Page 1

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

18-Mbit DDR-II+ SRAM 2-Word Burst

Architecture (2.5 Cycle Read Latency)

Features

Note

1. The QDR consortium specification for V

DDQ

is 1.5V + 0.1V. The Cypress QDR devices exceed the QDR consortium specification and are capable of supporting

V

DDQ

= 1.4V to VDD.

Functional Description

■ 18 Mbit density (2M x 8, 2M x 9, 1M x 18, 512K x 36)

■ 300 MHz to 400 MHz clock for high bandwidth

■ 2-Word burst for reducing address bus frequency

■ Double Data Rate (DDR) interfaces

(data transferred at 800 MHz) at 400 MHz

■ Read latency of 2.5 clock cycles

■ Two input clocks (K and K) for precise DDR timing

❐ SRAM uses rising edges only

■ Echo clocks (CQ and CQ) simplify data capture in high-speed

systems

■ Data valid pin (QVLD) to indicate valid data on the output

■ Synchronous internally self-timed writes

■ Core V

■ HSTL inputs and Variable drive HSTL output buffers

■ Available in 165-Ball FBGA p ackage (13 x 15 x 1.4 mm)

■ Offered in both Pb-free and non Pb-free packages

■ JTAG 1149.1-compatible test access port

■ Delay Lock Loop (DLL) for accurate data placement

= 1.8V ± 0.1V; IO V

DD

= 1.4V to V

DDQ

DD

[1]

Configurations

With Read Cycle Latency of 2.5 cycles:

CY7C1166V18 – 2M x 8

CY7C1177V18 – 2M x 9

CY7C1168V18 – 1M x 18

CY7C1170V18 – 512K x 36

The CY7C1166V18, CY7C1177V18, CY7C1168V18, and

CY7C1170V18 are 1.8V Synchronous Pipelined SRAMs

equipped with DDR-II+ architecture. The DDR-II+ consists of an

SRAM core with an advanced synchronous peripheral circuitry.

Addresses for read and write are latched on alternate rising

edges of the input (K) clock. Write data is registered on the rising

edges of both K and K

of K and K

. Each address location is associated with two 8-bit

. Read data is driven on the rising edges

words (CY7C1166V18), or 9-bit words (CY7C1 177V18), or 18-bit

words (CY7C1168V18), or 36-bit words (CY7C1170V18) that

burst sequentially into or out of the device.

Asynchronous inputs include output impedance matching input

(ZQ). Synchronous data outputs (Q, sharing the same physical

pins as the data inputs D) are tightly matched to the two output

echo clocks CQ/CQ

, eliminating the need for separately

capturing data from each individual DDR SRAM in the system

design.

All synchronous inputs pass through input registers controlled by

the K or K

registers controlled by the K or K

input clocks. All data outputs pass through output

input clocks. Writes are

conducted with on-chip synchronous self-timed write circuitry.

Selection Guide

Description 400 MHz 375 MHz 333 MHz 300 MHz Unit

Maximum Operating Frequency 400 375 333 300 MHz

Maximum Operating Current 1080 1020 920 850 mA

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 • 408-943-2600

Document Number: 001-06620 Rev. *D Revised March 06, 2008

[+] Feedback [+] Feedback

Page 2

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

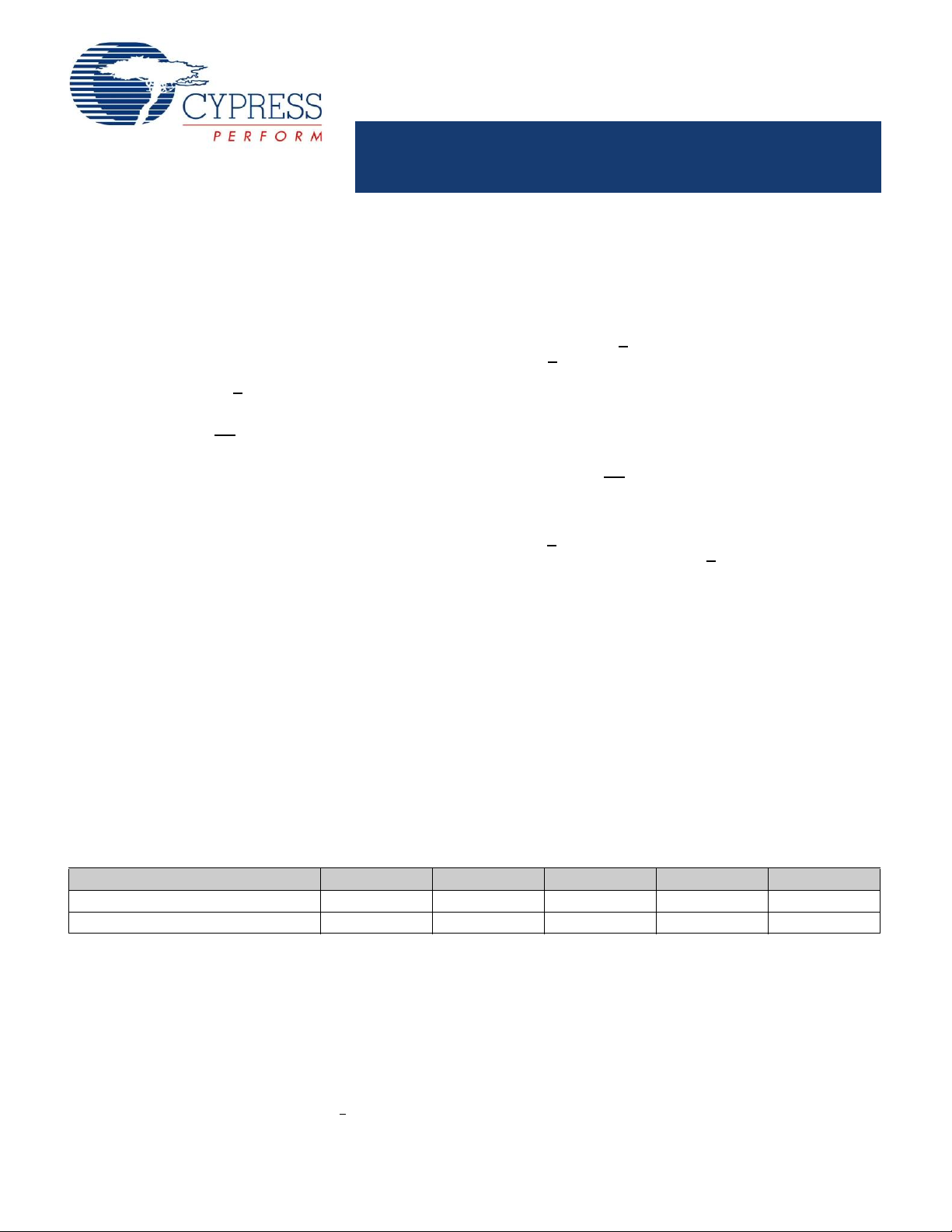

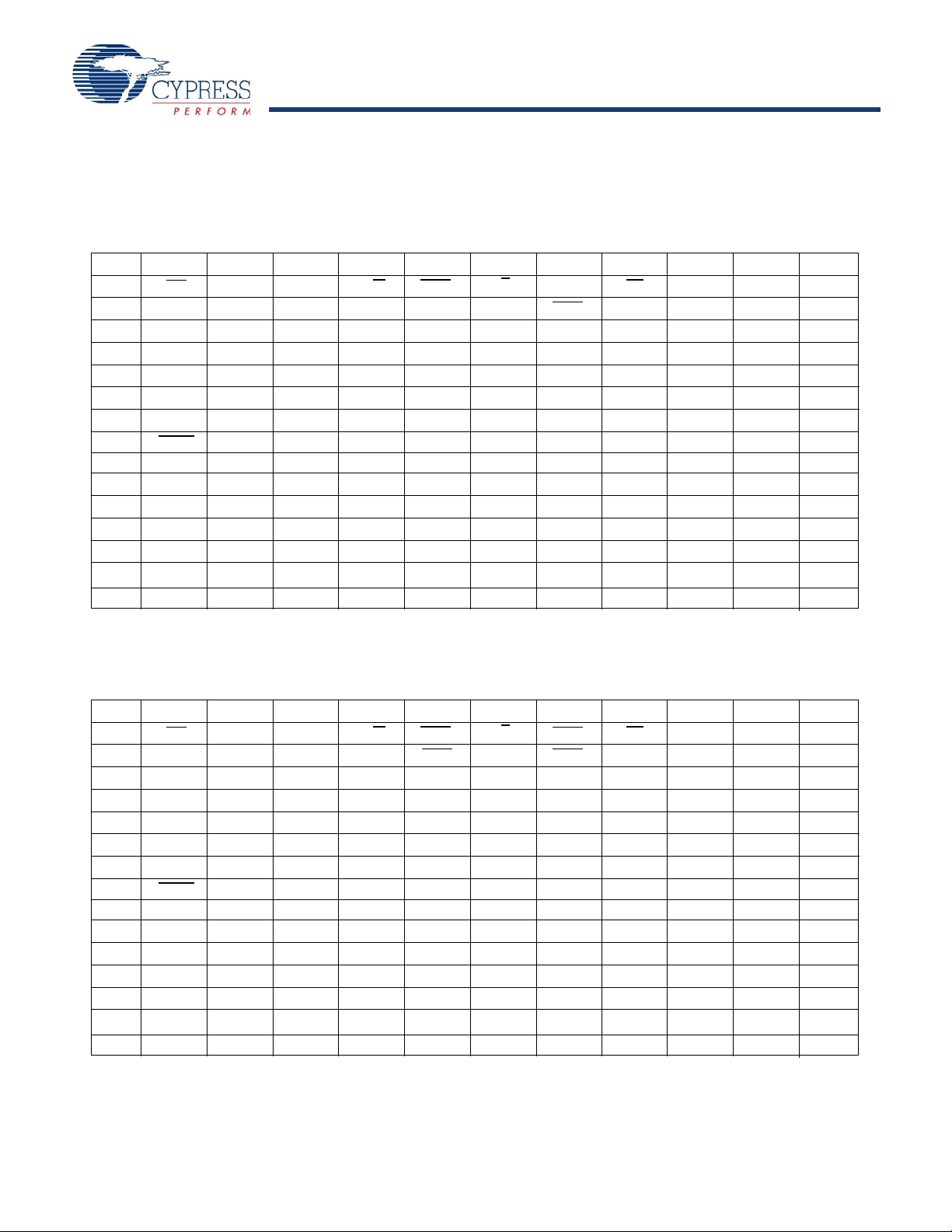

Logic Block Diagram (CY7C1166V18)

CLK

A

(19:0)

Gen.

K

K

Control

Logic

Address

Register

Read Add. Decode

Read Data Reg.

R/W

DQ

[7:0]

Output

Logic

Reg.

Reg.

Reg.

8

8

16

8

NWS

[1:0]

V

REF

Write Add. Decode

8

8

LD

Control

20

1M x 8 Array

1M x 8 Array

Write

Reg

Write

Reg

CQ

CQ

R/W

DOFF

QVLD

8

CLK

A

(19:0)

Gen.

K

K

Control

Logic

Address

Register

Read Add. Decode

Read Data Reg.

R/W

DQ

[8:0]

Output

Logic

Reg.

Reg.

Reg.

