Page 1

PRELIMINARY

CY14B104K, CY14B104M

4 Mbit (512K x 8/256K x 16) nvSRAM with

Real Time Clock

Features

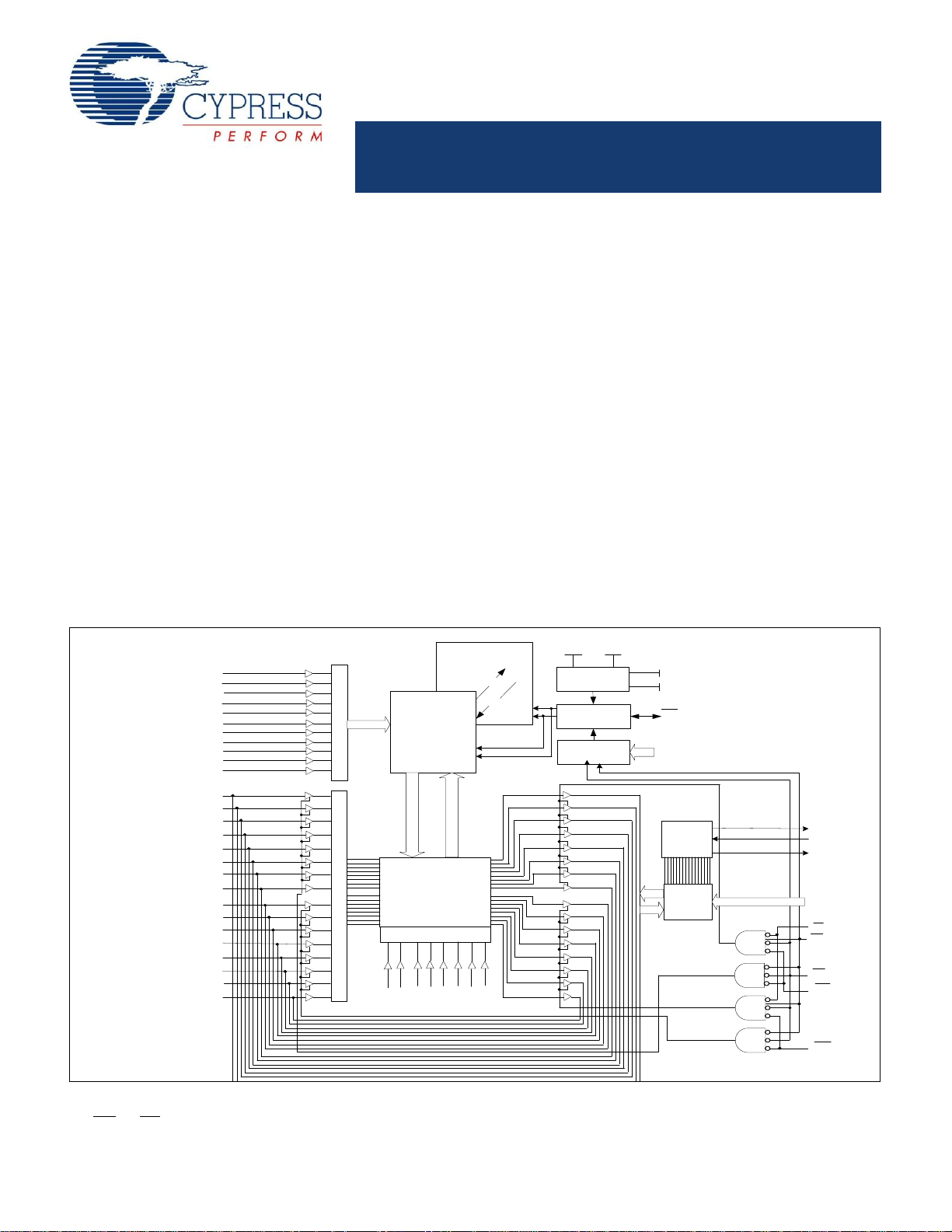

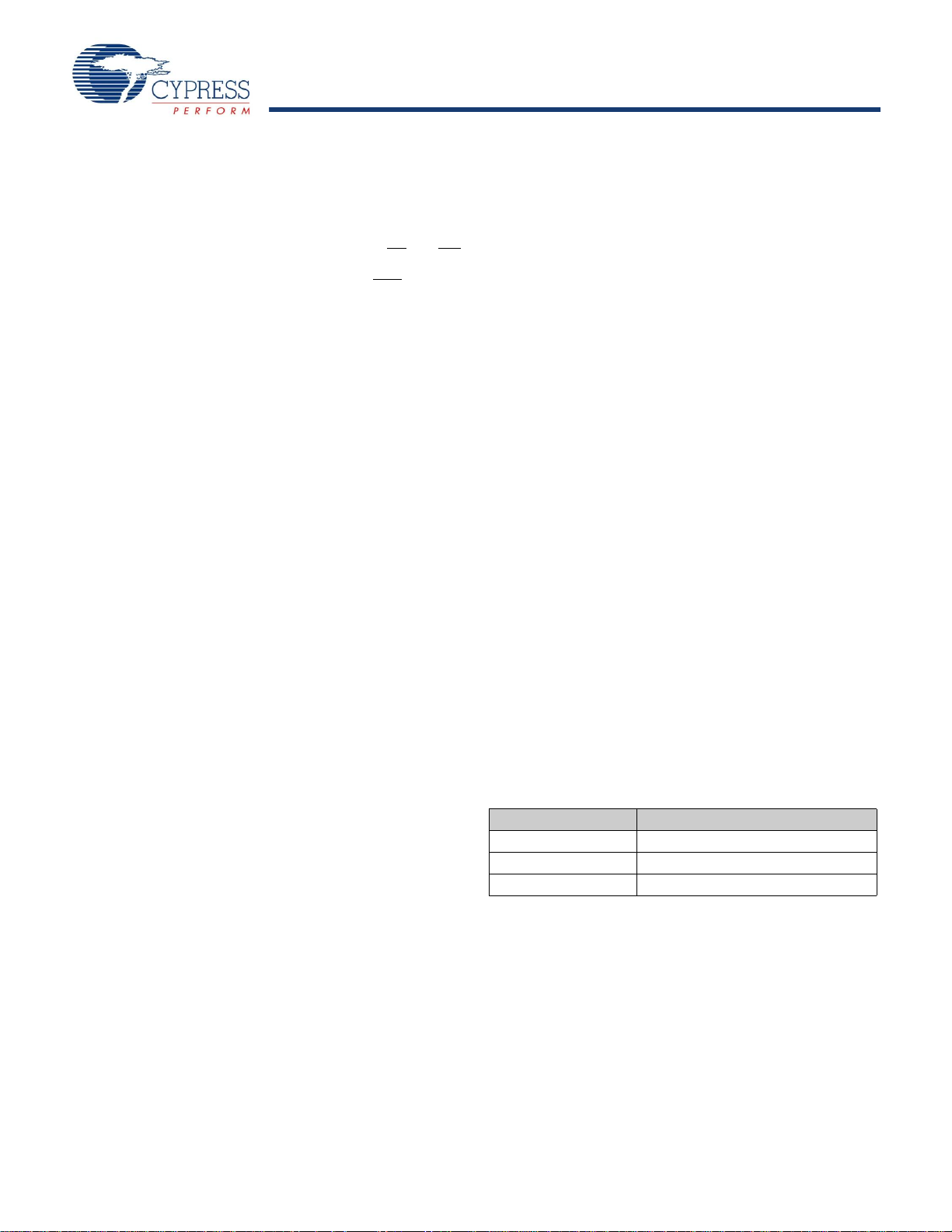

STATIC RAM

ARRAY

2048 X 2048

R

O

W

D

E

C

O

D

E

R

COLUMN I/O

COLUMN DEC

I

N

P

U

T

B

U

F

F

E

R

S

POWER

CONTROL

STORE/RECALL

CONTROL

Quatrum

Trap

2048 X 2048

STORE

RECALL

V

CC

V

CA

P

HSB

A9A

10

A

11

A12A13A14A15A

16

SOFTWARE

DETECT

A14-A

2

OE

CE

WE

BHE

BLE

A

0

A

1

A

2

A

3

A

4

A

5

A

6

A

7

A

8

A

17

A

18

DQ

0

DQ

1

DQ

2

DQ

3

DQ

4

DQ

5

DQ

6

DQ

7

DQ

8

DQ

9

DQ

10

DQ

11

DQ

12

DQ

13

DQ

14

DQ

15

RTC

MUX A18-A

0

X

1

X

2

INT

V

RTCbat

V

RTCcap

Logic Block Diagram

[1, 2, 3]

■ 20 ns, 25 ns, and 45 ns access times

■ Internally organized as 512K x 8 (CY14B104K) or 256K x 16

(CY14B104M)

■ Hands off automatic STORE on power down with only a small

capacitor

■ STORE to QuantumTrap

software, device pin, or AutoStore

■ RECALL to SRAM initiated by software or power up

■ High reliability

■ Infinite Read, Write, and RECALL cycles

■ 200,000 STORE cycles to QuantumTrap

■ 20 year data retention

■ Single 3V +20%, –10% operation

■ Data integrity of Cypress nvSRAM combined with full featured

Real Time Clock

®

nonvolatile elements is initiated by

®

on power down

■ Watchdog timer

■ Clock alarm with programmable interrupts

■ Capacitor or battery backup for RTC

■ Commercial and industrial temperatures

■ 44 and 54-pin TSOP II package

■ Pb-free and RoHS compliance

Functional Description

The Cypress CY14B104K/CY14B104M combines a 4-Mbit

nonvolatile static RAM with a full featured Real Time Clock in a

monolithic integrated circuit. The embedded nonvolatile

elements incorporate QuantumTrap technology producing the

world’s most reliable nonvolatile memory. The SRAM is read and

written infinite number of times, while independent nonvolatile

data resides in the nonvolatile elements.

The Real Time Clock function provides an accurate clock with

leap year tracking and a programmable, high accuracy oscillator.

The alarm function is programmable for periodic minutes, hours,

days or months alarms. There is also a programmable watchdog

timer for process control.

Notes

1. Address A

2. Data DQ

3. BHE

Cypress Semiconductor Corporation • 198 Champion Court • San Jose, CA 95134-1709 • 408-943-2600

Document #: 001-07103 Rev. *K Revised January 29, 2009

- A18 for x8 configuration and Address A0 - A17 for x16 configuration.

0

- DQ7 for x8 configuration and Data DQ0 - DQ15 for x16 configuration.

0

and BLE are applicable for x16 configuration only.

