M-Max Series

adjustable frequency drive

Quick start guide

Effective February 2010

Supersedes June 2009

M-Max Series adjustable frequency drive

February 2010

Important notice—please read

The product discussed in this literature is subject to terms and conditions outlined in Eaton

selling policies. The sole source governing the rights and remedies of any purchaser of this

equipment is the relevant Eaton selling policy.

NO WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OF FITNESS FOR

A PARTICULAR PURPOSE OR MERCHANTABILITY, OR WARRANTIES ARISING FROM

COURSE OF DEALING OR USAGE OF TRADE, ARE MADE REGARDING THE INFORMATION,

RECOMMENDATIONS AND DESCRIPTIONS CONTAINED HEREIN. In no event will Eaton be

responsible to the purchaser or user in contract, in tort (including negligence), strict liability

or otherwise for any special, indirect, incidental or consequential damage or loss whatsoever,

including but not limited to damage or loss of use of equipment, plant or power system, cost

of capital, loss of power, additional expenses in the use of existing power facilities, or claims

against the purchaser or user by its customers resulting from the use of the information,

recommendations and descriptions contained herein.

The information contained in this manual is subject to change without notice.

Cover Photo: Eaton’s M-Max Series adjustable frequency drive.

MN04020002E

For more information visit: www.eaton.com

i

M-Max Series adjustable frequency drive

Table of contents

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

List of Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety

Definitions and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Hazardous high voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Danger and dangerous electrical voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Before commencing the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

M-Max Series

About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Notes about the M-Max product enhancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Writing conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Rated operational data on the nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Mains voltages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Technical Data

Control signal terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operation

Checklist for commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hazard warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Error and Warning Messages

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Acknowledge fault message (Reset) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fault log (FLT) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarm messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Parameters

Control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Display unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

General information on menu navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Setting parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Parameter menu (PAR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Quick start wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Example: Motor parameters (P7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

List of parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Quick configuration (basis) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

All Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

February 2010

ii

For more information visit: www.eaton.com

MN04020002E

February 2010

List of figures

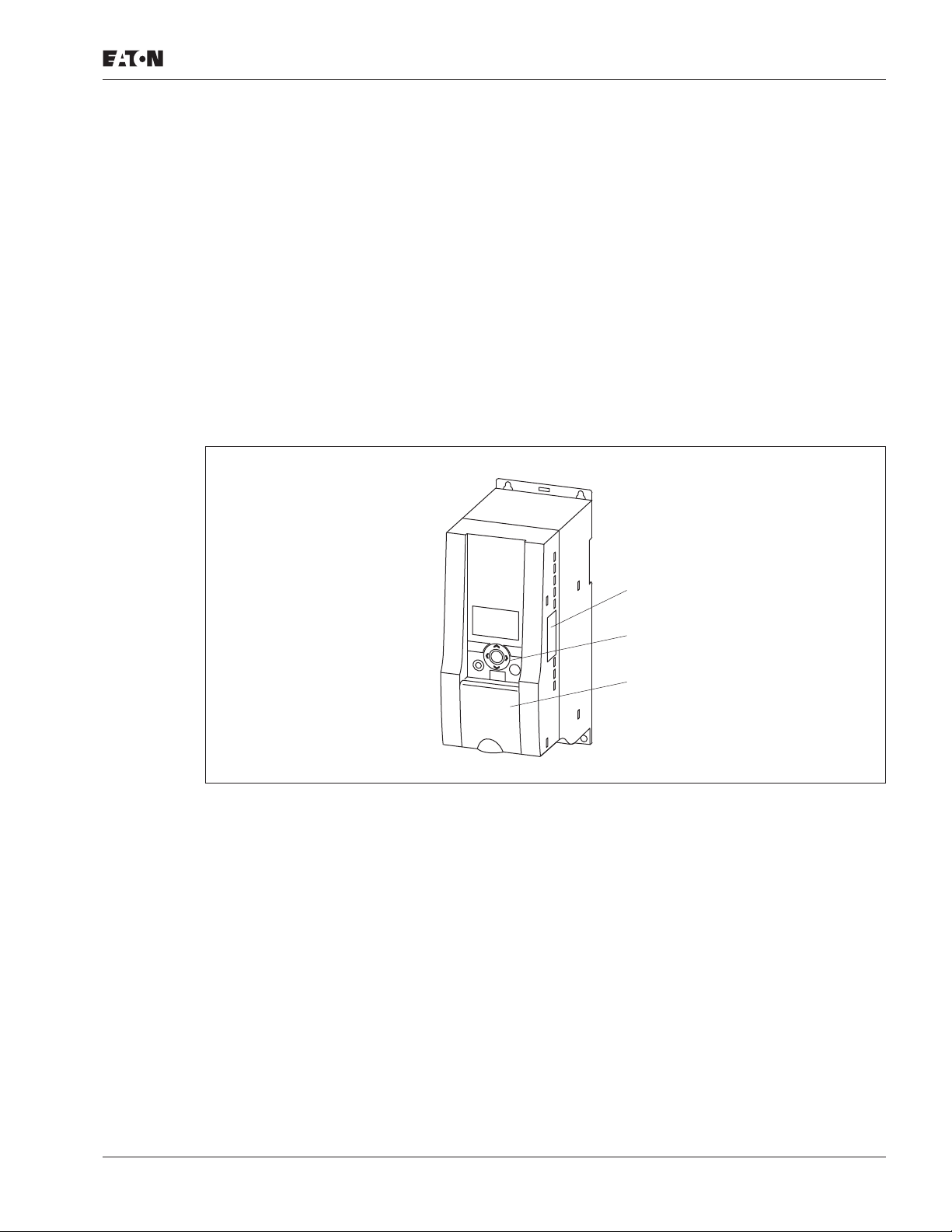

Figure 1: M-Max Series Adjustable Frequency Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