9

9

18

9

BWS

[0]

V

REF

Write Add. Decode

9

9

LD

Control

20

1M x 9 Array

1M x 9 Array

Write

Reg

Write

Reg

CQ

CQ

R/W

DOFF

QVLD

9

Logic Block Diagram (CY7C1177V18)

Document Number: 001-06620 Rev. *D Page 2 of 27

[+] Feedback [+] Feedback

Page 3

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

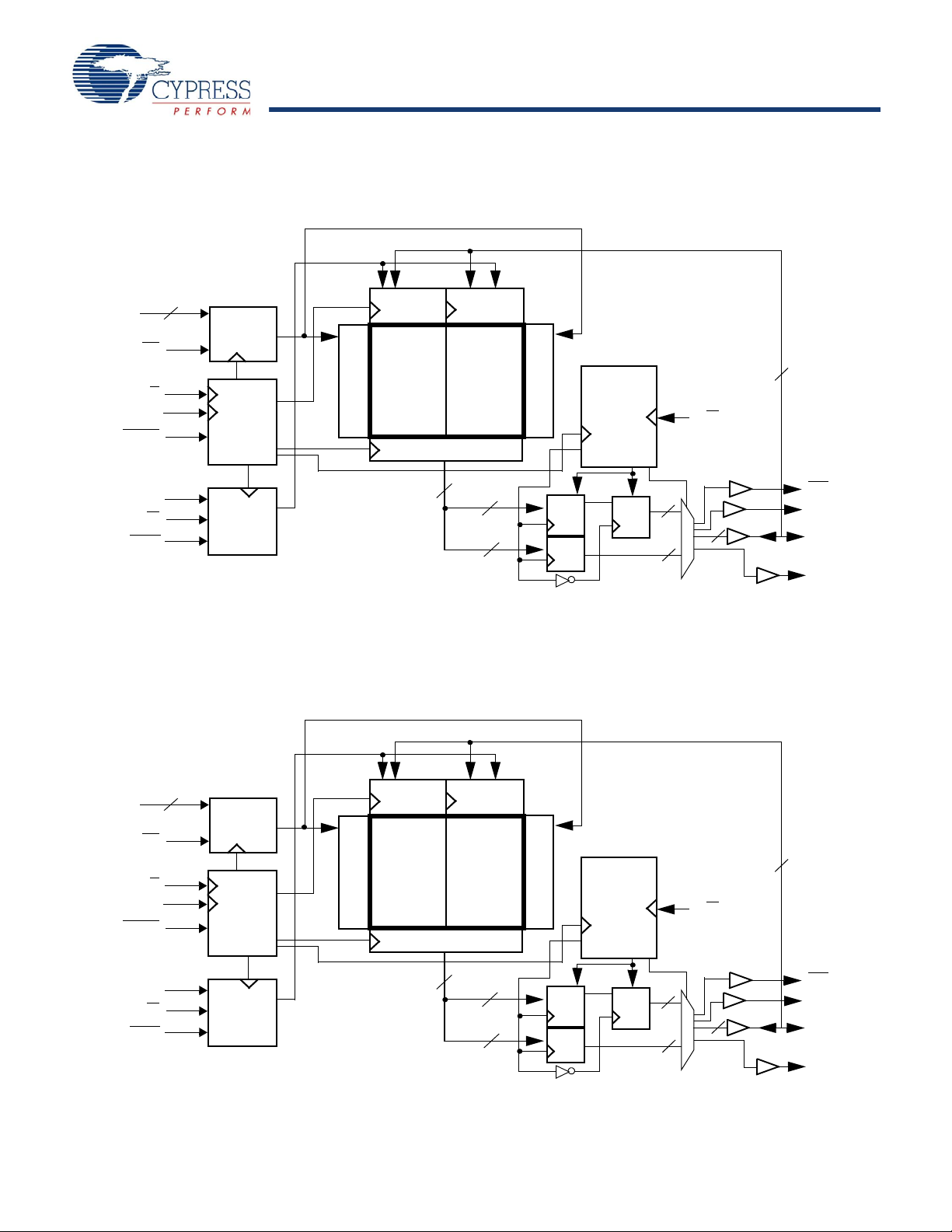

Logic Block Diagram (CY7C1168V18)

CLK

A

(18:0)

Gen.

K

K

Control

Logic

Address

Register

Read Add. Decode

Read Data Reg.

R/W

DQ

[17:0]

Output

Logic

Reg.

Reg.

Reg.

18

18

36

18

BWS

[1:0]

V

REF

Write Add. Decode

18

18

LD

Control

19

512K x 18 Array

512K x 18 Array

Write

Reg

Write

Reg

CQ

CQ

R/W

DOFF

QVLD

18

CLK

A

(17:0)

Gen.

K

K

Control

Logic

Address

Register

Read Add. Decode

Read Data Reg.

R/W

DQ

[35:0]

Output

Logic

Reg.

Reg.

Reg.

36

36

72

36

BWS

[3:0]

V

REF

Write Add. Decode

36

36

LD

Control

18

256K x 36 Array

256K x 36 Array

Write

Reg

Write

Reg

CQ

CQ

R/W

DOFF

QVLD

36

Logic Block Diagram (CY7C1170V18)

Document Number: 001-06620 Rev. *D Page 3 of 27

[+] Feedback [+] Feedback

Page 4

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

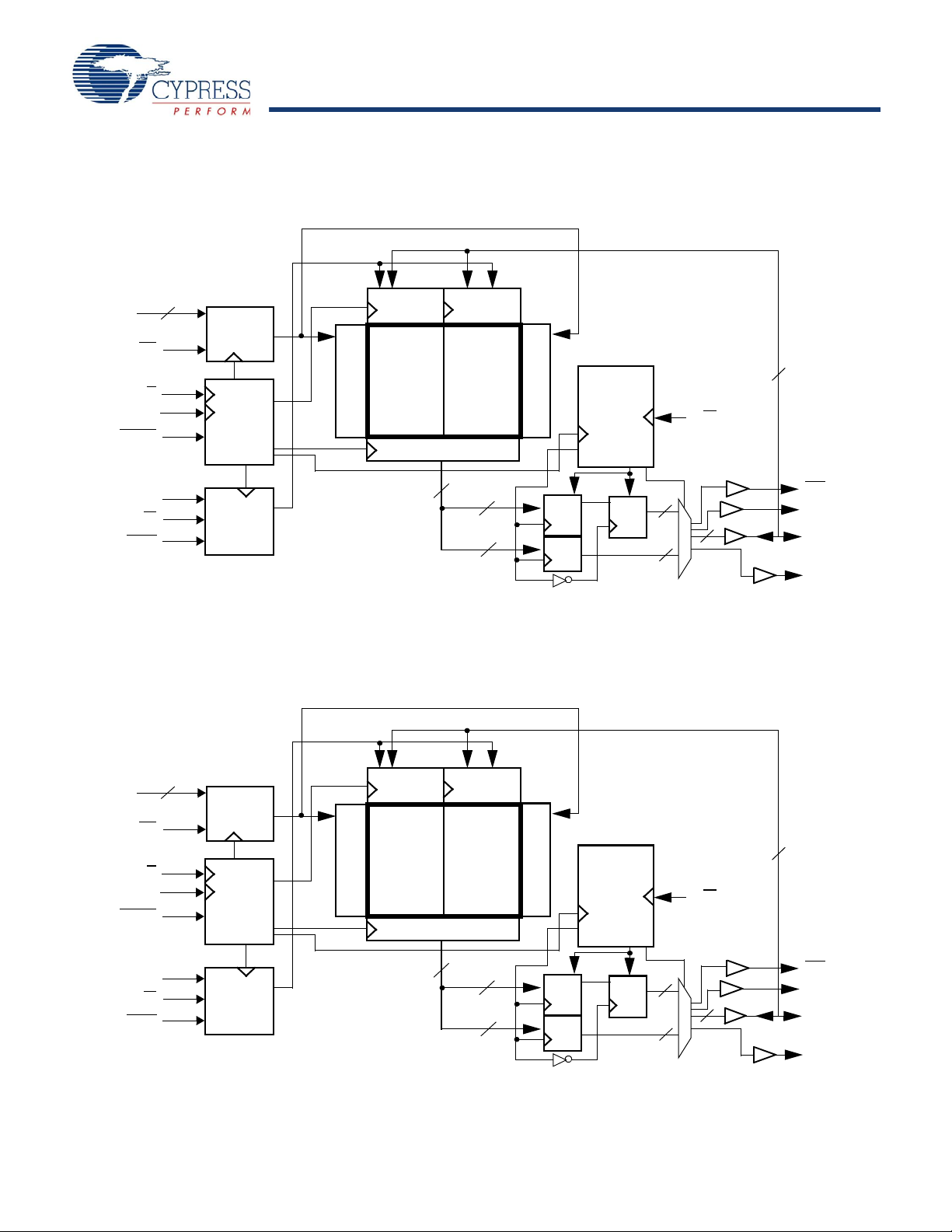

Pin Configurations

CY7C1166V18 (2M x 8)

165-Ball FBGA (13 x 15 x 1.4 mm) Pinout

234 5671

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

A

CQ

NC

NC

NC

NC

DOFF

NC

NC/72M A

NWS

1

KR/W

NC/144M

NC

NC

NC

NC

NC

TDO

NC

NC

NC

NC

NC

NC

TCK

NC

NC

A NC/288M

K

NWS

0

V

SS

AAA

NC V

SS

V

SS

V

SS

V

SS

V

DD

A

V

SS

V

SS

V

SS

V

DD

DQ4

NC

V

DDQ

NC

NC

NC

NC

DQ7

A

V

DDQ

V

SS

V

DDQ

V

DD

V

DD

DQ5 V

DDQ

V

DD

V

DDQ

V

DD

V

DDQ

V

DD

V

SS

V

DD

V

DDQ

V

DDQ

V

SS

V

SS

V

SS

V

SS

A

A

NC

V

SS

A

A

A

NC V

SS

NC V

SS

NC

NC

V

REF

V

SS

V

DD

V

SS

V

SS

A

V

SS

QVLD

NC

DQ6

NC

NC

NC

V

DD

A

891011

NC

A NC/36M

LD

CQ

A NC

NC

DQ3

V

SS

NC NC NC

NC

V

SS

NC

DQ2

NC

NC

NC

V

REF

NC

NC

V

DDQ

NC

V

DDQ

NC NC

V

DDQ

V

DDQ

V

DDQ

NCV

DDQ

NC

DQ1

NC

V

DDQ

V

DDQ

NC

V

SS

NC NC

NC

TDITMS

V

SS

A

NC

A

NC

NC

NC

ZQ

NC

DQ0

NC

NC

NC

NC

A

CY7C1177V18 (2M x 9)

