Page 1

CVS Controls Series 470

INSTRUCTION MANUAL

Head Office

Website: www.cvs-controls.com Email: info@cvs-controls.com

Piston Actuators

The CVS Series 470 is a double acting

pneumatic Piston Actuator, suitable

for use with Globe, Angle, Three Way,

and Reverse acting valves as well as

Steam Equipment. Capable of high

thrust applications to 19,500 lb-f,

with a maximum travel to 8 1/8

inches.

The CVS Series 470 Actuator may be

used in on/off applications, as well as

throttling service when used with a

positioner.

3900 101 Street

Edmonton, Alberta

T6E 0A5

Canad

a

ffice: (780) 437-3055

O

Fax: (780) 436-5461

Calgary Sales Office

3516 114 Avenue SE

Calgary, Alberta

T2Z 3V6

Canada

Office: (403) 250-1416

Fax: (403) 291-9487

Page 2

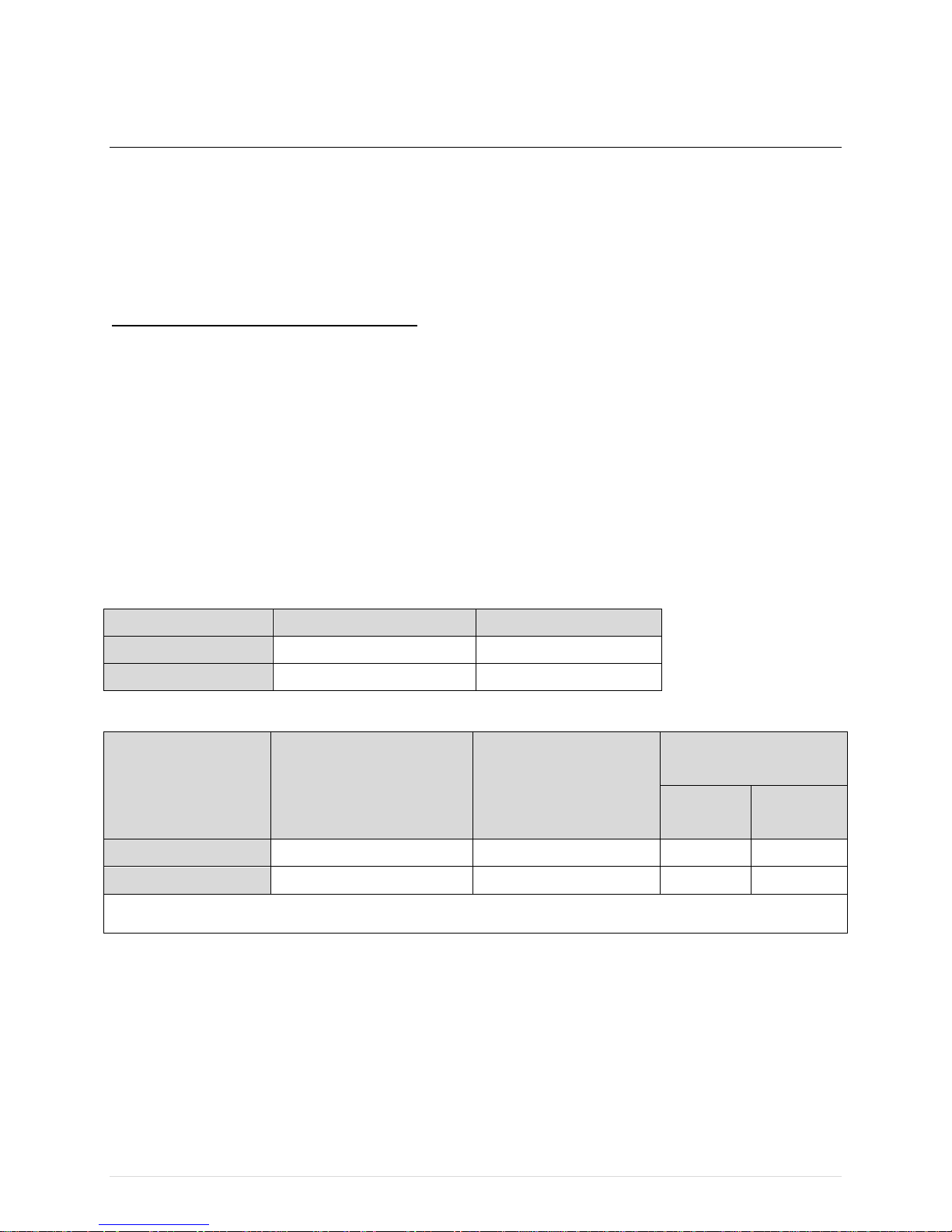

CVS Series 470 Piston Actuator – Specifications:

Model

Maximum Travel (in)

Piston Area (in2)

CVS 471-16-80

8 1/8

88.5

CVS 471-16-100

8 1/8

130.5

Stem Diameter (in)

Max allowable

Thrust*

Cast

Yoke**

Steel

Yoke

CVS 471-16-80

5

1 1/4

13200

13200

CVS 471-16-100

5

1 1/4

17000

19500

*reduce max thrust by 10% if using a positioner

** Cast Iron Yoke Standard

Standard Input: 3-15psig, 6-30psig or split range

Maximum Cylinder Pressure: 125psig, (*not to exceed max allowable thrust)

Temperature Rating: -30

o

F to 175oF, standard with Nitrile O-Rings

Material Specifications (Standard):

