Page 1

PowerXL™

DE1 Variable Speed Starter

Number 1 in efficiency

The easiest way of variable motor speed

NEW

Variation DE11

The new device category!

The PowerXL™ DE1

Variable Speed Starter

Page 2

Why use a variable speed starter? What advantages do variable speed starters have?

Variable speed starters are a new device category that is positioned between conventional motor starters and compact variable

frequency drives. This enables them to combine the advantages of three different device categories at the same time: motor starters,

soft starters, and variable frequency drives.

Advantages:

• Same ease of use as a motor starter.

• Starting current reduced to rated operational current at full torque from the start.

• Variable motor speed.

• Integrated motor protection.

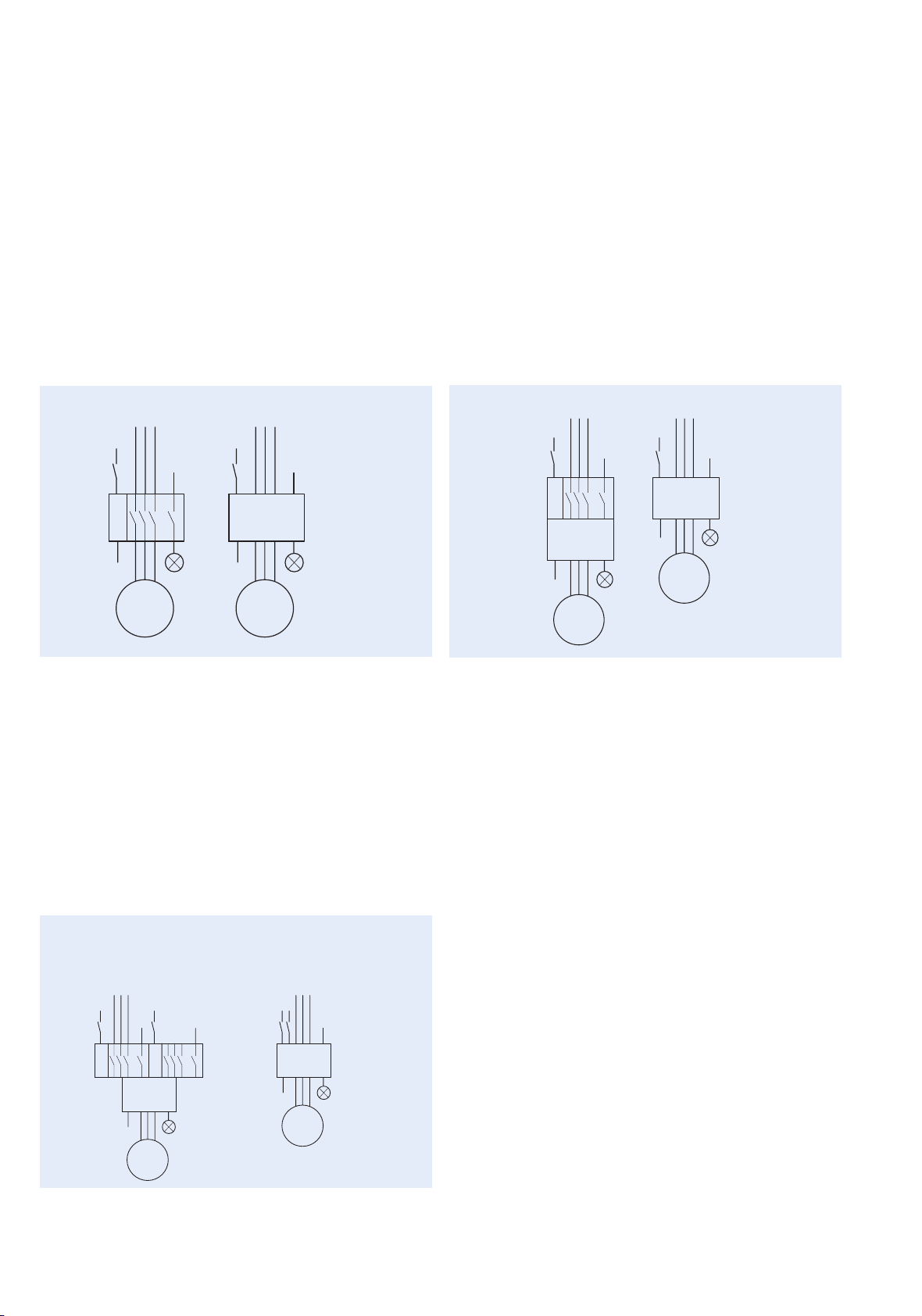

1 to 1 replacement for contactors

Mains

Start/stop

Contactor

Motor

Mains

Start/stop

DE1/DE11

Motor

Variable Speed Starter

• 1 to 1 switch from contactor to DE1

without parameter configuration

• Same low wiring complexity

Plus

• Variable motor speed

• Fixed motor speed at starting current = rated operational

current

• No control voltage circuit required

(already integrated into DE1)

1 to 1 replacement for motor starters/soft starters

Mains

Start/stop

Contactor

Motor Protection

Motor

Mains

Start/stop

DE1/DE11

Motor

Variable Speed Starter

• 1 to 1 switch from motor starter to DE1

without parameter configuration

• Same low wiring complexity

Plus

• Variable motor speed

• Fixed motor speed at starting current = rated operational

current

• No control voltage circuit required

(already integrated into DE1)

• No separate motor protection required

(motor protection integrated into DE1)

1 to 1 replacement for reversing starters/soft starters

Mains Mains

Anti-clockwise Rotation

Clockwise Rotation

DE1/DE11

Variable Speed Starter

Motor

Contactor

3

Clockwise Rotation

Motor Protection

Anti-clockwise Rotation

Motor

EATON PowerXL™ Variable Speed Starter

• 1 to 1 switch from reversing starter to DE1

without parameter configuration

• Same low wiring complexity

Plus

• Variable motor speed

• Fixed motor speed at starting current = rated operational

current

• No control voltage circuit required

(already integrated into DE1)

• No separate motor protection required

(motor protection integrated into DE1)

• No reversing contactor required

(significantly smaller size in terms of width)