234 5671

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

A

CQ

NC

NC

NC

NC

DOFF

NC

NC/72M A NC

K

R/W

NC/144M

NC

NC

NC

NC

NC

TDO

NC

NC

NC

NC

NC

NC

TCK

NC

NC

A NC/288M

K

BWS

0

V

SS

AAA

NC V

SS

V

SS

V

SS

V

SS

V

DD

A

V

SS

V

SS

V

SS

V

DD

DQ4

NC

V

DDQ

NC

NC

NC

NC

DQ7

A

V

DDQ

V

SS

V

DDQ

V

DD

V

DD

DQ5 V

DDQ

V

DD

V

DDQ

V

DD

V

DDQ

V

DD

V

SS

V

DD

V

DDQ

V

DDQ

V

SS

V

SS

V

SS

V

SS

A

A

NC

V

SS

A

A

A

NC V

SS

NC V

SS

NC

NC

V

REF

V

SS

V

DD

V

SS

V

SS

A

V

SS

QVLD

NC

DQ6

NC

NC

NC

V

DD

A

891011

DQ8

A NC/36M

LD

CQ

A NC

NC

DQ3

V

SS

NC NC NC

NC

V

SS

NC

DQ2

NC

NC

NC

V

REF

NC

NC

V

DDQ

NC

V

DDQ

NC NC

V

DDQ

V

DDQ

V

DDQ

NCV

DDQ

NC

DQ1

NC

V

DDQ

V

DDQ

NC

V

SS

NC NC

NC

TDITMS

V

SS

A

NC

A

NC

NC

NC

ZQ

NC

DQ0

NC

NC

NC

NC

A

Document Number: 001-06620 Rev. *D Page 4 of 27

[+] Feedback [+] Feedback

Page 5

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

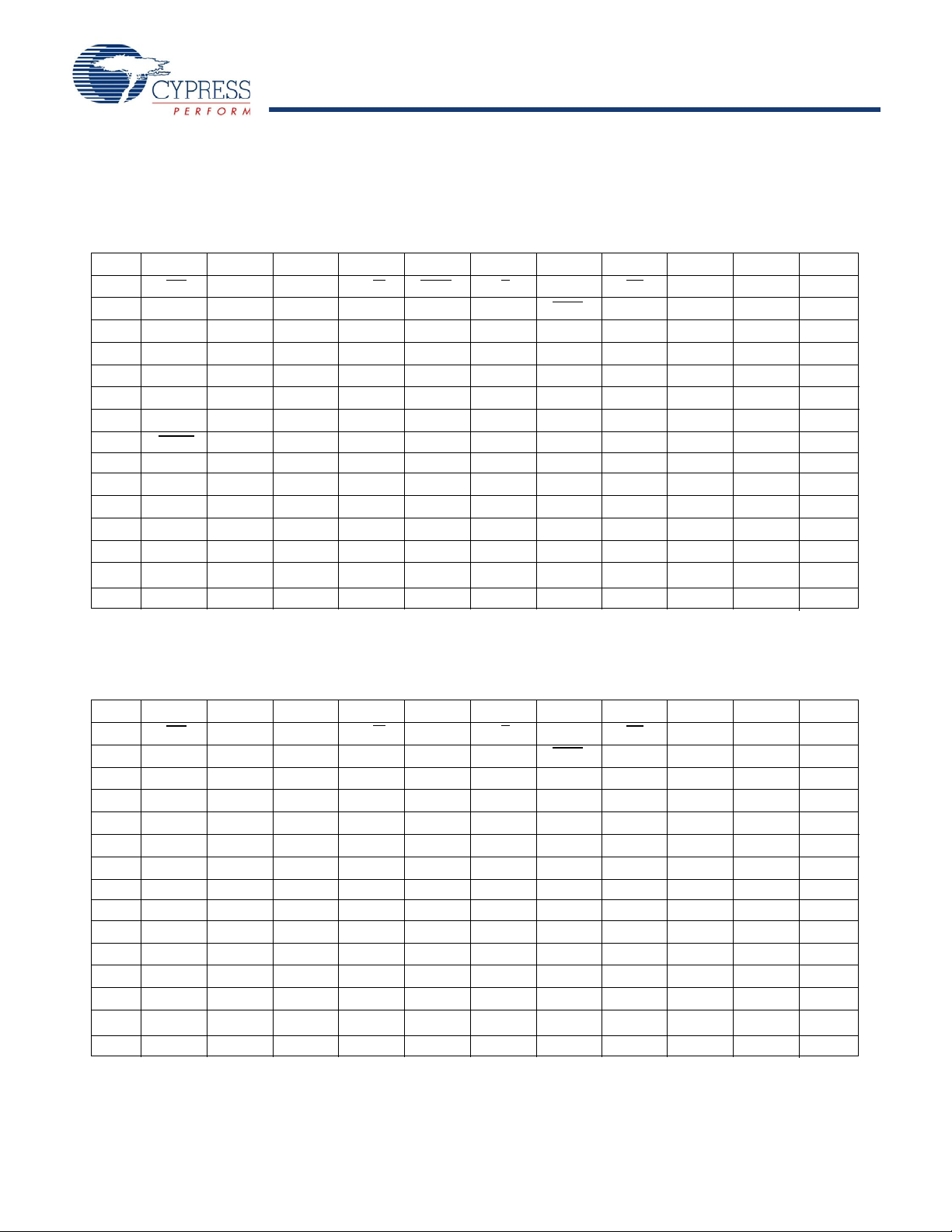

Pin Configurations (continued)

CY7C1168V18 (1M x 18)

165-Ball FBGA (13 x 15 x 1.4 mm) Pinout

234 5671

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

A

CQ

NC

NC

NC

NC

DOFF

NC

NC/72M A

BWS

1

K

R/W

NC/144M

DQ9

NC

NC

NC

NC

TDO

NC

NC

NC

NC

NC

NC

TCK

NC

NC

A NC/288M

K

BWS

0

V

SS

ANCA

DQ10 V

SS

V

SS

V

SS

V

SS

V

DD

A

V

SS

V

SS

V

SS

V

DD

DQ11

NC

V

DDQ

NC

DQ14

NC

DQ16

DQ17

A

V

DDQ

V

SS

V

DDQ

V

DD

V

DD

DQ13 V

DDQ

V

DD

V

DDQ

V

DD

V

DDQ

V

DD

V

SS

V

DD

V

DDQ

V

DDQ

V

SS

V

SS

V

SS

V

SS

A

A

NC

V

SS

A

A

A

NC V

SS

NC V

SS

DQ12

NC

V

REF

V

SS

V

DD

V

SS

V

SS

A

V

SS

QVLD

NC

DQ15

NC

NC

NC

V

DD

A

891011

DQ0

A NC/36M

LD

CQ

A NC

NC

DQ8

V

SS

NC DQ7 NC

NC

V

SS

NC

DQ6

NC

NC

NC

V

REF

NC

DQ3

V

DDQ

NC

V

DDQ

NC DQ5

V

DDQ

V

DDQ

V

DDQ

NCV

DDQ

NC

DQ4

NC

V

DDQ

V

DDQ

NC

V

SS

NC NC

NC

TDITMS

V

SS

A

NC

A

NC

NC

NC

ZQ

NC

DQ2

NC

DQ1

NC

NC

A

CY7C1170V18 (512K x 36)

234 5671

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

A

CQ

NC

NC

NC

NC

DOFF

NC

NC/144M NC/36M

BWS

2

K

R/W

BWS

1

DQ27

DQ18

NC

NC

NC

TDO

NC

NC

DQ31

NC

NC

NC

TCK

NC

DQ28

A

BWS

3

K

BWS

0

V

SS

ANCA

DQ19 V

SS

V

SS

V

SS

V

SS

V

DD

A

V

SS

V

SS

V

SS

V

DD

DQ20

DQ21

V

DDQ

DQ32

DQ23

DQ34

DQ25

DQ26

A

V

DDQ

V

SS

V

DDQ

V

DD

V

DD

DQ22 V

DDQ

V

DD

V

DDQ

V

DD

V

DDQ

V

DD

V

SS

V

DD

V

DDQ

V

DDQ

V

SS

V

SS

V

SS

V

SS

A

ANC

V

SS

A

A

A

DQ29 V

SS

NC V

SS

DQ30

NC

V

REF

V

SS

V

DD

V

SS

V

SS

A

V

SS

QVLD

NC

DQ33

NC

DQ35

DQ24

V

DD

A

891011

DQ0

A NC/72M

LD

CQ

A NC

NC

DQ8

V

SS

NC DQ17 DQ7

NC

V

SS

NC

DQ6

DQ14

NC

NC

V

REF

NC

DQ3

V

DDQ

NC

V

DDQ

NC DQ5

V

DDQ

V

DDQ

V

DDQ

DQ4V

DDQ

NC

DQ13

NC

V

DDQ

V

DDQ

NC

V

SS

NC DQ1

NC

TDITMS

V

SS

A

NC

A

DQ16

DQ15

NC

ZQ

DQ12

DQ2

DQ10

DQ11

DQ9

NC

A

Document Number: 001-06620 Rev. *D Page 5 of 27

[+] Feedback [+] Feedback

Page 6

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

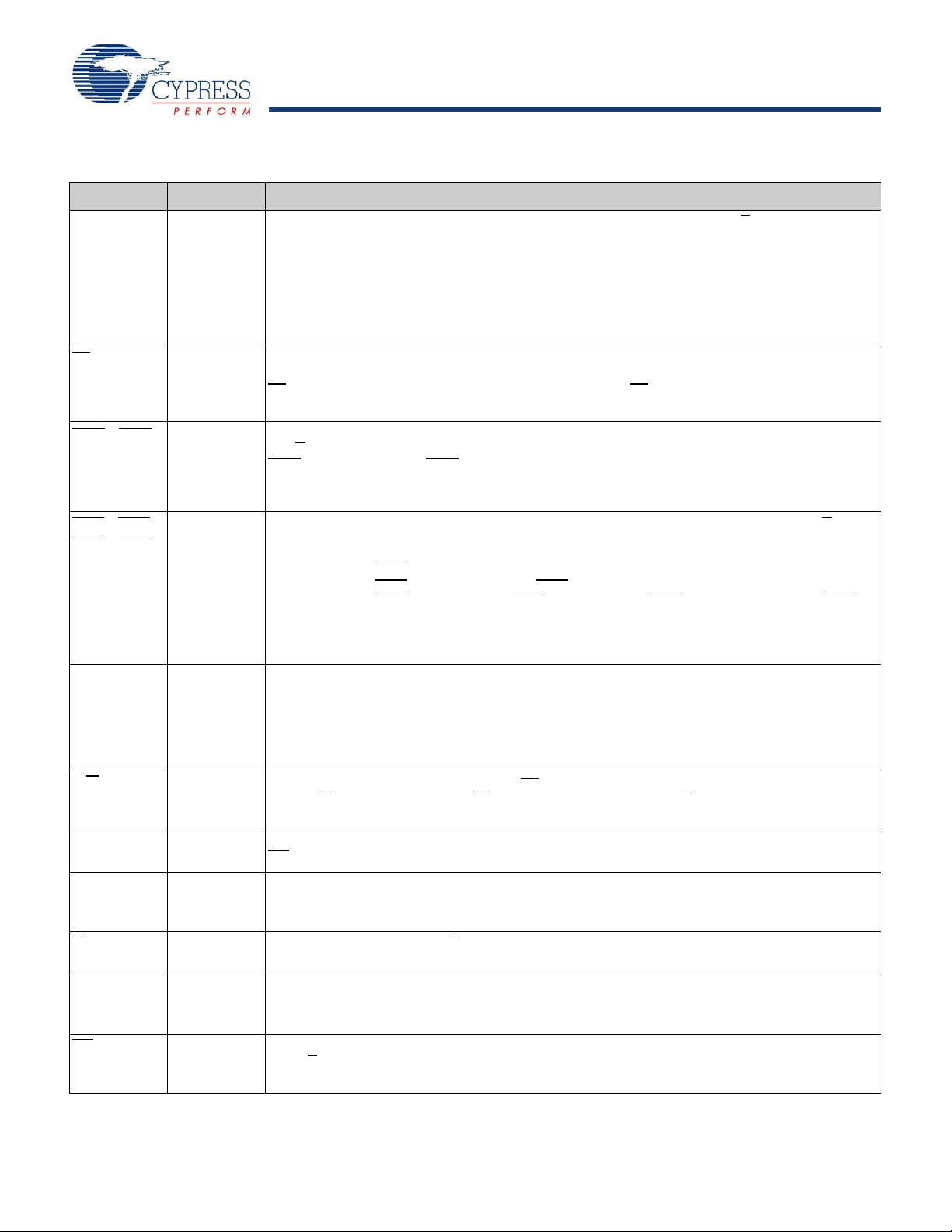

Pin Definitions

Pin Name IO Pin Description

DQ

[x:0]

Input OutputSynchronous

LD Input-

Synchronous

BWS

, Input-

1

Synchronous

Input-

,

1

Synchronous

3

NWS0, NWS

BWS

,

0

BWS

, BWS

2

Data Input Output Signals. Inputs are sampled on the rising edge of K and K clocks during valid

write operations. These pins drive out the requested data when a read operation is active. Valid data

is driven out on the rising edge of both the K and K clocks during read operations. When read access

is deselected, Q[x:0] are automatically tri-stated.

CY7C1 166V18 − DQ

CY7C1 177V18 − DQ

CY7C1 168V18 − DQ

CY7C1 170V18 − DQ

[7:0]

[8:0]

[17:0]

[35:0]

Synchronous Load. This input is brought LOW when a bus cycle sequence is to be defined. This

definition includes address and read/write direction. All transactions operate on a burst of two data.

LD

must meet the setup and hold times around edge of K. LD must meet the setup and hold times

around edge of K.

Nibble Write Select 0, 1 − Active LOW.(CY7C1166V18 Only) Sampled on the rising edge of the K

and K

clocks during write operations. It is used to select the nibble that is written into the device

NWS

controls D

0

All the Nibble Write Selects are sampled on the same edge as the data. Deselecting a Nibble Write

and NWS1 controls D

[3:0]

[7:4]

.

Select ignores the corresponding nibble of data and not written into the device.

Byte Write Select 0, 1, 2, and 3 − Active LOW. Sampled on the rising edge of the K and K clocks

during Write operations. It is used to select the byte that is written into the device during the current

portion of the write operations. Bytes not written remain unaltered.

CY7C1 177V18 − BWS

CY7C1 168V18 − BWS0 controls D

CY7C1 170V18 − BWS0 controls D

controls D

All the Byte Write Selects are sampled on the same edge as the data. Deselecting a Byte Write Select

[35:27]

.

controls D

0

[8:0]

and BWS1 controls D

[8:0],

, BWS1 controls D

[8:0]

[17:9].

