Page 1

Contents

Operating instructions

VacuStar L400

Doc-ID: 5028 / BA / EN

Release: Rev. 03 / 05.10.2018

The operating instructions must be read by the VacuStar L400 operator before start-up!

Page 2

2

Translation of the original operating manual

© CVS engineering GmbH

Großmattstraße 14

79618 Rheinfelden / Germany

Phone: +49 (0)7623 71741-0

Customer service: +49 (0)7623 71741-0

E-Mail: info@cvs-eng.de

Internet: www.cvs-eng.de

Page 3

Operating instructions VacuStar L400

Contents

3

1 General .................................................................................... 4

1.1 Information regarding the operating instructions ........... 4

1.2 Pictogram explanation ................................................... 5

1.3 Limitation of Liability ...................................................... 6

1.4 Copyright protection ....................................................... 6

1.5 Spare parts .................................................................... 7

1.6 Warranty conditions ....................................................... 7

1.7 Customer Service .......................................................... 7

2 Safety ...................................................................................... 8

2.1 Intended use .................................................................. 8

2.2 Acceptance and monitoring ........................................... 8

2.3 Operator's responsibility ................................................ 8

2.4 Operating personnel ...................................................... 9

2.4.1 Requirements ................................................. 9

2.5 Personal protective equipment ...................................... 9

2.6 Occupational safety and special risks ......................... 10

3 Technical data ...................................................................... 15

4 Design and function............................................................. 17

4.1 Design .......................................................................... 17

4.2 Function ....................................................................... 18

4.3 Control and display elements ...................................... 18

5 Transport and storage ......................................................... 19

5.1 Safety notes for transport ............................................ 19

5.2 Transport ...................................................................... 19

5.3 Storage ........................................................................ 19

6 Start-up and operation ........................................................ 20

6.1 Safety notes ................................................................. 20

6.2 Start-up ........................................................................ 20

6.3 Switching off ................................................................. 21

6.4 Inspections to be performed ........................................ 21

7 Maintenance ......................................................................... 23

7.1 Safety during maintenance work ................................. 23

7.2 Maintenance schedule ................................................. 23

7.3 Performance of maintenance work .............................. 25

8 Malfunctions ......................................................................... 27

8.1 Safety ........................................................................... 27

8.2 Recommissioning after corrective action ..................... 27

8.3 Malfunction table .......................................................... 28

9 Spare parts ........................................................................... 30

10 Decommissioning and disposal ......................................... 30

Index .............................................................................................. 31

Page 4

Operating instructions VacuStar L400

General

4

1 General

1.1 Information regarding the operating instructions

These operating instructions provide important information on how

to deal with the VacuStar L400. A precondition for safe operation is

the observance of all specified safety and handling instructions.

Furthermore, all local accident prevention regulations and general

safety regulations valid for the application area of the

VacuStar L400 must be observed.

Carefully read the operating instructions before starting any work! It

is a product component and must be kept in direct proximity of the

VacuStar L400, well accessible to the personnel at all times.

When passing the VacuStar L400 on to third parties, the operating

instructions must also be handed over.

Page 5

Operating instructions VacuStar L400

General

5

1.2 Pictogram explanation

Warning notes

Warning notes are characterised by pictograms in these operating

instructions. The warning notes are marked by signal words

expressing the extent of the hazard.

It is absolutely essential to observe the notes and to proceed with

caution in order to prevent accidents as well as bodily injuries and

property damage.

DANGER!

points to an immediately dangerous situation, which

can lead to death or serious injuries if it is not

avoided.

WARNING!

... points to an immediately dangerous situation,

which can lead to death or serious injuries if it is not

avoided.

CAUTION!

... points to a potentially dangerous situation, which

can lead to minor or light injuries if it is not avoided.

ATTENTION!

... points to a potentially dangerous situation, which

may lead to property damage if it is not avoided.

Hints and recommendations

NOTE!

… highlights useful hints and recommendations as

well as information for an efficient and trouble-free

operation.

Page 6

Operating instructions VacuStar L400

General

6

1.3 Limitation of Liability

All specifications and notes in these operating instructions were

compiled with consideration to the valid standards and regulations,

the state of the art as well as to our long-standing knowledge and

experience.

The manufacturer is not liable for damages caused by:

Non-observance of the operating instructions

Improper use

Deployment of non-trained personnel

Arbitrary modifications

Technical changes

Use of non-approved spare and wear parts.

The actual scope of supply may differ from the explanations and

illustrations described in this manual in case of special designs, if

additional order options are made use of, or due to latest technical

changes.

Incidentally, the responsibilities agreed upon in the delivery

contract, the general terms and conditions as well as the

manufacturer's conditions of delivery and the statutory provisions

valid at the time of contract conclusion shall apply.

Warranty

The manufacturer guarantees the correct functioning of the applied

process technology and the performance parameters identified.

The warranty period commences on the date the VacuStar L400 is

delivered to the customer.

Components are exempted from the warranty and from claims for

defects as far as wear and tear damage is concerned.

1.4 Copyright protection

NOTE!

Content details, texts, drawings, pictures and other

illustrations are protected by copyright and are

subject to industrial property rights. Any improper

use shall be liable to prosecution.

Any type and form of duplication also of extracts as well as the

exploitation and/or communication of the contents are not

permitted without the manufacturer’s written declaration of consent.

Page 7

Operating instructions VacuStar L400

General

7

1.5 Spare parts

WARNING!

