Cylon CBX series, FLX-4R4-H, FLX-8R8, CBX-8R8, FLX-8R8-H Technical Datasheet And Installation Manual

...

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 1 of

14

TECHNICAL DATASHEET & INSTALLATION GUIDE

CBX System

CBX System

CBX-8R8|CBX-8R8-H|FLX-4R4|FLX-4R4-H|FLX-8R8|FLX-8R8-H|FLX-16DI

DESCRIPTION

The CBX-8R8(-H) is a fully programmable BTL-listed BACnet®

Advanced Application Controller (B-AAC) that communicates on

an RS-485 local area network using the BACnet® MS/TP protocol.

This controller features 8 UniPuts™ with Relay and 8 Universal

Inputs as well as support for up to three FLX (Field Level

eXpansion) series extension modules providing up to 64 points

of control. FLX expansion modules are available in a variety of

options to allow maximum flexibility in achieving the required

point configuration.

The CBX-8R8(-H) is designed for a wide range of applications for

intelligent control of HVAC equipment, lighting control, and

electrical systems including metering applications.

APPLICATION

The CBX-8R8(-H) is suitable for controlling various equipment

such as; air handling units, boilers, chillers, cooling towers, pump

systems, central plant equipment, variable frequency drives,

lighting control and metering. The controller supports multi-

protocol communications simultaneously including BACnet®

MS/TP and Modbus® RTU.

The fully programmable CBX-8R8(-H) can be tailored to meet a

variety of applications by creating and modifying strategies using

Cylon's CXpro

HD

programming interface.

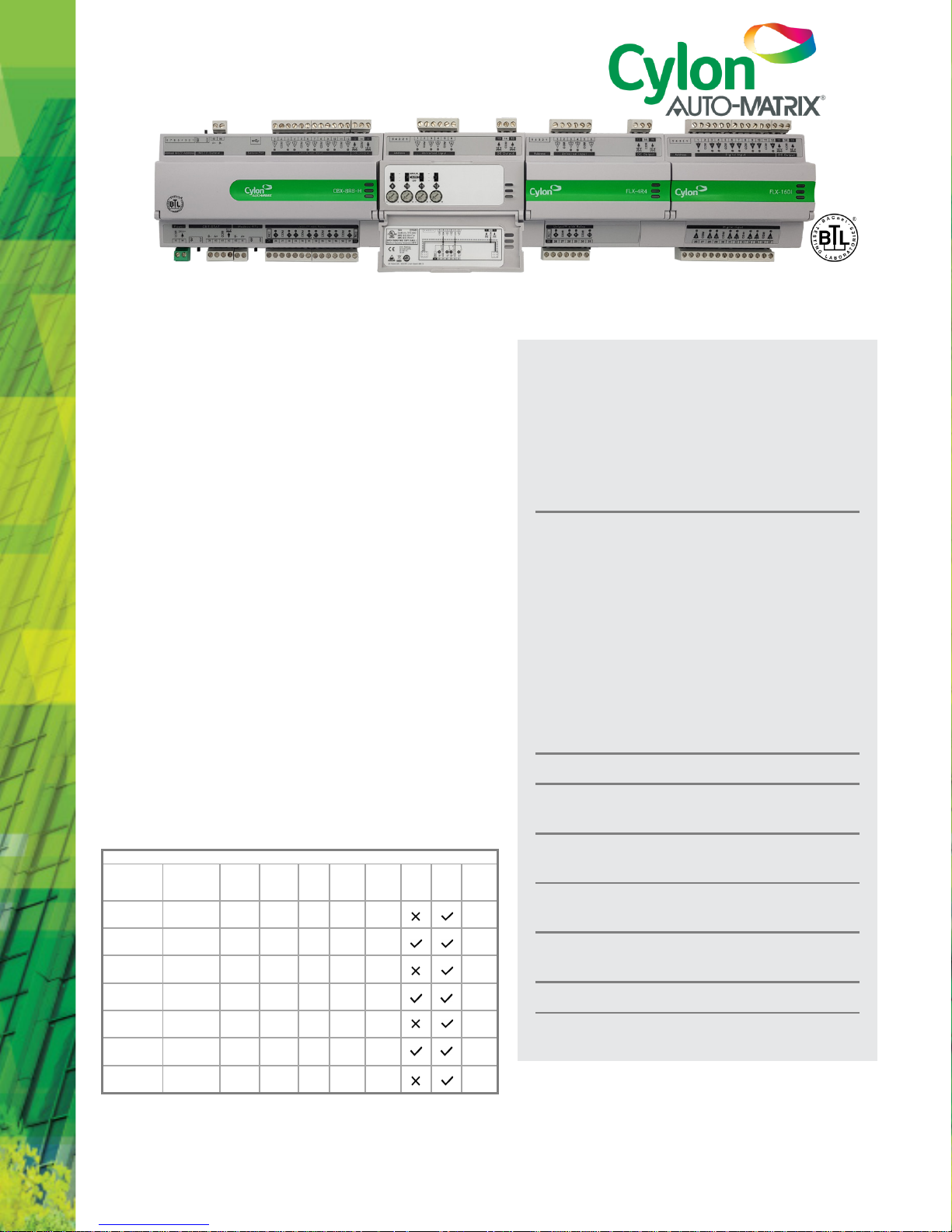

Product Selection Chart

Part Number

Module

Service

UniPutsTM

with Rel ay1

Universal

Inputs

Digital

Inputs

Modbus

RTU

Devices

CBT-STAT

Bus

HOA

Switch

& Pot.

18 V

Aux

Power

FLX

I/O

Modules

CBX-8R8

Main

Controller

8 8 0 4* 1

3

CBX-8R8-H

Main

Controller

8 8 0 4* 1

3

FLX-4R4

Expansion

Module

4 4 0 0 0

-

FLX-4R4-H

Expansion

Module

4 4 0 0 0

-

FLX-8R8

Expansion

Module

8 8 0 0 0

-

FLX-8R8-H

Expansion

Module

8 8 0 0 0

-

FLX-16DI

Expansion

Module

0 0 16 0 0

-

Note: 1 – UniPutsTM are software configurable for point types AI, DI, AO or DO-R.

