Page 1

I.L. 29C104C

File 29-000

Effective June 1998 Supersedes I.L. 29C104-B dated August 1997.

Cutler-Hammer

Installation Instructions for DK, KDB, KD, HKD, KDC, KW, HKW,

KWC, CKD, CHKD Circuit Breakers and Molded Case Switches

The recommendations and information contained herein

are based on Cutler-Hammer experience and judgment,

but should not be considered to be all-inclusive or covering every application or circumstance which may arise. If

any questions arise, contact Cutler-Hammer for further

information or instructions.

1. INTRODUCTION

General Information

The K-frame Series C circuit breaker (Figure 1-1) types

KD, HKD, and KDC are 600 Vac maximum rated

devices with interchangeable thermal-magnetic or electronic (Seltronic) trip units rated 400A maximum continuous current. Circuit breaker types KW, HKW, and KWC

are 660 Vac maximum rated devices using interchangeable adjustable thermal/adjustable magnetic or electronic trip units rated up to 400A continuous current. The

type KDB noninterchangeable trip circuit breaker is rated

600 Vac maximum with a maximum continuous current

rating of 400A. The type DK 240 Vac maximum circuit

breaker is also a noninterchangeable trip device with trip

unit ratings from 250A to 400A. Refer to Table 4-1 on

page 8 for all available trip unit ratings. Model D circuit

breakers are listed in accordance with Underwriters

Laboratories, Inc. Standard UL489 and satisfy the (P1)

requirements of the International Electrotechnical

Commission Recommendations No. IEC 157-1. Model

W circuit breakers satisfy the requirements of IEC C947-

2. Molded case switches are listed in accordance with

UL1087. For more information, see Frame Book 29-103.

100 Percent Rated K-Frame Circuit Breakers

CKD and CHKD circuit breakers are suitable for continuous operation at 100 percent of the frame rating if

used with an 90°C insulated wire and AL9CU terminals

in an enclosure which measures at least 24” high x 15”

wide x 6” deep. Ventilation is not required in an enclosure having these minimum dimensions. CKD and

CHKD 100 percent rated circuit breakers use electronic

trip units only.

This instruction leaflet (IL) gives procedures for installation and field testing of K-frame Series C circuit breakers. Instructions are also provided for replacement of

existing Cutler-Hammer circuit breaker types DA, LB,

LBB, HLB, JA, KA, and HKA. For this publication, the

term circuit breaker shall also include the molded case

switch.

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS ENERGIZED. DEATH, SEVERE PERSONAL INJURY, OR

SUBSTANTIAL PROPERTY DAMAGE CAN RESULT

FROM CONTACT WITH ENERGIZED EQUIPMENT.

ALWAYS VERIFY THAT NO VOLTAGE IS PRESENT

BEFORE PROCEEDING WITH THE TASK, AND

ALWAYS FOLLOW GENERALLY ACCEPTED SAFETY PROCEDURES.

CUTLER-HAMMER IS NOT LIABLE FOR THE MISAPPLICATION OR MISINSTALLATION OF ITS PRODUCTS.

The user is cautioned to observe all recommendations,

warnings, and cautions relating to the safety of personnel and equipment as well as all general and local

health and safety laws, codes, and procedures.

Figure 1-1 K-Frame Model D Series C Circuit Breaker

Frame with KT Trip Unit Installed

WARNING

Page 2

I.L. 29C104C

Page 2

Effective 6/98

2. INSTALLATION

The installation procedure consists of inspecting the circuit breaker and, as applicable, installing the trip unit and

rating plug, accessories, interphase barriers, and terminals; mounting the circuit breaker; connecting the line

and load conductors; torquing terminals; and attaching

terminal shields. Circuit breaker frames, trip units, rating

plugs, accessories, mounting hardware, and unmounted

terminals may be supplied in separate packages. To

install the circuit breaker, perform the following steps.

