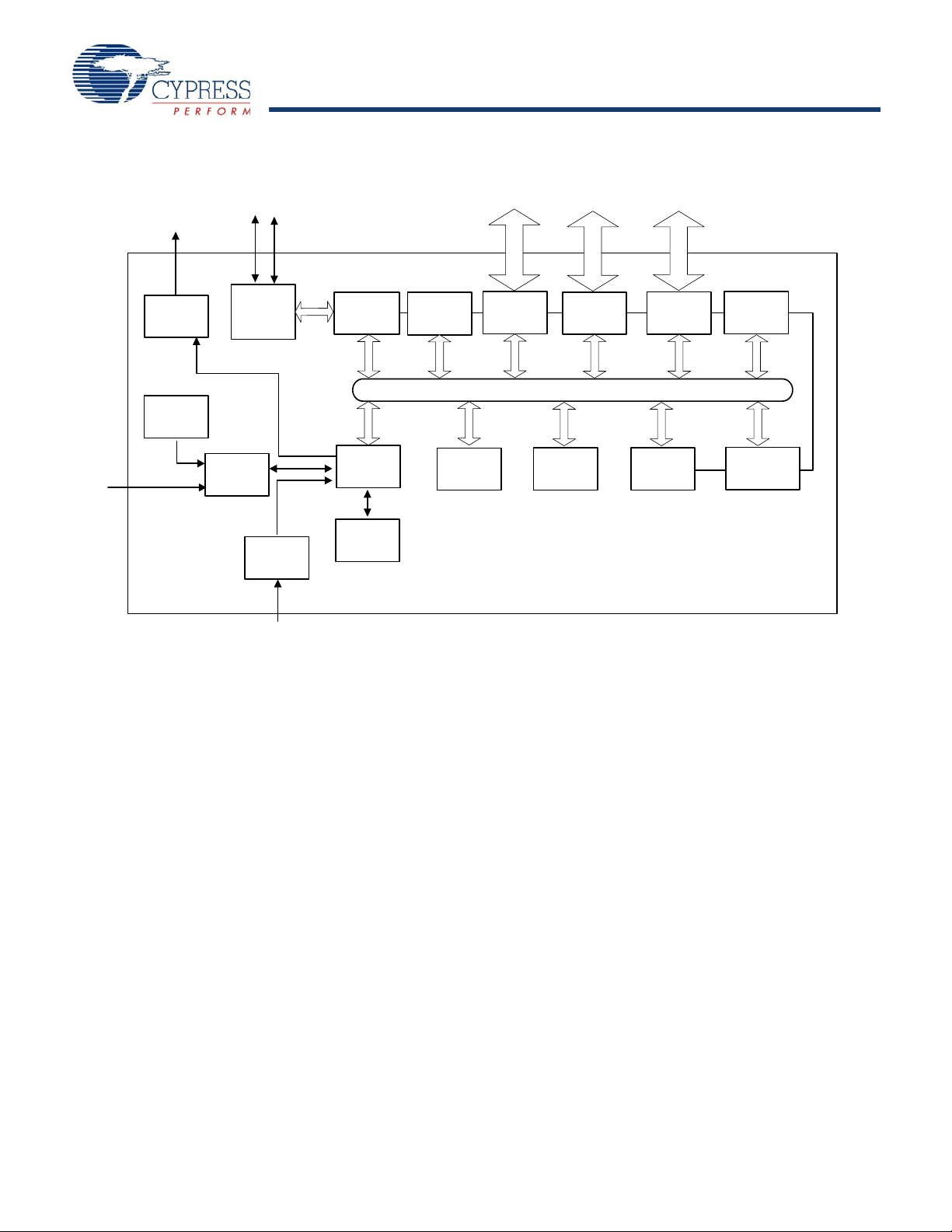

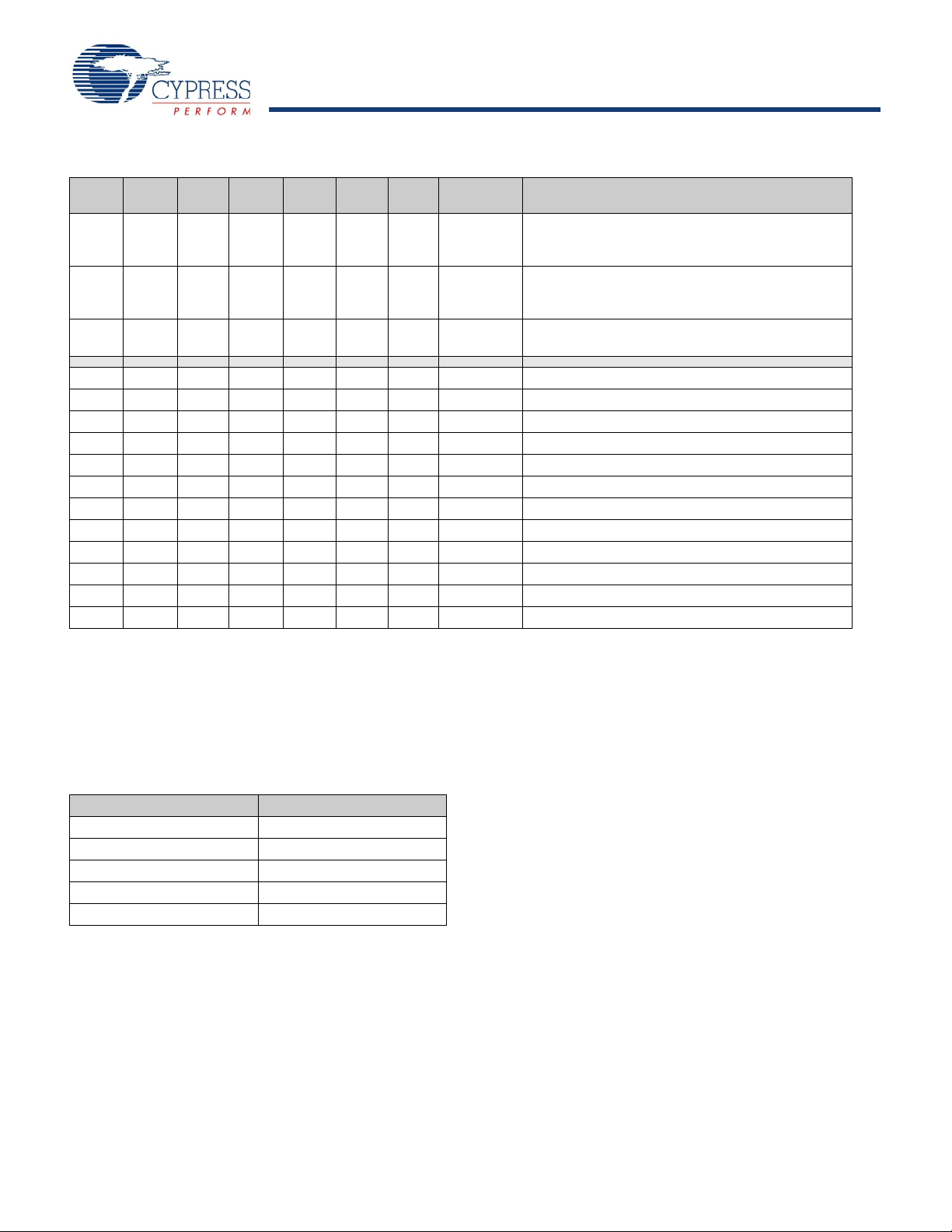

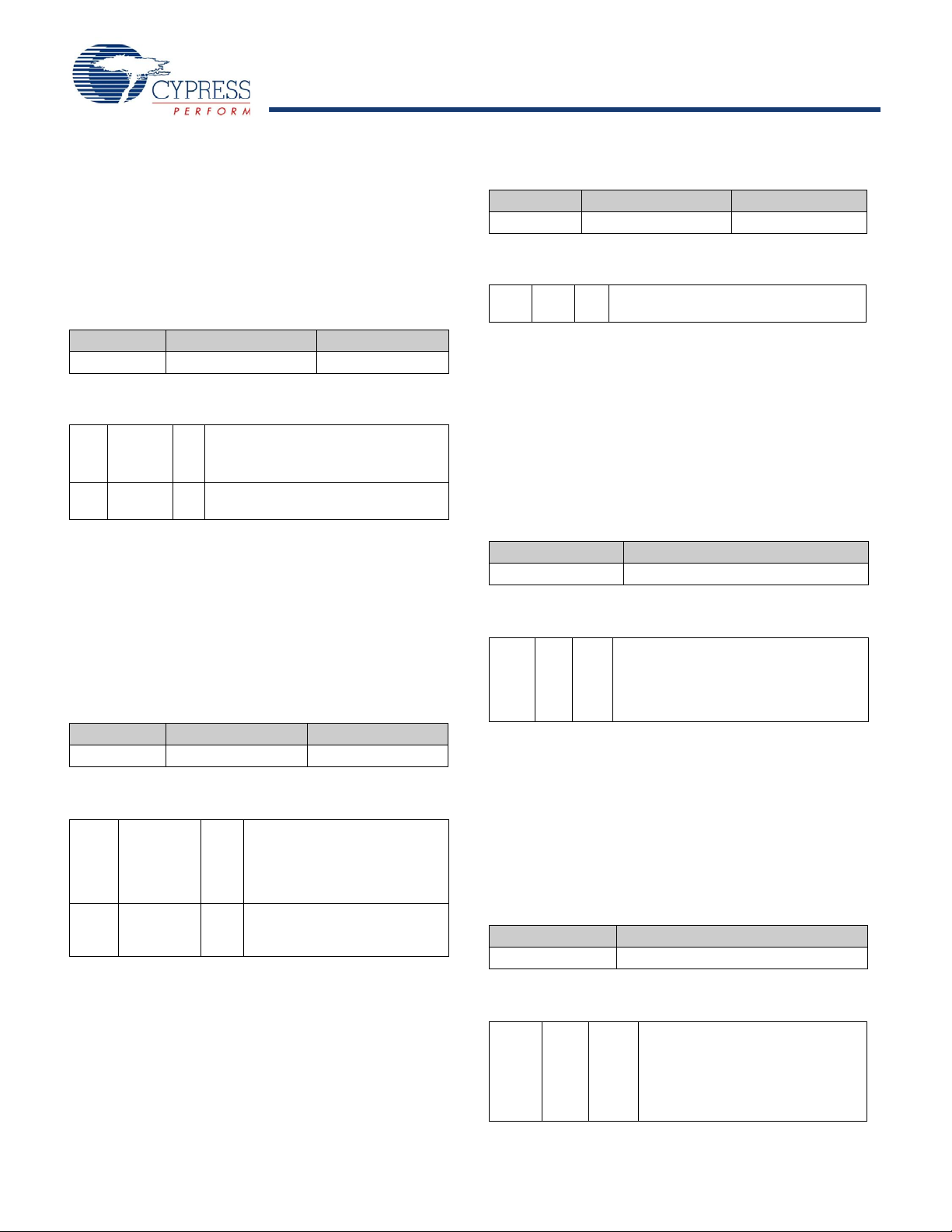

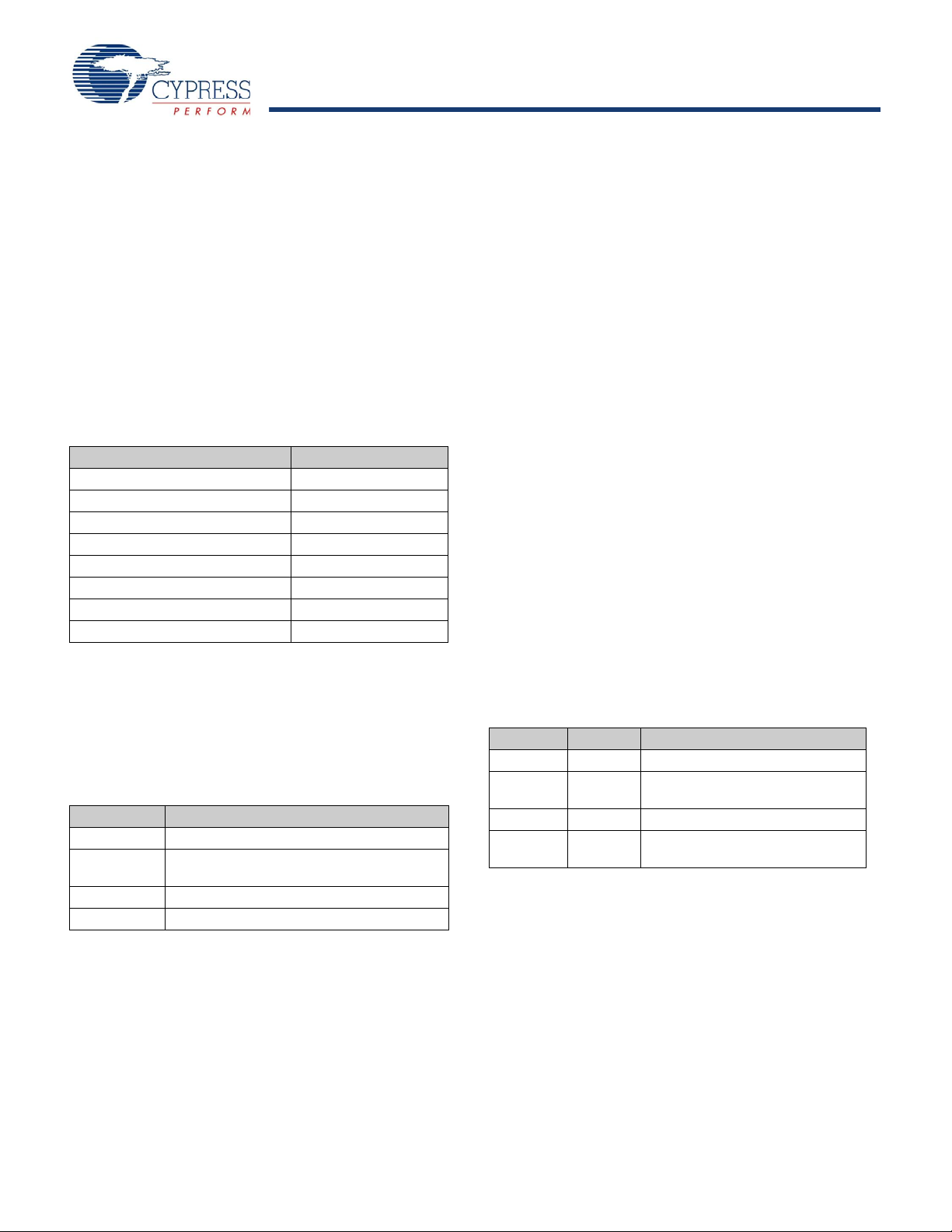

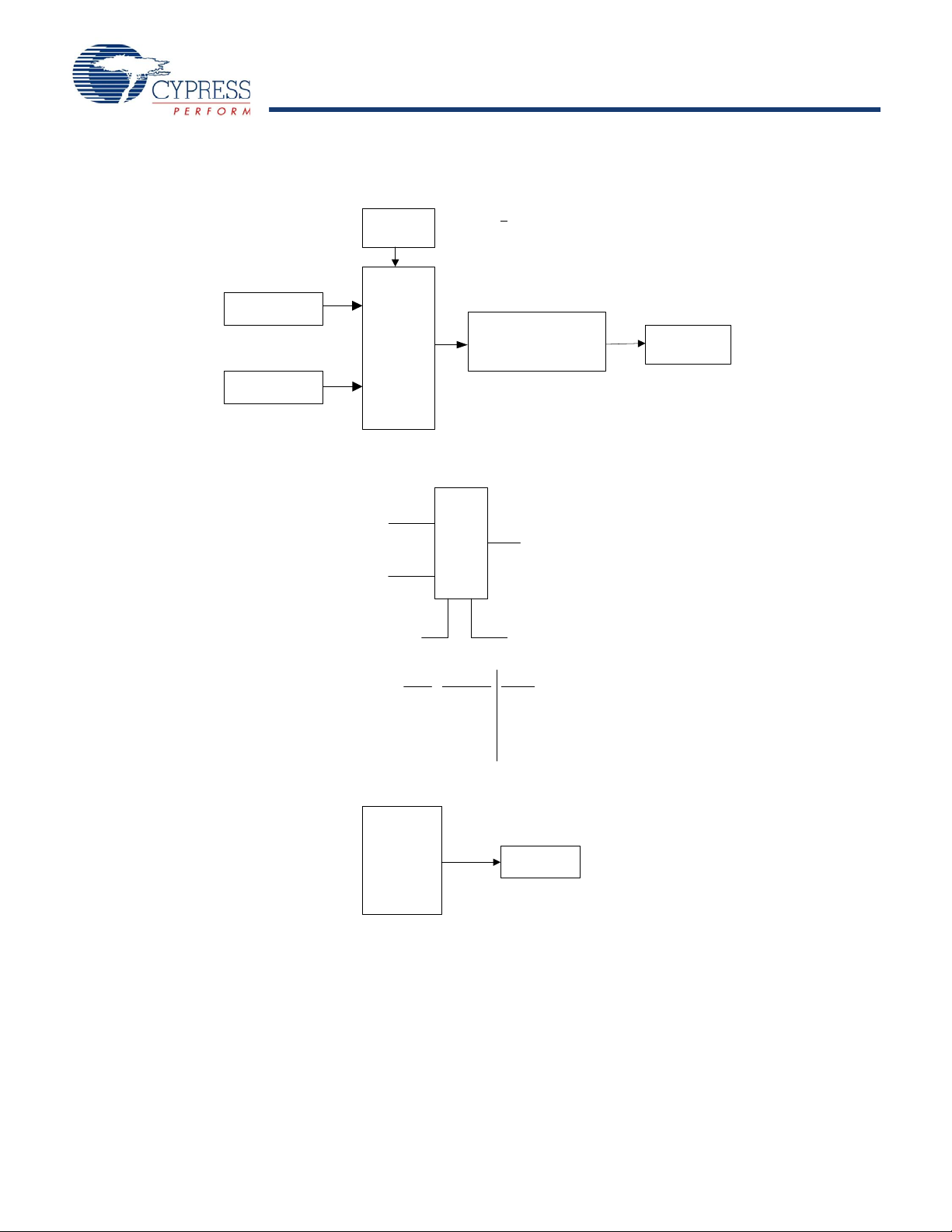

Page 2

CY7C63310, CY7C638xx

Internal

24 MHz

Oscillator

3.3V

Regulator

Clock

Control

POR /

Low-Voltage

Detect

Watchdog

Timer

RAM

Up to 256

Byte

M8C CPU

Flash

Up to 8K

Byte

Up to 14

Extended

IO Pins

Low-Speed

USB/PS2

Transceiver

and Pull up

Up to 6

GPIO

pins

Wake up

Timer

16-bit Free

running

timer

12-bit Timer

4 3VIO/SPI

Pins

Vdd

Interrupt

Control

Low-Speed

USB SIE

External Clock

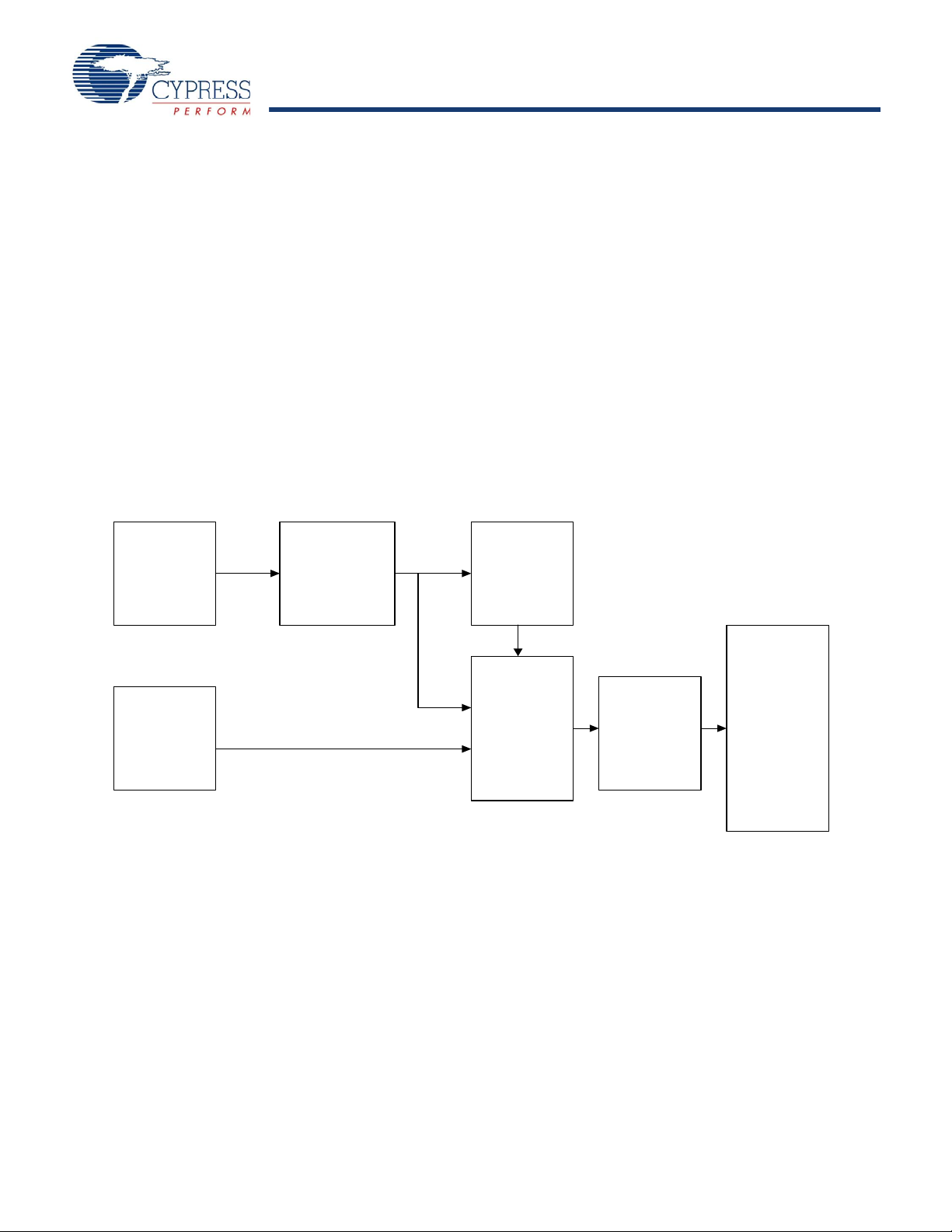

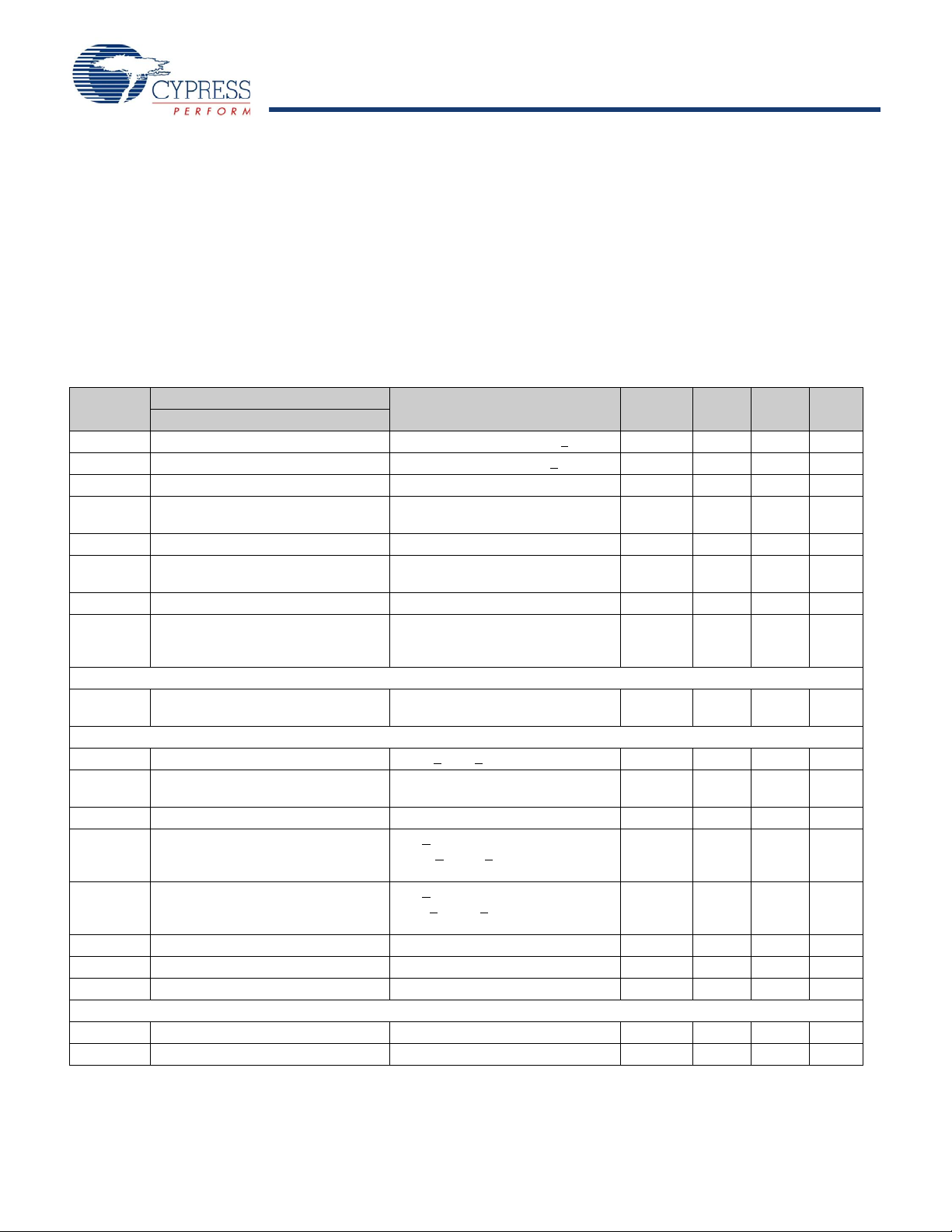

2. Logic Block Diagram

Document 38-08035 Rev. *K Page 2 of 83

[+] Feedback [+] Feedback

Page 3

CY7C63310, CY7C638xx

3. Introduction

Cypress has reinvented its leadership position in the low speed

USB market with a new family of innovative microcontrollers.

Introducing enCoRe II USB - “enhanced Component Reduction.”

Cypress has leveraged its design expertise in USB solutions to

advance its family of low speed USB microcontrollers, which

enable peripheral developers to design new products with a

minimum number of components. The enCoRe II USB

technology builds on the enCoRe family. The enCoRe family has

an integrated oscillator that eliminates the external crystal or

resonator, reducing overall cost. Also integrated into this chip are

other external components commonly found in low speed USB

applications, such as pull up resistors, wakeup circuitry, and a

3.3V regulator. Integrating these components reduces the

overall system cost.

The enCoRe II is an 8-bit Flash programmable microcontroller

with an integrated low speed USB interface. The instruction set

is optimized specifically for USB and PS/2 operations, although

the microcontrollers may be used for a variety of other embedded

applications.

The enCoRe II features up to 20 GPIO pins to support USB,

PS/2, and other applications. The IO pins are grouped into four

ports (Port 0 to 3). The pins on Port 0 and Port 1 may each be

configured individually while the pins on Ports 2 and 3 are

configured only as a group. Each GPIO port supports high

impedance inputs, configurable pull up, open drain output,

CMOS/TTL inputs, and CMOS output with up to five pins that

support a programmable drive strength of up to 50 mA sink

current. GPIO Port 1 features four pins that interface at a voltage

level of 3.3V. Additionally, each IO pin may be used to generate

a GPIO interrupt to the microcontroller. Each GPIO port has its

own GPIO interrupt vector; in addition, GPIO Port 0 has three

dedicated pins that have independent interrupt vectors (P0.2 P0.4).

The enCoRe II features an internal oscillator. With the presence

of USB traffic, the internal oscillator may be set to precisely tune

to USB timing requirements (24 MHz ±1.5%). Optionally, an

external 12 MHz or 24 MHz clock is used to provide a higher

precision reference for USB operation. The clock generator

provides the 12 MHz and 24 MHz clocks that remain internal to

the microcontroller. The enCoRe II also has a 12-bit programmable interval timer and a 16-bit Free Running Timer with

Capture Timer registers. In addition, the enCoRe II includes a

Watchdog timer and a vectored interrupt controller.

