查询CY28RS400供应商

CY28RS400

Clock Generator for ATI RS400 Chipset

Features

• Supports Intel CPU

• Selectable CPU frequencies

• Differential CPU clock pairs

• 100-MHz differential SRC clocks

• 48-MHz USB clock

• 33-MHz PCI clock

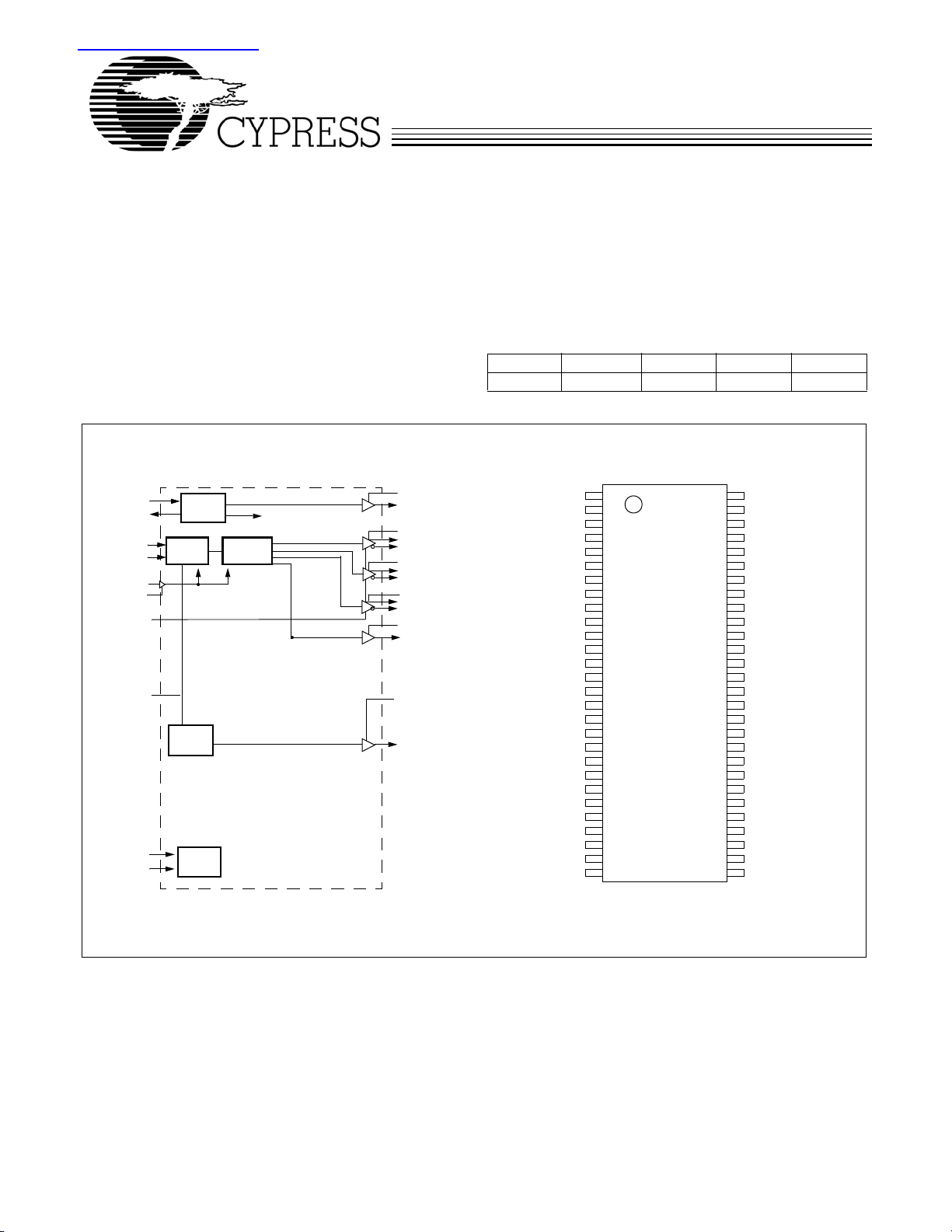

Block Diagram

XOUT

CPU_STP#

CLKREQ[0:1]#

FS_[C:A]

VTT_PWRGD#

IREF

SDATA

SCLK

XIN

PD

PLL1

PLL2

Logic

XTAL

OSC

I2C

PLL Ref Freq

Divider

Network

VDD_REF

REF[0:2]

VDD_CPU

CPUT[0:2], CPUC[0:2],

VDD_SRC

SRCT[0:5],SRCC[0:5]

VDD_SRCS

SRCST[0:1],SRCSC[0:1]

VDD_PCI

PCI

VDD_48 MHz

USB_48

VTT_PWRGD#/PD

• Low-voltage frequency select input

2

•I

C support with readback capabilities

• Ideal Lexmark Spread Spectrum profile for maximum

electromagnetic interference (EMI) reduction

• 3.3V power supply

• 56-pin SSOP and TSSOP packages

CPU SRC PCI REF USB_48

x3 x8 x1 x 3 x 1

Pin Configuration

Xin

XOUT

VDD_48

USB_48

VSS_48

SCLK

SDATA

FSC

CLKREQ#0

CLKREQ#1

SRCT5

SRCC5

VDD_SRC

VSS_SRC

SRCT4

SRCC4

SRCT3

SRCC3

VSS_SRC

VDD_SRC

SRCT2

SRCC2

SRCT1

SRCC1

VSS_SRC

SRCST1

SRCSC1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

CY28RS400

56

55

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

VDD_REF

VSS_REF

REF0/FSA

REF1/FSB

REF2

VDD_PCI

PCI0/409_410

VSS_PCI

CPU_STOP#

CPUT0

CPUC0

VDD_CPU

VSS_CPU

CPUT1

CPUC1

CPUT2

CPUC2

VDDA

VSSA

IREF

VSS_SRC1

VDD_SRC1

SRCT0

SRCC0

VDD_SRCS

VSS_SRCS

SRCST0

SRCSC0

56 SSOP/TSSOP

Cypress Semiconductor Corporation • 3901 North First Street • San Jose, CA 95134 • 408-943-2600