Note: * – CBX Modbus® RTU supports a total of 40 points across 4 devices

CBX-8R8

8 UniPuts™ + Relays

hardware connections that can be used as

inputs, outputs or relays (software selectable)

8 Universal Inputs

CBX-8R8-H

Including Hand/Off/Auto Local Override

Function

Field Level eXpansion Modules

FLX-4R4

4 UniPuts™ with Relay

4 Universal Inputs

FLX-8R8

8 UniPuts™ with Relay

8 Universal Inputs

FLX-16DI

16 Digital Inputs

FLX-4R4-H, FLX-8R8-H

Including Hand/Off/Auto Local Override

Function

Support for Cylon smart thermostat bus

LED status on all I/O channels provides

indication of fault or override status

Compact form factor to maximize enclosure

space

Scalable from 16 points to 64 points using FLX

modules

Easy module expansion using simple bus

connectors

Up to 64 Trendlogs, 1024 entries per Trendlog

Accurate Universal Inputs support a variety of

thermistors and RTDs that range from 0 to 450 kΩ

INSTALLATION GUID E : see page 5

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 2 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

SPECIFICATIONS

MECHANICAL

Size

(excluding terminal plugs)

CBX-8R8

CBX-8R8-H

166 x 89.5 x 57 mm [6.5 x 3.55 x 2.25”]

FLX-4R4

FLX-4R4-H

FLX-8R8

FLX-8R8-H

FLX-16DI

104 x 89.5 x 57 mm [4.1 x 3.55 x 2.25”]

Enclosure

Flame-Retardant ABS

DIN 43880 type-2 compatible

Mounting

DIN rail

CONNECTION

Note: Use Copper or Copper Clad Aluminum 70 °C conductors only.

Terminals

PCB mounted plug terminal connections

Conductor Area

Max: AWG 12 (3.31 mm2)

Min: AWG 22 (0.355 mm

2

)

ENVIRONMENT

Note: This equipment is intended for field instal lation within an enclosure.

Ambient Temperature

-25 °C … 50 °C (-13 °F … 122 °F)

Ambient Humidity

0% … 90% RH non-condensing

Storage Temperature

-30 °C … +70 °C (-22 °F … 158 °F)

EMC Immunity

EN 61326-1: 2013

EMC Emission

EN 61326-1: 2013

EN 61000-3-2: 2014

EN 61000-3-3: 2013

Approvals

UL Listed (CDN & US) UL916 Energy Management

Equipment – File No. E176435

ELECTRICAL

Supply Requirements

24 V AC ±20 % 50/60 Hz

Supply

Rating

CBX

50 VA (no FLX modules)

CBX + 1 x FLX

66 VA

CBX + 2 x FLX

82 VA

CBX + 3 x FLX

98 VA

FLX Power

Connection Proprietary FLX bus connector carries power and

comms from CBX-8R8(-H) unit. CBX-8R8(-H) can

supply power to up to 3 FLX modules.

Auxiliary

Power 18 V DC / 60 mA output

BACnet® Loading

¼ unit load device

PROCESSOR

Type

STM32 ARM Cortex-M3 proce ssor

Clock Speed

8 MHz crystal, 72 MHz internal processor clock rate

System Memory

1MByte external SRAM + 16 Mbyte external flash

(soldered to PCB not removable)

Real

-Time Clock Battery backed for 2 years minimum

COMMUNICATIONS

Local serial port

USB Micro-B socket (used as service port)

BACnet

® MS/TP port RS485 @ 9K6,19K2, 38K4, 57K6, 76K8 or 115k2

Baud

(defaults to 38K4). Max cable length 1.2 km

Modbus Port

Support for Modbus RTU

(4 Modbus devices or 40 points)

CBT-STAT Port

RS485 with a maximum cable length 500 m

FLX bus

115.2K Baud

Max bus length (including e xtension cables):

30 m / 10 0 ft. using 1 8 AWG conductors

15 m / 50 ft. using 22 AWG conduct ors

FLX bus Connection

FLX bus connector carries inter-module

communications and module power

INPUTS / OUTPUTS

Note: Shielded cable i s recommended for al l input connections.

UniPuts™ with Relay

When configured as Input:

Analog Input

Range: 0 ... 10 V @ 40 kΩ

Accuracy: ±0.5% full scale [50mV]

Resistance measurement

Range: 0 ... 450 kΩ

Accuracy: ±0.5% of measured resistance

Temperature measurement

Range: -40 °C ... +110 °C

Accuracy: 10k NTC sensors (e.g. 10k Type 2 ( 10K3A1) or

10k Type 3 (10K4A1) : ±0.3 °C, -40 to 90 °C (40°F to 194°F); ±0. 4 °C > 90 °C (194°F)

Current input

Range: 0 ... 20 mA @ 390 Ω

Note: Curre nt Input re quires user-supplied external

390 Ω resistanc e.

Accuracy: depends on user supplied external resistor

Digital Volt-Free contact, 2 mA contact-wettin g current

Pulse counting up to 20 Hz, 25 ms - 25 ms

When configured as

Output:

Analog Output 0 ... 10 V, 20 mA, 12-bit resolution

Digital Output 0 ... 10 V, 20 mA

Relay Contacts with ability to switch up to 24 V AC

Maximum Load: 24 V AC, 2 (1) A resistive (inductive)

for all relay contacts

Universal Inputs

Analog Input

Range: 0 ... 10 V @ 130 kΩ

Accuracy: ±0.5% full scale [50mV]

Resistance measurement

Range: 0 ... 450 kΩ

Accuracy: ±0.5% of measured resistance

Temperature measurement

Range: -40 °C ... +110 °C

Accuracy: 10k NTC sensors (e.g. 10k Type 2 ( 10K3A1) or

10k Type 3 (10K4A1) : ±0.3°C, -40 to 90°C (-40°F

to 194°F); ±0.4°C > 90°C (194°F)

Current input

Range: 0 ... 20 mA @ 390 Ω

Accuracy: ±0.5% full scale [100μA]

Digital Volt-Free contact, 2 mA contact-wettin g current

Pulse counting up to 20 Hz, 25 ms – 25 ms

Digital Inputs

Digital Volt-Free contact, 2 mA contact-wettin g current

Pulse counting up to 20 Hz, 25 ms – 25 ms

Notes: 1) All inputs and outputs are protected against short circuit, as well as over-

voltage up to 24 V AC.

2) Inputs use on-board 16-bit anal og to digital conve rtor.

3) 18 V DC supply, max 60mA per CBX/FLX unit , is available for powering

sensors.

