Cygnus 4+

Multi-Mode Ultrasonic Thickness Gauge

Operating Manual

Covers Gauge Model : M5-C4P

Doc No. M5-CYG4P-M-01_Iss5.doc

17 December 20 15

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

QUALITY POLICY STATEMENT

Cygnus Instruments’ mission is to be a premier supplier of niche test and

measurement instruments. To achieve this we will:

Customers

• Be dedicated to customer satisfaction by listening to direct and

indirect feedback regarding our performance and product

requirements in general.

• Design state-of-the-art products that are robust, reliable, simple-touse and compliant with applicable industry and regulatory

requirements.

• Provide products and services that meet or exceed customer

expectations in terms of performance, reliability and safety.

Internal Systems

• Operate effective and safe working practices that comply with ISO

9001:2008 and EN ISO/IEC 80079-34 and other applicable regulatory

and statutory requirements.

• Provide adequate resources to ensure product and service quality is

maintained.

• Set, communicate and measure performance objectives and targets

to promote continual improvement.

• Ensure employees are competent and involved in improvement and

customer satisfaction matters.

Suppliers

• Use suppliers and subcontractors who share our passion for customer

satisfaction and who consistently perform reliably.

2

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Contents

1. Important Notice .............................................................. 8

2. Introduction ...................................................................... 9

Cygnus 4+ Thickness Gauge ....................................................9

Cygnus Instruments ............................................................. 10

Gauge Kit Contents ............................................................... 11

Basic Gauge Kit ................................................................... 11

Kit supplied with Single Element Probe .................................... 11

Kit supplied with Twin Element Probe ...................................... 11

3. Gauge Preparation .......................................................... 12

Fitting the Batteries ............................................................. 12

Connecting the Probe ........................................................... 13

Fitting the Neck Strap .......................................................... 14

4. Selecting the Right Probe ................................................ 15

Measuring Meta ls ................................................................. 15

Measurement Modes Explai ned and Compared ......................... 16

Multiple Echo Mode (ME) (Mode 3) ....................................... 16

Single Echo Mode (SE) (Mode 2) ......................................... 16

Echo-Echo Mode (EE) (Mode 3) ........................................... 17

Measuring Non-Steels .......................................................... 17

Measuring Non-Metals .......................................................... 18

Single Element Probes and Protective Membranes ..................... 18

Measuring Higher Tem peratures .......................................... 19

Summary of Cygnus Probes .................................................. 21

Twin Element probes ......................................................... 21

Single Element probes ....................................................... 21

The ‘Probe Type’ Code ....................................................... 22

5. Gauge Operation ............................................................. 23

Gauge Controls ................................................................... 23

Turning the Gauge On .......................................................... 24

Turning the Gauge Off .......................................................... 24

Automatic Power Off .......................................................... 24

Measurement S c reen V iews ................................................... 25

Status Information ............................................................... 26

Taking Thickness Measurements ............................................ 27

Zeroing the Probe (twin element probes) .............................. 27

Taking the Thickness Measurement...................................... 27

Echo Indicators in Multiple Echo Mode .................................. 28

3

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

Measurement Stability Indication in SE & EE Modes ................ 29

Measuring Small Diameter Pipe & Tubes .................................. 30

Display Hold Function ........................................................... 30

Battery Life ......................................................................... 31

Battery Level .................................................................... 31

Low Battery Indication .......................................................... 32

6. Using the A-Scan Display ................................................ 33

Single Echo Mode ................................................................ 33

Measuring Over Corrosion Pits ............................................ 34

Echo-Echo Mode .................................................................. 35

Multiple Echo Mode .............................................................. 36

7. Calibration ...................................................................... 38

Why should I Calibrate my Thickness Gauge? ........................... 38

Calibration Options .............................................................. 39

Calibrating to a known thickness (Single or 1 Point) .................. 39

Two Point Calibration ........................................................... 41

Ladder Step Wedge ........................................................... 41

Two Point Calibration Procedure .......................................... 42

Probe Zero (twin element probes) .......................................... 44

Starting a Probe Zero from the Main Menu ............................ 45

Probe Zero Function .......................................................... 45

Setting the Velocity of Sound ................................................ 46

8. Gauge Setup ................................................................... 48

Menu Operation ................................................................... 48

Settings are Saved with the Probe Type .................................. 49

Inputting Numeric Values using the Navigation Keys ................. 50

Inputting Text using the Navigation Keys ................................ 50

Selecting the Probe Type ...................................................... 52

Automatic Probe Detection ................................................. 53

Measurement Un its .............................................................. 54

Resolution Setting ............................................................... 54

Limit Functions .................................................................... 55

Deep Coat Function (multiple ec ho mode) ............................... 58

9. Data Logging ................................................................... 61

Data Logging Features .......................................................... 61

Record Types ...................................................................... 62

Reference and Minimum Thicknesses ...................................... 62

Minimum Thickness Limit Alert ............................................ 62

Radia l Points ....................................................................... 62

4

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Measurement Co m m ent s ...................................................... 63

Loading Measurement Comments from a File ........................ 64

Grid Records ....................................................................... 64

Template Records ................................................................ 66

Data Logging Menu .............................................................. 66

Creating a new Record ......................................................... 66

Your Choices will be Saved for Next Time ............................. 68

Using a Template to Create a new Record................................ 69

User Field Input ................................................................ 69

Reviewing and Editing U s er Field Choices .............................. 69

Logging Thickness Measuremen t s ........................................... 70

Auto-Log Feature .............................................................. 71

Logging Obstructions and No-Readings ................................. 72

Changing Measurement Units whi l e D ata Logging................... 73

Re-taking the Last Measurement ............................................ 73

Stepping Backwards in the Record .......................................... 74

Adding Radial Points ............................................................ 75

Adding Measurement Comments ............................................ 77

Closing and Opening a Record ............................................... 78

Closing the Record ............................................................ 79

Opening a Record ............................................................. 79

Protecting a Record .............................................................. 80

Opening Protected Records ................................................. 82

Deleting Records ................................................................. 82

Deleting Individual Records ................................................ 83

Deleting All Records .......................................................... 84

Record Status ................................................................... 84

10. Data Logging Templates .............................................. 86

Templates .......................................................................... 86

Integrating with Microsoft Excel .......................................... 87

Measurement Points ............................................................. 87

User Fields ......................................................................... 88

User Field ‘List’ Type ......................................................... 88

11. Manual Gain Adjustment .............................................. 89

Manual Gain Mode ............................................................... 89

Turning on Manual Gain ..................................................... 89

Manual Gain Menu ............................................................ 90

Adjusting the Gain ............................................................ 91

Adjusting the Range .......................................................... 92

Measuring Below the Probes Minimum Thickness Specification . 93

5

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

12. Setup Menu .................................................................. 94

A-Scan Range ..................................................................... 94

Automatic ........................................................................ 94

Manual ............................................................................ 94

Vibrate Feature ................................................................... 94

Brightness Setting ............................................................... 94

Power Off Setting ................................................................ 95

Auto-Log ............................................................................ 95

Comments .......................................................................... 95

Set Time and Set Date ......................................................... 96

Set Time and Set Date ......................................................... 96

13. General Points On Thickness Gauging .......................... 97

14. Troubleshooting ........................................................... 98

The Gauge will not Switch On ................................................ 98

Difficulty obtaining a Reading ................................................ 98