If circuit breaker is replacing a DA, JA, KA, HKA, LB,

LBB, or HLB circuit breaker, refer to section 3 of

this instruction leaflet.

DK and KDB circuit breakers are factory sealed for

reverse feed applications under UL489. UL requires

that internal accessories be installed at the factory

in these types of circuit breakers.

If required, internal accessory installation in any

type of circuit breaker should be done before the

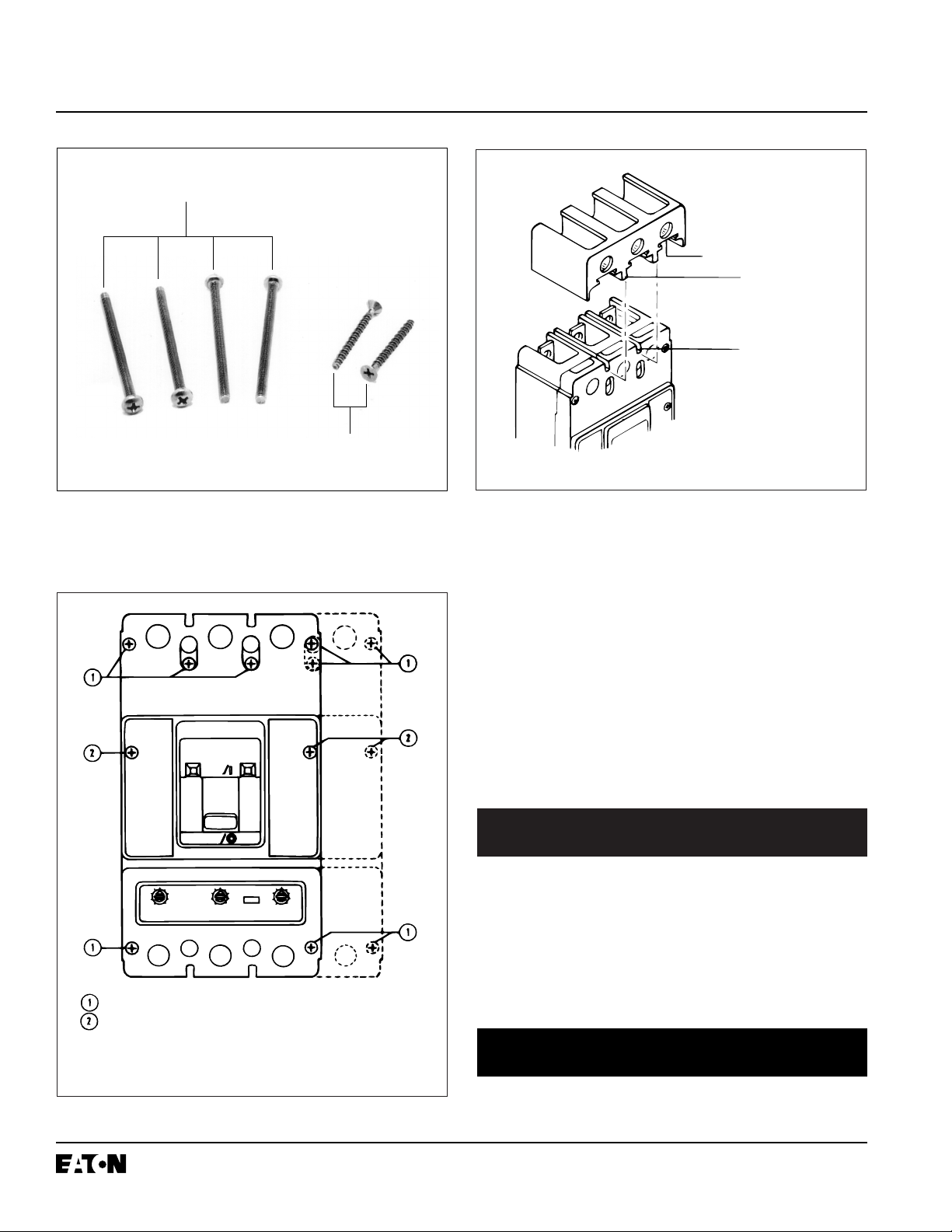

Figure 2-1 Cover Mounting Hardware

Flat Head, Thread

Forming Screws

Pan Head

Screws

Figure 2-2 Cover Screw Installation Positions

On

Off

Screw, .190-32 x 3.125 Inch Pan Head, Cross-Recessed.