SOFTWARE FEATURES

Maximum number of Stra tegy Blocks

1024

Maximum number of Trendlog Modules

64

Maximum internal Trendlog capacity (standard)

1024

Data Security

Strategy and Set points backed up in Flash

INTERFACE

Engineering Software

CXproHD

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 3 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

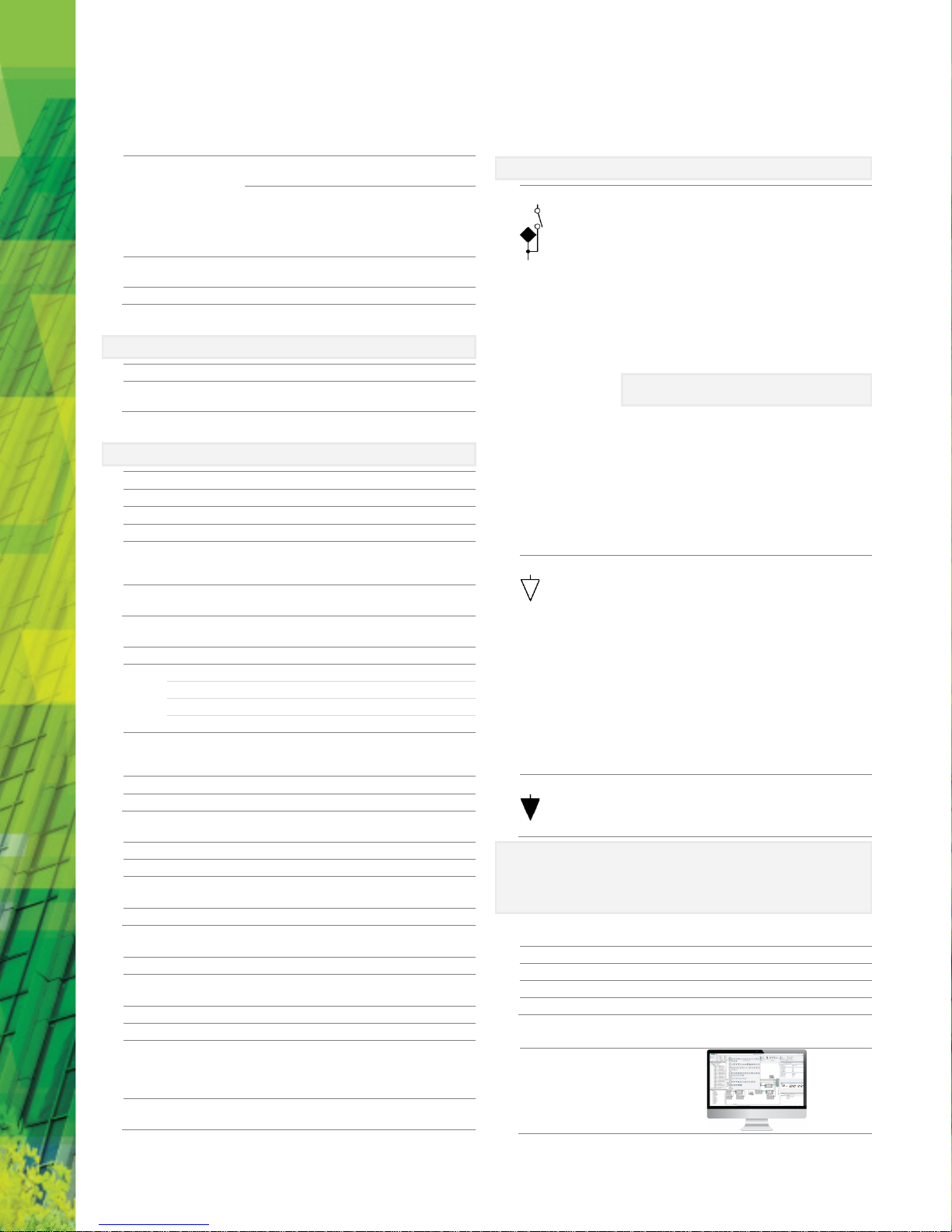

DIMENSIONS

WIRING

CBX-8R8 and CBX-8R8-H

FLX-4R4 and FLX-4R4H

FLX-8R8 and FLX-8R8H

FLX-16DI

Common

Relay Common

Point Numbers (24 V only)

Terminal Numbers

CAUTION - DANGER OF EXPLOSION IF BATTERY IS INCORRECTLY REPLACED.

REPLACE ONLY WITH THE SAME OR EQUIVALENT TYPE RECOMMENDED BY

THE MANUFAC TURER. DISPOSE OF USED BATTERIES AC CORDING TO THE

MANUFACTURER'S INSTRUCTIONS.

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 4 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