If Readings are Erratic or Unstable ......................................... 98

Tips for Optimising Battery Life .............................................. 98

15. Updating your Gauge ................................................. 100

Update Software ................................................................ 100

Gauge Firmware Files ......................................................... 100

16. Care and Servicing ..................................................... 101

Cleaning the Gauge ............................................................ 101

Batteries .......................................................................... 101

Environmental ................................................................... 101

Repairs ............................................................................ 101

Returning the Gauge for Servicing ........................................ 102

17. CygLink Computer Software ...................................... 103

Installing CygLink .............................................................. 104

Requirements ................................................................. 104

Upgrading ...................................................................... 104

Installing ....................................................................... 104

Connecting to the Gauge .................................................... 105

First time USB Connection ................................................ 105

Connecting the Gauge to CygLink f or t h e First Time ............. 106

Connecting to the Gauge Afterwards .................................. 107

Disconnecting from the Gauge .......................................... 107

Manual Connection Settings .............................................. 107

Status Bar ........................................................................ 107

Surveys ........................................................................... 108

6

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Creating a new Survey ..................................................... 108

Opening an Existing Survey .............................................. 109

Editing the Survey Info .................................................... 109

Managing the Survey ......................................................... 109

Sorting Survey Records ................................................... 109

Viewing Record Information .............................................. 110

Ref and Min Thickness ..................................................... 111

Protection State .............................................................. 112

Measurement Summary Stats ........................................... 112

Data Logger Records .......................................................... 112

Transferring Records from the Gauge ................................. 112

Viewing Thickness Measurements in a Record ...................... 114

Managing Measurements .................................................. 114

Viewing Measurement Information ..................................... 115

Adding Comments to Measurements .................................. 116

Viewing an A-Scan Graph ................................................. 117

Deleting all Records from the Gauge .................................. 118

Measurement Co m m ent List ................................................ 119

Material Veloc it y L is t .......................................................... 120

Creating a PDF Survey Report ............................................. 121

Exporting a Survey to a CSV File .......................................... 122

Templates ........................................................................ 123

Creating New Templates .................................................. 123

Editing Templates ........................................................... 124

Sending Templates to the Gauge ....................................... 127

Deleting Templates from the Gauge ................................... 128

Other Features .................................................................. 128

Setting the Time and Date on the Gauge ............................ 128

COM Port Numbers ............................................................ 128

Finding your COM Port Number ......................................... 128

18. Information ............................................................... 130

Technical Specifications ...................................................... 130

Table of Sound Velocities .................................................... 134

Reading Conversions ....................................................... 135

19. EU Declaration of Conformity ..................................... 136

20. Recycling and Disposal (EC Countries)....................... 137

21. Warranty Information ................................................ 138

22. Index ......................................................................... 139

7

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

The following important information must be read and

gauges.

1. Important Notice

understood by all users of Cygnus ultrasonic thickness

The correct use of Cygnus ultrasonic thickness gauges requires

identification of the correct equipment for the specific application

coupled with an appropriately trained and qualified operato r o r

technician. The incorrect use of this equipment, along with its

incorrect calibration, can result in serious financial loss due to

damage to components, fac i l it ies, personal injury and even death.

Neither Cygnus Instruments nor any of its employees or

representatives can be held respo n si ble for improper use of this

equipment. Proper training, a complete understanding of ultrasonic

wave propagation, thorough reading of this manual, proper

transducer selection, correct zeroin g of the transducer, correct

sound velocity, correct use of th e appropriate test blocks, proper

cable length and proper couplant selection all play a factor in

successful ultrasonic thickness gauging. Of critical importance is

the process of complete and accurate calibration of the

instrument.

This manual will provide instructions in the set up and operation of

the thickness gauge. Additiona l factors that can affect the use of

ultrasonic equipment are beyond t h e scope of this manual and to

that end it is understood that the operator of this equipment is a

well-trained inspector qualified by either their own organisation or

another outside agency to the appropriate level of both theory and

practical application of ultrasonics .

Therefore Cygnus Instruments recommends t h at users of its

ultrasonic thickness gauges should be formally qualified to a

minimum of UT “Level 1” (ASNT or PCN) which will provide

approximately 40 hours of training.

8

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

2. Introduction

Cygnus 4+ Thickness Gauge

The Cygnus 4+ Ultrasonic Thickness Gauge is a rugged,

handheld, battery-powered ins trument designed for high-reliability

thickness measurements in harsh environments using ultrasound.

It features a colour LCD display which can be easily read in most

light situations including sunlight.

The gauge can be used with a choice of Ultrasonic Probes, selected

to suit the material and thickness range to be measured.

The gauge can measure material thickness using three methods;

Single Echo, Echo-Echo or Multiple Echo. Echo-Echo an d Multiple

Echo allow measurements through su rface coatings which are

ignored. An A-Scan display provides the user with information that

can be used to visually verify the thickness measurem ent which

can displayed in Metric (mm) or Imperial (inch) units.

A Data Logging function can save thickness measurements and AScans in to a record file which can then be transferred to a

computer for analysis and report generation.

The gauge can easily be calibrated to a known thickness or to a

known Velocity of Sound.

The gauge is able to operate accurately over a wide range of

ambient temperatures and is environmentally sealed to IP67 for

use in wet conditions.

The gauge is a solid-state electronic instrument which, under

normal operating conditions, wil l give many years of active

service.

Although designed for ease of operation the first time user

should carefully read this manual to familiarise themselves

with the features of the Gauge.

9

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

63 Jalan Pemimpin #05-01,

577219 Singapore.

Cygnus Instruments

Cygnus Instruments Limited, founded in 1983, were pioneers in

the development of the Digital Ult rasonic Multiple-Echo Technique

used for measurement through coatings. This has long been the

standard required to ensure that accurate measurements are

taken without the need to first zero the gauge or remove any

coatings.

Our philosophy is to work closely with ea ch of our customers to

provide a range of products spec i fically for each application.

Cygnus Ultrasonic Thickness Gauges are designed to be simple to

use and to withstand the harsh environments that they are

intended for. We have built up an enviable reputation with our

customers in over 45 countries around the world.

Cygnus House, 30 Prince of Wales Road,

Dorchester, Dorset DT1 1PW England.

Tel: +44 (0) 1305 265533 Fax: +44 (0) 1305 269960

www.cygnus-instruments.com sales@cygnus-instruments.com

CYGNUS Instruments Inc. CYGNUS Singapore (S) Pte. Ltd.

1993 Moreland Parkway, Suite 202.

Annapolis, Maryland 21401, USA.

Tel: +1 410 267 9771 Tel : +65 6252 5909

Fax: +1 410 268 2013 Fax : +65 6251 1318

www.cygnusinstruments.com www.cygnus-instruments.sg

sales@cygnusinstruments.com sales@cygnus-instruments.sg

Pemimpin Industrial Building.

10

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Gauge Kit Contents

Basic Gauge Kit

1. Cygnus 4+ Gauge

2. Operating Manual (in side pouch)

3. Neck Strap (in side pouch)

4. Accessory Pouch, containing; 3 x AA Batteries, Blue

Couplant Gel.

Kit supplied with Single Element Probe

1. Ultrasonic Probe

2. Moulded Probe Cable (in side pouch)

3. 15mm (or ½”) Steel Test Block

4. Spare Membranes

5. Membrane Key

6. Membrane Couplant

Kit supplied with Twin Element Probe

1. Ultrasonic Probe

2. Moulded Probe Cable (in side pouch)

3. Ladder Step Wedge, 4 Step.

11

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

Press the bottom of the

The batteries are located

may leak out.

