Page 1

8"18-6, 8,

10

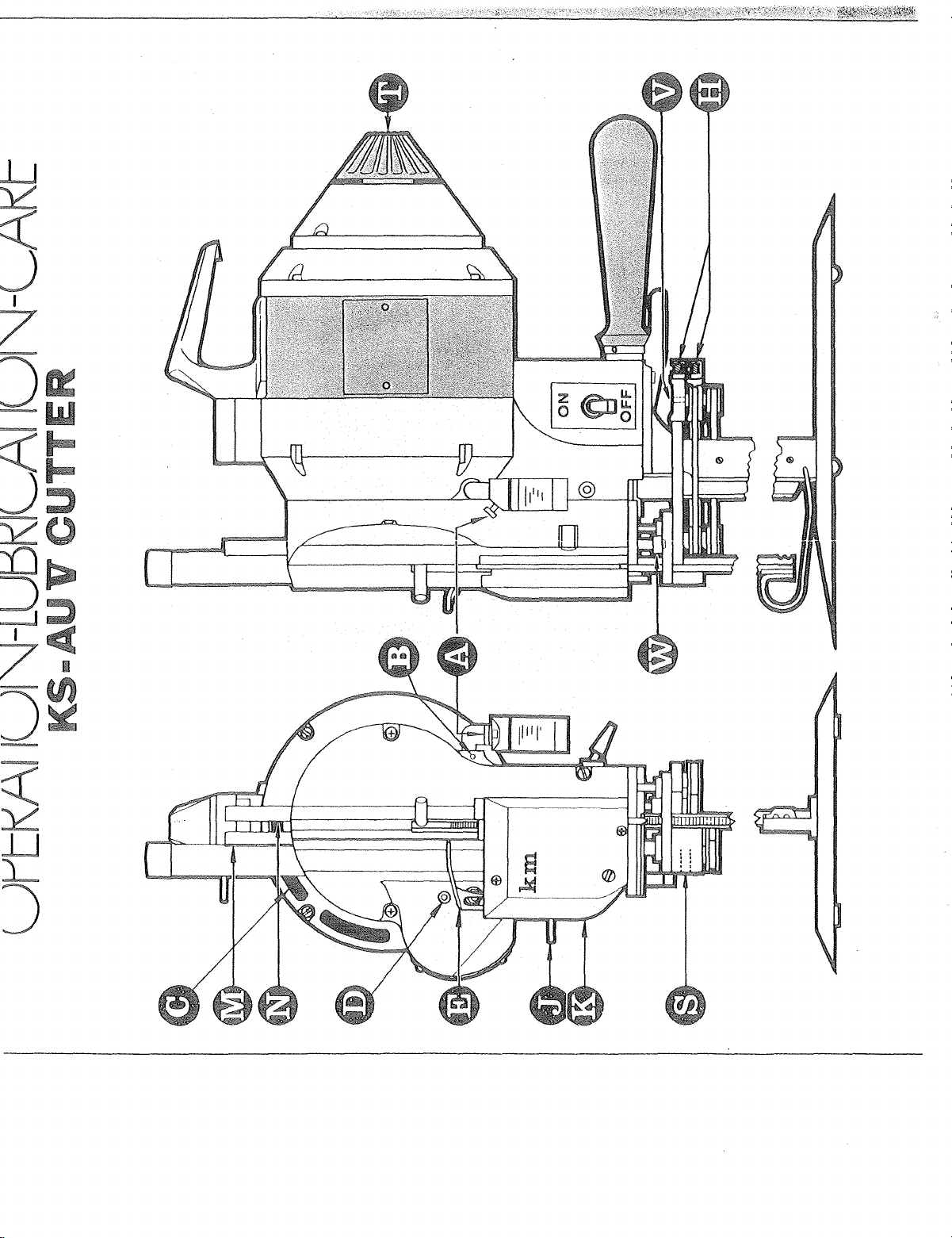

Page 2

Page 3

hole

B.

2.

Push

in T and

revolutions

to

turn

make

surfaces.

3.

The

sharpener

must

starting.

BE

CAREFUL

a.

Keep

the

machine

b.

Repeat

run

contact

c. Be

is as

d. In case

care

( 1) Be

(2)

e.

Use

any

short

on & off

continuously

for

surfaces.