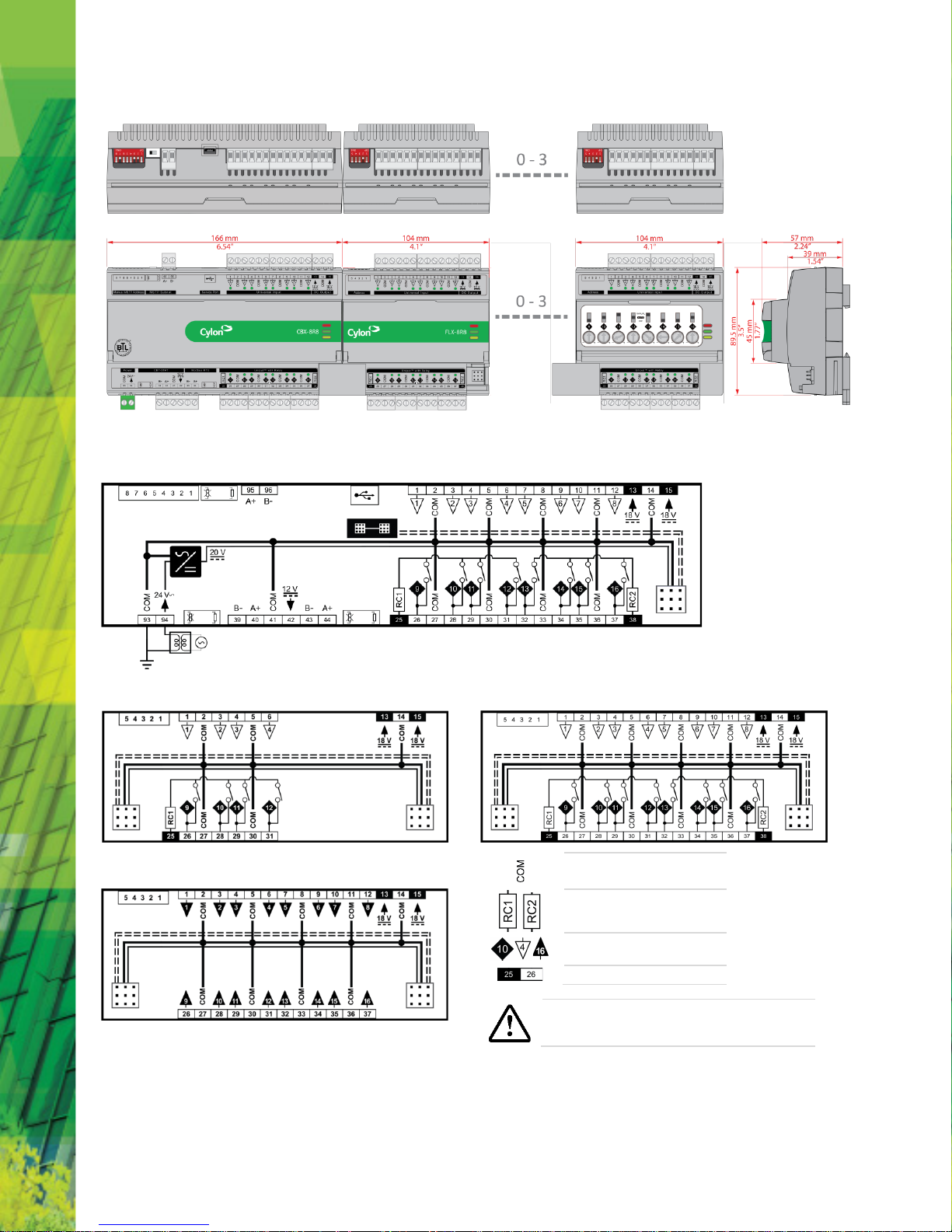

SYSTEM ARCHITECTURE

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 5 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

INSTALLATION GUIDE

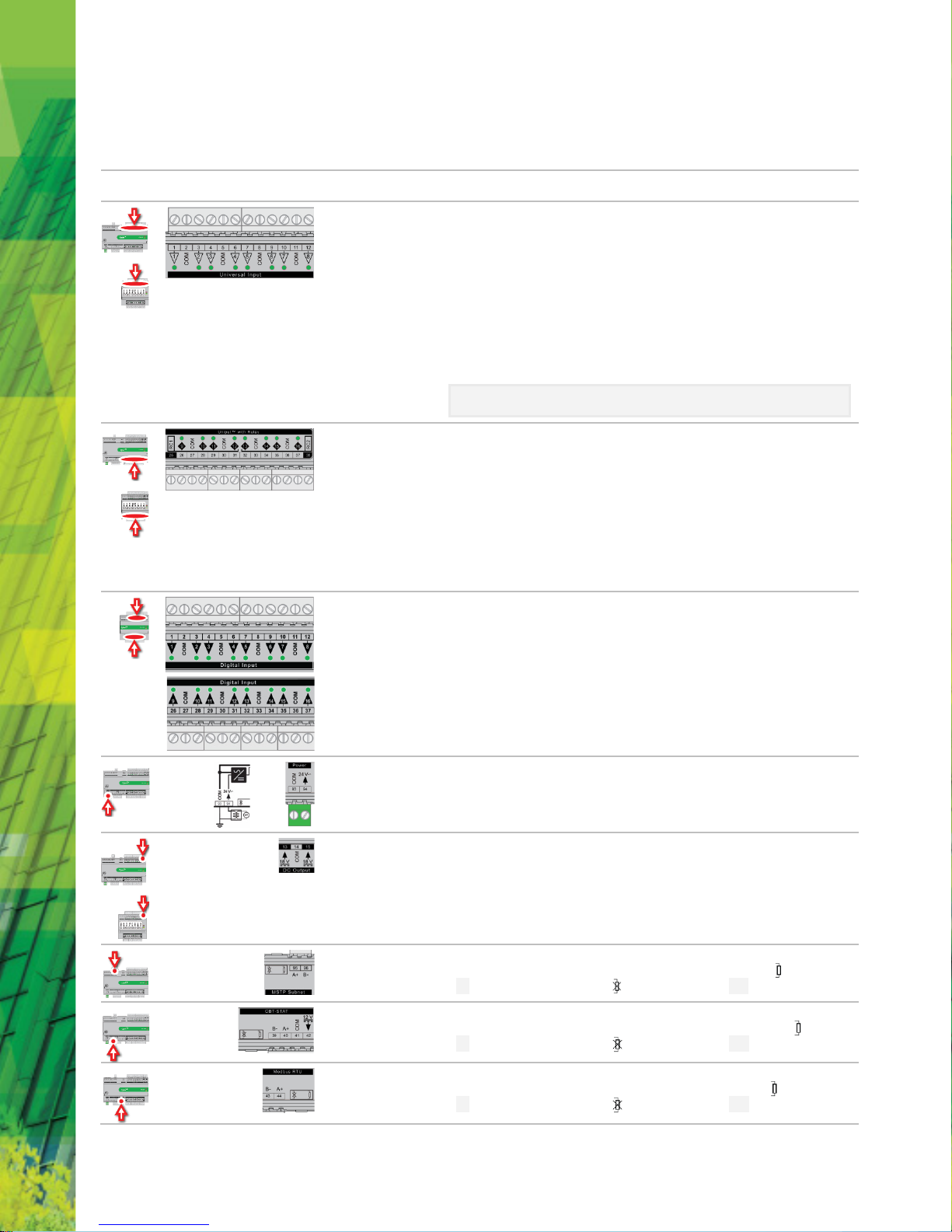

TERMINALS

Location

Illustration

Terminal

Numbers

Description

1 … 12

Universal Inputs

When input is configured as

Digital

:

• LED

Off

: open circuit or logic 'off'

• LED On: logic 'on'

When input is configured as

Resistor/thermistor

:

• LED

Off

: valid resistance connected (

Note

: 0 Ω is counted as valid)

• LED

Slow blink

: resistor/thermistor not connected

When input is configured as

Analog

:

• LED intensity is modulated by the analog signal

When the LED is blinking:

•

Fast blink

indicates error condition

•

Two short flashes followed by a value*

indicates the input is in an override state (overridden

by CXpro

HD

).

*Note: The LED intensity illustrates the value measured at the input terminals. The flash

indicates that this value has been overridden.

