Cutler Hammer, Div of Eaton Corp EDC Series Installation Instructions

Installation Instructions

CurrentWatch™ EDC Series Current Sensors

DC Current Sensor, Split Core Housing with Analog Output

WARNING

IN ORDER TO AVOID ELECTRIC SHOCK OR OTHER POSSIBLE INJURY:

• DO NOT USE THIS PRODUCT FOR HUMAN SAFETY APPLICATIONS.

IT WAS NOT DESIGNED, TESTED OR RECOMMENDED FOR THIS

USE.

• DO NOT USE THIS PRODUCT IN HAZARDOUS LOCATIONS (E.G.

EXPLOSIVE ATMOSPHERES). IT WAS NOT DESIGNED, TESTED OR

RECOMMENDED FOR THIS USE.

• ENSURE THE PRODUCT IS PROPERLY WIRED TO THE CORRECT

POWER SUPLLY FOR THE APPLICATION. REFER TO THE

SPECIFICATIONS AND WIRING DIAGRAMS IN THIS MANUAL.

MODELS COVERED IN THIS MANUAL

Catalog Number Description

EDC205SP Split Core, 24V AC/DC, 0-5V DC Output, 50/75/100A Range

EDC305SP Split Core, 24V AC/DC, 0-5V DC Output, 100/150/200A Range

EDC405SP Split Core, 24V AC/DC, 0-5V DC Output, 150/225/300A Range

EDC210SP Split Core, 24V AC/DC, 0-10V DC Output, 50/75/100A Range

EDC310SP Split Core, 24V AC/DC, 0-10V DC Output, 100/150/200A Range

EDC410SP Split Core, 24V AC/DC, 0-10V DC Output, 150/225/300A Range

EDC2420SP Split Core, 24V AC/DC, 4-20 mA Output, 50/75/100A Range

EDC3420SP Split Core, 24V AC/DC, 4-20 mA Output, 100/150/200A Range

EDC4420SP Split Core, 24V AC/DC, 4-20 mA Output, 150/225/300A Range

INTRODUCTION

The CurrentWatch™ EDC Series

combines a hall effect sensor and a

signal conditioner into a single, compact

package for use in DC current applications

up to 300A. The EDC Series has jumper

selected current input ranges and

industry standard outputs: 4-20 mA,

0-5V DC and 0-10V DC. Split core models provide for quick and easy

installation.

Note that this manual only covers split-core versions of the EDC

Series. For the solid-core manual, use publication P51926.

Eaton’s current sensor family encompasses a broad range of products

for cost-effective monitoring, status, and predictive maintenance.

Downtime and costly repairs can be avoided by utilizing Eaton’s

products and technologies in your control systems.

P51927 Rev 01

292004059

QUICK INSTALL GUIDE

The below steps can be followed to quickly install a CurrentWatch™

EDC Series sensor.

1. Run the wire to be monitored through the aperture, being sure

monitored current fl ow matches arrows on the sensor

2. Mount the sensor to a surface if needed

3. Connect output wiring

a. Use up to 14 AWG copper wires, tightening terminals to 4

inch-pounds of torque

b. For current output models (4-20 mA), make sure output load

is no more than 800 ohms

c. For voltage output models (0-5/0-10V DC), make sure output

load is at least 10 kilohms

3. Connect power using the appropriate power supply

4. Select range by positioning the Range Jumper

INSTALLATION

Considerations for all EDC Series models…

• Run wire to be monitored through the aperture (opening) of the

sensor

• Be sure monitored current fl ows in the same direction as the arrow

on the sensor (the arrow is located just above the hinge, with a

plus symbol on the left and a minus symbol on the right)

• These switches can be located in the same environment as

motors, contactors, heaters, pull-boxes and other electrical

enclosures

• Mounting can be done in any position or hung directly on a wire

with a wire tie

• Be sure to leave at least one inch distance between sensor and

other magnetic devices

• Press the tab in the direction

shown in the diagram to the right.