The enCoRe II has up to eight Kbytes of Flash for user code and

up to 256 bytes of RAM for stack space and user variables.

The power on reset circuit detects logic when power is applied

to the device, resets the logic to a known state, and begins

executing instructions at Flash address 0x0000. When power

falls below a programmable trip voltage, it generates a reset or

may be configured to generate an interrupt. There is a low

voltage detect circuit that detects when V

programmable trip voltage. It is configurable to generate an LVD

interrupt to inform the processor about the low voltage event.

POR and LVD share the same interrupt. There is no separate

interrupt for each. The Watchdog timer may be used to ensure

the firmware never gets stalled in an infinite loop.

drops below a

CC

The microcontroller supports 22 maskable interrupts in the

vectored interrupt controller. Interrupt sources include a USB bus

reset, LVR/POR, a programmable interval timer, a 1.024 ms

output from the free-running timer, three USB endpoints, two

capture timers, four GPIO Ports, three Port 0 pins, two SPI, a

16-bit free running timer wrap, an internal sleep timer, and a bus

active interrupt. The sleep timer causes periodic interrupts when

enabled. The USB endpoints interrupt after a USB transaction

complete is on the bus. The capture timers interrupt when a new

timer value is saved because of a selected GPIO edge event. A

total of seven GPIO interrupts support both TTL or CMOS

thresholds. For additional flexibility on the edge sensitive GPIO

pins, the interrupt polarity is programmed as rising or falling.

The free-running 16-bit timer provides two interrupt sources: the

1.024 ms outputs and the free running counter wrap interrupt.

The programmable interval timer provides up to 1 μsec

resolution and provides an interrupt every time it expires. These

timers are used to measure the duration of an event under

firmware control by reading the desired timer at the start and at

the end of an event, then calculating the difference between the

two values. The two 8-bit capture timer registers save a

programmable 8-bit range of the free-running timer when a GPIO

edge occurs on the two capture pins (P0.5, P0.6). The two 8-bit

captures may be ganged into a single 16-bit capture.

The enCoRe II includes an integrated USB serial interface

engine (SIE) that allows the chip to easily interface to a USB

host. The hardware supports one USB device address with three

endpoints.

The USB D+ and D– pins are optionally used as PS/2 SCLK and

SDATA signals so that products are designed to respond to

either USB or PS/2 modes of operation. The PS/2 operation is

supported with internal 5 KΩ pull up resistors on P1.0 (D+) and

P1.1 (D–), and an interrupt to signal the start of PS/2 activity. In

USB mode, the integrated 1.5 KΩ pull up resistor on D– may be

controlled under firmware. No external components are

necessary for dual USB and PS/2 systems, and no GPIO pins

need to be dedicated to switching between modes.

The enCoRe II supports in system programming by using the D+

and D– pins as the serial programming mode interface. The

programming protocol is not USB.

4. Conventions

In this data sheet, bit positions in the registers are shaded to

indicate which members of the enCoRe II family implement the

bits.

