Page 1

CY4611B – FX2LP USB to ATA/CF Reference Design Notes

Introduction

Cypress has two USB 2.0 High Speed Mass Storage

solutions. The AT2LP is a low-power fixed-function

Mass Storage solution for ATA devices. The

CY4611B is a flexible bridge solution that enables

additional features to be added to a USB 2.0 bridge

device. The Cypress EZ-USB FX2LP Mass Storage

reference design connects the EZ-USB FX2LP to

the following device types:

• IDE devices

3.5”, 2.5” Hard disk drives

• Compact Flash & micro drives

• ATAPI devices

ZIP drives

CD-ROM/R/RW drives

DVD-ROM/RAM/RW drives

Reference Design Contents

• FX2LP Mass Storage Reference Design

PCBA

• Reference Design Schematic in both PDF

and OrCAD source files

• Reference Design BOM

• Firmware source and object code

• Reference Design Notes (this document)

• UDMA White Paper

• Driver INF and .SYS files

• Operating Instructions

• Manufacturing tools

• Release Notes

• Errata

Background Information

You should be familiar with the USB Mass Storage

Class specification and general operation of

Cypress’ EZ-USB FX2LP to get the most from this

document. For more information please refer to

these specifications or Cypress’s EZ-USB FX2LP

Technical Reference Manual.

Mass Storage Class Specification

The USB Mass Storage Class specification contains

two subclasses, the CBI (Command, Bulk, Interrupt),

and the newer Bulk Only Transport. This reference

design complies with the Bulk Only subclass of the

USB Mass Storage Specification. The Bulk Only

subclass is supported by the Windows XP, 2000 and

ME drivers as well as MacOS 9 and X. Cypress

provides custom drivers for Windows and Macintosh

operating systems to add support for security and

SMART monitoring. The latest driver versions are

available on the Cypress website.

Firmware Overview

Note: CBW, CSW, dataTransferLength, and

“Persistent Stall” are defined in the “USB Mass

Storage Class, Bulk Only Transport” document

referenced below.

The firmware for the device is a straightforward

implementation of a USB Bulk Only Mass Storage

Device. After reset, it waits for a CBW packet,

checks it and then executes the data phase of the

command (if any). Once the data phase is

complete, the firmware sends a CSW packet to the

host. SETUP commands are handled in an ISR. A

timer ISR is used to poll VBUS and GPIOs. The

only commands that the firmware generates on its

own are SCSI Identify Device (to get the device

name) and ATA Identify Device (to get the device

serial number).

The CY4611B firmware supports both high speed

(480Mbps) and full speed (12Mbps) hosts.

Firmware Details

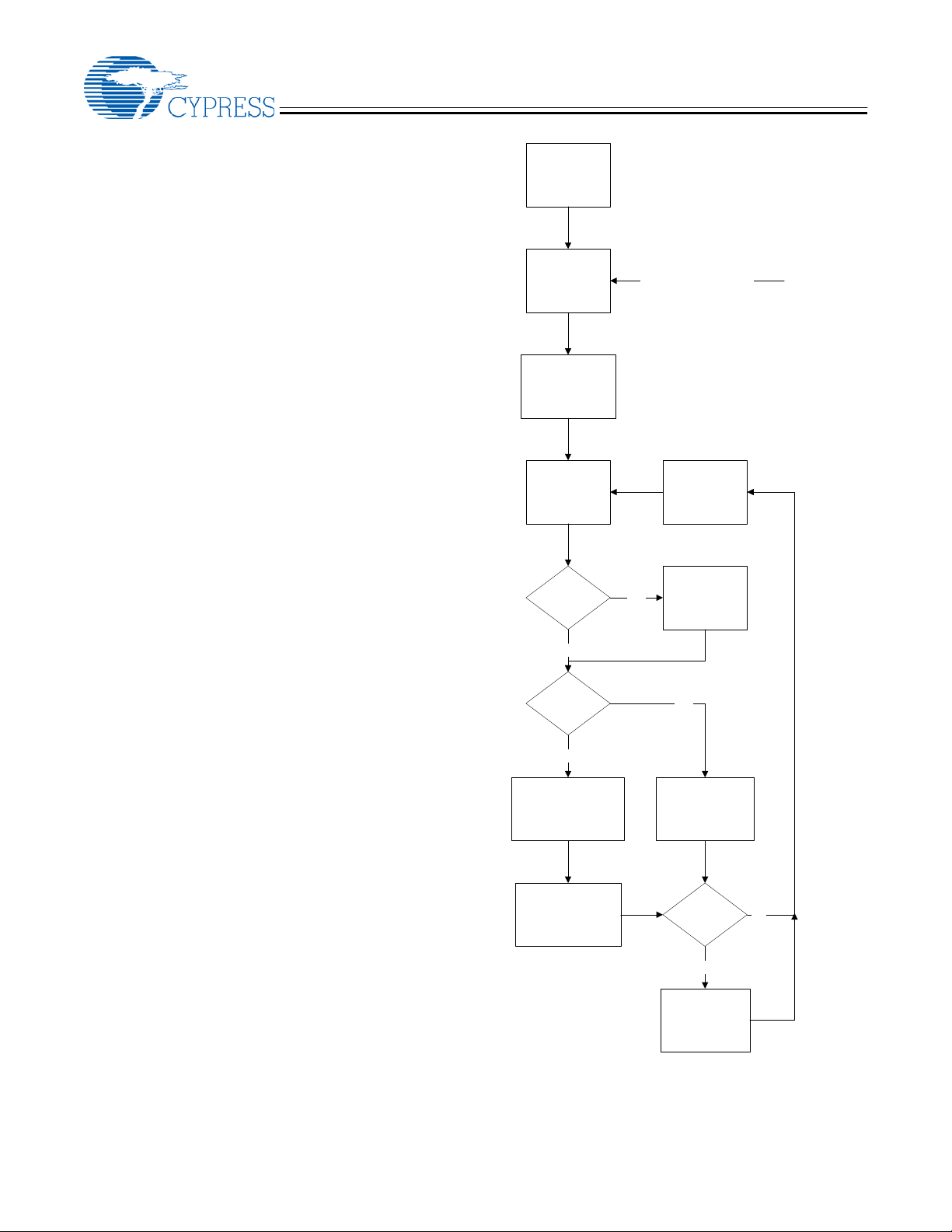

Refer to the flowchart on the following page for more

details.

There are three main sections in the firmware:

• Initialization

• Command (CBW) processing

• ISRs

The initialization code sets up the hardware, reads

the EEPROM configuration and detects the attached

drives. Initialization routines include

resetATAPIDevice, ATAInit, initUSB, TD_Init,

detectSCSIvsATA, and ATAPIIdDevice. When the

initialization code is complete, the hardware is set

up, drives are fully enumerated, GPIF is loaded and

the firmware is ready to accept CBW commands.

The CBW processing takes place in the TD_Poll()

loop. This loop also polls the sleep flag to determine

Cypress Semiconductor Corporation • 3901 North First Street • San Jose • CA 95134 • 408-943-2600

7/11/05

Page 2

EZ-USB FX2LP USB to ATA Reference Design Notes

if it is time for USB suspend. The final function of

the main loop is to poll for new removable (CF)

devices.

The ISRs have two main functions. They handle

SETUP command processing and background

polling for events like VBUS removal, GPIO changes

and ATA_ENABLE changes.

Main()

This routine calls the TD_Init and ATAInit routines

and then starts the master while(1) loop. The

while(1) loop polls the sleep flag and calls TD_Poll,

the main command processing routine.

ATAInit()

On a hard reset, TD_init() is called, which initializes

the hardware using initUSB(). The

resetATAPIDevice() routine is called to reset the

drive. After the drive has been reset the drive

discovery algorithm, detectSCSIvsATA(), is called

once for the master device and again for the slave

device.

Hardware

Reset of FX2

Initialize Hardware

[TD_Init, initUSB]

Initalize ATA Device

Detect ATAPI vs IDE

[resetATAPIDevice]

Wait for CBW

[TD_Poll()]

(USB Reset) or

(ATA_ENABLE -> disable)

in any state

Send CSW

[sendUSBS()]

detectSCSIvsATA()

The detectSCSIvsATA routine determines whether

the attached device is IDE or ATAPI by reading the

byte count registers. The scsi flag is set to 1 to

indicate an ATAPI device, scsi is set to 0 on an IDE

device. This routine sets the bDevicePresent flag

when a drive is successfully detected.

ATAPIIdDevice()

This routine is called to collect information from the

drive into internal data structures. This information

includes the max PIO or UDMA speed supported

and the serial number of the drive. If the device

supports PIO-3, PIO-4 or UDMA, this routine will

program the drive to run at the new speed.

LUN changed?

No

SCSI device?

[processCBW]

No

Translate ATAPI to IDE

command

generalIDEInCommand

generalIDEOutCommand

Send command to

device

[ideReadCommand

ideWriteCommand]

Yes

Change GPIF

Yes

Send command to

[sendSCSICommand]

TransferLen >

Transfer data via

PIO or UDMA

[Read/WritePIO16

Read/WriteUDMA()]

waveform s

device

data

0

Yes

No

Figure 1: Overall program flow

2

Page 3

EZ-USB FX2LP USB to ATA Reference Design Notes

TD_Poll()

As in all Cypress Frameworks based code, the main

code loop is called TD_Poll(). This routine is called

repeatedly until it detects a packet in the OUT buffer.