Document #: 38-07637 Rev. *B Revised October 19, 2004

CY28RS400

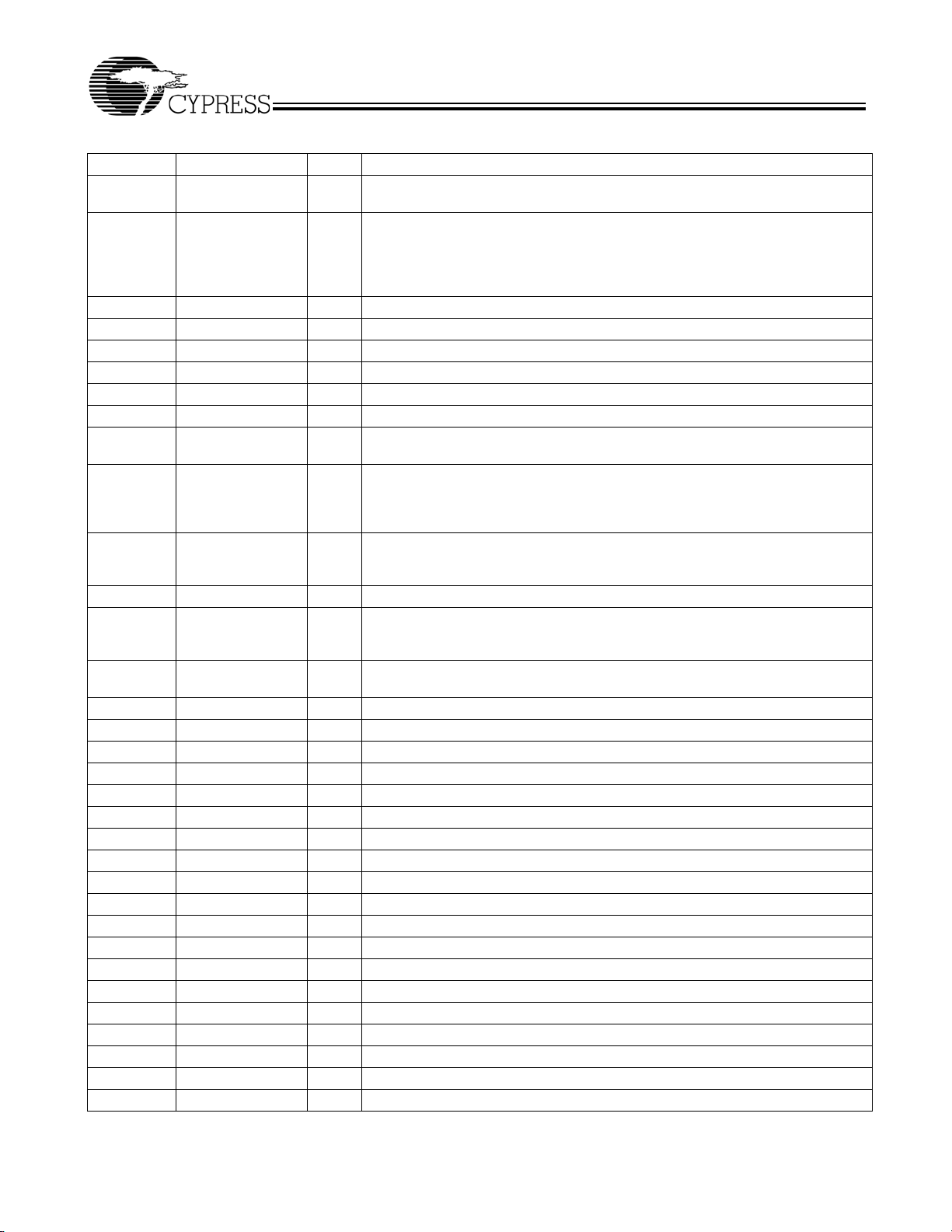

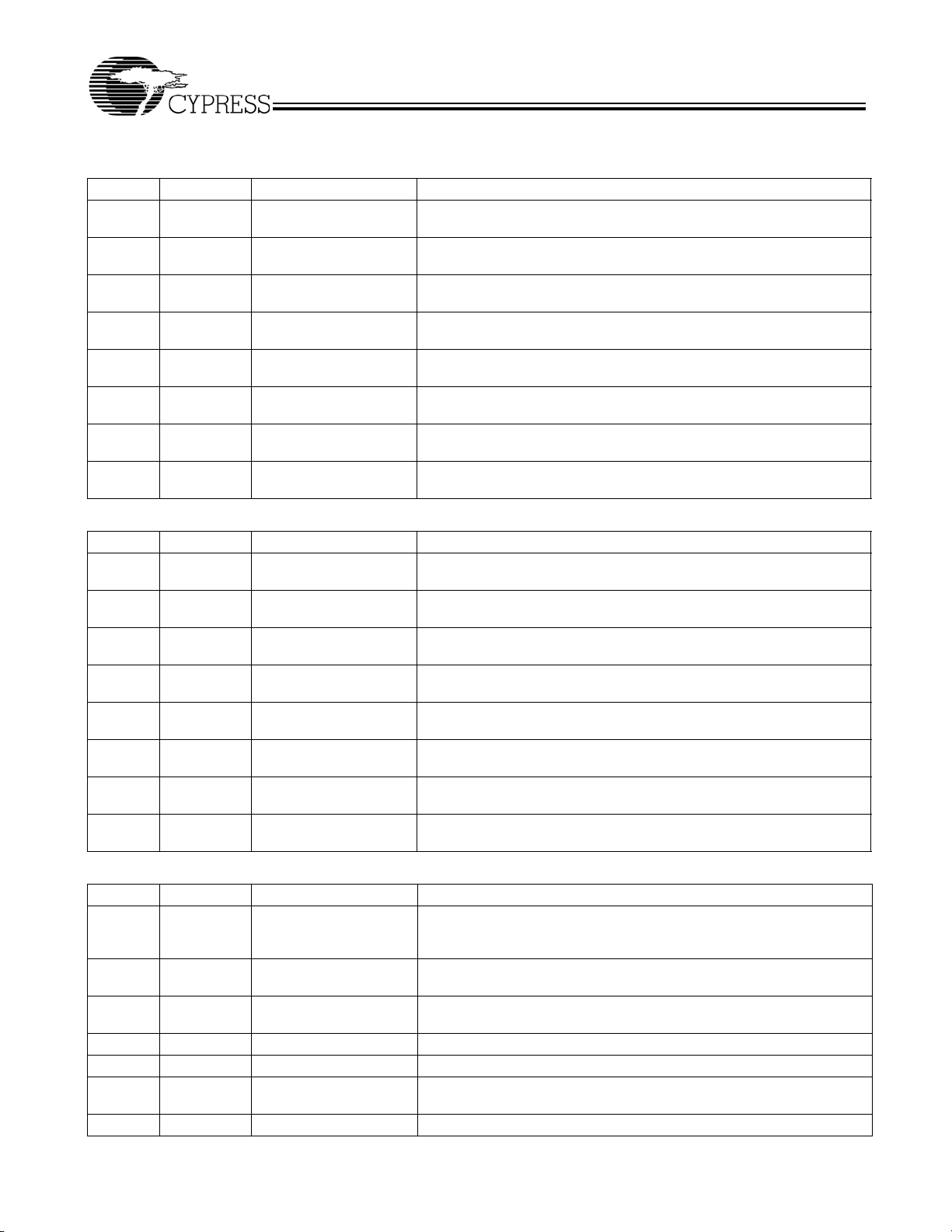

Pin Description

Pin No. Name Type Description

47,46,43,42,

41,40

50 PCI0/409_410 I/O,PD33-MHz clock output/CPU Frequency table Select

37 IREF I A precision resistor attached to this pin is connected to the internal current reference.

54 REF0/ FSA I/O, SE, 14.318MHz REF clock ouput/ CPU Frequency Select. Intel

53 REF1/FSB I/O, SE 14.318MHz REF clock ouput

52 REF2 O, SE 14.318MHz REF clock ouput. Intel Type-5 buffer.

7 SCLK I,PU SMBus-compatible SCLOCK.This pin has an internal pullup, but is tri-stated in power-down.

8 SDATA I/O, PU SMBus compatible SDATA.This pin has an internal pullup, but is tri-stated in power-down.

27, 28, 30, 29 SRCST/C[1:0] O, DIF Differential Selectable Serial reference clock. Intel Type-X buffer. Includes overclock

12, 13, 16,

17, 18, 19,

22, 23, 24, 25

,34,33

10,11 CLKREQ#[0:1] I, SE, PDOutput Enable control for SRCT/C. Output enable control required by Minicard

4 USB_48 O, SE 48-MHz clock output. Intel Type-3A buffer.

6 VTT_PWRGD#/PD IPD3.3V LVTTL input. This pin is a level sensitive strobe used to latch the FS_A, FS_B,

48 CPU_STP# I, PU 3.3V LVTTL input. This pin is used to gate the CPU outputs. CPU outputs are turned

9 FSC I 3.3V LVTTL input. CPU Clock Frequency Select

3 VDD_48 PWR 3.3V power supply for USB outputs

45 VDD_CPU PWR 3.3V power supply for CPU outputs

51 VDD_PCI PWR 3.3V power supply for PCI outputs

56 VDD_REF PWR 3.3V power supply for REF outputs

14, 21 VDD_SRC PWR 3.3V power supply for SRC outputs

35 VDD_SRC1 PWR 3.3V power supply for SRC outputs

32 VDD_SRCS PWR 3.3V power supply for SRCS outputs

39 VDDA PWR 3.3V Analog Power for PLLs

5 VSS_48 GND Ground for USB outputs

44 VSS_CPU GND Ground for CPU outputs

49 VSS_PCI GND Ground for PCI outputs

55 VSS_REF GND Ground for REF outputs

15, 20, 26 VSS_SRC GND Ground for SRC outputs

36 VSS_SRC1 GND Ground for SRC outputs

31 VSS_SRCS GND Ground for SRCS outputs

38 VSSA GND Analog Ground

1 XIN I 14.318-MHz Crystal Input

2 XOUT O 14.318-MHz Crystal Output

CPUT/C[2:0] O, DIF Differential CPU clock output.

Intel Type-X buffer.

Intel Type-5 buffer.

0 = 410 frequency select table

1 = 409 frequency select table.

This has an internal pull-down

Type-5 buffer.

/ CPU Frequency Select. Intel Type-5 buffer.

support through SMBUS

SRCT/C[5:0] O, DIF 100 MHz Differential Serial reference clock. Intel Type-X buffer.

specification. These pins have an internal pull-down.