Risk of injury by incorrect spare parts!

Incorrect or defective spare parts can result in

damage, malfunctions or total failure and also

impair safety.

Therefore:

– Use only the manufacturer's original spare

parts.

Procure spare parts from authorised dealers or directly from the

manufacturer. Refer to page 2 for address.

1.6 Warranty conditions

Warranty terms see "General Terms of Sale".

1.7 Customer Service

Our customer service can be contacted for any technical advice.

Information about the responsible contact person can be retrieved

by telephone, fax, E-mail or via the Internet at any time, refer to

manufacturer's address on page 2.

Page 8

Operating instructions VacuStar L400

Safety

8

2 Safety

2.1 Intended use

The compressor vacuum pump VacuStar L400 is intended

exclusively for the compression or suctioning of filtered air.

Only use VacuStar L400 for the intended use.

All specifications in the operating instructions must be strictly

adhered to (technical data, operating data, permissible working

range), refer to Page 15, chapter 3 in this regard.

All types of claims due to damage arising from improper use are

excluded. The operator alone shall be responsible for any damage

arising from improper use.

2.2 Acceptance and monitoring

The VacuStar L400 is not subject to any acceptance and

monitoring obligation.

2.3 Operator's responsibility

The VacuStar L400 is used for industrial purposes.

The operator of the VacuStar L400 is therefore subject to the legal

obligations concerning occupational safety.

The provisions valid at the place of installation as well as the safety

and accident prevention regulations of the Institution for statutory

accident insurance and prevention must be observed. The operator

must in particular:

inform himself on the valid industrial safety regulations.

determine the additional hazards that arise from the special

working conditions at the VacuStar L400's place of installation

by means of a hazard assessment.

implement the necessary rules of conduct for operation of the

VacuStar L400 at the place of installation by means of user

instructions.

check at regular intervals during the VacuStar L400's entire

period of use whether the user instructions correspond to the

current state of the body of rules and regulations.

adapt the operation instructions, if necessary to the new

regulations, standards, and operating conditions .

clearly regulate the responsibilities for installing, operating,

maintaining and cleaning the VacuStar L400.

ensure that all employees working on or with the VacuStar L400

have read and understood the operating instructions. In addition

he must at regular intervals train the employees in how to deal

with the VacuStar L400 and inform them about potential

hazards.

Page 9

Operating instructions VacuStar L400

Safety

9

In addition, it is the operator's responsibility to ensure that:

the machine is always in a technically perfect condition.

the machine is maintained in accordance with specified

maintenance intervals.

all safety equipment is regularly checked for completeness and

correct functioning.

2.4 Operating personnel

2.4.1 Requirements

WARNING!

Risk of injury in case of inadequate

qualification!

Improper handling can lead to considerable bodily

injuries and property damage.

Therefore:

– Have any activities only carried out by the

individuals designated for that purpose.

The operating instructions specify the following qualification

requirements for the different fields of activity:

Instructed persons

have been instructed during instructions provided by the

operator with regard to the work assigned to them and possible

hazards arising from improper conduct.

Specialists

are due to their technical training, knowledge and experience

and their knowledge of the pertinent regulations able to carry

out the work assigned to them and to independently recognize

potential hazards.

2.5 Personal protective equipment

When handling the VacuStar L400, it is necessary to wear

personal protective equipment, in order to minimise health

hazards.

Before carrying out any work, properly don the necessary

protective equipment such as gloves, safety goggles, etc. and

wear during work.

Page 10

Operating instructions VacuStar L400

Safety

10

2.6 Occupational safety and special risks

The remaining risks that result from the hazard analysis are

specified in the following section.

Observe the safety notes listed here and the warning notes in the

other chapters of these instructions to reduce health hazards and

to avoid dangerous situations.

Assembly of the VacuStar L400

The relevant dangerous spots on the VacuStar L400 are identified

by these pictograms:

DANGER!

General danger pictogram!

… denotes general dangerous situations for

individuals. Non-observance of the safety

instructions can result in severe injuries or

death. .

DANGER!

Danger of burns!

… denotes the presence of a hot surface.

Page 11

Operating instructions VacuStar L400

Safety

11

Hazard notes and occupational safety

For your own safety and that of the machine, the following

information must be observed and complied with:

Improper operation

DANGER!

Danger due to improper operation!

– Only use VacuStar L400 in a perfect technical

condition. Malfunctions that are relevant for

safety have to be promptly eliminated.

– Conversions of the VacuStar L400 are not

permissible and can impair safety.

– Never bridge any safety equipment or put it out

of operation.

– Any work on the VacuStar L400 and/or on

electrical equipment must be carried out by

specialised staff.

– Repair and maintenance work may only be

carried out when the VacuStar L400 is

stationary.

For this, the VacuStar L400 must be secured

against restarting!

– The VacuStar L400 may not be under pressure

or in a state of vacuum while work is being

carried out on it.

Close shut-off valve on the vehicle side and

vent the pipe between VacuStar L400 and shutoff valve or manually relieve excess pressure at

safety valve. Observe pressure gauge!

– The drive's protective equipment may only be

removed when the VacuStar L400 is stationary

and has to be correctly refitted after completion

of work.

– Only dismantle accidental contact protection

after VacuStar L400 and pipes have cooled

down.

– It is an environmental protection requirement

that any liquids arising during maintenance work

(e.g. oil) must be collected and disposed of in

an environmentally compatible manner.

