Page 1

Installation Instructions

CurrentWatch™ EGF Series Ground Fault Sensors

120V AC or 24V AC/DC, N.O. or N.C. SPST Latching Relay Output

WARNING

IN ORDER TO AVOID ELECTRIC SHOCK OR OTHER POSSIBLE INJURY:

• DO NOT USE THIS PRODUCT FOR HUMAN SAFETY APPLICATIONS.

IT WAS NOT DESIGNED, TESTED OR RECOMMENDED FOR THIS

USE.

• DO NOT USE THIS PRODUCT IN HAZARDOUS LOCATIONS (E.G.

EXPLOSIVE ATMOSPHERES). IT WAS NOT DESIGNED, TESTED OR

RECOMMENDED FOR THIS USE.

• ENSURE THE PRODUCT IS PROPERLY WIRED TO THE CORRECT

POWER SUPLLY FOR THE APPLICATION. REFER TO THE

SPECIFICATIONS AND WIRING DIAGRAMS IN THIS MANUAL.

MODELS COVERED IN THIS MANUAL

Catalog Number Description

EGF1NCLA050 120V AC, N.C. SPST Relay, 50 mA Setpoint

EGF1NOLA050 120V AC, N.O. SPST Relay, 50 mA Setpoint

EGF1NCLA100 120V AC, N.C. SPST Relay, 100 mA Setpoint

EGF1NOLA100 120V AC, N.O. SPST Relay, 100 mA Setpoint

EGF1NCLAT3 120V AC, N.C. SPST Relay, 5/10/30 mA Setpoint, Tri-Set

EGF1NOLAT3 120V AC, N.O. SPST Relay, 5/10/30 mA Setpoint, Tri-Set

EGF2NCLA050 24V AC/DC, N.C. SPST Relay, 50 mA Setpoint

EGF2NOLA050 24V AC/DC, N.O. SPST Relay, 50 mA Setpoint

EGF2NCLA100 24V AC/DC, N.C. SPST Relay, 100 mA Setpoint

EGF2NOLA100 24V AC/DC, N.O. SPST Relay, 100 mA Setpoint

EGF2NCLAT3 24V AC/DC, N.C. SPST Relay, 5/10/30 mA Setpoint, Tri-Set

EGF2NOLAT3 24V AC/DC, N.O. SPST Relay, 50/10/30 mA Setpoint, Tri-Set

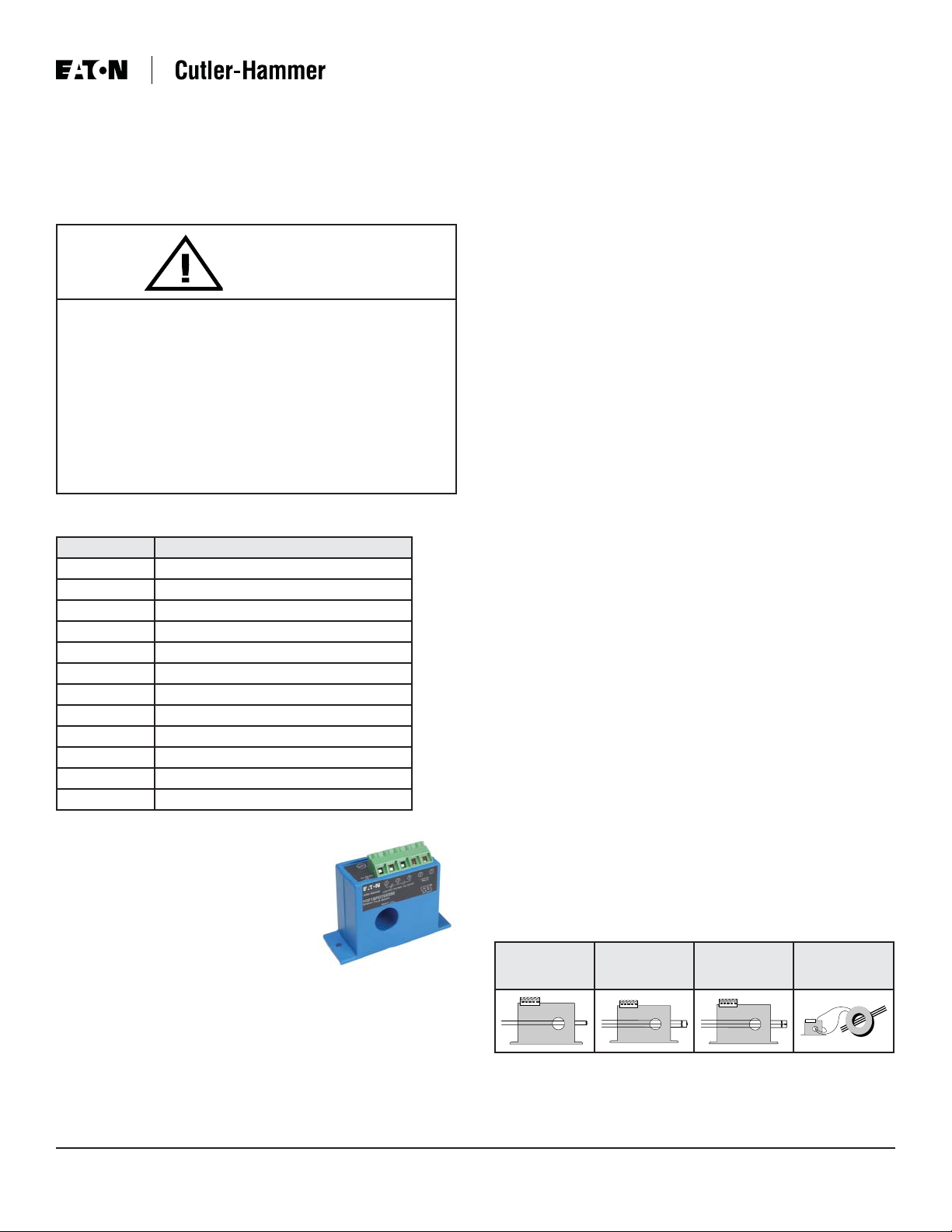

INTRODUCTION

The CurrentWatch™ EGF Series is a family of

ground fault (earth leakage) sensors. Ground

fault sensors help protect people, products, and

processes from damage by ground fault

conditions by monitoring all current-carrying

conductors in grounded single- and threephase delta or wye systems.

The EGF Series with mechanical outputs are

available in solid-core housings with a choice of N.O. or N.C. SPST

latching relays. All mechanical models can be ordered with a fi xed

setpoint or with a “tri-set” option, which provides three factory-set, fi eld

adjustable setpoints.

Note that this manual only covers EGF Series models listed in the