0 = Selected SRC outputs are enabled, 1 = Selected SRC outputs are disabled

FS_C and 409_410 inputs. After asserting VTT_PWRGD# (active low), this pin

becomes a realtime input for asserting power down (active high)

off two cycles after assertion of this pin

Document #: 38-07637 Rev. *B Page 2 of 19

CY28RS400

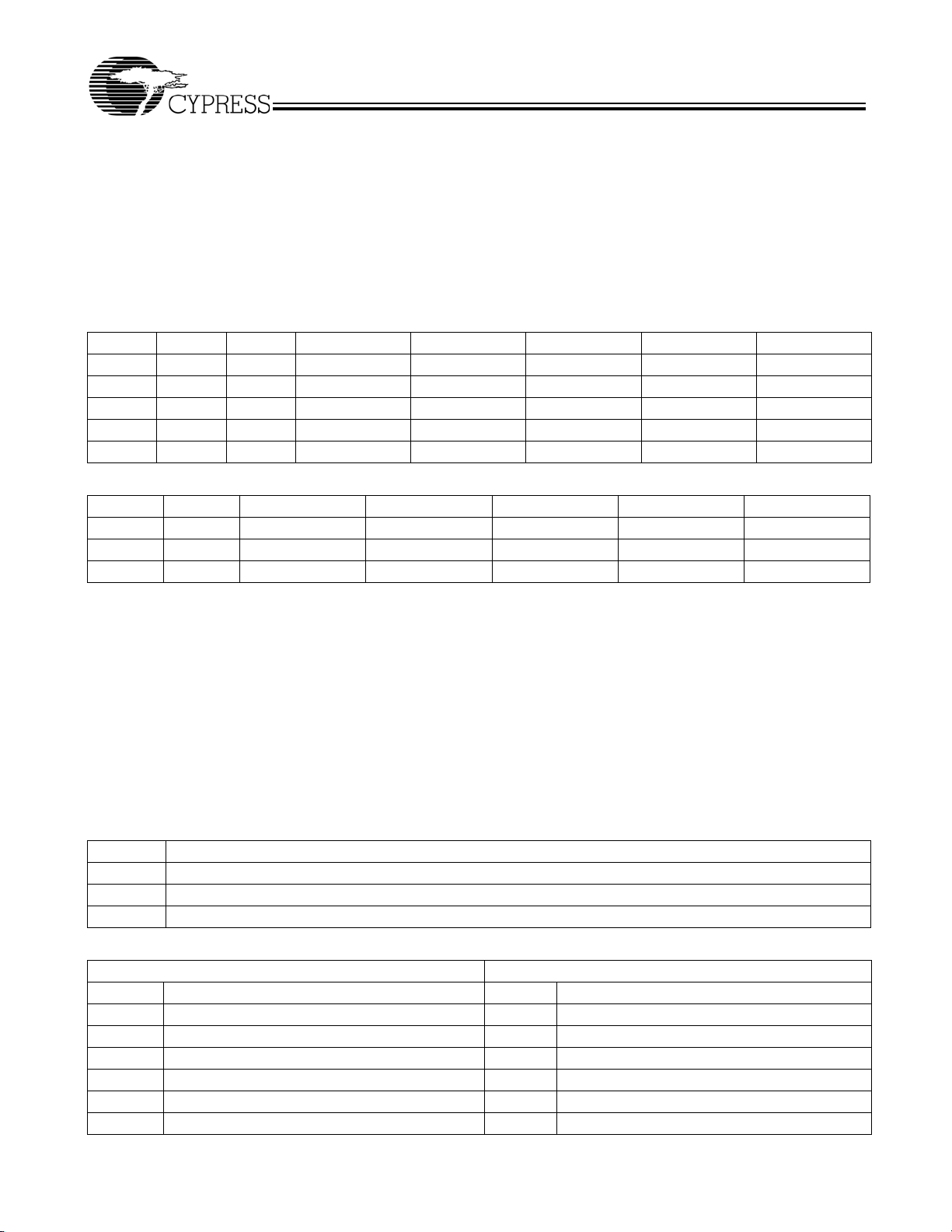

Frequency Select Pins (FS_A, FS_B, FS_C and

409_410)

Host clock frequency selection is achieved by applying the

appropriate logic levels to FS_A, FS_B, FS_C and 409_410

inputs prior to VTT_PWRGD# assertion (as seen by the clock

synthesizer). Upon VTT_PWRGD# being sampled low by the

clock chip (indicating processor VTT voltage is stable), the

clock chip samples the FS_A, FS_B, FS_C and 409_410 input

values. For all logic levels of FS_A, FS_B, FS_C and 409_410

VTT_PWRGD# employs a one-shot functionality in that once

Table 1. Frequency Select Table (FS_A FS_B FS_C) 410 mode, 409_410 = 0

FS_C FS_B FS_A CPU SRC PCIF/PCI REF0 USB

1 0 1 100 MHz 100 MHz 33 MHz 14.318 MHz 48 MHz

0 0 1 133 MHz 100 MHz 33 MHz 14.318 MHz 48 MHz

0 1 0 200 MHz 100 MHz 33 MHz 14.318 MHz 48 MHz

0 0 0 266 MHz 100 MHz 33 MHz 14.318 MHz 48 MHz

1 1 1 Reserved 100 MHz 33 MHz 14.318 MHz 48 MHz

Table 2. Frequency Select Table (FS_A FS_B) 410 mode, 409_410 = 1

FS_B FS_A CPU SRC PCIF/PCI REF0 USB

0 0 100 MHz 100 MHz 33 MHz 14.318 MHz 48 MHz

0 1 133 MHz 100 MHz 33 MHz 14.318 MHz 48 MHz

1 0 200 MHz 100 MHz 33 MHz 14.318 MHz 48 MHz

a valid low on VTT_PWRGD# has been sampled, all further

VTT_PWRGD#, FS_A, FS_B, FS_C and 409-410 transitions

will be ignored. There are 2 CPU frequency select tables. One

based on the CK409 specifications and one based on the

CK410 specifications. The table to be used is determined by

the value latched on the PCI0/409_410 pin by the

VTT_PWRGD/PD# pin. A '0' on this pin selects the 410

frequency table and a '1' on this pin selects the 409 frequency

table. In the 409 table, only the FS_A and FS_B pins influence

the frequency selection.

Serial Data Interface

To enhance the flexibility and function of the clock synthesizer,

a two-signal serial interface is provided. Through the Serial

Data Interface, various device functions, such as individual

clock output buffers, can be individually enabled or disabled.

The registers associated with the Serial Data Interface

initializes to their default setting upon power-up, and therefore

use of this interface is optional. Clock device register changes

are normally made upon system initialization, if any are

required. The interface cannot be used during system

operation for power management functions.

Table 3. Command Code Definition

Bit Description

7 0 = Block read or block write operation, 1 = Byte read or byte write operation

(6:5) Chip select address, set to ‘00’ to access device

(4:0) Byte offset for byte read or byte write operation. For block read or block write operations, these bits should be '00000'

Table 4. Block Read and Block Write Protocol

Block Write Protocol Block Read Protocol

Bit Description Bit Description

1 Start 1 Start

8:2 Slave address – 7 bits 8:2 Slave address – 7 bits

9 Write 9 Write

10 Acknowledge from slave 10 Acknowledge from slave

18:11 Command Code – 8 bits 18:11 Command Code – 8 bits

19 Acknowledge from slave 19 Acknowledge from slave

Data Protocol

The clock driver serial protocol accepts byte write, byte read,

block write, and block read operations from the controller. For

block write/read operation, the bytes must be accessed in

sequential order from lowest to highest byte (most significant

bit first) with the ability to stop after any complete byte has

been transferred. For byte write and byte read operations, the

system controller can access individually indexed bytes. The

offset of the indexed byte is encoded in the command code,

as described in Tab le 3.

The block write and block read protocol is outlined in Table 4

while Table 5 outlines the corresponding byte write and byte

read protocol. The slave receiver address is 11010010 (D2h).

Document #: 38-07637 Rev. *B Page 3 of 19

CY28RS400

Table 4. Block Read and Block Write Protocol (continued)