[+] Feedback

Page 2

PRELIMINARY

CY14B104K, CY14B104M

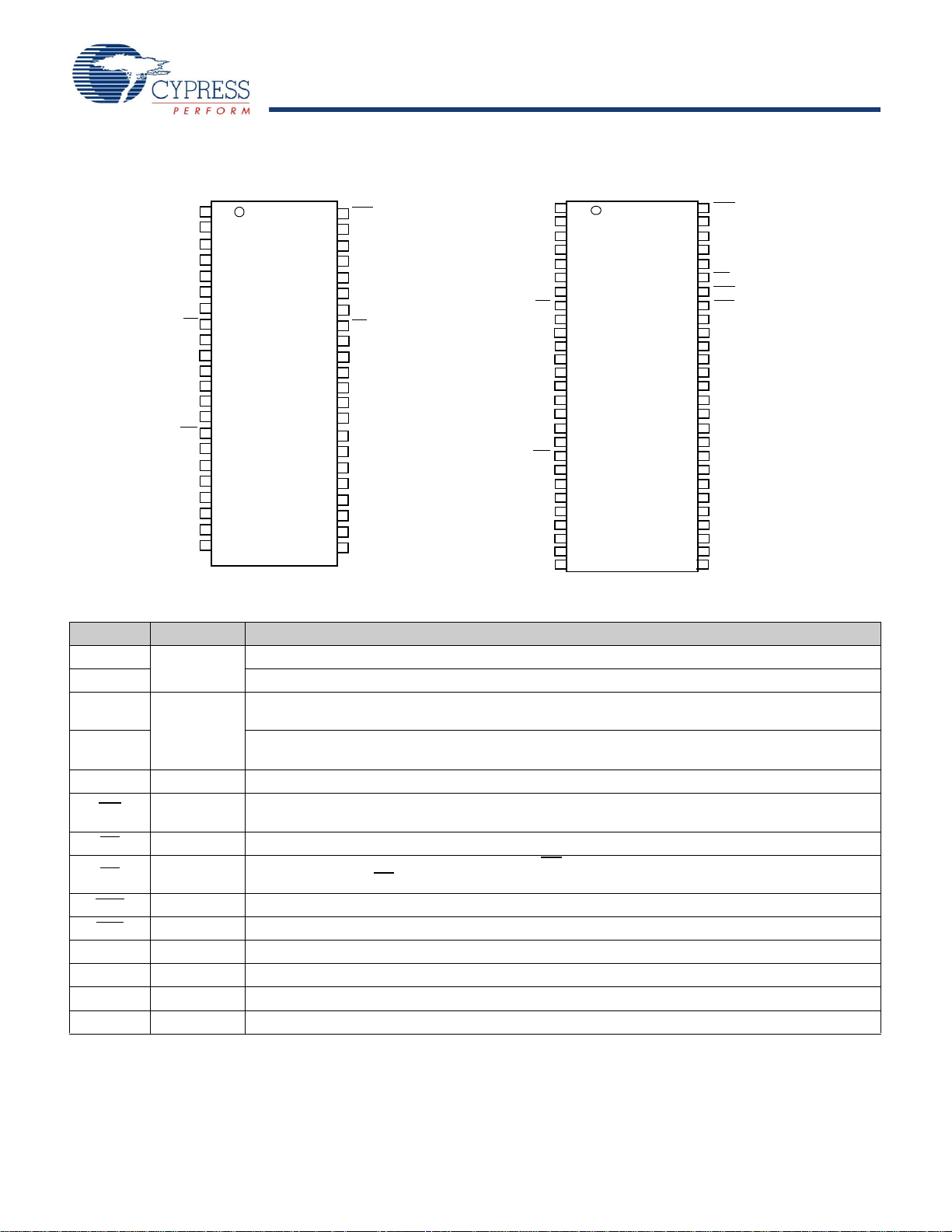

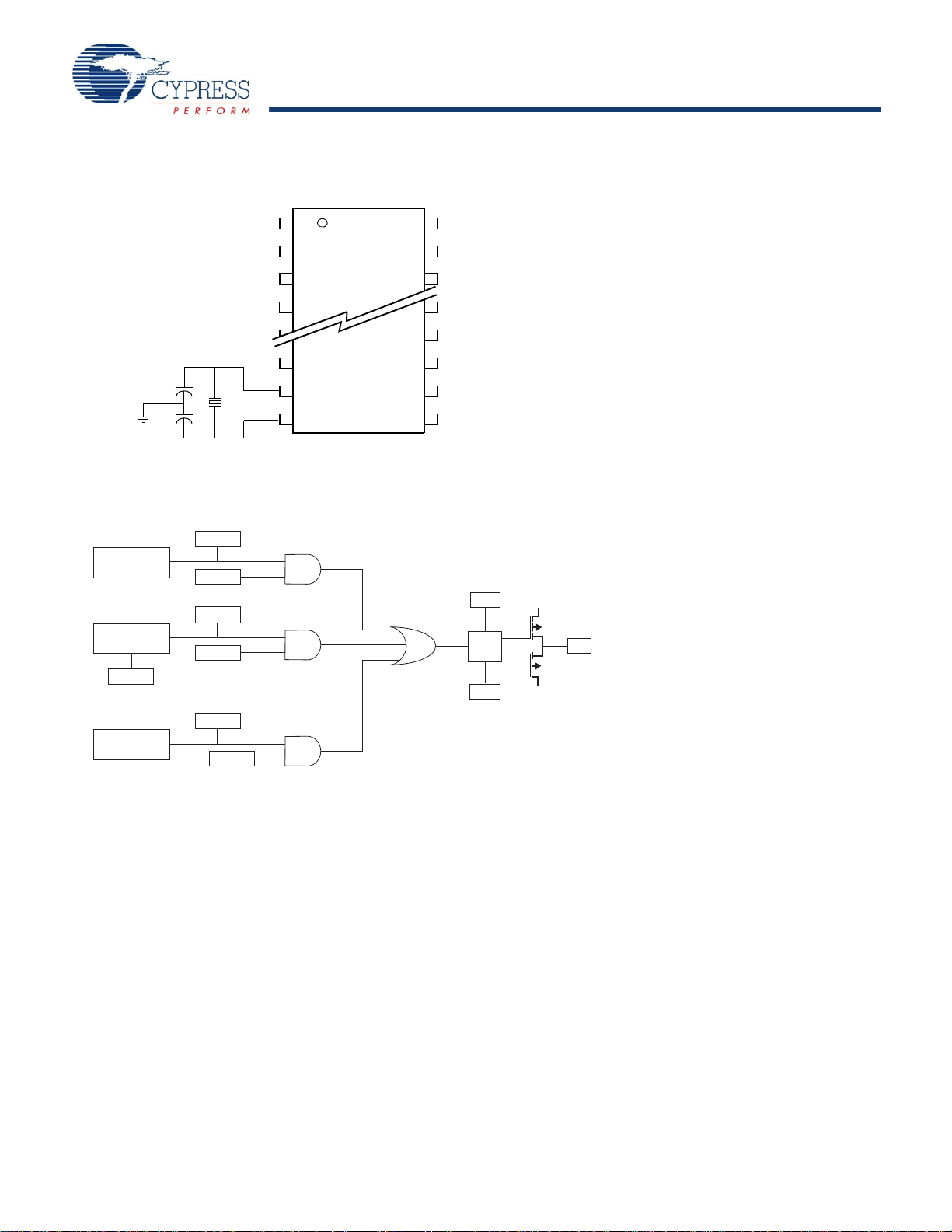

Pinouts

NC

A

8

X2

X1

V

SS

DQ

6

DQ5

DQ4

V

CC

A

13

DQ

3

A

12

DQ

2

DQ

1

DQ

0

OE

A

9

CE

NC

A

0

A

1

A

2

A

3

A

4

A

5

A

6

A

11

A

7

A

14

A

15

A

16

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

44 - TSOP II

Top View

(not to scale)

A

10

V

RTCbat

WE

DQ

7

HSB

INT

V

SS

V

CC

V

CAP

V

RTCcap

(x8)

DQ

7

DQ

6

DQ

5

DQ

4

V

CC

DQ

3

DQ

2

DQ

1

DQ

0

NC

A

0

A

1

A

2

A

3

A

4

A

5

A

6

A

7

V

CAP

WE

A

8

A

10

A

11

A

12

A

13

A

14

A

15

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

54 - TSOP II

Top View

(not to scale)

OE

CE

V

CC

INT

V

SS

NC

A

9

NC

NC

54

53

52

51

49

50

HSB

BHE

BLE

DQ

15

DQ

14

DQ

13

DQ

12

V

SS

DQ

11

DQ

10

DQ

9

DQ

8

(x16)

V

RTCcap

V

RTCbat

X2

X1

[4]

[4]

[5]

[5]

A

17

A

18

A

16

A

17

Notes

4. Address expansion for 8 Mbit. NC pin not connected to die.

5. Address expansion for 16 Mbit. NC pin not connected to die.

Table 1. Pin Definitions

Pin Name I/O Type Description

– A

A

0

18

– A

A

0

17

– DQ7Input/Output Bidirectional Data I/O Lines for x8 Configuration. Used as input or output lines depending on

DQ

0

DQ0 – DQ

15

NC No Connect No Connects. This pin is not connected to the die.

WE

CE

OE

BHE

BLE

X

1

X

2

V

RTCcap

V

RTCbat

Document #: 001-07103 Rev. *K Page 2 of 31

Input Address Inputs Used to Select one of the 524,288 bytes of the nvSRAM for x8 Configuration.

Address Inputs Used to Select one of the 262,144 words of the nvSRAM for x16 Configuration.

operation.

Bidirectional Data I/O Lines for x16 Configuration. Used as input or output lines depending on

operation.

Input Write Enable Input, Active LOW. When selected LOW, data on the I/O pins is written to the specific

address location.

Input Chip Enable Input, Active LOW. When LOW, selects the chip. When HIGH, deselects the chip.

Input Output Enable, Active LOW. The active LOW OE input enables the data output buffers during read

Input Byte High Enable, Active LOW. Controls DQ15 - DQ8.

Input Byte Low Enable, Active LOW. Controls DQ7 - DQ0.

Output Crystal Connection. Drives crystal on start up.

Input Crystal Connection. For 32.768 KHz crystal.

Power Supply Capacitor Supplied Backup RTC Supply Voltage. Left unconnected if V

Power Supply Battery Supplied Backup RTC Supply Voltage. Left unconnected if V

cycles. Deasserting OE

Figure 1. Pin Diagram - 44-PIn and 54-Pin TSOP II

HIGH causes the I/O pins to tri-state.

RTCcap

RTCbat

is used.

is used.

[+] Feedback

Page 3

PRELIMINARY

CY14B104K, CY14B104M

Table 1. Pin Definitions (continued)

0.1uF

Vcc

10kOhm

V

CAP

Vcc

WE

V

CAP

V

SS

Pin Name I/O Type Description

INT

V

V

SS

CC

Output Interrupt Output. Programmable to respond to the clock alarm, the watchdog timer, and the power

monitor. Also programmable to either active HIGH (push or pull) or LOW (open drain).

Ground Ground for the Device. Must be connected to ground of the system.

Power Supply Power Supply Inputs to the Device. 3.0V +20%, –10%

Input/Output Hardware STORE Busy (HSB). When LOW this output indicates that a Hardware STORE is in progress.

HSB

When pulled LOW external to the chip it initiates a nonvolatile STORE operation. A weak internal pull

up resistor keeps this pin HIGH if not connected (connection optional). After each STORE operation

HSB

is driven HIGH for short time with standard output high current.

V

CAP

Power Supply AutoStore Capacitor. Supplies power to the nvSRAM during power loss to store data from SRAM to

nonvolatile elements.

Device Operation

The CY14B104K/CY14B104M nvSRAM is made up of two

functional components paired in the same physical cell. These

are a SRAM memory cell and a nonvolatile QuantumTrap cell.

The SRAM memory cell operates as a standard fast static RAM.

Data in the SRAM is transferred to the nonvolatile cell (the

STORE operation), or from the nonvolatile cell to the SRAM (the

RECALL operation). Using this unique architecture, all cells are

stored and recalled in parallel. During the STORE and RECALL

operations SRAM read and write operations are inhibited. The

CY14B104K/CY14B104M supports infinite reads and writes

similar to a typical SRAM. In addition, it provides infinite RECALL

operations from the nonvolatile cells and up to 200K STORE

operations. See the “Truth Table For SRAM Operations” on

page 23 for a complete description of read and write modes.

SRAM Read

The CY14B104K/CY14B104M performs a read cycle whenever

and OE are LOW, and WE and HSB are HIGH. The address

CE

specified on pins A

data bytes or 262,144 words of 16 bits each are accessed. Byte

enables (BHE

, BLE) determine which bytes are enabled to the

output, in the case of 16-bit words. When the read is initiated by

an address transition, the outputs are valid after a delay of t

(read cycle 1). If the read is initiated by CE or OE, the outputs

are valid at t

data output repeatedly responds to address changes within the

ACE

tAA access time without the need for transitions on any control

input pins. This remains valid until another address change or

until CE

or OE is brought HIGH, or WE or HSB is brought LOW.

