Page 1

CDPS-CS4

Control System

Operation Manual

Operation Manual

Page 2

Page 3

DISCLAIMERS

The information in this manual has been carefully checked and

is believed to be accurate. Cypress Technology assumes no

responsibility for any infringements of patents or other rights of third

parties which may result from its use.

Cypress Technology assumes no responsibility for any inaccuracies

that may be contained in this document. Cypress also makes no

commitment to update or to keep current the information contained

in this document.

Cypress Technology reserves the right to make improvements to this

document and/or product at any time and without notice.

COPYRIGHT NOTICE

No part of this document may be reproduced, transmitted,

transcribed, stored in a retrieval system, or any of its part translated

into any language or computer le, in any form or by any means—

electronic, mechanical, magnetic, optical, chemical, manual, or

otherwise—without express written permission and consent from

Cypress Technology.

© Copyright 2011 by Cypress Technology.

All Rights Reserved.

Version 1.1 August 2011

TRADEMARK ACKNOWLEDGMENTS

All products or service names mentioned in this document may be

trademarks of the companies with which they are associated.

Page 4

SAFETY PRECAUTIONS

Please read all instructions before attempting to unpack, install or

operate this equipment and before connecting the power supply.

Please keep the following in mind as you unpack and install this

equipment:

• Always follow basic safety precautions to reduce the risk of re,

electrical shock and injury to persons.

• To prevent re or shock hazard, do not expose the unit to rain,

moisture or install this product near water.

• Never spill liquid of any kind on or into this product.

• Never push an object of any kind into this product through any

openings or empty slots in the unit, as you may damage parts

inside the unit.

• Do not attach the power supply cabling to building surfaces.

• Use only the supplied power supply unit (PSU). Do not use the PSU

if it is damaged.

• Do not allow anything to rest on the power cabling or allow any

weight to be placed upon it or any person walk on it.

• To protect the unit from overheating, do not block any vents or

openings in the unit housing that provide ventilation and allow for

sufcient space for air to circulate around the unit.

REVISION HISTORY

VERSION NO. DATE (DD/MM/YY) SUMMARY OF CHANGE

VR0 20/07/15 Preliminary release

Page 5

CONTENTS

1. Introduction ............................................ 1

2. Applications ........................................... 1

3. Package Contents ................................ 1

4. System Requirements ............................ 1

6. Operation Controls and Functions ....... 2

6.1 Front Panel ........................................2

6.2 Rear Panel .........................................3

6.3 Remote Control ................................ 4

6.4 IR Cable Pin Assignment..................4

6.5 RS-232 DTE Pin Assignment ..............5

6.6 RS-232 and Telnet Commands .......5

6.7 Software Application ....................... 7

6.8 Telnet Control ...................................8

6.9 WebGUI Control .............................10

6.9.1 Macro Settings ......................10

6.9.2 Extension Macro ....................13

6.9.3 Command Settings ............... 13

6.9.4 Network Settings ...................14

6.9.5 System Settings ...................... 15

7. Connection Diagram .......................... 16

8. Specications ...................................... 17

9. Acronyms ............................................. 18

Page 6

1

1. INTRODUCTION

By entering into a new era of smart world, the trend of controlling

everything with one nger is nowadays foreseen. Control System allows

your dream come true by providing not only direct but also indirect

control interfaces for all your devices. Direct control like IR, Relay and

DC controls allow users to maintain the traditional connection control

over the device whereas, indirect control like IR Learning, RS-232,

Telnet/WebGUI controls allow users with computing system or APP to

control over the devices. Overall, the management of all the controls

can be operated easily through IR remote control, RS-232, Telnet or

Ethernet protocols.

2. APPLICATIONS

• Smart Home Installation

• Even hall/Showroom control

3. PACKAGE CONTENTS

• 1×Control System

• 1× IR Learner Cable

• 4× IR Blaster Cables

• 4×3.5mm to 3.5mm IR Cables

• 4×Terminal Block Jacks

• 1×Remote Control

• 1×5 V/2.6 A Power Adaptor

• 1×Left and Right Rack Ears

• 1×Operation Manual

4. SYSTEM REQUIREMENTS

Input source equipment such as light, TV, power switch and ….etc.

and PC/Laptop.

