Page 1

INSTRUCTIONS

AND

PARTS MANUAL

CW-18

CIRCLE WELDER

Please record your equipment identication information below for future reference. This information can be found

on your machine nameplate.

Model Number

Serial Number

Date of Purchase

Whenever you request replacement parts or information on this equipment, always supply the information you

have recorded above.

LIT-CW18-IPM-0810

Telephone: 1-412-331-1776 • 1-800-245-3186 • Fax: 1-412-331-0383

CYPRESS WELDING EQUIPMENT INC.

A DIVISION OF WELD TOOLING CORPORATION

280 Technology Drive • Canonsburg, PA 15317-9564 USA

http://www.cypressweld.com

Page 2

PROTECT YOURSELF AND OTHERS FROM SERIOUS INJURY OR DEATH. KEEP

CHILDREN AWAY. BE SURE THAT ALL INSTALLATION, OPERATION, MAINTENANCE

AND REPAIR PROCEDURES ARE PERFORMED ONLY BY QUALIFIED INDIVIDUALS.

EQUIPMENT DAMAGE

ELECTRIC SHOCK can kill.

POSSIBLE.

1) The equipment is not waterproof.

Using the unit in a wet environment

may result in serious injury. Do not

touch equipment when wet or standing

in a wet location.

1) Do not plug in the power cord with

out rst verifying the equipment

is OFF and the cord input voltage is

the same as required by the machine

2) The unused connectors have power on

or serious damage may result.

them. Always keep the unused

connectors covered with the supplied

protective panels. Operation of the

machine without the protective panels

may result in injury.

2) Always verify both the pinion and

wheels are fully engaged before

applying power or equipment damage

may occur.

3) Never open the equipment without

rst unplugging the power cord or

serious injury may result.

4) Verify the customer-supplied power

connections are made in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC)

950.

5) Never remove or bypass the equip-

ment power cord ground. Verify the

equipment is grounded in accordance

with all applicable local and national

electrical safety codes. If none exist,

use International Electric Code (IEC)

950.

READ INSTRUCTIONS.

3) Do not leave the equipment

unattended.

4) Remove from the worksite and store in

a safe location when not in use.

FALLING EQUIPMENT

can cause serious

personal injury and

equipment damage.

Faulty or careless user installation is

possible. As a result, never stand or

walk underneath equipment.

MOVING PARTS can

cause serious injury.

1) Never try to stop the pinion from

moving except by removing power or

by using the STOP control.

Read the instruction manual before installing and using the equipment.

2

2) Do not remove any protective panels,

covers or guards and operate

equipment.

Page 3

HIGH FREQUENCY WARNINGS

SPECIAL PRECAUTIONS ARE REQUIRED WHEN USING PLASMA,

TIG OR ANY WELDING PROCESS THAT USES HIGH FREQUENCY

TO STRIKE AN ARC.

WARNING: HIGH FREQUENCY CAN EFFECT MACHINE

OPERATION AND THEREFORE, WELD QUALITY.

Read the precautions below before installing and using the equipment.

PRECAUTIONS:

1) Some plasma or welding cables are strong sources of high frequency interference.

NEVER lay a plasma or welding cable across the controls of the machine.

2) Always physically separate the plasma or welding cable leads from the machine

cables. For example, the plasma or welding cable leads should NEVER be bundled

with a pendant cable or the machine power cord. Maximize the separation between

any machine cables and the plasma or welding cables.

3) Strictly follow the grounding procedures specied for the plasma or welding unit.

NOTE: Some plasma and welding units produce exceptionally large amounts of

high frequency noise. They may require a grounding rod be driven into the earth

within six feet (2 meters) of the plasma or welding unit to become compatible with an

automatic cutting or welding process.

4) If the high frequency is produced using a spark gap, adjust the points so the gap is as

small as possible. The larger the gap, the higher the voltage and the higher the

interference.

5) Some plasma or welding units will inject high frequency interference into the AC

power line. Use separate power line branches whenever possible to power the plasma

or welding source and the machine. Do not plug them into the same outlet box.

6) High frequency noise may enter the machine through the plasma or welding supply

remote contactor leads. Some plasma and welding sources can produce noise spikes

of up to several thousand volts. These sources are not compatible with automated

cutting and welding equipment. It is recommended that the remote contactor leads

on these plasma or welding sources not be connected to the machine. An alternate

solution is to purchase a separate remote contactor isolation box.

3

Page 4

4

Page 5

CW-18 CIRCLE WELDER

INSTRUCTIONS AND PARTS MANUAL

TABLE OF CONTENTS

PAGE

6 ........ Introduction / Set-up and Operation

8 ........ LDC-NA3S NA-3 Wire Feeder Controls

10 ....... CWO-6210-CW18 Rotation Controls

11 ....... Technical Data / Dimensions

12 ....... CWO-1800 CW-18 Circle Welder / Parts List

13 ....... CWO-1800 CW-18 Circle Welder / Exploded View

14 ....... CWO-1800 CW-18 Circle Welder / Wiring Diagram / Electrical Component Chart

15 ....... CWO-3133 CW-11/CW-18 Collector with Power Racker

16 ....... CWO-1840 CW-18 Racking System / Exploded View / Parts List

16 ....... CWO-1690 Horizontal Racker / Exploded View / Parts List

17 ....... CWO-3165 CW-18 Housing Assembly / Exploded View / Parts List

17 ....... CWO-3205-11 7" Cam Assembly / Exploded View / Parts List

18 ....... CWO-3313 Brush Holder & Support Assembly / Exploded View / Parts List

18 ....... CWO-3359 Transmission 5:1 / Exploded View / Parts List

19 ....... CWO-3432 CW-18 Shaft Assembly / Exploded View / Parts List

19 ....... CWO-3490 Flux Hopper Assembly / Exploded View / Parts List

20 ....... CWO-3498-11 Wire Reel Assembly / Exploded View / Parts List

20 ....... CWO-3506 4066 Motor Assembly / Exploded View / Parts List

21 ....... CWO-3528 2" Flange Bearing w/Fasteners / Exploded View / Parts List

21 ....... CWO-3531 Motor & Transmission Plate Assembly / Exploded View / Parts List

22 ....... CWO-3534 Slide Bar Assembly / Exploded View / Parts List

22 ....... CWO-3537 Guard Assembly CW-18 / Exploded View / Parts List

23 ....... CWO-3538 CW-18 Camshaft & Spacer Assembly / Exploded View / Parts List

24 ....... CWO-3931 Small Brush Assembly / Exploded View / Parts List

24 ....... CWO-3969 Terminal Block Assembly / Exploded View / Parts List

25 ....... CWO-3971 Control Cable / Detail View / Parts List

25 ....... CWO-2978 Feeder Control Box Cable / Detail View / Parts List

26 ....... CWO-3974 33# Load Spring Assembly / Exploded View / Parts List

27 ....... CWO-6210-CW18 Rotation Control / Exploded View / Parts List

28 ....... CWO-6210-CW18 Rotation Control / Wiring Diagram / Electrical Component Chart

29 ....... CWO-3690-_ K231 Sub Arc Gun

30 ....... CWO-3710-_ Sub Arc Gun Assembly

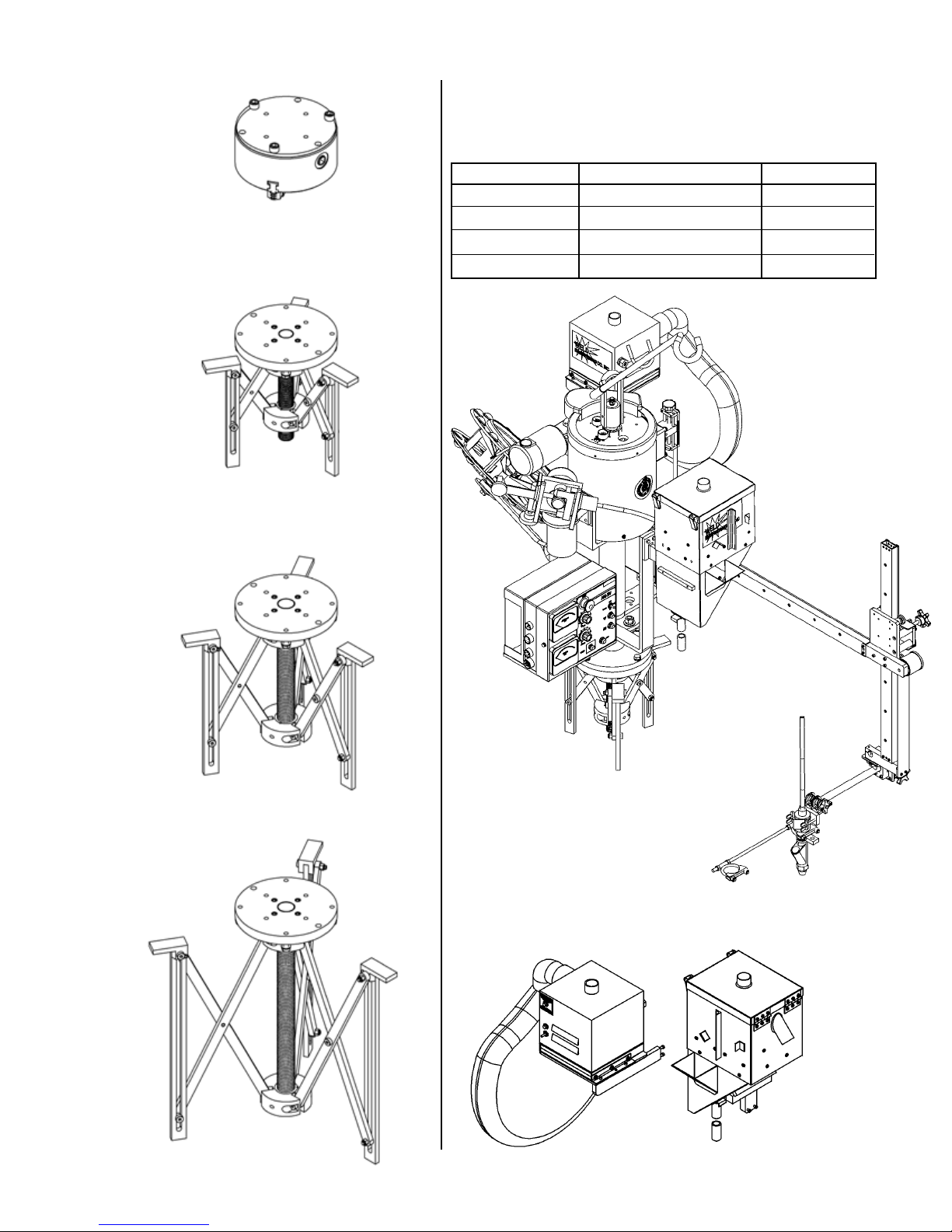

31 ....... 3-Jaw Expandable Chucks

32 ....... Optional Motorized Racking Equipment / CWO-1640-M / Exploded View / Parts List

32 ....... Optional Motorized Racking Equipment / CWP-3363 / Exploded View / Parts List

33 ....... Optional Motorized Racking Equipment / CWP-3351 / Exploded View / Parts List

34 ....... Optional Motorized Racking Equipment / PRS-1075 / Exploded View / Parts List

35 ....... Optional Motorized Racking Equipment / PRS-1100 / Exploded View / Parts List

36 ....... Optional Motorized Racking Equipment / PRS-1091-WD Wiring Diagram / Parts List

37 ....... Preventative Maintenance / CW-18 Circle Welder

40 ....... Warranty

Patents Pending

5

Page 6

INTRODUCTION

The CW-18 (CWO-1800) Circle Welder is designed for welding of nozzles into vessels or

domed heads utilizing SUB-ARC, MIG or FLUX CORED PROCESS, with gas shielding. The

CW-18 mounts on a 3-Jaw Chuck welding diameter 6” to 50” O.D.