Yoke: Cast Iron (standard) or WCB Steel (optional)

Cylinder and Piston: Aluminum

Seal Bushings: Brass

O-Rings: Nitrile

Other materials may be available upon request, please contact a CVS Controls

representative for more information.

Maximum Travel and Piston Area:

Specifications and Maximum Allowable Thrust:

Model

The CVS 471 Piston Actuator operates by pneumatic air loading pressure to one side of the

piston, and unloading the opposing side. Because no positioner is included, a loading device

such as a 4 way switch valve must be installed if no additional positioner has been ordered for

use in conjunction with the CVS 471 Actuator.

Yoke Boss Diameter

(in)

2 | Page

Page 3

CVS Series 470 Piston Actuator – Installation

CVS 471 Piston Actuator

Note: Ensure proper safety procedures are followed to avoid personal injury or property

damage.

CVS 471 Piston Actuator Installation

The CVS 471 Actuator should be installed in a location which will allow adequate room for

service, maintenance and removal if required.

1. Mounting of the CVS 471 Actuator is achieved by using the 8 supplied nuts and bolts,

rather than a yoke locknut. Although the actuator may be mounted in any position,

typical installation is with the CVS 471 in the vertical position above the control valve.

2. Stem connections should be made to clamp the actuator stem and valve plug stem

together to ensure proper travel of the valve.