TD_poll() checks the received packet for a valid

CBW signature. If one is found, it calls

processCBW(). If the packet is not a valid CBW, the

device enters a “persistent stall” condition awaiting a

device reset. ProcessCBW() checks to see if the

LUN has changed from the previous command. If

so, it reloads the GPIF with the proper waveforms

for the new LUN. It then calls

generalIDEInCommand() or

generalIDEOutCommand() depending on the

direction flag in the CBW. If the dataTransferLength

is non-zero, the readPIO16() or writePIO16()

routines are called to pass data directly from the

USB buffers to the drive using the GPIF.

SETUP messages are handled in an ISR, so they

may be received and responded to at any time. The

entire SETUP message will be handled within the

ISR, therefore long SETUP traffic will adversely

affect disk performance. This is not expected to be

an issue since Windows does not use SETUP

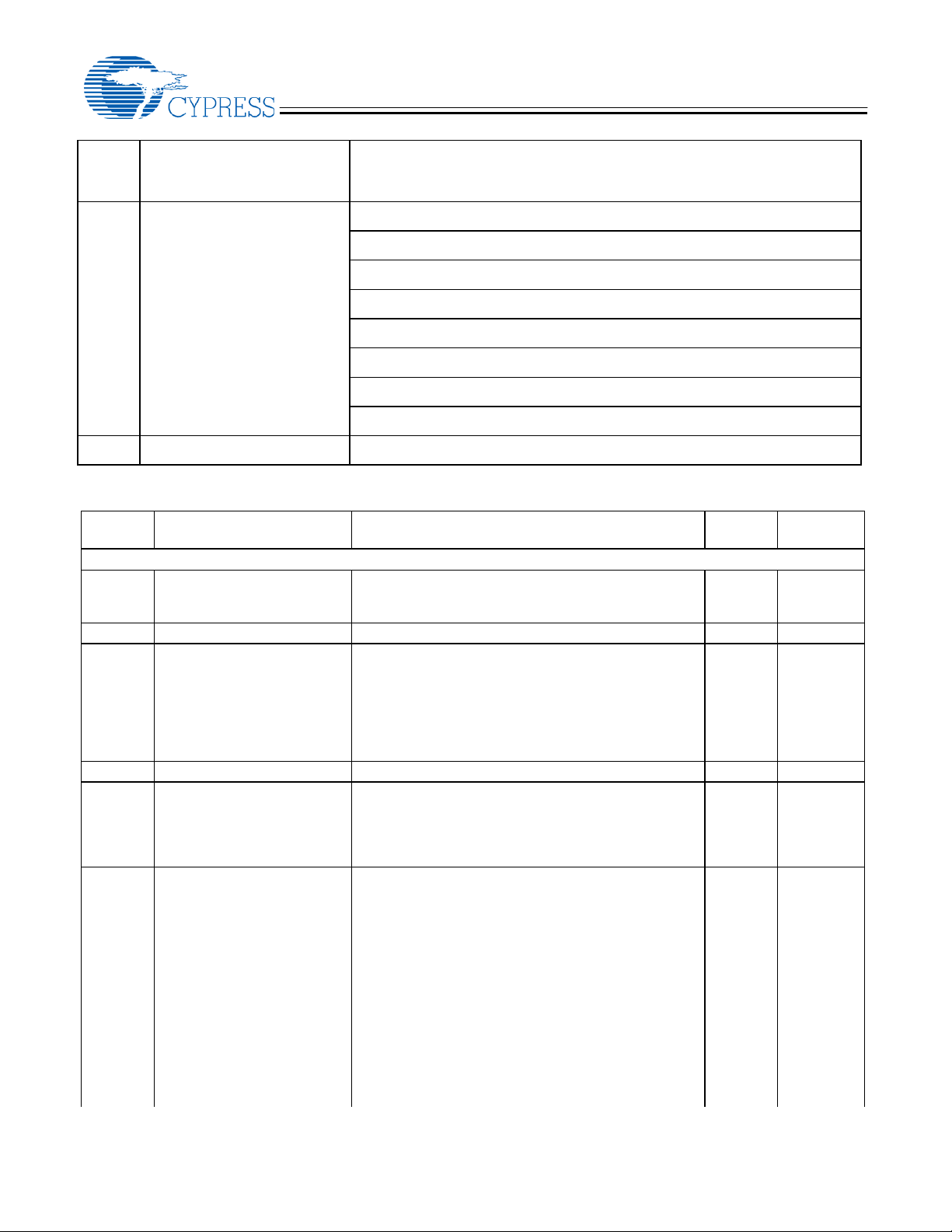

Filename Purpose

Dscr.a51 Descriptor table containing product/vendor ID, endpoint descriptions and other

information reported to the host on startup.

memcmp.a51 Fast memory compare routine

reset.a51 Assembly routine used to branch to 0 on USB reset.

Startup.a51 Modified Keil startup file that does not initialize any variables.

USBjmptbl.a51 USB interrupt vector table and other fixed-address blocks including space

allocation for EEPROM loader.

Atacb.c Processes ATACB (ATA Command Block) requests. The optional ATACB facility

allows IDE commands to be embedded within CBWs. This enables ANY

command to be sent to the device. This facility is used to allow access to security

features and SMART commands that do not have analogous SCSI commands.

atareset.c Contains hard reset routine, selection of IDE vs ATAPI protocol. Identifies device

characteristics, including serial number, capacity and transfer rate. Selects

transfer rate by loading new GPIF waveforms. Contains timer ISR that checks

VBUS and ATA_ENABLE.

fw.c Frameworks based main routine. This fw.c has major differences from the fw.c

released with the dev kit, since several implementation-specific functions have

been merged with the general startup code in this file.

gpif.c EZ-USB FX2LP low level i/o routines. Waveform descriptors. Routines for

loading the GPIF memory with the waveform descriptors.

Globals.c, Globals2.c Global variable definitions. The globals are split into two files to help the linker.

The linker will place all of the variables in a .c file in a single block. Splitting the

globals into two files allows some variables to be placed below the bit-

addressable memory (at 0x20) and some to be placed above the bit-addressable

memory.

packets after enumeration except to clear STALL

conditions.

ReadPIO16(), WritePIO16(), ReadUDMA(),

WriteUDMA()

These data transfer routines activate the GPIF to

move data to/from the FIFO memory to/from the

ATA bus. The data is read from the drive to the EP6

buffer. Write data moves from the host through the

EP2 buffer.

Resets

The firmware performs a hard reset of the drive on a

hard reset (power on). The firmware performs a soft

reset of the 8051 and drives on a USB Reset or

Mass Storage Class Reset.

File Descriptions

The FX2LP firmware is stored in its own directory.

All of the FX2LP firmware is contained in the FX2LP

source directory on the CD.

The purpose of the files in the source directory is

shown in the following table:

3

Page 4

EZ-USB FX2LP USB to ATA Reference Design Notes

Filename Purpose

ide.c Translates SCSI (ATAPI) commands sent by the host driver into IDE commands.

Calls low-level transfer routines in gpif.c.

periph.c TD_Init and TD_Poll(), misc init routines, misc util routines including our smaller

version of memmove.

scsi.c High level data transfer routines for ATAPI devices. (Named SCSI.c because

ATAPI devices use the SCSI command set.) Calls low-level transfer routines in

gpif.c.

Globals.h Global variable references

atapi.h Header file containing application specific items.

gpif.h Header file containing hardware specific items.

scsi.h SCSI command set

CY4611B.Opt Options for UV2 project

CY4611B.hex Output file from the linker. Combine.bat is used to merge this file with a

configuration file like AT2_Legacy_pinout.iic to produce a full image like

CY4611B_AT2_pinout.iic.