Page 12

Operating instructions VacuStar L400

Safety

12

Moving components

WARNING!

Risk of injury by moving components!

Powered rotating components can cause the most

serious injuries!

Therefore during operation:

– It is absolutely forbidden for persons to stay in

the hazard area or in the immediate vicinity!

– Do not put safety devices and/or functions out

of operation and do not render them inoperative

or bypass them.

– Never reach into open outlets and inlets or into

running equipment.

Before entering the hazard area:

– Switch off power supply and secure against

restarting.

– Wait for standstill of lagging components.

– Wait for automatic dissipation and/or discharge

of residual energies (compressed air).

Compressed air

WARNING!

Risk of injury due to compressed air!

Pneumatic energies can cause the most serious

injuries.

In the case of damage to individual components,

air can be discharged under high pressure and

injure e.g. the eyes. Therefore:

– Before starting any work, first depressurise

pressurised components. Pay attention to

accumulators. Accumulator pressure must also

be completely relieved.

Signposting

WARNING!

Risk of injury by illegible pictograms!

Labels and signs can become dirty or

unrecognisable in the course of time.

Therefore:

– Always keep safety, warning and operating

instructions in a well legible condition.

– Immediately replace damaged or obliterated

signs or labels.

Page 13

Operating instructions VacuStar L400

Safety

13

Improper transport

Danger!

Danger by falling down or tilting of the

VacuStar L400!

The weight of the VacuStar L400 may injure a

person and cause serious bruising!

Therefore:

– Depending on the dead weight and size of the

VacuStar L400, use a pallet on which the

VacuStar L400 can be moved by means of a

fork lift.

– For lifting the VacuStar L400, use suitable lifting

gear (slings, etc.) that is designed for the weight

of the VacuStar L400.

– When putting the slings in position, take care to

avoid putting stress on individual components.

– Only use the provided attachment points with

eye bolts.

Start-up and operation

WARNING!

Risk of injury due to improper start-up and

operation

Improper start-up and operation can lead to serious

bodily injuries or property damage. Therefore:

– Have all work during initial operation exclusively

performed by the manufacturer's employees or

by his authorised representatives or by trained

personnel.

– Start-up and operation may only be performed

by adequately qualified personnel that has been

authorised and instructed by the operator.

– Before the start of any work, ensure that all

covers and protective devices are correctly

installed and function correctly.

– Never override any protective equipment during

operation.

– Pay attention to tidiness and cleanliness in the

working area! Loosely stacked or scattered

components and tools are accident sources.

Page 14

Operating instructions VacuStar L400

Safety

14

Electrical system

DANGER!

Mortal danger due to electric current!

There is mortal danger in case of contact with live

components.

Activated electrically driven components can start

to move uncontrolled and cause severest injuries.

Therefore:

– Switch off the electric power supply before

commencing any work and secure against

restarting.

– Work on the electrical system, on individual

electrical components and on the connections

may only be carried out by electrical specialists.

Maintenance and troubleshooting

WARNING!

Risk of injury due to improper maintenance and

troubleshooting!

Improper maintenance and troubleshooting can

lead to serious bodily injuries or property damage.

Therefore:

– Maintenance work and troubleshooting work

may only be carried out by sufficiently qualified

and instructed personnel.

– Protect VacuStar L400 from being restarted,

switch off drives!

– Before starting any work, provide for sufficient

space and freedom of movement during

assembly.

– Pay attention to tidiness and cleanliness in the

assembly area! Loosely stacked or scattered

components and tools are accident sources.

If components must be replaced:

– Pay attention to correct installation of spare

parts.

– Properly reassemble all fastening elements.

– Observe screw tightening torques.

– Before restarting, ensure that all covers and

protective devices are correctly installed and

function correctly.

– After completion of maintenance work and

troubleshooting, check correct functioning of

safety equipment.

Page 15

Operating instructions VacuStar L400

Technical data

15

3 Technical data

General data

Unit

VacuStar L400

Rated speed / Speed range

[1/min]

1500 / 1000 to 1500

Suction temperature

[°C]

-20…+40

Geodetic height

[m]

0…1000

Content of oil container

[Litres]

4.6

Lubricating oil consumption

[ml/h]

85

Weight VacuStar L400 without accessories

[kg]

76

Tab. 1: General data

Operating data during compressor vacuum pump operation at

rated speed

Unit

VacuStar L400

Vacuum without cell venting / with cell venting 1)

[mbar]

200 / 100

Final overpressure at the pressure flange 2)

[bar]

0 to 0.5

Intake volume flow at 400 / 1000 mbar

[m3/h]

320 / 345

Power requirement at 400 mbar / 0.5 bar excess pressure

[kW]

7.4 / 10

Sound pressure level (at 7 m distance) at 200 mbar / 0.5 bar

excess pressure

[dB]

70 / 78

Weight VacuStar L400 with a four-way switching valve

[kg]

85

1) Final excess pressure at the pressure flange = 0 bar, suction and ambient temperature = 20 °C

2) Intake pressure at the suction flange = 1 bar, suction and ambient temperature = 20 °C

Tab. 2: Operating data VacuStar L400 during compressor vacuum pump operation at rated speed

Operating data during compressor operation at rated speed

Unit

VacuStar L400

Intake pressure

[mbar]

1000

Final overpressure at the pressure flange

1) 3)

[bar]

0 to 2.0

Intake pressure at 0 / 2.0 bar excess pressure 2)

[m3/h]

345 / 305

Power requirement at 0 / 2.0 bar excess pressure 2)

[kW]

8 / 19.0

Sound pressure level (at 7 m distance) at 2.0 bar excess pressure

2)

[dB]

77

Weight VacuStar L400 with mounting flange for suction and

pressure line

[kg]

79

1) Suction and ambient temperature = 20 °C

2) at rated speed

3) Protection via a safety valve

Tab. 3: Operating data VacuStar L400 during compressor operation at rated speed

Page 16

Operating instructions VacuStar L400

Technical data

16

Lubricating oil

The use of multigrade oils will damage the VacuStar L400. In that

case, the warranty on the part of CVS Engineering GmbH shall

cease.