sure

that

in

3-phase

ARROW-INDICATION

your

of

(HI)

been

The

The

no

MORE

genuine

trouble

cutter

the

following

sure

to

select

in

starting,

attained,

switch

is

continuous

more

than

THAN

KM

on

put

30

oil,

automatic

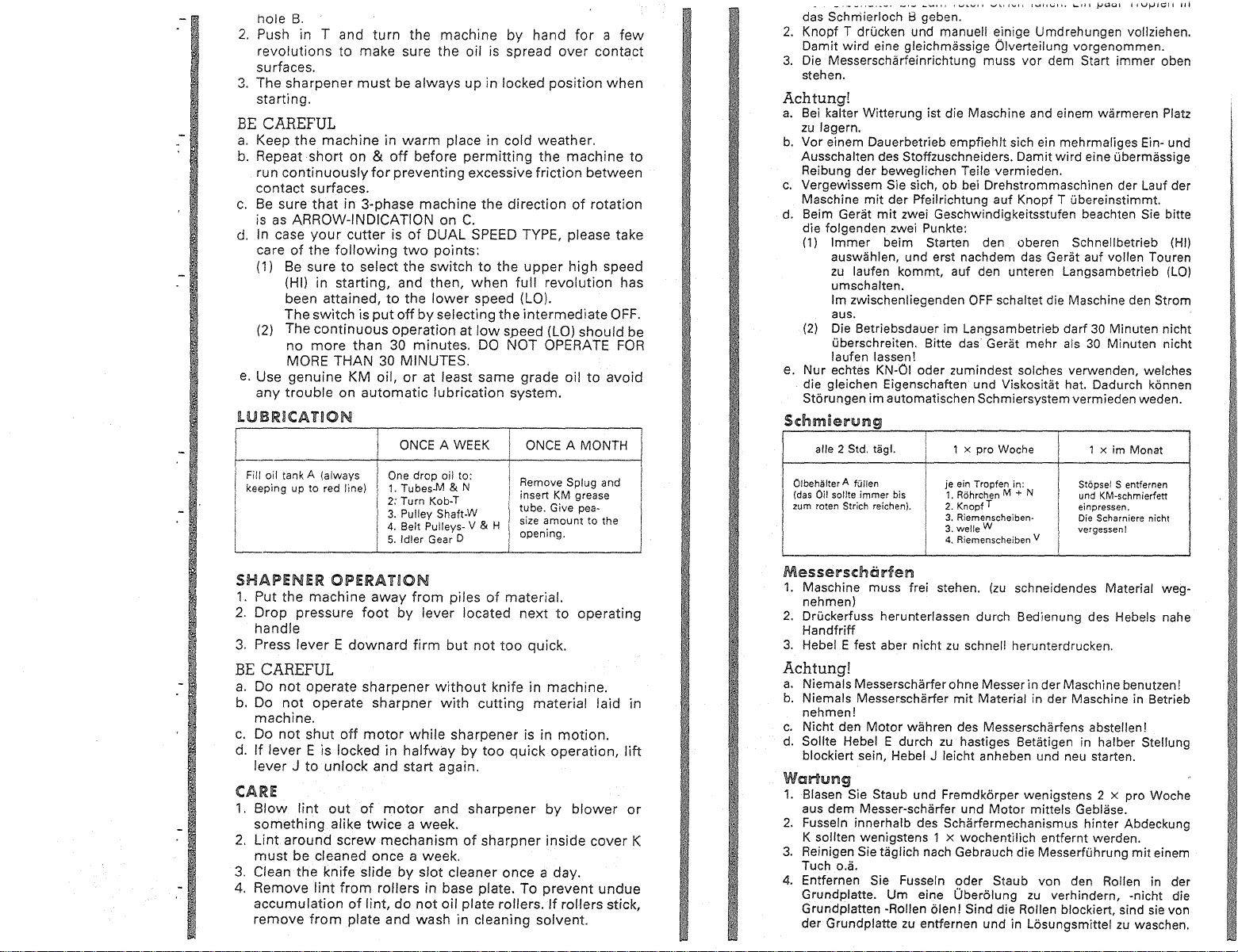

LUfEHUCATION

f- I

Fill

oil

tank A

up

(always

to

red line)

keeping

the

machine

sure

the

oil

be

always

in

warm

before

preventing

up

place

permitting

excessive

machine

on

DUAL

points:

switch

then,

lower

by

selecting

C.

SPEED TYPE,

to

when

speed

at

low

DO

is

of

two

the

and

to

the

off

operation

30

minutes.

MINUTES.

or

at

least

same

lubrication

ONCE A WEEK

One

drop

oil

1.

Tubes..M & N 1

2:

Turn

3.

Pulley Shaft.W

4.

Belt Pulleys- V & H I

5.

Idler

to:

Kob-T \

Gear D

is

in

in

the

the

the

by

spread

locked

cold

direction

speed

NOT

system.

I

j

hand

for a few

over

position

weather.

the

machine

friction

of

please

upper

high

full

revolution

(LO).

intermediate

(LO)

OPERATE FOR

grade

oil

ONCE

A MONTH

Remove

Splug

insert

KM

Give pea-

amount

grease

tube.

size

opening.

contact

when

between

rotation

take

speed

OFF.

should

to

avoid

and

to

the

to

has

be

_

·--··-·~-·

_,_.

._..,...,,,

''-''"'-'''

'-'~''"'''

!VI<'-'''•

._,,I

/-JOUI

ltVjJIC:!!

das Schrriierloch 8 geben.

2.

Knopf T drucken und manuel! einige Umdrehungen vollziehen.

wird

Damit

3.

Die Messerscharfeinrichtung muss

eine gleichmassige Oiverteilung vorgenommen.

vor

dem Start

immer

stehen.