CY4611B.Uv2 UV2 project file

AT2_Legacy_pinout.iic ~200 byte configuration file produced by blaster.exe

cy4611b_AT2_PINOUT.iic ~16K EEPROM binary image

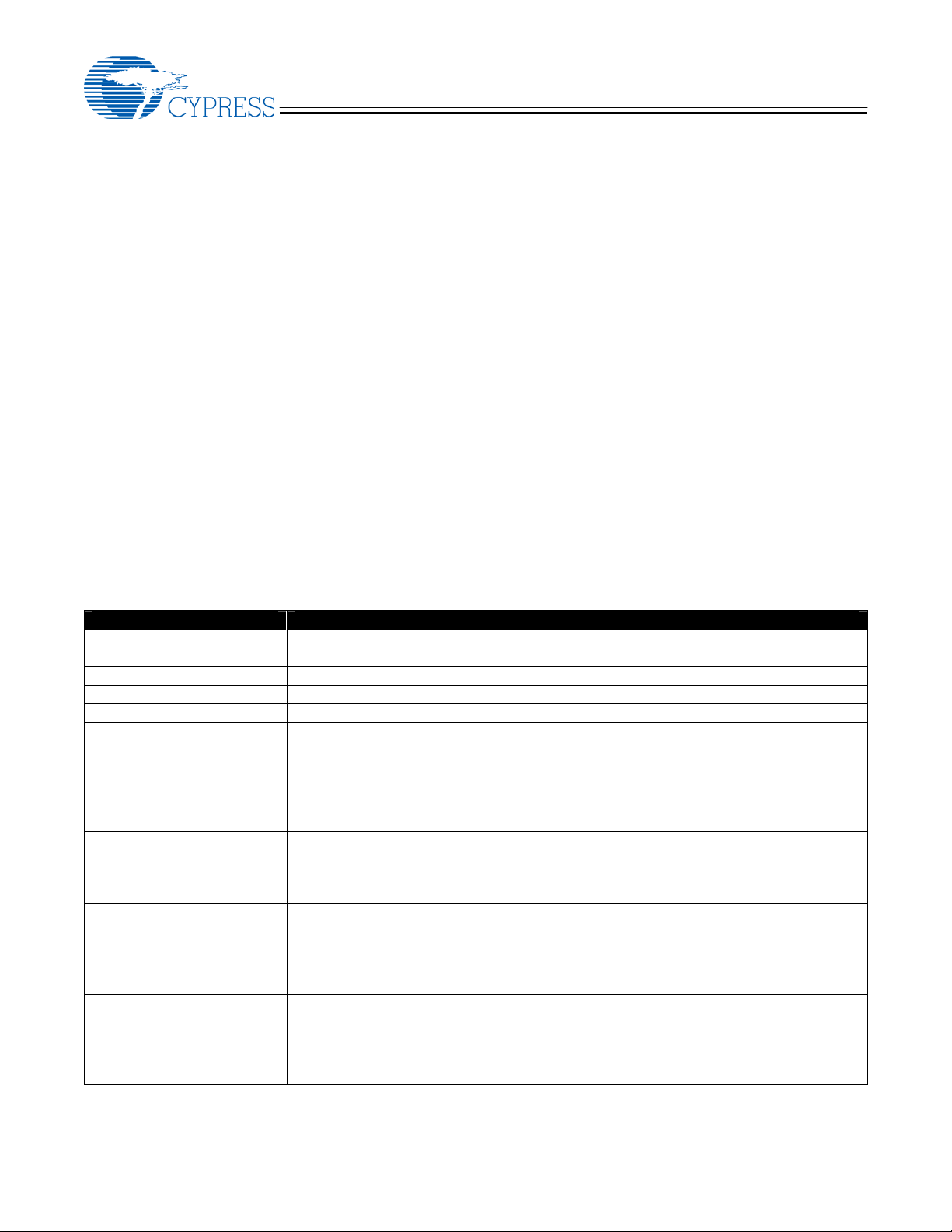

0000

EEPROM configuration area

Many of the commonly changed items in the

CY4611B configuration have been moved to a

dedicated EEPROM configuration area. Locating

these items in a dedicated area allows customization

of many firmware attributes like Vendor ID and

Product ID without compiling the firmware.

The format of this EEPROM configuration area is

copied from the AT2LP and AT2. If the EEPROM

configuration starts with 0x4d4d, the 56-pin package

pinout will match the AT2 pinout. If the EEPROM

configuration bytes 0 and 1 are 0x534b then the 56pin pinout will match AT2LP. See the end of this

document for a full description of the EEPROM

config space format. A configuration tool is provided

to assist you in creating and downloading your

configuration file. This configuration utility

(blaster.exe) can be found in the “manufacturing

tools” directory on your CD. Blaster.exe can

program or modify the EEPROM configuration on

your CY4611B board.

The area allocated to EEPROM can be changed by

modifying the value of CONFIG_SPACE_START in

atapi.h and changing the –x argument passed to

hex2bix. If your application needs more than 0x100

bytes of EEPROM configuration, several areas of

the code will have to change. One area is

sendDescriptor, which uses a BYTE offset within the

EEPROM config space.

0x3eff

0x3f00

0x3fff

Figure 2: EEPROM memory map

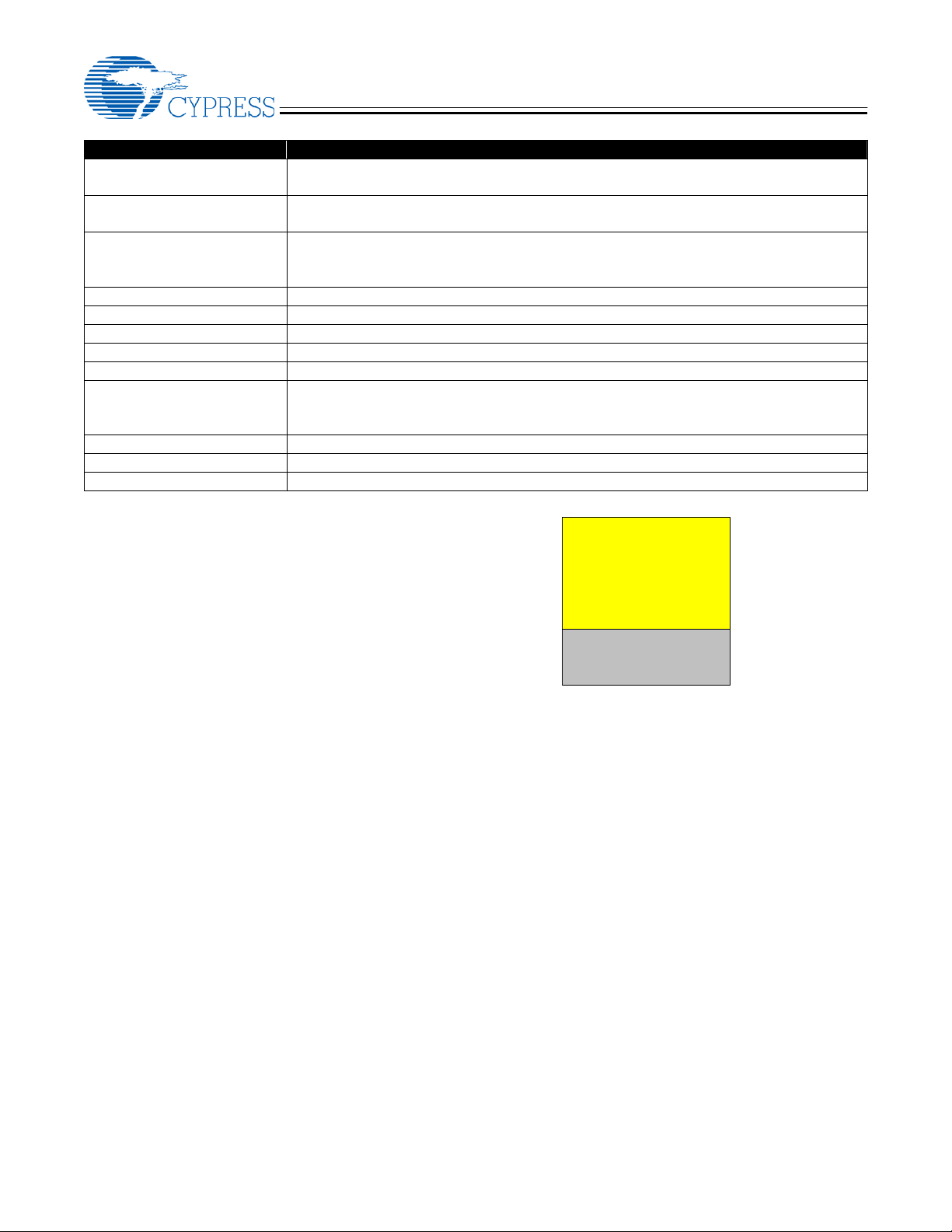

The EEPROM settings can be programmed in two

ways, interactively via blaster.exe or by creating a

file. To program the EEPROM interactively, insert

the “MFG mode” jumper and cycle power on your

board. The board will bind to the manufacturing

driver. You can then use the “write to device” button

in blaster.exe to program your EEPROM.