Features:

• Wire feeder with one set of drive rolls.

• 1/12 HP P.M. motor and rotational speed control.

• 600 AMP gun & cable assembly.

• Internal to NA3

• 50 ft. (15 m) power cable.

• 50 ft. (15 m) gas shielding hose.

• 50 ft. (15 m) weld cable.

• Quick disconnects for all cables.

• Pre and post ow controls.

• Wire reel adaptor for 60 lb. (27 kg) spools.

• Adjustable vertical and horizontal torch positioning system.

• Rise and fall cam assembly with 5” (125 mm) of travel.

• Brushes and collector rings for welding current, rated at 600 AMPS 100% duty cycle.

• Brushes and collector rings for all controls, eliminates cable and hose wrap.

NA 3 Control Provides:

• Wire Spool (amperage) control

• Voltage Control

• Wire burn back

• Weld contact

• Cold wire switch

• Weld start parameter adjustment

• Weld Crater parameter adjustment

SET-UP AND OPERATION:

POWER SOURCE:

Please refer to the included Lincoln NA3 user’s manual for welding power source requirements

and system set-up.

GUNS AND CABLES:

All circle welders come equipped with a gun and cable assembly. It is our recommendation that

at least once a week the liner be taken out of the cable and soaked overnight in a solvent solution. To keep the wire moving it is also recommended that a felt clip be saturated with a product

like Ferro Slick and feed through the incoming tube of the wire feeder at least once a day.

ADDITIONAL CABLES:

The circle welders are supplied with the following cables:

1. CWO-3971 50’ (15 m) power cable that connects the power source to the cable

connector on the top gear of the machine.

2. CWO-3040 50’ (15 m) weld cable that connects the lead coming out of the top of the

machine using the quick connect connector to your power supply.

3. CWO-9406 50’ (15 m) gas shielding hose that connects the gas tting on the top of the

shaft to your shielding gas supply.

6

Page 7

SET-UP AND OPERATION CONTINUED:

WIRE SPEED AND VOLTAGE ADJUSTMENT:

The wire speed control on the front of the LDC-NA3S Wire Feed Control box has a dial that is

calibrated directly in inches per minute. Set the voltage using the control on the power source.

RISE AND FALL OF THE CAM:

All circle welders are equipped with a rise and fall cam assembly. The cam assembly must be aligned before any other

settings can be made. To align the cam rotate the machine so

the horizontal rack is parallel to the pipe, then adjust the gun

holder so it is perpendicular to the horizontal rack. Position

torch tip to top dead center of joint. Loosen the set screws in

the brass block on the cam, and rotate the cam to the vertical

position as shown. Refasten set screws.

CAM SETTING:

The cam setting is equal to distance “B” subtracted from

distance “A”.

Example:

Let A=3 and B=2

B

A

B

A

3-2=1

The cam setting is 1.

WHEEL ADJUSTMENT:

The CW-18 Racking System CWO-1840 and the Small Vertical Racker

CWO-1690 are equipped with adjustable wheels. Always check these

components for proper wheel adjustment before using the machine. The

wheels need adjustment if you can cock or wiggle the components out of

alignment. The wheels should be snug but not prohibit movement along

the path of travel. The wheels with the hex stand offs are adjustable. To

adjust the wheels, loosen the hex bolt (A) until the adjustable bushing (B)

can be rotated. Correct the wheel alignment by rotating the adjustable

bushing (B). Once adjusted, hold the adjustable bushing (B) while

tightening the hex bolt (A). Recheck alignment.

Cam

Torch

Holder

B

Pipe

A

MACHINE CONTROLS:

Operational parameters can be set using the two control boxes. Please

refer to the section in this manual entitled CWO-6210-CW18 Rotational

Control for descriptions of the various speed and directional capabilities. For the LD-NA3S NA-3 Wire

Feeder Control; refer to the supplied NA-3 Semiautomatic Wire Feeder Manual from Lincoln Electric.

MAKING A WELD:

1. Position the gun to start position using the CWO-1840 Racking System.

2. Connect the ground cable to the workpiece. The ground cable must make good electrical

contact with the work.

3. Position the electrode in the joint. The end of the electrode may be lightly touching the

work.

4. With manual/auto switch in the “OFF” position, set rotation direction and speed.

5. Weld process and rotation are both started by throwing the manual/auto switch to auto.

6. Weld process and rotation are stopped by throwing the manual/auto switch to “OFF”.

7

Page 8

LDC-NA3S NA-3 WIRE FEEDER CONTROLS

A

B

C

J

I

H

G

F

A. Ammeter

B. Circuit breaker

C. Voltmeter

D E

D. Start

E. Stop

F. Inch up and inch down

G. Current control

H. Travel

I. Voltage control

J. Control power

8

Page 9

LDC-NA3S NA-3 WIRE FEEDER CONTROLS, CONT’D.

NOTE: For further information refer to Lincoln Electric NA-3 Operator’s Manual.

A. AMMETER

Indicates current only while welding.

B. CIRCUIT BREAKER

Protects the circuit from sever wire feed motor overload and short circuits. Press to reset.

Locate and correct the cause for overload.

C. VOLTMETER (Standard)

Indicated welding voltage only while welding. Also indicates OCV below 60 volts.

D. START

Push-button beings the welding cycle

E. STOP

Push-button initiated the stopping cycle at the end of the weld.

F. INCH UP & INCH DOWN

Press to inch electrode at the speed set by “Inch Speed” control on inner panel.

G. CURRENT CONTROL

Adjusts wire feed speed to control welding current.

H. TRAVEL

Turn to “Off” for no travel; “Hand Travel” for travel without welding; “Automatic Travel” for

welding operations. Speed and direction of travel are controlled by the travel mechanisms

control.

I. VOLTAGE CONTROL

Adjust arc volts by controlling power source output voltage.

J. CONTROL POWER

Turns input control power “On” and “Off”. Also used as an emergency “Off” in case of

malfunction.

*For further information on NA-3 Wire Feeder and controls, refer to Lincoln Electric NA-3

Wire Feeder Operators Manual.

9

Page 10

CWO-6210-CW18 ROTATION CONTROLS

Speed Control

Travel Direction

On/Off Switch

Pilot Light

SPEED CONTROL:

Controls the speed in which the machine travels. The depicted lines 0 to 100 should not be construed as inches per minute of travel. They should be considered as reference points only.

TRAVEL DIRECTION:

Controls the direction in which the machine will travel. Select forward for clockwise rotation,

brake for stop, and reverse for counterclockwise rotation.

ON/OFF SWITCH:

The on/off switch enables/disables power to the rotation control box.

PILOT LIGHT:

The pilot light indicates whether the machine is on/off as dictated by the on/off switch.

10

Page 11

TECHNICAL DATA

Input Voltage: 0-600 amps

Amperage: 115 VAC

Voltage: 0-50

Wire Sizes: 1/16’’-7/32’’ (1.6-5.6 mm)

Rotation Speed: .06-.72 rpm

Cam Range: 0’’-7’’ (0-175 mm)

Welding Radius: 0’’-25” (0-635 mm)

Shielding Gas: Solenoid Control

Height: 43’’ (1092 mm)

Net Weight: 360 lbs. (163.6 kg)

Shipping Weight: 490 lbs. (222.3 kg)

DIMENSIONS:

36”

(914 mm)

70”

(1778 mm)

43”

(1092 mm)

36.5”

(927 mm)

11

Page 12

CWO-1800 CW-18 CIRCLE WELDER / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-1123 CONTROL MT. SPACER BLOCK

2 1 CWO-1124 CW-18 CONTROL MT. PLATE

3 1 CWO-1690 LARGE HORIZONTAL RACK

4 1 CWO-1811 NA-3S MOUNT PLATE

5 1 CWO-1812 FLUX HOPPER SUPPORT

6 1 CWO-1813 WIRE FEEDER BRACKET

7 1 CWO-1814 INSULATOR PLATE

8 1 CWO-3133 COLLECTOR, CW-11/CW-18

9 1 CWO-1816 WIRE FEEDER ADAPTOR

10 1 CWO-3931 BRUSH RETAINER ASSEMBLY

11 1 CWO-1840 CW-18 RACKING SYSTEM

12 1 CWO-2020 FLUX RECOVERY SYSTEM (OPTIONAL)

13 1 CWO-3165 CW-18 HOUSING ASSEMBLY

14 1 CWO-3205-11 7’’ CAM ASSEMBLY CW-18

15 1 CWO-3218 CABLE SUPPORT BAR

16 1 CWO-3312 LIFTING LUG WELDMENT

17 1 CWO-3313 BRUSH HOLDER & SUPPORT

18 1 CWO-3359 TRANSMISSION SW-5:1 ASSEMBLY

19 1 CWO-3432 CW-18 SHAFT ASSEMBLY

20 1 CWO-3498-11 WIRE REEL ASSEMBLY CW-18

21 1 CWO-3506 4066 MOTOR ASSEMBLY

22 2 CWO-3528 2’’ FLANGE BEARING W/ FASTENERS

23 1 CWO-3531 MOTOR & TRANSMISSION PLT. ASSEMBLY

24 1 CWO-3534 SLIDE BAR MOUNTING ASSEMBLY

25 1 CWO-3537 GUARD ASSEMBLY CW-18

26 1 CWO-3538 CW-18 CAMSHAFT & SPACER ASSEMBLY

27 1 CWO-3690-5/32 SUB-ARC NOZZLE

28 1 CWO-3695-1/2 ADAPTOR K231 1/2’’