Page 7

2

5. FEATURES

• Supports IR Learning function allows IR signal to be accepted by

computing system

• Supports eight inputs with voltage of 0~15V

• Supports 1 IR Learning, 8 IR outputs, 8 trigger inputs, 8 Relay outputs,

2 COM ports, and 4 Ethernet ports

• Supports Baud rate from 4800bps to 115200bps

• Supports 10/100 Ethernet network connection

6. OPERATION CONTROLS AND FUNCTIONS

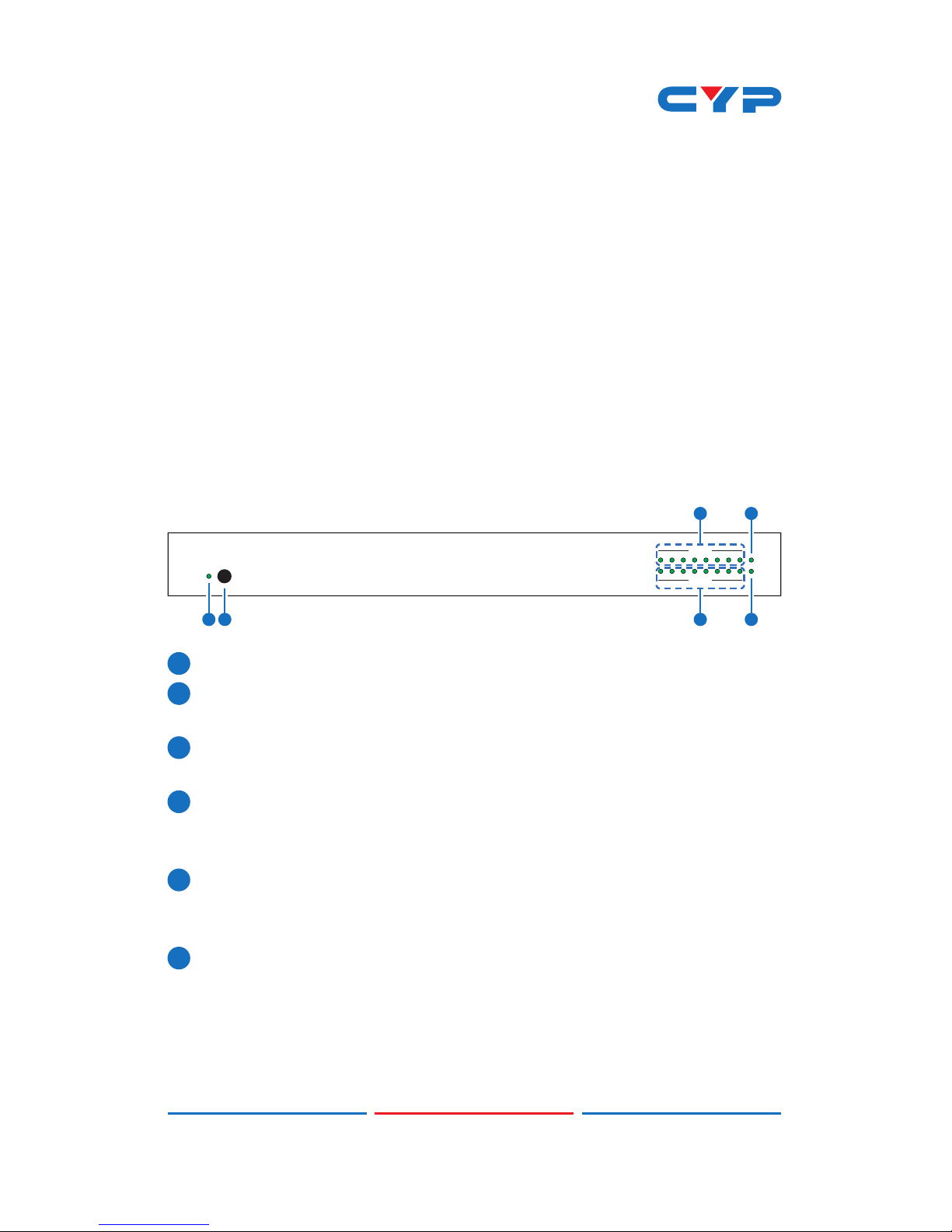

6.1 Front Panel

12345678

RELAY

INPUT

IR

COMMS

1 6

5

2 4

3

1

POWER LED: This LED will illuminate when the device is switched on.

2

IR WINDOW: Receives IR signal frquency from the remote control

and can trigger macro even 1~8.

3

RELAY LED: These LEDs represent the relay output connections

status.

4

INPUT LED: These LEDs will illuminate when trigger the input

connection obtain active high DC of 5~15V which is also when

signals has been triggered.

5

IR LED: This LED will illuminate when the device is receiving or

sending IR signal, under IR Learning process the LED will illuminate

also.

6

COMMS LED: This LED will illuminate when the COM port is sending

or receiving data, under Macro run command executing the LED

will be ashing according to the numbers of command send.