Available in all enCoRe II family members

CY7C638(1/2/3)3 only

Document 38-08035 Rev. *K Page 3 of 83

[+] Feedback [+] Feedback

Page 4

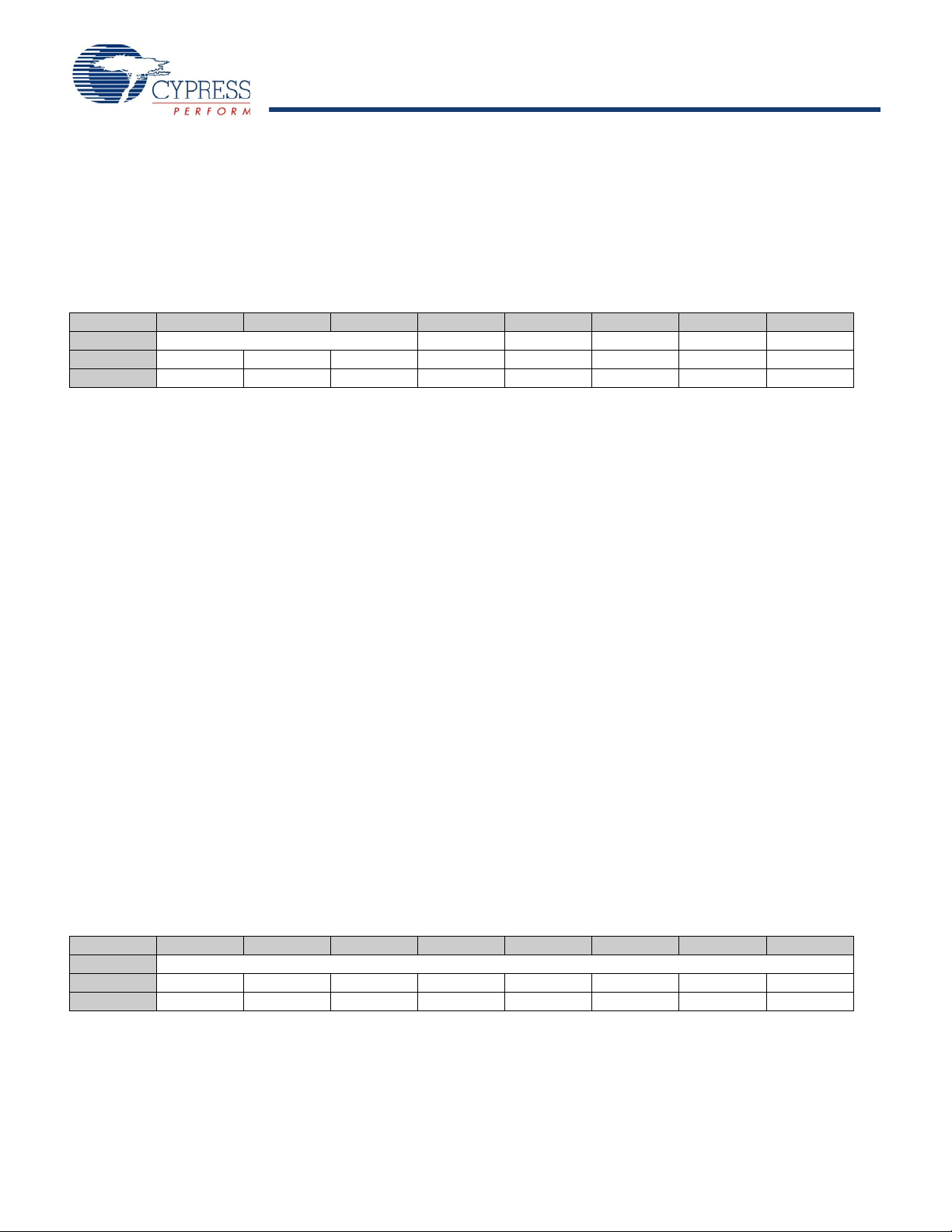

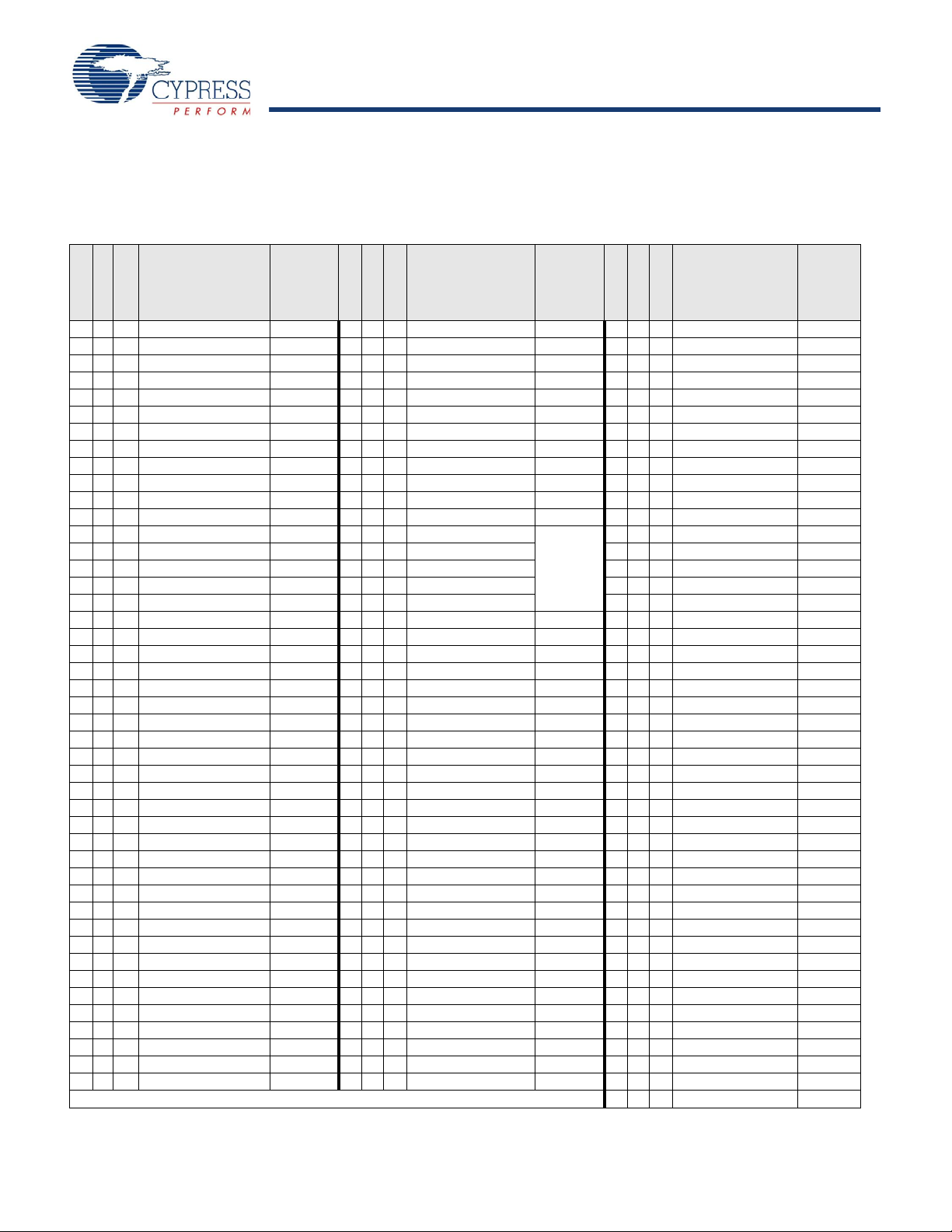

CY7C63310, CY7C638xx

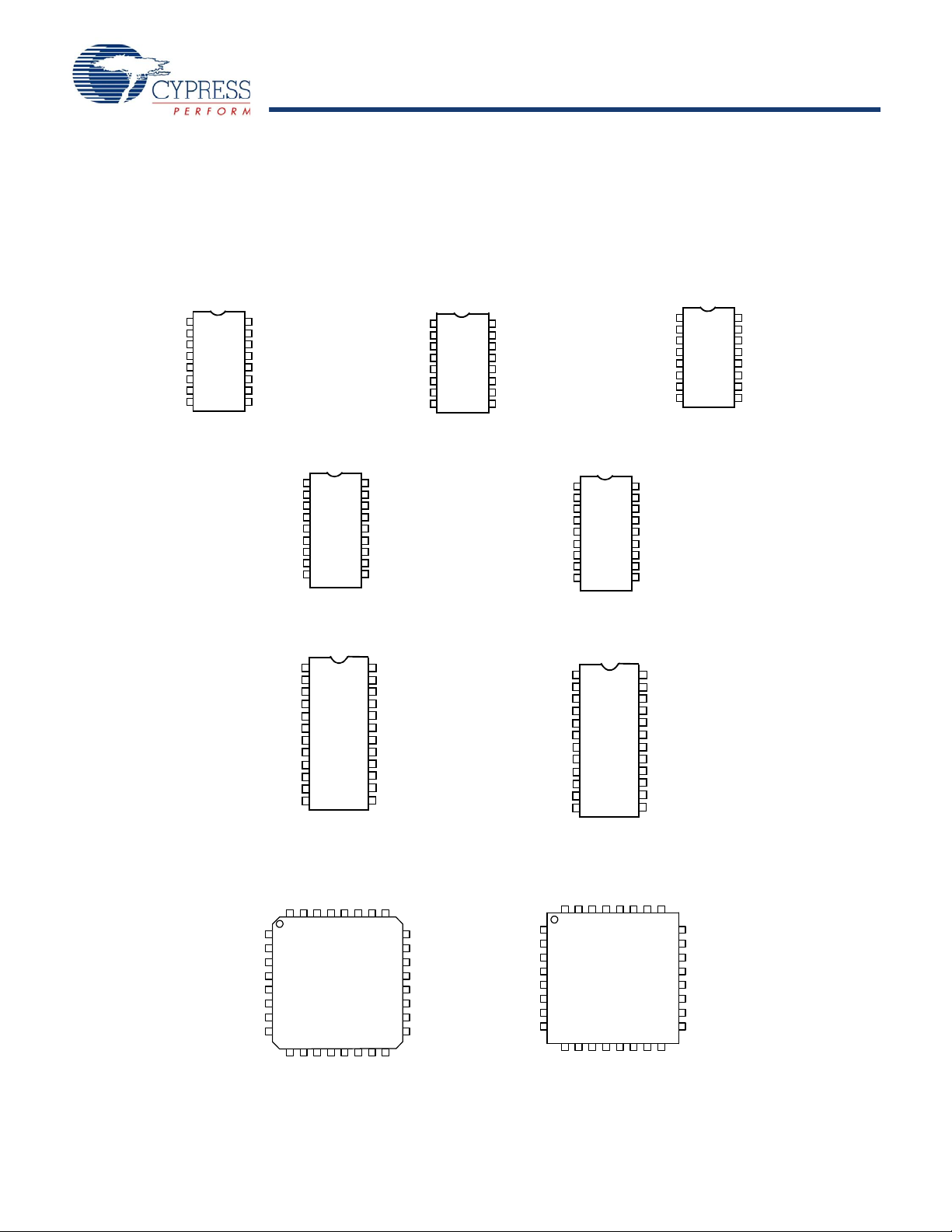

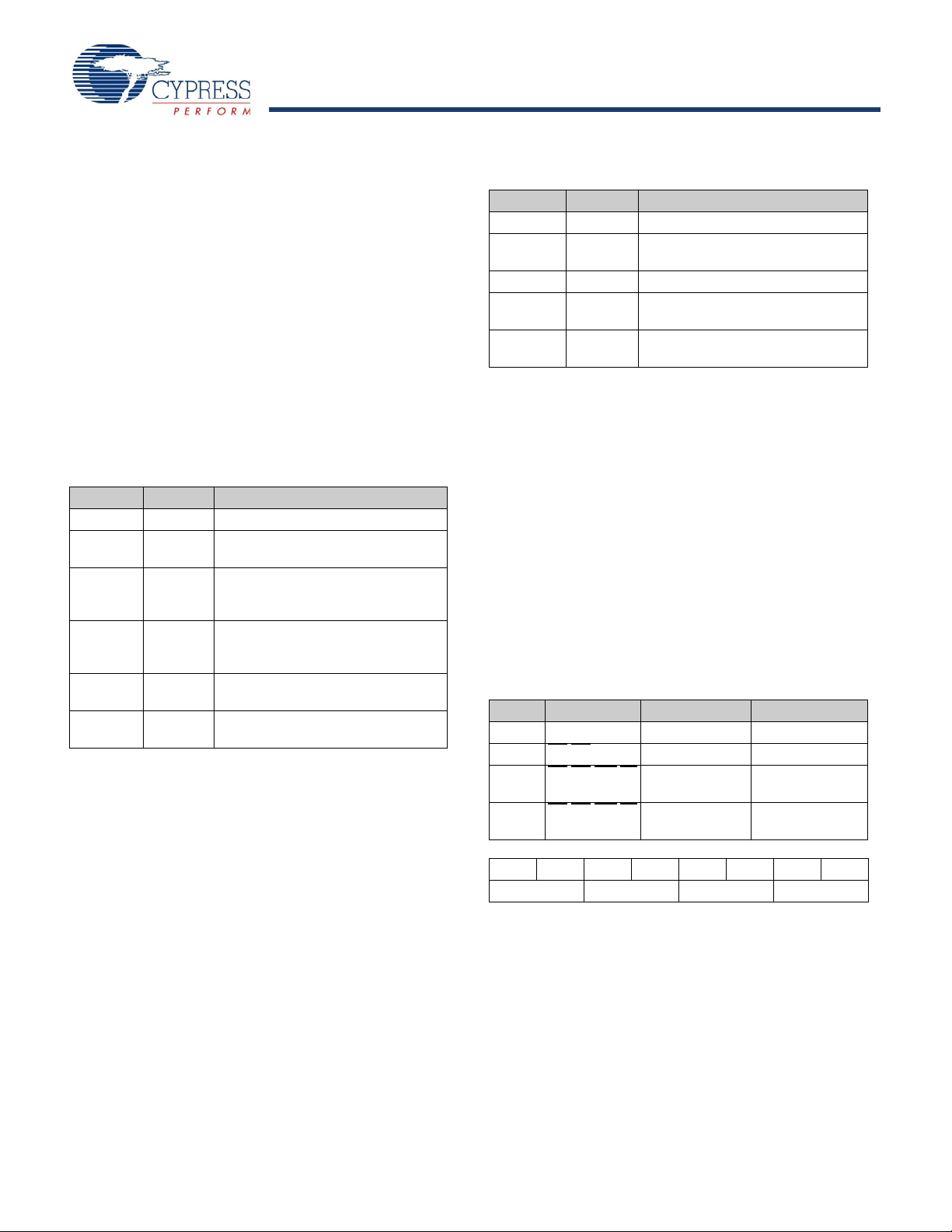

5. Pinouts

1

2

3

4

5

6

9

11

15

16

17

18

19

20

22

21

NC

P0.7

TIO1/P0.6

TIO0/P0.5

INT2/P0.4

INT1/P0.3

P0.0

P2.0

P1.5/SMOSI

P1.3/SSEL

P3.1

P3.0

V

CC

P1.2/VREG

P1.1/D–

P1.0/D+

14

P1.4/SCLK

10

P2.1

NC

V

SS

12

13

7

8

INT0/P0.2

P0.1

24

23

P1.7

P1.6/SMISO

24-Pin QSOP

CY7C63823

1

2

3

4

6

7

8

10

11

12

13

15

16

18

17

SSEL/P1.3

SCLK/P1.4

SMOSI/P1.5

SMISO/P1.6

P0.7

TIO0/P0.5

P1.2/VREG

P1.1/D–

P1.0/D+

P0.0

P0.1

P0.2/INT0

18-Pin PDIP

V

CC

9

TIO1/P0.6

INT2/P0.4

P0.3/INT1

CY7C63813

5

14

P1.7

V

SS

1

2

3

4

6

7

8

9

10

11

13

14

16

15

SSEL/P1.3

SCLK/P1.4

SMOSI/P1.5

SMISO/P1.6

TIO0/P0.5

INT1/P0.3

P1.2

P1.1/D–

P1.0/D+

P0.1

P0.2/INT0

P0.0

16-Pin PDIP

V

CC

INT2/P0.4

5

12

TIO1/P0.6

V

SS

Top View

CY7C63801, CY7C63310

1

2

3

4

6

7

8

9

10

11

13

14

16

15

TIO1/P0.6

TIO0/P0.5

INT2/P0.4

INT1/P0.3

P0.1

V

SS

P1.6/SMISO

P1.4/SCLK

P1.3/SSEL

P1.1/D–

P1.0/D+

V

CC

16-Pin SOIC

P1.5/SMOSI

P0.0

5

12

INT0/P0.2

P1.2

CY7C63801, CY7C63310

1

2

3

4

6

7

8

10

11

12

13

15

16

18

17

P0.7

TIO1/P0.6

TIO0/P0.5

INT2/P0.4

INT0/P0.2

P0.0

P1.7

P1.5/SMOSI

P1.4/SCLK

P1.2/VREG

V

CC

P1.1/D–

18-Pin SOIC

P1.6/SMISO

9

P0.1

V

SS

P1.0/D+

CY7C63813

5

14

INT1/P0.3

P1.3/SSEL

1

2

3

4

5

6

9

11

15

16

17

18

19

20

22

21

NC

P0.7

TIO1/P0.6

TIO0/P0.5

INT2/P0.4

INT1/P0.3

P0.0

P2.0

P1.6/SMISO

P3.0

P1.4/SCLK

P3.1

P1.2/VREG

P1.3/SSEL

V

CC

P1.1/D–

14

P1.5/SMOSI

10

P2.1

V

SS

P1.0/D+

12

13

7

8

INT0/P0.2

P0.1

24

23

NC

P1.7

24-Pin SOIC

CY7C63823

1

2

3

4

6

7

8

9

10

11

13

14

16

15

TIO1/P0.6

TIO0/P0.5

INT2/P0.4

INT1/P0.3

P0.1

V

SS

P1.6/SMISO

P1.4/SCLK

P1.3/SSEL

P1.1/D–

P1.0/D+

V

CC

P1.5/SMOSI

P0.0

5

12

INT0/P0.2

P1.2/VREG

CY7C63803

16-Pin SOIC

1

2

3

4

5

6

21

19

23

252226

20

24

18

9

8

12 1310 14 1611

17

15

7

272832

30 29

31

P0.6/TIO1

P0.5/TIO0

P0.4/INT2

P0.3/INT1

P0.2/INT0

P0.1

P0.0

P2.1

P2.0

NCNCNC

Vss

P1.0/D+

P1.1/D-

Vdd

NC

NC

P1.3/SSEL

P3.0

P3.1

P1.4/SCLK

P1.5/SMOSI

P1.6/MISO

P1.7

P0.7NCNCNCNC

NC

P1.2/VREG

1

2

3

4

5

6

21

19

23

252226

20

24

18

9

8

12 1310 14 1611

17

15

7

272832

30 29

31

P0.6/TIO1

P0.5/TIO0

P0.4/INT2

P0.3/INT1

P0.2/INT0

P0.1

P0.0

P2.1

P2.0

NCNCNC

Vss

P1.0/D+

P1.1/D-

Vdd

NC

NC

P1.3/SSEL

P3.0

P3.1

P1.4/SCLK

P1.5/SMOSI

P1.6/MISO

P1.7

P0.7NCNCNCNC

NC

P1.2/VREG

32-Pin QFN

CY7C63833

CY7C63833 32-Pin Sawn QFN

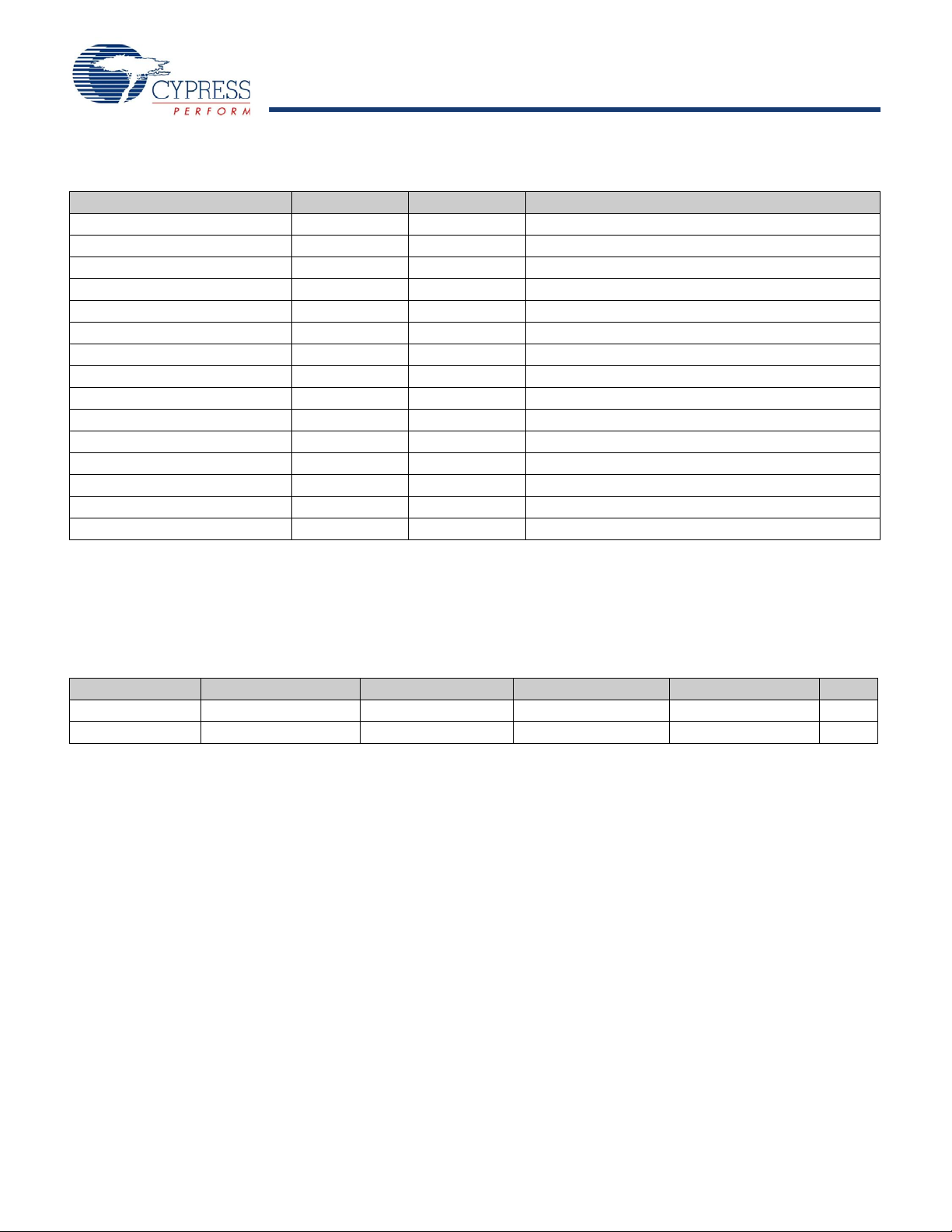

Figure 5-1. Pin Diagrams

Document 38-08035 Rev. *K Page 4 of 83

[+] Feedback [+] Feedback

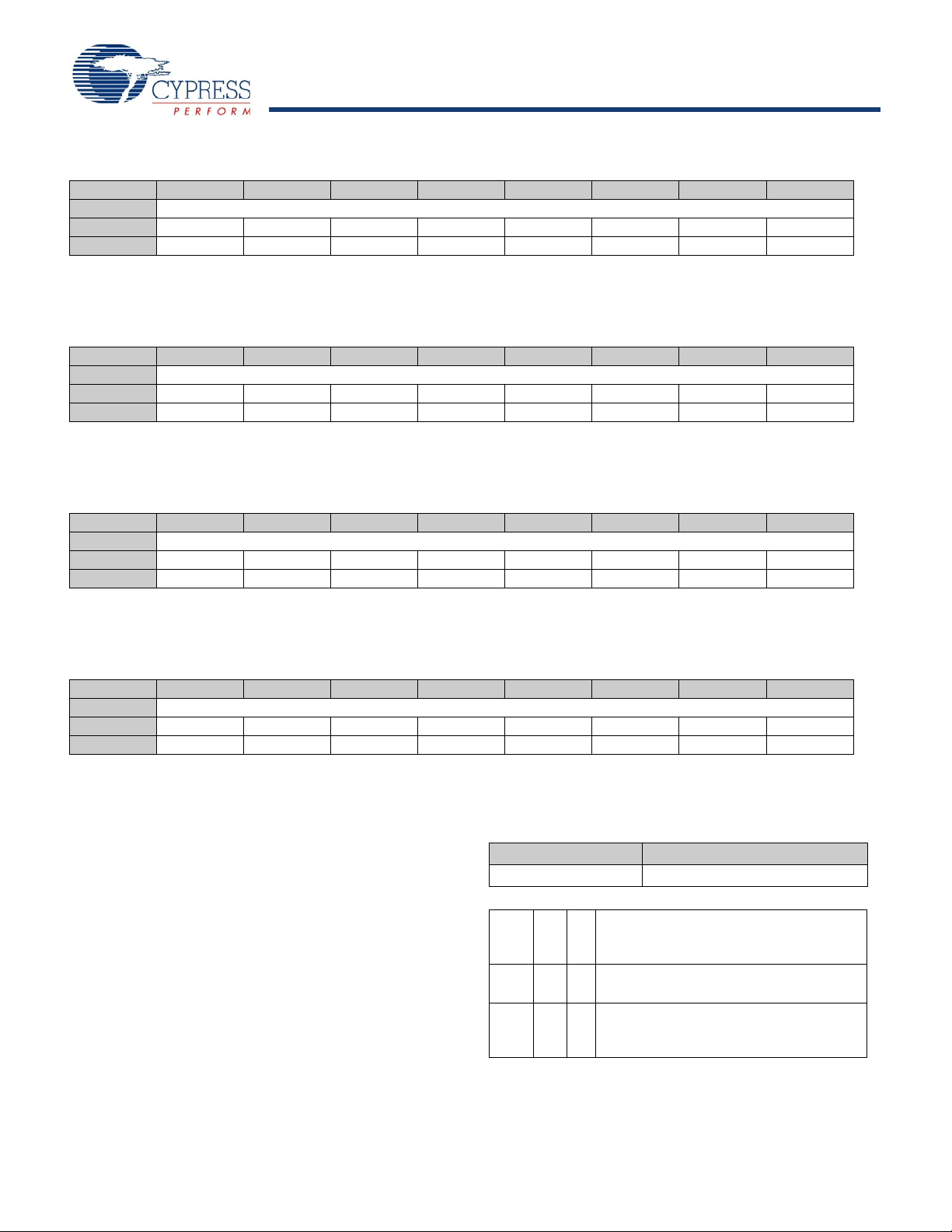

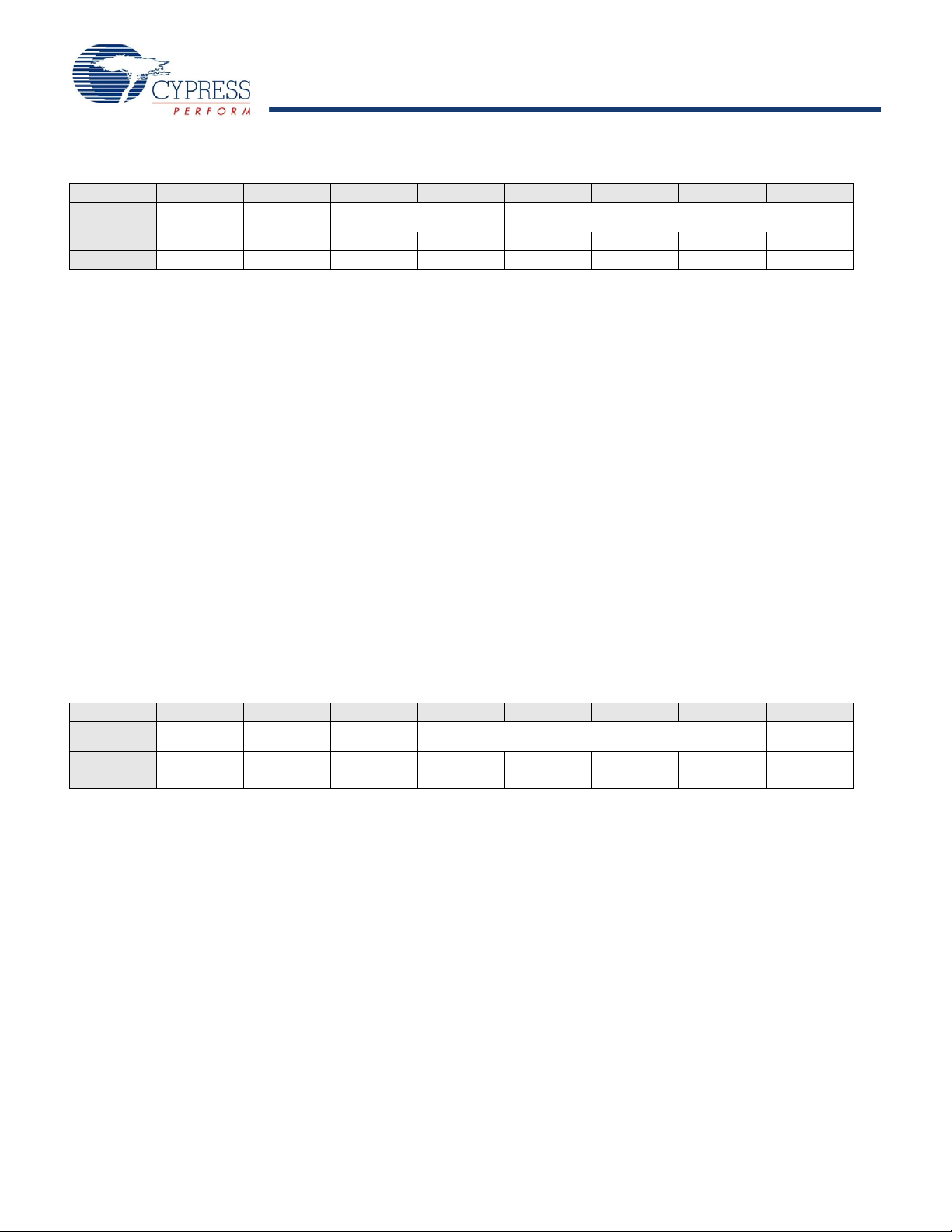

Page 5

CY7C63310, CY7C638xx

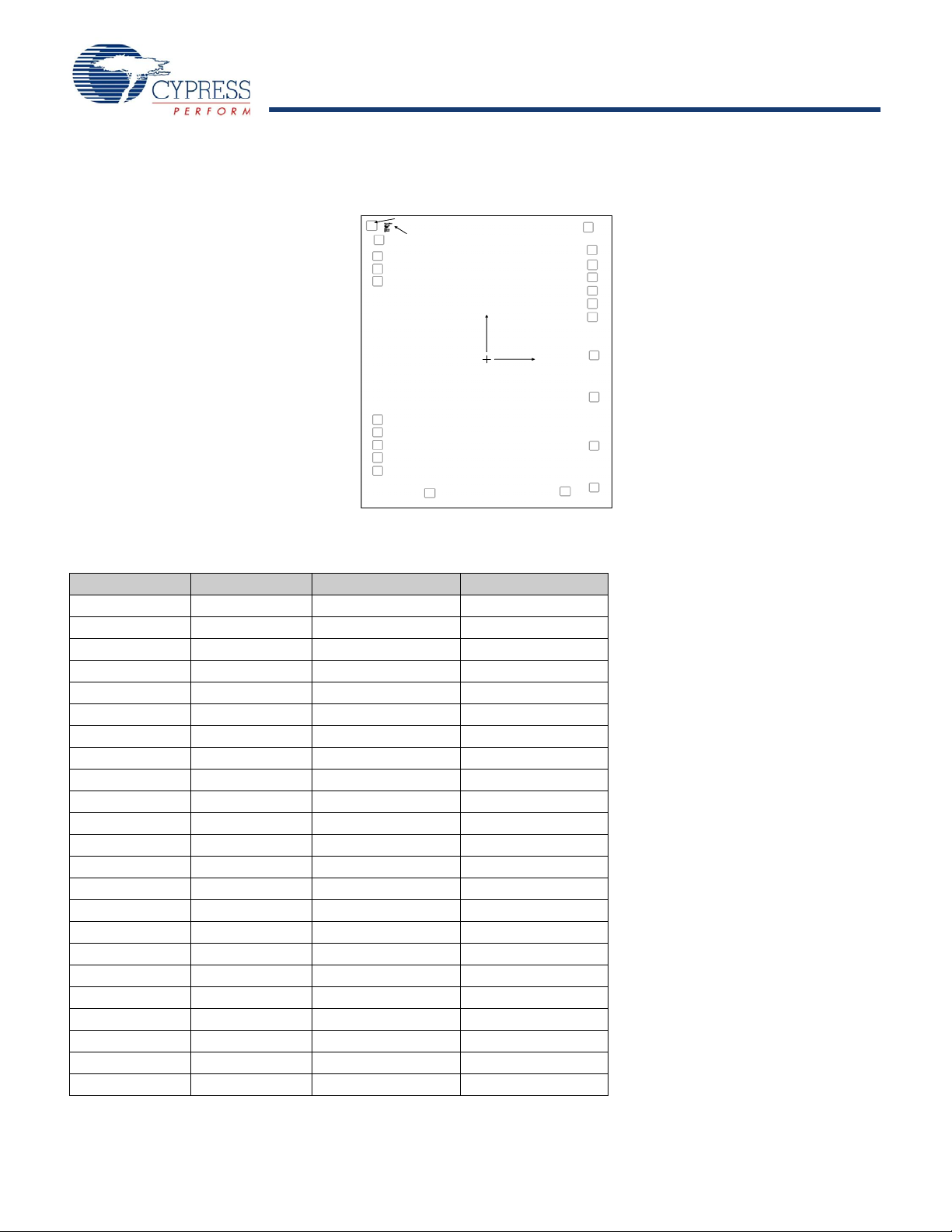

Figure 5-2. CY7C63823 Die Form

Die step = 1792.98 μm x 22 72.998 μm

Die size = 1727 μm x 2187 μ m

Bond pad op enin g = 70 μm x 70 μm

Die thickness = 14 mils

Legend

Cypress Logo

23

1

2

3

4

Y

5

6

7

8

9

10 11

Table 5-1. Die Pad Summary

Pad Number Pad Name X (microns) Y (microns)

1 P0.7 -742.730 911.990

2 P0.6 -755.060 792.200

3 P0.5 -755.060 699.300

4 P0.4 -755.060 606.400

5 P0.3 -755.060 -430.080

6 P0.2 -755.060 -522.980

7 P0.1 -755.060 -618.830

8 P0.0 CLKIN -755.060 -714.020

9 P2.1 -755.060 -810.220

10 P2.0 -393.580 -977.930

11 VSS 537.500 -964.700

12 PI.0 D+ 736.110 -936.680

13 P1.1 D– 736.110 -625.130

14 VDD 736.110 -260.670

15 P1.2 VREG 736.110 53.800

16 P1.3 723.510 336.780

17 P3.0 723.510 438.690

18 P3.1 723.510 532.880

19 P1.4 723.510 635.310

20 P1.5 SMOSI 723.510 728.220

21 P1.6 SMISO 723.510 839.290

22 P1.7 696.630 1008.480

23 Reserved -795.400 1023.270

22

21

20

19

18

17

16

X

15

14

13

12

Document 38-08035 Rev. *K Page 5 of 83

[+] Feedback [+] Feedback

Page 6

CY7C63310, CY7C638xx

Note

1. P1.0(D+) and P1.1(D–) pins must be in IO mode when used as GPIO and in I

sb

mode.

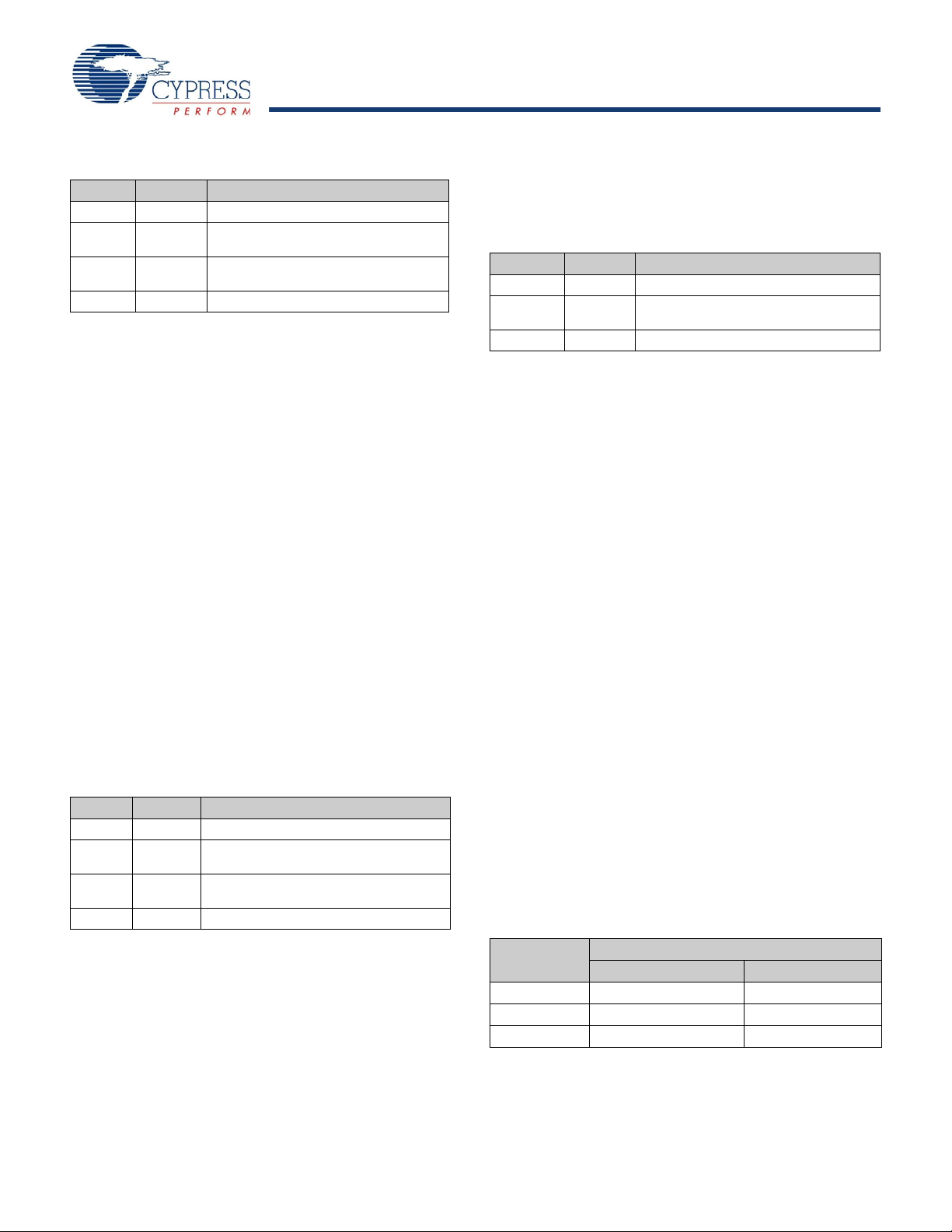

Table 5-2. Pin Description

32

QFN

24

QSOP

24

SOIC18SIOC18PDIP16SOIC16PDIP

Name Description

21 19 18 P3.0 GPIO Port 3. Configured as a group (byte).

22 20 19 P3.1

91111 P2.0GPIO Port 2. Configured as a group (byte).

81010 P2.1

14 14 13 10 15 9 13 P1.0/D+ GPIO Port 1 bit 0/USB D+

[1]

If this pin is used as a

General Purpose output, it draws current. This pin

must be configured as an input to reduce current

draw.

15 15 14 11 16 10 14 P1.1/D– GPIO Port 1 bit 1/USB D–

[1]

If this pin is used as a

General Purpose output, it draws current. This pin

must be configured as an input to reduce current

draw.

18 17 16 13 18 12 16 P1.2/VREG GPIO Port 1 bit 2. Configured individually.

3.3V if regulator is enabled. (The 3.3V regulator is not

available in the CY7C63310 and CY7C63801.) A 1-μF

min, 2-μF max capacitor is required on Vreg output.

20 18 17 14 1 13 1 P1.3/SSEL GPIO Port 1 bit 3. Configured individually.

Alternate function is SSEL signal of the SPI bus TTL

voltage thresholds. Although Vreg is not available