Screw, No. 8 x 1.63 Inch, Flat Head, Cross-Recessed,

Thread Forming.

Note: Hatched lines show additional pole and screws for

4-pole circuit breaker.

Figure 2-3 Terminal Cover Installation

Terminal Cover

Dovetails

Mounting

Slots

NOTICE

NOTICE

Page 3

I.L. 29C104C

Page 3

Effective 6/98

circuit breaker is mounted and connected. Refer to

individual accessory instruction leaflets.

2-1. Make sure that the circuit breaker is suitable for the

intended installation by comparing nameplate data with

existing equipment ratings and system requirements.

Inspect the circuit breaker for completeness, and check

for damage before mounting. Uninstalled cover mounting hardware is supplied in a plastic bag with the circuit

breaker frame. (See Figure 2-1.)

2-2. Remove installed cover screws and cover.

The circuit breaker handle must be in the tripped or

OFF position to remove the cover. Instructions for

installing the trip unit and accessories are supplied

with the devices.

2-3. If not already installed, mount trip unit and accessories (if required) in circuit breaker frame. Rating plug

must be installed in Seltronic trip units.

WHEN REMOVED AND REINSTALLED, THREADFORMING SCREWS WILL TRY TO REFORM THE

THREADS IN THE BASE. CARE SHOULD BE TAKEN

EVERY TIME A THREAD-FORMING SCREW IS USED

TO ENSURE THE SCREW STARTS IN THE ORIGINAL

THREADS. DAMAGED THREADS CAN RESULT IN

IMPROPER CIRCUIT BREAKER COVER RETENTION.

2-4. Replace cover and install pan-head screws followed by thread-forming screws as shown in Figure 2-2.