Page 8

3

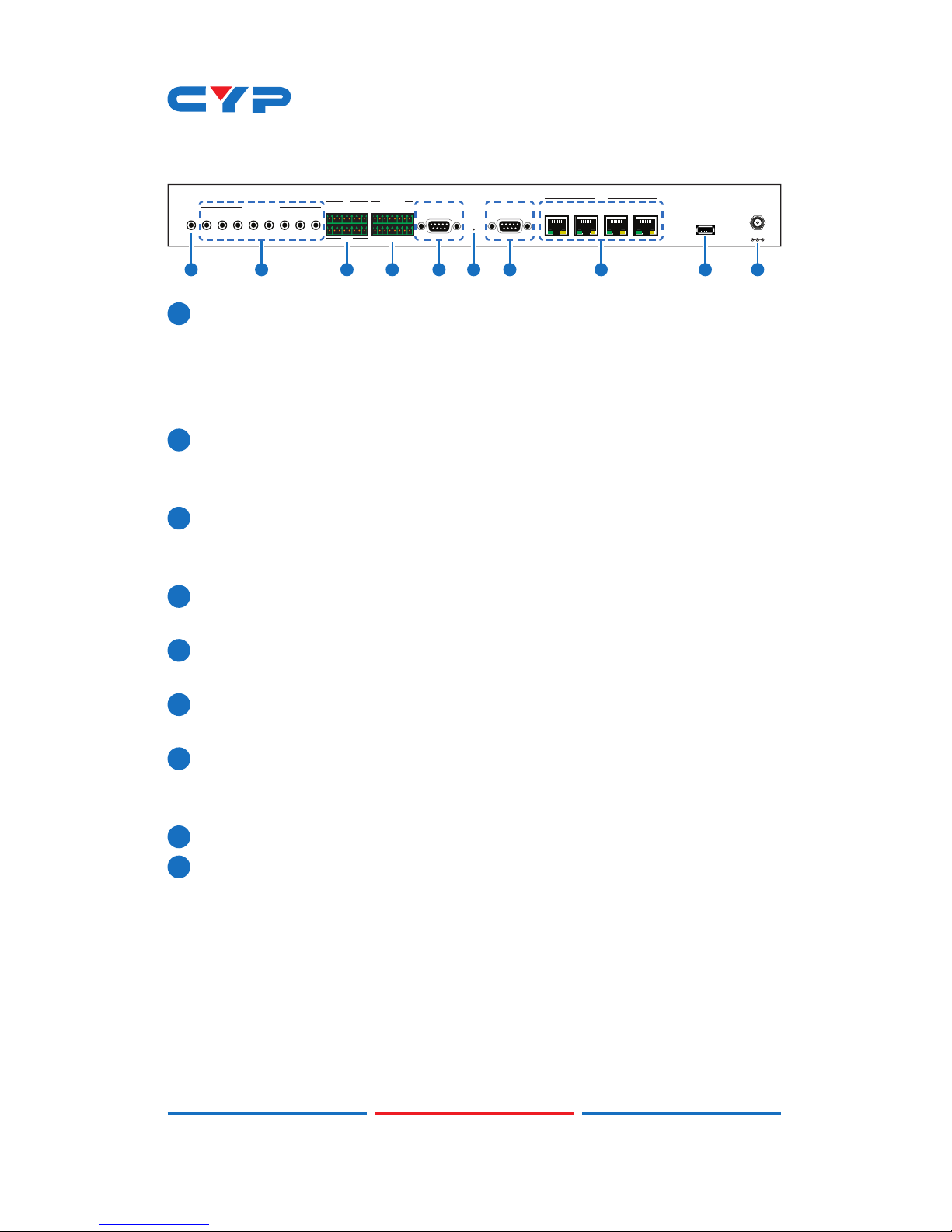

6.2 Rear Panel

1 2345678 12345678

GND

INFRARED OUT

1IRL 2345678

IN

RELAY OUT

COM 1 COM 2

RESET

LAN

DC 5V

1234

USB

1 62 3 4 5 5 7 8 9

1

IRL: Connect with IR Receiver included in the package for IR signal

learning. Send the IR signal that is to be learned by press on the

remote control in direct line-of-sight towards the Receiver and

record the IR data into digital format from WebGUI. For software

details please refers to section 6.9.3.

2

INFRARED OUT 1~8: Connect with IR Blaster for IR signal transmitting.

Place the IR Blaster in direct line-of-sight of the equipment to be

controlled.

3

IN 1~8: Connect with sensor device’s signal lines such as window

security alarm, door switch, and etc… for trigger signal sending

back to Control System.

4

RELAY OUT 1~8: Connect with control device’s power line cable

such as DC power supply to activate the control devices.

5

COM 1~2: Connect with RS-232 devices for command sending and

controllig the devices.

6

RESET: To reset IP back to factory default, press and hold the button

with pin for 10 seconds and both IR and comm LED will illuminate.