Page 3

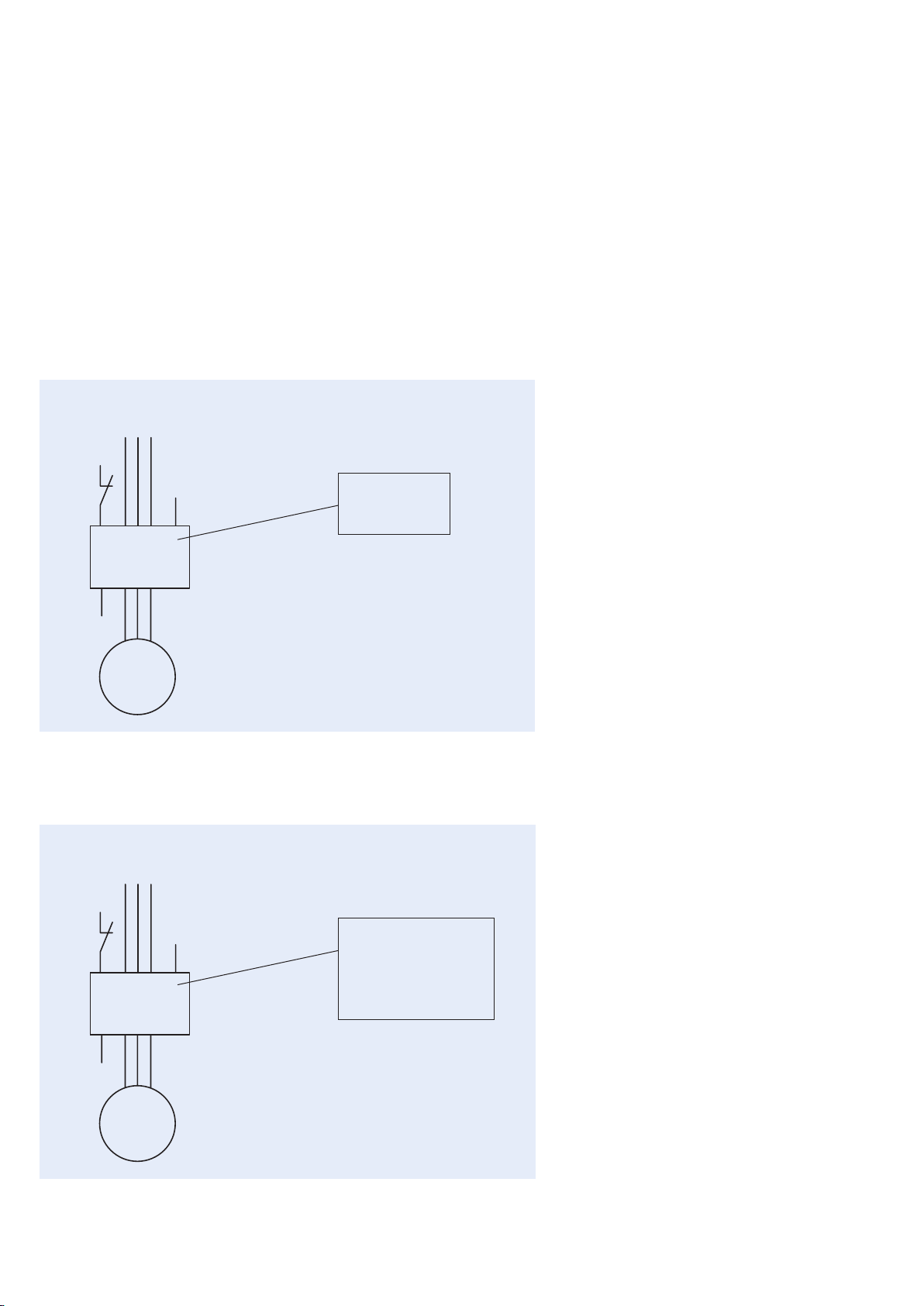

1 to 1 replacement for contactors, motor starters, reversing starters, and soft

Mains

Mains

starters while eliminating the need for control wiring with a control unit

• Start/stop

• Faster

• Slower

• Speed display

Operating unit

via integrated

Release

DE1/DE11

Variable

interface

Speed Starter

Motor

1 to 1 replacement for contactors, motor starters, and reversing starters while

eliminating the need for control wiring with a fieldbus connection

• No control wiring required

• Complete control via control unit

(control panel installation)

Plus

• Variable motor speed

• Fixed motor speed at starting current = rated

operational current

• No control voltage circuit required

(already integrated into DE1)

• No separate motor protection required

• (motor protection integrated into DE1)

• No reversing contactor required (significantly

smaller size in terms of width)

4

Release

DE1/DE11

Variable

Speed Starter

Motor

EATON PowerXL™ Variable Speed Starter

• Start/stop

• Faster

• Slower

• Speed display

CANopen (DE11)

SWD (option module

for DE1 and DE11)

Modbus RTU (standard

DE1 and DE11)

• No control wiring required

• Complete control via control unit (control panel

installation)

Plus

• Variable motor speed

• Fixed motor speed at starting current = rated

operational current

• No control voltage circuit required (already

integrated into DE1)

• No separate motor protection required

(motor protection integrated into DE1)

• No reversing contactor required (significantly

smaller size in terms of width)

Page 4

ENERGY

EFFICIENCY

ENERGY

EFFICIENCY

The PowerXL™ DE1 Variable Speed Starter –

one device, all the advantages

Ease of use and reliability or variable motor speed and improved energy efficiency?

