ly

Features

• High density

—30K to 200K usable gates

—512 to 3072 macrocells

—136 to 428 maximum I/O pins

—Twelve dedicated inputs including four clock pins,

four global I/O control signal pins and four JTAG

interface pins for boundary scan and reconfigurability

• Embedded memory

—80K to 480K bits embedded SRAM

• 16K to 96K bits of (dual-port) channel memory

• High speed – 233-MHz in-system operation

•AnyVolt™

—3.3V, 2.5V,1.8V, and 1.5V I/O capability

• Low-power operation

—0.18-mm six-layer metal SRAM-based logic p roces s

—Full-CMOS implementation of product term array

—Standby current as low as 5mA

• Simple timing model

—No penalty for using full 16 product terms/macroce ll

—No delay for single product term steering or sharing

• Flexible clocking

—Spread Aware™ PLL drives all four clock networks

—Four synchronous clock networks per device

—Locally generated product term clock

—Clock polarity control at each register

interface

• Allows 0.6% spread spectrum input clocks

• Several multiply, divide and phase shift options

Delta39K™ ISR™

CPLD Fami

CPLDs at FPGA Densities™

• Carry-chain logic for fast and efficient arithme tic operations

• Multiple I/O standards supported

—LVCMOS (3.3/3.0/2.5/1.8V), LVTTL, 3.3V PCI, SSTL2

(I-II), SSTL3 (I-II), HSTL (I-IV), and GTL+

• Compatible with NOBL™, ZBT™, and QDR™ SRAMs

• Programmable slew rate control on each I/O pin

• User-programmable Bus Hold capability on each I/O pin

• Fully 3.3V PCI-compliant (to 66-MHz 64-bit PCI spec,

rev. 2.2)

• CompactPCI hot swap ready

• Multiple package/pinout offering across all densities

—208 to 676 pins in PQFP, BGA, and FBGA packages

—Simplifies design migration across density

—Self-Boot™ solution in BGA and FBGA packages

• In-System Reprogrammable™ (ISR™)

—JTAG-compliant on-board programming

—Design changes do not cause pinout changes

• IEEE114 9.1 JTAG boundary scan

Development Software

®

• Warp

—IEEE 1076/1164 VHDL or IEEE 1364 Verilog context

sensitive editing

—Active-HDL FSM graphical finite state machine editor

—Active-HDL SIM post-synthesis timing simulator

—Architecture Explorer for detailed design analysis

—Static Timing Analyzer for critical path analysis

—Available on Windows

Windows NT™ for $99

—Supports all Cypress programmable logic products

95/98/2000/XP™ and

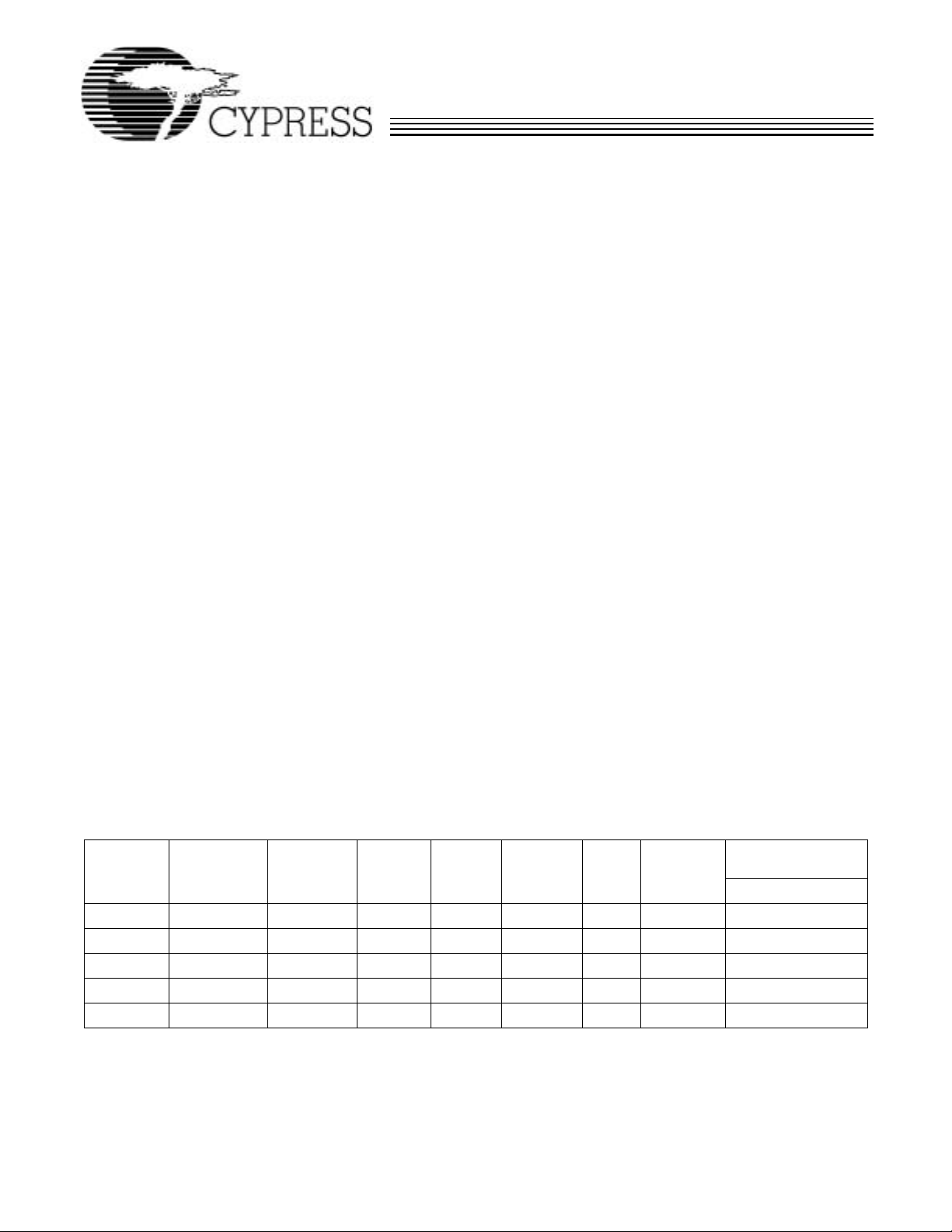

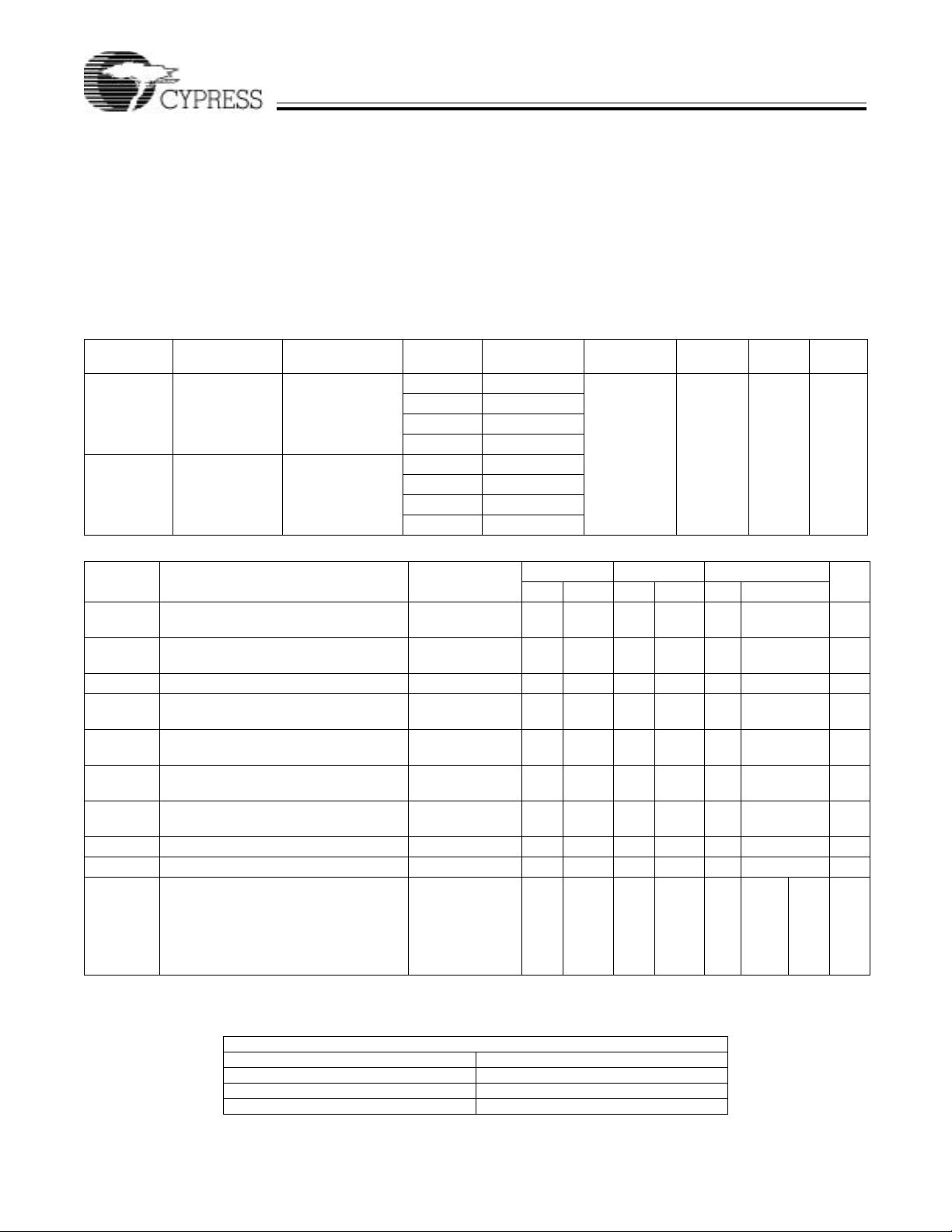

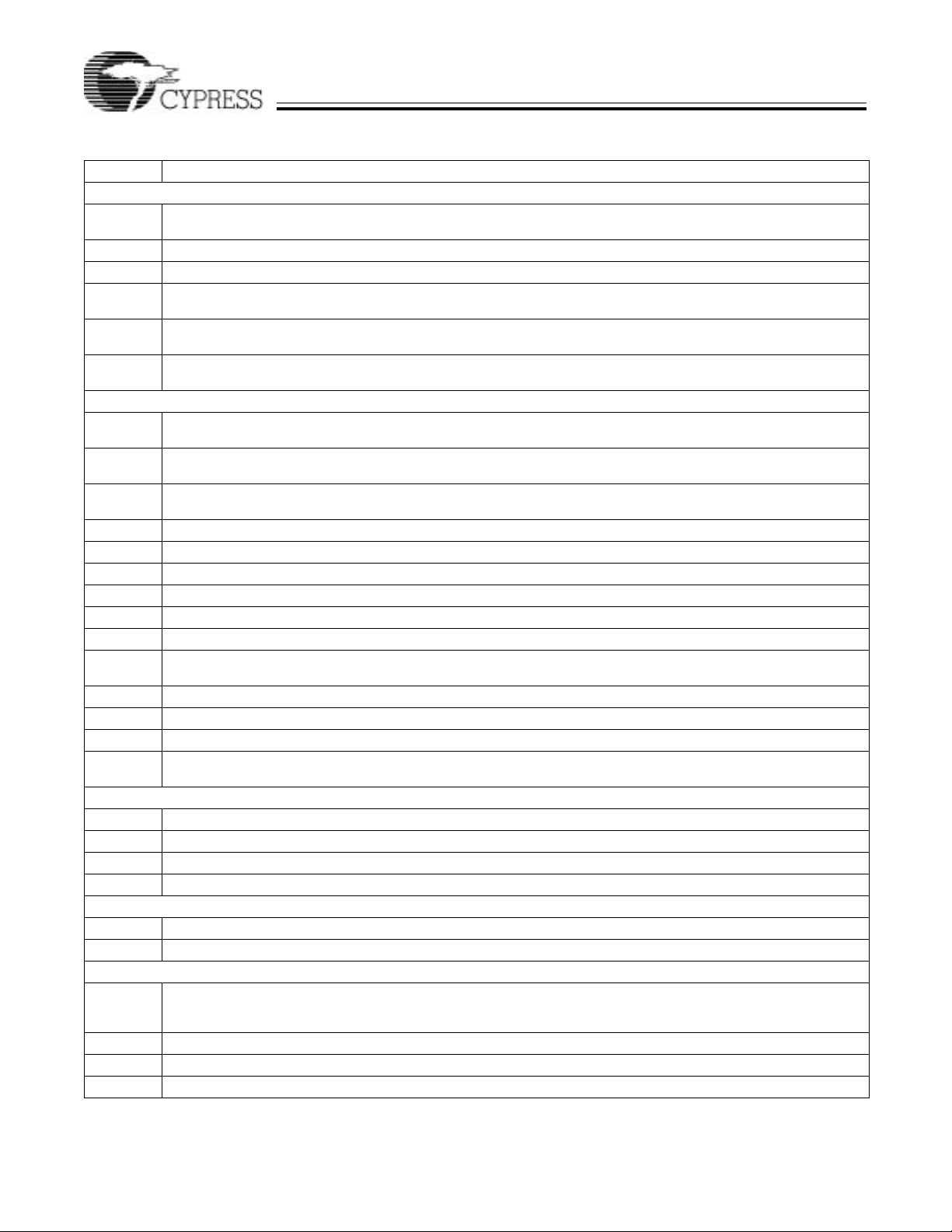

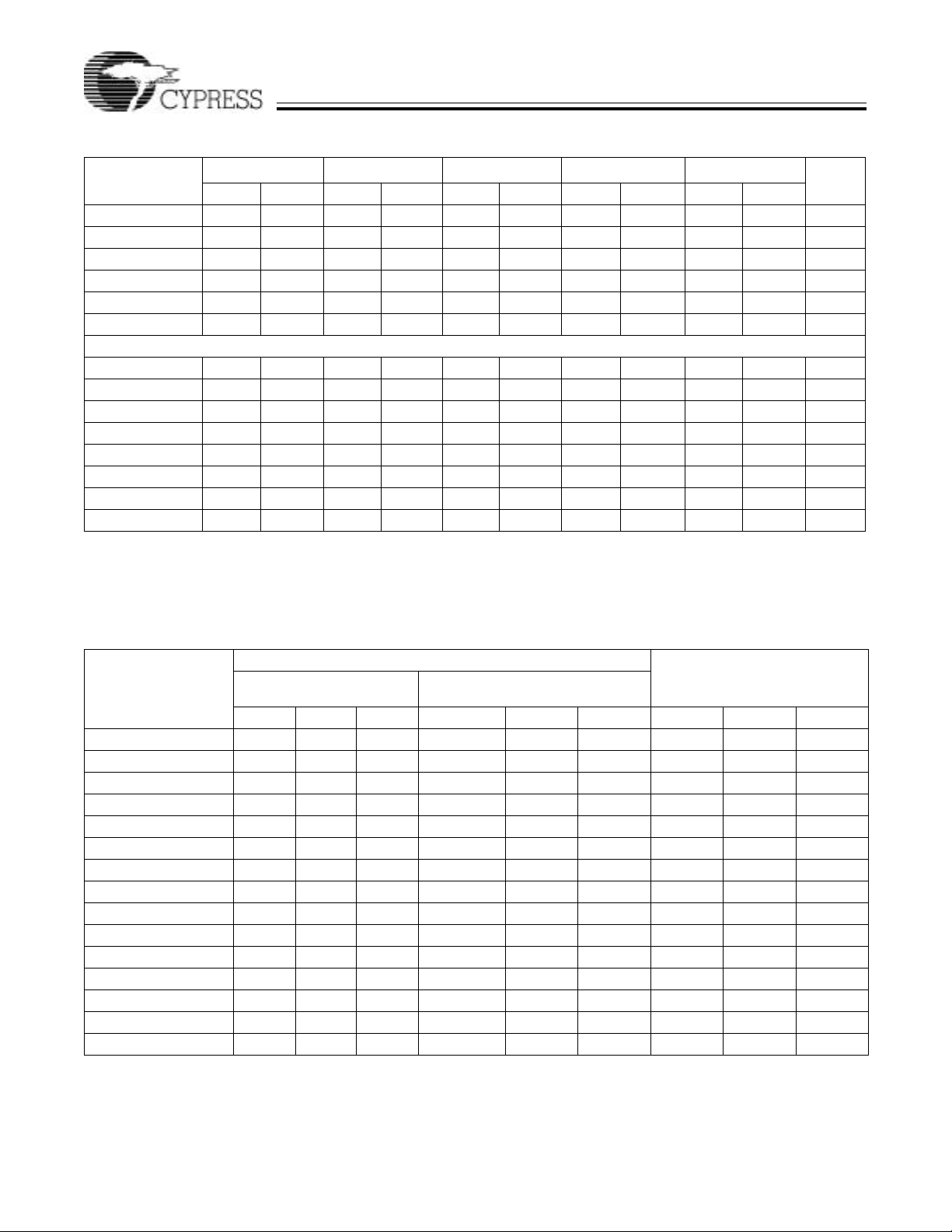

Delta39K™ ISR CPLD Family Members

Typical

[1]

Device

39K30 16K – 48K 512 64 16 174 233 7.2 5 mA

39K50

39K100 46K – 144K 1536 192 48 302 222 7.5 10 mA

39K165 77K – 241K 2560 320 80 386 181 8.5 20 mA

39K200 92K – 288K 3072 384 96 428 181 8.5 20 mA

Notes:

1. Upper limit of typical gates is calculated by assuming only 10% of the channel memory is used.

2. Standby I

Cypress Semiconductor Corporation • 3901 North First Street • San Jose • CA 95134 • 408-943-2600

Document #: 38-03039 Rev. *H Revised August 1, 2003

Gates

23K – 72K 768 96 24 218 233 7.2 5 mA

values are with PLL not utilized, no output load and stable inputs.