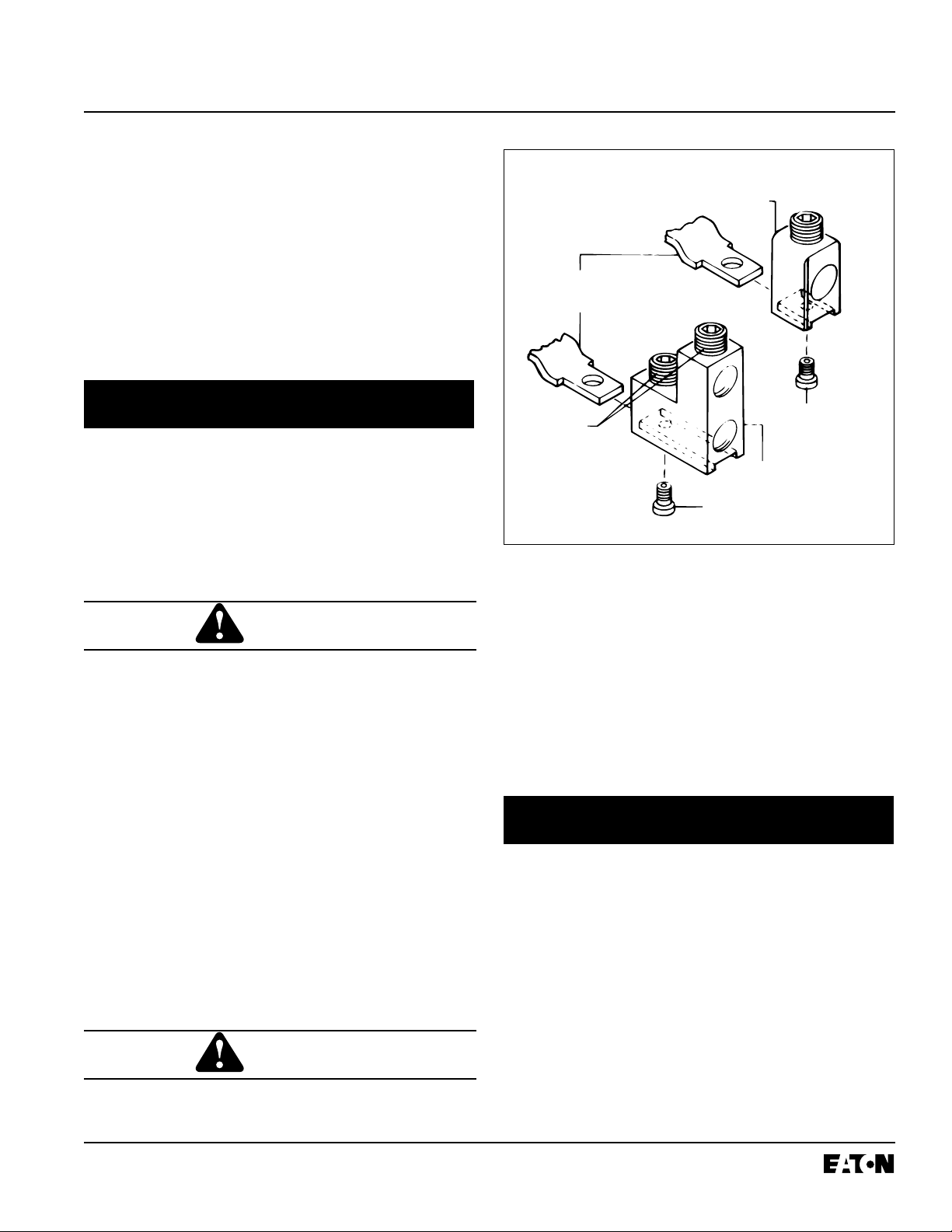

2-5. If not already installed, mount terminals as shown

in Figure 2-4. Secure the terminals to the circuit breaker

using a 7/32-inch socket wrench, and torque to 6-8 lb-ft

(8-11 N.m). After mounting the circuit breaker and

before installation of the conductors, the terminal mounting screw can be checked or retightened through the

terminal when the conductor screw is removed. If

Warning label is supplied with terminal, place on upper

portion of circuit breaker cover.

THE VOLTAGE IN ENERGIZED EQUIPMENT CAN

CAUSE DEATH OR SEVERE PERSONAL INJURY.

BEFORE MOUNTING THE CIRCUIT BREAKER IN AN

ELECTRICAL SYSTEM, MAKE SURE THERE IS NO

VOLTAGE PRESENT WHERE WORK IS TO BE PERFORMED. SPECIAL ATTENTION SHOULD BE PAID

TO REVERSE FEED APPLICATIONS TO ENSURE

NO VOLTAGE IS PRESENT.

Depending on the equipment configuration, the circuit breaker can be mounted using different styles

of hardware. The following steps describe how to

mount the circuit breaker using standard hardware.

When special hardware is needed (for example, with

the electrical operator), the instruction leaflet

describing the accessory also describes the special

mounting arrangements.

2-6. To mount the circuit breaker, perform the following

steps:

a. For individual surface mounting, drill mounting panel

using the drilling plan shown in Figure 2-5. For panelboard mounting, only load end support mounting

NOTICE

CAUTION

WARNING

Figure 2-4 Terminal Installation

TA300K/TA350K

T300K/T350K Terminals

Circuit Breaker

Terminal Conductors

Conductor

Screws

Terminal

Mounting

Screw

TA400K, TA401K, TA402K,

T400K Terminals

Terminal Mounting Screw

NOTICE

Page 4

I.L. 29C104C

Page 4

Effective 6/98

holes are required. For deadfront cover applications,

cut out cover to correct escutcheon dimensions, see

Figure 2-6.

b. If circuit breaker includes factory or field installed

internal accessories, make sure accessory wiring can

be reached when the circuit breaker is mounted.

c. Position circuit breaker on mounting surface.