0-18

or at t

or A

DOE

determines which of the 524,288

0-17

, whichever is later (read cycle 2). The

AA

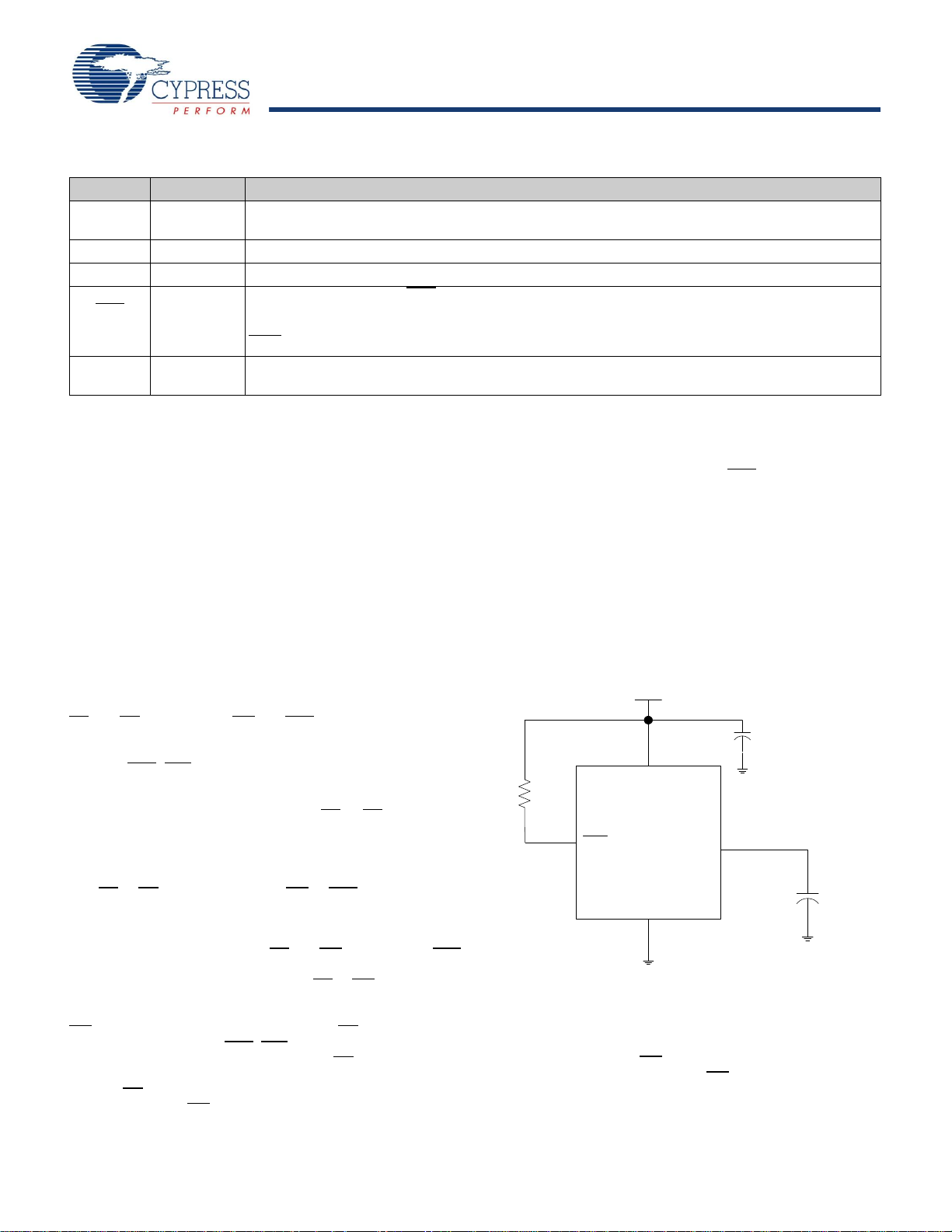

AutoStore Operation

The CY14B104K/CY14B104M stores data to the nvSRAM using

one of three storage operations. These three operations are:

Hardware STORE, activated by the HSB; Software STORE,

activated by an address sequence; AutoStore, on device power

down. The AutoStore operation is a unique feature of

QuantumTrap technology and is enabled by default on the

CY14B104K/CY14B104M.

During normal operation, the device draws current from V

charge a capacitor connected to the V

charge is used by the chip to perform a single STORE operation.

If the voltage on the VCC pin drops below V

automatically disconnects the V

operation is initiated with power provided by the V

pin from VCC. A STORE

CAP

pin. This stored

CAP

SWITCH

capacitor.

CAP

Figure 2. AutoStore Mode

to

CC

, the part

SRAM Write

A write cycle is performed when CE and WE are LOW and HSB

is HIGH. The address inputs must be stable before entering the

write cycle and must remain stable until CE

the end of the cycle. The data on the common I/O pins DO

are written into the memory if it is valid tSD before the end of a

WE

The Byte Enable inputs (BHE

written, in the case of 16-bit words. Keep OE

entire write cycle to avoid data bus contention on common I/O

lines. If OE

buffers t

Document #: 001-07103 Rev. *K Page 3 of 31

or WE goes HIGH at

controlled write or before the end of a CE controlled write.

, BLE) determine which bytes are

0-15

HIGH during the

is left LOW, internal circuitry turns off the output

HZWE

after WE goes LOW.

Figure 2 shows the proper connection of the storage capacitor

(V

) for automatic STORE operation. Refer to DC Electrical

CAP

Characteristics on page 14 for the size of the V

on the V

up should be placed on WE

This pull up is only effective if the WE

pin is driven to V

CAP

by a regulator on the chip. A pull

CC

to hold it inactive during power up.

signal is tri-state during

CAP

power up. Many MPUs tri-state their controls on power up. Verify

this when using the pull up. When the nvSRAM comes out of

. The voltage

[+] Feedback

Page 4

PRELIMINARY

CY14B104K, CY14B104M

power-on-recall, the MPU must be active or the WE

until the MPU comes out of reset.

To reduce unnecessary nonvolatile STOREs, AutoStore and

Hardware STORE operations are ignored unless at least one

write operation has taken place since the most recent STORE or

RECALL cycle. Software initiated STORE cycles are performed

regardless of whether a write operation has taken place. The

HSB signal is monitored by the system to detect if an AutoStore

cycle is in progress.

held inactive

Hardware STORE (HSB) Operation

The CY14B104K/CY14B104M provides the HSB pin to control

and acknowledge the STORE operations. The HSB

to request a Hardware STORE cycle. When the HSB

LOW, the CY14B104K/CY14B104M conditionally initiates a

STORE operation after t

only if a write to the SRAM has taken place since the last STORE

or RECALL cycle. The HSB pin also acts as an open drain driver

that is internally driven LOW to indicate a busy condition when

the STORE (initiated by any means) is in progress.

SRAM read and write operations, that are in progress when HSB

is driven LOW by any means, are given time t

before the STORE operation is initiated. However, any SRAM

write cycles requested after HSB

returns HIGH. In case the write latch is not set, HSB is not

HSB

driven LOW by the CY14B104K/CY14B104M but any SRAM

read and write cycles are inhibited until HSB

MPU or external source.

During any STORE operation, regardless of how it is initiated,

the CY14B104KA/CY14B104MA continues to drive the HSB

LOW, releasing it only when the STORE is complete. Upon

completion of the STORE operation, the

CY14B104K/CY14B104M remains disabled until the HSB

returns HIGH. Leave the HSB

. An actual STORE cycle begins

DELAY

goes LOW are inhibited until

is returned HIGH by

unconnected if it is not used.

DELAY

pin is used

pin is driven

to complete

pin

pin

Hardware RECALL (Power Up)

During power up or after any low power condition

(V

CC<VSWITCH

again exceeds the V

V

CC

is automatically initiated and takes t

this time, the HSB

reads and writes to nvSRAM are inhibited.

), an internal RECALL request is latched. When

pin is driven LOW by the HSB driver and all

on powerup, a RECALL cycle

SWITCH

HRECALL

to complete. During

To initiate the Software STORE cycle, the following read

sequence must be performed:

1. Read address 0x4E38 Valid READ

2. Read address 0xB1C7 Valid READ

3. Read address 0x83E0 Valid READ

4. Read address 0x7C1F Valid READ

5. Read address 0x703F Valid READ

6. Read address 0x8FC0 Initiate STORE cycle

The software sequence may be clocked with CE

reads. Both CE

executed. After the sixth address in the sequence is entered, the

STORE cycle starts and the chip is disabled. It is important to use

read cycles and not write cycles in the sequence. The SRAM is

activated again for read and write operations after the t

cycle time.

and OE must be toggled for the sequence to be

or OE controlled

STORE

Software RECALL

Data is transferred from the nonvolatile memory to the SRAM by

a software address sequence. A software RECALL cycle is

initiated with a sequence of read operations in a manner similar

to the Software STORE initiation. To initiate the RECALL cycle,

perform the following sequence of CE

operations:

1. Read address 0x4E38 Valid READ

2. Read address 0xB1C7 Valid READ

3. Read address 0x83E0 Valid READ

4. Read address 0x7C1F Valid READ

5. Read address 0x703F Valid READ

6. Read address 0x4C63 Initiate RECALL cycle

Internally, RECALL is a two step procedure. First, the SRAM data

is cleared; then, the nonvolatile information is transferred into the

SRAM cells. After the t

ready for read and write operations. The RECALL operation

does not alter the data in the nonvolatile elements.

cycle time, the SRAM is again

RECALL

or OE controlled read

Software STORE

Data is transferred from the SRAM to the nonvolatile memory by

a software address sequence. The CY14B104K/CY14B104M

Software STORE cycle is initiated by executing sequential CE

controlled read cycles from six specific address locations in

OE

exact order. During the STORE cycle, an erase of the previous

nonvolatile data is first performed, followed by a program of the

nonvolatile elements. After a STORE cycle is initiated, further

input and output are disabled until the cycle is completed.

Because a sequence of reads from specific addresses is used

for STORE initiation, it is important that no other read or write

accesses intervene in the sequence, or the sequence is aborted

and no STORE or RECALL takes place.