, BWS2 controls D

[17:9]

[26:18]

, and BWS3

ignores the corresponding byte of data and not written into the device.

A Input-

Synchronous

Address Inputs. Sampled on the rising edge of the K clock during active read and write operations.

These address inputs are multiplexed for both read and write operations. Internally, the device is

organized as 2M x 8 (two arrays each of1M x 8) for CY7C1166V18, 2M x 9 (two arrays each of 1M

x 9) for CY7C1177V18, 1M x 18 (two arrays each of 512K x 18) for CY7C1168V18, and 512K x 36

(two arrays each of 256K x 18) for CY7C1170V18. All the address inputs are ignored when the

appropriate port is deselected.

R/W

Input-

Synchronous

Synchronous Read/Write Input. When LD

when R/W

is HIGH, write when R/W is LOW) for loaded address. R/W must meet the setup and hold

is LOW, this input designates the access type (read

times around edge of K.

QVLD Valid Output

Indicator

K Input-

Clock

K

InputClock

Valid Output Indicator . The Q V alid indicates valid output data. QVLD is edge aligned with CQ and

CQ

.

Positive Input Clock Input. The rising edge of K is used to capture synchronous inputs to the device

and to drive out data through Q

edge of K.

when in single clock mode. All accesses are initiated on the rising

[x:0]

Negative Input Clock Input. K is used to capture synchronous inputs being presented to the device

and to drive out data through Q

when in single clock mode.

[x:0]

CQ Clock Output Synchronous Echo Clock Outputs. This is a free running clock and is synchronized to the input

clock (K) of the DDR-II+. The timings for the echo clocks are shown in the “Switching Characteristics”

on page 22.

CQ

Clock Output

Synchronous Echo Clock Outputs. This is a free running clock and is synchronized to the input

clock (K) of the DDR-II+. The timings for the echo clocks are shown in the “Switching Characteristics”

on page 22.

Document Number: 001-06620 Rev. *D Page 6 of 27

[+] Feedback [+] Feedback

Page 7

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Pin Definitions (continued)

Pin Name IO Pin Description

ZQ Input Output Impe dance Matching Input. This input is used to tune the device outputs to the system dat a

bus impedance. CQ, CQ, and Q

connected between ZQ and ground. Alternatively, this pin can be connected directly to V

enables the minimum impedance mode. This pin cannot be connected directly to GND or left unconnected.

DOFF Input DLL T urn Off − Active LOW. Connecting this pin to ground turns off the DLL inside the device. The

timings in the DLL turned off operation is different from those listed in this data sheet. For normal

operation, this pin can be connected to a pull up through a 10KΩ or less pull up resistor. The device

behaves in DDR-I mode when the DLL is turned off. In this mode, the device can be operated at a

frequency of up to 167 MHz with DDR-I timing.

TDO Output TDO for JTAG.

TCK Input TCK Pin for JTAG.

TDI Input TDI Pin for JTAG.

TMS Input TMS Pin for JTAG.

NC N/A Not Connected to the Die. Tie to any voltage level.

NC/36M N/A Not Connected to the Die. Tie to any voltage level.

NC/72M N/A Not Connected to the Die. Tie to any voltage level.

NC/144M N/A Not Connected to the Die. Tie to any voltage level.

output impedance are set to 0.2 x RQ, where RQ is a resistor

[x:0]

DDQ

, which

NC/288M N/A Not Connected to the Die. Tie to any voltage level.

V

V

V

V

REF

DD

SS

DDQ

Input-

Reference

Power Supply Power Supply Inputs to the Core of the Device.

Ground Ground for the Device.

Power Supply Power Supply Inputs for the Outputs of the Device.

Reference Volt age Input. Static input used to set the reference level for HSTL inputs, outputs, and

AC measurement points.

Document Number: 001-06620 Rev. *D Page 7 of 27

[+] Feedback [+] Feedback

Page 8

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Functional Overview

The CY7C1166V18, CY7C1177V18, CY7C1168V18, and

CY7C1170V18 are synchronous pipelined Burst SRAMs

equipped with a DDR interface.

Accesses are initiated on the rising edge of the p ositive input

clock (K). All synchronous input and output timing are referenced

to the rising edge of the Input clocks (K/K).

All synchronous data inputs (D

controlled by the rising edge of the input clocks (K and K

synchronous data outputs (Q

controlled by the rising edge of the input clocks (K and K

All synchronous control (R/W, LD, BWS

input registers controlled by the rising edge of the input clock

(K/K).

CY7C1168V18 is described in the following sections. The same

basic descriptions apply to CY7C1166V18, CY7C1177V18, and

CY7C1170V18.

Read Operations

The CY7C1168V18 is organized internally as a single array of

1M x 18. Accesses are completed in a burst of two sequential

18-bit data words. Read operations are initiated by asserting

R/W

HIGH and LD LOW at the rising edge of the positive input

clock (K). The address presented to address inputs is stored in

the read address register. Following the next two K clock rise, the

corresponding 18-bit word of data from this address location is

driven onto the Q

the subsequent rising edge of K the next 18-bit data word from

using K as the output timing reference. On

[17:0]

the address location generated by the burst counter is driven

onto the Q

rising edge of the input clock (K/K

. The requested data is valid 0.45 ns from the

[17:0]

internal logic, each read access must be allowed to complete.

Read accesses can be initiated on every rising edge of the

positive input clock (K).

When read access is deselected, the CY7C1168V18 first

completes the pending read transactions. Synchronous internal

circuitry automatically tri-states the outputs following the next

rising edge of the negative Input clock (K

seamless transition between devices without the insertion of wait

states in a depth expanded memory.

Write Operations

Write operations are initiated by asserting R/W LOW and LD

LOW at the rising edge of the positive input clock (K). The

address presented to address inputs is stored in the write

address register. On the following K clock rise the data presented

to D

provided BWS

rising edge of the Negative Input Clock (K

presented to D

provided BWS

is then written into the memory array at the specified location.

Write accesses can be initiated on every rising edge of the

positive input clock (K). This pipelines the dat a flow suc h that 18

bits of data can be transferred into the device on every rising

edge of the input clocks (K and K

When write access is deselected, the device ignores all inputs

after the pending write operations are completed.

is latched and stored into the 18-bit Write Data register

[17:0]

are both asserted active. On the subseque nt

[1:0]

is also stored into the Write Data register

[17:0]

are both asserted active. The 36 bits of data

[1:0]

) pass through input registers

[x:0]

) pass through output registers

[x:0]

) inputs pass through

[0:X]

). In order to maintain the

). This enables for a

) the information

).

). All

) also.

Byte Write Operations

Byte Write operations are supported by the CY7C1168V18. A

Write operation is initiated as described in the Write Operations

section. The bytes that are written are determined by BWS

BWS

which are sampled with each set of 18-bit data word.

1

Asserting the appropriate Byte Write Select input during the data

and

0

portion of a write enables the data being presented to be latched

and written into the device. Deasserting the Byte Write Select

input during the data portion of a write enables the data stored in

the device for that byte to remain unaltered. This feature can be

used to simplify read/modify/write operations to a Byte Write

operation.

Double Data Rate Operation

The CY7C1168V18 enables high-performance operation

through high clock frequencies (achieved through pipelining) and

double data rate mode of operation. The CY7C1168V18 requires

two No Operation (NOP) cycle when transitioning from a read to

a write cycle. At higher frequencies, some applications may

require a third NOP cycle to avoid contention.

If a read occurs after a write cycle, then the address and data for

the write are stored in registers. The write information must be

stored because the SRAM cannot perform the last word write to

the array without conflicting with the read. The data stays in this

register until the next write cycle occurs. On the first write cycle

after the read(s), the stored data from the earlier write is written

into the SRAM array. This is called a Posted Write.

If a read is performed on the same address on which a write is

performed in the previous cycle, the SRAM reads out the most

current data. The SRAM does this by bypassing the memory

array and reading the data from the registers.

Depth Expansion

Depth expansion requires replicating the LD control signal for

each bank. All other control signals can be common between

banks as appropriate.

Programmable Impedance

An external resistor, RQ, must be connected between the ZQ pin

on the SRAM and V

driver impedance. The value of RQ must be 5x the value of the

to enable the SRAM to adjust its output

SS

intended line impedance driven by the SRAM. The allowable

range of RQ to guarantee impedance matching with a tolerance

of ±15% is between 175Ω and 350Ω

, with V

output impedance is adjusted every 1024 cycles upon power up

=1.5V. The

DDQ

to account for drifts in supply voltage and temperature.

Echo Clocks

Echo clocks are provided on the DDR-II+ to simplify data capture

on high-speed systems. Two echo clocks are generated by the

DDR-II+. CQ is referenced with respect to K and CQ

enced with respect to K

. These are free-running clocks and are

is refer-

synchronized to the input clock of the DDR-II+. The timings for

the echo clocks are shown in the “Switching Characteristics” on

page 22.

Valid Data Indicator (QVLD)

QVLD is provided on the DDR-II+ to simplify data capture on high

speed systems. The QVLD is generated by the DDR-II+ device

along with data output. This signal is also edge-aligned with the

Document Number: 001-06620 Rev. *D Page 8 of 27

[+] Feedback [+] Feedback

Page 9

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

echo clock and follows the timing of any data pin. This signal is

Notes

2. X = “Don’t Care,” H = Logic HIGH, L = Logic LOW,

↑ represents rising edge.

3. Device powers up deselected and the outputs in a tri-state condition.

4. “A” represents address location latched by the devices when transaction was initiated and A + 1 represents the addresses sequence in the burst.

5. “t” represents the cycle at which a Read/Write operation is started. t + 1, t + 2, and t + 3 are the first, second, and third clock cycles succeeding the “t” clock cycle.

6. Data inputs are registered at K and K

rising edges. Data outputs are delivered on K and K rising edges.

7. Do K = K

= HIGH when clock is stopped. This is not essential, but permits most rapid restart by overcoming transmission line charging symmetrically.

asserted half a cycle before valid data arrives.

DLL

These chips use a Delay Lock Loop (DLL) that is designed to

function between 120 MHz and the specified maximum clock

frequency. The DLL may be disabled by applying ground to the

DOFF

pin. When the DLL is turned off, the device behaves in

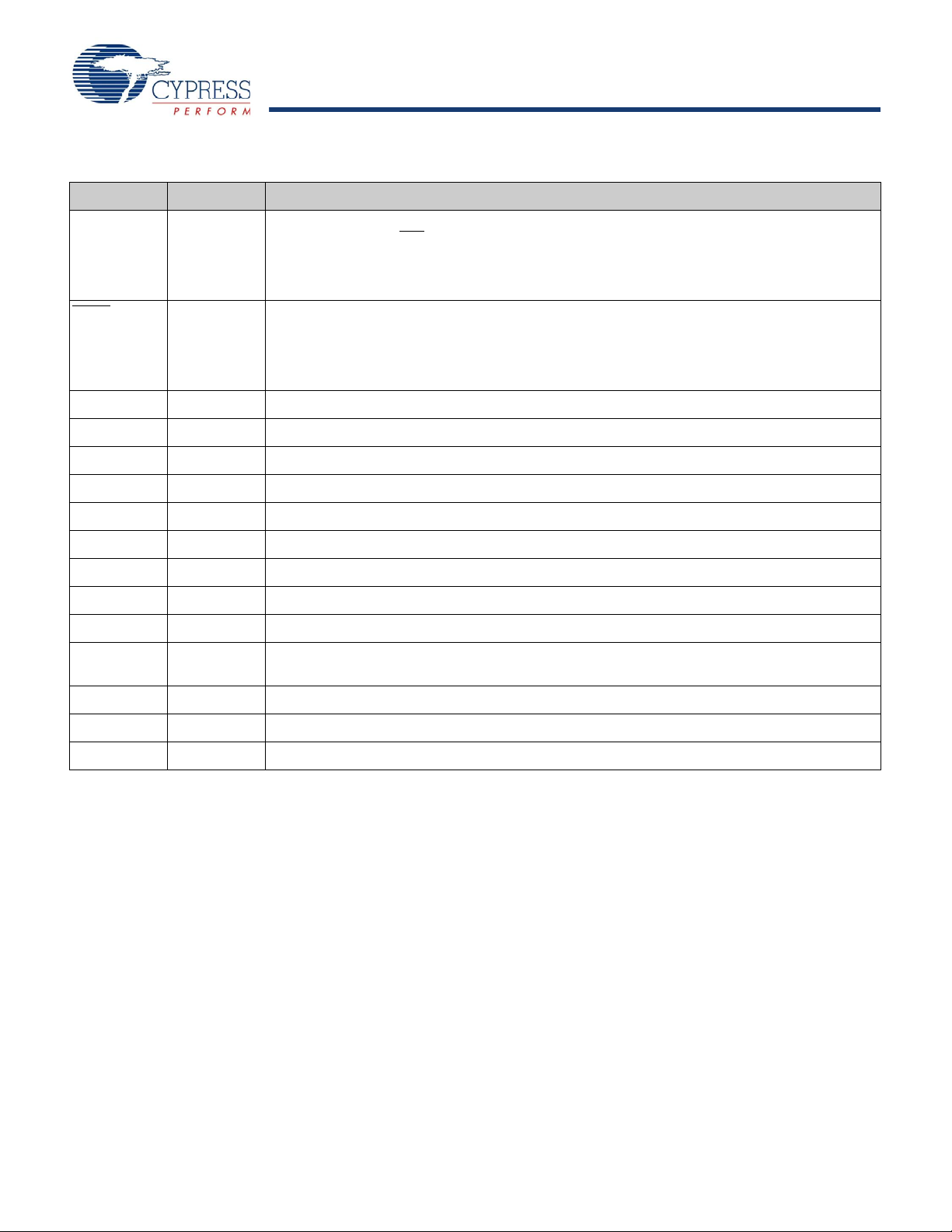

Application Example

Figure 1 shows two DDR-II+ used in an application.