Available for user code

CY4611.hex

EEPROM configuration

AT2LP_pinout.iic

4

Page 5

EZ-USB FX2LP USB to ATA Reference Design Notes

Figure 3: MFG Mode jumper location

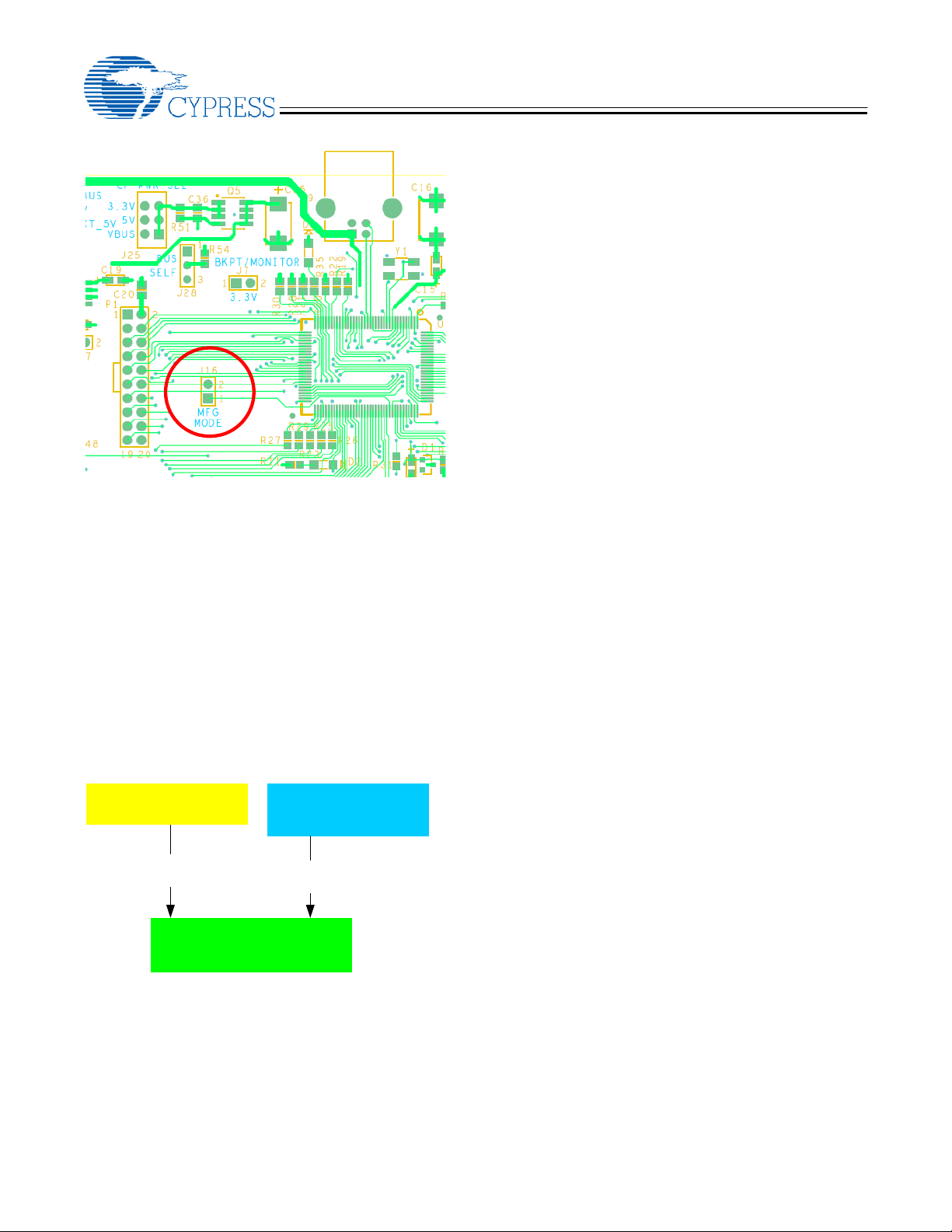

The default build script will automatically build a

unified image by combining cy4611b.hex with either

AT2_legacy_pinout.iic or AT2LP_pinout.iic to

produce CY4611B_AT2_PINOUT.iic or

CY4611B_AT2LP_PINOUT.iic.

The configuration section of the EEPROM can also

be modified without using the Keil tools. This

enables you to modify some settings (like the

Vendor ID and device name) without buying the Keil

tools. Just use the combine.bat file on the CD to

invoke hex2bix.exe.

cy4611b.hex

Output from Keil linker

hex2bix.exe

@0

CY4611B_AT2LP_PINOUT.iic

Binary file loaded to EEPROM

~16K bytes

AT2LP_PINOUT.iic

Saved from Blaster.exe

~200 bytes

hex2bix.exe

@0x3f00

Figure 4: Output files

Compile Time Configuration Settings

The most common configuration settings are

contained in the EEPROM configuration space

described above. However, command line options

and #defines control some of the compile time

settings used by the code. The major ones are

explained in the section below. To change some of

these settings, right-click on the project name in

uVision2 and select “options for target”, then select

the C51 tab.

Atapi.h contains additional #defines that can be

used to further customize the behavior of the

firmware. These can be found in a section of atapi.h

labeled “Configuration Settings”.

If you have one target platform, you will want to do

your customization in atapi.h. Creating defines in

the “options for target” tab allows you to create

multiple targets with different #defines. This is

useful if you have multiple targets (like debug vs

production).

DEVICE_TYPE_IS_SCSI

Setting this flag to 0 will remove most of the ATAPI

code from the EEPROM image. The resulting image

will only work with hard drive type devices. Set this

option to 0 to reduce code size.

Default Setting: 1

DEVICE_TYPE_IS_IDE

Setting this flag to 0 will remove most of the hard

drive / CF code from the EEPROM image. The

resulting image will only work with ATAPI devices.

Set this option to 0 to reduce code size.

Default Setting: 1

REVC_4611_BOARD

The first 4611 board with compactFlash support

changes several settings to make room for

compactFlash. These changes include moving the

interrupt input pin from PA0 to wakeup, and

multiplexing the VBUS sense with ATA_RESET.

This pinout is not recommended for new designs.

Default Setting: 0

Serial numbers

The USB Mass Storage specification requires that

each device have a unique serial number. Cypress

provides manufacturing tools to program your device

with a VID/PID and unique serial number. See the

5

Page 6

EZ-USB FX2LP USB to ATA Reference Design Notes

“manufacturing tools” directory on the CD for more

information.

Some customers want to read the serial number

from the ATA or ATAPI device rather than from the

EEPROM. The following flags enable this function

in the firmware:

USE_ATA_DEVICE_SERIAL_NUMBER

For ATA devices, determines if the firmware uses

the serial number reported by the device as the USB

serial number. If TRUE, firmware uses the serial

number reported by the device in response to the

IDENTIFY_DEVICE command. If FALSE, the

firmware sets the USB serial number index to 0 (i.e.

no serial number string is reported in the device

descriptor).

Default Setting: FALSE

USE_ATAPI_DEVICE_SERIAL_NUMBER

For ATAPI devices, determines if the firmware uses

the serial number reported by the device as the USB

serial number. If TRUE, firmware uses the serial

number reported by the device in response to

IDENTIFY_DEVICE command. If FALSE, the

firmware sets the USB serial number index to 0 (i.e.

no serial number string is reported in the device

descriptor). Many ATAPI devices do not report a

unique serial number. It is better to report no serial

number than to report a non-unique serial number.

Default Setting: FALSE

NIBBLE_CONVERT_SERIAL_NUMBER

Determines if the firmware converts each nibble of

the serial number reported by the device into a

single character of the USB serial number. The

Bulk-only mass storage class spec only allows HEX

characters (0-9 and A-F) in the device serial

number. Some devices report other ASCII

characters. Converting each nibble into HEX

assures spec compliance while maintaining the

uniqueness of the serial number.

Default Setting: FALSE

Build Targets

There are two build targets for the CY4611B. They

use exactly the same options for everything except

one item. The CY4611B_AT2LP_PINOUT target

includes the AT2LP_PINOUT.iic when it calls

hex2bix.exe while the

CY4611B_AT2_LEGACY_PINOUT Includes the

AT2_LEGACY_PINOUT.iic configuration file.

6

Page 7

EZ-USB FX2LP USB to ATA Reference Design Notes

Building the Software

Since the software is distributed on a CD, many

operating systems will set the read-only flag when

copying the data to your local directory. This flag

must be turned off before uVision2 will properly build

the .hex file. To do this, use “attrib –r *.*” at the

DOS command line or select all of the files in

Explorer, select “properties” and turn off the “readonly” checkbox in the “general” tab.

Once the files are no longer read-only, start the full

uVision2 or uVision3 environment (available

separately from www.keil.com

all” button. This will generate an image that can be

loaded with the control panel or the debugger. See

below for more information on debugging.

The firmware in this Reference Design has only

been tested with the release of the 3684 Dev Kit

contained on the release CD. Please install the

current Dev Kit before building.

The hex2bix.exe file in the software directory is

newer than the version in the CY3684 install.

Please use the version in the software directory.

You may have to delete the ezusb.lib file from your

project and add it again to get the correct path in the

Keil tools. The ezusb.lib file is installed at

c:\cypress\usb\target\lib by default.

Note: This Reference Design is too large to

compile with the 4K-demo version of the Keil

tools that is shipped with Cypress’ development

kits.

Warnings

When the firmware is linked, it will generate three

warnings. These warnings are expected. The linker

may have to run several iterations to optimize the

code and may generate this list two or three times

(and report six or nine warnings).

EZUSB_Delay is called from the timer0 ISR and

from the background code. This is not an issue

because any calls to the EZUSB_Delay function in

the ISR are followed by a soft reset.

The EEPROM read and write routines are only used

by the ISR during manufacturing and debugging

) and click the “build

operations. The background code is not active

during these operations.

*** WARNING L15: MULTIPLE CALL TO

FUNCTION

NAME: _EZUSB_DELAY/DELAY

CALLER1: ?C_C51STARTUP

CALLER2: ISRTIMER0/ATARESET

*** WARNING L15: MULTIPLE CALL TO

FUNCTION

NAME: _EEPROMWRITEBLOCK/EEPROM

CALLER1: ?C_C51STARTUP

CALLER2: ISR_SUDAV/PERIPH

*** WARNING L15: MULTIPLE CALL TO

FUNCTION

NAME: _EEPROMREAD/EEPROM

CALLER1: ?C_C51STARTUP

CALLER2: ISR_SUDAV/PERIPH

Using a CY3681 or CY3684 Board

The CY4611B software will run with the Keil

debugger on the FX2LP development board

(CY3684). This is a useful environment for

debugging startup issues by single stepping the

firmware. Note that the following changes to the

3684 board will be necessary:

1. Short solder points SP1, SP2 and SP3 to enable

ATA pullups.

2. Remove JP2 to remove VBUS power to the

board.

3. Connect VBUS (JP2 pin 2) to PA6 (P2 pin 13).

Put a 10K pulldown on this signal. This gives the

CPU the ability to sense VBUS.

4. Provide external 5v/ground to the board (JP2 pin

1 is a good 5v input). It will be very easy to use

the board if you solder a disk drive connector to

these pins.

5. Cut the Key pin (pin 20) on the ATA connector

(P8)

6. Add a 10K pulldown on DD7 (pin 3 on the 40-pin

connector).

7. Use the AT2_LEGACY configuration file.

Debugging without the Mass Storage Driver

Debugging specific commands requires a different

approach because the Mass Storage driver will

timeout while you are single stepping and may lock

up or reboot the host machine. The CY4611B

firmware can be bound to the Cyusb generic driver

by following these steps:

7

Page 8

EZ-USB FX2LP USB to ATA Reference Design Notes

1) Unplug the EEPROM jumper (J22)

2) Turn on power to your board. The board will

enumerate and bind to the generic driver

(CYUSB.sys).

