Page 1

CVS 7970

High-Low Pressure

Each CVS 7970 is a self-contained unit containing

Instruction Manual

Head Office

Website: www.cvs-controls.com E-Mail: info@cvs-controls.com

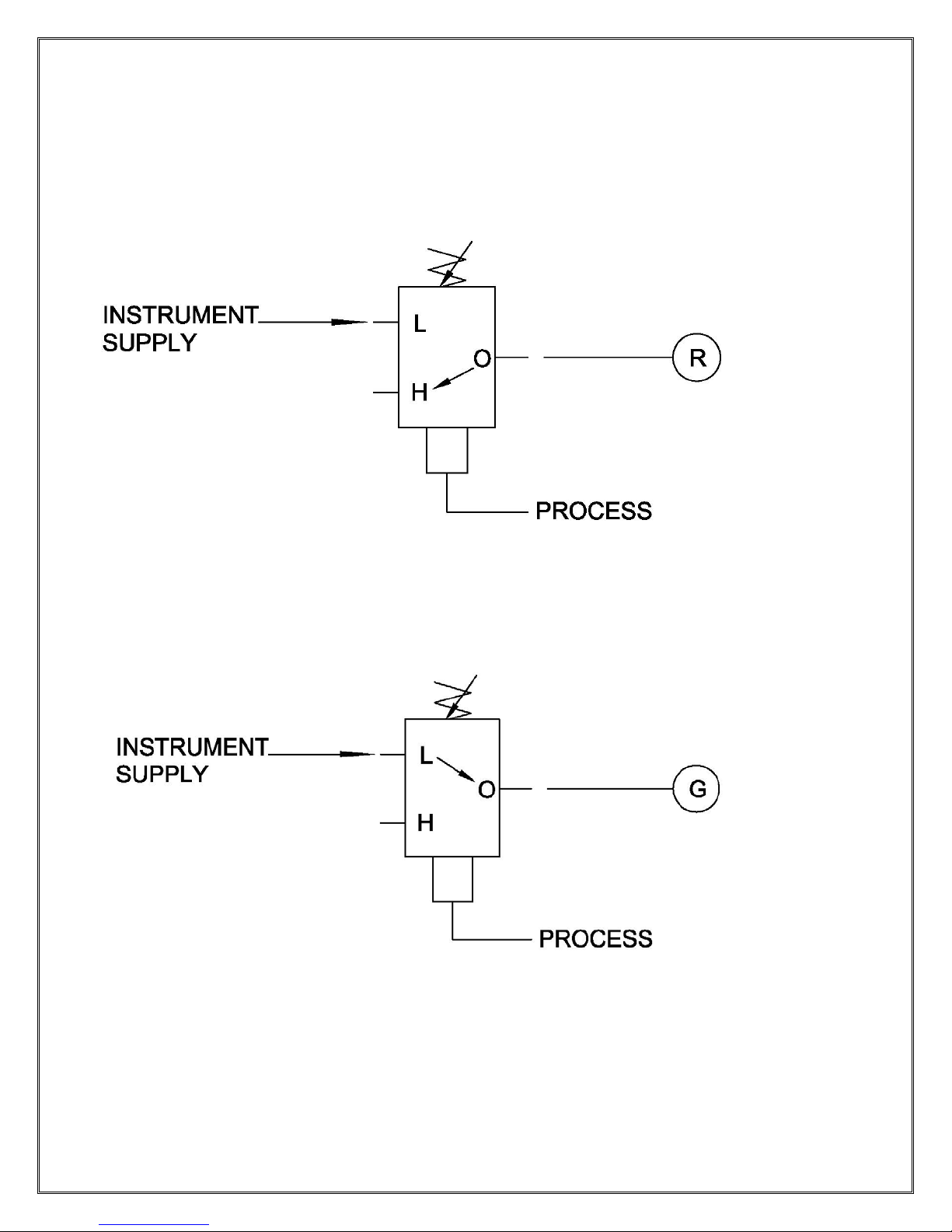

Figure 1: CVS 7970 High-Low Pressure Pilot

Pilot

Introduction

This instruction manual includes the following

information for CVS 7970 High-Low Pressure Pilot:

1. D

escription

2. Piston Arrangement Changeover Instructions

3. Parts Information

O

nly persons qualified through training or experience

should install, operate and service this equipment. If

you have any questions regarding this product or this

manual, please contact your CVS Controls Sales

Representative before proceeding.