Figure 1. Application Example

DDR-I mode (with 1.0 cycle latency and a longer access time).

For more information, refer to the application note, “DLL Considerations in QDRII/DDRII/QDRII+/DDRII+”. The DLL can also be

reset by slowing or stopping the input clocks K and K for a

minimum of 30 ns. However, it is not necessary for the DLL to be

reset to lock to the desired frequency. During power up, when the

DOFF

is tied HIGH, the DLL gets locked after 2048 cycles of

stable clock.

ZQ

CQ/CQ

K

K

R = 250ohms

DQ

A

SRAM#2

LD R/W

BUS

MASTER

(CPU or ASIC)

Echo Clock1/Echo Clock1

Echo Clock2/Echo Clock2

Addresses

Cycle Start

R/W

Source CLK

Source CLK

DQ

DQ

A

SRAM#1

LD R/W

Truth Table

The truth table for the CY7C1166V18, CY7C1177V18, CY7C1168V18, and CY7C1170V18 follows.

Operation K LD R/W DQ DQ

Write Cycle:

Load address; wait one cycle; input write data on consecutive

K and K

rising edges.

L-H L L D(A) at K (t + 1) ↑ D(A + 1) at K

ZQ

CQ/CQ

K

K

[2, 3, 4, 5, 6, 7]

R = 250ohms

(t + 1) ↑

Read Cycle: (2.5 Cycle Latency)

L-H L H Q(A) at K

(t + 2)↑ Q(A + 1) at K (t + 3) ↑

Load address; wait two and a half cycle; read data on consecutive K and K rising edges.

NOP: No Operation L-H H X High-Z High-Z

Standby: Clock Stopped Stopped X X Previous State Previous State

Document Number: 001-06620 Rev. *D Page 9 of 27

[+] Feedback [+] Feedback

Page 10

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Write Cycle Descriptions

Note

8. Is based on a write cycle was initiated in accordance with the Write Cycle Description Truth Table. Alter NWS

0

, NWS1, BWS0, BWS1, BWS2, and BWS3 on different

portions of a write cycle, as long as the setup and hold requirements are achieved.

The write cycle descriptions of CY7C1166V18 and CY7C1168V18 follows.

[2, 8]

BWS0/

NWS

0

BWS1/

NWS

K

1

K

Comments

L L L–H – During the Data portion of a write sequence:

CY7C1166V18 − both nibbles (D

CY7C1168V18 − both bytes (D

) are written into the device.

[7:0]

) are written into the device.

[17:0]

L L – L-H During the Data portion of a write sequence:

CY7C1166V18 − both nibbles (D

CY7C1168V18 − both bytes (D

) are written into the device.

[7:0]

) are written into the device.

[17:0]

L H L –H – During the Data portion of a write sequence:

CY7C1166V18 − only the lower nibble (D

CY7C1168V18 − only the lower byte (D

) is written into the device, D

[3:0]

) is written into the device, D

[8:0]

L H – L–H During the Data portion of a write sequence:

CY7C1166V18 − only the lower nibble (D

CY7C1168V18 − only the lower byte (D

) is written into the device, D

[3:0]

) is written into the device, D

[8:0]

H L L –H – During the Data portion of a write sequence:

CY7C1166V18 − only the upper nibble (D

CY7C1168V18 − only the upper byte (D

) is written into the device, D

[7:4]

) is written into the device, D

[17:9]

H L – L–H During the Data portion of a write sequence:

CY7C1166V18 − only the upper nibble (D

CY7C1168V18 − only the upper byte (D

) is written into the device, D

[7:4]

) is written into the device, D

[17:9]

H H L–H – No data is written into the devices during this portion of a write operation.

H H – L–H No data is written into the devices during this portion of a write operation.

remains unaltered.

[7:4]

remains unaltered.

[17:9]

remains unaltered.

[7:4]

remains unaltered.

[17:9]

remains unaltered.

[3:0]

remains unaltered.

[8:0]

remains unaltered.

[3:0]

remains unaltered.

[8:0]

The write cycle descriptions of CY7C1177V18 follows.

BWS

K K Comments

0

L L-H – During the Data portion of a Write sequence, the single byte (D

L – L-H During the Data portion of a Write sequence, the single byte (D

[2, 8]

[8:0]

[8:0]

H L-H – No data is written into the device during this portion of a Write operation.

H – L-H No data is written into the device during this portion of a Write operation.

) is written into the device.

) is written into the device.

Document Number: 001-06620 Rev. *D Page 10 of 27

[+] Feedback [+] Feedback

Page 11

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

The write cycle descriptions of CY7C1170V18 follows.

[2, 8]

BWS0BWS1BWS2BWS3K K Comments

LLLLL-H–During the data portion of a write sequence, all four bytes (D

the device.

LLLL–L-HDuring the data portion of a write sequence, all four bytes (D

the device.

L H H H L-H – During the data portion of a write sequence, only the lower byte (D

into the device. D

remains unaltered.

[35:9]

L H H H – L-H During the data portion of a write sequence, only the lower byte (D

into the device. D

remains unaltered.

[35:9]

H L H H L-H – During the data portion of a write sequence, only the byte (D

the device. D

[8:0]

and D

remains unaltered.

[35:18]

H L H H – L-H During the data portion of a write sequence, only the byte (D

the device. D

[8:0]

and D

remains unaltered.

[35:18]

H H L H L-H – During the data portion of a write sequence, only the byte (D

the device. D

[17:0]

and D

remains unaltered.

[35:27]

H H L H – L-H During the data portion of a write sequence, only the byte (D

the device. D

[17:0]

and D

remains unaltered.

[35:27]

H H H L L-H – During the data portion of a write sequence, only the byte (D

the device. D

remains unaltered.

[26:0]

H H H L – L-H During the data portion of a write sequence, only the byte (D

the device. D

remains unaltered.

[26:0]

) are written into

[35:0]

) are written into

[35:0]

[8:0]

[8:0]

) is written into

[17:9]

) is written into

[17:9]

) is written into

[26:18]

) is written into

[26:18]

) is written into

[35:27]

) is written into

[35:27]

) is written

) is written

HHHHL-H–No data is written into the device during this portion of a write operation.

HHHH–L-HNo data is written into the device during this portion of a write operation.

Document Number: 001-06620 Rev. *D Page 11 of 27

[+] Feedback [+] Feedback

Page 12

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

IEEE 1149.1 Serial Boundary Scan (JTAG)

These SRAMs incorporate a serial boundary scan test access

port (TAP) in the FBGA p ackage. This part is fully compliant with

IEEE Standard #1149.1-2001. The TAP operates using JEDEC

standard 1.8V IO logic levels.

Disabling the JTAG Feature

It is possible to operate the SRAM without using the JTAG

feature. To disable the TAP controller, TCK must be tied LOW

(VSS) to prevent clocking of the device. TDI and TMS are internally pulled up and may be unconnected. They may alternately

be connected to V

unconnected. Upon power up, the device comes up in a reset

state which does not interfere with the operation of the device.

Test Access Port—Test Clock

The test clock is used only with the TAP controller. All inputs are

captured on the rising edge of TCK. All outputs are driven from

the falling edge of TCK.

Test Mode Select

The TMS input is used to give commands to the TAP controller

and is sampled on the rising edge of TCK. It is allowable to leave

this pin unconnected if the TAP is not used. The pin is pulled up

internally, resulting in a logic HIGH level.

Test Data-In (TDI)

The TDI pin is used to serially input information into the registers

and connect to the input of any of the registers. The register

between TDI and TDO is chosen by the instruction that is loaded

into the TAP instruction register. For more information about

loading the instruction register, see “TAP Controller State

Diagram” on page 14. TDI is internally pulled up and uncon-

nected if the TAP is not used in an application. TDI is connected

to the most significant bit (MSB) on any register.

Test Data-Out (TDO)

The TDO output pin is used to serially clock data-out from the

registers. The output is active depending upon the curre nt state

of the TAP state machine (see “Instruction Codes” on page 17).

The output changes on the falling edge of TCK. TDO is

connected to the least significant bit (LSb) of any register.

Performing a TAP Reset

A Reset is performed by forcing TMS HIGH (VDD) for five rising

edges of TCK. This RESET does not affect the operation of the

SRAM and may be performed while the SRAM is operating. At

power up, the TAP is reset internally to ensure that TDO comes

up in a high-Z state.

TAP Registers

Registers are connected between the TDI and TDO pins and

enable data to be scanned into and out of the SRAM test circuitry.

Select only one register at a time through the instruction

registers. Data is serially loaded into the TDI pin on the rising

edge of TCK. Data is output on the TDO pin on the falling edge

of TCK.

through a pull up resistor. TDO must be left

DD

Instruction Register

Load three-bit instructions serially into the instruction regi ster.

This register is loaded when it is placed between the TDI and

TDO pins as shown in “TAP Controller Block Diagram” on

page 15. Upon power up, the instruction register is loaded with

the IDCODE instruction. It is also loaded with the IDCODE

instruction if the controller is placed in a reset state as described

in the previous section.

When the TAP controller is in the Capture IR state, the two least

significant bits are loaded with a binary “01” pattern to allow fault

isolation of the board level serial test path.

Bypass Register

To save time when serially shifting data through registers, it is

sometimes advantageous to skip certain chips. The bypass

register is a single-bit register that can be placed between TDI

and TDO pins. This enables data to be shifted through the SRAM

with minimal delay. The bypass register is set LOW (V

the BYPASS instruction is executed.

Boundary Scan Register

The boundary scan register is connected to all of the input and

output pins on the SRAM. Several no connect (NC) pins are also

included in the scan register to reserve pins for higher de nsity

devices.

The boundary scan register is loaded with the contents of the

RAM Input and Output ring when the TAP controller is in the

Capture-DR state and is then placed between the TDI and TDO

pins when the controller is moved to the Shift-DR state. Use the

EXTEST, SAMPLE/PRELOAD, and SAMPLE Z instructions to

capture the contents of the input and output ring.

The “Boundary Scan Order” on page 18 show the order in which

the bits are connected. Each bit corresponds to one of the bumps

on the SRAM package. The MSb of the register is connected to

TDI, and the LSb is connected to TDO.

Identification (ID) Register

The ID register is loaded with a vendor-specific 32-bit code

during the Capture-DR state when the IDCODE command is

loaded in the instruction register. The IDCODE is hardwired into

the SRAM and can be shifted out when the TAP controller is in

the Shift-DR state. The ID register has a vendor code and other

information described in the “Identification Register Definitions”

on page 17.

TAP Instruction Set

Eight different instructions are possible with the three-bit

instruction register. All combinations are listed in the “Instruction

Codes” on page 17. Three of these instructions are listed as

RESERVED and must not be used. The other five instructions

are described in this section.