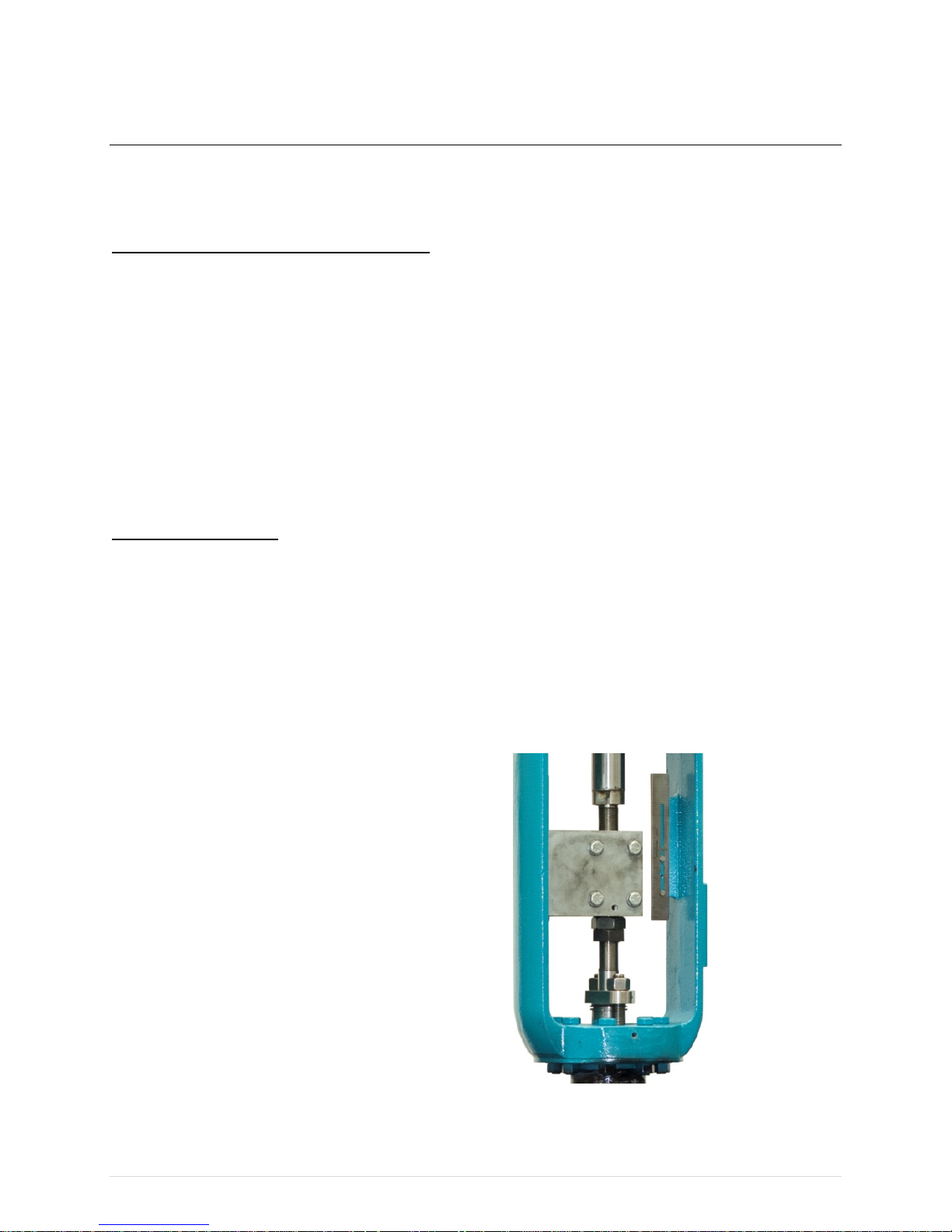

Stem Connections:

Note: Do not rotate the valve plug once it is seated to avoid damage to seating surface. Use

proper tools to avoid damaging the valve plug stem during travel adjustments. Should the stem

connections not be made properly in the stem connector, thread damage, or improper

operation may occur. The amount of each stem pressed in the stem connector should be equal

to or greater than the diameter of the stem itself. DO NOT loosen the stem connector cap

screws unless all pressure or force has been removed from the stems.

Typical Stem Connection

3 | Page

Page 4

CVS Series 470 Piston Actuator – Installation

Push Down to Close Installation – Direct Acting Valves:

1. After installation of the CVS 471 Actuator to the control valve set the actuator to the top of

its stroke and ensure the valve plug is in the closed position. Install two valve stem

locknuts, as well as travel indicator disc (if used) all the way onto the stem threads.

2. Apply pressure to the actuator until the piston rod of the CVS 471 has moved down from

the top of its stroke to the correct valve travel required.

3. Attach the Stem Connector to the Piston Rod and Valve Stem, tighten the 4 hex bolts once

in position.

4. Raise the stem locknuts and travel disc (if used) and secure against the bottom of the stem

connector.

5. Once the Stem Connector is secured, cycle the CVS 471 Actuator to verify the required

total travel settings are met, and that the valve plug seats properly before the actuator

makes contact with the lower travel stop adjustment.

Adjustments if needed:

Should minor travel adjustments be necessary, loosen the hex bolts slightly on the stem

connector. Tighten the stem locknuts together and make minor adjustments by turning the

valve stem into or out of the stem connector as needed using a wrench on the stem locknuts.

For major adjustments, repeat the stem connection of the valve and actuator as listed above.