above table. This installation manual does not cover EGF Series

models with auto-reset.

P51923 Rev 01

490050021

QUICK INSTALL GUIDE

The below steps can be followed to quickly install a CurrentWatch™

EGF Series switch.

1. Run all current carrying conductors through sensor window, using

an auxiliary current transformer if conductors do not fi t

2. Mount the sensor to a surface if needed

3. Connect output and power wiring

a. Use up to 14 AWG copper wires

b. Ensure power and load matches those shown on the sensor

label

4. Test the unit

a. Pressing the “TEST” button will test the sensor’s internal

circuits

b. CAUTION: The output and any connected loads will switch

during the test process

INSTALLATION AND MOUNTING

Considerations for all EGF Series sensors…

• Run wire to be monitored through the aperture (opening) in the

switch body, making sure all wires are oriented so that current

fl ows in the same direction (see “Principal of Operation” section

on reverse side)

• These sensors can be located in the same environment as motors,

contactors, heaters, pull-boxes and other electrical enclosures

• Mounting can be done in any position or hung directly on a wire

with a wire tie

• Be sure to leave at least one inch distance between sensor and

other magnetic devices

Considerations for wiring EGF Series sensors…

• Use up to 10 AWG copper wire and tighten terminals to 4.5 inchpounds torque

• Connect power wiring to terminals 1 and 2, making sure that the

power supply matches the power rating on the sensor label

• Connect output wiring to terminals 3 and 4

PRINCIPAL OF OPERATION

Under normal conditions, the current in one wire of a two wire load is

equal in strength but opposite in sign to the current in other wire. The

two wires create magnetic fi elds that cancel, a condition known as

“Zero Sum Current.” If any current leaks to ground (Ground Fault), the

two currents become unbalances and there is a net resulting magnetic

fi eld. The EGF Series sensor detects this minute fi eld and change the

output state. This concept extends to three phase systems such as 3wire Delta and to 4-wire Wye.