25 … 38

UniPuts™ + Relay

When a UniputTM channel is configured as an input, the LED signals are identical to Universal Inputs

above. When configured as an output the following apply:

When output is configured as

Digital

:

• LED

Off

: open circuit or logic 'off'

• LED On: logic 'on'

When output is configured as

Analog

:

• LED intensity is modulated by the analog signal

When the LED is blinking:

•

Fast blink

indicates error condition

•

Two short flashes followed by a value

indicates the output is in an override state

(overridden by CXproHD or HOA).

1 … 12,

26 … 37

Digital Inputs (FLX16DI only)

• LED

Off

: open circuit or logic 'off'

• LED On: logic 'on'

When the LED is blinking:

•

Fast blink

indicates error condition

•

Two short flashes followed by a value

indicates the output is in an override state

(overridden by CXpro

HD

).

93, 94 24 V AC Power

13 … 15

Auxiliary Power: 18 V DC o utput on 2 terminals, 60 mA total

95, 96

BACnet® MS/TP Port (RS-485) screw terminal

MS/TP subnet terminator switch is located beside the port. If the switch is towards the icon, then

termination is in and if the switch is towards the icon then termination is out.

39 … 42

UCU Room Display / CBT-STAT Port

The CBT-STAT bus Terminator Switch is located beside the port. If the switch is towards the icon, then

termination is in and if the switch is towards the icon then termination is out.

43, 44

Modbus RTU

The Modbus Terminator Switch is located beside the port. If the switch is toward s the icon, then

termination is in and if the switch is towards the icon then termination is out.

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 6 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

Location

Illustration

Description

Service Port (Micro USB)

8-Way MS/TP address DIP switch (CBX only)

The controller’s BACnet® MAC address can be set either electronically (USB or BACnet®) or manually using the 8-way

DIP swi tch.

1)

Manual setting for ease of replacement

: Setting the 8-way DIP sw itch to an address between 1 and 254, and

then cycling the power, will force the controller to update its MAC address to match the DIP settings. To

replace a manually-addressed controller in the field simply copy t he DIP s witch setting of the controller you are

replacing.

2)

Electronic setting for remote configuration

: Setting the 8-way DIP s witch to all zeros will allow the MAC address

to be set electronically either locally by USB or remotely over BACnet®.

It is also possible to use manual setting for initial commissioning, and then cycling the power to force the

controller to update its MAC address to match the DIP settings. To enable subsequent electronic configuration,

set the DIP switch to all zeros. The controller will retain the manually-set address until i t is electronically

overwritten.

5-Way FLX bus address DIP switch (FLX only).

This sets the address of the FLX unit on its local FLX bus.

Output Override (-H variants only: CBX-8R8-H, FLX-8R8-H, FLX-4R4-H)

Bottom position

: Off - outputs forced off.

Centre position

: Auto - outputs are controll ed by strategy.

Top position

: Manual – for digital outputs, the output is forced on. For analog outputs the knob setting controls the

output value.

Note: Manual position is supervised, i.e. the strategy is aware of the manual value.

Inter-module connection sockets

Inter-module connector

FLX bus terminator

Indicator LEDs

Off On Slow Blink Fast blink

Red LED

(Power)

Power is off Power is on

____

Unit Rebooting

____

Green LED

(Status)

Unit is not

running

Strategy Loaded

but no network

connectivity

Strategy Loaded and

device communicating

on network

No Strategy

loaded

Yellow LED

(FLX)

FLX bus

comms are ok

No FLX bus comm s FLX bu s address cl ash

FLX bus comms

error

During firmware upgrade the Yellow LED will remain on while the strategy/comms section reboots, and then the

LEDs will rotate Red-Green-Yellow while the IO section reboots.

Note: Durin g typical operation, the Red LED should be on, the Gree n

LED should be blinking, and the Yellow LED should be off.

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 7 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

INSTAL LATIO N

1. Apply power to the CBX-8R8(-H) ......................................................... 7

1.1. Set the CBX MS/TP Address........................................................................... 7

1.2. Connect 24 V AC Power to the CBX-8R8(-H) ................................................ 7

2. Connect t he CBX to the MS/TP Net work

.......................................................... 7

2.1. Attach RS-485 communication wires to the MS/TP Subnet port ................ 7

2.2. Terminate the MS/TP netw ork...................................................................... 8

3. Configure the CBX-8R8(-H) for BACnet® communications ................. 8

3.1. CBX-8R8(-H) Default Settings ........................................................................ 8

3.2. Connect CXproHD to the CBX-8R 8(-H) ........................................................... 8

3.3. (If required) Set Device In stance & MS/TP Address ........................................ 8

3.4. Confirm or set MS/TP parameter s ................................................................ 8

4. Connect the CBX-8R8(-H) to FLX units ................................................. 8

4.1. Set the FLX address........................................................................................ 8

4.2. Join or terminate the FLX bus ....................................................................... 9

4.3. (If required) Set up FLX bus ext ension .......................................................... 9

5. Add the Controller to the Site ............................................................ 10

5.1. Set Controller Date and Tim e ...................................................................... 10

5.2. Set I/O to a known Safe Mode .................................................................... 10

5.3. Set up the CBX and connected FLX in a Site ............................................... 10

5.4. Set up the Controller Strategy..................................................................... 11

1. APPLY POWER TO THE CBX-8R8(-H)

1.1. Set the CBX MS/TP Address

To communicate to other MS/TP devices on a BACnet® MS/TP network, the MS/TP

address must be set to a unique address within the MS/TP subnet. Where possible,

there should be no gaps between addresses. The BACnet® Instance Number must also

be unique for the BACnet®site.

The 8-way DIP switch can be used to set the MS/TP address when the device is first

powered on.

• The address is set in binary, from 1 (0000001) to 127 (1111111).

• A switch moved to the center (towards the ‘ON’ mark) represents 1, moved

to the edge represents 0.

• The right-most switch (labeled “1”) is the least-significant bit; the switch on

the left (labeled “8”) is the most-significant bit.

00000001

Address 1

01000000

Address 64

01011000

Address 88

11111111

Address255

0000000

Software Selectable*

*Note: If it is required that t he CBX-8R8(-H)’s address can be configured r emotely via

BACnet ® or electronically via USB, t hen once the CBX-8R8(-H) has been

powered up (Installation step 1.2) the 8-way DIP switch should be set to all zeros.

Setting the 8-way DIP switch to all zeros will allow the MAC address to be set

electronica lly either local ly by USB or remotely over BACnet®.

It is also possible to use manual setting for initial commissioning, and then

cycling the power to f orce the controller to update its M AC address to match

the DIP settings. To enable subsequent electronic configuration, set the DIP

switch t o all zeros. The contr oller wil l retain th e manually-set address until it is

electronica lly overwritten.

