Reduced Voltage Motor Starters

Run (FLA)

100%

Locked Rotor Torque

Time (Seconds)

Initial

Torque

Run

Max.

Allowed

100%

FLA

Current

Time (Seconds)

1.2

Operation

1

Starting and Stopping Modes

1

The S811 has a variety of starting and stopping methods to provide superior performance in the

most demanding applications. The motor can be started in either voltage ramp start or current

limit start mode. Kick start and soft stop are available within both starting modes.

1

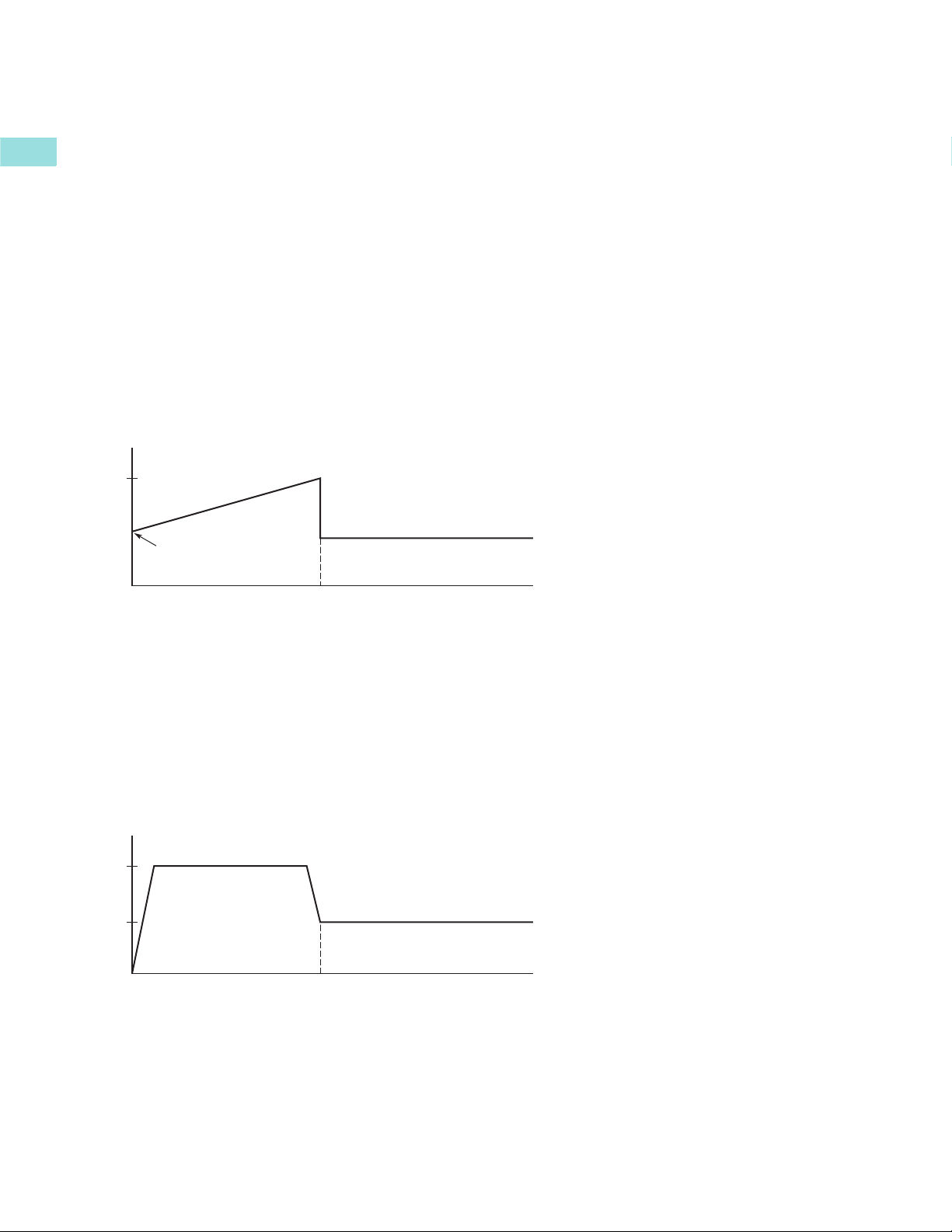

Voltage Ramp Start

1

Provides a voltage ramp to the

motor resulting in a constant

1

torque increase. The most

commonly used form of soft

1

start, this start mode allows

you to set the initial torque

value and the duration of the

1

ramp to full voltage

conditions. Bypass contactors

1

close after ramp time.

1

Starting Characteristics—Ramp Start

1

1

Solid-State Starters

●

Adjustable initial torque

0–85% of locked rotor

torque

●

Adjustable ramp time

0.5–180 seconds (can be

extended with factory

modification)

1

1

1

1

1

Current Limit Start

Limits the maximum current

1

available to the motor during

the start phase. This mode of

soft starting is used when it

1

becomes necessary to limit

the maximum starting current

1

due to long start times or to

protect the motor. This start

1

Starting Characteristics—Current Limit Start

1

1

1

1

1

mode allows you to set the

maximum starting current as a

percentage of locked rotor

current and the duration of the

current limit. Bypass

contactors close after current

limit time.