CC

Macrocells

Cluster

memory

(Kbits)

Channel

memory

(Kbits)

Maximum

I/O Pins

f

MAX2

(MHz)

Speed-tPD

Pin-to-Pin

(ns)

Standby I

TA = 25°C

3.3/2.5V

CC

[2]

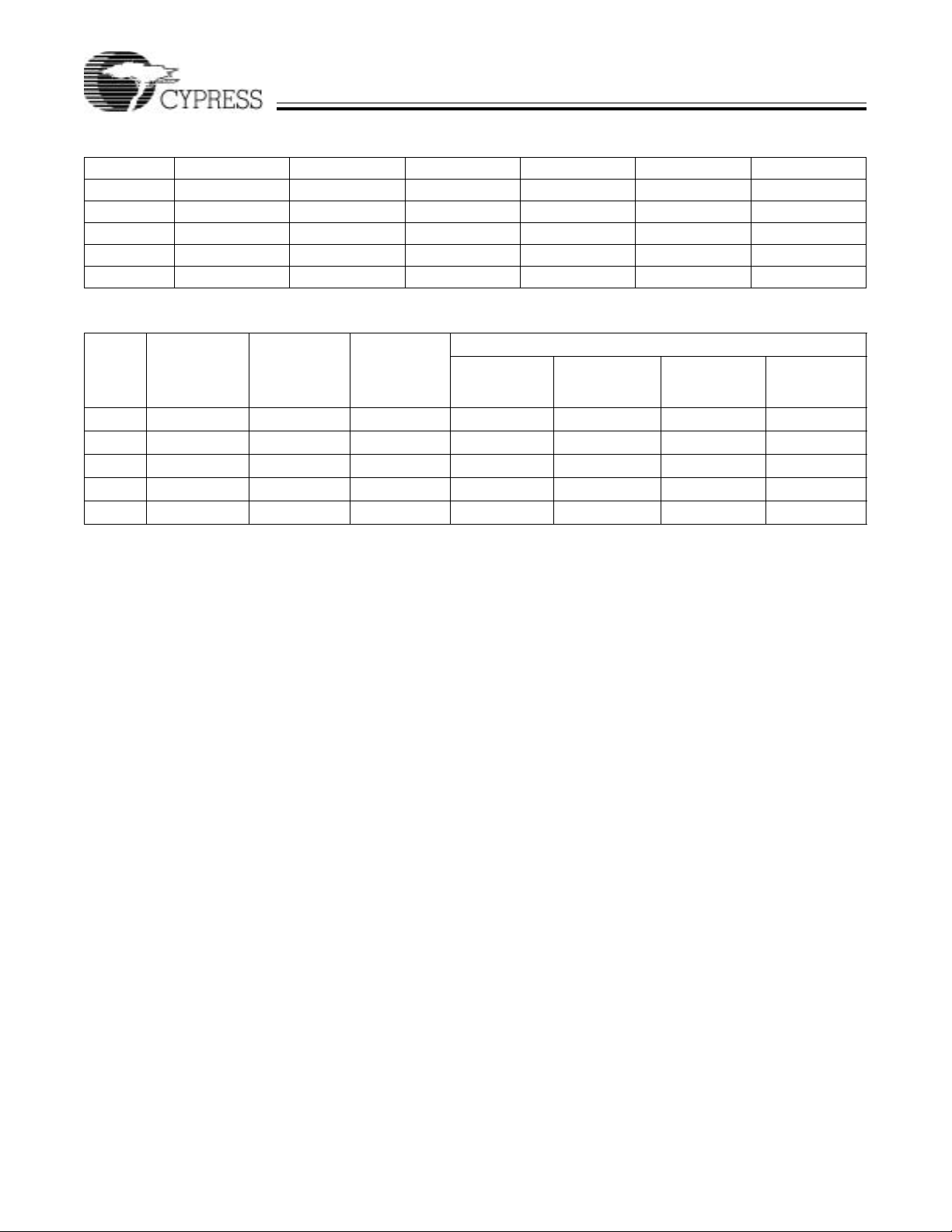

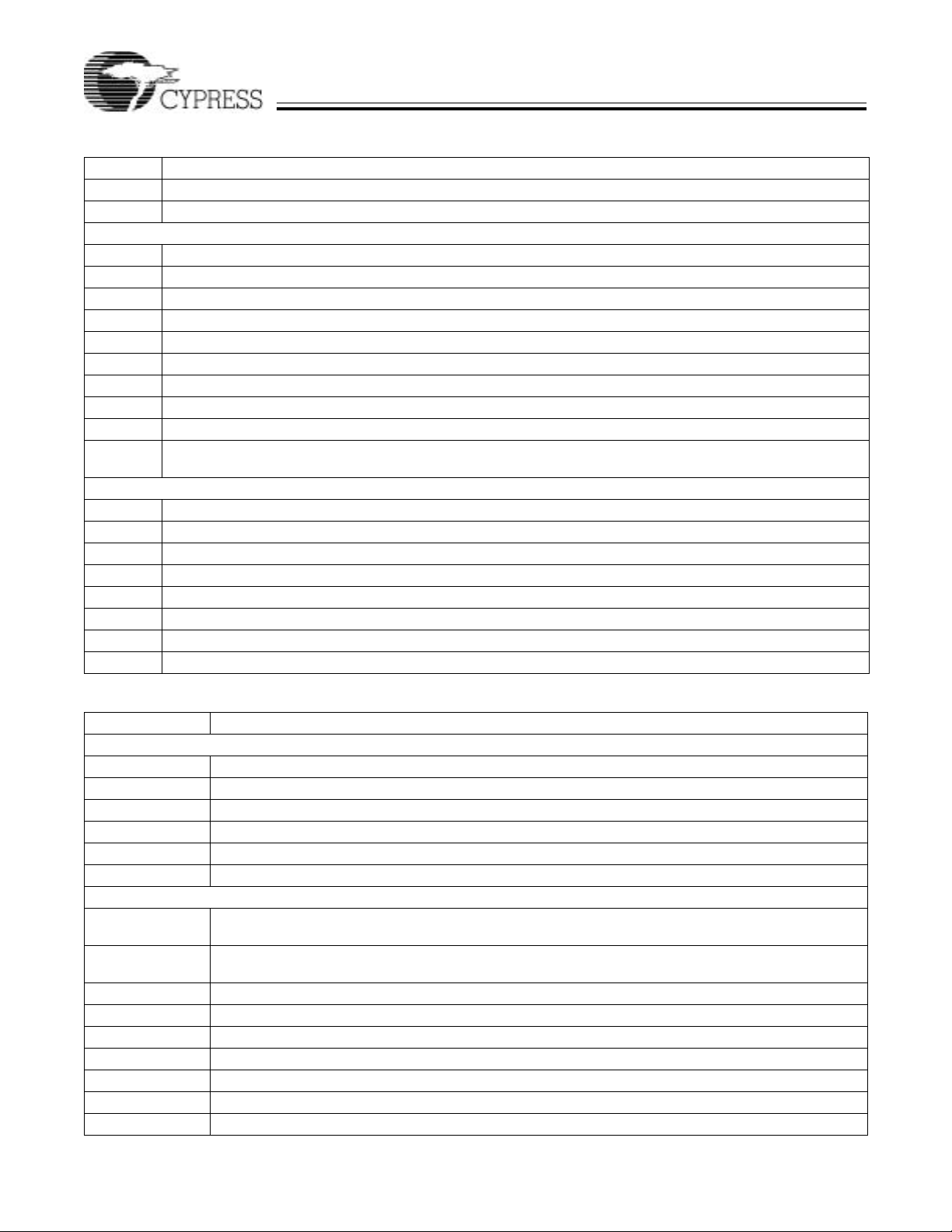

Delta39K™ ISR

™

ly

CC

[3]

233 200 181 125 83

Delta39K Speed Bins

Device V

39K30 3.3/2.5V X X X

39K50 3.3/2.5V X X X

39K100 3.3/2.5V X X X

39K165 3.3/2.5V X X X

39K200 3.3/2.5V X X X

CPLD Fami

Device Package Offering and I/O Count Including Dedicated Clock and Control Inputs

Self-Boot Solution

208 EQFP

Device

39K30 136 174 174

39K50 136 180 218 218

39K100 136 180 302 294 302

39K165 136 356 294 386

39K200 136 368 294 428

Notes:

3. Speed bins shown here are for commercial operating range. Please refer to Delta39K ordering information on industrial-range speed bins on page 38.

4. Self-boot solution integrates the boot PROM (flash memory) with Delta39K die inside the same package. This flash memory can endure at least 10,000

programming/erase cycles and can retain data for at least 100 years.

28 × 28 mm

0.5-mm pitch

256 FBGA

17 × 17 mm

1.0-mm pitch

484-FBGA

23 × 23 mm

1.0-mm pitch

256-FBGA

17 × 17 mm

1.0-mm pitch

388-BGA

35 × 35 mm

1.27-mm pitch

[4]

484-FBGA

23 × 23 mm

1.0-mm pitch

676-FBGA

27 × 27 mm

1.0-mm pitch

Document #: 38-03039 Rev. *H Page 2 of 86

Delta39K™ ISR

™

ly

GCLK[3:0]

PLL and Clock MUX

GCLK[3:0]

LB 0

LB 1

LB 2

Cluster

RAM

GCLK[3:0]

LB 0

LB 1

LB 2

Cluster

RAM

PIM

PIM

4

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

4

4

GCTL[3:0]

4

Channel

RAM

Channel

RAM

LB 0

LB 1

LB 2

Cluster

RAM

LB 0

LB 1

LB 2

Cluster

RAM

4

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

Channel

RAM

PIM

4 4

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

Channel

RAM

PIM

LB 0

LB 1

LB 2

Cluster

RAM

LB 0

LB 1

LB 2

Cluster

RAM

PIM

PIM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

CPLD Fami

I/O Bank 6I/O Bank 7

4

LB 0

LB 1

Channel

RAM

Channel

RAM

LB 2

Cluster

RAM

LB 0

LB 1

LB 2

Cluster

RAM

PIM

PIM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

4

Channel

RAM

4

Channel

RAM

I/O Bank 5

GCLK[3:0]