The gauge can be fitted with NiCad or NiMH rechargeable

batteries but this may alter the specified operating time.

3. Gauge Preparation

The gauge is supplied ready to use out of the box. Just insert the

batteries, connect the probe to th e gauge, turn on the power,

calibrate and you are ready to begin taking thickness

measurements.

Fitting the Batteries

The gauge requires 3 x AA/LR6/UM3 Ba t t eries. Cygnus supplies

and recommends Duracell Alkaline batteries. The batter ies are

located behind a cover on the rear of gauge. The hand strap can

be separated by a push-but t on buckle to gain access to the ba t t ery

cover. The battery cover is removed by pressing in with your

thumb the at the base to release the clip.

battery cover to release

the retaining clip and lift

up the battery cover.

underneath.

The gauge is protected

against electrical damage

from incorrect battery

insertion.

The battery compartment

itself is sealed to contain

any battery fluids that

12

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

To avoid damage from leaking batteries always remove the

not be covered by the warranty.

The connector is

batteries if the gauge will be unused for any length of time.

If the batteries run flat they may leak acid into the battery

compartment and damage the electrical contacts. This would

Connecting the Probe

The Cygnus probe lead uses a c u stom made cable that offers

superior flexibility and resistance t o oi l s and ultraviolet light. The

cable will not stiffen after exposure to ultraviolet light.

The connector uses original Lemo connectors for reliability. The

twin connectors are over-mounded to form a tough housing that

will provide a long lasting probe cable

Depending on the type of probe supplied the probe end will have

either a BNC or single Lemo 00 connector.

orientated with a ‘pip’

and can only be plugged

in one-way around.

To release the connector

simply pull back on the

connector body. DO NOT

pull the cable.

13

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

Wire loop fitted to the

The neck strap can then

Fitting the Neck Strap

The gauge is supplied with an adj u st able Neck Strap. The ends of

the neck strap clip onto two wire loops fitted to the gauge. These

wire loops are made from coated stainless steel.

gauge body.

Simply pass the loop

through the hole in the

gauge and back over the

other end.

be clipped on to the loops.

14

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

The gauge must be set for the probe connected to it, see

Selecting the Probe Type on page 52.

Recommended..

Probe

Measurement Mode

Steels

Any

Non to

Moderate

1 mm+

S5A

Multiple Echo

Steels

Any

Non to

Moderate

2 mm+

S3C

Multiple Echo

Steels

Any

Non to

Moderate

3 mm+

S2C

Multiple Echo

Steels

Any

Non to

Moderate

3 mm+

(0.12”+)

S2D

Multiple Echo

Steels

Non

Non to

Heavy

1 mm+

T7A

Single Echo

Steels

Non

Non to

Heavy

2 mm+

T5B

Single Echo

Cast

Iron

Non

Non to

Moderate

3 mm+

T2C

Single Echo

When measuring in Multiple Echo mode the coating will be

ignored and just the metal thickness measured.

4. Selecting the Right Probe

The performance of any thicknes s gauge, and its ability to get a

reliable measurement depends on selecting the right ultrasonic

probe for the application and conditions. Cygnus gauges are

therefore offered with a selection of probes suitable for most

thickness gauging applications.

The following section helps you se lect t h e right probe for the

application.

Measuring Metals

Material Coating Corrosion Thickness

The table above shows that to be able to measure coated and uncoated steels with non to heavy corrosion ideally you will require

at least two probes, in almost all applications this will be a S2C

probe and a T5B probe.

15

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

It is possible to use a Twin Elemen t ( T **) probe in Echo-

incorrect measurements.

Echo Mode to ignore thin paint coatings. However this

method does not have the ability to verify measurements

and without observing the A-Scan display it is possible to get

Measurement Modes Explained and Compared

Multiple Echo Mode (ME) (Mode 3)

Multiple Echo measurement mode is by far the most reliable and

quickest method for thickness measurements, because it works by

looking for three matched echoes it can verify the thickness

measurement is valid. This method has been used in all Cygnus

gauges since the late 1970s.

Multiple echo mode will ignore surface coatings (Through Coating

mode), there is no need to remove the paint to take a

measurement.

Also because it uses a single element (or single crystal) probe

there are no errors due to the V-path of the ultrasound beam

found in all twin element probes. This makes it simple to calibrate

– two point calibrations are not required.

However because it requires three echoes to take a measurement,

in heavily corroded steels there is often an insufficient number of

echoes so measurements may not be possible.

Single Echo Mode (SE) (Mode 2)

Single Echo measurement mod e is most useful on heavily corroded

metals where Multiple Echo fails. Because it only needs the first

return echo to take a measurement it performs well on virtually all

steel conditions.

However single echo mode will not ignore any surface coatings, so

if you measure through a coating it will give an incorrectly metal

thickness measurement . If the surface coating is very thin

(0.2mm / 0.01”) paint you can make an allowance for this error,

but thicker coatings introduce too much error to be practica l.

16

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Single echo measurements use a twin element (twin crystal)

probe, because there are two elements angled to a focal po int

there is a v-path error introduced. However this v-path error is

mostly corrected by the gauge, and furthermore by performing a

two point calibration.

Twin element probes requ ire “zeroing” at regular inter vals,

especially if the am b ient t em perature is changing.

To overcome some of the drawbacks of Single Echo measurements

the gauge has an A-Scan display that can be used to visually

verify the thickness measu rements are sensible and therefore

reliable. See section Using the A-Scan Display on page 33.

Echo-Echo Mode (EE) (Mode 3)

Echo-Echo mode uses a twin element probe, but measures

between the first two echoes. This method is intended to ignore

any thin surface coatings whilst still using a twin elem en t probe.

Echo-echo mode is not able to verify its measurements unlike

Multiple echo mode, therefo re it is liable to give incorre ct readings.

+

But as the Cygnus 4

gauge has an A-Scan display you can use

this to visually decide if the measurement given is correct.

Echo-echo mode must therefore b e used with caution, and only on

thin paint surface coatings (less than 0.5mm). It is recommended

a Single Echo measurement should also be made to help verify the

measurement makes sense (the Single Echo measurement should

always be slightly thicker due to the coating thickness).

Measuring Non-Steels

The gauge will measure the fo l lo wing non-steels;

• Aluminium alloys

• Copper and Brass alloys

• Titanium

Use the same rules as steels when selecting a suitable probe. The

gauge will ideally be re-calibrated to suit the metal being

17

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

measured, or the standard velocity of sound for that material

would be entered into the gauge.

Measuring Non-Metals

You can measure certain types of plastics with the gauge using a

twin element probe and the gauge set to Single Echo

measurement mode. Generally the harder the plastic the better,

soft materials like rubber or TPEs tend to absorb too much

ultrasound so only thin samples can be measured.

Engineering plastics like Acetal, Tufset (Polyurethane), Nylon and

High-density polyethylene (HDPE) can be measured successfully.

Rotationally Moulded pa r ts can generally be measured

successfully.

• You must use Single Echo mode to measure plastics.

• You must generally use a low frequency probe (i.e. T2C) to

measure plastics, but this will d epend on the properties of the

material.

• Any material with a closed-cell construction cannot be

measured.

• Any material with internal voi ds, air bubbles or honeycomb

cannot be measured.

