Page 1

AN64846

Getting Started with CapSense

®

Document No. 001-64846 Rev. *X

Cypress Semiconductor

198 Champion Court

San Jose, CA 95134-1709

http://www.cypress.com

Page 2

Copyrights

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 2

Copyrights

© Cypress Semiconductor Corporation, 2010-2018. This document is the property of Cypress Semiconductor Corporation

and its subsidiaries, including Spansion LLC (“Cypress”). This document, including any software or firmware included or

referenced in this document (“Software”), is owned by Cypress under the intellectual property laws and treaties of the

United States and other countries worldwide. Cypress reserves all rights under such laws and treaties and does not, except

as specifically stated in this paragraph, grant any license under its patents, copyrights, trademarks, or other intellectual

property rights. If the Software is not accompanied by a license agreement and you do not otherwise have a written

agreement with Cypress governing the use of the Software, then Cypress hereby grants you a personal, non-exclusive,

nontransferable license (without the right to sublicense) (1) under its copyright rights in the Software (a) for Software

provided in source code form, to modify and reproduce the Software solely for use with Cypress hardware products, only

internally within your organization, and (b) to distribute the Software in binary code form externally to end users (either

directly or indirectly through resellers and distributors), solely for use on Cypress hardware product units, and (2) under

those claims of Cypress’s patents that are infringed by the Software (as provided by Cypress, unmodified) to make, use,

distribute, and import the Software solely for use with Cypress hardware products. Any other use, reproduction,

modification, translation, or compilation of the Software is prohibited.

TO THE EXTENT PERMITTED BY APPLICABLE LAW, CYPRESS MAKES NO WARRANTY OF ANY KIND, EXPRESS

OR IMPLIED, WITH REGARD TO THIS DOCUMENT OR ANY SOFTWARE OR ACCOMPANYING HARDWARE,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. No computing device can be absolutely secure. Therefore, despite security measures

implemented in Cypress hardware or software products, Cypress does not assume any liability arising out of any security

breach, such as unauthorized access to or use of a Cypress product. In addition, the products described in these materials

may contain design defects or errors known as errata which may cause the product to deviate from published

specifications. To the extent permitted by applicable law, Cypress reserves the right to make changes to this document

without further notice. Cypress does not assume any liability arising out of the application or use of any product or circuit

described in this document. Any information provided in this document, including any sample design information or

programming code, is provided only for reference purposes. It is the responsibility of the user of this document to properly

design, program, and test the functionality and safety of any application made of this information and any resulting product.

Cypress products are not designed, intended, or authorized for use as critical components in systems designed or intended

for the operation of weapons, weapons systems, nuclear installations, life-support devices or systems, other medical

devices or systems (including resuscitation equipment and surgical implants), pollution control or hazardous substances

management, or other uses where the failure of the device or system could cause personal injury, death, or property

damage (“Unintended Uses”). A critical component is any component of a device or system whose failure to perform can

be reasonably expected to cause the failure of the device or system, or to affect its safety or effectiveness. Cypress is not

liable, in whole or in part, and you shall and hereby do release Cypress from any claim, damage, or other liability arising

from or related to all Unintended Uses of Cypress products. You shall indemnify and hold Cypress harmless from and

against all claims, costs, damages, and other liabilities, including claims for personal injury or death, arising from or related

to any Unintended Uses of Cypress products.

Cypress, the Cypress logo, Spansion, the Spansion logo, and combinations thereof, WICED, PSoC, CapSense, EZ-USB,

F-RAM, and Traveo are trademarks or registered trademarks of Cypress in the United States and other countries. For a

more complete list of Cypress trademarks, visit cypress.com. Other names and brands may be claimed as property of their

respective owners.

Page 3

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 3

Contents

1. Introduction .......................................................................................................................................................... 7

1.1 How to Use this Guide ................................................................................................................................. 7

1.2 Code Examples ........................................................................................................................................... 7

1.3 Cypress CapSense Differentiation ............................................................................................................... 7

1.4 CapSense Design Flow ............................................................................................................................... 8

1.5 Document Conventions ............................................................................................................................... 9

2. CapSense Technology ...................................................................................................................................... 10

2.1 CapSense System Overview ..................................................................................................................... 10

2.1.1 Hardware Component ................................................................................................................... 10

2.1.2 Firmware Component ................................................................................................................... 12

2.2 Capacitive Sensing Methods ..................................................................................................................... 12

2.2.1 Self Capacitance........................................................................................................................... 12

2.2.2 Mutual Capacitance ...................................................................................................................... 14

2.3 CapSense Sensing Technology ................................................................................................................ 15

2.3.1 Capacitance Conversion ............................................................................................................... 15

2.3.2 CapSense with Sigma Delta Modulator (CSD) ............................................................................. 15

2.4 CapSense Tuning ................................................................ ...................................................................... 17

2.4.1 Definitions ..................................................................................................................................... 18

2.4.2 SmartSense Auto-Tuning ............................................................................................................. 19

2.5 Signal-to-Noise Ratio (SNR) ...................................................................................................................... 21

2.5.1 Measuring SNR ............................................................................................................................ 22

2.6 CapSense Widgets .................................................................................................................................... 22

2.6.1 Buttons (Zero-Dimensional Sensors) ............................................................................................ 23

2.6.2 Sliders (One-Dimensional Sensors).............................................................................................. 24

2.6.3 Touchscreens and Trackpads (Two-Dimensional Sensors) ......................................................... 26

2.6.4 Proximity (Three-Dimensional Sensors) ....................................................................................... 26

2.7 Sensor Construction .................................................................................................................................. 27

2.7.1 Field-Coupled Via Copper Trace (PCB) ........................................................................................ 27

2.7.2 Field Coupled Via Spring/Gasket/Foam ........................................................................................ 27

2.7.3 Field Coupled Via Printed Ink ....................................................................................................... 28

2.7.4 Field Coupled via ITO Film on Glass ............................................................................................ 28

2.8 Liquid Tolerance ........................................................................................................................................ 28

2.8.1 Effect of Liquid Droplets and Liquid Stream on CapSense ........................................................... 29

2.8.2 Driven-Shield Signal and Shield Electrode ................................................................................... 31

2.8.3 Guard Sensor ............................................................................................................................... 31

2.8.4 Effect of Liquid Properties on the Liquid-Tolerance Performance ................................................. 32

2.9 Proximity Sensing ................................ ................................ ...................................................................... 33

2.9.1 Proximity-Sensing Applications Based on CapSense ................................................................... 33

Page 4

Contents

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 4

2.9.2 Proximity Sensing with CapSense ................................................................................................ 35

2.10 User Interface Feedback ........................................................................................................................... 35

2.10.1 Visual Feedback ........................................................................................................................... 35

2.10.2 Haptic Feedback ........................................................................................................................... 36

2.10.3 Audible Feedback ......................................................................................................................... 37

3. Design Considerations ..................................................................................................................................... 39

3.1 Overlay Selection ...................................................................................................................................... 39

3.1.1 Overlay Material............................................................................................................................ 39

3.1.2 Overlay Thickness ........................................................................................................................ 40

3.1.3 Overlay Adhesives ........................................................................................................................ 40

3.2 ESD Protection .......................................................................................................................................... 40

3.2.1 Preventing ESD Discharge ........................................................................................................... 41

3.2.2 Redirect ........................................................................................................................................ 41