Block Write Protocol Block Read Protocol

Bit Description Bit Description

27:20 Byte Count – 8 bits 20 Repeat start

28 Acknowledge from slave 27:21 Slave address – 7 bits

36:29 Data byte 1 – 8 bits 28 Read = 1

37 Acknowledge from slave 29 Acknowledge from slave

45:38 Data byte 2 – 8 bits 37:30 Byte Count from slave – 8 bits

46 Acknowledge from slave 38 Acknowledge

.... Data Byte /Slave Acknowledges 46:39 Data byte 1 from slave – 8 bits

.... Data Byte N –8 bits 47 Acknowledge

.... Acknowledge from slave 55:48 Data byte 2 from slave – 8 bits

.... Stop 56 Acknowledge

.... Data bytes from slave / Acknowledge

.... Data Byte N from slave – 8 bits

.... NOT Acknowledge

Table 5. Byte Read and Byte Write Protocol

Byte Write Protocol Byte Read Protocol

Bit Description Bit Description

1Start 1Start

8:2 Slave address – 7 bits 8:2 Slave address – 7 bits

9Write 9Write

10 Acknowledge from slave 10 Acknowledge from slave

18:11 Command Code – 8 bits 18:11 Command Code – 8 bits

19 Acknowledge from slave 19 Acknowledge from slave

27:20 Data byte – 8 bits 20 Repeated start

28 Acknowledge from slave 27:21 Slave address – 7 bits

29 Stop 28 Read

29 Acknowledge from slave

37:30 Data from slave – 8 bits

38 NOT Acknowledge

39 Stop

Document #: 38-07637 Rev. *B Page 4 of 19

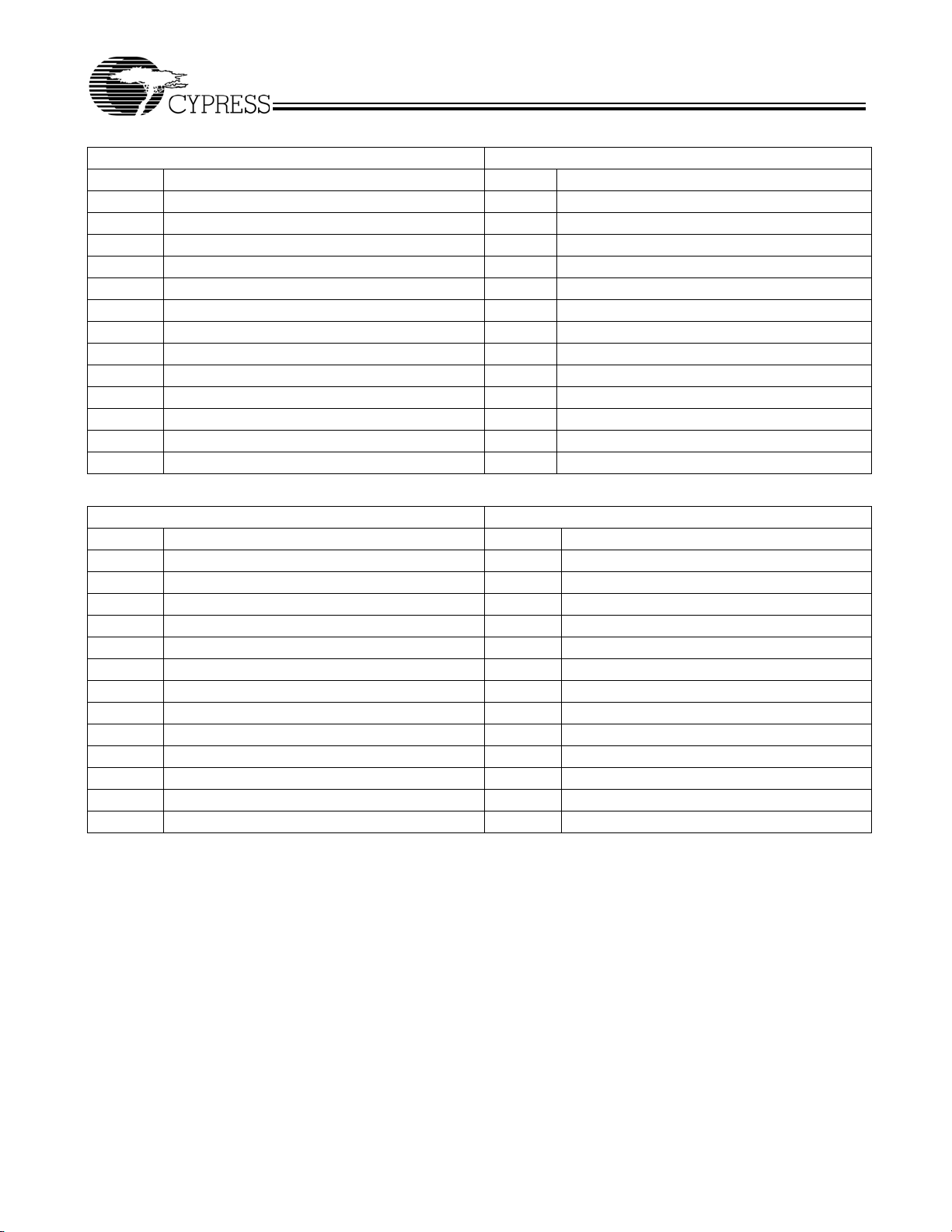

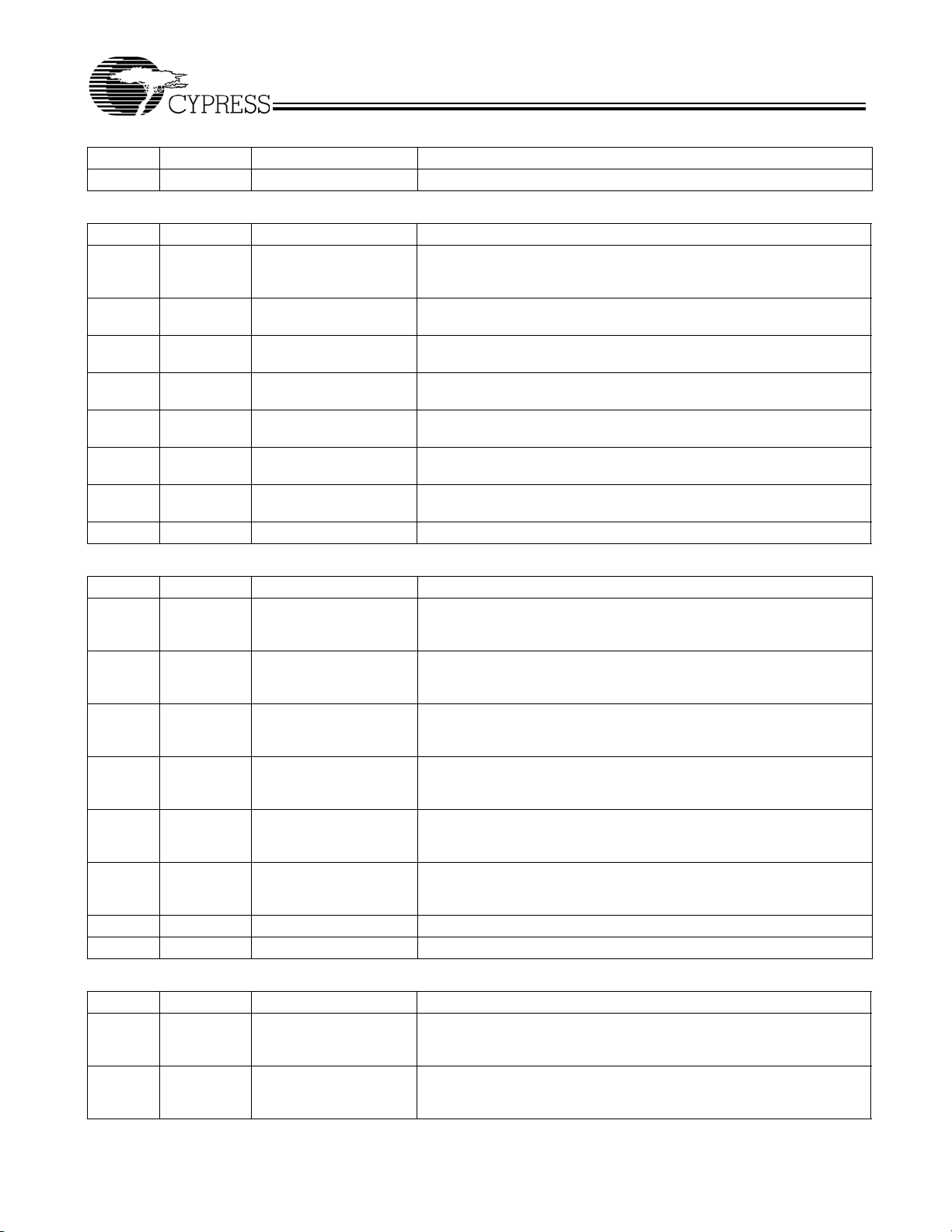

Control Registers

Byte 0:Control Register 0

Bit @Pup Name Description

7 1 SRC[T/C]5 SRC[T/C]5 Output Enable

0 = Disable (Hi-Z), 1 = Enable

6 1 SRC[T/C]4 SRC[T/C]4 Output Enable

0 = Disable (Hi-Z), 1 = Enable

5 1 SRC[T/C]3 SRC[T/C]3 Output Enable

0 = Disable (Hi-Z), 1 = Enable

4 1 SRC[T/C]2 SRC[T/C]2 Output Enable

0 = Disable (Hi-Z), 1 = Enable

3 1 SRC[T/C]1 SRC[T/C]1 Output Enable

0 = Disable (Hi-Z), 1 = Enable

2 1 SRC [T/C]0 SRC[T/C]0 Output Enable

0 = Disable (Hi-Z), 1 = Enable

1 1 SRCS[T/C]1 SRCS[T/C]1 Output Enable

0 = Disable (Hi-Z), 1 = Enable

0 1 SRCS[T/C]0 SRCS[T/C]0 Output Enable

0 = Disable (Hi-Z), 1 = Enable

Byte 1: Control Register 1

Bit @Pup Name Description

7 1 REF2 REF2 Output Enable

0 = Disable, 1 = Enable

6 1 REF1 REF1 Output Enable

0 = Disable, 1 = Enable

5 1 REF0 REF0 Output Enable

0 = Disable, 1 = Enable

4 1 PCI0 PCI0 Output Enable

0 = Disable, 1 = Enable

3 1 USB_48 USB_48MHz Output Enable

0 = Disable, 1 = Enable

2 1 CPU[T/C]2 CPU[T/C]2 Output Enable

0 = Disable (Hi-Z), 1 = Enable

1 1 CPU[T/C]1 CPU[T/C]1 Output Enable

0 = Disable (Hi-Z), 1 = Enable

0 1 CPU[T/C]0 CPU[T/C]0 Output Enable

0 = Disable (Hi-Z), 1 = Enable

CY28RS400

Byte 2: Control Register 2

Bit @Pup Name Description

7 1 CPUT/C

SRCT/C

6 1 USB_48 48MHz Output Drive Strength

5 1 PCI 33MHz Output Drive Strength

4 0 Reserved Reserved

3 1 Reserved Reserved

20 CPU

SRC

1 1 Reserved Reserved

Document #: 38-07637 Rev. *B Page 5 of 19

Spread Spectrum Selection

‘0’ = -0.35%

‘1’ = -0.50%

0 = 1x, 1 = 2x

0 = 1x, 1 = 2x

CPU/SRC Spread Spectrum Enable

0 = Spread off, 1 = Spread on

Byte 2: Control Register 2 (continued)

Bit @Pup Name Description

0 1 Reserved Reserved

Byte 3: Control Register 3

Bit @Pup Name Description

7 1 CLKREQ# CLKREQ# drive mode

0 = SRC clocks driven when stopped, 1 = SRC clocks tri-state when

stopped

6 0 CPU CPU pd drive mode

0 = CPU clocks driven when power down, 1 = CPU clocks tri-state

5 1 SRC SRC pd drive mode

0 = SRC clocks driven when power down, 1 = SRC clocks tri-state

4 0 CPU CPU_STOP# drive mode

0 = CPU clocks driven , 1 = CPU clocks tri-state

3 1 CPU2 Allow control of CPU2 with CPU_STOP#

0 = CPU2 is free running, 1 = CPU2 is stopped with CPU_STOP#

2 1 CPU1 Allow control of CPU1 with CPU_STOP#

0 = CPU1 is free running, 1 = CPU1 is stopped with CPU_STOP#

1 1 CPU0 Allow control of CPU0 with CPU_STOP#

0 = CPU0 is free running, 1 = CPU0 is stopped with CPU_STOP#

0 1 Reserved Reserved

CY28RS400

Byte 4: Control Register 4

Bit @Pup Name Description

7 0 SRC[T/C]5 SRC[T/C]5 CLKREQ0 control

1 = SRC[T/C]5 stoppable by CLKREQ#0 pin

0 = SRC[T/C]5 free running

6 0 SRC[T/C]4 SRC[T/C]4 CLKREQ#0 control

5 0 SRC[T/C]3 SRC[T/C]3 CLKREQ#0 control

4 0 SRC[T/C]2 SRC[T/C]2 CLKREQ#0 control

3 0 SRC[T/C]1 SRC[T/C]1 CLKREQ#0 control

2 0 SRC[T/C]0 SRC[T/C]0 CLKREQ#0 control

