Page 1

Ultra37000 CPLD Family

5V, 3.3V, ISR™ High-Performance CPLDs

Features

• In-System Reprogrammable™ (ISR™) CMOS CPLDs

— JTAG interface for reconfigurability

— Design changes do not cause pinout changes

— Design changes do not cause timing changes

• High density

— 32 to 512 macrocells

— 32 to 264 I/O pins

— Five dedicated inputs including four clock pins

• Simple timing model

— No fanout delays

— No expander delays

— No dedicated vs. I/O pin delays

— No additional delay through PIM

— No penalty for using full 16 product terms

— No delay for steering or sharing product terms

• 3.3V and 5V versions

• PCI-compatible

• Programmable bus-hold capabilities on all I/Os

• Intelligent product term allocator provides:

— 0 to 16 product terms to any macrocell

— Product term steering on an individual basis

— Product term sharing among local macrocells

• Flexible clocking

— Four synchronous clocks per device

— Product term clocking

— Clock polarity control per logic block

• Consistent package/pinout offering across all densities

— Simplifies design migration

— Same pinout for 3.3V and 5.0V devices

• Packages

— 44 to 400 leads in PLCC, CLCC, PQFP, TQFP, CQFP,

BGA, and Fine-Pitch BGA packages

— Lead (Pb)-free packages available

Note:

1. Due to the 5V-tolerant nature of 3.3V device I/Os, the I/Os are not clamped to V

[1]

General Description

The Ultra37000™ family of CMOS CPLDs provides a range of

high-density programmable logic solutions with unparalleled

system performance. The Ultra37000 family is designed to

bring the flexibility, ease of use, and performance of the 22V10

to high-density CPLDs. The architecture is based on a number

of logic blocks that are connected by a Programmable Interconnect Matrix (PIM). Each logic block features its own

product term array, product term allocator, and 16 macrocells.

The PIM distributes signals from the logic block outputs and all

input pins to the logic block inputs.

All of the Ultra37000 devices are electrically erasable and

In-System Reprogrammable (ISR), which simplifies both

design and manufacturing flows, thereby reducing costs. The

ISR feature provides the ability to reconfigure the devices

without having design changes cause pinout or timing

changes. The Cypress ISR function is implemented through a

JTAG-compliant serial interface. Data is shifted in and out

through the TDI and TDO pins, respectively. Because of the

superior routability and simple timing model of the Ultra37000

devices, ISR allows users to change existing logic designs

while simultaneously fixing pinout assignments and

maintaining system performance.

The entire family features JTAG for ISR and boundary scan,

and is compatible with the PCI Local Bus specification,

meeting the electrical and timing requirements. The

Ultra37000 family features user programmable bus-hold

capabilities on all I/Os.

Ultra37000 5.0V Devices

The Ultra37000 devices operate with a 5V supply and can

support 5V or 3.3V I/O levels. V

capability of interfacing to either a 5V or 3.3V bus. By

connecting the V

on the outputs. If V

meet 3.3V JEDEC standard CMOS levels and are 5V tolerant.

pins to 5V the user insures 5V TTL levels

CCO

is connected to 3.3V the output levels

CCO

These devices require 5V ISR programming.

Ultra37000V 3.3V Devices

Devices operating with a 3.3V supply require 3.3V on all V

pins, reducing the device’s power consumption. These

devices support 3.3V JEDEC standard CMOS output levels,

and are 5V-tolerant. These devices allow 3.3V ISR

programming.

, PCI V

CC

IH

= 2V.

connections provide the

CCO

CCO

Cypress Semiconductor Corporation • 3901 North First Street • San Jose, CA 95134 • 408-943-2600

Document #: 38-03007 Rev. *E Revised March 7, 2004

[+] Feedback

Page 2

Ultra37000 CPLD Family

Selection Guide

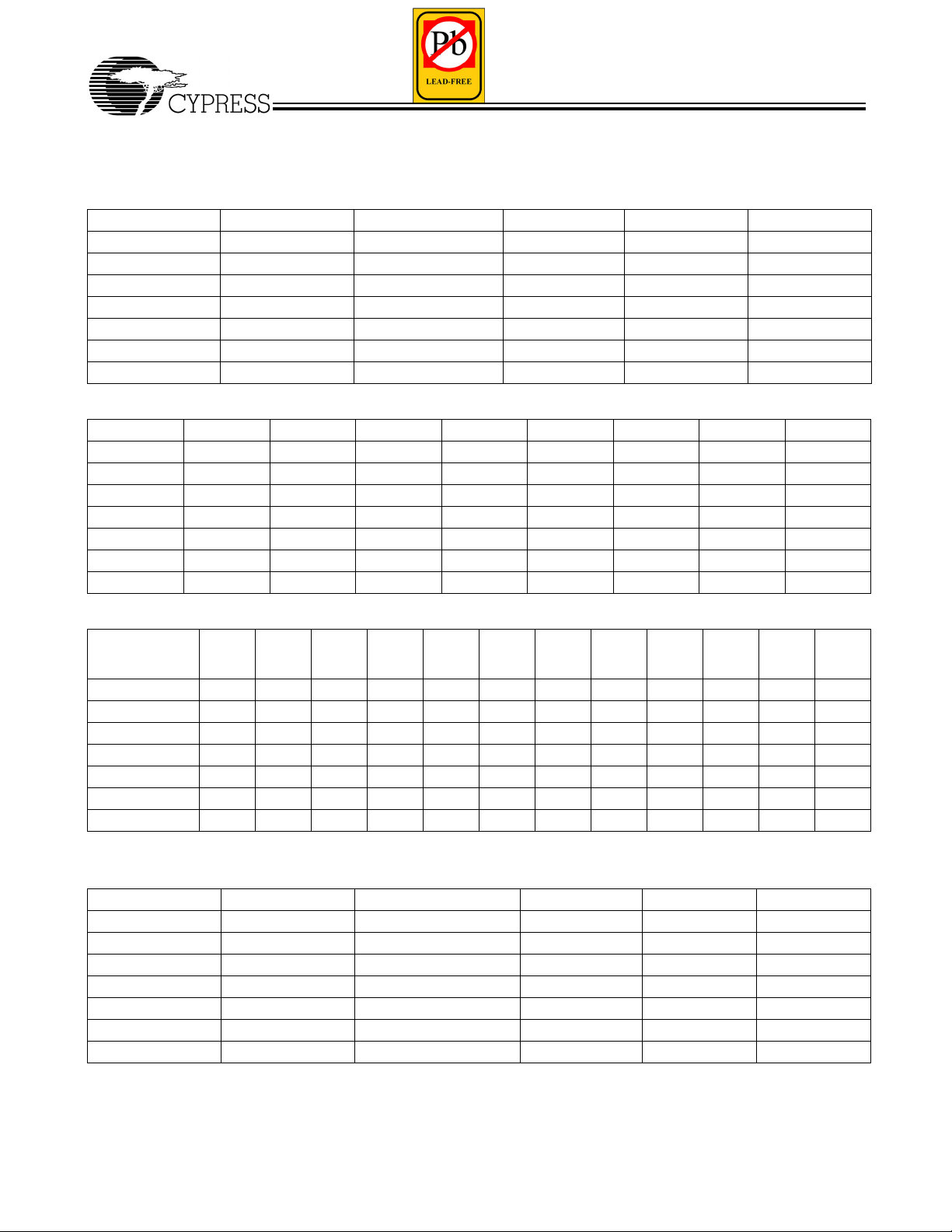

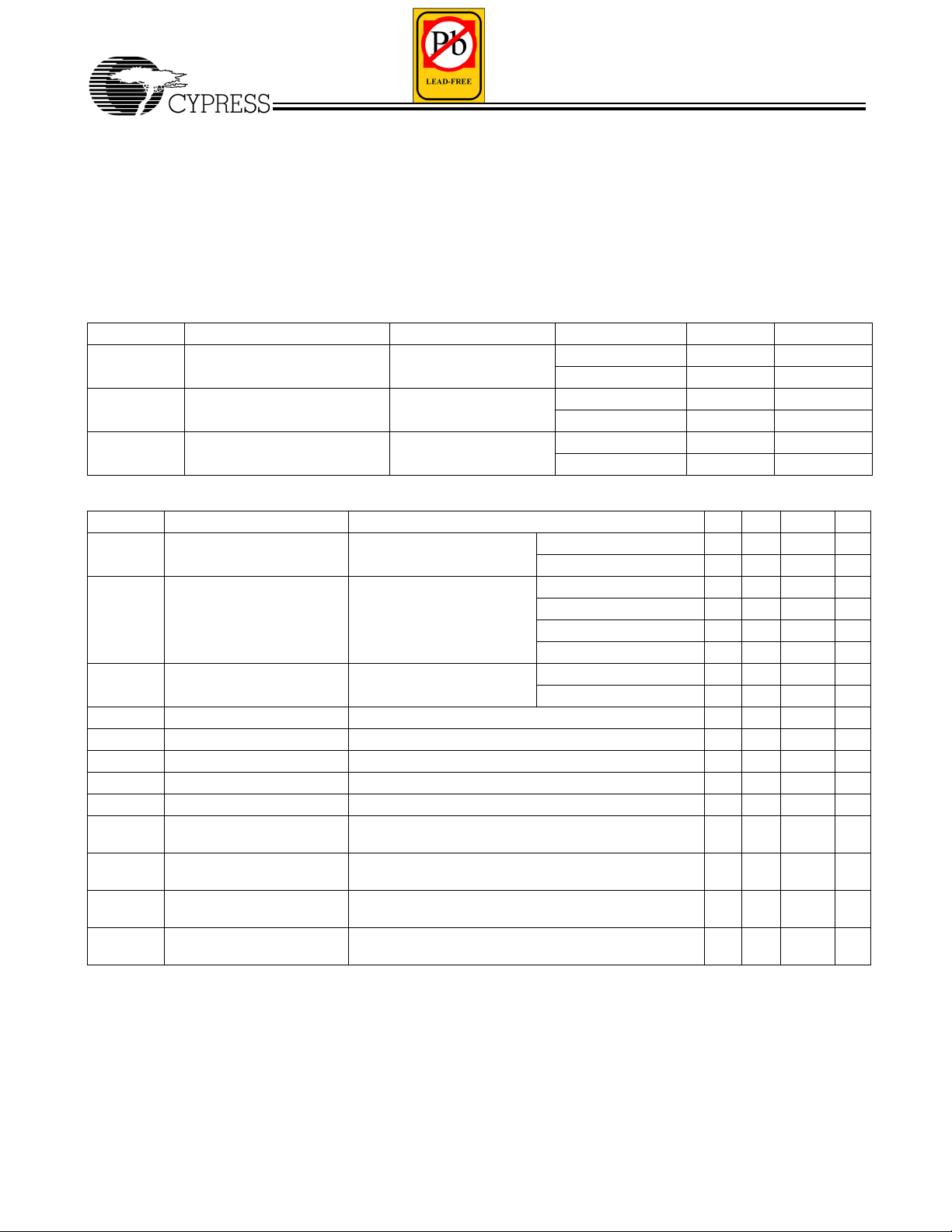

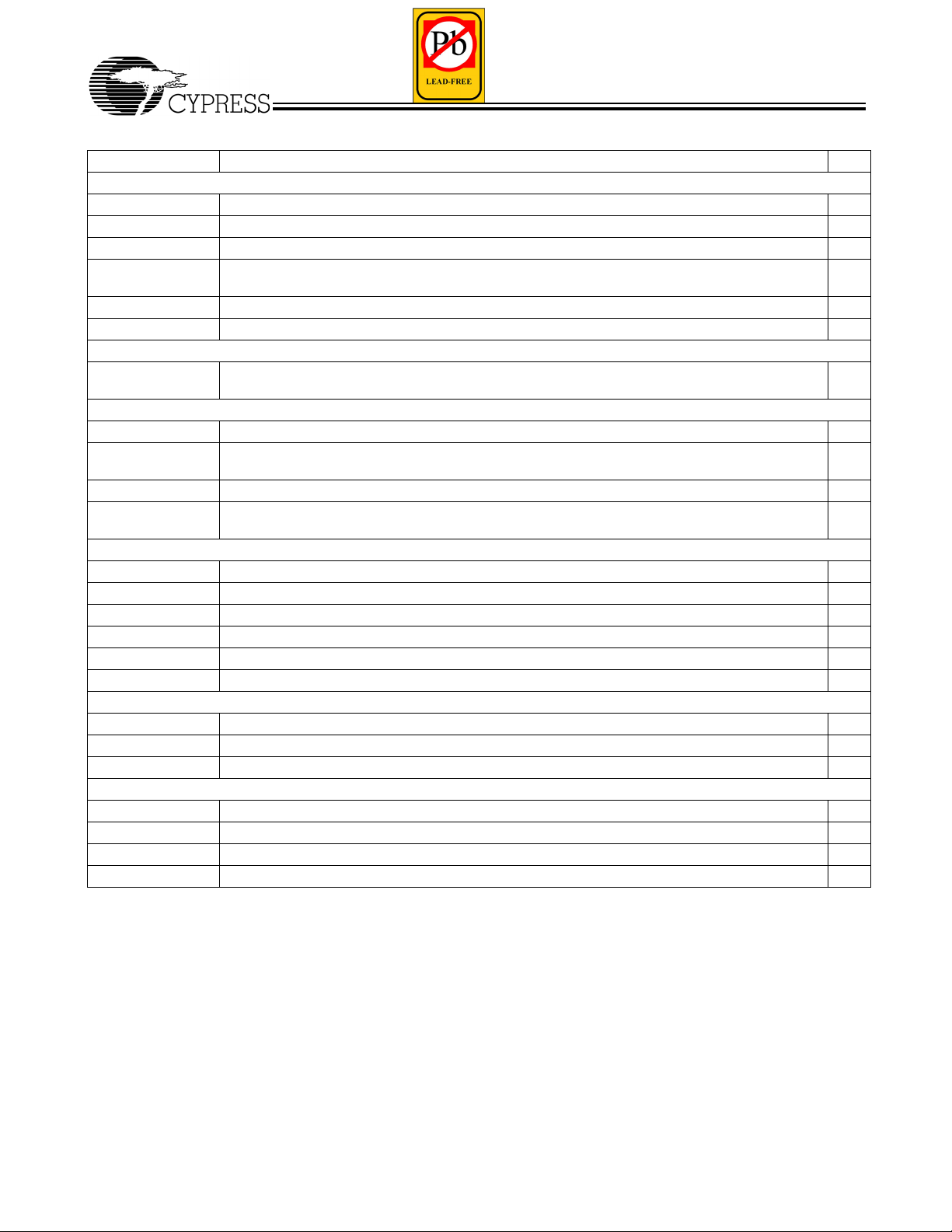

5.0V Selection Guide

General Information

Device Macrocells Dedicated Inputs I/O Pins Speed (t

CY37032 32 5 32 6 200

CY37064 64 5 32/64 6 200

CY37128 128 5 64/128 6.5 167

CY37192 192 5 120 7.5 154

CY37256 256 5 128/160/192 7.5 154

CY37384 384 5 160/192 10 118

CY37512 512 5 160/192/264 10 118

Speed Bins

Device 200 167 154 143 125 100 83 66

CY37032 X X X

CY37064 X X X

CY37128 X X X

CY37192 X X X

CY37256 X X X

CY37384 X X

CY37512 X X X

)Speed (f

PD

MAX

)

Device-Package Offering and I/O Count

Device

44-

Lead

TQFP

44-

Lead

PLCC

44-

Lead

CLCC

84-

Lead

PLCC

84-

Lead

CLCC

100-

Lead

TQFP

160-

Lead

TQFP

160-

Lead

CQFP

208-

Lead

PQFP

208-

Lead

CQFP

292-

Lead

PBGA

CY37032 37 37

CY37064 37 37 37 69 69

CY37128 69 69 69 133

CY37192 125

CY37256 133 133 165 197

CY37384 165 197

CY37512 165 165 197 269

3.3V Selection Guide

General Information

Device Macrocells Dedicated Inputs I/O Pins Speed (t

)Speed (f

PD

CY37032V 32 5 32 8.5 143

CY37064V 64 5 32/64 8.5 143

CY37128V 128 5 64/80/128 10 125

CY37192V 192 5 120 12 100

CY37256V 256 5 128/160/192 12 100

CY37384V 384 5 160/192 15 83

CY37512V 512 5 160/192/264 15 83

388-

Lead

PBGA

MAX

)