Document #: 001-07103 Rev. *K Page 4 of 31

or

[+] Feedback

Page 5

PRELIMINARY

CY14B104K, CY14B104M

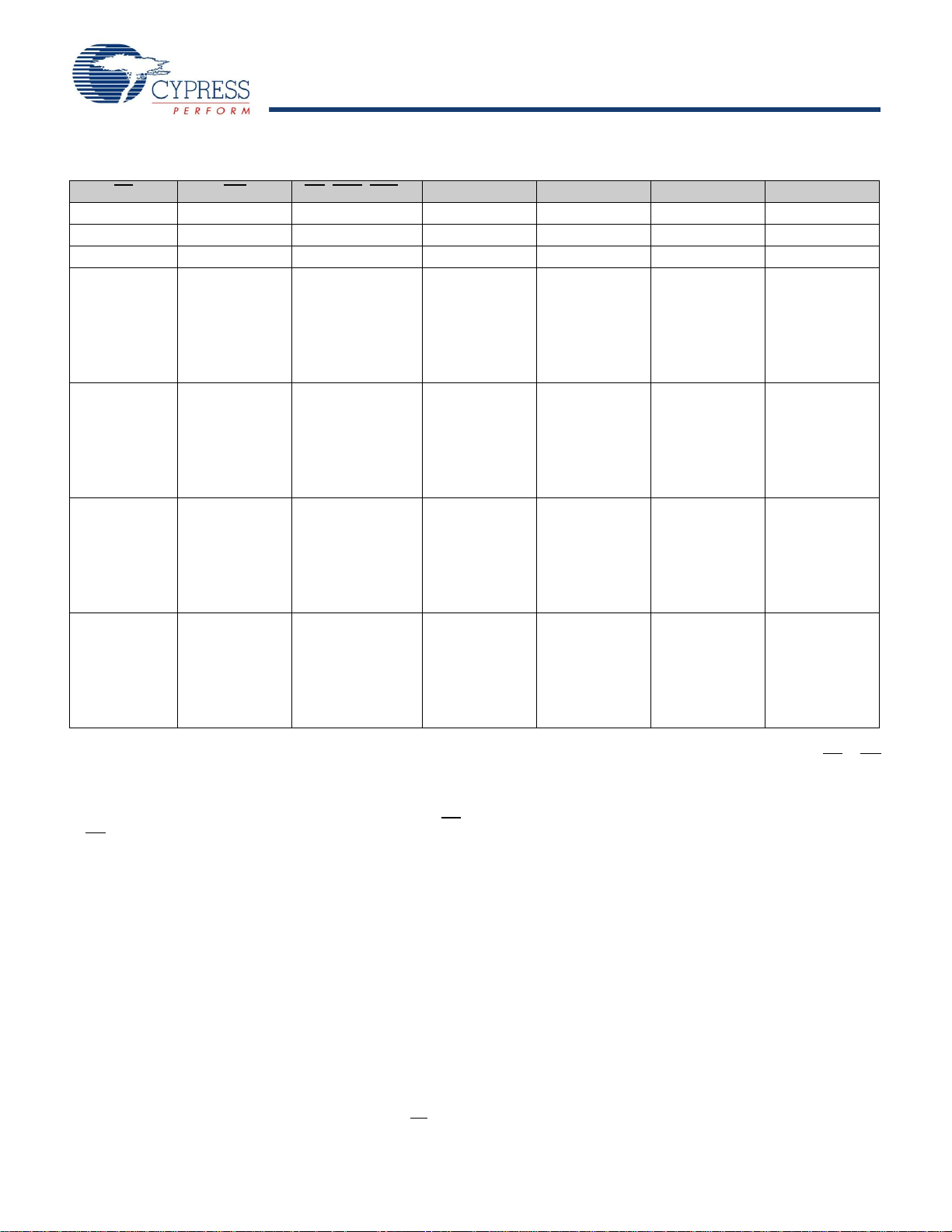

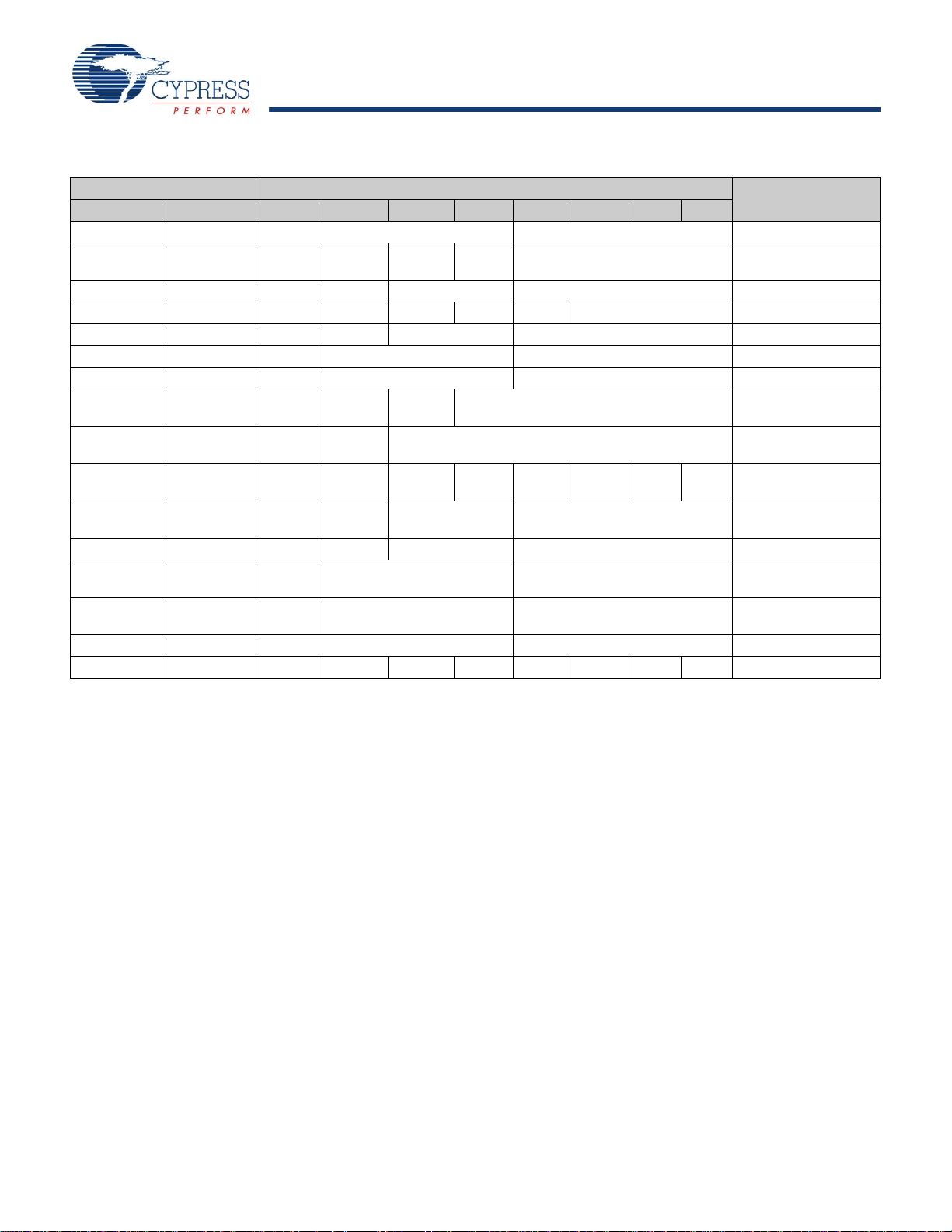

Table 2. Mode Selection

Notes

6. While there are 19 address lines on the CY14B104K (18 address lines on the CY14B104M), only the 13 address lines (A

14

- A2) are used to control software modes.

Rest of the address lines are don’t care.

7. The six consecutive address locations must be in the order listed. WE

must be HIGH during all six cycles to enable a nonvolatile cycle.

CE WE OE, BHE, BLE

H X X X Not Selected Output High Z Standby

L H L X Read SRAM Output Data Active

L L X X Write SRAM Input Data Active

L H L 0x4E38

L H L 0x4E38

L H L 0x4E38

L H L 0x4E38

0xB1C7

0x83E0

0x7C1F

0x703F

0x8B45

[6]

0

Mode I/O Power

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

AutoStore

Output Data

Output Data

Output Data

Output Data

Output Data

Output Data

Active

[7]

[3]

A15 - A

Disable

0xB1C7

0x83E0

0x7C1F

0x703F

0x4B46

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

AutoStore

Output Data

Output Data

Output Data

Output Data

Output Data

Output Data

Active

[7]

Enable

0xB1C7

0x83E0

0x7C1F

0x703F

0x8FC0

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Nonvolatile

Output Data

Output Data

Output Data

Output Data

Output Data

Output High Z

Active I

CC2

[7]

STORE

[7]

Active

0xB1C7

0x83E0

0x7C1F

0x703F

0x4C63

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Read SRAM

Nonvolatile

Output Data

Output Data

Output Data

Output Data

Output Data

Output High Z

RECALL

Preventing AutoStore

The AutoStore function is disabled by initiating an AutoStore

disable sequence. A sequence of read operations is performed

in a manner similar to the Software STORE initiation. To initiate

the AutoStore disable sequence, the following sequence of CE

or OE controlled read operations must be performed:

1. Read address 0x4E38 Valid READ

2. Read address 0xB1C7 Valid READ

3. Read address 0x83E0 Valid READ

4. Read address 0x7C1F Valid READ

5. Read address 0x703F Valid READ

6. Read address 0x8B45 AutoStore Disable

manner similar to the software RECALL initiation. To initiate the

AutoStore enable sequence, the following sequence of CE

controlled read operations must be performed:

1. Read address 0x4E38 Valid READ

2. Read address 0xB1C7 Valid READ

3. Read address 0x83E0 Valid READ

4. Read address 0x7C1F Valid READ

5. Read address 0x703F Valid READ

6. Read address 0x4B46 AutoStore Enable

If the AutoStore function is disabled or re-enabled, a manual

STORE operation (hardware or software) issued to save the

AutoStore state through subsequent power down cycles. The

part comes from the factory with AutoStore enabled.

AutoStore is re-enabled by initiating an AutoStore enable

sequence. A sequence of read operations is performed in a

Document #: 001-07103 Rev. *K Page 5 of 31

or OE

[+] Feedback

Page 6

PRELIMINARY

CY14B104K, CY14B104M

Data Protection

The CY14B104K/CY14B104M protects data from corruption

during low voltage conditions by inhibiting all externally initiated

STORE and write operations. The low voltage condition is

detected when V

CY14B104K/CY14B104M is in a write mode (both CE

are LOW) at power up, after a RECALL or STORE, the write is

inhibited until the SRAM is enabled after t

active). This protects against inadvertent writes during power up

or brown out conditions.

is less than V

CC

SWITCH

(HSB to output

LZHSB

. If the

and WE

Noise Considerations

Refer to CY application note AN1064.

Real Time Clock Operation

nvTIME Operation

The CY14B104K/CY14B104M offers internal registers that

contain clock, alarm, watchdog, interrupt, and control functions.

RTC registers use the last 16 address locations of the SRAM.

Internal double buffering of the clock and timer information

registers prevents accessing transitional internal clock data

during a read or write operation. Double buffering also

circumvents disrupting normal timing counts or the clock

accuracy of the internal clock when accessing clock data. Clock

and alarm registers store data in BCD format.

RTC functionality is described with respect to CY14B104K in the

following sections. The same description applies to

CY14B104M, except for the RTC register addresses. The RTC

register addresses for CY14B104K range from 0x7FFF0 to

0x7FFFF, while those for CY14B104M range from 0x3FFF0 to

0x3FFFF. Refer to Table 4 on page 10 and Tab l e 5 on page 11

for a detailed Register Map description.

Clock Operations

The clock registers maintain time up to 9,999 years in one

second increments. The time can be set to any calendar time and

the clock automatically keeps track of days of the week and

month, leap years, and century transitions. There are eight

registers dedicated to the clock functions, which are used to set

time with a write cycle and to read time during a read cycle.

These registers contain the time of day in BCD format. Bits

defined as ‘0’ are currently not used and are reserved for future

use by Cypress.

Reading the Clock

The double buffered RTC register structure reduces the chance

of reading incorrect data from the clock. The user must stop

internal updates to the CY14B104K time keeping registers

before reading clock data, to prevent reading of data in transition.

Stopping the register updates does not affect clock accuracy.

The updating process is stopped by writing a ‘1’ to the read bit

‘R’ (in the flags register at 0x7FFF0), and does not restart until a

‘0’ is written to the read bit. The RTC registers are then read while

the internal clock continues to run. After a ‘0’ is written to the read

bit (‘R’), all RTC registers are simultaneously updated within

20 ms

Setting the Clock

Setting the write bit ‘W’ (in the flags register at 0x7FFF0) to a ‘1’

stops updates to the time keeping registers and enables the time

to be set. The correct day, date, and time is then written into the

registers and must be in 24 hour BCD format. The time written is

referred to as the “Base Time”. This value is stored in nonvolatile

registers and used in the calculation of the current time.

Resetting the write bit to ‘0’ transfers the values of timekeeping

registers to the actual clock counters, after which the clock

resumes normal operation.

If the time written to the timekeeping registers is not in the correct

BCD format, each invalid nibble of the RTC registers continue

counting to 0xF before rolling over to 0x0 after which RTC

resumes normal operation.

Note The values entered in the timekeeping, alarm, calibration,

and interrupt registers need a STORE operation to be saved in

nonvolatile memory. Therefore, while working in AutoStore

disabled mode, the user must perform a STORE operation after

writing into the RTC registers for the RTC to work correctly.

Backup Power

The RTC in the CY14B104K is intended for permanently

powered operation. The V

depending on whether a capacitor or battery is chosen for the

application. When the primary power, V

V

The clock oscillator uses very little current, which maximizes the

backup time available from the backup source. Regardless of the

clock operation with the primary source removed, the data stored

in the nvSRAM is secure, having been stored in the nonvolatile

elements when power was lost.