1 1 Reserved Reserved

0 1 Reserved Reserved

Byte 5: Control Register 5

Bit @Pup Name Description

7 0 SRC[T/C]5 SRC[T/C]5 CLKREQ#1 control

6 0 SRC[T/C]4 SRC[T/C]4 CLKREQ#1 control

1 = SRC[T/C]4 stoppable by CLKREQ#0 pin

0 = SRC[T/C]4 free running

1 = SRC[T/C]3 stoppable by CLKREQ#0 pin

0 = SRC[T/C]3 free running

1 = SRC[T/C]2 stoppable by CLKREQ#0 pin

0 = SRC[T/C]2 free running

1 = SRC[T/C]1 stoppable by CLKREQ#0 pin

0 = SRC[T/C]1 free running

1 = SRC[T/C]1 stoppable by CLKREQ#0 pin

0 = SRC[T/C]1 free running

1 = SRC[T/C]5 stoppable by CLKREQ#1 pin

0 = SRC[T/C]5 free running

1 = SRC[T/C]4 stoppable by CLKREQ#1 pin

0 = SRC[T/C]4 free running

Document #: 38-07637 Rev. *B Page 6 of 19

CY28RS400

Byte 5: Control Register 5 (continued)

Bit @Pup Name Description

5 0 SRC[T/C]3 SRC[T/C]3 CLKREQ#1 control

4 0 SRC[T/C]2 SRC[T/C]2 CLKREQ#1 control

3 0 SRC[T/C]1 SRC[T/C]1 CLKREQ#1 control

2 0 SRC[T/C]0 SRC[T/C]0 CLKREQ#1 control

1 0 Reserved Reserved

0 0 Reserved Reserved

Byte 6: Control Register 6

Bit @Pup Name Description

7 0 TEST_SEL REF/N or Tri-state Select

6 0 TEST_MODE Test Clock Mode Entry Control

5 0 REF REF output drive strength.

4 0 Reserved Reserved

3 HW 409_410 409_410 reflects the value of the 409_410 pin sampled on power up. 0 =

2 HW FS_C FS_C Reflects the value of the FS_C pin sampled on power up. 0 = FS_C

1 HW FS_B FS_B Reflects the value of the FS_B pin sampled on power up. 0 = FS_B

0 HW FS_A FS_A Reflects the value of the FS_A pin sampled on power up. 0 = FS_A

1 = SRC[T/C]3 stoppable by CLKREQ#1 pin

0 = SRC[T/C]3 free running

1 = SRC[T/C]2 stoppable by CLKREQ#1 pin

0 = SRC[T/C]2 free running

1 = SRC[T/C]1 stoppable by CLKREQ#1 pin

0 = SRC[T/C]1 free running

1 = SRC[T/C]1 stoppable by CLKREQ#1 pin

0 = SRC[T/C]1 free running

1 = REF/N Clock, 0 = Tri-state

1 = REF/N or Tri-state mode, 0 = Normal operation

0 = Low drive, 1 = High drive.

409_410 was low during VTT_PWRGD# assertion

was low during VTT_PWRGD# assertion.

was low during VTT_PWRGD# assertion.

was low during VTT_PWRGD# assertion.

Byte 7: Vendor ID

Bit @Pup Name Description

7 0 Revision Code Bit 3

6 0 Revision Code Bit 2

5 0 Revision Code Bit 1

4 1 Revision Code Bit 0

3 1 Vendor ID Bit 3

2 0 Vendor ID Bit 2

1 0 Vendor ID Bit 1

0 0 Vendor ID Bit 0

Document #: 38-07637 Rev. *B Page 7 of 19

CY28RS400

Crystal Recommendations

The CY28RS400 requires a Parallel Resonance Crystal.

Substituting a series resonance crystal will cause the

CY28RS400 to operate at the wrong frequency and violate the

ppm specification. For most applications there is a 300-ppm

frequency shift between series and parallel crystals due to

incorrect loading.

Table 6. Crystal Recommendations

Frequency

(Fund)

Cut Loading Load Cap

14.31818 MHz AT Parallel 20 pF 0.1 mW 5 pF 0.016 pF 35 ppm 30 ppm 5 ppm

Drive

(max.)

Shunt Cap

(max.)

Motional

(max.)

Tolerance

(max.)

Stability

(max.)

Aging

(max.)

Crystal Loading

Crystal loading plays a critical role in achieving low ppm performance. To realize low ppm performance, the total capacitance

the crystal will see must be considered to calculate the appropriate capacitive loading (CL).

Figure 1. Crystal Capacitive Clarification

Calculating Load Capacitors

In addition to the standard external trim capacitors, trace

capacitance and pin capacitance must also be considered to

correctly calculate crystal loading. As mentioned previously,

the capacitance on each side of the crystal is in series with the

Clock Chip

The following diagram shows a typical crystal configuration

using the two trim capacitors. An important clarification for the

following discussion is that the trim capacitors are in series

with the crystal not parallel. It’s a common misconception that

load capacitors are in parallel with the crystal and should be

approximately equal to the load capacitance of the crystal.

This is not true.

crystal. This means the total capacitance on each side of the

crystal must be twice the specified crystal load capacitance

(CL). While the capacitance on each side of the crystal is in

series with the crystal, trim capacitors (Ce1,Ce2) should be

calculated to provide equal capacitive loading on both sides.

