IT. Intelligent soft starting solutions.

Eaton offers soft starters

that extend the life of your

mechanical components,

provide the safety and

reliability of 24V DC control

power, and retrofit into

existing enclosures and

Motor Control Centre

compartments. Not only

that, but Eaton’s IT. Soft

Starters’ small size and ridethrough capability will meet

the most demanding design

and system expectations.

With a direct focus on

control system design and

customer profitability, Eaton

is proud to offer the

Intelligent Technologies (IT.)

Soft Starters for reduced

voltage applications – a

complete offering for the

OEM and end-user

customers.

Our S752, S801 and S811

Soft Starters provide

controlled acceleration and

Eaton gives you the choice

With an impressive line of

soft starters designed with

small and large motor

applications in mind, Eaton

gives you choices. Whether

it’s the S752, S801 or the

communicating S811 line

of Soft Starters, you are

guaranteed to find an

Eaton solution to fit your

application needs.

Small size and easy

configuration make these

soft starters ideal for use in

the most demanding and

sophisticated commercial

and industrial applications.

We have IT. for every

application, offering a

complete range of solidstate reduced voltage

starters optimised to satisfy

your application

requirements.

deceleration of single and

three-phase motors and

offer a range of control and

application flexibility to

meet the needs of most

OEM and end-user

applications.

The low cost solutions to

reduced voltage starting

applications, the IT. solidstate soft starters have all

the features and options

you value.

From advanced starting and

stopping control, to

integrated functions and

motor protection and

communication capabilities,

the IT. line of soft starters

provides a unique

combination of soft starting

and flexible protective

features along with the

technological advances

you’ve come to expect from

Eaton’s products.

Why choose soft starting?

An Eaton IT. Soft Starter

uses Silicon Controlled

Rectifiers (SCRs) to

electronically reduce the

voltage output to the motor,

allowing for a ramp up to

the line voltage.

Soft starting a motor will

reduce mechanical

component shock,

minimising coupling and

shaft damage, preventing

rotor and winding failure,

and stopping drive belt

squeal and breakage. With

an IT. Soft Starter,

mechanical system

components can be

significantly reduced in size

because of lower starting

torque values (250-500%

FLA), which also prolongs

their life.

Soft starting can also

prevent damage to loads by

eliminating sudden system

acceleration and violent

speed variations –

contributing to fewer

mechanical breakdowns,

improving the quality of the

product and process. The

reduced inrush currents will

also decrease stress on the

electrical distribution

system, increasing the life

of electrical components.

Applications

Aggregate

•

Reduced starting torque

lowers stress on the

mechanical drive and

driven load, avoiding

injury and machinery

damage

• Overload protection along

with other sophisticated

trip features increase

reliability and uptime

• Low and medium voltage

solutions for aggregateduty applications with

simplified mounting for

the needed flexibility

• Communications allow for

real-time system

monitoring

• Customer service and

technical support when

you need it

Pumping/Wastewater

•

Reduces snapping of

belts, extending the life of

the belt 2-6 times

• Pump control algorithm

limits pressure surges,

maximising the life of

pumping and piping

systems while minimising

costs associated with

system downtime. It also

eliminates “water

hammer” so applications

require fewer pipe

hangers, which contribute

to fewer leaks, increasing

pump life

• Communications give you

the flexibility associated

with the real-time

monitoring of process

and diagnostic data and

insight into the condition

of equipment and processes

without a site visit

• Reduced torque decreases

stress on equipment,

lowering failure rates

HVAC

•

Communication

capabilities enable

integration into building

management systems for

easy monitoring and

troubleshooting

• Small size permits the use

of smaller panels and

enclosures, allowing you

to capitalise on significant

space savings

Conveyors

•

Smooth starts and stops

• No sliding or tilting

of goods

• No snapping of chains

or belts

• Communication capability

with IT. SNAP Modules

Compressors

•

Reduces starting currents

by 40-50% compared to

direct-on-line starters

• Provides fast start of the

compressor

Fans & Pumps

•

Reduces squealing or

snapping of belts,

extending the life 2

to 6 times

• Reduces inrush currents

• Unlimited starts and stops

• Soft Stop minimises

“water hammer”

