Cygnus 2+

Multi-mode Ultrasonic Thickness Gauge

Operating Manual

Covers Gauge Model : M5-C2P

Doc No. M5-CYG2P-M-01_Iss6.doc

18 October 2016

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

2

QUALITY POLICY STATEMENT

Cygnus Instruments’ mission is to be a premier supplier of niche test and

measurement instruments. To achieve this we will:

Customers

• Be dedicated to customer satisfaction by listening to direct and

indirect feedback regarding our performance and product

requirements in general.

• Design state-of-the-art products that are robust, reliable, simple-touse and compliant with applicable industry and regulatory

requirements.

• Provide products and services that meet or exceed customer

expectations in terms of performance, reliability and safety.

Internal Systems

• Operate effective and safe working practices that comply with ISO

9001:2008 and EN I SO/IEC 80079-34 and other applicable regulatory

and statutory requirements.

• Provide adequate resources to ensure product and service quality is

maintained.

• Set, communicate and measure performance objectives and targets

to promote continual improvement.

• Ensure employees are competent and involved in improvement and

customer satisfaction matters.

Suppliers

• Use suppliers and subcontractors who share our passion for customer

satisfaction and who consistently perform reliably.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

3

Contents

1. Important Notice .............................................................. 6

2. Introduction ...................................................................... 7

Cygnus 2+ Thickness Gauge ....................................................7

Cygnus Instruments ...............................................................8

Gauge Kit Contents ................................................................. 9

Basic Gauge Kit .....................................................................9

Kit supplied with Single Element Probe ......................................9

Kit supplied with Twin Element Probe ........................................9

3. Gauge Preparation .......................................................... 10

Fitting the Batteries ............................................................. 10

Connecting the Probe ........................................................... 11

Fitting the Hand Strap or Belt Clip .......................................... 12

Fitting the Neck Strap .......................................................... 13

4. Selecting the Right Probe ................................................ 15

Measuring Meta ls ................................................................. 15

Measurement Modes Explained and Compared ......................... 16

Multiple Echo Mode (ME) (Mode 3) ....................................... 16

Single Echo Mode (SE) (Mode 2) ......................................... 16

Echo-Echo Mode (EE) (Mode 3) ........................................... 17

Measuring Non-Steels .......................................................... 17

Measuring Non-Metals .......................................................... 18

Single Element Probes and Protective Membranes ..................... 18

Summary of Cygnus Probes .................................................. 21

Twin Element probes ......................................................... 21

Single Element probes ....................................................... 21

The ‘Probe Type’ Code ....................................................... 22

5. Gauge Operation ............................................................. 23

Gauge Controls ................................................................... 23

Turning the Gauge On .......................................................... 24

Turning the Gauge Off .......................................................... 24

Automatic Power Off .......................................................... 24

‘No Probe’ Message .............................................................. 24

Taking Thickness Measurements ............................................ 25

Zeroing the Probe (twin element probes) .............................. 25

Taking the Thickness Measurement...................................... 25

Echo Indicators in Multiple Echo Mode .................................. 26

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

4

Measurement Stability Indication in SE & EE Modes ................ 26

Measuring Small Diameter Pipe & Tubes .................................. 27

Battery Life ......................................................................... 28

Battery Level ...................................................................... 28

Low Battery Warning ............................................................ 28

6. Calibration ...................................................................... 29

Why should I Calibrate my Thickness Gauge? ........................... 29

Calibration Options .............................................................. 30

Calibrating to a known thickness (Single or 1 Point) .................. 30

Two Point Calibration ........................................................... 32

Ladder Step Wedge ........................................................... 32

Two Point Calibration Procedure .......................................... 32

Probe Zero (twin element probes) .......................................... 34

Starting a Probe Zero from the Main Menu ............................ 35

Probe Zero Function .......................................................... 35

Setting the Velocity of Sound ................................................ 36

7. Gauge Setup ................................................................... 38

Main Menu Operation ........................................................... 38

Settings are Saved with the Probe Type .................................. 39

Selecting the Probe Type ...................................................... 40

Automatic Probe Detection ................................................. 41

Measurement Un its .............................................................. 42

Resolution Setting ............................................................... 43

Deep Coat Function (multiple echo mode) ............................... 44

Vibrate Alert Function ........................................................... 46

Display Rotate Function ........................................................ 47

8. General Points On Thickness Gauging ............................. 49

9. Troubleshooting .............................................................. 50

The Gauge will not Switch On ................................................ 50

Difficulty obtaining a Reading ................................................ 50

If Readings are Erratic or Unstable ......................................... 50

Tips for Optimising Battery Life .............................................. 50

10. Updating your Gauge.................................................... 52

Update Software .................................................................. 52

Gauge Firmware Files ........................................................... 52

11. Care and Servicing ....................................................... 53

Cleaning the Gauge .............................................................. 53

Batteries ............................................................................ 53

Environmental ..................................................................... 53

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

5

Storage .............................................................................. 53

Repairs .............................................................................. 53

OLED Display ...................................................................... 54

Returning the Gauge for Servicing .......................................... 54

12. Information .................................................................. 55

Technical Specifications ........................................................ 55

Table of Sound Velocities ...................................................... 59

Reading Conversions ......................................................... 60

13. EU Declaration of Conformity ....................................... 61

14. Recycling and Disposal (EC Countries) ......................... 62

15. Warranty Information .................................................. 63

16. Index ........................................................................... 64

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

6

1. Important Notice

The following important information must be read and

understood by all users of Cygnus u ltrasonic thickness

gauges.

The correct use of Cygnus ultrasonic thickness gauges requires

identification of the correct equipment for the specific application

coupled with an appropriately trained and qua lified operator or

technician. The incorrect use of this equipment, along with its

incorrect calibration, can result in serious financial loss due to

damage to components, facilit ies, personal injury and even death.

N

either Cygnus Instruments nor any of its employees or

representatives can be held responsible for improper use of this

equipment. Proper training, a complete understanding of ultrasonic

wave propagation, thorough read ing of this manual, proper

transducer selection, correct zero i n g of the transducer, correct

sound velocity, correct use of the appropriate test blocks, proper

cable length and proper couplant selection all play a factor in

successful ultrasonic thickness gaugin g. Of critical importance is

the process of complete and accurate calibration of the

instrument.

This manual will provide instructions in the set up and operation of

the thickness gauge. Additional f actors that can affect the use of

ultrasonic equipment are beyond th e scope of this manual and to

that end it is understood that the operat or of this equipment is a

well-trained inspector qualified by either their own organisation or

another outside agency to the appropriate level of both theory and

practical application of ultrasonics .

T

herefore Cygnus Instruments recommends that users of its

ultrasonic thickness gauges should be formally qualified to a

minimum of UT “Level 1” (ASNT or PCN) which will provide

approximately 40 hours of tra in in g.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

7

2. Introduction

Cygnus 2+ Thickness Gauge

The Cygnus 2+ Ultrasonic Thickness Gauge is a rugged,

handheld, battery-powered instrument designed for high-reliability

thickness measurements in harsh environments using ultrasound.

The gauge can be used with a choice of Ultrasonic Probes, selected

to suit the material and thickness range to be measured.

The gauge can measure material thickness using three methods;

Single Echo, Echo-Echo or Multiple Echo. Echo-Echo and Multiple

Echo allow measurements through surf ace coatings which are

ignored.

Measurements can be displayed in either Metric (mm) or in

Imperial (inch) units. The gauge has an end–mounted OLED

(Organic LED) graphic display which can be easily read in most

light situations.

The gauge can easily be calibrated to a known thickness or to a

known Velocity of Sound.

The gauge is able to operate accurately over a wide range of

ambient temperatures and is environmentally sealed to IP67 for

use in wet conditions.

The gauge is a solid-state electronic instrument which, under

normal operating conditions, will give many years of active

service.

Although designed for ease of operation th e first time user

should carefully read this manual to familiarise themselves

with the features of the Gauge.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

8

Cygnus Instruments

Cygnus Instruments Limited, founded in 1983,

were pioneers in the development of the Digital

Ultrasonic Multiple-Echo Technique used for

measurement through coatings. This has long

been the standard required to ensure that

accurate measurements are taken without the

need to first zero the gauge or remove any

coatings.

O

ur philosophy is to work closely with each of our customers to

provide a range of products specif ically for each application.

Cygnus Ultrasonic Thickness Gaug es are designed to be simple to

use and to withstand the harsh env iron ments that they are

intended for. We have built up an enviable reputation with our

customers in over 45 countries around the world.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

9

Gauge Kit Contents

Basic Gauge Kit

1. Cygnus 2 Gauge

2. Operating Manual (in side pouch)

3. Neck Strap (in side pouch)

4. Accessory Pouch, containing; 3 x AA Batteries, Blue

Couplant Gel.

Kit supplied with Single Element Probe

1. Ultrasonic Probe

2. Moulded Probe Cable (in side pouch)

3. 15mm (or ½”) Steel Test Block

4. Spare Membranes

5. Membrane Key

6. Membrane Couplant

Kit supplied with Twin Element Probe

1. Ultrasonic Probe

2. Moulded Probe Cable (in side pouch)

3. Ladder Step Wedge (if ordered)

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

10

3. Gauge Preparation

The gauge is supplied ready to use out of the box . Just insert the

batteries, connect the probe to the gauge, turn on the power and

you are ready to take thickness m ea su rements.

Fitting the Batteries

The gauge requires 3 x AA/LR6/UM3 Batteries. Cygnus supplies

and recommends Duracell Alkaline batteries. The batteries are

located behind a cover on the rear of gauge. The hand strap can

be separated by a push-button buckle to gain access to the bat t ery

cover. The battery cover is removed by pressing in with your

thumb the at the base to release the clip.

Press the bottom of the

battery cover to release

the retaining clip and lift

up the battery cover.

The batteries are located

underneath.

The gauge is protected

against electrical damage

from incorrect battery

insertion.

The battery compartment

itself is sealed to contain

any battery fluids that

may leak out.