Why not both? Eaton's new device category is closing the gap between

conventional motor starters and variable frequency drives. It combines all the

benefits in one device: The new PowerXL™ DE1 variable speed starter, now

available in version DE11 for machine building applications as well.

Energy efficiency has never been simpler!

Perfectly equipped for the new ErP Directive

To achieve the energy efficiency required by the ErP Directive,

applications with simple functionality such as pumps and fans are

facing increased demands for drive technology with variable motor

speed. Variable frequency drives are designed for more complex

applications and as such require a greater level of expert knowledge.

The new PowerXL™ DE1 Variable Speed Starter takes a different

approach. It helps users to achieve the required energy efficiency

levels for the application at hand by adjusting the motor speed – all

without making mounting or commissioning more complex than for

a conventional motor starter.

The new DE11 version for machine building

applications with expanded features:

• CANopen onboard

• Plug-in control signal terminals

• Configurable relay output

™

So simple:

• Out-of-the-box commissioning

without parameterization

• Trip-free design ensures maximum

machine availability

• As easy to install and use as a motor

starter

• No special drives, engineering skills

or knowledge required

So variable:

• Variable motor speed

• Parameters can be optionally

configured using plug-in configuration

module

• Optional use of the PowerXL

drivesConnect software

• Optional communication via

SmartWire-DT and other accessories

• DE11 version with onboard CANopen

2

DE1 and DE11 (CANopen) variable speed starters from 0.25 to 7.5 kW

EATON PowerXL™ Variable Speed Starter

Page 5

Trip-free design ensures maximum machine availability

No switch-off in borderline situations

Overload, overcurrent, overtemperature or energy recovery -- in real life there are always situations

that can lead into a trip of the drive system or application. The new DE1 Variable Speed Starter

features a trip-free design that automatically prevents tripping in borderline situations. Following

features guarantee a maximum of machine availability:

Auto-Reset, e.g. in case of overload

Various application-related faults such as

overcurrent at blocked rotor or frequent motor

starts are protected by the Variable Speed

Starter. After a relevant trip the DE1 will

optionally restart up to 9 times automatically and

without any manual operation.

DC braking, e.g. for wind tunnel applications

A temporary output of DC voltage will brake the

motor before starting (protection against

overcurrent trips on passively driven motors,

such as on the wind tunnel on ventilation

systems) and stopping.

Extensive motor protection

The DE1 Variable Speed Starter offers internal

motor protection plus direct thermistor motor

protection and short-circuit protection.

DC regulation in the event of imbalance

Automatic brake ramp extension at high inertia

and output frequency boost in case of imbalance

within the application to prevent an overvoltage

trip.

PWM regulation, e.g. in case of high ambient

temperatures

Automatic reduction of the PWM frequency

(switching frequency) in case of high load and/or

high ambient temperatures.

60 ° C without derating

Ambient temperature 60 ° C do not require

derating (for details see chart on page 8)

Commissioning

As easy to use as a motor starter

No special knowledge of drives is required for the new DE1 Variable Speed Starter – either for

installation or commissioning. The compact Variable Speed Starter is as easy and convenient to use

as a conventional motor starter.

The device is unpacked and simply wired like a motor starter – that's it. The DE1 Variable Speed Starter is

ready to go. It couldn't be easier! In addition, the "out-of-the-box comissioning" reduces the chances of

installation faults to a minimum and at the same time it makes installation faster and more cost-efficient!

1 32 4

Snap the Variable Speed Starter on

the DIN-Rail.

Connect mains and motor cables. Wire control terminals.

EATON PowerXL™ Variable Speed Starter

Switch on and the motor runs with

its speed controlled.

