Page 1

CapSense® Design Guide

AN66308 - CY8CMBR2044

Doc. No. 001-66308 Rev. *F

Cypress Semiconductor

198 Champion Court

San Jose, CA 95134-1709

Phone (USA): 800.858.1810

Phone (Intnl): 408.943.2600

http://www.cypress.com

Page 2

Copyrights

Copyrights

© Cypress Semiconductor Corporation, 2010-2017. This document is the property of Cypress Semiconductor Corporation and its subsidiaries,

including Spansion LLC (“Cypress”). This document, including any software or firmware included or referenced in this d ocument (“Software”), is

owned by Cypress under the intellectual property laws and treaties of the United States and other countries worldwide. Cypress reserves all rights

under such laws and treaties and does not, except as specifically stated in this paragraph, grant any license under its patents, copyrights,

trademarks, or other intellectual property rights. If the Software is not accompanied by a license agreement and you do not otherwise have a written

agreement with Cypress governing the use of the Software, then Cypress hereby grants you a personal, non-exclusive, nontransferable license

(without the right to sublicense) (1) under its copyright rights in the Software (a) for Software provided in source code form, to modify and reproduce

the Software solely for use with Cypress hardware products, only internally within your organization, and (b) to distribute the Software in binary code

form externally to end users (either directly or indirectly through resellers and distributors), solely for use on Cypress hardware product units, and (2)

under those claims of Cypress’s patents that are infringed by the Software (as provided by Cypress, unmodified) to make, use, distribute, and import

the Software solely for use with Cypress hardware products. Any other use, reproduction, modification, translation, or compilation of the Software is

prohibited.

TO THE EXTENT PERMITTED BY APPLICABLE LAW, CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS OR IMPLIED, WITH

REGARD TO THIS DOCUMENT OR ANY SOFTWARE OR ACCOMPANYING HARDWARE, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. To the extent permitted by applicable law, Cypress

reserves the right to make changes to this document without further notice. Cypress does not assume any liability arising out of the application or

use of any product or circuit described in this document. Any information provided in this document, including any sample design information or

programming code, is provided only for reference purposes. It is the responsibility of the user of this document to properly design, program, and test

the functionality and safety of any application made of this information and any resulting product. Cypress products are not designed, intended, or

authorized for use as critical components in systems designed or intended for the operation of weapons, weapons systems, nuclear installations, lifesupport devices or systems, other medical devices or systems (including resuscitation equipment and surgical implants), pollution control or

hazardous substances management, or other uses where the failure of the device or system could cause personal injury, death, or property damage

(“Unintended Uses”). A critical component is any component of a device or system whose failure to perform can be reasonably expected to cause

the failure of the device or system, or to affect its safety or effectiveness. Cypress is not liable, in whole or in part, and you shall and hereby do

release Cypress from any claim, damage, or other liability arising from or related to all Unintended Uses of Cypress products. You shall indemnify

and hold Cypress harmless from and against all claims, costs, damages, and other liabilities, including claims for personal injury or death, arising

from or related to any Unintended Uses of Cypress products.

Cypress, the Cypress logo, Spansion, the Spansion logo, and combinations thereof, WICED, PSoC, CapSense, EZ-USB, F-RAM, and Traveo are

trademarks or registered trademarks of Cypress in the United States and other countries. For a more complete list of Cypress trademarks, visit

cypress.com. Other names and brands may be claimed as property of their respective owners

AN66308 - CY8CMBR2044 CapSense® Design GuideDoc. No. 001-66308 Rev. *F 2

Page 3

Contents

1. Introduction .................................................................................................................................................................... 5

1.1 Abstract ................................................................................................................................................................. 5

1.2 Cypress’s CapSense Documentation Ecosystem .................................................................................................. 5

1.3 CY8CMBR2044 CapSense Express™ Device Features ....................................................................................... 7

1.4 Document Conventions ......................................................................................................................................... 9

2. CapSense Technology ................................................................................................................................................ 10

2.1 CapSense Fundamentals .................................................................................................................................... 10

2.2 Capacitive Sensing Method ................................................................................................................................. 11

2.2.1 CapSense Sigma-Delta (CSD) ............................................................................................................... 11

2.3 SmartSense Auto-Tuning .................................................................................................................................... 13

2.3.1 Process Variation.................................................................................................................................... 13

2.3.2 Reduced Design Cycle Time .................................................................................................................. 13

3. CapSense Schematic Design ..................................................................................................................................... 15

3.1 CY8CMBR2044 Configuration Options ............................................................................................................... 15

3.1.1 CapSense Buttons (CSx) ........................................................................................................................ 15

3.1.2 General-Purpose Outputs (GPOx) .......................................................................................................... 15

3.1.3 Modulation Capacitor (C

3.1.4 Button Auto Reset (ARST) ...................................................................................................................... 16

3.1.5 Toggle ON/OFF ...................................................................................................................................... 16

3.1.6 Flanking Sensor Suppression (FSS) ....................................................................................................... 17

3.1.7 LED ON Time ......................................................................................................................................... 18

3.1.8 System Diagnostics ................................................................................................................................ 19

3.1.9 Scan Rate/Sleep ..................................................................................................................................... 21

3.1.10 Serial Debug Data Out ............................................................................................................................ 22

3.2 Design Toolbox .................................................................................................................................................... 25

3.2.1 General Layout Guidelines ................................ ..................................................................................... 25

3.2.2 Layout Estimator ..................................................................................................................................... 26

3.2.3 CP, Power Consumption and Response Time Calculator ....................................................................... 27

3.2.4 Design Validation .................................................................................................................................... 28

) .................................................................................................................. 15

MOD

4. Electrical and Mechanical Design Considerations ................................................................................................... 30

4.1 Overlay Selection ................................................................................................................................................ 30

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 3

4.1.1 Bonding Overlay to PCB ......................................................................................................................... 31

Page 4

Contents

4.2 ESD Protection .................................................................................................................................................... 31

4.2.1 Prevent ................................................................................................................................................... 31

4.2.2 Redirect .................................................................................................................................................. 31

4.2.3 Clamp ..................................................................................................................................................... 31

4.3 Electromagnetic Compatibility (EMC) Considerations ......................................................................................... 32

4.3.1 Radiated Interference ............................................................................................................................. 32

4.3.2 Conducted Immunity and Emissions ....................................................................................................... 32

4.4 PCB Layout Guidelines ....................................................................................................................................... 32

5. Low-Power Design Considerations ........................................................................................................................... 33

5.1 System Design Recommendations ...................................................................................................................... 33

5.2 Calculating Average Power ................................................................................................................................. 33

5.2.1 Button Scan Rate (TR) ............................................................................................................................ 33

5.2.2 Scan Time (TS) ....................................................................................................................................... 34

5.2.3 Average Current in NO TOUCH State (I

5.2.4 Average Current in TOUCH State (I

5.2.5 Average Standalone Current (I

5.2.6 Average Current (I

5.2.7 Average Power (P

) ............................................................................................................................ 35

AVE

) ............................................................................................................................. 36

AVE

AVE_T

) ..................................................................................................... 35

AVE_SA

5.2.8 Example Calculation ............................................................................................................................... 36

5.3 Sleep Modes........................................................................................................................................................ 37

5.3.1 Low-Power Sleep Mode .......................................................................................................................... 37

5.3.2 Deep Sleep Mode ................................................................................................................................ ... 37

) ....................................................................................... 35

AVE_NT

) ............................................................................................... 35

6. Resources .................................................................................................................................................................... 38

6.1 Website ............................................................................................................................................................... 38

6.2 Datasheet ............................................................................................................................................................ 38

6.3 Design Toolbox .................................................................................................................................................... 38

6.4 Multi-Chart ........................................................................................................................................................... 38

6.5 Design Support .................................................................................................................................................... 39

7. Appendix ...................................................................................................................................................................... 40

7.1 Schematic Example ............................................................................................................................................. 40

7.1.1 Schematic 1: Four Buttons with Four GPOs ........................................................................................... 40

7.1.2 Schematic 2: Three Buttons with Advanced Features enabled .............................................................. 42

Acronyms ...................................................................................................................................................................... 43

Glossary ................................................................................................................................................................................ 44

Revision History ................................................................................................................................................................... 50

Document Revision History ........................................................................................................................................... 50

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 4

Page 5

1. Introduction

Abstract

This document describes how to implement capacitive sensing functionality using Cypress’s CapSense

CY8CMBR2044 device. The following topics are covered in this guide:

Features of the CY8CMBR2044

CapSense principles of operation

Configuration options of the CY8CMBR2044 device

Using the Design Toolbox with the CY8CMBR2044

System electrical and mechanical design considerations for the CY8CMBR2044

Low-power design considerations for the CY8CMBR2044

Additional resources and support for designing CapSense into your system

®

Express

Cypress’s CapSense Documentation Ecosystem

Figure 1-1 and Table 1-1 summarize the CapSense documentation ecosystem. These resources allow the

implementers to quickly access the information they need to complete a CapSense product design. Figure 1-1 shows

a typical product design cycle with capacitive sensing; this document covers the topics highlighted in green. Table 1-1

offers links to supporting documents for each of the numbered tasks in Figure 1-1.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 5

Page 6

Introduction

3. Select CapSense device based on

required functionality

2. Specify system requirements and

characteristics

11. Preproduction build (prototype)

12. Test and evaluate system functionality and

CapSense performance

Meets

specifications?