3.2.3 Clamp ................................................................................................ ................................ ........... 42

3.3 Electromagnetic Compatibility (EMC) Considerations ............................................................................... 42

3.3.1 Radiated Interference and Emissions ........................................................................................... 42

3.3.2 Conducted Immunity and Emissions ............................................................................................. 53

3.4 Software Filtering ....................................................................................................................................... 54

3.4.1 Average Filter ............................................................................................................................... 54

3.4.2 IIR Filter ........................................................................................................................................ 56

3.4.3 Median Filter ................................................................................................................................. 57

3.4.4 Jitter Filter ..................................................................................................................................... 58

3.4.5 Event-Based Filters ...................................................................................................................... 60

3.4.6 Rule-Based Filters ........................................................................................................................ 60

3.5 Power Consumption .................................................................................................................................. 60

3.5.1 Active and Sleep Current .............................................................................................................. 60

3.5.2 Average Current ........................................................................................................................... 60

3.5.3 Response Time Versus Power Consumption ............................................................................... 61

3.6 Proximity Sensing Design .......................................................................................................................... 62

3.6.1 Implementing Proximity Sensing with CapSense ......................................................................... 62

3.6.2 Proximity Sensor Design .............................................................................................................. 64

3.6.3 Factors Affecting Proximity Distance ............................................................................................ 65

3.7 Pin Assignments ................................................................................................................................ ........ 69

3.8 PCB Layout Guidelines ............................................................................................................................. 71

3.8.1 Parasitic Capacitance, CP ................................................................ ............................................. 71

3.8.2 Board Layers ................................................................................................................................ 71

3.8.3 Board Thickness ........................................................................................................................... 72

3.8.4 Button Design ............................................................................................................................... 72

3.8.5 Slider Design ................................................................................................................................ 73

3.8.6 Sensor and Device Placement ..................................................................................................... 79

3.8.7 Trace Length and Width ............................................................................................................... 80

3.8.8 Trace Routing ............................................................................................................................... 80

3.8.9 Crosstalk Solutions ....................................................................................................................... 81

3.8.10 LEDs Close to CapSense Sensors ............................................................................................... 82

3.8.11 Vias ............................................................................................................................................... 82

3.8.12 Ground Plane ............................................................................................................................... 83

3.8.13 Power Supply Layout Recommendations ..................................................................................... 83

3.8.14 Shield Electrode and Guard Sensor ............................................................................................. 85

Page 5

Contents

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 5

3.8.15 CapSense System Design with Single Layer PCB ....................................................................... 88

3.8.16 CapSense System Design with ITO.............................................................................................. 88

3.9 PCB Assembly and Soldering.................................................................................................................... 88

4. CapSense Selector Guide ................................................................................................................................. 89

4.1 Defining CapSense Requirements ............................................................................................................ 89

4.2 CapSense Portfolio .................................................................................................................................... 91

4.2.1 Configurable CapSense Controllers (CapSense Express Family) ................................ ................ 91

4.2.2 Programmable CapSense Controllers .......................................................................................... 93

5. CapSense Resources ...................................................................................................................................... 100

5.1 CapSense Design Guides and Application Notes.................................................................................... 103

5.2 Additional CapSense Resources ............................................................................................................. 103

5.2.1 Cypress Document Manager ...................................................................................................... 103

5.2.2 Website ....................................................................................................................................... 103

5.3 Software Tools ......................................................................................................................................... 105

5.3.1 Integrated Development Environments ....................................................................................... 105

5.3.2 Data Monitoring Tools ................................................................................................................. 106

5.3.3 CapSense Tuner......................................................................................................................... 106

5.3.4 EZ-Click™ .................................................................................................................................. 107

5.3.5 Bridge Control Panel ................................................................................................................... 107

5.4 Development Kits .................................................................................................................................... 107

5.4.1 PSoC 4 Development Kits .......................................................................................................... 107

5.4.2 PSoC 3 and PSoC 5LP Development Kits .................................................................................. 107

5.4.3 CapSense Express Development Kits ........................................................................................ 108

5.4.4 PSoC 1 Development Kits .......................................................................................................... 108

5.4.5 Kits for Programming and Debugging ......................................................................................... 108

5.5 Design Support ........................................................................................................................................ 108

A. Springs ............................................................................................................................................................. 109

A.1 Finger-Introduced Capacitance ............................................................................................................... 109

A.1.1 Mounting Springs to the PCB ..................................................................................................... 111

A.2 CapSense and Mechanical Button Combination ..................................................................................... 112

A.3 Design Examples ..................................................................................................................................... 112

B. Schematic and Layout Checklist .................................................................................................................... 114

B.1 Schematic Checklist ................................................................................................................................ 114

B.1.1 Decoupling Capacitor ................................................................................................................. 114

B.1.2 Bulk Capacitor ............................................................................................................................ 114

B.1.3 Pin Assignment ........................................................................................................................... 114

B.1.4 C

MOD

........................................................................................................................................... 114

B.1.5 RB ............................................................................................................................................... 115

B.1.6 Series Resistor on CapSense Lines ........................................................................................... 115

B.1.7 Series Resistor on Communication Lines ................................................................................... 115

B.2 Layout Checklist ...................................................................................................................................... 116

B.2.1 Buttons ....................................................................................................................................... 117

B.2.2 Slider .......................................................................................................................................... 117

B.2.3 Overlay ................................ ....................................................................................................... 118

B.2.4 Sensor Traces ............................................................................................................................ 118

Page 6

Contents

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 6

B.2.5 Vias on Sensors.......................................................................................................................... 118

B.2.6 Ground Plane/Mesh .................................................................................................................... 118

B.2.7 Series Resistor ........................................................................................................................... 118

B.2.8 Shield Electrode.......................................................................................................................... 119

B.2.9 Guard Sensor ............................................................................................................................. 119

C. Clearance Between Sensor and Ground ....................................................................................................... 120

D. PSoC 1 In-Circuit Emulation (ICE) Pods ........................................................................................................ 123

D.1 Evaluation Pods ....................................................................................................................................... 123

D.2 In-Circuit Emulation (ICE) Pod Kits .......................................................................................................... 123

Glossary .................................................................................................................................................................... 124

Revision History ....................................................................................................................................................... 129

Page 7

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 7

1. Introduction

<

1.1 How to Use this Guide

This guide is an ideal starting point for those who are new to capacitive touch sensing (CapSense®). You can use this

guide to:

Become familiar with the technology underlying CapSense solutions

Understand important design considerations, such as schematic, layout, and EMI (Electro Magnetic Interference)

Select the right device for your application

Find a CapSense resource to help with your design

When you are ready to design your application, consult the Design Guide specific to the CapSense device family you

have selected. Refer to the Glossary for the definitions of CapSense terms.

1.2 Code Examples

To access an ever-growing list of hundreds of PSoC code examples, visit our code examples webpage. You can also

explore the PSoC 4 video library here.

1.3 Cypress CapSense Differentiation

Capacitive touch sensing has changed the face of industrial design in products such as cellphones, PCs, consumer

electronics, automotive, and white goods. Cypress CapSense solutions bring elegant, reliable, and easy-to-use

capacitive touch sensing functionality to your design. Our capacitive touch sensing solutions have replaced more than

four billion mechanical buttons. A CapSense-based user interface design has the following advantages over a

mechanical-buttons based design:

Mechanical buttons are less reliable and wear out over time due to the physical movement. CapSense designs do

not involve moving parts.