Achtung!

a.

Bei

kalter Witterung ist die Maschine and einem warmeren Platz

zu

lagern.

b.

Vor einem Dauerbetrieb empfiehlt sich ein mehrmaliges Ein- und

Ausschalten des Stoffzuschneiders. Dam it

wird

eine Gbermassige

Reibung der beweglichen Teile vermieden.

c.

Vergewissem Sie sich, ob bei Drehstrommaschinen der Lauf der

Maschine

d. Beim

Gerat

mit

der Pfeilrichtung auf Knopf T Gbereinstimmt.

mit

zwei Geschwindigkeitsstufen beachten Sie bitte

die folgenden zwei Punkte:

(1)

lmmer

beim Starten den oberen Schnellbetrieb (HI)

auswahlen, und erst nachdem das Gerat auf vollen Touren

zu

laufen kommt, auf den unteren Langsambetrieb

umschalten.

lm

zwischenliegenden

OFF

schaltet die Maschine den Strom

a us.

(2)

Die Betriebsdauer

Gberschreiten. Bitte

im

Langsambetrieb darf

das

Gerat mehr als

30

Minuten nicht

30

Minuten nicht

laufen lassen!

KN-01

e. Nur echtes

oder zumindest seiches verwenden, welches

die gleichen Eigenschaften und Viskositiit hat. Dadurch konnen

Storungen

im

automatischen Schmiersystem vermieden weden.

Schmierung

aile 2 Std. tag!. 1 x

Oibeh§lter A

(das

zum

fUJien

Oil

sollte immer

roten Strich reichen).

bis

pro

je

ein

Tropfen in:

1.

Rohrchen

2.

KnopfT

3.

Riemenscheiben-

3.

welle W

4.

Riemenscheiben

Woche

M + N

1 x

im

Monat

Stopsel

S entfernen

und

KM-schmierfett

einpressen.

Die

Scharniere nicht

vergessen!

V

Ill

oben

(LO)

SHAP!ENER OPERATION

1.

Put

the

2.

Drop

machine

pressure

away

foot

by

from

lever

piles

located

of

material.

next

to

handle

3.

Press

BE

CAREFUL

a.

Do

b.

Do

lever E downard

not

operate

not

operate

sharpener

firm

sharpner

but

without

with

not

too

knife

cutting

quick.

in

machine.

material

machine.

c.

Do

not

shut

off

motor

while

d.

If

lever E is

lever J to

locked

unlock

in

and

halfway

start

again.

sharpener

by

too

is

quick

in

motion.

operation,

CARIE

1.

Blow

lint

out

of

something

2.

Lint

around

must

3.

Clean

4.

Remove

accumulation

remove

be

the

from

alike

screw

cleaned

knife

lint

from

of

plate

motor

twice a week.

mechanism

once a week.

slide

rollers

lint,

and

by

do

and

slot

in

not

wash

sharpener

of

cleaner

base

oil

plate

in

sharpner

once a day.

plate.

rollers.

cleaning

by

To

prevent

solvent.

blower

inside

If

rollers

operating

laid

lift

or

cover

undue

stick,

in

K

Messerscharfen

1.

Maschine muss frei stehen.

(zu

schneidendes Material weg-

nehmen)

2.

DrGckerfuss herunterlassen durch Bedienung des Hebels nahe

Handfriff

3.

Hebel E fest aber nicht

zu

schnell herunterdrucken.

Achtung!

a.

Niemals Messerscharfer ohne Messer in der Maschine benutzen I

b.

Niemals Messerscharfer

mit

Material in der Maschine in Betrieb

nehmen!

c.

Nicht den

d.

Sollte Hebel E durch

Motor

wahren des Messerschiirfens abstellen!

zu

hastiges Betatigen in halber Stellung

blockiert sein, Hebel J Ieicht anheben und neu starten.

Wartung

1.

Blasen Sie Staub und Fremdkorper wenigstens 2 x pro Woche

aus dem Messer-scharfer und

2.

Fusseln innerhalb des Scharfermechanismus hinter Abdeckung

K sollten wenigstens

3.

Reinigen Sie taglich nach Gebrauch die MesserfGhrung mit einem

Tuch

4.

o.a.

Entfernen Sie Fusseln oder Staub von den Rollen in der

1 x wochentilich entfernt werden.

Grundplatte. Um eine

Grundplatten

Grundplatte

der

-Rollen olen! Sind die Rollen blockiert, sind sie von

zu

entfernen und in Losungsmittel

Motor

Oberolung

mittels Geblase.

zu

verhindern, -nicht die

zu

waschen.