• After placing the wire in the

aperture, press the hinged portion

fi rmly downward until a click is

heard and the tab pops out fully.

• Keep split-core contact areas

clean. Silicon grease is factory applied on the mating surfaces to

prevent rust and improve performance. Be careful not to allow

grit or dirt into the grease in the contact area, particularly on core

mating surfaces of split core models. Sensor operation could be

impaired if mating surfaces do not have good contact. Check

visually before closing.

RANGE SELECTION

The CurrentWatch™ EDC Series sensors feature fi eld selectable ranges.

The ranges are factory calibrated, eliminating time consuming and

inaccurate fi eld setting of zero or span.

Setting Range

1. Determine the normal operating amperage of your monitored

current

2. Select the range this is equal to or slightly higher than the normal

operating amperage

3. Place the Range Jumper in the appropriate position

Important:

Keep contact areas clean

To open:

Press tab inward

towards hinge

Effective: April 2007 Page 1

Questions? Call our Sensor Application Engineers at (800) 426-9184.

P51927 Rev 01

292004059

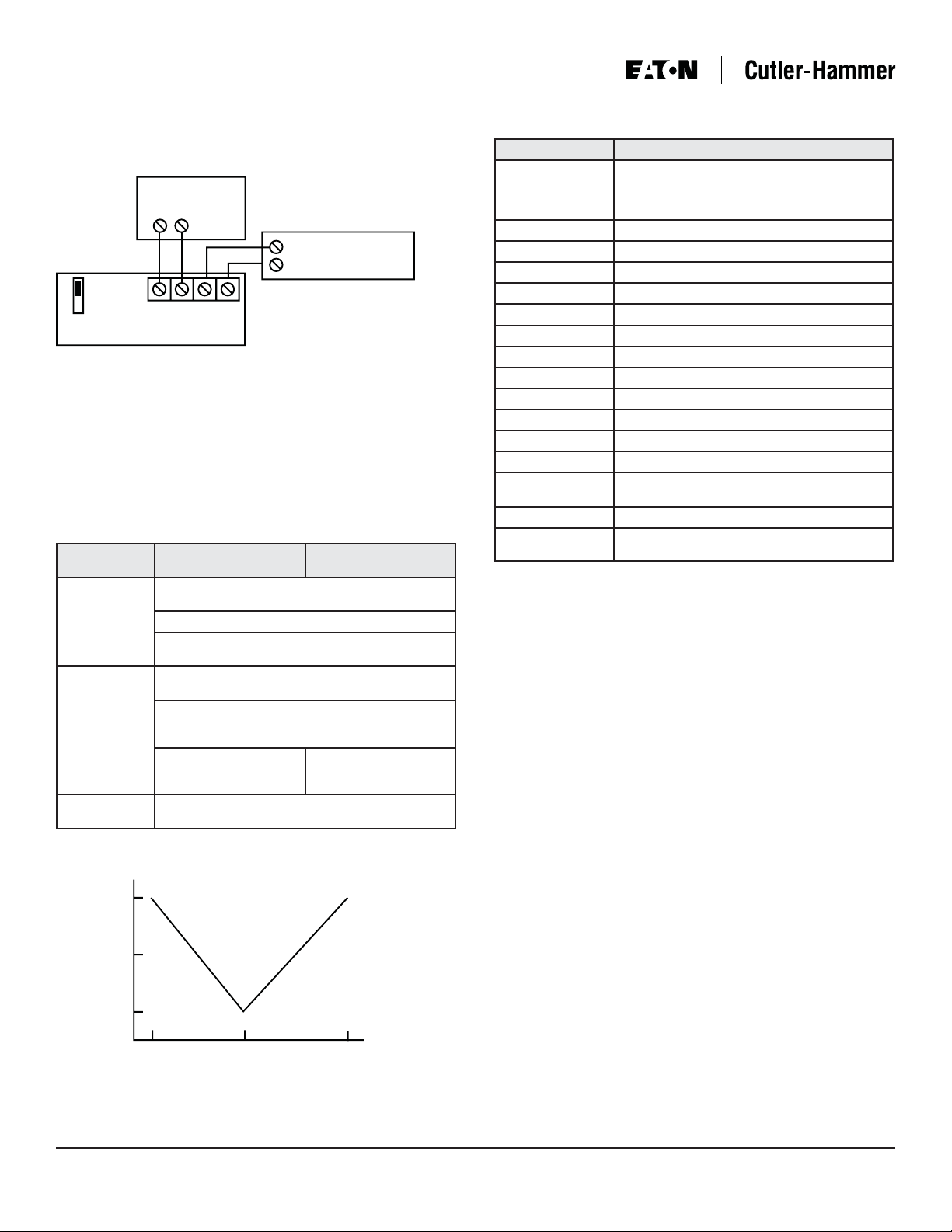

OUTPUT WIRING

Connect control or monitoring wires to the sensor. Use up to 14 AWG

copper wire and tighten terminals to 4 inch-pounds torque.

Power Supply

(22-38V AC/DC)

Range

Jumper

Mid

High

(+)(-)

1 (-) 2(+) 3(-) 4 (+)

Power Output

(-)

Load

(Controller, Meter...)

(+)

Connection Notes:

• For current output models, the current loop is powered by the

sensor. Maximum loop impedance is 800 ohms.

• For voltage output models, the signal is powered by the sensor.

Minimum output load (impedance) is 10 kilohms.

• Deadfront captive screw terminals

• Use 12-22 AWG solid or stranded

• Remove jumper entirely for Low Range operation

• Observe polarity

TROUBLESHOOTING

Problem

Sensor has no output Monitored load is not DC or is not on. Check that the monitored load is

Output signal is

too low