with the CY7C63310, 3.3V IO is still available.

23 21 20 15 2 14 2 P1.4/SCLK GPIO Port 1 bit 4. Configured individually.

Alternate function is SCLK signal of the SPI bus TTL

voltage thresholds. Although Vreg is not available

with the CY7C63310, 3.3V IO is still available.

24 22 21 16 3 15 3 P1.5/SMOSI GPIO Port 1 bit 5. Configured individually.

Alternate function is SMOSI signal of the SPI bus TTL

voltage thresholds. Although Vreg is not available

with the CY7C63310, 3.3V IO is still available.

25 23 22 17 4 16 4 P1.6/SMISO GPIO Port 1 bit 6. Configured individually.

Alternate function is SMISO signal of the SPI bus TTL

voltage thresholds. Although Vreg is not available

with the CY7C63310, 3.3V IO is still available.

26 24 23 18 5 P1.7 GPIO Port 1 bit 7. Configured individually.

TTL voltage threshold.

7 9 9 8 13 7 11 P0.0 GPIO Port 0 bit 0. Configured individually.

On CY7C638xx and CY7C63310, external clock

input when configured as Clock In.

6 8 8 7 12 6 10 P0.1 GPIO Port 0 bit 1. Configured individually.

On CY7C638xx and CY7C63310, clock output when

configured as Clock Out.

57761159P0.2/INT0GPIO Port 0 bit 2. Configured individually.

Optional rising edge interrupt INT0.

46651048P0.3/INT1GPIO Port 0 bit 3. Configured individually.

Optional rising edge interrupt INT1.

3 5 5 4 9 3 7 P0.4/INT2 GPIO Port 0 bit 4. Configured individually.

Optional rising edge interrupt INT2.

Document 38-08035 Rev. *K Page 6 of 83

[+] Feedback [+] Feedback

Page 7

CY7C63310, CY7C638xx

Table 5-2. Pin Description (continued)

32

QFN

2 4 4 3 8 2 6 P0.5/TIO0 GPIO Port 0 bit 5. Configured individually

1 3 3 2 7 1 5 P0.6/TIO1 GPIO Port 0 bit 6. Configured individually

32 2 2 1 6 P0.7 GPIO Port 0 bit 7. Configured individually

10 1 1 NC No connect

11 12 24 NC No connect

12 NC No connect

17 NC No connect

19 NC No connect

27 NC No connect

28 NC No connect

29 NC No connect

30 NC No connect

31 NC No connect

16 16 15 12 17 11 15 Vcc Supply

13 13 12 9 14 8 12 V

24

QSOP

24

SOIC18SIOC18PDIP16SOIC16PDIP

Name Description

Alternate function Timer capture inputs or Timer

output TIO0

Alternate function Timer capture inputs or Timer

output TIO1

Not present in the 16 pin PDIP or SOIC package

SS

Ground

6. CPU Architecture

This family of microcontrollers is based on a high performance,

8-bit, Harvard architecture microprocessor. Five registers control

the primary operation of the CPU core. These registers are

affected by various instructions, but are not directly accessible

through the register space by the user.

Table 6-1. CPU Registers and Register Names

CPU Register Register Name

Flags CPU_F

Program Counter CPU_PC

Accumulator CPU_A

Stack Pointer CPU_SP

Index CPU_X

The 16-bit Program Counter Register (CPU_PC) allows direct

addressing of the full 8 Kbytes of program memory space.

The Accumulator Register (CPU_A) is the general purpose

register, which holds the results of instructions that specify any

of the source addressing modes.

The Index Register (CPU_X) holds an offset value that is used

in the indexed addressing modes. Typically, this is used to

address a block of data within the data memory space.

The Stack Pointer Register (CPU_SP) holds the address of the

current top of the stack in the data memory space. It is affected

by the PUSH, POP, LCALL, CALL, RETI, and RET instructions,

which manage the software stack. It is also affected by the SWAP

and ADD instructions.

The Flag Register (CPU_F) has three status bits: Zero Flag bit

[1]; Carry Flag bit [2]; Supervisory State bit [3]. The Global

Interrupt Enable bit [0] globally enables or disables interrupts.

The user cannot manipulate the Supervisory State status bit [3].

The flags are affected by arithmetic, logic, and shift operations.

The manner in which each flag is changed is dependent upon

the instruction being executed, such as AND, OR, XOR, and

others. See Table 8-1 on page 12.

Document 38-08035 Rev. *K Page 7 of 83

[+] Feedback [+] Feedback

Page 8

CY7C63310, CY7C638xx

7. CPU Registers

The CPU registers in enCoRe II devices are in two banks with 256 registers in each bank. Bit[4]/XIO bit in the CPU Flags register

must be set/cleared to select between the two register banks Table 7-1 on page 8

7.1 Flags Register

The Flags Register is set or reset only with logical instruction.

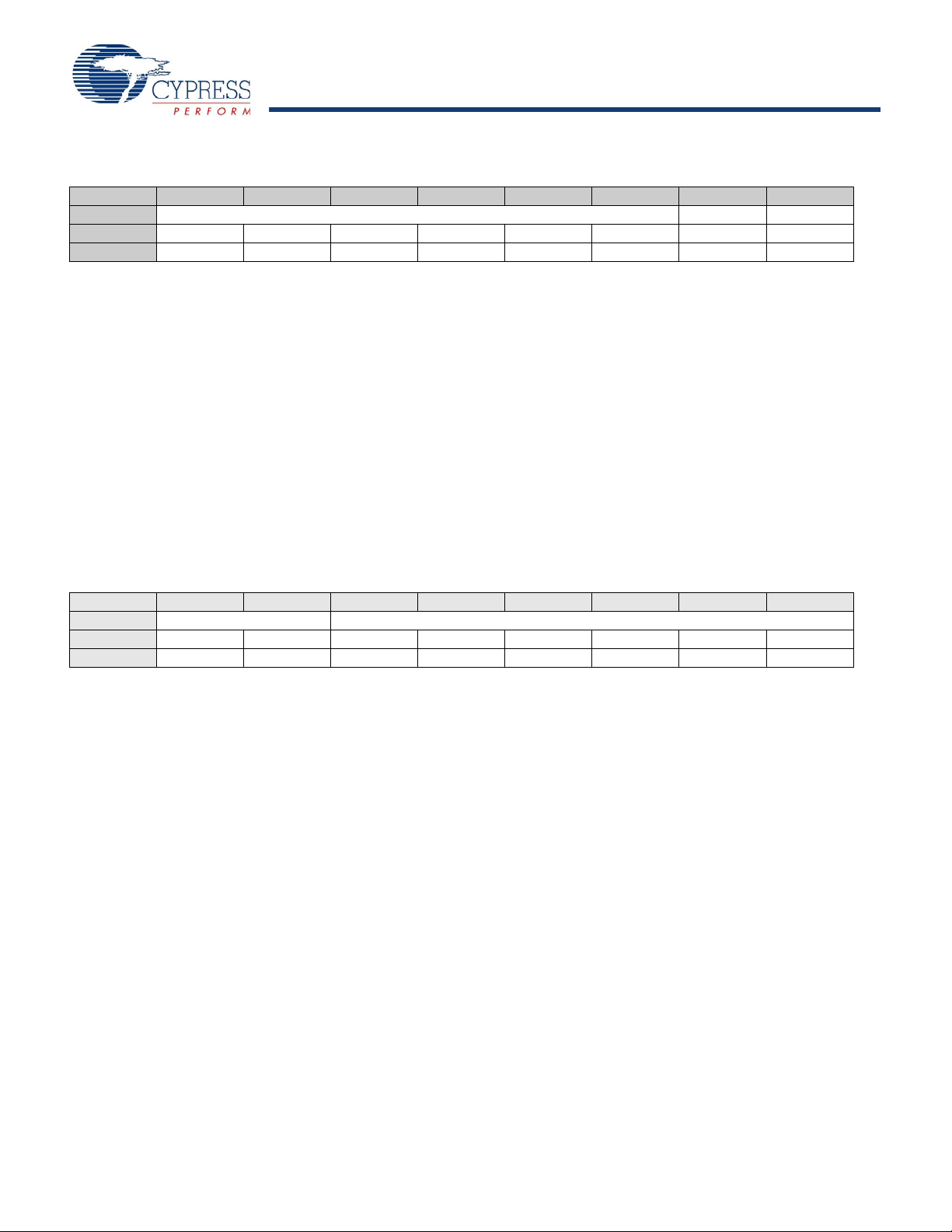

Table 7-1. CPU Flags Register (CPU_F) [R/W]

Bit # 7 6 5 4 3 2 1 0

Field Reserved XIO Super Carry Zero Global IE

Read/Write – – – R/W R RW RW RW

Default 00000010

Bit [7:5]: Reserved

Bit 4: XIO

Set by the user to select between the register banks

0 = Bank 0

1 = Bank 1

Bit 3: Super

Indicates whether the CPU is executing user code or Supervisor Code. (This code cannot be accessed directly by the user.)

0 = User Code

1 = Supervisor Code

Bit 2: Carry

Set by the CPU to indicate whether there has been a carry in the previous logical/arithmetic operation.

0 = No Carry

1 = Carry

Bit 1: Zero

Set by the CPU to indicate whether there has been a zero result in the previous logical/arithmetic operation.

0 = Not Equal to Zero

1 = Equal to Zero

Bit 0: Global IE

Determines whether all interrupts are enabled or disabled

0 = Disabled

1 = Enabled

Note CPU_F register is only readable with the explicit register address 0xF7. The OR F, expr and AND F, expr instructions must

be used to set and clear the CPU_F bits.

