Instructional Leafl et IL03901001E

Effective June 2009

DS6 series soft start controllers

Introduction

Eaton’s Cutler-Hammer姞 DS6 solid-state soft

start controller is an electronic, self-contained

panel- or enclosure-mounted motor soft-starting

device. It provides three-phase induction motors

with a smooth start, both mechanically and electrically. The DS6 line uses four silicon-controlled

rectifiers (SCRs) that are connected in a full wavepower bridge on two phases. The voltage and current applied to the motor are controlled by varying

the SCR conduction period. This, in turn, controls

the torque developed by the motor. After the

motor reaches speed, a bypass contactor is energized to bypass the SCRs. The DS6 is designed

to fulfill the industrial service requirements of

applications such as chiller starters, pump panels,

and machine tools. This device meets all relevant

specifications set forth by UL姞 508, IEC 60947-4-2,

CE, C-Tick, and CSA姞.

This leaflet covers basic installation and setup. No

publication can take into account every possible

situation. If you require further assistance with any

aspect of this product or a particular application,

contact Eaton.

Inspection

General

Upon receipt of the unit, verify that the catalog

number and unit options stated on the shipping

container match those stated on the order/

purchase form.

Inspect the equipment upon delivery. Report any

carton damage to the carrier prior to accepting the

delivery. Have this information noted on the freight

bill. Eaton is not responsible for damage incurred

in shipping.

Unpacking

Remove all packing material from the unit. Be

sure to remove all packing material from the

lug location.

Check the unit for any signs of shipping damage.

If damage to the product is found after unpacking,

report it to the freight company. Retain the packing materials for the carrier to review.

Verify that the unit’s catalog number and options

match those stated on the order/purchase form.

Instructional Leafl et IL03901001E

Effective June 2009

DS6 series soft start controllers

Storage

It is recommended that the unit be stored in its original shipping

box/crate until it is to be installed.

The unit should be stored in a location where:

•

The ambient temperature is between –13°F to 140°F

(–25°C to 60°C)