Mechanical buttons pose problems when moisture seeps through the gaps in the assembly. CapSense-based front

panels can be completely sealed under the overlay.

Mechanical buttons require a small force to operate compared to the touch buttons and this force can increase

over time due to the accumulation of dirt in the gaps.

Mechanical buttons require multiple parts and increase the BOM cost whereas many CapSense designs consist

of only a PCB and an overlay with adhesive.

Mechanical buttons include the cost of tools required to make cutouts in the front panel. CapSense designs do not

require such cutouts.

Mechanical buttons yield poor aesthetics compared to the sleek and elegant touch buttons. CapSense designs

also offer more flexibility in designing the user interface in terms of button shape and graphical representation.

Cypress’ robust CapSense solutions leverage our flexible Programmable System-on-Chip (PSoC) architecture, which

accelerates time-to-market, integrates critical system functions, and reduces BOM cost. Cypress offers a wide range

of configurable and programmable CapSense controllers. Configurable CapSense controllers are hardware or I2C

configurable. Programmable devices provide complete flexibility to meet your exact design requirements, including

reducing BOM cost by integrating further system functionality. Following are some of the unique features offered by

CapSense products.

Page 8

Introduction

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 8

Robust sensing technology

High noise immunity

High-performance sensing across a variety of overlay materials and thicknesses

SmartSense™ Auto-Tuning technology

Proximity sensing

Liquid-tolerant operation

Complete user interface solution including audio, visual, and haptic feedback

Low power consumption

Wide operating voltage range (1.71 V - 5.5 V)

Small form-factor packaging

Reduced BOM cost with integrated features like ADC, DAC, timer, counter, and PWM

1.4 CapSense Design Flow

Figure 1-1 depicts the typical flow of a CapSense product design. This flow is similar to any other electronic system

design flow except that CapSense designs involve an additional step called Tuning. This is the process of finding the

optimum values for various hardware and software parameters required for CapSense operation. These parameters

vary depending on the board layout, sensor dimensions, overlay properties, and application requirements such as

power consumption and response time. Therefore, this step is usually performed when the pre-production builds are

available. Many of the CapSense devices support Cypress’s Auto-tuning algorithm called SmartSense that

automatically sets parameters for optimal performance after the design phase and continuously compensates for

system, manufacturing, and environmental changes.

The enclosure or casing design is an integral part of a CapSense product design as the aesthetic feel and the

performance of the end product depend on the casing material and its design. Since the casing acts as an overlay for

the sensors, the touch-sensing performance depends on the overlay properties such as thickness and material type.

Therefore, it is important to test and evaluate the performance along with the overlay material, which is similar to the

one used in the end-product right from the prototype stage.

Page 9

Introduction

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 9

Figure 1-1. Typical CapSense Product Design Flow

1.5 Document Conventions

Convention

Usage

Courier New

Displays file locations, user entered text, and source code:

C:\ ...cd\icc\

Italics

Displays file names and reference documentation:

Read about the sourcefile.hex file in the PSoC Designer User Guide.

File > Open

Represents menu paths:

File > Open > New Project

Bold

Displays commands, menu paths, and icon names in procedures:

Click the File icon and then click Open.

Times New Roman

Displays an equation:

2 + 2 = 4

Text in gray boxes

Describes Cautions or unique functionality of the product.

Page 10

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 10

2. CapSense Technology

<

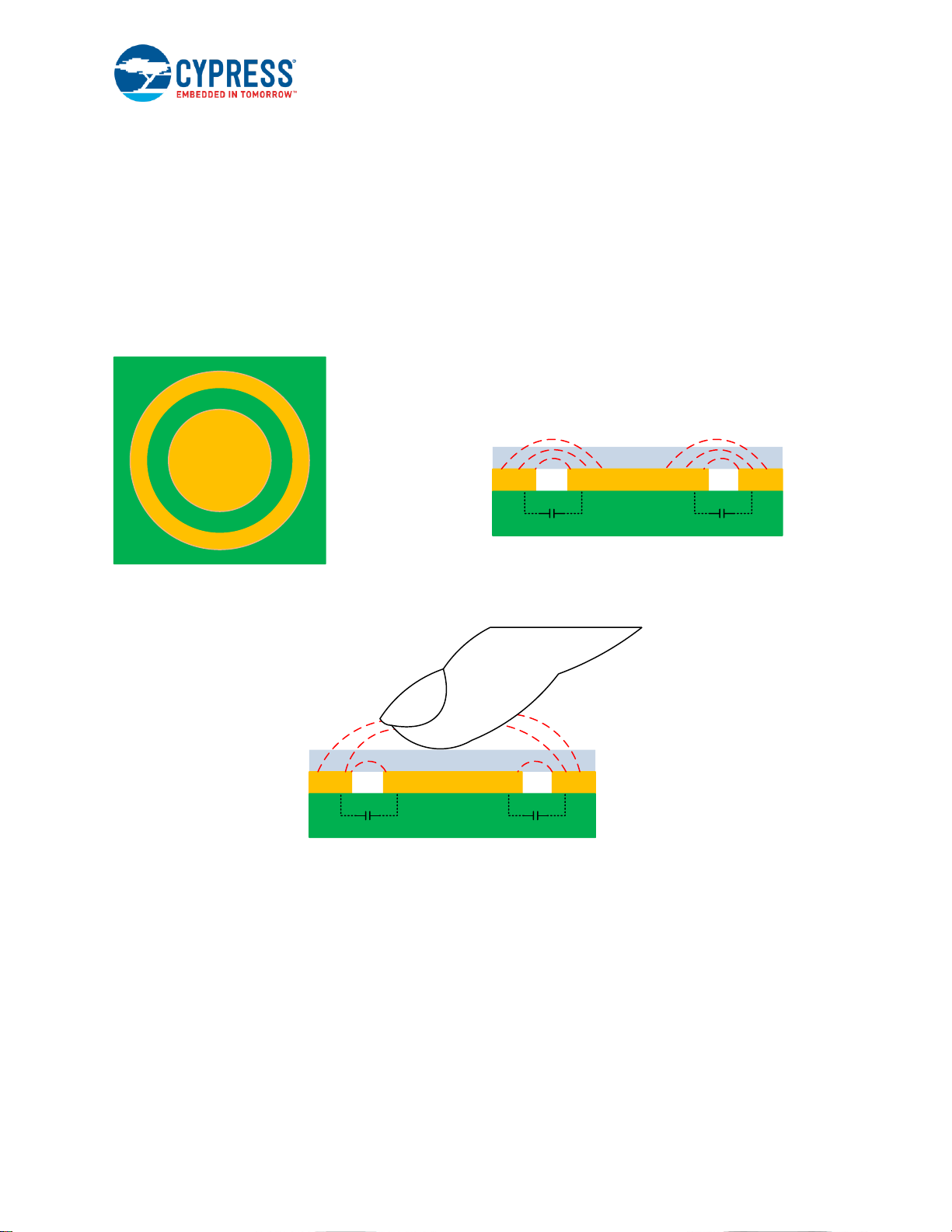

Cypress’ CapSense controllers use changes in capacitance to detect the presence of a finger on or near a touch

surface, as shown in Figure 2-1. This touch button example illustrates a capacitive sensor replacing a mechanical

button. The sensing function is achieved using a combination of hardware and firmware. See the Glossary for the

definitions of CapSense terms.