Instructions are loaded into the TAP controller during the Shif t-IR

state when the instruction register is placed between TDI and

TDO. During this state, instructions are shifted through the

instruction register through the TDI a nd TDO pins. To execute

the instruction after it is shifted in, the TAP controller must be

moved into the Update-IR state.

) when

SS

Document Number: 001-06620 Rev. *D Page 12 of 27

[+] Feedback [+] Feedback

Page 13

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

IDCODE

The IDCODE instruction causes a vendor-specific 32-bit code to

be loaded into the instruction register. It also places the

instruction register between the TDI and TDO pins and enable s

the IDCODE to be shifted out of the device when the TAP

controller enters the Shift-DR state. The IDCODE instruction is

loaded into the instruction register upon power up or whenever

the TAP controller is supplied a test logic reset state.

SAMPLE Z

The SAMPLE Z instruction causes the boundary scan register to

be connected between the TDI and TDO pins when the TAP

controller is in a Shift-DR state. The SAMPLE Z command puts

the output bus into a High-Z state until the next command is

supplied during the Update IR state.

SAMPLE/PRELOAD

SAMPLE/PRELOAD is a 1149.1 mandatory instruction. When

the SAMPLE/PRELOAD instructions are loaded into the instruction register and the TAP controller is in the Capture-DR state, a

snapshot of data on the inputs and output pins is captured in the

boundary scan register.

The user must be aware that the TAP controller clock can only

operate at a frequency up to 20 MHz, while the SRAM clock

operates more than an order of magnitude faster. Because there

is a large difference in the clock frequencies, it is possible that

during the Capture-DR state, an input or output undergoes a

transition. The TAP may then try to capture a signal while in

transition (metastable state). This does not harm the device, but

there is no guarantee as to the value that is captured.

Repeatable results may not be possible.

To guarantee that the boundary sc an register captures the correct value of a signal, the SRAM signal must be stabilized long

enough to meet the TAP controller's capture setup plus hold

times (t

correctly if there is no way in a design to stop (or slow) the clock

during a SAMPLE/PRELOAD instruction. If this is an issue, it is

still possible to capture all other signals and simply ignore the

value of the CK and CK

After the data is captured, it is possible to shift out the data by

putting the TAP into the Shift-DR state. This places the boundary

scan register between the TDI and TDO pins.

and tCH). The SRAM clock input might not be captured

CS

captured in the boundary scan register.

PRELOAD enables an initial data pattern to be placed at the

latched parallel outputs of the boundary scan register cells before the selection of another boundary scan test operation.

The shifting of data for the SAMPLE and PRELOAD phases can

occur concurrently when required—that is, while data captured

is shifted out, the preloaded data can be shifted in.

BYPASS

When the BYPASS instruction is loaded in the instruction register

and the TAP is placed in a Shift-DR state, the bypass register is

placed between the TDI and TDO pins. The advantage of the

BYPASS instruction is that it shortens the boundary scan path

when multiple devices are connected together on a board.

EXTEST

The EXTEST instruction enables the preloaded data to be driven

out through the system output pins. This instruction also selects

the boundary scan register to be connected for serial access

between the TDI and TDO in the shift-DR controller state.

EXTEST Output Bus Tri-State

IEEE Standard 1149.1 mandates that the TAP controller is able

to put the output bus into a tri-state mode.

The boundary scan register has a special bit located at bit #47.

When this scan cell, called the “extest output bus tri-state”, is

latched into the preload register during the Update-DR state in

the TAP controller, it directly controls the state of the output

(Q-bus) pins, when the EXTEST is entered as the current

instruction. When HIGH, it enables the output buffers to drive the

output bus. When LOW, this bit places the output bus into a

High-Z condition.

Set this bit by entering the SAMPLE/PRELOAD or EXTEST

command, and then shifting the desired bit into that cell, during

the Shift-DR state. During Update-DR, the value loaded into that

shift-register cell latches into the preload register. When the

EXTEST instruction is entered, this bit directly controls the output

Q-bus pins. Note that this bit is preset HIGH to enable the output

when the device is powered up, and also when the T AP controller

is in the Test-Logic-Reset state.

Reserved

These instructions are not implemented but are reserved for

future use. Do not use these instructions.

Document Number: 001-06620 Rev. *D Page 13 of 27

[+] Feedback [+] Feedback

Page 14

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

TAP Controller State Diagram

TEST-LOGIC

RESET

TEST-LOGIC/

IDLE

SELECT

DR-SCAN

CAPTURE-DR

SHIFT-DR

EXIT1-DR

PAUSE-DR

EXIT2-DR

UPDATE-DR

SELECT

IR-SCAN

CAPTURE-IR

SHIFT-IR

EXIT1-IR

PAUSE-IR

EXIT2-IR

UPDATE-IR

1

0

1

1

0

1

0

1

0

0

0

1

1

1

0

1

0

1

0

0

0

1

0

1

1

0

1

0

0

1

1

0

Note

9. The 0/1 next to each state represents the value at TMS at the rising edge of TCK.

Figure 2 shows the tap controller state diagram.

Figure 2. Tap Controller State Diagram

[9]

Document Number: 001-06620 Rev. *D Page 14 of 27

[+] Feedback [+] Feedback

Page 15

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

TAP Controller Block Diagram

0

012..

29

3031

Boundary Scan Register

Identification Register

012..

.

.106

012

Instruction Register

Bypass Register

Selection

Circuitry

Selection

Circuitry

TAP Controller

TDI

TDO

TCK

TMS

Notes

10.These characteristics pertain to the TAP inputs (TMS, TCK, TDI and TDO). Parallel load levels are specified in the Electrical Characteristics Table.

11.Overshoot: V

IH

(AC) < V

DDQ

+ 0.35V (pulse width less than t

CYC

/2), undershoot: VIL(AC) > −0.3V (pulse width less than t

CYC

/2).

12.All voltage refer to ground.

Figure 3. Tap Controller Block Diagram

TAP Electrical Characteristics

The Tap Electrical Characteristics table over the operating range follows.

Parameter Description Test Conditions Min Max Unit

Output HIGH Voltage I

Output HIGH Voltage I

Output LOW Voltage IOL = 2.0 mA 0.4 V

Output LOW Voltage IOL = 100 μA0.2V

Input HIGH Voltage 0.65 VDDV

Input LOW Voltage –0.3 0.35 V

Input and Output Load Current GND ≤ VI ≤ V

V

V

V

V

V

V

I

OH1

OH2

OL1

OL2

IH

IL

X

[10, 11, 12]

= −2.0 mA 1.4 V

OH

= −100 μA1.6 V

OH

DD

+ 0.3 V

DD

DD

−55μA

V

Document Number: 001-06620 Rev. *D Page 15 of 27

[+] Feedback [+] Feedback

Page 16

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

TAP AC Switching Characteristics

t

TL

t

TH

(a)

TDO

C

L

= 20 pF

Z

0

= 50

Ω

GND

0.9V

50

Ω

1.8V

0V

ALL INPUT PULSES

0.9V

Test Clock

Test Mode Select

TCK

TMS

Test Data In

TDI

Test Data Out

t

TCYC

t

TMSH

t

TMSS

t

TDIS

t

TDIH

t

TDOV

t

TDOX

TDO

Notes

13.t

CS

and tCH refer to the setup and hold time requirements of latching data from the boundary scan register.

14.Test conditions are specified using the load in TAP AC test conditions. t

R/tF

= 1 ns

The Tap AC Switching Characteristics over the operating range follows.

Parameter Description Min Max Unit

t

TCYC

t

TF

t

TH

t

TL

TCK Clock Cycle Time 50 ns

TCK Clock Frequency 20 MHz

TCK Clock HIGH 20 ns

TCK Clock LOW 20 ns

Setup Times

t

TMSS

t

TDIS

t

CS

TMS Setup to TCK Clock Rise 5 ns

TDI Setup to TCK Clock Rise 5 ns

Capture Setup to TCK Rise 5 ns

Hold Times

t

TMSH

t

TDIH

t

CH

TMS Hold after TCK Clock Rise 5 ns

TDI Hold after Clock Rise 5 ns

Capture Hold after Clock Rise 5 ns

Output Times

t

TDOV

t

TDOX

TCK Clock LOW to TDO Valid 10 ns

TCK Clock LOW to TDO Invalid 0 ns

[13, 14]

TAP Timing and Test Condition

The Tap Timing and Test Conditions for the CY7C1166V18, CY7C1177V18, CY7C1168V18, and CY7C1170V18 follows.

Figure 4. TAP Timing and Test Conditions

[14]

Document Number: 001-06620 Rev. *D Page 16 of 27

[+] Feedback [+] Feedback

Page 17

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Identification Register Definitions

Instruction Field

Revision Number

(31:29)

Cypress Device ID

(28:12)

Cypress JEDEC ID

(11:1)

ID Register

Presence (0)

CY7C1166V18 CY7C1177V18 CY7C1168V18 CY7C1170V18

000 000 000 000 Version number.

11010111000000101 11010111000001101 1 1010111000010101 11010111000100101 Defines the type of

00000110100 00000110100 00000110100 00000110100 Allows unique

1 1 1 1 Indicates the

Value

Description

SRAM.

identification of

SRAM vendor.

presence of an ID

register.

Scan Register Sizes

Register Name Bit Size

Instruction 3

Bypass 1

ID 32

Boundary Scan 107

Instruction Codes

Instruction Code Description

EXTEST 000 Captures the input output ring contents.

IDCODE 001 Loads the ID register with the vendor ID code and places the register between TDI

SAMPLE Z 010 Capture s the Input Output contents. It places the boundary scan register between

RESERVED 011 Do Not Use: This instruction is reserved for future use.

SAMPLE/PRELOAD 100 Captures the input output ring contents. It places the boundary scan register between

RESERVED 101 Do Not Use: This instruction is reserved for future use.

RESERVED 110 Do Not Use: This instruction is reserved for future use.

BYPASS 111 Places the bypass register between TDI and TDO. This operation does not affect

and TDO. This operation does not affect SRAM operation.

TDI and TDO. This forces all SRAM output drivers to a High-Z state.

TDI and TDO. This operation does not affect the SRAM operation.

SRAM operation.