During backup operation, the CY14B104K consumes a

maximum of 300 nanoamps at room temperature. User must

choose capacitor or battery values according to the application.

Backup time values based on maximum current specifications

are shown in the following table. Nominal backup times are

approximately two times longer.

Table 3. RTC Backup Time

Using a capacitor has the obvious advantage of recharging the

backup source each time the system is powered up. If a battery

is used, a 3V lithium is recommended and the CY14B104K

sources current only from the battery when the primary power is

removed. However the battery is not recharged at any time by

the CY14B104K. The battery capacity must be chosen for total

anticipated cumulative down time required over the life of the

system.

the device switches to the backup power supply.

SWITCH

Capacitor Value Backup Time

0.1F 72 hours

0.47F 14 days

1.0F 30 days

RTCcap

or V

pin is connected

RTCbat

, fails and drops below

CC

Stopping and Starting the Oscillator

The OSCEN bit in the calibration register at 0x7FFF8 controls

the enable and disable of the oscillator. This bit is nonvolatile and

is shipped to customers in the “enabled” (set to 0) state. To

preserve the battery life when the system is in storage, OSCEN

Document #: 001-07103 Rev. *K Page 6 of 31

[+] Feedback

Page 7

PRELIMINARY

CY14B104K, CY14B104M

must be set to ‘1’. This turns off the oscillator circuit, extending

the battery life. If the OSCEN bit goes from disabled to enabled,

it takes approximately one second (two seconds maximum) for

the oscillator to start.

While system power is off, If the voltage on the backup supply

(V

the oscillator may fail.The CY14B104K has the ability to detect

oscillator failure when system power is restored. This is recorded

in the OSCF (Oscillator Failed bit) of the flags register at the

address 0x7FFF0. When the device is powered on (V

above V

If the OSCEN bit is enabled and the oscillator is not active within

the first 5 ms, the OSCF bit is set to “1”. The system must check

for this condition and then write ‘0’ to clear the flag. Note that in

addition to setting the OSCF flag bit, the time registers are reset

to the “Base Time” (see Setting the Clock on page 6), which is

the value last written to the timekeeping registers. The control or

calibration registers and the OSCEN bit are not affected by the

‘oscillator failed’ condition.

The value of OSCF must be reset to ‘0’ when the time registers

are written for the first time. This initializes the state of this bit

which may have become set when the system was first powered

on.

To reset OSCF, set the write bit “W” (in the Flags register at

0x7FFF0) to a “1” to enable writes to the Flag register. Write a

“0” to the OSCF bit and then reset the write bit to “0” to disable

writes.

RTCcap

or V

SWITCH

) falls below their respective minimum level,

RTCbat

) the OSCEN bit is checked for “enabled” status.

CC

goes

Calibrating the Clock

The RTC is driven by a quartz controlled crystal with a nominal

frequency of 32.768 kHz. Clock accuracy depends on the quality

of the crystal and calibration. The crystals available in market

typically have an error of +

CY14B104K employs a calibration circuit that improves the

accuracy to +1/–2 ppm at 25°C. This implies an error of +2.5

seconds to -5 seconds per month.

The

calibration circuit adds or subtracts counts from the oscillator

divider circuit to achieve this accuracy. The number of pulses that

are suppressed (subtracted, negative calibration) or split (added,

positive calibration) depends upon the value loaded into the five

calibration bits found in Calibration register at 0x7FFF8. The

calibration bits occupy the five lower order bits in the Calibration

register. These bits are set to represent any value between ‘0’

and 31 in binary form. Bit D5 is a sign bit, where a ‘1’ indicates

positive calibration and a ‘0’ indicates negative calibration.

Adding counts speeds the clock up and subtracting counts slows

the clock down. If a binary ‘1’ is loaded into the register, it corresponds to an adjustment of 4.068 or –2.034 ppm offset in oscillator error, depending on the sign.

Calibration occurs within a 64-minute cycle. The first 62 minutes

in the cycle may, once per minute, have one second shortened

by 128 or lengthened by 256 oscillator cycles. If a binary ‘1’ is

loaded into the register, only the first two minutes of the

64-minute cycle are modified. If a binary 6 is loaded, the first 12

are affected, and so on. Therefore, each calibration step has the

effect of adding 512 or subtracting 256 oscillator cycles for every

125,829,120 actual oscillator cycles, that is, 4.068 or –2.034 ppm

of adjustment per calibration step in the Calibration register.

To determine the required calibration, the CAL bit in the Flags

register (0x7FFF0) must be set to ‘1’. This causes the INT pin to

20 ppm to +35 ppm. However,

toggle at a nominal frequency of 512 Hz. Any deviation

measured from the 512 Hz indicates the degree and direction of

the required correction. For example, a reading of 512.01024 Hz

indicates a +20 ppm error. Hence, a decimal value of –10

(001010b) must be loaded into the Calibration register to offset

this error.

Note Setting or changing the Calibration register does not affect

the test output frequency.

To set or clear CAL, set the write bit “W” (in the flags register at

0x7FFF0) to “1” to enable writes to the Flag register. Write a

value to CAL, and then reset the write bit to “0” to disable writes.

Alarm

The alarm function compares user programmed values of alarm

time and date (stored in the registers 0x7FFF1-5) with the corresponding time of day and date values. When a match occurs, the

alarm internal flag (AF) is set and an interrupt is generated on

INT pin if Alarm Interrupt Enable (AIE) bit is set.

There are four alarm match fields - date, hours, minutes, and

seconds. Each of these fields has a match bit that is used to

determine if the field is used in the alarm match logic. Setting the

match bit to ‘0’ indicates that the corresponding field is used in

the match process. Depending on the match bits, the alarm

occurs as specifically as once a month or as frequently as once

every minute. Selecting none of the match bits (all 1s) indicates

that no match is required and therefore, alarm is disabled.

Selecting all match bits (all 0s) causes an exact time and date

match.

There are two ways to detect an alarm event: by reading the AF

flag or monitoring the INT pin. The AF flag in the flags register at

0x7FFF0 indicates that a date or time match has occurred. The

AF bit is set to “1” when a match occurs. Reading the flags

register clears the alarm flag bit (and all others). A hardware

interrupt pin may also be used to detect an alarm event.

To set, clear or enable an alarm, set the ‘W’ bit (in Flags Register

- 0x7FFF0) to ‘1’ to enable writes to Alarm Registers. After writing

the alarm value, clear the ‘W’ bit back to “0” for the changes to

take effect.

Note CY14B104K requires the alarm match bit for seconds

(0x7FFF2 - D7) to be set to ‘0’ for proper operation of Alarm Flag

and Interrupt.

Watchdog Timer

The Watchdog Timer is a free running down counter that uses

the 32 Hz clock (31.25 ms) derived from the crystal oscillator.

The oscillator must be running for the watchdog to function. It

begins counting down from the value loaded in the Watchdog

Timer register.

The timer consists of a loadable register and a free running

counter. On power up, the watchdog time out value in register

0x7FFF7 is loaded into the Counter Load register. Counting

begins on power up and restarts from the loadable value any time

the Watchdog Strobe (WDS) bit is set to ‘1’. The counter is

compared to the terminal value of ‘0’. If the counter reaches this

value, it causes an internal flag and an optional interrupt output.

You can prevent the time out interrupt by setting WDS bit to ‘1’

prior to the counter reaching ‘0’. This causes the counter to

reload with the watchdog time out value and to be restarted. As

long as the user sets the WDS bit prior to the counter reaching

the terminal value, the interrupt and WDT flag never occur.

Document #: 001-07103 Rev. *K Page 7 of 31

[+] Feedback

Page 8

PRELIMINARY

CY14B104K, CY14B104M

New time out values are written by setting the watchdog write bit

1 Hz

Oscillator

Clock

Divider

Counter

Zero

Compare

WDF

WDS

Load

Register

WDW

D

Q

Q

Watchdog

Register

write to

Watchdog

Register

32 Hz

32,768 KHz

to ‘0’. When the WDW is ‘0’, new writes to the watchdog time out

value bits D5-D0 are enabled to modify the time out value. When

WDW is ‘1’, writes to bits D5-D0 are ignored. The WDW function

enables a user to set the WDS bit without concern that the

watchdog timer value is modified. A logical diagram of the

watchdog timer is shown in Figure 3. Note that setting the

watchdog time out value to ‘0’ disables the watchdog function.

The output of the watchdog timer is the flag bit WDF that is set if

the watchdog is allowed to time out. If the Watchdog Interrupt

Enable (WIE) bit in the Interrupt register is set, a hardware

interrupt on INT pin is also generated on watchdog timeout. The

flag and the hardware interrupt are both cleared when user reads

the Flags registers.

Figure 3. Watchdog Timer Block Diagram

determine the cause of the interrupt. The INT pin driver has two

bits that specify its behavior when an interrupt occurs.

An Interrupt is raised only if both a flag is raised by one of the

three sources and the respective interrupt enable bit in Interrupts

register is enabled (set to ‘1’). After an interrupt source is active,

two programmable bits, H/L and P/L, determine the behavior of

the output pin driver on INT pin. These two bits are located in the

Interrupt register and can be used to drive level or pulse mode

output from the INT pin. In pulse mode, the pulse width is

internally fixed at approximately 200 ms. This mode is intended

to reset a host microcontroller. In the level mode, the pin goes to

its active polarity until the Flags register is read by the user. This

mode is used as an interrupt to a host microcontroller. The

control bits are summarized in the following section.

Interrupts are only generated while working on normal power and

are not triggered when system is running in backup power mode.

Note CY14B104K generates valid interrupts only after the

Powerup Recall sequence is completed. All events on INT pin

must be ignored for t

HRECALL

duration after powerup.

Interrupt Register

Watchdog Interrupt Enable - WIE. When set to ‘1’, the

watchdog timer drives the INT pin and an internal flag when a

watchdog time out occurs. When WIE is set to ‘0’, the watchdog

timer only affects the WDF flag in Flags register.

Alarm Interrupt Enable - AIE. When set to ‘1’, the alarm match

drives the INT pin and an internal flag. When AIE is set to ‘0’, the

alarm match only affects the AF Flags register.

Power Fail Interrupt Enable - PFE. When set to ‘1’, the power

fail monitor drives the pin and an internal flag. When PFE is set

.

Power Monitor

The CY14B104K provides a power management scheme with

power fail interrupt capability. It also controls the internal switch

to backup power for the clock and protects the memory from low

V

access. The power monitor is based on an internal band gap

CC

reference circuit that compares the V

threshold.

As described in the section “AutoStore Operation” on page 3,

when V

STORE operation is initiated from SRAM to the nonvolatile

is reached as VCC decays from power loss, a data

SWITCH

elements, securing the last SRAM data state. Power is also

switched from V

operate the RTC oscillator.

to the backup supply (battery or capacitor) to

CC

When operating from the backup source, read and write operations to nvSRAM are inhibited and the clock functions are not

available to the user. The clock continues to operate in the

background. The updated clock data is available to the user

t

HRECALL

“AutoStore/Power Up RECALL” on page 20)

Interrupts

The CY14B104K has Flags register, Interrupt register, and

Interrupt logic that can signal interrupt to the microcontroller.

There are three potential sources for interrupt: watchdog timer,

delay after VCC is restored to the device (see

power monitor, and alarm timer. Each of these can be individually

enabled to drive the INT pin by appropriate setting in the Interrupt

register (0x7FFF6). In addition, each has an associated flag bit

in the Flags register (0x7FFF0) that the host processor uses to

Document #: 001-07103 Rev. *K Page 8 of 31

voltage to V

CC

SWITCH

to ‘0’, the power fail monitor only affects the PF flag in Flags

register.

High/Low - H/L. When set to a ‘1’, the INT pin is active HIGH

and the driver mode is push pull. The INT pin drives high only

when V

is active LOW and the drive mode is open drain. The INT pin

is greater than V

CC

. When set to a ‘0’, the INT pin

SWITCH

must be pulled up to Vcc by a 10k resistor while using the

interrupt in active LOW mode.