The gauge can be fitted with NiCad or NiMH rechargeable

batteries but this may alter the specified operating time.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

11

To avoid damage from leaking batteries always remove the

batteries if the gauge will be unused for any length of time.

If the batteries run flat they may leak acid into the battery

compartment and damage the electrical contacts. This would

not be covered by the warranty.

Connecting the Probe

The Cygnus probe lead uses a cus t om made cable that offers

superior flexibility and resistance to oil s and ultraviolet light. The

cable will not stiffen after exposure to ultraviolet light.

T

he connector uses original Lemo connectors for reliability. The

twin connectors are over-mounded to form a tough housing that

will provide a long lasting probe cable

T

he connector is orientated with a ‘pip’ and can only be plugged in

one-way around.

Depending on the type

of probe supplied the

probe end will have

either a twin Lemo 00,

BNC or single Lemo 00

connector.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

12

To release the connector

simply pull back on the

connector body. DO NOT

pull the cable.

Fitting the Hand St ra p or Belt Clip

The gauge is supplied fitted with an adjustable elasticated Hand

Strap. This can be easily removed and the optional Krusell

®

belt

clip attachment fitted instead.

Elasticated Hand Strap

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

13

Optional Krusell® belt clip

attachment parts.

There are four Pozidrive screws

holding the hand strap or Krusell®

belt clip attachment in place. Two

are under the battery c o ver.

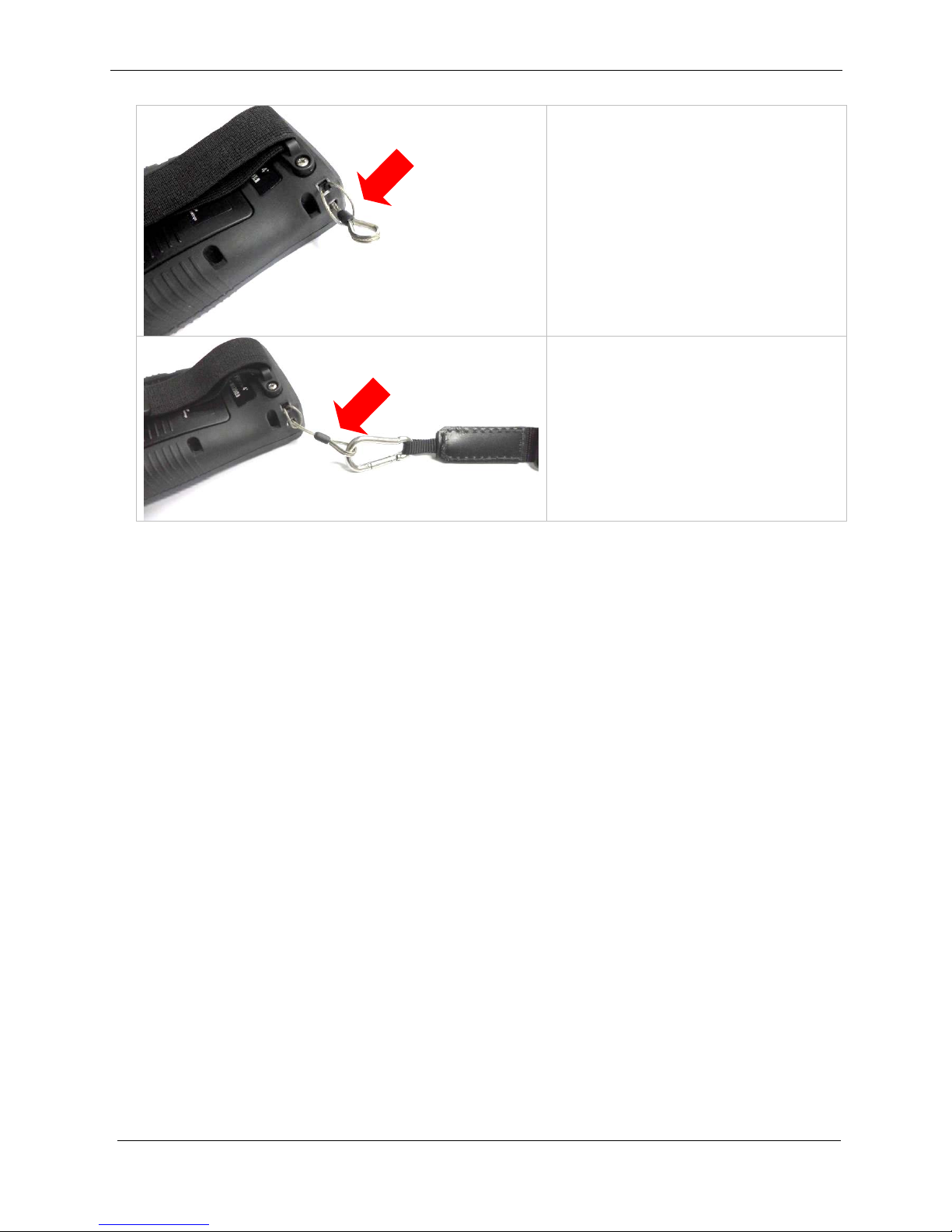

Fitting the Neck Strap

The gauge is supplied with an adjustable Neck Strap. The ends of

the neck strap clip onto two wire loops fitted to the gauge. These

wire loops are made from coated stainless steel.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

14

Wire loop fitted to the

gauge body.

Simply pass the loop

through the hole in the

gauge and back over the

other end.

The neck strap can then be

clipped on to the loops.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

15

4. Selecting the Right Probe

The performance of any thickness gauge, and its ability to get a

reliable measurement depends on selecting the right ultrasonic

probe for the application and con ditio n s. Cygnus gauges are

therefore offered with a selection of probes suitable for most

thickness gauging applications.

The following section helps you select the right probe for the

application.

The gauge must be set for the probe connected to it, see

Selecting the Probe Type on page 40.

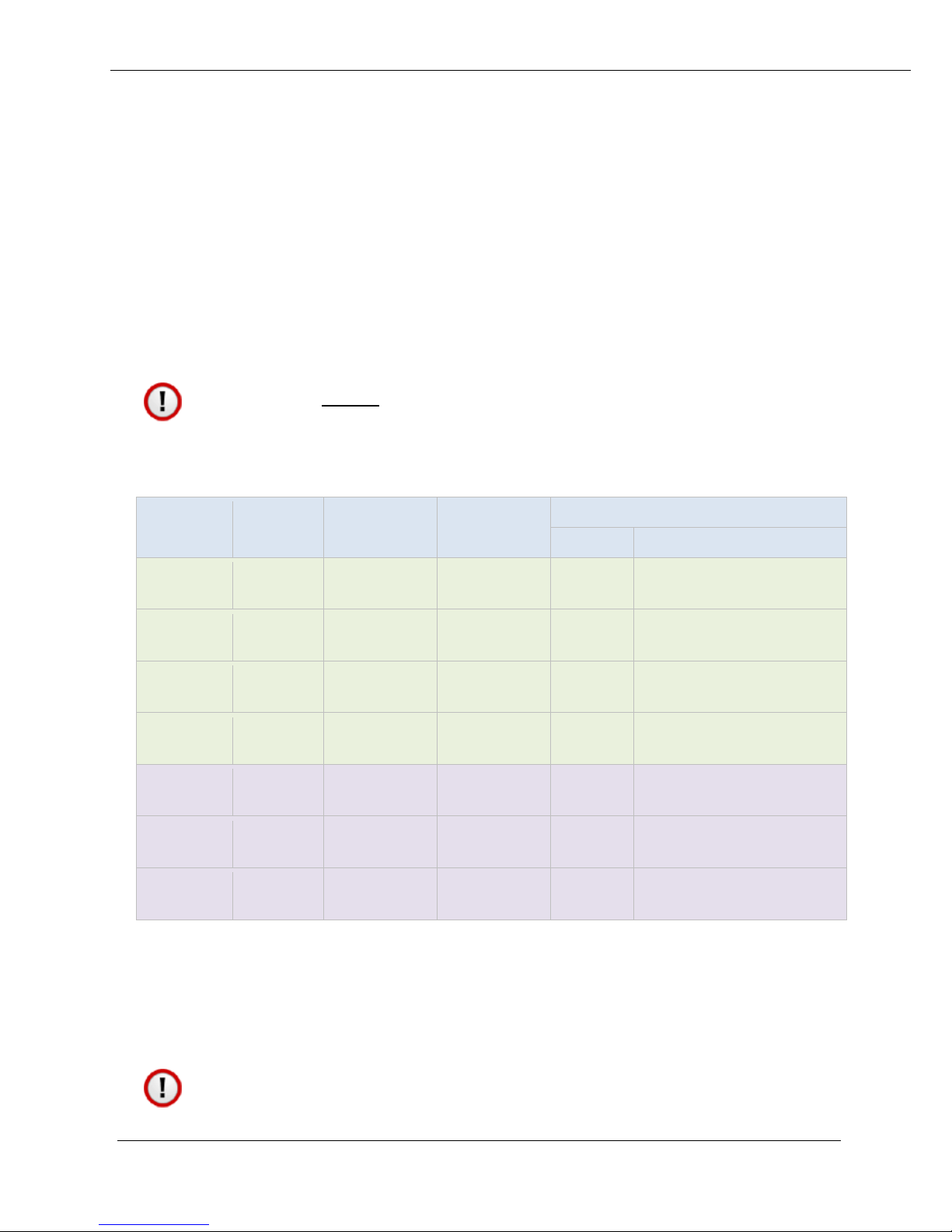

Measuring Metals

Material Coating Corrosion Thickness

Recommended..

Probe

Measurement Mode

Steels

Any

Non to

Moderate

1 mm+

S5A

Multiple Echo

Steels

Any

Non to

Moderate

2 mm+

S3C

Multiple Echo

Steels

Any

Non to

Moderate

3 mm+

S2C

Multiple Echo

Steels

Any

Non to

Moderate

3 mm+

(0.12”+)

S2D

Multiple Echo

Steels

Non

Non to

Heavy

0.8 mm+

(0.03”+)

T7A

Single Echo

Steels

Non

Non to

Heavy

1.5 mm+

(0.06”+)

T5B

Single Echo

Cast

Iron

Non

Non to

Moderate

2.5 mm+

(0.1”+)

T2C

Single Echo

The table above shows that to be able to measure coated and uncoated steels with non to heavy corrosion ideally you will require

at least two probes, in almost all applications this will be a S2C

probe and a T5B probe.