•

The relative humidity is between 0% and 95%, noncondensing

•

The environment is dry, clean, and noncorrosive

•

The unit will not be subjected to high shock or

vibration conditions

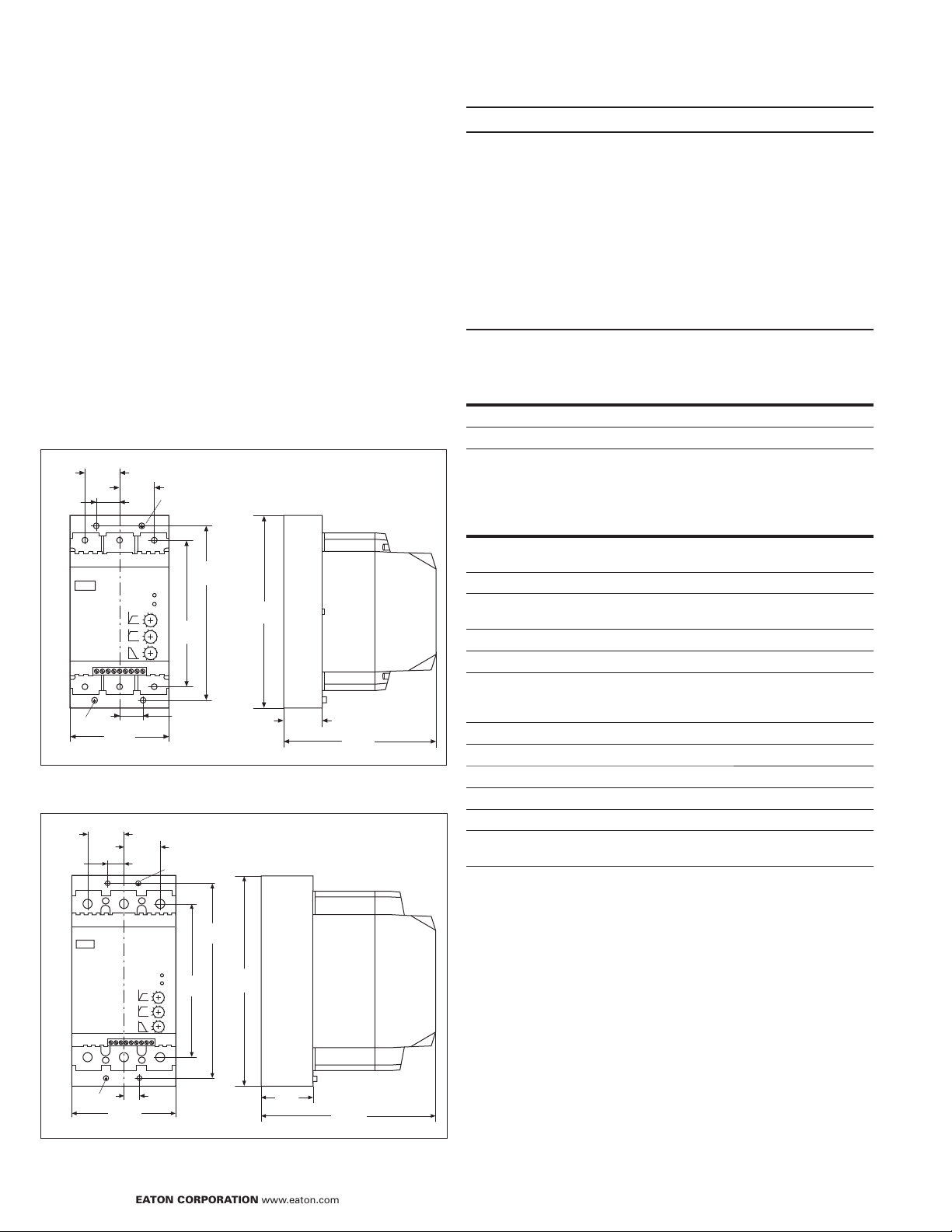

Mounting instructions

The DS6 solid-state soft start controller is easy to mount. It does not

require any special tools. To aid you with panel layout, refer to the

dimension drawings shown in Figure 1 and Figure 2. Drill and tap

holes per mounting hole/slot locations as shown. To mount the unit,

use all the hardware specified in Table 1 of this leaflet. Tighten to

the specified torque.

1.18

(30.0)

1.18

PE

(93.0)

1.38

(35.0)

3.66

(30.0)

1.38

(35.0)

PE

(129.0)

(22.5)

PE

5.08

0.86

6.34

(161.0)

6.89

(175.0)

1.38

(35.0)

5.47

(139.0)

0.86

(22.5)

Figure 1. 25- to 75-Horsepower Models

0.59

(15.0)

DANGER—HIGH VOLTAGE

HAZARDOUS VOLTAGE CAN CAUSE ELECTRIC SHOCK AND BURNS. TO

AVOID SHOCK HAZARD, DISCONNECT ALL POWER TO THE CONTROLLER,

MOTOR, OR OTHER CONTROL DEVICES BEFORE ANY WORK IS PERFORMED

ON THIS EQUIPMENT. FAILURE TO DO SO WILL RESULT IN PERSONAL

INJURY, DEATH, OR SUBSTANTIAL PROPERTY DAMAGE.

DO NOT APPLY A DISCONNECT DEVICE ON THE OUTPUT OF THE DS6 SOFT

START CONTROLLER UNLESS A MEANS TO TURN OFF THE DEVICE WHEN

DISCONNECT SWITCH IS OPEN IS UTILIZED. OPENING THE DISCONNECT

WHILE THE SOFT START CONTROLLER IS OPERATING MAY CAUSE A MALFUNCTION. CLOSING THE DISCONNECT SWITCH WHILE THE SOFT START

CONTROLLER IS OPERATING WILL RESULT IN POTENTIAL EQUIPMENT

DAMAGE AND PERSONNEL HAZARD.

Table 1. Mounting Hardware and Torque Specifications

Frame Size

25–75 hp 5 mm x 55 mm 2 80 lb-in (9 Nm) 4.0 (1.8)

100–150 hp 6 mm x 65 mm 2 123 lb-in (14 Nm) 8.2 (3.7)

Screw Size + Flat

and Lock Washer Quantity

Table 2. Environmental Requirements

Description Requirements

Operating temperature 32°F to 104°F (0°C to 40°C) up to 140°F (60°C) with derating

Storage temperature –13°F to 140°F (–25°C to 60°C )

Elevation Up to 1000m; up to 2000m with derating of 1% rated current

Humidity Functional to 95% noncondensing.