13. Production

Yes

No

= Topics covered in this document

1. Understand CapSense technology

4. Mechanical

Design

5. Schematic

capture and

PCB layout

Design for CapSense

9. Programming PSoC

†

10. CapSense

Configuration*

6. PSoC Designer project

creation†

7. Firmware

development†

8. CapSense tuning†

*

†

= Applicable to MBR family of devices only

= Applicable to programmable devices only

Figure 1-1. Typical CapSense Product Design Flow

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 6

Page 7

Introduction

Numbered Design Task of

Figure 1-1

Supporting Cypress CapSense® Documentation

1

Getting Started with CapSense

2

CY8CMBR2044 Device Datasheet

3

Getting Started with CapSense

4

This document

5

This document

6

Not applicable for CY8CMBR2044

7

Not applicable for CY8CMBR2044

8

Not applicable for CY8CMBR2044

9

Not applicable for CY8CMBR2044

10

This document

11

This document

Table 1-1. Cypress Documents That Support Numbered Design Tasks of Figure 1-1

CY8CMBR2044 CapSense Express™ Device Features

Cypress’s CY8CMBR2044 is an ultra-low power device that can quickly and easily add CapSense capacitive touch

sensing to your user interface. This device uses hardware to perform system configuration, eliminating the need for

software tools, firmware development and device programming. The features of the device are listed as follows. For

more details, see CY8CMBR2044 Configuration Options.

Easy-to-use capacitive button controller

Four-button solution configurable through Hardware straps

No software tools or programming required

Four general-purpose outputs (GPOs)

GPOs are linked to CapSense buttons

GPOs support direct LED drive

Robust noise performance

Specifically designed for superior noise immunity to external radiated and conducted noise

Low radiated noise emission

SmartSense™ Auto-Tuning

Saves time and effort in device tuning

CapSense parameters dynamically set in runtime

Maintains optimal button performance even in noisy environment

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 7

Page 8

Introduction

Wide parasitic capacitance CP range ( 5 pF – 40 pF)

System Diagnostics of CapSense buttons – reports any faults at device power-up

Button shorted to Ground

Button shorted to VDD

Button to button short

Improper value of modulator capacitor (C

Parasitic capacitance (CP) out of range

Advanced features

Toggle ON/OFF feature on GPOs

Flanking Sensor Suppression (FSS) provides robust sensing even with closely spaced buttons

Configurable LED ON Time after button release

Button output reset if touched for excessive time

User-controlled Button Scan Rate

Serial Debug Data output

o Simplifies production line testing and system debug

Wider operating voltage range

1.71 V to 5.5 V – ideal for both regulated and unregulated battery applications

Low power consumption

Supply current in run mode as low as 15 µAa per button

Deep Sleep current: 100 nA

Industrial temperature range: –40 ºC to + 85 ºC

16-pad Quad Flat No leads (QFN) package (3 mm x 3 mm x 0.6 mm)

a

Power consumption calculated with 1.7% touch time, 500 ms Button Scan Rate, Cp of each button < 19 pF

MOD

)

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 8

Page 9

Introduction

Convention

Usage

Courier New

Displays file locations, user entered text, and source code:

C:\ ...cd\icc\

Italics

Displays file names and reference documentation:

Read about the sourcefile.hex file in the PSoC Designer User Guide.

[Bracketed, Bold]

Displays keyboard commands in procedures:

[Enter] or [Ctrl] [C]

File > Open

Represents menu paths:

File > Open > New Project

Bold

Displays commands, menu paths, and icon names in procedures:

Click the File icon and then click Open.

Times New Roman

Displays an equation:

2 + 2 = 4

Text in gray boxes

Describes Cautions or unique functionality of the product.

Document Conventions

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 9

Page 10

2. CapSense Technology

CY8CMBR2044

C

MOD

Sensor

Capacitors

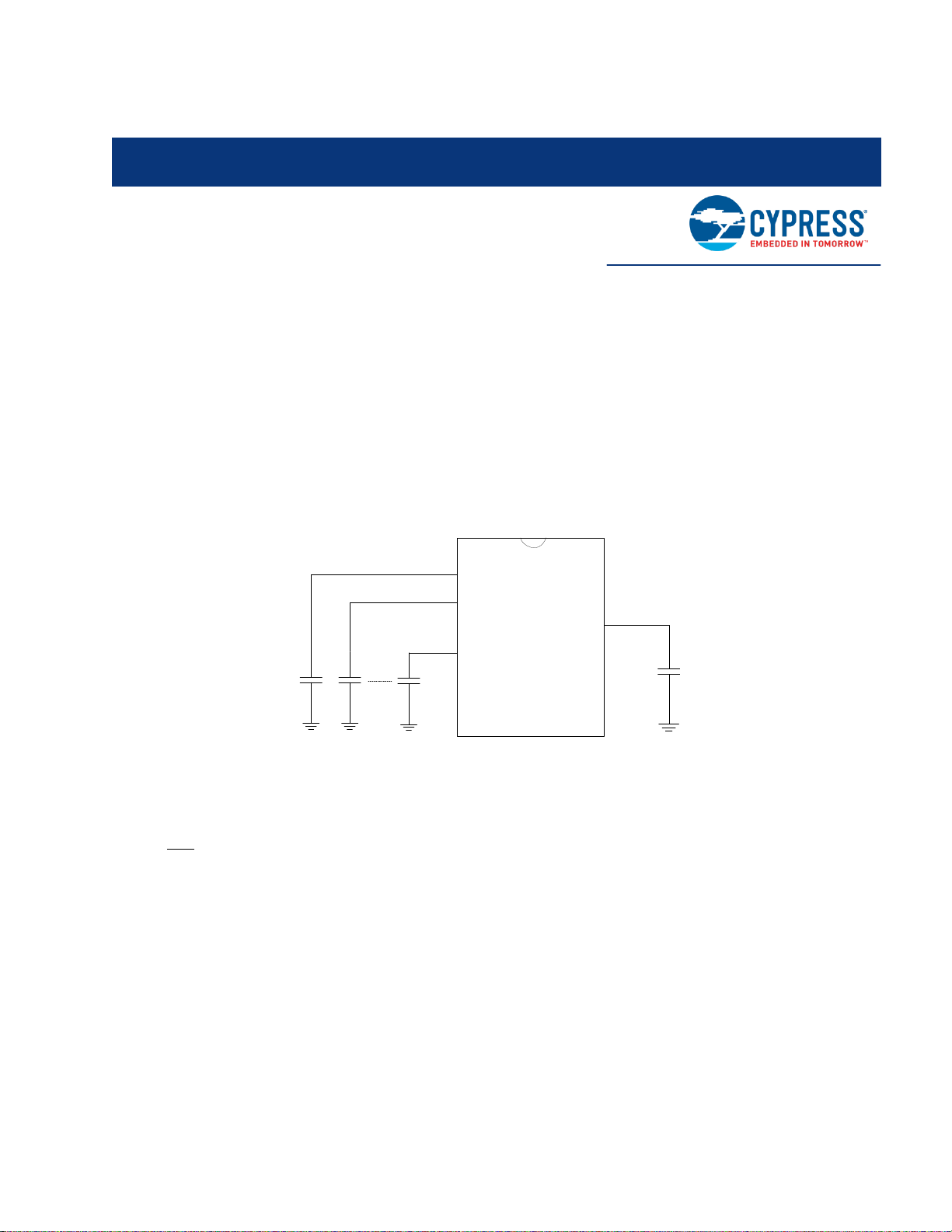

CapSense Fundamentals

CapSense is a touch sensing technology that works by measuring the capacitance of each input pin on the

CapSense controller that has been designated as a sensor. As shown in Figure 2-1, the total capacitance on each of

the sensor pins can be modeled as equivalent lumped capacitors with values of C

sensors. Circuitry internal to the CY8CMBR2044 device converts the magnitude of each CX into a digital code that is

stored for post-processing. A modulating capacitor, C

C

will be discussed in more detail in Capacitive Sensing Method.