6. After required travel has been achieved, secure the Stem Connector hex bolts. Lock the

stem locknuts against the Stem connector. Finally, adjust the actuators travel scale on the

yoke to reflect the correct valve position.

7. Using a gauge to measure the pressure to the actuator, make final adjustments to the

actuator, or positioner if used, setting the start and end points of travel for the required

instrument range.

4 | Page

Page 5

CVS Series 470 Piston Actuator – Installation

Push Down to Open Installation – Reverse Acting Valves:

1. Once the CVS 471 actuator is installed, pressure the actuator in order to cycle the Piston

Rod to the extreme upward position. Reverse loading pressure to move the Piston Rod

lower approximately 1/8”.

2. Raise the valve stem upwards in order to seat the valve plug.

3. Attach the Stem Connector to the valve stem and piston rod. Tighten the 4 Stem connector

hex bolts.

4. If a travel indicator disc, raise it to the stem connector and secure with the stem locking

nuts. The travel indicator should point to show the valve being in the open position, with

the actuator piston at the bottom of its stroke. Make adjustments to the travel indicator

scale as needed to properly show the valve position as needed.

5. Once the Stem Connector is secured, cycle the CVS 471 Actuator to verify the required

total travel settings are met, and that the valve plug seats properly before the actuator

makes contact with the lower travel stop adjustment.

Adjustments if needed:

Should minor travel adjustments be necessary, loosen the hex bolts slightly on the stem

connector. Tighten the stem locknuts together and make minor adjustments by turning the

valve stem into or out of the stem connector as needed using a wrench on the stem locknuts.

6. After required travel has been achieved, secure the Stem Connector hex bolts. Lock the

stem locknuts against the Stem connector. Finally, adjust the actuators travel scale on the

yoke to reflect the correct valve position.

7. Using a gauge to measure the pressure to the actuator, make final adjustments to the

actuator, or positioner if used, setting the start and end points of travel for the required

instrument range.

5 | Page

Page 6

CVS Series 470 Piston Actuator – Inspection and Maintenance

Certain operating conditions may require increased inspection and maintenance intervals.

Note: Ensure proper Safety and Lockout procedures are followed prior to inspection.

Relieve all pressure to the actuator and disconnect air supply line to avoid sudden open or

close action of the valve.

Shut off process to the valve or use bypass to isolate and relieve process from both sides of

the valve installation.

1. Verify the control valve is bypassed, pressure is relieved, and proper safety procedures are

followed.

2. Remove the stem connector.

3. Remove the Socket Head Cap Screws connecting the Piston Cylinder to the Piston Cylinder

Flange.

4. Remove the cylinder from the cylinder flange. It may be necessary to use a flathead

screwdriver or similar to pry the connection, once all cap screws have been removed.

5. The Piston and Piston Rod should be able to be removed with the Piston Cylinder when

lifting off of the Cylinder Flange. Once removed the Piston and Rod may be pulled out of

the Piston Cylinders open end. Take caution to not score or damage the cylinder walls.

6. Remove the Upper and Lower Seal Bushings. The Upper Seal Bushing is located at the top

end of the Piston Cylinder, the Lower Seal Bushing is located on the top end of the actuator

yoke.

Once disassembled, inspect all components for excessive wear or damage. Replace worn

O-Rings as required, lubricate with Lubriplate Mag-1 or equivalent.

Reassembly: in order to reassemble the Piston Rod Extension after removal from the Piston

Rod, clean the threads and inspect for visible damage, replace if necessary. Apply Loctite 242

or equivalent thread sealant. The torque value for the Piston rod Extension it 150 ft/lbs .

Reassemble the CVS 471 Actuator in reverse order as described above.

Contact a CVS Controls Ltd. representative for more information or to order spare parts as

required.