Document #: 38-03007 Rev. *E Page 2 of 64

[+] Feedback

Page 3

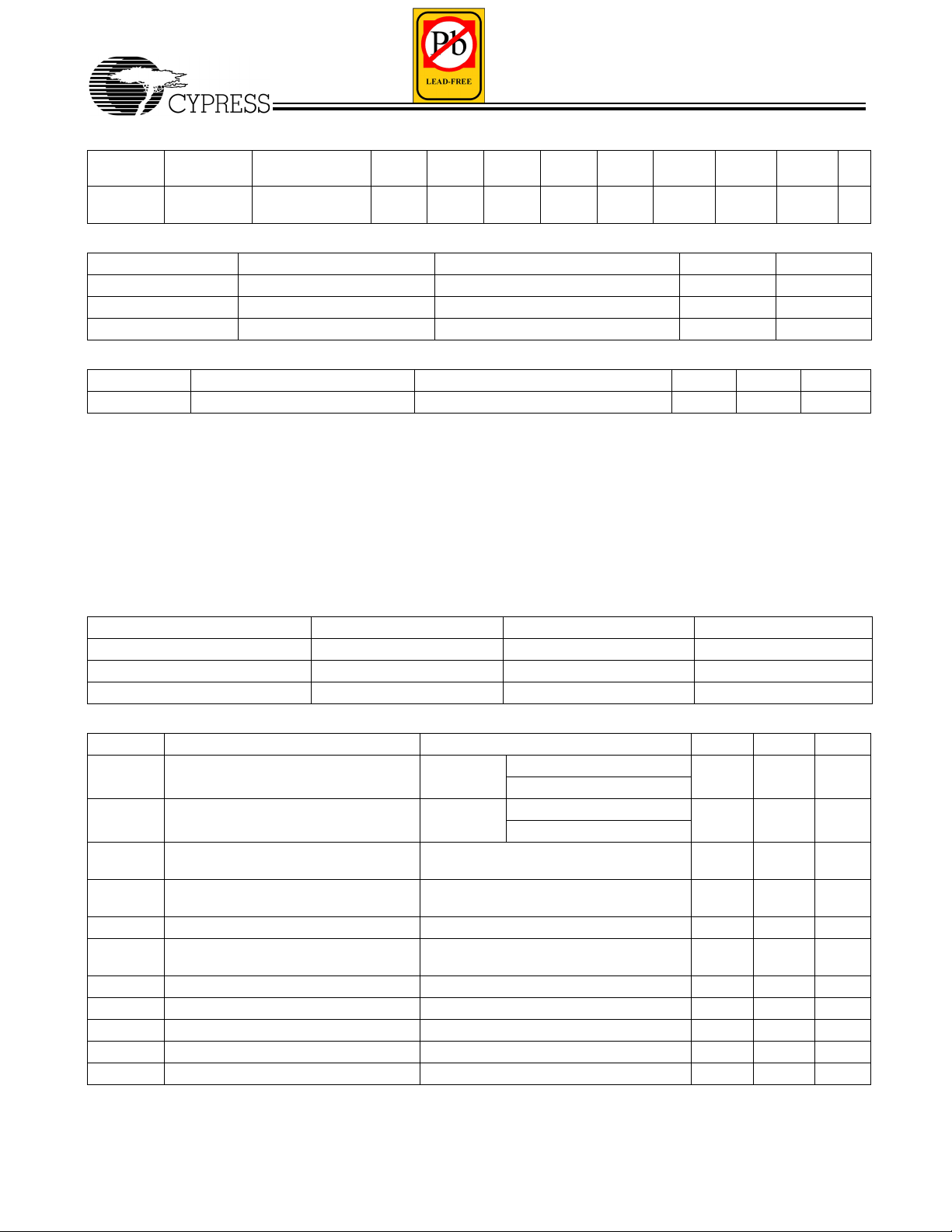

Ultra37000 CPLD Family

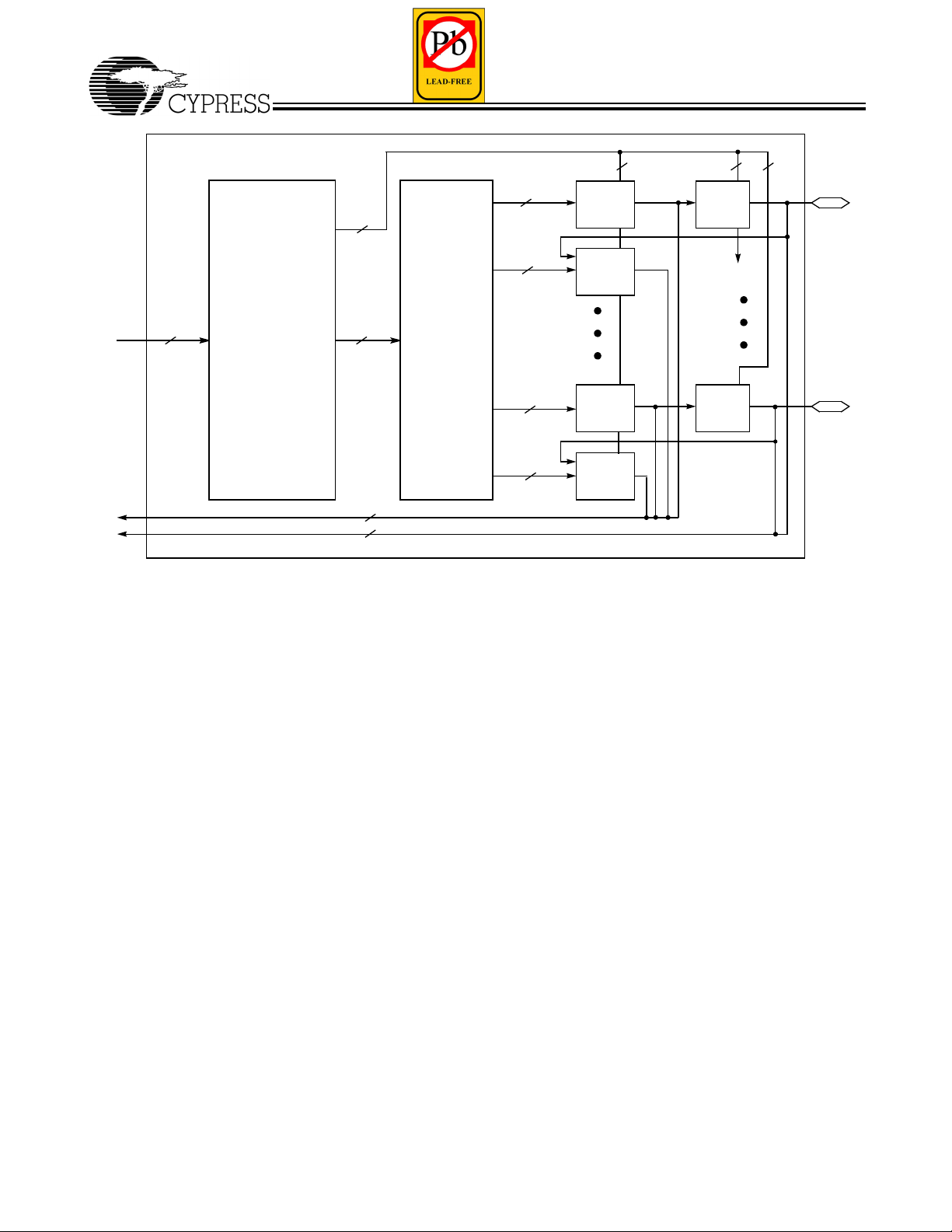

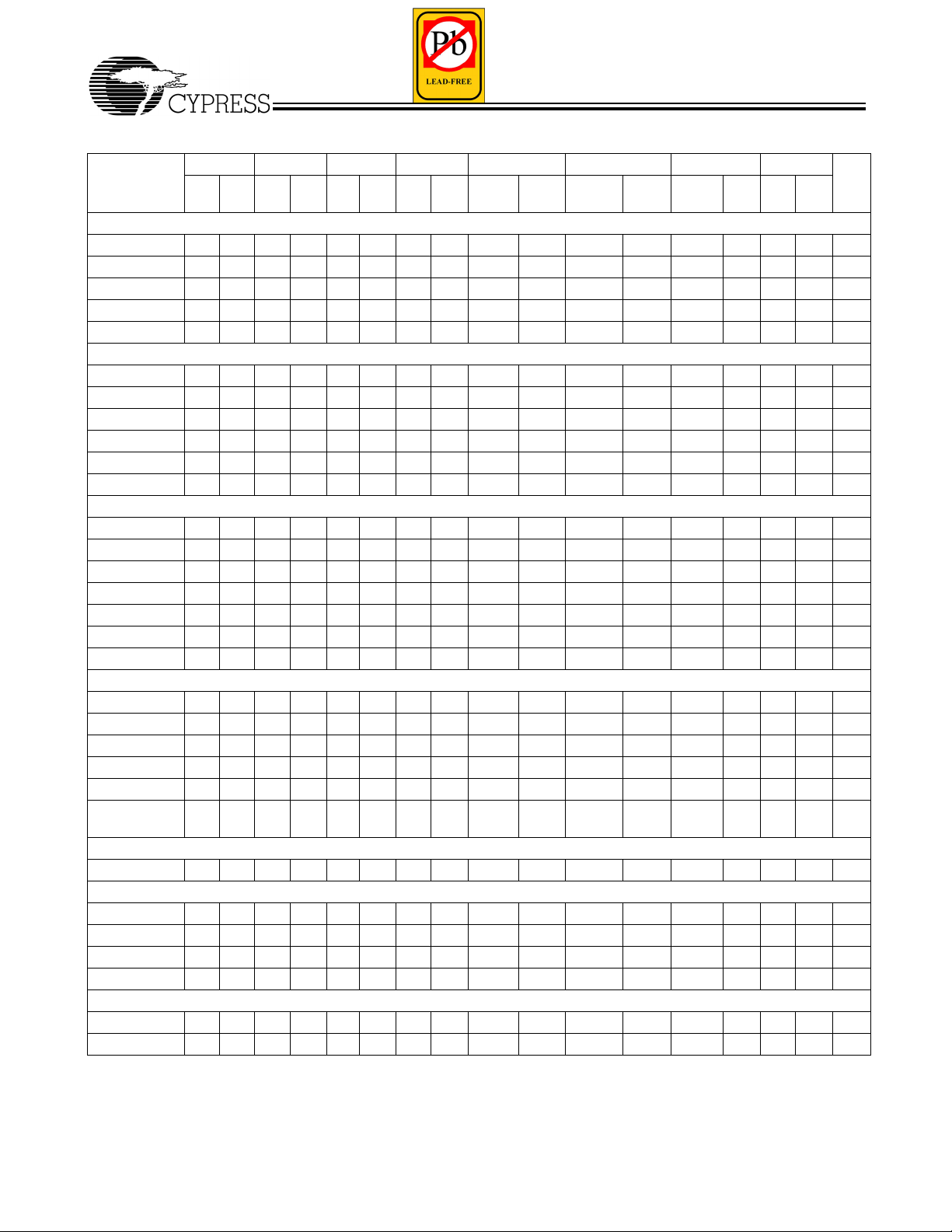

Speed Bins

Device 200 167 154 143 125 100 83 66

CY37032V X X

CY37064V X X

CY37128V X X

CY37192V XX

CY37256V XX

CY37384V XX

CY37512V XX

Device-Package Offering and I/O Count

Device

44-

44-

Lead

TQFP

48-

Lead

CLCC

84-

Lead

FBGA

100-

Lead

CLCC

100-

Lead

TQFP

160-

Lead

FBGA

160-

Lead

TQFP

208-

Lead

CQFP

Lead

208-

PQFP

292-

Lead

CQFP

Lead

256-

PBGA

388-

Lead

Lead

FBGA

PBGA

CY37032V 37 37

CY37064V 37 37 37 69 69

CY37128V 69 69 85 133

CY37192V 125

CY37256V 133 133 165 197 197

CY37384V 165 197

CY37512V 165 165 197 269 269

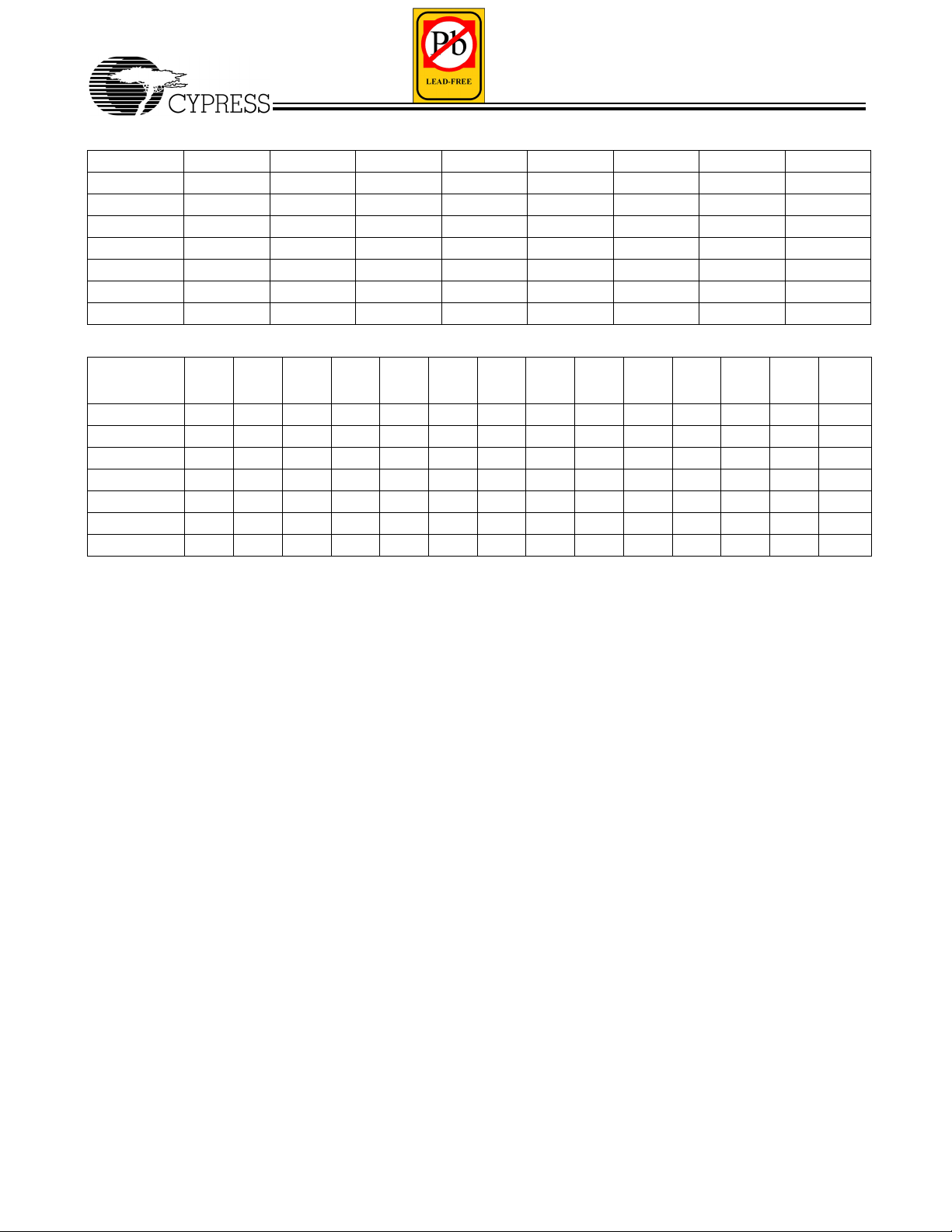

Architecture Overview of Ultra37000 Family

Programmable Interconnect Matrix

The PIM consists of a completely global routing matrix for

signals from I/O pins and feedbacks from the logic blocks. The

PIM provides extremely robust interconnection to avoid fitting

and density limitations.

The inputs to the PIM consist of all I/O and dedicated input pins

and all macrocell feedbacks from within the logic blocks. The

number of PIM inputs increases with pin count and the number

of logic blocks. The outputs from the PIM are signals routed to

the appropriate logic blocks. Each logic block receives 36

inputs from the PIM and their complements, allowing for 32-bit

operations to be implemented in a single pass through the

device. The wide number of inputs to the logic block also

improves the routing capacity of the Ultra37000 family.

An important feature of the PIM is its simple timing. The propagation delay through the PIM is accounted for in the timing

specifications for each device. There is no additional delay for

traveling through the PIM. In fact, all inputs travel through the

PIM. As a result, there are no route-dependent timing parameters on the Ultra37000 devices. The worst-case PIM delays

are incorporated in all appropriate Ultra37000 specifications.

Routing signals through the PIM is completely invisible to the

user. All routing is accomplished by software—no hand routing

is necessary. Warp

automatically route designs for the Ultra37000 family in a

matter of minutes. Finally, the rich routing resources of the

Ultra37000 family accommodate last minute logic changes

while maintaining fixed pin assignments.