Note: If no address had previously been set (e.g. when the device is received from the

factory), then a device tha t is powered-on with the DIP sw itch set to all zeros

will use t he last 2 digits of its s erial number as its initial address.

The MS/TP baud rate must match on all devices on the MS/TP subnet.

1.2. Connect 24 V AC Power to the CBX-8R8(-H)

For the ini tial configuration of the device, the controller must f irst be powered on .

Note: Service Port (USB connection) must no t be connec ted until after the de vice is

powered on.

The CBX-8R8(-H) requires 24 V AC supplied from an externally mounted power

transformer. One conductor of the transformer must be grounded to an earth ground

to avoid damage to the controller. This conductor will be wired to the COM (common)

terminal of the controller. The wiring diagram is shown here:

Note: Ensure the 24 V AC and Common wires are correctly connected to the

controller. If the wires are swapped, it may cause damage to anything

connected t o the controller.

2. CONNECT THE CBX TO THE MS/TP NETWORK

2.1. Attach RS-485 communication wires to

the MS/TP Subnet port

Wiring the RS-485 network involves connecting the A+ (95) and B- (96) terminals in a

daisy-chained configuration. One end of the network will be connected to the

Fieldbus of the Network-level controller or BACnet® router. At the other end of the

network, the last device must be “terminated” by either installing a 100 Ω … 120 Ω

resistor or, if the last device is a CBX, users can switch the MS/TP Subnet terminator

switch (located beside the MS/TP port) towards the icon. This will effectively terminate

the network. The shield (screen) must be carried through the entire network.

If the RS-485 network is wired to an eSC, then the shield will be grounded at the eSC.

If the RS-485 network is wired to a CBR, the shield must be grounded at one point on

the network as shown below:

Network-level Cont roller or Ro uter

CBX-8R8(-H)

Network Segment end

- - - - - -

CBX-8R8(-H)

Network end

Shield connected at end of

network only

Network

Termination

switch set to OFF

Shield continuous

throughout the

network

Network cable segment

daisy-chained to next device

Network Termination

switch set to ON at end

of network

Shield connected to earth

at one end of network

only

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 8 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

2.2. Terminate the MS/TP network

If the CBX-8R8(-H) is the last device on the RS-485 network, then its MS/TP subnet

terminator switch must be set to “in”

3. CONFIGURE THE CBX-8R8(-H) FOR

BACNET® COMMUNICATIONS

3.1. CBX-8R8(-H) Default Settings

The CBX-8R8(-H) is shipped with the following default settings:

MS/TP Address: last 2 digits of the numeric portion of the seri al number*

BACnet® Instance

Number:

entire numeric portion of the Controlle r's serial number*

MS/TP Baud Rate: 38,400 bps

*Note CBX serial numbers are structured as “CCBX” followed by a sequential

number fo llowed by a letter : CCBX (numeric portion) (letter)

Note If the ‘numeric portion’ of the Controller serial number ends with ‘00’ then

the MS/TP addre ss is set to 100 rather than 0 to avoid conflict with the CBR

default MS/TP address.

e.g. If the Controller serial number is CCBX727458C, the ‘numeric portion’ is

727458. In that case the MS/TP address would be 58 and the BACnet

Instance Number would be 727458.

If the Controller serial num ber is CCBX812300C, the ‘numeric portion’ is

812300. In that case the MS/TP address would be 100 and the BACnet

Instance Number would be 812300.

3.2. Connect CXproHD to the CBX-8R8(-H)

Connect the laptop to the CBX-8R8(-H) through a BACnet® Router such as CBR or

ASPECT® Control Engine (ACE - Matrix or Nexus Series) via Ethernet, or directly

using a standard Micro-B USB cable.

Note: When the CXproHD PC is connec ted to the CBX USB port for the first time,

you will be pr ompted to install a driver. Install “ STMicroelectronics Virtual

COM port ”, and then sel ect the corresponding serial port i n CXpro

HD

to

connect to the CBX. If you are using Windows 8.1 this driver may not be

available by default, please c ontact Cylon TSG for a copy of the drive r.

Once connected to the controller, it is possible to change the settings on the

controller using CXpro

HD

- for details see the CXproHD User Guide (MAN0133)

available from the Cylon support site (http://support.cylon.com

).

Note: It is not requ ired to cha nge the Site Number or Comms Controller preset

values. It is however recommended to match the Field Controller address

with the MS/TP Station a ddress (see below).

3.3. (If required) Set Device Instance & MS/TP

Address

Note: This is only possible if the MS/TP address switch is set to Zero.

3.4. Confirm or set MS/TP parameters

MS/TP Baud Rate is the Baud rate at which all the other devices on the subnet

(Fieldbus) are communicating. All devices must be configured for the same baud

rate for communications on the subnet.

Device ID is the BACnet device instance number. Every BACnet controller within

the site must receive a unique BACne t instance number to ensure pr oper

communications. This BA Cnet i nstance number should be unique even across

subnets. By default, it is set is set to the entire numeric portion of the Controller's

serial number. See the Cylon BACnet® Manual (MAN0106US) for further

information.

Device Name is the user-assigne d name for the controller. This is not necessary

for BACnet communications; however, it is useful to name each controller for

organizational purposes.

APDU Timeout Seconds leave this at the default setting of 3 seconds.

MS/TP Station is the device MS/TP address. This is the unique address users

must give each controller on the subnet (Fieldbus).

MS/TP Max Masters is the maximum address that this controller will poll when in

the “poll for masters” state. Because thi s is a BACnet master device, it will go into

this state to search for the next BACnet master device to pass the token to. To

optimize the speed of the netw ork, it is recommended that the last master device

on the subnet be set at the maximum MS/TP addre ss on the network. For

example, if the last device on the subnet (Fieldbus) is the CBX at address 63, then

users would set the MS/TP Max Masters to 63. This will speed up

communications as it will not go into the “poll for masters” state and immediately

pass the token back to the eSC or CBM at MS/TP address 0.

See the Cylon BACnet® Manu al (MAN0106US ) for more details regarding this

functionality and for other tips on optimizing the BACnet network.

4. CONNECT THE CBX-8R8(-H) TO FLX

UNITS

The I/O capabilities of a CBX-8R8(-H) can be extended by the addition of FLX-8R8

and FLX-8R8-H devices.

These are connected to the CBX-8R8(-H) by means of a standard module

interconnector (FLX bus connector), one of which is shipped with each FLX device.

