SVX9000 Drives

Quick Start Guide

Effective November 2011

Supersedes December 2003

CONTENT

STEP 1 — Keypad Operation Overview

STEP 2 — Standard Wiring Diagrams and Connections

STEP 3 — Start-Up Wizard

STEP 4 — Operating and Programming Menu

STEP 5 — Faults and Warning Indication

STEP 6 — Monitoring Menu

Navigation

STEP 1

Keypad Operation Overview

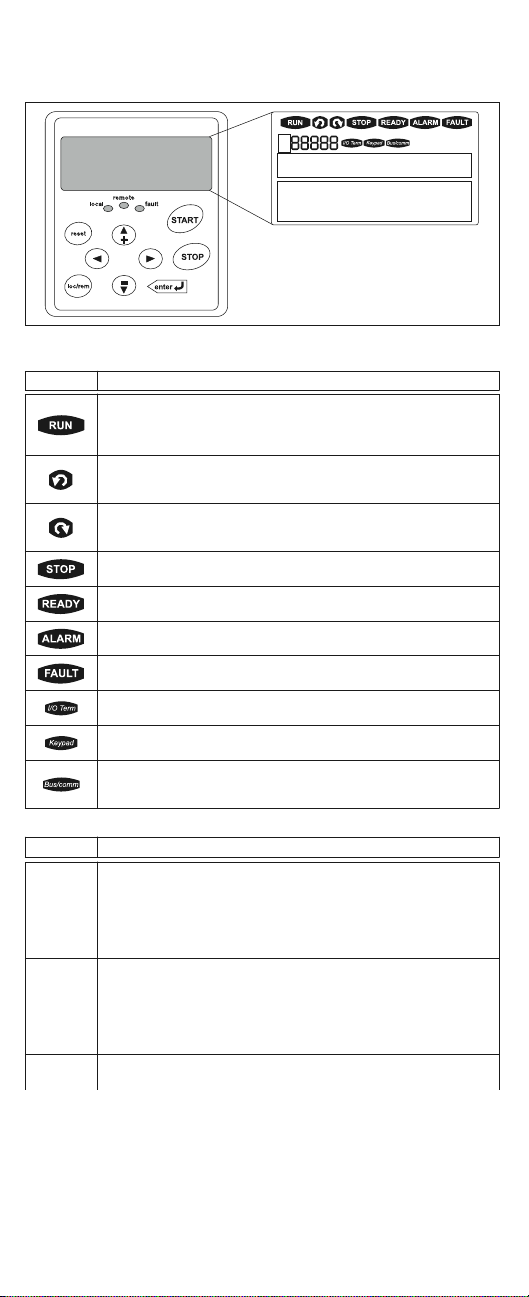

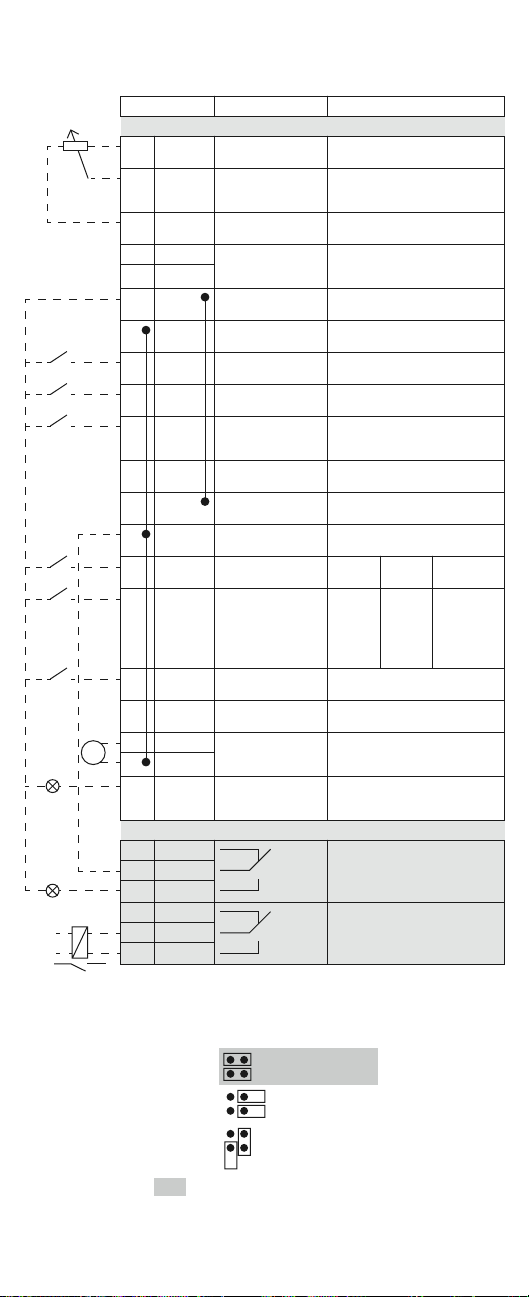

Keypad and Display

LCD Status Indicators

Indicator Description

Run

Indicates that the SVX9000 is running and controlling the load. Blinks

when a stop command has been given but the SVX9000 is still

ramping down.

Counterclockwise Operation

The output phase rotation is BAC, corresponding to counterclockwise

rotation of most motors.

Clockwise Operation

The output phase rotation is ABC, corresponding to clockwise rotation

of most motors.

Stop

Indicates that the SVX9000 is stopped and not controlling the load.

Ready

Indicates that the SVX9000 is ready to be started.

Alarm

Indicates that there is one or more active drive alarm(s).

Fault

Indicates that there is one or more active drive fault(s).

I/O Terminal

Indicates that the I/O terminals have been chosen for control.

Keypad

Indicates that the keypad has been chosen for control.

Bus/Communications

Indicates that the communications bus control has been chosen for

control.

LED Status Indicators

Indicator Description

local

Local — Steady Illumination

Indicates that the SVX9000 is ready to be started and operated from

the Local mode.

Local — Flashing

Indicates that the SVX9000 is ready for operating command to select

remote

Local or Remote operation.

Remote

Indicates that the SVX9000 is operating and controlling the load

remotely.

Remote — Flashing

Indicates that the SVX9000 is ready for operating command to select

fault

Local or Remote operation.

Fault

Indicates that there is one or more active drive fault(s).

1 SVX9000 Drives

MN04003009E—November 2011 www.eaton.com

STEP 1 (Continued)