®

and third-party development packages

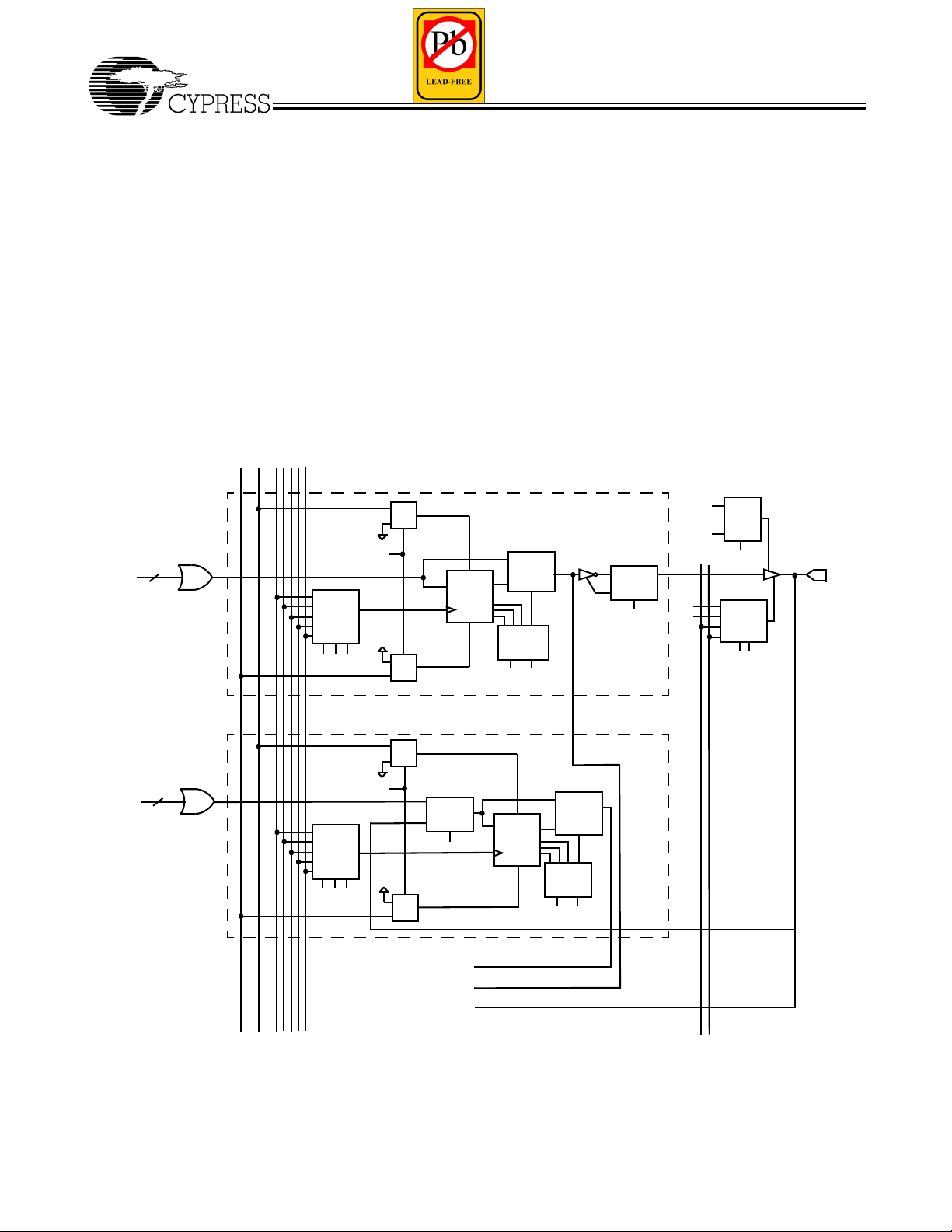

Logic Block

The logic block is the basic building block of the Ultra37000

architecture. It consists of a product term array, an intelligent

product-term allocator, 16 macrocells, and a number of I/O

cells. The number of I/O cells varies depending on the device

used. Refer to Figure 1 for the block diagram.

Product Term Array

Each logic block features a 72 x 87 programmable product

term array. This array accepts 36 inputs from the PIM, which

originate from macrocell feedbacks and device pins. Active

LOW and active HIGH versions of each of these inputs are

generated to create the full 72-input field. The 87 product

terms in the array can be created from any of the 72 inputs.

Of the 87 product terms, 80 are for general-purpose use for

the 16 macrocells in the logic block. Four of the remaining

seven product terms in the logic block are output enable (OE)

product terms. Each of the OE product terms controls up to

eight of the 16 macrocells and is selectable on an individual

macrocell basis. In other words, each I/O cell can select

between one of two OE product terms to control the output

buffer. The first two of these four OE product terms are

available to the upper half of the I/O macrocells in a logic block.

The other two OE product terms are available to the lower half

of the I/O macrocells in a logic block.

The next two product terms in each logic block are dedicated

asynchronous set and asynchronous reset product terms. The

final product term is the product term clock. The set, reset, OE

and product term clock have polarity control to realize OR

functions in a single pass through the array.

400-

Lead

FBGA

Document #: 38-03007 Rev. *E Page 3 of 64

[+] Feedback

Page 4

FROM

PIM

72 x 87

PRODUCT TERM

ARRAY

Ultra37000 CPLD Family

2

3

0−16

PRODUCT

TERMS

7

8036

PRODUCT

TERM

ALLOCATOR

0−16

PRODUCT

TERMS

MACRO-

CELL

0

MACRO-

CELL

1

I/O

CELL

0

to cells

2

2, 4, 6 8, 10, 12

TO

PIM

16

8

Figure 1. Logic Block with 50% Buried Macrocells

Low-Power Option

Each logic block can operate in high-speed mode for critical

path performance, or in low-power mode for power conservation. The logic block mode is set by the user on a logic block

by logic block basis.

Product Term Allocator

Through the product term allocator, software automatically

distributes product terms among the 16 macrocells in the logic

block as needed. A total of 80 product terms are available from

the local product term array. The product term allocator

provides two important capabilities without affecting performance: product term steering and product term sharing.

Product Term Steering

Product term steering is the process of assigning product

terms to macrocells as needed. For example, if one macrocell

requires ten product terms while another needs just three, the

product term allocator will “steer” ten product terms to one

macrocell and three to the other. On Ultra37000 devices,

product terms are steered on an individual basis. Any number

between 0 and 16 product terms can be steered to any

macrocell. Note that 0 product terms is useful in cases where

a particular macrocell is unused or used as an input register.

Product Term Sharing

Product term sharing is the process of using the same product

term among multiple macrocells. For example, if more than

one output has one or more product terms in its equation that

are common to other outputs, those product terms are only

programmed once. The Ultra37000 product term allocator

allows sharing across groups of four output macrocells in a

0−16

PRODUCT

TERMS

0−16

PRODUCT

TERMS

MACRO-

CELL

14

MACRO-

CELL

15

I/O

CELL

14

variable fashion. The software automatically takes advantage

of this capability—the user does not have to intervene.

Note that neither product term sharing nor product term

steering have any effect on the speed of the product. All

worst-case steering and sharing configurations have been

incorporated in the timing specifications for the Ultra37000

devices.

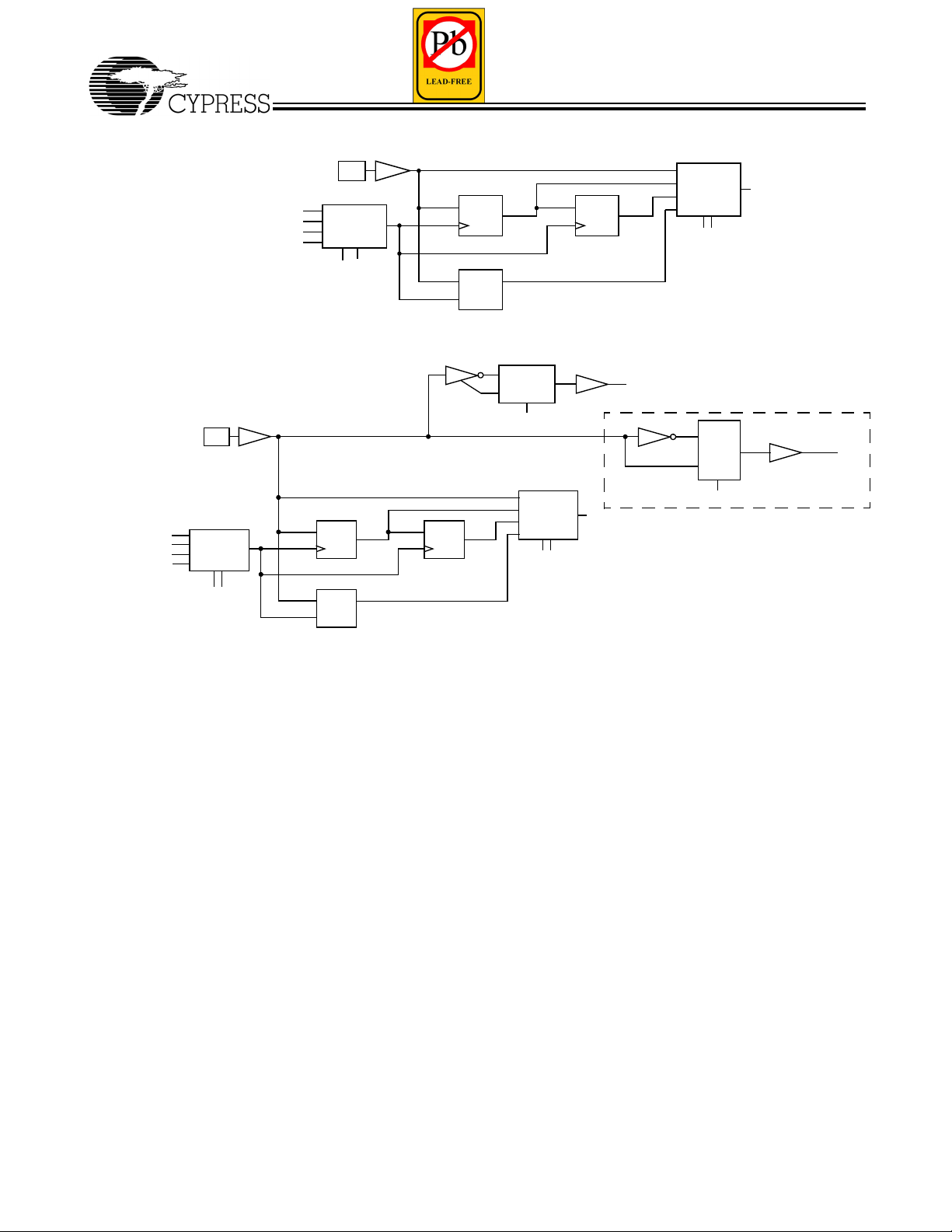

Ultra37000 Macrocell

Within each logic block there are 16 macrocells. Macrocells

can either be I/O Macrocells, which include an I/O Cell which

is associated with an I/O pin, or buried Macrocells, which do

not connect to an I/O. The combination of I/O Macrocells and

buried Macrocells varies from device to device.

Buried Macrocell

Figure 2 displays the architecture of buried macrocells. The

buried macrocell features a register that can be configured as

combinatorial, a D flip-flop, a T flip-flop, or a level-triggered

latch.

The register can be asynchronously set or asynchronously

reset at the logic block level with the separate set and reset

product terms. Each of these product terms features programmable polarity. This allows the registers to be set or reset

based on an AND expression or an OR expression.

Clocking of the register is very flexible. Four global

synchronous clocks and a product term clock are available to

clock the register. Furthermore, each clock features programmable polarity so that registers can be triggered on falling as

well as rising edges (see the Clocking section). Clock polarity

is chosen at the logic block level.

Document #: 38-03007 Rev. *E Page 4 of 64

[+] Feedback

Page 5

Ultra37000 CPLD Family

The buried macrocell also supports input register capability.

The buried macrocell can be configured to act as an input

register (D-type or latch) whose input comes from the I/O pin

associated with the neighboring macrocell. The output of all

buried macrocells is sent directly to the PIM regardless of its

configuration.

I/O Macrocell

Figure 2 illustrates the architecture of the I/O macrocell. The

I/O macrocell supports the same functions as the buried

macrocell with the addition of I/O capability. At the output of the

macrocell, a polarity control mux is available to select active

LOW or active HIGH signals. This has the added advantage

of allowing significant logic reduction to occur in many applications.

The Ultra37000 macrocell features a feedback path to the PIM

separate from the I/O pin input path. This means that if the

macrocell is buried (fed back internally only), the associated

I/O pin can still be used as an input.

I/O MACROCELL

FROM PTM

0−16

PRODUCT

TERMS

0

1

2

3

4

C24

C0

C1

0

1

C25

D/T/L

O

1

0

Bus Hold Capabilities on all I/Os

Bus-hold, which is an improved version of the popular internal

pull-up resistor, is a weak latch connected to the pin that does

not degrade the device’s performance. As a latch, bus-hold

maintains the last state of a pin when the pin is placed in a

high-impedance state, thus reducing system noise in

bus-interface applications. Bus-hold additionally allows

unused device pins to remain unconnected on the board,

which is particularly useful during prototyping as designers can

route new signals to the device without cutting trace connections to V

note Understanding Bus-Hold—A Feature of Cypress CPLDs.

or GND. For more information, see the application

CC

Programmable Slew Rate Control

Each output has a programmable configuration bit, which sets

the output slew rate to fast or slow. For designs concerned with

meeting FCC emissions standards the slow edge provides for

lower system noise. For designs requiring very high performance the fast edge rate provides maximum system performance.

FAST

SLEW

SLOW

0

1

DECODE

C2 C3

O

P

Q

R

O

0

1

C4

“0”

“1”

C26

0

1

2

3

C6 C5

I/O CELL

O

BURIED MACROCELL

FROM PTM

0−16

PRODUCT

TERMS

ASYNCHRONOUS

BLOCK RESET

ASYNCHRONOUS

BLOCK PRESET

0

1

2

3

4

C24

C0

C1

4 SYNCHRONOUS CLOCKS (CLK0,CLK1,CLK2,CLK3)

1 ASYNCHRONOUS CLOCK(PTCLK)

0

1

C25

0

O

1

Q

1

0

C7

D/T/L Q

FEEDBACK TO PIM

FEEDBACK TO PIM

FEEDBACK TO PIM

0

1

DECODE

C2 C3

O

OE0

OE1

P

R

Figure 2. I/O and Buried Macrocells

Document #: 38-03007 Rev. *E Page 5 of 64

[+] Feedback

Page 6

FROM CLOCK

POLARITY MUXES

0

1

2

3

C10

INPUT PIN

O

C11

D

Q

D

Q

LE

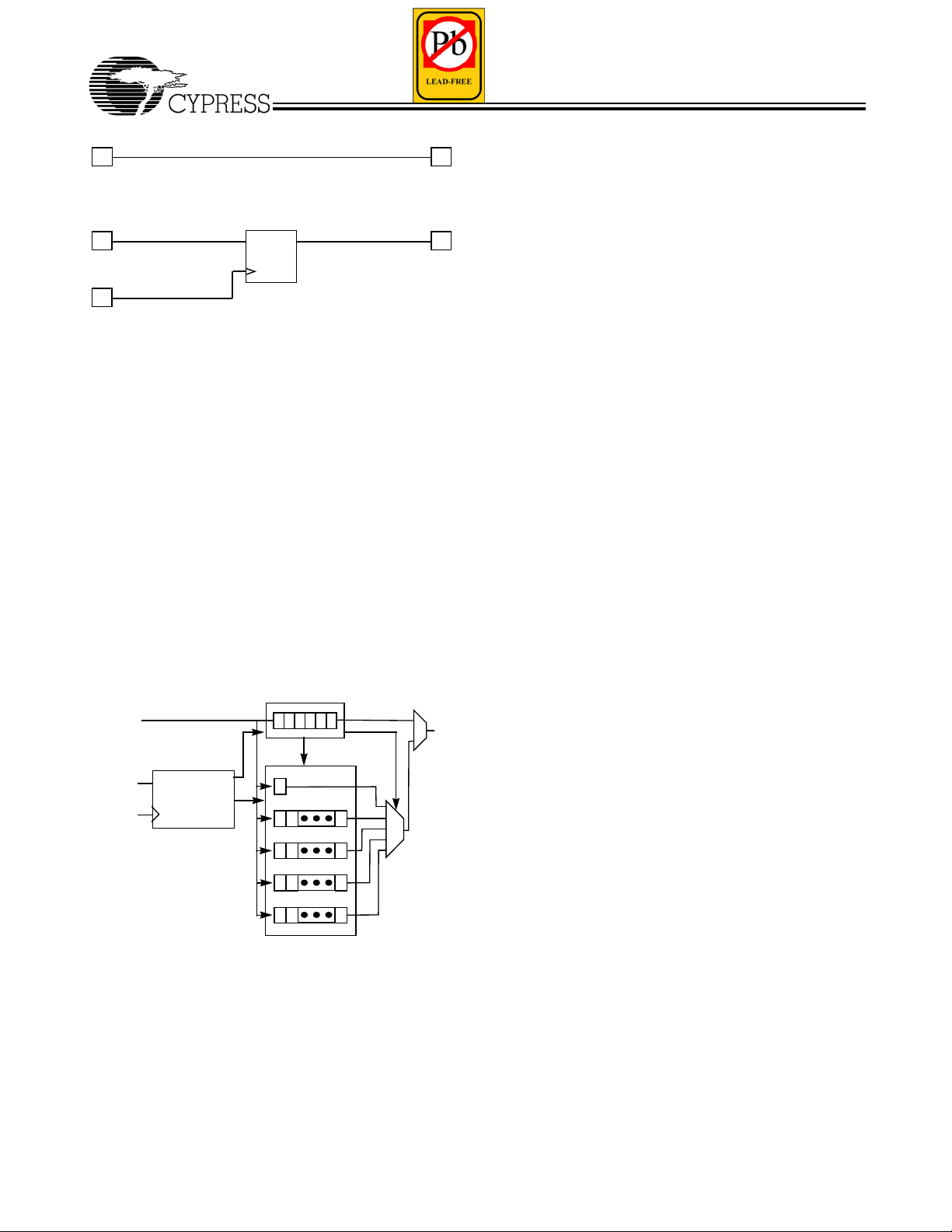

Figure 3. Input Macrocell

Ultra37000 CPLD Family

0

1

O

D

Q

2

3

C12 C13

TO PIM

INPUT/CLOCK PIN

FROM CLOCK

POLARITY INPUT

CLOCK PINS

0

1

O

2

3

C8

C9

D

Q

D

Q

LE

D

Figure 4. Input/Clock Macrocell

Clocking

Each I/O and buried macrocell has access to four synchronous

clocks (CLK0, CLK1, CLK2 and CLK3) as well as an

asynchronous product term clock PTCLK. Each input

macrocell has access to all four synchronous clocks.