Table 7-2. CPU Accumulator Register (CPU_A)

Bit # 7 6 5 4 3 2 1 0

Field CPU Accumulator [7:0]

Read/Write ––––––––

Default 00000000

Bit [7:0]: CPU Accumulator [7:0]

8-bit data value holds the result of any logical/arithmetic instruction that uses a source addressing mode

Document 38-08035 Rev. *K Page 8 of 83

[+] Feedback [+] Feedback

Page 9

CY7C63310, CY7C638xx

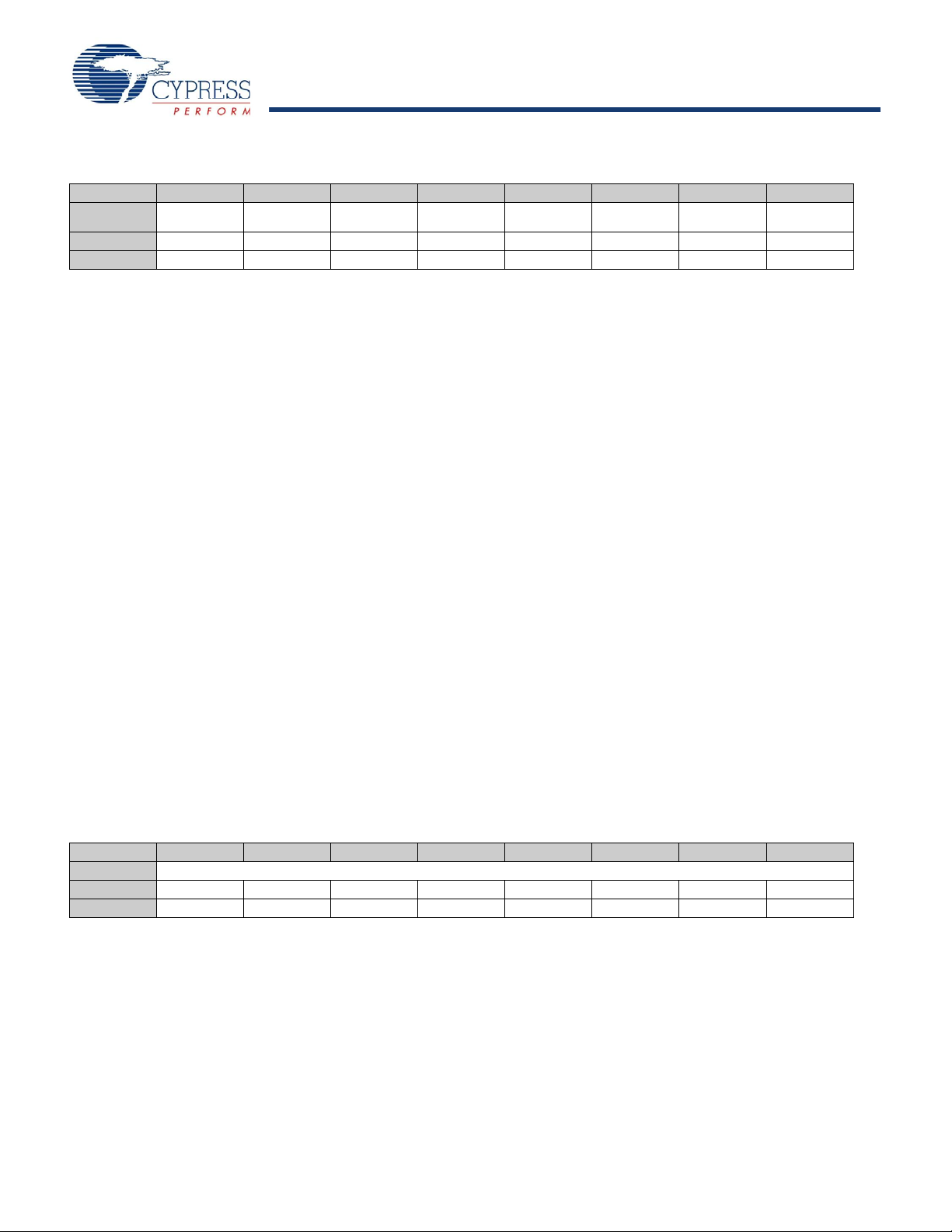

Table 7-3. CPU X Register (CPU_X)

Bit # 7 6 5 4 3 2 1 0

Field X [7:0]

Read/Write ––––––––

Default 00000000

Bit [7:0]: X [7:0]

8-bit data value holds an index for any instruction that uses an indexed addressing mode.

Table 7-4. CPU Stack Pointer Register (CPU_SP)

Bit # 7 6 5 4 3 2 1 0

Field Stack Pointer [7:0]

Read/Write ––––––––

Default 00000000

Bit [7:0]: Stack Pointer [7:0]

8-bit data value holds a pointer to the current top of the stack.

Table 7-5. CPU Program Counter High Register (CPU_PCH)

Bit # 7 6 5 4 3 2 1 0

Field Program Counter [15:8]

Read/Write ––––––––

Default 00000000

Bit [7:0]: Program Counter [15:8]

8-bit data value holds the higher byte of the program counter.

Table 7-6. CPU Program Counter Low Register (CPU_PCL)

Bit # 7 6 5 4 3 2 1 0

Field Program Counter [7:0]

Read/Write ––––––––

Default 00000000

Bit [7:0]: Program Counter [7:0]

8-bit data value holds the lower byte of the program counter.

7.2 Addressing Modes

7.2.1 Source Immediate

The result of an instruction using this addressing mode is placed

in the A register, the F register, the SP register, or the X register,

which is specified as part of the instruction opcode. Operand 1

is an immediate value that serves as a source for the instruction.

Arithmetic instructions require two sources; the second source is

the A or the X register specified in the opcode. Instructions using

this addressing mode are two bytes in length.

Table 7-7. Source Immediate

Opcode Operand 1

Instruction Immediate Value

Examples

ADD A 7 The immediate value of 7 is added with the

Accumulator and the result is placed in the

Accumulator.

MOV X 8 The immediate value of 8 is moved to the X

register.

AND F 9 The immediate value of 9 is logically ANDed with

the F register and the result is placed in the F

register.

Document 38-08035 Rev. *K Page 9 of 83

[+] Feedback [+] Feedback

Page 10

CY7C63310, CY7C638xx

7.2.2 Source Direct

The result of an instruction using this addressing mode is placed

in either the A register or the X register, which is specified as part

of the instruction opcode. Operand 1 is an address that points to

a location in the RAM memory space or the register space that

is the source of the instruction. Arithmetic instructions require

two sources; the second source is the A register or X register

specified in the opcode. Instructions using this addressing mode

are two bytes in length.

7.2.4 Destination Direct

The result of an instruction using this addressing mode is placed

within the RAM memory space or the register space. Operand 1

is an address that points to the location of the result. The source

for the instruction is either the A register or the X register, which

is specified as part of the instruction opcode. Arithmetic instructions require two sources; the second source is the location

specified by Operand 1. Instructions using this addressing mode

are two bytes in length.

Table 7-8. Source Direct

Opcode Operand 1

Instruction Source Address

Examples

ADD A [7] The value in the RAM memory location at

address 7 is added with the Accumulator,

and the result is placed in the Accumulator.

MOV X REG[8] The value in the register space at address

8 is moved to the X register.

7.2.3 Source Indexed

The result of an instruction using this addressing mode is placed

in either the A register or the X register, which is specified as part

of the instruction opcode. Operand 1 is added to the X register

forming an address that points to a location in the RAM memory

space or the register space that is the source of the instruction.

Arithmetic instructions require two sources; the second source is

the A register or X register specified in the opcode. Instructions

using this addressing mode are two bytes in length.

Table 7-9. Source Indexed

Opcode Operand 1

Instruction Source Index

Examples

Table 7-10. Destination Direct

Opcode Operand 1

Instruction Destination Address

Examples

ADD [7] A The value in the memory location at

address 7 is added with the Accumulator, and the result is placed in the

memory location at address 7. The

Accumulator is unchanged.

MOV REG[8] A The Accumulator is moved to the

register space location at address 8.

The Accumulator is unchanged.

7.2.5 Destination Indexed

The result of an instruction using this addressing mode is placed

within the RAM memory space or the register space. Operand 1

is added to the X register forming the address that points to the

location of the result. The source for the instruction is the A

register. Arithmetic instructions require two sources; the second

source is the location specified by Operand 1 added with the X

register. Instructions using this addressing mode are two bytes

in length.

Table 7-11. Destination Indexed

Opcode Operand 1

Instruction Destination Index

ADD A [X+7] The value in the memory location at

address X + 7 is added with the

Accumulator, and the result is placed

in the Accumulator.

MOV X REG[X+8] The value in the register space at

address X + 8 is moved to the X

register.

Example

ADD [X+7] A The value in the; memory location at

address X+7 is added with the Accumulator, and the result is placed in the

memory location at address x+7. The

Accumulator is unchanged.

Document 38-08035 Rev. *K Page 10 of 83

[+] Feedback [+] Feedback

Page 11

CY7C63310, CY7C638xx

7.2.6 Destination Direct Source Immediate

The result of an instruction using this addressing mode is placed

within the RAM memory space or the register space. Operand 1

is the address of the result. The source of the instruction is

Operand 2, which is an immediate value. Arithmetic instructions

require two sources; the second source is the location specified

by Operand 1. Instructions using this addressing mode are three

bytes in length.

Table 7-12. Destination Direct Source Immediate

Opcode Operand 1 Operand 2

Instruction Destination Address Immediate Value

Examples

ADD [7] 5

MOV REG[8] 6 The immediate value of 6 is moved into the

The value in the memory location at address

7 is added to the immediate value of 5, and

the result is placed in the memory location at

address 7.

register space location at address 8.

7.2.7 Destination Indexed Source Immediate

The result of an instruction using this addressing mode is placed

within the RAM memory space or the register space. Operand 1

is added to the X register to form the address of the result. The

source of the instruction is Operand 2, which is an immediate

value. Arithmetic instructions require two sources; the second

source is the location specified by Operand 1 added with the X

register. Instructions using this addressing mode are three bytes

in length.

Table 7-13. Destination Indexed Source Immediate

Opcode Operand 1 Operand 2

Instruction Destination Index Immediate Value

Examples

ADD [X+7] 5 The value in the memory location at

address X+7 is added with the

immediate value of 5, and the result

is placed in the memory location at

address X+7.

MOV REG[X+8] 6 The immediate value of 6 is moved

into the location in the register space

at address X+8.

7.2.8 Destination Direct Source Direct

The result of an instruction using this addressing mode is placed

within the RAM memory. Operand 1 is the address of the result.

Operand 2 is an address that points to a location in the RAM

memory that is the source for the instruction. This addressing

mode is only valid on the MOV instruction. The instruction using

this addressing mode is three bytes in length.

.

Table 7-14. Destination Direct Source Direct

Opcode Operand 1 Operand 2

Instruction Destination Address Source Address

Example

MOV [7] [8] The value in the memory location at address 8

is moved to the memory location at address 7.

7.2.9 Source Indirect Post Increment

The result of an instruction using this addressing mode is placed

in the Accumulator. Operand 1 is an address pointing to a

location within the memory space, which contains an address

(the indirect address) for the source of the instruction. The

indirect address is incremented as part of the instruction

execution. This addressing mode is only valid on the MVI

instruction. The instruction using this addressing mode is two

bytes in length. Refer to the PSoC Designer: Assembly

Language User Guide for further details on MVI instruction.

Table 7-15. Source Indirect Post Increment

Opcode Operand 1

Instruction Source Address Address

Example

MVI A [8] The value in the memory location at address

8 is an indirect address. The memory location

pointed to by the indirect address is moved

into the Accumulator. The indirect address is

then incremented.

7.2.10 Destination Indirect Post Increment

The result of an instruction using this addressing mode is placed

within the memory space. Operand 1 is an address pointing to a

location within the memory space, which contains an address

(the indirect address) for the destination of the instruction. The

indirect address is incremented as part of the instruction

execution. The source for the instruction is the Accumulator. This

addressing mode is only valid on the MVI instruction. The

instruction using this addressing mode is two bytes in length.

Table 7-16. Destination Indirect Post Increment

Opcode Operand 1

Instruction Destination Address Address

Example

MVI [8] A The value in the memory location at

address 8 is an indirect address. The

Accumulator is moved into the memory

location pointed to by the indirect

address. The indirect address is then

incremented.

Document 38-08035 Rev. *K Page 11 of 83

[+] Feedback [+] Feedback

Page 12

CY7C63310, CY7C638xx

8. Instruction Set Summary

Notes

2. Interrupt routines take 13 cycles before execution resumes at interrupt vector table.

3. The number of cycles required by an instruction is increased by one for instructions that span 256 byte boundaries in the Flash memory space.

The instruction set is summarized in Ta bl e 8- 1 numerically and serves as a quick reference. If more information is needed, the

Instruction Set Summary tables are described in detail in the PSoC Designer Assembly Language User Guide (available on the

Cypress web site at http://www.cypress.com).

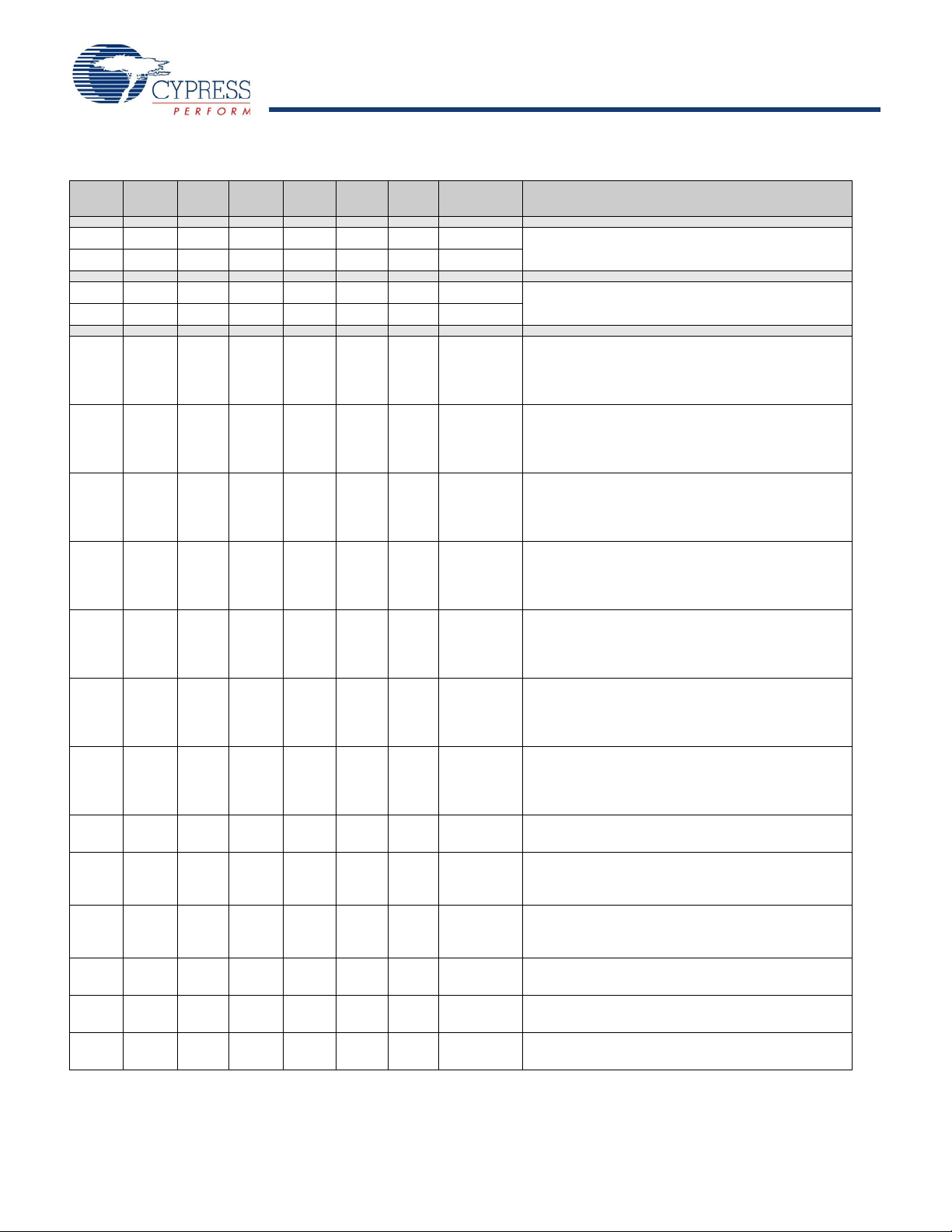

Table 8-1. Instruction Set Summary Sorted Numerically by Opcode Order

Opcode Hex

Cycles

Bytes

Instruction Format Flags

00 15 1 SSC 2D 8 2 OR [X+expr], A Z 5A 5 2 MOV [expr], X

01 4 2 ADD A, expr C, Z 2E 9 3 OR [expr], expr Z 5B 4 1 MOV A, X Z

02 6 2 ADD A, [expr] C, Z 2F 10 3 OR [X+expr], expr Z 5C 4 1 MOV X, A

03 7 2 ADD A, [X+expr] C, Z 30 9 1 HALT 5D 6 2 MOV A, reg[expr] Z

04 7 2 ADD [expr], A C, Z 31 4 2 XOR A, expr Z 5E 7 2 MOV A, reg[X+expr] Z

05 8 2 ADD [X+expr], A C, Z 32 6 2 XOR A, [expr] Z 5F 10 3 MOV [expr], [expr]

06 9 3 ADD [expr], expr C, Z 33 7 2 XOR A, [X+expr] Z 60 5 2 MOV reg[expr], A

07 10 3 ADD [X+expr], expr C, Z 34 7 2 XOR [expr], A Z 61 6 2 MOV reg[X+expr], A

08 4 1 PUSH A 35 8 2 XOR [X+expr], A Z 62 8 3 MOV reg[expr], expr

09 4 2 ADC A, expr C, Z 36 9 3 XOR [expr], expr Z 63 9 3 MOV reg[X+expr], expr

0A 6 2 ADC A, [expr] C, Z 37 10 3 XOR [X+expr], expr Z 64 4 1 ASL A C, Z

0B 7 2 ADC A, [X+expr] C, Z 38 5 2 ADD SP, expr 65 7 2 ASL [expr] C, Z

0C 7 2 ADC [expr], A C, Z 39 5 2 CMP A, expr

0D 8 2 ADC [X+expr], A C, Z 3A 7 2 CMP A, [expr] 67 4 1 ASR A C, Z

0E 9 3 ADC [expr], expr C, Z 3B 8 2 CMP A, [X+expr] 68 7 2 ASR [expr] C, Z

0F 10 3 ADC [X+expr], expr C, Z 3C 8 3 CMP [expr], expr 69 8 2 ASR [X+expr] C, Z

10 4 1 PUSH X 3D 9 3 CMP [X+expr], expr 6A 4 1 RLC A C, Z

11 4 2 SUB A, expr C, Z 3E 10 2 MVI A, [ [expr]++] Z 6B 7 2 RLC [expr] C, Z

12 6 2 SUB A, [expr] C, Z 3F 10 2 MVI [ [expr]++], A 6C 8 2 RLC [X+expr] C, Z

13 7 2 SUB A, [X+expr] C, Z 40 4 1 NOP 6D 4 1 RRC A C, Z

14 7 2 SUB [expr], A C, Z 41 9 3 AND reg[expr], expr Z 6E 7 2 RRC [expr] C, Z

15 8 2 SUB [X+expr], A C, Z 42 10 3 AND reg[X+expr], expr Z 6F 8 2 RRC [X+expr] C, Z

16 9 3 SUB [expr], expr C, Z 43 9 3 OR reg[expr], expr Z 70 4 2 AND F, expr C, Z

17 10 3 SUB [X+expr], expr C, Z 44 10 3 OR reg[X+expr], expr Z 71 4 2 OR F, expr C, Z

18 5 1 POP A Z 45 9 3 XOR reg[expr], expr Z 72 4 2 XOR F, expr C, Z

19 4 2 SBB A, expr C, Z 46 10 3 XOR reg[X+expr], expr Z 73 4 1 CPL A Z

1A 6 2 SBB A, [expr] C, Z 47 8 3 TST [expr], expr Z 74 4 1 INC A C, Z

1B 7 2 SBB A, [X+expr] C, Z 48 9 3 TST [X+expr], expr Z 75 4 1 INC X C, Z

1C 7 2 SBB [expr], A C, Z 49 9 3 TST reg[expr], expr Z 76 7 2 INC [expr] C, Z

1D 8 2 SBB [X+expr], A C, Z 4A 10 3 TST reg[X+expr], expr Z 77 8 2 INC [X+expr] C, Z