Pulse/Level - P/L. When set to a ‘1’ and an interrupt occurs, the

INT pin is driven for approximately 200 ms. When P/L is set to a

‘0’, the INT pin is driven high or low (determined by H/L) until the

Flags or Control register is read.

When an enabled interrupt source activates the INT pin, an

external host reads the Flags registers to determine the cause.

Remember that all flags are cleared when the register is read. If

the INT pin is programmed for Level mode, then the condition

clears and the INT pin returns to its inactive state. If the pin is

programmed for Pulse mode, then reading the flag also clears

the flag and the pin. The pulse does not complete its specified

duration if the Flags register is read. If the INT pin is used as a

host reset, the Flags register is not read during a reset

Flags Register

The Flag register has three flag bits: WDF, AF, and PF, which can

be used to generate an interrupt. They are set by the watchdog

timeout, alarm match, or power fail monitor respectively. The

processor can either poll this register or enable interrupts when

a flag is set. These flags are automatically reset once the register

is read. The flags register is automatically loaded with the value

0x00 on power up (except for the OSCF bit. See “Stopping and

Starting the Oscillator” on page 6.)

[+] Feedback

Page 9

PRELIMINARY

CY14B104K, CY14B104M

Figure 4. RTC Recommended Component Configuration

Recommended Values

Y

1

= 32.768 KHz (6 pF)

C

1

= 21 pF

C2 = 21 pF

X

1

X

2

Y1

C2

C1

Note: The recommended values for C1 and C2 include

board trace capacitance.

Watchdog

Timer

Power

Monitor

Clock

Alarm

VINT

WDF

WIE

PF

PFE

AF

AIE

P/L

Pin

Driver

H/L

INT

V

CC

V

SS

WDF - Watchdog Timer Flag

WIE - Watchdog Interrupt

PF - Power Fail Flag

PFE - Power Fail Enable

AF - Alarm Flag

AIE - Alarm Interrupt Enable

P/L - Pulse Level

H/L - High/Low

Enable

Figure 5. Interrupt Block Diagram

Document #: 001-07103 Rev. *K Page 9 of 31

[+] Feedback

Page 10

PRELIMINARY

CY14B104K, CY14B104M

Table 4. RTC Register Map

Note

8. Upper Byte D

15-D8

(CY14B104MA) of RTC registers are reserved for future use

9. ( ) designates values shipped from the factory.

10. This is a binary value, not a BCD value.

Register BCD Format Data

CY14B104K CY14B104M D7 D6 D5 D4 D3 D2 D1 D0

[8]

[9]

Function/Range

0x7FFFF 0x3FFFF 10s Years Years Years: 00–99

0x7FFFE 0x3FFFE 0 0 0 10s

Months Months: 01–12

Months

0x7FFFD 0x3FFFD 0 0 10s Day of Month Day Of Month Day of Month: 01–31

0x7FFFC 0x3FFFC 0 0 0 0 0 Day of week Day of week: 01–07

0x7FFFB 0x3FFFB 0 0 10s Hours Hours Hours: 00–23

0x7FFFA 0x3FFFA 0 10s Minutes Minutes Minutes: 00–59

0x7FFF9 0x3FFF9 0 10s Seconds Seconds Seconds: 00–59

0x7FFF8 0x3FFF8 OSCEN

(0)

0x7FFF7 0x3FFF7 WDS

0Cal Sign

Calibration (00000) Calibration Values

(0)

WDW (0) WDT (000000) Watchdog

(0)

0x7FFF6 0x3FFF6 WIE (0) AIE (0) PFE (0) 0 H/L

P/L (0) 0 0 Interrupts

(1)

0x7FFF5 0x3FFF5 M (1) 0 10s Alarm Date Alarm Day Alarm, Day of Month:

01–31

0x7FFF4 0x3FFF4 M (1) 0 10s Alarm Hours Alarm Hours Alarm, Hours: 00–23

0x7FFF3 0x3FFF3 M (1) 10 Alarm Minutes Alarm Minutes Alarm, Minutes:

00–59

0x7FFF2 0x3FFF2 M (1) 10 Alarm Seconds Alarm, Seconds Alarm, Seconds:

00–59

0x7FFF1 0x3FFF1 10s Centuries Centuries Centuries: 00–99

0x7FFF0 0x3FFF0 WDF AF PF OSCF 0 CAL (0) W (0) R (0) Flags

[10]

[10]

[10]

[10]

Document #: 001-07103 Rev. *K Page 10 of 31

[+] Feedback

Page 11

PRELIMINARY

CY14B104K, CY14B104M

Table 5. Register Map Detail

Register

CY14B104K CY14B104M

0x7FFFF 0x3FFFF

0x7FFFE 0x3FFFE

0x7FFFD 0x3FFFD

0x7FFFC 0x3FFFC

0x7FFFB 0x3FFFB

0x7FFFA 0x3FFFA

0x7FFF9 0x3FFF9

Description

Time Keeping - Years

D7 D6 D5 D4 D3 D2 D1 D0

10s Years Years

Contains the lower two BCD digits of the year. Lower nibble (four bits) contains the value for years;

upper nibble (four bits) contains the value for 10s of years. Each nibble operates from 0 to 9. The

range for the register is 0–99.

Time Keeping - Months

D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 10s Month Months

Contains the BCD digits of the month. Lower nibble (four bits) contains the lower digit and operates

from 0 to 9; upper nibble (one bit) contains the upper digit and operates from 0 to 1. The range

for the register is 1–12.

Time Keeping - Date

D7 D6 D5 D4 D3 D2 D1 D0

0 0 10s Day of Month Day of Month

Contains the BCD digits for the date of the month. Lower nibble (four bits) contains the lower digit

and operates from 0 to 9; upper nibble (two bits) contains the 10s digit and operates from 0 to 3.

The range for the register is 1–31. Leap years are automatically adjusted for.

Time Keeping - Day

D7 D6 D5 D4 D3 D2 D1 D0

0 0 0 0 0 Day of Week

Lower nibble (three bits) contains a value that correlates to day of the week. Day of the week is a

ring counter that counts from 1 to 7 then returns to 1. The user must assign meaning to the day

value, because the day is not integrated with the date.

Time Keeping - Hours

D7 D6 D5 D4 D3 D2 D1 D0

0 0 10s Hours Hours

Contains the BCD value of hours in 24 hour format. Lower nibble (four bits) contains the lower

digit and operates from 0 to 9; upper nibble (two bits) contains the upper digit and operates from

0 to 2. The range for the register is 0–23.

Time Keeping - Minutes

D7 D6 D5 D4 D3 D2 D1 D0

0 10s Minutes Minutes

Contains the BCD value of minutes. Lower nibble (four bits) contains the lower digit and operates

from 0 to 9; upper nibble (three bits) contains the upper minutes digit and operates from 0 to 5.

The range for the register is 0–59.

Time Keeping - Seconds

D7 D6 D5 D4 D3 D2 D1 D0

0 10s Seconds Seconds

Contains the BCD value of seconds. Lower nibble (four bits) contains the lower digit and operates

from 0 to 9; upper nibble (three bits) contains the upper digit and operates from 0 to 5. The range

for the register is 0–59.

Document #: 001-07103 Rev. *K Page 11 of 31

[+] Feedback

Page 12

PRELIMINARY

CY14B104K, CY14B104M

Table 5. Register Map Detail (continued)

Register

CY14B104K CY14B104M

0x7FFF8 0x3FFF8

OSCEN Oscillator Enable. When set to 1, the oscillator is stopped. When set to 0, the oscillator runs.

Calibration

Sign

Calibration These five bits control the calibration of the clock.

0x7FFF7 0x3FFF7

WDS Watchdog Strobe. Setting this bit to 1 reloads and restarts the watchdog timer. Setting the bit to

WDW Watchdog Write Enable. Setting this bit to 1 disables any WRITE to the watchdog timeout value

WDT Watchdog timeout selection. The watchdog timer interval is selected by the 6-bit value in this

0x7FFF6 0x3FFF6

WIE Watchdog Interrupt Enable. When set to 1 and a watchdog timeout occurs, the watchdog timer

AIE Alarm Interrupt Enable. When set to 1, the alarm match drives the INT pin and the AF flag. When

PFE Power Fail Enable. When set to 1, the power fail monitor drives the INT pin and the PF flag. When

0 Reserved for future use

H/L High/Low. When set to 1, the INT pin is driven active HIGH. When set to 0, the INT pin is open

P/L Pulse/Level. When set to 1, the INT pin is driven active (determined by H/L) by an interrupt source

0x7FFF5 0x3FFF5

M Match. When this bit is set to 0, the date value is used in the alarm match. Setting this bit to 1

D7 D6 D5 D4 D3 D2 D1 D0

OSCEN 0 Calibration

Disabling the oscillator saves battery or capacitor power during storage.

Determines if the calibration adjustment is applied as an addition (1) to or as a subtraction (0) from

the time-base.

D7 D6 D5 D4 D3 D2 D1 D0

WDS WDW WDT

0 has no effect. The bit is cleared automatically after the watchdog timer is reset. The WDS bit is

write only. Reading it always returns a 0.

(D5–D0). This allows the user to set the watchdog strobe bit without disturbing the timeout value.

Setting this bit to 0 allows bits D5–D0 to be written to the watchdog register when the next write

cycle is complete. This function is explained in more detail in Watchdog Timer on page 7.

register. It represents a multiplier of the 32 Hz count (31.25 ms). The range of timeout value is

31.25 ms (a setting of 1) to 2 seconds (setting of 3 Fh). Setting the watchdog timer register to 0

disables the timer. These bits can be written only if the WDW bit was set to 0 on a previous cycle.

D7 D6 D5 D4 D3 D2 D1 D0

WIE AIE PFE 0 H/L P/L 0 0

drives the INT pin and the WDF flag. When set to 0, the watchdog timeout affects only the WDF

flag.

set to 0, the alarm match only affects the AF flag.

set to 0, the power fail monitor affects only the PF flag.

drain, active LOW.

for approximately 200 ms. When set to 0, the INT pin is driven to an active level (as set by H/L)

until the flags register is read.

D7 D6 D5 D4 D3 D2 D1 D0

M 0 10s Alarm Date Alarm Date

Contains the alarm value for the date of the month and the mask bit to select or deselect the date

value.

causes the match circuit to ignore the date value.

Description

Calibration/Control

Calibration

Sign

WatchDog Timer

Interrupt Status/Control

Alarm - Day

Document #: 001-07103 Rev. *K Page 12 of 31

[+] Feedback

Page 13

PRELIMINARY

CY14B104K, CY14B104M

Table 5. Register Map Detail (continued)

Register

CY14B104K CY14B104M

0x7FFF4 0x3FFF4

M Match. When this bit is set to 0, the hours value is used in the alarm match. Setting this bit to 1

0x7FFF3 0x3FFF3

M Match. When this bit is set to 0, the minutes value is used in the alarm match. Setting this bit to 1

0x7FFF2 0x3FFF2

M Match. When this bit is set to 0, the seconds value is used in the alarm match. Setting this bit to

0x7FFF1 0x3FFF1

0x7FFF0 0x3FFF0

WDF Watchdog Timer Flag. This read only bit is set to 1 when the watchdog timer is allowed to reach

AF Alarm Flag. This read only bit is set to 1 when the time and date match the values stored in the

PF Power Fail Flag. This read only bit is set to 1 when power falls below the power fail threshold

OSCF Oscillator Fail Flag. Set to 1 on power up if the oscillator is enabled and not running in the first 5

CAL Calibration Mode. When set to 1, a 512 Hz square wave is output on the INT pin. When set to 0,

W Write Enable: Setting the W bit to 1 freezes updates of the RTC registers. The user can then write

R Read Enable: Setting R bit to 1, stops clock updates to user RTC registers so that clock updates

D7 D6 D5 D4 D3 D2 D1 D0

M 10s Alarm Hours Alarm Hours

Contains the alarm value for the hours and the mask bit to select or deselect the hours value.

causes the match circuit to ignore the hours value.