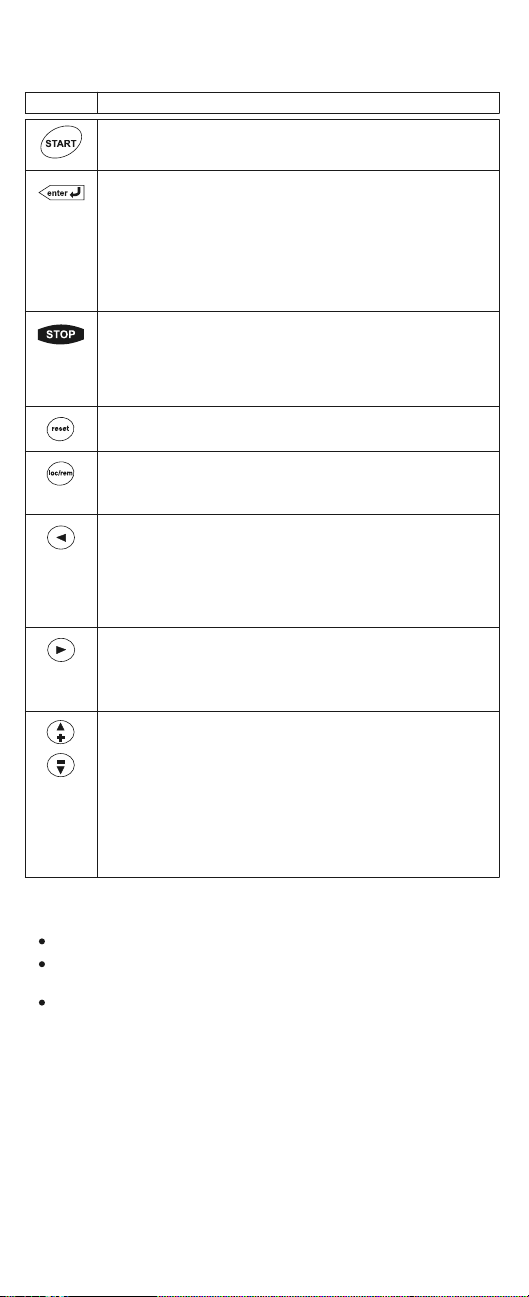

Navigation Buttons

Button Description

Start

This button operates as the START button for normal operation when

the “Keypad” is selected as the active control.

Enter

This button is used in the parameter edit mode to save the parameter

setting and move to the next parameter …

•

to reset the Fault History if pressed while in the “Fault History”

menu.

•

to confirm the acceptance of a change.

•

to change a virtual button status while in the “Button” menu.

•

to confirm the start-up list at the end of the Start-Up Wizard.

•

when the “Operate” menu is active, to exit the “Operate” submenu.

Stop

This button has two integrated operations. The button operates as

STOP button during normal operation …

•

motor STOP from the keypad, which is always active unless

disabled by the “StopButtonActive” parameter.

•

used to reset the active faults.

Reset

Resets the active faults.

Local / Remote

Switches between LOCAL and REMOTE control for start, speed

reference and reverse functions. The control locations corresponding

to local and remote can be selected within an application.

Left Arrow

•

navigation button, movement to left.

•

in parameter edit mode, exits mode, backs up one step.

•

cancels edited parameter (exit from a parameter edit mode).

•

When in “Operate” menu will move backward through menu.

•

At end of “Start-Up Wizard”, repeats the “Start-Up Wizard”

setup menu.

Right Arrow

•

navigation button, movement to right.

•

enter parameter group mode.

•

enter parameter mode from group mode.

•

When in “Operate” menu will move forward through menu.

Up and Down Arrows

•

move either up or down a menu list to select the desired menu item.

•

editing a parameter/password, while the active digit/character is

scrolled.

•

increase/decrease the reference value of the selected parameter.

•

in the “Operate” menu, will cause the display of the active reference

source and value and allow its change if the keypad is the active

reference source. Used to set the password (if defined) when

leaving the “Operate” menu.

•

scroll through the “Active Faults” menu when the SVX9000 is

stopped.

Menu Navigation

Navigation Tips

To navigate within one level of a menu, use the up and down arrows.

To move deeper into the menu structure and back out, use the right

and left arrows.

To edit a parameter, navigate to show that parameter’s value, and press

the right arrow button to enter the edit mode. In edit mode, the

parameter value will flash.

SVX9000 Drives

MN04003009E—November 2011 www.eaton.com

2

STEP 1 (Continued)

When in edit mode, the parameter value can be changed by pressing

the up or down arrow keys.

When in edit mode, pressing the right arrow a second time will allow

you to edit the parameter value digit by digit.

To confirm the parameter change you must press the ENTER button.

The value will not change unless the ENTER button is pushed.

Some parameters can not be changed while the SVX9000 is running.

The screen will display LOCKED if you attempt to edit these parameters

while the drive is running. Stop the drive to edit these parameters. See

the SVX9000 Application Manual for identification of these parameters

specific to your chosen application.

Main Menu

The data on the control keypad are arranged in menus and submenus. The

first menu level consists of M1 to M8 and is called the Main Menu. The Main

Menu is illustrated on Page 7. Some of the submenus will vary for each

application choice.