29 1 CWO-3697 QCC 72’’ LINER

30 1 CWO-3968 CW-18 BASE PLATE

31 1 CWO-3969 TERMINAL BLOCK ASSEMBLY

32 1 CWO-4900 33# LOAD SPRING

33 1 CWO-5074 1-1/2’’ ID TRANTORQUE

34 1 CWO-5793 GEAR ALUMINUM

35 1 CWO-6210-CW18 M-14 ROTATION CONTROL

36 1 LDC-0010 NA-3 WIRE FEEDER ASSEMBLY

37 1 LDC-NA3S NA-3S WIRE FEEDER CONTROL

38 1 CWO-1820 FLUX HOPPER SUPPORT ASSEMBLY

12

Page 13

CWO-1800 CW-18 CIRCLE WELDER / EXPLODED VIEW

15

16

12

21

20

37

32

23

36

25

34

33

10

8

14

18

26

31

17

22

3

6

7

9

13

24

1

22

38

5

4

12

2

35

29

28

12

19

27

30

13

Page 14

CWO-1800 CW-18 CIRCLE WELDER / WIRING DIAGRAM / ELECTRICAL

COMPONENT CHART

1

4

5

13

14

9

14

8

3

7

6

11

ELECTRICAL COMPONENT CHART

ITEM DESCRIPTION PART NUMBER

1 NA-3 Wire Feeder LDC-0010

2 Weld Cable 4/0 50’ CWO-3040

3 Collector for CW-11/CW-18 CWO-3133

4 Brush Holder Support CWO-3313

5 4006 Motor Assy. CWO-3506

6 NA-3 Wire Feeder Control LDC-NA3S

7 Small Retainer Brush CWO-3931

8 Terminal Block Assy. CWO-3969

9 Weld Cable 4/0 CWO-3970

10 Weld Cable Inlet 4/0 CWO-3972

11 Feeder Control Box Cable CWO-2978

12 M-14 Rotational Control CWO-6210-CW18

13 K231 Sub Arc Gun CWO-3710-_

14 Weld Cable 4/0 6’ CWO-3970-72

12

10

2

Page 15

CWO-3133 CW-11/CW-18 COLLECTOR WITH POWER RACKER

14, 21

9, 18, 22

15

6

2

4

3

10

5

19

8

7

13, 17 (4X)

23

12, 16 (4X)

1

11

15

ITEM QTY PART NUMBER DESCRIPTION

1 1 BUG-1034 PANEL CONNECTOR 4-T, M

2 12 CWO-3127 BRASS RING 4.250’’ DIA X .188’’ THK

3 1 CWO-5739 BRASS RING 4.250’’ DIA X 3.750 THK

4 13 CWO-5744 MICARTA SPACER

5 1 CWO-5745 TOP COLLECTOR PLATE

6 1 CWO-5746 CB-2 BOTTOM COLLECTOR PLATE

7 1 CWO-5747 MICARTA SPACER W/NOTCH

8 1 CWO-5758 MICARTA SLEEVE .495’’ O.D. X 391’’ I.D. X 4.500’’ LG

9 2 CWO-5760 MICARTA SLEEVE .495’’ O.D. X .391 I.D. X 8.000’’ LG

10 1 CWO-5770 MICARTA SLEEVE 1.875’’ O.D. X 1.5000’’ I.D. X 7.750’’ LG

11 1 CWO-6068 PANEL CONNECTOR 9-T, M

12 4 FAS-0205 RND HD SCR 4-40 X 1/2’’

13 4 FAS-0215 RND HD SCR 6-32 X 1/2’’

14 1 FAS-0397 HEX HD CAP SCR 3/8-16 X 3/4’’

15 4 FAS-0455 SET SCR 1/4-20 X 1/2’’ CUP POINT

16 4 FAS-1305 HEX NUT 4-40

17 4 FAS-1310 HEX NUT 6-32

18 2 FAS-3397 HEX HD CAP SCR 3/8-16 X 8-1/2’’

19 1 TERM-5494 #8 RING, RED

20 1 W05-2025 GREEN WIRE 20 GA 2-1/2’’

21 1 WAS-0260 3/8’’ WASHER

22 2 WAS-0262 3/8’’ SPLIT LOCKWASHER

23 140’’ WRE-1601 16 AWG. WHITE TEFLON

15

Page 16

CWO-1840 CW-18 RACKING SYSTEM / EXPLODED VIEW / PARTS LIST

2

1

ITEM QTY PART NUMBER DESCRIPTION

3

6

1 1 ABR-1050 V-GUIDE WAYS 40”

2 1 ABR-1060 V-GUIDE WAYS 33”

3 1 CWO-1675 VERTICAL RACKER

4 1 CWO-1695 ATTACHMENT BLOCK

5 1 CWO-3023-S TORCH ANGLE ADJUSTER

6 1 CWO-3460 33# LOAD SPRING ASSY.

4

5

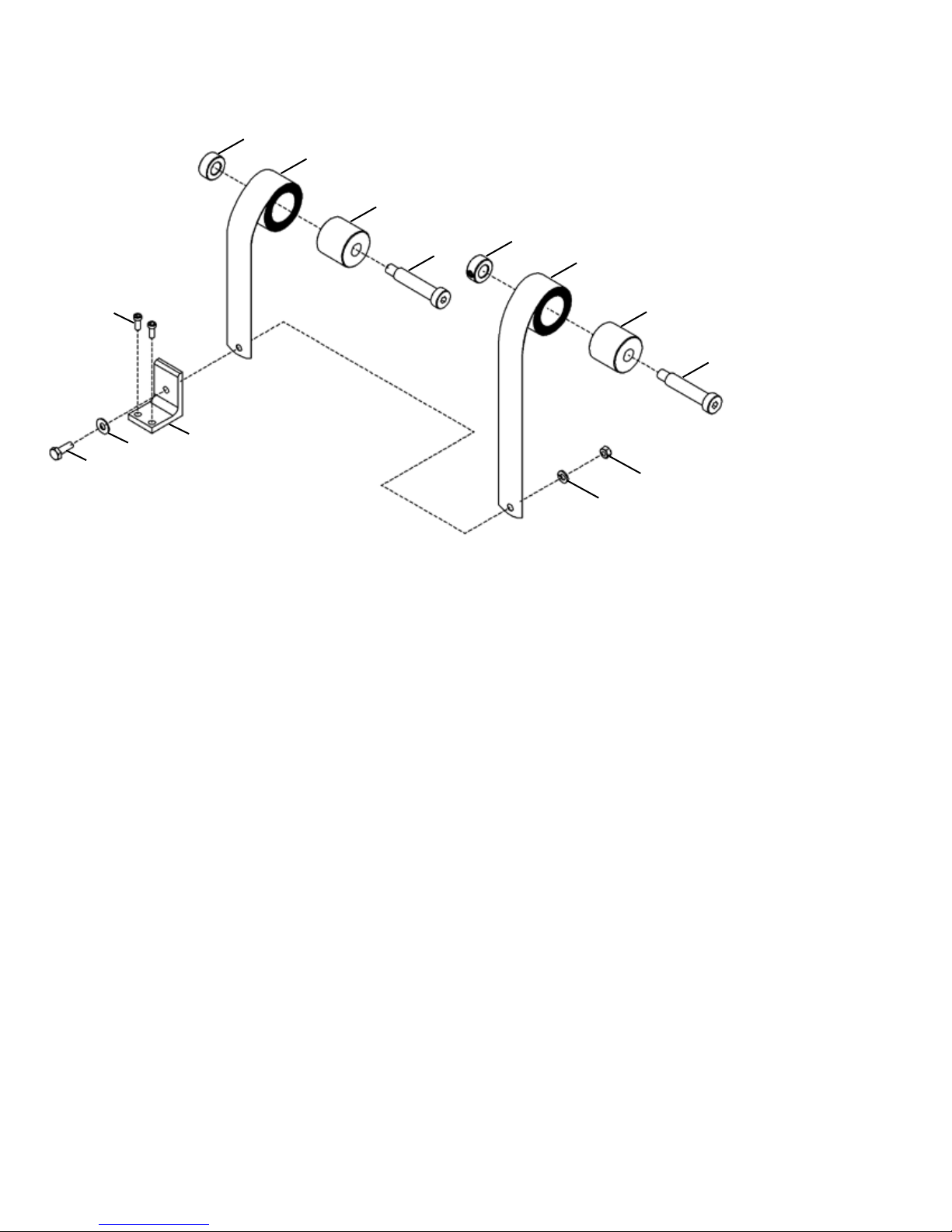

CWO-1690 HORIZONTAL RACKER / EXPLODED VIEW / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1 BUG-2032 KNOB, BLACK

2 1 CWO-1671 RACKER SHIELD

3 1 CWO-1678 RACKER PLATE

4 1 CWO-1679 PINION 11T

5 2 CWO-1680 W2 FIXED LEG & WHEEL ASSY.

6 2 CWO-1681 W2 ADJ. LEG & WHEEL ASSY.

7 1 CWO-1687 MOUNT PLATE (LARGE RACKER)

8 2 CWO-4326 FIXED LEG & WHEEL ASSY.

9 2 CWO-4327 ADJ. LEG & WHEEL ASSY.

10 2 FAS-0559 SOC HD CAP SCR 1/4-20 X 1”

11 1 FAS-1307 HEX JAM NUT 3/4-16

12 1 MUG-1141 BEARING COLLET

13 1 MUG-1142 KNOB, LOCKING

14 1 MUG-1144 SHAFT

15 2 MUG-1453 STAND-OFF

16 1 MUG-1579 RETAINING RING

17 3 WAS-0240 1/4” SAE WASHER

F= FIXED WHEEL PLACEMENT

7

A= ADJUSTABLE WHEEL PLACEMENT

1

16

13

14

12

11

10

17

2

3

A

F

6

A

15

5

F

4

A

16

9

F

A

8

F

Page 17

CWO-3165 CW-18 HOUSING ASSEMBLY / EXPLODED VIEW / PARTS LIST

1

5

8

4

3

2

6

7

5

8

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-4133 1/4-18 NPSM HEX PLUG, BRASS

2 1 CWO-5842 CENTER TUBE HOUSING, CW-18

3 1 CWO-5845 TOP HOUSING PLATE, CW-18

4 1 CWO-5853 LOWER HOUSING PLATE, CW-18

5 2 CWO-5980 PLASTIC BUSHING

6 3 CWO-9339 ANGLE FOR GUARD

7 3 FAS-0535 SOC HD CAP SCR 10-24 X 1/2”

8 8 FAS-0548 SOC HD CAP SCR 10-32 X 3/4” LOW HEAD

CWO-3205-11 7" CAM ASSEMBLY / EXPLODED VIEW / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 2 BUG-2098 DELRIN WASHER 3/8”

2 1 BUG-9012 LOCKING COLLAR

3 2 CWO-4027 END PLATE 4” CAM

4 1 CWO-4330 CENTER BLOCK .625” BORE

5 1 CWO-4032 KNOB

6 1 CWO-4328 BASE PLATE ROD

7 1 CWO-4331 SCREW ROD

8 2 CWO-4332 ROD

9 1 CWO-5199 SCALE

10 4 FAS-0434 SET SCR #10-24 X 3/8”

11 1 FAS-0444 SET SCR #10-32 X 3/8”

12 2 FAS-0495 SET SCR 3/8”-16 X 1/2”

13 4 FAS-0534 SOC HD CAP SCR #10-24 X 3/8”