1E 9 3 SBB [expr], expr C, Z 4B 5 1 SWAP A, X Z 78 4 1 DEC A C, Z

1F 10 3 SBB [X+expr], expr C, Z 4C 7 2 SWAP A, [expr] Z 79 4 1 DEC X C, Z

20 5 1 POP X 4D 7 2 SWAP X, [expr] 7A 7 2 DEC [expr] C, Z

21 4 2 AND A, expr Z 4E 5 1 SWAP A, SP Z 7B 8 2 DEC [X+expr] C, Z

22 6 2 AND A, [expr] Z 4F 4 1 MOV X, SP 7C 13 3 LCALL

23 7 2 AND A, [X+expr] Z 50 4 2 MOV A, expr Z 7D 7 3 LJMP

24 7 2 AND [expr], A Z 51 5 2 MOV A, [expr] Z 7E 10 1 RETI C, Z

25 8 2 AND [X+expr], A Z 52 6 2 MOV A, [X+expr] Z 7F 8 1 RET

26 9 3 AND [expr], expr Z 53 5 2 MOV [expr], A 8x 5 2 JMP

27 10 3 AND [X+expr], expr Z 54 6 2 MOV [X+expr], A 9x 11 2 CALL

28 11 1 ROMX Z 55 8 3 MOV [expr], expr Ax 5 2 JZ

29 4 2 OR A, expr Z 56 9 3 MOV [X+expr], expr Bx 5 2 JNZ

2A 6 2 OR A, [expr] Z 57 4 2 MOV X, expr Cx 5 2 JC

2B 7 2 OR A, [X+expr] Z 58 6 2 MOV X, [expr] Dx 5 2 JNC

2C 7 2 OR [expr], A Z 59 7 2 MOV X, [X+expr] Ex 7 2 JACC

Opcode Hex

Cycles

Bytes

Instruction Format Flags

[2, 3]

if (A=B) Z=1

if (A<B) C=1

Opcode Hex

Cycles

Bytes

Instruction Format Flags

66 8 2 ASL [X+expr] C, Z

Fx 13 2 INDEX Z

Document 38-08035 Rev. *K Page 12 of 83

[+] Feedback [+] Feedback

Page 13

CY7C63310, CY7C638xx

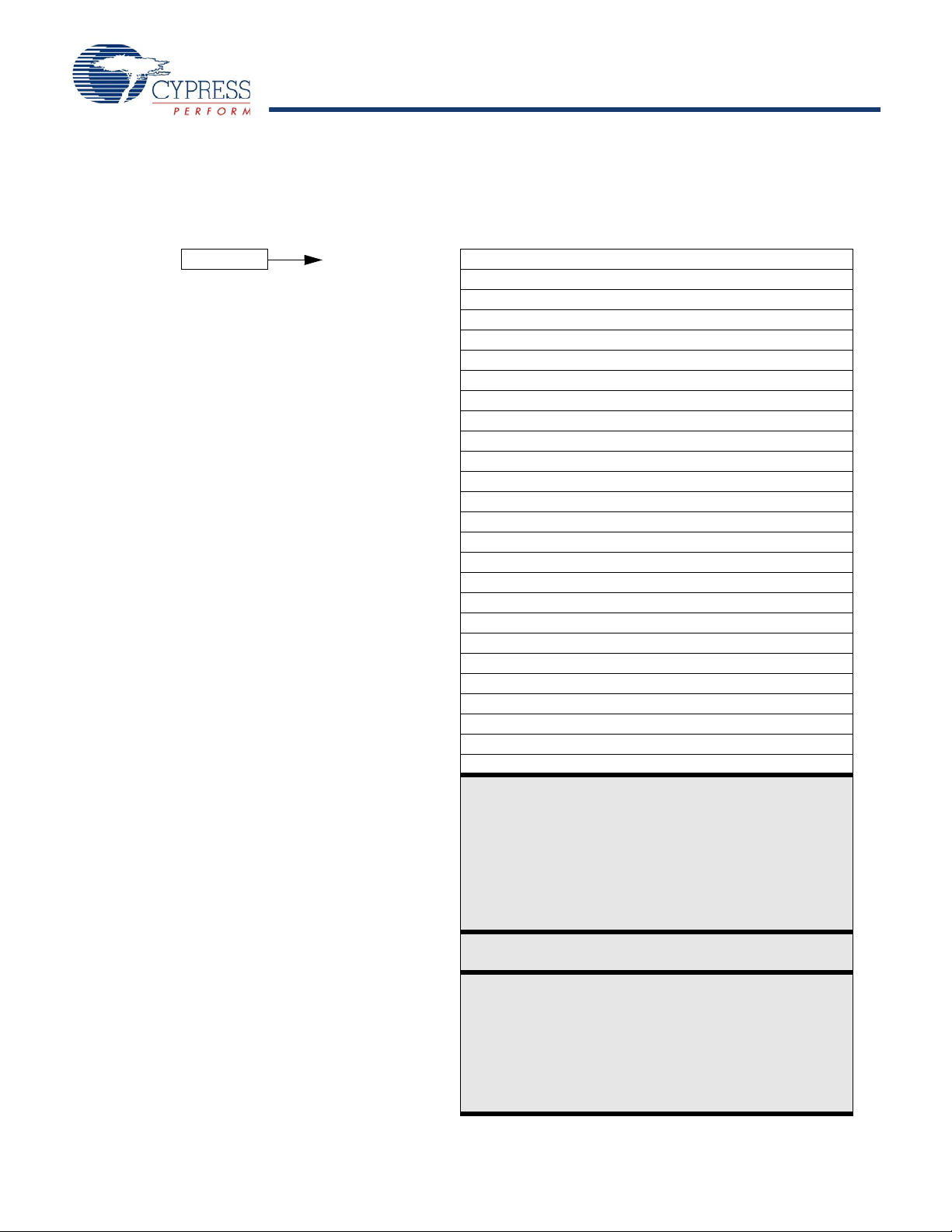

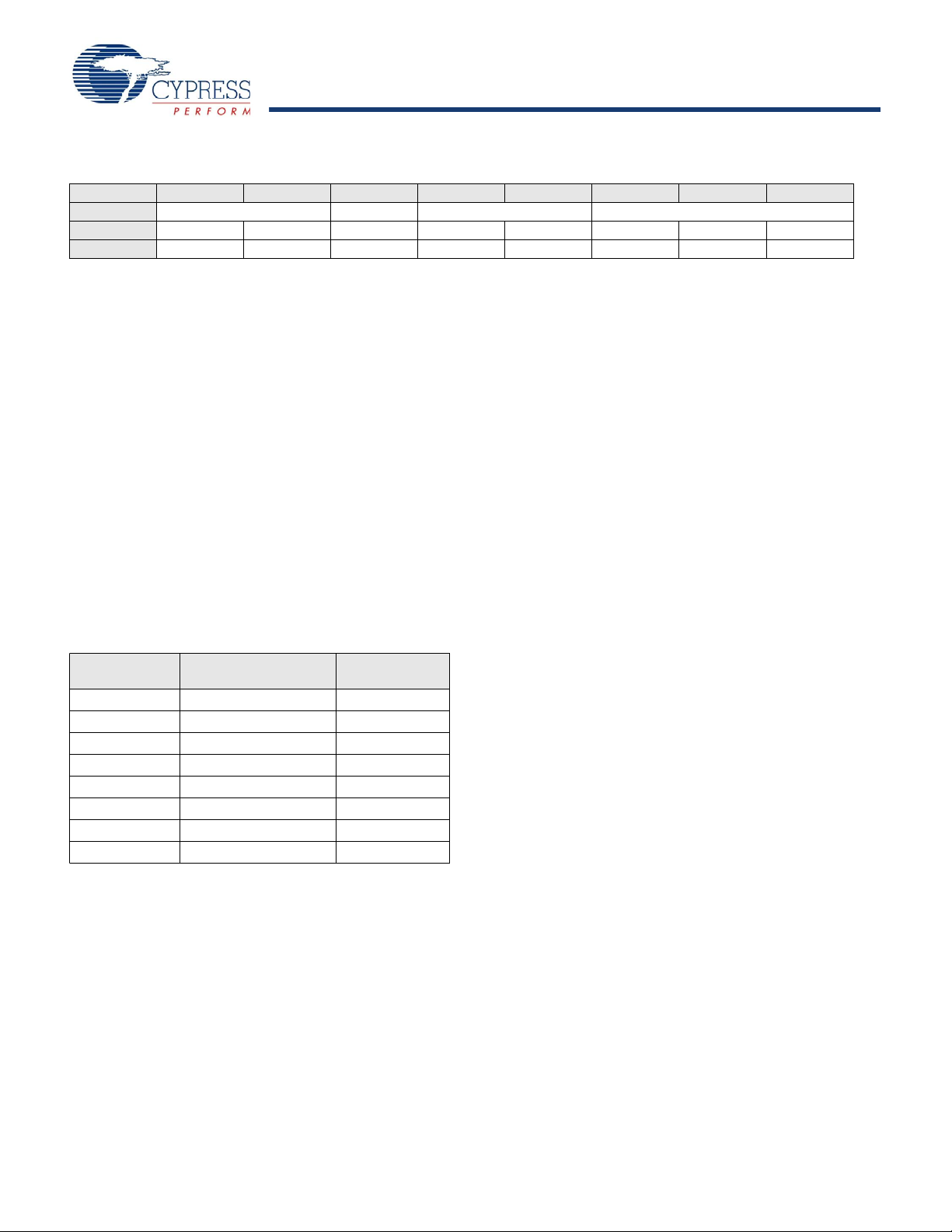

9. Memory Organization

9.1 Flash Program Memory Organization

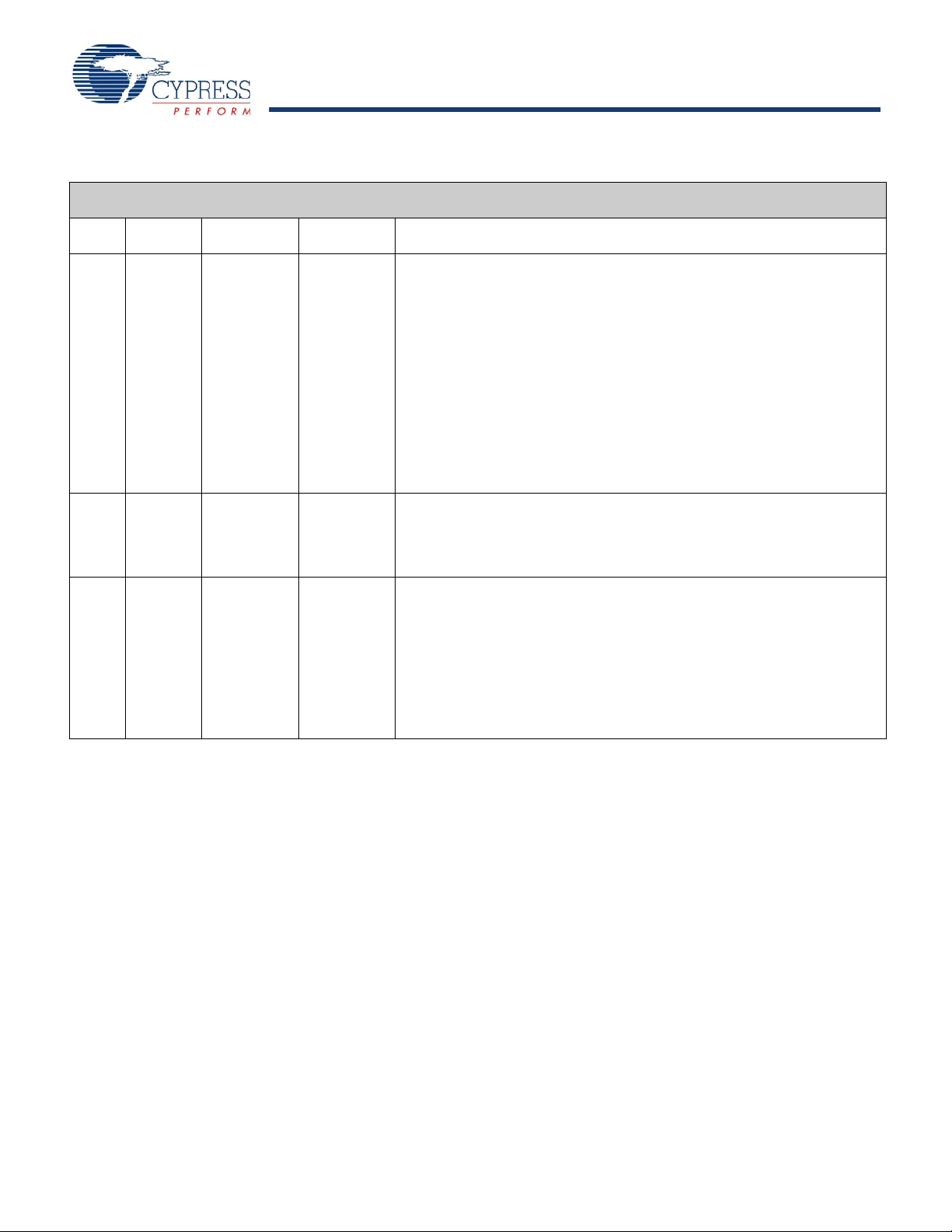

Figure 9-1. Program Memory Space with Interrupt Vector Table

after reset Address

16-bit PC 0x0000 Program execution begins here after a reset

0x0004 POR/LVD

0x0008 INT0

0x000C SPI Transmitter Empty

0x0010 SPI Receiver Full

0x0014 GPIO Port 0

0x0018 GPIO Port 1

0x001C INT1

0x0020 EP0

0x0024 EP1

0x0028 EP2

0x002C USB Reset

0x0030 USB Active

0x0034 1 ms Interval timer

0x0038 Programmable Interval Timer

0x003C Timer Capture 0

0x0040 Timer Capture 1

0x0044 16-bit Free Running Timer Wrap

0x0048 INT2

0x004C PS2 Data Low

0x0050 GPIO Port 2

0x0054 GPIO Port 3

0x0058 Reserved

0x005C Reserved

0x0060 Reserved

0x0064 Sleep Timer

0x0068 Program Memory begins here (if below interrupts not used ,

program memory can start lower)

0x0BFF 3 KB ends here (CY7C63310)

0x0FFF 4 KB en ds here (CY7C63801)

0x1FFF 8 KB en ds here (CY7C638x3)

Document 38-08035 Rev. *K Page 13 of 83

[+] Feedback [+] Feedback

Page 14

CY7C63310, CY7C638xx

9.2 Data Memory Organization

The CY7C63310/638xx microcontrollers provide up to 256 bytes of data RAM.

Figure 9-2. Data Memory Organization

after reset Address

8-bit PSP 0x00 Stack begins here and grows upward.

Top of RAM Memory 0xFF

9.3 Flash

This section describes the Flash block of the enCoRe II. Much of

the user visible Flash functionality including programming and

security are implemented in the M8C Supervisory Read Only

Memory (SROM). The enCoRe II Flash has an endurance of

1000 cycles and a 10 year data retention capability.

9.3.1 Flash Programming and Security

All Flash programming is performed by code in the SROM. The

registers that control the Flash programming are only visible to

the M8C CPU when it executes out of SROM. This makes it

impossible to read, write or erase the Flash by bypassing the

security mechanisms implemented in the SROM.

Customer firmware can program the Flash only through SROM

calls. The data or code images are sourced through any interface

with the appropriate support firmware. This type of programming

requires a ‘boot-loader’, which is a piece of firmware resident on

the Flash. For safety reasons this boot-loader must not be

overwritten during firmware rewrites.

The Flash provides four extra auxiliary rows that are used to hold

Flash block protection flags, boot time calibration values,

configuration tables, and any device values. The routines for

accessing these auxiliary rows are documented in the section

SROM on page 14 section. The auxiliary rows are not affected

by the device erase function.

9.3.2 In System Programming

Most designs that include an enCoRe II part have a USB

connector attached to the USB D+ and D– pins on the device.

These designs require the ability to program or reprogram a part

through the USB D+ and D– pins alone.

The enCoRe II devices enable this type of in system

programming by using the D+ and D– pins as the serial

programming mode interface. This allows an external controller

to enable the enCoRe II part to enter the serial programming

mode, and then use the test queue to issue Flash access

functions in the SROM. The programming protocol is not USB.

9.4 SROM

The SROM holds code that boots the part, calibrates circuitry,

and performs Flash operations (Table 9-1 on page 14 lists the

SROM functions). The functions of the SROM are accessed in

the normal user code or operating from Flash. The SROM exists

in a separate memory space from the user code. The SROM

functions are accessed by executing the Supervisory System

Call instruction (SSC), which has an opcode of 00h. Before

executing the SSC the M8C’s accumulator must be loaded with

the desired SROM function code from Table 9-1 on page 14.

Undefined functions cause a HALT if called from the user code.

The SROM functions are executing code with calls; as a result,

the functions require stack space. With the exception of Reset,

all of the SROM functions have a p arameter block in SRAM that

must be configured before executing the SSC. Table 9-2 on page

15 lists all possible parameter block variables. The meaning of

each parameter, with regards to a specific SROM function, is

described later in this section.

Table 9-1. SROM Function Codes

Function Code Function Name Stack Space

00h SWBootReset 0

01h ReadBlock 7

02h WriteBlock 10

03h EraseBlock 9

05h EraseAll 11

06h TableRead 3

07h CheckSum 3

Document 38-08035 Rev. *K Page 14 of 83

[+] Feedback [+] Feedback

Page 15

CY7C63310, CY7C638xx

Two important variables that are used for all functions are KEY1

and KEY2. These variables are used to help discriminate

between valid SSCs and inadvertent SSCs. KEY1 must always

have a value of 3Ah, while KEY2 must have the same value as

the stack pointer when the SROM function begins execution.

This would be the Stack Pointer value when the SSC opcode is

executed, plus three. If either of the keys do not match the

expected values, the M8C halts (with the exception of the

SWBootReset function). The following code puts the correct

value in KEY1 and KEY2. The code starts with a halt, to force the

program to jump directly into the setup code and not run into it.

halt

SSCOP: mov [KEY1], 3ah

mov X, SP

mov A, X

add A, 3

mov [KEY2], A

Table 9-2. SROM Function Parameters

Variable Name SRAM Address

Key1/Counter/Return Code 0,F8h

Key2/TMP 0,F9h

BlockID 0,FAh

Pointer 0,FBh

Clock 0,FCh

Mode 0,FDh

Delay 0,FEh

PCL 0,FFh

9.4.1 Return Codes

The SROM also features Return Codes and Lockouts.

Return codes aid in the determination of the success or failure of

a particular function. The return code is stored in KEY1’s position

in the parameter block. The CheckSum and TableRead functions

do not have return codes because KEY1’s position in the

parameter block is used to return other data.

Table 9-3. SROM Return Codes

Return Code Description

00h Success

01h Function not allowed due to level of protection

on block.

02h Software reset without hardware reset.

03h Fatal error, SROM halted.

Read, write, and erase operations may fail if the target block is

read or write protected. Block protection levels are set during

device programming.

The EraseAll function overwrites data in addition to leaving the

entire user Flash in the erase state. The EraseAll function loops

through the number of Flash macros in the product, executing

the following sequence: erase, bulk program all zeros, erase.

After all the user space in all the Flash macros are erased, a

second loop erases and then programs each protection block

with zeros.

9.5 SROM Function Descriptions

9.5.1 SWBootReset Function

The SROM function, SWBootReset, is the function that is

responsible for transitioning the device from a reset state to

running user code. The SWBootReset function is executed

whenever the SROM is entered with an M8C accumulator value

of 00h: the SRAM parameter block is not used as an input to the

function. This happens by design after a hardware reset,

because the M8C's accumulator is reset to 00h or when the user

code executes the SSC instruction with an accumulator value of

00h. The SWBootReset function is not executed when the SSC

instruction is executed with a bad key value and a non-zero

function code. An enCoRe II device executes the HALT

instruction if a bad value is given for either KEY1 or KEY2.

The SWBootReset function verifies the integrity of the calibration

data by way of a 16-bit checksum, before releasing the M8C to

run user code.

9.5.2 ReadBlock Function

The ReadBlock function is used to read 64 contiguous bytes

from Flash: a block.

This function first checks the protection bits and determines if the

desired BLOCKID is readable. If the read protection is turned on,

the ReadBlock function exits setting the accumulator and KEY2

back to 00h. KEY1 has a value of 01h, indicating a read failure.

If read protection is not enabled, the function reads 64 bytes from

the Flash using a ROMX instruction and stores the results in the

SRAM using an MVI instruction. The first of the 64 bytes are

stored in the SRAM at the address indicated by the value of the

POINTER parameter. When the ReadBlock completes

successfully, the accumulator, KEY1, and KEY2 all have a value

of 00h.

Table 9-4. ReadBlock Parameters

Name Address Description

KEY1 0,F8h 3Ah

KEY2 0,F9h Stack Pointer value, when SSC is

executed.

BLOCKID 0,FAh Flash block number

POINTER 0,FBh First of 64 addresses in SRAM

where returned data must be stored.