Typically these materials cannot be measured with the gauge;

• Concrete

• Wood

• Thermal insu la t ion mater ials

• Foams

• Composites

Single Element Probes and Protective Mem branes

All Cygnus single element probes h ave a soft face and are

therefore fitt ed with a Polyurethane Membrane which provides

18

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Check the membrane regular ly as it is important the

membrane is changed as soon as it shows any signs of wear.

Probe Body

Locking Ring

Polyurethane Membrane

Knurled Ring

better contact on rough surfa ces and protects the probe face from

wear, prolonging the life of the probe.

Single Element Probe Membrane Parts.

Single Element Probe Membrane Locking Key

Measuring Higher Temperatures

The polyurethane membranes fitted to the s ingle e lement probes

are suitable for measuring surface temperatures up to 75°C. For

measuring higher temperatures Teflon Membranes are available

and suitable for surface temperat ures up to 150°C. Contact

Cygnus instruments to order Teflon membranes.

19

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

Unscrew the Knurled Ring from the

2.

Use the Membrane Key to unscrew

discarded.

3.

Place a new membran e into th e end

4.

Screw the Locking Ring back inside

5.

Place a few drops of Membrane

6.

Screw the Knurled Ring back onto

Knurled Ring down.

7.

You should see the membrane has

a very thin film of couplant between

bubbles.

Changing the Protective Membrane on Single element Probes

end of the Probe.

the Locking Ring from inside the

Knurled Ring. The old membrane

can then be removed and

of the Knurled Ring ensuring it

locates in the groove.

the Knurled Ring and tighten with

the Membrane K ey.

Couplant on to the probe face.

the probe. Use your thumb to

squeeze the couplant from under

the membrane as you tighten the

itself and the probe face with no air

20

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

T2C

12mm

2 MHz

3 to 250 mm

0.12 to 10”

Attenuative materials

Cast irons, plastics

T5B

8mm

5 MHz

2 to 200 mm

0.08 to 8”

General purpose

Most metals

T7A

5mm

7.5 MHz

1 to 50 mm

0.04 to 2”

Thin metals

S2C

13mm

2.25 MHz

3 to 250 mm

General purpose probe suitable

Coated metals

S2D

19mm

2.25 MHz

3 to 250 mm

As S2C but has longer focal

on thicker materials

S3C

13mm

3.5 MHz

2 to 150 mm

Coated metals

S5C

13mm

5.0 MHz

1 to 50 mm

Coated metals

S5A

6mm

5.0 MHz

1 to 50 mm

Small diameter tubes

Coated metals

Summary of Cygnus Probes

Twin Element probes

Probe

Type

Size Frequency

Single Element probes

Probe

Type

Size Frequency

Range in

Steel

(SE Mode)

Range in

Steel

Typical Uses

Typical Uses

for most applications that can

use Multiple Echo

measurement.

0.75”

0.12 to 10”

point (33 mm) and narrower

beam so may perform better

Thin metals

21

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

S

2

C

Size

D 19mm

The ‘Probe Type’ Code

Single or Twin

Crystal

Frequency in MHz

A 6mm

B 8mm

C 13mm

22

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Probe

Power

Select

Menu

Navigation

5. Gauge Operation

Gauge Controls

End view of gauge

Connections

Keys

Key

Key

Keys

Front view of gauge

23

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

Press the Power key

2.

Cygnus Instruments Logo is

displayed

3.

The gauge details are displayed;

4.

The gauge is ready to use

1.

Press & Hold the Power key,

2.

The display shows ‘power-off’ and

Turning the Gauge On

Model

Serial Number

Version Number

Run Time

Turning the Gauge Off

the gauge turns off.

Automatic Power Off

By default the gauge will turn off automatically after 5 minutes of

in activity.

24

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

1.

Use the Left and Right

2.

Basic Screen

3.

A-Scan Screen

Taking thickness measurements or accessing the menu will reset

the activity timer back to zero.

You can change the activity time value the Setup menu, see Power

Off Setting on page 95.

Measurement Screen Views

The gauge has three measurement screens that can be quickly

changed using the left and right navigation keys. These screens

offer three views to suit the situation.

navigation keys to move

between the th ree screens

Just shows a large thickness

measurement value.

Show the thickness

measurement and a live A-Scan

display of the ultrasound signals

received.

25

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

4.

Data Logging Screen

Battery

Level

Measurement

Mode

Deep Coat

Function

Velocity, or

‘Calibrated’

Probe

Type

When data logging is active this

screen shows details of logged

measurements.

Status Information

At the top of the display is an area that shows information about

the gauge’s status;

• Battery Level

• Velocity of Sound value / Calibra tion Status

• Probe Type

• Measurement Mo de

• Deep Coat Function

Probe Type; when the probe is connected the background colour is

green, when disconnected it is grey.

Measurement Mo d es;

26

ME Multiple Echo

EE Echo-echo

SE Single Echo

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

It is recommended to frequently perform a Probe Zero

especially if conditions such as temperature are changing.

1.

Remove all scale, rust, dirt or loose

2.

Apply ultrasonic couplant to the test

3.

Place the probe-face on the clean,

4.

The gauge will display a thickness

Multiple Echo mode).

Taking Thickness Measurements

Taking ultrasonic thickness measurements is a straight forwar d

process that involves first making sure the surface is clean and

prepared, applying an ultrasonic couplant gel then placing the

probe on the surface and observing the display for the

measurement.

Zeroing the Probe (twin element probes)

When a twin element probe is connected to the gauge (and the

gauge is set to the correct probe) you must first perform a Probe

Zero before you can begin takin g measurements. For instructions

see Probe Zero Function on page 45.

Taking the Thickness Measurement

coatings and brush the test area clean.

surface.

lubricated test surface and make firm

contact applying gentle pressure.

measurement.

(Or an indication of Echo Strength if no

valid measurement has been found in

27

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

1 Bar Flashing:

2.

1 steady + 1 Bar Flashing:

3.

2 steady + 1 Bar Flashing:

4.

3 steady + 1 Bar Flashing:

Echo Indicators in Multiple Echo Mode

Should the gauge be unable to detect a stable multiple echo signal

it displays an Echo indication to help the operator locate a suitable

position.

No echoes detected

Only 1 echo detected

Only 2 echoes detected

3 echoes detected but they are

not matched

28

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

1.

Initial measurements will be

2.

If the measurement remains stable

To help obtain a multiple echo reading the operator should

continue to move the probe around to locate a suitable reflector ,

using a slight rocking motion.

Measurement Stability Indication in SE & EE Modes

To help indicate when a Single Echo or Echo-Echo measure ment is

stable – and thus probably reliable – the gauge changes the

thickness measurement number colour from Red to Green when

the measurement has been stable for 2 consecutive seconds.

When measuring using Single Echo or Ech o-Echo mode once you

have a measurement keep the p robe still and wait for the gauge to

signal a “stable reading”.

If the ultrasound signal is poor or erratic then the thickness value

may remain red – thus indicating the measurement may not be

reliable.

displayed as red numbers.

for 2 consecutive seconds then the

measurement will change to

green.

Stable is defined as; the thickness measurement changing no

more than + or - the Resolution setting.

Example.

29

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

The dividing line on the face of the probe should be at

1.

A thickness measurement is

Pipe

Probe Face

Probe Face Division is at

The Resolution is set to 0.05mm, therefor the thickness

measurement must not change by more than +0.05mm or

-0.05mm for 2 seconds or more to be “stable”.