Dedicated Inputs/Clocks

Five pins on each member of the Ultra37000 family are designated as input-only. There are two types of dedicated inputs

on Ultra37000 devices: input pins and input/clock pins.

Figure 3 illustrates the architecture for input pins. Four input

options are available for the user: combinatorial, registered,

double-registered, or latched. If a registered or latched option

is selected, any one of the input clocks can be selected for

control.

Figure 4 illustrates the architecture for the input/clock pins.

Like the input pins, input/clock pins can be combinatorial,

registered, double-registered, or latched. In addition, these

pins feed the clocking structures throughout the device. The

clock path at the input has user-configurable polarity.

Product Term Clocking

In addition to the four synchronous clocks, the Ultra37000

family also has a product term clock for asynchronous

clocking. Each logic block has an independent product term

clock which is available to all 16 macrocells. Each product term

clock also supports user configurable polarity selection.

0

O

1

C12

0

1

O

2

Q

3

C10C11

TO CLOCK MUX ON

ALL INPUT MACROCELLS

TO PIM

0

O

1

C13, C14, C15 OR C16

CLOCK POLARITY MUX

ONE PER LOGIC BLOCK

FOR EACH CLOCK INPUT

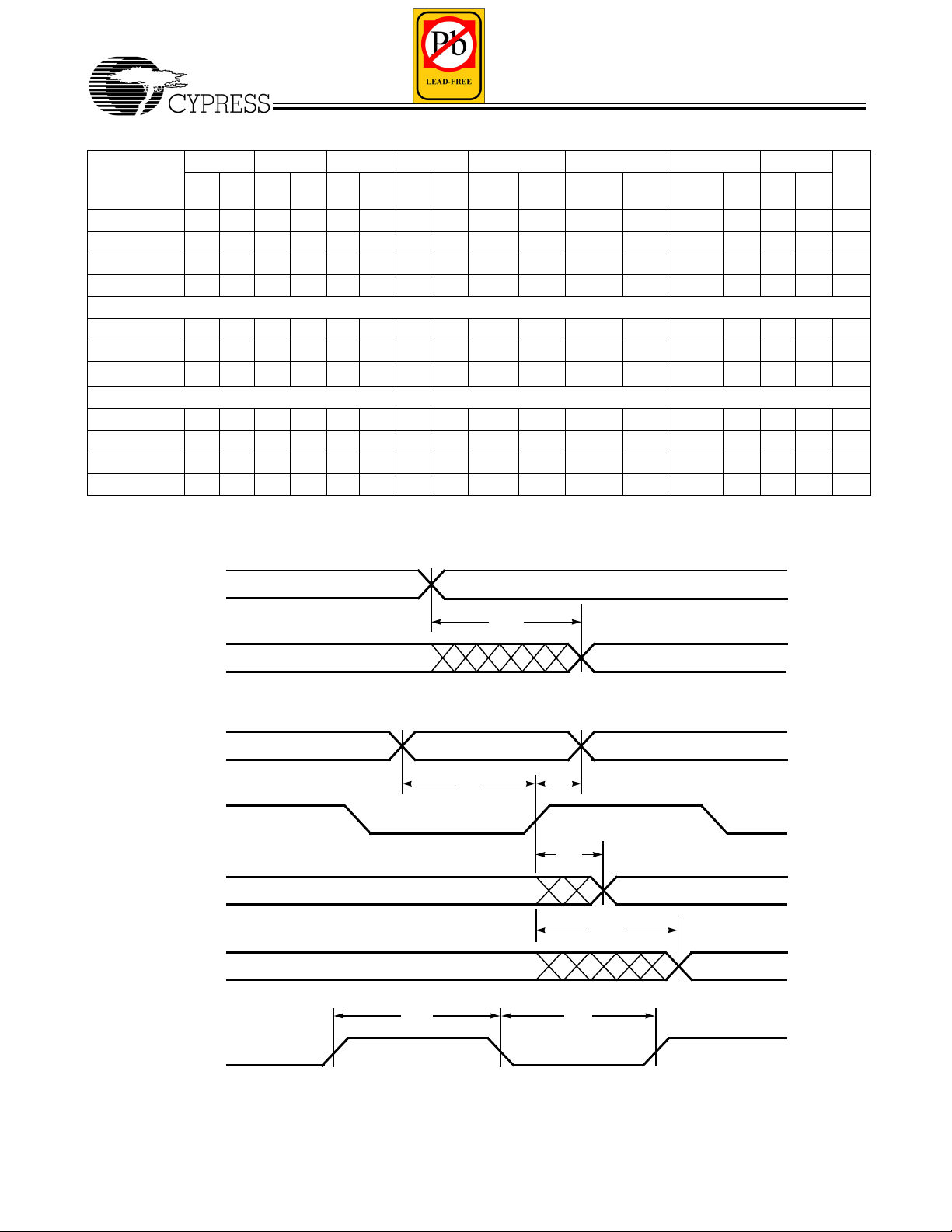

Timing Model

One of the most important features of the Ultra37000 family is

the simplicity of its timing. All delays are worst case and

system performance is unaffected by the features used.

Figure 5 illustrates the true timing model for the 167-MHz

devices in high speed mode. For combinatorial paths, any

input to any output incurs a 6.5-ns worst-case delay regardless

of the amount of logic used. For synchronous systems, the

input set-up time to the output macrocells for any input is 3.5

ns and the clock to output time is also 4.0 ns. These measurements are for any output and synchronous clock, regardless

of the logic used.

The Ultra37000 features:

• No fanout delays

• No expander delays

• No dedicated vs. I/O pin delays

• No additional delay through PIM

• No penalty for using 0–16 product terms

• No added delay for steering product terms

• No added delay for sharing product terms

• No routing delays

• No output bypass delays

The simple timing model of the Ultra37000 family eliminates

unexpected performance penalties.

TO CLOCK MUX

IN EACH

LOGIC BLOCK

Document #: 38-03007 Rev. *E Page 6 of 64

[+] Feedback

Page 7

Ultra37000 CPLD Family

COMBINATORIAL SIGNAL

t

= 6.5 ns

INPUT

tS = 3.5 ns

INPUT

CLOCK

PD

REGISTERED SIGNAL

D,T,L O

t

CO

OUTPUT

= 4.5 ns

OUTPUT

Figure 5. Timing Model for CY37128

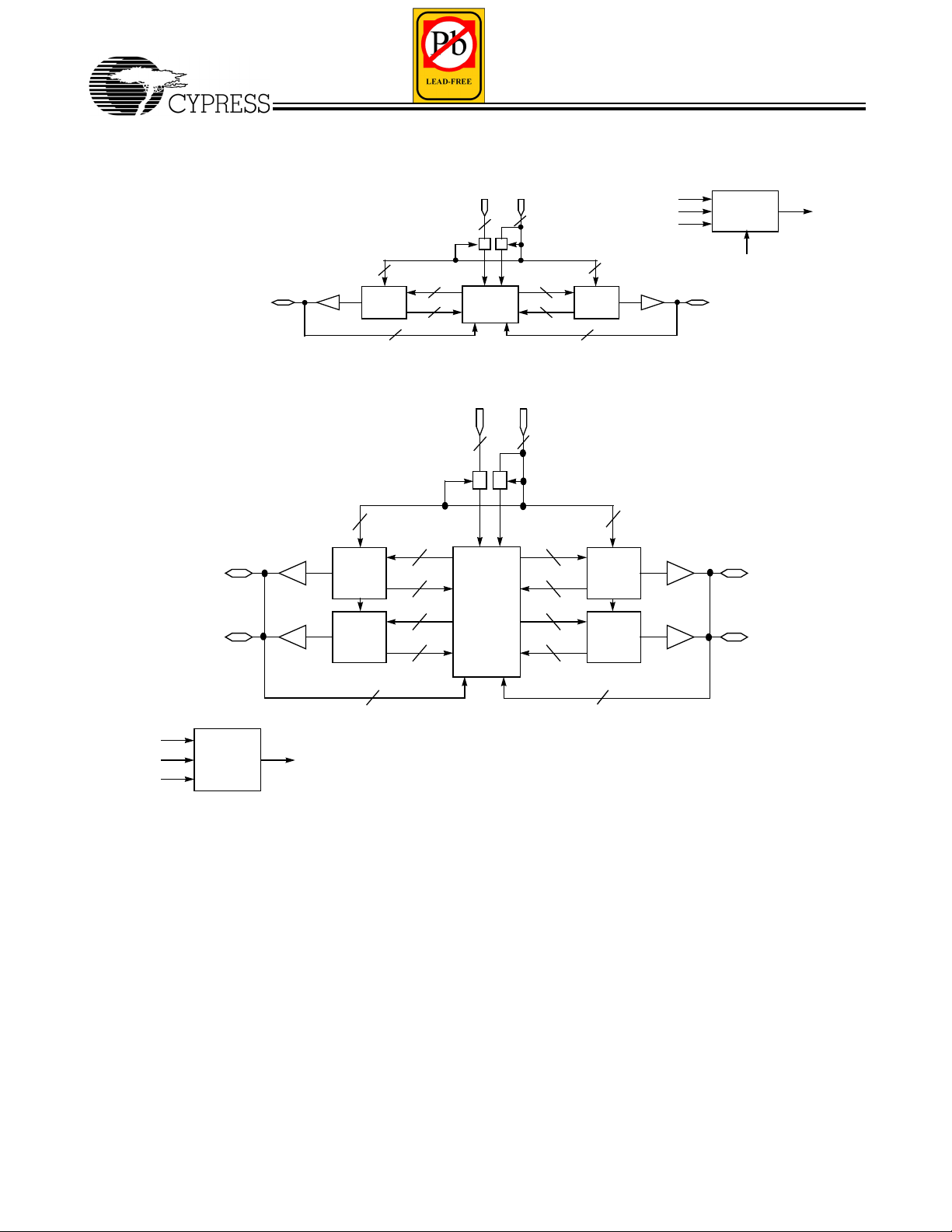

JTAG and PCI Standards

PCI Compliance

5V operation of the Ultra37000 is fully compliant with the PCI

Local Bus Specification published by the PCI Special Interest

Group. The 3.3V products meet all PCI requirements except

for the output 3.3V clamp, which is in direct conflict with 5V

tolerance. The Ultra37000 family’s simple and predictable

timing model ensures compliance with the PCI AC specifications independent of the design.

IEEE 1149.1-compliant JTAG

The Ultra37000 family has an IEEE 1149.1 JTAG interface for

both Boundary Scan and ISR.

Boundary Scan

The Ultra37000 family supports Bypass, Sample/Preload,

Extest, Idcode, and Usercode boundary scan instructions. The

JTAG interface is shown in Figure 6.

Instruction Register

TDI

TMS

TCK

JTAG

TAP

CONTROLLER

Bypass Reg.

Boundary Scan

idcode

Usercode

ISR Prog.

Data Registers

Figure 6. JTAG Interface

In-System Reprogramming (ISR)

In-System Reprogramming is the combination of the capability

to program or reprogram a device on-board, and the ability to

support design changes without changing the system timing

or device pinout. This combination means design changes

during debug or field upgrades do not cause board respins.

The Ultra37000 family implements ISR by providing a JTAG

compliant interface for on-board programming, robust routing

TDO

resources for pinout flexibility, and a simple timing model for

consistent system performance.

Development Software Support

Warp

Warp is a state-of-the-art compiler and complete CPLD design

tool. For design entry, Warp provides an IEEE-STD-1076/1164

VHDL text editor, an IEEE-STD-1364 Verilog text editor, and a

graphical finite state machine editor. It provides optimized

synthesis and fitting by replacing basic circuits with ones

pre-optimized for the target device, by implementing logic in

unused memory and by perfect communication between fitting

and synthesis. To facilitate design and debugging, Warp

provides graphical timing simulation and analysis.

Warp Professional

Warp Professional contains several additional features. It

provides an extra method of design entry with its graphical

block diagram editor. It allows up to 5 ms timing simulation

instead of only 2 ms. It allows comparison of waveforms before

and after design changes.

Warp Enterprise

Warp Enterprise provides even more features. It provides

unlimited timing simulation and source-level behavioral

simulation as well as a debugger. It has the ability to generate

graphical HDL blocks from HDL text. It can even generate

testbenches.

Warp is available for PC and UNIX platforms. Some features

are not available in the UNIX version. For further information

see the Warp for PC, Warp for UNIX, Warp Professional and

Warp Enterprise data sheets on Cypress’s web site

(www.cypress.com).

Third-Party Software

Although Warp is a complete CPLD development tool on its

own, it interfaces with nearly every third party EDA tool. All

major third-party software vendors provide support for the

Ultra37000 family of devices. Refer to the third-party software

data sheet or contact your local sales office for a list of

currently supported third-party vendors.

Programming

There are four programming options available for Ultra37000

devices. The first method is to use a PC with the 37000

UltraISR programming cable and software. With this method,

the ISR pins of the Ultra37000 devices are routed to a

connector at the edge of the printed circuit board. The 37000

UltraISR programming cable is then connected between the

parallel port of the PC and this connector. A simple configuration file instructs the ISR software of the programming

operations to be performed on each of the Ultra37000 devices

in the system. The ISR software then automatically completes

all of the necessary data manipulations required to accomplish

the programming, reading, verifying, and other ISR functions.

For more information on the Cypress ISR Interface, see the

ISR Programming Kit data sheet (CY3700i).

The second method for programming Ultra37000 devices is on

automatic test equipment (ATE). This is accomplished through

a file created by the ISR software. Check the Cypress website

for the latest ISR software download information.

™

™

Document #: 38-03007 Rev. *E Page 7 of 64

[+] Feedback

Page 8

Ultra37000 CPLD Family

The third programming option for Ultra37000 devices is to

utilize the embedded controller or processor that already

exists in the system. The Ultra37000 ISR software assists in

this method by converting the device JEDEC maps into the

ISR serial stream that contains the ISR instruction information

and the addresses and data of locations to be programmed.

The embedded controller then simply directs this ISR stream

to the chain of Ultra37000 devices to complete the desired

reconfiguring or diagnostic operations. Contact your local

sales office for information on availability of this option.

The fourth method for programming Ultra37000 devices is to

use the same programmer that is currently being used to

program F

For all pinout, electrical, and timing requirements, refer to

device data sheets. For ISR cable and software specifications,

refer to the UltraISR kit data sheet (CY3700i).

Third-Party Programmers

As with development software, Cypress support is available on

a wide variety of third-party programmers. All major third-party

programmers (including BP Micro, Data I/O, and SMS) support

the Ultra37000 family.

LASH370i devices.