MOD

, is used by the CapSense controller’s internal circuitry.

MOD

Figure 2-1. CapSense Implementation in a CY8CMBR2044 Device

through C

X,1

for a design with n

X,n

Each sensor input pin is connected to a sensor pad by traces, vias, or both, as necessary. A nonconductive overlay is

required to cover the sensor pad and constitutes the product’s touch interface. When a finger comes into contact with

the overlay, the conductivity and mass of the body effectively introduces a grounded conductive plane parallel to the

sensor pad. This action is represented in Figure 2-2. This arrangement constitutes a parallel plate capacitor, whose

capacitance is given by the following equation:

Equation 1

Where:

CF = The capacitance affected by a finger in contact with the overlay over a sensor

ε

= Free space permittivity

0

ε

= Dielectric constant (relative permittivity) of overlay

r

A = Area of finger and sensor pad overlap

D = Overlay thickness

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 10

Page 11

CapSense Technology

Figure 2-2. Section of typical CapSense PCB with the Sensor being activated by a Finger

In addition to the parallel plate capacitance, a finger in contact with the overlay causes electric field fringing between

itself and other conductors in the immediate vicinity. Typically, the effect of these fringing fields is minor, and it can

usually be ignored.

Even without a finger touching the overlay, the sensor input pin has some parasitic capacitance (CP). CP results from

the combination of the CapSense controller internal parasitic and electric field coupling among the sensor pad,

traces, and vias, and other conductors in the system, such as ground plane, other traces, any metal in the product’s

chassis or enclosure, and so on. The CapSense controller measures the total capacitance (CX) connected to a

sensor pin.

When a finger is not touching a sensor, use this equation:

Equation 2

With a finger on the sensor, CX equals the sum of CP and CF:

Equation 3

In general, CP is an order of magnitude greater than CF. CP usually ranges from 10 pF to 20 pF, but in extreme cases

it can be as high as 40 pF. CF usually ranges from 0.1 pF to 0.4 pF.

Capacitive Sensing Method

CY8CMBR2044 device supports the CapSense Sigma Delta (CSD) with SmartSense™ Auto-Tuning for converting

sensor capacitance (CX) into digital counts. The CSD method is described in the following sections.

CapSense Sigma-Delta (CSD)

The CSD method in the CY8CMBR2044 device incorporates CX into a switched capacitor circuit, as shown in

Figure 2-3. The sensor (CX) is alternatively connected to GND and the Analog MUX (AMUX) bus by the non-

overlapping switches Sw1 and Sw2, respectively. Sw1 and Sw2 are driven by a precharge clock to bleed a current

(ISENSOR) from the AMUX bus. The magnitude of ISENSOR is directly proportional to the magnitude of CX. The sigma-

delta converter samples AMUX bus voltage and generates a modulating bit stream that controls the constant current

source (IDAC), which charges AMUX such that the average AMUX bus voltage is maintained at VREF. The sensor

bleeds off the charge ISENSOR from the modulating capacitor (CMOD). CMOD, in combination with Rbus, forms a low-pass

filter that attenuates precharge switching transients at the sigma-delta converter input.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 11

Page 12

CapSense Technology

Cx

isensor

Sigma-Delta

Converter

Precharge

Clock

Cmod

High-Z

input

Sw1

Sw2

CY8CMBR2044

Gnd

= External Connection

AMUX

Bus

Vref

Rbus

Gnd

IDAC

Figure 2-3. CSD Block Diagram

In maintaining the average AMUX voltage at a steady state value (VREF), the sigma-delta converter matches the

average charge current (IDAC) to ISENSOR by controlling the bit stream duty cycle. The sigma-delta converter stores the

bit stream over the duration of a sensor scan, and the accumulated result is a digital output value, known as raw

count, which is directly proportional to CX. This raw count is interpreted by high-level algorithms to resolve the sensor

state. Figure 2-4 plots the CSD raw counts from a number of consecutive scans during which the sensor is touched

and then released by a finger. As explained in CapSense Fundamentals, the finger touch causes CX to increase by

CF, which in turn causes raw counts to increase proportionally. By comparing the shift in steady state raw count level

to a predetermined threshold, the high-level algorithms can determine whether the sensor is in an ON (Touch) or OFF

(No Touch) state.

Figure 2-4. CSD Raw Counts During a Finger Touch

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 12

Page 13

CapSense Technology

SmartSense Auto-Tuning

Tuning the touch-sensing user interface is a critical step in ensuring proper system operation and a pleasant user

experience. In the typical design flow, the button interface is tuned in the initial design phase, during system

integration, and before the production ramp. Because it’s an iterative process, tuning can be time-consuming.

SmartSense Auto-Tuning was developed to simplify the user interface development cycle. It is easy to use and

reduces the design cycle time by eliminating the hassles of further manual tuning in prototype and manufacturing

stages. SmartSense Auto-Tuning tunes each CapSense button automatically at power up and then monitors and

maintains optimum button performance during runtime. This technology adapts for manufacturing variation in PCBs

and overlays and automatically tunes out noise from sources such as LCD inverters, AC lines, and switch-mode

power supplies.

Process Variation

SmartSense Auto-Tuning for the CY8CMBR2044 is designed to work with button parasitic capacitance in the range of

5 pF to 40 pF, (typical button CP values range from 10 pF to 20 pF). The sensitivity parameter for each button is set

automatically, based on the characteristics of that particular button. The parameter improves the yield in mass

production because every button maintains a consistent response regardless of the CP variation (from 5 pF to 40 pF)

between the buttons. Parasitic capacitance of the individual buttons can vary due to PCB layout and trace length,

PCB manufacturing process variation, or vendor-to-vendor PCB variation within a multi-sourced supply chain. The

sensitivity of a button depends on its parasitic capacitance; higher CP values decrease sensitivity, resulting in

decreased finger touch signal amplitude. In some cases, a change in CP detunes the system, resulting in unfavorable

button performance (either too sensitive or insensitive) or even a nonoperational button. In either situation, you must

retune the system and, in some cases, you need to requalify the user interface subsystem. SmartSense Auto-Tuning

resolves these issues.

SmartSense Auto-Tuning makes platform designs possible. For example, consider the capacitive touch sensing

multimedia keys on a laptop computer; the spacing between the buttons depends on the size of the laptop and the

keyboard layout. In this example, the wide-screen machine has larger spaces between the buttons than a standardscreen model would. The additional space means increased trace length between the button and the CapSense

controller. The bigger trace length, in turn, leads to a higher parasitic capacitance of the button. As a result, the

parasitic capacitance of the CapSense buttons can vary in different models of the same platform design. Though the

buttons’ functionality is identical for all of the laptop models, the buttons must be tuned for each model. SmartSense

Auto-Tuning lets you do platform designs using the recommended practices shown in the PCB Layout in Getting

Started with CapSense.