4

LB 0

LB 1

I/O Bank 1 I/O Bank 0

LB 2

Cluster

RAM

PIM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

Channel

RAM

LB 0

LB 1

LB 2

Cluster

RAM

4 4

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

Channel

RAM

PIM

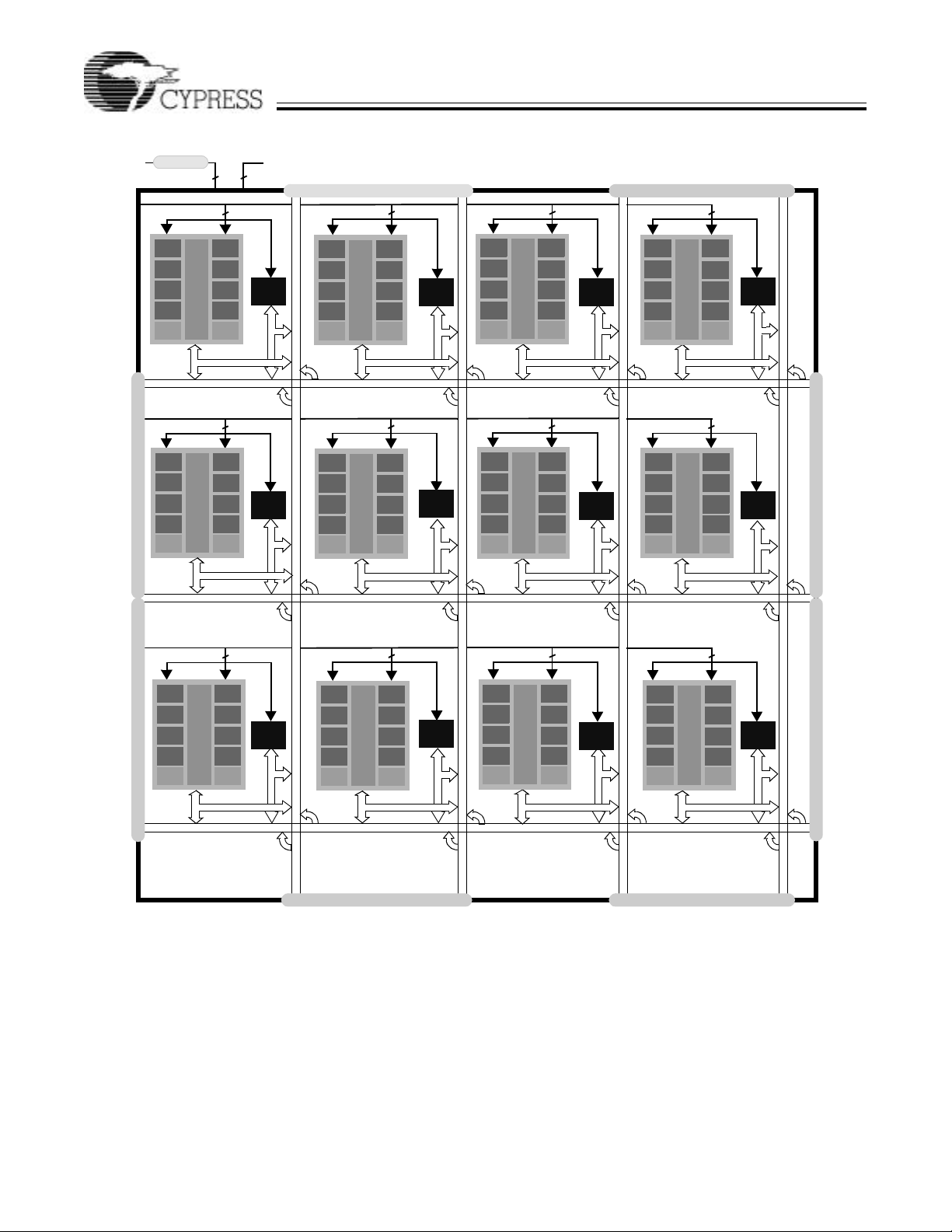

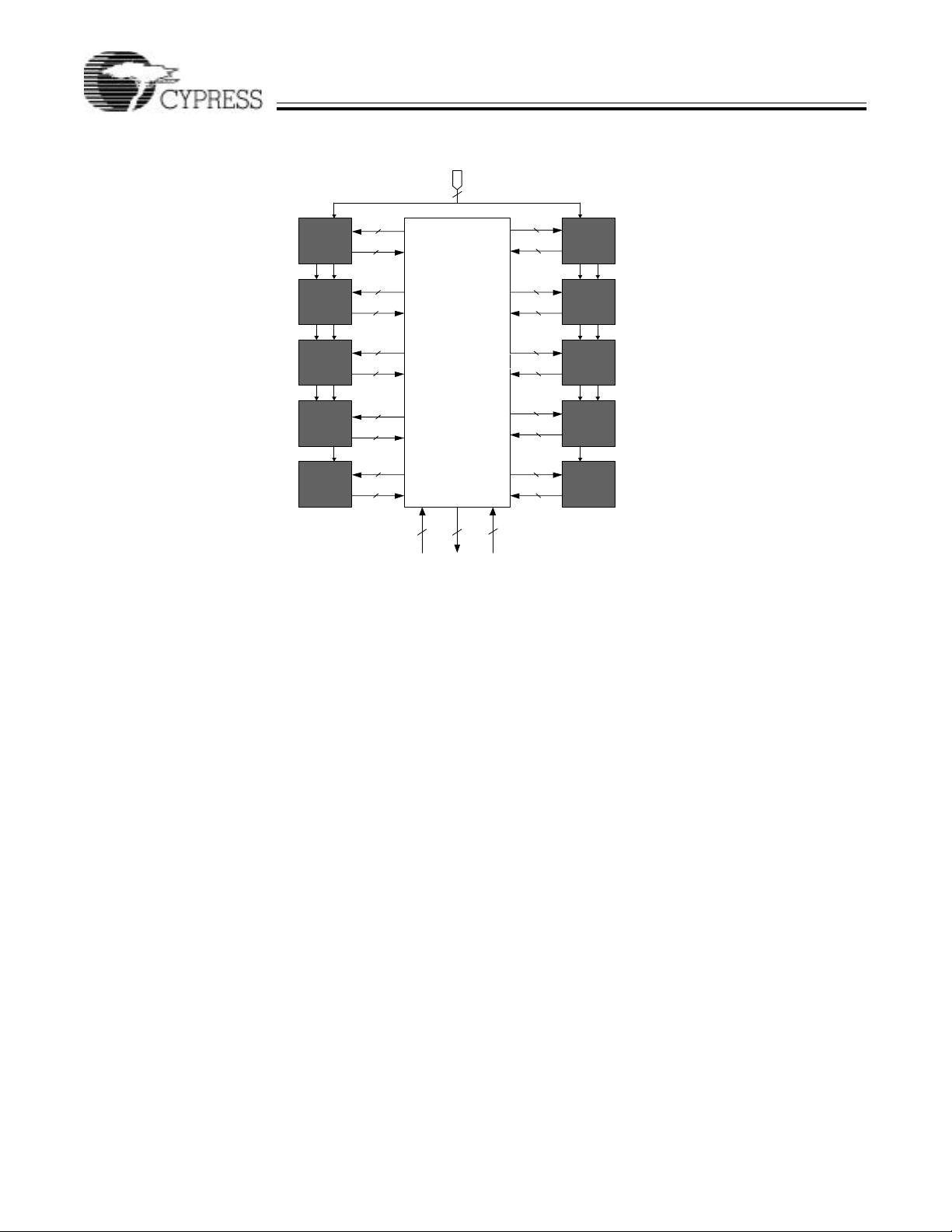

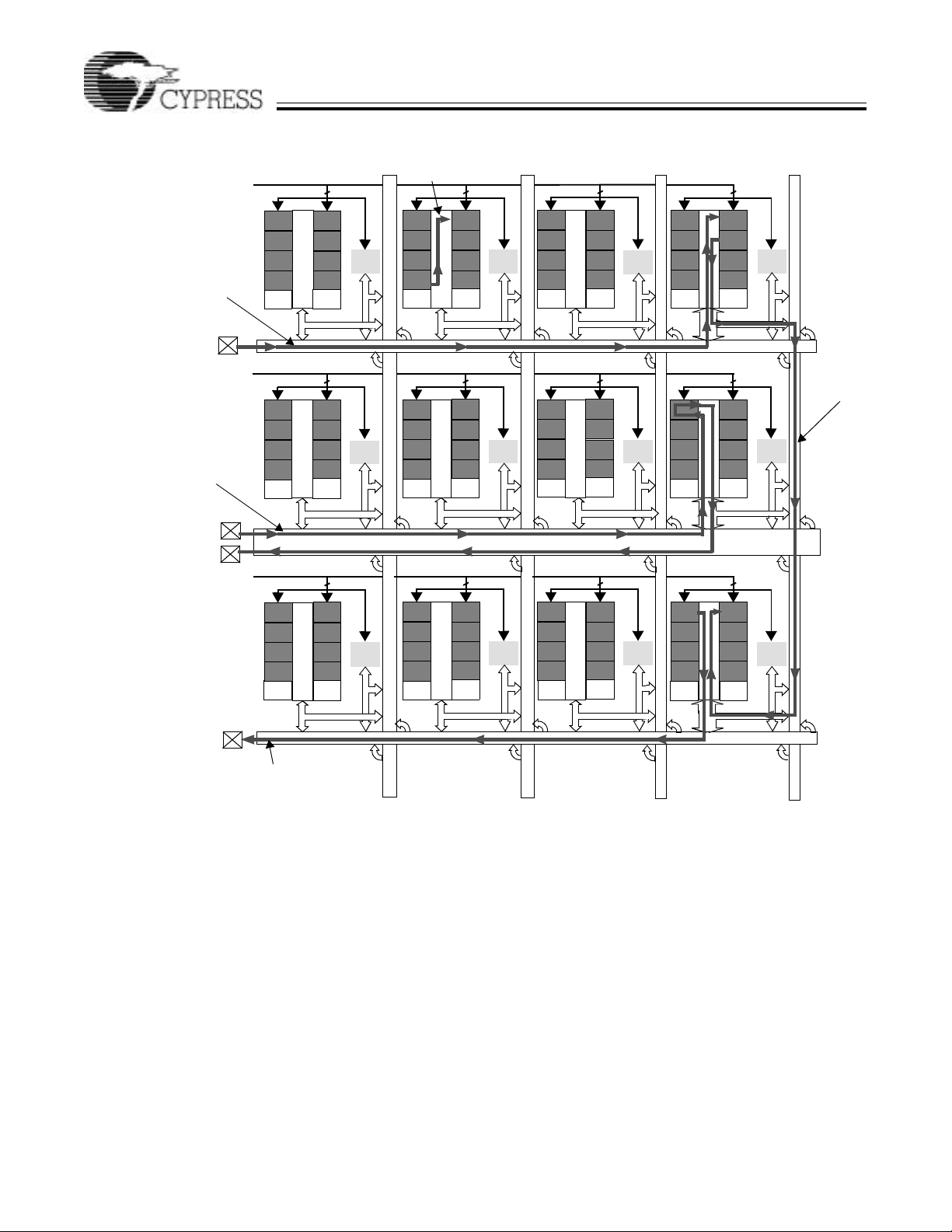

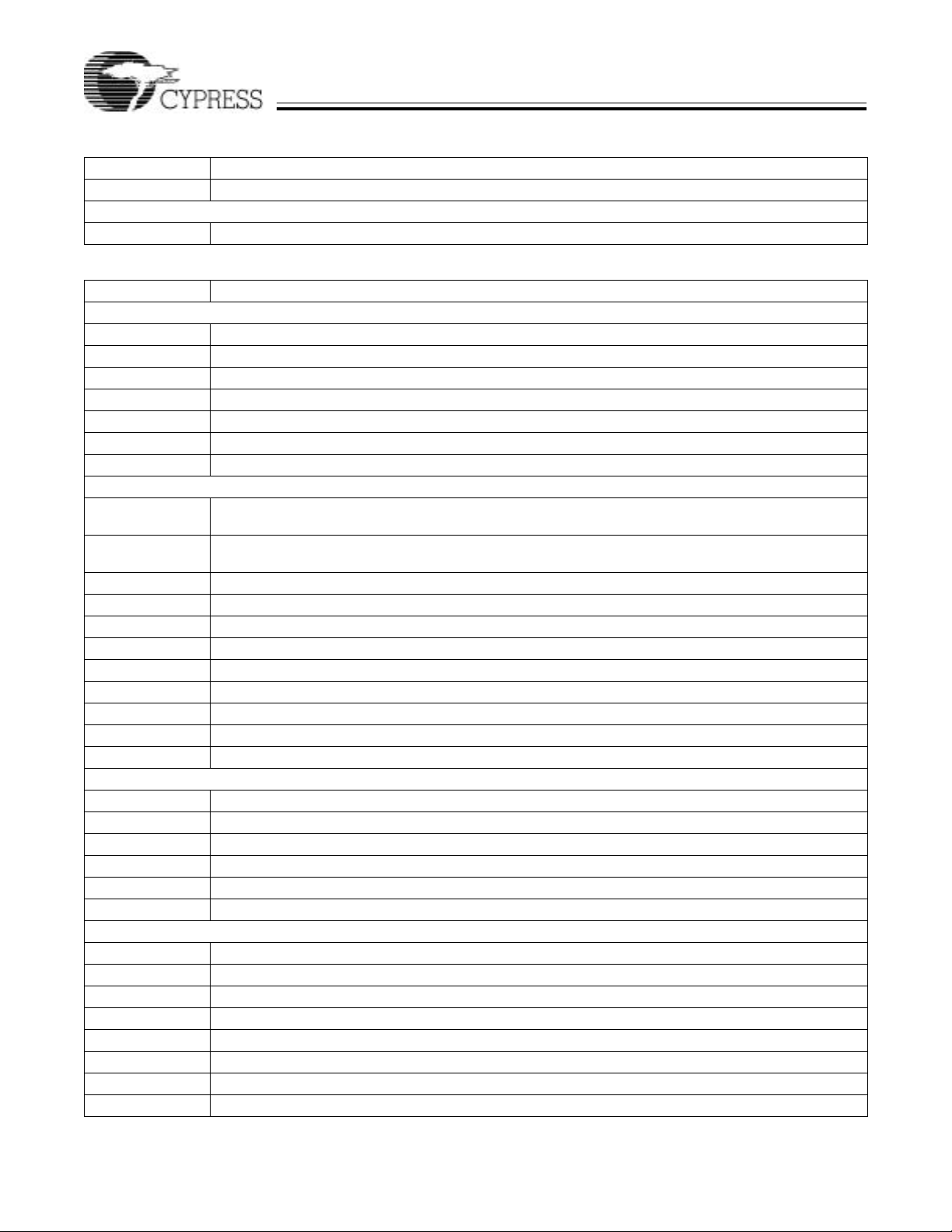

Figure 1. Delta39K100 Block Diagram (Three Rows × Four Columns) with I/O Bank Structure

General Description

The Delta39K family, based on a 0.18-mm, six-layer metal

CMOS logic process, offers a wide range of high-density

solutions at unparalleled system performance. The Delta39K

family is designed to combine the high speed, predictable

timing, and ease of use of CPLDs with the high densities and

low power of FPGAs. With devices ranging from 30,000 to

200,000 usable gates, the family features devices ten times

the size of previously available CPLDs. Even at these large

densities, the Delta39K family is fast enough to implement a

fully synth esizable 64-bit, 66-MHz PCI core.

4

LB 0

LB 1

LB 2

Cluster

RAM

PIM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

Channel

RAM

LB 0

LB 1

LB 2

Cluster

RAM

PIM

LB 7

LB 6

LB 5

LB 4LB 3

Cluster

RAM

Channel

RAM

I/O Bank 4

I/O Bank 3I/O Bank 2

The architecture is based on Logic Block Clusters (LBC) that

are connected by Horizontal and Vertical (H and V) routing

channels. Each LBC features eight individual Logic Blocks

(LB) and two cluster memo ry b loc ks . Adj ac ent to eac h LBC i s

a channel memory block, w hich can be acces sed directly from

the I/O pins. Both types of memory blocks are highly configurable and can be c as ca ded i n w id t h and depth. See Figure 1

for a block diagram of the Delta39K architecture.

All the members of th e Delt a39K fa mi ly have C ypres s’ s hig hly

regarded In-System Reprogrammability (ISR) feature, which

simplifies both design and manufacturing flows, thereby

reducing costs. The ISR feature provides the ability to recon-

Document #: 38-03039 Rev. *H Page 3 of 86

Delta39K™ ISR

™

ly

figure the devices without having design changes cause

pinout or timing changes in most cases. The Cypress ISR

function is implemented through a JTAG-compliant serial

interface. Data is shifted in and out through the TDI and TDO

pins respectively. Superior routability, simple timing, and the

ISR allows users to chan ge exist ing logic de signs whil e simultaneously fixing pinout assignments and maintaining system

performance.

The entire family features JTAG for ISR and boundary scan,

and is compatible with the PCI Local Bus specification,

meeting the electrical and tim ing requirements. The Delt a3 9K

family also features user programmable bus-hold and slew

rate control capabilities on each I/O pi n.

AnyVolt Interface

All Delta39KV devices feature an on-chip regulator, which

accepts 3.3 V or 2.5V on the V

to 1.8V internally , the voltage level at which the core operate s.

supply pins and step s it down

CC

With Delta39K’s AnyVolt technology, the I/O pins can be

connected to either 1.8V, 2.5V, or 3.3V. All Delta39K devices

are 3.3V-tolerant regardless of V

or VCC settings.

CCIO

Table 1.

Device V

CC

39KV 3.3V or 2.5V 3.3V or 2.5V or 1.8V or 1.5V

V

CCIO

[5]

CPLD Fami

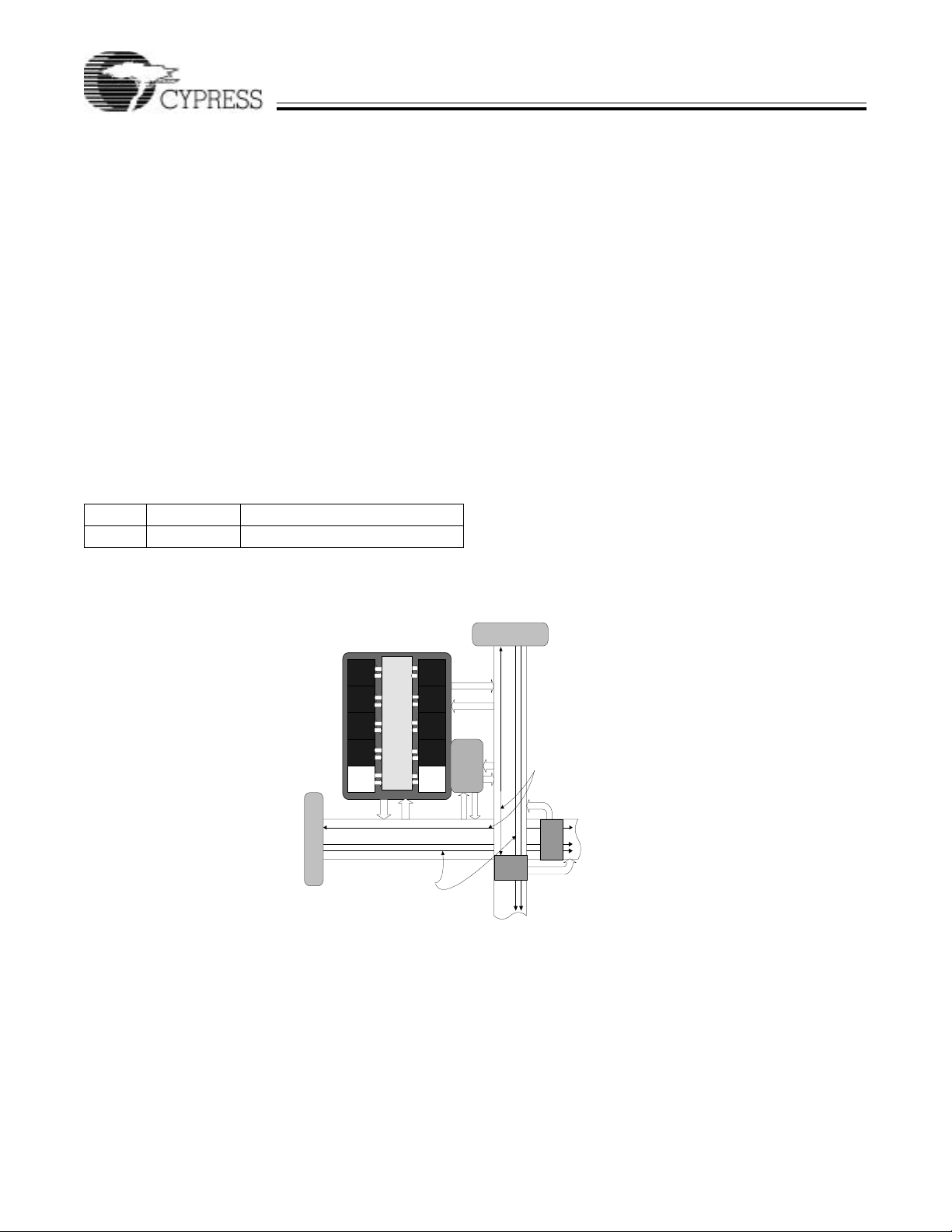

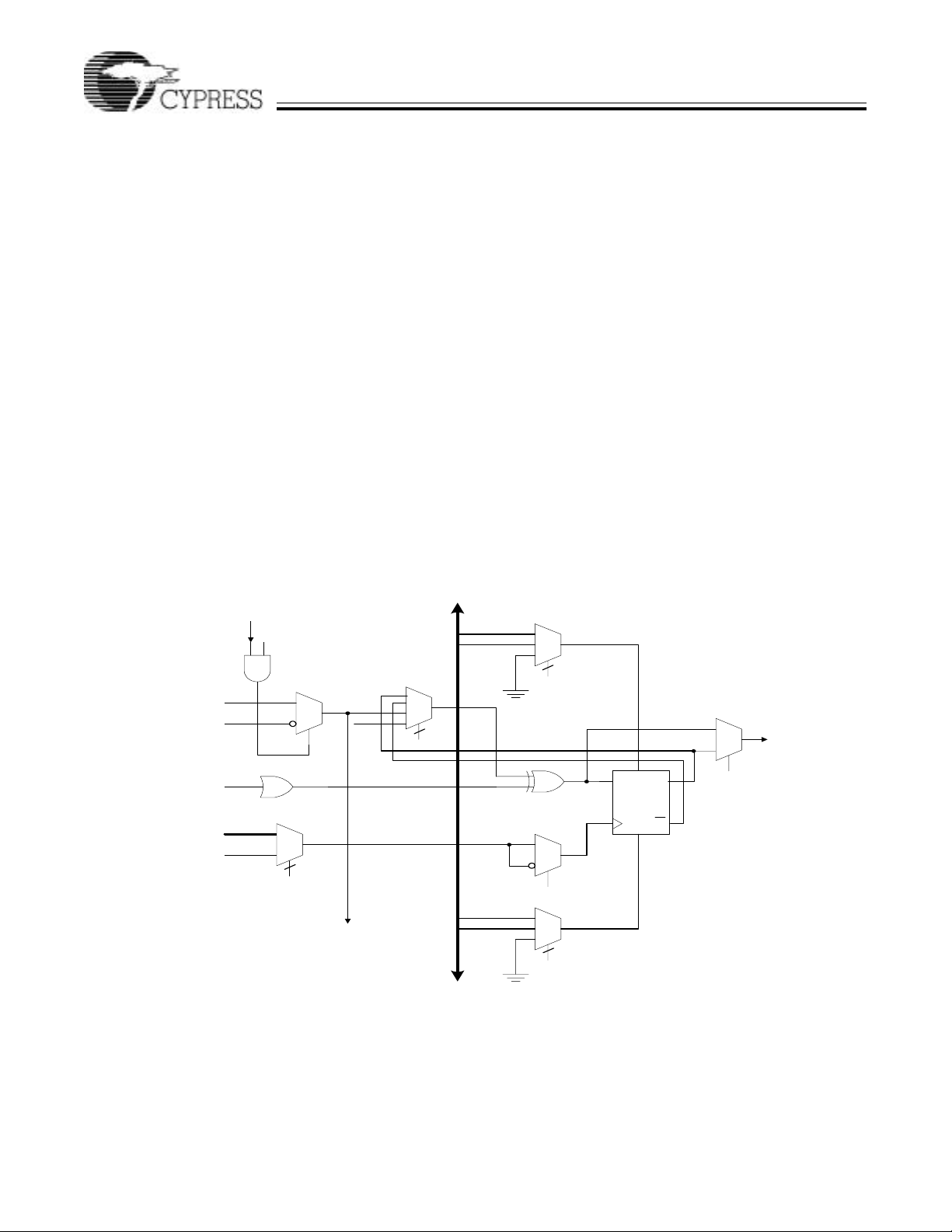

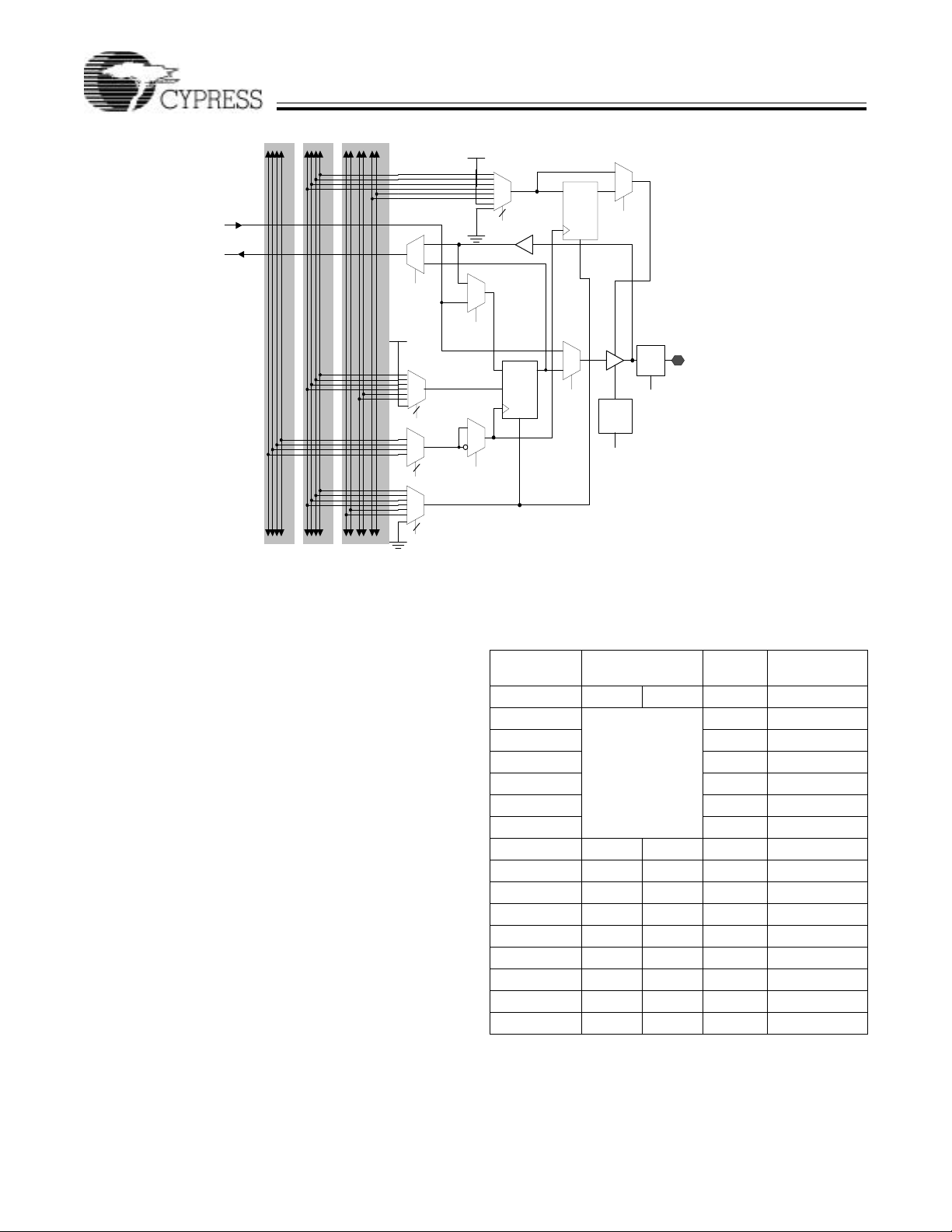

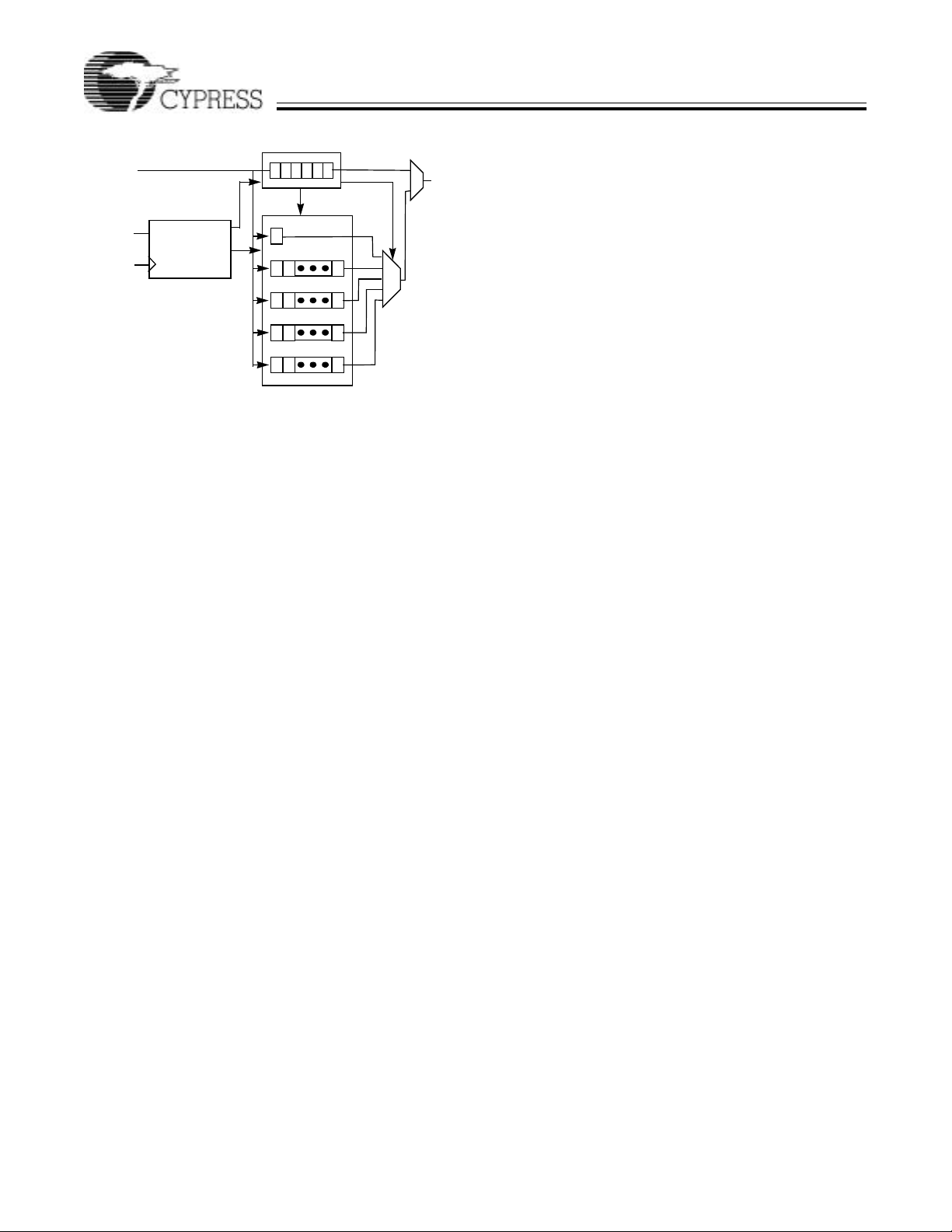

Global Routing Description

The routing architecture of the Delta39K is made up of

horizontal and vertical (H and V) routing channels. These

routing channels allow signals from each of the Delta39K

architectural com ponents to c ommunicate with on e another . In

addition to the horizontal and vertical routing channels that

interconnect the I/O ban ks, chann el memory bl ocks, and logi c

block clusters, each LBC contains a Programmable Interconnect Matrix (PIM™), which is used to route signals

among the logic blocks and the cluster memory blocks.