Only single grade oils with the following specification are permitted

for operation:

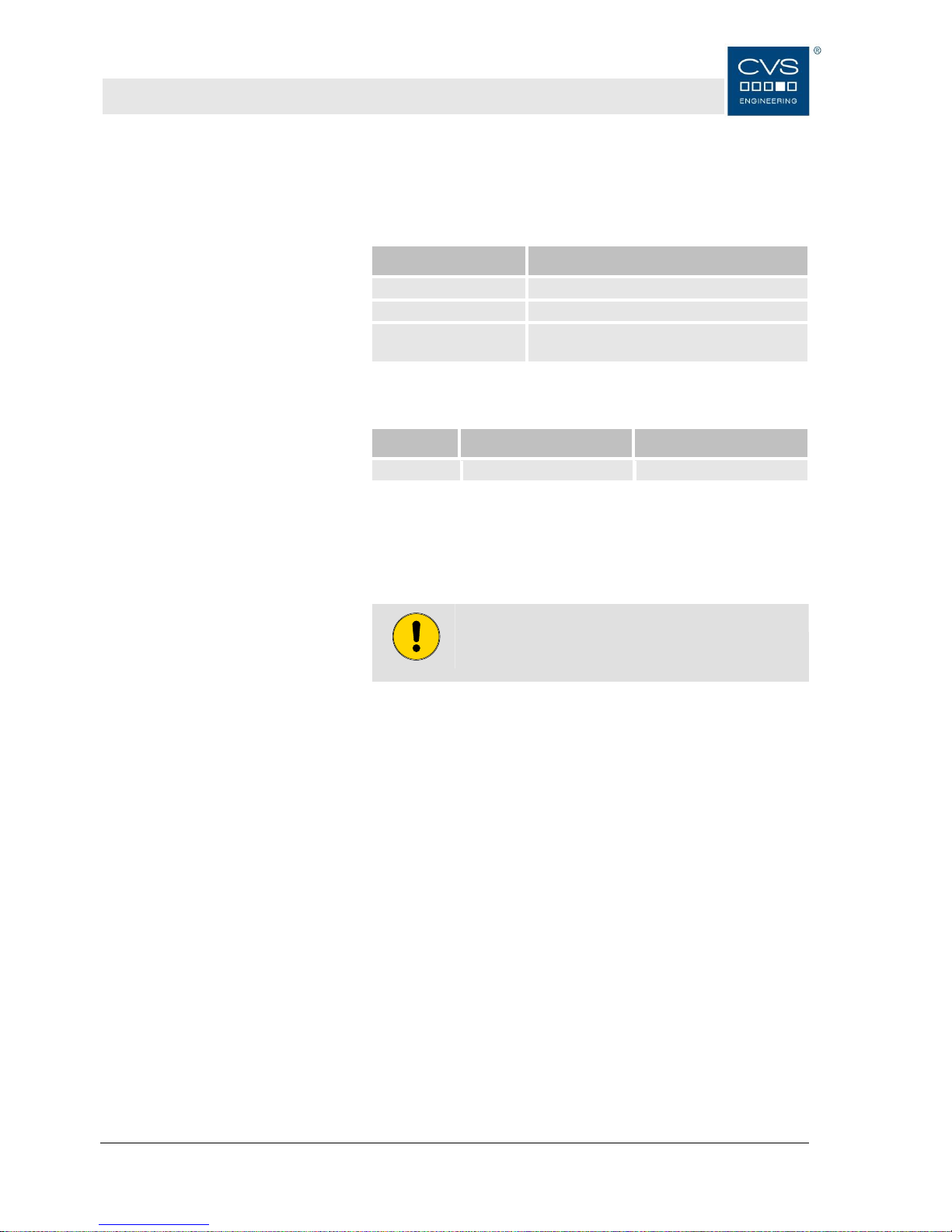

Specification

Value

API

CF/CF4 or higher

ACEA

E2 or higher

Viscosity:

Suction temperature > 10 °C: SAE 40

Suction temperature < 10 °C: SAE 30

Tab. 4: Lubricating oils

Lubricating oil types

Recommended oil types

Brand

Suction temp. > 10 °C

Suction temp. < 10 °C

CVS

CVS Lube 4000

CVS Lube 3000

Other oil types on request.

Tab. 5: Lubricating oil types

ATTENTION!

Do not use any synthetic lubricants!

Page 17

Operating instructions VacuStar L400

Design and function

17

4 Design and function

4.1 Design

Fig. 1: Design VacuStar L400 with and without a four-way switching valve

A: Compressor vacuum pump operation with four-way switching valve

The air feed direction (suction or pressure) is selected by the position of the switching lever.