5

Page 6

Run

Stat

atus

Run

Status

Run

n

Run

Savings 30 %

The new PowerXL™ DE1

Variable Speed Starter

Parameterization by screwdriver

DXE-EXT-SET (plug-in configuration module)

Beyond the out-of-the-box commissioning that eliminates the

need for parameterization, the user also has the option of using

the plug-in DXE-EXT-SET configuration module to adjust the

default settings of key parameters such as ramp time, motor

protection and control terminal function to fit the current

application. All that is needed is a screwdriver.

Furthermore the DE1 naturally also offers the opportunity to carry

out the parameterization using the external remote device with

LED display, which is part of the PowerXL product portfolio.

Furthermore, the drivesConnect software also keeps the new

Variable Speed Starter easy to use, just like it does for the entire

PowerXL family. The software allows DE1 users the

parameterization or readout via laptop, and to copy parameters

from one drive to another with the parameter copy stick.

Your Connection to the Future

Integration into the innovative SmartWire-DT communication system

The DE1 has an optional Modbus interface and can communicate

to Eaton's innovate SmartWire-DT communication system. For

you, that means efficiency at all levels.

1

EMS Electronic motor starter

2

PKZ Motor-protective circuit-breaker

3

PKE Motor-protective circuit-breaker

4

DS7 Soft starter

5

PowerXL™ DC1 Variable frequency drive

6

PowerXL™ DE1 Variable Speed Starter

Cost reduction with SmartWire-DT

Rely on technology that makes complicated mechanical

engineering processes simple: The intelligent SmartWire-DT

system shifts the I/O level to the bus subscriber. SmartWire-DT

allows for simple and straightforward structures that can be

configured quickly while eliminating the I/O level on PLCs. The data

transparency achieved this way makes diagnostics and

maintenance simpler, cutting the time and resources spent on

wiring, testing and commissioning by up to 85 %.

SmartWire-DT

Conventional solution

2

3

1

4

5

6

Planning /

Engineering

6

EATON PowerXL™ Variable Speed Starter

Material

Wiring Comis-

sioning

Maintenance

Page 7

COST

EFFICIENCY

COST

EFFICIENCY

Saving time and costs

The new PowerXL DE1 Variable Speed Starter compared to conventional variable frequency drives

Comparison 1: Standard wiring via terminals

Time required to parameterize the DE1 Variable Speed Starter vs.

a standard commercial variable frequency drive (e.g. motor potentiometer function)

70 %

Comparison 2: Integration of DE1 into SmartWire-DT vs. standard wiring

Time required for integration of DE1 into SmartWire-DT vs. standard wiring into standard

commercial variable frequency drive

80 %

DE1 Variable Speed Starter Variable frequency drive

time savings

time savings

So simple, so clever

Ideally suited for applications with limited functionality yet needing variable motor speed

The ErP Directive and

the increasing levels of

automation in machines are

pushing the need for variable

frequency drives even for

simple applications. The

DE1 Variable Speed Starter

is the ideal solution in all

cases where a variable motor

speed is required but where

a variable frequency drive

would be too complex and its

expansive functionality would

be definitely oversized.

Applications in which a direct start

is unacceptable for mechanical

reasons or due to the overly high

start-up current, which, however,

do not permit a reduced starting

torque.

Applications in which the motors

have a constant speed, but in which

the frequency does not correspond

to the line frequency (such as

motors at 18,000 rpm).

It is ideally suited even for

fixed speed applications:

• reduced starting current

at full torque

• for constant speed motors,

where the required frequency

does not correspond to

the line frequency (e.g.

high speed motors)

• no thermal overload at a

high frequency of starts

Applications in which a motor

starter is currently being used but

which will need a variable motor

speed going forward to comply

with the EU standards.

Applications in which a simple

variable frequency drive has been

used to date, but for which the

functionality of that drive is too

complex.