Measuring Small Diameter Pipe & Tubes

When measuring small diameter pipe and tubes with a twin

element probe, 75mm (3”) or u n der, you must ensure the face of

the probe is correctly aligned to th e curvature of the pipe

otherwise measurements may be inaccurate.

right angles to the length of the pipe.

Display Hold Function

The thickness measurement can be ‘Held’ or frozen by simply

pressing the X/Cancel key while in any measurement screen.

displayed

right angles to the pipe

30

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

2.

Press the X/Cancel key to hold the

3.

Press the X/Cancel key to un-hold

Battery almost full

thickness measurement.

The measurement value now has

a light blue border to indicate it’s

held or froze.

the thickness measurement.

Battery Life

The gauge will operate continuously for approximately 10 hrs

when fitted with Duracell Alkaline 1500 mA/hr batteries.

Battery Level

A battery level graphic is displayed at the top left position of the

display (arrowed);

31

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

Battery about 1/2 full

Battery low

Low battery indication

Flat Battery message

Low Battery Indication

The gauge will perio dically f la sh a r ed Lo w Battery warning sign

when the batteries have approximately 1 hour of use remaining.

When the batteries are exhausted the gauge will display a Flat

Battery message for 5 seconds then turn off automatically.

32

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

This A-Scan shows a good clear

Good Signal

6. Using the A-Scan Display

To help ensure reliable measurements in Single Echo and EchoEcho measurements the gauge has an A-Scan display that can be

used to visually verify the thickn ess measurements are sensible

and therefore reliable. With some practice any user can quickly

and easily use the A-Scan to decide if the measurement is correct.

To view the A-Scan display use the Left and Right navigation keys

to switch between the measurement screen views (see

Measurement S c reen V iews on page 25).

The A-Scan display shows the actual ultrasound echo pulses as

received by the gauge; these echo pulses are used by the gauge

to determine the thickness measurement if possible.

The gauge works by generating a short pulse of ultrasound that is

coupled into the object you are measuring. This pulse then travels

through the object and is reflected back to the probe as an echo

by either the back-wall of the object and/or any internal flaws or

corrosion pits. When the echo pulse hits the probe surface a signal

is received by the gauge, this signal is shown on the A-scan

display as an echo peak, the taller the peak the stringer the signal.

Single Echo Mode

The A-Scan display is very useful when measuring in Single Echo

modes, as there is no verification of the thickness measurement

observing the A-Scan display will help the user verify the echo

detected is the correct one – the back-wall echo.

ultrasound signal.

There is a well-defined back-wall echo

and the arrow is correctly placed.

The measurement value of 1 2.7 is stable

when green in colour.

33

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

This A-Scan shows a very weak

fails then try another position.

You should be careful not to attempt t o t ake a single echo

ultrasound signal.

There is no clear correct back-wall echo

and the gauge is unable to determ in e a

thickness measurement.

You should try moving the probe to find

a better reflector, first rotate the probe

to see if that gets a measurement, if that

Measuring Over Corrosion Pits

thickness measurement when there is a void or corrosion pit

Weak Signal

directly underneath the probe face as the gauge may

incorrectly measure the depth of the couplant.

Large Corrosion Pit s.

34

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

This A-Scan shows an incorrect

Corroded Metal

Couplant

Probe

Avoid Measuring Directly Over Corrosion Pits.

Pit

The A-Scan display can assist you - you will see an unclear

ultrasound signal with unclear back wall reflections.

measurement that may be from

measuring couplant inside a pit .

Echo-Echo Mode

Like Single Echo mode the A-Scan can be very useful when taking

measurement through coatin g u sing Echo-Echo mode. Echo-Echo

mode measures thickness by measuring the time between two

consecutive echo signals, in ideal conditions this is a good reliable

method of thickness measurement thorough coating, but when

corrosion starts to degrade the echoes the gauge could measure

between two incorrect echoes and give a wrong reading. Here the

35

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

This A-Scan shows an unclear Echo-Echo

then another location.

The gauge measures between the se two echo

A-Scan can assist, by observing the echo signals you can decide of

the thickness measurement given makes sense and is reliable.

signals to calculate the thickness. This is a good

clear signal so the measurement is reliable.

The two purple arrows mark th e points the gauge

has measured between.

measurement.

The echoes are scattered and although

the gauge has given a thickness

measurement of 5.5mm it ma y no t be

accurate. Try first rotating the probe

Multiple Echo Mode

Although Multiple Echo mode has the benefit if providing “echo

matched” verified thickness measurements and can be used

reliably without observing the A-S can display, the A-Scan display

can sometimes help where measurements are difficult or suspect.

36

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

This A-Scan shows a good Multiple-Echo

This A-Scan shows a Multiple-Echo

This A-Scan shows no Multiple-Echo

SE or EE mode.

measurement on a new steel sample.

The echo signals are distinct a n d clear.

The three purple arrows mark t he

positions the gauge used for the

thickness measurement.

measurement from a corroded steel

sample.

The three echo signals have been picked

out ok, but there is less clarity ar ou n d

echo 2 and 3.

measurement.

The echo signals are all over th e display,

there are no distinct echoes for the

gauge to pick out. You should move the

probe to another location, or t ry using

37

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

7. Calibration

Why should I Calibrate my Thickness Gauge?

Ultrasonic thickness gauges measure time in order to measure the

thickness of the material being tested. It relies on the principal

that sound travels through a material at a constant velocity or

speed. If you can accurately measure the time it takes to travel

through a material and you know its velocity then you can

calculate its thickness;

Thickness = time x velocity

2

Modern thickness gauge are easily capable of measuring time

accurately to 10 Nano seconds (0.000,000,01 second) so this is

considered to be more than sufficiently accurate.

This means the accuracy of any thickness gauge measurement

relies principally on the velocity being correct for the material

being measured.

There are tables listing the velocity of most common metals and

materials, but these velocities are only “typical” values. For

example Mild Steel has a typical velocity of 5920 m/s – but in

practice when measuring a variety of mild steel samples the

velocity can range anywhere from 5860 to 5980 m/s.

This means if you want to achi eve the most accurate thickness

measurements you must calibrate your thickness gauge to a

sample of the same material you will be testing – and a sample

that you can accurately measure the thickness of with a Vernier or

micrometer.

Your measurements are only as good as your calibration

Instructions for calibrating the gauge can be found on page 39

onwards.

38

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

1.

Accurately measure the

25.40

Calibration Options

The Gauge is supplied tested and calibrated. The Gauge will have

been calibrated to measure thickness through steel (grade

S355JO) with a velocity of sound of 5920 m/s.

Either a 15mm or 1/2” Test Block is supplied with the kit so the

Gauge can be quickly checked for correct operation. Note, this test

block is not intended to be used for calibration of the Gauge.

The best way to calibrate the Gauge is to Calibrate using a

Known Thickness using a sample of the material you intend to

measure. This method determines the velocity of sound for

the material sample, which will always be more accurate than

using a ‘general’ velocity value. For calibration instructions

see page 39.

If there is no test sample available the Gauge can be calibrated by

Setting the Velocity of Sound directly. A table on page 134

at the

back of this manual lists common ma t erials and their velocity of

sound value. For calibration instructions see page

40.

A third method is to leave the Gauge set to its factory-preset value

for Steel [5920 m/s or 0.2332 in/us], and then use a Conversion

Factor from the table of velocities on page 134

.