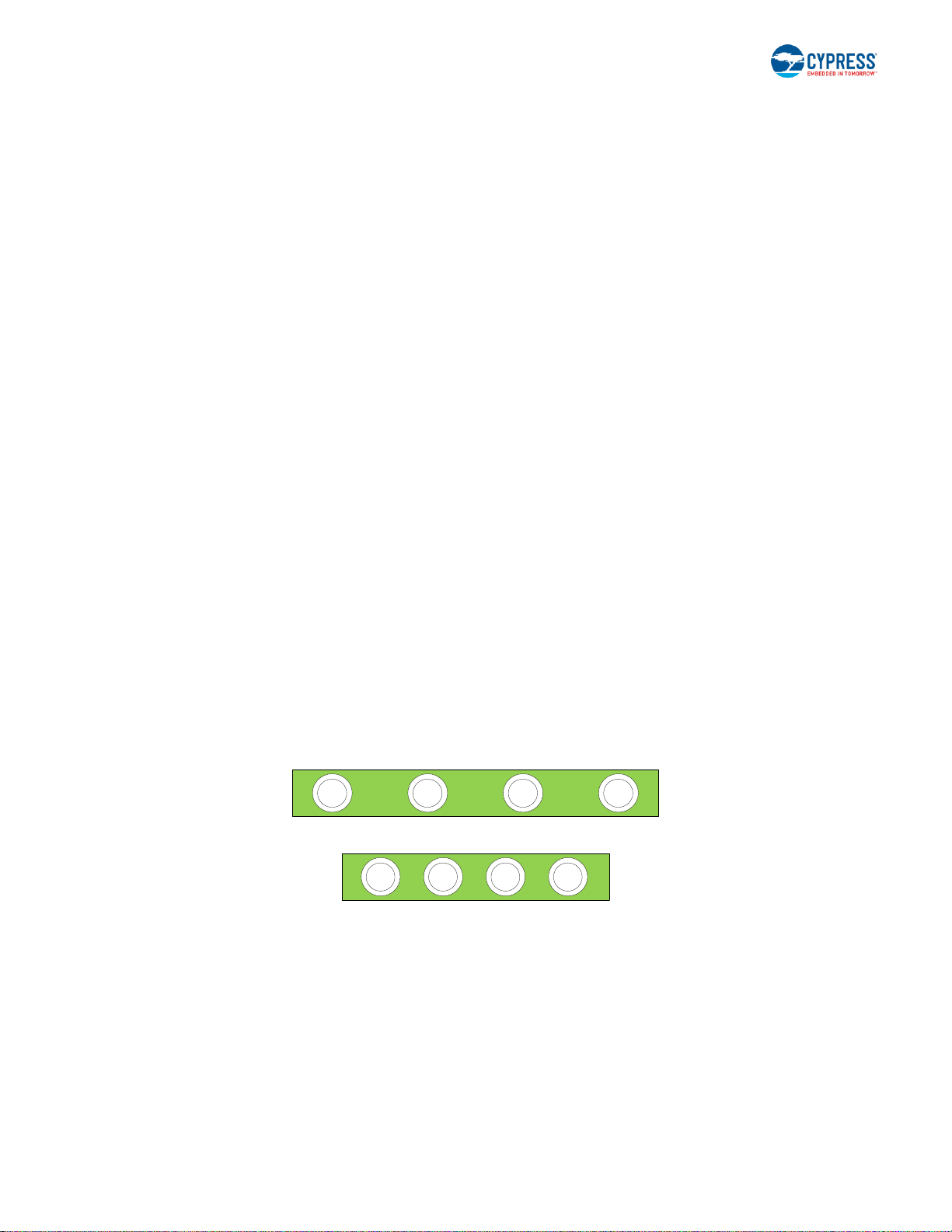

Figure 2-5. Design of Laptop Multi-Media Keys for 21-inch Model

Figure 2-6. Design of Laptop Multi-Media Keys for 15-inch Model with Same Functionality and Button Size

Reduced Design Cycle Time

When you design a capacitive button interface, the most time-consuming tasks are firmware development, layout,

and button tuning. With a typical touch-sensing controller, the button must be retuned when the same design is

ported to different models or when the mechanical dimensions change in the PCB or the button PCB layout. A design

with SmartSense™ Auto-Tuning meets these challenges because it needs no firmware development, no manual

tuning, and no retuning. In addition, SmartSense™ Auto-Tuning speeds up a typical design cycle. Figure 2-7

compares the design cycles of a typical touch-sensing controller and a SmartSense™ Auto-Tuning-based design.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 13

Page 14

CapSense Technology

Feasibility

Study

Schematics

Design

PCB Layout

Design

Mechanical Design

Review

System

Integration

Retuning for any

changes

Tuning process

Production Fine

Tuning

Design

Validation

Production

Typical capacitive user interface Design Cycle

Firmware

Development

Feasibility

Study

Schematics

Design

PCB Layout

Design

Mechanical Design

Review

System

Integration

Design

Validation

Production

CapSense® Express with SmartSense™ Auto-Tuning based

capacitive user interface Design Cycle

Device

Configuration

Figure 2-7. Typical Capacitive Interface Design Cycle Comparison

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 14

Page 15

3. CapSense Schematic Design

CY8CMBR2044 Configuration Options

Cypress’s CY8CMBR2044 enables you to implement capacitive touch sensing using only hardware. This section

provides an overview of the CapSense controller pins and how to configure them.

Figure 3-1. CY8CMBR2044 Pin Diagram

CapSense Buttons (CSx)

The CY8CMBR2044 controller has four capacitive sense inputs, CS0–CS3. Each capacitive button requires a

connection to one of the capacitive sense inputs. You must ground all unused CapSense (CSx) inputs pins.

General-Purpose Outputs (GPOx)

There are four active LOW outputs on the CY8CMBR2044 controller, GPO0–GPO3. Each output, GPOx, is driven by

its corresponding capacitive sensing input, CSx. You can use GPOs to directly drive LEDs or to replace mechanical

switches. GPOs are in strong drivea mode. You must leave all unused GPOs floating.

Modulation Capacitor (C

Connect a 2.2-nF (±10%) capacitor to the C

a

When a pin is in strong drive mode, it is pulled up to VDD when the output is HIGH and pulled down to Ground when the output is

LOW. The output cannot be floating.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 15

MOD

)

pin.

MOD

Page 16

CapSense Schematic Design

ARST Pin Connection

Button Auto Reset Period

(seconds)

Ground

5

5 kΩ (10%) resistor to ground

20

VDD or floating

No Limit

CS0

GPO0

Auto Reset period

GPO0 is not driven after

Auto Reset period

Button is touched for more

than the Auto Reset period

Toggle/FSS Pin Connection

Toggle ON/OFF

FSS

Ground

Disabled

Disabled

1.5 kΩ (5%) resistor to ground

Enabled

Disabled

5.1 kΩ (5%) resistor to ground

Disabled

Enabled

VDD

Enabled

Enabled

Button Auto Reset (ARST)

Button Auto Reset determines the maximum time a GPOx is driven when CSx is continuously touched. This feature

prevents a button from getting stuck if a metal object s placed too close to it. The ARST period can be configured to

be 5 seconds or 20 seconds. The Button Auto Reset is defined in Table 3-1 and shown in Figure 3-2.

Table 3-1. ARST Pin Configuration

Figure 3-2. Button Auto Reset

After the GPOx is turned off because of Button Auto Reset feature and after the button is released, do not touch the

button for a specific amount of time (T) given, as follows:

T equals 220 ms, if the CSx input is released within 2 seconds after Button Auto Reset period is elapsed.

T equals 220 ms plus the Button Scan Rate, if the CSx input is released after 2 seconds, after Button Auto

Reset period is elapsed.

Toggle ON/OFF

When Toggle ON/OFF is enabled, the state of GPOx changes on every rising edge of CSx. Toggle ON/OFF

configuration is defined in Table 3-2 and shown in Figure 3-3.

Table 3-2. Toggle/FSS Pin Configuration

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 16

Page 17

CapSense Schematic Design

CS0

GPO0

Figure 3-3. Example of Toggle ON/OFF Feature

Flanking Sensor Suppression (FSS)

FSS helps to distinguish closely spaced buttons by allowing only one CSx to be in the TOUCH state at a time. If a

finger contacts multiple CSx buttons, only the first one to sense a TOUCH state will turn ON.

FSS also is useful when a button can produce opposite effects – for example, an interface with two buttons for

brightness control (UP or DOWN).

FSS configuration is defined in Table 3-2 and shown in Figure 3-4 and Figure 3-5.

Figure 3-4. FSS Implementation, Single Button Touched

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 17

Page 18

CapSense Schematic Design

CS0

GPO0

LED ON Time

Figure 3-5. FSS Implementation, Multiple Buttons Touched

LED ON Time

LED ON Time specifies the duration for which GPOx is driven low after CSx is released. LED ON Time can range

from 0 ms to 2000 ms.

Figure 3-6. LED ON Timing

The LED ON Time duration, D, is configurable from the Delay pin. For different values of resistors connected to the

Delay pin, the time can be varied. The resistor, R

Equation 4

Where:

D is a multiple of 20 ms

Table 3-3 provides some example values for the Delay pin configuration and the resulting LED ON Time. R

resistor tolerance should be less than 1 percent.

, is defined by Equation 4.