Document #: 38-03007 Rev. *E Page 8 of 64

[+] Feedback

Page 9

Logic Block Diagrams

Ultra37000 CPLD Family

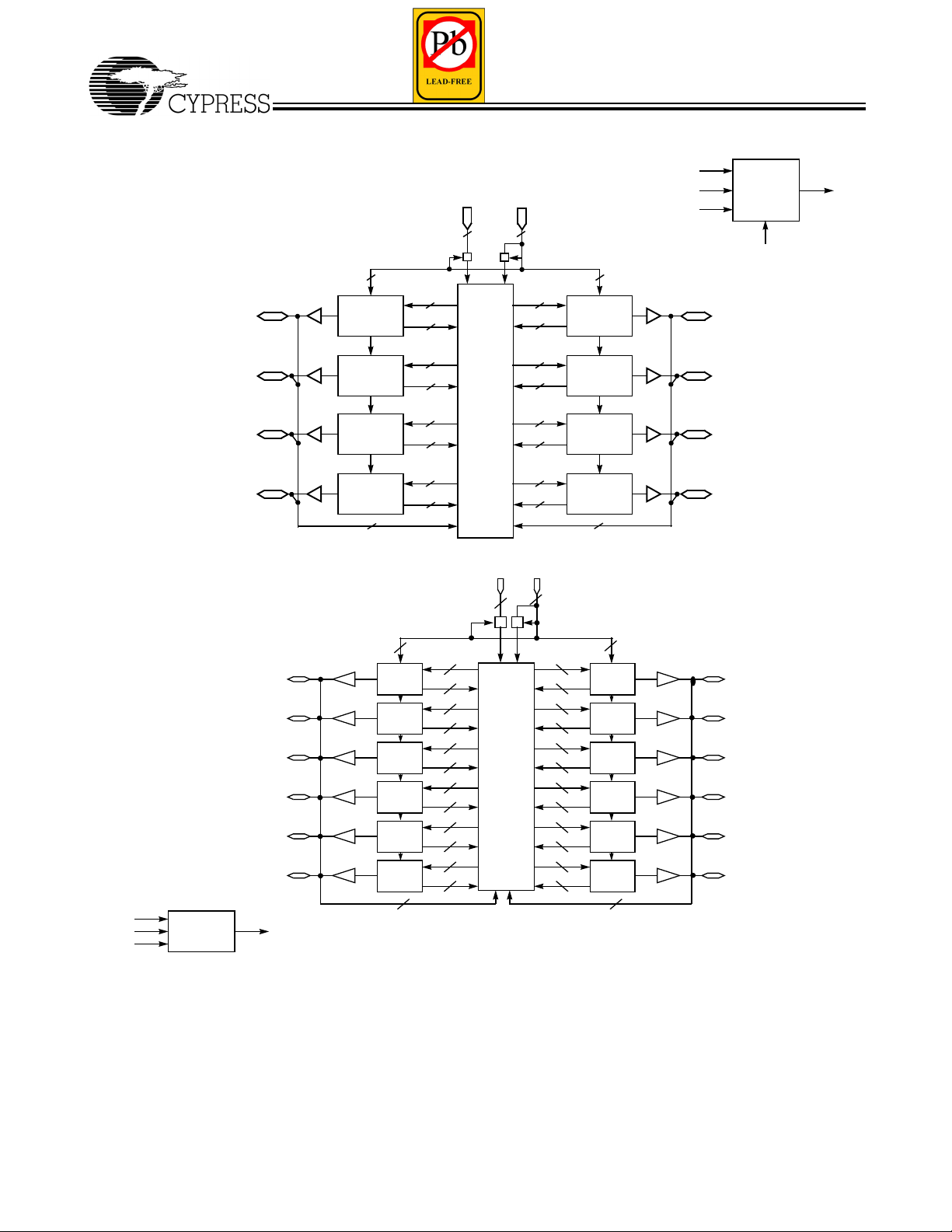

CY37032/CY37032V

I/O

CY37064/CY37064V

-I/O

I/O

0

15

I/O16-I/O

31

−I/O

0

16 I/Os

16 I/Os

16 I/Os

15

BLOCK

4

LOGIC

BLOCK

A

LOGIC

BLOCK

B

4

LOGIC

A

Clock/

Input

Input

1

36

16

16

PIM

4

36

LOGIC

BLOCK

16

B

16

TDI

TCK

TMS

4

16 I/Os

JTAG Tap

Controller

JTAG

I/O16−I/O

TDO

EN

31

Clock/

Input

Input

1

4

4

36

16

36

16

LOGIC

BLOCK

16 I/Os

I/O48-I/O

63

D

36

16

PIM

36

16

LOGIC

BLOCK

16 I/Os

I/O32-I/O

47

C

TDI

TCK

TMS

JTAG Tap

Controller

TDO

32

32

Document #: 38-03007 Rev. *E Page 9 of 64

[+] Feedback

Page 10

Logic Block Diagrams (continued)

Ultra37000 CPLD Family

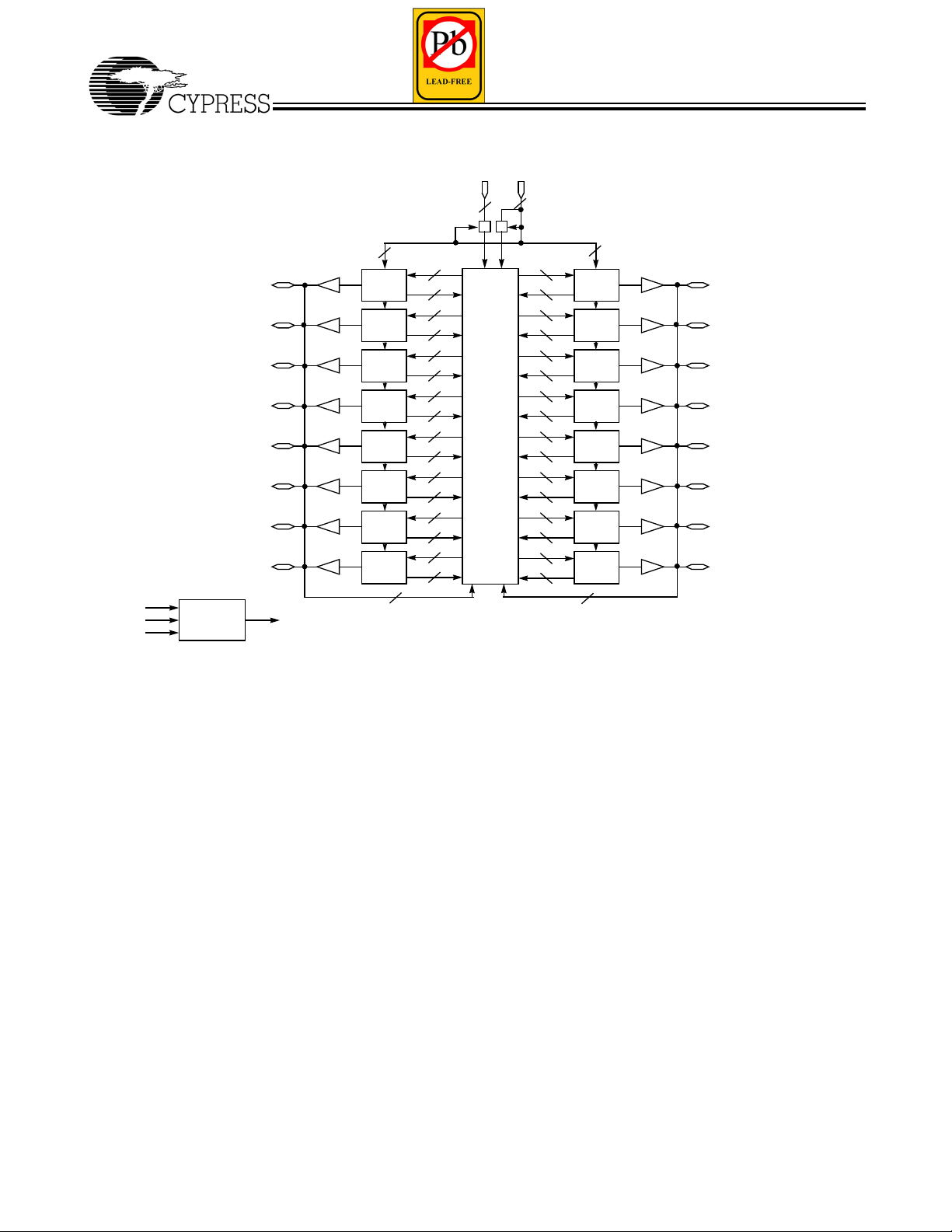

CY37128/CY37128V

I/O

–I/O

0

I/O16–I/O

I/O32–I/O

I/O28–I/O

CY37192/CY37192V

15

31

47

63

16 I/Os

16 I/Os

16 I/Os

16 I/Os

CLOCK

INPUTS

INPUTS

41

INPUT

MACROCELL

INPUT/CLOCK

MACROCELLS

4 4

LOGIC

BLOCK

A

LOGIC

BLOCK

B

LOGIC

BLOCK

C

LOGIC

BLOCK

D

64

36

16

36

16

PIM

36

16

36

16

36 36

Input

1

16

36

16

Clock/

Input

16

36

16

LOGIC

BLOCK

LOGIC

BLOCK

LOGIC

BLOCK

LOGIC

BLOCK

64

4

TDI

TCK

TMS

JTAG Tap

Controller

JTAG

EN

TDO

16 I/Os

I/O

–I/O

112

H

16 I/Os

G

I/O96–I/O

127

111

16 I/Os

F

I/O80–I/O

95

16 I/Os

E

I/O64–I/O

79

TDI

TCK

TMS

JTAG Tap

Controller

–I/O

I/O

0

I/O10–I/O

I/O20–I/O

I/O30–I/O

I/O40–I/O

I/O50–I/O

10 I/Os

9

10 I/Os

19

10 I/Os

29

10 I/Os

39

10 I/Os

49

10 I/Os

59

TDO

LOGIC

BLOCK

L

LOGIC

BLOCK

K

LOGIC

BLOCK

J

LOGIC

BLOCK

I

LOGIC

BLOCK

H

LOGIC

BLOCK

G

6060

4

10 I/Os

I/O

–I/O

110

119

10 I/Os

I/O

–I/O

100

109

10 I/Os

I/O90–I/O

99

10 I/Os

I/O80–I/O

89

10 I/Os

I/O70–I/O

79

10 I/Os

I/O60–I/O

69

4

LOGIC

BLOCK

A

LOGIC

BLOCK

B

LOGIC

BLOCK

C

LOGIC

BLOCK

D

LOGIC

BLOCK

E

LOGIC

BLOCK

F

36

16

36

16

36

16

36

16

36

16

36

16

PIM

36

16

36

16

36

16

36

16

36

16

36

16

Document #: 38-03007 Rev. *E Page 10 of 64

[+] Feedback

Page 11

Logic Block Diagrams (continued)

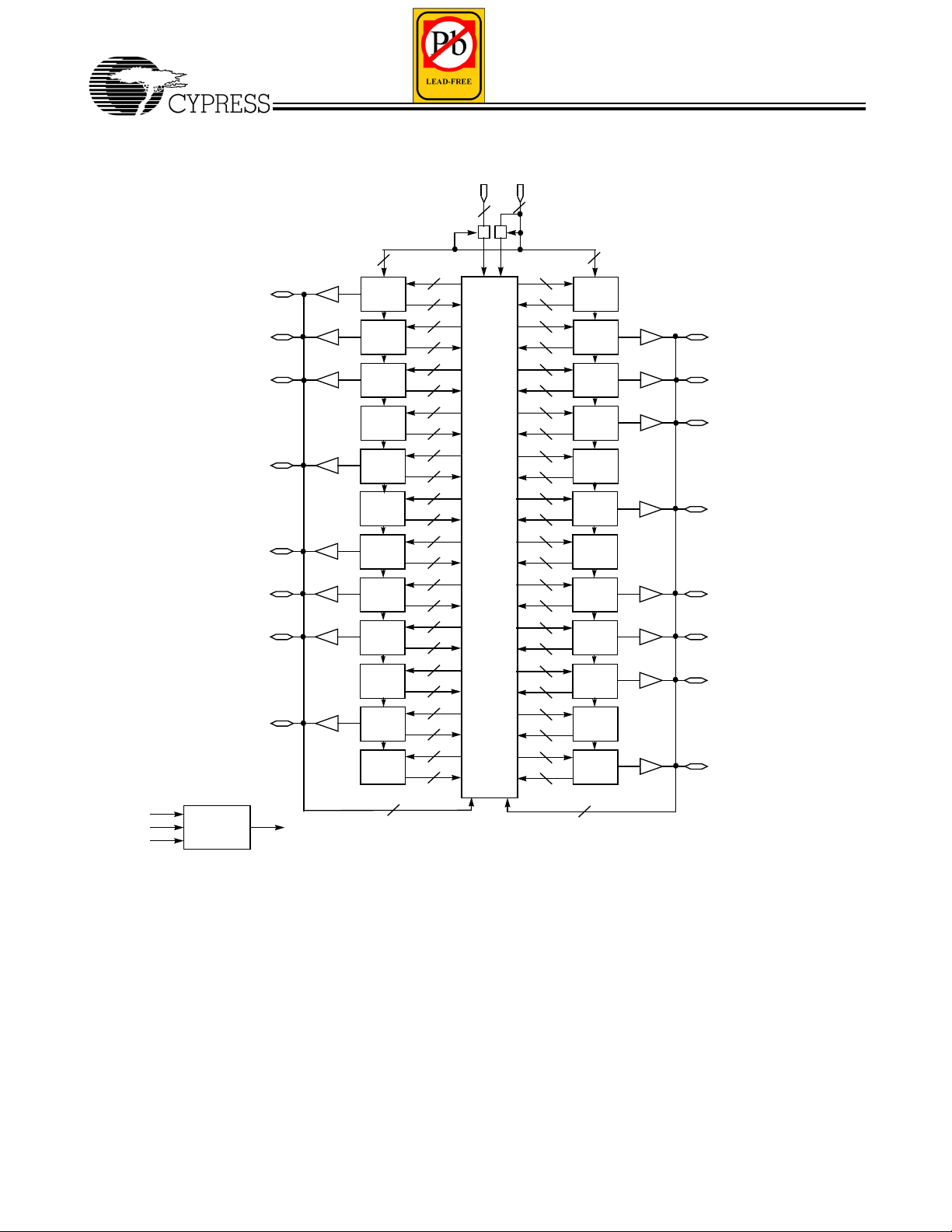

CY37256/CY37256V

Input

1

Clock/

Input

Ultra37000 CPLD Family

4

TDI

TCK

TMS

I/O

I/O12−I/O

I/O24−I/O

I/O36−I/O

I/O48−I/O

I/O60−I/O

I/O72−I/O

I/O84−I/O

JTAG Tap

Controller

0

−I/O

12 I/Os

11

12 I/Os

23

12 I/Os

35

12 I/Os

47

12 I/Os

59

12 I/Os

71

12 I/Os

83

12 I/Os

95

TDO

4

LOGIC

BLOCK

A

LOGIC

BLOCK

B

LOGIC

BLOCK

C

LOGIC

BLOCK

D

LOGIC

BLOCK

E

LOGIC

BLOCK

F

LOGIC

BLOCK

G

LOGIC

BLOCK

H

36

16

36

16

36

16

36

16

36

PIM

16

36

16

36

16

36

16

96

36

LOGIC

BLOCK

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

P

LOGIC

BLOCK

O

LOGIC

BLOCK

N

LOGIC

BLOCK

M

LOGIC

BLOCK

L

LOGIC

BLOCK

K

LOGIC

BLOCK

J

LOGIC

BLOCK

I

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

I/O

−I/O

180

I/O

−I/O

168

I/O

−I/O

156

I/O

−I/O

144

I/O

−I/O

132

I/O

−I/O

120

I/O

−I/O

108

I/O96−I/O

191

179

167

155

143

131

119

107

96

4

Document #: 38-03007 Rev. *E Page 11 of 64

[+] Feedback

Page 12

Logic Block Diagrams (continued)