Labels with accessory connection schematic diagrams are provided on the side of the circuit breaker.

A note should be made of the diagrams if the labels

cannot be seen when the circuit breaker is mounted.

d. Install circuit breaker mounting screws, washers, and

nuts. Tighten screws firmly, but do not exceed 28

pounds-inches (3 N.m.).

WHEN ALUMINUM CONDUCTORS ARE USED, THE

APPLICATION OF A SUITABLE JOINT COMPOUND

IS RECOMMENDED TO REDUCE THE POSSIBILITY

OF TERMINAL OVERHEATING. OVERHEATING CAN

CAUSE NUISANCE TRIPPING AND DAMAGE TO

THE CIRCUIT BREAKER.

When a dual conductor terminal (Catalog No.

TA401K, TA400K, or T400K) is installed on the circuit breaker and a single conductor is used, the

conductor should be installed in the terminal opening nearest to the circuit breaker terminal mounting

conductor.

2-7. Connect line and load conductors and accessory

leads.

2-8. When step-type terminals (Cat. No. TA400K,

TA401K, TA402K, and T400K) are used, terminal

shields (supplied with the terminals) must be installed

on the circuit breaker (Figure 2-3). Warning label supplied with the kit must be attached to the circuit breaker

front cover.

2-9. If required, install terminal shield on circuit breaker

cover with mounting screws provided.

2-10. After the circuit breaker is installed, check all

mounting hardware and terminal connecting hardware

for correct torque loading. Torque values for line/load

Figure 2-5 Circuit Breaker Mounting Bolt Drilling Plans

2, 3 Pole Breakers

4 Pole Breaker

Circuit

Breaker

Handle

C

L

CLCircuit Breaker Handle

.844

(21.44)

8.438

(214.32)

4.922

(125.01)

3.516

(89.31)

1.719

(43.66)

1.719

(43.66)

.859

(21.82)

1.719

(43.66)

.250-20 (M6-1.0) TAP

- 4 Holes

.250-20 (M6-1.0) TAP

- 6 Holes

Figure 2-6 Circuit Breaker Escutcheon Dimensions for

3- and 4-Pole Circuit Breakers

Circuit Breaker HandleC

L

Circuit Breaker HandleC

L

Trip Unit

Access Area

.344R

(8.74)

.921

(23.39)

3.750

(95.25)

1.640

(41.66)

1.250

(31.75)

1.313

(33.35)

1.88R

(4.77)

4.782

(121.46)

2.625

(66.67)

2.391

(60.73)

CAUTION

NOTICE

NOTICE

Page 5

I.L. 29C104C

Page 5

Effective 6/98

terminals are given in Table 2-1 and on the circuit

breaker nameplate.

3. REPLACEMENT OF EXISTING CUTLER-HAMMER

CIRCUIT BREAKERS TYPES DA, JA, KA, HKA, LB,

LBB, AND HLB

Although the physical size of the K-frame Series C circuit breakers is the same as the DA, JA, KA, HKA, LB,

LBB, and HLB family, there are certain differences that

must be considered when making replacements.

• Circuit breaker mounting details, panel cutouts, and

terminal centerline locations are identical.

• Handle locations, handle throw, and terminal connection details are different. Therefore, existing handle

mechanisms and externally-mounted accessories,

including electrical operator, key interlocks, etc., must

be replaced or mounting details modified. Consult

Cutler-Hammer for additional information.

DO NOT ATTEMPT TO INSTALL OR PERFORM

MAINTENANCE ON EQUIPMENT WHILE IT IS ENERGIZED. DEATH, SEVERE PERSONAL INJURY, OR

SUBSTANTIAL PROPERTY DAMAGE CAN RESULT

FROM CONTACT WITH ENERGIZED EQUIPMENT.