DELAY

DELAY

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 18

Page 19

CapSense Schematic Design

R

DELAY

(Ω)

Approx. LED ON Time

(ms)

Grounded

0

120

20

200

40

280

60 … …

7960

1980

8040

2000

> 8040

2000

Pulled to VDD

2000

Floating

2000

CS0

GPO0

CS1

GPO1

Start LED ON Time

Counter

Restart LED ON

Time Counter

Reset LED ON

Time Counter

LED ON Time

Table 3-3. R

Value for LED ON Time

DELAY

Place R

between the Delay pin and ground. LED ON Time varies from device to device. It is ±12% accurate at

DELAY

room temperature and ±18% accurate at a temperature range of -40 °C to +85 °C.

If a Button Auto Reset is triggered for CSx, LED ON Time is not applied on GPOx. LED ON Time is disabled if Toggle

ON/OFF is enabled.

LED ON Time applies only to one GPOx at a time, meaning the LED ON Time counter resets every time a CSx

transitions to a NO TOUCH state. Figure 3-7 illustrates how LED ON Time operates: CS1 resets the LED ON Time

counter, causing GPO0 to turn OFF prematurely.

Figure 3-7. LED ON Timing Diagram for Multiple Buttons

System Diagnostics

A built-in Power-on Self Test (POST) mechanism performs some tests at power-on reset (POR), which can be useful

in production testing. If any button fails these tests, a 5 ms pulse is sent out on the corresponding GPO within 175 ms

after POR. The following tests are performed on all of the buttons:

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 19

Page 20

CapSense Schematic Design

CY8CMBR2044

Button

shorting

CY8CMBR2044

Button

shorting

V

DD

CY8CMBR2044

Button

shorting

Button

Button Shorted to Ground

If any button is found to be shorted to ground, it is disabled.

Figure 3-8. Button Shorted to Ground

Button Shorted to VDD

If any button is found to be shorted to VDD, it is disabled.

Figure 3-9. Button Shorted to VDD

Button to Button Short

If two or more buttons are found to be shorted to each other, all of these buttons are disabled.

Figure 3-10. Button to Button Short

Improper Value of C

Recommended value of C

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 20

MOD

is 2.2 nF ± 10%.

MOD

Page 21

CapSense Schematic Design

5ms pulse

GPO3

GPO2

GPO1

(High)

GPO0

(High)

5ms pulse

If the value of C

is found to be less than 1 nF or greater than 4 nF, all the buttons are disabled.

MOD

Button CP > 40 pF

If the parasitic capacitance (CP) of any button is found to be more than 40 pF, that button is disabled.

Figure 3-11.ExampleShowing CS), CS1 Passing the POST and CS2, CS3 Failing

Scan Rate/Sleep

Use this pin to set the button scan rate and sleep mode operation of the CY8CMBR2044. Do not leave this pin

floating.

Button Scan Rate

The button scan rate specifies the time between successive button scans by the device. An external resistor

determines the button scan rate for the CY8CMBR2044. You can use the Cp, Power Consumption and Response

Time Calculator to determine the scan rate resistor value or Table 3-4.The button scan rate is configurable from

20 ms to 531 ms.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 21

Page 22

CapSense Schematic Design

Table 3-4. Resistor Value Selection for Button Scan Rate

Button Scan Rate varies from device to device. It is ±12 percent accurate at room temperature and ±18 percent

accurate at a temperature range of -–40 °C to +85 °C.

Sleep Mode

There are two possible configurations:

1. Connect the Button Scan Rate resistor to ground. This enables low power sleep mode

2. Connect the Button Scan Rate resistor to an external Master (host processor) and configure the host pin to be

HIGH (VDD). This enables deep sleep mode.

Further details are in the Sleep Modes section.

Serial Debug Data Out

Serial Debug Data reports firmware revision, CapSense status, GPO status, raw count, baseline, difference count,

and parasitic capacitance for all buttons. When Serial Debug Data is enabled this information is output on a single

CSx pin. To enable Serial Data Out, pull down the CSx pin where you want the serial data to appear with a 5.6-kΩ

resistor with a 5-percent tolerance. If more than one CSx pin is pulled down, debug data is sent out only on one CSx

pin. The priority is:

CS0 > CS1 > CS2 > CS3

The Cypress Multi-Chart Tool can be used to view the data. The Serial Debug Data is sent by the device in the order

according to Table 3-5. The MultiChart tool arranges the data in the format as shown in Table 3-6.

Serial data is sent out with ~115,200 baud rate.

For designs using less than four CapSense buttons, the unused CS pin should be selected for Serial Debug Data.

For designs using all four CapSense buttons, use two CSx pins for Serial Debug Data. For example, pull down CS0

with a 5.6-kΩ resistor and read the data for CS1, CS2, and CS3. Next, pull down CS1 with a 5.6-kΩ resistor and read

the data for CS0, CS2, and CS3.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 22

Page 23

CapSense Schematic Design

Byte

Data

Notes

0

0x0D

Dummy data for multi chart

1

0x0A

2

0x00 – 3

FW_Revision

Firmware Revision

4

0x00 – 5

CS0_Cp

CS0 parasitic capacitance (pF) in Hex

6

CS0_RawCount_MSB

Unsigned 16-bit integer

7

CS0_RawCount_LSB

8

CS1_RawCount_MSB

Unsigned 16-bit integer

9

CS1_RawCount_LSB

10

CS2_RawCount_MSB

Unsigned 16-bit integer

11

CS2_RawCount_LSB

12

CS3_RawCount_MSB

Unsigned 16-bit integer

13

CS3_RawCount_LSB

14

CS_Status

Gives CapSense button status, least significant bit (LSB) contains CS0 status

15

GPO_Status

Gives GPO status, LSB contains GPO0 status

16

0x00 – 17

CS1_Cp

CS1 parasitic capacitance (pF) in Hex

18

CS0_Baseline_MSB

Unsigned 16-bit integer

19

CS0_Baseline_LSB

20

CS1_Baseline_MSB

Unsigned 16-bit integer

21

CS1_Baseline_LSB

22

CS2_Baseline_MSB

Unsigned 16-bit integer

23

CS2_Baseline_LSB

24

CS3_Baseline_MSB

Unsigned 16-bit integer

25

CS3_Baseline_LSB

26

0x00 – 27

CS2_Cp

CS2 parasitic capacitance (pF) in Hex

28

0x00 – 29

CS3_cp

CS3 parasitic capacitance (pF) in Hex

30

CS0_DiffCount_MSB

Unsigned 16-bit integer

31

CS0_DiffCount_LSB

32

CS1_DiffCount_MSB

Unsigned 16-bit integer

33

CS1_DiffCount_LSB

34

CS2_DiffCount_MSB

Unsigned 16-bit integer

35

CS2_DiffCount_LSB

36

CS3_DiffCount_MSB

Unsigned 16-bit integer

Table 3-5. Serial Data Output Sent by CY8CMBR2044

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 23

Page 24

CapSense Schematic Design

Byte

Data

Notes

37

CS3_DiffCount_LSB

38

0x00

Dummy data for MultiChart

39

0xFF

40

0xFF

#

Raw Count Array

Baseline Array

Signal array

MSB

LSB

MSB

LSB

MSB

LSB

0

0x00

FW_Revision

CS_Status

GPO_Status

0x00

CS2_Cp

1

0x00

CS0_Cp

0x00

CS1_Cp

0x00

CS3_Cp

2

CS0_RawCount

CS0_Baseline

CS0_DiffCount

3

CS1_RawCount

CS1_Baseline

CS1_DiffCount

4

CS2_RawCount

CS2_Baseline

CS2_DiffCount

5

CS3_RawCount

CS3_Baseline

CS3_DiffCount

Table 3-6. Serial Debug Data Arranged in Multichart

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 24

Page 25

CapSense Schematic Design

Design Toolbox

The Design Toolbox helps you to design a CY8CMBR2044 CapSense solution. It offers basic information about the

board layout and feature settings and recommends whether the design is fit for mass production.

General Layout Guidelines

The table below summarizes the layout guidelines for the CY8CMBR2044. These guidelines are discussed in

Electrical and Mechanical Electrical and Mechanical Design Considerations of this guide. For a thorough treatment of

this material, see Getting Started with CapSense, Section 3.7.