When measuring in Multiple Echo mode the coating will be

ignored and just the metal thickness measured.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

16

It is possible to use a Twin Element (T**) probe in Echo-

Echo Mode to ignore thin paint coatings. However this

method does not have the ability to verify measurements

and without an A-Scan display it is possible to get incorrect

measurements.

Measurement Modes Explained and Compared

Multiple Echo Mode (ME) (Mode 3)

Multiple Echo measurement mode is by far the most reliable and

easy method for thickness measurements, because it works by

looking for three matched echoes it can verify the thickness

measurement is valid. This method has been used in all Cygnus

gauges since the late 1970s.

Multiple echo mode will ignore surface coatings (Through Coating

mode), there is no need to remove the paint to take a

measurement.

Also because it uses a single element (or single crystal) probe

there are no errors due to the V-pat h of the ultrasound beam

found in all twin element probes. This makes it simple to calibrate

– two point calibrations are not required.

However because it requires three echoes to take a measurement,

in heavily corroded steels there is often an insufficient number of

echoes so no measurement is possible.

Single Echo Mode (SE) (Mode 2)

Single Echo measurement mode is most useful on heavily corroded

metals where Multiple Echo fails. Because it only needs the first

return echo to take a measurement it performs well on virtually all

steel conditions.

However single echo mode will not ignore any surface coatings, so

if you measure through a coating it will give an incorrectly metal

thickness measurement . If the surface coating is very thin paint

(0.2mm / 0.01”) you can make an allowance for this error, but

thicker coatings introduce too much error to be practical.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

17

Single echo measurements use a twin element (twin element)

probe, because there are two e l ements angled to a focal point

there is a v-path error introduced. However this v-path error is

mostly corrected by the gauge, and furthermore by performing a

two point calibration.

Twin element probes require “zeroing” at regular intervals,

especially if the ambient temperature is changing.

Echo-Echo Mode (EE) (Mode 3)

Echo-Echo mode uses a twin elem ent probe, but measures

between the first two echoes. This method is intended to ignore

any thin surface coatings whilst stil l using a twin element probe.

Echo-echo mode is not able to verify its measurements unlike

Multiple echo mode, therefore it is liable to give incorrect readings.

As the Cygnus 2

+

gauge does not have an A-Scan display there is

no way the user can check the measurement is correct.

Echo-echo mode must therefore be used with caution, and only on

thin paint surface coatings (less than 0.5mm). It is recommended

a Single Echo measurement should also be made to help verify the

measurement makes sense (th e Single Echo measurement shou ld

always be slightly thicker due to the coating thickness).

Measuring Non-Steels

The gauge will measure the following non-steels;

• Aluminium alloys

• Copper and Brass alloys

• Titanium

Use the same rules as steels when selecting a suitable probe. The

gauge will ideally be re-calibrated to suit the metal being

measured, or the standard velocity of sound for that material

would be entered into the gauge.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

18

Measuring Non-Metals

You can measure certain types of plastics with the gauge using a

twin element probe and the gauge set to Single Echo

measurement mode. Generally the hard e r the plastic the better,

soft materials like rubber or TPE s tend to absorb too much

ultrasound so only thin samples c an be measured.

Engineering plastics like Acetal, Tufset (Polyurethane), Nylon and

High-density polyethylene (HDPE) can be measured successfully.

Rotationally mounded parts can generally be measured

successfully.

• You must use Single Echo mode to measure plastics.

• You must generally use a low frequency probe (i.e. T2C) to

measure plastics, but this will depend on the properties of the

material.

• Any material with a closed-cell construction cannot be

measured.

• Any material with internal voids, air bubbles or honeycomb

cannot be measured .

Typically these materials cannot be measured with the gauge;

• Concrete

• Wood

• Thermal insulation ma t e r ials

• Foams

• Composites

Single Element Probes and Protective Memb r an es

All Cygnus single element probes ha ve a soft face and are

therefore fitted with a Polyurethane Mem brane which provides

better contact on rough surfaces and protects the probe face from

wear, prolonging the life of the probe.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

19

Check the membrane regularly as it is important the

membrane is changed as soon as i t sh ows any signs of wear.

Single Element Probe Membrane Parts.

Single Element Probe Membrane Locking Key

Probe Body

Locking Ring

Polyurethane Membrane

Knurled Ring

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

20

Changing the Protective Membrane on Single element Probes

1.

Unscrew the Knurled Ring from the

end of the Probe.

2.

Use the Membrane Key to unscrew

the Locking Ring from inside the

Knurled Ring. The old membrane

can then be removed and

discarded.

3.

Place a new membran e into th e en d

of the Knurled Ring ensuring it

locates in the groove.

4.

Screw the Locking Ring back inside

the Knurled Ring and tighten with

the Membrane Key.

5.

Place a few drops of Membrane

Couplant on to the probe face.

6.

Screw the Knurled Ring back onto

the probe. Use your thumb to

squeeze the couplant from under

the membrane as you tighten the

Knurled Ring down.

7.

You should see the membrane has

a very thin film of couplant between

itself and the probe face with no air

bubbles.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

21

Measuring Higher Temperatures

The polyurethane membranes fitted to t he single element probes

are suitable for measuring surface temperatures up to 70°C

(160°F). For measuring higher tempe ratures Teflon membranes

are available and suitable for surface temperatures up to 150°C

(300°F) with intermittent contact. Contact Cygnus instruments to

order Teflon membranes.

When measuring high temperatures limit the time the probe is in

contact with the hot surface to less th an 4 seconds and ensure the

probe has sufficient time between measu rements to cool down.

Summary of Cygnus Probes

Twin Element probes

Probe

Type

Size Frequency

Range in

Steel

(SE Mode)

Typical Uses

T2C

12mm

2 MHz

2.5 to 250

mm

0.1 to 10”

Attenuative materials

Cast irons, plastics

T5B

8mm

5 MHz

1.5 to 200

mm

0.06 to 8”

General purpose

Most metals

T7A

5mm

7.5 MHz

0.8 to 50 mm

0.03 to 2”

Thin metals

Single Element probes

Probe

Type

Size Frequency

Range in

Steel

Typical Uses

S2C

13mm

2.25 MHz

3 to 250 mm

General purpose probe suitable

for most applications that can

use Multiple Echo

measurement.

Coated metals

S2D

19mm

0.75”

2.25 MHz

3 to 250 mm

0.12 to 10”

As S2C but has longer focal

point (33 mm) and narrower

beam so may perform better

on thicker materials

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

22

S3C

13mm

3.5 MHz

2 to 150 mm

Coated metals

S5C

13mm

5.0 MHz

1 to 50 mm

Coated metals

S5A

6mm

5.0 MHz

1 to 50 mm

Small diameter tubes

Thin metals

Coated metals

The ‘Probe Type’ Code

S

2

C

Single or Twin

Crystal

Frequency in MHz

Size

A 6mm

B 8mm

C 13mm

D 19mm

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

23

5. Gauge Operation

Gauge Controls

End view of gauge

Front view of gauge

OLED

Display

Probe

Connection

Power /

Cancel

Key

Select

Keys

Menu

Key

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

24

Turning the Gauge On

1.

Press the Power key

2.

Cygnus Instruments name is displ ayed

3.

The model and serial number are

displayed

4.

The firmware & hardware version are

displayed

6.

The gauge is ready to use

Turning the Gauge Off

1.

Press & Hold the Power key,

2.

The display shows ‘power-off’ and the

gauge turns off.

Automatic Power Off

The gauge will turn off automatically after 5 minutes of in activity.

Taking thickness measurements or accessing the menu will reset

the 5 minute timer back to zero.

‘No Probe’ Message

1.

If the gauge cannot detect a probe a

message will be disp layed.

2.

This message should disappear when a

probe is connected to the gauge.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

25

Taking Thickness Measurements

Taking ultrasonic thickness measurements is a straight forward

process that involves first making sure the surface is clean and

prepared, applying an ultrasonic couplant gel then placing the

probe on the surface and observing the display for the

measurement.

Zeroing the Probe (twin element probes)

When a twin element probe is conn ected to the gauge (and the

gauge is set to the correct probe) you must first perform a Probe

Zero before you can begin taking measurements. For instructions

see Probe Zero Function on page 35.

It is recommended to frequently perform a Probe Zero if

conditions such as temperature are changing.

Taking the Thickness Measurement

1.

Remove all scale, rust, dirt or loo se

coatings and brush the test area cl ea n .

2.

Apply ultrasonic couplant to the test

surface.

3.

Place the probe-face on the clean,

lubricated test surface and make firm

contact applying gentle pressure.

4.

The gauge will display a thickness

measurement.

(Or an indication of Echo Strength if no

valid measurement has been found in

Multiple Echo mode).

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

26

5.

When a thickness measurement is

displayed the display also shows the

Measurement Mode and the Units.

SE = Single Echo mode

EE = Echo-Echo mode

ME = Multiple Echo mode

Echo Indicators in Multiple Echo Mode

Should the gauge be unable to detect a stable multiple echo signal

it displays an Echo indication to help the operator lo cate a suitable

position.

1.

1 Bar Flashing:

No echoes detected

2.

1 steady + 1 Bar Flashing:

Only 1 echo detected

3.

2 steady + 1 Bar Flashing:

Only 2 echoes detected

4.

3 steady + 1 Bar Flashing:

3 echoes detected but they are not

matched

To help obtain a multiple echo reading the operator should

continue to move the probe around to locate a suitable reflector,

using a slight rocking motion.