7

LAN 1~4: Connect with PC/Laptop or intra-net hub and also the

LAN connection of the control devices for Telnet/WebGUI control

over the devices.

8

USB: This slot is reserved for factory rmware update only.

9

DC 5V: Plug the 5V DC power supply into the unit and connect the

adaptor to an AC outlet.

Page 9

4

6.3 Remote Control

1

1~8: Press these buttons to trigger input signal

of input 1~8 for control system to activate the

corresponding command or setting.

6.4 IR Cable Pin Assignment

3

1

2

3

2

1

IR Blaster

Power

IR Signal

NC

IR Signal

Power

Grounding

IR Learner

CR-157

56

78

34

12

1

Page 10

5

6.5 RS-232 DTE Pin Assignment

DATA TERMINAL EQUIPMENT

Pin Assignment

1 NC

2 RxD

3 TxD

4 NC

5 GND

6 NC

7 NC

8 NC

9 NC

Baud Rate: 4800~115200bps

Data bit: 7~8 bits

Parity: None, Odd, Even

Flow Control: None

Stop Bit: 1~2 Bits

6.6 RS-232 and Telnet Commands

COMMAND DESCRIPTION PARAMETER

IPCONFIG Display the current IP

congure

NONE

SIPADDR XXX.XXX.

XXX.XXX

Set Ethernet IP address XXX=0~255

SNETMASK XXX.

XXX. XXX.XXX

Set Ethernet net mask XXX=0~255

SGATEWAY XXX.