Calibrating to a known thickness (Single or 1 Point)

This method of calibrating the gauge is more accurate than using a

standard velocity value as the gauge calculates the velocity of

sound for the sample material.

You can use this calibration method for all measurement modes.

thickness of your sample

material.

mm

39

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

2.

Place the Probe on the sample

3.

Access the Menu and scroll down

4.

While holding the probe firmly

5.

...use the Up and Down keys to

6.

When done press the OK/Select

Or press the X/Cancel key to exit

and verify the gauge can get a

thickness value.

to the ‘Calibration’ group. Then

scroll right to the ‘1 Point Cal’

item.

Press the Ok/Select key to open

the ‘1 Point Cal’ function

on the sample and while a

steady thickness measurement

is displayed..

adjust the thickness to the

required value.

key to save the calibration. A

Calibration Saved message wil l

be shown.

without saving the calibration.

When a Calibration has been made a ‘1PC’ indictor is displayed at

the top of the measurement screen in the status area (1PC =

Single Point Calibration).

40

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

To achieve maximum accuracy in Single Echo mode

Typically a Ladder Step Wedge is

‘1PC’ Indicator

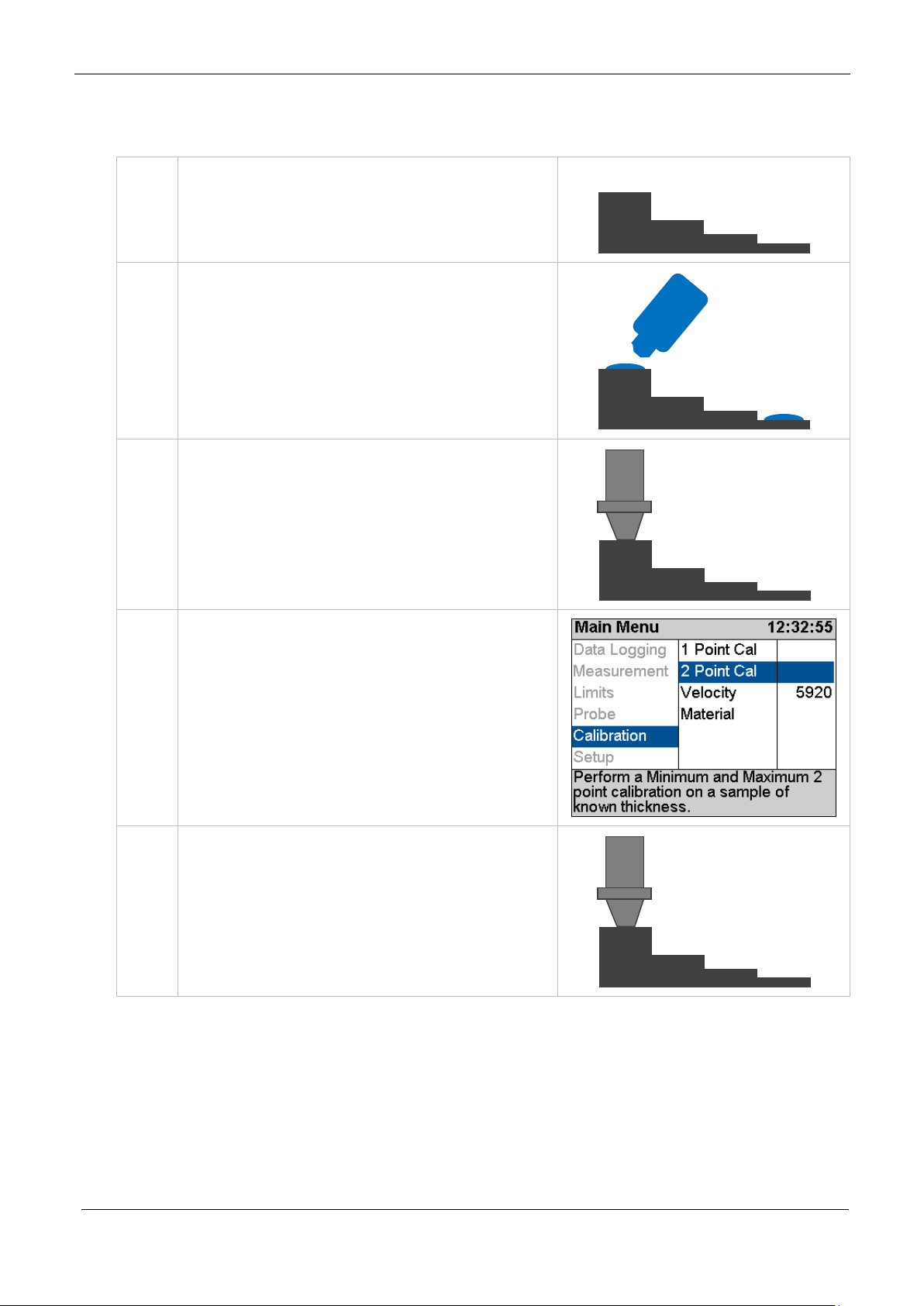

Two Point Calibration

The Two Point Calibration option is only available in Single Echo

and Echo-Echo modes.

Two point calibration allows the gauge to be calibrated against two

reference thicknesses of the same material, one at the minimum

(thin) thickness range the other at the maximum (thick) thickness

range.

you must perform a Two Point Calibration – your

measurement is only as good as your calibration.

When performing a two point calibration both sample thicknesses

should be made from the same material. The temperature of the

sample material should be the c lo se to t he temperature of the

material to be meas ur ed .

The gauge will automatically compensate for v-path error in

addition to either single or two point calibrations.

Ladder Step Wedge

used to calibrate the probe and

gauge for Steel. The ladder step

wedge has 4 or 5 different

thicknesses typically ranging from

2.5 mm to 20.0 mm. You would

typically choose to calibrate using

the 2.5 and 20 mm thicknesses.

Ladder Step Wedges

41

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

Assuming you have a step

2.

Wipe clean the step wedge then

3.

Place the Probe on the sample

4.

Access the Menu and scroll down

5.

Start with the Thick sample –

20.00

2.50

Two Point Calibration Procedure

wedge of known thicknesses

add some fresh couplant to the

step wedge

and verify the gauge can get a

thickness value.

to the ‘Calibration’ group. Then

scroll right to the ‘2 Point Cal’

item.

Press the Ok/Select key to open

the ‘2 Point Cal’ screen

Maximum thickness.

42

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

6.

While holding the probe firmly

7.

When the correct measurement

key

8.

Next measure the Thin sample –

9.

While holding the probe firmly

10.

When the correct measurement

key

on the thick sample and while a

steady thickness measurement

is displayed..

...use the Up and Down Select

keys to adjust the thickness to

the required value.

is displayed press the OK/Select

Minimum thickness.

on the thin sample and while a

steady thickness measurement

is displayed..

...use the Up and Down Select

keys to adjust the thickness to

the required value.

is displayed press the OK/Select

43

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

11.

The 3rd screen lets you check the

12.

When done press the OK/Select

Or press the X/Cancel key to exit

It is recommended to frequently perform a Probe Zero

calibration is correct my

checking a few different

measurements on the step

wedge.

key to save the calibration. A

Calibration Saved message wil l

be shown.

without saving the calibration.

Probe Zero (twin element probes)

Twin element probes must be zeroed to compensate for any wear

or operating temperature changes. The gauge will always perform

a Probe Zero when first turned on or when a twin element probe is

connected.