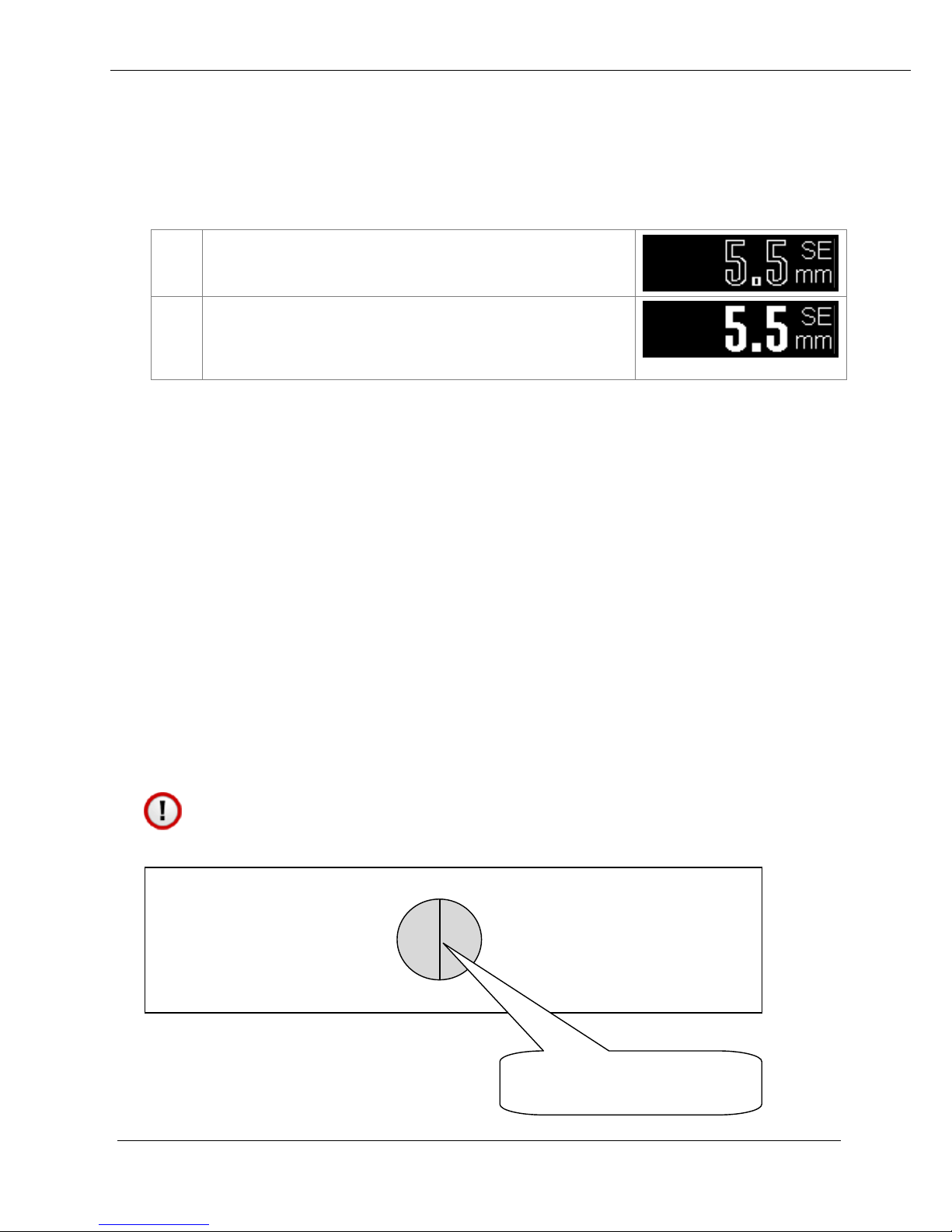

Measurement Stability Indication in SE & EE Modes

To help indicate when a Single Ech o or Ech o-Echo measurement is

stable – and thus probably reliable – the gauge changes the

thickness measurement number from Hollow to Solid when the

measurement has been stable for 2 consecutive seconds.

When measuring using Single Echo or Ech o-Echo mode once you

have a measurement keep the probe still and wait for the gauge to

signal a “stable reading”.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

27

If the ultrasound signal is poor or erratic then the thickness value

may remain hollow – thus indicating the measurement may not be

reliable.

1.

Initial measurements will be displayed

as hollow numbers.

2.

If the measurement remains sta ble for

2 consecutive seconds then th e

measurement will change to solid.

Stable is defined as; the thickness measurement changing no

more than + or - the Resolut ion setting.

Example.

The Resolution is set to 0.05mm, therefor the thickness

measurement must not change by more than +0.05mm or

-0.05mm for 2 seconds or more to be “stable”.

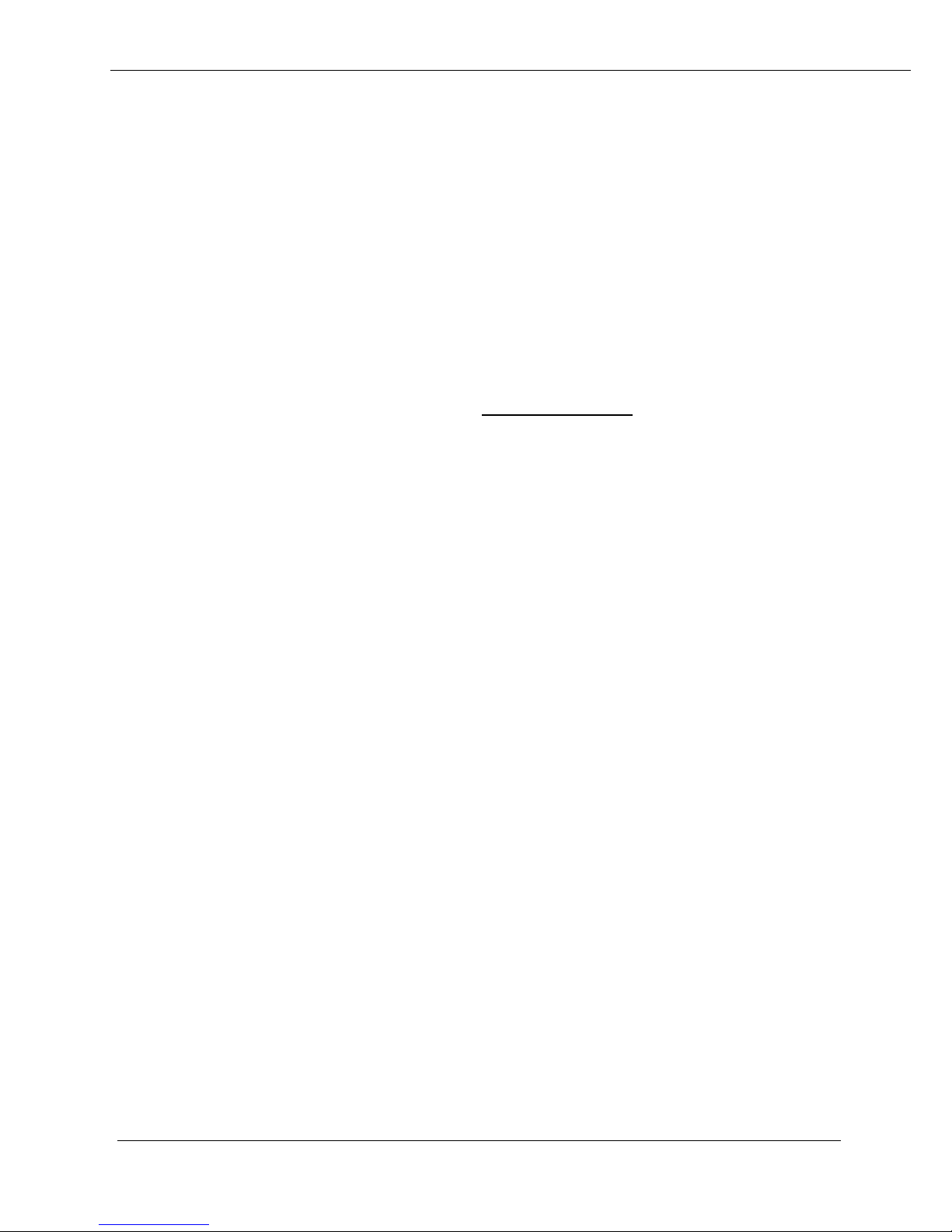

Measuring Small Diameter Pipe & Tubes

When measuring small diameter pipe and tubes with a twin

element probe, 75mm (3”) or under, you must ensure the face of

the probe is correctly aligned to the curvature of the pipe

otherwise measurements may be inaccurate.

The dividing line on the face of the probe should be at

right angles to the length of the pipe.

Pipe

Probe Face

Probe Face Division is at

right angles to the pipe

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

28

Battery Life

The gauge will operate continuously for approximately 10 hrs

when fitted with Duracell Alkaline 1500 mA/hr batteries.

Battery Level

When not displaying a thickness measurement the display shows a

battery level gauge.

Note. The battery level gauge moves slowly up and down the

display to avoid display “burn in”.

Battery almost full

Battery about 1/3 full

Battery flat

Low Battery Warning

The gauge will periodically flash a Low Battery warning messa ge

when the batteries have approximately 1 hour of use remaining.

Low battery warning

When the batteries are exhausted the gauge will display a Flat

Battery message for 5 seconds then turn off automatically.

Turn off message

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

29

6. Calibration

Why should I Calibrate my Thickness Gauge?

Ultrasonic thickness gauges measure time in order to measure the

thickness of the material being tested. The rely on the principal

that sound travels through a mat erial at a constant velocity or

speed. If you can accurately measure the time it takes to travel

through a material and you know its velocity then you can

calculate its thickness;

Thickness = time x velocity

2

Modern thickness gauge are easily capable of measuring time

accurately to 10 nano seconds (0.000,000,01 seconds) so this is

considered to be more than sufficiently accurate.

This means the accuracy of any thickness gauge measurement

relies principally on the velocity being correct for the material

being measured.

There are tables listing the velocit y of most common metals and

materials, but these velocities are only “typical” values. For

example Mild Steel has a typical velocity of 5920 m/s – but in

practice when measuring a variety of mild steel samples the

velocity can range anywhere from 5860 to 5980 m/s.

