Manual

11/16 MN040022EN

PowerXL

™

DC1…E1

Variable Frequency Drives

Parameter Manual

Parameter

P-01 f-max Sets the upper limit for the speed of the motor.

P-02 f-min Sets the lower limit for the speed of the motor

…

Designation Description DS

This can be set to any value between “f-min” and 5x the “motor nom frequency”.

When “Motor Nom Frequency” (P-09) is changed, P-01 is set to the value of P-09.

”Motor Nom Speed” (P-10) = 0, the maximum speed limit will be displayed in Hz.

”Motor Nom Speed” (P-10) > 0, the maximum speed limit will be displayed in rpm.

This can be set to any value between 0 and “f-max” (P-01). When “Motor Nom

Frequency” (P-09) is changed, P-01 is set to zero.

50.0 Hz

0.0 Hz

All proprietary names and product designations are brand names or trademarks

registered to the relevant title holders.

Break-Down Service

Please call your local representative:

http://eaton.com/moeller/aftersales

or

Hotline After Sales Service:

+49 (0) 180 5 223822 (de, en)

AfterSalesEGBonn@eaton.com

For customers in US/Canada contact:

EatonCare Customer Support Center

Call the EatonCare Support Center if you need assistance with placing an order,

stock availability or proof of shipment, expediting an existing order, emergency

shipments, product price information, returns other than warranty returns, and

information on local distributors or sales offices.

Voice: 877-ETN-CARE (386-2273) (8:00 a.m. – 6:00 p.m. EST)

After-Hours Emergency: 800-543-7038 (6:00 p.m. – 8:00 a.m. EST)

Drives Technical Resource Center

Voice: 877-ETN-CARE (386-2273) option 2, option 6

(8:00 a.m. – 5:00 p.m. Central Time U.S. [UTC-6])

email: TRCDrives@Eaton.com

www.eaton.com/drives

Original operating manual

The German-language edition of this document is the original operating manual.

Translation of the original operating manual

All editions of this document other than those in German language are translations of

the original operating manual.

1. Edition 2016, publication date 08/16

2. Edition 2016, publication date 11/16

© 2016 by Eaton Industries GmbH, 53105 Bonn

Authors: Jörg Randermann, Heribert Joachim

Redaction: René Wiegand

All rights reserved, also for the translation.

No part of this manual may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, electronic, mechanical, photocopying,

micro-filming, recording or otherwise, without the prior written permission of

Eaton Industries GmbH, Bonn.

Subject to alteration.

Danger!

Dangerous electrical voltage!

Before commencing the installation

• Disconnect the power supply of the device.

• Ensure that devices cannot be accidentally retriggered.

• Verify isolation from the supply.

• Ground and short-circuit.

• Cover or enclose neighbouring units that are live.

• Follow the engineering instructions (IL) of the device

concerned.

• Only suitably qualified personnel in accordance with

EN 50110-1/-2 (VDE 0105 Part 100) may work on this device/

system.

• Before installation and before touching the device ensure

that you are free of electrostatic charge.

• The functional earth (FE) must be connected to the

protective earth (PE) or to the potential equalizing.

The system installer is responsible for implementing this

connection.

• Connecting cables and signal lines should be installed so

that inductive or capacitive interference do not impair the

automation functions.

• Install automation devices and related operating elements

in such a way that they are well protected against unintentional operation.

• Suitable safety hardware and software measures should

be implemented for the I/O connection so that a cable or

wire breakage on the signal side does not result in

undefined states in the automation device.

• Ensure a reliable electrical isolation of the low voltage for

the 24 V supply. Only use power supply units complying

with IEC 60364-4-41 or HD 384.4.41 S2 (VDE 0100 part 410).

• Deviations of the mains voltage from the nominal value

must not exceed the tolerance limits given in the technical

data, otherwise this may cause malfunction and

dangerous operation.

• Emergency-Stop devices complying with IEC/EN 60204-1

must be effective in all operating modes of the automation

devices. Unlatching the emergency switching off devices

must not cause restart.

• Built-in devices for enclosures or cabinets must only be

run and operated in an installed state, desk-top devices or

portable devices only when the housing is closed.

• Measures should be taken to ensure the proper restart of

programs interrupted after a voltage dip or failure. This

Eaton Industries GmbH

should not cause dangerous operating states even for a

Safety instructions

short time. If necessary, emergency switching off devices

should be implemented.

• Wherever faults in the automation system may cause

damage to persons or property, external measures must

be implemented to ensure a safe operating state in the

event of a fault or malfunction (for example, by means of

separate limit switches, mechanical interlocks, etc.).

• During operation, and depending on their degree of

protection, variable frequency drives may have live,

uninsulated, moving, and/or rotating parts, as well as hot

surfaces.

• The impermissible removal of the required cover,

improper installation or incorrect operation of the motor or

variable frequency drive can cause the failure of the

device and serious injury and/or material damage.

• Comply with all applicable national accident prevention

regulations (e.g. BGV A3) when working with energized

variable frequency drives.