Ultra37000 CPLD Family

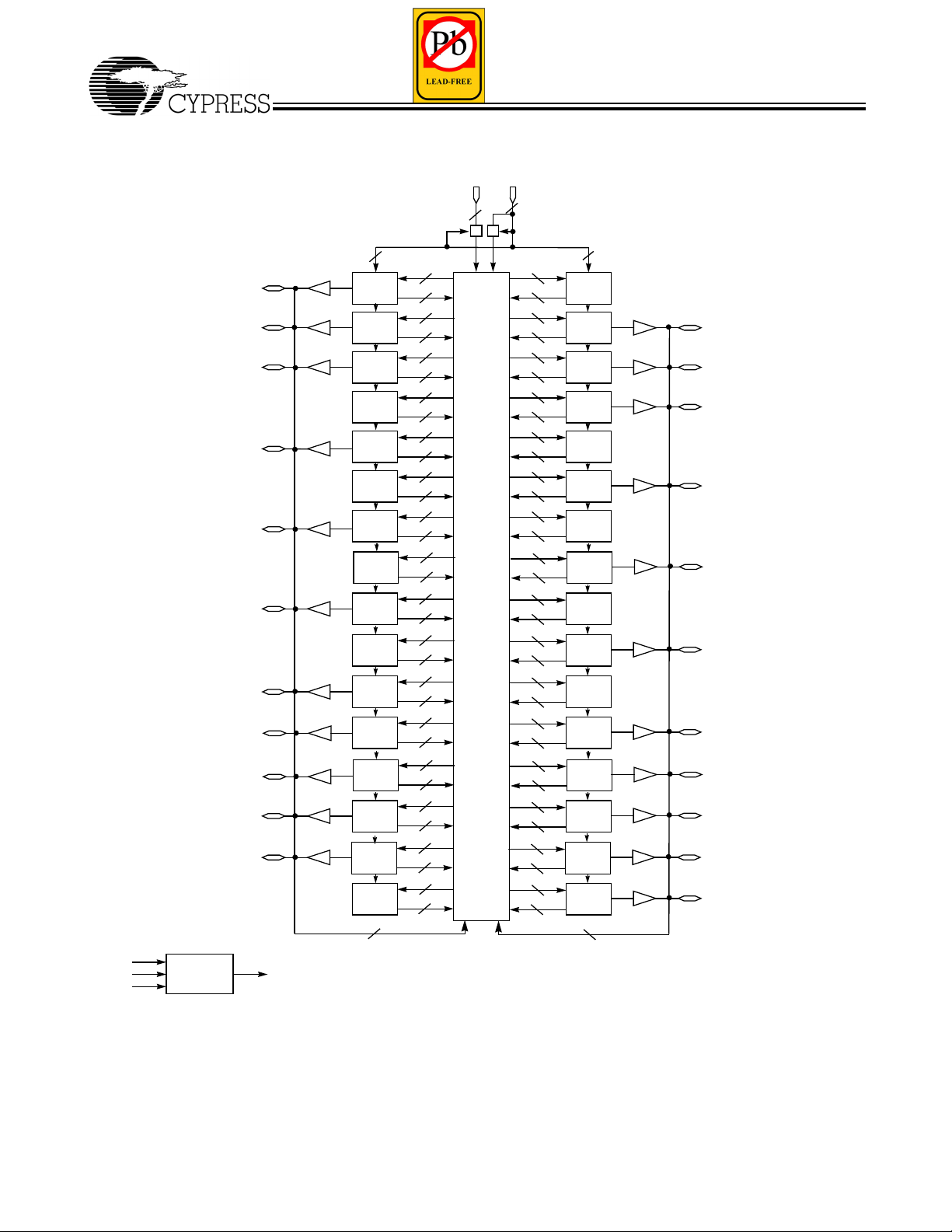

CY37384/CY37384V

I/O

0

I/O12−I/O

I/O24−I/O

I/O

36

I/O48−I/O

I/O60−I/O

I/O72−I/O

I/O

84

−I/O

−I/O

−I/O

12 I/Os

11

12 I/Os

23

12 I/Os

35

12 I/Os

47

12 I/Os

59

12 I/Os

71

12 I/Os

83

12 I/Os

95

4

LOGIC

BLOCK

AA

LOGIC

BLOCK

AB

LOGIC

BLOCK

AC

LOGIC

BLOCK

AD

LOGIC

BLOCK

AE

LOGIC

BLOCK

AF

LOGIC

BLOCK

AG

LOGIC

BLOCK

AH

LOGIC

BLOCK

AI

LOGIC

BLOCK

AJ

LOGIC

BLOCK

AK

LOGIC

BLOCK

AL

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

Input

1

PIM

Clock/

Input

4

4

36

LOGIC

BLOCK

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

BL

LOGIC

BLOCK

BK

LOGIC

BLOCK

BJ

LOGIC

BLOCK

BI

LOGIC

BLOCK

BH

LOGIC

BLOCK

BG

LOGIC

BLOCK

BF

LOGIC

BLOCK

BE

LOGIC

BLOCK

BD

LOGIC

BLOCK

BC

LOGIC

BLOCK

BB

LOGIC

BLOCK

BA

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

168

156

144

132

120

108

96

96

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

191

179

167

155

143

131

119

107

TDI

TCK

TMS

JTAG Tap

Controller

TDO

96

96

Document #: 38-03007 Rev. *E Page 12 of 64

[+] Feedback

Page 13

Logic Block Diagrams (continued)

Ultra37000 CPLD Family

CY37512/CY37512V

I/O

I/O12−I/O

I/O24−I/O

I/O36−I/O

I/O48−I/O

I/O60−I/O

I/O72−I/O

I/O84−I/O

I/O

I/O

108

I/O

120

Input

Clock/

Input

1

4

12 I/Os

−I/O

0

11

12 I/Os

23

12 I/Os

35

12 I/Os

47

12 I/Os

59

12 I/Os

71

12 I/Os

83

12 I/Os

95

12 I/Os

−I/O

96

107

12 I/Os

−I/O

119

12 I/Os

−I/O

131

LOGIC

BLOCK

AA

LOGIC

BLOCK

AB

LOGIC

BLOCK

AC

LOGIC

BLOCK

AD

LOGIC

BLOCK

AE

LOGIC

BLOCK

AF

LOGIC

BLOCK

AG

LOGIC

BLOCK

AH

LOGIC

BLOCK

AI

LOGIC

BLOCK

AJ

LOGIC

BLOCK

AK

LOGIC

BLOCK

AL

LOGIC

BLOCK

AM

LOGIC

BLOCK

AN

LOGIC

BLOCK

AO

LOGIC

BLOCK

AP

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

PIM

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

4

4

36

LOGIC

BLOCK

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

36

16

BP

LOGIC

BLOCK

BO

LOGIC

BLOCK

BN

LOGIC

BLOCK

BM

LOGIC

BLOCK

BL

LOGIC

BLOCK

BK

LOGIC

BLOCK

BJ

LOGIC

BLOCK

BI

LOGIC

BLOCK

BH

LOGIC

BLOCK

BG

LOGIC

BLOCK

BF

LOGIC

BLOCK

BE

LOGIC

BLOCK

BD

LOGIC

BLOCK

BC

LOGIC

BLOCK

BB

LOGIC

BLOCK

BA

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

12 I/Os

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

252

240

228

216

204

192

180

168

156

144

132

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

−I/O

263

251

239

227

215

203

191

179

167

155

143

132132

TDI

TCK

TMS

JTAG Tap

Controller

TDO

Document #: 38-03007 Rev. *E Page 13 of 64

[+] Feedback

Page 14

Ultra37000 CPLD Family

5.0V Device Characteristics

Maximum Ratings

(Above which the useful life may be impaired. For user guidelines, not tested.)

Storage Temperature .................................–65°C to +150°C

Ambient Temperature with

Power Applied.............................................–55°C to +125°C

Supply Voltage to Ground Potential............... –0.5V to +7.0V

Operating Range

Range Ambient Temperature

[2]

[2]

Junction Temperature Output Condition V

DC Voltage Applied to Outputs

in High-Z State................................................–0.5V to +7.0V

DC Input Voltage ............................................–0.5V to +7.0V

DC Program Voltage............................................. 4.5 to 5.5V

Current into Outputs .................................................... 16 mA

Static Discharge Voltage...........................................> 2001V

(per MIL-STD-883, Method 3015)

Latch-up Current.....................................................> 200 mA

CC

V

CCO

Commercial 0°C to +70°C 0°C to +90°C 5V 5V ± 0.25V 5V ± 0.25V

3.3V 5V ± 0.25V 3.3V ± 0.3V

Industrial –40°C to +85°C –40°C to +105°C 5V 5V ± 0.5V 5V ± 0.5V

3.3V 5V ± 0.5V 3.3V ± 0.3V

[3]

Military

–55°C to +125°C –55°C to +130°C 5V 5V ± 0.5V 5V ± 0.5V

3.3V 5V ± 0.5V 3.3V ± 0.3V

5.0V Device Electrical Characteristics Over the Operating Range

Parameter Description Test Conditions Min. Ty p. Max. Unit

V

OH

Output HIGH Voltage VCC = Min. IOH = –3.2 mA (Com’l/Ind)

IOH = –2.0 mA (Mil)

V

OHZ

Output HIGH Voltage with

Output Disabled

[5]

VCC = Max. IOH = 0 µA (Com’l)

IOH = 0 µA (Ind/Mil)

IOH = –100 µA (Com’l)

IOH = –150 µA (Ind/Mil)

V

OL

Output LOW Voltage VCC = Min. IOL = 16 mA (Com’l/Ind)

IOL = 12 mA (Mil)

V

IH

V

IL

I

IX

I

OZ

I

OS

I

BHL

I

BHH

I

BHLO

I

BHHO

Notes:

2. Normal Programming Conditions apply across Ambient Temperature Range for specified programming methods. For more information on programming the

Ultra37000 Family devices, please refer to the Application Note titled “An Introduction to In System Reprogramming with the Ultra37000.”

3. T

A

4. I

OH

5. Tested initially and after any design or process changes that may affect these parameters.

6. When the I/O is output disabled, the bus-hold circuit can weakly pull the I/O to above 3.6V if no leakage current is allowed. Note that all I/Os are output disabled

during ISR programming. Refer to the application note “Understanding Bus-Hold” for additional information.

7. These are absolute values with respect to device ground. All overshoots due to system or tester noise are included.

8. Not more than one output should be tested at a time. Duration of the short circuit should not exceed 1 second. V

problems caused by tester ground degradation.

Input HIGH Voltage Guaranteed Input Logical HIGH Voltage for all Inputs

Input LOW Voltage Guaranteed Input Logical LOW Voltage for all Inputs

Input Load Current VI = GND OR VCC, Bus-Hold Disabled –10 10 µA

Output Leakage Current VO = GND or VCC, Output Disabled, Bus-Hold Disabled –50 50 µA

Output Short Circuit Current

Input Bus-Hold LOW

[5, 8]

VCC = Max., V

= 0.5V –30 –160 mA

OUT

VCC = Min., VIL = 0.8V +75 µA

Sustaining Current

Input Bus-Hold HIGH

VCC = Min., VIH = 2.0V –75 µA

Sustaining Current

Input Bus-Hold LOW

VCC = Max. +500 µA

Overdrive Current

Input Bus-Hold HIGH

VCC = Max. –500 µA

Overdrive Current

is the “Instant On” case temperature.

= –2 mA, IOL = 2 mA for TDO.

[4]

2.4 V

[4]

[6]

[6]

[4]

= 0.5V has been chosen to avoid test

OUT

2.4 V

[6]

[6]

[4]

[7]

2.0 V

[7]

–0.5 0.8 V

4.2 V

4.5 V

3.6 V

3.6 V

0.5 V

0.5 V

CCmax

V

Document #: 38-03007 Rev. *E Page 14 of 64

[+] Feedback

Page 15

Ultra37000 CPLD Family

Inductance

Parameter Description Test Conditions

L Maximum Pin

Capacitance

[5]

Inductance

[5]

V

= 5.0V

IN

at f = 1 MHz

44-Lead

TQFP

44-Lead

PLCC

44-Lead

CLCC

84-Lead

PLCC

84-Lead

CLCC

100-Lead

TQFP

160-Lead

TQFP

208-Lead

PQFP Unit

25285 8 9 11nH

Parameter Description Test Conditions Max. Unit

C

I/O

C

CLK

C

DP

Endurance Characteristics

Input/Output Capacitance VIN = 5.0V at f = 1 MHz at TA = 25°C 10 pF

Clock Signal Capacitance VIN = 5.0V at f = 1 MHz at TA = 25°C 12 pF

Dual-Function Pins

[5]

[9]

VIN = 5.0V at f = 1 MHz at TA = 25°C 16 pF

Parameter Description Test Conditions Min. Typ . Unit

N Minimum Reprogramming Cycles Normal Programming Conditions

3.3V Device Characteristics

Maximum Ratings

(Above which the useful life may be impaired. For user guidelines, not tested.)

Storage Temperature .................................–65°C to +150°C

Ambient Temperature with

Power Applied.............................................–55°C to +125°C

Supply Voltage to Ground Potential............... –0.5V to +4.6V

Operating Range

[2]

Range Ambient Temperature

DC Voltage Applied to Outputs

in High-Z State................................................–0.5V to +7.0V

DC Input Voltage ............................................–0.5V to +7.0V

DC Program Voltage............................................. 3.0 to 3.6V

Current into Outputs ......................................................8 mA

Static Discharge Voltage...........................................> 2001V

(per MIL-STD-883, Method 3015)

Latch-up Current.....................................................> 200 mA

[2]

Junction Temperature V

[2]

1,000 10,000 Cycles

[10]

CC

Commercial 0°C to +70°C 0°C to +90°C 3.3V ± 0.3V

Industrial –40°C to +85°C –40°C to +105°C 3.3V ± 0.3V

[3]

Military

–55°C to +125°C –55°C to +130°C 3.3V ± 0.3V

3.3V Device Electrical Characteristics Over the Operating Range

Parameter Description Test Conditions Min. Max. Unit

V

OH

Output HIGH Voltage VCC = Min. IOH = –4 mA (Com’l)

IOH = –3 mA (Mil)

V

OL

Output LOW Voltage VCC = Min. IOL = 8 mA (Com’l)

IOL = 6 mA (Mil)

V

IH

V

IL

I

IX

I

OZ

I

OS

I

BHL

I

BHH

I

BHLO

I

BHHO

Notes:

9. Dual pins are I/O with JTAG pins.

10. For CY37064VP100-143AC, CY37064VP100-143BBC, CY37064VP44-143AC, CY37064VP48-143BAC; Operating Range: V

Input HIGH Voltage Guaranteed Input Logical HIGH Voltage for

all Inputs

Input LOW Voltage Guaranteed Input Logical LOW Voltage for

all Inputs

[7]

[7]

Input Load Current VI = GND OR VCC, Bus-Hold Disabled –10 10 µA

Output Leakage Current VO = GND or VCC, Output Disabled,

Bus-Hold Disabled

Output Short Circuit Current

[5, 8]

VCC = Max., V

= 0.5V –30 –160 mA

OUT

Input Bus-Hold LOW Sustaining Current VCC = Min., VIL = 0.8V +75 µA

Input Bus-Hold HIGH Sustaining Current VCC = Min., VIH = 2.0V –75 µA

Input Bus-Hold LOW Overdrive Current VCC = Max. +500 µA

Input Bus-Hold HIGH Overdrive Current VCC = Max. –500 µA

[4]

[4]

[4]

[4]

2.4 V

0.5 V

2.0 5.5 V

–0.5 0.8 V

–50 50 µA

is 3.3V± 0.16V.