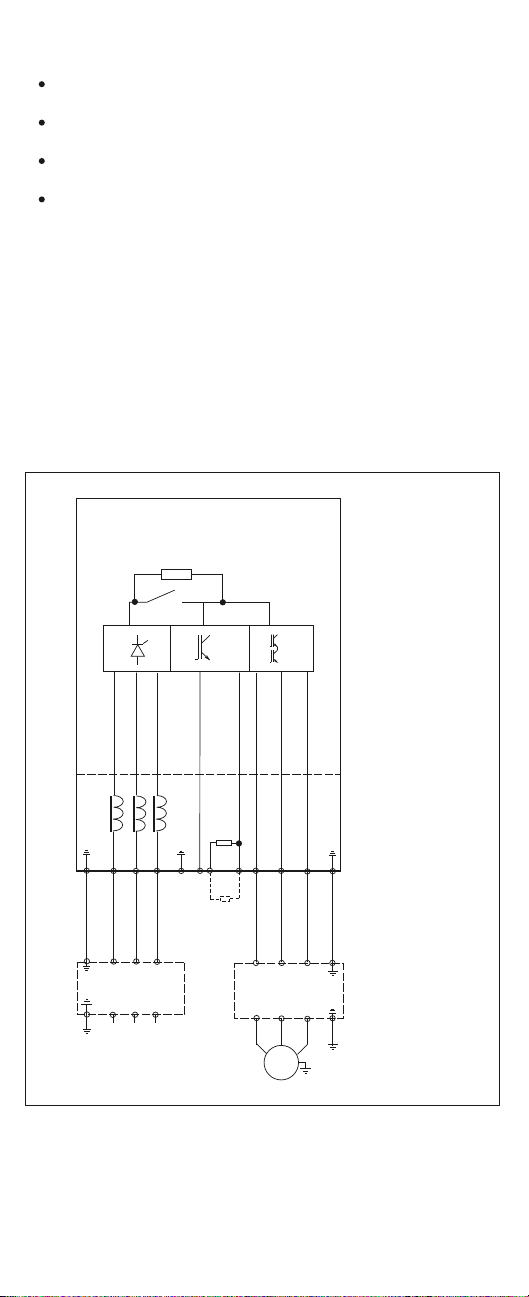

STEP 2

Standard Wiring Diagrams and Terminal Locations

Power and Motor Wiring Terminal Schematic for SVX9000 Drives

Power

Board

230V 1 – 15 hp

480V 1-1/2 – 30 hp

Control

Board

UVW

BR

B+

L3

L1 L2

External

RFI-Filter

(Optional)

L1 L2

L3

B-

(Optional)

BR

R- T1T2T

External

Filter

(Optional)

M

3~

3

SVX9000 Power and Motor Wiring for Low Horsepower Drives (1 – 30 hp)