Figure 2 is a block diagram of the routing channels that

interface within the Del t a39 K arc hit ecture. The LBC is exactly

the same for every member of the Delta39K CPLD family.

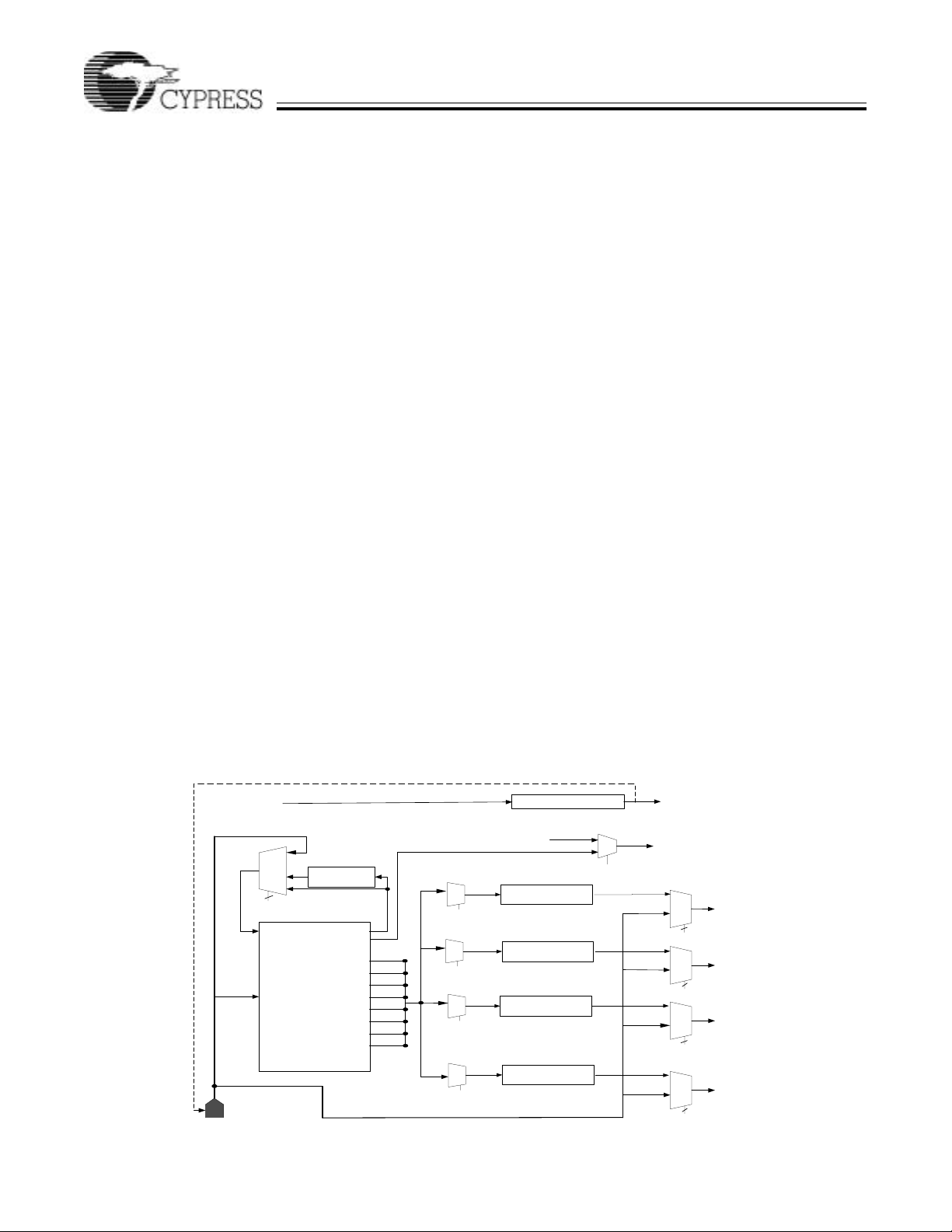

Logic Block Cluster (LBC)

The Delta39K architecture consists of several logic block

clusters, each of which have eight Logic Blocks (LB) and two

cluster memory blocks connected via a Programmable Interconnect Matrix (PIM) as shown in Figure 3. Each cluster

memory block consists of 8-Kbit single-port RAM, which is

configurable as synchronous or asynchronous. The cluster

memory blocks can be cascaded with other cluster memory

blocks within the same LBC as well as other LBCs to

implement larger m emory func tions. If a clus ter me mory bloc k

is not specifically utilized by the designer, Cypress’s Warp

software can au tom ati ca lly us e it to implement large blo ck s of

logic.

All LBCs interface with each other via horizontal and vertical

routing channels.

Note:

5. For HSTL only.

I/O Block

Cluster

PIM

LB

72

LB

64

LB

LB

Channel

Memory

Cluster

Block

Memory

Block

64

LB

LB

LB

LB

Cluster

Memory

Block

72

I/O Block

Pin inputs from the I/O cells

drive dedicated tracks in the

horizontal and vertical routing

channels

Figure 2. Delta39K Routing Interface

Channel memory

outputs drive

dedicated tracks in the

horizontal and vertical

routing channels

H-to-V

PIM

V-to-H

PIM

Document #: 38-03039 Rev. *H Page 4 of 86

Delta39K™ ISR

™

ly

Clock Inputs

n

Logic

Block

0

CC CC CC

Logic

Block

1

Logic

Block

2

Logic

Block

3

Cluster

Memory

0

Horizontal Routing

36

16

36

16

36

16

36

16

25

8

64 Inputs From

Channel

GCLK[3:0]

4

PIM

144 Outputs to

Horizontal and Vertical

cluster-to-channel PIMs

Logic

36

Block

16

Logic

36

Block

16

Logic

36

Block

16

Logic

36

Block

16

Cluster

25

Memory

8

CC = Carry Chai

64 Inputs From

Vertical Routing

Channel

CPLD Fami

7

CC CC CC

6

5

4

1

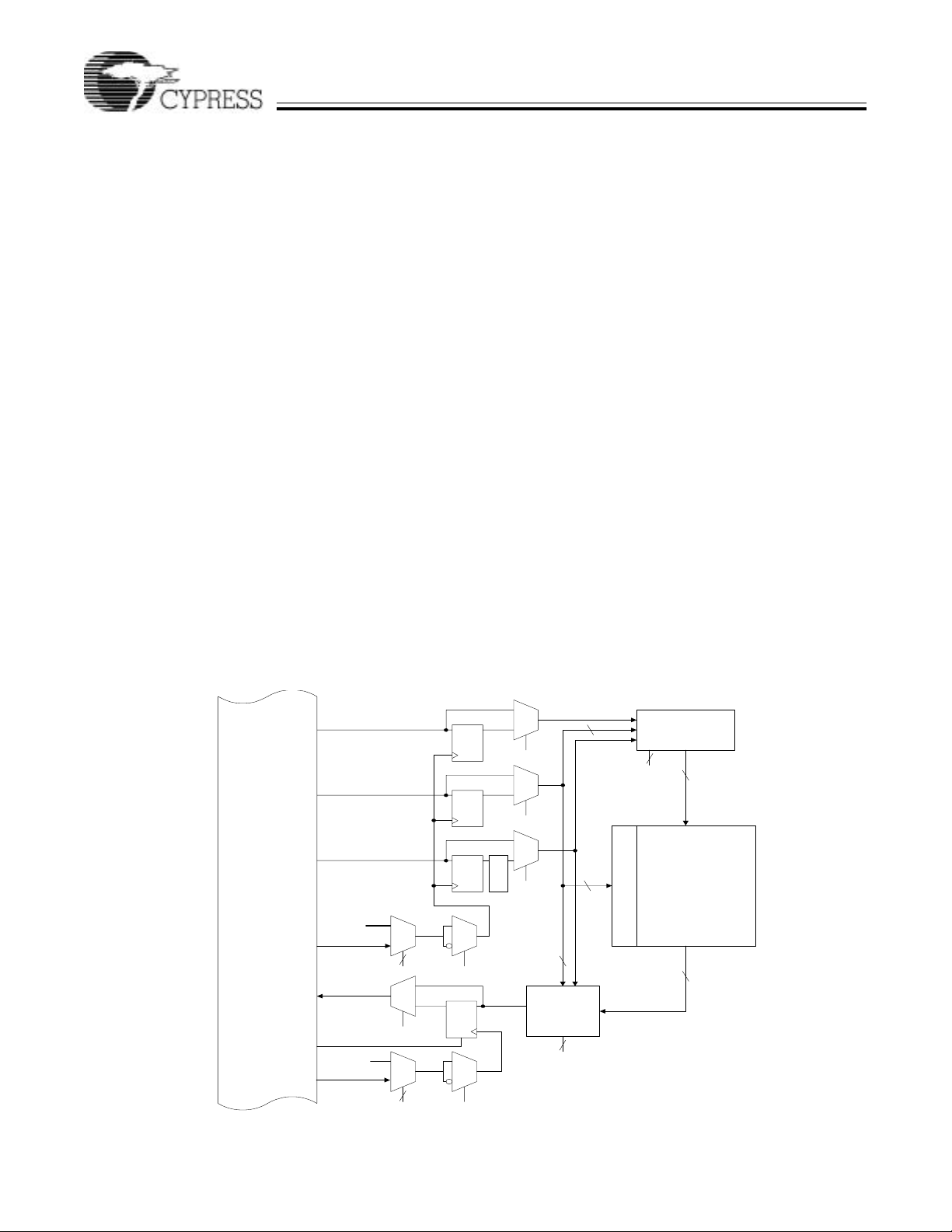

Figure 3. Delta39K Logic Block Cluster Diagram

Logic Block

The LB is the basic buildin g block of the Delta 39K architecture.

It consists of a product term array, an intelligent product-term

allocator, and 16 macrocells.

Product Term Array

Each logic block features a 72 x 83 programmable product

term array. This array accepts 36 inputs from the PIM. These

inputs originate from device pins and macrocell feedbacks as

well as cluster memory and channel memory feedbacks.

Active LOW and active HIGH ver sions of each of thes e input s

are generated to create the full 72-input field. The 83 product

terms in the array can be created from any of the 72 inputs.

Of the 83 product terms, 80 are for general-purpose use for

the 16 macrocell s in the logic block. T wo of the remaining three

product terms in the logic bloc k are used as asynchro nous set

and asynchronous reset product te rms. The fi nal produc t term

is the Product Term clock (PTCLK) and is shared by all 16

macrocells within a logic block.

Product Term Allocator

Through the product term allocator, Warp software automatically distributes the 80 pro duct terms as needed amo ng the 16

macrocells in the logic block. The product term allocator

provides two important capabilities without affecting performance: product term steering and product term sharing.

Product Term Steering

Product term steering is the process of assigning product

terms to macroce lls as n eeded . For ex ampl e, if o ne macr ocell

requires ten product te rms whil e anoth er needs just thre e, the

product term allocator will “steer” ten product terms to one

macrocell and three to the other. On Delta39K devices,

product terms are stee red on an indivi dual ba sis. An y nu mber

between 1 and 16 product terms can be steered to any

macrocell.

Product Term Sharing

Product term sharing is the pr ocess of usin g the same product

term among multiple macrocell s. For example, i f more than

one function has one or more produ ct terms in it s equation th at

are common to other functions, those product terms are only

programmed once. The Delta39K product term allocator

allows sharing across groups of four macrocells in a variable

fashion. The software automatically takes advantage of this

capability so that the user does not have to intervene.

Note that neither product term sharing nor product term

steering have any effect on the speed of the product. All

steering and sharing c onfiguration s have been incorporated i n

the timing specifications for the Delta39K devices.

.

Document #: 38-03039 Rev. *H Page 5 of 86

Delta39K™ ISR

™

ly

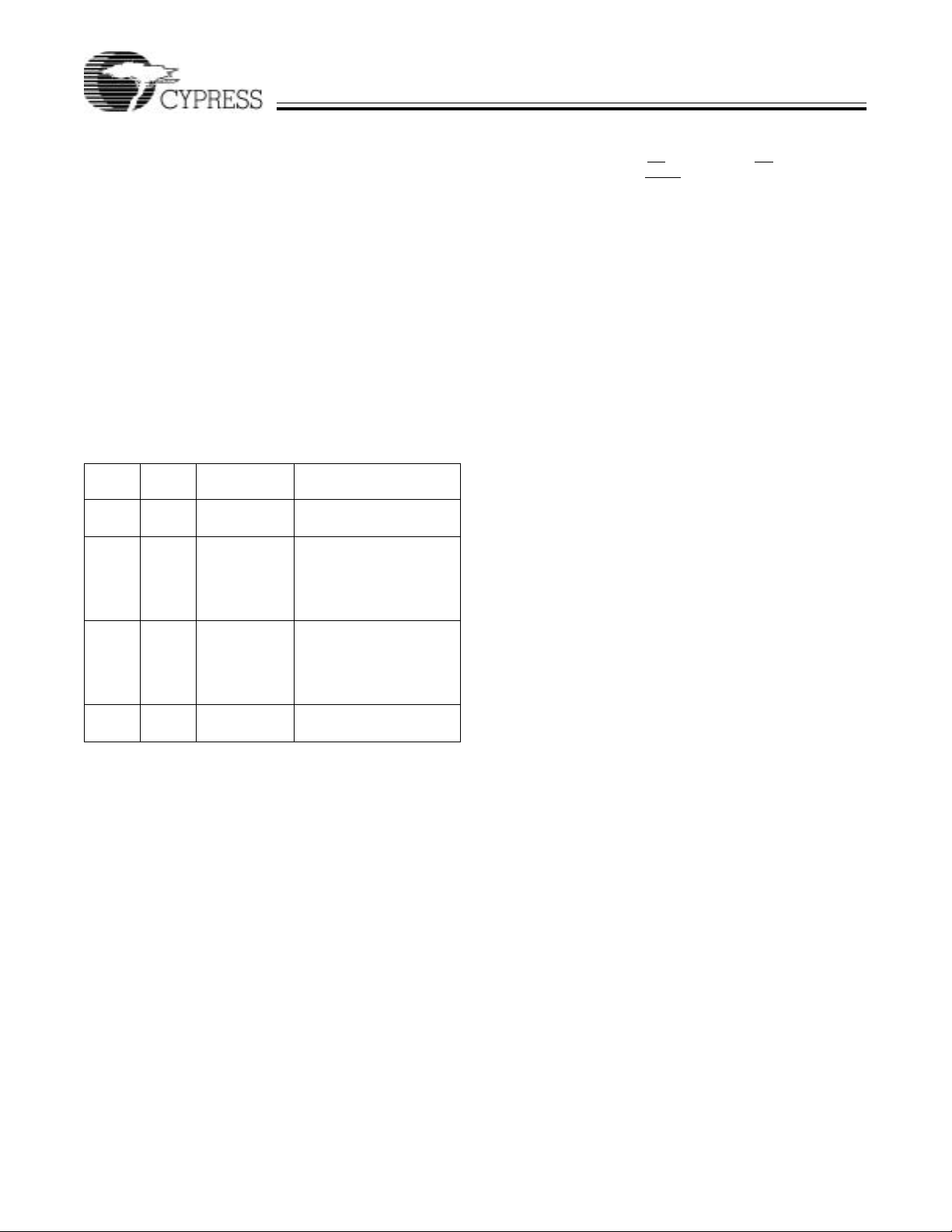

Macrocell

Within each logic block there are 16 macrocells. Each

macrocell accepts a sum of up to 16 product terms from the

product term array. The sum of these 16 product terms can be

output in either registered or combinatorial mode. Figure 4

displays th e b l oc k dia g r am of th e m ac r oc el l. T h e re g is t er c an

be asynchronously preset or asynchronously reset at the

macrocell level with the separate preset and reset product

terms. Each of these product terms features programmable

polarity. This allows the registers to be preset or reset based

on an AND expression or an OR expression.

An XOR gate in the Delta39K macrocell allows for many

different types of equations to be realized. It can be used as a

polarity mux to implement the true or complement form of an

equation in the product term array or as a to ggl e to tu rn the D

flip-flop into a T flip-flop. The carry-chain input mux allows

additional flexibil ity fo r the i mplem ent ation of dif fere nt type s of

logic. The macrocell can utilize the carry chain logic to

implement adders, subtractors, magnitude comparators,

parity tree, or even generic XOR logic. The output of the

macrocell is either registered or combinatorial.