3) Plug the EEPROM jumper back in so your code

can access the config data in the EEPROM.

4) Open cyconsole and select options/EZ-USB

interface

5) Hit the “Load Mon” button

6) Start the Keil debugger and download your

firmware via the Keil debugger

Once the firmware is bound to the generic driver,

commands can be sent to the device using the

control panel. An easy way to do this is to construct

a file containing the command and use the FileTrans

button to send it.

1) Start the Keil debugger; download your firmware

2) Run the firmware, it will enumerate and bind to

the general purpose driver

3) Start the control panel.

4) Do a “get pipes” on the control panel. This will

fill in the pipe fields.

5) Select the OUT pipe and hit the FileTrans

button.

6) Select your command file.

7) Manually transfer the IN or OUT data required

by the command

8) Do a final IN to collect the CSW.

Difference between ATAPI and IDE

devices

Although both ATAPI and IDE devices attach to the

same 40 pin cable, they operate using different

protocols, much like TCP/IP and NetBEUI share the

same Ethernet wire, but cannot talk to each other.

ATAPI commands are basically SCSI commands

sent over an ATA interface.

This firmware will support both ATAPI and IDE task

file commands. It will detect the type of device after

reset. If the device is an IDE device, the ATAPI

commands received over USB will be translated into

IDE task file commands. One way to gain additional

code space is to eliminate one of the supported

protocols.

ATACB – ATA Command Block

The ATA Command Block (ATACB) feature enables

the host to directly access the ATA register file on

the device. This allows the host to send IDE

commands that don’t have direct SCSI translations.

It also provides a powerful debug capability.

ATACB commands are transferred in the Command

Block Wrapper Command Block (CBWCB) portion of

the Command Block Wrapper (CBW) as shown

below:

bit

Byte

0-3

4-7

8-11

12

13

14

15

16

17

18

19

20-27

28-30

The ATACB is distinguished from other command

blocks by having the first two bytes of the command

block match the bVSCBSignature and

bVSCBSubCommand values that are defined in the

configuration area of the EEPROM. Only command

blocks that have a valid bVSCBSignature and

bVSCBSubCommand are interpreted as ATA

Command Blocks. All other fields of the CBW and

restrictions on the CBWCB remain as defined in the

USB Mass Storage Class Bulk-Only Transport

Specification. The ATACB must be 16 bytes in

length. The following table and text defines the fields

of the ATACB.

7 6 5 4 3 2 1 0

dCBWSignature

dCBWTag

dCBWDataTransferLength

bmCBWFlags

Reserved (0)

Reserved

(0)

bVSCBSignature

bVSCBSubCommand

bmATACBActionSelect

bmATACBRegisterSelect

bATACBTransferBlockCount

bATACBTaskFileWriteData

Reserved

bCBWLUN

bCBWCBLength

8

Page 9

EZ-USB FX2LP USB to ATA Reference Design Notes

Windows Boot Support

The current level of boot functionality will allow you

to boot to DOS or Win9x Safe Mode from a Hard

Drive or CDROM. You cannot currently boot to

Windows due to issues with the way Windows

attempts to access a boot drive directly. Boot

functionality has been tested with both Phoenix and

AMI BIOS.

48 bit LBA Addressing

The ATA-6 spec contains support for large drives

with 48-bit Logical Block Addresses (LBAs). This

reference design supports the 48-bit addressing

method. However, the SCSI commands passed by

the Mass Storage Class Specification only support

32-bit LBAs, which limits support to 2^41 (2Tera)

bytes on a 512-byte sectored device.

How this design uses GPIF

The FX2LP design takes advantage of its internal

GPIF (General Programmable InterFace) to move

data from the endpoint buffers to the mass storage

device. For more details on the EZ-USB FX2LP and

GPIF, see the EZ-USB FX2LP Technical Reference

Manual and the UDMA white paper on this CD.

This design contains several GPIF waveforms:

• PIO-0

• PIO-3

• PIO-4

• Multi-word DMA

• UDMA/33

• UDMA/66

The firmware selects one of these waveforms based

on the information returned by the device from the

IDENTIFY DEVICE command. If there are two

devices with different capabilities attached to the

FX2LP, the firmware will reload the GPIF waveforms

when the host addresses a different LUN.

References

USB Mass Storage Class – Bulk Only Transport,

USB Mass Storage DWG. (www.usb.org)

USB Mass Storage Class – Overview Specification,

USB Mass Storage DWG. (www.usb.org)

USB Specification – Revision 2.0, USB

Implementers Forum. (www.usb.org)

EZ-USB FX2LP Technical Reference Manual,

Revision 2.1, Cypress (www.cypress.com)

ATA/ATAPI-6 Specification, Proposed ANSI

Standard (www.t13.org).

SCSI-3 Specification (www.t10.org)

ATACB format

Byte Field Name Field Description

0 bVSCBSignature This field indicates to the CY7C68300B/CY7C68301B that the ATACB contains

a vendor-specific command block. This value of this field must match the value

in Config space offset 0x04 for this vendor-specific command to be recognized.

1 bVSCBSubCommand This field must be set to 0x24 for ATACB commands.

2 bmATACBActionSelect This field controls the execution of the ATACB according to the bitfield values:

Bit 7 IdentifyPacketDevice This bit indicates that the data phase of the

command will contain ATAPI (0xA1) or ATA (0xEC) IDENTIFY device data.

Setting IdentifyPacketDevice when the data phase does not contain IDENTIFY

device data will result in unspecified device behavior.

0 = Data phase does not contain IDENTIFY device data

1 = Data phase contains ATAPI or ATA IDENTIFY device data

Bit 6 UDMACommand This bit enables supported UDMA device transfers.

Setting this bit when a non-UDMA capable device is attached will result in

undetermined behavior.

0 = Do not use UDMA device transfers (only use PIO mode)

1 = Use UDMA device transfers

Bit 5 DEVOverride This bit determines whether the DEV bit value is taken from

the value assigned to the LUN during start-up or from the ATACB.

0 = The DEV bit will be taken from the value assigned to the LUN during start-up

1 = The DEV bit will be taken from the ATACB field 0x0B, bit 4

9

Page 10

EZ-USB FX2LP USB to ATA Reference Design Notes

Bit 4 DErrorOverride This bit controls the device error override feature. This bit

should not be set during a bmATACBActionSelect TaskFileRead.

0 = Data accesses are halted if a device error is detected

1 = Data accesses are not halted if a device error is detected

Bit 3 PErrorOverride This bit controls the phase error override feature. This bit

should not be set during a bmATACBActionSelect TaskFileRead.

0 = Data accesses are halted if a phase error is detected

1 = Data accesses are not halted if a phase error is detected

Bit 2 PollAltStatOverride This bit determines whether or not the Alternate Status

register will be polled and the BSY bit will be used to qualify the ATACB

operation.

0 = The AltStat register will be polled until BSY=0 before proceeding with the

ATACB operation

1 = The ATACB operation will be executed without polling the AltStat register.

Bit 1 DeviceSelectionOverride This bit determines when the device selection will

be performed in relation to the command register write accesses.

0 = Device selection will be performed prior to command register write accesses

1 = Device selection will be performed following command register write

accesses

Bit 0 TaskFileRead This bit determines whether or not the taskfile register data

selected in bmATACBRegisterSelect is returned. If this bit is set, the

dCBWDataTransferLength field must be set to 8.

0 = Execute ATACB command and data transfer (if any)

1 = Only read taskfile registers selected in bmATACBRegisterSelect and return

0x00h for all others. The format of the 12 bytes of returned data is as follows:

• Address offset 0x00 (0x3F6) Alternate Status

• Address offset 0x01 (0x1F1) Features / Error

• Address offset 0x02 (0x1F2) Sector Count

• Address offset 0x03 (0x1F3) Sector Number

• Address offset 0x04 (0x1F4) Cylinder Low

• Address offset 0x05 (0x1F5) Cylinder High

• Address offset 0x06 (0x1F6) Device / Head

• Address offset 0x07 (0x1F7) Command / Status

3 bmATACBRegisterSelect This field controls which of the taskfile register read or write accesses occur.

Taskfile read data will always be 8 bytes in length, and unselected register data

will be returned as 0x00. Register accesses occur in sequential order as outlined

below (0 to 7).

Bit 0 (0x3F6) Device Control / Alternate Status

Bit 1 (0x1F1) Features / Error

Bit 2 (0x1F2) Sector Count

Bit 3 (0x1F3) Sector Number

Bit 4 (0x1F4) Cylinder Low

Bit 5 (0x1F5) Cylinder High

Bit 6 (0x1F6) Device / Head

Bit 7 (0x1F7) Command / Status

4 bATACBTransferBlockCount This value indicates the maximum requested block size in 512-byte incre ments.

This value must be set to the last value used for the “Sectors per block” in the

SET_MULTIPLE_MODE command. Legal values are 0, 1, 2, 4, 8, 16, 32, 64,

and 128 where 0 indicates 256 sectors per block. A command failed status will

be returned if an illegal value is used in the ATACB.

10

Page 11

EZ-USB FX2LP USB to ATA Reference Design Notes

5-12 bATACBTaskFileWriteData These bytes contain ATA register data used with ATA command or PIO write

operations. Only registers selected in bmATACBRegisterSelect are required to

hold valid data when accessed. The registers are as follows.