• The electrical installation must be carried out in

accordance with the relevant regulations (e.g. with regard

to cable cross sections, fuses, PE).

• All transport, installation, commissioning and maintenance work must only be carried out by trained personnel

(observe IEC 60364, HD 384 or DIN VDE 0100 and national

accident prevention regulations).

• If applicable, systems in which variable frequency drives

are installed must be equipped with additional monitoring

and protective devices in accordance with the applicable

safety regulations, e.g., the German Equipment and

Product Safety Act, accident prevention regulations, etc.

Making changes to the variable frequency drives by using

the operating software is allowed.

• Keep all covers and doors closed during operation.

• When designing the machine, the user must incorporate

mechanisms and measures that limit the consequences of

a drive controller malfunction or failure (an increase in

motor speed or the motor?9s sudden stop) so as to prevent

hazards to people and property, e.g.:

– Additional stand-alone devices for monitoring parame-

ters that are relevant to safety (speed, travel, end

positions, etc.)

– Electrical and non-electrical safety devices (interlocks

or mechanical locks) for mechanisms that protect the

entire system

– Due to the possibility of there being capacitors that are

still holding a charge, do not touch live device parts or

terminals immediately after disconnecting the variable

frequency drives from the supply voltage. Heed the

corresponding labels on the variable frequency drives

I

II

Content

0 About this manual ..................................................................... 3

0.1 Target group................................................................................. 3

0.2 List of revisions ............................................................................ 3

0.3 Writing conventions ..................................................................... 4

0.3.1 Hazard warnings of material damages ......................................... 4

0.3.2 Hazard warnings of personal injury .............................................. 4

0.3.3 Tips............................................................................................... 4

1 General........................................................................................ 5

1.1 Parameter Groups ........................................................................ 5

1.2 Menu structure ............................................................................ 6

2 HMI device .................................................................................. 7

2.1 Control unit elements................................................................... 7

2.2 Setting parameters....................................................................... 8

2.3 Resetting parameters (RESET)..................................................... 8

2.4 Extended parameter set............................................................... 9

2.5 “Monitor” submenu..................................................................... 10

2.6 Control via keypad........................................................................ 11

3 Control signal terminals ............................................................ 12

3.1 Correspondence between inputs/outputs and terminals............. 12

3.2 Configuration of the control signal terminals ............................... 16

3.2.1 P-12 = 0: Terminal-based operation ............................................. 16

3.2.2 P-12 = 1: digital setpoint value, 1 operating direction.................. 17

3.2.3 P-12 = 2: digital setpoint value, 2 operating directions ................ 18

3.2.4 P-12 = 3: Control via Modbus with internal acceleration and

deceleration ramps....................................................................... 19

3.2.5 P-12 = 4: Control via Modbus, ramps via Modbus....................... 20

3.2.6 P-12 = 5: PI controller .................................................................. 21

3.2.7 P-12 = 6: PI controller with AI1 totaling ....................................... 22

3.2.8 P-12 = 7: Control via CAN with internal acceleration and

deceleration ramps....................................................................... 23

3.2.9 P-12 = 8: Control via CAN, ramps via Modbus............................. 24

3.2.10 P-12 = 9: SWD control + setpoint value ...................................... 25

3.2.11 P-12 = 10: SWD control ............................................................... 26

3.2.12 P-12 = 11: SWD setpoint value.................................................... 27

3.2.13 P-12 = 13: SWD control + setpoint value, DI ENA....................... 28

DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com 1

4 Messages.................................................................................... 29

4.1 List of messages.......................................................................... 29

4.2 Messages after a data transfer with a DX-COM-STICK2 ............. 31

4.3 Operating status indicators .......................................................... 31

5 Parameters ................................................................................. 32

5.1 “Monitor” parameter group......................................................... 32

5.2 “Basic” parameter group............................................................. 35

5.3 “Extended” parameter group ...................................................... 38

5.4 “Advanced” parameter group...................................................... 46

2 DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com

0 About this manual

0 About this manual

0.1 Target group

This manual provides special information that is intended to enable you to

configure the parameters for a DC1…E1 variable frequency drive according

to your needs.

The details apply to the indicated hardware and software versions.

0.1 Target group

0.2 List of revisions

→

This manual (MN040022EN) is intended for engineers and electricians.

Electrical engineering and physics-related knowledge and skills will be

required in order to be able to commission the corresponding devices.

We assume that you have a good knowledge of engineering fundamentals

and that you are familiar with handling electrical systems and machines, as

well as with reading technical drawings.

Publication date Page Keyword new modified deleted

11/16 P-12 = 12: SWD control + setpoint value,

08/16 – Initial issue

For a general description (installation, technical data, etc.) of

DC1…E1 variable frequency drives, please refer to manual

MN040023EN (“Installation Manual”).

✓

auto

DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com 3

0 About this manual

0.3 Writing conventions

0.3 Writing conventions

Symbols with the following meaning are used in this manual:

▶ Indicates instructions to be followed.