Carry Chain Logic

The Delta39 K macrocell featu res carry chain l ogic which is

used for fast and eff ici en t imp lementation of arithmetic ope rations. The carry logic connects macrocells in up to four logic

blocks for a total of 64 macrocells. Effective data path opera-

CPLD Fami

tions are implemented through the use of carry-in arithmetic,

which drives through the circuit quickly. Figure 4 shows that

the carry chain logic within the macrocell consists of two

product terms (CPT0 and CPT1) from the PTA and an input

carry-in for carry logic. The inputs to the carry chain mux are

connected directly t o the produc t terms in the PTA. The output

of the carry chain mux generates the carry-out for the next

macrocell in the logic bl ock as wel l as the l ocal car ry inpu t that

is connected to an inp ut of the XOR input m ux. Carry-i n and a

configuration bit are inputs to an AND gate. This AND gate

provides a method of segmenting the carry chain in any

macrocell in the logic block.

Macrocell Clocks

Clocking of the register is highly flexible. Four global

synchronous clocks (GCLK[3:0]) and a PTCLK are available

at each macrocell register. Furthermore, a clock polarity mux

within each macrocell allows the register to b e clocked on the

rising or the falling edge (see macrocell diagram in Figure 4).

PRESET/RESET Configurations

The macrocell register can be asynchronously preset and

reset using the PRESET and RESET mux. Both signals are

active high and c an be controll ed by either o f two Preset/Res et

product terms (PRC[1:0] in Figure4) or GND. In situations

where the PRESET and RESET are active at the same time,

RESET takes priority over PRESET.

(from macrocell n-1)

CPT0

CPT1

FROM PTM

Up To 16 PTs

GCLK[3:0]

PTCLK

Carry In

Clock Mux

C

Carry Chain

Mux

3

C

Carry Out

(to macrocell n+1)

PRESET

0

1

XOR Input

Mux

C

2

C

PRC[1:0]

0

1

Mux

3

C

Clock

Polarity

Mux

C

3

C

RESET

Mux

Output

Mux

To PIM

PSET

D

Q

Q

RES

C

Figure 4. Delta39K Macrocell

Document #: 38-03039 Rev. *H Page 6 of 86

Delta39K™ ISR

™

ly

Embedded Memory

Each member of the Delta39K family contains two types of

embedded memory blocks. The channel memory block is

placed at the intersection of horizontal and vertical routing

channels. Each chan nel memor y block is 4096 bit s in size an d

can be configured as asynchrono us or synchro nous Dual- Port

RAM, Single-Port RAM, Read-Only memory (ROM), or

synchronous FIFO memory. The memory organization is

configurable as 4K × 1, 2K × 2, 1K × 4 and 512K × 8. The

second type of memory block is located within each LBC and

is referred to as a cluster memory block. Each LBC contains

two cluster memory blocks that are 8192 bits in size. Similar

to the channel memor y blocks, the c luster memory blocks ca n

be configured as 8K × 1, 4K × 2, 2K × 4 and 1K × 8

asynchronous or synchronous Single-Port RAM or ROM.

Cluster Memory

Each logic blo ck clu ster o f the Delt a39 K cont ain s two 8192-b it

cluster memory blocks. Figure 5 is a block diagram of the

cluster memory block and the interface of the cluster memory

block to the cluster PIM.

The output of the c luster memory block c an be optionally re gistered to perform synchronous pipelining or to register

asynchronous Read and Write operations. The output

registers contain an as ynchronous RESET which can be use d

in any type of sequential logic circuits (e.g., state machines).

There are four global clocks (GCLK[3:0]) and one local clock

available for the i nput and t he out put regis ters. The l ocal cloc k

for the input registers is independent of the one used for the

output registers. The local clock is generated in the user

design in a macrocell or comes from an I/O pin.

CPLD Fami

Cluster Memory Initialization

The cluster memory po wers up in an undefined st ate, but is set

to a user-defined k nown state durin g configuration. T o facilit ate

the use of look-up-t able (LUT) logic and ROM applications, th e

cluster memory blocks can be initialized with a given set of

data when the device is configured at power up. For LUT and

ROM applications, the user cannot write to memory blocks.

Channel Memory

The Delta39K architecture includes an embedded memory

block at each crossing point of horizontal and vertical routing

channels. The channel memory is a 4096-bit embedded

memory block that can be configured as asynchronous or

synchronous single-port RAM, dual-port RAM, ROM, or

synchronous FIFO memory.

Data, address, and control inputs to the channel memory are

driven from horizontal and vertical routing channels. All data

and FIFO logic output s drive dedicated trac ks in the horizont al

and vertical routing channels. The clocks for the channel

memory bloc k are selected from f our global clocks a nd pin

inputs from the horizontal and vertical channels. The clock

muxes also inc lude a p olarity mux for e ach clock s o that t he

user can choose an inverted clock.

Dual-Port (Channel Memory) Configuration

Each port has distinct addre ss inputs, as wel l as separate dat a

and control inputs that can be accessed simultaneously. The

inputs to the Dual-Port mem ory are driv en from the hori zont al

and vertical routing channels. The data outputs drive

dedicated tracks in the routing channels. The interface to the

routing is such that Port A of the Dual-Po rt interface s primarily

with the horizontal routing channel and Port B interfaces

primarily with the vertical routing channel.

2

Write

Control

Logic

8

C

1024x8

Asynchronous

SRAM

8

Cluster PIM

GCLK[3:0]

Local CLK

DOUT[7:0]

RESET

GCLK[3:0]

Local CLK

DIN[7:0]

ADDR[12:0]

WE

Read

Control

Logic

2

3

Row Decode (1024 Rows)

10

3

C

DQ

C

DQ

C

Pulse

Write

DQ

C

5:1

3

C

C

5:1

3

C

DQ

R

Figure 5. Block Diagram of Cluster Memory Block

Document #: 38-03039 Rev. *H Page 7 of 86

Delta39K™ ISR

™

ly

The clocks for each port of the Dual-Port configuration are

selected from four global clocks and two local clocks. One

local clock is sourced from the horizontal channel and the

other from the vertical channel. The data outputs of the dualport memory can also be registered. Clocks for the output

registers are also selected from four global clocks and two

local clocks. O ne c lo ck p ola rity m ux p er port al low s t he us e of

true or complement polarity for input and output clocking

purposes.

Arbitration

The Dual-Port configuration of the Channel Memory Block

provides arbitrat ion when bot h ports a ccess the sam e address

at the same time. Depending on the memory operation being

attempted, one port always gets priority. See Table 2 for

details on which port gets priority for Read and Write operations. An active-LOW “Address Match” signal is generated

when an address collision occurs.

Table 2. Arbitration Result: Address Match Signal

Becomes Active

Port A Port B

Read Read No arbitration

Write Read Port A gets

Read Write Port B gets

Write Write Port A gets

FIFO (Channel Memory) Configuration

The channel memory blocks are also configurable as

synchronous FIFO RAM. In the FIFO mode of operation, the

channel memory block supports all normal FIFO operations

without the use of any general-purpose logic resources in the

device.

Result of

Arbitration Comment

Both ports read at the

required

priority

priority

priority

same time

If Port B requests first then

it will read the current

data. The output will then

change to the newly

written data by Port A

If Port A requests first then

it will read the current

data. The output will then

change to the newly

written data by Port B

Port B is blocked until Port

A is finished writing

The FIFO block contains all of the necessary FIFO flag logic,

including the Read an d Write address poi nters. The FIFO flags

include an empty/ful l flag (EF

mable almost-empty /ful l (PAEF

uration has the ab ility to perform simultaneo us Read and W rite

operations using two separate clocks. These clocks may be

tied together for a single operation or may run independently

for asynchronous Re ad/Write (with re gard to each other) appl ications. The data and control inputs to the FIFO block are

driven from the horizontal or vertical routing channels. The

data and flag o utpu t s are driv en onto dedicated routing trac k s

in both the horizont al and vertical routing channels . This allows

the FIFO blocks to be exp anded by using multipl e FIFO bloc ks

on the same horizon tal or vertical rout ing ch annel without any

speed penalty.

In FIFO mode, the Write and Read ports are controlled by

separate clock and enable signals. The clocks for each port

are selected from four global clocks and two local clocks.

One local clock is sourced from the horizont al channel an d the

other from the vertical channel. The data outputs from the

Read port of the FIFO can also be registered. One clock

polarity mux per port allo ws using true or com plem ent pol arity

for Read and Write operations. The Write operation is

controlled by the clock and the Write enable pin. The Read

operation is controlled by the clock and the Read enable pin.

The enable pins can be sourced from horizontal or vertical

channels.

Channel Memory Initialization

The channel memory powers up in an undefined state, but is

set to a user-defined known state du ring configuration. T o faci litate the use of look-up-table (LUT) logic and ROM applications, the channel memory blocks can be initialized with a

given set of data when the device is configured at power up.

For LUT and ROM applications, the user cannot write to

memory blocks.

Channel Memory Routing Interface

Similar to LBC outputs, the channel memory blocks feature

dedicated tracks in the hori zontal and vertical routing channels

for the data outputs and the flag outputs, as shown in

Figure 6. This allows the channel memory blocks to be

expanded easi ly. These dedic ated li nes can b e route d to I/O

pins as chip outputs or to other logic block clusters to be used

in logic equations.

), half-full flag (HF), an d program-

CPLD Fami

) flag output. The FIFO confi g-

Document #: 38-03039 Rev. *H Page 8 of 86

Delta39K™ ISR

™

ly

All channel memory

k

inputs are driven from

the routing channels

4096-bit Dual-Port

Array

Configurable as

Async/Sync Dual-Port

or Sync FIFO

Configurable as

4K x 1, 2K x 2, 1K x 4,

and 512 x 8 block sizes

All channel memory outputs

drive dedicated tracks in the

routing channels

Horizontal Channel

Figure 6. Block Diagram of Channel Memory Block

Vertical Channel

CPLD Fami

Global Cloc

Signals

GCLK[3:0]

I/O Banks

The Delta39K interfaces the horizontal and vertical routing

channels to the pins through I/O banks. There are eight I/O

banks per device as shown in Figure 7, and all I/Os from an

I/O bank are loca ted in the sam e section o f a packa ge for PCB

layout convenience.

Delta39K devices support True Vertical Migration™ (i.e., for

each package type, Delta39K devices of different densities

keep given pins in the same I/O banks). This allows for easy

and simple im plementation o f multiple I/O s tandards during the

design and proto typ ing ph ase, before a final dens ity h as bee n

determined. Please refer to the application n ote titl ed “Family,

Package and Densi ty Migration in Delt a 39K and Quantum3 8K

CPLDs.”

Each I/O bank contain s several I/O cells, and each I/O ce ll

contains an input/output register, an output enable register,

programmabl e slew rate contr ol and progr ammabl e bus h old

control logic. Each I/O cell drives a pin output of the device;

the cell also suppli es an i npu t to the d ev ic e tha t c onn ec ts to a

dedicated track in the assoc ia ted rout ing channel.

Each I/O bank can use any supported I/O standard by

supplying appropriate V

uring the I/O through the Warp software. All the V

V

and V

number of I/O standards sup ported by an I/O bank at any given

time.

The number of I/Os which can be used in each I/O bank

depend on the type of I/O s tand ards an d the num ber of V

and GND pins being used. This restriction is derived from the

electromigration limit of the V

chip. Please refer to the note on page 17 and the application

note titled “Delta39K Fam ily Device I/ O St andards and Config-

urations” for details.

and V

REF

pins in an I/O bank must be connected to the same V

CCIO

voltage respectively. This requirement restricts the

CCIO

CCIO

voltages and con fig-

CCIO

and GND bussing on the

REF

and

REF

CCIO

I/O Cell

Figure 8 is a block diagram of the Delta39K I/O cell. The I/O

cell contains a thre e-s t ate inp ut bu ffer, an outp ut bu ffer, an d a

register that can be configured as an input or output register.

The output b uffer has a sl ew rate cont rol option that can be

used to configure the output for a slower slew rate. The input

of the device and the pin output can each be configured as

registered or combinatorial; however, only one path can be

configured as registered in a given design.

The output enable in an I/O cell can be selected from one of

the four global control signals or from one of two Output

Control Channel (OCC) signals. The output enable can be

configured as always enabled or always disabled or it can be

controlled by one of the remaining inputs to the mux. The

selection is done via a mux that includes V

inputs.

and GND as

CC

bank 6bank 7

bank 0bank 1

Delta39K

Delta39K

bank 4 bank 5

bank 2 bank 3

Figure 7. Delta39K I/O Bank Block Diagram

Document #: 38-03039 Rev. *H Page 9 of 86

Delta39K™ ISR

™

ly

From

Output PIM

To Routing

Channel

Registered OE

OE Mux

DQ

3

C

Clock

Polarity

Mux

C

C

Register Input

Mux

DQ

E

RES

Output Mux

C

Input

Mux

Global Clock Signals

Global I/O Control Signals

Output Control Channel OCC

C

Register Enable

Mux

3

C

Clock Mux

2

C

Register Reset

Mux

3

C

Mux

C

RES

Bus

Hold

C

Slew

Rate

Control

C

CPLD Fami

I/O

Figure 8. Block Diagram of I/O Cell

I/O Signals

There are four dedicated inputs (GCTL[3:0]) that are used as

Global I/O Control Signals available to every I/O cell. These

global I/O control signals may be used as output enables,

register resets and register clock enables as shown in

Figure 8. These global control signals, driven from four

dedicated pins, can only be used as active-high signals and

are available only to the I/O cells thereby implementing fast

resets, register and output enables.

In addition, there are six OCC signals available to each I/O

cell. These control signals may be used as output enables,

register resets and register clock enables as shown in

Figure 8. Unlike global control signals, these OCC signal can

be driven from internal logic or and I/O pin.

One of the four global clocks can be selected as the clock for

the I/O cell regi ster . The c lock mux out put is an input to a cl ock

polarity mux that all ows the input /output register to be c locked

on either edge of the clock

Slew Rate Control

The output buffer has a slew rate control option. This allows

the output buffer to slew at a fast rate (3 V/ns) or a slow rate

(1 V/ns). All I/Os default to fast slew rate. For designs

concerned with meeting FCC emissions standards the slow

edge provides for lower system noise. For designs requiring

very high performance the fast edge rate provides maximum

system performance.

Table 3.

I/O Standards

I/O

Standard V

(V) V

REF

CCIO

Termination

Voltage (VTT)

Min. Max.

LVTTL N/A 3.3V N/A

LVCMOS 3.3V N/A

LVCMOS3 3.0V N/A

LVCMOS2 2.5V N/A

LVCMOS18 1.8V N/A

3.3V PCI 3.3V N/A

GTL+ 0.9 1.1 N/A 1.5

SSTL3 I 1.3 1.7 3.3V 1.5

SSTL3 II 1.3 1.7 3.3V 1.5

SSTL2 I 1.15 1.35 2.5V 1.25

SSTL2 II 1.15 1.35 2.5V 1.25

HSTL I 0.68 0.9 1.5V 0.75

HSTL II 0.68 0.9 1.5V 0.75

HSTL III 0.68 0.9 1.5V 1.5

HSTL IV 0.68 0.9 1.5V 1.5

Document #: 38-03039 Rev. *H Page 10 of 86

Delta39K™ ISR

™

ly

G

0

Programmable Bus Hold

On each I/O pin, user-programmable-bus-hold is included.

Bus-hold, which is an improved version of the popular internal

pull-up resistor, is a weak latch connected to the pin that does

not degrade the device’s performance. As a latch, bus-hold

maintains the last state of a pin when the pin is placed in a

high-impedance state, thus reducing system noise in businterface applications. Bus-hold additionally allows unused

device pins to remain unconnected on the board, which is

particularly useful during prototyping as designers can route

new signals to the device with out cutti ng trac e co nne ctions to

or GND. For more information, see the application note

V

CC

titled “Understanding Bus-Hold–A Feature of Cypress

CPLDs.”

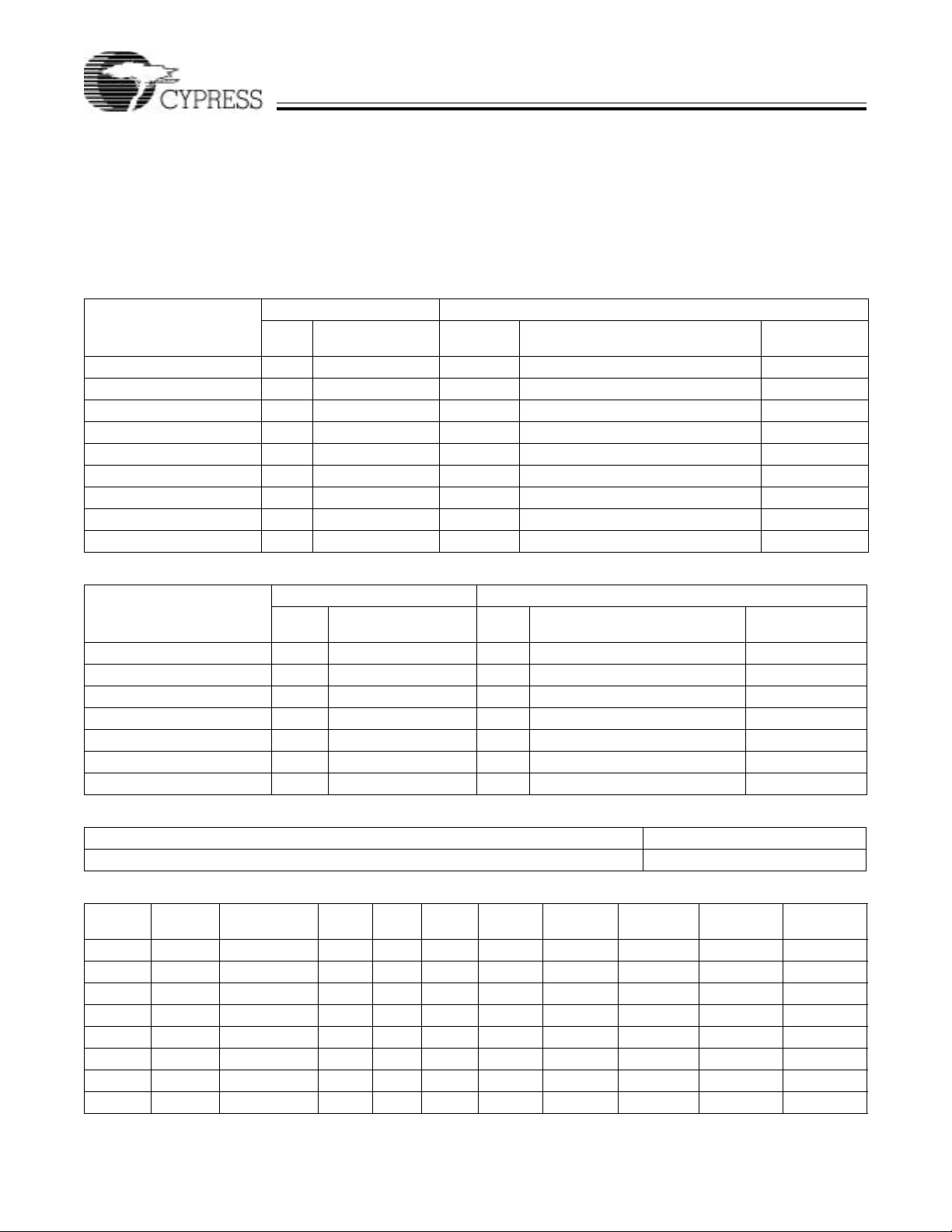

Clocks

Delta39K has four dedicated clock input pins (GCLK[3:0]) to

accept system clocks. One of these clocks (GCLK[0]) may be

selected to drive an on-chip phase-locked loop (PLL) for

frequency modulation (see Figure 9 for details).