Figure 2-1. Illustration of a Capacitive Sensor Application

2.1 CapSense System Overview

CapSense touch sensing solutions include the entire system environment in which they operate. This includes:

Hardware components such as PCB and guard sensor

Firmware component to process the sensor data

2.1.1 Hardware Component

The CapSense controller resides within a larger system composed of a printed circuit board (PCB), and a touch-surface

called the overlay that protects the PCB.

Figure 2-2. Exploded View of the CapSense Hardware

Page 11

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 11

The capacitive sensor pads of a sensor board are formed by the PCB traces. The most common PCB format is a twolayer board with sensor pads and a hatched ground plane (see Ground Plane) on the top, and the electrical components

on the bottom. The ground plane is also provided in the bottom layer surrounding the electrical components. The

electrical components include the CapSense controller and associated parts that convert the sensor capacitance into

digital raw counts. Figure 2-3 shows a cross-sectional view of a two-layer board stack-up. The four-layer design is an

option when the board area must be minimized. PCB layout plays a very important role in CapSense system

performance. Best practices are discussed in the device-specific Design Guides.

Figure 2-3. Two-Layer Stack-Up of a CapSense Board

2.1.1.1 Ground Plane

In general, a proper ground plane on the PCB reduces both RF emissions and interference. However, solid grounds

near CapSense sensors, or traces connecting these sensors to the PSoC pins, increase the parasitic capacitance of

the sensors. The increase in parasitic capacitance is unwanted as it reduces the sensitivity. It is thus recommended

that you use hatched ground planes surrounding the sensor and on the bottom layer of the PCB, below the sensors,

as Figure 2-4 shows. Typical hatching for the ground fill is 7-mil line, 45 mil spacing on the top layer, and 7-mil line, and

70-mil spacing on the bottom layer. The same hatch-fill on the top layer is driven with shield signal when liquid tolerance

is required. Refer to Liquid Tolerance to learn more.

Figure 2-4. Ground Fill on a PCB

Page 12

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 12

2.1.2 Firmware Component

Firmware is a vital component of the CapSense system. It processes the raw count data and makes logical decisions.

The amount of firmware development required for your application depends on which CapSense controller family you

select.

Devices from the CapSense Express family are fully configurable either through hardware or through I2C and do not

require any firmware development on the CapSense controller. The finger touch data is sent to a host for higher level

processing; see Figure 2-5. These devices are appropriate for systems where simplicity of design and short time-tomarket are the key requirements.

Figure 2-5. Example CapSense Express System Implementation

Capacitance

Measurement

(Hardware)

Decision

Logic

(Firmware)

CapSense Controller

Decision

Logic

(Firmware)

Non-CapSense

Actions

Application

Functions

Host

Sensors

The programmable devices allow complex system-level integration. These controllers can process the raw count data

as well as perform other system functions.

See CapSense Selector Guide for additional details. Cypress’ PSoC Creator™ and PSoC Designer accommodate

firmware development in C and assembly languages. See Software Tools for more information on this and other tools.

2.2 Capacitive Sensing Methods

Capacitance can be measured between two points using either self-capacitance or mutual capacitance. The left side

of Figure 2-6 shows the self-capacitance method and the right side shows the mutual-capacitance method.

Figure 2-6. Self-Capacitance and Mutual-Capacitance Methods

Z

V

x

+

_ C

x

Self Capacitance

Tx Rx

V

1

+

_

Mutual Capacitance

C

x

V

2

+

_

I

2.2.1 Self Capacitance

Self-capacitance uses a single pin and measures the capacitance between that pin and ground. A self-capacitance

sensing system operates by driving current on a pin connected to a sensor and measuring the voltage. When a finger

is placed on the sensor, it increases the measured capacitance. Self-capacitance sensing is best suited for

single-touch sensors, such as buttons and sliders.

Cypress’s CapSense solutions use self-capacitance sensing because it enables efficient use of pins for single-touch

sensors and sliders.

In a CapSense self-capacitance system, the sensor capacitance measured by the controller is called CS. When a finger

is not on the sensor, CS equals the parasitic capacitance (CP) of the system. This parasitic capacitance is a simplification

of the distributed capacitance that includes the effects of the sensor pad, the overlay, the trace between the CapSense

Page 13

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 13

controller pin and the sensor pad, the vias through the circuit board, and the pin capacitance of the CapSense controller.

CP is related to the electric field around the sensor pad. Although the following diagram shows field lines only around

the sensor pad, the actual electric field is more complicated.

Figure 2-7. CP and Electric Field

When a finger touches the sensor surface, it forms a simple parallel plate capacitor with the sensor pad through the

overlay. The result is called finger capacitance, CF, and is defined by Equation 1. CF is a simplification of a distributed

capacitance that includes the effects of the human body and the return path to the circuit board ground.

Equation 1

Where:

ε

0

= Free space permittivity

ε

r

= Dielectric constant of overlay

A = Area of finger and sensor pad overlap

D = Overlay thickness

Figure 2-8. CapSense System Equivalent Model

With a finger on the sensor surface, CS equals the sum of CP and CF.

Equation 2

Page 14

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 14

2.2.2 Mutual Capacitance

Figure 2-9 shows the button sensor layout for mutual-capacitance sensing. Mutual-capacitance sensing measures the

capacitance between two electrodes. One of the electrodes is called the transmit (TX) electrode and the other electrode

is called the receive (RX) electrode.

In a mutual-capacitance measurement system, a digital voltage (signal switching between V

DDD

and GND) is applied

to the TX pin and the amount of charge received on the RX pin is measured. The amount of charge received on the

RX electrode is directly proportional to the mutual capacitance (CM) between the two electrodes.

When a finger is placed between the TX and RX electrodes, the mutual-capacitance decreases to C

1

M

as shown in

Figure 2-10. Because of the reduction in mutual-capacitance, the charge received on the RX electrode also decreases.

The CapSense system measures the amount of charge received on the RX electrode to detect the touch/no touch

condition.

Figure 2-9. Mutual Capacitance Sensing Working

Overlay

RXTX TX

RX Electrode

PCB

RX

Electrode

TX Electrode

C

M

C

M

Figure 2-10. Mutual Capacitance with Finger Touch

Overlay

RXTX TX

RX Electrode

PCB

C

1

M

C

1

M

The mutual-capacitance effect is best suited to multi-touch systems such as touchscreens and trackpads. Cypress

offers mutual-capacitance-based trackpad solutions for consumer applications and TrueTouch® touchscreen solutions

for automotive and home appliance applications. Contact your local Cypress sales office directly for more information.

To find your local sales office, click here.

Page 15

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 15

2.3 CapSense Sensing Technology

This section explains the self-capacitance measurement method implemented in CapSense devices.

2.3.1 Capacitance Conversion

The CapSense hardware converts the sensor capacitance into a digital count, called raw count. The raw count is

interpreted as either a TOUCH or NO TOUCH state for the sensor, as Figure 2-11 shows. The numerical value of the

raw count is the digital representation of the sensor capacitance, and increases as the capacitance increases as

explained in Section 2.3.2 . The raw count is directly proportional to the average current drawn out by the sensor

capacitance, which increases when the sensor capacitance increases. Sensitivity is a measure of how much the output

will change for a given change on the input. The sensitivity of the CapSense sensor has units of counts-per-pF.