EATON PowerXL™ Variable Speed Starter

7

Page 8

Overview of advantages and specifications

Ordering information variable speed starter DE1

Input

voltage

[V]

220 – 240 0.25 0.30 1 220 – 240 3 1.4 IP20_x 1 DE1-121D4FN-N20N* 174327

400 – 480 0.37 0.5 3 400 – 480 3 1.3 IP20_x 1 DE1-341D3FN-N20N 174333 DE1-341D3NN-N20N 177365

Motor

Motor

[kW]

0.37 0.5 1 220 – 240 3 2.3 IP20_x 1 DE1-122D3FN-N20N* 174328

0.55 0.5 1 220 – 240 3 2.7 IP20_x 1 DE1-122D7FN-N20N 174329 DE1-122D7NN-N20N 177361

0.75 0.75 1 220 – 240 3 4.3 IP20_x 1 DE1-124D3FN-N20N 174330 DE1-124D3NN-N20N 177362

1.50 2 1 220 – 240 3 7.0 IP20_x 1 DE1-127D0FN-N20N 174331 DE1-127D0NN-N20N 177363

2.20 3 1 220 – 240 3 9.6 IP20_x 2 DE1-129D6FN-N20N 174332 DE1-129D6NN-N20N 177364

0.75 1 3 400 – 480 3 2.1 IP20_x 1 DE1-342D1FN-N20N 174334 DE1-342D1NN-N20N 177366

1.50 2 3 400 – 480 3 3.6 IP20_x 1 DE1-343D6FN-N20N 174335 DE1-343D6NN-N20N 177367

2.20 3 3 400 – 480 3 5.0 IP20_x 2 DE1-345D0FN-N20N 174336 DE1-345D0NN-N20N 177368

3.00 3 3 400 – 480 3 6.6 IP20_x 2 DE1-346D6FN-N20N 174337 DE1-346D6NN-N20N 177369

4.00 5 3 400 – 480 3 8.5 IP20_x 2 DE1-348D5FN-N20N 174338 DE1-348D5NN-N20N 177370

5.50 7.5 3 400 – 480 3 11.3 IP20_x 2 DE1-34011FN-N20N 174339 DE1-34011NN-N20N 177371

7.50 10 3 400 – 480 3 16.0 IP20_x 2 DE1-34016FN-N20N** 174340

[HP]

Input

phases

Output

voltage

Output

phases

Output

current

[A]

Degree

of pro-

tection

Size Part no.

selection with

EMC filter

Article no. Part no.

selection without

EMC filter

DE1-121D4NN-N20N*

DE1-122D3NN-N20N*

DE1-34016NN-N20N**

Article no.

177359

177360

177372

* no horizontal installation

** >50 ° C derating

Ordering information variable speed starter DE11

Input

voltage

220 – 240 0,25 0,3 1 220 – 240 3 1,4 IP20 1 DE11-121D4FN-N20N* 180650 DE11-121D4NN-N20N* 180656

400 – 480 0,37 0,5 3 400 – 480 3 1,3 IP20 1 DE11-341D3FN-N20N 180662 DE11-341D3NN-N20N 180670

[V]

Motor

Motor

[HP]

Input

phases

[kW]