ALWAYS VERIFY THAT NO VOLTAGE IS PRESENT

BEFORE PROCEEDING WITH THE TASK, AND

ALWAYS FOLLOW GENERALLY ACCEPTED SAFETY PROCEDURES.

When replacing an existing circuit breaker of the

types listed above, make sure the voltage, continuous current, and interrupting rating of the new circuit breaker is suitable.

3-1. If existing circuit breaker is equipped with a handle

mechanism, remove the mechanism. Refer to Frame

Book 29-103 for ordering information on new handle

mechanisms.

3-2. Disconnect accessory electrical leads and main

conductors.

3-3. Remove all external accessories that would

impede removal of the circuit breaker.

3-4. Remove circuit breaker from installation.

3-5. Install K-Frame Series C circuit breaker that has

been prepared using steps 2-1 through 2-3 to fit installation requirements given below.

Panelboard Installation

Two types of panelboard construction/circuit breaker

mounting arrangements are covered in the following

procedures: convertible distribution panels (CDP),

where the circuit breakers are mounted in a dual horizontal arrangement; and other panelboard constructions, where the existing circuit breaker is used as a

main disconnect and mounted vertically.

TO AVOID OVERHEATING, DO NOT INSTALL KFRAME SERIES C CIRCUIT BREAKERS WITH TRIP

UNITS RATED ABOVE 225A ON EXISTING 225A JA,

KA, OR HKA PANELBOARD CONNECTING STRAPS.

When existing CDP panelboard connecting straps

are retained, a supplementary adapter and clip

(Catalog No. TAD3) must be used to compensate for

the change in height of the new circuit breaker terminal connections. The adapter may be used on either

WARNING

NOTICE

CAUTION

NOTICE

Table 2-1 Terminal Types

Terminal Terminal Screw AWG Metric Wire Torque

Cat. No. Material Head Wire Wire Type Value

Body Type Range Range lb-in

(N.m.)

TA300K Aluminum Socket 3-350(1) 35-185 Cu/AI 275 (31)

TA350K Aluminum Socket 250-500(1) 120-240 Cu/AI 375 (42)

TA400K Aluminum Socket 3/0-250(2) 95-120(2) Cu/AI 275 (31)

TA401K Aluminum Socket 250(2) 120(2) Cu/AI 275 & 375

or or (31 &42)

500(1) 240(1) Cu/AI 375 (42)

TA402K Aluminum Socket 500-750(1) 240-300 Cu/AI 550 (62)

T300K Copper Socket 3-350(1) 35-185 Cu Only 275 (31)

T350K Copper Socket 250-500(1) 120-240 Cu Only 375 (42)

T400K Copper Socket 3/0-250(2) 95-120(2) Cu Only 275 (31)

Page 6

I.L. 29C104C

Page 6

Effective 6/98

side of the circuit breaker terminal mounting conductor permitting continued use of top or bottom

mounted connecting straps. If Series C panelboard

connecting straps that mount from the rear of the

circuit breaker are used, the adapter is not required.

3-6. When required, position the TAD3 adapter under

those circuit breaker terminal connectors that will be

bolted to the panelboard connecting straps. Secure

adapters with the spring clips supplied. Refer to instructions supplied with adapter.

3-7. Position circuit breaker in correct location on panelboard chassis.

3-8. Install socket-head bolts through circuit breaker

terminal connectors and screw into panelboard connecting straps. Torque to 120 pound-inches (16.9 N.m).

3-9. Install circuit breaker mounting screws, washers,

and nuts in load end of circuit breaker. Tighten screws

firmly, but do not exceed 28 pound-inches (3 N.m.).

3-10. After mounting the circuit breaker, refer to section

2 for instructions how to connect main conductors and

accessory leads, as required.