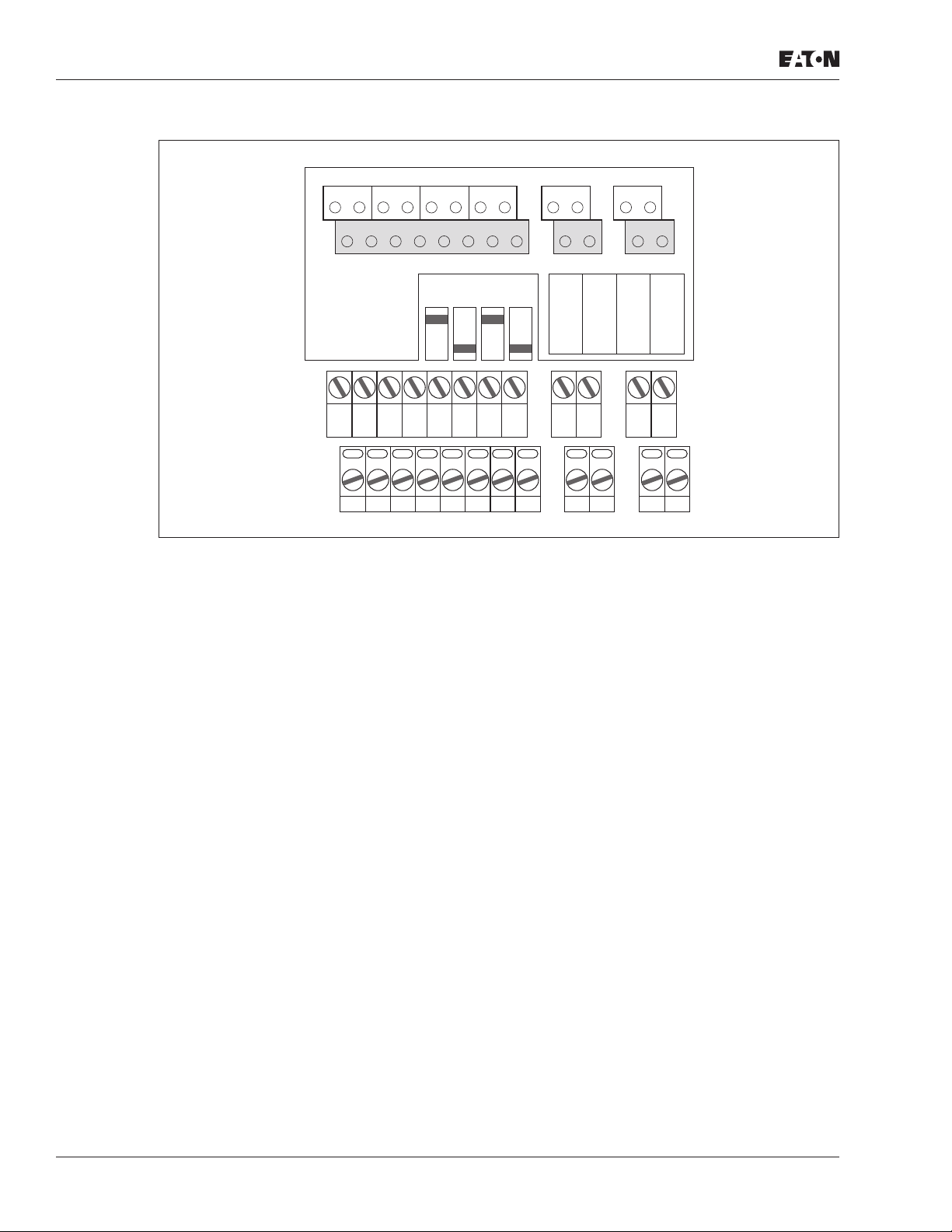

Figure 2: Control Signal Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

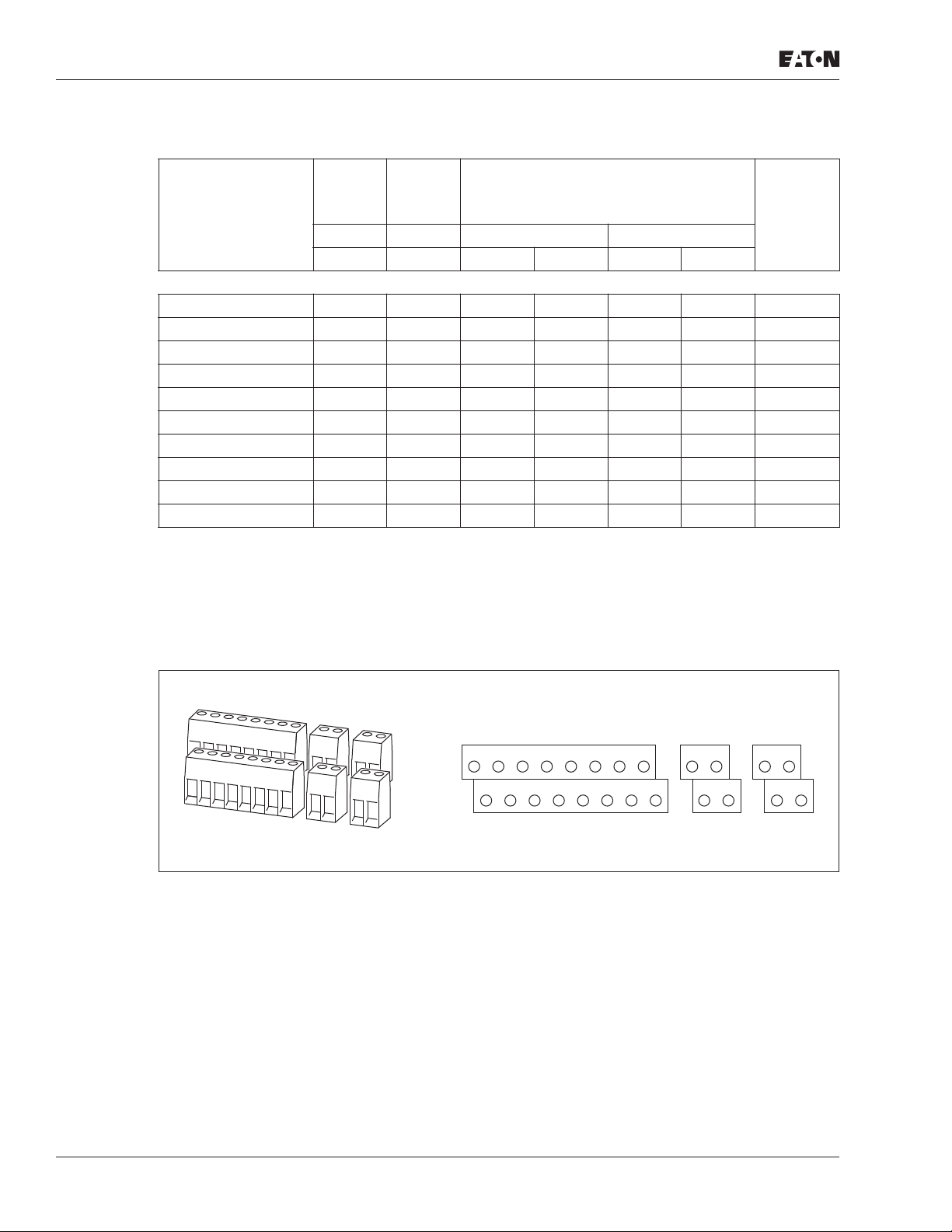

Figure 3: Schematic Arrangement and Designation of Control Signal Terminals . . . . . . . . 8

Figure 4: Block Diagram MMX11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Figure 5: MMX12 Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Figure 6: Block Diagram MMX32 and MMX34 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Figure 7: Error Message Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Figure 8: Example of an Alarm Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Figure 9: View: Control Unit With LCD Display, Function Keys, and Interface . . . . . . . . . . . 20

Figure 10: LCD Display (Areas) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Figure 11: Operational Data Indicator (Operational) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 12: Parameter Menu (P1.1 = 1, Quick-Configuration) . . . . . . . . . . . . . . . . . . . . . . . . . 26

Figure 13: Schematic Representation of Parameter Access. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 14: Motor Parameters From Ratings Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 15: Circuits (Delta, Star) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