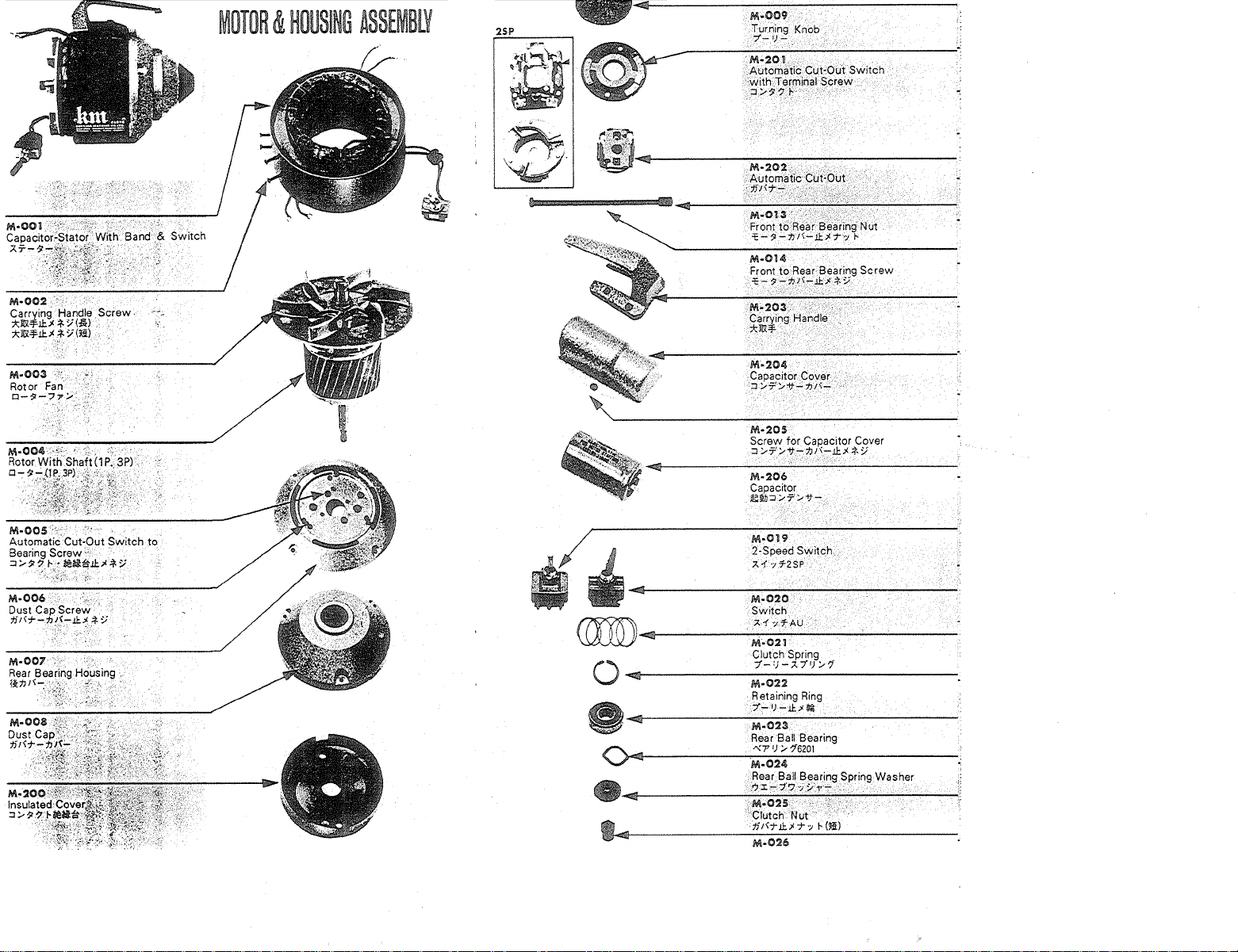

Page 4

MOTOR

&

HOUSING

ASS

y

M·009

Turning Knob

7'-•J-

M·201

Automatic Cut-Out

'with.Terrnim31

::J

/$<?I'·

screw

Switch

M·002

Carrying Handle.

;*:ltl'f.J.I::.;<:jc~(:l\\)

;*:ltl'f.J.I::.;<;:j<~(~)

M·003

Rotor

Fan

Cl-$1-77

M·OO$

Automatic.

Bearing

Screw.:

:::J:.-$1?

1-

,..

··-

M-006

Dust Cap

tiJI7-:IJ(5-J.I::.;<,;);~

M·007

Rear

Bearing Housing

l~:IJJI-.

•,

',,·~-~:;'

Screw.

;.-:

:: . . ·

Cut-Out

Switch

to

d@:*f.~J.I::.;<.:);~

"' ' ' .

\?,;~"\

.. . '··

Screw

•,,.

-!:

·'

.

,\.

'

~·

COOID

0

0...

•

~

M·202

Automatic

tfll-j--,.

M·014

Front

M·204

Capacitor Cover

:::J/7/"t-:IJil-

M·205

Screw

M·206

Capacitor

&~Jp

M·C>19

M~020

M·022

.

M·024

.Rea.r

... ·

.·.·•

Cut'but

'

to

Rear Bearing

'1:-$'-:IJJ\-J.I::.)< *;;

for

::J

2-Speed

7.1'·;d'2SP

Switch

7.1

.M~021

Clutch

7'-

Retaining

7'-•J-J.I::.><1!ll

M·023

Rear Ball Bearing

,-..:7

";I..-

M·025

Clutch Nut

nt\7J.I::.>'7·:;

M·026

Capacitor Cover

:..-7:..-<t-:IJJ\-J.I::.;<

:..-7:..-<t-

Switch.