0.3.1 Hazard warnings of material damages

NOTICE

Warns about the possibility of material damage.

0.3.2 Hazard warnings of personal injury

CAUTION

0.3.3 Tips

→

→

Warns of the possibility of hazardous situations that may

possibly cause slight injury.

WARNING

Warns of the possibility of hazardous situations that could result

in serious injury or even death.

DANGER

Warns of hazardous situations that result in serious injury or

death.

Indicates useful tips.

All the specifications in this manual refer to the hardware and

software versions documented in it.

→

4 DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com

More information on the devices described here can be found

on the Internet under:

www.eaton.eu/powerxl

as well as:

www.eaton.eu/documentation

1 General

1.1 Parameter Groups

1 General

1.1 Parameter Groups

The DC1 variable frequency drive’s functions are configured with the use of

parameters. These parameters are subdivided into four groups (P00-01 to

P00-50, P-01 to P-14, P-15 to P-59, and P-60 to P-68):

Table 1: Parameter Groups

Parameter group Theme

P00-01 – P00-50 Monitor

P-01 – P-14 Basic

P-15 – P-59 Extended

P-60 – P-68

Advanced

→

Default settings

By default (= unit as supplied), only parameter group 1 (“Basic”) will be

accessible.

Extended parameter set

Level 2 (“Extended”) can be accessed by using parameter P-14 to enter

the correct password.

The default password is:

• Access to level 2: 101

Users can change this password as required:

• Password for Level 2 with: P-37

• Advanced parameter set:

Can be accessed by entering the password for level 2 (P-37 + 100)

The following page (“Menu structure“) features a diagram

showing how to switch between parameter groups.

DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com 5

1 General

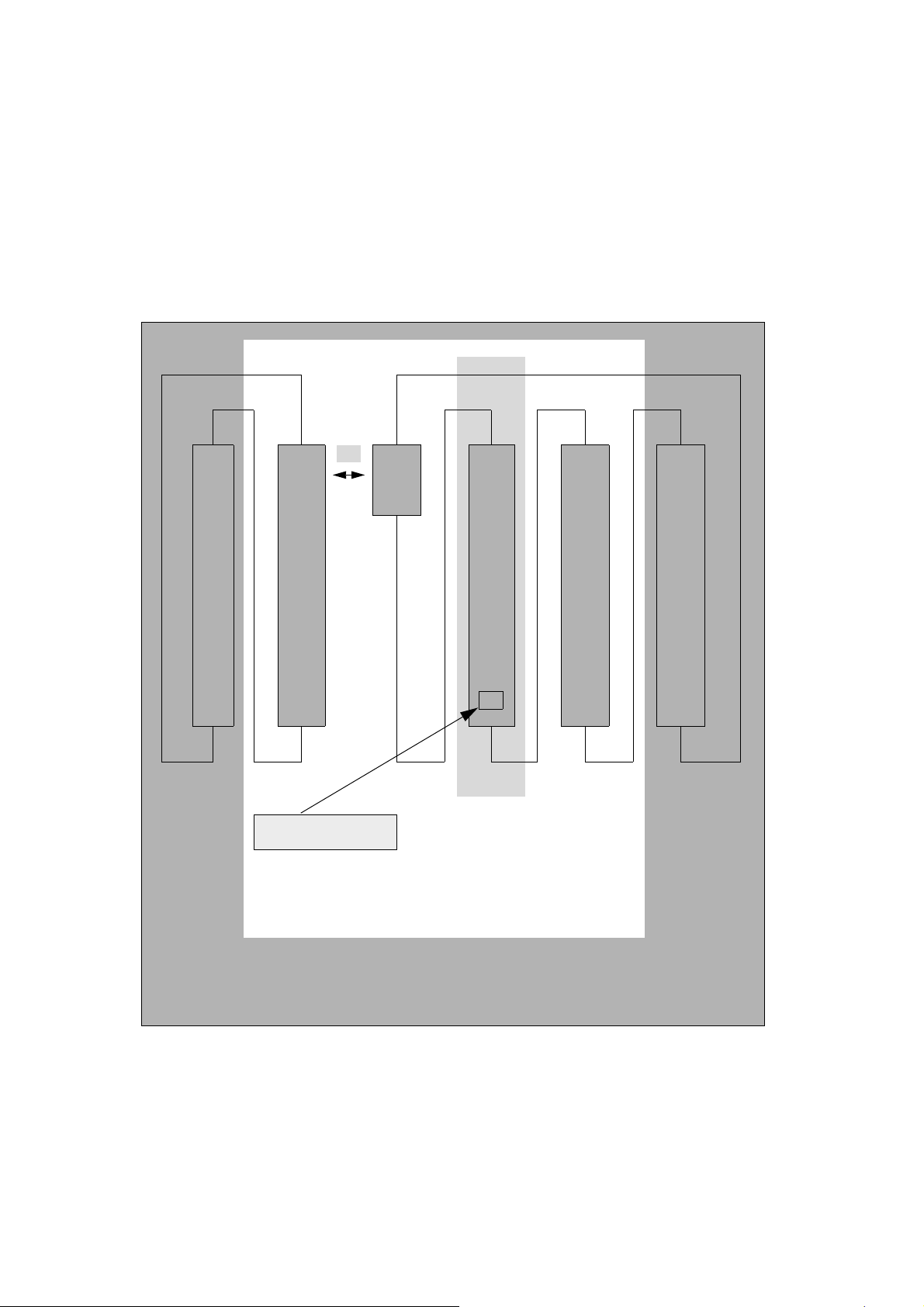

1.2 Menu structure

1.2 Menu structure

Monitor

OK

P00- P00- P0- P- P- P-

31 01 00 01 15 60

32 02 02 16 61

Basic

Extended

∙ ∙ ∙ ∙ ∙

▲▼ ▲▼ ▲▼ ▲▼ ▲▼

∙ ∙ ∙ ∙ ∙

∙ ∙ ∙ ∙ ∙

∙ ∙ ∙ ∙ ∙

49 19 13 58 67

50 20 14 59 68

Advanced

Level 1

Password entry

Level 2, extended (password set with: P-37, default

password = 101)

Level 3, advanced (password set with: P-37 + 100, default password = 201)

6 DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com

2 HMI device

2.1 Control unit elements

2 HMI device

2.1 Control unit elements

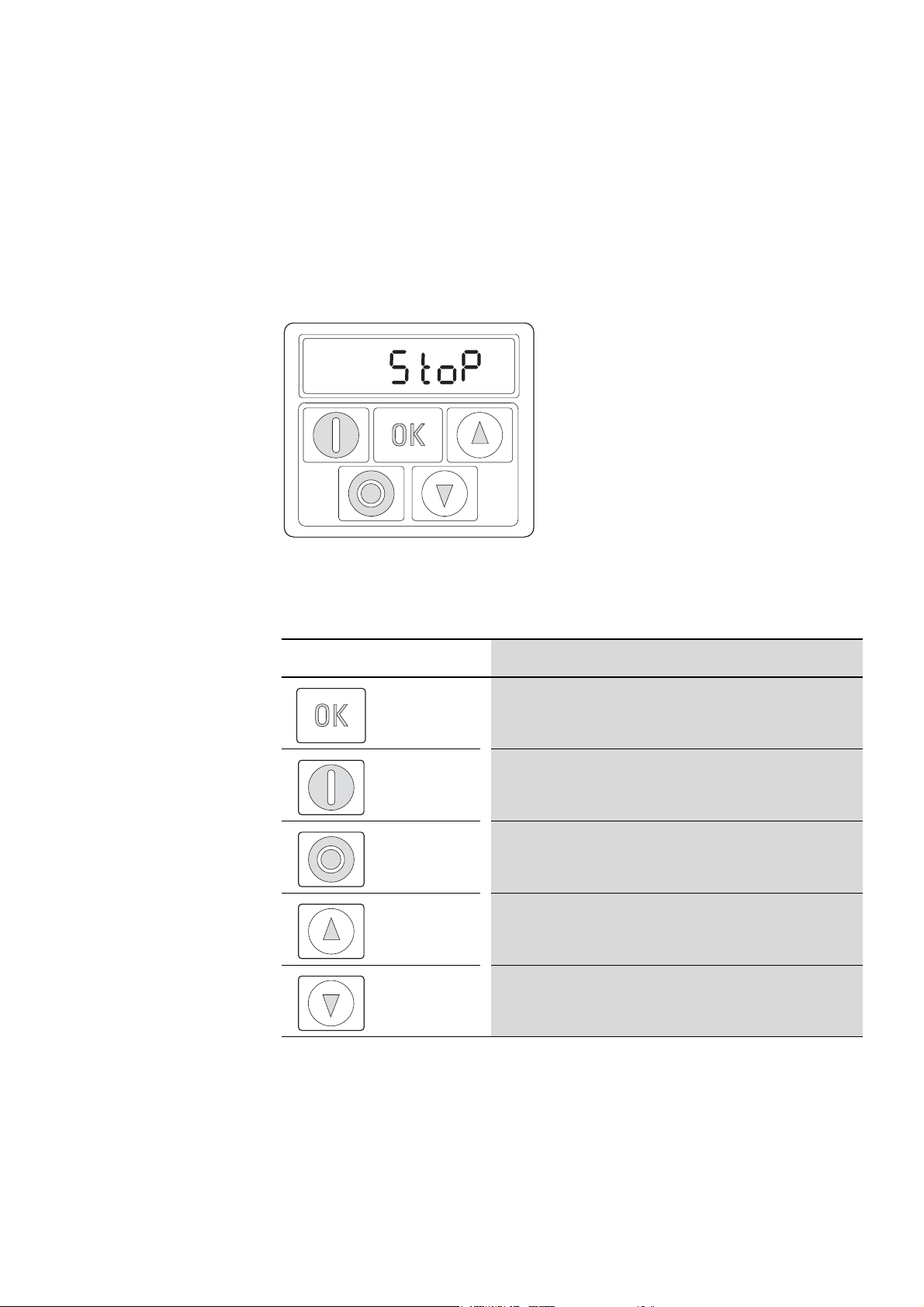

The following figure shows the elements of the DC1 variable frequency drive

integrated operating unit.