12

10

3

7

11

10

3

4

6

2

1

8

1

9

5

13

17

Page 18

CWO-3313 BRUSH HOLDER & SUPPORT ASSEMBLY / EXPLODED VIEW /

PARTS LIST

2

9

8

2

2

1

10

11

12

1

4

1

3

5

6

5

12

13

7

ITEM QTY PART NUMBER DESCRIPTION

1 3 CWO-4046 LARGE BRUSH HOLDER

2 6 CWO-4337 LARGE BRUSH 1-1/2” X 3/4” X 2”

3 1 CWO-4472 BRUSH HOLDER SUPPORT CW-18

4 1 CWO-4473 ATTACHMENT BAR CW-18

5 2 CWO-5548 MICARTA SPACER

6 1 CWO-5549 MICARTA BUSHING

7 1 FAS-0305 HEX HD CAP SCR 1/2-13 X 2”

8 1 FAS-0309 HEX HD CAP SCR 1/2-13 X 1”

9 4 FAS-0357 HEX HD CAP SCR 1/4-20 X 3/4”

10 1 FAS-3304 HEX HD CAP SCR 1/2-13 X 4”

11 4 WAS-0243 1/4” SPLIT LOCKWASHER

12 3 WAS-0280 1/2” SAE WASHER

13 3 WAS-0281 1/2” SPLIT LOCKWASHER

CWO-3359 TRANSMISSION 5:1 / EXPLODED VIEW / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-4347 TRANSMISSION 5:1

2 4 FAS-0359 HEX HD CAP SCR 1/4-20 X 1”

3 4 FAS-1351 1/4-20 HEX NUT

4 4 WAS-0240 1/4” SAE WASHER

5 4 WAS-0243 1/4” LOCK WASHER

6 1 UNI-1024 SLAVE PINION

1

4

2

18

5

3

6

Page 19

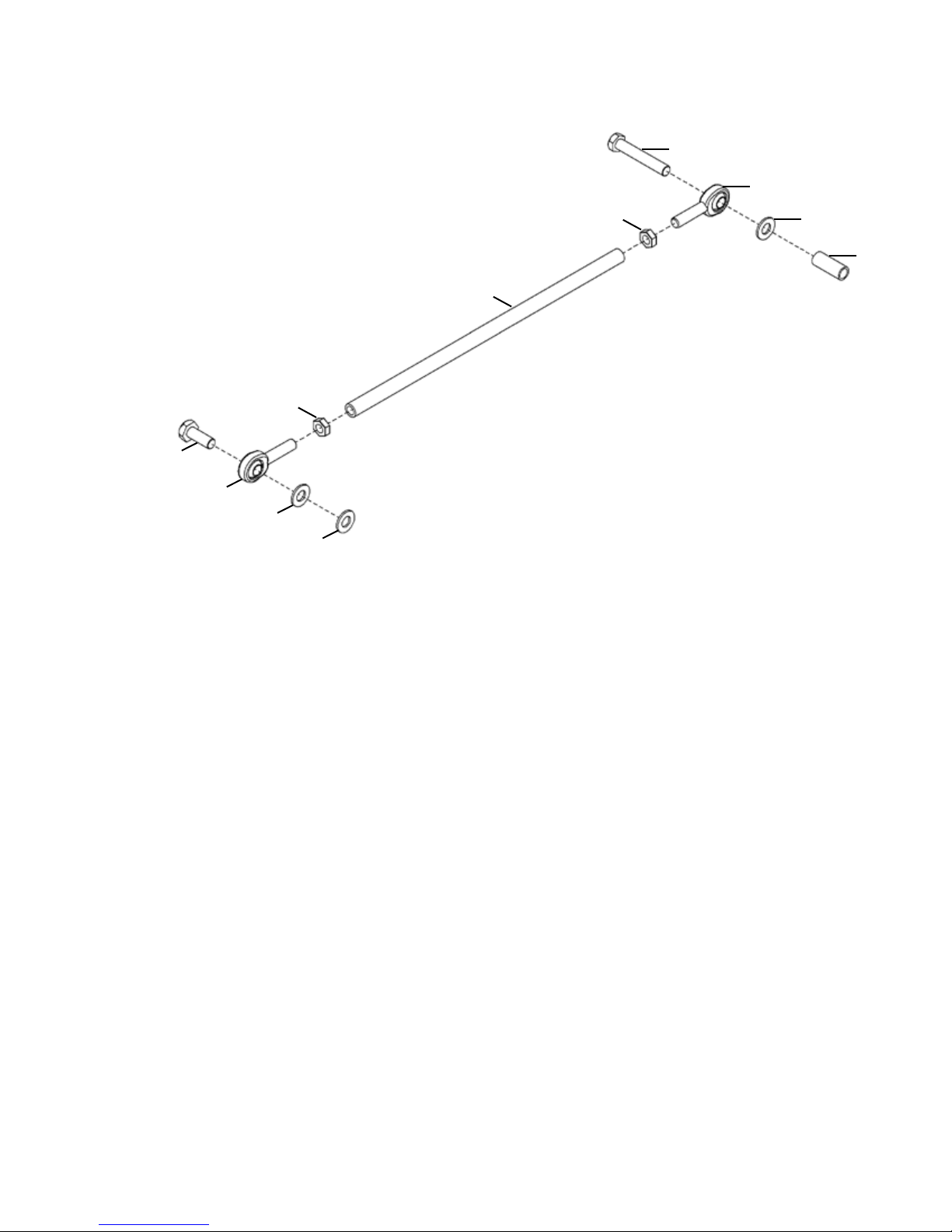

CWO-3432 CW-18 SHAFT ASSEMBLY / EXPLODED VIEW / PARTS LIST

1

2

3

2

ITEM QTY PART NUMBER DESCRIPTION

1 1 BUG-9096 OUTLET BUSHING, OXYGEN

2 2 CWO-4507 O-RING, OXYGEN, GAS

3 1 CWO-5779 SHAFT CW-18

CWO-3490 FLUX HOPPER ASSEMBLY / EXPLODED VIEW / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-3757 HOPPER SUPPORT ROD

2 1 CWO-3760 CLAMP BLOCK 1/2”

3 1 CWO-3478 1-3/4” HOSE BARB

4 1 CWO-3769 FLUX HOPPER STEEL 12”

5 1 GOF-3019 HANDLE W/ BOLTS

N/S 1 CWO-3491-48 FLUX HOSE 3/4” ID X 1” OD X 48” LG

5

2

4

1

3

19

Page 20

CWO-3498-11 WIRE REEL ASSEMBLY / EXPLODED VIEW / PARTS LIST

1

ITEM QTY PART NUMBER DESCRIPTION

1 1 BUG-3293 REEL, 60 LBS.

2 1 CWO-3217-11 WIRE REEL SUPPORT ASSEMBLY CW18

3 2 FAS-1301 HEX NUT 1/2-13

4 2 FAS-2305 HEX HD CAP SCR 1/2-13 X 1-3/4”

5 2 WAS-0281 1/2” LOCK WASHER

4

2

5

3

CWO-3506 4066 MOTOR ASSEMBLY / EXPLODED VIEW / PARTS LIST

2

6

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-3620 MOTOR MOUNT BRACKET

7

5

2 1 CWO-4846 RIGHT ANGLE DC MOTOR

4066

3 1 CWO-5767 GEAR PM MOTOR 147

4 1 FAS-0453 SET SCR 1/4-20 X 1/4”

5 4 FAS-0559 SOC HD CAP SCR 1/4-20 X 1”

4

3

1

20

6 3 TERM WTE 1508 #8 FORK, BLUE

7 4 WAS-0243 1/4” SPLIT LOCK WASHER

Page 21

CWO-3528 2” FLANGE BEARING w/FASTENERS / EXPLODED VIEW / PARTS

LIST

2

5

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-1511 1/8” PIPE PLUG BLACK IRON

2 1 CWO-4482 FLANGE BEARING 2” BORE

3 2 FAS-1398 9/16-12 HEX NUT

4 2 FAS-3305 HEX HD CAP SCR 9/16-12 X 2”

5 2 WAS-0290 9/16” SAE WASHER

6 2 WAS-0291 9/16” SPLIT LOCK WASHER

6

1

3

CWO-3531 MOTOR & TRANSMISSION PLATE ASSEMBLY / EXPLODED VIEW

/ PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1 BUG-1338 I.D. PLATE

2 1 CWO-5788 COVER PLATE

3 1 CWO-5887 MOTOR & TRANSMISSION PLATE

4 1 CWO-5888 END PLATE

5 5 FAS-0359 HEX HD CAP SCR 1/4-20 X 1”

6 8 FAS-1390 HEX NUT 3/8-16

7 3 FAS-2372 HEX HD CAP SCR 5/16-18 X 1-1/4”

8 2 FAS-2374 HEX HD CAP SCR 5/16-18 X 1-3/4”

9 4 FAS-2398 HEX HD CAP SCR 3/8-16 X 3”

10 5 WAS-0243 1/4” SPLIT LOCK WASHER

11 5 WAS-0251 5/16” SLPIT LOCK WASHER

12 4 WAS-0260 3/8” WASHER

13 8 WAS-0262 3/8” SPLIT LOCK WASHER

5

4

6

6

5

7

5

3

2

9

1

7

8

8

7

21

Page 22

CWO-3534 SLIDE BAR ASSEMBLY / EXPLODED VIEW / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-3912 SLIDE BAR ASSEMBLY

2 2 CWO-9033 TOP / BOTTOM VERTICAL SLIDE

PLATE

3 2 FAS-0399 HEX HD CAP SCR 3/8-16 X 1”

4 4 FAS-2372 HEX HD CAP SCR 5/16-18 X

1-1/4”

4

5

2

5 4 WAS-0251 5/16” SPLIT LOCKWASHER

6 2 WAS-0262 3/8” SPLIT LOCKWASHER

1

2

6

3

CWO-3537 GUARD ASSEMBLY CW-18 / EXPLODED VIEW / PARTS LIST

1

3

5

2

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-5094 UPPER GUARD CB-2, CB-3, CW-7, CW18

2 1 CWO-9142 LOWER GUARD CW-18

3 4 FAS-1376 RIVET 1/8” DIA X 3/8”

4 3 FAS-1455 T.C. SLT HEX 1/4-20 X 1/4” w/WASHER

5 4 FAS-0261 3/8” WASHER / .056 THK

4

22

Page 23

CWO-3538 CW-18 CAMSHAFT & SPACER ASSEMBLY / EXPLODED VIEW /

PARTS LIST

8

1

7

9

3

4

6

5

2

9

9

ITEM QTY PART # DESCRIPTION

1 1 CWO-4352 BALL JOINT END 3/8-16 R.H.

2 1 CWO-5042 BALL JOINT END 3/8-16 L.H.