·:-'TAU

.

Spn~g:..-1·

:;

-;>.

7')

.

Ring

I)

:.-1'6201

Ball

B.

ea.

7''7

·:;

;,i..,.·"-

Screw

*;;

rin.

g

s.

p.rin·g···W.

: '

H~l.

ashe.

r

Page 5

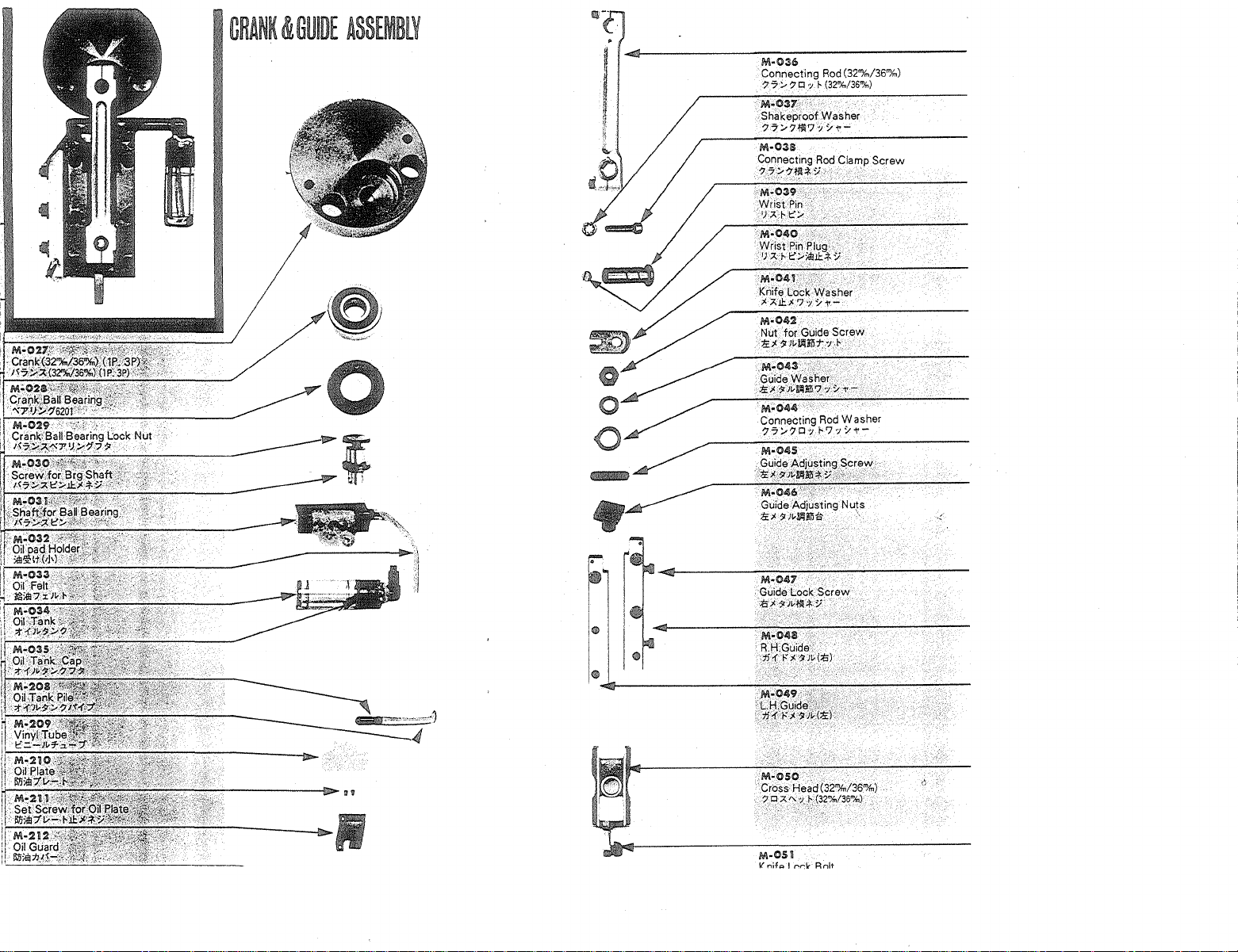

CRANK & GUIDE

ASSEMBLY

--·

M·036

Connecting

7 / 7 0

I

i

,;}

7

M·037',,,

Shakeproof Washer

77/7-!ll?·;t:/'1'-

M·03il

Connecting

77,>7-!11:!'-:J

M·039

yt~sr~~

M·040

Wrist

I);<:

!111~041,,,/

Knife

";7,Jl:;< '7

M·042

Nut for Guide Screw

:!i.>'1'M.tlBil:t:-;~

0~

()

0

~djusting~cre'll,··

-

--~~~~~-~~0~44~~~~----~----

Connecting

77/70·;t

:!i.>'9'Ji:-ID!Bil.:!<:J.;;0;

Rod

·;t

t-(32'%/36%)

Rod

Clamp Screw

<

.,

Pin

Plug

0

E;"/i£llJ.!::!<

:J

Lock

Washer

•;t:/'1'-

..