●

Maximum current of

0–85% locked rotor current

●

Adjustable ramp time

0.5–180 seconds (can be

extended with factory

modification)

1

1

1

1

1

Reduced Voltage Motor Starters

100%

Locked Rotor Torque

Ramp

Time (Seconds)

Kick

Start

Run (FLA)

Ramp

Time (Seconds)

Run

Solid-State Starters

1.2

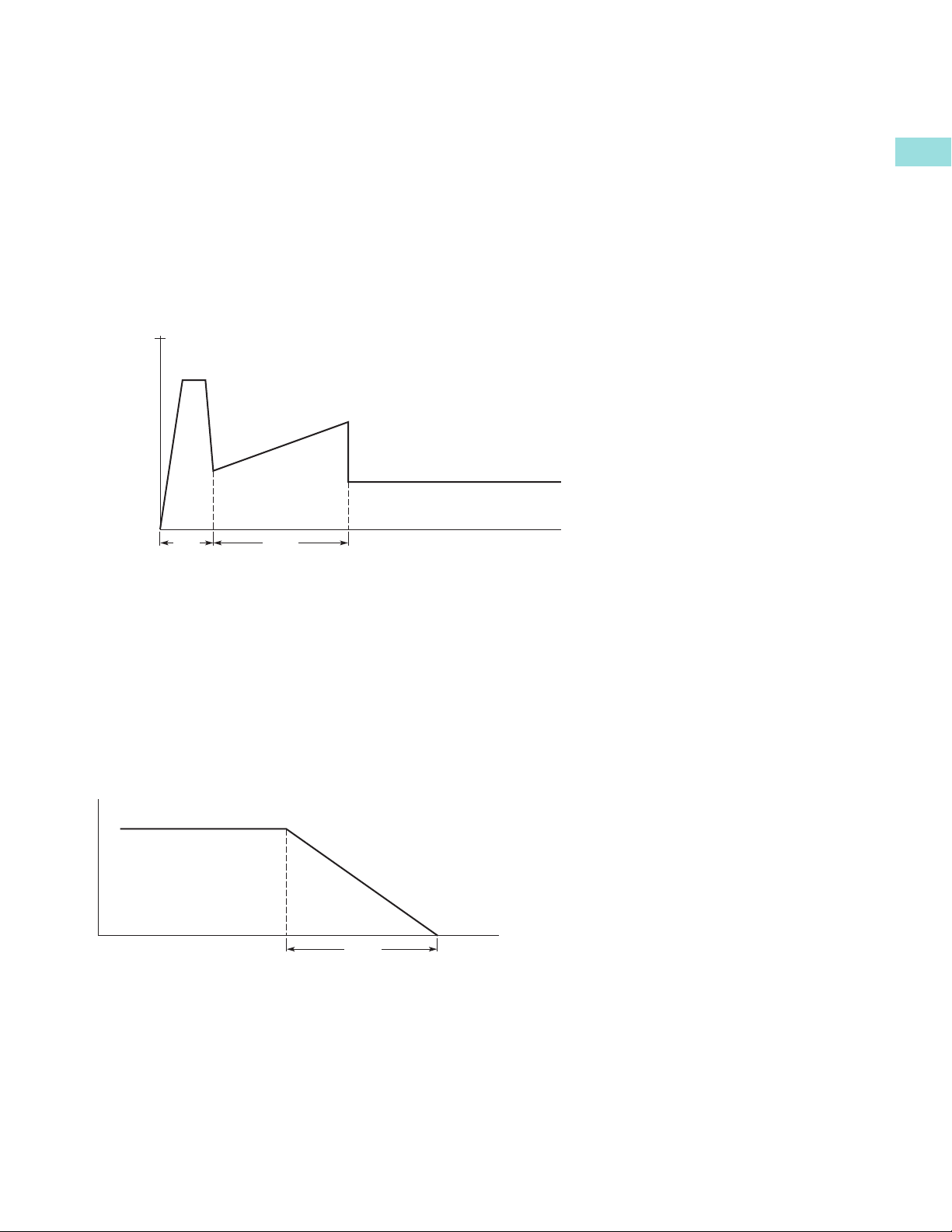

Kick Start

Selectable feature in both

voltage ramp start and

current limit start modes.

Provides a current and torque

“kick” for 0 to 2.0 seconds.

This provides greater initial

current to develop additional

torque to breakaway a high

friction load.

Starting Characteristics—Kick Start

●

●

0–85% of locked rotor

torque

0–2.0 seconds duration

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Soft Stop

Allows for a controlled

stopping of a load. Used

when a stop-time that is

greater than the coast-to-stop

time is desired. Often used

with high friction loads where

a sudden stop may cause

system or load damage.

Starting Characteristics—Soft Stop

●

Stop time = 0–60 seconds

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1.2

Edge and Level Sensing Control

1

Edge Sensing

Edge sensing requires

1

+24 Vdc power be

momentarily applied to Pin 1

1

(with terminal P at +24 Vdc)

to initiate a start under all

1

conditions. After a stop or

fault occurs, the +24 Vdc

must be removed, then

1

reapplied to pin 1 before

another start can occur. This

1

control configuration should

be used when restarting of

1

the motor after a fault or stop

must be supervised manually

1

or as a part of a control

scheme. The cycling of

+24 Vdc power to Terminal 1

1

before starting is required

regardless of the position

1

of the auto reset switch on

the DIM.

1

1

1

Reduced Voltage Motor Starters

Solid-State Starters

Level Sensing

Level sensing will enable a

motor to restart after a fault

is cleared without cycling

+24 Vdc power to Terminal 1

as long as:

●

Terminal P is supplied with

+24 Vdc (to start from

Terminal Block, Input #3

must also be enabled)

●

The auto reset switch on

the DIM is set to enabled

●

All faults have been reset

This control configuration

should be used where it is

desirable to restart a motor

after a fault without additional

manual or automatic control.

An example of this condition

would be on a remote

pumping station where it is

desirable to automatically

restart a pump after a power

outage without operator

intervention.

Note: If the auto reset feature

is used, CAUTION must be

exercised to ensure that any

restart occurs in a safe manner.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Loading...

Loading...