Individually Mounted Devices

With the change in height of the circuit breaker terminal

connector, K-frame Series C circuit breakers can be

used to replace individually mounted existing types DA,

JA, KA, HKA, LB, LBB, and HLB circuit breakers only

when the following conditions are considered:

Fixed Rear Connecting Studs

New Series C fixed rear connecting studs will be required.

Refer to Frame Book 29-103 for ordering information.

Plug-In Support Blocks

New male plug-in adapters will be required. Existing stationary support block receptacles can be used with new

Series C male plug-in adapters. Refer to Frame Book

29-103 for ordering information.

Front or Rear Connected Bus Bars

Use existing connecting details coupled with K-Frame

terminal adapter kit (Catalog No. TAD3).

4. MANUAL OPERATION, AND THERMALMAGNETIC TRIP UNIT ADJUSTMENT

Manual Operation

Manual operation of the circuit breaker is controlled by

the circuit breaker handle and the PUSH-TO-TRIP but-

ton in the trip unit. The circuit breaker handle has three

positions, two of which are shown on the cover with

raised lettering to indicate ON and OFF. On the sliding

handle barrier, ON, OFF, and trip are also shown by a

color-coded strip for each circuit breaker handle position: red for ON, white for tripped, and green for OFF.

(See Figure 4-1.)

Circuit Breaker Reset

After an automatic or accessory initiated trip, or a manual PUSH-TO-TRIP operation, the circuit breaker is reset

by moving the circuit breaker handle to the extreme

OFF position.

In the event of a thermal trip in a thermal magnetic

type trip unit, the circuit breaker cannot be reset

until the thermal element in the trip unit cools. A circuit breaker with an electronic type trip unit can be

reset immediately.

No circuit breaker should be reclosed until the cause of

trip is known and the situation rectified.

NOTICE

Figure 4-1 Circuit Breaker Manual Controls

Handle Postition Indicator

Color: Red - On

White - Trip

Green - Off (Reset)

On

Trip

Off

(Reset)

On

Off

International

Symbols

Thermal-Magnetic

Trip Unit Adjustment

Button (3 Places)

Push-to-Trip

Button

On/

Off/

Page 7

I.L. 29C104C

Page 7

Effective 6/98

PUSH-TO-TRIP Button

The PUSH-TO-TRIP button checks the circuit breaker

tripping function and is used to periodically exercise the

operating mechanism in thermal-magnetic trip units. The

button is designed to be operated by a small screwdriver.

The rating plug in Seltronic trip units is the PUSH-TOTRIP button and is operated by finger pressure. There is

no PUSH-TO-TRIP button in the molded case switch.

Thermal-Magnetic Trip Unit Adjustment

The magnetic element of each pole of the trip unit can

be adjusted by rotating the adjustment buttons on the

front face of the trip unit with a screwdriver. The buttons

have several settings as indicated on the nameplate

with values in multiples of the trip unit ampere rating (Ith)

as shown in Figure 4-2. To adjust the setting, rotate

each button clockwise until arrow button points to

desired setting.

Interchangeable Trip Units

For additional information on thermal-magnetic trip

units, refer to I.L. 29C603, and for electronic (Seltronic)

trip units, refer to I.L. 29C604. (IL supplied with trip unit.)

5. INSPECTION AND FIELD TESTING

Series C molded case circuit breakers are designed to

provide years of almost maintenance-free operation.

The following procedure describes how to inspect and

test a circuit breaker in service.

Inspection and Field Testing

Circuit breakers in service should be inspected periodically. The inspection should include the following checks

5-1 through 5-8.

THE VOLTAGES IN ENERGIZED EQUIPMENT CAN

CAUSE DEATH OR SEVERE PERSONAL INJURY.

BEFORE INSPECTING THE CIRCUIT BREAKER IN

AN ELECTRICAL SYSTEM, MAKE SURE THERE IS

NO VOLTAGE PRESENT WHERE WORK IS TO BE

PERFORMED. SPECIAL ATTENTION SHOULD BE

PAID TO REVERSE FEED APPLICATIONS TO

ENSURE NO VOLTAGE IS PRESENT.