4.1. Set the FLX address

Each of the FLX units connected to a single CBX must have an address that is

unique on that CBX’s FLX bus. The address is set by the 5-way DIP switch.

The terminals on a FLX unit will be accessible within the CBX Strategy with point

numbers prefixed by this address as illustrated below:

Inter-module bus

Address

DIP switch setting Point numbers

00001

1

101 … 116

00010

2

201 … 216

00011

3

301 … 316

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 9 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

Note: If there are 2 devices on the same FLX bus w ith the same address –including

0, the address of the CBX - then the bottom (yellow) status LED wil l blink

slowly to indicate a FLX bus address clash

4.2. Join or terminate the FLX bus

Place the devices side-by-side and place the FLX bus connector into

the two adjacent sockets at once.

The end device on a CBX set (either a FLX device or the CBX itself if no FLX devices

are connected) must have a terminator inserted into its interconnector socket.

One terminator is shipped with each CBX-8R8(-H) device.

4.3. (If required) Set up FLX bus extension

If a FLX device cannot be located beside a CBX device or another FLX device then

The FLX bus can be connected by cable using two FLX-RMC Remote Module

Connectors, sold separately.

Connect cables to the two supplied FLX-RMC screw-terminal connectors as shown

above with the appropriate length of cable.

Note: Use Copper or Copper Clad Aluminum conductors only. Multiple wired

connections can be used between FLX mod ules, but the t otal FLX bus FL X

bus length must not exceed the following lengths:

Cable gauge

Max length

AWG 18

30 m / 100 ft.

AWG 22

15 m / 50 ft.

Remove the Interconnect (if installed) from the right-hand side of the FLX or CBX

where the RMC is to be installed.

Slide one RMC connector into the T-slot of the CBX or FLX at the point at which

the BUS is to be extended.

Replace the Interconnect

Slide the other RMC connector into the Left-Hand T-slot of the remote FLX.

Insert the second interconnect

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 10 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

5. ADD THE CONTROLLER TO THE SITE

5.1. Set Controller Date and Time

Use CXproHD to set the controller’s Date and Time.

Alternatively, if a device on the site has been set up as a Time Sync Master, then

the CBX-8R8(-H) controller time will be automatically updated.

5.2. Set I/O to a known Safe Mode

Before connecting equipment to the CBX-8R8(-H) or FLX devices, carry out a Wipe

Controller command from CXpro

HD

to put I/O into a Kno wn Safe Mode :

• In CXpro

HD

select Wipe Controller from the Controller tab on the Ribbon .

In the Wipe Controller dialog, click in the ' Wipe All' checkbox.

• Click on the ' Wipe ' button.

When the Wipe operation is complete, a ' Controller Wiped ' message is displayed:

5.3. Set up the CBX and connected FLX in a

Site

In the Cylon Configuration Utility (CCConfig) select the CBR Comms Controller to

which the CBX device is connected, and add a new controller by clicking the Add

button:

In the New Field Controller Details dialog change the Controller Type to CBX8R8.

This will cause an I/O Modules table to become visible in the New Field Controller

Details dialog:

If the CBX device has one or more FLX modules connected to it, add the same

number of entries in the I/O Modules table:

When FLX modules have been added, the specific FLX type can be set in the I/O

Modules Table Type Column:

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 11 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

If you attempt to add more modules than the CBX can support, an error message

will be displayed:

When the correct number of FLX modules has been added, enter a Device Instance

number and click OK.

Note: The IO module configuration can be changed later by openin g the FL X

Module Configuration dialog fr om the Site Tree :

In the Strate gy drawing, IO blocks can be added up to the total on the configured

FLX modules plus the CBX onboard IO.

Note: If a FLX module is deleted fr om a CBX configuration (in CCConfig) after the

Strategy drawing has been set up, the blocks associa ted with that FLX’s IO

will be ‘greyed out’ to indicate that they are inactive.

5.4. Set up the Controller Strategy

In CXproHD, double-click on the controller in the Site Tree to open its Strategy:

If there is no existing Strategy in the controller, an invitation to cre ate a new one

will be displayed:

Click Yes to open a new blank stra tegy drawing:

Add strategy blocks and points to create the required strategy – see MAN0133

CXpro

HD

User Guide for m ore detail.

Note that in CBX-8R8(-H) controllers there are:

• a total of 1024 strategy bl ocks, numbered 1 - 1024

• a total of 1024 analog virtual points 1 - 1024

• a total of 1024 binary virtual points 1 - 1024

• a minimum of 16 and a maximum of 64 hardware points:

oThe first 16 are nu mbered 1-16, represent ing the intern al I/O in the CBX

oThe 16 points in an attached FLX with MS/TP address set to “1” are numbered 1 01-116

oThe 16 points in an attached FLX with MS/TP address set to “2” are numbered 2 01-216

oThe 16 points in an attached FLX with MS/TP address set to “3” are numbered 3 01-316

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 12 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

OPERATION

Inputs and Outputs ............................................................................................... 12

Auxiliary Power out puts ....................................................................................... 13

Using a Keypad with the CBX ............................................................................... 13

Output Override .................................................................................................... 14

Inputs and Outputs

The CBX-8R8(-H), FLX-8R8 and FLX-8R8-H have identical I/O capabilities – each has

a set of 8 Universal Inputs and a set of 8 UniPuts

TM

with relay.

FLX-4R4 and FLX- 4R4-H have 4 Universal Inputs and 4 UniPuts

TM

with relay.

FLX-16DI has 16 Digital Inputs only.

Any of the terminals can be configured as inputs. Any of the UniPut™ terminals

can be configured as an output.

Input modes

Universal Input terminals and UniPut™ terminals can be configured as inputs in

almost identical fashion:

Measurement

Mode

Universal Input

UniPut™ as Input:

Digital

Input

Resistance

Resistance measurement

Range: 0 ... 450 kΩ

Accuracy: ±0.5% of measured resistance

-

Temperature measurement

Range: -40 °C ... +110 °C

Accuracy: 10k NTC sensors (e.g. 10k Type 2 (10K3A1) o r

10k Type 3 (10K4A1) : ±0.3 °C, -40 to 90 °C (-40°F

to 194°F); ±0.4 °C > 90 °C (194°F)

-

Digital Volt-Free contact, 2 mA contact-wetting c urrent

Pulse counting (volt-free)

up to 20 Hz, 25 ms – 25 ms

-

-

24 V AC Detect

-

Voltage

Analog Input

Range: 0 ... 10 V

@ 130 kΩ

Accuracy: ±0.5% f ull scale

[50mV]

Analog Input

Range: 0 ... 10 V

@ 40 kΩ

Accuracy: ±0.5% full scale

[50mV]

-

Pulse counting (0 … 10 V) up t o 20 Hz, 25 m s – 25 ms -

Current

Current input

Range: 0 ... 20 mA

@ 390 Ω

Accuracy: ±0.5% full sca le

[100μA]

Current input

Range: 0 ... 20 mA

@ 390 Ω

Note:

Current Input

requires user-

supplied

external 390 Ω res istance.