The global clock tree for a Delta39K device can be driven by

a combination of the dedicated clock pins and/or the PLLderived clocks. The global clock tree consists of four global

clocks that go to e ve ry m ac roc el l, m em ory b loc k, and I/O cell.

Clock Tree Distribution

The global clock tree performs two prima ry functions. Firs t, the

clock tree generates the fou r global clocks by mult iplexing four

dedicated clocks from the package pins and four PLL driven

clocks. Second, the clo ck tree distributes the fo ur global clocks

to every cluster, channel memory, and I/O block on the die.

The global clock tree is designed such that the clock skew is

minimized while maintaining an acceptable clock delay.

Spread Aware PLL

Each device in the Delta39K family features an on-chip PLL

designed using S pre ad Aware t echnology for lo w EMI applications. In general, PLLs are used to implement time-divisionmultiplex circuits to achieve higher performance with fewer

device resources.

off-chip signal (external feedback)

INTCLK0, INTCLK1, INTCLK2, INTCLK3

GCLK1

Clock Tree

Delay

2

C

fb

GCLK0

Source

Clock

PLL

X1, X2, X3, X4, 5X,

X6, X8, X16

CLK[3:0]

fb

Lock

Clk

0

0

0

Clk 45

Clk

0

90

0

Clk 135

0

Clk 180

Clk

0

225

Clk

0

270

Clk

0

315

Figure 9. Block Diagram of Spread Aware PLL

Phase selection

Phase selection

Phase selection

Phase selection

CPLD Fami

For example, a system th at operates on a 32-bit dat a path th at

runs at 40 MHz can be implemented with 16-bit circuitry that

runs internally at 80 MHz. PLLs can also be used to take

advantage of the positioning of the internally generated clock

edges to shift performance towards improved setup, hold or

clock-to-out times.

There are several freq uen cy multi pl y (X1 , X2 , X3, X4, X5, X6,

X8, X16) and divide (/1, /2, /3, /4, /5, /6, /8, /16) options

available to create a wide range of clock frequencies from a

single clock input (GCLK[0 ]). For increased flexibility , there are

seven phase shifting options which allow clock skew/deskew

by 45°, 90°, 135°, 180°, 225°, 270°, or 315°.

The Spread Aware feature refers to the ability of the PLL to

track a spread-spectrum input clock such that its spread is

seen on the outp ut clock wi th the PLL s taying l ocked. The total

amount of spread on th e inpu t clock shou ld be li mited to 0.6 %

of the fundamental frequency. Spread Aware feature is

supported only with X1, X2, and X4 multiply options.

The Voltage Controlled Oscillator (VCO), the core of the

Delta39K PLL is designed to operate within the frequency

range of 100 MHz to 266 MHz. Hence, the multiply option

combined with input (GCLK[0]) frequency should be selected

such that this VCO operating frequency requirement is met.

This is demonstrated in Table 4 (columns 1, 2, and 3).

Another feature of this PLL is the ability to drive the output

clock (INTCLK) of f the Delt a39K chip to clock o ther devi ces on

the board, as shown in Figure 9 above. This off-chip clock is

half the frequency o f the out put clo ck as it h as to go through a

register (I/O register or a macrocell register).

This PLL can also be used for board de-skewing purpose by

driving a PLL output clock off-chip, routing it to the other

devices on the board and feed ing it ba ck to the PLL’s external

feedback input (GCLK[1]). When this feature is used, only

limited multiply, divide and phase shift options can be used.

Table 4 describes the valid multiply and d ivide option s that can

be used without extern al feedback. Table 5 describes the valid

multiply and divide options that can be used with an external

feedback.

Normal I/O signal path

Any Register (TFF)

Divide

¸ 1-6,8,16

Divide

¸ 1-6,8,16

Divide

¸ 1-6,8,16

Divide

¸ 1-6,8,16

Send a global clock off

chip

Lock Detect/IO pin

C

GCLK0

2

GCLK1

2

GCLK2

2

GCLK3

2

INTCLK

C

INTCLK1

C

INTCLK2

C

INTCLK3

C

Document #: 38-03039 Rev. *H Page 11 of 86

Delta39K™ ISR

™

ly

Table 6 describes the valid phase shift options that can be

used with or without an external feedback.

Table 7 is an example of the effect of all the available divide

and phase shift options on a VCO output of 250 MHz. It also

shows the effect of division on the duty cycle of the resultant

clock. Note that the duty cycle is 50-50 when a VCO output is

divided by an even number. Also note that the phase shift

applies to the VCO output and not to the divided output.

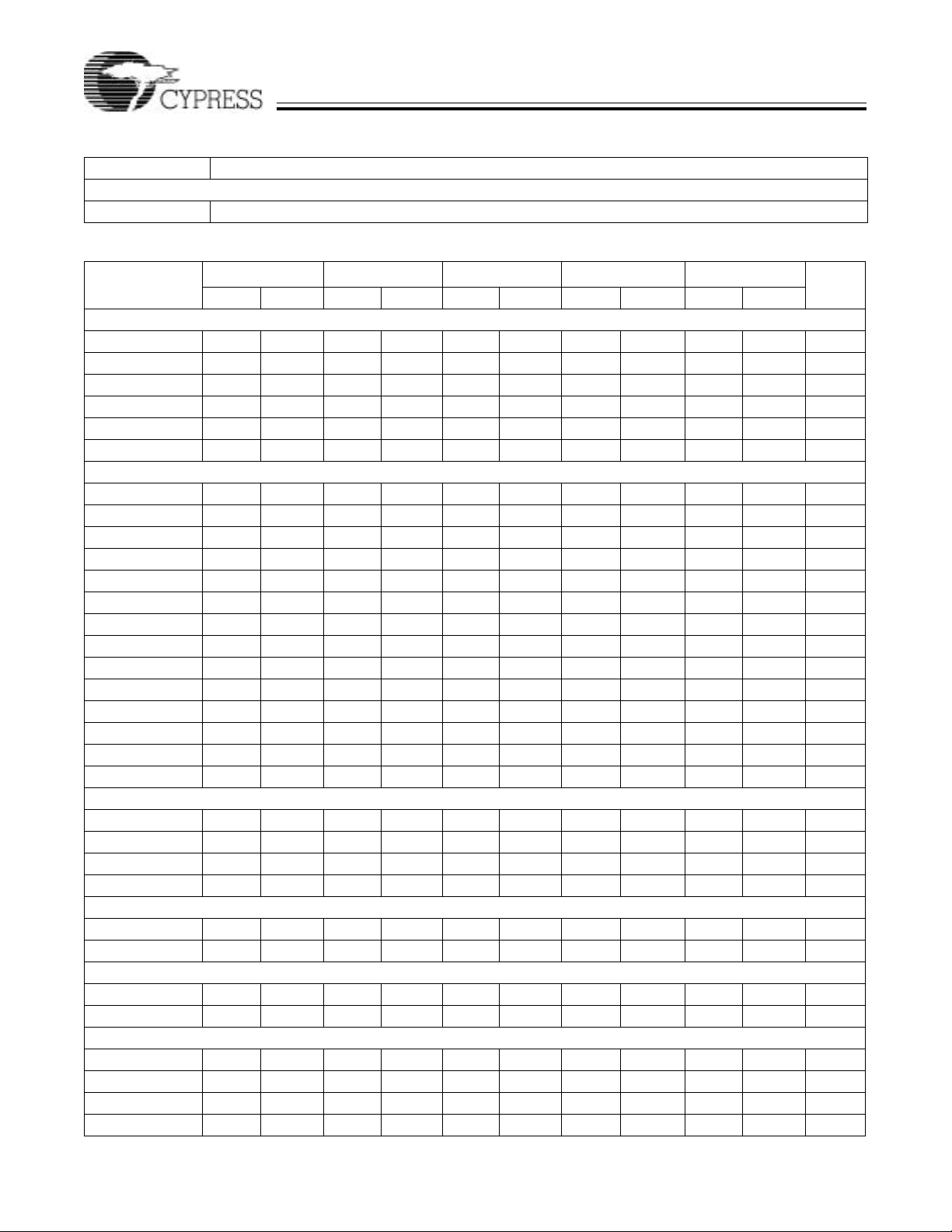

Table 4. Valid PLL Multiply and Divide Options—without External Feedback

Input Frequency

(GCLK[0])

(MHz)

f

PLLI

DC–12.5 N/A N/A N/A DC–12.5 DC–6.25

100–133 1 100–133 1–6, 8, 16 6.25–133 3.125–66

50–133 2 100–266 1–6, 8, 16 6.25–266 3.125–133

33.3–88.7 3 100–266 1–6, 8, 16 6.25–266 3.1–266

25–66 4 100–266 1–6, 8, 16 6.25–266 3.125–133

20–53.2 5 100–266 1–6, 8, 16 6.25–266 3.1–133

16.6–44.3 6 100–266 1–6, 8, 16 6.25–266 3.1–133

12.5–33 8 100–266 1–6, 8, 16 6.25–266 3.125–133

12.5–16.625 16 200–266 1–6, 8, 16 6.25–266 3.125–133

Valid Multiply Options Valid Divide Options

Value

VCO Output

Frequency (MHz) Value

For more details o n th e arc hi tec ture an d o pera tio n of thi s PL L

please refer to the applicat ion note entitled “Delta3 9K PLL and

Clock Tree”.

Output Frequency (INTCLK[3:0])

f

PLLO

(MHz)

CPLD Fami

Off-chip Clock

Frequency

Table 5. Valid PLL Multiply and Divide Options—With External Feedback

Valid Multiply Options Valid Divide Options

Input (GCLK) Frequency

50–133 1 100–266 1 100–266 50–133

25–66.5 1 100–266 2 50–133 25–66.5

16.67–44.33 1 100–266 3 33.33–88.66 16.67–44.33

12.5–33.25 1 100–266 4 25–66.5 12.5–33.25

12.5–26.6 1 125–266 5 25–53.2 12.5–26.6

12.5–22.17 1 150–266 6 25–44.34 12.5–22.17

12.5–16.63 1 200–266 8 25–33.25 12.5–16.63

Table 6. Recommended PLL Phase Shift Options

0°,45°, 90°, 135°, 180°, 225°, 270°, 315° 0°

Table 7. Timing of Clock Phases for all Divide Options for a V

Divide

Factor

1 4 40–60 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

2 8 50 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

3 12 33–67 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

4 16 50 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

5 20 40–60 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

6 24 50 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

8 32 50 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

16 64 50 0 0.5 1.0 1.5 2.0 2.5 3.0 3.5

(MHz)

f

PLLI

Period

(ns) Duty Cycle%0°(ns)

Value

Without External Feedback With External Feedback

VCO Output

Frequency (MHz) Value

CO

45°

(ns)

90°

(ns)

Output (INTCLK) Frequency

Output Frequency of 250 MHz

135°

(ns)

180°

(ns)

f

PLLO

(MHz)

225°

(ns)

Off-chip Clock

Frequency

270°

(ns)

315°

(ns)

Document #: 38-03039 Rev. *H Page 12 of 86

Delta39K™ ISR

™

ly

CompactPCI Hot Swap

The CompactPCI Hot Swap specification allows the removal

and insertion of cards into CompactPCI sockets without

switching-off the bus. Delta39K CPLDs can be used as a

CompactPCI host or target on these cards.

This feature is useful in telecommunication and networking

applications as it allows implementation of high availability

systems, where repairs and upgrades can be done without

downtime.

Delta39K CPLDs are CompactPCI Hot Swap Ready per

CompactPCI Hot Swap specification R2.0, with the following

exception:

• The I/O cells do not provide bias voltage support. External

resistors can be used to achieve this, per sectio n 3.1.3.1 of

the CompactPCI Hot Swap specification R2.0. A simple

board level sol ution is prov ided in the ap plication note titled

“Hot-Swapping Delta39K and Quantum38K CPLDs.”

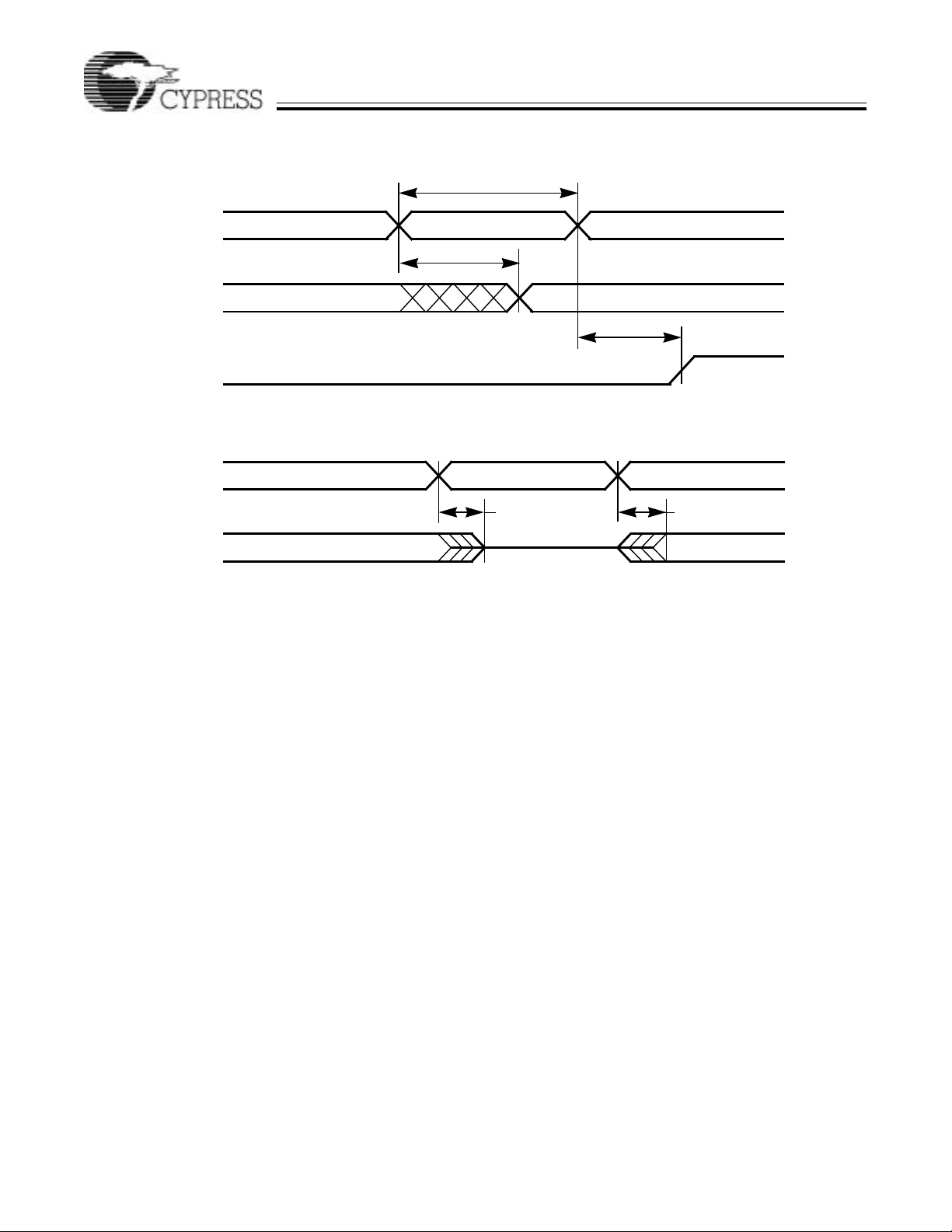

Timing Model

One important feature of the Delta39K family is the simplicity

of its timing. All combinatorial and registered/synchronous

delays are worst case and system performance is static (as

shown in the AC specs section) as long as data is routed

through the same horizontal and vertical channels. Figure 10

illustrates the true timing model for the 200-MHz devices. For

synchronous cloc king of macroc ells, a del ay is i ncurr ed from

macrocell cloc k to macrocell clock o f separate Logic Blocks

within the same cluster, as well as separate Logic Blocks

within differe nt clusters. This is respectively shown as t

t

in Figure 10. For combinatorial paths, any input to any

SCS2

SCS

and

output (from corner to corner on the device), incurs a worstcase delay in the 3 9K100 regardless of the amo unt of l ogic or

which horizontal and vertical channels are u sed. This is the t

shown in Figure 10. For synchronous systems, the input setup time to the outp ut macrocel l register and the clock to o utput

time are shown as the parameters t

the Figure 10. These measurements are for any output and

synchronous clock, regardless of the logic placement.

The Delta39K features:

• no dedicated vs. I/O pin delays

• no penalty for using 0 – 16 product terms

• no added delay for steering product terms

• no added delay for sharing product terms

• no output bypass delays.

The simple timing model of the Delta39K family eliminates

unexpected performance penalties.

Family, Package, and Density Migration in Delta39K

CPLDs

The Delta39K CPLDs combine dense logic, embedded memory and configurable I/O standards. Further de sign flexibil ity is

added by the easy m igra tio n options available be tw een d if f erent packages and densities of Delta39K CPLD offerings.

This migration flexibility makes changes or additions to

designs simple even after PCB layout. It also provides the

ability for experimental designs to be used on production

PCBs. Please refer to the application note titled “Family,

Package, and Density Migration in Delta39K CPLDs.”

CPLD Fami

MCS

and t

MCCO

shown in

PD

Document #: 38-03039 Rev. *H Page 13 of 86

Delta39K™ ISR

™

ly

t

t

MCS

PD

GCLK[3:0]

PIM

PIM

LB 7

LB 6

LB 5

LB 4

RAM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

LB 0

LB 1

LB 2

LB 3

Cluster Cluster

RAM

GCLK[3:0]

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

4

4

Channel

RAM

Channel

RAM

t

SCS

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

PIM

PIM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

4

4

Channel

Channel

RAM

RAM

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

PIM

PIM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

4

4

Channel

RAM

Channel

RAM

CPLD Fami

4

LB 0

LB 1

LB 2

LB 3

SRAM

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

8 Kb

PIM

PIM

LB 7

LB 6

LB 5

LB 4

8 Kb

SRAM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

4

Channel

RAM

Channel

RAM

t

SCS2

GCLK[3:0]

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

t

MCCO

PIM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

4

Channel

RAM

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

PIM

Figure 10. Timing Model for 39K100 Device

IEEE 1149.1-compliant JTAG Operation

The Delta39K family has an IEEE 1149.1 JTAG interface for

both Boundary Scan and ISR operations.

Four dedicated pins are reserved on each device for use by

the Test Access Port (TAP).

Boundary Scan

The Delta39K family supports Bypass, Sample/Preload,

Extest, Intest, Idcode and Usercode boundary scan instructions. The JTAG interface is shown in Figure 11.

In-System Reprogramming (ISR)

In-System Reprogram ming is the combi nation of the cap ability

to program or reprogram a device on-board, and the ability to

support design changes without changing the system timing

or device pinout. This combination means design changes

during debug or field upgrades do not cause board respins.

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

4

Channel

RAM

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

PIM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

4

Channel

RAM

LB 0

LB 1

LB 2

LB 3

Cluster

RAM

PIM

LB 7

LB 6

LB 5

LB 4

Cluster

RAM

4

Channel

RAM

The Delta39K family implements ISR by providing a JTAG

compliant int e rf ac e f or on -bo a rd p r ogr a mmi ng, r obu st ro ut i ng

resources for pinout flexibility, and a simple timing model for

consistent system performance.