B: Compressor or vacuum pump operation with mounting flange for suction and pressure line

1 Drive shaft

2 Cell ventilation connection

3 Thread for eye bolt

4 Temperature and pressure measuring point

5 Oil filling

6 Rating plate of VacuStar L400

7 Rotation arrow

8 Rating plate oil

9 Oil reservoir

10 Switching lever

11 Pressure connection

(for illustrated lever setting)

12 Four-way switching valve

13 Suction connection

(for illustrated lever setting)

14 Mounting flange for lines

15 Suction opening for cooling air

16 Connection for measuring control line

Page 18

Operating instructions VacuStar L400

Design and function

18

4.2 Function

Functional principle

Sliding vane compressor vacuum pumps work according to the

displacement principle.

Due to the rotor's eccentric arrangement inside the casing, limited,

crescent-shaped working chambers are created by means of the

rotor vanes, which are enlarged or reduced with every turn of the

rotor.

Cleaned air is drawn in via the suction connection (pos. 13) and

reaches the pressure line after being compressed via the pressure

connection (pos. 11).

Lubrication

The VacuStar L400 is lubricated by means of an oil pump. Oil is

pumped from the oil reservoir via the oil lines to the

VacuStar L400's lubricating points.

Cooling

The VacuStar L400 is air-cooled. Heat removal is performed by

casing ribs on the lid and casing surface with targeted cooling air

guidance, via a ventilation wheel on the drive shaft.

Drive

The VacuStar L400 can be powered via:

Articulated shaft

V-belt

Flexible coupling

Details about the drives and their design can be found in the

separate mounting instructions for the VacuStar L400.

4.3 Control and display elements

Depending on the installation situation, different display elements

such as pressure gauge, temperature gauge and negative

pressure display are mounted.

Page 19

Operating instructions VacuStar L400

Transport and storage

19

5 Transport and storage

5.1 Safety notes for transport

See chapter 2.6.

5.2 Transport

The VacuStar L400 fastened on a pallet must be transported by

means of a fork lift or suitable lifting gear. The lifting gear must be

designed for the weight of the VacuStar L400.

For future transports:

Seal all open connections with protective caps

(prevents penetration of dirt and water)

Secure against vibrations

Securely fasten the VacuStar L400 prior to transport (e.g. screw

it onto a pallet)

Transport and put down the VacuStar L400 with a fork lift or

secure with straps and lift with suitable lifting gear.

5.3 Storage

Storage of packages

Store packages under the following conditions:

Do not store outdoors.

Store dry and dust free.

Do not expose to aggressive media.

Protect against solar irradiation.

Avoid mechanical vibrations.

Storage temperature: -10 to +60 °C

Relative humidity: max. 95%, non-condensing

If storage lasts longer than 3 months, regularly check the

general condition of all parts and of the packaging.

To keep moisture away from the VacuStar L400's workspace,

bags with desiccant must be placed into the inlets and outlets.

These must be removed before start-up.

Page 20

Operating instructions VacuStar L400

Start-up and operation

20

6 Start-up and operation

6.1 Safety notes

See chapter 2.6.

6.2 Start-up

Inspection prior to initial start-up

Top up lubricating oil according to lubricating oil schedule. Oil

level in the oil supply tank at least to the middle of the oil sight

glass.

Start-up

Open present shut-off devices

Select with VacuStar L400 during compressor vacuum pump

operation at suction or pressure operation with four-way

switching valve.

Attention: Switching valve must only be operated in the two end

positions. Intermediate positions are not permitted.

Start the VacuStar L400 drive.

Adjust speed.

Check operating data

Inspections during operation

The following inspections have to be carried out during operation:

Prior to every start-up and during operation, the oil level must

be checked and topped up if necessary.

Open shut-off devices. Always turn the four-way cock until it hits

the stop, intermediate positions are not permitted.

Switch on drive and check whether pressure or vacuum are

created.

Pay attention to abnormal noises and leaks during operation. If

necessary, switch off VacuStar L400.

Drain condensate at the condensate and safety traps. Vessel

may not be in a state of vacuum when condensate is drained.

Checking the operating data:

The speed must range between 1000…1500 min-1.

Check positive working pressure at the pressure gauge

(permissible pressure refer to rating plate).

Check the operating vacuum at the vacuum meter (permissible

vacuum refer to rating plate).

The compression end temperature at 20 °C suction temperature

may not exceed the following values:

150 °C at 400 mbar operating vacuum

120 °C at 0.5 mbar excess pressure

Page 21

Operating instructions VacuStar L400

Start-up and operation

21

6.3 Switching off

Switch off the VacuStar L400 as follows:

Switch off drive for the VacuStar L400.

Close the shut-off valves (if installed)

Drain the safety tank. Tank may not be under pressure then.

6.4 Inspections to be performed

Lubricating oil inspection

Only lubricating oils pursuant to the lubricants specifications

lubricating oil schedule (Tab. 4, Other oil types on request.

Tab. 5

Check oil level at the inspection glass. Oil level in the oil supply

tank at least to the middle of the oil sight glass. The oil level may

not drop below the bottom mark on the oil inspection glass.

Non-return valve inspection

The non-return valve is maintenance-free, but is subject to wear

like all other moving parts. We recommend a visual inspection

every 3 months. In this connection, the non-return valve must be

dismantled, cleaned, freed of deposits and checked for freedom of

motion.