~

Rod

~'7·;t:/'l'-

(32'%/36%)

'

Washer

'i

'

I

I·

I.

~~

•

~~~~:~~j~~t\ng

:!i.>'1!1t-i1lBil~

!111·048

R.H;Guide

:ti11"" 1f)V(;f;)

M·051

!tnifA

ll"r:ir

~u~s

'

Rnlt

Page 6

FRONT

GOVER

ASSEMBlY

M-059,

..

:

g;.:

...

'·

·.·.·

• ·

...

. ·.'

..

down

:

Guide:8old Down Screw($} • (L)

n-1

t' >':>'lvJl:;J:y(SHL)

M·06.9

LowerLH.S).larpener'hold

tlii7

M•Ool:'·:

Stud.

tlii"1:'>1"Jl:;<;j:,)i,,:;;.

n

.;? . :(;

:'>.7J<Jl:;i777

tower

1-(1.<)

, .

t.:.H.ty~.ountaing

Nut

\.

M-066

Ground Clip

:'>-.>:1-Jv?

..

M·.067.

··~.··

Attacpme!'tPiu~

.

•:

3.i\l~~7?:'1::

M~06s.·.··:

TerminaiBiock Complete(3P)

3.'11!:'>.-:"

M~069

Attacnmer\t

!t~-:171

M·071

Terminal Sleeve

~~::itA

M-072

Terminal Contact

:>'-.>:1-Jv::il:A

M·073·

Operating Handle (With Nut)

t<71 ;1'"::-rJH:f-·y

•J

!.;:\:. · .....

-t:

Jv"1Cl·y?

•. · ·'

v.-:1

Complete(3P)·

i .

.·

...

Plug(

Complete)

with

Htl

···.···.

Pin

1111

M·074

· Operating f:iandle Lock Nut only

'':,-)'Jv,:l-·1 ~ ·

M·075

Switch Cover Screw

lii!:IJJ\--:fv-lll:.tV

M·2U

Switch Cover

ii1J:IJ;\-7v-"

Page 7

. ,

·'i'·

.

ii

II

n

r

I

r·

I

~

~

w

i.

i

r

ii

~

~

~~·

~

i

STANDARD

&

BASE

PlATES

M-077$

Plate Wing

"'"

f-Wi('j')

M·077L

Plate

x.,

HlH:k)

M-078

Plate Complete( Rubber Mounted Rollers)

"'"

(Cl-7-f\f~fit~o)

M-0110.. ·

··•.Rubbe.r

·

CJ-?-:J/7

~~oa~~<;:

Roller· ·

Cl.+7.-;:'

l<l/:1

1

)-

Mo.un.ted

1

)-

.

f.

.·:

. .

Ro.

l~rfCom

..

.t...?

plet<:ll

·>

v s /l;J'l!!'

H:J

.· · ..

•

l

f

J

•

·~

q

~

~

I

:\

:r

0~

.

M.~Oilll.

·'

:>.,:

::·•;:: , ..

,,,..,

:··

JhroatPiates/VIJith S

..

i;·}~EJ~~~:;~:~~~.

...

Page 8

AUTOMATiC

SHARPENER

ASSEMBlY

Knob for Pressure Foot

l'l'ii.li!i?ll:i'>

M·231 '

Screw for Knob

?ll:hJ!:)i;Jt:;

M·IOII

Stop Nut

for

!1!1Si57·>

M·107

Spacer Tube

1--,t:':t.&itB'l~+

...._,

M~OS

Washerfor

J: T!IJp'fi

M·I04.

Nut

J:Tliliti1i"(:!i:·:6)

M·102

Collar

J:TliliT?·1:/¥M·l09

Spring for Pressure Foot Lock

l'l':tlili:tt.--'I';<?'•J:-1'

ln'W

I

jo.

-v

~

~¢i.0~;;:;-

' 'ii' Pressure. Foot Lever Screw

~

...,._-

1'

~

......--~

~

j(iO

c;

-

~-

-----

__,.

M·llO

Spring

·~~-;(?'0:-1'

M·216

Pressure Foot

l'l'5i.lili6'

/

M·1l3

Screw

!tllill'l'ii.Jl:>';lt:l

M·217•"

Pressure

--~,.~~-----'~'~·~~--~'~'-------~--------------

M·ll5'•:·

;;l't.--'l'vtl-ll:.>':l::l

M·ll6.

Spring for Pressure Foot Lever

:lv-'l'vt'-.o:?'•J:-'1

.M~117~

.'Set.$crew

'_;,:l£.'1--':;.t.!:::).::*-Y',,.

Screw Shaft

oll:>':t-·11-

.·

.

,,,

...._

6"

7"'

8"

,.,...,

"'

"'

"'

Screw Shaft L.H. '

I'

7';

:/

,.

'::-

.for.'

Screw

Shaft

for

Lower Screw Shaft

·

. .

for

Latch

Rod

7"

8"

9"

10"

for Pressure Foot. Shoe

Foot

Lever

. . .

..

· .

..

·

for

cam

Shaft ..

, ,,

Rod

9"

10"

i

M~lll

Cam

Spring

~~;<?'U:-1'

~

~

~

~

p)

A.·~.-r.~~.~.··

"'--J~'r

n

- .

~~

(9

II 1

~--

••

'--~'-

M·l19

::17

{

- /

~~

'F:t!J

-

-<1111

IP

• Pr'!:ssure Foot

-·~----~l'l'~.:<.~lili~~~~~~--------------------

Lock Screw & Spring Washer

<iflilvJI-Jl:;<

lRiilvll:-;<

<ifi!!!t.-JI-'1''7·>:.-,.-

M·120

Lock(only)Pressure Foot

l'l'ii.lili:ft.--'1'

Nut & Screw for

l'l'.:<.lili?v-'l'll::l::l