Figure 3-12. Design Layout Recommendations

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 25

Page 26

CapSense Schematic Design

Layout Estimator

The Layout Estimator provides the minimum button size and maximum trace length recommendation based on the

intended end-system requirements and industrial design. The inputs include the overlay material, overlay thickness,

and trace capacitance of circuit board material. Refer to Figure 3-13, Table B, to learn the dielectric constants for

different overlay materials and the trace capacitance per unit length for different PCBs. Table A calculates the

minimum button diameter and maximum trace length for the design, based on three relative ranges of system noise.

Low, medium, and high noise is a relative figure of merit to help you with button development. Noise conditions can

vary button to button based on the end-system environment. If the noise conditions are unknown, use medium noise

conditions as the starting point. The actual noise seen at each button will be determined in the design validation step

described in Design Validation.

Use the outputs of this sheet to guide the sensor board layout process and then check the design prior to prototyping

with the CP, Power Consumption and Response Time Calculator sheet as detailed Cp, Power Consumption and

Response Time Calculator.

Figure 3-13. Layout Estimator

Inputs:

Overlay thickness

Overlay dielectric constant

Capacitance of trace per inch of board

Outputs:

Recommended minimum button diameter and maximum trace length for different noise conditions

Button to ground clearance

Note The button diameter of each button can be different in the design based on whether the noise varies button to

button.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 26

Page 27

CapSense Schematic Design

CP, Power Consumption and Response Time Calculator

After the board layout has been completed, use this calculator to check the design before building the button board

prototype. To verify the CP value of each button, insert the button diameters and trace lengths into Table A. After you

enter the information, the toolbox confirms whether each button is within the specified CP range of 5 pF to 40 pF. The

power calculator in Table B is used to optimize power consumption. Power consumption is a function of the button

scan rate, which is set by the resistor value on the ScanRate/Sleep pin. Refer to Section 3.4 Scan Rate and Table

3-4. Table C outputs the button response time based on the inputs in Tables A and B.

Figure 3-14. CP, Power Consumption and Response Time Calculator

Inputs:

Button diameter and trace length of CS0–CS3 as designed in layout

Button Scan rate resistor value

The percentage of time a finger is on the buttons

Outputs:

Parasitic Capacitance (CP) for each sensor. Confirms whether the CP values are within the specified range

of 5 pF to 40 pF

Power consumption per button

Button response time

After you have built and tested the prototype board, you can determine the actual parasitic capacitance (CP) and

noise condition (noise count) of each button according to the Section 3.1.10 Serial Debug Data Out. Use this

information and the Design Validation Sheet to validate the design, as detailed in Section 0Design Validation

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 27

Page 28

CapSense Schematic Design

Design Validation

After you have prototyped and tested the button board, use the Serial Debug Data Out test mode (Section 3.1.10

Serial Debug Data Out) to capture the raw count, baseline, difference count, and parasitic capacitance for all buttons.

To enter this information into Table C of the sheet, follow these steps –

1. Enable the Serial Debug Data Out feature by connecting a 5.6 kΩ resistor to GND on any CSx pin.

2. Power on the device and connect the CSx pin to the computer through a COM/RS232 port.

3. Open MultiChart and configure it as following –

a. Select PORT - <Specify PORT number>

b. Port Speed – 115200

c. Visible points – 1000

d. Log file name – “C:\MultiChart log\CY8CMBR2044.csv”

To know more about MultiChart, see AN2397 – CapSense Data Viewing Tools

4. Click on “Enable/disable log-file”. This will automatically store the data to the log file. Log this data for at least

300 samples.

5. Click on “Enable/disable log-file”. This will stop logging the data.

6. Open the log file once. The toolbox will automatically be updated with the relevant data.

Table A shows the various design parameter values, taken up from the previous sheets, so that you need not enter

any data in this sheet. This sheet provides a pass/fail grade for the prototype board. If your design fails, you can

redesign your system by entering new values in Table A and further recommendations/results will be given. If your

design passes, leave the “New value” column in Table A blank.

Figure 3-15 Design Validation

Inputs:

If the design passes – None

If the design fails –

o New overlay thickness, overlay material permittivity, button diameter for each individual button, and

trace capacitance

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 28

Page 29

CapSense Schematic Design

o Button Scan Rate resistor value used in design

o Percentage of time a finger is on the buttons

Outputs:

Power consumption per button

Design change recommendations. The Design Toolbox provides recommendations based on the actual

values from the design if the button size or trace lengths are outside of best design practices.

If the button board does not pass, the Design Toolbox will provide recommendations. There are four areas that can

be changed to remedy a failing design: button size, trace length, overlay material, and overlay thickness. Changing

the button size or trace length requires a board spin, while changing the overlay material or thickness, or both, may

be a shorter path to a passing design. The best solution depends on where the project stands in the development

process and the end-system requirements. The Design Toolbox will guide you to a passing outcome.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 29

Page 30

4. Electrical and Mechanical Design

Considerations

Material

Breakdown Voltage (V/mm)

Min. Overlay Thickness at 12 kV (mm)

Air

1200–2800

10

Wood – dry

3900

3

Glass – common

7900

1.5

Glass – Borosilicate (Pyrex®))

13,000

0.9

PMMA Plastic (Plexiglas®)

13,000

0.9

ABS

16,000

0.8

Polycarbonate (Lexan®)

16,000

0.8

Formica

18,000

0.7

FR-4

28,000

0.4

PET Film – (Mylar®)

280,000

0.04

Polymide film – (Kapton®)

290,000

0.04

When designing a capacitive touch sense technology into your application it is crucial to keep in mind that the

CapSense device exists within a larger framework. Careful attention to every detail, including PCB layout, user

interface, and end-user operating environment, leads to robust and reliable system performance. For in-depth

information, refer to Getting Started with CapSense.

Overlay Selection

In CapSense Equation 1 was presented for finger capacitance

Where:

ε

= Free space permittivity

0

ε

= Dielectric constant of overlay

r

A = Area of finger and sensor pad overlap

D = Overlay thickness

To increase the CapSense signal strength, choose an overlay material with a higher dielectric constant, decrease the

overlay thickness, and increase the button diameter. The Design Toolbox helps you to design a robust and reliable

CY8CMBR2044 solution, as discussed in the chapter CapSense Schematic Design.

Table 4-1. Overlay Material Dielectric Strength

Conductive material cannot be used as an overlay because it interferes with the electric field pattern. Therefore, do

not use paint containing metal particles.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 30

Page 31

Electrical and Mechanical Design Considerations

ESD Protection device

Input

Capacitance

Leakage

Current

Contact

Discharge

maximum limit

Air Discharge

maximum limit

Manufacturer

Part Number

Littlefuse

SP723

5 pF

2 nA

8 kV

15 kV

Vishay

VBUS05L1-DD1

0.3 pF

0.1 µA <

±15 kV

±16 kV

NXP

NUP1301

0.75 pF

30 nA

8 kV

15 kV

Bonding Overlay to PCB

Because the dielectric constant of air is very low, an air gap between the overlay and the button degrades the

performance of the button. To eliminate the gap, use a nonconductive adhesive to bond the overlay to the CapSense

PCB. A transparent acrylic adhesive film from 3M™ called 200MP is qualified for use in CapSense applications. This

special adhesive is dispensed from paper-backed tape rolls (3M™ product numbers 467MP and 468MP).

ESD Protection

Robust ESD tolerance is a natural byproduct of thoughtful system design. By considering how the contact discharge

occurs in your end product, particularly in your user interface, you can withstand an 18-kV discharge event without

incurring any damage to the CapSense controller.

CapSense controller pins can withstand a direct 12-kV event. In most cases, the overlay material provides sufficient

ESD protection for the controller pins. Table 4-1 lists the thickness of various overlay materials required to protect the

CapSense sensors from a 12-kV discharge as specified in IEC 61000-4-2. If the overlay material does not provide

sufficient ESD protection, apply countermeasures in the following order: Prevent, Redirect, Clamp.

Prevent

Make sure all paths on the touch surface have a breakdown voltage greater than potential high-voltage contacts. In

addition, design your system to maintain an appropriate distance between the CapSense controller and possible

sources of ESD. If it is not possible to maintain adequate distance, place a protective layer of a high-breakdownvoltage material between the ESD source and CapSense controller. One layer of 5-mil-thick Kapton® tape will

withstand 18 kV.

Redirect

If your product is densely packed, it may not be possible to prevent the discharge event. In this case, you can protect

the CapSense controller by controlling where the discharge occurs. Place a guard ring on the perimeter of the circuit

board that is connected to chassis ground. As recommended in PCB Layout Guidelines, using a hatched ground

plane around the button can redirect the ESD event away from the button and CapSense controller.