XTAL

Ci2

X2

Ce2

Pin

3 to 6p

Cs2

Trace

2.8pF

Trim

33pF

Cs1

Ci1

X1

Ce1

Figure 2. Crystal Loading Example

Document #: 38-07637 Rev. *B Page 8 of 19

CY28RS400

As mentioned previously, the capacitance on each side of the

crystal is in series with the crystal. This mean the total capacitance on each side of the crystal must be twice the specified

load capacitance (CL). While the capacitance on each side of

the crystal is in series with the crystal, trim capacitors

(Ce1,Ce2) should be calculated to provide equal capacitance

loading on both sides.

Use the following formulas to calculate the trim capacitor

values for Ce1 and Ce2.

Load Capacitance (each side)

Ce = 2 * CL – (Cs + Ci)

Total Capacitance (as seen by the crystal)

CLe

=

()

1

Ce1 + Cs1 + Ci1

1

+

1

Ce2 + Cs2 + Ci2

CL ...................................................Crystal load capacitance

CLe .........................................Actual loading seen by crystal

using standard value trim capacitors

Ce .....................................................External trim capacitors

Cs.............................................. Stray capacitance (terraced)

Ci ...........................................................Internal capacitance

(lead frame, bond wires etc.)

CL ...................................................Crystal load capacitance

CLe .........................................Actual loading seen by crystal

using standard value trim capacitors

Ce .....................................................External trim capacitors

Cs.............................................. Stray capacitance (terraced)

Ci ...........................................................Internal capacitance

(lead frame, bond wires etc.)

PD

CPUT, 133MHz

PD (Power-down) Clarification

The VTT_PWRGD# /PD pin is a dual function pin. During initial

power up, the pin functions as VTT_PWRGD#. Once

VTT_PWRGD# has been sampled low by the clock chip, the

pin assumes PD functionality. The PD pin is an asynchronous

active high input used to shut off all clocks cleanly prior to

shutting off power to the device. This signal is synchronized

internal to the device prior to powering down the clock synthesizer. PD is also an asynchronous input for powering up the

system. When PD is asserted high, all clocks need to be driven

to a low value and held prior to turning off the VCOs and the

crystal oscillator.

PD (Power-down) – Assertion

When PD is sampled high by two consecutive rising edges of

CPUC, all single-ended outputs will be held low on their next

high to low transition and differential clocks must held high or

Hi-Zd (depending on the state of the control register drive

mode bit) on the next diff clock# high to low transition within

four clock periods. When the SMBus PD drive mode bit corresponding to the differential (CPU, SRC, and DOT) clock output

of interest is programmed to ‘0’, the clock output are held with

“Diff clock” pin driven high at 2 x Iref, and “Diff clock#” tristate.

If the control register PD drive mode bit corresponding to the

output of interest is programmed to “1”, then both the “Diff

clock” and the “Diff clock#” are three-state. Note the example

below shows CPUT = 133 MHz and PD drive mode = ‘1’ for all

differential outputs. This diagram and description is applicable

to valid CPU frequencies 100,133,200 and 266MHz. In the

event that PD mode is desired as the initial power-on state, PD

must be asserted high in less than 10 uS after asserting

Vtt_PwrGd#.

PD Deassertion

The power-up latency is less than 1.8 ms. This is the time from

the deassertion of the PD pin or the ramping of the power

supply until the time that stable clocks are output from the

clock chip. All differential outputs stopped in a three-state

condition resulting from power down will be driven high in less

than 300 µs of PD deassertion to a voltage greater than 200

mV. After the clock chip’s internal PLL is powered up and

locked, all outputs will be enabled within a few clock cycles of

each other. Below is an example showing the relationship of

clocks coming up.

CPUC, 133MHz

SRCT 100MHz

SRCC 100MHz

USB, 48MHz

DOT96T

DOT96C

PCI, 33 MH z

REF

Figure 3. Power-down Assertion Timing Waveform

Document #: 38-07637 Rev. *B Page 9 of 19

Tsta ble

PD

CPUT, 133MHz

CPUC, 133MHz

SRCT 100MHz

SRCC 100MHz

USB, 48MHz

DOT96T

DOT96C

PCI, 33MHz

REF

<1.8nS

Tdrive_PWRDN#

<300µS, >200mV

Figure 4. Power-down Deassertion Timing Waveform

CPU_STP# Assertion

The CPU_STP# signal is an active low input used for

synchronous stopping and starting the CPU output clocks

while the rest of the clock generator continues to function.

When the CPU_STP# pin is asserted, all CPU outputs that are

set with the SMBus configuration to be stoppable via assertion

of CPU_STP# will be stopped within two–six CPU clock

periods after being sampled by two rising edges of the internal

CPUC clock. The final states of the stopped CPU signals are

CY28RS400

CPUT = HIGH and CPUC = LOW. There is no change to the

output drive current values during the stopped state. The

CPUT is driven HIGH with a current value equal to 6 x (Iref),

and the CPUC signal will be Hi-Z. When the control register

CPU_STP Hi-Z bit corresponding to the output of interest is

programmed to ‘1’, the final state of the stopped CPU clock is

low (due to external 50 ohm pull-down resistor), both CPUT

clock and CPUC clock outputs will not be driven.

CPU_STP#

CPUT

CPUC

Figure 5. CPU_STP# Assertion Waveform

CPU_STP# Deassertion

The deassertion of the CPU_STP# signal will cause all CPU

outputs that were stopped to resume normal operation in a

synchronous manner. Synchronous manner meaning that no

short or stretched clock pulses will be produce when the clock

resumes. The maximum latency from the deassertion to active

outputs is 2 - 6 CPU clock cycles.

CPU_STP#

CPUT

CPUC

CPUT Internal

CPUC Internal

Tdrive_CPU_STP#,10nS>200mV

Figure 6. CPU_STP# Deassertion Waveform

Document #: 38-07637 Rev. *B Page 10 of 19

CPU_STOP#

CPUT(Free Runni ng

CPUC(Free Running

CPUT(Stoppable)

CPUC(Stoppable)

CY28RS400

1.8mS

PD

CPU_STOP#

PD

CPUT(Free Running)

CPUC(Free Running)

CPUT(Stoppable)

CPUC(Stoppable)

Figure 7. CPU_STP#= Driven, CPU_PD = Driven

Figure 8. CPU_STP# = Hi-Z, CPU_PD = Hi-Z

CLK_REQ[0:1]# Description

The CLKREQ#[1:0] signals are active low input used for clean

stopping and starting selected SRC outputs. The outputs

controlled by CLKREQ#[1:0] are determined by the settings in

register bytes 4 and 5. The CLKREQ# signal is a de-bounced

signal in that it’s state must remain unchanged during two

consecutive rising edges of DIFC to be recognized as a valid

assertion or de-assertion. (The assertion and de-assertion of

this signal is absolutely asynchronous).

CLK_REQ[0:1]# De-assertion [Low to High transition]

The impact of deasserting the CLKREQ#[1:0] pins is all DIF

outputs that are set in the control registers to stoppable via

de-assertion of CLKREQ#[1:0] are to be stopped after their

next transition. When the control register CLKREQ# drive

mode bit is programmed to ‘0’, the final state of all stopped

1.8mS

SRC signals is SRCT clock = High and SRCC = Low. There is

to be no change to the output drive current values, SRCT will

be driven high with a current value equal 6 x Iref,. When the

control register CLKREQ# drive mode bit is programmed to

‘1’, the final state of all stopped DIF signals is low, both SRCT

clock and SRCC clock outputs will not be driven.

CLK_REQ[0:1]# Assertion [High to Low transition]

All differential outputs that were stopped are to resume normal

operation in a glitch free manner. The maximum latency from

the assertion to active outputs is between two–six SRC clock

periods (two clocks are shown) with all SRC outputs resuming

simultaneously. If the CLKREQ# drive mode bit is

programmed to ‘1’ (three-state), the all stopped SRC outputs

must be driven high within 10 ns of CLKREQ#[1:0] assertion

to a voltage greater than 200 mV.