Elevators

Smooth starts and stops

•

• Reduced wear on belts,

gears, chains, clutches,

shafts and bearings –

decreasing required

maintenance and

extending the life

• Reduced inrush currents

to minimise voltage

disturbances

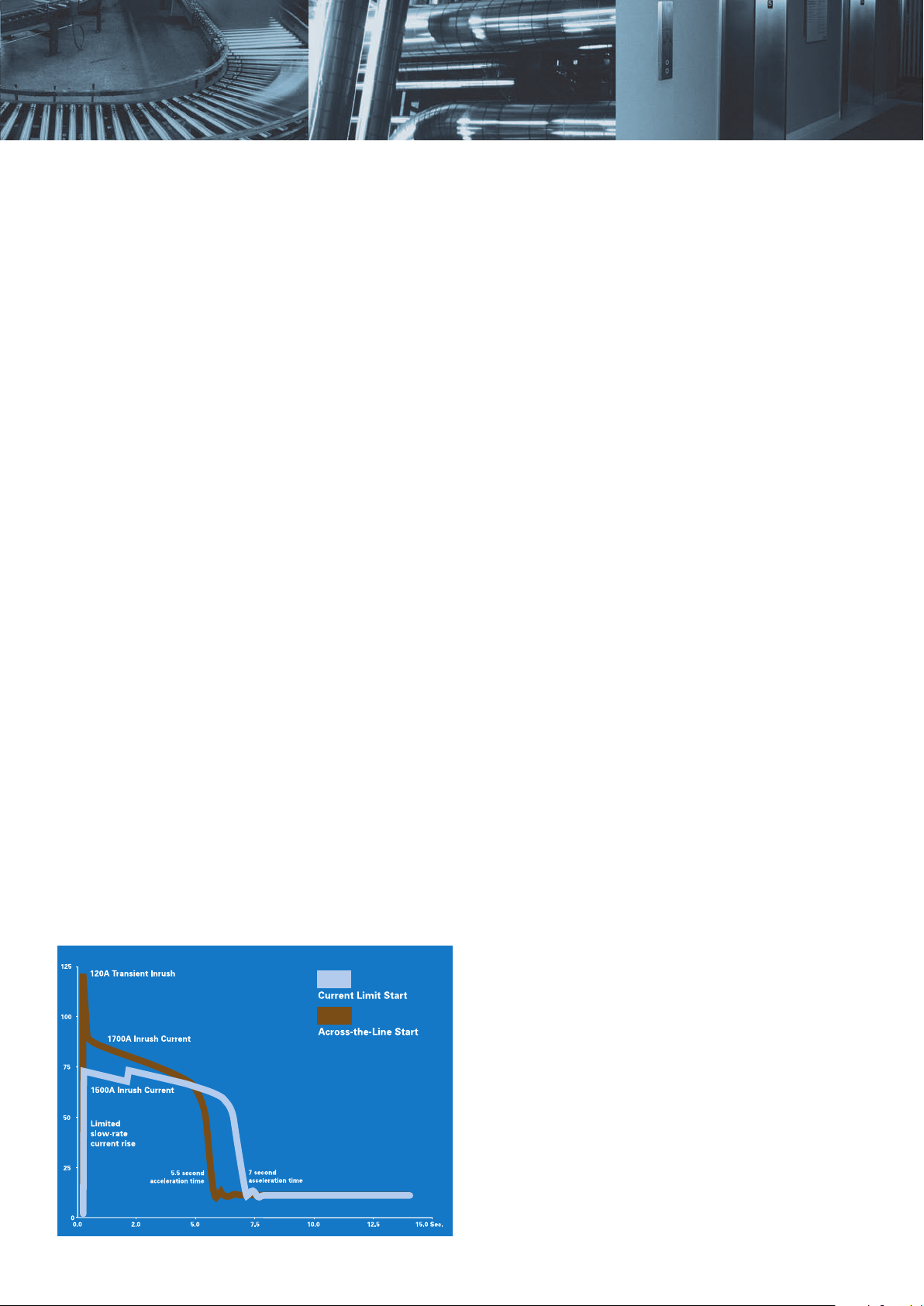

Soft starting vs. direct-on-line starting

Other benefits include:

•

Soft stopping where a

stop time is greater than

coast to rest time — a

feature that is beneficial

in material handling,

conveyor and pumping

applications.

Pumping/Wastewater

•

Reducing line brown-outs

and reducing or

eliminating the costs

associated with power

distribution violations. An

IT. Soft Starter controls

peak power demand

while a full-voltage starter

can apply from 600 up to

800% FLA on start-up.

What value do Eaton IT. Soft Starters offer your business?