Operating orientation Less than 30 degrees from horizontal

Minimum clearance—

upper and lower

Minimum clearance—sides 0.0 inches (0 mm)

Minimum clearance—face 0.198 inches (5 mm)

Shock resistance 8g for 11 ms in any direction.

Vibration resistance 2M2 EN 60721-3-2: 10g (3.5 mm amplitude, 9 to 200 Hz)

Environment Suitable for installation in a pollution Degree 2 environment

Emissions The device is suitable for use in industrial environments in

of 1% of rated current per Kelvin

for each 100m

2.165 inches (55 mm) to a wall, 0.984 inches (25 mm) to a

NZM1 (size 1), 1.378 inches (35 mm) to a NZM2 (size 2), consult documentation of the breaker used (ionization emissions)

accordance with EN 55011/22 Class A

Torque

Requirements

Unit Weight

Lbs (kg)

7.87

(200.0)

8.47

(215.0)

2.07

(52.5)

PE

4.25

(108.0)

0.59

(15.0)

6.22

(158.0)

Figure 2. 100- to 150-Horsepower Models

2

EATON CORPORATION www.eaton.com

7.01

(178.0)

DS6 series soft start controllers

Instructional Leafl et IL03901001E

Effective June 2009

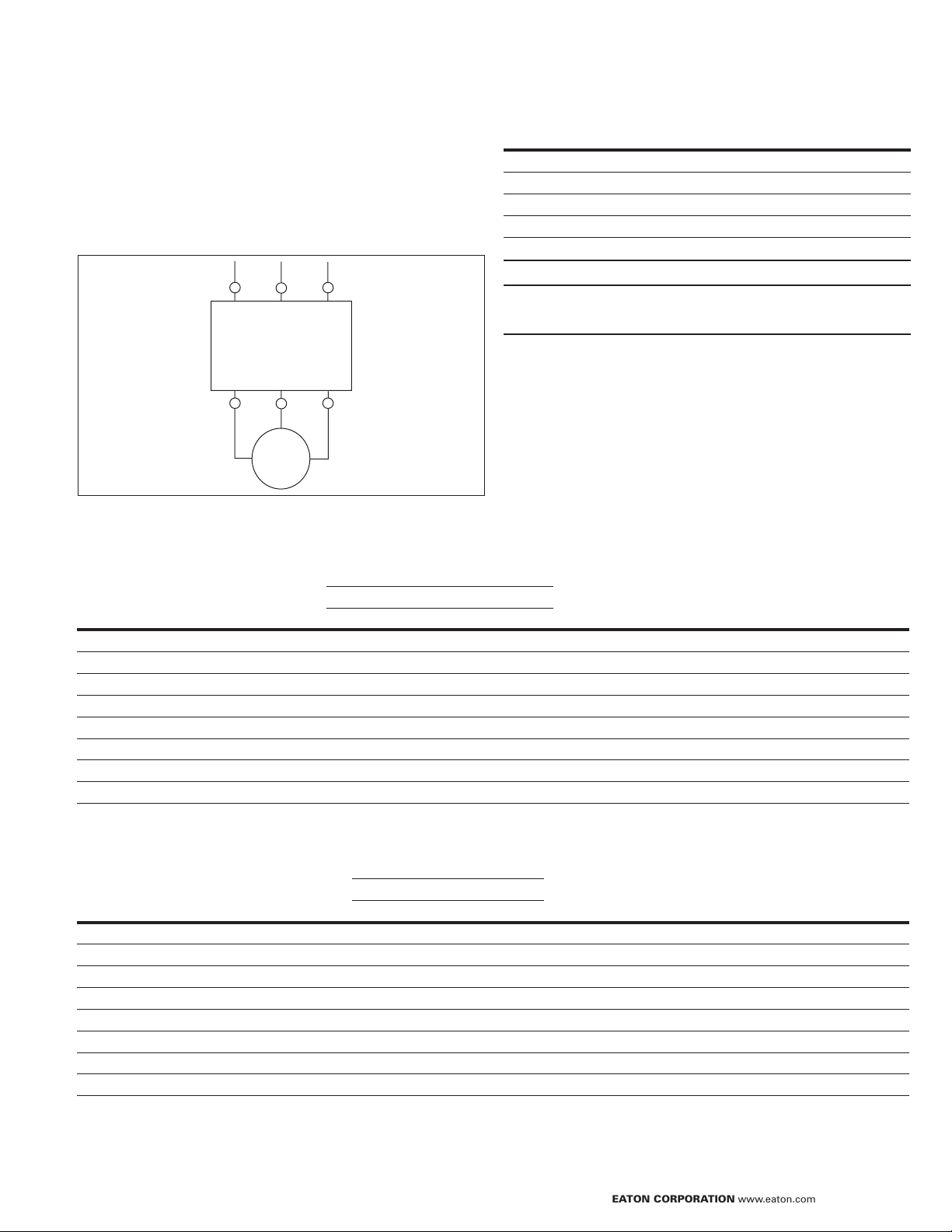

Power wiring

Using the wiring diagrams in Figure 3, Figure 4, and Table 3 as

guides, connect the line, motor, and power supply wiring in

accordance with appropriate local and national codes.

ote: N To provide optimum motor protection, the line and motor power wiring

should be tightly bundled and run perpendicular to the orientation of the DS6.

Soft start controller to motor cable length is not to exceed 325 ft (100m).

5

1

L2 L3

L1

3

Table 3. Power Wire Sizing and Torque Requirements

Frame Size Wire Size Torque Wire Strip Length

25–75 hp 12–8 AWG 53 lb-in 0.65 in

25–75 hp 6–2/0 AWG 80 lb-in 0.65 in

100–150 hp 12–8 AWG 44 lb-in 0.87 in

100–150 hp 6 AWG—350 kcmil 123 lb-in 0.87 in

DANGER

HAZARDOUS VOLTAGE. WILL CAUSE DEATH OR SERIOUS INJURY.