Document Number: 001-06620 Rev. *D Page 17 of 27

[+] Feedback [+] Feedback

Page 18

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Boundary Scan Order

Bit # Bump ID Bit # Bump ID Bit # Bump ID Bit # Bump ID

0 6R 27 11H 54 7B 81 3G

1 6P 28 10G 55 6B 82 2G

26N 299G 566A 831J

3 7P 30 11F 57 5B 84 2J

4 7N 31 11G 58 5A 85 3K

57R 329F 594A 863J

6 8R 33 10F 60 5C 87 2K

7 8P 34 11E 61 4B 88 1K

8 9R 35 10E 62 3A 89 2L

9 11P 36 10D 63 1H 90 3L

10 10P 37 9E 64 1A 91 1M

11 10N 38 10C 65 2B 92 1L

12 9P 39 11D 66 3B 93 3N

13 10M 40 9C 67 1C 94 3M

1411N 419D 681B 951N

15 9M 42 11B 69 3D 96 2M

16 9N 43 11C 70 3C 97 3P

1711L 449B 711D 982N

18 11M 45 10B 72 2C 99 2P

19 9L 46 11A 73 3E 100 1P

20 10L 47 Internal 74 2D 101 3R

2111K 489A 752E 1024R

22 10K 49 8B 76 1E 103 4P

23 9J 50 7C 77 2F 104 5P

24 9K 51 6C 78 3F 105 5N

25 10J 52 8A 79 1G 106 5R

26 11J 53 7A 80 1F

Document Number: 001-06620 Rev. *D Page 18 of 27

[+] Feedback [+] Feedback

Page 19

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

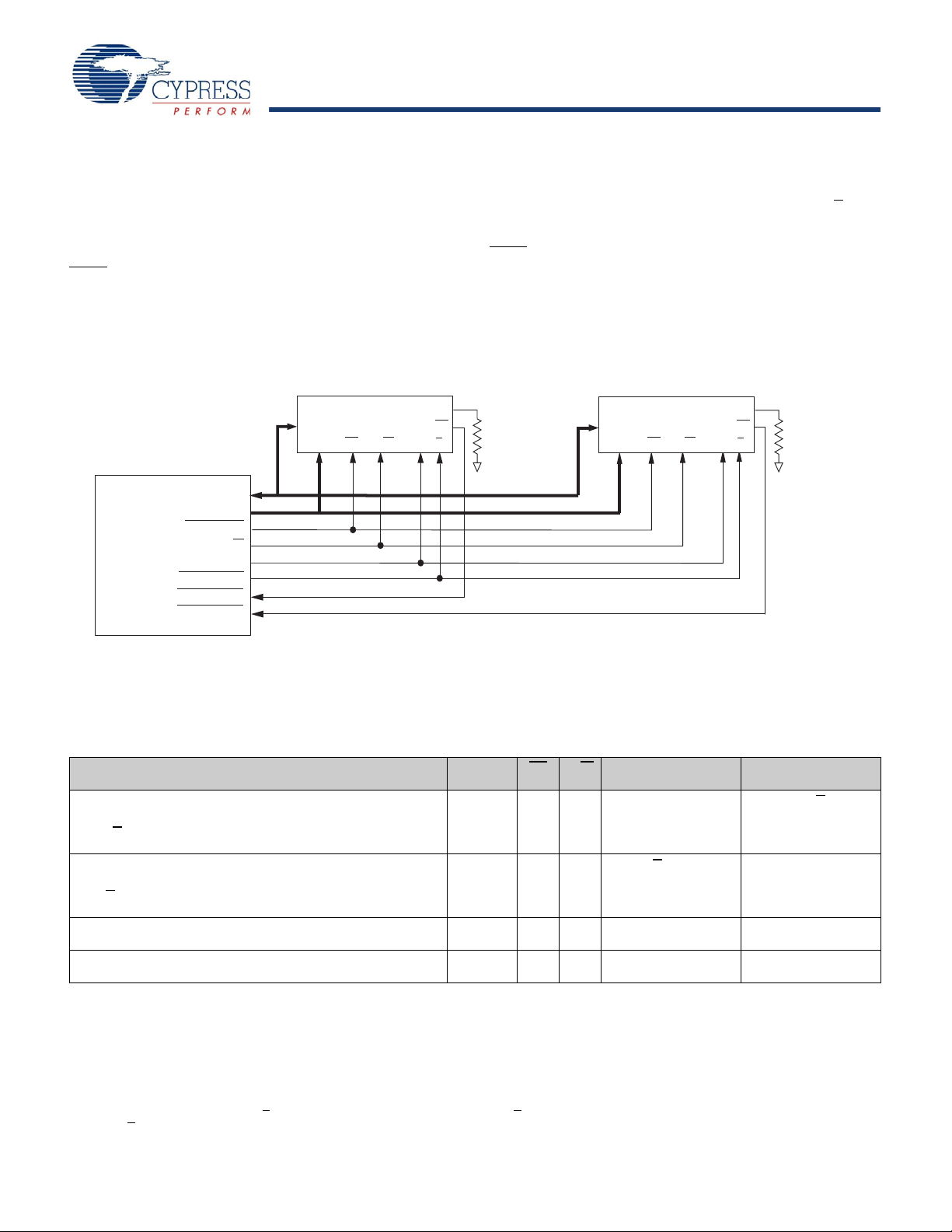

Power Up Sequence in DDR-II+ SRAM

K

K

Fix HIGH (tie to V

DDQ

)

VDD/V

DDQ

DOFF

Clock Start (Clock Starts after VDD/V

DDQ

is Stable)

Unstable Clock > 2048 Stable Clock

Start Normal

Operation

~

~

VDD/V

DDQ

Stable (< + 0.1V DC per 50 ns)

DDR-II+ SRAMs must be powered up and initialized in a

predefined manner to prevent undefined operations. During

power up, when the DOFF is tied HIGH, the DLL gets locked after

2048 cycles of stable clock.

Power Up Sequence

■ Apply power with DOFF tied HIGH (all other inputs can be HIGH

or LOW)

❐ Apply V

❐ Apply V

■ Provide stable power and clock (K, K) for 2048 cycles to lock

the DLL.

before V

DD

before V

DDQ

DDQ

or at the same time as V

REF

REF

Power Up Waveforms

Figure 5. Power Up Waveforms

DLL Constraints

■ DLL uses K clock as its synchronizing input. The input must

have low phase jitter, which is specified as t

■ The DLL functions at frequencies down to 120 MHz.

■ If the input clock is unstable and the D LL is enabl ed, the n the

DLL may lock onto an incorrect frequency, causing unstable

SRAM behavior. T o avoid this, provide 2048 cycles stable clock

to relock to the desired clock frequency.

~

~

KC Var

.

Document Number: 001-06620 Rev. *D Page 19 of 27

[+] Feedback [+] Feedback

Page 20

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Maximum Ratings

Notes

15.Power up: Is based on a linear ramp from 0V to V

DD

(min) within 200 ms. During this time V

IH

< V

DD

and V

DDQ

< V

DD.

16.Outputs are impedance controlled. I

OH

= –(V

DDQ

/2)/(RQ/5) for values of 175Ω < RQ < 350Ω.

17.Outputs are impedance controlled. I

OL

= (V

DDQ

/2)/(RQ/5) for values of 175Ω < RQ < 350Ω

18.V

REF

(min) = 0.68V or 0.46V

DDQ

, whichever is larger, V

REF

(max) = 0.95V or 0.54V

DDQ

, whichever is smaller.

19.The operation current is calculated with 50% read cycle and 50% write cycle.

Exceeding maximum ratings may shorten the useful life of the

device. User guidelines are not tested .

Storage Temperature ................................ –65°C to + 150°C

Ambient Temperature with Powe r Applied. –55°C to + 125°C

Supply Voltage on VDD Relative to GND.......–0.5V to + 2.9V

Supply Voltage on V

DC Applied to Outputs in High-Z .........–0.5V to V

DC Input Voltage

Relative to GND..... –0.5V to + V

DDQ

[11]

...............................–0.5V to VDD + 0.3V

DDQ

DD

+ 0.3V

Current into Outputs (LOW).........................................20 mA

Static Discharge Voltage (MIL-STD-883, M 3015).... >2001V

Latch up Current..................................................... >200 mA

Operating Range

Range

Temperature V

Commercial 0°C to +70°C 1.8 ± 0.1V 1.4V to

Industrial –40°C to +85°C

Ambient

DD

[15]

V

DDQ

V

DD

Electrical Characteristic

The DC Electrical Characteristics over the operating range follows.

Parameter Description Test Conditions Min Typ Max Unit

V

DD

V

DDQ

V

OH

V

OL

V

OH(LOW)

V

OL(LOW)

V

IH

V

IL

I

X

I

OZ

V

REF

[19]

I

DD

I

SB1

Power Supply Voltage 1.7 1.8 1.9 V

IO Supply Voltage 1.4 1.5 V

Output HIGH Voltage Note 16 V

Output LOW Voltage Note 17 V

Output HIGH Voltage IOH = –0.1 mA, Nominal Impedance V

Output LOW Voltage IOL = 0.1 mA, Nominal Impedance V

Input HIGH Voltage V

Input LOW Voltage –0.15 V

Input Leakage Current GND ≤ VI ≤ V

Output Leakage Current GND ≤ VI ≤ V

Input Reference Voltage

VDD Operating Supply V

[18]

Typical Value = 0.75V 0.68 0.75 0.95 V

= Max, I

DD

f = f

= 1/t

max

Automatic Power Down Current Max VDD,

Both Ports Deselected,

V

≥ VIH or VIN ≤ VIL

IN

f = f

= 1/t

max

Inputs Static

[12]

/2 – 0.12 V

DDQ

/2 – 0.12 V

DDQ

– 0.2 V

DDQ

SS

+ 0.1 V

REF

DDQ

Output Disabled –2 2 μA

DDQ,

OUT

CYC

= 0 mA,

300 MHz 850 mA

333 MHz 920 mA

–2 2 μA

/2 + 0.12 V

DDQ

/2 + 0.12 V

DDQ

DDQ

REF

375 MHz 1020 mA

400 MHz 1080 mA

300 MHz 250 mA

333 MHz 260 mA

CYC

,

375 MHz 290 mA

400 MHz 300 mA

DD

DDQ

0.2 V

+ 0.15 V

– 0.1 V

[15]

V

V

AC Input Requirements

[11]

Over the operating range

Parameter Description Test Conditions Min Typ Max Unit

V

IH

V

IL

Document Number: 001-06620 Rev. *D Page 20 of 27

Input HIGH Voltage V

Input LOW Voltage –0.24 – V

+ 0.2 – V

REF

DDQ

REF

+ 0.24 V

– 0.2 V

[+] Feedback [+] Feedback

Page 21

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Capacitance

1.25V

0.25V

R = 50Ω

5pF

INCLUDING

JIG AND

SCOPE

ALL INPUT PULSES

DEVICE

R

L

= 50Ω

Z

0

= 50Ω

V

REF

= 0.75V

V

REF

= 0.75V

[20]

0.75V

UNDER

TEST

0.75V

DEVICE

UNDER

TEST

OUTPUT

0.75V

V

REF

V

REF

OUTPUT

ZQ

ZQ

(a)

SLEW RATE= 2 V/ns

RQ =

250

Ω

(b)

RQ =

250

Ω

Note

20.Unless otherwise noted, test conditions are based on a signal transition time of 2V/ns, timing reference levels of 0.75V, V

REF

= 0.75V, RQ = 250Ω, V

DDQ

= 1.5V , inpu t

pulse levels of 0.25V to 1.25V, and output loading of the specified I

OL/IOH

and load capacitance shown in (a) of AC Test Loads and Waveforms.

Tested initially and after any design or process change that may affect these parameters.

Parameter Description Test Conditions Max Unit

Input Capacitance TA = 25°C, f = 1 MHz,

C

IN

C

CLK

C

O

Clock Input Capacitance 6 pF

Output Capacitance 7pF

V

V

= 1.8V

DD

DDQ

= 1.5V

5pF

Thermal Resistance

Tested initially and after any design or process change that may affect these parameters.

Parameter Description Test Conditions

Θ

JA

Θ

JC

Thermal Resistance

(junction to ambient)

Thermal Resistance

(junction to case)

Test conditions follow standard test methods and

procedures for measuring thermal impedance, in

accordance with EIA/JESD51.

AC Test Loads and Waveforms

Figure 6. AC Test loads and Waveforms

165 FBGA

Package

17.2 °C/W

4.15 °C/W

Unit

Document Number: 001-06620 Rev. *D Page 21 of 27

[+] Feedback [+] Feedback

Page 22

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Switching Characteristics

Notes

21. When a part with a maximum frequency above 300 MHz is operating at a lower clock frequency, it requires the input timings of the frequency range in which it is being

operated and outputs data with the output timings of that fre quency range.

22.This part has a voltage regulator internally; t

POWER

is the time that the power must be supplied above V

DD

minimum initially before a read or write operation can be

initiated.

23.These parameters are extrapolated from the input timing parameters (t

KHKH

- 250 ps, where 250 ps is the internal jitter. An input jitter of 200 ps (t

KC Var

) is already

included in the t

KHKH

). These parameters are only guaranteed by design and are not tested in production.

24.t

CHZ

, t

CLZ

, are specified with a load capacitance of 5 pF as in (b) of “AC Test Loads and Waveforms” on page 21. Transition is measured ± 100 mV from steady-state

voltage.

25.At any voltage and temperature t

CHZ

is less than t

CLZ

and t

CHZ

less than tCO.

26.t

QVLD

spec is applicable for both rising and falling edges of QVLD signal.

27.Hold to >V

IH

or <VIL.