Keeping heat under control

All the IT. Soft Starters

featured here have run

bypass mode, designed to

significantly reduce the heat

generated by the starter,

minimising enclosure sizes

and costs. The sophisticated

design removes the soft

starter SCRs from the circuit

after the contacts close

during the bypass

operation. This reduces the

internal heating created by

the SCRs, while the bypass

contactor directly connects

the motor to the line and

improves system efficiency

by reducing internal power

losses. On top of that, the

bypass contactor is internal

to the soft starter,

eliminating the need for

additional devices and

further reducing enclosure

sizes and minimising

installation time.

Packaged IT. Soft Starters

give you more motor

current in dramatically

reduced enclosures. This is

possible because IT. has

fewer parts and generates

less heat, which gives you

more power per MCC

section or square mm of

wall space. IT. gives you the

maximum performance in

the smallest package.

The graph illustrates the

typical heat loss from

conventional Soft Starters

No need to worry when IT. is at work

compared to that of Eaton’s

IT. Soft Starters. What does

less heat mean? It means

substantial cost savings

Soft starter heat lost comparison

S801, S811 Soft Starter

when it comes to enclosure

sizes and enclosure

ventilating requirements.

Eaton IT. Soft Starters

feature IP20 rated fingersafe terminals, with 24V DC

control. When your

personnel and equipment

are at risk, nothing but the

safest, most reliable soft

starter will do – IT. is the

answer.

The hazards of human

contact with AC current are

well known; low voltage DC

control power eliminates

hazards for personnel while

working on control systems.

From a global perspective,

one DC voltage bypasses

the need to transform the

variety of AC input voltages

used worldwide. Again,

improving safety conditions

and reducing system costs.

The S752, S801 and S811

use a 24V DC pulse width

modulated coil control for

the bypass contactor that

results in minimum power,

only 5.0W steady state. 24V

DC control reduces the risk

of injury and damage from

electrical shock and short

circuit faults. The PWM coils

in combination with an

efficient IT. Power Supply,

work to reduce or eliminate

the negative effects of

electrical system

disturbances, brown-outs

and protect against power

loss. Also, the removable

and lockable control terminal

block eliminates control wiring

errors when replacing a

device, providing yet

another level of safety.

Nothing is more costly than

system downtime – why not

choose an IT. Soft Starter

and be confident in the

safety and integrity of your

control system?

The perfect fit

The small size of IT. Soft

Starters make them the

perfect option for existing

soft starting or retrofitting

applications. At sizes that

are 55-91% smaller than

leading competitors’ soft

starters of the same ratings,

IT. is the answer.

The S752, S801 and S811

combine the overload and

bypass contactor into one

device for fast and easy

installation. Functions

traditionally provided by

multiple devices are now

offered in one compact

package. With their small

size, they can easily fit in

place of existing soft

starters, star-delta starters

or direct-on-line IEC

starters. This feature allows

easy upgrades to existing

systems.

Often an application may

call for variable motor

speed, requiring the use of

a drive. In critical

applications, a direct-on-line

starter may be used as a

bypass in the event that the

drive fails. The small

footprint of the IT. Soft

Starter enables it to fit in

the enclosure with the

drive, filling the role of the

bypass while your system

reaps the benefits of

reduced voltage starting.

Maintaining your integrity

What better way to protect

your system’s integrity than

by improving the ridethrough capability of your

control products?

Nothing is more costly than

system downtime – why not

choose an IT. Soft Starter

with the appropriately

matched Eaton 24V DC

power supply and be

confident in the integrity of

your control system?

Integral run bypass and overload protection.

A small but complete package.

IT. S752 Soft Starter

The IT. S752 is very compact,

multi-functional, easy to

install and easy to program.

The device is available in

configurations to be applied

either in the line of the motor,

or in the delta windings of

the motor. The in-line device

is available for current ranges

from 0.25 to 50 amps. The

With its integral solid-state

overload protection and run

bypass contactor, the IT.

S752 eliminates the need to

purchase additional devices

– reducing component,

wiring, panel and enclosure

costs. The S752 is available

as a component for panel

mounting.

inside-the-delta device is

available for current ranges

from 0.44 to 86 amps.

IT. S752

Control functions

Initial torque control 0–95%

Soft start 0.5–30 seconds

Soft stop 0–30 seconds

Electrical ratings (standard duty ratings)

Operating voltage (Ue) 200–600 V AC

In-line current capacity 50A

Inside-the-delta current capacity 78A

Control steady state current 200mA

Inrush current (during bypass) 3.63A @ 50mS

Max in-line power @ 440V AC – 30kW

Max inside-the-delta power @ 440V AC – 45kW

Operating frequency 47–63 Hz

Environmental ratings

Operating temperature -35 to 40°C

Storage temperature -40 to 80°C

Altitude 2000m

Humidity 95% Non-condensin\g

Vibration IEC 68–2–6 3g 10–150 Hz

Standards and Certifications

IEC 60947-4-2 UL Listed (NMFT)

EN 60947-4-2 CSA Certified (321106)

CE Marked CSA Elevator Duty (241103)

Key features

Advanced selectable protective

•

features safeguard the motor and

system against a variety of

system faults.