CC

Document #: 38-03007 Rev. *E Page 15 of 64

[+] Feedback

Page 16

Ultra37000 CPLD Family

Inductance

Parameter Description Test Conditions

L Maximum Pin

Capacitance

[5]

Inductance

[5]

V

= 3.3V

IN

at f = 1 MHz

44-

Lead

TQFP

44-

Lead

PLCC

44-

Lead

CLCC

84-

Lead

PLCC

84-

Lead

CLCC

100-

Lead

TQFP

160-

Lead

TQFP

208-

Lead

PQFP Unit

252858911nH

Parameter Description Test Conditions Max. Unit

C

I/O

C

CLK

C

DP

Endurance Characteristics

Input/Output Capacitance VIN = 3.3V at f = 1 MHz at TA = 25°C 8 pF

Clock Signal Capacitance VIN = 3.3V at f = 1 MHz at TA = 25°C 12 pF

Dual Functional Pins

[5]

[9]

VIN = 3.3V at f = 1 MHz at TA = 25°C 16 pF

Parameter Description Test Conditions Min. Typ . Unit

N Minimum Reprogramming Cycles Normal Programming Conditions

[2]

1,000 10,000 Cycles

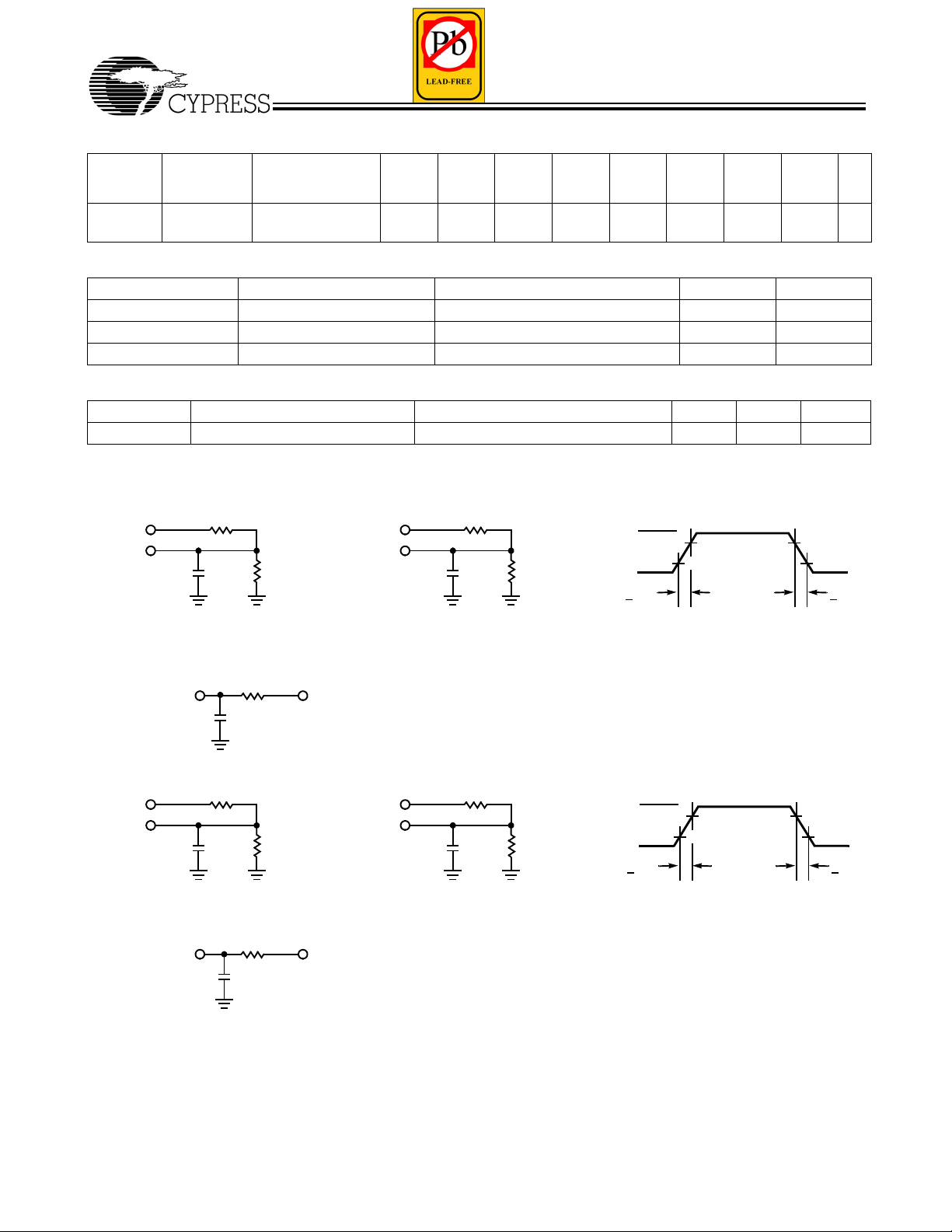

AC Characteristics

5.0V AC Test Loads and Waveforms

5 pF

238Ω (COM'L)

319Ω (MIL)

170Ω (COM'L)

236Ω (MIL)

3.0V

GND

ALL INPUT PULSES

90%

10%

<2 ns

(c)

238Ω (COM'L)

5V

OUTPUT

INCLUDING

JIG AND

SCOPE

Equivalent to: THÉVENIN EQUIVALENT

OUTPUT

319Ω (MIL)

35 pF

170Ω (COM'L)

236Ω (MIL)

(a) (b)

99Ω (COM'L)

136Ω (MIL)

5V

OUTPUT

INCLUDING

JIG AND

SCOPE

2.08V (COM'L)

2.13V (MIL)

90%

10%

<2 ns

5 OR 35 pF

3.3V AC Test Loads and Waveforms

5 pF

295Ω (COM'L)

393Ω (MIL)

340Ω (COM'L)

453Ω (MIL)

3.0V

GND

<2 ns

ALL INPUT PULSES

90%

10%

(c)

90%

10%

<2 ns

295Ω (COM'L)

3.3V

OUTPUT

INCLUDING

JIG AND

SCOPE

Equivalent to: THÉVENIN EQUIVALENT

OUTPUT

393Ω (MIL)

35 pF

340Ω (COM'L)

453Ω (MIL)

(a) (b)

158Ω (COM’L)

270Ω (MIL)

5 OR 35 pF

3.3V

OUTPUT

INCLUDING

JIG AND

SCOPE

1.77V (COM'L)

1.77V (MIL)

Document #: 38-03007 Rev. *E Page 16 of 64

[+] Feedback

Page 17

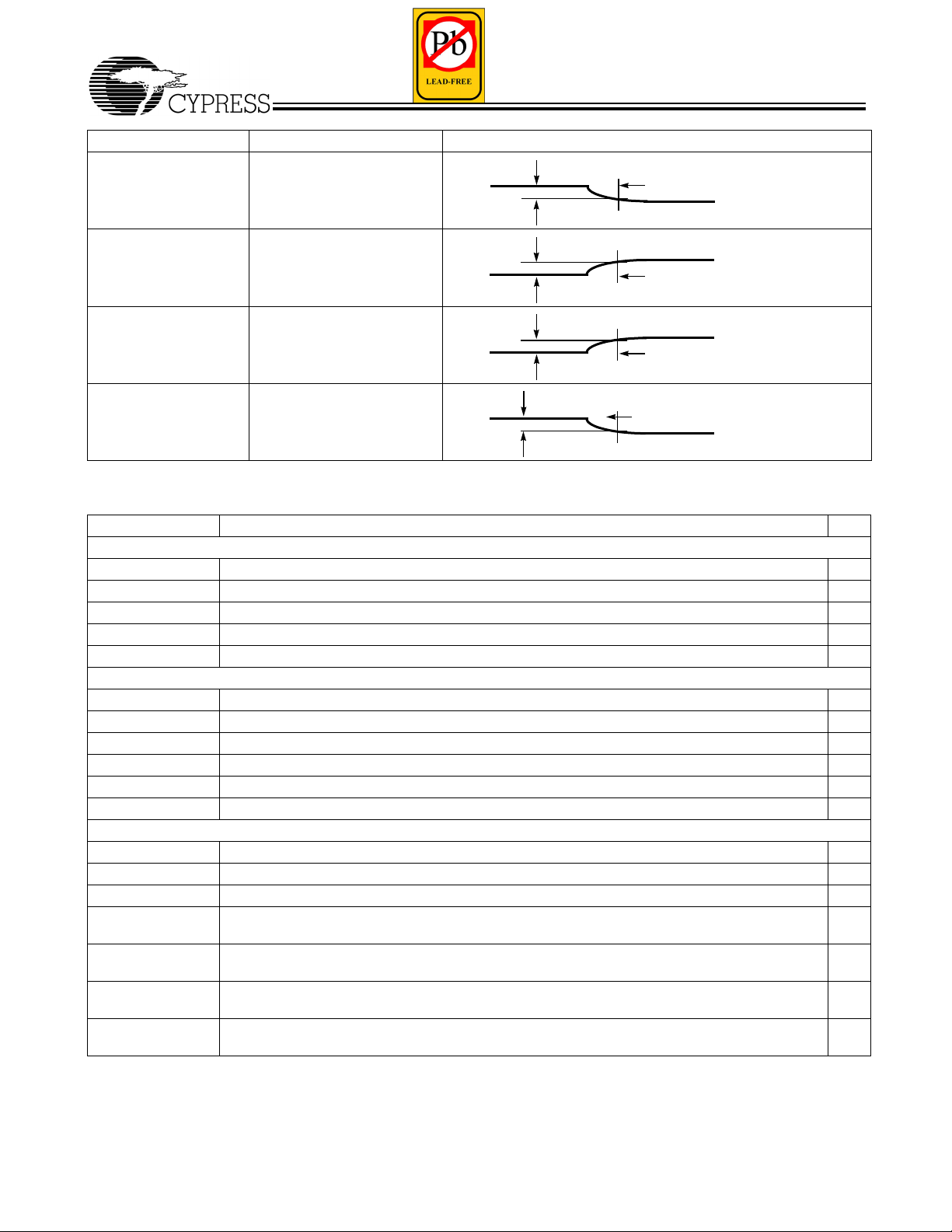

Ultra37000 CPLD Family

t

ER(–)

t

ER(+)

t

EA(+)

t

EA(–)

[11]

V

X

1.5V

2.6V

1.5V

V

the

Output Waveform—Measurement Level

V

OH

0.5V

0.5V

V

OL

0.5V

V

X

V

X

0.5V

V

X

V

X

V

OH

V

OL

Parameter

(d) Test Waveforms

Switching Characteristics Over the Operating Range

[12]

Parameter Description Unit

Combinatorial Mode Parameters

[13, 14, 15]

t

PD

t

PDL

t

PDLL

[13, 14, 15]

t

EA

[11, 13]

t

ER

[13, 14, 15]

[13, 14, 15]

Input to Combinatorial Output ns

Input to Output Through Transparent Input or Output Latch ns

Input to Output Through Transparent Input and Output Latches ns

Input to Output Enable ns

Input to Output Disable ns

Input Register Parameters

t

WL

t

WH

t

IS

t

IH

t

ICO

t

ICOL

[13, 14, 15]

[13, 14, 15]

Clock or Latch Enable Input LOW Time

Clock or Latch Enable Input HIGH Time

Input Register or Latch Set-up Time ns

Input Register or Latch Hold Time ns

Input Register Clock or Latch Enable to Combinatorial Output ns

Input Register Clock or Latch Enable to Output Through Transparent Output Latch ns

[8]

[8]

Synchronous Clocking Parameters

[14, 15]

t

CO

[13]

t

S

t

H

[13, 14, 15]

t

CO2

[13]

t

SCS

[13]

t

SL

t

HL

Notes:

measured with 5-pF AC Test Load and tEA measured with 35-pF AC Test Load.

11. t

ER

12. All AC parameters are measured with two outputs switching and 35-pF AC Test Load.

13. Logic Blocks operating in Low-Power Mode, add t

14. Outputs using Slow Output Slew Rate, add t

15. When V

= 3.3V, add t

CCO

Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) or Latch Enable to Output ns

Set-Up Time from Input to Sync. Clk (CLK0, CLK1, CLK2, or CLK3) or Latch Enable ns

Register or Latch Data Hold Time ns

Output Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) or Latch Enable to Combinatorial Output

Delay (Through Logic Array)

Output Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) or Latch Enable to Output Synchronous

Clock (CLK

, CLK1, CLK2, or CLK3) or Latch Enable (Through Logic Array)

0

Set-Up Time from Input Through Transparent Latch to Output Register Synchronous Clock (CLK0

CLK

, CLK2, or CLK3) or Latch Enable

1

Hold Time for Input Through Transparent Latch from Output Register Synchronous Clock (CLK0,

CLK

, CLK2, or CLK3) or Latch Enable

1

to this spec.

LP

to this spec.

to this spec.

3.3IO

SLEW

ns

ns

ns

ns

ns

ns

Document #: 38-03007 Rev. *E Page 17 of 64

[+] Feedback

Page 18

Ultra37000 CPLD Family

Switching Characteristics Over the Operating Range (continued)

[12]

Parameter Description Unit

Product Term Clocking Parameters

[13, 14, 15]

t

COPT

t

SPT

t

HPT

t

ISPT

t

IHPT

t

CO2PT

[13]

[13, 14, 15]

Product Term Clock or Latch Enable (PTCLK) to Output ns

Set-Up Time from Input to Product Term Clock or Latch Enable (PTCLK) ns

Register or Latch Data Hold Time ns

Set-Up Time for Buried Register used as an Input Register from Input to Product Term Clock or

Latch Enable (PTCLK)

Buried Register Used as an Input Register or Latch Data Hold Time ns

Product Term Clock or Latch Enable (PTCLK) to Output Delay (Through Logic Array) ns

Pipelined Mode Parameters

[13]

t

ICS

Input Register Synchronous Clock (CLK0, CLK1, CLK2, or CLK3) to Output Register Synchronous

Clock (CLK

, CLK1, CLK2, or CLK3)

0

Operating Frequency Parameters

f

MAX1

f

MAX2

f

MAX3

f

MAX4

Maximum Frequency with Internal Feedback (Lesser of 1/t

Maximum Frequency Data Path in Output Registered/Latched Mode (Lesser of 1/(tWL + tWH),

1/(t

S+tH

), or 1/tCO)

[5]

, 1/(tS + tH), or 1/tCO)

SCS

Maximum Frequency with External Feedback (Lesser of 1/(tCO + tS) or 1/(tWL + tWH)

Maximum Frequency in Pipelined Mode (Lesser of 1/(tCO + tIS), 1/t

or 1/t

SCS

[5]

)

, 1/(tWL + tWH), 1/(tIS + tIH),

ICS

[5]

[5]

Reset/Preset Parameters

t

RW

[13]

t

RR

[13, 14, 15]

t

RO

t

PW

[13]

t

PR

[13, 14, 15]

t

PO

Asynchronous Reset Width

Asynchronous Reset Recovery Time

Asynchronous Reset to Output ns

Asynchronous Preset Width

Asynchronous Preset Recovery Time

Asynchronous Preset to Output ns

[5]

[5]

[5]

[5]

User Option Parameters

t

LP

t

SLEW

t

3.3IO

Low Power Adder ns

Slow Output Slew Rate Adder ns

3.3V I/O Mode Timing Adder

[5]

JTAG Timing Parameters

t

S JTAG

t

H JTAG

t

CO JTAG

f

JTAG

Set-up Time from TDI and TMS to TCK

Hold Time on TDI and TMS

Falling Edge of TCK to TDO

[5]

[5]

Maximum JTAG Tap Controller Frequency

[5]

[5]

ns

ns

MHz

MHz

MHz

MHz

ns

ns

ns

ns

ns

ns

ns

ns

ns

Document #: 38-03007 Rev. *E Page 18 of 64

[+] Feedback

Page 19

Ultra37000 CPLD Family

Switching Characteristics Over the Operating Range

200 MHz 167 MHz

Parameter

Min.

Max.

Min.

Combinatorial Mode Parameters

[13, 14, 15]

t

PD

t

PDL

t

PDLL

[13, 14, 15]

t

EA

[11, 13]

t

ER

[13, 14, 15]

[13, 14, 15]

6 6.5 7.5 8.5 10 12 15 20 ns

11 12.5 14.5 16 16.5 17 19 22 ns

12 13.5 15.5 17 17.5 18 20 24 ns

8 8.5 11 13 14 16 19 24 ns

8 8.5 11 13 14 16 19 24 ns

Input Register Parameters

t

WL

t

WH

t

IS

t

IH

t

ICO

t

ICOL

[13, 14, 15]

[13, 14, 15]

2.5 2.5 2.5 2.5 3 3 4 5 ns

2.5 2.5 2.5 2.5 3 3 4 5 ns

2 222 2 2.5 3 4ns

2 222 2 2.5 3 4ns

11 11 11 12.5 12.5 16 19 24 ns

12 12 12 14 16 18 21 26 ns

Synchronous Clocking Parameters

[14, 15]

t

CO

t

S

t

H

t

CO2

t

SCS

t

SL

t

HL

[13]

[13, 14, 15]

[13]

[13]

4 4 4.5 6 6.5

44555.5

0000 0 0 0 0ns

9.5 10 11 12 14 16 19 24 ns

5 66.57 8

7.5 7.5 8.5 9 10 12 15 15 ns

0 000 0 0 0 0ns

Product Term Clocking Parameters

[13, 14, 15]

t

COPT

t

SPT

t

HPT

t

ISPT

t

IHPT

t

CO2PT

15]

[13]

[13, 14,

7101013 13 13 1520ns

2.5 2.5 2.5 3 5 5.5 6 7 ns

2.5 2.5 2.5 3 5 5.5 6 7 ns

0000 00 00ns

6 6.5 6.5 7.5 9 11 14 19 ns

12 14 15 19 19 21 24 30 ns

154 MHz 143 MHz 125 MHz 100 MHz 83 MHz 66 MHz

Max.

Min.

Max.

Min.

[12]

Max.

[16]

[16]

Min.

Min.

Max.

[18]

8

[18]

8

[16]

Max.

Min.

[17]

6

6.5

Max.

[17]

10 12 15 ns

Min.

Unit

Max.