0,37 0,5 1 220 – 240 3 2,3 IP20 1 DE11-122D3FN-N20N* 180651 DE11-122D3NN-N20N* 180657

0,55 0,5 1 220 – 240 3 2,7 IP20 1 DE11-122D7FN-N20N 180652 DE11-122D7NN-N20N 180658

0,75 0,75 1 220 – 240 3 4,3 IP20 1 DE11-124D3FN-N20N 180653 DE11-124D3NN-N20N 180659

1,50 2 1 220 – 240 3 7,0 IP20 1 DE11-127D0FN-N20N 180654 DE11-127D0NN-N20N 180660

2,20 3 1 220 – 240 3 9,6 IP20 2 DE11-129D6FN-N20N 180655 DE11-129D6NN-N20N 180661

0,75 1 3 400 – 480 3 2,1 IP20 1 DE11-342D1FN-N20N 180663 DE11-342D1NN-N20N 180671

1,50 2 3 400 – 480 3 3,6 IP20 1 DE11-343D6FN-N20N 180664 DE11-343D6NN-N20N 180672

2,20 3 3 400 – 480 3 5,0 IP20 2 DE11-345D0FN-N20N 180665 DE11-345D0NN-N20N 180673

3,00 3 3 400 – 480 3 6,6 IP20 2 DE11-346D6FN-N20N 180666 DE11-346D6NN-N20N 180674

Output

voltage

Output

phases

Output

current

[A]

Degree

of pro-

tection

Size Part no.

selection with

EMC filter

Article no. Part no.

selection without

EMC filter

Article no.

4,00 5 3 400 – 480 3 8,5 IP20 2 DE11-348D5FN-N20N 180667 DE11-348D5NN-N20N 180675

5,50 7,5 3 400 – 480 3 11,3 IP20 2 DE11-34011FN-N20N 180668 DE11-34011NN-N20N 180676

7,50 10 3 400 – 480 3 16,0 IP20 2 DE11-34016FN-N20N** 180669 DE11-34016NN-N20N** 180677

* no horizontal installation

** >50 ° C derating

8

EATON PowerXL™ Variable Speed Starter

Page 9

⌀1

⌀2

Technical Data

Supply voltage 1 AC 230 V / 3 AC 400/480 V

Line frequency 50/60 Hz ± 10 %

Overload 150 %

Output frequency 0…300 Hz

Switching frequency 1~: 4/8/12/16/24/32 kHz

3~: 10/12/14/16/18/20kHz

Mounting DIN, mounting plate, side-by-side

horizontal (90°)*

EMC C1 5m* , C2 10m, C3 25m

Leakage current < 3.5 mA AC / 10 mA DC

Short-circuit resistence Yes

Altitude 2000 m (derating above 1000 m)

Ambient temperature 60 ° C (For details see table on page 8)

Enclosure IP 20 / NEMA 0

International standards

c

*) Details see table on page 8

**) Only DE1-12..

Relay outputs 1 Configurable in DE11

Voltage 230 V AC / 30 V DC

Current AC1 / DC1 6A/5A

Number of input terminals 4

Analog input

Resolution 12-bit

Voltage 0–10 V, (0) 4–20 mA

Energy consumption at 10 V 0.12 mA

Digital input

High level 9…30 V

Energy consumption at 10/24 V 1.15/3 mA

Maximum load for the internal 10-V

20 mA

power supply

Accessory Articles

PowerXL™ selection aid

This selection aid can be used to quickly select the drive required for your application and the corresponding switchgear, protective

devices, chokes, and filters.

Description Part no. Article no. Description Part no. Article no. Description Part no. Article no.

DE1 parameterization module

Dimensions

[mm (in)]

DXE-EXT-SET 174621 Parameter copy stick DX-COM-STICK 169134 Remote display DX-KEY-LED 169132

b2

⌀

L2/N

L1/L

L3

b

b1

b4 b3

0 V +10 V

2 3 4

1

13 14

W

U

V

a1

a

c1

c

a a1 b b1 b2 b3 b4 c c1 Ø1 Ø2 kg (lbs)

FS1 45 (1.77) 25 (0.98) 230 (9.06) 220 (8.88) 5 (0.2) 64 (2.52) 166 (6.54) 168 (6.61) 6.5 (0.26) 5.1 (0.2) 10 (0.39) 1.04 (2.29)

FS2 90 (3.54) 50 (1.97) 230 (9.06) 220 (8.66) 5 (0.2) 64 (2.52) 166 (6.54) 168 (6.61) 6.5 (0.26) 5.1 (0.2) 10 (0.39) 1.68 (3.7)

EATON PowerXL™ Variable Speed Starter

9

Loading...

Loading...