This means if you want to achieve the most accurate thickness

measurements you must calibrate your thickness gauge to a

sample of the same material you will be testing – and a sample

that you can accurately measure the thickness of with a Vernier or

micrometer.

Your measurements are only as good as your calibration

Instructions for calibrating the gauge can be found on page 30

onwards.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

30

Calibration Options

The Gauge is supplied tested and calibrated. The Gauge will have

been calibrated to measure thickness through steel (grade

S355JO) with a velocity of sound of 5920 m/s.

Either a 15mm or 1/2” Test Block is supplied with the kit so the

Gauge can be quickly checked for correct operation. Note, this test

block is not intended to be used for calibration of the Gauge.

The best way to calibrate the Gauge is to Calibrate to a

Known Thickness using a sample of the material you intend

to measure. This method determines the velocity of sound

for the material sample, which will always be more accurate

than using a ‘general’ velocity value. For calibration

instructions see

Calibrating to a known thickness (Single or

1 Point) on page 30 and Two Point Calibration on page 30.

If there is no test sample available the Gauge can be calibrated by

Setting the Velocity of Sound directly. A Tab l e of Sound Velocities

on page 59 lists common materials and their velocity of sound

value. For instructions on Setting the Velocity of Sound see page

36.

A third method is to leave the Gauge set to its factory-preset value

for Steel [5920 m/s or 0.2332 in/us], and then use a Conversion

Factor from the Table of Sound Velocities on page 59.

Calibrating to a known thickness (Single or 1 Point)

This method of calibrating the gauge is more accurate than using a

standard velocity value as the gauge calculates the velocity of

sound for the sample mater ia l .

You can use this calibration meth od for all measurement modes.

1.

Accurately measure the

thickness of your sample

material.

25.40

mm

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

31

2.

Place the Probe on the sample

and verify the gauge can get a

thickness value.

3.

Press the Menu key

4.

Press the Up Select key to get to

the Calibrate Single Point item

5.

Press the Menu key to start

calibration

6.

While holding the probe firmly

on the sample, and while a

steady thickness measurement

is displayed..

7.

...use the Up and Down Select

keys to adjust the thickness to

the required value.

8.

When done press the Menu key

to save the calibration.

Or press the Power / Cancel to

exit without saving the

calibration.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

32

Two Point Calibration

The Two Point Calibration option is only available in Sin gle Echo

and Echo-Echo modes.

Two point calibration allows the gauge to be calibrated against two

reference thicknesses of the same material, one at the minimum

(thin) thickness range the other at the maximum (thick) thickness

range.

To achieve maximum accuracy in Single Echo mode

you must perform a Two Point Calibration – your

measurement is only as good as your calibration.

When performing a two point cali bration both sample thicknesses

should be mad e from the same material. Th e temperature of the

sample material should be the close to t he temperature of the

material to be measu r ed.

The gauge will automatically com pensa te for v-path error in

addition to either single or two poin t calibrations.

Ladder Step Wedge

Typically a Ladder Step Wedge is

used to calibrate the probe and

gauge for Steel. The ladder step

wedge has 4 or 5 different

thicknesses typically ranging from

2.5 mm to 20.0 mm. You would

typically choose to calibrate us ing

the 2.5 and 20 mm thicknesses.

Ladder Step Wedges

Two Point Calibration Procedure

1.

Assuming you have a step

wedge of known thicknesses

20.00

2.50

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

33

2.

Wipe clean the step wedge then

add some fresh couplant to the

step wedge

3.

Place the Probe on the sample

and verify the gauge can get a

thickness value.

4.

Press the Menu key

5.

Press the Up Select key to get to

the Calibrate Two Point item

6.

Press the Menu key to start

calibration

7.

Start with the Thick sample –

Maximum thickness.

While holding the pr o be firmly

on the thick sample, and while a

steady thickness measurement

is displayed..

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

34

...use the Up and Down Select

keys to adjust the thickness to

the required value.

8.

When the correct measurement

is displayed press the menu key

9.

Next measure t he Thin sample –

Minimum thickness.

While holding the probe firmly

on the thin sample, and while a

steady thickness measurement

is displayed..

...use the Up and Down Select

keys to adjust the thickness to

the required value.

10.

When done press the Menu key

to save the calibration.

Or press the Power / Cancel to

exit without saving the

calibration.

Probe Zero (twin element probes)

Twin element probes must be zeroed to compensate for any wear

or operating temperature changes. The gauge will always perform

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

35

a Probe Zero when first turned on or when a twin element probe is

connected.

If the probe gets significantly warmer during use this can cause a

shift in the zero position and thus introduce small errors in the

thickness measurement. Typically a 20° C change in temperature

the measurements can shift by 0.1 mm.

It is recommended to frequently perform a Probe Zero

if conditions such as temperature are changing.

See also Zeroing the Probe (twin element probes) on page 25.

Starting a Probe Zero from the Main Menu

1.

Press the Menu key

2.

Press the Up Select key to get to

the Probe Zero item

3.

Press the Menu key

Probe Zero Function

4.

Display shows the Zero Probe message.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

36

5.

Press the Up select key to proceed

6.

Wipe any couplant from the probe face

7.

Press the Up select key to proceed

8.

The gauge measures the probe zero

point.

9.

If the Probe Zero fails a message will be

displayed.

• Check the probe has not been

unplugged or the cable is

damaged/faulty.

• The probe face must be clea n and

in the air.

• Are you using a non-Cygnus

probe?

Setting the Velocity of Sound

The gauge uses the Velocity of So u n d value to calculate the

material thickness value. It is therefore important the velocity

value is set for the material being measured.

If you perform a Calibration (single or two point) the Velocity

of Sound will be set for you during the calibration – so you

don’t need to adjust it afterwards .

You can manually set the velocity of sou n d value if required,

normally you would do this if;

• You can’t perform a calibrat ion

• You want to use the same velocity setting as last time

• You want to use a velocity from a material list

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

37

A list of velocity of sound values for common material can be

found on page 59.

1.

Press the Menu key

2.

Press the Up Select key to get to

the Velocity item

3.

Press the Menu key to change

the velocity value

4.

Use the Up and Down Select

keys to adjust the velocity value

as required

5.

When done press the Menu key

to save the new value.

Or press the Power / Cancel to

exit without saving.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

38

7. Gauge Setup

Main Menu Operation

1.

Press the Menu key..

2.

..to display the Main Menu.

3.

Press the Up select key to scroll around

the Main Menu items one at a time.

The Down select key will scroll in t h e

other direction.

4.

Change the Meas ure m ent Mode

5.

Set the Probe Type

6.

Do a Probe Zero

(twin element probes only)

7.

Set the Velocity of sound

8.

Perform a Single Point Calibration

9.

Perform a Single Point Calibration

(twin element probes only)

10.

1

Turn the Deep Coat function on or off

(single element probes only)

11.

Set the measurement Resolution

1

Deep Coat must be enabled – contact Cygnus for instructions.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

39

12.

Set measurement Units

13.

Set the Vibrate option

14.

Set the Display Rotation option

15.

To exit the menu press the Power /

Cancel key once.

16.

If you want to change or select the

item currently displayed simply press

the Menu button

17.

If the item has a number of choices

you can use the Up and Down keys to

step through each option.

Example.

Units goes from mm to inch.

18.

To save your choice press the me n u

key.

To cancel without saving press the

Power / Cancel key.

Settings are Saved with the Probe Type

Certain gauge settings are saved against the probe type. This

allows each probe type to have different settings that will be

recalled when that probe is re-connected and the probe type is

correctly set. The following settings are saved with each probe

type;

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

40

• Measurement mode

• Units

• Resolution

• Velocity of sound

• Calibration

• Deep Coat (if a single element probe)

Selecting the Probe Type

The Probe Type must be set to the probe connected to it. If

the wrong probe is selected the gauge will not measure

accurately if at all.

The gauge can Auto Detect certain types of probes when they are

first connected to the gauge, or you can manually select the probe

from a list.

These probes can be Auto Detect ed;

T2C, T5B, T7A, S2C

These probes must be selected manually;

S2D, S3C, S5A & S5C

1.

Press the Menu key

2.

Press the Up Select key to get to

the Probe Type item

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

41

3.

Press the Menu key to change

the probe type

4.

Use the Up and Down Select

keys to select from Auto or a

specific probe type

5.

When done press the Menu key

to save the new value.

Or press the Power / Cancel to

exit without saving.

Remember settings and calibration is saved with each probe

type. So if you change the probe type you may find a setting

has changed – this is normal.

The reason settings are saves wit h each probe type is so you

can swap probes during a survey without having to recalibrate each time.

Also you may want Multiple Echo measurements in 0.1mm

resolution but Single Echo measurements in 0.01mm

resolution.

Automatic Probe Detection

The Automatic Probe Detection works by listening to how the

probe behaves when first plugged in. For that reason the probe

MUST BE in the air and not coupled to a surface when plugging in

or turning on the gauge.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

42

When Probe Type = Auto and a probe is connected a message will

be displayed informing what type of probe was det ecte d;

Observe this message and check it matches the probe connected

to the gauge.

If the gauge fails to correctly detect the probe type then you must

select it manually from the list of probes. See Selecting the Probe

Type on page 40.