M-Max Series adjustable frequency drive

List of tables

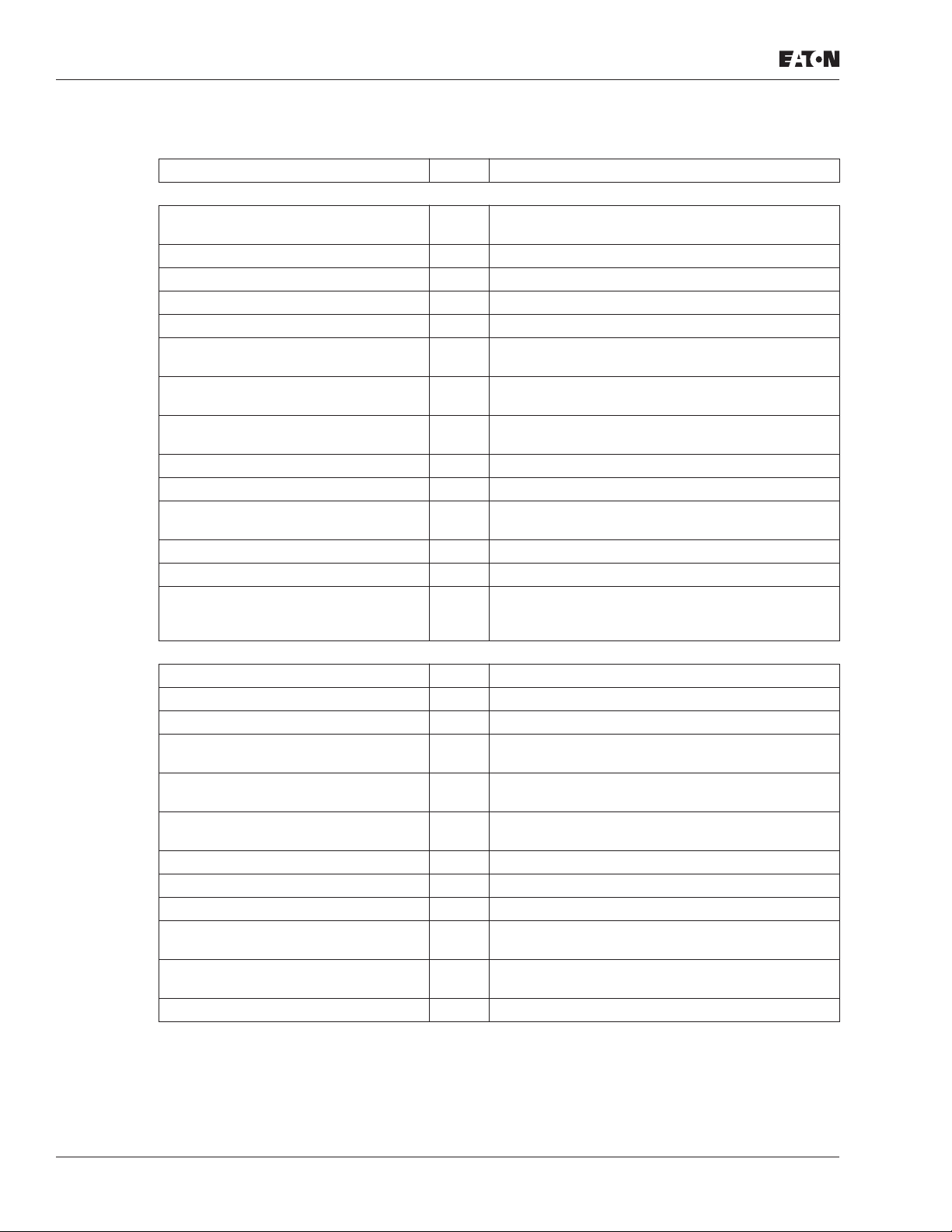

Table 1: Nameplate Inscriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Table 2: General Rated Operational Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Table 3: Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

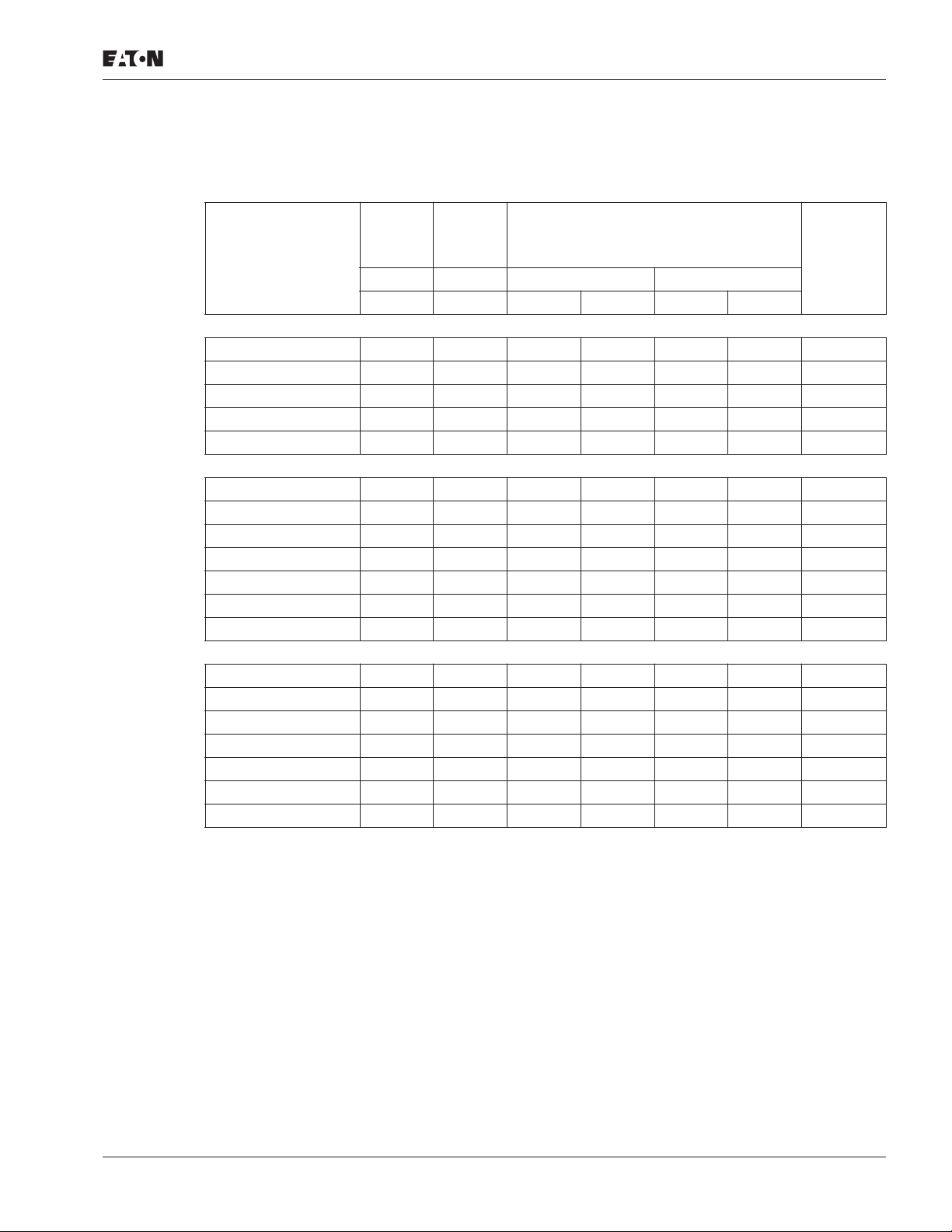

Table 4: Cable Cross Section (Cu): 0.5 – 1.5 mm

Table 5: List of Fault Messages (F) and Warning Messages (AL). . . . . . . . . . . . . . . . . . . . . . 18