XXX. XXX.XXX

Set Ethernet gateway XXX=0~255

SIPMODE Set Ethernet IP mode N=STATIC/DHCP

VER Show unit rmware version NONE

REBOOT System reboot NONE

Page 11

6

COMMAND DESCRIPTION PARAMETER

FADEFAULT All congure set to factory

default*

NONE

ETH_FADEFAULT All Ethernet congure set

to factory

NONE

HELP (?) Show command list NONE

HELP N Show description of

command

N=COMMAND NAME

RELAY N N1 Relay control N[PORT]=1~2

N1[MODE]=CLOSE/OPEN

IREMIT N N1 N2 Send IR contenet N[PORT]=1~8,

N1[MODE]=(0)CYP, N2=IR

EMIT DATA (STRING)

COMSEND COM N N1Send command to COM

port

N[PORT]=1~2

N1=COMMAND DATA

(1~512 CHARS)

COMCONF N N1

N2 N3 N4

Driver RS-232 cong show

COM port settings

N[PORT]=1~2

N1[BAUDRATE]=4800, 9600,

19200, 38400, 57600, 115200

N2[DATA LEN]= 7, 8

N3[PARITY]=(0)NONE (1),

ODD (2)EVEN

N4[STOP BIT]=1,2

MACRO STOP N Stop Macro control N[PORT]=1~15

MACRO RUN N Run Macro control N[PORT]=1~15

Note:

1. Any commands will not be executed unless followed by a carriage

return. Commands are case-sensitive.

2. Please ensure that all commands and settings have been saved

before performing this command with Asterisk (*) as the procedure

may restore all settings back to default.

Page 12

7

6.7 Software Application

Please download the software from www.cypress.com.tw with le

name CDPS V2.000 and save it in a directory where you may use it

later.

Connect the Control System with an active network system and open

the CDPS V2.000 application from the directory in a PC/Laptop. Click

on Find Devices on Network and a list of the devices connected within

the network system will show up.

Double click on the product name and an InfoFrom will appear to

show the products’ detail.

Then user may use the IP Address to nd the control device through

Telnet, WebGUI or even RS-232/Hyper Terminal tools.

Page 13

8

6.8 Telnet Control

To access the Telnet control in Windows 7, click on the 'Start' menu

and type "cmd" in the Search eld then press enter.

Under Windows XP go to the 'Start' menu and click on "Run", type

"cmd" with then press enter.

Under Mac OS X, go to Go→Applications→Utilities→Terminal

See below for reference.

Once in the command line interface (CLI) type "telnet", then the IP

address of the unit and "23", then hit enter.

Page 14

9

This will bring us into the unit which we wish to control. Type "help" to

list the available commands.

Note: Commands will not be executed unless followed by a carriage

return. Commands are case-sensitive. If the IP is changed then the IP

Address required for Telnet access will also change accordingly.

Page 15

10

6.9 WebGUI Control

On a PC/Laptop that is connected to an active network system,

open a web browser and type device’s IP address (default setting IP:

192.168.1.50 ) on the web address entry bar.

A security page will appear to ask for User and Password, please key

in “admin” for both and click Submit to enter. The browser will display

device’s Macro Setting, Extension Macro, Command, Network &

System Settings control pages for users to control.

6.9.1 Macro Settings

Click on 'Macro Settings' to execute or rename macro. There are

5 Macros inserted as default setting for testing the control system's

functionality. Click on Macro 1~5 to demonstrate the functions:

• Macro 1: Close relay from 1~8 sequentially every 100ms

• Macro 2: Open relay from 1~8 sequentially every 100ms

• Macro 3: Toggles relay from 1~8 sequentially every 100ms

• Macro 4: Send IR signal from 1~8 sequentially every 100ms with LED

illuminant on front panel.

• Macro 5: Send out command "Hello World" from COM port 1~2

sequentially every 100ms.

Page 16

11

Click on the mark to edit the command settings. Up/down

arrows are to move the command up or down and button is to

delete the command.

Click on Insert button/Add to insert commands. Command can be

set to control the Control System/SysCMD, other devices connected

within the same Telnet system/Internet area, RS-232 COM ports, IR and

Relay devices connected through the Relay outputs of Control System

with delay time. It is suggested the delay time is >100ms once the

setting is conmed, double click on Save Change.