Safety valve inspection

The safety valve is no regulating device!

The operational capability must be checked on start-up and

later at weekly intervals.

The safety valve must be secured against misadjustment. Blocking

or manipulating the safety valve can have penal consequences if it

gives rise to an accident. Any warranty claims shall also be

forfeited in such a case.

The nominal opening pressure may not exceed the maximum

permissible final overpressure (refer to rating plate) or the

permissible system pressure, provided the latter is lower.

Functional testing is carried out by actuating the manual ventilation

with the VacuStar L400 running.

Inspection of the ventilating valve

As a matter of principle, a ventilating valve must be installed as

safety element on the VacuStar L400's suction side. When the set

vacuum is reached, the ventilating valve opens and admits

atmospheric auxiliary air into the system. The operational capability

must be checked weekly with the aid of a vacuum meter at the

VacuStar L400's inlet. In case of systems without cell ventilation,

the vacuum may not drop below the permissible value of 200 mbar.

In case of systems with cell ventilation, the vacuum may not drop

below the permissible value of

100 mbar.

Page 22

Operating instructions VacuStar L400

Start-up and operation

22

Inspection of cell ventilation

The VacuStar L400 has been prepared for operation with cell

ventilation. The connection is located opposite of the pressure and

suction connection. If your system's cell ventilation is connected,

you may operate the VacuStar L400 up to a vacuum of 100 mbar.

A suction filter is located in the cell ventilation line. The filter must

be cleaned weekly and replaced in case of visible damage.

Height wear rotor vanes

Based on a daily runtime of 3 to 4 hours, the initial inspection

should be performed after approx. 6 months. For further

inspections, see page 24, Tab. 6 "Maintenance schedule".

Measuring height wear

1. Disassemble four-way switching valve or mounting flange.

2. Check vane recess with sliding calliper. The rotor vanes must

be replaced if the sliders show a recess of more than 5 mm as

compared to the rotor jacket.

Fig. 2: Measuring the height wear rotor vanes

Page 23

Operating instructions VacuStar L400

Maintenance

23

7 Maintenance

7.1 Safety during maintenance work

See chapter 2.6 "Occupational safety and special risks".

Personal protective equipment

The following must be worn during all maintenance work:

Safety working clothing

Protective gloves

Safety shoes

Safety goggles

Environmental protection

Observe the following information with regard to environmental

protection during maintenance:

Remove emerging, used or excessive grease at all lubricating

points that are manually supplied with lubricant and dispose of

in accordance with valid local regulations.

Collect exchanged oil in suitable containers and dispose of in

accordance with valid local regulations.

7.2 Maintenance schedule

The following describes the maintenance work that is necessary for

an optimum, trouble-free operation. Maintenance intervals must be

observed.

If increased wear of individual components or functional groups is

determined during regular inspections, the operator has to reduce

the required maintenance intervals on the basis of the actual signs

of wear.

Changes compared to normal operation (increased power

consumption, temperatures, vibrations, noises, etc. or response of

monitoring systems) lead to the assumption that the functions are

impaired. These then have to be subjected to an inspection by

specialised staff.

In case of queries regarding the maintenance work and intervals:

contact the manufacturer (service address page 2).

For maintenance schedule refer to next page.

Page 24

Operating instructions VacuStar L400

Maintenance

24

Maintenance schedule

Interval

Maintenance work

To be carried out by

Every 15 minutes

Check operating speed

Operator

Check operating pressure / vacuum

Check air outlet temperature

Daily

Check condensate

Operator

Check safety trap

Check silencer

Check oil level and top up with fresh oil if necessary

Weekly

Check safety valve

Operator

Check ventilating valve

Clean VacuStar L400

Clean vacuum filter

Check V-belt, V-belt tension and re-tension if necessary

Clean cell ventilation filter, replace if damaged

Monthly

Clean oil tank

Operator

Check fastening screws and tighten if necessary

Check shaft sealing rings for tightness

(no oil may leak from them)

quarterly

Check rotor vane wear

(replace vane at more than 5 mm)

Specialised staff

Check cell ventilation valve

Specialised staff

Half-yearly

Check non-return valve of VacuStar L400

Specialised staff

5,000 oh / 3 years

Replace shaft sealing rings

Specialised staff

10,000 oh / 5 years

Replace bearings

Specialised staff

Tab. 6: Maintenance schedule

Page 25

Operating instructions VacuStar L400

Maintenance

25

7.3 Performance of maintenance work

Cleaning the VacuStar L400

Carrying out cleaning work:

1. Switch off system and secure against restarting.

2. Remove soiling appropriately. Observe the following:

Do not use aggressive cleaning agents.

Pay attention during cleaning that no water gets into the

compression chamber.

Exercise special caution when cleaning with high-pressure

cleaning systems.

Absorb oil deposits with oil-absorbing materials (e.g. sawdust).

After cleaning work, check that all previously opened covers

and safety equipment are correctly installed and function

correctly.

After wet cleaning, warm up the VacuStar W for a few minutes.

Cooling of the VacuStar L400

To warrant best cooling, the protective grid apertures must be free

of deposits.

Suction air filter

The contamination state is usually indicated by a maintenance

display. If maintenance is required, open filter casing and replace

filter cartridge.

Action after lengthy standstill

If the standstill of the VacuStar L400 installed inside the vehicle

lasts for more than a month, we recommend putting the

VacuStar L400 into operation once a month for 15 minutes.