Table 6: Control Unit Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Table 7: Areas of the LCD Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Table 8: LCD Display in Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Table 9: Quick Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Table 10: Predefined Application Parameters From Parameter P1.2 . . . . . . . . . . . . . . . . . . . 32

Table 11: All Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

MN04020002E

For more information visit: www.eaton.com

iii

M-Max Series adjustable frequency drive

Safety

Definitions and symbols

This symbol indicates high voltage. It calls your attention to items

or operations that could be dangerous to you and other persons

operating this equipment. Read the message and follow the

instructions carefully.

This symbol is the “Safety Alert Symbol.” It occurs with either of

two signal words: CAUTION or WARNING, as described below.

February 2010

VOLTAGE

WARNING

Indicates a potentially hazardous situation which, if not avoided,

can result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided,

can result in minor to moderate injury, or serious damage to the

product. The situation described in the CAUTION may, if not

avoided, lead to serious results. Important safety measures are

described in CAUTION (as well as WARNING).

Hazardous high voltage

Motor control equipment and electronic controllers are connected

to hazardous line voltages. When servicing drives and electronic

controllers, there may be exposed components with housings or

protrusions at or above line potential. Extreme care should be taken

to protect against shock.

Stand on an insulating pad and make it a habit to use only one

hand when checking components. Always work with another

person in case an emergency occurs. Disconnect power before

checking controllers or performing maintenance. Be sure

equipment is properly grounded. Wear safety glasses whenever

working on electronic controllers or rotating machinery.

CAUTION

VOLTAGE

iv

For more information visit: www.eaton.com

MN04020002E

February 2010

Cautions and notices

Read this manual thoroughly and make sure you understand the procedures before you

attempt to install, set up, or operate Eaton’s M-Max Series adjustable frequency drive.

Cautions

Notices

M-Max Series adjustable frequency drive

CAUTION

Be ABSOLUTELY sure not to connect two functions to one and

same output in order to avoid function overruns and to ensure

flawless operation.

CAUTION

The calculated model does not protect the motor if the airflow to

the motor is reduced by blocked air intake grill.

The inputs , unlike the outputs , cannot be changed in RUN state.

Danger and dangerous electrical voltage

Before commencing the installation

Disconnect the power supply of the device.

Ensure that devices cannot be accidentally restarted.

Verify isolation from the supply.

Earth and short circuit the device.

Cover or enclose any adjacent live components.

Follow the engineering instructions IL04020001E for the device

concerned.

Only suitably qualified personnel in accordance with EN 50110-1/-2

(VDE 0105 Part 100) may work on this device/system.

Before installation and before touching the device, ensure that you

are free of electrostatic charge.

The functional earth (FE, PES) must be connected to the protective

earth (PE) or the potential equalization. The system installer is

responsible for implementing this connection.

Notice

MN04020002E

Connecting cables and signal lines should be installed so that

inductive or capacitive interference does not impair the automation

functions.

Install automation devices and related operating elements in such a

way that they are well protected against unintentional operation.

For more information visit: www.eaton.com

v

M-Max Series adjustable frequency drive

Suitable safety hardware and software measures should be

implemented for the I/O interface so that an open circuit on the

signal side does not result in undefined states in the automation

devices.

Ensure a reliable electrical isolation of the extra-low voltage of the

24V supply. Only use power supply units complying with IEC 603644-41 (VDE 0100 Part 410) or HD384.4.41 52.

Deviations of the mains voltage from the rated value must not

exceed the tolerance limits given in the specifications, otherwise

this may cause malfunction and dangerous operation.

Emergency stop devices complying with IEC/EN 60204-1 must be

effective in all operating modes of the automation devices.

Unlatching the emergency-stop devices must not cause a restart.

Devices that are designed for mounting in housings or control

cabinets must only be operated and controlled after they have been

installed and with the housing closed. Desktop or portable units

must only be operated and controlled in enclosed housings.

February 2010

Measures should be taken to ensure the proper restart of programs

interrupted after a voltage dip or failure. This should not cause

dangerous operating states even for a short time. If necessary,

emergency-stop devices should be implemented.

Wherever faults in the automation system may cause injury or

material damage, external measures must be implemented to

ensure a safe operating state in the event of a fault or malfunction

(for example, by means of separate limit switches, mechanical

interlocks, etc.).

Depending on their degree of protection, frequency inverters may

contain live bright metal parts, moving or rotating components, or

hot surfaces during and immediately after operation.

Removal of the required covers, improper installation or incorrect

operation of motor or frequency inverter may cause the failure of

the device and may lead to serious injury or damage.

The applicable national accident prevention and safety regulations

apply to all work carried on live frequency inverters.