3 SVX9000 Drives

MN04003009E—November 2011 www.eaton.com

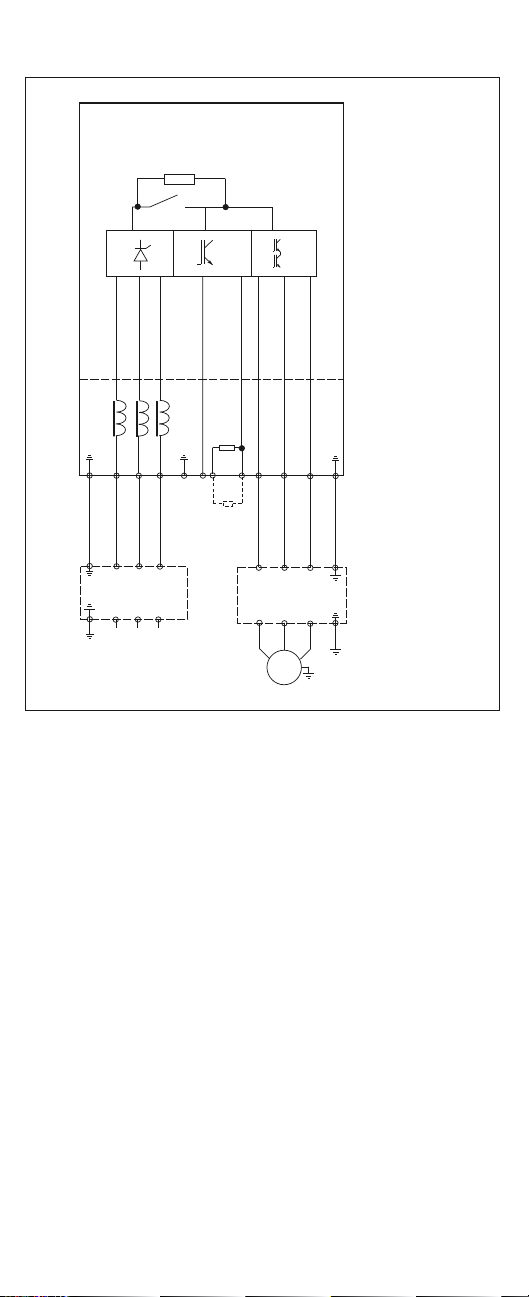

STEP 2 (Continued)

L1 L2

L3 B-

BR

R-

B+

BR

(Optional)

UVW

T1T2T

3

Power

Board

230V 20 – 30 hp

480V 40 – 250 hp

Control

Board

External

RFI-Filter

(Optional)

L3

L1 L2

SVX9000 Power and Motor Wiring for

Large Horsepower Drives (20 – 250 hp)

External

Filter

(Optional)

M

3~

SVX9000 Drives

MN04003009E—November 2011 www.eaton.com

4

STEP 2 (Continued)

Standard Application Default I/O Configuration

Reference

potentiometer

1 – 10 kW

READY

RUN

220V

AC

Terminal Signal Description

OPTA1

1 +10V

2 AI1+ Analog input,

3 AI1- I/O Ground Ground for reference and

4 AI2+ Analog input,

5 AI2-

6 +24V Control voltage

7 GND I/O ground Ground for reference and

8 DIN1 Start forward

9 DIN2 Start reverse

10 DIN3 External

11 CMA Common for DIN1

12 +24V Control voltage

13 GND I/O ground Ground for reference and

14 DIN4 Multi-step speed

15 DIN5 Multi-step speed

Reference output Voltage for potentiometer,

ref

voltage range

0 – 10V DC

etc.

Voltage input frequency

reference

controls

current range

0 – 20 mA

output

Current input frequency

reference

Voltage for switches, etc.

max 0.1A

controls

(programmable)

(programmable)

fault input

(programmable)

– DIN3

output

Contact closed = start forward

Contact closed = start reverse

Contact open

Contact closed = fault

Connect to GND or +24V

Voltage for switches (see #6)

controls

select 1

select 2

DIN4 DIN5 Frequency

Open

Closed

Open

Closed

16 DIN6 Fault reset Contact open = no action

17 CMB Common for DIN4

18 AO1+ Output frequency

mA

19 AO1-

20 DO1 Digital output

– DIN6

Analog output

READY

Contact closed = fault reset

Connect to GND or +24V

Programmable

Range 0 – 20 mA/R

max. 500

Programmable

Open collector, I

U ≤

48V DC

OPTA2

21 RO1 Relay

22 RO1

output 1

RUN

23 RO1

24 RO2 Relay

25 RO2

output 2

FAULT

26 RO2

Note:

For more information on jumper selections, see the

9000X AF Drives User Manual, Chapter 4

Jumper Block X3:

CMA and CMB Grounding

CMB connected to GND

CMA connected to GND

CMB isolated from GND

CMA isolated from GND

CMB and CMA internally connected

together, isolated from GND

Open

Open

Closed

Closed

W

.

= no fault

ref.

Ref.U

Multi-step

ref.1

Multi-step

ref.2

Ref.Iin

,

L

≤ 50 mA,

in

5 SVX9000 Drives

= Factory default.

MN04003009E—November 2011 www.eaton.com

Loading...

Loading...