Figure 2-11. Sensing Algorithm Output

2.3.2 CapSense with Sigma Delta Modulator (CSD)

Cypress’s CSD method shown in Figure 2-12 uses a switched capacitor circuit on the front end of the system to convert

the sensor capacitance (CP) to an equivalent resistor (see Figure 2-13). A Sigma-Delta modulator then converts the

current measured through the equivalent resistor into a digital count. When a finger (CF) is on the sensor, the

capacitance increases and the equivalent resistance decreases. This causes an increase in current through the resistor,

which the Sigma-Delta modulator balances by controlling the Modulation IDAC, resulting in an increase in the digital

count. The Sigma Delta converter maintains the voltage of Analog Mux Bus (AMUXBUS) at a constant V

REF

(typically

1.2 V) with the help of a CMOD capacitor. An external resistor (RS) in-series with the sensor along with the AMUXBUS

resistance (R

bus

) helps to improve noise immunity. The recommended value for RS is 560 Ω.

Figure 2-12. CSD Block Diagram

C

P

isensor

Sigma-Delta

Converter

Sense Clock

CMOD

HI-Z

Input

SW1

SW2

CSD

GND

= External Connection

AMUX

Bus

Rbus

Vref

2.2nF/X7R/5V

Modulation

IDAC

R

S

C

F

Compensation

IDAC

Modulator Clock

GND

Raw Count Output

Page 16

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 16

Figure 2-13. Equivalent Resistor Model

C

S

R

eq

AMUXBUS

SW

1

SW

2

AMUXBUS

I

CS

I

CS

I

CS

Two non-overlapping, out-of-phase clocks of frequency FSW (see Figure 2-14) control the switches SW1 and SW2. FSW

should be selected such that the sensor completely charges and discharges.

Figure 2-14. Voltage Across Sensor Capacitance

V

t

V

REF

(1.2V)

0

T

SW

= 1/F

SW

SW

1

OPEN

SW

2

CLOSED

SW

1

CLOSED

SW

2

OPEN

The continuous switching of SW1 and SW2 forms an equivalent resistance Req, as Figure 2-13 shows. The value of the

equivalent resistance RS is:

Equation 3

Where:

CS = Total sensor capacitance = Parasitic capacitance (CP) + Finger capacitance (CF)

FSW = Frequency of the switching clock or Sense Clock Frequency

Equation 4 gives the average current taken by the sensor capacitor from the AMUXBUS.

Equation 4

Equation 5 shows the raw count equation when only Modulation IDAC (single IDAC mode) is used and Equation 6

shows the raw count when both Modulation IDAC and Compensation IDAC (Dual IDAC mode) are used. The dual IDAC

mode gives more sensitivity and produces more count for a specific finger capacitance compared to the single IDAC

mode.

R

Equation 5

Equation 6

Where:

N = Scan resolution of the Sigma-Delta modulator in bits. CSD supports up to 16-bit resolution.

The CapSense architecture and its features vary slightly depending on the device. For example, some devices do not

support dual IDAC mode. The architecture presented here is available in many of the CapSense controllers. Refer to

the device-specific Design Guide to learn about the sensing technology implemented for that device.

Page 17

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 17

The fourth-generation CapSense functionality in PSoC 4 S-Series, PSoC 4100S Plus, and PSoC 4100PS devices is

an improved version of the previous generation. The main differences between the two generations of CapSense

architecture are listed in Table 2-1.

Table 2-1. Comparison of CapSense Architecture

Feature

Third-Generation

CapSense

Fourth-Generation

CapSense

Advantages of Fourth-Generation

over Third-Generation CapSense

Sensing Modes

Self-Cap and Mutual Cap

Self-Cap, Mutual Cap and

ADC mode

Multiple functionality

IDAC Modes

Sourcing or Sinking Mode

Sourcing Mode

-

Self-Cap Range

5 pF – 60 pF

5 pF – 200 pF

Supports high-CP-design applications

VREF

1.2 V

0.6 V to VDDA-0.6 V

Improved SNR

IDAC LSB Size

1.2 µA, 2.4 µA

37.5 nA, 300 nA, 2.4 µA

Improved Sensitivity

Split IDAC Capability

Requires two IDACs

Requires one IDAC1

Improved Sensitivity

EMI Reduction - Digital

-

Spread Spectrum - CSD

Controlled

Spread Spectrum clock is generated by

hardware and CPU is completely free.

10-bit ADC

No

Yes

ADC using CSD hardware

HW State Machine

No

Yes

CPU no longer required for Initialization

or for Spread Spectrum SenseClk

generation

The CapSense hardware in PSoC 4 S-Series, PSoC 4100S Plus, and PSoC 4100PS support both self-capacitanceand mutual capacitance-based capacitive sensing. The hardware also supports input voltage measurement when

CapSense scanning is not in progress. Refer to the CapSense chapter in the respective device datasheet for a detailed

explanation of the CapSense hardware in PSoC 4 S-Series, PSoC 4100S Plus, and PSoC 4100PS devices. Refer to

PSoC 4100S and PSoC 4100S Plus: PSoC 4 Architecture Technical Reference Manual (TRM), PSoC 4000S Family:

PSoC® 4 Registers Technical Reference Manual (TRM), and PSoC 4100S Plus Registers Technical Reference Manual

(TRM) for the basic knowledge of fourth-generation CapSense architecture.

2.4 CapSense Tuning

Optimal CapSense system performance depends on the board layout, button dimensions, overlay material, and

application requirements. In addition to these factors, switching frequency and threshold levels must be carefully

selected for robust and reliable performance. Tuning is the process of determining the optimum values for these

parameters. Tuning is required to maintain high sensitivity to touch and to compensate for process variations in the

sensor board, overlay material, and environmental conditions.

Many of the CapSense devices support SmartSense, Cypress’ Auto-tuning algorithm, which automatically sets

parameters for optimal performance and continuously compensates for system, manufacturing and environmental

changes. See SmartSense Auto-Tuning for more information.

This section gives an introduction about the tuning process. For details on all the parameters involved in CapSense

operation and the step-by-step tuning procedure, refer to the device-specific Design Guide. Cypress provides many

tools to make tuning and data monitoring easy. Refer to Data Monitoring Tools to learn more about these tools.

The following section defines some terms that will help you understand the tuning process.

1

Requires one IDAC if compensation and modulation IDAC split is 50-50; if it is not 50-50, it requires two IDACs.

Page 18

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 18

2.4.1 Definitions

Raw Count: As seen in Figure 2-19, sensor capacitance is converted into a count value by the CapSense

algorithm. The unprocessed count value is referred to as raw count. Processing of the raw count results in ON/OFF

states for the sensor.

Baseline: The raw count value of a sensor may vary gradually due to changes in the environment such as

temperature and humidity. Therefore, the raw count is low-pass filtered to create a new count value known as

baseline that keeps track of and compensates for the gradual changes in raw count. The baseline is less sensitive

to sudden changes in the raw count caused by a touch. Therefore, the baseline value provides the reference level

for computing the signals (explained below). Figure 2-15 shows the concept of raw count, baseline and signal.

Figure 2-15. Raw Count and Baseline

baseline

raw count

signal = raw count - baseline

sensor OFF sensor OFFsensor ON

Difference Count or Signal: Subtracting the baseline level from the raw count produces the difference count that

is used in the ON/OFF decision process.