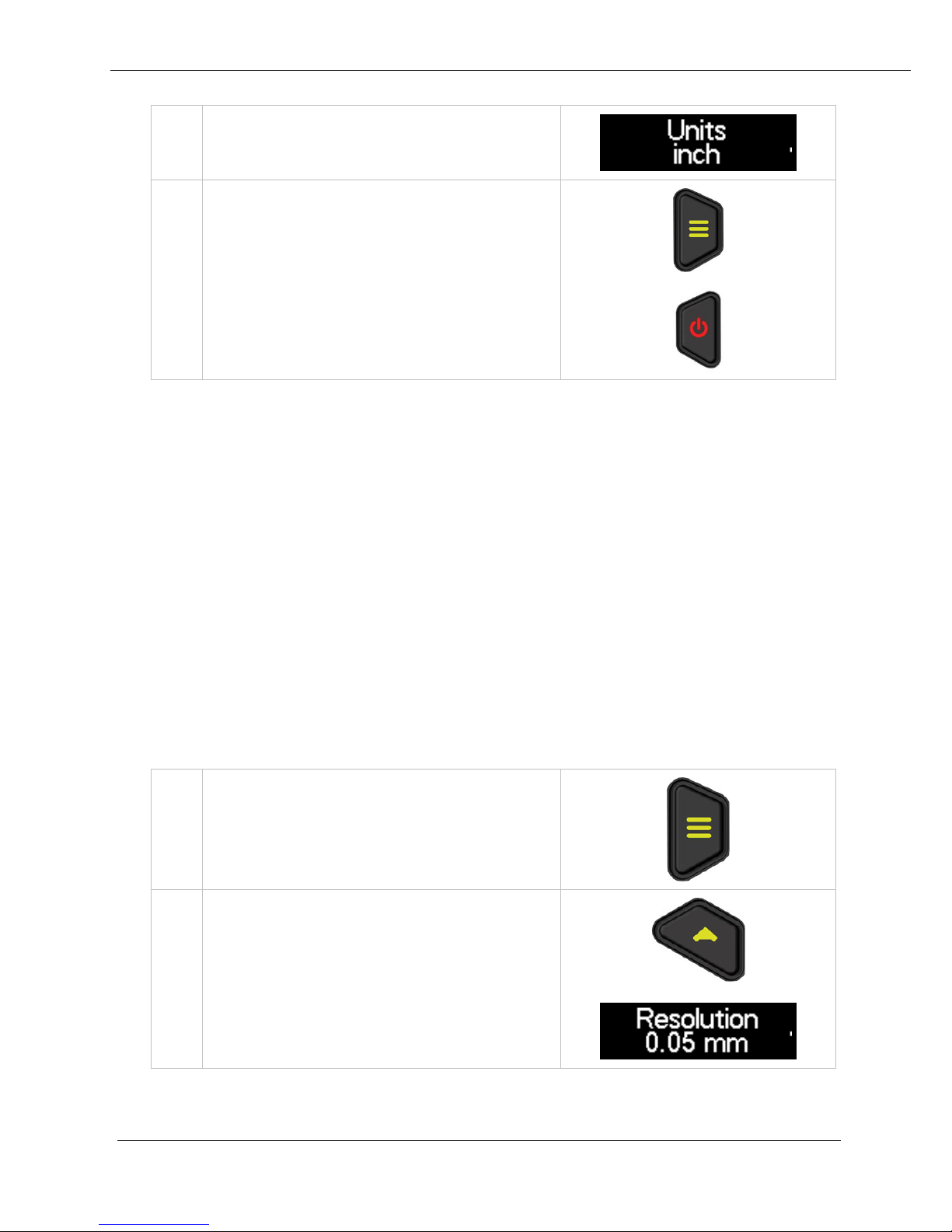

Measurement Units

The Gauge can display thickness measurements in either Metric

(mm) or Imperial (inch). Changing the measurement units will not

affect the calibration.

1.

Press the Menu key

2.

Press the Up Select key to get to

the Units item

3.

Press the Menu key to change

the value

4.

Use the Up and Down Select

keys to switch from mm to Inch

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

43

5.

When done press the Menu key

to save the new value.

Or press the Power / Cancel to

exit without saving.

Resolution Setting

The gauge can display thickness measurements in three resolution

settings:

• 0.1 mm 0.005 inch

• 0.05 mm 0.002 inch

• 0.01 mm 0.001 inch

For general metal corrosion measurement the 0.1 mm setting is

recommended.

To change the Resolution setting:

1.

Press the Menu key

2.

Press the Up Select key to get to

the Resolution item

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

44

3.

Press the Menu key to change

the value

4.

Use the Up and Down Select

keys to switch from mm to Inch

5.

When done press the Menu key

to save the new value.

Or press the Power / Cancel to

exit without saving.

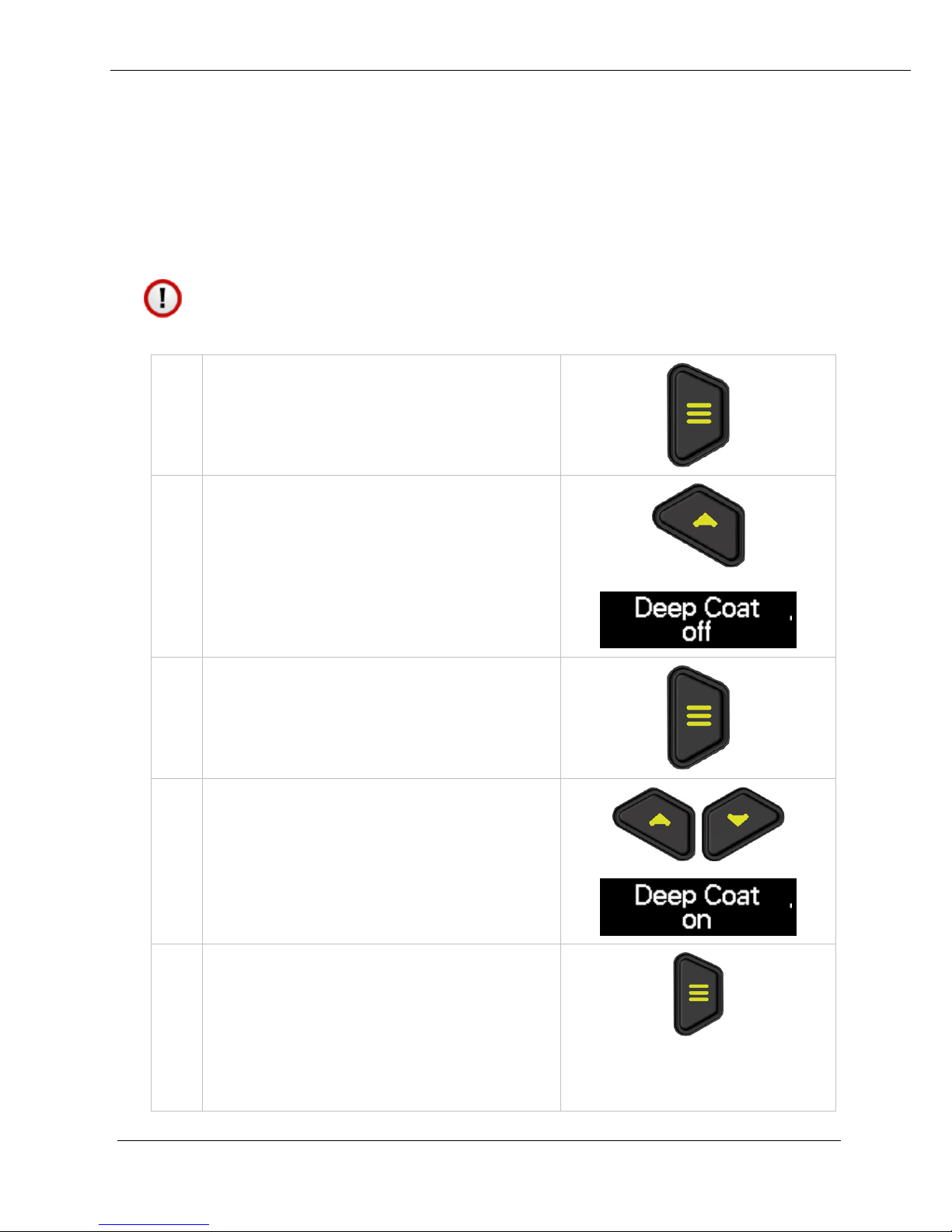

Deep Coat Function (multiple echo mode)

The Deep Coat function is not available from the Main Menu

by default. To show the Deep Coat option in the menu please

contact Cygnus for instructions.

In Multiple Echo mode with the Deep Coat turned Off the gauge

can measure through most protective coatings up to 3 mm (0.11”)

thick when using a S2C type probe. Coatings like paint, anti-foul,

hard plastics and epoxy shou ld present no problems as long as

they have not de-laminated/de-bonded from the metal surface.

In Multiple Echo mode with Deep Coat turned On will allow the

gauge to measure through coat in gs over 3mm (0.11”) thick up to

a maximum of around 20 mm (0.78”) depending on the properties

of the coating material.

Measuring through thick coatings is ultimate ly limited by how well

the coating material allows the ultrasound to pass through, soft

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

45

coatings like rubber or bitumen don’t transmit ultrasound very

well.

Deep Coat is only available in Multiple Echo mode.

Using Deep Coat will not affect the calibration.

Turn Deep Coat Off when NOT measuring through thick

coatings otherwise this may cause inaccurate measurements.

1.

Press the Menu key

2.

Press the Up Select key to get to

the Deep Coat item

3.

Press the Menu key to change

the value

4.

Use the Up and Down Select

keys to switch from On to Off

5.

When done press the Menu key

to save the new setting.

Or press the Power / Cancel to

exit without saving.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

46

Vibrate Alert Function

The gauge can vibrate to alert the user when a thickness

measurement has been made. Thi s feature can be turned on or off

as required.

In Single Echo and Echo-Echo measurement mod es the vibrate

alert will be triggered when a stable measurement is detected. See

Measurement Stability Indication in SE & EE Modes on page 26.

1.

Press the Menu key

2.

Press the Up Select key to get to

the Vibrate item

3.

Press the Menu key to change

the value

4.

Use the Up and Down Select

keys to change the setting from

On to Off

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

47

5.

When done press the Menu key

to save the new value.

Or press the Power / Cancel to

exit without saving.

Display Rotate Function

If the gauge is worn on a belt using t h e Krusell belt clip the end

display will be upside down. To rotate the display so it can be read

set the Display Rotate function to ‘y es’. Now the thickness

measurement display will be rotated 180 degrees.

When you remove the gauge from the belt clip and access the

Main menu the display will rotate back the normal way around so

you can hold the gauge normally.

1.

Press the Menu key

2.

Press the Up Select key to get to

the Rotate Display item

3.

Press the Menu key to change

the value

4.

Use the Up and Down Select

keys to change the setting

between yes and no

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

48

no = don’t rotate.

yes = rotate 180 degrees

5.