Clamp

Because CapSense sensors are purposely placed in close proximity to the touch surface, it may not be practical to

redirect the discharge path. In this case, consider including series resistors or special-purpose ESD protection

devices.

The recommended series resistance value is 560 Ω.

A more effective method is to provide special-purpose ESD protection devices on the vulnerable traces. Note that

ESD protection devices for CapSense need to be low in capacitance. Table 4-2 lists devices recommended for use

with CapSense controllers.

Table 4-2. Low-Capacitance ESD Protection Devices Recommended for CapSense

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 31

Page 32

Electrical and Mechanical Design Considerations

Button CP Range

Sink Current Limit per GPO

Sink Current Limit for Device

5 pF ≤ CP ≤ 12 pF

25 mA

120 mA

12 pF ≤ CP ≤ 21 pF

20 mA

20 mA

21 pF ≤ CP ≤ 40 pF

6 mA

6 mA

Electromagnetic Compatibility (EMC) Considerations

Radiated Interference

Radiated electrical energy can influence system measurements and potentially influence the operation of the

processor core. The interference enters the CY8CMBR2044 chip at the PCB level, through CapSense button traces

and any other digital or analog inputs. The Layout guidelines for minimizing the effects of RF interference follow:

Ground Plane: provide a ground plane on the PCB

Series Resistor: place series resistors within 10 mm of the CapSense controller pins

o The recommended series resistance for CapSense input lines is 560 Ω

Trace Length: Minimize trace length whenever possible

Current Loop Area: Minimize the return path for current. To reduce the impact of parasitic capacitance,

hatched ground is given within 1 cm of the buttons and traces, instead of solid fill.

RF Source Location: Partition systems with noise sources, such as LCD inverters and switched-mode

power supplies (SMPS), to keep the interference separated from CapSense inputs. Shielding the power

supply is another common technique to prevent interference.

Conducted Immunity and Emissions

Noise entering a system through interconnections with other systems is referred to as conducted noise. Examples

include power and communication lines. Because the CapSense controllers are low-power devices, you must avoid

conducted emissions. The following guidelines will help to reduce conducted emission and immunity:

Use decoupling capacitors.

Add a bidirectional filter on the input to the system power supply. This is effective for both conducted

emissions and immunity. A pi-filter can prevent power supply noise from effecting sensitive parts and also

prevent the switching noise of the part itself from coupling back onto the power planes.

If the CapSense controller PCB is connected to the power supply by a cable, minimize the cable length and

consider using a shielded cable.

To filter out high-frequency noise, place a ferrite bead around power supply or communication lines.

PCB Layout Guidelines

The Design Toolbox will help you design a robust and reliable CY8CMBR2044 CapSense PCB layout, as discussed

in Section 0

If your design uses the GPOs to sink current to the CapSense controller, and there is a lot of noise in the CapSense

system, use series resistors on all of the GPOs to limit sink current. Sink current limit is determined by the maximum

button CP in your design at 5 V, as show in Table 4-3.

Table 4-3. GPO Sink Current Limit for Low Output Voltage

Detailed PCB layout guidelines are available in Getting Started with CapSense, Section 3.7.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 32

Page 33

5. Low-Power Design Considerations

System Design Recommendations

Cypress’s CY8CMBR2044 is designed to meet the low-power requirements of battery powered applications.

To minimize power consumption, take these steps:

Ground all unused CapSense inputs

Minimize CP using the design guidelines in Getting Started with CapSense, Section 3.7.1.

Reduce supply voltage

Use a higher Button Scan Rate or Deep Sleep operating mode, refer to Button Scan Rate.

Calculating Average Power

The Design Toolbox, which is the tool of choice, automates the power consumption calculations described in the

following sections. The average power consumed by the CY8CBMR2044 is determined by calculating the parameters

below:

1. Button Scan rate, TR

2. Scan time, TS

3. Average current in a NO TOUCH state, I

4. Average current in a TOUCH state, I

5. Average standalone current, I

6. Average current, I

7. Average power, P

AVE

AVE

AVE_SA

AVE_T

Button Scan Rate (TR)

Control the Button Scan rate though the external resistor connected to the ScanRate/Sleep pin of CY8CMBR2044.

The following equation provides the approximate scan rate:

Where:

R = value of external resistor (in ohms).

Refer to Table 3-4 to find the appropriate resistor value.

Response Time (T

Selecting the Scan Rate means balancing the response time and power consumption requirements of your

application.

Equation 5

)

RES

AVE_NT

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 33

Page 34

Low-Power Design Considerations

CP

(pF)

Button Sensitivity Constant

(K)

Button connected to Ground

0

5 pF ≤ CP ≤ 10 pF

1

10 pF < CP ≤ 22 pF

2

23 pF < CP ≤ 40 pF

4

Parameter

Typ

Max

TFW

1.50 ms

1.57 ms

I

SLEEP

1.07 µA

1.5 µA

TS

From Equation 7

+5% from TYP value

TR

Table 3-4

±10 from Value

I

ACTIVE

2.67 mA

3.8 mA

Response time, T

senses a TOUCH state. The CY8CMBR2044 device has two different response times. The first is the time it takes to

respond when the device wakes up from low power mode:

Equation 6

Where:

TR = Scan Rate

And the second is the time it takes to respond to any subsequent TOUCH after it wakes up, 80 ms.

is the amount of time the CY8CMBR2044 takes to produce a valid signal on GPOx after CSx

RES,

Scan Time (TS)

Approximate scan time can be calculated using:

Where:

K

= button sensitivity constant for CSx.

CSX

TFW = Firmware execution time, from Table 5-2.

Table 5-1. Button Sensitivity Constant

Equation 7

Table 5-2. Average Current Parameters

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 34

Page 35

Low-Power Design Considerations

Average Current in NO TOUCH State (I

AVE_NT

)

Equation 8

Where:

TR = Button Scan Rate

TS = Scan time

I

= current consumed by CY8CMBR2044 during low power sleep mode, from Table 5-2

SLEEP

I

= current consumed by CY8CMBR2044 during active operation, from Table 5-2

ACTIVE

Average Current in TOUCH State (I

AVE_T

)

Equation 9

Where:

TS = Scan time

I

= current consumed by CY8CMBR2044 during low power sleep mode, from Table 5-2

SLEEP

I

= current consumed by CY8CMBR2044 during active operation, from Table 5-2

ACTIVE

Average Standalone Current (I

AVE_SA

)

Equation 10

Where

P = percentage of time CS is in the TOUCH state compared to total time CY8CMBR2044 is on

I

= average current for in the NO TOUCH state

AVG_NT

I

= average current in the TOUCH state

AVG_T

Average Current (I

AVE

)

Equation 11

Where:

T

= time device is in standalone mode

SA

TDS = time device is in deep sleep mode

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 35

Page 36

Low-Power Design Considerations

Average Power (P

Equation 12

AVE

)

Where:

I

= average current

AVE

Example Calculation

As an example of how to calculate average power, consider a CapSense user interface on a bluetooth headset with

three well-designed buttons. The CP for all three buttons is between 10 pF and 22 pF. The buttons are scanned at a

rate of 507 ms.

The scan time can be calculated using a sensor constant of 2 for all three buttons and Equation 13:

Equation 13

The average current in NO TOUCH state is calculated as follows using Equation 14 and the maximum values for

I

and I

SLEEP

The average current in TOUCH state is calculated as follows using Equation 15:

To calculate the average current, assume your headset receives 50 calls in an 8-hour business day and the user

touches a CapSense button every 20 seconds during each call. This means your design operates in a TOUCH state

about 1.8 percent of the 8 hours during which the headset is turned on. The average current consumption of the

design is calculated as follows using Equation 16:

Equation 16

Assuming this design does not utilize deep sleep mode and that it operates at 1.71 V the average power is calculated

as follows using Equation 17:

Equation 17

:

ACTIVE

Equation 14

Equation 15

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 36

Page 37

Low-Power Design Considerations

Scan all buttons with 20 ms Scan

Rate (Scan time + Sleep time)

NO button touched for

2 secs?

Yes

Scan all buttons with user defined

scan rate.

Is any button active?

Yes

No

No

Sleep Modes

Cypress’s CY8CMBR2044 can be configured to operate in either low-power sleep mode or deep sleep mode.