3 1 CWO-9081 SPACER CW-18

4 1 CWO-9353 PIPE FOR CAM SHAFT CW-18

5 1 FAS-0399 HEX HD CAP SCR 3/8-16 X 1”

6 2 FAS-1395 HEX NUT 3/8-24

7 1 FAS-1396 HEX NUT 3/8-24 LH

8 1 FAS-2396 HEX HD CAP SCR 3/8-16 X 2-1/4”

9 3 WAS-0260 3/8” SAE WASHER

23

Page 24

CWO-3931 SMALL BRUSH ASSEMBLY / EXPLODED VIEW / PARTS LIST

1

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWO-3947 12 POSITION SMALL BRUSH ASSY

1

2 12 CWO-5831 1/8” x 1/8” x 1/8” BRUSH

3 12 CWO-5874 1/8” BRUSH HOLDER

4 12 CWO-5875 CAP

5 12 CWO-5876 CLIP

6 1 CWO-9067 SMALL BRUSH RETAINER BLOCK, CW18

7 1 CWO-9082 RETAINER SUPPORT

8 2 FAS-0359 SOC HD CAP SCR 10-24 X 1”

9 1 FAS-0593 SOC HD CAP SCR 3/8-16 X 1-1/2”

10 12 TERM-WTE-1508 #8 FORK, BLUE

11 1 WAS-0260 3/8” SAE WASHER

12 1 WAS-0262 3/8” SPLIT LOCKWASHER

7

8

CWO-3931 SMALL RETAINER BLOCK

11

12

9

ASSEMBLY / DETAIL VIEW

6

2, 3, 4, 5

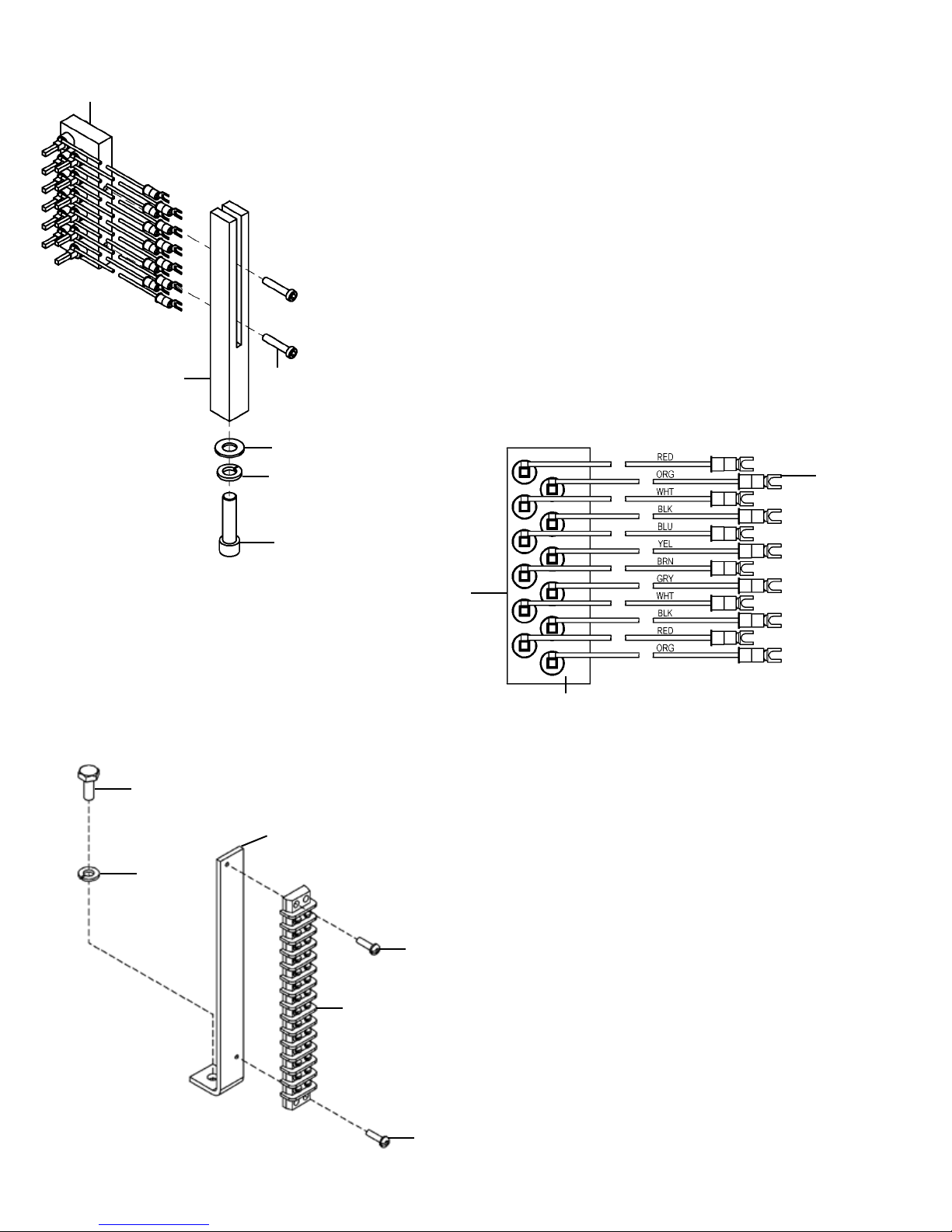

CWO-3969 TERMINAL BLOCK ASSEMBLY / EXPLODED VIEW / PARTS LIST

4

ITEM QTY PART NUMBER DESCRIPTION

2

5

1 1 CWO-6726 TERMINAL BLOCK 14-PIN

2 1 CWO-9071 TERMINAL BLOCK

SUPPORT CW-18

3 2 FAS-0215 RND HD SCR 6-32 X 1/2”

4 1 FAS-0356 HEX HD CAP SCR 1/4-20 X 5/8”

10

24

5 1 WAS-0243 1/4” SPLIT LOCK WASHER

3

1

3

Page 25

CWO-3971 CONTROL CABLE / DETAIL VIEW / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 600” 900-4-016 16/10 SO CABLE

2 1 BUG-5552-B CABLE CLAMP

3 1 BUG-6069-P CABLE CONNECTOR 9-T, F

4 9 TERM-WTE-0602 #6 FORK, BLUE

CWO-2978 FEEDER CONTROL BOX CABLE / DETAIL VIEW / PARTS LIST

ITEM QTY PART NUMBER DESCRIPTION

1 32” 900-4-016 16/10 SO CABLE

2 1 BUG-5552-B CABLE CLAMP

3 1 BUG-6069-P CABLE CONNECTOR 9-T, F

4 9 TERM-WTE-0602 #6 FORK, BLUE

25

Page 26

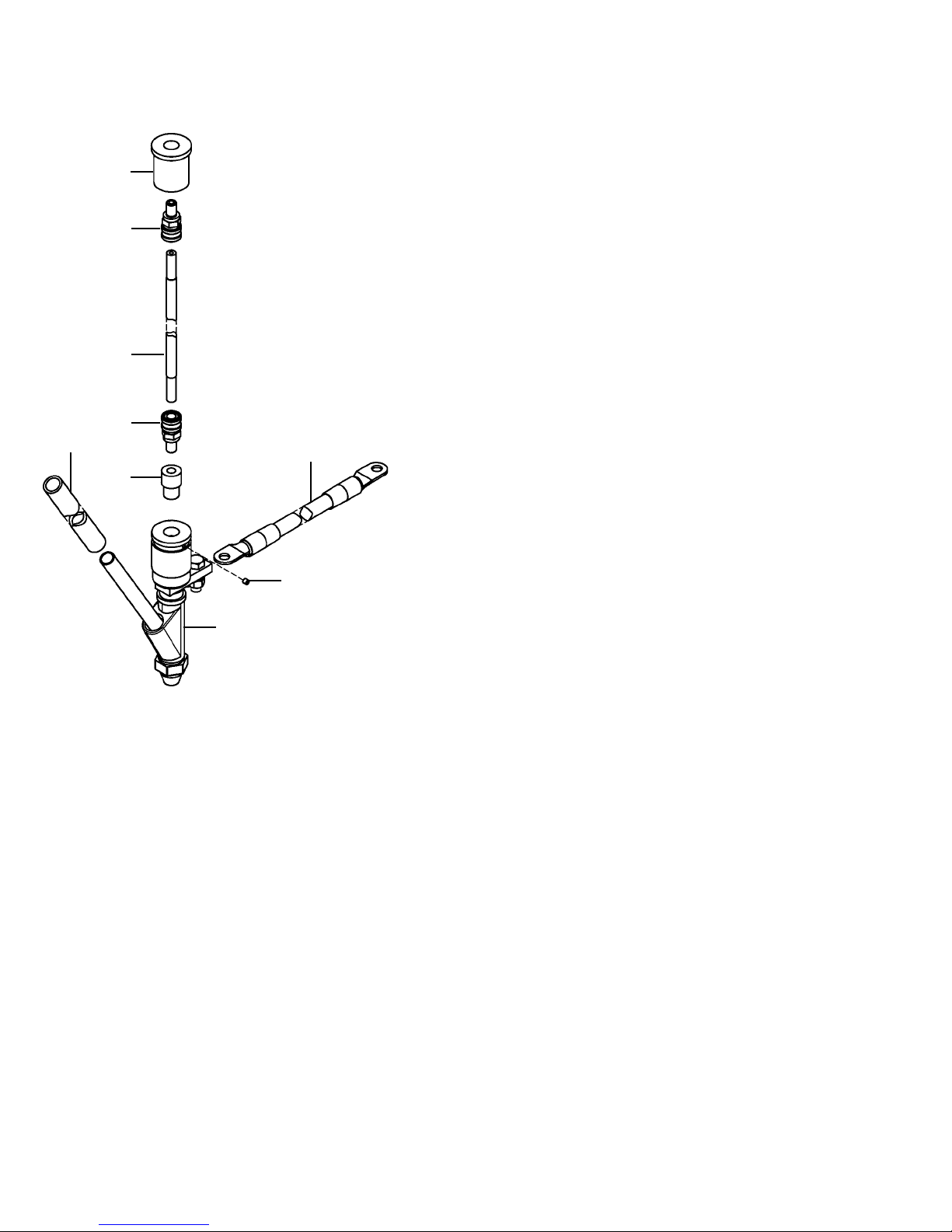

CWO-3974 33# LOAD SPRING ASSEMBLY / EXPLODED VIEW / PARTS

2

1

3

2

8

1

6

9

5

4

10

3

7

ITEM QTY PART # DESCRIPTION

1 2 CWO-4074 SPRING 16.5#

2 2 CWO-5707 COLLAR W/ SET SCREW

3 2 CWO-5773 INSERT 1-1/2” OD

4 1 CWO-9230 SPRING RETAINER ANGLE

5 1 FAS-0357 HEX HD CAP SCR 1/4-20 X 3/4”

6 2 FAS-0555 SOC HD CAP SCR 1/4-20 X 1/2”