When done press the Menu key

to save the new setting.

Or press the Power / Cancel to

exit without saving.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

49

8. General Points On Thickness Gauging

On very rough surfaces and especially if both sides are badly

corroded, it is often necessary to move the Probe around to locate

a back wall reflector. Sometimes a slight rocking movement can

help find reflectors which are otherwise impossible.

Badly corroded sections can also be soaked with a light lubricating

oil to improve ultrasound coupling through to the good material.

Always ensure that there is p lenty of couplant present for good

contact, but beware that on a pitted surface the Gauge may just

measure the couplant-filled pit, always avoid measuring directly

over external pits.

Beware that in extreme conditions or if the plate is of poor quality

and contains many inclusions the ultrasound will be scattered to

such an extent that measurement may not be possible.

Beware that the multiple-echo technique will not work if the front

and back surfaces of the mater ial being measured are not close to

parallel. Also note that long narrow bars cannot be gauged along

their length with the multiple-echo method.

The Gauge should not be used near arc-welding equipment, as th is

affects its performance.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

50

9. Troubleshooting

The Gauge will not Switch On

• Are the batteries exhausted?

• Check the batteries are inserted correctly.

Difficulty obtaining a Reading

• Check that the Probe lead is properly connected to both Probe

and Gauge.

• Check the gauge is set for the probe connected.

• Check the condition of the lead, replace if necessary.

• Check the Probe and its membrane are properly assembled (if

a single element probe).

• On heavily corroded areas this is often a problem, try and

take measurements in adjacent areas of the same material.

You could also consider using a twin element probe in single

echo mode.

• Check the Gauge and Probe together on a test block, if there

is still no reading the Gauge may require servicing.

If Readings are Erratic or Unstable

• Check that the Probe-lead is properly connected to both

Probe and Gauge.

• Check that the Probe and its membrane are correctly

assembled with sufficient couplant between the probe face

and membrane (if a single element probe).

• Check the Probe Type is suitable for the probable minimum

thickness of the material being measured. Probe frequencies

too low cause doubling and tripling of the actual thickness.

Tips for Optimising Battery Life

• Couplant left on the probe face will stop the gaug e e ntering

low power saving mode – so wipe couplant off the probe face

between measurement sessions.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

51

• When measuring on very heavily corroded metal with single

element probes the gauge uses more power searching for a

multiple echo match – this can significantly reduce battery

life. So if you are frequently measuring on very heavy

corrosion consider using a twin element probe as this will

require less power to get measurements.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

52

10. Updating your Gauge

As part of our policy of ongoing development and product

improvement Cygnus may issue firmware updates for your model

of gauge. The firmware on the gauge can be easily updated by

the user using update software downloaded from the Cygnus

website.

Before updating your gauge note the model and serial number of

the gauge (se e Turning the Gauge On on page Error! Bookmark

not defined.). You can then check on the Cygnus website if your

gauge has the latest firmware version, and if not proceed to

download the update software.

You can check for the latest gauge firmware on the Cygnus

website [ http://www.cygnus-instruments.com

]. Navigate to

Support -> Downloads -> Technical Software and look for a

PDF document called ‘M5 Surface Gauge Firmware Version Info’

view this document to find the latest version for your gauge along

with any changes made. Note yo u will n eed to create an account

to access this section of the website.

Update Software

To update a gauge you must first download and install the ‘Cygnus

M5 Surface Gauge Updater’ software. This is available from the

Cygnus website in the Support -> Downloads -> Technical

Software section. There is a PDF document with instructions

available.

Gauge Firmware Files

You must download the appropriate Gauge Firmware file for the

model of gauge, there are three to ch oose from; Cygnus 2/2

+

,

Cygnus 4/4

+

or Cygnus 6+ PRO.

Once downloaded the gauge can be easily updates via the USB

cable connecting the gauge to the computer. The whole process

takes about 2 minutes. There is a PDF document with detailed

instructions available on the website.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

53

11. Care and Servicing

Cleaning the Gauge

Clean the Gauge and accessories with a damp cloth. Use

water with a mild detergent household cleaner.

Do not use solvents to clean the Gauge.

Do not use any abrasive cleaner, especially on the display

window.

Do not immerse the Gauge in liquid when cleaning.

Batteries

Always remove the batteries if the Gauge will not be used for

more than a few days.

Only use leak-proof batteries, Cygnus recommend Duracell

batteries.

Environmental

Do not immerse the Gauge in liquids. The gauge is designed

to be IP67 but it is not intended for use in water.

Do not subject the Gauge to temperatures greater than 50˚C

(122˚F).

Do not store the Gauge for long periods in conditions of high

humidity.

Storage

Do not store the Gauge in temperatures greater than 35˚C

(95˚F).

Repairs

There are no user serviceable parts inside the Gauge.

Therefore all repair work should be carried out by Cygnus

Instruments or by an Authorised Cygnus Service dealer.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

54

OLED Display

Avoid leaving the gauge in direct sunlight as the high

temperatures generated can shorten the life of the OLED display.

Returning the Gauge for Servicing

A full Manufacturer’s Factory Service is available from Cygnus

Instruments.

The Complete Kit should always be returned for Service or

Repair, including all Probes and Leads.

Cygnus Gauges are renowned for their reliability, very often

problems with getting measurements are simply due to the way

the Gauge is being used.

However, if you do need to return y ou r Gauge for Repair please let

us know the details of the problem, to help us guarantee the best

possible service:

• Is the problem Intermittent Behaviour?

• Is there a problem turning the Gauge On?

Or a problem with the Gauge turning itself Off?

• Does the Gauge constantly give Incorrect Readings, or

Unsteady Readings?

• Is it not possible to Calibrate the Gauge?

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

55

12. Information

Technical Specifications

Cygnus M5-C2P Technical Specifications

General Attributes

Size

84 mm x 130 mm x 35 mm (W x H x D)

(3.3 in x 5.1 in x 1.4 in)

Weight

Gauge with batteries 300 g (10.5 oz.)

Power Supply

3 x AA / R6 Batteries.

Probe Sockets

2 x Lemo 00

Operating Temperature Range

-10°C to +50°C (14°F to 122°F)

Storage Temperature Range

-10°C to +35°C (14°F to 95°F)

Battery Operation Time

Approximately 10 hrs. continuous measurem ent with fully

charged Duracell Alkaline LR6 batteries.

Battery Voltage Range

Min 3.0 V dc, Max 4.5 V dc

Battery Type

AA Size. LR6 Alkaline / HR6 NiMH.

Low Battery Indication

Batte ry level indication on display with low battery warning

message.

PRF

N/A

Monitor Outputs

N/A

Through Coating

Measurements

Multiple-Echo mode with Single element 0° probe;

• Through coating measurement for coatings up to 3 mm

thick as standard depending on coating velocity.

• Deep Coat mode provides ability to measure through

thicker coatings depending on coating material.

Echo-Echo mode with Twin element probe;

• Through coating measurement for coatings up to 1 mm

thick as standard depending on coating velocity.

Materials

Sound velocity from 1000 m/s to 9000 m/s

[0.0390 in/us to 0.3543 in/us]

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

56

Cygnus M5-C2P Technical Specifications

Measurement Ranges

(in steel)

Single element 0° probes in Multiple Echo mode;

S2C/D probe

3 to 250 mm

[0.120 in. to 10.00 in.]

S3C probe

2 to 150 mm

[0.080 in. to 6.000 in.]

S5C/A probes

1 to 50 mm

[0.040 in. to 2.000 in.]

Twin element probes in Single Echo mode;

T2C probe

2.5 to 250 mm

[0.098 in. to 10.00 in.]

T5B probe

1.5 to 200 mm

[0.059 in. to 7.900 in.]

T7A probe

0.8 to 50 mm

[0.031 in. to 2.000 in.]

Twin element probes in Echo-Echo mode;

T2C probe

5.0 to 50 mm

[0.200 in. to 2.000 in.]

T5B probe

4.0 to 50 mm

[0.160 in. to 2.000 in.]

T7A probe

3.0 to 25 mm

[0.120 in. to 1.000 in.]

Probe Zero

Twin element probes are zeroed in the air without the need of

a zero block. The user is prompted to zero the probe at power

up and after a probe change.

Single element probes in multiple echo mode do not need to

be zeroed.

Measurement Modes

Single Echo mode with Twin element probe. Measures

thickness using the time from the delay line (ze ro point) to the

first back-wall echo. (UT Mode 2)

Echo-Echo mode with Twin element probe. Measures thickness

using the time between the first and second back-wall echoes.

(UT Mode 3)

Multiple Echo using Single element probe. Uses three matched

and verified back-wall echoes to determine the material

thickness and ignore surface coatings.

High Temperature

Measurement

All standard single element and twin element probes:

Allows continuous measurement up to 75°C (160°F).

Resolution

Single Echo and Echo-Echo measurement modes;

Low

0.1 mm

[0.005”]

Medium

0.05 mm

[0.002”]

High

0.01 mm

[0.001”]

Multiple Echo measurement modes;

Low

(measurement > 120 mm)

0.1 mm

[0.005”]

Medium

(measurement < 120 mm)

0.05 mm

[0.002”]

Accuracy

±0.1 mm (±0.004”) or 0.1% of thickness measurement whichever is

the greatest.

Display

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

57

Cygnus M5-C2P Technical Specifications

Type of Display

OLED Monochrome

Display Size

128 x 32 Pixels. 25.58 mm (W) x 6.38 mm (H)

Display Information

Digital Thickness Value. Settings. Battery Level.

Transmitter

Shape of Pulse

Square

Pulse Energy : Voltage (peakto-peak)

70 V p-p

Pulse Energy : Rise Time

3 ns (max)

Pulse Energy : Pulse Duration

S2C : 220 ns

S2D : 220 ns

S3C : 100 ns

S5A / S5C : 67ns

T2C : 220 ns

T5B : 100 ns

T7A : 67 ns

HT5 : 100 ns

Receiver

Gain Control

Automatic Gain Control depending on probe and measurement

mode.