Command set to control the devices within the same telent system

or internet area require to set its IP and Port number and it is strongly

recommand to set the delay time >500ms in order to secure a

successful command sending. Command set to control the Relay

devices require to set the Port number. Click on Save Change to

conrm the setting.

Page 17

12

Page 18

13

6.9.2 Extension Macro

Click on 'Extension Macro' to execute/edit more Macro action up to 8

more.

6.9.3 Command Settings

Click on 'Command Settings' to edit or delete commands up to 128

sets. Insert the command directly in the bottom colum of Command

Edit and name the command on the top colum then click on Save

Changes to store the command.

For IR command Learning, press IR Learn rst then press the remote

control in direct line-of-sight to the IR Reciever connected from the IRL

port within 5 seconds. A comand string will show in the bottom colum.

Click on Save Changes to store the command.

For IR command saving, insert the command on the bottom colum

and click on CYP/RAW HEX which indicate the IR command type

and click on Save changes to store the command. Under uncertainty

Page 19

14

of the IR command type click on RAW HEX to ensure a successful

command saving.

Command under 128 characters including space can be build up

to 128 commands, command over 128 characters and under 512

characters including space can be build up to 32 command in

addition with 96 commands of 128 characters under. Click on Save

Change to save the command inserted.

6.9.4 Network Settings

Click on 'Network Settings' to set the device’s IP conguration. Once

the changes are saved the system will reset the IP address on device

automatically and user will need to re-enter the IP address to continue

the WebGUI control.

Page 20

15

6.9.5 System Settings

Click on 'System Settings' to reset the WebGUI login password and

save or download the Macro settings. Reset to Default allows IP and

login ID & password to be reset back to factory default.

Note: Please ensure that all commands and settings have been saved

before performing Reset as this procedure may restore all settings

back to factory default.

Page 21

16

7. CONNECTION DIAGRAM

1 2345678 12345678

GND

INFRARED OUT

1IRL2345678

IN

RELAY OUT

COM 1COM 2

RESET

LAN

DC 5V

1234

USB

Blind

Control

Lighting

Control

DC

Control

Alarm

Sensor

POWERLOCK

MENU OUTA

1B2C3D4

IN

E

5F6G7H8

POWERLOCK

MENU OUTA

1B2C3D4

IN

E

5F6G7H8

POWER LOCK

MENU OUTA

1B2C3D4

IN

E

5F6G7H8

Integrated 3rd Party Control

Internet

Connected

RouterRS-232 Control System

LAN

RS-232

IR Learner

LAN

Connections

Power

Supply

IP Control Enabled

Devices

RS-232 Control System

IR Blaster

Page 22

17

8. SPECIFICATIONS

Input Ports 8×Triggers (Ternimal Block), 4×LAN (RJ-45),

1×IR Learner

Output Ports 8×Replays (Ternimal Block), 8×IR Blasters,

2×COM (9-pin D-sub)

IR Out Frequency 30~50 kHz

IR Learner Frequency 30~55 kHz

Baud Rate 4800~115200 bps

Power Supply 5 V/2.6 A DC (US/EU standards, CE/FCC/UL

certied)

ESD Protection Human body model:

±8 kV (air-gap discharge)

±4 kV (contact discharge)

Dimensions 432 mm (W)×174 mm (D)×44 mm (H)/

Jack Excluded

432 mm (W)×181 mm (D)×49 mm (H)/

Jack Included

Weight 2186 g

Chassis Material Metal

Color Black

Operating Temperature 0˚C~40˚C/32˚F~104˚F

Storage Temperature −20˚C~60˚C/−4˚F~140˚F

Relative Humidity 20~90% RH (non-condensing)

Power Consumption 7.7 W

Page 23

18

9. ACRONYMS

ACRONYM COMPLETE TERM

CLI Command Line Interface

GUI Graphical User Interface

IP Internet Protocol

IR

Infrared

IRL Infrared Learning

LAN Local Area Network

Page 24

Home page: http://www.cypress.com.tw

CYPRESS TECHNOLOGY CO., LTD

Loading...

Loading...