Document 38-08035 Rev. *K Page 15 of 83

[+] Feedback [+] Feedback

Page 16

CY7C63310, CY7C638xx

9.5.3 WriteBlock Function

The WriteBlock function is used to store data in the Flash. Data

is moved 64 bytes at a time from SRAM to Flash using this

function. The WriteBlock function first checks the protection bits

and determines if the desired BLOCKID is writable. If write

protection is turned on, the WriteBlock function exits setting the

accumulator and KEY2 back to 00h. KEY1 has a value of 01h,

indicating a write failure. The configuration of the WriteBlock

function is straightforward. The BLOCKID of the Flash block,

where the data is stored, must be determined and stored at

SRAM address FAh.

The SRAM address of the first of the 64 bytes to be stored in

Flash must be indicated using the POINTER variable in the

parameter block (SRAM address FBh). Finally, the CLOCK and

DELAY value must be set correctly. The CLOCK value determines the length of the write pulse that is used to store the data

in the Flash. The CLOCK and DELAY values are dependent on

the CPU speed and must be set correctly.

Table 9-5. WriteBlock Parameters

Name Address Description

KEY1 0,F8h 3Ah

KEY2 0,F9h Stack Pointer value, when SSC is

executed.

BLOCKID 0,FAh 8KB Flash block number (00h–7Fh)

4KB Flash block number (00h–3Fh)

3KB Flash block number (00h–2Fh)

POINTER 0,FBh First of 64 addresses in SRAM, where

the data to be stored in Flash is

located before calling WriteBlock.

CLOCK 0,FCh Clock divider used to set the write

pulse width.

DELAY 0,FEh For a CPU speed of 12 MHz set to

56h.

9.5.4 EraseBlock Function

The EraseBlock function is used to erase a block of 64

contiguous bytes in Flash. The EraseBlock function first checks

the protection bits and determines if the desired BLOCKID is

writable. If write protection is turned on, the EraseBlock function

exits setting the accumulator and KEY2 back to 00h. KEY1 has

a value of 01h, indicating a write failure. The EraseBlock function

is only useful as the first step in programming. When a block is

erased, the data in the block is not one hundred percent

unreadable. If the objective is to obliterate data in a block, the

best method is to perform an EraseBlock followed by a WriteBlock of all zeros.

To set up the parameter block for the EraseBlock function,

correct key values must be stored in KEY1 and KEY2. The block

number to be erased must be stored in the BLOCKID variable

and the CLOCK and DELAY values must be set based on the

current CPU speed.

Table 9-6. EraseBlock Parameters

Name Address Description

KEY1 0,F8h 3Ah

KEY2 0,F9h Stack Pointer value, when SSC is

BLOCKID 0,FAh Flash block number (00h–7Fh)

CLOCK 0,FCh Clock divider used to set the erase

DELAY 0,FEh For a CPU speed of 12 MHz set to

9.5.5 ProtectBlock Function

The enCoRe II devices offer Flash protection on a block by block

basis. Table 9-7 lists the protection modes available. In this table,

ER and EW indicate the ability to perform external reads and

writes. For internal writes, IW is used. Internal reading is

permitted by way of the ROMX instruction. The ability to read by

way of the SROM ReadBlock function is indicated by SR. The

protection level is stored in two bits according to Table 9-7.

These bits are bit packed into the 64 bytes of the protection

block. As a result, each protection block byte stores the

protection level for four Flash blocks. The bits are packed into a

byte, with the lowest numbered block’s protection level stored in

the lowest numbered bits Ta bl e 9- 7.

The first address of the protection block contains the protection

level for blocks 0 through 3; the second address is for blocks 4

through 7. The 64th byte stores the protection level for blocks

252 through 255.

Table 9-7. Protection Modes

Mode Settings Description Marketing

00b SR ER EW IW Unprotected Unprotected

01b SR

10b SR ER EW IW Disable external

11b S R

76543210

Block n+3 Block n+2 Block n+1 Block n

The level of protection is only decreased by an EraseAll, which

places zeros in all locations of the protection block. To set the

level of protection, the ProtectBlock function is used. This

function takes data from SRAM, starting at address 80h, and

ORs it with the current values in the protection block. The result

of the OR operation is then stored in the protection block. The

EraseBlock function does not change the protection level for a

block. Because the SRAM location for the protection data is fixed

and there is only one protection block per Flash macro, the

ProtectBlock function expects very few variables in the

parameter block to be set before calling the function. The

parameter block values that must be set, besides the keys, are

the CLOCK and DELAY values.

ER EW IW Read protect Factory upgrade

ER EW IW Disable internal

executed.

pulse width.

56h

Field upgrade

write

Full protection

write

Document 38-08035 Rev. *K Page 16 of 83

[+] Feedback [+] Feedback

Page 17

CY7C63310, CY7C638xx

Table 9-8. ProtectBlock Parameters

Name Address Description

KEY1 0,F8h 3Ah

KEY2 0,F9h Stack Pointer value when SSC is

executed.

CLOCK 0,FCh Clock divider used to set the write pulse

width.

DELAY 0,FEh For a CPU speed of 12 MHz set to 56h.

9.5.6 EraseAll Function

The EraseAll function performs a series of steps that destroy the

user data in the Flash macros and resets the protection block in

each Flash macro to all zeros (the unprotected state). The

EraseAll function does not affect the three hidden blocks above

the protection block, in each Flash macro. The first of these four

hidden blocks is used to store the protection table for its eight

Kbytes of user data.

The EraseAll function begins by erasing the user space of the

Flash macro with the highest address range. A bulk program of

all zeros is then performed on the same Flash macro, to destroy

all traces of the previous contents. The bulk program is followed

by a second erase that leaves the Flash macro in a state ready

for writing. The erase, program, erase sequence is then

performed on the next lowest Flash macro in the address space

if it exists. After the erase of the user space, the protection block

for the Flash macro with the highest address range is erased.

Following the erase of the protection block, zeros are written into

every bit of the protection table. The next lowest Flash macro in

the address space then has its protection block erased and filled

with zeros.

The end result of the EraseAll function is that all user data in the

Flash is destroyed and the Flash is left in an unprogrammed

state, ready to accept one of the various write commands. The

protection bits for all user data are also reset to the zero state

The parameter block values that must be set, besides the keys,

are the CLOCK and DELAY values.

Table 9-9. EraseAll Parameters

Name Address Description

KEY1 0,F8h 3Ah

KEY2 0,F9h Stack Pointer value when SSC is

executed.

CLOCK 0,FCh Clock divider used to set the write pulse

width.

DELAY 0,FEh For a CPU speed of 12 MHz set to 56h

9.5.7 TableRead Function

The TableRead function gives the user access to part specific

data stored in the Flash during manufacturing. It also returns a

Revision ID for the die (not to be confused with the Silicon ID).

Table 9-10. Table Read Parameters

Name Address Description

KEY1 0,F8h 3Ah

KEY2 0,F9h Stack Pointer value when SSC is

executed.

BLOCKID 0,FAh Table number to read.

The table space for the enCoRe II is simply a 64 byte row broken

up into eight tables of eight bytes. The tables are numbered zero

through seven. All user and hidden blocks in the CY7C638xx

parts consist of 64 bytes.

An internal table (Table 0) holds the Silicon ID and returns the

Revision ID. The Silicon ID is returned in SRAM, while the

Revision and Family IDs are returned in the CPU_A and CPU_X

registers. The Silicon ID is a value placed in the table by

programming the Flash and is controlled by Cypress Semiconductor Product Engineering. The Revision ID is hard coded into

the SROM and also redundantly placed in SROM Table 1. This

is discussed in more detail later in this section.

SROM Table 1 holds Family/Die ID and Revision ID values for

the device and returns a one-byte internal revision counter. The

internal revision counter starts out with a value of zero and is

incremented when one of the other revision numbers is not incremented. It is reset to zero when one of the other revision

numbers is incremented. The internal revision count is returned

in the CPU_A register. The CPU_X register is always set to FFh

when Table 1 is read. The CPU_A and CPU_X registers always

return a value of FFh when Tables 2-7 are read. The BLOCKID

value, in the parameter block, indicates which table must be

returned to the user. Only the three least significant bits of the

BLOCKID parameter are used by TableRead function for

enCoRe II devices. The upper five bits are ignored. When the

function is called, it transfers bytes from the table to SRAM

addresses F8h–FFh.

The M8C’s A and X registers are used by the TableRead function

to return the die’s Revision ID. The Revision ID is a 16-bit value

hard coded into the SROM that uniquely identifies the die’s

design.

The return values for corresponding Table calls are tabulated as

shown in Table 9-11 on page 17

Table 9-11. Return va lues for Table Read

Table Number

0

1

2-7

Revision ID Family ID

Internal Revision Counter 0xFF

0xFF 0xFF

Return Value

A X

Document 38-08035 Rev. *K Page 17 of 83

[+] Feedback [+] Feedback

Page 18

CY7C63310, CY7C638xx

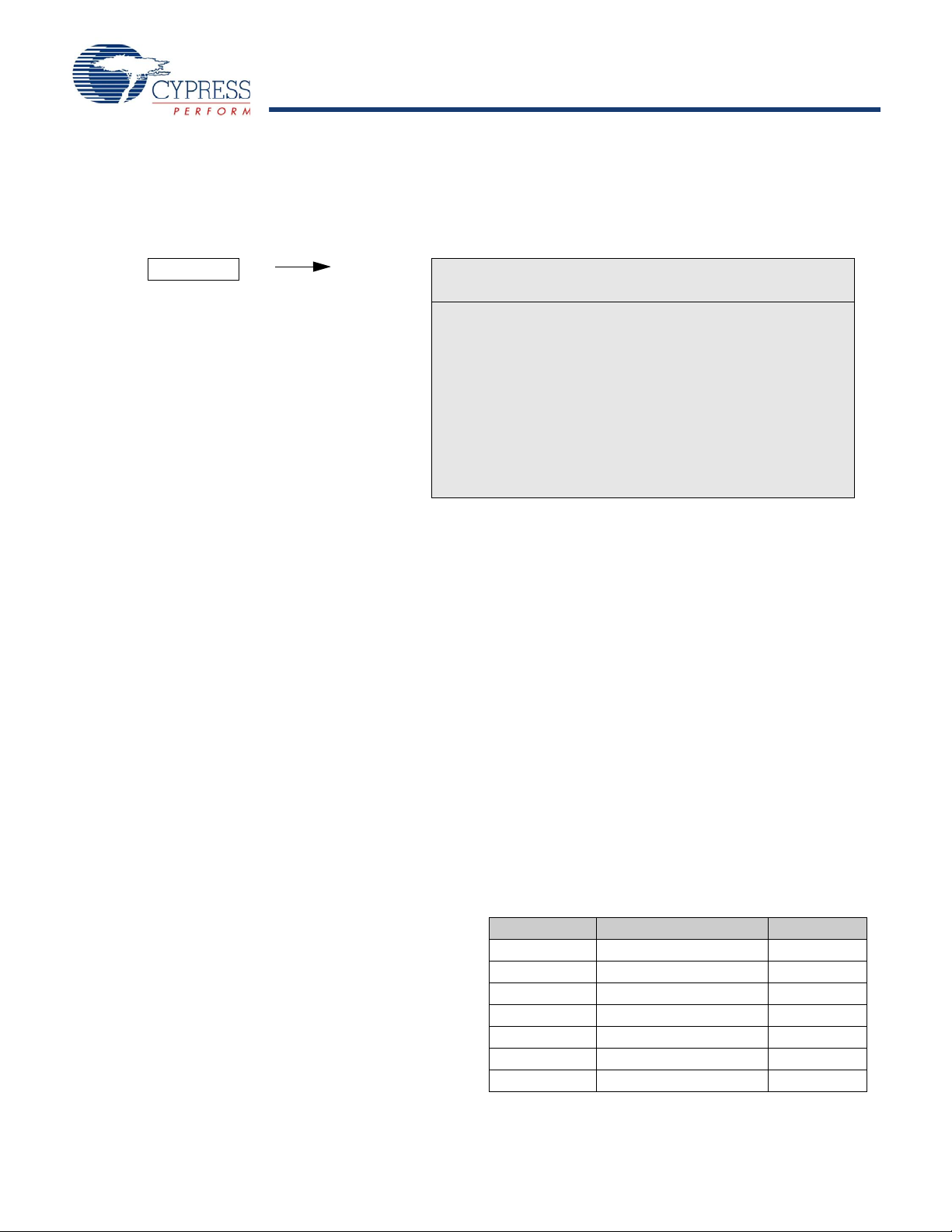

Figure 9-3. SROM Table

F8h F9h FAh FB h FCh FDh FEh FFh

Table 0

Table 1

Table 2

Table 3

Table 4

Table 5

Table 6

Table 7

Silicon ID

[15-8]

Silicon ID

[7-0]

Family/

Die ID

Revision

ID

The Silicon IDs for enCoRe II devices are stored in SROM tables in the part, as shown in Figure 9-3.

The Silicon ID can be read out from the part using SROM Table reads (Table 0). This is demonstrated in the following pseudo code.

As mentioned in the section SROM on page 14, the SROM variables occupy address F8h through FFh in the SRAM. Each of the

variables and their definition is given in the section SROM on page 14.

AREA SSCParmBlkA(RAM,ABS)

org F8h // Variables are defined starting at address F8h

SSC_KEY1: ; F8h supervisory key

SSC_RETURNCODE: blk 1 ; F8h result code

SSC_KEY2 : blk 1 ;F9h supervisory stack ptr key

SSC_BLOCKID: blk 1 ; FAh block ID

SSC_POINTER: blk 1 ; FBh pointer to data buffer

SSC_CLOCK: blk 1 ; FCh Clock

SSC_MODE: blk 1 ; FDh ClockW ClockE multiplier

SSC_DELAY: blk 1 ; FEh flash macro sequence delay count

SSC_WRITE_ResultCode: blk 1 ; FFh temporary result code

_main:

mov A, 0

mov [SSC_BLOCKID], A// To read from Table 0 - Silicon ID is stored in Table 0

//Call SROM operation to read the SROM table

mov X, SP ; copy SP into X

mov A, X ; A temp stored in X

add A, 3 ; create 3 byte stack frame (2 + pushed A)

mov [SSC_KEY2], A ; save stack frame for supervisory code

; load the supervisory code for flash operations

mov [SSC_KEY1], 3Ah ;FLASH_OPER_KEY - 3Ah

mov A,6 ; load A with specific operation. 06h is the code for Table read Table 9-1

SSC ; SSC call the supervisory ROM

// At the end of the SSC command the silicon ID is stored in F8 (MSB) and F9(LSB) of the SRAM

.terminate:

jmp .terminate

Document 38-08035 Rev. *K Page 18 of 83

[+] Feedback [+] Feedback

Page 19

CY7C63310, CY7C638xx

9.5.8 Checksum Function

The Checksum function calculates a 16-bit checksum over a

user specifiable number of blocks, within a single Flash macro

(Bank) starting from block zero. The BLOCKID parameter is

used to pass in the number of blocks to calculate the checksum

over. A BLOCKID value of 1 calculates the checksum of only

block 0, while a BLOCKID value of 0 calculates the checksum of

all 256 user blocks. The 16-bit checksum is returned in KEY1 and

KEY2. The parameter KEY1 holds the lower eight bits of the

checksum and the parameter KEY2 holds the upper eight bits of

the checksum.

The checksum algorithm executes the following sequence of

three instructions over the number of blocks times 64 to be

checksummed.

romx

add [KEY1], A

adc [KEY2], 0

Table 9-12. Checksum Parameters

Name Address Description

KEY1 0,F8h 3Ah

KEY2 0,F9h Stack Pointer value when SSC is

executed.

BLOCKID 0,FAh Number of Flash blocks to calculate

checksum on.

10. Clocking

When using the 32 kHz oscillator, the PITMRL/H registers must

be read until 2 consecutive readings match before the result is

considered valid. The following firmware example assumes the

developer is interested in the lower byte of the PIT.

Read_PIT_counter:

mov A, reg[PITMRL]

mov [57h], A

mov A, reg[PITMRL]

mov [58h], A

mov [59h], A

mov A, reg[PITMRL]

mov [60h], A

;;;Start comparison

mov A, [60h]

mov X, [59h]

sub A, [59h]

jz done

mov A, [59h]

mov X, [58h]

sub A, [58h]

jz done

mov X, [57h]

;;;correct data is in memory location 57h

done:

mov [57h], X

ret

The enCoRe II has two internal oscillators, the Internal 24 MHz

Oscillator and the 32 kHz Low power Oscillator.

The Internal 24 MHz Oscillator is designed such that it may be

trimmed to an output frequency of 24 MHz over temperature and

voltage variation. With the presence of USB traffic, the Internal

24 MHz Oscillator may be set to precisely tune to the USB timing

requirements (24 MHz ± 1.5%). Without USB traffic, the Internal

24 MHz Oscillator accuracy is 24 MHz ± 5% (between 0°–70°C).

No external components are required to achieve this level of

accuracy.

The internal low speed oscillator of nominally 32 kHz provides a

slow clock source for the enCoRe II in suspend mode, particularly to generate a periodic wakeup interrupt and also to provide

a clock to sequential logic during power up and power down

events when the main clock is stopped. In addition, this oscillator

can also be used as a clocking source for the Interval Timer clock

(ITMRCLK) and Capture Timer clock (TCAPCLK). The 32 kHz

Low power Oscillator can operate in low power mode or can

provide a more accurate clock in normal mode. The Internal

32 kHz Low power Oscillator accuracy ranges (between

0°–70° C) follow:

■

5V Normal mode: –8% to + 16%

■

5V LP mode: +12% to + 48%

Document 38-08035 Rev. *K Page 19 of 83

[+] Feedback [+] Feedback

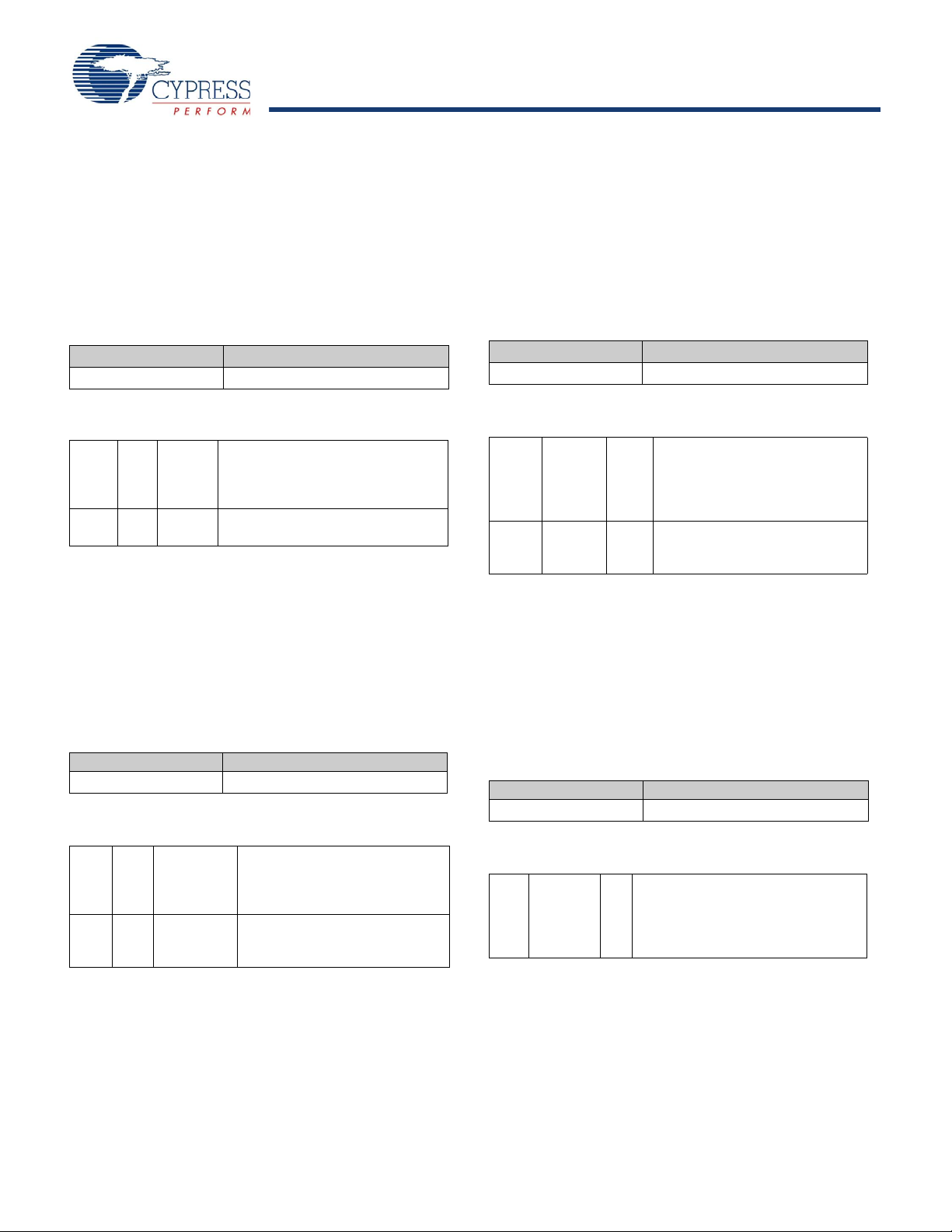

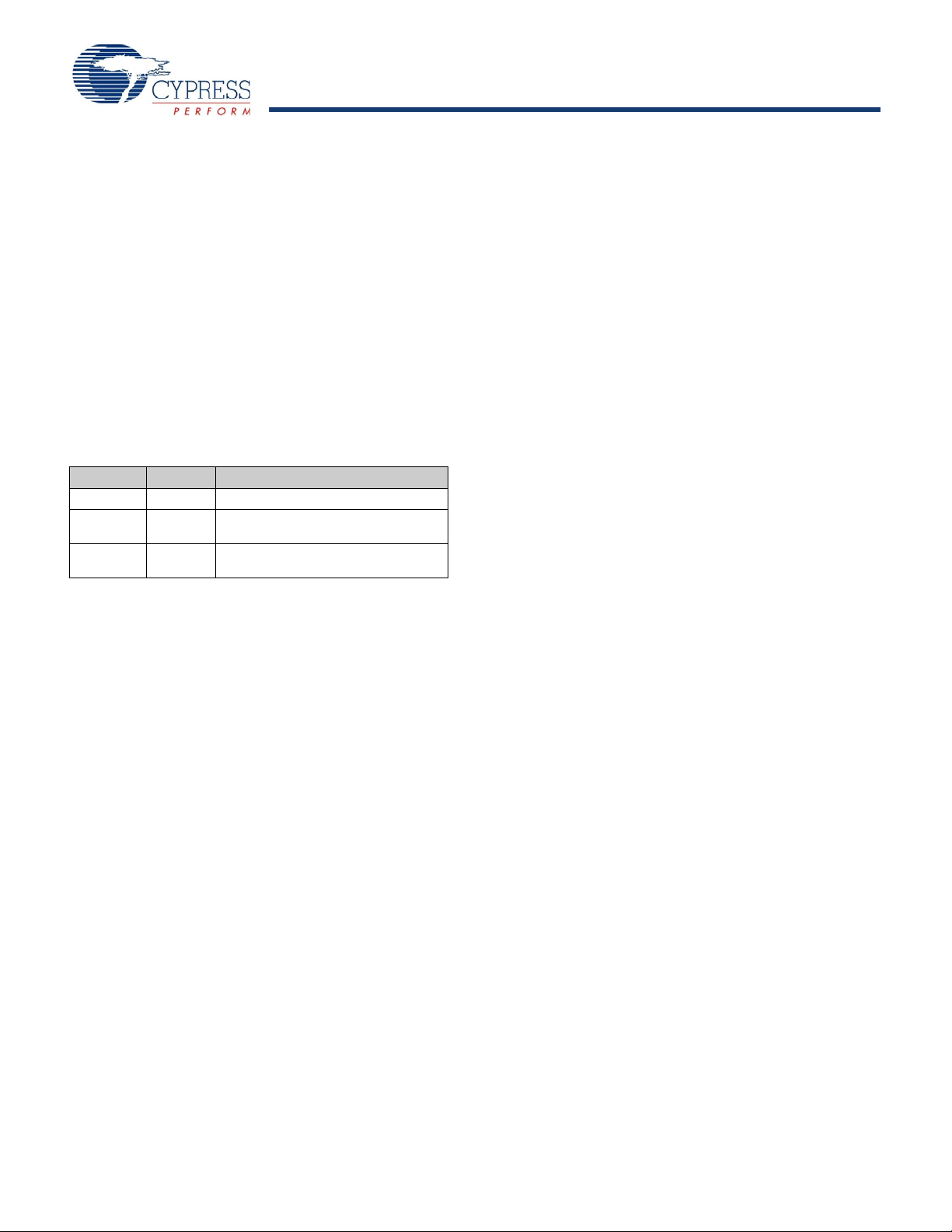

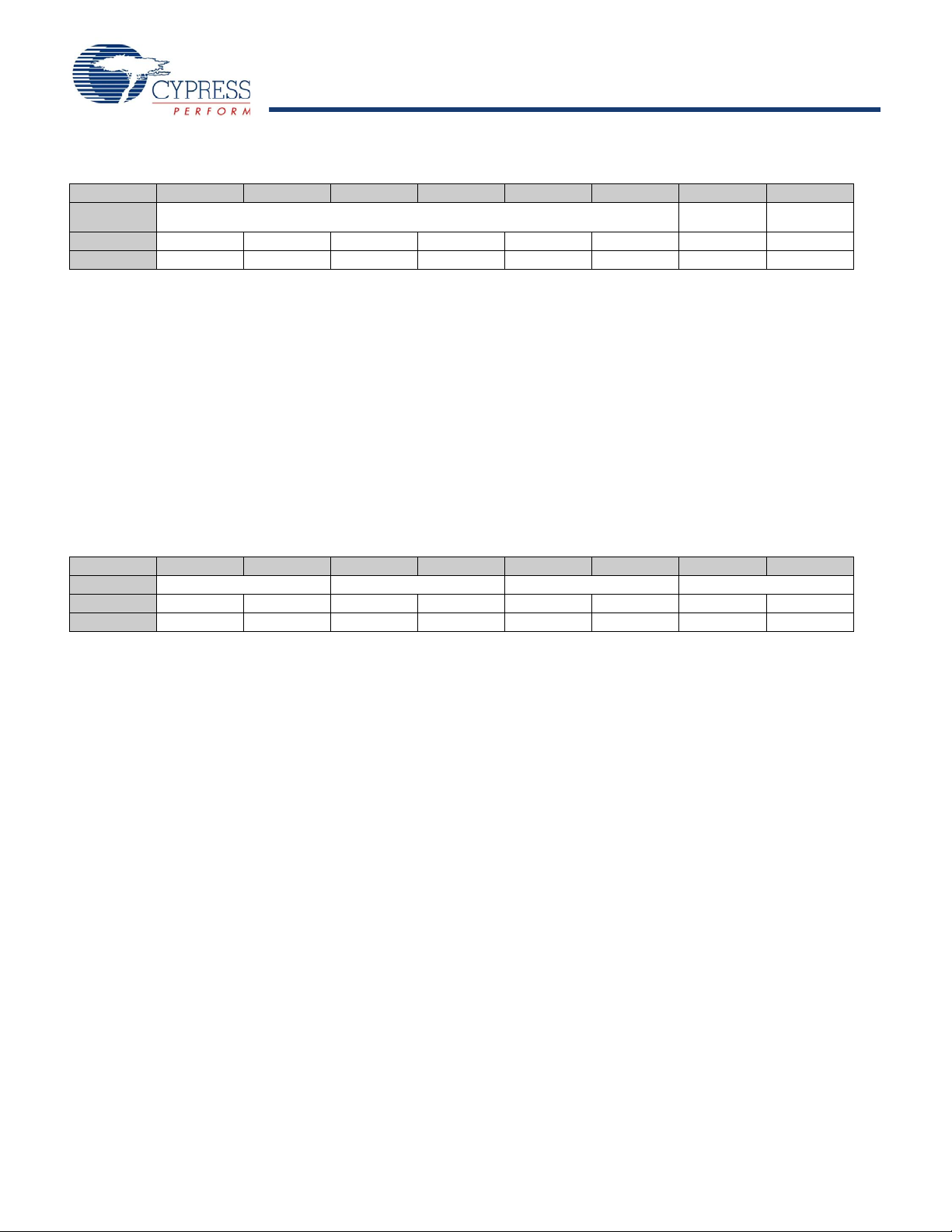

Page 20

CY7C63310, CY7C638xx

CPU_CLK

EXT

24 MHz

MUX

CLK_USB

SEL SCALE

CLK_24MHz

CLK_EXT

CPUCLK

SEL

MUX

SCALE (divide by 2

n

,

n = 0-5,7)

CLK_32

KHz

LP OSC

32 KHz

SEL

SCALE

OUT

0X

12 MHz

0X

12 MHz

1

1

EXT/2

11

EXT

Figure 10-1. Clock Block Diagram

Document 38-08035 Rev. *K Page 20 of 83

[+] Feedback [+] Feedback

Page 21

CY7C63310, CY7C638xx

10.1 Clock Architecture Description

The enCoRe II clock selection circuitry allows the selection of

independent clocks for the CPU, USB, Interval Timers and

Capture Timers.

The CPU clock CPUCLK is sourced from an external clock or the

Internal 24 MHz Oscillator. The selected clock source is

optionally divided by 2

23).

USBCLK, which must be 12 MHz for the USB SIE to function

properly, is sourced by the Internal 24 MHz Oscillator or an

external 12 MHz/24 MHz clock. An optional divide by two allows

the use of 24 MHz source.

n

, where n is 0-5,7 (see Table 10-4 on page

The Timer Capture clock (TCAPCLK) is sourced from an external

clock, Internal 24 MHz Oscillator, or the Internal 32 kHz low

power oscillator.

The CLKOUT pin (P0.1) is driven from one of many sources. This

is used for test and is also used in some applications. The

sources that drive the CLKOUT follow:

■

CLKIN after the optional EFTB filter

■

Internal 24 MHz Oscillator

■

Internal 32 kHz low power oscillator

■

CPUCLK after the programmable divider

The Interval Timer clock (ITMRCLK), is sourced from an external

clock, the Internal 24 MHz Oscillator, the Internal 32 kHz low

power oscillator, or from the timer capture clock (TCAPCLK). A

programmable prescaler of 1, 2, 3, 4 then divides the selected

source.

Table 10-1. IOSC Trim (IOSCTR) [0x34] [R/W]

Bit # 7 6 5 4 3 2 1 0

Field foffset[2:0] Gain[4:0]

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 0 0 0 D D D D D

The IOSC Calibrate register calibrates the internal oscillator. The reset value is undefined but during boot the SROM writes a

calibration value that is determined during manufacturing test. This value does not require change during normal use. This is

the meaning of ‘D’ in the Default field.

Bit [7:5]: foffset [2:0]

This value is used to trim the frequency of the internal oscillator. These bits are not used in factory calibration and are zero.

Setting each of these bits causes the appropriate fine offset in oscillator frequency.

foffset bit 0 = 7.5 kHz

foffset bit 1 = 15 kHz

foffset bit 2 = 30 kHz

Bit [4:0]: Gain [4:0]

The effective frequency change of the offset input is controlled through the gain input. A lower value of the gain setting increases

the gain of the offset input. This value sets the size of each offset step for the internal oscillator. Nominal gain change

(kHz/offsetStep) at each bit, typical conditions (24 MHz operation):

Gain bit 0 = –1.5 kHz

Gain bit 1 = –3.0 kHz

Gain bit 2 = –6 kHz

Gain bit 3 = –12 kHz

Gain bit 4 = –24 kHz

Document 38-08035 Rev. *K Page 21 of 83

[+] Feedback [+] Feedback

Page 22

CY7C63310, CY7C638xx

Table 10-2. LPOSC Trim (LPOSCTR) [0x36] [R/W]

Bit # 7 6 5 4 3 2 1 0

Field 32 kHz Low

Read/Write R/W – R/W R/W R/W R/W R/W R/W

Default 0 D D D DDD D

Power

Reserved 32 kHz Bias Trim [1:0] 32 kHz Freq Trim [3:0]

This register is used to calibrate the 32 kHz Low speed Oscillator. The reset value is undefined but during boot the SROM writes

a calibration value that is determined during manufacturing tests. This value does not require change during normal use. This

is the meaning of ‘D’ in the Default field. If the 32 kHz Low power bit is written, care must be taken to not disturb the

32 kHz Bias Trim and the 32 kHz Freq Trim fields from their factory calibrated values.

Bit 7: 32 kHz Low Power

0 = The 32 kHz Low speed Oscillator operates in normal mode

1 = The 32 kHz Low speed Oscillator operates in a low power mode. The oscillator continues to function normally, but with

reduced accuracy.

Bit 6: Reserved

Bit [5:4]: 32 kHz Bias Trim [1:0]

These bits control the bias current of the low power oscillator.

0 0 = Mid bias

0 1 = High bias

1 0 = Reserved

1 1 = Reserved

Note Do not program the 32 kHz Bias Trim [1:0] field with the reserved 10b value because the oscillator does not oscillate at all

corner conditions with this setting.

Bit [3:0]: 32 kHz Freq Trim [3:0]

These bits are used to trim the frequency of the low power oscillator.

Table 10-3. CPU/USB Clock Config (CPUCLKCR) [0x30] [R/W]

Bit # 7 6 5 4 3 2 1 0

Field Reserved USB CLK/2

Read/Write – R/W R/W – – – – R/W

Default 0 0 0 0 0 0 0 0

Disable

USB CLK Select Reserved CPUCLK Select

Bit 7: Reserved

Bit 6: USB CLK/2 Disable

This bit only affects the USBCLK when the source is the external clock. When the USBCLK source is the Internal 24 MHz

Oscillator, the divide by two is always enabled

0 = USBCLK source is divided by two. This is the correct setting to use when the Internal 24 MHz Oscillator is used, or when

the external source is used with a 24 MHz clock

1 = USBCLK is undivided. Use this setting only with a 12 MHz external clock

Bit 5: USB CLK Select

This bit controls the clock source for the USB SIE.

0 = Internal 24 MHz Oscillator. With the presence of USB traffic, the Internal 24 MHz Oscillator is trimmed to meet the USB

requirement of 1.5% tolerance (see Table 10-5 on page 24)

1 = External clock—Internal Oscillator is not trimmed to USB traffic. Proper USB SIE operation requires a 12 MHz or 24 MHz

clock accurate to <1.5%.

Bit [4:1]: Reserved

Bit 0: CPU CLK Select

0 = Internal 24 MHz Oscillator.

1 = External clock—External clock at CLKIN (P0.0) pin.

Note The CPU speed selection is configured using the OSC_CR0 Register (Table 10-4 on page 23).

Document 38-08035 Rev. *K Page 22 of 83

[+] Feedback [+] Feedback

Page 23

CY7C63310, CY7C638xx

Table 10-4. OSC Control 0 (OSC_CR0) [0x1E0] [R/W]

CPU Speed

[2:0]

CPU when Internal

Oscillator is selected External Clock

000 3 MHz (Default) Clock In/8

001 6 MHz Clock In/4

010 12 MHz Clock In/2

011 24 MHz Clock In/1

100 1.5 MHz Clock In/16

101 750 kHz Clock In/32

110 187 kHz Clock In/128

111 Reserved Reserved

Bit # 7 6 5 4 3 2 1 0

Field Reserved No Buzz Sleep Timer [1:0] CPU Speed [2:0]

Read/Write – – R/W R/W R/W R/W R/W R/W

Default 0 0 0 0 0 0 0 0

Bit [7:6]: Reserved

Bit 5: No Buzz

During sleep (the Sleep bit is set in the CPU_SCR Register—Table 11-1 on page 27), the LVD and POR detection circuit is turned

on periodically to detect any POR and LVD events on the VCC pin (the Sleep Duty Cycle bits in the ECO_TR are used to control

the duty cycle—Table 13-3 on page 32). To facilitate the detection of POR and LVD events, the No Buzz bit is used to force the

LVD and POR detection circuit to be continuously enabled during sleep. This results in a faster response to an LVD or POR

event during sleep at the expense of a slightly higher than average sleep current.

0 = The LVD and POR detection circuit is turned on periodically as configured in the Sleep Duty Cycle.

1 = The Sleep Duty Cycle value is overridden. The LVD and POR detection circuit is always enabled.

Note The periodic Sleep Duty Cycle enabling is independent with the sleep interval shown in the Sleep [1:0] bits below.

Bit [4:3]: Sleep Timer [1:0]

Note Sleep intervals are approximate.

Bit [2:0]: CPU Speed [2:0]

The enCoRe II may operate over a range of CPU clock speeds. The reset value for the CPU Speed bits is zero; as a result, the

default CPU speed is one-eighth of the internal 24 MHz, or 3 MHz

Regardless of the CPU Speed bit’s setting, if the actual CPU speed is greater than 12 MHz, the 24 MHz operating requirements

apply. An example of this scenario is a device that is configured to use an external clock, which supplies a frequency of 20 MHz.

If the CPU speed register’s value is 0b011, the CPU clock is at 20 MHz. Therefore, the supply voltage requirements for the device

are the same as if the part were operating at 24 MHz. The operating voltage requirements are not relaxed until the CPU speed

is at 12 MHz or less.

Note Correct USB operations require the CPU clock speed be at least 1.5 MHz or not less than USB clock/8. If the two clocks

have the same source, then the CPU clock divider must not be set to divide by more than 8. If the two clocks have different

sources, the maximum ratio of USB Clock/CPU Clock must never exceed 8 across the full specification range of both clock

sources.

Note This register exists in the second bank of IO space. This requires setting the XIO bit in the CPU flags register.

Document 38-08035 Rev. *K Page 23 of 83

[+] Feedback [+] Feedback

Page 24

CY7C63310, CY7C638xx

Table 10-5. USB Osclock Clock Configuration (OSCLCKCR) [0x39] [R/W]

Bit # 7 6 5 4 3 2 1 0

Field Reserved Fine Tune Only USB Osclock

Read/Write – – – – – – R/W R/W

Default 0 0 0 0 0 0 0 0

Disable

This register is used to trim the Internal 24 MHz Oscillator using received low speed USB packets as a timing reference. The

USB Osclock circuit is active when the Internal 24 MHz Oscillator provides the USB clock.

Bit [7:2]: Reserved

Bit 1: Fine Tune Only

0 = Fine and Course tuning

1 = Disable the oscillator lock from performing the coarse-tune portion of its retuning. The oscillator lock must be allowed to

perform a coarse tuning to tune the oscillator for correct USB SIE operation. After the oscillator is properly tuned, this bit is set

to reduce variance in the internal oscillator frequency that would be caused course tuning.

Bit 0: USB Osclock Disable

0 = Enable. With the presence of USB traffic, the Internal 24 MHz Oscillator precisely tunes to 24 MHz ± 1.5%

1 = Disable. The Internal 24 MHz Oscillator is not trimmed based on USB packets. This setting is useful when the internal

oscillator is not sourcing the USBSIE clock.

Table 10-6. Timer Clock Config (TMRCLKCR) [0x31] [R/W]

Bit # 7 6 5 4 3 2 1 0

Field TCAPCLK Divider TCAPCLK Select ITMRCLK Divider ITMRCLK Select

Read/Write R/W R/W R/W R/W R/W R/W R/W R/W

Default 1 0 0 0 1 1 1 1

Bit [7:6]: TCAPCLK Divider [1:0]

TCAPCLK Divider controls the TCAPCLK divisor.

0 0 = Divider Value 2

0 1 = Divider Value 4

1 0 = Divider Value 6

1 1 = Divider Value 8

Bit [5:4]: TCAPCLK Select

The TCAPCLK Select field controls the source of the TCAPCLK.

0 0 = Internal 24 MHz Oscillator

0 1 = External clock—external clock at CLKIN (P0.0) input.

1 0 = Internal 32 kHz low power oscillator

1 1 = TCAPCLK Disabled

Note The 1024 μs interval timer is based on the assumption that TCAPCLK is running at 4 MHz. Changes in TCAPCLK frequency

causes a corresponding change in the 1024 μs interval timer frequency.

Bit [3:2]: ITMRCLK Divider

ITMRCLK Divider controls the ITMRCLK divisor.

0 0 = Divider value of 1

0 1 = Divider value of 2

1 0 = Divider value of 3

1 1 = Divider value of 4

Bit [1:0]: ITMRCLK Select

0 0 = Internal 24 MHz Oscillator

0 1 = External clock—external clock at CLKIN (P0.0) input.

1 0 = Internal 32 kHz low power oscillator

1 1 = TCAPCLK

Document 38-08035 Rev. *K Page 24 of 83

[+] Feedback [+] Feedback

Page 25

CY7C63310, CY7C638xx

10.1.1 Interval Timer Clock (ITMRCLK)

System

Clock

Clock

Timer

Configuration