Low-Power Sleep Mode

When the CY8CMBR2044 device operates in low power sleep mode, the device draws 1 µA when not scanning the

CS inputs. The scan rate determines the amount of time. The behavior of CY8CMBR2044 controller in low-power

sleep mode is described in Figure 5-1.

Figure 5-1. Low-Power Sleep Mode

Because low-power sleep mode does not require a host processor to operate, it is also referred to as standalone

mode.

Deep Sleep Mode

If the CY8CMBR2044 is used in a system with a host processor, the ScanRate/Sleep control pin can be used to

operate in deep sleep mode. When the host processor provides logic high to this input pin, the CY8CMBR2044 is put

into deep sleep mode. This mode consumes 0.1 µA (typ) of current. When the host drives a GND signal to the same

input pin, the CY8CMBR2044 wakes up from sleep and operates in low-power sleep mode.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 37

Page 38

6. Resources

Website

Visit Cypress’s CapSense Controllers website to access all of the reference material discussed in this section.

Find a variety of technical resources at the CY8CMBR2044 web page.

Datasheet

The datasheet for the CapSense CY8CMBR2044 device is available at www.cypress.com.

CY8CMBR2044

Design Toolbox

The interactive Design Toolbox will enable you to design a robust and reliable CY8CMBR2044 CapSense solution.

Watch the Design Tool Box example video on web.

Multi-Chart

Multi-Chart is a simple PC tool for real-time CapSense data viewing and logging. The application allows you to view

data from up to 48 sensors, save and print charts, and save data for later analysis in a spreadsheet.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 38

Page 39

Resources

Design Support

To ensure the success of your CapSense solutions, Cypress has a variety of design support channels.

Knowledge Based Articles –Browse technical articles by product family or perform a search on various

CapSense topics.

CapSense Application Notes – a wide variety of application notes built on information presented in this

document.

White Papers – Learn about advanced capacitive touch interface topics.

Cypress Developer Community – Connect with the Cypress technical community and exchange information.

CapSense Product Selector Guide – See the complete product offering of Cypress CapSense product line.

Video Library – Quickly get up to speed with tutorial videos

CY8CMBR2044 Videos – Get up to speed quickly with an overview of the product features and design

toolbox.

Quality & Reliability – Cypress is committed to complete customer satisfaction. At our Quality website you

can find reliability and product qualification reports.

Technical Support – World class technical support is available on-line.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 39

Page 40

7. Appendix

Schematic Example

Schematic 1: Four Buttons with Four GPOs

In the above schematic, the device is configured as:

CS0 – CS3 pins: 560 Ω to CapSense buttons

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 40

o Four CapSense buttons (CS0 – CS3)

Page 41

Appendix

GPO0 – GPO3 pins: LED and 560 Ω to VDD

o CapSense buttons driving four LEDs (GPO0 – GPO3)

CMOD pin: 2.2 nF to Ground

o Modulator capacitor

XRES pin: Floating

o For external reset

Toggle/FSS pin: Ground

o Toggle ON/OFF disabled

o FSS disabled

ARST pin: 5 kΩ to Ground

o Button Auto Reset enabled, Auto Reset Period = 20 seconds

Delay pin: Ground

o LED ON Time disabled

ScanRate/Sleep pin: Ground

o User configured scan rate = 20 ms

To enable Serial Debug Data output, connect a 5.6 kohm resistor on R9 or R12.

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 41

Page 42

Appendix

Schematic 2: Three Buttons with Advanced Features enabled

In the above schematic, the device is configured as:

CS0 – CS2 pins: 560 Ω to CapSense buttons; CS3 pin: Ground

o Three CapSense buttons (CS0 – CS2)

o CS3 not used in design

GPO0 – GPO2 pins: LED and 560 Ω to VDD; GPO3 floating; GPO0-GPO1 pins interfaced to Master

o CapSense buttons driving three LEDs (GPO0 – GPO2)

o GPO0, GPO1 interfaced to master for direct status read

CMOD pin: 2.2 nF to Ground

o Modulator capacitor

XRES pin: Floating

o For external reset

Toggle/FSS pin: 5.1 kΩ to Ground

o Toggle ON/OFF disabled

o FSS enabled

ARST pin: 5 kΩ to Ground

o Button Auto Reset enabled, Auto Reset period = 20 seconds

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 42

Page 43

Appendix

Acronym

Description

AC

Alternating current

ARST

Auto Reset

CF

Finger capacitance

CP

Parasitic capacitance

CS

CapSense

CSD

CapSense Sigma Delta

EMC

Electromagnetic Compatibility

ESD

Electrostatic Discharge

FSS

Flanking Sensor Suppression

GPO

General-Purpose Output

MSB

Most significant bit

LCD

Liquid Crystal Display

LED

Light-Emitting Diode

LSB

Least significant bit

PCB

Printed Circuit Board

POR

Power on Reset

POST

Power on Self-Test

RF

Radio Frequency

SMPS

Switched Mode Power Supply

Delay pin: 4 kΩ to Ground

o LED ON Time of 1000 ms

ScanRate/Sleep pin: 560 Ω to Master

o User configured scan rate = 30 ms

o Master to control device operating mode

To enable Serial Debug Data output, connect a 5.6 kohm resistor on R11.

Acronyms

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 43

Page 44

Glossary

AMUXBUS

Analog multiplexer bus available inside PSoC that helps to connect I/O pins with multiple internal analog

signals.

SmartSense™ Auto-Tuning

A CapSense algorithm that automatically sets sensing parameters for optimal performance after the

design phase and continuously compensates for system, manufacturing, and environmental changes.

Baseline

A value resulting from a firmware algorithm that estimates a trend in the Raw Count when there is no

human finger present on the sensor. The Baseline is less sensitive to sudden changes in the Raw Count

and provides a reference point for computing the Difference Count.

Button or Button Widget

A widget with an associated sensor that can report the active or inactive state (that is, only two states) of

the sensor. For example, it can detect the touch or no-touch state of a finger on the sensor.

Difference Count

The difference between Raw Count and Baseline. If the difference is negative, or if it is below Noise

Threshold, the Difference Count is always set to zero.

Capacitive Sensor

A conductor and substrate, such as a copper button on a printed circuit board (PCB), which reacts to a

touch or an approaching object with a change in capacitance.

CapSense®

Cypress’s touch-sensing user interface solution. The industry’s No. 1 solution in sales by 4x over No. 2.

CapSense Mechanical Button Replacement (MBR)

Cypress’s configurable solution to upgrade mechanical buttons to capacitive buttons, requires minimal

engineering effort to configure the sensor parameters and does not require firmware development. These

devices include the CY8CMBR3XXX and CY8CMBR2XXX families.

Centroid or Centroid Position

A number indicating the finger position on a slider within the range given by the Slider Resolution. This

number is calculated by the CapSense centroid calculation algorithm.

Compensation IDAC

A programmable constant current source, which is used by CSD to compensate for excess sensor CP.

This IDAC is not controlled by the Sigma-Delta Modulator in the CSD block unlike the Modulation IDAC.

CSD

AN66308 - CY8CMBR2044 CapSense® Design Guide, Doc. No. 001-66308 Rev. *F 44

Page 45

Glossary

CapSense Sigma Delta (CSD) is a Cypress-patented method of performing self-capacitance (also called

self-cap) measurements for capacitive sensing applications.

In CSD mode, the sensing system measures the self-capacitance of an electrode, and a change in the

self-capacitance is detected to identify the presence or absence of a finger.

Debounce

A parameter that defines the number of consecutive scan samples for which the touch should be present

for it to become valid. This parameter helps to reject spurious touch signals.

A finger touch is reported only if the Difference Count is greater than Finger Threshold + Hysteresis for a

consecutive Debounce number of scan samples.

Driven-Shield

A technique used by CSD for enabling liquid tolerance in which the Shield Electrode is driven by a signal

that is equal to the sensor switching signal in phase and amplitude.

Electrode

A conductive material such as a pad or a layer on PCB, ITO, or FPCB. The electrode is connected to a

port pin on a CapSense device and is used as a CapSense sensor or to drive specific signals associated

with CapSense functionality.

Finger Threshold

A parameter used with Hysteresis to determine the state of the sensor. Sensor state is reported ON if the

Difference Count is higher than Finger Threshold + Hysteresis, and it is reported OFF if the Difference

Count is below Finger Threshold – Hysteresis.

Ganged Sensors

The method of connecting multiple sensors together and scanning them as a single sensor. Used for

increasing the sensor area for proximity sensing and to reduce power consumption.