10 ns

10 ns

Pipelined Mode Parameters

t

ICS

[13]

56678

[16]

10 12 15 ns

Operating Frequency Parameters

f

MAX1

f

MAX2

f

MAX3

f

MAX4

200 167 154 143 125

200 200 200 167 154 153

125 125 105 91 83 80

167 167 154 125 118 100 83 66 MHz

[16]

100 83 66 MHz

[17]

[17]

[18]

125

100 MHz

62.5 50 MHz

Reset/Preset Parameters

t

RW

[13]

t

RR

Notes:

16. The following values correspond to the CY37512 and CY37384 devices: t

17. The following values correspond to the CY37192V and CY37256V devices: t

for the CY37512 devices: t

18. The following values correspond to the CY37512V and CY37384V devices: t

8 8 8 8 10 12 15 20 ns

10 10 10 10 12 14 17 22 ns

= 7 ns.

S

= 5 ns, tS = 6.5 ns, t

CO

= 6 ns, tS = 7 ns, f

CO

= 6.5 ns, tS = 9.5 ns, and f

CO

= 8.5 ns, t

SCS

= 143 MHz, f

MAX2

ICS

= 105 MHz.

MAX2

= 8.5 ns, f

= 77 MHz, and f

MAX3

MAX1

= 118 MHz.

MAX4

= 100 MHz; and

Document #: 38-03007 Rev. *E Page 19 of 64

[+] Feedback

Page 20

Ultra37000 CPLD Family

Switching Characteristics Over the Operating Range (continued)

200 MHz 167 MHz

Parameter

[13, 14, 15]

t

RO

t

PW

[13]

t

PR

[13, 14, 15]

t

PO

Min.

12 13 13 14 15 18 21 26 ns

8 8 8 8 10 12 15 20 ns

10 10 10 10 12 14 17 22 ns

12 13 13 14 15 18 21 26 ns

User Option Parameters

t

LP

t

SLEW

t

3.3IO

[19]

2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5 ns

3333 3 3 33ns

0.3 0.3 0.3 0.3 0.3 0.3 0.3 0.3 ns

JTAG Timing Parameters

t

S JTAG

t

H JTAG

t

CO JTAG

f

JTAG

0 000 00 00ns

20 20 20 20 20 20 20 20 ns

20 20 20 20 20 20 20 20 ns

20 20 20 20 20 20 20 20 MHz

Max.

Min.

154 MHz 143 MHz 125 MHz 100 MHz 83 MHz 66 MHz

Max.

Min.

Max.

Min.

Max.

Min.

Switching Waveforms

Combinatorial Output

[12]

Max.

Min.

Max.

Min.

Max.

Min.

Unit

Max.

INPUT

COMBINATORIAL

OUTPUT

Registered Output with Synchronous Clocking

INPUT

SYNCHRONOUS

CLOCK

REGISTERED

OUTPUT

REGISTERED

OUTPUT

SYNCHRONOUS

CLOCK

t

WH

t

PD

t

S

t

H

t

CO

t

CO2

t

WL

Note:

19. Only applicable to the 5V devices.

Document #: 38-03007 Rev. *E Page 20 of 64

[+] Feedback

Page 21

Switching Waveforms (continued)

Registered Output with Product Term Clocking Input Going Through the Array

INPUT

Ultra37000 CPLD Family

t

SPT

t

HPT

PRODUCT TERM

CLOCK

t

COPT

REGISTERED

OUTPUT

Registered Output with Product Term Clocking Input Coming From Adjacent Buried Register

INPUT

t

ISPT

t

IHPT

PRODUCT TERM

CLOCK

t

CO2PT

REGISTERED

OUTPUT

Latched Output

INPUT

t

SL

t

HL

LATCH ENABLE

t

PDL

t

CO

LATCHED

OUTPUT

Document #: 38-03007 Rev. *E Page 21 of 64

[+] Feedback

Page 22

Switching Waveforms (continued)

Registered Input

REGISTERED

INPUT

Ultra37000 CPLD Family

INPUT REGISTER

CLOCK

COMBINATORIAL

OUTPUT

CLOCK

Clock to Clock

INPUT REGISTER

CLOCK

OUTPUT

REGISTER CLOCK

Latched Input

LATCHED INPUT

t

WH

t

IS

t

ICS

t

ICO

t

IH

t

WL

t

SCS

LATCH ENABLE

COMBINATORIAL

OUTPUT

LATCH ENABLE

t

PDL

t

IS

t

WH

t

IH

t

ICO

t

WL

Document #: 38-03007 Rev. *E Page 22 of 64

[+] Feedback

Page 23

Switching Waveforms (continued)

Latched Input and Output

LATCHED INPUT

LATCHED

OUTPUT

Ultra37000 CPLD Family

t

PDLL

INPUT LATCH

ENABLE

OUTPUT LATCH

ENABLE

LATCH ENABLE

Asynchronous Reset

INPUT

REGISTERED

OUTPUT

CLOCK

t

ICOL

t

ICS

t

WH

t

SL

t

WL

t

RW

t

RO

t

RR

t

HL

Asynchronous Preset

t

PW

INPUT

t

PO

REGISTERED

OUTPUT

t

PR

CLOCK

Output Enable/Disable

INPUT

t

ER

t

EA

OUTPUTS

Document #: 38-03007 Rev. *E Page 23 of 64

[+] Feedback

Page 24

Power Consumption

Typical 5.0V Power Consumption

CY37032

60

50

40

30

Icc (mA)

20

10

0

0 50 100 1 50 200 250

Ultra37000 CPLD Family

High Speed

Low Power

Frequency (MHz)

CY37064

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 5.0V, TA = Room Temperature

CC

90

80

70

60

50

Icc (mA)

40

30

20

10

0

0 20 40 60 80 100 120 140 160 180

Frequency (MHz)

Low Power

High Speed

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 5.0V, TA = Room Temperature

CC

Document #: 38-03007 Rev. *E Page 24 of 64

[+] Feedback

Page 25

Typical 5.0V Power Consumption (continued)

CY37128

160

Ultra37000 CPLD Family

CY37192

140

120

100

Low Power

80

Icc (mA)

60

40

20

0

0 20 40 60 80 100 120 140 160 180

Frequency (MHz)

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 5.0V, TA = Room Temperature

CC

300

250

High Speed

High Speed

200

150

Icc (mA)

100

50

0

0 20 40 60 80 100 120 140 160 180

Low Power

Frequency (MHz)

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 5.0V, TA = Room Temperature

CC

Document #: 38-03007 Rev. *E Page 25 of 64

[+] Feedback

Page 26

Typical 5.0V Power Consumption (continued)

CY37256

300

250

200

150

Icc (mA)

100

50

0

0 20 40 60 80 100 120 140 160 180

Ultra37000 CPLD Family

High Speed

Low Power

Frequency (M Hz)

CY37384

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 5.0V, TA = Room Temperature

CC

500

450

400

350

300

250

Icc (mA)

200

150

100

50

0

0 20 40 60 80 100 120 140 160

Low Power

Frequency (MHz)

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 5.0V, TA = Room Temperature

CC

High Speed

Document #: 38-03007 Rev. *E Page 26 of 64

[+] Feedback

Page 27

Typical 5.0V Power Consumption (continued)

CY37512

600

Ultra37000 CPLD Family

500

400

300

Icc (mA)

200

100

0

0 20 40 60 80 100 120 140 160

Typical 3.3V Power Consumption

CY37032V

30

25

Low Power

Frequency (MHz)

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 5.0V, TA = Room Temperature

CC

High Speed

High Speed

20

15

Icc (mA)

10

5

0

0 20 40 60 80 100 120 140 160

Low Power

Frequency (MHz)

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 3.3V, TA = Room Temperature

CC

Document #: 38-03007 Rev. *E Page 27 of 64

[+] Feedback

Page 28

Typical 3.3V Power Consumption (continued)

CY37064V

45

40

35

30

25

Icc (mA)

20

15

10

5

0

0 20 40 60 80 100 120 140

Ultra37000 CPLD Family

High Speed

Low Power

Frequency (MHz)

CY37128V

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 3.3V, TA = Room Temperature

CC

80

70

60

50

40

Icc (mA)

30

20

10

0

0 20 40 60 80 100 120 140

Frequency (M Hz)

Low Power

High Speed

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 3.3V, TA = Room Temperature

CC

Document #: 38-03007 Rev. *E Page 28 of 64

[+] Feedback

Page 29

Typical 3.3V Power Consumption (continued)

CY37192V

120

Ultra37000 CPLD Family

CY37256V

100

80

60

Icc (mA)

40

20

0

0 20 40 60 80 100 120

Frequency (MHz)

Low Power

High Speed

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 3.3V, TA = Room Temperature

CC

140

120

100

High Speed

80

Icc (mA)

60

40

20

0

0 20 40 60 80 100 120

Frequency (M Hz)

Low Power

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 3.3V, TA = Room Temperature

CC

Document #: 38-03007 Rev. *E Page 29 of 64

[+] Feedback

Page 30

Typical 3.3V Power Consumption (continued)

CY37384V

200

Ultra37000 CPLD Family

CY37512V

180

160

140

120

100

Icc (mA)

80

60

40

20

0

0 102030405060708090

Frequency (M Hz)

Low Power

High Speed

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 3.3V, TA = Room Temperature

CC

250

200

High Speed

150

Icc (mA)

100

50

0

0 1020304050 60708090

Frequency (MHz)

Low Power

The typical pattern is a 16-bit up counter, per logic block, with outputs disabled.

V

= 3.3V, TA = Room Temperature

CC

Document #: 38-03007 Rev. *E Page 30 of 64

[+] Feedback

Page 31

Ultra37000 CPLD Family

Pin Configurations

[20]

I/O5/TCK

I/O

I/O

CLK2/I

JTAG

GND

CLK0/I

I/O

I/O

I/O

I/O

EN

10

11

44-pin TQFP (A44)

Top View

0

2

3

4

I/O

I/O

I/O

I/O1I/O

44 43 42 4041 39 38 37 3536 34

1

2

6

3

7

4

0

5

6

7

1

8

8

9

9

10

11

14

/TMS

I/O

15

CC

V

I/O

12

I/O

13

I/O

GND

18 19 20 222113 14 15 171612

GND

CCO

V

16

31

28

I/O29I/O30I/O

I/O

33

32

31

30

29

28

27

26

25

24

23

I/O27/TDI

I/O

26

I/O

25

I/O

24

CLK1/I

4

GND

I

3

CLK3/I

2

I/O

23

I/O

22

I/O

21

20

I/O

I/O18I/O17I/O

/TDO

19

I/O

I/O5/TCK

I/O

I/O

CLK2/I

JTAG

EN

GND

CLK0/I

I/O

I/O

I/O

I/O

44-pin PLCC (J67) / CLCC (Y67)

Top View

2

4

I/O3I/O

65 34 2

7

8

6

9

7

10

0

11

12

13

1

14

8

15

9

16

10

17

11

18

19 20 2221 23 24 2726 2825

12

I/O

I/O

/TMS

13

I/O

14

0

I/O

I/O1I/O

GND

1

15

CC

V

GND

I/O

I/O

CCO

V

43 42 4041

44

16

I/O

17

31

28

I/O29I/O30I/O

I/O

I/O27/TDI

39

I/O

38

37

36

35

34

33

32

31

30

29

18

I/O

I/O

/TDO

20

26

I/O

25

I/O

24

CLK1/I

GND

I

3

CLK3/I

I/O

23

I/O

22

I/O

21

4

2

19

I/O

Document #: 38-03007 Rev. *E Page 31 of 64

[+] Feedback

Page 32

Ultra37000 CPLD Family

Pin Configurations

Note:

20. For 3.3V versions (Ultra37000V), V

[20]

(continued)

48-ball Fine-Pitch BGA (BA50)

Top View

12345678

V

A I/O

5

TCK

BV

CC

CCLK2/ I0I/O7I/O6GND GND I/O25I/O24I

DJTAGENI/O8I/O9GND GND I/O22I/O23CLK3/ I

ECLK0/ I1I/O12I/O11I/O10I/O16I/O20I/O21V

F I/O

13

TMS

= VCC.

CCO

I/O3I/O1I/O31I/O30VCCI/O27

CC

I/O4I/O2I/O0I/O29I/O28I/O26CLK1/ I

VCCI/O14I/O15I/O17I/O18VCCI/O19

84-lead PLCC (J83) / CLCC (Y84)

Top View

7

6

5

4

3

2

1

0

CCO

CC

GND

V

I/O

I/O

I/O

GND

I/O

I/O

I/O

I/O

I/O

V

EN

JTAG

TDI

4

3

2

CC

TDO

63

62616059585756

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

98 67 5

11

10

12

I/O

8

13

I/O

9

I/O

I/O

I/O

I/O

I/O

CCO

GND

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

GND

14

15

11

16

12

17

13

18

14

19

15

20

0

21

22

23

1

16

24

17

25

18

26

19

27

20

28

21

29

22

30

31

23

33

32

34

24

I/O

3736

35 39 44 45

25

I/O

38

/TMS

I/O27I/O28I/O29I/O30I/O

26

I/O

/TCK

10

CLK0/I

V

CLK1/I

I/O

Note:

21. This pin is a N/C, but Cypress recommends that you connect it to V

43

84 8182 80 79

2

83

1

42414340

2

31

I

to ensure future compatibility.

CC

[21]

GND

CCO

V

I/O32I/O33I/O34I/O35I/O36I/O

CC

V

7778 76 75

GND

74

73

I/O

55

I/O

I/O

I/O

I/O

I/O

I/O

I/O

CLK3/I

GND

V

CCO

CLK2/I

I/O

I/O

I/O

I/O

I/O

I/O

I/O

I/O

/TDI

54

53

52

51

50

49

48

4

3

47

46

45

44

43

42

41

40

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

/TDO

38

54

53525150

39

GND

I/O

4948

4746

37

I/O

Document #: 38-03007 Rev. *E Page 32 of 64

[+] Feedback

Page 33

Ultra37000 CPLD Family

Pin Configurations

TCK

GND

I/O

8

I/O

9

I/O

10

I/O

11

I/O

12

I/O

13

I/O

14

I/O

15

CLK0/I

0

V

CCO

N/C

GND

CLK

1/I1

I/O

16

I/O

17

I/O

18

I/O

19

I/O

20

I/O

21

I/O

22

I/O

23

V

CCO

NC

[20]

(continued)

NC

100 9798 96

99

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27 28 3029 31 32 3534 36 3833

7654321

CCO

I/O

I/O

V

I/O

95 94

I/O

100-lead TQFP (A100)

Top View

0

CCO

I/O

I/O

I/O

GND

I/O

V

89 88 8687 8593 92 84

9091

37

NC

63

CC

V

62616059585756

I/O

I/O

I/O

N/C

I/O

I/O

I/O

I/O

I/O

GND

NC

83 82 81 80 79 78 77 76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

4241

4039

43 44 45 46 48 49 50

47

TDI

V

CCO

I/O

55

I/O

54

I/O

53

I/O

52

I/O

51

I/O

50

I/O

49

I/O

48

CLK3/I

GND

NC

V

CCO

CLK2/I

I/O

47

I/O

46

I/O

45

I/O

44

I/O

43

I/O

42

I/O

41

I/O

40

GND

NC

4

3

TMS

GND

I/O24I/O25I/O26I/O27I/O28I/O29I/O30I/O

31

I

CCO

V

[21 ]

NC

GND

CC

I/O32I/O33I/O34I/O35I/O36I/O37I/O38I/O

V

39

CCO

TDO

V

2

Document #: 38-03007 Rev. *E Page 33 of 64

[+] Feedback

Page 34

Ultra37000 CPLD Family

Pin Configurations

[20]

(continued)

100-ball Fine-Pitch BGA (BB100) for CY37064V

Top V iew

12345678910

A NC NC I/O7I/O5I/O2I/O62I/O60I/O58I/O57I/O

BI/O9I/O8I/O6I/O4I/O1I/O63VCCI/O59I/O55NC

C I/O10TCK VCCI/O3NC NC I/O61V

D I/O11NC I/O12I/O13I/O0NC I/O51I/O52CLK3/

E I/O14CLK0/

F I/O17NC NC I/O16GND GND NC NC I2I/O

G I/O22CLK1/

H I/O23TMS VCCI/O20NC I/O32I/O42VCCTDO I/O

JNCI/O26I/O28NC I/O31I/O33I/O35I/O37I/O39I/O

K I/O24I/O25I/O27I/O29I/O30I/O34I/O36I/O38NC NC

I/O15NC GND GND I/O48I/O49CLK2/

I

0

I/O21I/O19I/O18I/O46I/O45I/O44NC I/O

I

1

CC

TDI I/O

I/O

I

4

I/O

I

3

56

54

53

50

47

43

41

40

100-ball Fine-Pitch BGA (BB100) for CY37128V

Top V iew

12345678910

A NC I/O9I/O8I/O6I/O3I/O76I/O74I/O72I/O71I/O