D7 D6 D5 D4 D3 D2 D1 D0

M 10s Alarm Minutes Alarm Minutes

Contains the alarm value for the minutes and the mask bit to select or deselect the minutes value.

causes the match circuit to ignore the minutes value.

D7 D6 D5 D4 D3 D2 D1 D0

M 10s Alarm Seconds Alarm Seconds

Contains the alarm value for the seconds and the mask bit to select or deselect the seconds’ value.

1 causes the match circuit to ignore the seconds value.

D7 D6 D5 D4 D3 D2 D1 D0

Contains the BCD value of centuries. Lower nibble contains the lower digit and operates from 0

to 9; upper nibble contains the upper digit and operates from 0 to 9. The range for the register is

0-99 centuries.

D7 D6 D5 D4 D3 D2 D1 D0

WDF AF PF OSCF 0 CAL W R

0 without being reset by the user. It is cleared to 0 when the Flags register is read or on power up

alarm registers with the match bits = 0. It is cleared when the Flags register is read or on power up.

V

SWITCH

ms of operation. This indicates that RTC backup power failed and clock value is no longer valid.

This bit survives power cycle and is never cleared internally by the chip. The user must check for

this condition and write '0' to clear this flag.

the INT pin resumes normal operation. This bit defaults to 0 (disabled) on power up.

to RTC registers, Alarm registers, Calibration register, Interrupt register and Flags register. Setting

the W bit to 0 causes the contents of the RTC registers to be transferred to the time keeping

counters if the time has been changed (a new base time is loaded). This bit defaults to 0 on power

up.

are not seen during the reading process. Set R bit to 0 to resume clock updates to the holding

register. Setting this bit does not require W bit to be set to 1. This bit defaults to 0 on power up.

Description

Alarm - Hours

Alarm - Minutes

Alarm - Seconds

Time Keeping - Centuries

10s Centuries Centuries

Flags

. It is cleared to 0 when the Flags register is read or on power up.

Document #: 001-07103 Rev. *K Page 13 of 31

[+] Feedback

Page 14

PRELIMINARY

CY14B104K, CY14B104M

Maximum Ratings

Notes

11. Typical conditions for the active current shown on the DC Electrical characteristics are average values at 25°C (room temperature), and V

CC

= 3V. Not 100% tested.

12. The HSB

pin has I

OUT

= -2 uA for VOH of 2.4V when both active HIGH and LOW drivers are disabled. When they are enabled standard VOH and VOL are valid. This

parameter is characterized but not tested.

13. V

CAP

(Storage capacitor) nominal value is 68uF.

Exceeding maximum ratings may impair the useful life of the

device. These user guidelines are not tested.

Storage Temperature ................................. –65°C to +150°C

Maximum Accumulated Storage Time

At 150°C Ambient Temperature................................... 1000h

At 85°C Ambient Temperature..................... ........... 20 Years

Ambient Temperature with

Power Applied ............................................ –55°C to +150°C

Supply Voltage on V

Voltage Applied to Outputs

in High-Z State.......................................–0.5V to V

Input Voltage...........................................–0.5V to Vcc + 0.5V

Relative to GND ..........–0.5V to 4.1V

CC

+ 0.5V

CC

Transient Voltage (<20 ns) on

Any Pin to Ground Potential .................. –2.0V to V

CC

+ 2.0V

Package Power Dissipation

Capability (T

= 25°C) ................................................... 1.0W

A

Surface Mount Pb Soldering

Temperature (3 Seconds) .......................................... +260°C

DC Output Current (1 output at a time, 1s duration).....15 mA

Static Discharge Voltage.......................................... > 2001V

(per MIL-STD-883, Method 3015)

Latch Up Current ................................................... > 200 mA

Operating Range

Range Ambient Temperature V

Commercial 0°C to +70°C 2.7V to 3.6V

CC

Industrial –40°C to +85°C 2.7V to 3.6V

DC Electrical Characteristics

Over the Operating Range (VCC = 2.7V to 3.6V)

Parameter Description Test Conditions Min Max Unit

I

CC1

I

CC2

I

CC3

I

CC4

I

SB

I

IX

I

OZ

V

V

V

V

V

[12]

IH

IL

OH

OL

CAP

[11]

[13]

Average Vcc Current tRC = 20 ns

t

= 25 ns

RC

= 45 ns

t

RC

Values obtained without output loads (I

OUT

= 0 mA)

Commercial 65

65

50

Industrial 70

70

mA

mA

mA

mA

52

Average VCC Current

during STORE

Average VCC Current

at t

= 200 ns, 3V,

RC

25°C typical

Average V

during AutoStore

CAP

Current

Cycle

VCC Standby Current CE > (VCC – 0.2V). All others V

All Inputs Don’t Care, VCC = Max.

Average current for duration t

STORE

All I/P cycling at CMOS levels.

Values obtained without output loads (I

OUT

= 0 mA).

All Inputs Don’t Care, VCC = Max.

Average current for duration t

current level after nonvolatile cycle is complete.

STORE

< 0.2V or > (VCC – 0.2V). Standby

IN

10 mA

35 mA

5mA

5mA

Inputs are static. f = 0 MHz.

Input Leakage Current

(except HSB

)

Input Leakage Current

(for HSB

)

Off State Output

Leakage Current

= Max, VSS < V

V

CC

= Max, VSS < V

V

CC

VCC = Max, VSS < V

or WE < V

IL

< V

IN

CC

< V

IN

CC

< VCC, CE or OE > V

OUT

or BHE/BLE > V

IH

–1 +1 μA

–100 +1 μA

–1 +1 μA

IH

Input HIGH Voltage 2.0 VCC + 0.5 V

Input LOW Voltage VSS – 0.5 0.8 V

Output HIGH Voltage I

Output LOW Voltage I

Storage Capacitor Between V

= –2 mA 2.4 V

OUT

= 4 mA 0.4 V

OUT

pin and VSS, 5V Rated 61 180 μF

CAP

Document #: 001-07103 Rev. *K Page 14 of 31

[+] Feedback

Page 15

PRELIMINARY

CY14B104K, CY14B104M

Data Retention and Endurance

3.0V

OUTPUT

5 pF

R1

R2

789Ω

3.0V

OUTPUT

30 pF

R1

R2

789Ω

577Ω

577Ω

Note

14. These parameters are only guaranteed by design and are not tested.

Parameter Description Min Unit

DATA

NV

C

R

Data Retention 20 Years

Nonvolatile STORE Operations 200 K

Capacitance

In the following table, the capacitance parameters are listed.

Parameter Description Test Conditions Max Unit

C

IN

C

OUT

Input Capacitance TA = 25°C, f = 1 MHz,

Output Capacitance 7 pF

[14]

V

= 0 to 3.0V

CC

7pF

Thermal Resistance

In the following table, the thermal resistance parameters are listed.

Parameter Description Test Conditions 44 TSOP II 54 TSOP II Unit

Θ

Θ

JA

JC

Thermal Resistance

(Junction to Ambient)

Thermal Resistance

(Junction to Case)

Figure 6. AC Test Loads

[14]

Test conditions follow standard

test methods and procedures

for measuring thermal

impedance, in accordance

with EIA/JESD51.

31.11 30.73 °C/W

5.56 6.08 °C/W

AC Test Conditions

Input Pulse Levels ....................................................0V to 3V

Input Rise and Fall Times (10% - 90%)........................ <3 ns

Input and Output Timing Reference Levels.................... 1.5V

Document #: 001-07103 Rev. *K Page 15 of 31

[+] Feedback

Page 16

PRELIMINARY

CY14B104K, CY14B104M

Table 6. RTC Characteristics

Notes

15. From either V

RTCcap

or V

RTCbat.

Parameters Description Test Conditions Min Typ Max Units

[15]

I

BAK

V

RTCbat

V

RTCcap

RTC Backup Current Room Temperature (25oC) 300 nA

Hot Temperature (85

o

C) 450 nA

RTC Battery Pin Voltage 1.8 3.0 3.3 V

RTC Capacitor Pin Voltage 1.5 3.0 3.6 V

tOCS RTC Oscillator Time to Start 1 2 sec

Document #: 001-07103 Rev. *K Page 16 of 31

[+] Feedback

Page 17

PRELIMINARY

CY14B104K, CY14B104M

AC Switching Characteristics

Address

Data Output

Address Valid

Previous Data Valid

Output Data Valid

t

RC

t

AA

t

OHA

Notes

16. WE

must be HIGH during SRAM read cycles.

17. Device is continuously selected with CE

, OE and BHE / BLE LOW.

18. Measured ±200 mV from steady state output voltage.

19. If WE

is LOW when CE goes LOW, the outputs remain in the high impedance state.

20. HSB

must remain HIGH during READ and WRITE cycles.

Parameters

Cypress

Parameters

SRAM Read Cycle

t

ACE

[16]

t

RC

[17]

t

AA

t

DOE

[17]

t

OHA

[14, 18]

t

LZCE

[14, 18]

t

HZCE

[14, 18]

t

LZOE

[14, 18]

t

HZOE

[14]

t

PU

[14]

t

PD

t

DBE

[14]

t

LZBE

[14]

t

HZBE

SRAM Write Cycle

t

WC

t

PWE

t

SCE

t

SD

t

HD

t

AW

t

SA

t

HA

[14, 18,19]

t

HZWE

[14, 18]

t

LZWE

t

BW

Alt

Parameters

t

ACS

t

RC

t

AA

t

OE

t

OH

t

LZ

t

HZ

t

OLZ

t

OHZ

t

PA

t

PS

Chip Enable Access Time 20 25 45 ns

Read Cycle Time 20 25 45 ns

Address Access Time 20 25 45 ns

Output Enable to Data Valid 10 12 20 ns

Output Hold After Address Change 3 3 3 ns

Chip Enable to Output Active 3 3 3 ns

Chip Disable to Output Inactive 8 10 15 ns

Output Enable to Output Active 0 0 0 ns

Output Disable to Output Inactive 8 10 15 ns

Chip Enable to Power Active 0 0 0 ns

Chip Disable to Power Standby 20 25 45 ns

- Byte Enable to Data Valid 10 12 20 ns

- Byte Enable to Output Active 0 0 0 ns

- Byte Disable to Output Inactive 8 10 15 ns

t

WC

t

WP

t

CW

t

DW

t

DH

t

AW

t

AS

t

WR

t

WZ

t

OW

Write Cycle Time 20 25 45 ns

Write Pulse Width 15 20 30 ns

Chip Enable To End of Write 15 20 30 ns

Data Setup to End of Write 8 10 15 ns

Data Hold After End of Write 0 0 0 ns

Address Setup to End of Write 15 20 30 ns

Address Setup to Start of Write 0 0 0 ns

Address Hold After End of Write 0 0 0 ns

Write Enable to Output Disable 8 10 15 ns

Output Active after End of Write 3 3 3 ns

- Byte Enable to End of Write 15 20 30 ns

Description

20 ns 25 ns 45 ns

Min Max Min Max Min Max

Unit

Switching Waveforms

Document #: 001-07103 Rev. *K Page 17 of 31

Figure 7. SRAM Read Cycle 1: Address Controlled

[16, 17, 20]

[+] Feedback

Page 18

PRELIMINARY

CY14B104K, CY14B104M

Switching Waveforms

Address ValidAddress

Data Output

Output Data Valid

Standby

Active

High Impedance

CE

OE

BHE, BLE

I

CC

t

HZCE

t

RC

t

ACE

t

AA

t

LZCE

t

DOE

t

LZOE

t

DBE

t

LZBE

t

PU

t

PD

t

HZBE

t

HZOE

Notes

21. CE

or WE must be >VIH during address transitions.