CLKREQ#X

SRCT(free running)

SRCC(free running)

SRCT(stoppable)

SRCT(stoppable)

Figure 9. CLK_REQ#[0:1] Assertion/Deassertion Waveform

Document #: 38-07637 Rev. *B Page 11 of 19

CY28RS400

FS_A, FS_B,FS_C

VTT_PWRGD#

PWRGD_VRM

VDD Clock Gen

Clock State

Clock Outputs

Clock VCO

VDD_A = 2.0V

Power Off

S0

State 0

Off

Off

0.2-0.3mS

Delay

State 1

Wait for

VTT_PWRGD#

On

Sample Sels

State 2 State 3

Figure 10. VTT_PWRGD# Timing Diagram

S1

Delay

VTT_PWRGD# = Low

>0.25mS

S3

VDD_A = off

Normal

Operation

VTT_PWRGD# = toggle

Device is not affected,

VTT_PWRGD# is ignored

On

S2

Sample

Inputs straps

Wait for <1.8m s

Enable Outputs

Figure 11. Clock Generator Power-up/Run State Diagram

Document #: 38-07637 Rev. *B Page 12 of 19

CY28RS400

Absolute Maximum Conditions

Parameter Description Condition Min. Max. Unit

V

DD Core Supply Voltage –0.5 4.6 V

VDDA Analog Supply Voltage –0.5 4.6 V

V

IN Input Voltage Relative to VSS –0.5 VDD+0.5 VDC

TS Temperature, Storage Non Functional –65 +150 °C

T

A Temperature, Operating Ambient Functional 0 70 °C

T

J Temperature, Junction Functional – 150 °C

ESDHBM ESD Protection (Human Body Model) MIL-STD-883, Method 3015 2000 – V

Ø

JC Dissipation, Junction to Case Mil-Spec 883E Method 1012.1 – 20 °C/W

Ø

JA Dissipation, Junction to Ambient JEDEC (JESD 51) – 60 °C/W

UL-94 Flammability Rating At 1/8 in. V–0

MSL Moisture Sensitivity Level 1

Multiple Supplies: The voltage on any input or I/O pin cannot exceed the power pin during power-up. Power supply sequencing is NOT required.

DC Electrical Specifications

Parameter Description Condition Min. Max. Unit

VDD_REF,

VDD_CPU,

VDD_PCI,

VDD_SRC,

VDD_48,

V

IL_FS

V

IH_FS

VILSMBUS Input Low Voltage SDATA, SCLK – 1.0 V

V

IHSMBUS Input High Voltage SDATA, SCLK 2.2 – V

V

VIH Input High Voltage 2.0 VDD + 0.3 V

I

IL Input Leakage Current except Pull-ups or Pull downs 0<VIN<VDD –5 5 mA

V

OL Output Low Voltage IOL = 1 mA – 0.4 V

VOH Output High Voltage IOH = 1 mA 2.4 - V

I

OZ High-Impedance Output Current –10 10 uA

C

C

OUT Output Pin Capacitance 3 5 pF

L

IN Pin Inductance –7nH

V

XIH Xin High Voltage 0.7*VDD VDD V

V

XIL Xin Low Voltage 00.3*VDD V

IDD Dynamic Supply Current At max load and frequency – 450 mA

IPD

IPD

AC Electrical Specifications

Parameter Description Condition Min. Max. Unit

Crystal

T

DC

3.3V Operating Voltage 3.3V ± 5% 3.135 3.465 V

FS_A,FS_B and FS_C Input Low Voltage VSS – 0.3 0.35 V

FS_A,FS_B and FS_C Input Low Voltage 0.7 V

IL Input Low Voltage VDD V

IN Input Pin Capacitance 3 5 pF

Power Down Supply Current PD asserted, Outputs driven – 75 mA

D

Power Down Supply Current PD asserted, Outputs Hi-Z – 2 mA

T

– 0.3 0.8 V

SS

+ 0.5 V

DD

XIN Duty Cycle The device will operate reliably with

input duty cycles up to 30/70 but the

REF clock duty cycle will not be

47.5 52.5 %

within specification

Document #: 38-07637 Rev. *B Page 13 of 19

CY28RS400

AC Electrical Specifications (continued)

Parameter Description Condition Min. Max. Unit

T

PERIOD

T

/ T

R

F

T

CCJ

L

ACC

CPU at 0.7V

T

DC

T

PERIOD

T

PERIOD

T

PERIOD

T

PERIOD

T

PERIODSS

T

PERIODSS

T

PERIODSS

T

PERIODSS

T

PERIODAbs

T

PERIODAbs

T

PERIODAbs

T

PERIODAbs

T

PERI-

ODSSAbs

T

PERI-

ODSSAbs

T

PERI-

ODSSAbs

T

PERI-

ODSSAbs

T

CCJ

T

/ T

R

F

T

RFM

∆T

R

∆T

F

T

SKEW Any CPU to CPU Clock Skew Measured at crossing point Vox – 100 ps

V

HIGH

V

LOW

V

OX

V

OVS

V

UDS

V

RB

SRC

T

DC

T

PERIOD

XIN Period When XIN is driven from an external

clock source

XIN Rise and Fall Times Measured between 0.3VDD and

0.7V

DD

69.841 71.0 ns

– 10.0 ns

XIN Cycle to Cycle Jitter As an average over 1-µs duration – 500 ps

Long-term Accuracy Over 150 ms – 300 ppm

CPUT and CPUC Duty Cycle Measured at crossing point V

100-MHz CPUT and CPUC Period Measured at crossing point V

133-MHz CPUT and CPUC Period Measured at crossing point V

200-MHz CPUT and CPUC Period Measured at crossing point V

266-MHz CPUT and CPUC Period Measured at crossing point V

100-MHz CPUT and CPUC Period, SSC Measured at crossing point V

133-MHz CPUT and CPUC Period, SSC Measured at crossing point V

200-MHz CPUT and CPUC Period, SSC Measured at crossing point V

266-MHz CPUT and CPUC Period, SSC Measured at crossing point V

100-MHz CPUT and CPUC Absolute period Measured at crossing point V

133-MHz CPUT and CPUC Absolute period Measured at crossing point V

200-MHz CPUT and CPUC Absolute period Measured at crossing point V

266-MHz CPUT and CPUC Absolute period Measured at crossing point V

100-MHz CPUT and CPUC Absolute period,

Measured at crossing point V

SSC

133-MHz CPUT and CPUC Absolute period,

Measured at crossing point V

SSC

200-MHz CPUT and CPUC Absolute period,

Measured at crossing point V

SSC

266-MHz CPUT and CPUC Absolute period,

Measured at crossing point V

SSC

CPUT/C Cycle to Cycle Jitter Measured at crossing point V

CPUT and CPUC Rise and Fall Times Measured from VOL = 0.175 to

V

= 0.525V

OH

Rise/Fall Matching Determined as a fraction of

2*(T

– TF)/(TR + TF)

R

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

OX

45 55 %

9.997001 10.00300 ns

7.497751 7.502251 ns

4.998500 5.001500 ns

3.748875 3.751125 ns

9.997001 10.05327 ns

7.497751 7.539950 ns

4.998500 5.026634 ns

3.748875 3.769975 ns

9.912001 10.08800 ns

7.412751 7.587251 ns

4.913500 5.086500 ns

3.663875 3.836125 ns

9.912001 10.13827 ns

7.412751 7.624950 ns

4.913500 5.111634 ns

3.663875 3.854975 ns

–95ps

175 700 ps

–20%

Rise Time Variation – 250 ps

Fall Time Variation – 250 ps

Voltage High Math averages Figure 13 660 850 mv

Voltage Low Math averages Figure 13 –150 – mv

Crossing Point Voltage at 0.7V Swing 250 550 mv

Maximum Overshoot Voltage

–

V

HIGH

0.3

+

Minimum Undershoot Voltage –0.3 – V

Ring Back Voltage See Figure 13. Measure SE – 0.2 V

SRCT and SRCC Duty Cycle Measured at crossing point V

100-MHz SRCT and SRCC Period Measured at crossing point V

OX

OX

45 55 %

9.997001 10.00300 ns

V

Document #: 38-07637 Rev. *B Page 14 of 19

CY28RS400

AC Electrical Specifications (continued)

Parameter Description Condition Min. Max. Unit

T

PERIODSS

T

PERIODAbs

T

PERI-

ODSSAbs

T

SKEW

T

SKEW Any SRCS clock to Any SRCS clock Skew Measured at crossing point Vox - 250 ps

T

CCJ

L

ACC

T

/ T

R

F

T

RFM

∆T

R

∆T

F

V

HIGH

V

LOW

V

OX

V

OVS

V

UDS

V

RB

PCI

T

DC

T

PERIOD

T

PERIODSS

T

PERIODAbs

T

PERI-

ODSSAbs

T

HIGH

T

LOW

T

/ T

R

F

T

CCJ

USB

T

DC

T

PERIOD

T

PERIODAbs

T

HIGH

T

LOW

T

/ T

R

F

T

CCJ

REF

T

DC

T

PERIOD

T

PERIODAbs

100-MHz SRCT and SRCC Period, SSC Measured at crossing point V

100-MHz SRCT and SRCC Absolute Period Measured at crossing point V

100-MHz SRCT and SRCC Absolute Period, SSC Measured at crossing point V

Any SRCT/C to SRCT/C Clock Skew Measured at crossing point V

SRCT/C Cycle to Cycle Jitter Measured at crossing point V

SRCT/C Long Term Accuracy Measured at crossing point V

SRCT and SRCC Rise and Fall Times Measured from VOL = 0.175 to

V

= 0.525V

OH

Rise/Fall Matching Determined as a fraction of

2*(T

– TF)/(TR + TF)