Page 26

Operating instructions VacuStar L400

Maintenance

26

Action after sucking over of foreign

matter

If foreign matter has been sucked over into the VacuStar L400,

proceed as follows:

Allow VacuStar L400 to cool down.

Unscrew the locking screw in the inlet (fig. 1, pos. 16)

Open vehicle box to allow the VacuStar L400 to be run without

vacuum or pressure build-up.

Switch on VacuStar L400 and allow approx. 0.5…1 l of a diesel-

oil-mixture (1:1 mixing ratio) to be sucked into the

VacuStar L400 through the hole in the inlet at approx. 1000 min

-

1

.

Afterwards, allow another 0.2 - 0.5 l clean oil to be sucked in via

the inlet.

Completely remove this diesel-oil-mixture from the VacuStar

L400 and do not allow to collect in the downstream silencer fire hazard!

Switch off VacuStar L400 and re-attach locking screw. Perform

a lubricating oil inspection pursuant to chapter 6.4 before the

VacuStar L400 is restarted.

Page 27

Operating instructions VacuStar L400

Malfunctions

27

8 Malfunctions

This chapter describes possible causes of malfunctions and

troubleshooting tasks.

Reduce the maintenance intervals if similar malfunctions occur

repeatedly due to above-average intensive use so intervals

correspond to the actual load.

Contact the manufacturer in case of malfunctions that cannot be

repaired with the aid of the following information ( p. 2)!

8.1 Safety

See chapter 2.6 "Occupational safety and special risks".

Personnel

The trouble shooting work described at this point can be carried

out by the operator, unless otherwise indicated.

Some work may only be carried out by specially trained

specialised staff or exclusively by the manufacturer himself.

This is specifically pointed out in the description of the individual

malfunctions.

Only electrical specialists may carry out work on the electrical

system.

Components and parts may only be replaced by specialised

staff.

Personal protective equipment

See chapter 2.5.

Environmental protection

See chapter 7.1.

Conduct in the case of

malfunctions

The following basically applies:

1. Immediately trigger an EMERGENCY-STOP in case of

malfunctions constituting an immediate danger for individuals

or material assets.

2. Switch of all power supplies and secure against restarting.

3. Inform person in charge at the place of installation.

4. Depending on the type of malfunction, have the cause

determined and eliminated by responsible and authorised

specialised personnel.

8.2 Recommissioning after corrective action

After corrective action or trouble shooting:

1. Reset emergency stops.

2. Acknowledge error message or malfunction at the control

system.

3. Ensure that nobody is staying in the hazard area.

4. Start in accordance with the instructions in chapter „start-up“.

Page 28

Operating instructions VacuStar L400

Malfunctions

28

8.3 Malfunction table

Malfunction:

Possible cause

Corrective action

Execution

VacuStar L400's

delivery rate

decreases

Vacuum filter soiled

Clean vacuum filter

Operator

Leaky suction line / fittings

Look for leaky spots and

eliminate leak

Specialised staff

Speed too low

Adjust speed

Operator

Wear of rotor vanes,

possibly caused by dirt or liquids

that have gotten into the

VacuStar L400 (sucking over of

foreign matter)

Replace rotor vane, remove

dirt and have VacuStar L400

overhauled at an authorised

workshop

Specialised staff

Abnormal noise

emission

VacuStar L400 is badly aligned.

Align the VacuStar L400

precisely.

Specialised staff

Bearing defective

Replace bearing (or have it

replaced)

Lack of lubricating oil

Top up oil, clean oil reservoir

and suction filter

Operator

Unsuitable lubricating oil

Fill in oil according to

lubrication schedule

Operator

Rotor vanes are jammed

Check rotor vanes

Specialised staff

Casing bore shows grooves or

corrugations due to the

aspiration of dirt

Have casing bore re-turned

and honed at an authorised

workshop. In case of heavily

soiled intake air, install fine

filter

Specialised staff

Wrong speed

Maintain speed range

Operator

Changed pressure

Maintain nominal pressure

Operator

Changed vacuum

Maintain nominal vacuum,

check exhaust system and

clean if necessary

Operator

Non-return valve rattles

Check non-return valve

Specialised staff

Foreign bodies in the

VacuStar L400

Remove foreign matter. Flush

out the VacuStar L400.

Specialised staff

Slide breakage

Switch off the VacuStar L400

at once and repair it.

Specialised staff

Compressed air

temperature too

high

End pressure too high

Maintain nominal pressure

Operator

Exhaust silencer clogged

Replace exhaust silencer

Specialised staff

Four way cock in wrong position

Correctly adjust four way cock

Operator

Non-return valve is stuck

Check non-return valve and

clean if necessary

Specialised staff

Vacuum filter clogged

Clean vacuum filter

Operator

Vacuum too high

Maintain nominal vacuum

Operator

Page 29

Operating instructions VacuStar L400

Malfunctions

29

Malfunction:

Possible cause

Corrective action

Execution

Operating

pressure or

operating vacuum

is not obtained

Pressure gauge or vacuum

meter do not indicate correctly

Replace pressure gauge or

vacuum meter

Specialised staff

V-belts are slipping

Check V-belt tension and retension if necessary

Operator

Four way cock in wrong position

Correctly adjust four way cock

Operator

Condensate drain cock open

Close condensate drain cock

Operator

Silt or liquid has

gotten into the

VacuStar L400

Foreign matter has been sucked

over into the VacuStar L400

Rinse thoroughly with dieseloil-mixture at lowest

permissible speed and without

pressure or vacuum,

afterwards add lubricating oil

according to chapter

Lubricating oil inspection

page 21.