Frequency Range

1.0 MHz to 10.0 MHz (-6dB)

Other Information

Data Output and Storage

Non.

Data Connector

USB Mini B Connector under battery cover.

Can be used to update the gauge firmware and load gauge

settings.

Calibration setting storage

Calibration Data stored to Internal Flash Memory

Calibration Mechanisms

Not required for Mult iple Echo mode.

Automatic V-path correction for twin element probes.

Option of two point calibration for twin element probes.

Display & Recall Facilities

N/A

Display Response Time

125 ms / 500 ms

Printer Output

N/A

Environmental Rating

IPX67 (Water immersion 1 metre depth for 30 minutes)

MIL STD 810G Method 501.6 (High Temp +55°C)

MIL STD 810G Method 502.6 (Low temp -20°C)

MIL STD 810G Method 507.6 (Humidity 95%)

MIL STD 810G Method 512.6 (Immersion 1m, 30min)

Shock & Impact

MIL STD 810G Method 514.7 (Vibration)

MIL STD 810G Method 516.7 (Shock 20g)

MIL STD 810G Method 516.7 (Transit Drop 1.22m)

Compliance

RoHS Complia n t.

Designed for BS EN 15317:2000.

CE Marked including EMC.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

58

Specifications are subject to change for p roduct improvement.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

59

Table of Sound Velocities

Velocities will vary according to the pre cise grade and processing

conditions of the material being measured.

This table is included as a guide only.

Wherever possible, the Gauge should always be calibrated on

the material under test.

These Velocities are given in good faith and are believed to

be accurate within the limits described above.

No liability is accepted for errors.

Velocities given are the compressional wave velocity cl.

Material

Velocity of Sound (V)

Conversion

Factor (f)

m/s in/us

Aluminium (alloyed)

6380

0.2512

1.078

Aluminium (2014)

6320

0.2488

1.068

Aluminium (2024 T4)

6370

0.2508

1.076

Aluminium (2117 T4)

6500

0.2559

1.098

Brass (CuZn40)

4400

0.1732

0.743

Brass (Naval)

4330

0.1705

0.731

Brass (CuZn30)

4700

0.1850

0.794

Copper

4700 - 5000

0.1850 – 0.1969

0.794 – 0.845

Core Ten

5920

0.2331

1.000

Grey Cast Iron

4600

0.1811

0.777

Inconel

5700

0.2244

0.963

Lead

2150

0.0846

0.363

Monel

5400

0.2126

0.912

Nickel

5630

0.2217

0.951

Phosphor Bronze

3530

0.1390

0.596

Mild Steel

5920

0.2331

1.000

Tool Steel

5870

0.2311

0.992

Stainless Steel 302

5660

0.2228

0.956

Stainless Steel 347

5790

0.2279

0.978

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

60

Stainless Steel 304

5664

0.2229

0.956

Stainless Steel 314

5715

0.2250

0.965

Stainless Steel 316

5750

0.1163

0.971

Tin

3320

0.1307

0.561

Titanium

6100 - 6230

0.2402 – 0.2453

1.030 – 1.052

Tungsten Carbide

6660

0.2622

1.125

Epoxy Resin

2500

0.0986

0.422

Acrylic

2730

0.1076

0.461

Nylon (Polyamid e)

2620

0.1032

0.443

Reading Conversions

If only a few measurements are to be taken on a material other

than Steel, it may be easier to leave the calibration set for Steel

and merely convert th e readings by multiply ing by the

Conversion Factor for the material being measured.

This method avoids unnecessary recalibration.

Example.

The Gauge is calibrated for Steel [5920 m/s], but the reading is

being taken on Copper [4700 m/s] :

T = t x V

COPPER

/ V

STEEL

= t x 4700 / 5920

= t x 0.794

thus : T = t x f [ where: f = V

COPPER

/ V

STEEL

]

where : T = true thickness of Copper being measured

t = actual reading obtained

f = Conversion Factor (from table)

V

COPPER

= Sound Velocity in Copper : 4700 m/s

V

STEEL

= Sound Velocity in Steel : 5920 m/s

The Conversion Factor f: is given for various materials in the

Table of Sound Velocities

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

61

13. EU Declaration of Conformity

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

62

14. Recycling and Disposal (EC Countries)

The WEEE Directive (Waste Electrical and Electronic Equipment

2002/96.EC) has been put into place to ensure that products are

recycled using best available treatment, recovery and recycling

techniques to ensure human health and high environmental

protection.

The Gauge has been designed and manufactured with high quality

materials and components which can be recycled and reused. It

may contain hazardous substances that could impact health and

the environment. In order to avoid the dissemination of those

substances in our environment and to diminish the pressure on

natural resources we encourage you to dispose of this product

correctly.

D

O NOT dispose of this product with general household

waste.

D

O dispose of the complete product i n cluding cables,

plugs and accessories in the designed WEEE collection

facilities.

T

his product may also be returned to th e agent or manufacturer

who supplied it for safe end-of-life disposal.

C

ygnus Instruments Ltd registration number for The WEEE

Directive is WEE/HE1274RU.

M5-CYG2P-M-01_Iss6.doc

Cygnus 2+ Operating Manual

63

15. Warranty Information

LIMITED THREE YEAR WARRANTY

FOR CYGNUS ULTRASONIC THICKNESS GA UGES

1. Cygnus Instruments Limited (“CYGNUS”) warrants that, subject as set out below,

the Products manufactured by it (excluding consumables, batteries, probes, leads,

microphones and telescopic extensions) will be free from defects in materials and

workmanship for a period of three years from the date of purchase either from

CYGNUS or from an Authorised CYGNUS Distributor. Batteries, probes, leads,

microphones and telescopic extensions are warranted for 6 months. This warranty is

limited to the original Purchaser of the Product and is not transferab le. During the

warranty period, CYGNUS will repair, replace or refund, at its option, any defective

Products at no additional charge, provided that the product is returned by the

original Purchaser, shipping prepaid, to CYGNUS or an Authorised CYGNUS

Distributor. If shipped by mail or any common carrier, the Purchaser must insure

and accept all liability for loss or damage to the Product and must use shipping

containers equivalent to the original packaging. Replacement products or parts will

be furnished on an exchange basis only. All replaced products or parts become the

property of CYGNUS.

2. Any defects in ma terials or workm a ns hi p m us t be n otified to CYGNU S by the

Purchaser within seven days after the discovery of the defect or failure.

3. Dated proof of purchase must be provided by the Purchaser when requesting

warranty work to be performed or making any other claim under this warranty.

CYGNUS will not be liable under this warranty unless the total price for the Product

was paid by the due date for pay me nt.

4. This warranty does not exten d to any pro du ct s whic h have be en da ma ge d as a

result of, accident, misuse or abuse, natural or personal disaster, service,

modification or repair by anyone other than CYGNUS or an Authorised CYGNUS

Service Centre, failure to properly store or maintain the Product, negligence,

abnormal working conditions, fair wear and tear, or failure to follow the instructions

issued by CYGNUS in relation to the Product.

5. Except as expressly set forth above or in the CYGNUS Terms of Sale, subject to

which the Products were purchased, all warranties, conditions or other terms implied

by Statute or Common Law are extended to the fullest extent permitted by law.

6. Except in respect of death or personal injury caused by the negligence of Cygnus,

Cygnus shall not be liable to the Purchaser or to any other person by reason of any

representation (unless fraudulent), or any implied warranty, condition or other term,

or any duty at common law, or under the express terms of the contract for purchase

of the Products, for loss of profit or for any indirect, special or consequential loss or

damage, costs, expenses or other claims for compensation whatsoever (whether

caused by the negligence of Cygnus, its employees or agents or otherwise) which

arise out of or in connection with the supply of the Products or their use or resale by

the Purchaser or by any other person. The entire liability of Cygnus under or in

connection with the Products shall not exceed the price paid for the Products, except

as expressly provided in this warranty.

Cygnus 2+ Operating Manual

M5-CYG2P-M-01_Iss6.doc

64

16. Index

Automatic Power Off, 24

Batteries

Fitting, 10

Level, 28

Life, 28

Low Battery Warning, 28

NiCad, 10

NiMH, 10

Belt Clip, 13

BS EN 15317:2007, 30

Calibration

Conversion Factor, 60

Ladder Step Wedge, 32

Single Point, 30

Two Point Calibration, 32

Velocity of Sound, 36

Deep Coat, 44

Display

Rotate, 47

Disposal, 62

Echo-Echo, 17

Gauge

Cleaning, 53

Display, 23

Keys, 23

Serial Number, 24

Version Number, 24

Hand Strap, 12

Ignore Coatings, 16

Imperial, 42

Main Menu, 38

Measurement

Pitted surface, 49

Measurement

Resolution, 43

Rough surfaces, 49

Small Pipes, 27

Stability, 26

Units, 42

Metric, 42

Multiple Echo, 16

Echo Bars, 26

Neck Strap, 13

No Probe Message, 24

Plastics, 18

Power button, 24

Probes

Automatic Detection, 41

Cable, 11

Connector, 23

Knurled Ring, 20

Membrane Couplant, 20

Membrane Key, 2 0

Polyurethane Membrane

Membrane, 18

Type, setting, 40

Zero, 34

Recycling, 62

Repair, 54

Resolution, 43

Service, 54

Single Echo, 16

Sound Velocities, 59

Test block, 30

Thick Coatings, 44

Thickness Measurement, 25

Troubleshooting, 50

Units, 42

Vibrate Alert, 46

Warranty, 63

WEEE Directive, 62

Zeroing, 34

ALPINE

COMPONENTS

Postal Address

Alpine Components Ltd

Innovation Centre, Highfield Drive

Churchfields

St. Leonards-on-

Sea

TN38 9UH

United Kingdom

Telephone

01424 858118

Website Address

www.alpine-

components.co.uk

"Alpine Components" is the abbreviated trading name for "Alpine Components Limited"

The company has been trading since 1991 and was incorporated on 13/11/2006 in the United Kingdom

Company Registration Number: 05996485

VAT Number: GB583598190

Loading...

Loading...