Over the operating range

Cypress

Parameter

t

POWER

t

CYC

t

KH

t

KL

t

KHKH

Consortium

Parameter

t

KHKH

t

KHKL

t

KLKH

t

KHKH

Setup Times

t

SA

t

SC

t

SCDDR

t

SD

t

AVKH

t

IVKH

t

IVKH

t

DVKH

Hold Times

t

HA

t

HC

t

HCDDR

t

HD

t

KHAX

t

KHIX

t

KHIX

t

KHDX

Output Times

t

CO

t

DOH

t

CCQO

t

CQOH

t

CQD

t

CQDOHtCQHQX

t

CQH

t

CQHCQHtCQHCQH

t

CHZ

t

CLZ

t

QVLD

t

CHQV

t

CHQX

t

CHCQV

t

CHCQX

t

CQHQV

t

CQHCQL

t

CHQZ

t

CHQX1

t

QVLD

DLL Timing

t

KC Var

t

KC lock

t

KC ResettKC Reset

t

KC Var

t

KC lock

[20, 21]

VDD(Typical) to the first Access

K Clock Cycle Time 2.50 8.40 2.66 8.40 3.0 8.40 3.3 8.40 ns

Input Clock (K/K) HIGH 0.4–0.4–0.4–0.4–t

Input Clock (K/K) LOW 0.4–0.4–0.4–0.4–t

K Clock Rise to K Clock Rise

(rising edge to rising edge)

Address Setup to K Clock Rise 0.4 – 0.4 – 0.4 – 0.4 – ns

Control Setup to K Clock Rise (LD, R/W) 0.4–0.4–0.4–0.4– ns

Double Data Rate Control Setup to Clock (K/K)

Rise (BWS

D

Setup to Clock (K/K) Rise 0.28–0.28–0.28–0.28– ns

[X:0]

Address Hold after K Clock Rise

Control Hold after K Clock Rise (LD, R/W) 0.4–0.4–0.4–0.4– ns

Double Data Rate Control Hold after Clock (K/K)

Rise (BWS

D

Hold after Clock (K/K) Rise 0.28–0.28–0.28–0.28– ns

[X:0]

K/K Clock Rise to Data Valid – 0.45 – 0.45 – 0.45 – 0.45 ns

Data Output Hold after K/K Clock Rise

(Active to Active)

K/K Clock Rise to Echo Clock Valid – 0.45 – 0.45 – 0.45 – 0.45 ns

Echo Clock Hold after K/K Clock Rise –0.45 – –0.45 – –0.45 – –0.45 – ns

Echo Clock High to Data Valid – 0.2 – 0.2 – 0.2 – 0.2 ns

Echo Clock High to Data Invalid –0.2 – –0.2 – –0.2 – –0.2 – ns

Output Clock (CQ/CQ) HIGH

CQ Clock Rise to CQ Clock Rise

(rising edge to rising edge)

Clock (K/K) Rise to High-Z (Active to High-Z)

Clock (K/K) Rise to Low-Z

Echo Clock High to QVLD Valid

Clock Phase Jitter – 0.20 – 0.20 – 0.20 – 0.20 ns

DLL Lock Time (K) 2048 – 2048 – 2048 – 2048 – Cycles

K Static to DLL Reset

Description

[22]

, BWS1, BWS2, BWS3)

0

, BWS1, BWS2, BWS3)

0

[23]

[24, 25]

[27]

[26]

[23]

400 MHz 375 MHz 333 MHz 300 MHz

Min Max Min Max Min Max Min Max

1–1–1–1–ms

1.06–1.13–1.28–1.40– ns

0.28–0.28–0.28–0.28– ns

0.4–0.4–0.4–0.4– ns

0.28–0.28–0.28–0.28– ns

–0.45 – –0.45 – –0.45 – –0.45 – ns

0.81–0.88–1.03–1.15– ns

0.81–0.88–1.03–1.15– ns

[24, 25]

–0.45–0.45–0.45–0.45ns

–0.45 – –0.45 – –0.45 – –0.45 – ns

–0.20 0.20 –0.20 0.20 –0.20 0.20 –0.20 0.20 ns

30–30–30–30– ns

Unit

CYC

CYC

Document Number: 001-06620 Rev. *D Page 22 of 27

[+] Feedback [+] Feedback

Page 23

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Switching Waveform

Notes

28.Q00 refers to output from address A0. Q01 refers to output from the next internal burst address following A0, i.e., A0 + 1.

29.Outputs are disabled (High-Z) one clock cycle after a NOP.

Read/Write/Deselect Sequence

Figure 7. Waveform for 2.5 Cycle Read Latency

[28, 29]

LD

R/W

QVLD

DQ

NOP

1

K

t

KH

K

A

READ

2

t

KL

t

t

HC

SC

A0

t

t

HA

SA

(Read Latency = 2.5 Cycles)

t

CYC

READ

3

A1

t

KHKH

t

QVLD

NOP

4

t

CLZ

t

t

t

CCQO

CQOH

NOP WRITEWRITE

5

Q00

CO

t

Q01

QVLD

t

DOH

Q10

NOP

6

Q11

t

CQD

t

CQDOH

7

A2

t

CHZ

89

A3

t

HD

D20

t

SD

D21

t

SD

READ

A4

t

HD

D30 D31

NOP

10

t

QVLD

NOP

11

12

Q40

CQ

CQ

t

CQOH

t

CCQO

Document Number: 001-06620 Rev. *D Page 23 of 27

t

CQH

t

CQHCQH

DON’T CARE

UNDEFINED

[+] Feedback [+] Feedback

Page 24

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Ordering Information

Not all of the speed, package and temperature ranges are available. Contact your local sales representative or visit www.cypress.com

for actual products offered.

Speed

(MHz) Ordering Code

400 CY7C1166V18-400BZC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Commercial

CY7C1 177V18-400BZC

CY7C1 168V18-400BZC

CY7C1 170V18-400BZC

CY7C1 166V18-400BZXC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-400BZXC

CY7C1 168V18-400BZXC

CY7C1 170V18-400BZXC

CY7C1166V18-400BZI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Industrial

CY7C1 177V18-400BZI

CY7C1 168V18-400BZI

CY7C1 170V18-400BZI

CY7C1 166V18-400BZXI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-400BZXI

CY7C1 168V18-400BZXI

CY7C1 170V18-400BZXI

375 CY7C1166V18-375BZC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Commercial

CY7C1 177V18-375BZC

CY7C1 168V18-375BZC

CY7C1 170V18-375BZC

CY7C1 166V18-375BZXC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-375BZXC

CY7C1 168V18-375BZXC

CY7C1 170V18-375BZXC

CY7C1166V18-375BZI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Industrial

CY7C1 177V18-375BZI

CY7C1 168V18-375BZI

CY7C1 170V18-375BZI

CY7C1 166V18-375BZXI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-375BZXI

CY7C1 168V18-375BZXI

CY7C1 170V18-375BZXI

Package

Diagram Package Type

Operating

Range

Document Number: 001-06620 Rev. *D Page 24 of 27

[+] Feedback [+] Feedback

Page 25

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Ordering Information (continued)

Not all of the speed, package and temperature ranges are available. Contact your local sales representative or visit www.cypress.com

for actual products offered.

Speed

(MHz) Ordering Code

333 CY7C1166V18-333BZC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Commercial

CY7C1 177V18-333BZC

CY7C1 168V18-333BZC

CY7C1 170V18-333BZC

CY7C1 166V18-333BZXC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-333BZXC

CY7C1 168V18-333BZXC

CY7C1 170V18-333BZXC

CY7C1166V18-333BZI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Industrial

CY7C1 177V18-333BZI

CY7C1 168V18-333BZI

CY7C1 170V18-333BZI

CY7C1 166V18-333BZXI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-333BZXI

CY7C1 168V18-333BZXI

CY7C1 170V18-333BZXI

300 CY7C1166V18-300BZC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Commercial

CY7C1 177V18-300BZC

CY7C1 168V18-300BZC

CY7C1 170V18-300BZC

CY7C1 166V18-300BZXC 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-300BZXC

CY7C1 168V18-300BZXC

CY7C1 170V18-300BZXC

CY7C1166V18-300BZI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Industrial

CY7C1 177V18-300BZI

CY7C1 168V18-300BZI

CY7C1 170V18-300BZI

CY7C1 166V18-300BZXI 51-85180 165-Ball Fine Pitch Ball Grid Array (13 x 15 x 1.4 mm) Pb-Free

CY7C1 177V18-300BZXI

CY7C1 168V18-300BZXI

CY7C1 170V18-300BZXI

Package

Diagram Package Type

Operating

Range

Document Number: 001-06620 Rev. *D Page 25 of 27

[+] Feedback [+] Feedback

Page 26

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Package Diagram

A

1

PIN 1 CORNER

15.00±0.10

13.00±0.10

7.00

1.00

Ø0.50 (165X)

Ø0.25 M C A B

Ø0.05 M C

B

A

0.15(4X)

0.35±0.06

SEATING PLANE

0.53±0.05

0.25 C

0.15 C

PIN 1 CORNER

TOP VIEW

BOTTOM VIEW

2345678910

10.00

14.00

B

C

D

E

F

G

H

J

K

L

M

N

11

1110986754321

P

R

P

R

K

M

N

L

J

H

G

F

E

D

C

B

A

A

15.00±0.10

13.00±0.10

B

C

1.00

5.00

0.36

-0.06

+0.14

1.40 MAX.

SOLDER PAD TYPE : NON-SOLDER MASK DEFINED (NSMD)

NOTES :

PACKAGE WEIGHT : 0.475g

JEDEC REFERENCE : MO-216 / DESIGN 4.6C

PACKAGE CODE : BB0AC

51-85180-*A

Figure 8. 165-Ball FBGA (13 x 15 x 1.4 mm), 51-85180

Document Number: 001-06620 Rev. *D Page 26 of 27

[+] Feedback [+] Feedback

Page 27

CY7C1166V18, CY7C1177V18

CY7C1168V18, CY7C1170V18

Document History Page

Document Title: CY7C1166V18/CY7C1177V18/CY7C1168V18/CY7C1170V18, 18-Mbit DDR-II+ SRAM 2-Word Burst

Architecture (2.5 Cycle Read Latency)

Document Number: 001-06620

REV. ECN No. Issue Date

** 430351 See ECN NXR New data sheet

*A 461654 See ECN NXR Revised the MPNs from

*B 497629 See ECN NXR Changed the V

*C 1175245 See ECN VKN/KKVTMP Converted from preliminary to final

*D 2199066 See ECN VKN/AESA Added footnote# 19 related to I

Orig. of

Change

Description of Change

CY7C1177BV18 to CY7C1166V18

CY7C1168BV18 to CY7C1177V18

CY7C1170BV18 to CY7C1168V18

Changed t

t

from 10 ns to 5 ns and changed t

CH

Switching Characteristics table

TH

and t

from 40 ns to 20 ns, changed t

TL

, t

TMSS

from 20 ns to 10 ns in TAP AC

TDOV

TDIS

, tCS, t

Modified Power Up waveform

operating voltage to 1.4V to VDD in the Features section, in

Operating Range table and in the DC Electrical Characteristics table

DDQ

Added foot note in page 1

Changed the Maximum rating of Ambient T emperature with Power Applied from

–10°C to +85°C to –55°C to +125°C

Changed V

istics table and in the note below the table

(max) spec from 0.85V to 0.95V in the DC Electrical Character-

REF

Updated foot note 21 to specify Overshoot and Undershoot Spec

Updated Θ

Removed x9 part and its related information

JA

and Θ

JC

values

Updated foot note 24

Added x8 and x9 parts

Updated logic block diagram for x18 and x36 parts

Changed I

for 375 MHz, 733 mA to 920 mA for 333 MHz, 685 mA to 850 mA for 300 MHz

values from 830 mA to 1080 mA for 400 MHz, 794 mA to 1020 mA

DD

Changed ISB values from 235 mA to 300 mA for 400 MHz, 227 mA to 290 mA

for 375 MHz, 212 mA to 260 mA for 333 MHz, 201 mA to 250 mA for 300 MHz

Changed t

Changed Θ

CYC(max)

Updated Ordering Information table

spec to 8.4 ns for all speed bins

value from 13.48 °C/W to 17.2 °C/W

JA

DD

TMSH

, t

TDIH

,

© Cypress Semiconductor Corporation, 2006- 2008. The infor mation cont ain ed herein is subj ect to change wi thout notice. C ypress Semiconductor Corporation assumes no responsibility for the use of

any circuitry other than circuitry embodied in a Cypress product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor intend ed to be us ed for

medical, life support, life saving, critica l contr o l or safety applications, unless pursuant to an express wr i tte n ag reement with Cypress. Furthermore, Cypress does not authorize i t s pro ducts for use as

critical components in life-support systems where a malfunction or fa ilure may reasonably be expe cted to result in significa nt injury to the us er . The inclu sion of Cypress p roducts in life -support systems