7 1 FAS-1351 HEX NUT 1/4-20

8 2 FAS-2697 SOC HD SHR 1/2 X 2 X 3/8-16

9 1 WAS-0240 1/2 SAE WASHER

10 1 WAS-0243 1/4” SPLIT LOCK WASHER

8

26

Page 27

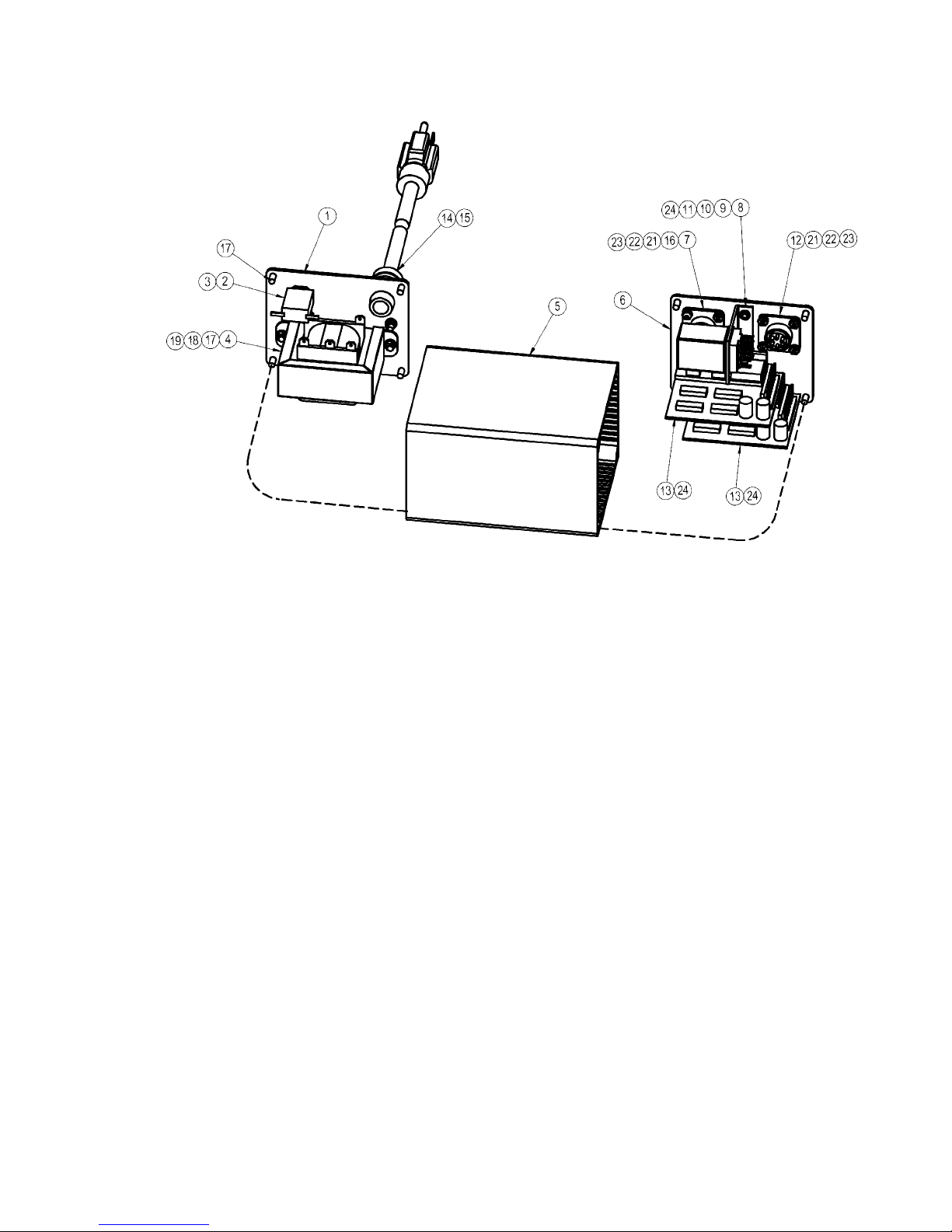

CWO-6210-CW18 ROTATION CONTROL / EXPLODED VIEW / PARTS LIST

3

20 (x3)

2

13,14,21

23

8

13

13

19

(x10)

29

22

12

6 (x2)

15, 17

14

15, 16

21

29

11

24

10

21

14

18

1

9

ITEM QTY PART NUMBER DESCRIPTION

1 1 ARM-2279 Toggle Switch

2 1 BUG-9445 Power Cord

3 1 CON-PS04M Plug, Straight 4-Pin Male

4 1 BUG-9687 Knob Fluted

5 1 BUG-9694 Knob

6 2 CSR-WTE-1597 Cord Strain Relief

7 1 CWO-6216 Rotation Box Front Panel

8 1 CWO-5547B Rotation Box Rear Panel

9 1 CWO-6206 Indicator Light

10 1 CWO-6527 0-90V Spd Ctrl w/Isolator

11 1 CWO-6839 Rotation Control Case

12 1 CWO-6802 Rotation Box Cover

13 6 FAS-0115 #6-32 x 1/2” Pan Head Zinc

14 6 FAS-1310 Hex Nut 6-32

15 2 FHO-0188 Fuse Holder

16 1 MPD-1026 Fuse 2 Amp

17 1 FUS-0257 Fuse 3 Amp

18 1 MUG-1258-1 Rotary Switch Assembly

19 10 SCW-WTE-0264 #6-32 x 1/4” Sht Mt Scr

20 3 TERM-WTE-0197 #6 Red Fork

21 6 WAS-0211 #6 Internal Star Washer

22 42’’ WRE-WTE-0501 18/3 SJO 300V Cord

23 1 MUG-1589 Hole Plug .500’’

24 1 BUG-1562 Multi-turn Potentiometer

25 4 FAS-0401 #4-40 X 3/8’’ Pan Hd

26 4 SCF-1001 #4-40 Self Clinching Nut

27 1 BUG-1764 Meter Display Board

28 1 MDS-1011 Display Bezel

29 6 BUG-3331 Hole Plug 1/4’’

21, 14, 13

7

27

4

5

28

25, 26 (x4)

27

Page 28

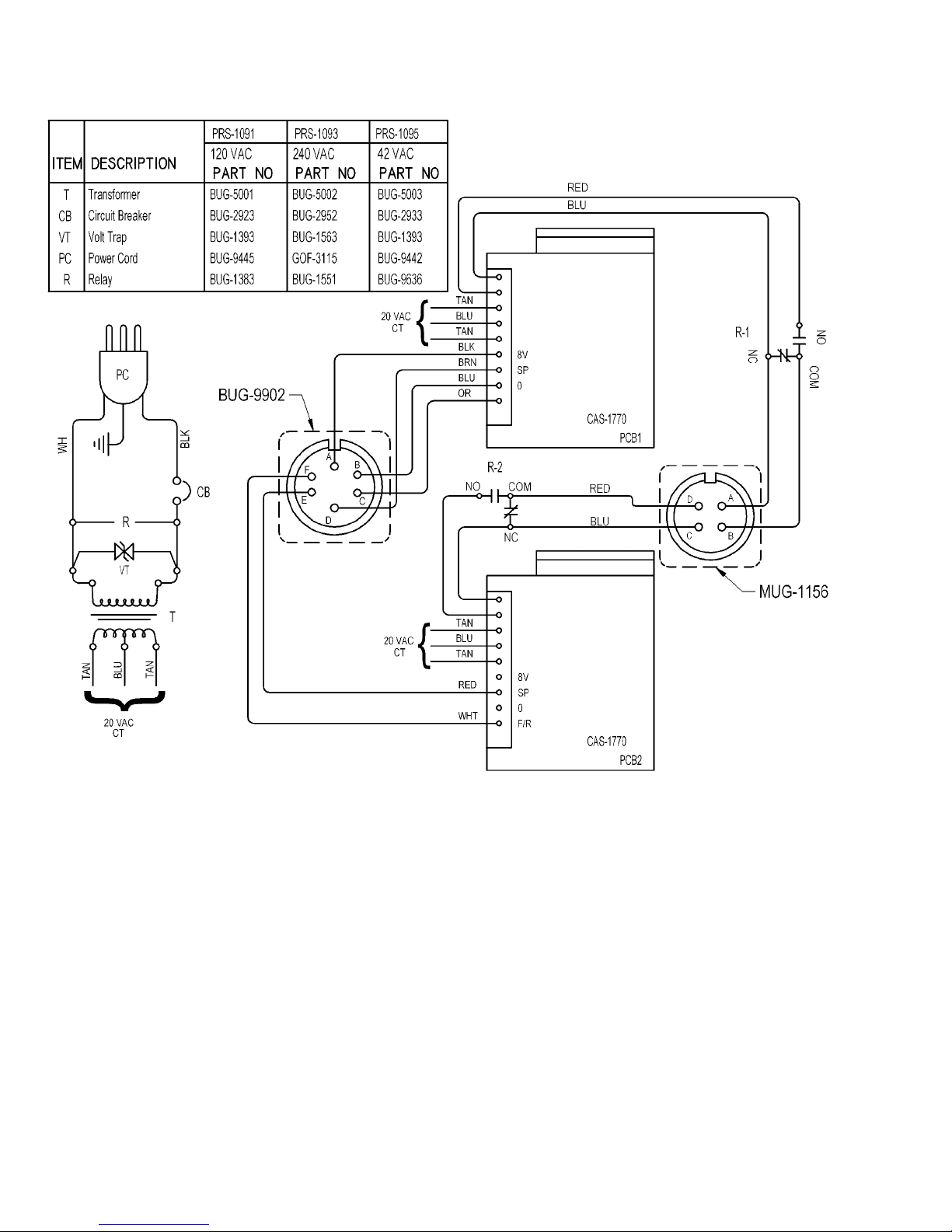

CWO-6210-CW18 ROTATION CONTROL / WIRING DIAGRAM / ELECTRICAL

COMPONENT CHART

3

6

2

4

5

= INDICATES ITEMS THAT ARE SUPPLIED TOGETHER.