If the probe gets significantly war mer during use this can cause a

shift in the zero position and thus introduce small errors in the

thickness measurement. Typically a 20° C change in te mperature

the measurements can shift by 0 .1 mm.

especially if conditions such as temperature are

changing.

See also Zeroing the Probe (twin element probes) on page 27.

44

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

1.

Access the Menu and scroll down

2.

Display shows the Zero Probe

3.

Press the OK/Select key to

Starting a Probe Zero from the Main Menu

to the ‘Probe’ group. Then scroll

right to the ‘Zero’ item.

Press the Ok/Select key to start

the ‘Zero’ function

Probe Zero Function

message.

Important - Wipe any couplant

from the probe face

proceed

The gauge measures the probe

zero point…

..this takes about 2 seconds.

45

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

4.

If the Probe Zero fails a message

Probe Zero process.

If you perform a Calibration the Velocity of Sound will be set

will be d is p layed.

• Check the probe has not

been unplugged or the

cable is damaged/faulty.

• The probe face must be

clean and in the air.

• Are you using a non-

Cygnus probe?

You must un-plug the probe,

then plug it back in to re-try the

Setting the Velocity of Sound

The gauge uses the Velocity of Sound value to calculate the

material thickness value. It is therefore i mportant the velocity

value is set correctly for the mat erial being measured.

for you during the calibration – so you don’t need to adjust it

afterwards.

You can manually set the velocity of sound value if required;

normally you would do this if;

• You can’t perform a cal ibration

• You want to use the same velocity setting as last time

• You want to use a velocity from a material list

A list of velocity of sound values for common material can be

found on page 134.

46

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

1.

Access the Menu and scroll down

3.

If there has been a previous

4.

Use the Up and Down keys to

5.

When done press the OK/Select

Or press the X/Cancel key to exit

without saving.

to the ‘Calibration’ group. Then

scroll right and select ‘Velocity’.

Press the Ok/Select key to open

the ‘Velocity’’ function

Calibration a message will warn

that changing the velocity w i l l

alter the calibration;

Press the OK/Select key to

continue, or X/Cancel to abort.

adjust the velocity value as

required

Use the Left and Right keys to

highlight the digit to change.

key to save the changes.

When the velocity has been manually set the value is displayed at

the top of the measurement screen in the status area.

Velocity of Sound value ‘5920 m/s’

47

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

Press the Menu key,

2.

the Main Menu is displayed

3.

Use the four Navigation keys to

4.

Use the Up and Down keys to

5.

Press the Right key to move to

8. Gauge Setup

Menu Operation

scroll around the Main Menu

select a group in the left

column..

the items in that group in the

right column.

Then use the Up and Down keys

to select from the right column

48

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

6.

If you want to change or select

button

7.

Then use the Navigation keys to

8.

Press the green Ok/Select key to

9.

Or press the red X/Cancel key to

6.

Press the Left key to go back to

12.

To exit the menu press the Menu

the item currently displayed

simply press the green Ok/Select

highlight the required setting or

option

save your choice

abort

the main group if you want to

make another selection

or red X/Cancel key once.

Settings are Saved with the Probe Type

Certain gauge settings are saved against the probe type. This

allows each probe type to have different settings that will be

recalled when that pro be is re-connected and the probe type is

correctly set. The following settings are saved with each probe

type;

49

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

The units digit is highlighted.

2.

Pressing the Left key will move

this value only.

3.

Pressing the Left key will move

change this value only.

4.

Pressing the Left key will move

change this value only.

• Units

• Resolution

• Velocity of sound

• Calibration

• Deep Coat

Inputting Numeric Values using the Navigation Keys

Some menu functions require the user to input a numeric value

using the navigation keys. This is done ‘digit’ as a time, using the

Left and Right keys to select the digit, then the Up and Down keys

to change the highlighted digits va lu e.

Pressing Up or Down will change

the units value only.

the highlight to the tens digit.

Pressing Up or Down will change

the highlight to the hundreds

digit. Pressing Up or Down will

the highlight to the thousands

digit. Pressing Up or Down will

Inputting Text using the Navigatio n Keys

Some functions may require alphanumeric text to be input into the

gauge. This is done using a special alphanumeric entry screen and

the navigation keys.

50

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

1.

The screen is divided into ‘virtual’

enter the character or perfor m t he

function.

2.

To enter the word CYGNUS you

3.

There are ‘keys’ for

4.

When you have entered your

keys like a QWERTY keyboard.

You move the Blue highlight

around using the 4 navigation

keys.

Then press the Ok/Select key to

would move the blue highlight

from Ok to ‘C’ then press the

Ok/Select key, then move to the

‘Y’…

Delete last = Del

Space = Spc

Clear all = Clr

Move = ◄ ►

Toggle case = ▲

word just move the highlight to

the green ‘Ok’ at the bottom and

press the Ok/Select key.

51

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

The Probe Type must be set to match the probe connected to

measure accurately if at all.

1.

Access the Menu and scroll down

Selecting the Probe Type

the gauge. If the wrong probe is s elected the gauge will not

The gauge can Auto Detect certain types of probes when they ar e

first connected to the gauge, or you can manually select the probe

from a list.

These probes can be Auto Detected; T2C, T5B, T7A & S2C

These probes must be selected manually; S3C, S5A & S5C

The Probe Type is displayed is displayed at the top of the

measurement screen in the status area. When a probe is

connected the background is green. When no probe is detected the

background is grey.

S2C Probe Selected and Connected

S2C Probe Selected but NOT Connected

to the ‘Probe’ group. Then scroll

right and select ‘Probe Type’.

Press the Ok/Select key to open

the ‘Probe Type’ function

52

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

2.

Use the Up and Down keys to

3.

Press the OK/Select key to save.

Or press the X/Cancel key to exit

Remember settings and calibrat i on is saved with each probe

calibrate each time.

select the Probe Ty pe req u ire d

without saving.

type. So if you change the probe t ype you may find a setting

has changed – this is normal.

The reason settings are saved with each probe type is so you

can swap probes during a survey without having to re-

Automatic Probe Detection

The Automatic Probe Detection feature works by listening to how

the probe behaves when it is first plugged in. For that reason the

probe MUST BE in the air and not coupled to a surface when

plugging in or turning on the gauge.

When Probe Type set to Auto and a probe is connected the gauge

will try and determine the probe type – this will be displayed at

the top of the screen on the ri ght .

S2C Probe Selected and Connected

Observe this probe type displayed and check it matches the probe

connected to the gauge.

53

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

Access the Menu and scroll down

2.

Use the Up and Down keys to

4.

Press the OK/Select key to save.

Or press the X/Cancel key to exit

If the gauge fails to correct ly det ect the probe type then you must

select if manually from the list of probes. See Selecting the Probe

Type on page 52.

Measurement Units

The Gauge can display thickness measurements in either Metric

(mm) or Imper ial (inch). Changing the measurement units will not

affect the calibration.

to the ‘Measurement’ group .

Then scroll right and select

‘Units’.

Press the Ok/Select key to open

the ‘Units’ function

switch from mm to Inch

without saving.

Resolution Setting

The gauge can display thickness measurements in three resolution

settings:

• 0.1 mm 0.005 inch All Modes

54

• 0.05 mm 0.002 inch All Modes

• 0.01 mm 0.001 inch SE and EE Modes only

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

1.