Single Phase

(Phase to Neutral or

Phase to Phase)

Three-Phase Delta

(Includes Neutral if

Load Uses Neutral)

Three-Phase Wye

(Include Neutral if

Load Uses Neutral)

Three-Phase Load

(Using Auxiliary CT)

Effective: April 2007 Page 1

Questions? Call our Sensor Application Engineers at (800) 426-9184.

Page 2

P51923 Rev 01

490050021

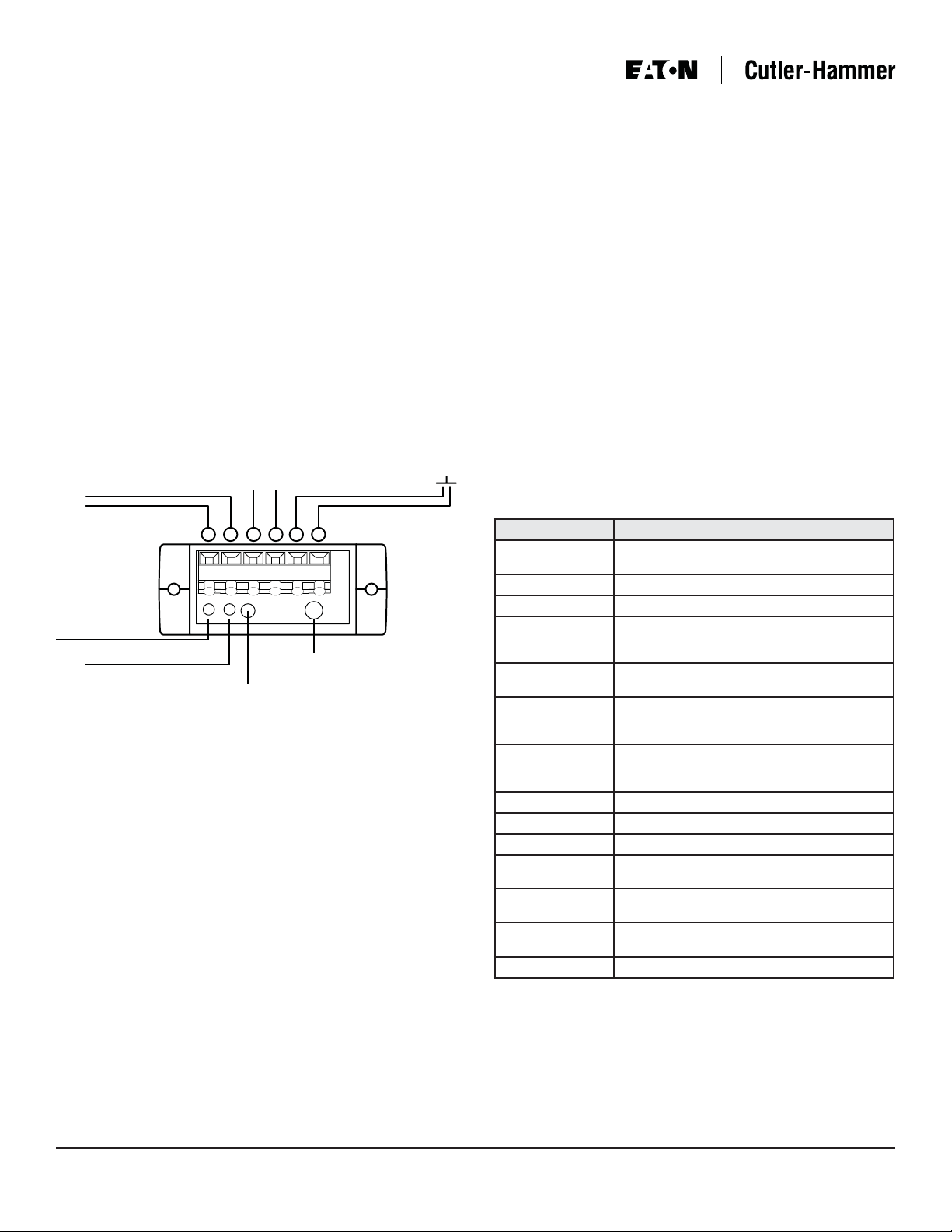

WIRING

Use up to 14 AWG copper wire and tighten terminals to 4.5 inchpounds torque. See diagram below.

Power

Connect power wiring to Terminals 1 and 2. Be sure that the power

supply matches the power rating on the sensor label.

Output

Connect output wiring to Terminals 3 and 4.

Reset Switch

Connect a momentary dry contact to the Reset Terminals 5 and 6. Limit

wire run to 200 feet of 18 AWG or larger wire.