Description

The CVS 7970 is a versatile sensor that can be

programmed to detect and react to either increasing

pressure or decreasing pressure with an adjustab le

range of 2 to 10,000 PSI (.138 to 689.5 bar).

hen used within standard safety systems, a

W

pressure sensor monitors a specific media or

process pressure source for changes to the normal

operating range. Loss of pressure within the control

circuit will begin a shutdown sequence or trigger an

alarm, and pressure sensors can also indirectly

operate on/off flow control valves or pneumatic

driven pumps.

T

he CVS 7970 is a two position, three-way pilot with

universal ports (H, O, L), automatic reset (spring

return) and pressure balance spool.

3900 – 101 Street

Edmonton, Alberta, Canada T6E 0A5

Office: (780) 437-3055

Fax: (780) 436-5461

necessary components for four different piston

arrangements. Changeover instructions and

drawings are included in this manual. Parts which

are not installed in your current piston arrangement

are kept in an enclosed storage tube. Machined

within the piston housing of the CVS 7970 is a

convenient 1/8”–27 NPT Female process connection

and 1/2” NPT Male process connection.

Calgary Sales Office

Calgary, Alberta, Canada T2Z 3V6

3516 114 Avenue SE

Office: (403) 250-1416

Fax: (403) 291-9487

Page 2

2

Table 1: CVS 7970 Specifications

Characteristic

Dimensions

Dimensions

1.750” diameter x 8.0” length

Working

Pressure

Process Pressure Inlet

10,000 PSI Maximum (689.5 bar)

Control Ports

125 PSI Maximum (8.62 bar)

Process Pressure Inlet

1/2”-14 NPT M and 1/8”-27 NPT F

Control Ports

1/4”-18 NPT F

Weight

3.5 lbs / 1.6 kg

Panel Hole Cutout Size

1 5/8” (39.81 mm)

M=Male, F=Female

Introduction continued

4. Loosen the lock nut and remove from the

Connections

One particular advantage of the CVS 7970 is its

adjustment range capability. Because of the

complete supplied components, there is no need to

purchase and store additional sets of matching

piston and spring components. The installation or

reorientation of the existing piston components

allows for an adjustment range capability of 2 to

10,000 PSI. This is especially convenient for remote

facilities which require changes to pressure settings

to match changes in process conditions.

The CVS 7970 is available in a High-Low

configuration using two pilots mounted and tubed to

a carbon steel or stainless steel manifold (Figure 8).

Your choice of 2-1/2” NPT process or gauge

connections are available. This design allows for

completely independent setting of the high and low

pilots spanning the range of 2 psi to 10,000 psi. This

configuration is available in Auto Reset (not shown)

or Manual Reset (shown, pg 8).

Piston Arrangement

Changeover Instructions

The information in this manual, including the parts

listings and piston detail drawings, will assist you in

completing the Piston Arrangement Changeover.

Caution: Consult and follow the established

safety procedures of your facility prior to

beginning disassembly of any CVS Control s

product. Ensure that all pressure is

exhausted from the system prior to

performing any service work. Failure to

remove the pressure from the system can

result in serious personal injury .

1. Isolate and depressurize the control system.

2. Disconnect the control circuit instrumentation

tubing from control valve, as well as the

monitored process connection from the

piston housing.

3. Where possible, remove the CVS 7970 from

the service location to perform the

changeover in a clean work environment.

adjusting cap. (See figure 2)

5. Gently relieve all spring tension by fully

unscrewing the adjusting cap. This allows

access to the storage tube.

6. Unscrew the piston housing from the valve

body.

7. Turn the piston housing upside down and tap

it gently on a flat, clean surface to remove

the piston arrangement. The pistons should

slide out easily.

8. Thoroughly clean the piston components,

including the piston housing and internal

bores, using warm water and a liquid

detergent. Do not use abrasive tools or

acidic cleansers. Dry all components with a

cloth or paper towel.

9. Lightly lubricate all components and seals,

and assemble the piston arrangement as

desired according to the enclosed detail

drawing.

10. When inserting the new piston arrangement

into the piston housing, apply even pressure.

Press evenly using both thumbs on the

piston’s outer edges for the insertion of the

1-1/8”, 1/2” and 3/16” piston arrangements.

11. For the 1/4” piston insertion, install the 1/4”

piston first, using a needle-nosed pliers.

Then press the other piston components into

place.

12. Lightly lubricate the threads of the piston

housing, body and spring housing. Be sure

to use a grease or medium appropriate for

stainless steel.

13. Reassemble the pressure pilot.

14. Adjust the pressure setting to the required

amount, and function test the pressure pilot.

When the desired setting is achieved, tighten

the lock nut securely against the adjusting

cap.