The electrical installation must be carried out in accordance with

the relevant regulations (e.g., with regard to cable cross sections,

fuses, PE).

Transport, installation, commissioning and maintenance work must

be carried out only by qualified personnel (IEC 60364, HD 384 and

national occupational safety regulations).

vi

Installations containing frequency inverters must be provided with

additional monitoring and protective devices in accordance with

the applicable safety regulations. Modifications to the frequency

inverters using the operating software are permitted.

For more information visit: www.eaton.com

MN04020002E

February 2010

M-Max Series adjustable frequency drive

MN04020002E

For more information visit: www.eaton.com

vii

M-Max Series adjustable frequency drive

February 2010

viii

For more information visit: www.eaton.com

MN04020002E

February 2010

M-Max Series

About this manual

Notes about the M-Max Series product enhancement

This third edition of the quick reference guide describes the extended functionality (as of

production date January 2010, see Figure 1 ) of the M-Max Series of adjustable frequency drives

Key features of this enhancement are:

●

New controller board with a higher-performance microprocessor

●

Field bus interfaces on device side

Two additional control keys

●

●

Extended functionality of the digital and analog inputs and outputs

M-Max Series adjustable frequency drive

.

B

A

C

K

RESE

T

L

O

C

REM

OK

I

Figure 1: M-Max Series Adjustable Frequency Drive

MN04020002E

For more information visit: www.eaton.com

1

M-Max Series adjustable frequency drive

February 2010

AI2

GND DO–

4 5 13 14 15 16 18 20 22 23 26

12367

+ 10V AI1 GND

DI4 DI5 DI6 AO DO+

9

8

24V

Dl-C

DI1 DI2 DI3 A

R13

R14 – R24

10 25

B R21 R22

AJ 1

– +

LOGIC

AJ 2

V mA

24

V mA

RS 485

Term

Figure 2: Control Signal Terminals

This quick reference guide contains selected information about the M-Max Series adjustable

frequency drives.

This quick reference guide is a summary of manual MN04020001E and contains technical

data, parameter lists and information about operating the adjustable frequency drives. It is

intended to support experienced, qualified users in the use of the M-Max Series adjustable

frequency drive.

It is assumed that you have thoroughly read manual MN04020001E and that the adjustable

frequency drive has been correctly installed and commissioned as described in manual

MN04020001E and installation instructions IL04020001E.

2

For more information visit: www.eaton.com

MN04020002E

February 2010

Writing conversions

The symbols used in this manual have the following meanings:

Indicates instructions to be followed

!

M-Max Series adjustable frequency drive

Indicates useful tips and additional information.

Caution!

warns of the risk of material damage.

Warning!

Warns about the possibility of serious property damage and minor injuries.

Danger!

Warns about the possibility of major property damage and serious injuries or death.

In order to make it easier to follow the manual, the name of the current chapter is shown

in the header of the left-hand page and the name of the current section is shown in the

header of the right-hand page. This does not apply to pages at the start of a chapter or to

empty pages at the end of a chapter.

In order to make it easier to understand some of the figures included in this manual, the

housing of the adjustable frequency drive, as well as other safety-relevant parts, have

been left out. However, it is important to note that the adjustable frequency drive must

only be operated with its housing placed properly, as well as with all required safetyrelevant parts.

All the specifications in this manual refer to the hardware and software versions

documented in it.

For more detailed indications and explanations on project planning, installation, and

parameter configuration, please consult manual

The complete documentation for the M-Max Series of frequency converters is stored

electronically on a CD-ROM. This CD-ROM is part of the scope of supply.

Additional information on the series described here can be found on the Internet under:

www.eaton.com/M-Max

MN04020001E

MN04020002E

For more information visit: www.eaton.com

3

M-Max Series adjustable frequency drive

Rated operational data on the nameplate

The device-specific rated operational data for M-Max Series adjustable frequency drives

is shown on the nameplate on the device's side and on the back of the control signal

terminal cover.

The inscription of the nameplates has the following meaning (example):

Table 1: Nameplate Inscriptions

Label Meaning

February 2010

MMX34AA3D3F0-0 Part no.:

Input Power connection rating:

Output Load side (motor) rating:

Power Assigned motor rating

S/N Serial number

IP20/Open Type Degree of protection of the enclosure: IP20,

40W09 Manufacturing date

MMX = M-Max Series adjustable frequency drive

3 = Three-phase power connection

4 = 400V voltage category

AA = Instance (Software version A and alphanumerical display)

3D3 = 3.3A rated current (3-decimal-3)

F = Integrated radio interference suppression filter

0 = IP20 protection class

0 = No integrated optional assembly

Three-phase AC voltage (U

380 – 480V voltage, 50/60 Hz frequency, input phase current (4.0A)

Three-phase AC voltage (0 – U

frequency (0 – 320 Hz)

1.1 kW at 400 V/1.5 hp at 460V for a four-pole internally cooled or

surface-cooled three-phase asynchronous motor

(1500 rpm at 50 Hz/ 1800 rpm at 60 Hz)

Adjustable frequency drive is an electrical apparatus.

Read the manual (in this case

electrical connections and commissioning.

UL (cUL ) Open type

Calendar week 40 of the year 2009

3~ AC),

e

), output phase current (3.3A), output

e

MN04020001E

) before making any

Mains voltages

The given rated operational voltages in Table 2 are based on the standardized rated values in

centrally earthed star networks.