Configuration

Each device of the Delta39K fa mily is available in a volatile an d

a Self-Boot package . Cypres s’s CPLD boot EEPROM is used

to store configuration data for the volatile solution and an

embedded on-chip FLASH m emory device is used for th e SelfBoot solution.

For volatile Delta39K packages, programming is defined as

the loading of a user’s design into the external CPLD boot

EEPROM. For Self-Boot Delta39K packa ges, program ming is

defined as the loading of a user’s design into the on-chip

FLASH internal to the Delta39K package. Configuration is

defined as the load ing of a user’s design int o the Delta39 K die.

Document #: 38-03039 Rev. *H Page 14 of 86

Delta39K™ ISR

™

ly

Instruction Register

O

TDI

TMS

TCLK

Configuration can begin in two ways. It can be initiated by

toggling the Reconfig pin from LOW to HI GH, or by issuing th e

appropriate IEEE STD 1149.1 JTAG instruction to the

Delta39K device via the JTAG interface. There are two IEEE

STD 1149.1 JTAG instructions that initiate configu rati on of th e

Delta39K. The Self Config instruction causes the Delta39K to

(re)configure with data stored in the serial boot PROM or the

embedded FLASH memory. The Load Config instruction

causes the Delta39K to (re)configure according to data

provided by other sources such as a PC, automatic test

equipment (ATE), or an embedded micro-controller/pro cess or

via the JTAG interface. For more informatio n on configuring

Delta39K devices, refer to the application note titled “Config-

uring Delta39K/Quantum38K” at http://www.cypress.com.

There are two configuration options available for issuing the

IEEE STD 1 149. 1 JTAG instructions to the Delta39K. Th e first

method is to use a PC with the C3ISR programming cable and

software. With this method, the ISR pins of the Delta39K

devices in th e sys tem are rou ted to a co nnecto r a t the edg e of

the printed circuit board. The C3ISR programming cable is

then connected between the PC and this connector. A simple

configuration file instructs the ISR software of the

programming operations to be performed on the Delta39K

devices in the system. The ISR software then automatically

completes all of the necessary data manipulations req uir ed to

accomplish configuration, reading, verifying, and other ISR

functions. For more i nform at ion on the Cypress ISR i nterface,

see the ISR Programming Kit data sheet (CY3900i).

The second configuration option for the Delta39K is to utilize

the embedded contr oller or proc essor that alrea dy exists i n the

system. The Delta3 9K ISR soft war e as si sts in th i s me tho d by

converting the device HEX file into the ISR serial stream that

contains the ISR instruction information and the addresses

and data of locations to be configured. The embedded

controller then simply directs this ISR stream to the chain of

JTAG

TAP

CONTROLLER

Figure 11. JTAG Interface

Bypass Reg.

Boundary Scan

idcode

Usercode

ISR Prog.

Data Registers

TD

Delta39K devices to complete the desired reconfiguration or

diagnostic operat ions. Cont act y our loc al sa les o f fice for inf ormation on the availability of this option.

Programming

The on-chip FLASH device o f the Delta39K Se lf-Boot package

is programmed by issuing the appropriate IEEE STD 1149.1

JTAG instruction to the internal FLASH memory via the JTAG

interface. This can be done automatically using ISR/STAPL

software. The configuration bits are sent from a PC through

the JTAG port into the Delta39K via the C3ISR programming

cable. The dat a is th en int ernally p assed from De lt a39K t o the

on-chip FLASH. For more information on how to program the

Delta39K through ISR/STAPL, please refer to the ISR/STAPL

User Guide.

The external CPLD boot EEPROM used to store confi guration

data for the Delt a39K vo latile pa ckage is progr ammed throug h

Cypress’s CYDH2200E CPLD Boot PROM Programming Kit

via a two-wire interface. For more information on how to

program the CPLD boot EEPROM, please refer to the data

sheet titled “CYDH2200E CPLD Boot PROM Programming

Kit.” For more information o n the architecture and tim ing specification of the boot EEPROM, refer to the data sheet titled

“512K/1Mb CPLD Boot EEPROM” or “2-Mbit CPLD Boot

EEPROM.”

Third-Party Programmers

Cypress support is available on a wide variety of third-party

programmers. All major programmers (including BP Micro,

System General, Hi-Lo) support the Delta39K family.

CPLD Fami

Development Software Support

Warp

Warp is a state-of-the-art desig n environment for design ing

with Cypress programmable logic. Warp utilizes a subset of

IEEE 1076/1164 VHDL and IEEE 1364 as the Hardware

Description Language (HDL) for design entry. Warp accepts

VHDL or Veri log inpu t, synth esize s and opti mize s the entere d

design, and outputs a configuration bitstream for the desired

Delta39K device. For simulation, Warp provides a graphical

waveform simulator as well as VHDL and Verilog Timing

Models.

VHDL and Verilog are open, powerful, non-proprietary

Hardware Description Languages (HDLs) that are standards

for behavioral design entry and simulation. HDL allows

designers to learn a single lan guage that is useful for all fac ets

of the design process.

Third-Party Software

Cypress products are supported in a number of third-party

design entry and simulation tools. Refer to the third-party

software data sheet or contact your local sales office for a list

of currently supported third party vendors.

Document #: 38-03039 Rev. *H Page 15 of 86

Delta39K™ ISR

™

ly

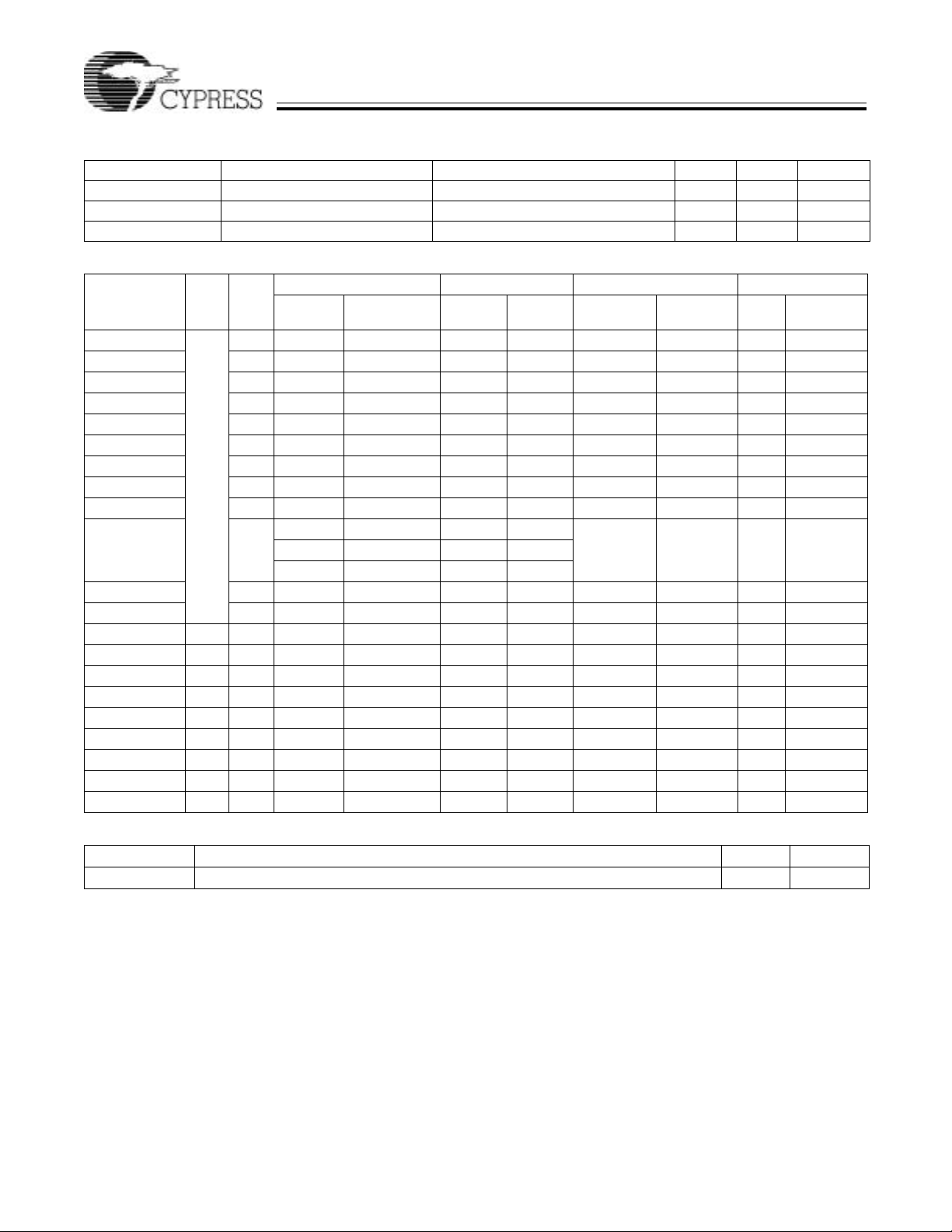

Maximum Ratings

(Above which the useful life may be impaired. For user guidelines, not tested.)

Storage Temperature

(39K200, 208 EQFP) .................................–45°C to +125°C

Storage Temperature

(all other densities and packages)..............–65°C to +150°C

Soldering Temperature.................................................220°C

Ambient Temperature with

Power Applied...............................................–40°C to +85°C

Operating Range

Range

Temperature

Commercial 0°C to +70°C 0°C to +85°C 3.3V 3.3V ± 0.3V 3.3V ± 0.3V or

Industrial –40°C to +85°C –40°C to +100°C 3.3V 3.3V ± 0.3V

Ambient

Junction

Temperature

Output

Condition V

2.5V 2.5V ± 0.2V

1.8V 1.8V ± 0.15V

1.5V 1.5V ± 0.1V

2.5V 2.5V ± 0.2V

1.8V 1.8V ± 0.15V

1.5V 1.5V ± 0.1V

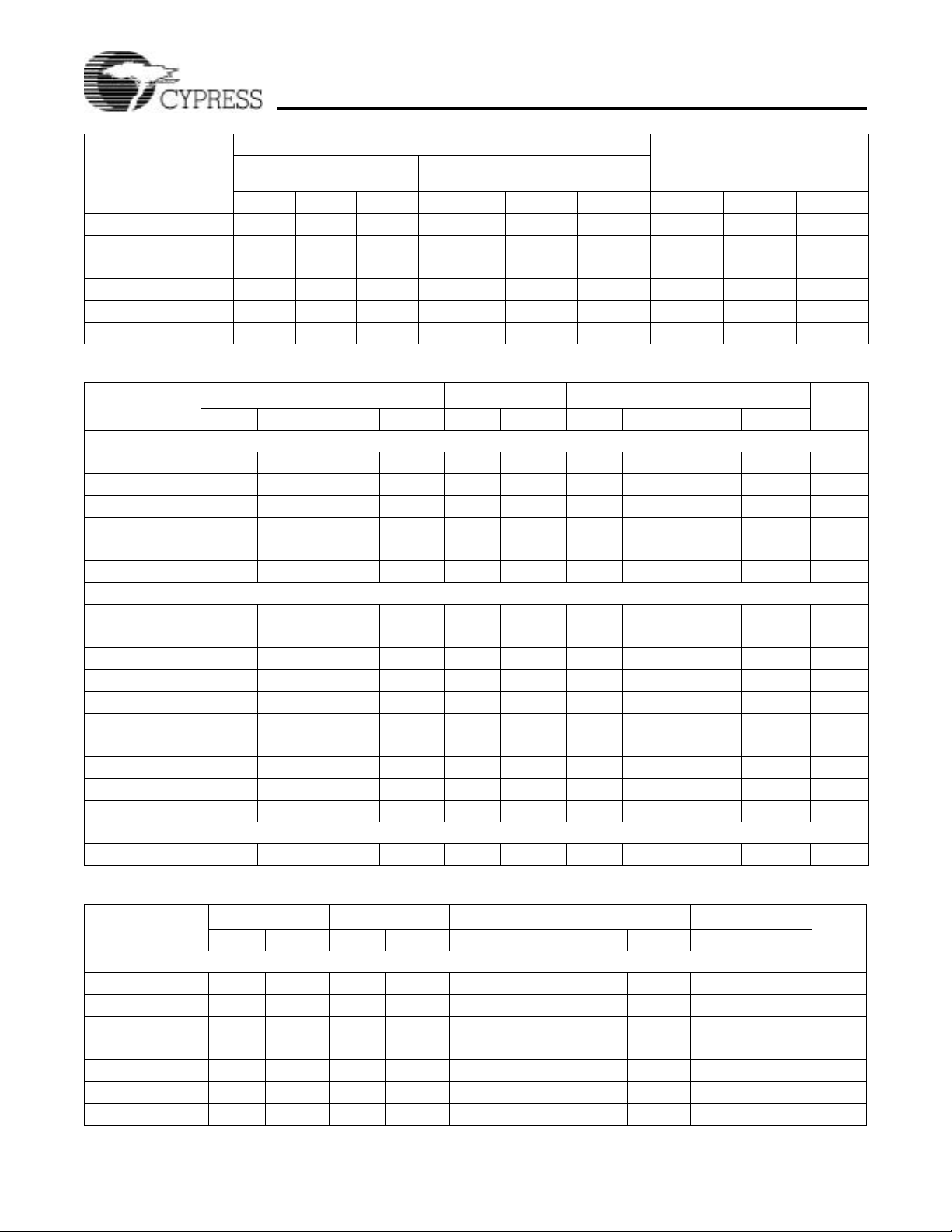

DC Characteristics

Parameter Description

V

DRINT

V

DRIO

[7]

I

IX

I

OZ

I

OS

I

BHL

I

BHH

I

BHLO

I

BHHO

I

CC0

[8]

Data Retention VCC Voltage

(config data may be lost below this)

Data Retention V

(config data may be lost below this)

CCIO

Voltage

Input Leakage Current GND ≤ VI ≤ 3.6V –10 10 –10 10 –10 10 µA

Output Leakage Current GND ≤ VO ≤

Output Short Circuit Current V

Input Bus Hold LOW Sust aining Cu rrent VCC = Min.

Input Bus Hold H IGH Sustaining Current VCC = Min.

Input Bus Hold LOW Overdrive Current VCC = Max. +250 +200 +150 µA

Input Bus Hold H IGH O verdr ive Cu rrent VCC = Max. –250 –200 –150 µA

Standby Current

Conditions

V

CCIO

CCIO

V

OUT

= V

V

PIN

= V

V

PIN

39K30

39K50

39K100

39K165

39K200

Junction Temperature...................................................135°C

V

to Ground Potential...................................–0.5V to 4.6V

CC

V

to Ground Potential................................–0.5V to 4.6V

CCIO

DC Voltage Applied to Outputs

in High-Z state..................................................–0.5V to 4.5V

DC Input voltage...............................................–0.5V to 4.5V

DC Current into Outputs........................................± 20 mA

Static Discharge Voltage

(per JEDEC EIA./JESD22–A114A)............................>2001V

Latch-up Current.....................................................>200 mA

CCIO

V

CC

2.5V ± 0.2V

(39KV)

[5]

[5]

V

= 3.3V V

Test

CCIO

CCIO

1.5 1.5 1.5 V

1.2 1.2 1.2 V

–10 10 –10 10 –10 10 µA

= Max.

–160 –160 –160 µA

= 0.5V

+40 +30 +25 µA

IL

–40 –30 –25 µA

IH

All bins

20

20

30

60

60

CPLD Fami

V

V

Same as

= 2.5V V

All bins

20

20

30

60

60

/

CCJTAG

CCCNFGVCCPLLVCCPRG

Same as

V

CCIO

CCIO

–125 bin

V

CC

= 1.8V

3

3

5

10

10

–83 bin

12

12

20

40

40

[6]

3.3V ±

0.3V

UnitMin. Max. Min. Max. Min. Max.

µA

Note:

6. DC current into outputs is 36 mA with HSTL III, 48 mA with HSTL IV, and 36 mA with GTL+ (with 25W pull-up resistor and V

7. Input Le akag e cu rren t is ± 10µA for all the pins on all the Delta39K package except the following pins in Delta39K100 packages: The input leakage current spec

for these pins in ±200µA

Package Pins

388-BGA B4, C2

484-FBGA B8, G9

676-FBGA F11, J11

8. Not more than one output should be tested at a time. Duration of the short circuit should not exceed 1 second. V

problems caused by tester-ground degradation. Tested initially and after any design or process changes that may affect these parameters.

Delta39K100

= 0.5V has been chosen to avoid test

OUT

Document #: 38-03039 Rev. *H Page 16 of 86

TT

= 1.5).

Delta39K™ ISR

™

ly

CPLD Fami

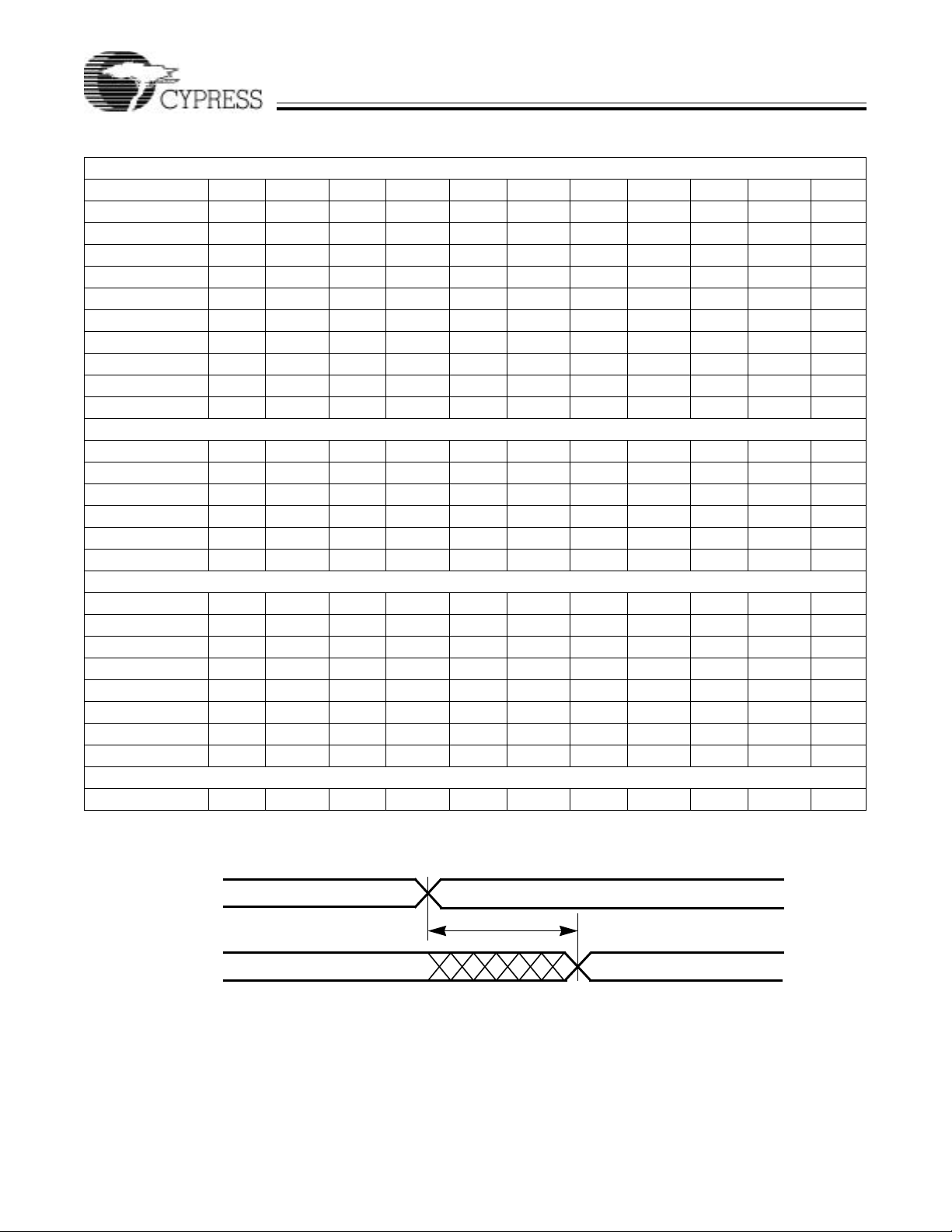

Capacitance

Parameter Description Test Conditions Min. Max. Unit

C

I/O

C

CLK

C

PCI

DC Characteristics (I/ O)

I/O Standards

LVTTL –2 mA N/A 3.3 –2 mA 2.4 2 mA 0.4 2.0V V

LVTTL –4 mA 3.3 –4 mA 2.4 4 mA 0.4 2.0V V

LVTTL –6 mA 3.3 –6 mA 2.4 6 mA 0.4 2.0V V

LVTTL –8 mA 3.3 –8 mA 2.4 8 mA 0.4 2.0V V

LVTTL –12 mA 3.3 –12 mA 2.4 12 mA 0.4 2.0V V

LVTTL –16 mA 3.3 –16 mA 2.4 16 mA 0.4 2.0V V

LVTTL –24 mA 3.3 –24 mA 2.4 24 mA 0.4 2.0V V

LVCMOS 3.3 –0.1 mA V

LVCMOS3 3.0 –0.1 mA V

LVCMOS2

LVCMOS18 1.8 –2 mA V

3.3V PCI 3.3 –0.5 mA 0.9V

GTL+ 1.0

SSTL3 I 1.5 3.3 –8 mA V

SSTL3 II 1.5 3.3 –16 mA V

SSTL2 I 1.25 2.5 –7.6 mA V

SSTL2 II 1.25 2.5 –15.2 mA V

HSTL I 0.75 1.5 –8 mA V

HSTL II 0.75 1.5 –16 mA V

HSTL III 0.9 1.5 –8 mA V

HSTL IV 0.9 1.5 –8 mA V

Configuration Parameters

Parameter Description Min. Unit

t

RECONFIG

Power-up Sequence Requirements

• Upon power-up, al l the output s rema in three-st ated unt il all

the V

the part has completed configuration.