Momentary Reset

Only close the reset terminals momentarily—the sensor will not work

properly if the reset terminals are closed (shorted) continuously. Limit

wire run to 200 feet of 18 AWG or larger wire.

Parallel Reset Connection

Multiple sensors may be connected to the same reset switch in parallel.

Only the sensors that have detected a fault and have latched will

be reset. A sensor will not reset unless the fault has dropped below

setpoint.

Output (3 and 4)

Power Supply Input (1 and 2)

Power (Green) LED

(On if Power is Applied)

Red Status LED (On When Tripped)

123456

GR

Setpoint Adjustment

(Located Under Label)

External Reset Button (5 and 6)

TEST

Test Button

(Caution: Will Activate Output Relay)

OPERATION

The EGF Series latching ground fault sensors operating in one of two

states: Reset or Latched. If control power is removed, the sensor

remains in it’s last state (latched or reset).

Reset

The sensor has not detected a fault and the output is in the “normal”

position. For Normally Open (N.O.) sensors, the contact is normally

open in the reset condition. For Normally Closed (N.C.) sensors, the

contact is normally closed in the reset position.

Latched

Upon detecting a fault or when the TEST switch is pressed, the output

will switch and “latch.” The output will remain latched until the ground

fault is removed and the output is reset by a momentary dry contact on

Terminals 5 and 6.

Testing

To test operation, gently press the TEST button. This simulates a fault

and tests the internal switching circuits. After the test is complete,

reset the sensor with a momentary dry contact on Terminals 5 and 6.

CAUTION: Any circuit connected to the sensor will be operated.

Adjusting Setpoint

While not as precise as having it set at the factory, the setpoint can be

adjusted in the fi eld. See wiring diagram for location of potentiometer.

The best way to adjust the trip point is to develop a load of the

magnitude at which you want the sensor to trip. A resistor of

4,000 ohms should provide a load of 30 mA at 120V AC, or a night light

bulb of 4 watts should relate to 33 mA. With the load energized and

passing through the sensing aperture, turn the potentiometerclockwise

until the sensor trips. Then, back one-eighth of a turn and the setpoint

should be correct.

When used with an external current transformer (CT), the sensor will

be set to trip at a point much lower than without the CT. This set point

adjustment should be done with the load passing through the CT in that

application.

POWER SUPPLY NOTES

All low-current ground-fault sensors are sensitive devices that require

reasonable care in system design to avoid false trips caused by high

electrical noise levels. Keep in mind that the best way to reduce noise in

a system is to suppress it at its source.

• Keep the sensor power isolated from noisy circuits

• Do not power the sensor with the same circuit that switches

contactors or other high current inductive loads

SYSTEM GROUNDING

Good design practice and code require that all AC power systems be

grounded. The EGF Series sensors are designed to work on grounded

AC power systems. They may not operate properly on ungrounded

systems.

SPECIFICATIONS

Specifi cation Value

Power Supply 120V AC (Operates from 66-132V)

24V AC/DC (Operates from 19.2-28.8V)

Voltage Range Up to 1,500V AC (Monitored Circuit)

Power Consumption 2.5W

Output Latching Electromechanical Relay

Normally Open Models Latch Closed Upon Sensed Fault Current

Normally Closed Models Latch Open Upon Sensed Fault Current

Output Rating 1.0A @ 120V AC

2.0A @ 30V AC

Response Time At 5% Over Setpoint: 200 ms

At 50% Over Setpoint: 60 ms

At 500% Over Setpoint: 15 ms

Setpoint Range Selectable by Model

Fixed Setpoints: 50, 100 mA

Adjustable Setpoints: 5, 10, 30 mA (By Jumper)

Setpoint Adjustment See “Adjust Setpoint” in “Operation” Section

Frequency Range 50-400Hz (Monitored Circuit)

Housing UL94 V0 Flammability Rated

Dimensions Case: 2.5 in. H x 2.8 in. W x 1.5 in. D (64x71x38mm)

Aperture: 0.75 in. (19mm)

LED Green = Power Supply Energized

Red = Relay Has Operated

Environmental Operating Temperature: +5 to +158° F (-15 to +70° C)

Humidity: 0-95% RH, Non-Condensing

Approvals UL Recognized

Effective: April 2007 Page 2

Questions? Call our Sensor Application Engineers at (800) 426-9184.

Loading...

Loading...