The thresholds are offset by a constant amount from the baseline level. The thresholds have the following

functions:

Noise Threshold: A parameter used to differentiate signal from noise. If the raw count is above noise threshold,

then the baseline is not updated and the difference count indicates the difference between raw count and baseline.

If the raw count is below the noise threshold, then the baseline is updated and the difference count is zero. See

Figure 2-16 for details.

Finger Threshold: A parameter used with Hysteresis to determine the state of the sensor, as Equation 6 and

Figure 2-16 show.

Equation 6

Hysteresis: A parameter used with Finger Threshold to determine the state of the sensor, as Equation 6 and

Figure 2-16 shows. Hysteresis provides immunity against noisy transitions of sensor state.

Page 19

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 19

Figure 2-16. Hysteresis

Sensor ONSensor OFF Sensor OFF

Finger Threshold + Hysteresis

Finger Threshold - Hysteresis

Finger Threshold

2.4.2 SmartSense Auto-Tuning

2.4.2.1 What Is SmartSense?

Tuning the touch sensing user interface is a critical step in ensuring proper system operation and a pleasant user

experience. The typical design flow involves tuning the sensor interface in the initial design phase, during system

integration, and finally production fine-tuning before the production ramp. Because tuning is an iterative process, it can

be time-consuming. SmartSense Auto-Tuning helps to simplify the user interface development cycle. In addition, the

method is easy to use and reduces the design cycle time by eliminating the tuning process throughout the product

development cycle, from prototype to mass production.

2.4.2.2 What Does SmartSense Do?

SmartSense tunes each CapSense sensor automatically at power-up and then monitors and maintains optimum sensor

performance during runtime. The number of parameters to be tuned is reduced from 17 in CSD to 4 with SmartSense.

Power-up tuning: SmartSense tunes the parameters of each sensor based on the individual sensor parasitic

capacitance to get the desired sensitivity for the sensor.

Runtime tuning: Noise in the system is measured dynamically. The thresholds are adjusted accordingly for each

sensor to overcome false triggering due to dynamic variations in noise in the CapSense system.

2.4.2.3 How and Where is SmartSense Helpful?

SmartSense technology adapts for manufacturing variations in PCBs, overlays, and noise generators, such as LCD

inverters, AC line noise, and switch-mode power supplies and automatically tunes them out. SmartSense handles

changes in system environment, such as temperature, humidity, and noise sources such as RF, SMPS, LCD Inverter,

and AC line noise.

The following sections describe scenarios in which SmartSense is instrumental in adapting to the external noise. By

maintaining a robust signal-to-noise ratio, the false triggering of buttons is prevented.

Page 20

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 20

2.4.2.3.1 Different Noise Levels in Different Designs

SmartSense technology dynamically tunes itself (adjusts noise and finger thresholds) for different noise environments.

In Figure 2-17, Design A and Design B have different noise levels. To maintain a minimum SNR of 5:1, you must adjust

the dynamic threshold. SmartSense does this automatically, allowing seamless transition from one model to another

with minimal or no tuning required.

Figure 2-17. Different Noise Levels in Design A and B Being Compensated Automatically

2.4.2.3.2 Noise Spikes During Production

SmartSense technology also automatically tunes out the noise spikes (in production) that may not be seen during the

design stage, as indicated in Figure 2-18. This is a powerful SmartSense feature that prevents false button presses in

the end system, which prevents a failure analysis for a mass production design.

Figure 2-18. Finger Threshold Dynamically Adjusted to Prevent False Button Touches

Page 21

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 21

2.4.2.4 When Is Manual-Tuning Advantageous?

SmartSense allows a device to calibrate itself for optimal performance and complete the entire tuning process

automatically. This technology will meet the needs of most designs, but, in the case where SmartSense will not work

or there are specific SNR or power requirements, the CapSense CSD parameters can be manually adjusted to meet

system requirements. This is called manual tuning. Some advantages of manual tuning, as opposed to SmartSense

Auto-tuning are:

Strict control over parameter settings: SmartSense sets all of the parameters automatically. However, there may

be situations where you need strict control over the parameters. For example, use manual tuning if you need to

strictly control the time CSD takes to scan a group of sensors. This can be done to reduce EMI in systems.

Supports higher parasitic capacitances: SmartSense supports parasitic capacitances as high as 45 pF for a 0.2-

pF finger capacitance, and as high as 35 pF for a 0.1-pF finger capacitance. If the parasitic capacitance is higher

than the value supported by SmartSense, use manual tuning.

Refer to the device-specific Design Guide for the step-by-step procedure on manual tuning.

2.5 Signal-to-Noise Ratio (SNR)

Signal is a generic engineering term that can have many meanings. For CapSense applications, signal is defined as

the change in the raw count between the OFF and ON states. Signal is also called Difference Count.

Noise is another term that has many meanings. The following discussion presents a definition of CapSense noise that

uses a simple mathematical model of the sensor output over time.

When the sensor is in the OFF state, the counts, X(t), can be modeled by an average count and a noise component.

Equation 7

X0 is the average of X(t)

N0(t) is the noise component for t during the OFF state

The same model applies when the sensor is in the ON state.

Equation 8

X1 is the average of X(t)

N1(t) is the noise component for t during the ON state

X0 is called the baseline level of the raw counts. The difference between X1 and X0 is called the signal, S.

Equation 9

The noise components N0(t) and N1(t) are similar but not identical. For example, N1(t) usually contains a higher level

of AC line noise in finger sensing applications compared to N0(t). This occurs because the human body acts as an

antenna to 50-Hz and 60-Hz line noise, and the finger contact with the sensor overlay couples the noise into the

CapSense system.

We define the noise level N as the worst case measured peak noise in the OFF state.

Equation 10

Thus, CapSense SNR, is defined as the ratio of signal (S) to noise (N).

Equation 11

Based on the experiments and knowledge from many CapSense applications, Cypress recommends a minimum SNR

of 5:1 to ensure sufficient margin between noise and signal for robust ON/OFF operation.

Page 22

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 22

Figure 2-19. Signal and Noise

2.5.1 Measuring SNR

SNR should be measured in the noise environment where CapSense is intended to be used. In other words, measure

the system SNR under worst-case noise conditions.

The first step in measuring SNR is to monitor the raw count for each sensor. This can be done using data logging to a

text file and plotting in a spreadsheet, or using the Cypress Bridge Control Panel and Miniprog3 or by using the Tuner

tool, which directly displays the SNR, available with the CapSense component in PSoC Creator (see Data Monitoring

Tools for more details). Refer to AN2397 – CapSense Data Viewing Tools that teaches how to monitor raw count using

these tools. Whatever the method, the raw count should be observed for SNR measurement. The difference count

should not be used in the measurement of SNR since it is a function of the baseline update process, which involves

filtering (filling the "bucket") and nonlinear threshold events.

Another factor to consider is how the signal is produced. The worst-case ON and OFF scenario should be used when

measuring SNR. If the system is designed to sense the presence of a finger, then measure SNR with a light touch of

the sensor area, and position the contact point slightly off-center. For automated testing, a worst-case finger touch

(0.1 pF) can often be simulated by an equivalent metal disc that is the size and shape of a small coin.

As an example of measuring SNR, consider the raw count waveform in Figure 2-19.