• The part will not start configuration until V

V

nominal voltage.

Notes:

9. PCI spec (rev 2.2) requires the IDSEL pin to have capacitance less than or equal to 8 pF. Delta39K Pin Tables starting from page 45, identify all the I/O pins in

10. The number of I/Os which can be used in each I/O bank depends on the type of I/O standards and the number of V

11. See “Power-up Sequence Requirements” below for V

12. 25W resistor terminated to termination voltage of 1.5V.

pins have powered-up to the nom in al voltage and

CC

, V

CCJTAG

a given package, which can be used as IDSEL in a PCI design. All other I/O pins meet the PCI requirement of capacitance less than or equal to 10 pf.

to the application note titled “Delta39K and Quantum38K I/O Standards and Configurations” for details.

• The source current limit per I/O bank per Vccio pin is 165 mA.

• The sink current limit per I/O bank per GND pin is 230 mA.

CCCNFG

Input/Output Capacitance V

Clock Signal Capacitance V

PCI-compliant

V

V

REF

(V)

[10]

CCIO

(V)

[9]

Capacitance V

(V) V

V

OH

@ I

=VOH (min.) @ I

OH

CCIO

CCIO

2.5 –0.1 mA 2.1 0.1 mA 0.2 1.7V V

–1.0 mA 2.0 1.0 mA 0.4

–2.0 mA 1.7 2.0 mA 0.7

CCIO

[11]

CCIO

CCIO

CCIO

CCIO

CCIO

CCIO

CCIO

CCIO

Reconfig pin LOW time before it goes HIGH 200 ns

, V

CCPLL

and V

CCPRG

CC

have reached

CCIO

= V

in

= V

in

= V

in

@ f = 1 MHz 25°C 10 pF

CCIO

@ f = 1 MHz 25°C 5 12 pF

CCIO

@ f = 1 MHz 25°C 8 pF

CCIO

(V) V

OL

VOL

=

OL

(max.) Min. Max. Min. Max.

– 0.2V 0.1 mA 0.2 2.0V V

– 0.2V 0.1 mA 0.2 2.0V V

– 0.45V 2.0 mA 0.45 0.65V

CCIO

1.5 mA 0.1V

[12]

36 mA

CCIO

0.6 V

– 1.1V 8 mA 0.7 V

– 0.9V 16 mA 0.5 V

– 0.62V 7.6 mA 0.54 V

– 0.43V 15.2 mA 0.35 V

– 0.4V 8 mA 0.4 V

– 0.4V 16 mA 0.4 V

– 0.4V 24 mA 0.4 V

– 0.4V 48 mA 0.4 V

•V

pins can be powered up in any order. This includes

CC

VCC, V

CCIO

s on a bank should be tied to the same potential

CCIO

and powered up together.

s (even the unused banks) need to be pow ered up

CCIO

to at least 1.5V before configuration has compl eted.

, V

CCIO

•All V

,

•All V

CCIOVCCIO

0.5V

CCIOVCCIO

+ 0.2 V

REF

+ 0.2 V

REF

+ 0.2 V

REF

+ 0.18 V

REF

+ 0.18 V

REF

+ 0.1 V

REF

+ 0.1 V

REF

+ 0.1 V

REF

+ 0.1 V

REF

, V

CCJTAG

• Maximum ramp time for all V

voltage in 100 ms.

requirement.

(V) V

IH

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.8V

CCIO

+ 0.3 –0.3V 0.7V

CCIO

+ 0.3 –0.3V 0.35V

+ 0.5 –0.5V 0.3V

+ 0.3 –0.3V V

CCIO

+ 0.3 –0.3V V

CCIO

+ 0.3 –0.3V V

CCIO

+ 0.3 –0.3V V

CCIO

+ 0.3 –0.3V V

CCIO

+ 0.3 –0.3V V

CCIO

+ 0.3 –0.3V V

CCIO

+ 0.3 –0.3V V

CCIO

, V

CCIO

, V

CCCNFG

s should be 0V to nominal

CC

and GND pins being used. Please refer

CCPLL

and V

(V)

IL

REF

REF

REF

REF

REF

REF

REF

REF

REF

CCPRG

CCIO

CCIO

– 0.2

– 0.2

– 0.2

– 0.18

– 0.18

– 0.1

– 0.1

– 0.1

– 0.1

.

Document #: 38-03039 Rev. *H Page 17 of 86

Delta39K™ ISR

™

ly

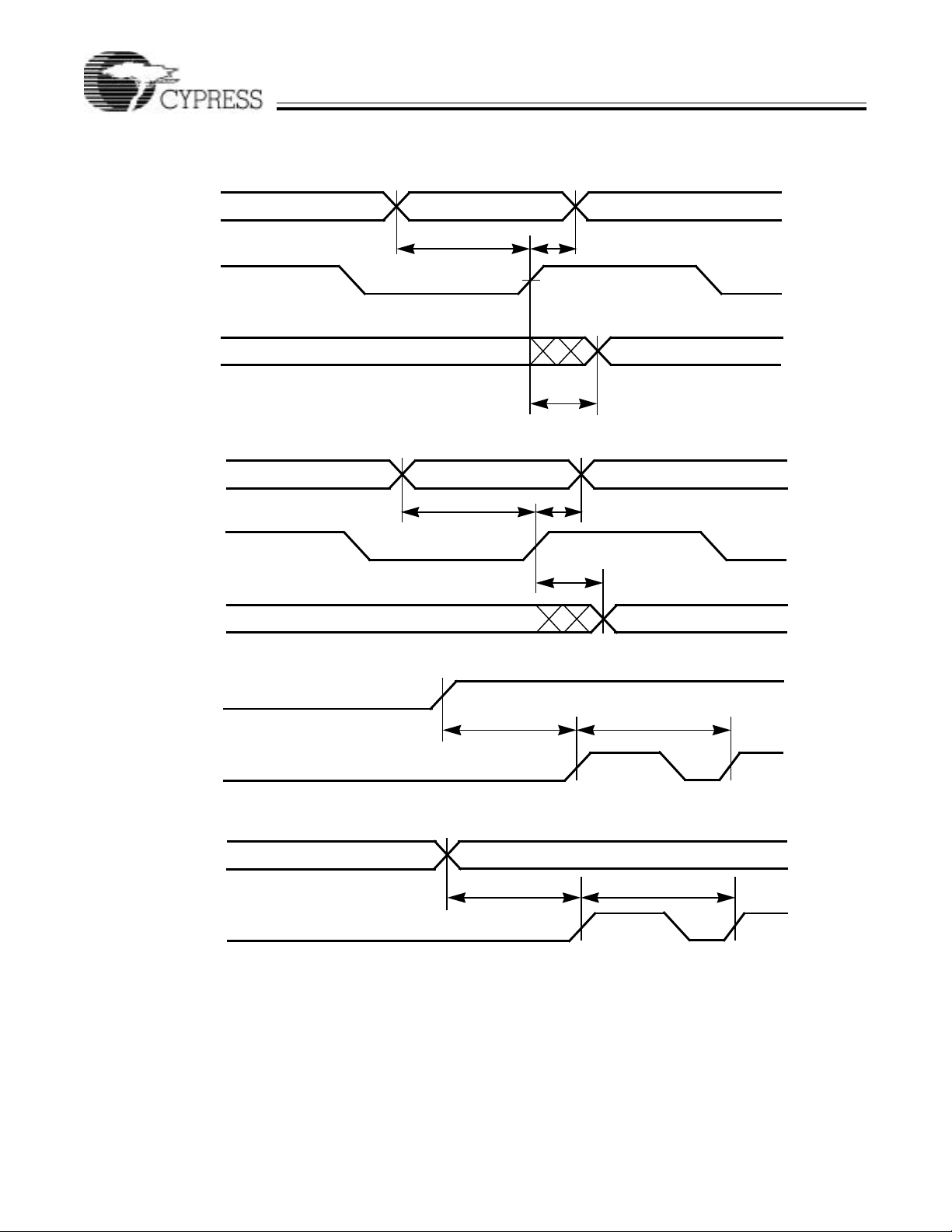

Switching Characteristics — Parameter Descriptions Over the Operating Range

Parameter Description

Combinatorial Mode Parameters

t

PD

t

EA

t

ER

t

PRR

t

PRO

t

PRW

Synchronous Clocking Parameters

t

MCS

t

MCH

t

MCCO

t

IOS

t

IOH

t

IOCO

t

SCS

t

SCS2

t

ICS

t

OCS

t

CHZ

t

CLZ

f

MAX

f

MAX2

Product Term Clock

t

MCSPT

t

MCHPT

t

MCCOPT

t

SCS2PT

Channel Interconnect Parameters

t

CHSW

t

CL2CL

Miscellaneous Delays

t

CPLD

t

MCCD

t

IOD

t

IOIN

Note:

13. Add t

Delay from any pin input, through a ny cluster on the c hannel a ssociated with tha t pin inp ut, to an y pin ou tput on th e

horizontal or vertical channel associated with that cluster

Global control to output enable

Global control to output disable

Asynchronous macrocell RESET o r PRESET recovery ti me from any pi n input on t he horizon tal or verti cal channel

associated with the cluster the macrocell is in

Asynchronous macrocell RESET or PRESET from any pin input on the horizontal or vertical channel associated

with the cluster that the macrocell is in to any pin output on those same channels

Asynchronous macroc ell RESET or PRESET min imum pulse width, from a ny pin inpu t to a macroc ell in the farthest

cluster on the horizontal or vertical channel the pin is associated with

Set-up time of any i nput pi n t o a mac rocell in an y cl ust er on t he cha nnel assoc iated with th at inp ut pin , relati ve to a

global clock

Hold time of any input pin to a macrocell in any cluster on the channel associated with that input pin, relative to a

global clock

Global clock to output of any macrocell to any output pin on the horizontal or vertical channel associated with the

cluster that macrocell is in

Set-up time of any input pin to the I/O cell register associated with that pin, relative to a global clock

Hold time of any input pin to the I/O cell register associated with that pin, relative to a global clock

Clock to output of an I/O cell register to the output pin associated with that register

Macrocell clock to macrocell clock through array logic within the same cluster

Macrocell clock to macrocell clock through array logic in different clusters on the same channel

I/O register clock to any macrocell clock in a cluster on the channel the I/O register is associated with

Macrocell clock to any I/O register clock on the horizontal or vertical channel associated with the cluster that the

macrocell is in

Clock to output disable (high-impedance)

Clock to output enable (low-impedance)

Maximum frequency with internal feedback—within the same cluster

Maximum frequenc y with int ernal feed back—w ithin dif ferent clusters at the op posite e nds of a horizont al or v ertical

channel

Set-up time for macrocell used as input register, from input to product term clock

Hold time of macrocell used as an input register

Product term clock to output delay from input pin

Register to register delay through array logic in different clusters on the same channel using a product term clock

Adder for a signal to switch from a horizontal to vertical channel and vice-versa

Cluster-to-cluster delay adder (through channels and channel PIM)

Delay from the input of a cluster PIM, th rough a macro cell in the c luster , back to a cluster PIM i nput. This p arameter

can be added to the tPD and t

signal path

parameters for each extra pass through the AND/OR array required by a given

SCS

Adder for carry chain logic per macrocell

Delay from the input of the output buffer to the I/O pin

Delay from the I/O pin to the input of the channel buffer

to signals making a horizontal to vertical channel switch or vice-versa.

CHSW

CPLD Fami

[13]

Document #: 38-03039 Rev. *H Page 18 of 86

Delta39K™ ISR

™

ly

Switching Characteristics — Parameter Descriptions Over the Operating Range

Parameter Description

t

CKIN

t

IOREGPIN

PLL Parameters

t

MCCJ

t

DWSA

t

DWOSA

t

LOCK

t

INDUTY

f

PLLI

f

PLLO

f

PLLVCO

P

SAPLLI

f

MPLLI

JTAG Parameters

t

JCKH

t

JCKL

t

JCP

t

JSU

t

JH

t

JCO

t

JXZ

t

JZX

Cluster Memory Timing Parameter Descriptions Ov er the Op erating Range

Parameter Description

Asynchronous Mode Parameters

t

CLMAA

t

CLMPWE

t

CLMSA

t

CLMHA

t

CLMSD

t

CLMHD

Synchronous Mode Parameters

t

CLMCYC1

t

CLMCYC2

t

CLMS

t

CLMH

t

CLMDV1

t

CLMDV2

t

CLMMACS1

t

CLMMACS2

t

MACCLMS1

Delay from the clock pin to the input of the clock driver

Delay from the I/O pin to the input of the I/O register

Maximum cycle to cycle jitter time

PLL zero phase delay with clock tree deskewed

PLL zero phase delay without clock tree deskewed

Lock time for the PLL

Input duty cycle

Input frequency of the PLL

Output frequency of the PLL

PLL VCO frequency of operation

Percentage modulation allowed (spread awareness) on the PLL input clock

Frequency of modulation allowed on PLL input clock. This specifies how fast the f

(1–P

SAPLLI

/100) and f

PLLI

* (1+ P

SAPLLI

/100)

TCLK HIGH time

TCLK LOW time

TCLK clock period

JTAG port set-up time (TDI/TMS inputs)

JTAG port hold time (TDI/TMS inputs)

JTAG port clock to output time (TDO)

JTAG port valid output to high impedance (TDO)

JTAG port high impedance to valid output (TDO)

Cluster memory access time. Delay from address change to Read data out

Write Enable pulse width

Address set-up to the beginning of Write Enable with both signals from the same I/O block

Address hold after the end of Write Enable with both signals from the same I/O block

Data set-up to the end of Write Enable

Data hold after the end of Write Enabl e

Clock cycle time for flow through Read and Write operations (from macro cell register through cluster memory

back to a macrocell register in the same cluster)

Clock cycle time for pipelined Read and Write operations (from cluster memory input register through the

memory to cluster memory output register)

Address, data, and WE set-up time of pin inputs, relative to a global clock

Address, data, and WE hold time of pin inputs, relative to a global clock

Global clock to data valid on output pins for flow through data

Global clock to data valid on output pins for pipelined data

Cluster memory input clock to macr oc el l clock in the same cluster

Cluster memory output clock to macrocell clock in the same cluster

Macrocell clock to cluster memory input clock in the same cluster

CPLD Fami

[13]

(continued)

sweeps between f

PLLI

PLLI

*

Document #: 38-03039 Rev. *H Page 19 of 86

Delta39K™ ISR

™

ly

Cluster Memory Timing Parameter Descriptions Ov er the Op erat ing Range (continued)

Parameter Description

t

MACCLMS2

Internal Parameters

t

CLMCLAA

Channel Memory Timing Parameter Descriptions Over the Operating Range

Parameter Description

Dual Port Asynchronous Mode Parameters

t

CHMAA

t

CHMPWE

t

CHMSA

t

CHMHA

t

CHMSD

t

CHMHD

t

CHMBA

Dual Port Synchronous Mode Parameters

t

CHMCYC1

t

CHMCYC2

t

CHMS

t

CHMH

t

CHMDV1

t

CHMDV2

t

CHMBDV

t

CHMMACS1

t

CHMMACS2

t

MACCHMS1

t

MACCHMS2

Synchronous FIFO Data Parameters

t

CHMCLK

t

CHMFS

t

CHMFH

t

CHMFRDV

t

CHMMACS

t

MACCHMS

Synchronous FIFO Flag Parameters

t

CHMFO

t

CHMMACF

t

CHMFRS

t

CHMFRSR

t

CHMFRSF

t

CHMSKEW1

t

CHMSKEW2

t

CHMSKEW3

Macrocell clock to cluster memory output clock in the same cluster

Asynchronous cluster memory access time from input of cluster memory to output of cluster memory

Channel memory access time. Delay from address change to Read data out

Write enable pulse width

Address set-up to the beginning of Write enable with both signals from the same I/O block

Address hold after the end of Write enable with both signals from the same I/O block

Data set-up to the end of Write enable

Data hold after the end of Write enable

Channel memory asynchronous dual port address match (busy access time)

Clock cycle time for flow through Read and Write operations (from macrocell register through channel

memory back to a macrocell register in the same cluster)

Clock cycle time for pipeline d Read and Write operatio ns (from channel memo ry input register through the

memory to channel memory output register)

Address, data, and WE set-up time of pin inputs, relative to a global clock

Address, data, and WE hold time of pin inputs, relative to a global clock

Global clock to data valid on output pins for flow through data

Global clock to data valid on output pins for pipelined data.

Channel memory synchronous dual-port address match (busy, clock to data valid)

Channel memory input clock to macrocell clock in the same cluster

Channel memory output clock to macrocell clock in the same cluster

Macrocell clock to channel memory input clock in the same cluster

Macrocell clock to channel memory output clock in the same cluster

Read and Write minimum clock cycle time