View

Push buttons

Figure 1: Operating unit view

Table 2: Keypad elements – Buttons

Button Attribute ID Explanation

OK • Opens and closes the parameter interface

• Saves parameter values

START

STOP • Stops the variable frequency drive

UP • Increases the speed

DOWN • Decreases the speed

• Starts the variable frequency drive

• Changes the operating direction

• Reset – Resetting after an error message

• Increases the parameter value

• Decreases the parameter value

1)

2)

1)

1)

1)

Hint:

1) Only if P-12 = 1 (one operating direction) or = 2 (two operating directions)

2) Only if P-12 = 2

DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com 7

2 HMI device

2.2 Setting parameters

2.2 Setting parameters

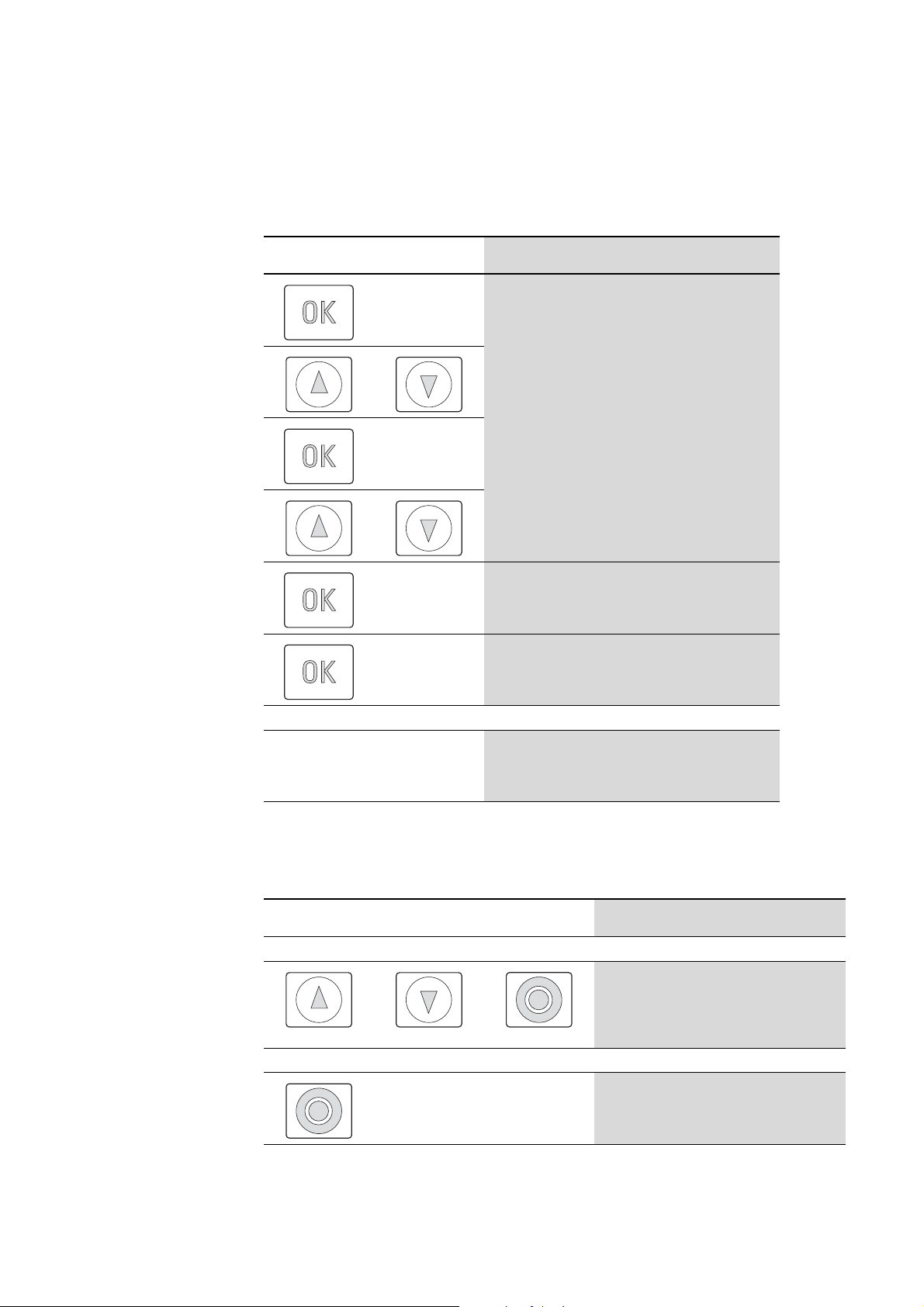

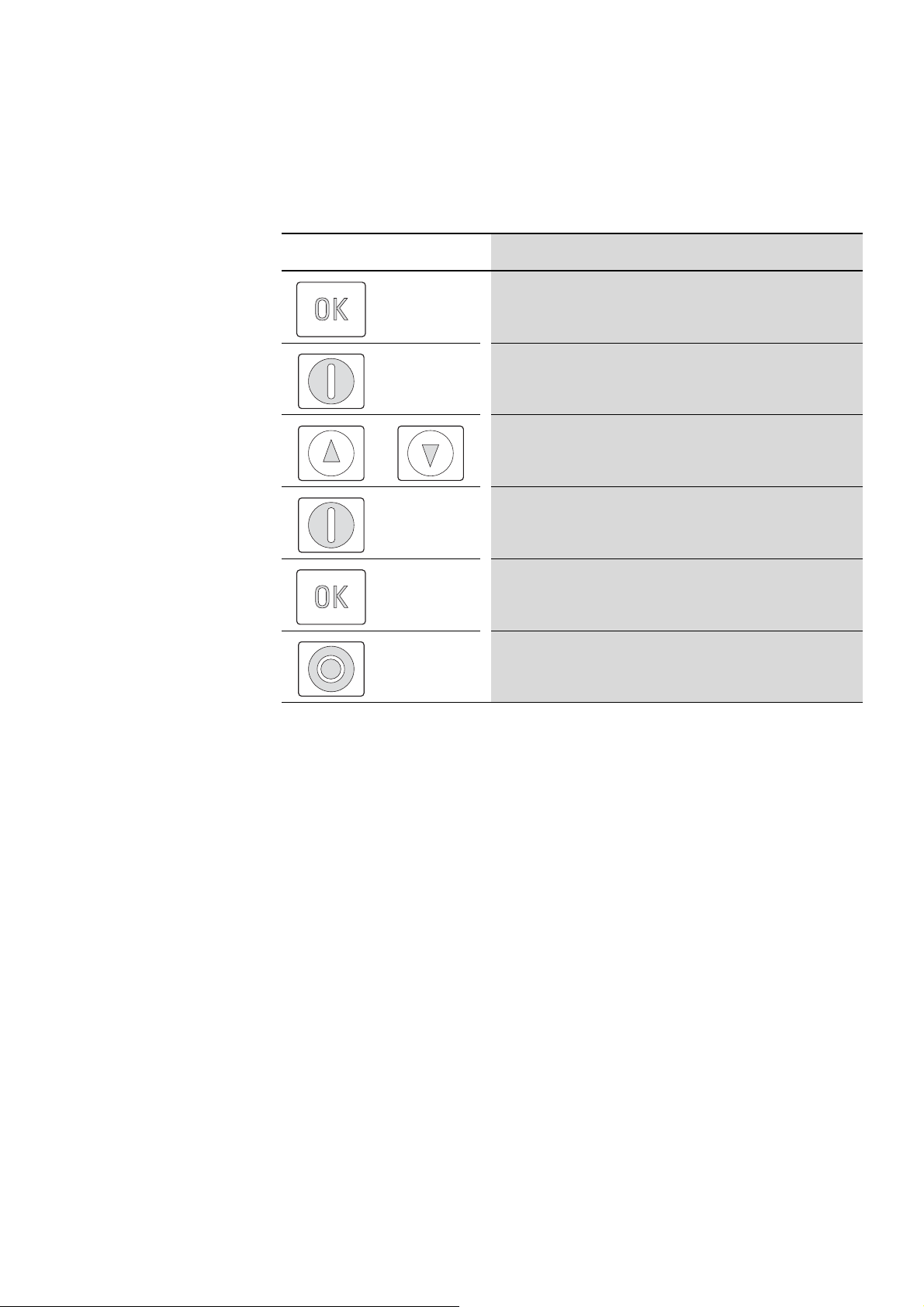

Table 3: Navigating within the keypad

Commands Description

Press the OK button and hold it down for two seconds in

order to access the parameter interface

→ The display will show the parameter that was last

used.

Use the ▲ and ▼ buttons to select a parameter

Press the OK button.

Use the ▲ and ▼ buttons to change the parameter’s

value

Navigating between parameter groups

2.3 Resetting parameters (RESET)

Table 4: Resetting parameters (RESET)

Commands Description

Restoring default settings

Resetting after a fault

Press the OK button to confirm the parameter value

change.

Press the OK button and hold it down for two seconds in

order to exit the parameter interface

The parameters are in sequential order.

This means that moving forward from the last parameter

in a parameter group will take you to the first parameter

in the next parameter group and the other way around.

Press the ▲ and ▼ and STOP buttons and hold

them down for two seconds

→ All parameters will be restored to their default

settings.

The keypad will display

Press the STOP button to reset the unit after a

fault

P-dEF.