6 | Page

Page 7

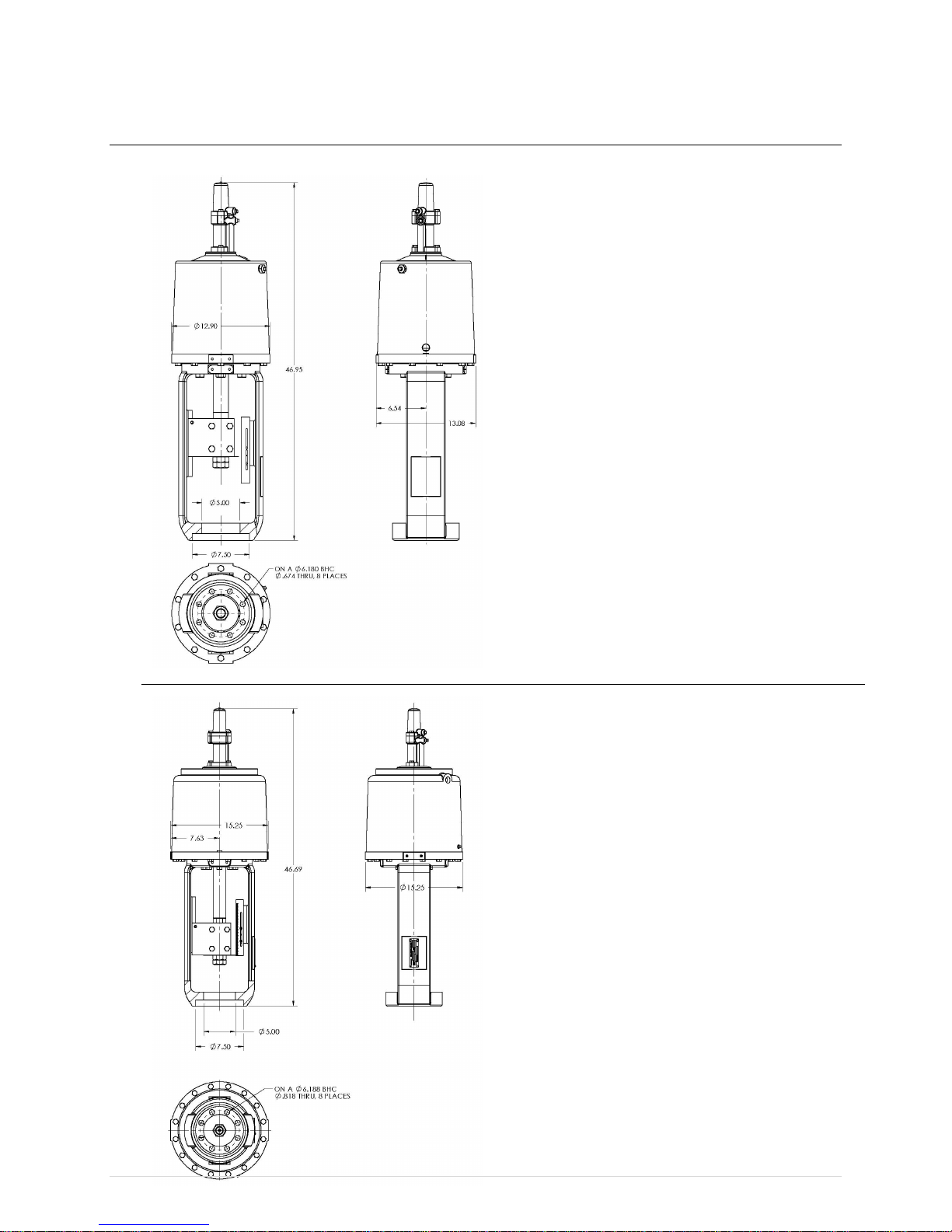

CVS Series 470 Piston Actuator – Dimensions (inches)