ELECTRICAL COMPONENT CHART

ITEM DESCRIPTION PART NUMBER

1 Toggle Switch ARM-2279

2 Red Neon Lamp CWO-6206

3 Speed Control Board w/Resistor CWO-6525

4 Fuse 2 amp MPD-1026

5 Fuse 3 amp FUS-0257

6 Rotary Switch MUG-1258-1

1

28

Page 29

CWO-3690-_ K231 SUB ARC GUN

2

ITEM QTY PART # DESCRIPTION

3

4

5

1

6

11A

11

7

*7 1 PXS-10125-_ CONTACT TIP (SPECIFY WIRE

SIZE*)

10 1 PXT-9967-30 FLUX CONE ROLL PIN

11 1 PXT-13835 3/4’’X7’’ FLUX HOSE W/FBR INS

11A 1 PXT-3835-IN FIBER INSULATOR

12 1 BUG-3161-P CONE BODY ASSEMBLY

13 1 BUG-3163 LOCKING FERRULE

14 1 BUG-3164 FLUX CONE (KP2085-1)

15 1 BUG-3165 RETAINING NUT

1 1 PXS-15106-3/32 NOZZLE INSERT

2 1 PXT-10570 SOCKET HEAD SCREW

3 1 PXS-10493-1 NOZZLE INSULATOR

4 1 PXS-121312 HEX HD SCR 1 1/2’’ & NUT 1/2’’13

5 1 PXT-9967-10 NOZZLE BODY ROLL PIN

6 1 CWO-8052 NOZZLE BODY

8 1 PXS-10138 FLUX CONE PLUG (INSULATOR)

9 1 PXT-9078-1 THUMB SCREW

8

9

10

12

13

14

15

*WIRE SIZES AVAILABLE:

PART # WIRE SIZE

CWO-3690-1/16 1/16’’ (1.6 mm)

CWO-3690-5/64 5/64’’ (2.0 mm)

CWO-3690-3/32 3/32’’ (2.4 mm)

CWO-3690-1/8 1/8’’ (3.2 mm)

CWO-3690-5/32 5/32’’ (4.0 mm)

CWO-3690-3/16 3/16’’ (4.8 mm)

CWO-3690-7/32 7/32’’ (5.6 mm)

*REPLACEMENT CONTACT TIPS AVAILABLE:

PART # WIRE SIZE

CWO-8048 5/64’’ (2.0 mm)

CWO-8049 3/32’’ (2.4 mm)

CWO-8050 5/32’’ (4.0 mm)

CWO-8051 1/8’’ (3.2 mm)

PXS-10125XL-7/64 7/64’’ (2.8 mm)

PXS-10125XL-1/16 1/16’’ (1.6 mm)

PXS-10125XL-3/16 3/16’’ (4.8 mm)

PXS-10125XL-7/32 7/32’’ (5.6 mm)

29

Page 30

CWO-3710-_ SUB ARC GUN ASSEMBLY

1

2

3

ITEM QTY PART # DESCRIPTION

1 1 CWO-1816 WIRE FEED ADAPTOR

2 2 CWO-1817 BULK HEAD CONNECTOR QCB

3 1 CWO-3697 QCC 72’’ (1829 mm) LINER

4 1 CWO-3695-1/2 ADAPTOR K231 1/2’’

5 1 CWO-3970-72 WELD CABLE 4/0 ASSY 72’’

(1829 mm) LG

6 1 CWO-3690-1/8 SUB-ARC NOZZLE 1/8’’

1 CWO-3690-3/16 SUB-ARC NOZZLE 3/16’’

1 CWO-3690-5/32 SUB-ARC NOZZLE 5/32’’

7 1 CWO-3491-48 FLUX HOSE 3/4” ID x 1” OD

8 1 FAS-0452 SET SCR 1/4-20 X 1/4

9* 1 BUG-2708 CLAMP

2

7

5

*Item not shown in drawing.

4

DRIVE ROLLS

8

6

PART # DESCRIPTION QTY

LDC-0013 3/32’’-7/32’’ (2.4-5.6 mm) WIRE SIZES 2

LDC-0014 1/16’’-3/32 (1.6-2.4 mm) WIRE SIZES 2

LDC-0015 .035’’-.052’’ (.9-1.3 mm) SOLID WIRE 1

30

Page 31

3-JAW EXPANDABLE CHUCKS

CWO-3660

CWO-3661

3-Jaw Expandable Chucks

Mounts and automatically centers the Circle Welder

on nozzles with or without anges. As shown below.

PART NUMBER FOR NOZZLE I.D.’S WEIGHT

CWO-3660 2”-8” (51-204 mm) 68 lbs. (31 kg)

CWO-3661 8”-16” (204-405 mm) 36 lbs. (16 kg)

CWO-3362 10”-24” (255-610 mm) 51 lbs. (23 kg)

CWO-3663 16”-42” (406-1065 mm) 64 lbs. (29 kg)

CWO-3662

CWO-3663

Options:

CWO-2020 Flux Recovery System

31

Page 32

OPTIONAL MOTORIZED RACKING EQUIPMENT / CWO-1640-M / EXPLODED

VIEW / PARTS LIST

2

1

ITEM QTY PART # DESCRIPTION

3

4

1 1 ABR-1050-MH MOTORIZED HORIZONTAL V-GUIDE WAYS 40”

2 1 ABR-1060-MV MOTORIZED VERTICAL V-GUIDE WAYS 33”

3 1 CWO-1675-MV MOTORIZED VERTICAL RACKER

4 1 CWO-1695 ATTACHMENT BLOCK

5 1 CWO-3023-1 TORCH ANGLE ADJUSTER 16”

6 1 CWO-3460 33# LOAD SPRING ASSEMBLY

6

5

OPTIONAL MOTORIZED RACKING EQUIPMENT / CWP-3363 / EXPLODED

VIEW / PARTS LIST

2

3

2

ITEM QTY PART # DESCRIPTION

3

1 1 CWO-1687 PLATE

2 4 CWO-4326 WHEEL & LEG ASSY., FIXED

3 4 CWO-4327 WHEEL & LEG ASSY., ADJUSTABLE

1

3

2

3

32

2

Page 33

OPTIONAL RACKING MOTORIZED RACKING/ CWP-3351 / EXPLODED VIEW /

PARTS LIST

2

3

11

12

13

1

4

6

21

10

8

5

20

19

18

7

13, 11

11

16

17

8

15

16

9

14

ITEM QTY PART NUMBER DESCRIPTION

1 1 CWP-3355 Hvy Duty Rack 150:1 No Mounting Bracket

2 1 CWO-5933 Jaw Coupling 3/8" & 5/8" Bores With Spider

3 2 CWO-5565 5/8" Pillow Block

4 1 CWP-3354 Screw for Mtrzd Hrz Hvy Duty Rack

5 1 CWP-3353 Mtrzd Hrz Slide Hvy Duty Rack

6 2 CWP-3362 Stud 1/2-13 All Thread

7 1 CWO-3865 1"-6 Acme Nut and Bar Assembly

8 5 CWO-9038 Hold Down Clip

9 2 CWO-9065 T-3 Track 36" Lg

10 1 CWP-3356 Horiz P.M. Motor Bracket #970 Mod

11 6 FAS-1301 Hex Nut 1/2-13

12 2 WAS-0281 1/2 Split Lockwasher Zinc Plated

13 4 WAS-0280 1/2 SAE Flat

14 4 FAS-2591-SS Soc Hd Cap Scr 3/8-16 x 1-1/4 Stainless Steel

15 4 FAS-1444-SS Phil Pan Hd Scr 10/32 x 3/8" Stainless Steel

16 10 FAS-0359-SS Hex Hd Cap Scr 1/4-20 x 1" Stainless Steel

17 1 FAS-0399 Hex Hd Cap Scr 3/8-16 x 1"