In ring-type networks (e.g., Europe) the rated voltage corresponds the value of the consumer

networks (e.g., 230V, 400V) at the utility company’s transfer point.

In star-type mains (e.g., North America) the rated voltage at the utility company’s transfer

point is higher than in the consumer network. For example: 120V 115V, 240V 230V,

480V 460V.

4

For more information visit: www.eaton.com

MN04020002E

February 2010

M-Max Series adjustable frequency drive

Table 2:

General Rated Operational Data

Technical data Unit Value

General

Standards and regulations EMC: IEC/EN 61800-3,

Safety: IEC/EN 61800-5, UL 508C

Certifications and manufacturer’s

declarations on conformity

EMC: CE, CB, c-Tick

Safety: CE, CB, UL, cUL, phenum rated

Production quality RoHS, ISO 9001

Climatic proofing < 95%, average relative humidity,

noncondensing (EN 50178)

Air quality

Chemical vapors IEC 721-3-3: Device in operation, Class 3C2

Mechanical particles IEC 721-3-3: Device in operation, Class 3S2

Ambient temperature

Operation ºC –10 to +50

Storage ºC –40 to +70

Installation altitude H 0 – 1000m above sea level, over 1000m with 1%

power reduction per 100m, maximum 2000m,

at maximum +50ºC ambient temperature.

2000m maximum for corner grounded device,

4500m for non-corner grounded device

Mounting position Vertical (± 90 degrees lateral rotation)

Protection type IP20

Busbar tag shroud BGV A3 (VBG4, finger and back-of-hand safe)

Overvoltage category/degree of

—

pollution

Mechanical shock resistance IEC 68-2-27

Storage and transport: 15g, 11 ms

(in the packaging)

UPS drop test (for applicable UPS weights)

Vibration EN 60068-2-6

3 – 150 Hz, oscillation amplitude 1 mm (Peak)

at 3 – 15.8 Hz, maximum acceleration amplitude 1g

at 15.8 – 150 Hz

Emitted interference with internal EMC

filter (maximum motor cable length)

C2: Class A in 1st environment (residential area with

commercial utilization)

C3: Class A in 2nd environment (Industrial)

MMX11 C2 (5m), C3 (30m)

MMX12, MMX32 C2 (5m), C3 (30m)

MMX34 C2 (5m), C3 (30m)

Power Section

Rated operational voltage at 50/60 Hz ±10 %

MMX11 U

MMX12 U

MMX32 U

MMX34 U

e

e

e

e

1 AC 115V (110V – 15% ... 120V + 10%)

1 AC 230V (208V – 15% ... 240V + 10%)

3 AC 230V (208V – 15% ... 240V + 10%)

3 AC 400V (380V – 15% ... 480V + 10%)

MN04020002E

For more information visit: www.eaton.com

5

M-Max Series adjustable frequency drive

Table 2: General Rated Operational Data (continued)

Technical data Unit Value

Power Section (continued)

Mains network configuration

(AC power supply network)

Mains switch-on frequency Maximum one time per minute

Mains current THD >120%

Short-circuit current max. < 50 kA

Mains frequency f

Pulse frequency (switching frequency

of the inverter)

Operating mode V/Hz-characteristic curve control (WE), sensorless

Output voltage U

Output frequency f

Frequency resolution (set point value) Hz 0.01

Rated operational current I

Overload current 150% for 60s every 600s

Starting current 200% for 2s every 20s

Braking torque Maximum 30% M

Control Section

Control voltage (output) V DC 24, max. 50 mA

Reference voltage (output) V DC 10, max. 10 mA

Input, digital, parameter definable 6 x, max. +30 Vdc, R

Permitted residual ripple with external

control voltage (+24V)

Input, analog, parameter definable

Resolution

Output, analog, parameter definable 1 x 0 – 10 Vdc, max. 10 mA

Resolution Bit 10

Output, digital, parameter definable 1 x Transistor, max. 48 Vdc, max. 50 mA

Output relay, parameter definable 1 x N/O 250 Vac maximum 2A/250 Vdc,

Output relay, parameter definable 1 x C/O 250 Vac maximum 2A/250 Vdc,

Serial interface RS-485/Modbus RTU

With MMX34AA014F0-0, the maximum permitted ambient temperature is limited to +40 ºC

and the maximum pulse frequency (f

PWM

) to 4 kHz.

Center-point grounded star network (TN-S network)

Phase grounded AC networks are not permitted.

LN

f

PWM

50/60 Hz (45 – 66 Hz ±0%)

1 kHz – 16 kHz (WE: 6 kHz)

vector control (open loop)

2

2

e

3 AC 230V (MMX11), 3 AC U

(MMX12, MMX32, MMX34)

0 – 320 Hz (WE: 0 – 50 Hz)

100% continuous current at maximum +50ºC

ambient temperature

up to maximum 100% M

MMX34…4D3... with external braking resistance

Max. 5% U

2 x 0 – +10 Vdc , R

R

Bit 10

maximum 0.4A

maximum 0.4A

~ 200

B

ohm

/U

a

for all sizes

N

> 12k ohm

i

a

> 200k

i

e

only as of size

N

ohm /0 (4) – 20 mA,

February 2010

6

For more information visit: www.eaton.com

MN04020002E

February 2010

Technical Data

Table 3: Technical Data

Part Number

Power Connection Voltage: 1 AC 115V, 50/60 Hz (94 – 132V ± 0%, 45 – 66 Hz ± 0%)