l'l'ii..

M·122

M·I23

Slide for Pressure Foot

;t:;

?'•)

li!i:fv-'l'll:7·>

Lock

/'1'7

Pres

1-

..

for Release Lever

·>

;.-

1'-

Ft Lock

Bracket

Rod

Page 9

AUTOMATIC

SHARPENER

ASSEMBlY

~----

rffl Spring

I

Jo-

~

.

"(lk'lra~t"

~

~

·-~

~

II'

~·"

~-""'

'iii'~

f

------

~

~

~

-::17

.(

- /

~

~~

o·~e!!....

..

__

!!WI!!f"4''+

~--.

ill

~----:i'll-:-:;t-:-ja<~;l).;_/(_-

M·230

Knob for Pressure Foot

jljl~i1$?:l:h

M·231

Screw

for Knob

?:l:hJJ:.)<:?-V

M·lOS

Stop Nut for Screw Shaft

!ll!llli

:r

·;; ~ J.b<

M·107

Spacer Tube

J::'Fif!ll!llli:t·;;

M•106

Screw Shaft With Extension

:l:Ti11!6"-8", 9"-10"

M·105

Washer.for Screw -Shaft L.H.

J:T!mb1H

M·104

Nut

J:Tif:i5'1' t:(:tr:·:E) .

M-102·

Collar

J:TifT'7

M·I09

Spring for Pressure Foot Lock

i'll~if'1v-'f::<:7'>J

jllf~l10

*~~-::<:7'U/7

M·216

Pressure Foot

jljl~if6"

M·ll3

Screw

;t:.Jl!!i'!l;tJ.E•;<

M·217

Pressure Foot Lever

___

7~·~"'---~~v~'-'-----------------------

~~!!~re

:tv-~v,\.-JJ:;<:I;:/

M·l16

Spring

7v-~t:-;\-::<:7''J

M·H7

Set Screw for

~kt'/JJ:;<;?-V

M·118C

Cam.

~t..

M·l19

Lock Screw & Spring Washer

lilllii!v;\-J.I:;<

lil!iii!t.-l(-

lil!lii!t.-f\-'¥'7·;;~-1'-

M~120

Lock(only)Pressure Foot

i'!l;ci*/'v-~

Nut & Screw for

i'll~i*7v-~JJ::~;,;;

i'!l;ti1$7v-u:r,,_

M·122

Pr~ssure

M•l23

~!irl,:;:.

:r

f-6"

····.

·.

· ·

!<.'7

·;;

~

.. · ..

for Screw

·

·

for

Lower

·;;

~

'~'-

. M·111

_for

Latch

7"

8"

9"

for Pressure

:7-Y

Foot Lever Screw

for

Pressure Foot Lever

M·l185

Cam

1JkJ.i:;<;I;V

;/;

1

::<:

7'

)

Foot Lock Bracket

__________________

ft"'\r

Pro~<::ltro

Rod

·;;

r-

7"

8"

9"

10"

~:.:.

Shaft

L.H. &

R.H.

Screw Shaft

/-1

Cam

Spring

~k::<:7'U/7

Rod

10"

Foot

·:·:

Cam

:/

/7'7

Shoe

/'1

Shaft

Screw

for Release Lever

·;;

~

'1'-

Pres

Ft Lock

~f"'ryt

p,...,,-j

_

Page 10

AUTOMATIC

SHARPENER

ASSEMBlY

-41------

.....__

...,.__

M·i35

Right Hand Follower Nut

:tll~'\'7

f-7·> f.(;i;;)

M·i36

R.H.Square Shaft

Jll~.'\'71-

JllP,7 ~ (;t;l

M-137

Left Hand Follower Nut

Jll~'\'71-7·>

M·i311

LH.Souare Shaft

:tll~'\'7

:tll~'\'71-(:ii:)

M·139

Push

1'

M-.140

Roll

P-11-t"/

M•l41

Driver Shaft With Gear

M·l42

Screw for Spreader

i:W:J.!:f'JJ.!:.><t~

M·l43

Spreader

jlj!

(;i;;)

6"-8"

9"-10"

H:ir'l

H:ir'l

6"-8"

9"-10"

Rod

J.!:

1111

Pin

for Push

Rod

4

....

-

Pin

Pin

J.!:.

)Yj

M~150.

Retaining.Ring

?

1)

t!;.,.

M·Ul

Thrust Washers for Spiral Gear

3:i!J-·'I'-'7·J~'I'-

M~l52

_

.It

I Shaft for Crank

J

O

...oil:

c....

e

Lock Nut foi.Crank.Shaft

2:i!J-"i';t.,-

'M·U3

2

....

M-154

· Washer, for Crank

'2.'1'.1'-~.'1'71-'7·>~'1'-

···~~·~~~i~~'16'r.B~UB~aring

':1-i).:..?7/?ll;<$j!

M-156

·''···

..

·!

1-

'7

.,

:;.; , ""-

...

{><,r,;

; .

-:

..

P.f7t-.77

<:

~~'1'71-

I-·

,.,,,

Shaft

·'

.·

Page 11

lOWER

GEAR

BRACKET

ASSEMBlY

1

00

~

~

~ ~

'

M·173

,

Guide,Back

A,>

M·ll'S

Screw for

A

:;r

M·l77

LH.Siide

"<:Jt-};!;f*l(:lr:)

M·Hil

Spring for

--:Jv

~;~~~::~~~.,;;,

77:..-/ll:><:t-'J

of.

Standard

r'll>~''lS"

, r,

s",

Guide

with

Pulley

1'

Back(With

*:;

Pulley

Slide

1

1

:..-1

('7

:..-

r;i;f*lll:.><