18 1 WAS-0262 3/8" Split Lock Washer Zinc Plated

19 1 WAS-0260 3/8 Washer Zinc Plated

20 4 FAS-0555 Soc Hd Cap Scr 1/4-20 x 1/2

21 4 WAS-0243 1/4" Split Lock Washer Zinc Plated

33

Page 34

OPTIONAL MOTORIZED RACKING EQUIPMENT/ PRS-1075 / EXPLODED

VIEW / PARTS LIST

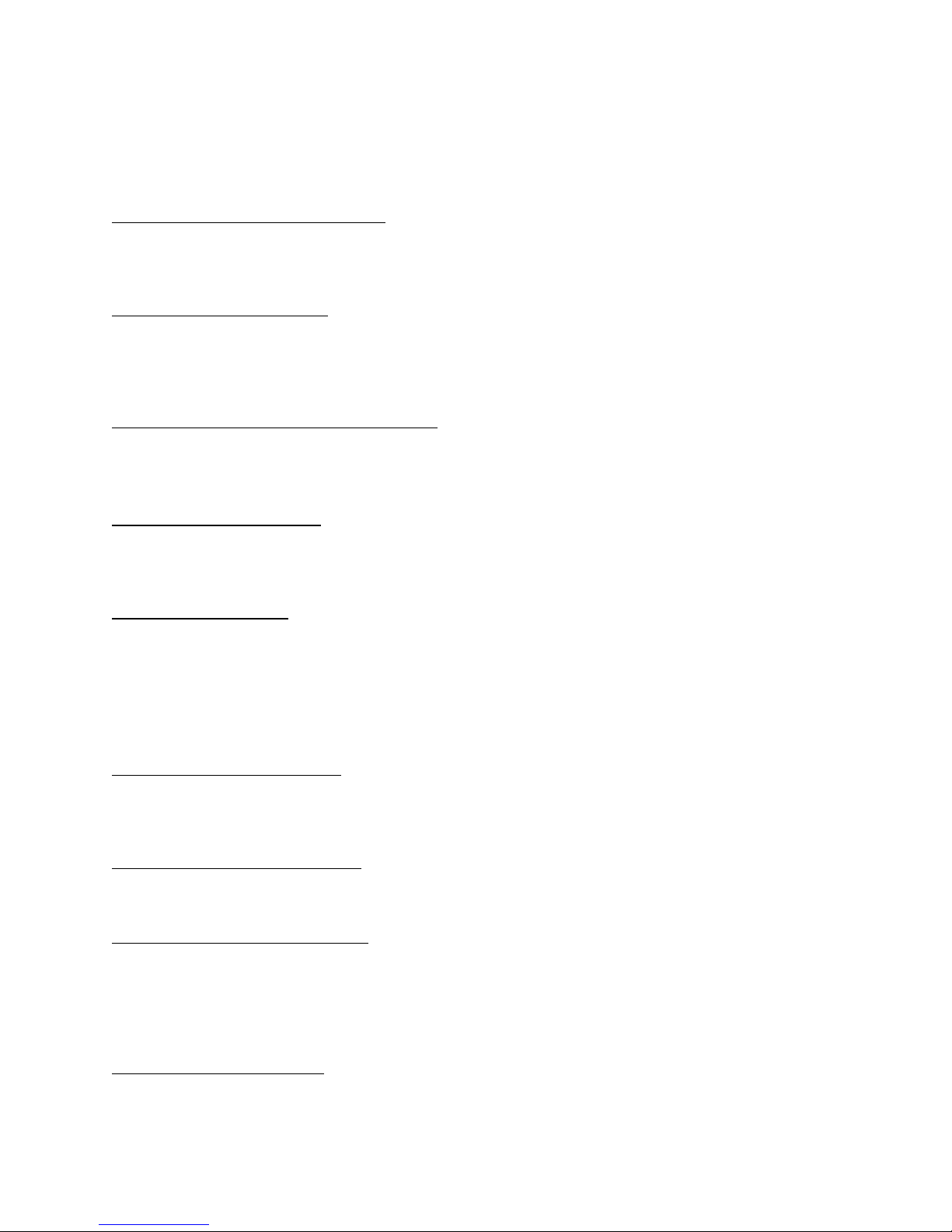

34

Page 35

OPTIONAL MOTORIZED RACKING EQUIPMENT/ PRS-1100/ EXPLODED VIEW

/ PARTS LIST

ITEM Component Item Description 120vac 240vac 42vac

1 PRS-1111 INPUT END PANEL 1

2 BUG-2923 .7 AMP CIRCUIT BREAKER 1

BUG-2952 .5 AMP CIRCUIT BREAKER 1

BUG-2933 2 AMP CIRCUIT BREAKER 1

3 BUG-2924 “RESET SEAL, TRANSPARENT” 1

4 BUG-5001 TRANSFORMER 115VAC 1

BUG-5002 TRANSFORMER 240VAC 1

BUG-5003 TRANSFORMER 42VAC 1

5 PRS-1110 ENCLOSURE 1

6 PRS-1112 OUTPUT END PANEL 1

7 MUG-1156 PANEL CONNECTOR, 4-T, F 1

8 BUG-1404 RELAY BRACKET 1

9 BUG-1411 HOLD DOWN SPRING 1

10 BUG-1384 RELAY SOCKET & SPRING 1

11 BUG-1383 RELAY, 4PDT, 3A 120V, PLUG IN 1

BUG-1551 RELAY 3A, 240VAC 1

BUG-9636 RELAY 48VAC 1

12 BUG-9902 PANEL CONNECTOR, 6-T, F 1

13 CAS-1770 SPEED CONTROL (IRON ROTOR) 2

14 BUG-9446 CORD GRIP 1

15 BUG-9445 POWER CORD (120VAC SHOWN) 1 1

GOF-3115 LINE CORD 240VAC 1

16 BUG-9628 CAP & CHAIN ASSY 1

17 FAS-0124 8/32 X 3/8 PAN HD, Di-CHROME 10

18 FAS-1320 HEX NUT 8-32 3

19 WAS-0221 #8 INTERNAL STAR LOCKWASHER 3

20 SCW WTE 0514 #8-32 X 3/8" PAN HEAD, ZINC 1

21 FAS-0204 RND HD SLT SCR 4-40 X 3/8 ZINC 8

22 FAS-1305 HEX NUT 4-40 8

23 WAS-0201 #4 INTERNAL STAR LOCKWASHER 8

24 FAS-0112 PAN HD SLT 6-32 X 1/4 BLACK 6

N/S SFX-1292 BUMPER, CYLINDRICAL .14 X .50" 4

35

Page 36

OPTIONAL MOTORIZED RACKING EQUIPMENT/ PRS-1091-WD WIRING

DIAGRAM/ PARTS LIST

36

Page 37

PREVENTIVE MAINTENANCE / CW-18 CIRCLE WELDER

IMPORTANT: Make sure the input power at the power source is turned off and the 50’ weld

cable is disconnected from the circle welder prior to working inside the circle welder.

AFTER DAILY USE:

Refer to CW-18 Exploded View Parts List. (Pg. 12)

Large Horizontal Racker Item #3:

Inspect wheels and remove all dirt, grease, weld spatter and rust. Adjust wheels for snug t and

smooth operation. Lubricate racker pinion and wheels with a dry teon or graphite spray lubricant.

Racking System Item #11:

Inspect gear rack, hardened ways and wheels, remove all dirt, grease, weld spatter and rust.

Check hardened ways for nicks and replace if necessary. Lubricate with a dry teon or graphite

spray lubricant. Adjust wheels for snug t and smooth operation. Lubricate racker pinion with a

dry teon or graphite spray lubricant.

Slide Bar Mounting Assembly Item #24:

Inspect hardened ways remove all dirt, grease and weld spatter. Check hardened ways for nicks

and replace if necessary. Lubricate with a dry teon or graphite spray lubricant.

Refer to CW-18 Electrical Component Chart. (Pg. 14)

CW-18 Collector Item #3:

Inspect cable connector to make sure threads are not stripped and that the connector is not

cracked. Ensure that the connector is fastened properly to the large aluminum gear item #34 on

the CW-18 Exploded View Parts List.

NA-3 Control Cables:

For all cables leading to NA-3 Control box, inspect cable connector to make sure threads are not

stripped and that the connector is not cracked. Check the cable for cuts, missing insulation and

burn spots, replace if necessary.

EVERY SIX MONTHS:

Refer to CW-18 Exploded View Parts List. (Pg. 12)

7” Cam Assembly Item #14:

Inspect the slide rails and the cam pinion. Remove all dirt, grease and weld spatter. Do not

grease slide rails or cam pinion. Lubricate with a dry teon or graphite spray lubricant. Replace

cam pinion if excessively worn. Tighten all fasteners as needed.

Wire Reel Assembly Item #20:

Periodically coat the wire wheel shaft with a thin layer of grease as needed. Inspect the shoe assembly and replace if excessively worn.

P.M. Motor Assembly Item #21:

Do not grease this pinion. Inspect the drive pinion. Remove all dirt, grease and weld spatter.

Lubricate with a dry teon or graphite spray lubricant. Replace pinion if excessively worn. Check

set screw and tighten if necessary. Adjust motor assembly using the four adjustable mounting

fasteners so that proper gear mesh is achieved between the aluminum gear item #34 and the

motor drive pinion.

Aluminum Gear Item #34:

Do not grease this gear. Inspect gear teeth remove all dirt, grease and weld spatter. Lubricate

with a dry teon or graphite spray lubricant. Replace gear if excessively worn.

37

Page 38

PREVENTIVE MAINTENANCE / CW-18 CIRCLE WELDER, CONT’D.

Refer to CW-18 Electrical Component Chart. (Pg. 14)

NA-3 Wire Feeder Assembly Item #1:

Check brushes for wear. Brushes should be replaced when their length is less than 1/4 inch.

Replace strain relief on wire if pulled out of motor housing.

Brush Holder & Support Item #4:

Inspect brush holder. Make sure constant tension is being applied on the brushes. Brushes

should move freely within the brush holder. Check brushes for arc build-up. If brushes are pitted

they will need replaced. Remove the brushes and sand them to ensure a smooth contact surface. Make sure all fasteners are tight.

NA-3 Wire Feed Control Item #6:

Open control box, use an air hose to blow out dust and dirt. Check all wires for breaks and

replace if necessary. Check all electrical connectors and plugs. If an electrical component fails

refer to NA-3 Wire Feeder Control electrical component chart for replacement parts or return for

service.

Small Brush Retainer Assembly Item #7:

Inspect black brush holders for cracks and replace if needed. Check and make sure all wires

are soldered properly to the holders. Replace the brushes when their length is less than 1/2 inch

long. Remove the brushes and sand them to ensure a smooth contact surface. Make sure all

fasteners are tight.

Terminal Block Item #8:

Inspect the plastic terminal strip and make sure it is not cracked, replace if necessary. Make

sure all terminal connections are tight. Make sure all ground wires are connected to the mounting screws of the terminal strip.

M-14 Rotation Control Item #12:

Open control box use an air hose to blow out dust and dirt. Check all wires for breaks and replace if necessary. Check all electrical connectors and plugs. If an electrical component fails

refer to CWO-6210-CW18 Rotation Control electrical component chart for replacement parts or

return for service.

EVERY TWELVE MONTHS:

Refer to CW-18 Exploded View Parts List. (Pg. 12)

Transmission 5:1 Assembly Item #18:

Inspect for excessive wear and tear. Keep the transmission assembly clean and lubricate with

Lubriplate #630-AA.

P.M. Motor Assembly Item #21:

Bodine gear motor lubrication. Fill gear motor to oil level indicator with worm gear oil conforming

to AGMA#5EP compounded (SAE#90) oil or Bodine lubricant (#L-23). Do not overll.

2” Bearing With Fasteners Item #22:

Do not grease the bearing, it is greased for life by the manufacturer. If the grease tting has not

been removed and plugged we suggest that you do so now. Earlier models may not have been

plugged at time of assembly.

NA-3 Wire Feeder Assembly Item #36:

Apply graphite grease to the gear teeth. Inspect the drive roll portion of the assembly, clean

as necessary. Do not use solvents on the idle roll because it may wash the lubricant out of the

bearings. Do not apply grease to the drive rolls.

38

Page 39

PREVENTIVE MAINTENANCE / CW-18 CIRCLE WELDER, CONT’D.

Refer to CW-18 Electrical Component Chart. (Pg. 14)

CW-18 Collector Item #3:

The collector ring should be sanded once a year. If the collector ring is pitted too badly it should

be replaced. Inspect all wires coming out of the collector ring for cut or missing insulation. All

wires should be fastened to the center shaft with a nylon cable tie. Tighten four set screws if

needed.

Weld Cable Inlet 4/0 Item #10:

Ensure that the cable is fastened tightly to the collector ring. Inspect the cable for cut or missing

insulation. Make sure the micarta insulation tube on the cable is in good condition. Replace the

cable if necessary.

NA-3 Control Cables :

For all cables leading to the NA-3 Control Box, inspect the cable for cuts or missing insulation.

Ensure that the elbow connector is not damaged. Ensure that all terminal ends are snug. Replace cable if necessary.

Solenoid Adaptor Kit (Optional):

Inspect for damage. Replace if necessary.

39

Page 40

WARRANTY

Model _____________________________

Limited 3-Year Warranty

For a period ending one (1) year from the date of invoice, Manufacturer warrants that any new machine or part is free

from defects in materials and workmanship and Manufacturer agrees to repair or replace at its option, any defective part

or machine. HOWEVER, if the invoiced customer registers the Product Warranty by returning the Warranty Registration

Card supplied with the product within 90 days of the invoice date, or by registering on-line at www.bugo.com, Manufacturer

will extend the warranty period an additional two (2) years which will provide three (3) total years from the date of original

invoice to customer. This warranty does not apply to machines which, after Manufacture’s inspection are determined by

Manufacturer to have been damaged due to neglect, abuse, overloading, accident or improper usage. All shipping and

handling charges will be paid by the customer.

The foregoing express warranty is exclusive and Manufacturer makes no representation or warranty (either express or

implied) other than as set forth expressly in the preceding sentence. Specifically, Manufacturer makes no express or

implied warranty of merchantability or fitness for any particular purpose with respect to any goods. Manufacturer shall not

be subject to any other obligations or liabilities whatsoever with respect to machines or parts furnished by Manufacturer.

Manufacturer shall not in any event be liable to Distributor or any customer for any loss of profits, incidental or consequential damages or special damages of any kind. Distributor’s or customer’s sole and exclusive remedy against Manufacturer

for any breach of warranty, negligence, strict liability or any other claim relating to goods delivered pursuant hereto shall be

for repair or replacement (at Manufacturer’s option) of the machines or parts affected by such breach.

Distributor’s Warranty:

Serial No. __________________________

Date Purchased: ____________________

Where Purchased:___________________

In no event shall Manufacturer be liable to Distributor or to any customer thereof for any warranties, representations or

promises, express or implied, extended by Distributor without the advance written consent of Manufacturer, including but

not limited to any and all warranties of merchantability or fitness for a particular purpose and all warranties, representations

or promises which exceed or are different from the express limited warranty set forth above. Distributor agrees to indemnify

and hold Manufacturer harmless from any claim by a customer based upon any express or implied warranty by Distributor

which exceeds or differs from Manufacturer’s express limited warranty set forth above.

HOW TO OBTAIN SERVICE:

If you think this machine is not operating properly, re-read the instruction manual carefully, then call your Authorized

BUG-O dealer/distributor. If they cannot give you the necessary service, write or phone us to tell us exactly what

difculty you have experienced. BE SURE to mention the MODEL and SERIAL numbers.

40

Loading...

Loading...