MMX11AA1D7.... 1.7 2.6 0.25 1.4 1/3

MMX11AA2D4.... 2.4 3.6 0.37 2.0 1/2 2.2 FS2

MMX11AA2D8.... 2.8 4.2 0.55 2.7 3/4 2.2 FS2

MMX11AA3D7.... 3.7 5.6 0.75 3.2 1 3.2 FS2

MMX11AA4D8.... 4.8 7.2 1.10 4.6 1-1/2 4.2 FS3

Power Connection Voltage: 1 AC 230V, 50/60 Hz (177 – 264V ± 0%, 45 – 66 Hz ± 0%)

MMX12AA1D7.... 1.7 2.6 0.25 1.4 1/3

MMX12AA2D4.... 2.4 3.6 0.37 2.0 1/2 2.2 FS1

MMX12AA2D8.... 2.8 4.2 0.55 2.7 3/4 2.2 FS1

MMX12AA3D7.... 3.7 5.6 0.75 3.2 1 3.2 FS2

MMX12AA4D8.... 4.8 7.2 1.10 4.6 1-1/2 4.2 FS2

MMX12AA7D0.... 7.0 10.5 1.50 6.3 2 6.8 FS2

MMX12AA9D6.... 9.6 14.4 2.20 8.7 3 9.6 FS3

Power Connection Voltage: 3AC 230V, 50/60 Hz (177 – 264V ± 0%, 45 – 66 Hz ± 0%)

MMX32AA1D7.... 1.7 2.6 0.25 1.4 1/3

MMX32AA2D4.... 2.4 3.6 0.37 2.0 1/2 2.2 FS1

MMX32AA2D8.... 2.8 4.2 0.55 2.7 3/4 2.2 FS1

MMX32AA3D7.... 3.7 5.6 0.75 3.2 1 3.2 FS2

MMX32AA4D8.... 4.8 7.2 1.10 4.6 1-1/2 4.2 FS2

MMX32AA7D0.... 7.0 10.5 1.50 6.3 2 6.8 FS2

MMX32AA011.... 11.0 14.4 2.20 8.7 3 9.6 FS3

Rated motor currents for normal four-pole internally cooled and surface-cooled three-phase asynchronous motors

(1500 rpm at 50 Hz, 1800 rpm at 60 Hz).

Calculated motor rating (no normalized value). The mains voltage of 115V is raised to 230V (output voltage) through

an internal voltage double connection.

Rated

Operational

Current

I

e

Overload

Current

(150%) Assigned Motor Rating

I

e150

P (230V, 50 Hz) P (230V, 60 Hz)

[A] [A] [kW] [A]

M-Max Series adjustable frequency drive

[hp] [A]

1.5

1.5

1.5

Installation

Size

FS2

FS1

FS1

MN04020002E

For more information visit: www.eaton.com 7

M-Max Series adjustable frequency drive

Table 3: Technical Data (continued)

Part Number

Power Connection Voltage: 3 AC 400V/460V, 50/60 Hz (323 – 528V ± 0%, 45 – 66 Hz ± 0%)

MMX34AA1D3.... 1.3 2.0 0.37 1.1 1/2 1.1 FS1

MMX34AA1D9.... 1.9 2.9 0.55 1.5 3/4 1.6 FS1

MMX34AA2D4.... 2.4 3.6 0.75 1.9 1 2.1 FS1

MMX34AA3D3.... 3.3 5.0 1.10 2.6 1-1/2 3 FS2

MMX34AA4D3.... 4.3 6.5 1.50 3.6 2 3.4 FS2

MMX34AA5D6.... 5.6 8.4 2.20 5.0 3 4.8 FS2

MMX34AA7D6.... 7.6 11.4 3.00 6.6 4 7.6 FS3

MMX34AA9D0.... 9.0 13.5 4.00 8.5 5.5 7.6 FS3

MMX34AA012.... 12.0 18.0 5.50 11.3 7-1/2 11 FS3

MMX34AA014.... 14.0 21.0 7.50

Rated motor currents for normal four-pole internally-cooled and surface-cooled three-phase asynchronous motors

(1500 rpm at 50 Hz, 1800 rpm at 60 Hz).

Allocated motor output at a maximum ambient temperature of +40ºC and a maximum pulse frequency of 4 kHz.

Operation with reduced load torque (about –10% MN).

Rated

Operational

Current

I

e

Overload

Current

(150%) Assigned Motor Rating

I

e150

P (230V, 50 Hz) P (230V, 60 Hz)

[A] [A] [kW] [A]

(15.2)

February 2010

[hp] [A]

10

14 FS3

Installation

Size

Control signal terminals

The control section, with the corresponding control signal terminals, is shown below.

AI2

DO– GND

4 5 13 14 15 16 18 20 22 23 26

12367

+ 10V AI1 GND

DI4 DI5 DI6 AO DO+

9

8

24V

DI-C

DI1 DI2 DI3 A B R22 R21

R13

R14 – R24

10 25 24

Figure 3: Schematic Arrangement and Designation of Control Signal Terminals

8 For more information visit: www.eaton.com

MN04020002E

Loading...

Loading...