R

OX

OX

OX

OX

OX

OX

9.997001 10.05327 ns

10.12800 9.872001 ns

9.872001 10.17827 ns

– 250 ps

– 125 ps

– 300 ppm

175 700 ps

–20%

Rise TimeVariation – 125 ps

Fall Time Variation – 125 ps

Voltage High Math averages Figure 13 660 850 mv

Voltage Low Math averages Figure 13 –150 – mv

Crossing Point Voltage at 0.7V Swing 250 550 mV

Maximum Overshoot Voltage

–

V

HIGH

0.3

+

Minimum Undershoot Voltage –0.3 – V

Ring Back Voltage See Figure 13. Measure SE – 0.2 V

PCI Duty Cycle Measurement at 1.5V 45 55 %

Spread Disabled PCI Period Measurement at 1.5V 29.99100 30.00900 ns

Spread Enabled PCI Period, SSC Measurement at 1.5V 29.9910 30.15980 ns

Spread Disabled PCI Period Measurement at 1.5V 29.49100 30.50900 ns

Spread Enabled PCI Period, SSC Measurement at 1.5V

29.49100 30.65980 ns

PCI high time Measurement at 2.4V 12.0 – ns

PCI low time Measurement at 0.4V 12.0 – ns

PCI rise and fall times Measured between 0.8V and 2.0V

1.0 4.0

PCI Cycle to Cycle Jitter Measurement at 1.5V – 500 ps

Duty Cycle Measurement at 1.5V 45 55 %

Period Measurement at 1.5V 20.83125 20.83542 ns

Absolute Period Measurement at 1.5V 20.48125 21.18542 ns

USB high time Measurement at 2.4V 8.094 10.036 ns

USB low time Measurement at 0.4V 7.694 9.836 ns

Rise and Fall Times Measured between 0.8V and 2.0V

1.0 2.0

Cycle to Cycle Jitter Measurement at 1.5V – 350 ps

REF Duty Cycle Measurement at 1.5V 45 55 %

REF Period Measurement at 1.5V 69.8203 69.8622 ns

REF Absolute Period Measurement at 1.5V 68.82033 70.86224 ns

V

V/n

s

V/n

s

Document #: 38-07637 Rev. *B Page 15 of 19

CY28RS400

AC Electrical Specifications (continued)

Parameter Description Condition Min. Max. Unit

T

/ T

R

F

T

CCJ

ENABLE/DISABLE and SET-UP

T

STABLE

T

SS

T

SH

Test and Measurement Set-up

For PCI Single-ended Signals and Reference

The following diagram shows the test load configurations for

the single-ended PCI, USB, and REF output signals.

REF Rise and Fall Times Measured between 0.8V and 2.0V

0.5 4.0

REF Cycle to Cycle Jitter Measurement at 1.5V – 1000 ps

Clock Stabilization from Power-up – 1.8 ms

Stopclock Set-up Time 10.0 – ns

Stopclock Hold Time 0 – ns

Measurement

Point

5pF

Measurement

Point

5pF

PCI/

USB

12Ω

12Ω

60Ω

60Ω

V/n

s

12Ω

12Ω

REF

12Ω

Figure 12. Single-ended Load Configuration

For Differential CPU and SRC Output Signals

The following diagram shows the test load configuration for the

differential CPU and SRC outputs.

CPUT

SRCT

CPUC

SRCC

IR E F

475Ω

33Ω

33Ω

100 Ω

49.9Ω

100 Ω

49.9Ω

60Ω

60Ω

60Ω

Measurement

Point

5pF

Measurement

Point

5pF

Measurement

Point

5pF

Measurement

Point

2pF

Measurement

Point

2pF

Figure 13. 0.7V Load Configuration

Document #: 38-07637 Rev. *B Page 16 of 19

g

CY28RS400

2.4V

1.5V

0.4V

3.3V si

-

3.3V

T

R

T

DC

nals

T

F

-

0V

Figure 14. Single-ended Output Signals (for AC Parameters Measurement)

Ordering Information

Part Number Package Type Product Flow

Standard

CY28RS400OC 56-pin SSOP Commercial, 0° to 70°C

CY28RS400OCT 56-pin SSOP – Tape and Reel Commercial, 0

CY28RS400ZC 56-pin TSSOP Commercial, 0

CY28RS400ZCT 56-pin TSSOP – Tape and Reel Commercial, 0

Lead-free

CY28RS400OXC 56-pin SSOP Commercial, 0° to 70°C

CY28RS400OXCT 56-pin SSOP – Tape and Reel Commercial, 0

CY28RS400ZXC 56-pin TSSOP Commercial, 0

CY28RS400ZXCT 56-pin TSSOP – Tape and Reel Commercial, 0

° to 70°C

° to 70°C

° to 70°C

° to 70°C

° to 70°C

° to 70°C

Package Diagrams

28

29

0.088

0.092

0.025

BSC

56-Lead Shrunk Small Outline Package O56

.020

1

0.395

0.420

0.292

0.299

56

0.720

0.730

0.008

0.0135

0.008

0.016

0.095

0.110

SEATING PLANE

0.110

GAUGE PLANE

DIMENSIONS IN INCHES MIN.

.010

0°-8°

0.024

0.040

MAX.

0.005

0.010

51-85062-*C

Document #: 38-07637 Rev. *B Page 17 of 19

Package Diagrams (continued)

56-Lead Thin Shrunk Small Outline Package, Type II (6 mm x 12 mm) Z56

0.249[0.009]

28

29 56

1

5.994[0.236]

6.198[0.244]

7.950[0.313]

8.255[0.325]

CY28RS400

DIMENSIONS IN MM[INCHES] MIN.

MAX.

REFERENCE JEDEC MO-153

PACKAGE WEIGHT 0.42gms

PART #

Z5624 STANDARD PKG.

ZZ5624 LEAD FREE PKG.

13.894[0.547]

14.097[0.555]

0.851[0.033]

0.950[0.037]

Purchase of I2C components from Cypress or one of its sublicensed Associated Companies conveys a license under the Philips

2

C Patent Rights to use these components in an I2C system, provided that the system conforms to the I2C Standard Specification

I

0.500[0.020]

BSC

0.170[0.006]

0.279[0.011]

0.051[0.002]

0.152[0.006]

1.100[0.043]

MAX.

0.20[0.008]

SEATING

PLANE

GAUGE PLANE

0.25[0.010]

0°-8°

0.508[0.020]

0.762[0.030]

0.100[0.003]

0.200[0.008]

51-85060-*C

as defined by Philips. ATI is a registered trademark of ATI Technologies Inc. HyperTransport is a trademark of the HyperTransport

Technology Consortium. Intel and Pentium are registered trademarks of Intel Corporation. AMD is a registered trademark of

Advanced Micro Devices, Inc. All product and company names mentioned in this document are trademarks of their respective

holder.

Document #: 38-07637 Rev. *B Page 18 of 19

© Cypress Semiconductor Corporation, 2004. The information contained herein is subject to change without notice. Cypress Semiconductor Corporation assumes no responsibility for the use

of any circuitry other than circuitry embodied in a Cypress product. Nor does it convey or imply any license under patent or other rights. Cypress products are not warranted nor intended to be

used for medical, life support, life saving, critical control or safety applications, unless pursuant to an express written agreement with Cypress. Furthermore, Cypress does not authorize its

products for use as critical components in life-support systems where a malfunction or failure may reasonably be expected to result in significant injury to the user. The inclusion of Cypress

products in life-support systems application implies that the manufacturer assumes all risk of such use and in doing so indemnifies Cypress against all charges.

Document History Page

Document Title: CY28RS400 Clock Generator for ATI RS400 Chipset

Document Number: 38-07637

REV. ECN NO. Issue Date

** 204582 See ECN RGL New data sheet

*A 215824 See ECN RGL Minor Change: To post on the external web

*B 278494 See ECN RGL Changed pins 10 and 11 from internal Pull up to Pull down .

Orig. of

Change Description of Change

Changed polarity of CLKREQ#

Added register byte 3 bits [1:3] for CPU Stop control.

Removed all 166, 333 and 400-MHz references

Changed the USB Rise/Fall times from 1.0 to 0.5V/ns

CY28RS400

Document #: 38-07637 Rev. *B Page 19 of 19

Loading...

Loading...