~~~A

s·.

")

lvm

10·

Washer)

~,.

-1;tl

......

0

....

~

....,.__

~

_,.

J

('~-------------------

M·lU

Nut for Sharpener Shoe Screw

'<Jt-

t-l'!'~ll:>'

:1-

'"

1-

M·lU

Screw

for Sharpner Shoe

'<it-

1-l'l'~.tl:>'

*:;

M·

llil6

R.H.Sha~p~e~~~

--:Jt-

t-l'!';cA

~e·;~"P'""

'<Jot-I'!'~A1''J:-'1(:1r:)

Shoe Spring

:--1 (;E)

Shoo

Sp,>og

Page 12

L

10

~~~~~~r~r&~·~==&··~;~.c~~·

- w

(ijj)

«

tESSORY-

KM

\El\ECTRICCI.Oll\

KAIAAKURA

IIRAIICIIES

MOII)'f.l

CUilllllG

TOKYO

BOl.

lfi\S-

r.u

!11\"CH\'11.\t

IIIAGOYil.

< ' )

OSI\Il!l.

-

16

~--·

-.----~

..

~~~~~~~~~~------------~~~~~~~-

-

Page 13

OKM

o

HIGH

("1'

SPEED

;<;[:'-

STEEL

H~)

<>SPECIAL

(g

~WI)

ALLOY

STEEL

; <)SIZE:

*We

Leather

-t-1' o

<)KM

*There

are

on

the

~-Ib~~~~~T~Q)4maffAij:J'9.MI!Ji$-~-&ihU>&Wa~&~~

s;&U'T~

1--------------f-C-O-T--T-O-N-.

<)KNIFE

6".

7".

can

also

offer

materials

:-,

1::'.

=--iv,

ABRASIVE

four

different

cutting

materials.

"'·

GRITS

COARSE

il80

11100

MEDIUM

FINE

11120

FINE

11180

PROTECTOR

8".

9".

10"

the

Wave

Knife

v-!f-;l'dl'fHQ)1<fi!Jir:;&

BELT

grits

of

Abrasive

(liliJ.:ll)

cmm

(<P§)

(l!li§)

(@llli)

recommended

BelL

For

CANVAS.

~

Thic & Hard

~

1.~

/t\::X..,

l!i[jj!,<l)J)>roc't.<T.>

-Thin

ML?-JC,..><

i1Jil'!<T.>

KILTING.

-Thin & Soft

~Jt-T

-r

>ll'Jl'!'Z"l#t=

tor

the

Nylon.

Vinyl

1-

t~ilt}]'bl!lWh

best

results.

APPLICATION

DENIM.

T'

=.L...

_W_O_O_L_.

material

'J"'.Al!i·

t.

<1)

GEORGETTE

::.--

"f~

:;·

~>p

select

(ffl;£)

LEATHER

material

v;r-:w;

_H_O_S-IE_R_Y_.

....

material

3

~

-e··:.t

,,

JJ'l'

t.<T.>

T

t;

.....

t-i¥···

•J

:<

it

depend

and

9.

__

AU

9"

-10".

AU

7"

--

8".

AU6".

<)KM

s

CLIP

M

L

EU

5"

4"

•

li

Oj

8"

Page 14

Loading...

Loading...