13-15 Reserved These bytes must be set to 0x00 for ATACB commands.

ATACB Address Offset 0x05 (0x3F6) Device Control

ATACB Address Offset 0x06 (0x1F1) Features

ATACB Address Offset 0x07 (0x1F2) Sector Count

ATACB Address Offset 0x08 (0x1F3) Sector Number

ATACB Address Offset 0x09 (0x1F4) Cylinder Low

ATACB Address Offset 0x0A (0x1F5) Cylinder High

ATACB Address Offset 0x0B (0x1F6) Device

ATACB Address Offset 0x0C (0x1F7) Command

EEPROM configuration format

EEPROM

Address

AT2LP Configuration

0x00 I2C EEPROM signature byte 0 I2C EEPROM signature byte 0. This byte must be 0x53.

0x01 I2C EEPROM signature byte 1 I2C EEPROM signature byte 1. This byte must be 0x4B 0x4B

0x02 APM Value ATA Device Automatic Power Management Value. If an

0x03 Unused 0x80

0x04 bVSCBSignature Value Value in the first byte of the CBW CB field that

0x05 Reserved Bits (7:6) 0x07

Enable mode page 8 Bit (5)

Disable wait for INTRQ Bit (4)

BUSY Bit Delay Bit (3)

Field Name Field Description Required

Contents

0x53

For CY7C68300A compatibility mode, these bytes

should be set to 0x4D4D.

0x00

attached ATA device supports APM and this field

contains other than 0x00, the AT2LP will issue a

SET_FEATURES command to Enable APM with this

value during the drive initialization process. Setting APM

Value to 0x00 disables this functionality. This value is

ignored with ATAPI devices.

0x24

designates that the CB is to be decoded as vendor

specific ATA commands instead of the ATAPI command

block. See section 7 for more detail on how this byte is

used.

Set to 1 to enable the write caching mode page (page

8). If this page is enabled, Windows will disable write

caching by default which will limit write performance.

Set to 1 to poll status register rather than waiting for

INTRQ. Setting this bit to 1 will improve USB BOT test

results but may introduce compatibility problems with

some devices.

Enables a delay of up to 120 ms at each read of the

DRQ bit where the device data length does not match

the host data length. This allows the

Suggested

Contents

11

Page 12

CY7C68300B/CY7C68301B to work with most devices

that incorrectly clear the BUSY bit before a valid status

is present.

0x06 ATA UDMA Enable Bit (7)

0x07 Reserved

Short Packet Before Stall Bit (2)

Determines if a short packet is sent prior to the STALL

of an IN endpoint. The USB Mass Storage Class Bulk-

Only Speci fication allows a device to send a short or

zero-length IN packet prior to returning a STALL

handshake for certain cases. Certain host controller

drivers may require a short packet prior to STALL.

1 = Force a short packet before STALL.

0 = Don’t force a short packet before STALL.

SRST Enable Bit (1)

Determines if the firmware is to do an SRST reset

during drive initialization. At least one reset must be

enabled. Do not set SRST to 0 and Skip Pin Reset to 1

at the same time.

1 = Perform SRST during initialization.

0 = Don’t perform SRST during initialization.

Skip Pin Reset Bit (0)

Skip ARESET# assertion. When this bit is set, the

firmware will bypass ARESET# during any initialization

other than power up. Do not set SRST to 0 and Skip Pin

Reset to 1 at the same time.

0 = Allow ARESET# assertion for all resets.

1 = Disable ARESET# assertion except for power-on

reset cycles.

Enable Ultra DMA data transfer support for ATAPI

devices. If enabled, and if the ATAPI device reports

UDMA support for the indicated modes, the firmware

will utilize UDMA data transfers at the highest

negotiated rate possible.

0 = Disable ATA device UDMA support.

1 = Enable ATA device UDMA support.

ATAPI UDMA Enable Bit (6)

Enable Ultra DMA data transfer support for ATAPI

devices. If enabled, and if the ATAPI device reports

UDMA support for the indicated modes, the

FIRMWARE will utilize UDMA data transfers at the

highest negotiated rate possible.

0 = Disable ATAPI device UDMA support.

1 = Enable ATAPI device UDMA support.

UDMA Modes Bit (5:0)

These bits select which UDMA modes, if supported, are

enabled. Setting to 1 enables. Multiple bits may be set.

The FIRMWARE will operate in the highest enabled

UDMA mode supported by the device. The FIRMWARE

supports UDMA modes 2, 3, and 4 only.

Bit Descriptions

5 Reserved. Must be set to 0.

4 Enable UDMA mode 4.

3 Reserved. Must be set to 0.

2 Enable UDMA mode 2.

1 Reserved. Must be set to 0.

0 Reserved. Must be set to 0.

Bits(7:3)

Must be set to 0.

EZ-USB FX2LP USB to ATA Reference Design Notes

0xD4

0x07

12

Page 13

EZ-USB FX2LP USB to ATA Reference Design Notes

Multiword DMA mode

PIO Modes

0x08 Pin Configurations 0x78

0x09 Reserved Bits (7:6) 0x00

BUTTON_MODE Bit (7)

SEARCH_ATA_BUS Bit (6)

BIG_PACKAGE Bit (5)

ATA_EN Bit (4)

DISKRDY Polarity Bit (3)

HS Indicator Enable Bit (2)

Drive Power Valid Polarity Bit (1)

Drive Power Valid Enable Bit (0)

Bit (2)

This bit selects multi-word DMA. If this bit is set and the

drive supports it, multi-word DMA is used.

Bits(1:0)

These bits select which PIO modes, if supported, are

enabled. Setting to 1 enables. Multiple bits may be set.

The FIRMWARE will operate in the highest enabled PIO

mode supported by the device. The FIRMWARE

supports PIO modes 0, 3, and 4 only. PIO mode 0 is

always enabled by internal logic.

Bit Descriptions

1 Enable PIO mode 4.

0 Enable PIO mode 3.

Button mode. Set this bit to 1 to enable ATAPUEN,

PWR500# and DRVPWRVLD to become button inputs

returned on bits 2, 1, and 0 of EP1IN

Enables a search performed at RESET to detect nonremovable ATA and ATAPI devices. Systems with only

a removable device (like CF readers) will set this bit to

0. Systems with one removable device and one nonremovable device will set this bit to 1.

Package Select. Set this bit to 1 when using the 100-pin

device.

ATA sharing enable. Allows ATA bus sharing with other

host devices. If ATA_EN=1 the ATA interface will be

driven when VBUS_ATA_ENABLE is LOW. If

ATA_EN=0 the ATA interface will be placed into Hi-Z

state whenever VBUS_ATA_ENABLE is LOW.

‘0’ =ATA signals Hi-Z when VBUS_ATA_ENABLE is

LOW.

‘1’ = ATA signals driven when VBUS_ATA_ENABLE is

LOW.

DISKRDY active polarity.

‘0’ = Active LOW polarity.

‘1’ =Active HIGH polarity.

Enables GPIO2_nHS pin to indicate the current

operating speed of the device (if output is enabled).

‘0’ = Normal GPIO operation.

‘1’ = High-speed indicator enable.

Controls the polarity of DRVPWRVLD pin

‘0’ =Active LOW (“connector ground” indication)

‘1’ =Active HIGH (power indication from device)

Enable for the DRVPWRVLD pin. When this pin is

enabled, the FIRMWARE will enumerate a removable

IDE device (normally CompactFlash) as the master

device.

‘0’ =pin disabled (most systems)

‘1’= pin enabled (CompactFlash systems)

13

Page 14

EZ-USB FX2LP USB to ATA Reference Design Notes

General Purpose IO Pin

Output Enable

0x0A Reserved

General Purpose IO Pin Data

0x0B Identify Device String Pointer

LUN0

0x0C Identify Device String Pointer

LUN1

0x0D Delay after reset Number of 20-ms ticks to wait between RESET and

0x0E Reserved Bits (7:4) 0x00

0x0F Reserved Must be set to 0x00. 0x00

Device Descriptor

0x10 bLength Length of device descriptor in bytes. 0x12

0x11 bDescriptor Type Descriptor type. 0x01

0x12 bcdUSB (LSB) USB Specification release number in BCD. 0x00

0x13 bcdUSB (MSB) 0x02

0x14 bDeviceClass Device class. 0x00

0x15 bDeviceSubClass Device subclass. 0x00

0x16 bDeviceProtocol Device protocol. 0x00

0x17 bMaxPacketSize0 USB packet size supported for default pipe. 0x40

0x18 idVendor (LSB) Your Vendor

0x19 idVendor (MSB)

0x1A idProduct (LSB) Product ID. Your

Enable CF UDMA Bit (3)

Fixed number of logical

units = 2

Fixed number of logical

units = 1

Search ATA on VBUS

removed

Must be set to zero.

Bits (5:0)

GPIO[5:0] Hi-Z control.

‘0’ = Output enabled (GPIO pin is an output).

‘1’ = Hi-Z (GPIO pin is an input).

Bits (7:6)

Must be set to zero.

Bits (5:0)

If the output enable bit is set, these bits select the value

driven on the GPIO pins.

If this value is 00, the Identify Device data will be taken

from the device. If this string is non-zero, it is used as a

pointer to a 24 byte ASCII (non-Unicode) string in the

EEPROM. This string will be used as the device

identifier. This string is used by many operating systems

as the user-visible name for the device.

attempting to access the drive.