CVS 471-16 Size 80

CVS 471-16 Size 100

7 | Page

Page 8

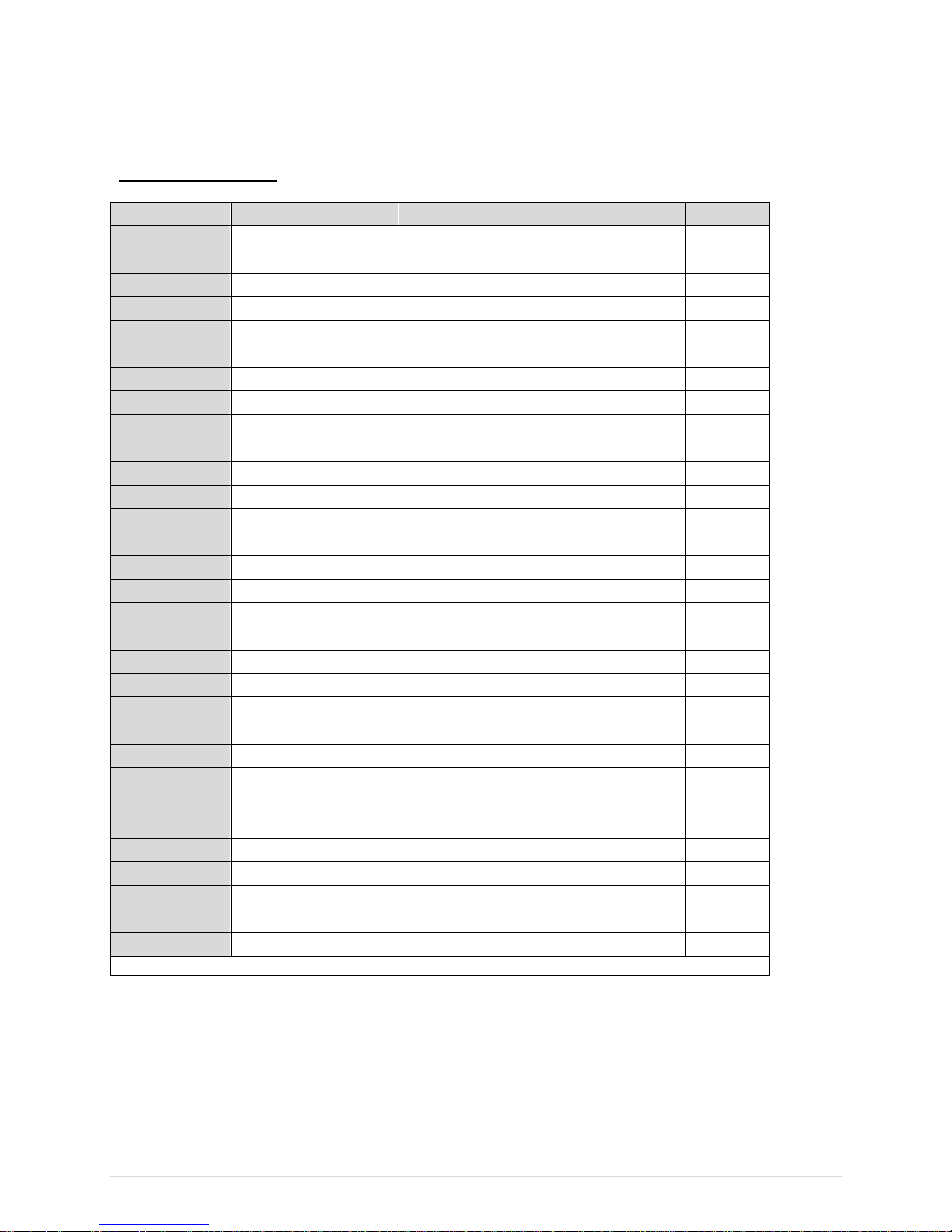

CVS Series 470 Piston Actuator – Assembly

CVS 471-16 Size 80:

8 | Page

Page 9

CVS Series 470 Piston Actuator – Assembly

Item Number

Part Number

Description

Quantity

1

CVS 2R853346582

Piston Rod Extension

1

2

CVS 1H865114042

Upper Seal Bushing

1

3

CVS 1D348306992

O-Ring, Nitrile

1

4

CVS 1E736906992

O-Ring, Nitrile

1

5

CVS 1P3957X0012

Spring Retainer Spacer

1

6

CVS 1H862 506992

O-Ring1 7

CVS 2H873707062

Piston 1 8

CVS 1H862506962

O-Ring1 9

CVS 1A771132982

Cap Screw

10

10

CVS 20A6353X012

Cylinder Flange

1

11

CVS 1A485724052

Cap Screw

4

12

CVS 10A6354X012

Stem Connector

1

13

CVS 470A008

Travel Indicator Scale

1

14

CVS 1A343128982

Screw 2 15

CVS 0W073524122

Hex Nut 2 16

CVS 1H8909X0012

Spring Retainer

1

17

CVS 1A649528992

Pipe Plug

1

18

CVS 1H872024102

Piston Nut

1

19

CVS 1H862706992

O-Ring1 20

CVS 1C334206992

O-Ring

1

21

CVS 1L249718992

Elbow

1

22

CVS 1H866017012

Cylinder Tubing

1

23

CVS 1R945614042

Lower Seal Bushing

1

24

CVS 30A6352X012

Yoke 1 25

CVS 1H863538992

Name Plate

1

26

CVS 1A368228982

Drive Screw

4

CVS 471-16 Size 80:

9 | Page

Page 10

CVS Series 470 Piston Actuator – Assembly

238

Apply Lubriplate Mag-1, or equivalent

239

Apply Loctite 242, or equivalent

CVS 471-16 Size 100:

10 | Page

Page 11

CVS Series 470 Piston Actuator – Assembly

Item Number

Part Number

Description

Quantity

1

CVS 32A1321X012

Yoke, D65-45-12

1

2

CVS 2R8514X0012

Piston Rod, 416 SST, Cr-pl

1

3

CVS 10A6354X012

Connecting Block, 1018

1

4

CVS 1R945614042

Lower Seal Bushing, Brass C36000

1

5

CVS 1A771132982

Cap Screw, 1/2-13 X 2.13

16

6

CVS 32A1322X012

Cylinder Flange, D65-45-12

1

7

CVS 1U181124012

Travel Stop, Steel

1

8*

CVS 1H862606992

O-Ring, Nitrile

2

9

CVS 3U8248000A2

Cylinder Assembly

1

10*

CVS 1E736906992

O-Ring, Nitrile

1

11

CVS 1A344924052

Cap Screw, Steel, pl, 3/8-16 X 1.00

4

12

CVS 2R8537X0022

Positioner Extension, AL356.0 T6

1

13

CVS 2R853346582

Piston Rod Extension, 416 SST

1

14

CVS 2H888507062

Cylinder Cover, AL356.0 T6

1

15*

CVS 1C853806992

O-Ring, Nitrile

2

16

CVS 2R8537X0012

Insert, 6061 T6

2

17

CVS 1A649528992

Pipe Plug, 1/4 NPT

3

18*

CVS 1D348306992

O-Ring, Nitrile

1

19

CVS 1H865114042

Upper Seal Bushing, Brass C36000

1

20

CVS 1H872024102

Piston Nut, Steel

1

21

CVS 2H873707062

Piston, AL356.0 T6

1

22*

CVS 1H862706992

O-Ring, Nitrile

1

23*

CVS 1C334206992

O-Ring, Nitrile

1

24

CVS 1R281124052

Cap Screw, 9-16-12 X 1.50

8

25*

CVS 1R946499012

Wiper Scraper, SKF504272

1

26

CVS 2R851338982

Travel Indicator Scale, 302 SST

1

27

CVS 1A368228982

Drive Screw, 302 SST, .13 X .20

4

28

CVS 18A5089X0A2

Name Plate, 302 SST

1

29

CVS 1A343128982

Screw, 10-24 X .50

2

30

CVS 0W073524122

Hex Nut, 1 1/4

2

31

CVS 10A6358X012

Travel Indicator Disc, 302 SST

1

*Recommended Spare Parts

CVS 471-16 Size 100:

11 | Page

Page 12

Website: www.cvs-controls.com Email: info@cvs-controls.com

Head Office

September 2014

3900 101 Street

Edmonton, Alberta

T6E 0A5

Canada

Office: (780) 437-3055

Fax: (780) 436 5461

Calgary Sales Office

3516 114 Avenue SE

Calgary, Alberta

T2Z 3V6

Canada

Office: (403) 250-1416

Fax: (403) 291-9487

12 | Page

Loading...

Loading...