SOME COMMERCIAL CLEANING AGENTS WILL

DAMAGE THE NAMEPLATES OR MOLDED PARTS.

MAKE SURE THAT CLEANING AGENTS OR SOLVENTS USED TO CLEAN THE CIRCUIT BREAKER

ARE SUITABLE FOR THE JOB.

5-1. Remove dust, dirt, soot, grease, or moisture from

the surface of the circuit breaker using a lint-free dry

cloth, brush, or vacuum cleaner. Do not blow debris into

circuit breaker. If contamination is found, look for the

source and eliminate the problem.

5-2. Switch circuit breaker to ON and OFF several

times to be sure that the mechanical linkages are free

and do not bind. If mechanical linkages are not free,

replace circuit breaker.

On molded case switches, there is no PUSH-TO

TRIP feature. Omit step 5-3 when installing a molded

case switch and proceed with step 5-4.

5-3. With the circuit breaker in the ON position, press

the PUSH-TO-TRIP button to mechanically trip the circuit breaker. Trip, reset, and switch circuit breaker ON

several times. If mechanism does not reset each time

the circuit breaker is tripped, replace the circuit breaker.

5-4. Check base, cover, and operating handle for

cracks, chipping, and discoloration. Circuit breakers

should be replaced if cracks or severe discoloration is

found.

5-5. Check terminals and connectors for looseness or

signs of overheating. Overheating will show as discoloration, melting, or blistering of conductor insulation, or

WARNING

CAUTION

NOTICE

Figure 4-2 Trip Unit Magnetic Adjustment Buttons

Adjustment Buttons

7.5

10 5

7.5

10 5

7.5

10 5

Thermal

Magnetic

Trip Unit

Push-to-Trip

Amps

(Ith)

C

Cat

No.

Magnetic (Im)

Multiples Of I

th

Page 8

Cutler-Hammer

Pittsburgh, Pennsylvania U.S.A.

Effective 6/98 (ISI)

Style 6632C41H04

Printed in U.S.A.

I.L. 29C104C

Page 8

as pitting or melting of conductor surfaces due to arcing.

If there is no evidence of overheating or looseness, do

not disturb or tighten the connections. If there is evidence of overheating, terminations should be cleaned or

replaced. Before re-energizing the circuit breaker, all

terminations and cable should be refurbished to the condition when originally installed.

5-6. Check circuit breaker mounting hardware, and

tighten if necessary.

5-7. Check area where circuit breaker is installed for

any safety hazards, including personal safety and fire

hazards. Exposure to certain types of chemicals can

cause deterioration of electrical connections.

5-8. The operation of circuit breakers with Seltronic trip

units can be field tested periodically using the Seltronic

test kit. (See Frame Book 29-103.)

Field Testing

Any field testing should be done in accordance with

applicable NEMA Standard.

Trip Unit Types

Thermal-Magnetic Amperes I

th

Electronic (Seltronic➀) Amperes I

th

Circuit Fixed Adjustable Adjustable Fixed Adjustable Adjustable

Breaker Thermal Thermal

➁

Magnetic Rating Rating Instantaneous/

Types Multiples Plug Plug Short-time

of I

th

➂

Multiples

of I

th

➂

DK 250 5 to 10

300

350

400

KDB, KD, 100 200 200-400 2 to 8

HKD, KDC 125 225 250-400

150 250 315-400

175 300

KW, HKW, 200 160-200 350

KWC

➁

225 200-250 400

250 250-315

300 313-400

350

400

Table 4-1 Available Trip Unit Ratings

➀ Not available with types DK or KDB

➁ Not UL listed

➂ For adjustable thermal trip units, the magnetic setting is a multiple of the maximum thermal setting. For Seltronic trip units, the

instantaneous/short time setting is a multiple of the rating plug rating.

Loading...

Loading...