‘1’ = Allow UDMA to be used with removable-media

devices

‘0’ = UDMA will not be used with removable-media

devices

Some CF devices will interfere with UDMA if the UDMA

lines are connected to them. This bit tells the

FIRMWARE if the UDMA lines are connected to the

removable-media device.

Bit (2)

If bits 1 and 2 are both 0, the number of logical units will

be determined by searching the ATA and CF buses for

devices.

Bit (1)

If bits 1 and 2 are both 0, the number of logical units will

be determined by searching the ATA and CF buses for

devices.

Bit (0)

Search for ATA devices when VBUS returns. If this bit is

set, the ATA bus will be searched for ATA devices every

time FIRMWARE is plugged into a computer.

Vendor ID. Cypress’s Vendor ID may only be used for

evalu ation purposes, and not in released products.

0x00

0x00

0x00

0x00

ID

14

Page 15

EZ-USB FX2LP USB to ATA Reference Design Notes

Product ID

0x1B idProduct (MSB)

0x1C bcdDevice (LSB) Device release number in BCD LSB (product release

number).

0x1D bcdDevice (MSB) Device release number in BCD MSB (silicon release

number).

0x1E iManufacturer Index to manufacturer string. This entry must equal half

of the address value where the string starts or 0x00 if

the string does not exist.

0x1F iProduct Index to product string. This entry must equal half of the

address value where the string starts or 0x00 if the

string does not exist.

0x20 iSerialNumber Index to serial number string. This entry must equal half

of the address value where the string starts or 0x00 if

the string does not exist. The USB Mass Storage Class

Bulk-Only Transport Specification requires a unique

serial number (in upper case, hexadecimal characters)

for each device.

0x21 bNumConfigurations Number of configurations supported. 1 for mass

storage: 2 for HID: 3 for CSM

Device Qualifier

0x22 bLength Length of device descriptor in bytes. 0x0A

0x23 bDescriptor Type Descriptor type. 0x06

0x24 bcdUSB (LSB) USB Specification release number in BCD. 0x00

0x25 bcdUSB (MSB) USB Specification release number in BCD. 0x02

0x26 bDeviceClass Device class. 0x00

0x27 bDeviceSubClass Device subclass. 0x00

0x28 bDeviceProtocol Device protocol. 0x00

0x29 bMaxPacketSize0 USB packet size supported for default pipe. 0x40

0x2A bNumConfigurations Number of configurations supported. 0x01

0x2B bReserved Reserved for future use. Must be set to zero. 0x00

Configuration Descriptor

0x2C bLength Length of configuration descriptor in bytes. 0x09

0x2D bDescriptorType Descriptor type. 0x02

0x2E bTotalLength (LSB) Number of bytes returned in this configuration. This

includes the configuration descriptor plus all the

interface and endpoint descriptors.

0x2F bTotalLength (MSB) 0x00

0x30 bNumInterfaces Number of interfaces supported. 0x01

0x31 bConfiguration Value The value to use as an argument to Set Configuration to

select the configuration. This value must be set to 0x01.

0x32 iConfiguration Index to the configuration string. This entry must equal

half of the address value where the string starts, or 0x00

if the string does not exist.

0x33 bmAttributes Device attributes for this configuration.

Bit (7) Reserved. Must be set to 1.

Bit (6) Self-powered. Must be set to 1.

Bit (5) Remote wake-up. Must be set to 0.

Bits (40) Reserved. Must be set to 0.

0x34 bMaxPower Maximum power consumption for this configuration.

Units used are mA*2 (i.e., 0x31 = 98 mA, 0xF9 = 498

mA). 0x00 reported for self-powered devices.

Your release

number

0x53

0x69

0x75

0x03

0x20

0x01

0x00

0xC0

0x01

15

Page 16

EZ-USB FX2LP USB to ATA Reference Design Notes

Note: A value of 0x00 or 0x01 results in the 56-pin

package configuring itself for self-powered mode,

whereas a value

greater than 0x01 results in the 56-pin package

reporting itself as bus-powered. This is regardless of

what address 0x33 is set to reflect in the 56-pin

package.

Interface and Endpoint Descriptors

Interface Descriptor

0x35 bLength Length of interface descriptor in bytes. 0x09

0x36 bDescriptorType Descriptor type. 0x04

0x37 bInterfaceNumber Interface number. 0x00

0x38 bAlternateSetting Alternate setting. 0x00

0x39 bNumEndpoints Number of endpoints. 0x02

0x3A bInterfaceClass Interface class. 0x08

0x3B bInterfaceSubClass Interface subclass. 0x06

0x3C bInterfaceProtocol Interface protocol. 0x50

0x3D iInterface Index to first interface string. This entry must equal half

of the address value where the string starts or 0x00 if

the string does not exist.

USB Bulk Out Endpoint

0x3E bLength Length of this descriptor in bytes. 0x07

0x3F bDescriptorType Endpoint descriptor type. 0x05

0x40 bEndpointAddress This is an Out endpoint, endpoint number 2. 0x02

0x41 bmAttributes This is a bulk endpoint. 0x02

0x42 wMaxPacketSize (LSB) 0x00

0x43 wMaxPacketSize (MSB)

0x44 bInterval High-speed interval for polling (maximum NAK rate). Set

USB Bulk In Endpoint

0x45 bLength Length of this descriptor in bytes. 0x07

0x46 bDescriptorType Endpoint descriptor type. 0x05

0x47 bEndpointAddress This is an In endpoint, endpoint number 8. 0x88

0x48 bmAttributes This is a bulk endpoint. 0x02

0x49 wMaxPacketSize (LSB) 0x00

0x4A wMaxPacketSize (MSB)

0x4B bInterval High-speed interval for polling (maximum NAK rate). Set

(Optional) HID Interface Descriptor

0x4C bLength Length of HID interface descriptor 0x09

0x4D bDescriptorTypes Interface descriptor type 0x04

0x4E bInterfaceNumber Number of interfaces (2) 0x02

0x4F bAlternateSetting Alternate setting 0x00

0x50 bNumEndpoints Number of endpoints used by this interface 0x01

0x51 bInterfaceClass Class code 0x03

0x52 bInterfaceSubClass Sub class 0x00

0x53 bInterfaceSubSubClass sub sub class 0x00

0x54 iInterface Index of string descriptor 0x00

Max data transfer size. To be set by speed (Full speed

0x0040; High speed 0x0200)

to zero for full speed.

Max data transfer size. Automatically set by AT2 (Full

speed 0x0040; High speed 0x0200)

to zero for full speed.

0x00

0x02

0x00

0x02

0x00

16

Page 17

EZ-USB FX2LP USB to ATA Reference Design Notes

USB Interrupt In Endpoint

0x5E bLength Length of this descriptor in bytes. 0x07

0x5F bDescriptorType Endpoint descriptor type. 0x05

0x60 bEndpointAddress This is an In endpoint, endpoint number 1. 0x81

0x61 bmAttributes This is an interrupt endpoint. 0x03

0x62 wMaxPacketSize (LSB) 0x02

0x63 wMaxPacketSize (MSB)

0x64 bInterval Interval for polling (max. NAK rate). 0x10

(Optional) HID Descriptor

0x55 bLength Length of HID descriptor 0x09

0x56 bDescriptorType Descriptor Type HID 0x21

0x57 bcdHID (LSB) 0x10

0x58 bcdHID (MSB)

0x59 bCountryCode Country Code 0x00

0x5A bNumDescriptors Number of class descriptors (1 report descriptor) 0x01

0x5B bDescriptorType Descriptor Type 0x22

0x5C wDescriptorLength (LSB) 0x22

0x5D wDescriptorLength (MSB)

Terminator Descriptors

0x65 Terminator 0x00

(Optional) HID Report Descriptor

0x66 Usage_Page Vendor defined - FFA0 0x06

0x67 0xA0

0x68 0xFF

0x69 Usage 0x09

0x6A

0x6B Collection 0xA1

0x6C

0x6D Usage 0x09

0x6E

Input Report

0x6F Usage 0x09

0x70

0x71 Logical_Minimum 0x15

0x72

0x73 Logical_Maximum 0x25

0x74

0x75 Report_Size 0x75

0x76

0x77 Report_Count 0x95

0x78

0x79 Input 0x81

0x7A

Output Report

0x7B Usage 0x09

0x7C

0x7D Logical_Minimum Logical Minimum (-128) 0x15

Max data transfer size.

0x00

HID Class Specification release number (1.10)

0x01

Length of HID report descriptor

0x00

Vendor defined

0xA5

Application

0x01

Vendor defined

0xA6

Vendor defined

0xA7

-128

0x80

127

0x7F

8 bits

0x08

2 fields

0x02

Input (Data, Variable, Absolute)

0x02

Usage - vendor defined

0xA9

17

Page 18

EZ-USB FX2LP USB to ATA Reference Design Notes

0x7E 0x80

0x7F Logical_Maximum 0x25

0x80

0x81 Report_Size 0x75

0x82

0x83 Report_Count 0x95

0x84

0x85 Output 0x91

0x86

0x87

(optional) Standard Content Security Interface Descriptor

0x88 bLength Byte length of this descriptor 0x09

0x89 bDescriptorType Interface Descriptor type 0x0D

0x8A bInterfaceNumber Number of interface. 0x02

Logical Maximum (127)

0x7F

Report Size 8 bits

0x08

Report Count 2 fields

0x02

Output (Data, Variable, Absolute

0x02

End Collection 0xC0

0x8B bAlternateSetting Value used to select an alternate setting for the

interface identified in prior field

0x8C bNumEndpoints 0x02

0x8D bInterfaceClass

0x8E bInterfaceSubClass Must be set to zero 0x00

0x8F bInterfaceProtocol Must be set to zero 0x00

0x90 iInterface Index of a string descriptor that describes this Interface

Channel Descriptor

0x91 bLength Byte length of this descriptor 0x09

0x92 bDescriptorType channel descriptor type 0x22

0x93 bChannelID Number of the channel, must be a zero based value

0x94 bmAttributes Bits(7:5)

0x95 Bit (4:0)

0x96 bRecipient Identifier of the target recipient

0x97 bRecipientAlt alternate setting for the interface to which this channel

0x98 bRecipientLogicalUnit Recipient Logical Unit

0x99 bMethod Index of a class-specific CSM descriptor That describes

Number of endpoints used by this interface (excluding

endpoint 0) that are CSM dependent

that is unique across the device

Must be set to 0.