Operator

Power requirement

too high

Speed too high

Maintain speed limit

Operator

End pressure too high

Maintain nominal pressure,

actuate / check safety valve

Operator

Pressure gauge indicates

incorrectly

Replace pressure gauge

Operator

Exhaust silencer clogged

Replace exhaust silencer

Specialised staff

Lack of lubricating

oil despite full oil

tank

Oil intake strainer in oil tank

clogged

Clean oil tank and intake

strainer, check oil lines

Operator

Safety valve blows

off

Closed valves in the pressure

line

Open valves

Operator

Clogging in pressure system

Eliminate clogging

Operator

Exhaust silencer clogged

Replace exhaust silencer

Specialised staff

Ventilating valve

responds

Closed valves in the suction line

Open valves

Operator

Suction filter clogged

Clean suction filter, if

necessary replace filter

cartridge

Operator

Compressed air

blows off at shaft

end and oil is

leaking

Seal damaged

Replace radial shaft sealing

rings in sealing cover

Specialised staff

Rubber smell (at

V-belt drive)

V-belts slip due too insufficient

belt tension

Check belt tension, re-tension

if necessary

Operator

End pressure too high

Maintain nominal pressure

Operator

Reversing of Vbelts

Insufficient belt tension

Check belt tension, re-tension

if necessary

Operator

Worn V-belts

Put on new V-belts

Operator

Pulleys are not aligned

Align pulleys

Specialised staff

Worn V-belt pulleys

Replace pulleys

Specialised staff

Tab. 7: Malfunction table

Page 30

Operating instructions VacuStar L400

Spare parts

30

9 Spare parts

We recommend stocking a service package as well as a suction

filter cartridge.

The service package comprises all wear parts that are required for

a normal repair.

Customer Service

In case of queries regarding the product, spare part orders, repairs,

replacement machines and dispatch of fitters, please contact our

customer service: Phone: +49 (0)7623 71741-0

Spare and wear parts

Service package

990 008-SP

Filter cartridge to cell venting

432 151-00

Filter cartridge to suction air filter

432 161-00

10 Decommissioning and disposal

A VacuStar L400 that is no longer usable should not be recycled

as complete unit, but disassembled into individual components and

recycled according to material types. Non-recyclable materials

have to be disposed of in an environmentally compatible manner.

Prior to decommissioning and disposal of the VacuStar L400, it

must be completely separated from the surrounding units.

The disassembly and disposal of the VacuStar L400 may only

be carried out by specialised staff.

If hazardous or poisonous material were conveyed, the

VacuStar L400 must be decontaminated prior to disposal.

The VacuStar L400 has to be disposed of in accordance with

the respective country-specific regulations.

Page 31

Operating instructions VacuStar L400

Index

31

Index

A

Acceptance ........................................................... 8

Action sucking over ............................................ 26

C

Cleaning

VacuStar L400 ................................................ 25

Components, moving .......................................... 12

Compressed air .................................................. 12

Contact person ..................................................... 7

Cooling.......................................................... 18, 25

Copyright protection ............................................. 6

Customer Service ................................................. 7

D

Danger of burns .................................................. 10

Danger pictogram ............................................... 10

Danger pictograms ............................................. 10

Dangers .............................................................. 10

Design ................................................................. 17

Display elements ................................................ 18

Disposal .............................................................. 30

Drive ................................................................... 18

E

Environmental protection .............................. 23, 27

F

Function .............................................................. 18

I

Improper operation ............................................. 11

Inspection

30/38 rotor vane .............................................. 22

during operation .............................................. 20

Lubricating oil .................................................. 21

Non-return valve ............................................. 21

prior to initial start-up ...................................... 20

Safety valve .................................................... 21

Ventilating valve ........................................ 21, 22

Instructions ........................................................... 9

Intended use ......................................................... 8

L

Lengthy standstill ................................................25

Liability .................................................................. 6

Lubricating oil ......................................................16

Lubricating oil types ............................................16

Lubrication ..........................................................18

M

Maintenance .......................................................23

Maintenance .......................................................14

Maintenance schedule ........................................23

Maintenance work ...............................................25

Malfunction table .................................................28

Malfunctions ........................................................27

O

Occupational safety ............................................10

Operating elements ............................................18

Operating instructions ........................................... 4

Operating personnel ............................................. 9

Operation ..................................................... 13, 20

Operator ................................................................ 8

P

Personnel

Trouble shooting .............................................27

Protective equipment ............................... 9, 23, 27

R

Recommissioning ...............................................27

S

Safety ..............................................................8, 27

Safety notes ........................................... 19, 20, 23

Signposting .........................................................12

Spare parts .....................................................7, 30

Specialists ............................................................. 9

Start-up ........................................................ 13, 20

Storage ...............................................................19

Suction air filter ...................................................25

Switching off........................................................21

Symbols in the instructions ................................... 5

Page 32

Operating instructions VacuStar L400

Decommissioning and disposal

32

T

Technical data.................................................... 15

Transport ...................................................... 13, 19

Trouble shooting ................................................ 14

W

Warranty ........................................................... 6, 7

Page 33

Loading...

Loading...