15. Connect the instrumentation tubing and the

pressure connection to the monitored

process.

16. Introduce pressure to the pressure pilot’s

control circuit and monitored process inlet.

Resume normal operation.

Page 3

3

CVS 7970 High-Lo w Pres sur e Pilot

Key

Part Number

Qty.

Description

Material

1

CVS79710A

1

Adjusting Cap

Black Delrin

2

CVS79702A

1

5/16” Ball Bearing

Stainless Steel

3

CVS7911A

1

Spring Guide

Black Delrin

4

CVS7970A

1

Spring

302 Stainless Steel

5

CVS79712A

2

Lock Nut

Black Delrin

6

CVS79709A

1

Spring Housing

316 Stainless Steel

7

CVS79708

1

Stop Plate

316 Stainless Steel

8

CVS79704A

1

Body Housing

316 Stainless Steel

9

CVS79707A

1

Upper Stem

316 Stainless Steel

10

CVS79706A

1

Lower Stem

316 Stainless Steel

11

CVS79703A

1

Small Piston

316 Stainless Steel

12

CVS79705

1

Stop Washer

316 Stainless Steel

13

CS79702

1

Large Piston

316 Stainless Steel

14

CVS797014

1

Snap Ring

304 Stainless Steel

15

CVS79701A

1

Piston Housing

316 Stainless Steel

16

V-75-010

2

Seal

Viton Coated TFE

17

V-75-008

2

Seal

Viton Coated TFE

18

V-75-119

1

Seal

Viton Coated TFE

19

TFE-008

1

Back-Up Ring

Teflon

20

V-75-008

1

Seal

Viton Coated TFE

21

CVS79713A

1

1/4” Piston

316 Stainless Steel

22

V-75-006

1

Seal

Viton Coated TFE

23

TFE-006

1

Back-Up Ring

Teflon

24

TFE-012

1

Back-Up Ring

Teflon

25

V-75-012

1

Seal

Viton Coated TFE

CS7970-BK

1

Piston O-Ring Kit (Body Housing)

V-75-008 1 Seal

Viton Coated TFE

V-75-010 1 Seal

Viton Coated TFE

CVS7970-PK

1

Piston O-Ring Kit (Body Housing)

V-75-006 1 Seal

Viton Coated TFE

V-75-008 1 Seal

Viton Coated TFE

V-75-012 1 Seal

Viton Coated TFE

V-75-119 1 Seal

Viton Coated TFE

TFE-006 1 Back-Up-Ring

Teflon

TFE-008 1 Back-Up Ring

Teflon

TFE-012 1 Back-Up Ring

Teflon

Figure 2: Adjusting Cap / Storage Tube

Access

Table 2: Parts List

Seal Kits

Page 4

4

Figure 3: CVS 7970 High-Low Pressure Pilot Assembly

Page 5

5

Figure 4: 3/16 Piston Arrangement Enlarged Detail Drawing

For pressures from 5900 to 10,000 PSI (407 to 690 bar)

Key

Part Number

Qty.

Description

Material

11

CVS79703A

1

Small Piston

316 Stainless Steel

13

CS79702

1

Large Piston

316 Stainless Steel

14

CVS797014

1

Snap Ring

304 Stainless Steel

18

V-75-119

1

Seal

Viton Coated TFE

19

TFE-008

1

Back-Up Ring

Teflon

20

V-75-008

1

Seal

Viton Coated TFE

Figure 5: 1/4” Piston Arrangement Enlarged Detail Drawing

Key

Part Number

Qty.

Description

Material

11

CVS79703A

1

Small Piston

316 Stainless Steel

13

CS79702

1

Large Piston

316 Stainless Steel

14

CVS797014

1

Snap Ring

304 Stainless Steel

19

TFE-008

1

Back-Up Ring

Teflon

20

V-75-008

1

Seal

Viton Coated TFE

21

CVS79713A

1

1/4” Piston

316 Stainless Steel

22

V-75-006

1

Seal

Viton Coated TFE

23

TFE-006

1

Back-Up Ring

Teflon

For pressures from 1440 to 5900 PSI (99 to 407 bar)

Page 6

6

Figure 7: 1-1/8” Piston Arrangement Enlarged Detail Drawing

Key

Part Number

Qty.

Description

Material

11

CVS79703A

1

Small Piston

316 Stainless Steel

12

CVS79705

1

Stop Washer

316 Stainless Steel

13

CS79702

1

Large Piston

316 Stainless Steel

14

CVS797014

1

Snap Ring

304 Stainless Steel

18

V-75-119

1

Seal

Viton Coated TFE

19

TFE-008

1

Back-Up Ring

Teflon

20

V-75-008

1

Seal

Viton Coated TFE

Figure 6: 1/2” Piston Arrangement Enlarged Detail Drawing

For pressures from 290 to 1440 PSI (20 to 99 bar)

Key

Part Number

Qty.