0 = Not used

1 = Interface

2 = Endpoint

3...31 = Reserved values

If Recipient type field of bmAttributes = 1 then

bRecipient field is the bInterfaceNumber

If Recipient type field of bmAttributes = 2 then

bRecipient field is an endpoint address, where:

D7: Direction (0 = Out, 1 = IN)

D6...D4: reserved and set to zero

D3...D0: Endpoint number

applies

0x0D

0x00

18

Page 19

EZ-USB FX2LP USB to ATA Reference Design Notes

one of the Content Security Methods (CSM) offered by

the device

0x9A bMethodVariant CSM Variant descriptor

CSM Descriptor

0x9B bLength Byte length of this descriptor 0x06

0x9C bDescriptorType CSM Descriptor type 0x23

0x9D bMethodID Index of a class-specific CSM descriptor that describes

on of the Content Security Methods offered by the

device.

0x9E iCSMDescriptor Index of string descriptor that describes the Content

Security Method

0x9F bcdVersion (LSB) CSM Descriptor Version number 0x10

0xA0 bcsVersion (MSB) 0x02

0xA1 Terminator 0x00

USB String DescriptorIndex 0 (LANGID)

0xA2 bLength LANGID string descriptor length in bytes. 0x04

0xA3 bDescriptorType Descriptor type. 0x03

0xA4 LANGID (LSB) Language supported. The CY7C68300B supports one

LANGID value.

0x01

0x09

19

Page 20

EZ-USB FX2LP USB to ATA Reference Design Notes

0xC1 bString Unicode character MSB. 0x00

0xC2 bString Unicode character LSB. “o” 0x6F

0xC3 bString Unicode character MSB. 0x00

0xC4 bString Unicode character LSB. “n” 0x6E

0xC5 bString Unicode character MSB. 0x00

0xC6 bString Unicode character LSB. “d” 0x64

0xC7 bString Unicode character MSB. 0x00

0xC8 bString Unicode character LSB. “u” 0x75

0xC9 bString Unicode character MSB. 0x00

0xCA bString Unicode character LSB. “c” 0x63

0xCB bString Unicode character MSB. 0x00

0xCC bString Unicode character LSB. “t” 0x74

0xCD bString Unicode character MSB. 0x00

0xCE bString Unicode character LSB. “o” 0x6F

0xCF bString Unicode character MSB. 0x00

0xD0 bString Unicode character LSB. “r” 0x72

0xD1 bString Unicode character MSB. 0x00

USB String DescriptorProduct

0xD2 bLength String descriptor length in bytes (including bLength). 0x2C

0xD3 bDescriptorType Descriptor type. 0x03

0xD4 bString Unicode character LSB. “U” 0x55

0xD5 bString Unicode character MSB. 0x00

0xD6 bString Unicode character LSB. “S” 0x53

0xD7 bString Unicode character MSB. 0x00

0xD8 bString Unicode character LSB. “B” 0x42

0xD9 bString Unicode character MSB. 0x00

0xDA bString Unicode character LSB. “2” 0x32

0xDB bString Unicode character MSB. 0x00

0xDC bString Unicode character LSB. “.” 0x2E

0xDD bString Unicode character MSB. 0x00

0xDE bString Unicode character LSB. “0” 0x30

0xDF bString Unicode character MSB. 0x00

0xE0 bString Unicode character LSB. “ ” 0x20

0xE1 bString Unicode character MSB. 0x00

0xE2 bString Unicode character LSB. “D” 0x53

0xE3 bString Unicode character MSB. 0x00

0xE4 bString Unicode character LSB. “i” 0x74

0xE5 bString Unicode character MSB. 0x00

0xE6 bString Unicode character LSB. “s” 0x6F

0xE7 bString Unicode character MSB. 0x00

0xE8 bString Unicode character LSB. “k” 0x72

0xE9 bString Unicode character MSB. 0x00

USB String DescriptorSerial Number (Note: The USB Mass Storage Class specification requires a unique serial number in

each device. Not providing a unique serial number can cause the operating system to crash. The serial number must be at

least 12 characters, but some USB hosts will only treat the last 12 characters of the serial number as unique.)

0xEA bLength String descriptor length in bytes (including bLength). 0x22

0XEB bDescriptor Type Descriptor type. 0x03

20

Page 21

EZ-USB FX2LP USB to ATA Reference Design Notes

0XEC bString Unicode character LSB. “1” 0x31

0XED bString Unicode character MSB. 0x00

0XEE bString Unicode character LSB. “2” 0x32

0XEF bString Unicode character MSB. 0x00

0XF0 bString Unicode character LSB. “3” 0x33

0xF1 bString Unicode character MSB. 0x00

0xF2 bString Unicode character LSB. “4” 0x34

0xF3 bString Unicode character MSB. 0x00

0xF4 bString Unicode character LSB. “5” 0x35

0xF5 bString Unicode character MSB. 0x00

0xF6 bString Unicode character LSB. “6” 0x36

0xF7 bString Unicode character MSB. 0x00

0xF8 bString Unicode character LSB. “7” 0x37

0xF9 bString Unicode character MSB. 0x00

0xFA bString Unicode character LSB. “8” 0x38

0xFB bString Unicode character MSB. 0x00

0xFC bString Unicode character LSB. “9” 0x39

0xFD bString Unicode character MSB. 0x00

0xFE bString Unicode character LSB. “0” 0x30

0xFF bString Unicode character MSB. 0x00

0X100 bString Unicode character LSB. “A” 0x41

0X101 bString Unicode character MSB. 0x00

0X102 bString Unicode character LSB. “B” 0x42

0X103 bString Unicode character MSB. 0x00

Identify Device String (Note: This is not a Unicode string. It is the ASCII string returned by the device in the Identify Device

information. It is a fixed length (24 bytes). Changing this string may cause CD authoring software to incorrectly identify the

device.)

0X104 Device name byte 1 ASCII Character “C” 0x43

0X105 Device name byte 2 ASCII Character “y” 0x79

0X106 Device name byte 3 ASCII Character “p” 0x70

0X107 Device name byte 4 ASCII Character “r” 0x72

0X108 Device name byte 5 ASCII Character “e” 0x65

0X109 Device name byte 6 ASCII Character “s” 0x73

0X10A Device name byte 7 ASCII Character “s” 0x73

0X10B Device name byte 8 ASCII Character “ “ 0x20

0X10C Device name byte 9 ASCII Character “C” 0x43

0X10D Device name byte 10 ASCII Character “u” 0x75

0X10E Device name byte 11 ASCII Character “s” 0x73

0X10F Device name byte 12 ASCII Character “t” 0x74

0X110 Device name byte 13 ASCII Character “o” 0x6f

0X111 Device name byte 14 ASCII Character “m” 0x6d

0X112 Device name byte 15 ASCII Character “ ” 0x20

0X113 Device name byte 16 ASCII Character “N“ 0x4e

0X114 Device name byte 17 ASCII Character “a“ 0x61

0X115 Device name byte 18 ASCII Character “m“ 0x6d

0X116 Device name byte 19 ASCII Character “e“ 0x65

0X117 Device name byte 20 ASCII Character “ ” 0x20

21

Page 22

EZ-USB FX2LP USB to ATA Reference Design Notes

0X118 Device name byte 21 ASCII Character “L” 0x4c

0X119 Device name byte 22 ASCII Character “U” 0x55

0X11A Device name byte 23 ASCII Character “N” 0x4e

0X11B Device name byte 24 ASCII Character “0” 0x30

0x11C to

0x1FF

Note: More than 0X100 bytes of configuration are shown for example only. The firmware only supports 0X100 total bytes. This

is controlled by the CONFIG_SPACE_START value in atapi.h. CONFIG_SPACE_START must match the –x address passed

to hex2bix when the files are combined. If more than 0x100 bytes of config space are used, the routines that access config

space must be changed to use a WORD offset rather than a BYTE offset.

Unused ROM Space Amount of unused ROM space will vary depending on

strings.

0xFF

Document Revision History

Revision # Date Comments

2.50 4/5/05 Updated for release 2.50. Removed multiple targets, moved many options to

EEPROM. Added CY3684 references.

2.30 7/5/02 Updated for release 2.30. Added compact flash, multiple device support.

2.20 5/1/02 Updated for release 2.20

2.10 2/1/01 Updated for new board, added flowchart

2.09 12/1/01 Updated for final release.

2.0B8 8/15/01 Minor typographical and technical corrections.

2.0B7 7/1/01 Added information about unified code image.

2.0B5 5/20/01 Added DVD support info

2.0B1 3/26/01 Revised for Beta release.

Added more file descriptions

Added build instructions

2.0 11/29/00 Initial Release

22

Loading...

Loading...