• Run bypass mode greatly reduces

internal heating created by the

power dissipation across the

SCRs. The bypass contactor

directly connects the motor to the

line and improves system efficiency by

reducing internal power losses. Less heat minimises

enclosure size and cooling requirements and maximises

the life of all devices in the enclosure.

• Internal run bypass contactor and overload protection

eliminate the need for additional devices, thereby

reducing enclosure sizes, minimising installation and

wiring time and reducing overall assembly size and cost.

• Wide range of overload FLA settings (31 – 100% of rated

current) and selectable trip class (10, 20, 30) offers users

the flexibility to fine tune the starter to match specific

application requirements.

• 24V DC control module enhances personnel and

equipment safety.

• Communications enabled with the addition of a SNAP

(Starter Network Adapter Product).

Initial torque control, soft start and soft stop

Soft Start

Ramp Up time

0.5 to 30 sec.

Soft Stop

Ramp Down time

0 to 30 sec.

Initial Torque

0 to 95%

Motor Voltage

Time

S752 Control

Function Diagram

Control, monitor, protect.

The S801 and the communicating IT. S811 Soft Starter

Eaton’s IT. S801 revolutionised

the reduced voltage motor

control marketplace with its

advanced feature set and

small size. The S811 offers

all the popular features as

the S801, but adds enhanced

functionality with the new

IT. S801/S811

Control functions

Voltage ramp start

Initial torque control 0–85%

Soft start 0.5–180 seconds

Current limit start

Maximum current 0–85%

Soft start 0.5–180 seconds

Kick-start 0–85%, 0–2 sec

Soft stop 0–60 seconds

Electrical ratings

Operating voltage (Ue) 200–600 V AC

Max current capacity 1000A

Steady state current 1.0A N–T Frames

Inrush current Amps 10

Operating frequency 47–63Hz

Environmental ratings

Operating temperature -30 to 40°C

Storage temperature -50 to 70°C

Altitude 2000m

Humidity 95% Non-condensing

Standards and Certifications

IEC 60947-4-2 cULus Listed (File # E202571)

EN 60947-4-2 UL Listed (NMFT)–Frame N37 to V85

CE Marked CSA Elevator (2411 01)

CSA Certification

DIM (Digital Interface Module)

and communications

capabilities. Designed to

control the acceleration and

deceleration of 3-phase

motors up to 690V, the S811

is available from 11 amps

through 1,000 amps.

690V option T–V Frames

1.4A V–Frame

Key features S801/S811

Internal run bypass contactors and overload protection

•

eliminate the need for additional devices, thereby

reducing enclosure sizes, minimising installation and

wiring time and reducing overall assembly size and cost.

• Kick-start feature enables soft starting of high friction loads.

• Pump control option with sophisticated pump algorithms

on both starting and stopping that minimize the pressure

surges that cause water hammer. The pump control

option will maximise the life of the pump and piping

systems while minimising the downtime caused by

system failure.

Key features S811

•

The DIM (Digital Interface Module) on the S811 provides

an intuitive, easy to use human interface with powerful

configuration tools to maximise system performance.

• Door or device mounted, the DIM enables users to safely

configure, commission, monitor and troubleshoot the

system at the electrical panel without opening the

enclosure door.

• System operating parameters can be monitored

enterprise-wide through a communications network.

Increase process uptime by providing data for process

management and preventive diagnostics.

• Built-in communications capabilities through Eaton QC

(Quick Connect) Port. The QCPort allows the soft starter

to be connected to a variety of networks, including

DeviceNet, EtherNet/Modbus and Profibus. The S811

communication parameters can be configured with the

DIM or through the network using CH Studio.

S811 monitoring capabilities

Phase currents

Average current

Current as a % of FLA

Thermal memory

Phase voltage

Average voltage

Control voltage

Device temperature

Start count

Breaker status

Fault queue

S811 protective features

Electronic motor overload

Short circuit coordination with Eaton

circuit breakers or with fuses

Jam

Stall

SCR over temperature

Phase loss

Phase imbalance

Automatic or manual reset

Phase reversal

Shorted SCR detection

Open SCR detection

Under current

Under voltage

Over voltage

Diagnostics fault queue

Loading...

Loading...