Accuracy: depends on

user supplied

external resistor

-

Note: Inputs use on-board 16-bit ana log to digital conve rtor.

Note: All inputs and outputs are protecte d against short circuit, as well a s over-

voltage up to 24 V AC.

Hardware point numbers for these inputs in the CBX-8R8(-H)'s strategy:

CBX

1

… 8

9

… 16

FLX address 1

101

…

108

109

…

116

FLX address 2

201

…

208

209

…

216

FLX address 3

301 … 308 309 …316

Resistance Input mode (Passive Input)

Passive Inputs are all those devices that vary in resistance, including switch

contacts. These all require a current supplied by the CBX-8R8(-H) terminal so that

this resistance can be measured.

The passive sensor types supported by the CBX-8R8(-H) are:

• Pre-programmed Passive Temperature Sensors.

• Potentiometer (normally used as a 0 to 10 KΩ or a 1 KΩ to 11 KΩ variable

resistor to give a 0 to 100 % output).

• Volt-Free Digital Input (the controller strategy measures the contact resistance

and gives a 0 or 1 output).

• Straightforward Resistance measurement. This can be used with the Make

Linear block to give a temperature output for temperature sensors that are not

factory pre-programmed into the CBX-8R8(-H).

In CXproHD simply select ‘Resistance ’ sensor type in the Point Module and select

Pulsed in the Advanced parameters (the Pulsed option increases accuracy by

eliminating any self-heating in the passive temperature sensor, while the

Continuous option can trade absolute accuracy for speed).

In Passive Input Mode the Uniputs™ and Universal Inputs configure like this:

Note: The refere nce voltage can be pulsed or continuous, using the solid state

switch.

A pulsed reference gives optimum accuracy by eliminating self-heating in

the sensor, and this is the defa ult setting.

UniPutTM 24 V AC Detection

If 24 V AC is connected to a Uniput™ terminal, then the 24 V AC Detect circuit will

detect this and will open switch SW1. SW1 stays open for the duration of the 24 V

AC state. When 24 V AC is removed from the Uniput™ terminal then the short

circuit or open circuit states can again be detected.

Voltage input mode (Active Input)

Note: Inp ut Impedance for Univer sal Input terminals is 130 kΩ.

Input Impe dance for Uniput™ terminals is 40 kΩ.

The 0 … 10 V input is used for Active analog and binary measureme nts. ‘Active’

means that there is no current supplied by the CBX-8R8(-H) fo r the sensor, as the

signal is generated completely by the Sensor.

The ‘mV’ sensor setting gives a value between 0 and 10,000, which represents

voltage in mV.

In 0 ... 10V Input Mode, the Uniputs™ configure like this:

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 13 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

Current Input mode (Active Input)

The Current Input is used for 0 ... 20 mA or 4 ... 20 mA Active sensors.

4 ... 20 mA scaling can easily be achieved using CXproHD by entering range

values in the Point Module ‘ Advanced ’ parameters.

Output modes

UniPut™ terminals can generate an output as follows:

Analog Output 0 ... 10 V, 20 mA, 12-bit resolution

Digital Output 0 ... 10 V, 20 mA

Relay Contacts with ability to switch up to 24 V AC

Maximum Load: 24 V AC, 2 (1) A resistive (inductive) for all relay contacts

Analog 0 … 10 V output mode

In Analog 0 ... 10 V output Mode, the UniputsTM configure themselves like this:

where the D/A is the digital to analog converter. All circuitry is fully protected

against 24 V AC .

Digital 0 … 10 V output mode

In Digital 0 ... 10 V output Mode, the Uniputs™ configure in the same way as for

analog:

In this mod e the output toggle s between the volt ages defined as “ON” and “OFF”.

Relay Mode

In Relay mode the UniputsTM are configured with a single relay common for each

half of the terminals:

Auxiliary Power outputs

The CBX and FLX modules each have two 18 V DC outputs, for I/O devices that

require loop power.

For 3-wire connections return can be through any COM terminal, but it is

recommended that Auxiliary power wiring is through terminal 14, the COM

between the two Auxiliary power terminals.

The DC output terminals provide a minimum of 18 V DC, but the combined load

(on each IO module) must remain below 60 mA.

Using a Keypad with the CBX

A CBT-STAT or UCU Room Display keypad can be connected to the CBX at the

CBT-STAT port.

Note: If UCU Room Display is used, refer to t he DS0064 UCU10FC/K for the

corresponding Strategy Point Setup.

DS0119 rev 40 ©2018 Cylon All Rights Reserved. Subject to change without notice

WWW.CYLON.COM

WWW.CYLON-AUTOMATRIX.COM

page 14 of

14

CBX System

TECHNICAL DATASHEET & INSTALLATION GUIDE

Output Override

HOA variants (CBX-8R8-H, FLX-4R4-H and FLX-8R8-H) include hardware override

switches for each of their outputs. The override controls are located behind the

flap on the front of the device:

CBX-8R8-H

FLX-4R4-H

FLX-8R8-H

And consist of a switch and a rotary knob for each output:

The channel number correspon ding to the switch is shown directly below the switch.

The switch can be set to one of 3 position s:

When a switch is set to the

Centre position

the

corresponding output channel is set to Auto mode – the

output is controlled by strategy.

The rotary knob has no effect in this mode.

When a switch is set to the

Bottom position

the

corresponding output is forced to Off – both the strategy

setting and the rotary knob have no effect.

When a switch is set to the Top position the corresponding

output is set to Manual mode

• for digital outputs, the output is forced on

• for analog outputs the rotary knob setting controls the

output value.

Note: Manual positi on is super vised, i.e. the strategy is

aware of the manual value.

The Controller Strategy can determine if an override is in place is by connecting to

the Override point on the output module:

The value of the Override point will be '0' when the output is active and ‘1’ when

the point has been manually overridden. This allows the strate gy to react to the

fact that a point has been overridden.

Note: The corres ponding terminal LED will indicate the override condition.

Loading...

Loading...