Access the Menu and scroll down

2.

Use the Up and Down keys to

3.

Press the OK/Select key to save.

Or press the X/Cancel key to exit

without saving.

For general metal corrosion measurement the 0.1 mm

resolution setting is recommended.

To change the Resolution setting:

to the ‘Measurement’ group .

Then scroll right and select

‘Resolution’.

Press the Ok/Select key to open

the ‘Resolution’ function

select the required Resolution

Limit Functions

The gauge has a Limit function t hat can be used to;

• Give visual indication of measurements between minimum,

reference and maximum limits.

• Vibrate Alert the operator if measurements are o utside the

minimum or maximum limits

55

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

Limits are setup;

bar positioned at the Reference point.

The Limit function can be turne d ON or OFF as required and the

Vibrate Alert can be enabled as required.

There are three Limit measurement values you can set;

• Minimum Limit – this is the lowest t h i ckness measurement,

measurements under this value will cause an Alert

• Reference Limit – this is the ‘correct’ thickness value, or

when corrosion monitoring this is usually set to the thickness

of the steel/material when it was new.

• Maximum Limit – this is the highest thickness measu rement,

measurements over this value will cause an Alert. This limit is

optional and can be set to zero.

When Limits are enabled the measurement screen displays a

horizontal bar-graph showing the limits and the current

measurement in relation to these limits. The colour of the bar also

changes from light green to dark green to red as the measurement

moves from the reference value to the minimum or maximum

limits.

Thickness Measurement = Reference = Light Green Bar.

Limit Example

Minimum = 5.00 mm

Reference = 10.00 mm

Maximum = 20.00 mm

The thickness measurement is 10.05

mm so the bar-graph shows a green

56

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Now the thickness measurement is

Now the thickness measurement i s

Now the thickness measurement i s

Now the thickness measurement i s

operator if enabled.

8.05 mm so the bar-graph shows a

dark green bar positioned left of the

Reference point.

5.10 mm so the bar-graph shows a

red bar positioned at the Minimum

point.

20.00 mm so the bar-graph shows a

red bar positioned at the Maximum

point.

25.45 mm so the bar-graph shows a

red bar positioned past the Maximum

point.

This exceeds the Maximum limit so

will cause a Vibrate Alert to the

57

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

1.

Access the Menu and scroll down

2.

Use the Up and Down keys to

Or press the X/Cancel key to exit

3.

Use the Up and Down keys to

4.

Use the navigation keys to

Or press the X/Cancel key to exit

to the ‘Limits’ group. Then scroll

right and select ‘Limits’.

Press the Ok/Select key to open

the ‘Limits’ function

turn Limits On or Off…

Press the OK/Select key to save.

without saving.

select the Minimum, Reference,

Maximum or Vibrate settings

Press the Ok/Select key to open

the selected item

change the setting..

Press the OK/Select key to save.

without saving.

Deep Coat Function (multiple echo mode)

With the Deep Coat turned Off and in multiple echo (ME) mode the

gauge can measure through most protective coatings up to 3 mm

(0.11”) thick when using a S2C type probe. Coatings like paint,

anti-foul, hard plastics and epoxy sh ould present no problems as

58

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

Turn Deep Coat Off when NOT measuring through thick

coatings otherwise this may cause inaccurate measurements.

1.

Access the Menu and scroll down

2.

Use the Up and Down keys to

3.

Press the OK/Select key to save.

Or press the X/Cancel key to exit

long as they have not de-laminated/de-bonded from the metal

surface.

With Deep Coat turned On this will allow the gauge to measure

through coatings over 3mm (0.11”) thick up to a maximum of

around 20 mm (0.78”) depending on the properties of the coating

material.

Measuring through thick coatings is ultimately limited by how well

the coating material allows the ultrasound to pass through, soft

coatings like rubber or bitumen d on ’t transmit ultrasound very

well.

Using Deep Coat will not affect the calibration.

to the ‘Measurement’ group .

Then scroll right and select

‘Deep Coat’.

Press the Ok/Select key to open

the ‘Deep Coat’ option

select Deep Coat On or Off

without saving.

59

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

When Deep Coat is turned On a ‘DC’ indicator will be displayed in

the status area at the top of the measurement screen.

DC = Deep Coat is ON.

60

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

The Cygnus 4+ gauge just offers Basic data logging features

requires an ‘enabler file’ that can be ordered from Cygnus.

Basic

Full

Linear Records

●

●

Auto-Log Feature

●

●

Protect Record

●

●

Grid Records

●

Templates

●

Radia l Points

●

Measurement Co m m ent s

●

9. Data Logging

The Cygnus 4+ gauge has a comprehens ive Data Logging feature

that allows thickness measurements and A-Scans to be saved in a

data logging Record. These Records can be quickly created by the

user so the measurements can be organised in separate records

according to the survey being carried out. Records can later be

transferred to a computer for viewing, analysis and report

generation or export to a CSV file.

The process of data logging is simply;

1. Create a new Record

2. Log your thickness measurements - pressing the Ok key to

save each thickness measurement

3. Complete the Record when all the measurements have been

taken – the record is safely saved on th e removable SD card

Data Logging Features

as normal.

However the gauge can easily be field-upgraded to Full data

logging features should you decide you need more

functionality. The upgrade can be done any time and just

61

Cygnus 4+ Operating Manual

M5-CYG4P-M-01_Iss5.doc

Record Types

There are three record ty pes available;

1. Linear – this is simply a list of thickness measurements

saved in the order they are taken.

2. Grid – this arranges the thickness measurements into a row

and column grid layout. You can c h oose f rom 16 different grid

patterns.

3. Template – this uses a custom template to specify how

many thickness measurements are required along with

optional additional information such as serial numbers or

lists.

Reference and Minimum Thicknesses

Each record can have an optional Reference and Minimum

thickness value set. When logging measurements these limits are

used to colour the measurement values and in the case of the

minimum limit alert the user if the measurement is under tha t

limit.

1. Ref. Thk. – This is the Reference Thickness value for th e

whole record. If you are surveying steel that was 12mm thick

when new then this would be your reference thickness.

2. Min. Thk. – This is the Minimum Thickness value for the

whole record. If you take any measurements under this value

they will be coloured Red to highlight them.

Minimum Thickness Limit Alert

When logging thickness measurements if a logged measurement

falls under the Min. Thk. limit a double-vibrate alert is produced to

alert the user.

Radial Points

(Only available with Full data logging)

Both Linear and Grid Records can have a set of Radial Points

added to any logged thickness measurement to further detail an

62

M5-CYG4P-M-01_Iss5.doc

Cygnus 4+ Operating Manual

8 additional radial

plate

area of interest or heavy corrosion. The user can add up to 12

additional thickness measurements around the principal

measurement in a ‘clock-face’ pattern.

For example, when logging thickness measurements on a pipe,

tank or plate it is sometimes necessary to add additional

measurement points radially around a badly corroded or thin area

to detail the extent of the thinn i n g or corrosion.

measurement points.

See Adding Comments to Measurements on page 116.

Measurement Comments

Each measurement point can optionally have comments added to

it. There is a list of 8 pre-set comments each of u p to 24

characters in length. By having a list of pre-set comments the user

can quickly add comments by just selected the ones that are

appropriate, this also standardises the information you want

recording.

Typical comments for a corrosion survey could be;

1. Pitted Surface

2. Corrosion Blister

3. Corrosion Pin-holes