X0 = 5925 counts

X1 = 6055 counts

S = 130 counts

N = 5940 - 5910 = 30 counts

SNR = 130:30 = 4.3:1

2.6 CapSense Widgets

CapSense widgets consist of one or more CapSense sensors, which as a unit represent a certain type of user interface.

CapSense widgets are broadly classified into four categories – Buttons (Zero-Dimensional), Sliders (One-Dimensional),

Touchpads/Trackpads (Two-Dimensional), and Proximity sensors (Three-Dimensional). Figure 2-20 shows button,

slider, and proximity sensor widgets. This section explains the basic concepts of different CapSense widgets. For a

detailed explanation of sensor construction, see Sensor Construction.

Page 23

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 23

Figure 2-20. Several types of Widgets

Button Sensor Slider Sensor Proximity Sensor

2.6.1 Buttons (Zero-Dimensional Sensors)

CapSense buttons replace mechanical buttons in a wide variety of applications such as home appliances, medical

devices, white goods, lighting controls and many other products. It is the simplest type of CapSense widget, consisting

of a single sensor. A CapSense button gives one of two possible output states: active (finger is present) or inactive

(finger is not present). These two states are also called ON and OFF states, respectively. To get higher reliability, lower

cost, and appealing industrial design, use CapSense buttons instead of mechanical buttons.

2.6.1.1 Simple Buttons

The simplest capacitive sensor consists of a copper pad connected to a CapSense controller pin with a trace. A button

is defined as the combination of the copper sensor pad and the nonconductive overlay material. The button is

surrounded by a grounded copper hatch separated by an annular gap. Each button requires one I/O pin of the

CapSense controller.

Figure 2-21. Typical Simple Buttons

2.6.1.2 Matrix Buttons

In applications requiring a high number of buttons such as a calculator keypad or a QWERTY keyboard, capacitive

sensors can be arranged in a matrix, as Figure 2-22 shows. This allows a design to have more buttons than there are

I/O pins on the CapSense controller when using a self-capacitance method.

Figure 2-22. Typical Matrix Buttons

A matrix button design consists of two groups of capacitive sensors: Row sensors and Column sensors. When a button

is touched, it can be resolved by identifying the row and column sensors that are both in the TOUCH state. The number

of buttons supported by the matrix is equal to the product of the number of rows and the number of columns.

Equation 12

Using a matrix button design can significantly reduce the number of I/O pins required. For example, the matrix in Figure

2-22 implements 12 buttons, but requires only seven I/O pins for sensors. Additional dedicated pins need to be assigned

to external components, depending on the sensing method selected.

Page 24

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 24

Matrix buttons can only be sensed one at a time. When more than one row or column sensor is in the TOUCH state,

then the finger location cannot be resolved, and the situation is considered an invalid condition. Some applications

require multiple buttons to be sensed simultaneously, such as a keyboard with a Shift, Ctrl, and Alt key. In this case,

the Shift, Ctrl, and Alt keys should be designed as individual buttons, or should be changed to a mutual-capacitance

sensor design. See Mutual Capacitance to learn about Cypress products that support mutual-capacitance technology.

2.6.2 Sliders (One-Dimensional Sensors)

Sliders are used for controls requiring gradual adjustments. Examples include a lighting control (dimmer), volume

control, graphic equalizer, and speed control. A slider is built using an array of capacitive sensors called segments that

are placed adjacent to one another. Actuation of one segment results in partial actuation of physically adjacent

segments. By using an interpolation method called a centroid, you can achieve a higher resolution than the number of

slider segments. A centroid calculation example is given in Section 2.6.2.1. In a typical application, a slider with five

segments can resolve at least 100 physical finger positions on the slider. High resolution makes for smooth transitions

in light or sound as a finger glides across a slider.

2.6.2.1 Linear Sliders

In a linear slider, each CapSense controller I/O pin is connected to one slider segment. A zigzag pattern (double

chevron) as shown in Figure 2-23 is recommended for slider segments. This layout ensures that when a segment is

touched, the adjacent segments are also partially touched. Sensor data from multiple sensors improves the estimation

of finger position. The maximum number of slider segments is a function of the number of available CapSense controller

pins and the required response time.

Figure 2-23. Linear Slider

The centroid equation for a linear slider follows. The CapSense algorithm considers only three slider segments, the

segment with the maximum signal and its two adjacent segments, for the centroid calculation.

Equation 13

Where:

X – Index of the segment that has the maximum signal

Si – Signal of the segment at index i

Resolution – Total number of finger positions to be resolved on the slider

n – Number of segments in the slider

Assuming a linear slider with 5 segments and a resolution of 100, let us now see an example of centroid calculation for

the signal pattern shown in Figure 2-24. This signal pattern indicates that the finger is touching segment 2.

Page 25

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 25

Figure 2-24. Example Signal Pattern on a Linear Slider

0 0

150

100

110

0 1 2 3 4

Segment Index

Signal

Segment 2 has the maximum signal of 150 and its adjacent segments 1 and 3 have the signals of 100 and 110

respectively. Segments 0 and 4 do not have a signal since the finger is away from them. Now, the calculated centroid

position is 51 (rounded) as shown in the following equation. Note that the CapSense algorithm subtracts the Noise

Threshold (see Definitions to learn about Noise Threshold) from the signal before calculating the centroid, which is not

shown here for simplification. Refer to the CapSense component datasheet to learn more.

Equation 14

2.6.2.2 Diplexed Sliders

In a diplexed slider, each CapSense controller I/O pin is connected to two different slider segments. This allows a

design to have twice as many slider segments as there are I/O pins. For example, a diplexed 16-segment slider requires

only eight CapSense controller I/O pins.

Figure 2-25. 16-Segment Diplexed Slider

For a diplexed slider to work properly, the slider segments must be connected to the CapSense controller I/O pins in a

pre-determined order. The first half of the segments are connected to the CapSense controller I/O pins sequentially (0,

1, 2 …7) and operate similar to a linear slider. The second half of the segments are connected to the same CapSense

controller I/O pins in a non-sequential order. This order exploits the fact that activation of one segment results in partial

actuation of neighboring segments. While slider actuation of one half of the slider results in aliasing on to the other half,

the levels will be scattered in the untouched half. Sensing algorithms search for strong adjacent segment actuation and

ignore scattered actuation to determine finger position on the slider accurately.

Page 26

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 26

2.6.2.3 Radial Sliders

Radial sliders are similar to linear sliders in that finger position is estimated using data from adjacent sensors; however,

radial sliders are continuous (does not have a beginning or end), as Figure 2-26 shows. Refer to the CapSense

component datasheet to learn about the centroid equation for a radial slider.

Figure 2-26. Radial Slider

Area contacted by finger

2.6.3 Touchscreens and Trackpads (Two-Dimensional Sensors)

A trackpad (also known as touch pad) has two linear sliders arranged in an X and Y pattern, enabling it to locate a

finger’s position in both X and Y dimensions. Figure 2-27 shows a typical arrangement of a track pad sensor.

Figure 2-27. Trackpad Sensor Arrangement

2.6.4 Proximity (Three-Dimensional Sensors)

Proximity sensors detect the presence of a hand or other conductive object before it makes contact with the touch

surface. Imagine a hand stretched out to operate a car audio system in the dark. The proximity sensor causes the

buttons of the audio system to glow through backlight LEDs when the user's hand is near. One implementation of a

proximity sensor consists of a long trace on the perimeter of the user interface, as shown in Figure 2-28. Another way

to implement a proximity sensor is by ganging sensors together. See Proximity Sensing to learn more.