Description

Material

11

CVS79703A

1

Small Piston

316 Stainless Steel

13

CS79702

1

Large Piston

316 Stainless Steel

18

V-75-119

1

Seal

Viton Coated TFE

24

TFE-012

1

Back-Up Ring

Teflon

25

V-75-012

1

Seal

Viton Coated TFE

For pressures from 10 to 290 PSI (.689 to 20 bar)

Page 7

7

Item Number Part Number

Description Qty.

1 CV S 7910A Adjusting Cap, Black Delrin 1

2 CV S 7920A 6/16" Ball Be ari ng, SST 1

3 CV S 7911A Spring Guide, Black Delrin 1

4 CV S 7970A Spri ng, 302 Stainless Steel 1

5 CV S 79712A Lock Nut, Black Delrin 2

6 CV S 79709A Spring Housing, 316 SST 1

7 CV S 79708A Stop Plate, 316 SST 1

8 CV S 79704A Body Housi ng, 316 SST 1

9 CV S 79707A Upper Stem, 316 SST 1

10 CV S 79706A Lowe r Stem, 316 SST 1

11 CV S 79730 Adapter, Low Pressure , 316 SST 1

12 CV S 79701LP Pi ston Housi ng, 316 SST 1

13 V-75-145 o-ring, Viton Coated TFE 2

14 CV S 79702LP Piston, LP, 316 SST 1

15 CV S 79731 Wiper Ring, Viton 1

16 V-75-010 Seal, Viton Coated TFE 2

17 V-75-008 Seal, Viton Coated TFE 2

Figure 8 – CVS Series 7970 Low Pressure Pilot – Adjustment 2 to 15 PSI, Assembly

CVS Series 7970 Low Pressure Pilot – Adjustment 2 to 15 PSI, Parts List

Page 8

8

Figure 9: CVS Series 7970 High-Low Pressure Pilot Switch

Low Pilot

High Pilot

Low Pilot

High Pilot

Hi-Low Pressure Pilot - Manual Reset

Low Pressure Valve:

*Out Port To Valve

*Hi Port To Vent

High Pressure Valve:

*High Port To (air/gas) Supply (Max Supply Pressure 125 psi)

*Low Port To vent

Manifold:

*Either port for process

Page 9

9

Instructional Schematic: Pressure Sensing Low – Decreasing (PSL)

Reducing Pressure

Inlet Pressure Absent

Unactuated - Monitored process control pressure has

Inlet Pressure Applied

Gaining Pressure

Actuated - Monitored process control pressure has

operation.

Normally Closed – Loss of Instrument (output) pressure, when sensed inlet pressure decreases below

the low pressure setting.

DECREASED below the Low Pressure Setting, or is absent.

INCREASED above the Low Pressure Setting. Normal

Page 10

10

Instructional Schematic: Pressure Sensing High – Increasing (PSH)

Gaining Pressure

Inlet Pressure Applied

Unactuated - Monitored process control pressure is applied,

but is BELOW the high pressure setting. Normal operation.

Reducing Pressure

Inlet Pressure Applied

Actuated – Monitored process control pressure has

Normally Open – Loss in Instrument (output) pressure, when sensed inlet pressure increases above the

high pressure setting.

INCREASED ABOVE the high pressure setting.

Page 11

11

Notes:

Page 12

12

Rev 5 Feb 2016

Head Office

3900 – 101 Street

Webs ite: www.cvs-controls.com E-Mail: info@cvs-controls.com

CVS Controls Ltd. strives for the highest levels of quality and accuracy. The information included in this publication is presented f or

Edmonton, Alberta, Canada T6E 0A5

Office: (780) 437-3055

Fax: (780) 436-5461

Calgary Sales Office

3516 114 Avenue SE

Calgary, Alberta, Canada T2Z 3V6

Office: (403) 250-1416

Fax: (403) 291-9487

informational purposes only. CVS Controls Ltd. reserves the right to modify or change, and improve design, process, and

specifications without written notice. Under no circumstance is the information contained to be interpreted to be a

guarantee/warranty with regard to our products or services, applicability or use.

Selection, use and maintenance are the sole responsibility of the end user and purchaser. CVS Controls assumes no liability for the

selection use and maintenance of any product.

Printed in Canada

Loading...

Loading...