HAZARDOUS VOLTAGE IS PRESENT IN THE OFF/STOP STATUS OF THE SOFT

START CONTROLLER WHEN THE LINE VOLTAGE IS ENERGIZED.

DS6

T1

4

T2

M

3~

2

T3

6

Figure 3. Power Wiring Diagram for 230/400 and 400/460V

Line Voltages

Table 4. Product Selection—Horsepower Ratings

Motor Power

Rated

Current

Catalog Number

DS6-34DSX041N0-N 40 10 10 30 HFD3150L 150A Class RK5

DS6-34DSX055N0-N 52 15 20 40 HFD3200L 200A Class RK5

DS6-34DSX068N0-N 65 20 25 50 HJD3250 200A Class RK5

DS6-34DSX081N0-N 77 25 30 60 HKD3300 300A Class RK5

DS6-34DSX099N0-N 96 30 30 75 HKD3350 350A Class RK5

DS6-34DSX134N0-N 124 40 50 100 HKD3350 500A Class RK5

DS6-34DSX161N0-N 156 50 60 125 HLD3450 500A Class RK5

DS6-34DSX196N0-N 180 60 75 150 HLD3500 500A Class RK5

(A)

200V 230V 460V

(hp) (hp) (hp)

Maximum Allowable

Breaker Size

Maximum Allowable

Fuse Size

Maximum values are higher than allowed per NEC姞 430.52 and UL 508A 31.1.

Table 5. Product Selection—kW Ratings According to IEC 60947-4-2

Motor Power

Rated

Current

Catalog Number

DS6-34DSX041N0-N 41 11 22 HFD3150L 150A Class RK5

DS6-34DSX055N0-N 55 15 30 HFD3200L 200A Class RK5

DS6-34DSX068N0-N 68 15 37 HJD3250 200A Class RK5

DS6-34DSX081N0-N 81 22 45 HKD3300 300A Class RK5

DS6-34DSX099N0-N 99 30 55 HKD3350 350A Class RK5

DS6-34DSX134N0-N 134 30 75 HKD3350 500A Class RK5

DS6-34DSX161N0-N 161 45 90 HLD3450 500A Class RK5

DS6-34DSX196N0-N 196 55 110 HLD3500 500A Class RK5

Maximum values are higher than allowed per NEC 430.52 and UL 508A 31.1.

Considerations:

1. Either XTOB, C306, or C396 series or equivalent overload protection devices may be selected.

2. Isolation contactor is optional for normal applications. It is recommended for mains isolation.

(A)

230V 400V

(kW) (kW)

Maximum Allowable

Breaker Size

EATON CORPORATION www.eaton.com

Maximum Allowable

Fuse Size

3

Loading...

Loading...