Figure 8. SRAM Read Cycle 2: CE Controlled

[3, 16, 20]

BHE, BLE

Data Input

Data Output

Document #: 001-07103 Rev. *K Page 18 of 31

CE

WE

Figure 9. SRAM Write Cycle 1: WE

t

SA

Previous Data

t

WC

Address ValidAddress

t

SCE

t

BW

t

AW

t

PWE

t

SD

t

HZWE

High Impedance

Controlled

[3, 19, 20, 21]

t

HA

t

HD

Input Data Valid

t

LZWE

[+] Feedback

Page 19

PRELIMINARY

CY14B104K, CY14B104M

Switching Waveforms

Data Output

Data Input

Input Data Valid

High Impedance

Address Valid

Address

t

WC

t

SD

t

HD

BHE, BLE

WE

CE

t

SA

t

SCE

t

HA

t

BW

t

PWE

Data Output

Data Input

Input Data Valid

High Impedance

Address ValidAddress

t

WC

t

SD

t

HD

BHE, BLE

WE

CE

t

SCE

t

SA

t

BW

t

HA

t

AW

t

PWE

(Not applicable for RTC register writes)

Note

22. Only CE

and WE controlled writes to RTC registers are allowed. BLE pin must be held LOW before CE or WE pin goes LOW for writes to RTC register.

Figure 10. SRAM Write Cycle 2: CE Controlled

[3, 19, 20, 21]

Figure 11. SRAM Write Cycle 3: BHE and BLE Controlled

[6, 19, 20, 21, 22]

Document #: 001-07103 Rev. *K Page 19 of 31

[+] Feedback

Page 20

PRELIMINARY

CY14B104K, CY14B104M

AutoStore/Power Up RECALL

V

SWITCH

V

HDIS

V

VCCR ISE

t

STORE

t

STORE

t

HHHD

t

HHHD

t

DELAY

t

DELAY

t

LZHSB

t

LZHSB

t

HRECALL

t

HRECALL

HSB OUT

Autostore

POWER-

UP

RECALL

Read & Write

Inhibited

(

RWI)

POWER-UP

RECALL

Read & Write

BROWN

OUT

Autostore

POWER-UP

RECALL

Read & Write

POWER

DOWN

Autostore

Note

24

Note

24

Note

27

Notes

23. t

HRECALL

starts from the time VCC rises above V

SWITCH.

24. If an SRAM write has not taken place since the last nonvolatile cycle, no AutoStore or Hardware STORE takes place.

25. On a Hardware STORE, Software STORE / RECALL, AutoStore Enable / Disable and AutoStore initiation, SRAM operation continues to be enabled for time t

DELAY

.

26. Read and Write cycles are ignored during STORE, RECALL, and while VCC is below V

SWITCH.

27. HSB pin is driven HIGH to VCC only by internal 100kOhm resistor, HSB driver is disabled.

Parameters Description

[23]

t

HRECALL

t

STORE

t

DELAY

V

SWITCH

t

VCCRISE

[14]

V

HDIS

t

LZHSB

t

HHHD

Power Up RECALL Duration 20 20 20 ms

[24]

STORE Cycle Duration 8 8 8 ms

[25]

Time Allowed to Complete SRAM Cycle 20 25 25 ns

Low Voltage Trigger Level 2.65 2.65 2.65 V

VCC Rise Time 150 150 150 μs

HSB Output Driver Disable Voltage 1.9 1.9 1.9 V

HSB To Output Active Time 5 5 5 μs

HSB High Active Time 500 500 500 ns

Switching Waveforms

20 ns 25 ns 45 ns

Min Max Min Max Min Max

Figure 12. AutoStore or Power Up RECALL

Unit

[26]

Document #: 001-07103 Rev. *K Page 20 of 31

[+] Feedback

Page 21

PRELIMINARY

CY14B104K, CY14B104M

Software Controlled STORE and RECALL Cycle

t

RC

t

RC

t

SA

t

CW

t

CW

t

SA

t

HA

t

LZCE

t

HZCE

t

HA

t

HA

t

HA

t

DELAY

t

STORE/tRECALL

t

HHHD

t

LZHSB

High Impedance

Address #1 Address #6Address

CE

OE

HSB(STOREonly)

DQ (DATA)

RWI

t

RC

t

RC

t

SA

t

CW

t

CW

t

SA

t

HA

t

LZCE

t

HZCE

t

HA

t

HA

t

HA

t

DELAY

Address #1 Address #6Address

CE

OE

DQ (DATA)

t

SS

28. The software sequence is clocked with CE

controlled or OE controlled reads.

29. The six consecutive addresses must be read in the order listed in Table 1. WE

must be HIGH during all six consecutive cycles.

30. This is the amount of time it takes to take action on a soft sequence command. Vcc power must remain HIGH to effectively register command.

31. Commands such as STORE and RECALL lock out IO until operation is complete which further increases this time. See the specific command.

In the following table, the software controlled STORE and RECALL cycle parameters are listed.

Parameters Description

t

RC

t

SA

t

CW

t

HA

t

RECALL

[32, 33]

t

SS

STORE/RECALL Initiation Cycle Time 20 25 45 ns

Address Setup Time 0 0 0 ns

Clock Pulse Width 15 20 30 ns

Address Hold Time 0 0 0 ns

RECALL Duration 200 200 200 μs

Soft Sequence Processing Time 100 100 100 μs

20 ns 25 ns 45 ns

Min Max Min Max Min Max

Switching Waveforms

Figure 13. CE and OE Controlled Software STORE and RECALL Cycle

[28, 29]

Unit

[29]

Figure 14. Autostore Enable and Disable Cycle

Document #: 001-07103 Rev. *K Page 21 of 31

[+] Feedback

Page 22

PRELIMINARY

CY14B104K, CY14B104M

Hardware STORE Cycle

.

Address #1 Address #6 Address #1 Address #6

Soft Sequence

Command

t

SS

t

SS

CE

Address

V

CC

t

SA

t

CW

Soft Sequence

Command

t

CW

Notes

32. This is the amount of time it takes to take action on a soft sequence command. Vcc power must remain HIGH to effectively register command.

33. Commands such as STORE and RECALL lock out IO until operation is complete which further increases this time. See the specific command.

Parameters Description

t

DHSB

t

PHSB

HSB To Output Active Time when write latch not set 20 25 25 ns

Hardware STORE Pulse Width 15 15 15 ns

20 ns 25 ns 45 ns

Min Max Min Max Min Max

Unit

Switching Waveforms

Write latch set

HSB (IN)

HSB (OUT)

DQ (Data Out)

RWI

Write latch not set

HSB (IN)

HSB (OUT)

RWI

t

DELAY

t

PHSB

t

DELAY

t

PHSB

Figure 15. Hardware STORE Cycle

t

STORE

HSB pin is driven high to V

100kOhm resistor,

HSB driver is disabled

SRAM is disabled as long as HSB (IN) is driven low

t

DHSB

t

DHSB

[24]

t

LZHSB

t

HHHD

only by Internal

CC

[32, 33]

Figure 16. Soft Sequence Processing

Document #: 001-07103 Rev. *K Page 22 of 31

[+] Feedback

Page 23

PRELIMINARY

CY14B104K, CY14B104M

Truth Table For SRAM Operations

HSB should remain HIGH for SRAM Operations.

For x8 Configuration

CE WE OE Inputs and Outputs

H X X High Z Deselect/Power down Standby

L H L Data Out (DQ

–DQ7); Read Active

0

L H H High Z Output Disabled Active

L L X Data in (DQ

–DQ7); Write Active

0

For x16 Configuration

CE WE OE BHE BLE Inputs and Outputs

H X X X X High-Z Deselect/Power down Standby

L X X H H High-Z Output Disabled Active

L H L L L Data Out (DQ

L H L H L Data Out (DQ

L H L L H Data Out (DQ

L H H L L High-Z Output Disabled Active

L H H H L High-Z Output Disabled Active

L H H L H High-Z Output Disabled Active

L L X L L Data In (DQ

L L X H L Data In (DQ

L L X L H Data In (DQ

[2]

–DQ

DQ

8

DQ

–DQ7 in High-Z

0

DQ

–DQ

8

–DQ7 in High-Z

DQ

0

Mode Power

[2]

–DQ15) Read Active

0

–DQ7);

0

in High-Z

15

–DQ15);

8

–DQ15) Write Active

0

–DQ7);

0

in High-Z

15

–DQ15);

8

Read Active

Read Active

Write Active

Write Active

Mode Power

Document #: 001-07103 Rev. *K Page 23 of 31

[+] Feedback

Page 24

PRELIMINARY

CY14B104K, CY14B104M

Part Numbering Nomenclature

Option:

T - Tape & Reel

Blank - Std.

Speed:

20 - 20 ns

25 - 25 ns

Data Bus:

K - x8 + RTC

M - x16 + RTC

Density:

104 - 4 Mb

Voltage:

B - 3.0V

Cypress

CY14 B 104 K ZS P 20 X C T

NVSRAM

14 - AutoStore + Software STORE + Hardware STORE

Temperature:

C - Commercial (0 to 70°C)

I - Industrial (–40 to 85°C)

Pb-Free

Package:

ZS - TSOP II

P - 54 Pin

Blank - 44 Pin

45 - 45 ns

Document #: 001-07103 Rev. *K Page 24 of 31

[+] Feedback

Page 25

PRELIMINARY

CY14B104K, CY14B104M

Ordering Information

Speed

(ns)

20 CY14B104K-ZS20XCT 51-85087 44-pin TSOPII Commercial

CY14B104K-ZS20XC 51-85087 44-pin TSOPII

CY14B104K-ZS20XIT 51-85087 44-pin TSOPII Industrial

CY14B104K-ZS20XI 51-85087 44-pin TSOPII

CY14B104M-ZSP20XCT 51-85160 54-pin TSOPII Commercial

CY14B104M-ZSP20XC 51-85160 54-pin TSOPII

CY14B104M-ZSP20XIT 51-85160 54-pin TSOPII Industrial

CY14B104M-ZSP20XI 51-85160 54-pin TSOPII

25 CY14B104K-ZS25XCT 51-85087 44-pin TSOPII Commercial

CY14B104K-ZS25XC 51-85087 44-pin TSOPII

CY14B104K-ZS25XIT 51-85087 44-pin TSOPII Industrial

CY14B104K-ZS25XI 51-85187 44-pin TSOPII

CY14B104M-ZSP25XCT 51-85160 54-pin TSOPII Commercial

CY14B104M-ZSP25XC 51-85160 54-pin TSOPII

CY14B104M-ZSP25XIT 51-85160 54-pin TSOPII Industrial

CY14B104M-ZSP25XI 51-85160 54-pin TSOPII

45 CY14B104K-ZS45XCT 51-85087 44-pin TSOPII Commercial

CY14B104K-ZS45XC 51-85087 44-pin TSOPII

CY14B104K-ZS45XIT 51-85087 44-pin TSOPII Industrial

CY14B104K-ZS45XI 51-85187 44-pin TSOPII

CY14B104M-ZSP45XCT 51-85160 54-pin TSOPII Commercial

CY14B104M-ZSP45XC 51-85160 54-pin TSOPII

CY14B104M-ZSP45XIT 51-85160 54-pin TSOPII Industrial

CY14B104M-ZSP45XI 51-85160 54-pin TSOPII

All parts are Pb-free. The above table contains Preliminary information. Please contact your local Cypress sales representative for availability of these parts.

Ordering Code

Package

Diagram

Package Type

Operating

Range

Document #: 001-07103 Rev. *K Page 25 of 31

[+] Feedback

Page 26

PRELIMINARY

CY14B104K, CY14B104M

Package Diagrams

MAX

MIN.

DIMENSION IN MM (INCH)

11.938 (0.470)

PLANE

SEATING

PIN 1 I.D.

44

1

18.517 (0.729)

0.800 BSC

0°-5°

0.400(0.016)

0.300 (0.012)

EJECTOR PIN

R

G

OKE

A

X

S

11.735 (0.462)

10.058 (0.396)

10.262 (0.404)

1.194 (0.047)

0.991 (0.039)

0.150 (0.0059)

0.050 (0.0020)

(0.0315)

18.313 (0.721)

10.058 (0.396)