Output signal is

always at maximum

Solution for Current

Output Models (4-20 mA)

DC and that it is actually on.

Polarity is not properly matched. Check and correct wiring polarity.

For split core models, the core contact area may be dirty. Open the

sensor and clean the contact area.

The jumper may be set in a range that is too high for current being

monitored. Move jumper to the correct range.

Power supply is inadequate. Check power supply. Make sure it is of

suffi cient voltage with all loads at maximum. The current draw of EDC

Series sensors is 2.0 VA.

Output load is too high. Check

output load, being sure it is no

more than 800 ohms.

The jumper may be set in a range that is too low for current being

sensed. Change the jumper position.

Solution for Voltage

Output Models (0-5/0-10V DC)

Output load is too low. Check

output load, making sure it is at

least 10 kilohms.

SPECIFICATIONS

Specifi cation Value

Power Supply 24V AC/DC (22-38V AC/DC)

Power input and output signal are not isolated.

Caution: Do not connect Grounded AC Supply to the Output

Negative (-), as sensor damage may occur.

Power Consumption 2 VA

Current Ranges Selectable by Model: 50, 75, 100, 150, 200, 225, 300A

Output Signal Unipolar: 0-20 mA, 4-20 mA, 0-5V DC or 0-10V DC

Output Polarity Unipolar: Current Magnitude Only

Response Time 100 ms (90% of Step Change)

Repeatability 1% FS

Frequency Range DC

Accuracy 1% FS

Linearity 0.75%

Isolation Voltage 3 kV (Monitored Line to Output)

Sensing Aperture 0.85 in. (21.7mm) sq.

Housing UL94 V0 Flammability Rated

Environmental Operating Temperature: -4 to +122° F (-20 to +50° C)

Humidity: 0-95% RH, Non-Condensing

Temperature Drift 0.01% / Degree C

Approvals UL 508 Industrial Control Equipment (Pending, USA and Canada)

CE Certifi ed

OUTPUT POLARITY

100%

O

U

T

50%

P

U

T

0%

-Amps 0 + Amps

Effective: April 2007 Page 2

Unipolar

(Magnitude Only)

Questions? Call our Sensor Application Engineers at (800) 426-9184.

Loading...

Loading...