Figure 2-28. Proximity Sensor

Proximity Sensor

Page 27

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 27

2.7 Sensor Construction

A capacitive sensor can be constructed using different materials depending on the application requirement. In a typical

sensor construction, a conductive pad or surface that senses the user touches is connected to the pin of the capacitive

controller using a conductive trace or link. This whole arrangement is placed below a non-conductive overlay material

and the user interacts on top of the overlay. A very common method of sensor construction is to etch copper pads and

traces on a FR4 PCB. However, in touchscreen applications, Indium Tin Oxide (ITO) is used to construct transparent

sensors. This section presents various methods of constructing a sensor and the features of each method so that you

can choose one that fits your requirements.

2.7.1 Field-Coupled Via Copper Trace (PCB)

Figure 2-29. Field Coupled Using PCB

Features of a PCB-based design:

Most common implementation

Copper pads etched on the surface of the PCB act as sensor pads

Electric field emanates from the copper sensor pad to ground plane

No mechanical moving parts

A nonconductive overlay serves as the touch surface for the button

Ideal topology for simple flat panel designs

Low BOM cost

2.7.2 Field Coupled Via Spring/Gasket/Foam

Figure 2-30. Field Coupled Via Spring

Features of a design based on springs/gaskets/foam:

Electrical field coupled from PCB to overlay using a compressed spring, or conductive gasket or foam (Closed-cell

conductive foam should be used. Materials that absorb moisture should be avoided.)

Conductive material itself acts as capacitive sensor pad

No mechanical moving parts. Springs and foam do not move

Any non-conductive overlay serves as the button touch surface

Page 28

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 28

Ideal topology for curved, sloping, or otherwise irregular front panels

Ideal for designs where touch sensor surface is physically separated from silicon or mother board

Ideal for designs where CapSense and mechanical button combination is desired

2.7.3 Field Coupled Via Printed Ink

Features of a design based on printed ink:

Electric field coupled with printed patterns on a flexible substrate using conductive ink

High series resistance due to higher sheet resistance (ohms-per-square) of printed ink compared to copper.

However, the series resistance of the materials such as silver loaded inks, ITO, and PEDOT depend on the

thickness variation as their sheet resistance is relatively low.

High parasitic capacitance due to thin PCB substrate

No mechanical moving parts, but substrate is flexible

Coupled to the touch sensor surface with a nonconductive overlay

Ideal topology for flexible front panels

Flexible PCB can be one-layer or two-layer film

2.7.4 Field Coupled via ITO Film on Glass

Features of a design based on ITO film:

Electric field coupled with printed or deposited patterns on glass

Higher series resistance of ITO films compared to copper

No mechanical moving parts

Ideal topology for graphical front panels

2.8 Liquid Tolerance

CapSense is used in a variety of applications such as home appliances, automotive, and industrial applications. These

applications require robust CapSense operation even in the presence of mist, moisture, water, ice, and humidity

changes. In a CapSense design, false sensing of touch may happen due to the presence of a film of liquid or liquid

droplets on the touch surface. Cypress’s CapSense sensing method can compensate for variation in raw count due to

mist, moisture, water, ice, and humidity changes and provide a robust, reliable, CapSense operation.

Figure 2-31. CapSense-based Touch User Interface in a Washing Machine with Liquid Tolerance

To compensate for changes in raw count due to mist, moisture, and humidity changes, the CapSense sensing method

continuously adjusts the baseline of the sensor to prevent sensor false triggers. To compensate for changes in raw

count due to a liquid droplet or liquid flow, you should implement a Shield Electrode and a Guard Sensor to provide

robust touch sensing, as Figure 2-32 shows. All sensor pins can optionally have a 560-Ω series resistor for improved

noise immunity.

Page 29

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 29

When liquid droplets are present on the touch surface and if the shield electrode is implemented, the CapSense system

can reliably work even in the presence of liquid droplets and report sensor ON/OFF status. When there is a liquid flow

or a liquid pool on the touch surface, the CapSense system detects the liquid by using a guard sensor and disables the

scanning for all other sensors in the system to prevent false triggers. Therefore, when there is a liquid flow or liquid

pool on the touch surface, the CapSense system will not detect a finger touch as long as the liquid is present on the

touch surface.

Figure 2-32. Shield Electrode (SH) and Guard Sensor (GUARD) Connected to CapSense Controller

CS1

CS3

CS2

SH

GUARD

Shield Electrode

Guard Sensor

Button Sensor

560 Ω

560 Ω

560 Ω

560 Ω

CapSense

Controller

2.8.1 Effect of Liquid Droplets and Liquid Stream on CapSense

To understand the effect of a liquid droplet or a liquid stream on a CapSense sensor, consider a CapSense system in

which the hatch fill around the sensor is connected to ground, as Figure 2-33 (a) shows. Surrounding the sensor with

a hatch fill connected to ground improves the noise immunity of the sensor. The parasitic capacitance of sensor is

denoted as CS in Figure 2-33 (b).

Figure 2-33. Typical CapSense System Layout

BTN1

Hatch Fill

Connected to

Ground

Button Sensor

560 Ω

CapSense

Controller

CapSense

Controller

560 Ω

C

S

(a)

(b)

As shown in Figure 2-34, when a liquid droplet falls on the touch surface, due to its conductive nature, it provides a

strong coupling path for the electric field lines to return to ground and therefore adds a capacitance CLD in parallel to

CP. When the sensor is charged and discharged, the capacitance CLD draws some amount of charge from the AMUX

bus because of the nonzero voltage difference across the capacitance CLD. This increases the overall capacitance seen

by the CapSense circuitry and results in an increase in the sensor raw count. In some cases, where the liquid is highly

conductive (salty water or water with high mineral content), the increase in raw count when a liquid droplet falls on the

touch surface might be equal to the increase in raw count due to a finger touch and thus causes false triggers, as Figure

2-35 shows.

Figure 2-34. Capacitance Added by Liquid Droplet when the Hatch Fill Is Connected to Ground

BTN1

Hatch Fill

Connected to

Ground

Button Sensor

560 Ω

CapSense

Controller

CapSense

Controller

560 Ω

C

S

C

LD

Liquid Droplet

CS – Sensor Parasitic Capacitance

Page 30

CapSense Technology

AN64846 - Getting Started with CapSense® Doc. No. 001-64846 Rev. *X 30

C

LD

– Capacitance added by Liquid Droplet

Figure 2-35. Effect of Liquid Droplet when the Hatch Fill Around the Sensor Is Connected to Ground

To compensate the capacitance added by the liquid droplet to the CapSense circuitry, you should drive the hatch fill

surrounding the sensor with the driven-shield signal.

As shown in Figure 2-36, when the hatch fill surrounding the sensor is connected to the driven-shield signal and when

a liquid droplet falls on the touch surface, because the voltage on both the sides of liquid droplet is kept at the same

potential, the capacitance C

LD

added by the liquid droplet is nullified. Because the voltage difference across the

capacitance C

LD

is zero, it will not draw any charge from the AMUX bus and, therefore, the increase in the raw count

when a liquid droplet falls on the sensor will be very small, as Figure 2-37 shows.