8 DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com

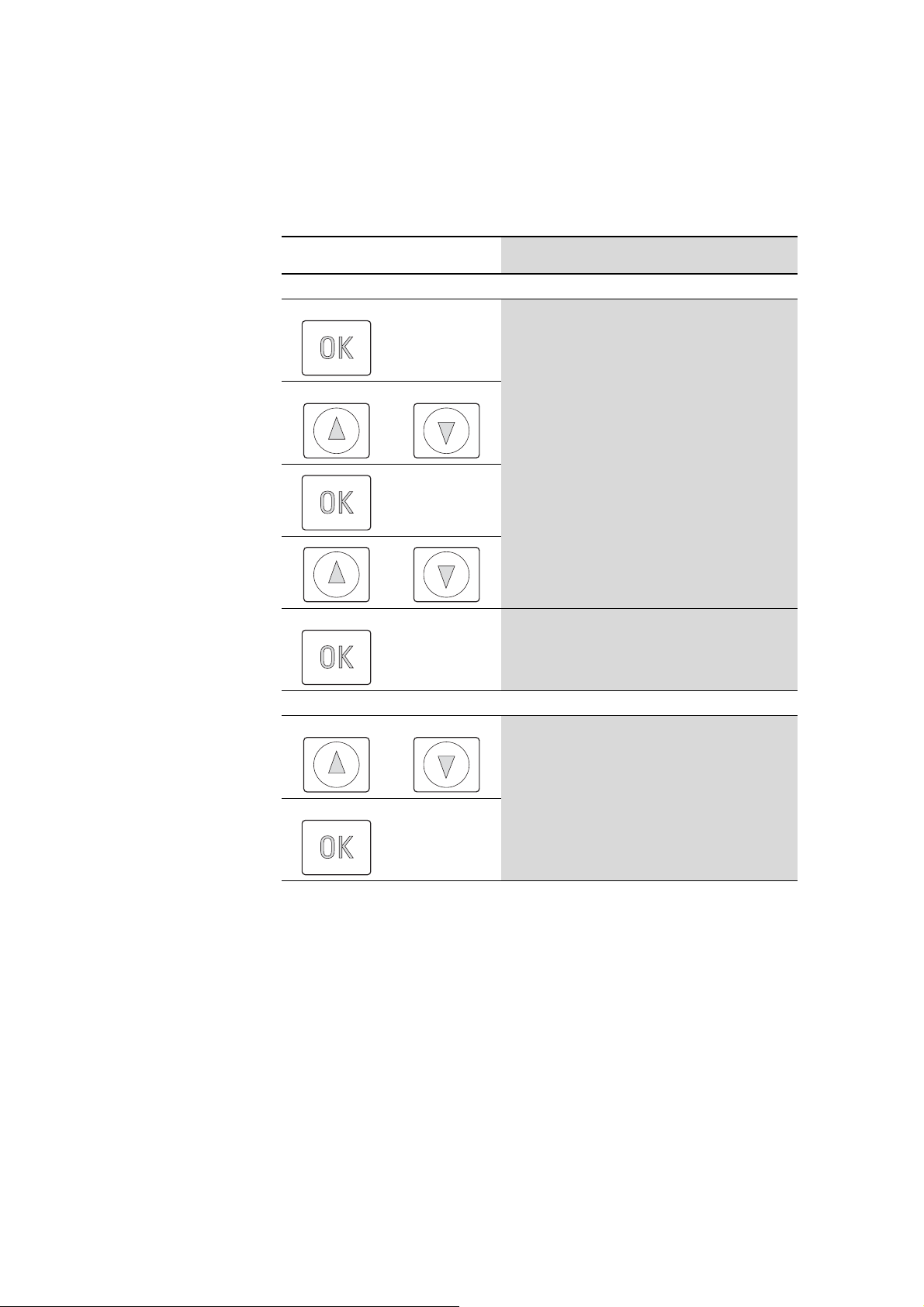

2.4 Extended parameter set

Table 5: Enabling and disabling access to the extended parameter set

Commands

Enabling access to the extended parameter set

2 HMI device

2.4 Extended parameter set

Description

Press the OK button and hold it down for two seconds in

order to access the parameter interface

→ The display will show the parameter that was last

used.

Use the ▲ and ▼ buttons to select parameter P-14

Press the OK button.

Use the ▲ and ▼ buttons to enter the password set with

P-37 (default setting: 101)

Press the OK button to confirm

The extended parameter set (parameters > P-14 and

→

display values P00-…) will now be available.

Disabling access to the extended parameter set

Use the ▲ and ▼ buttons to set a value for P-14 that does

not match the password (P-37).

Press the OK button to confirm

→

Only the “basic parameters”, i.e., parameters P-01 to

P-14, will be accessible now.

The extended parameter set (default setting for P-37 = 101)

→

contains parameters P-01 to P-59.

Additional parameters (up to to P-68) can be configured for

specific applications. The password that needs to be entered in

P-14 is equal to the value yielded by P-37 + 100.

DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com 9

2 HMI device

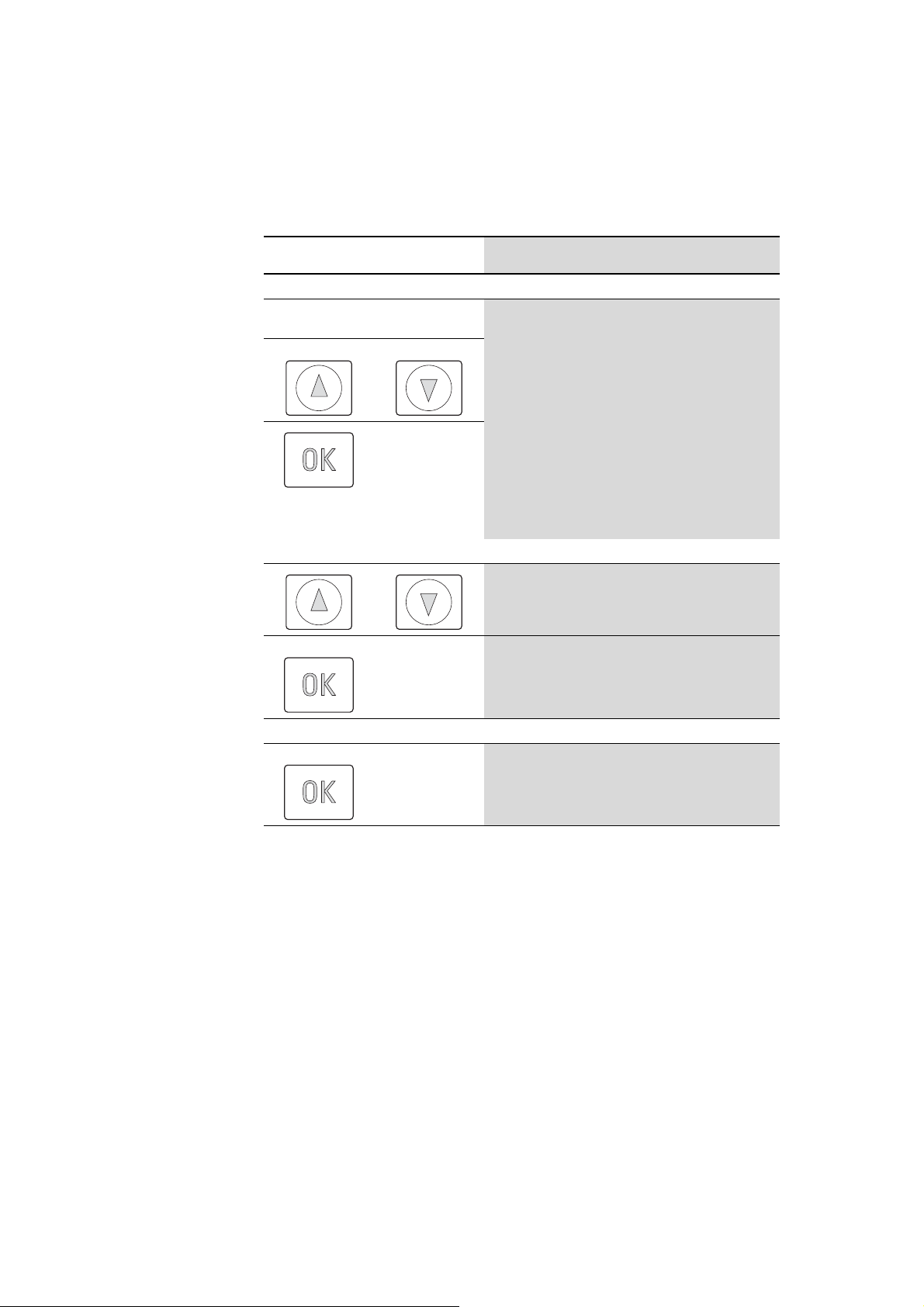

2.5 “Monitor” submenu

2.5 “Monitor” submenu

Table 6: “Monitor” submenu

Commands

Accessing the "Monitor" submenu

Navigating within the “Monitor” submenu

Description

Access to parameter level 2 must have already been

enabled with P-14.

Use the ▲ and ▼ buttons to select parameter P-00.

Press the OK button.

The submenu with P00-01 to P00-30 will now be

→

accessible.

Hint:

The parameter range from P00-01 to P00-50 is available

in the menu for advanced users (level 3).

Use the ▲ and ▼ buttons to select parameters P00-01 to

P00-30 (or P00-01 to P00-50 in the case of level 3).

Exiting the “Monitor” submenu

Press the OK button to confirm.

Press the OK button (several times if necessary).

→

Only parameter P-00 will be available now.

10 DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com

2.6 Control via keypad

Table 7: Control via keypad

Button Attribute ID

OK P-12 = 1 or = 2

START

2 HMI device

2.6 Control via keypad

Explanation

• P-12 = 1: one operating direction (FWD)

• P-12 = 2: two operating directions (FWD/REV)

Starts the variable frequency drive

▲ Increase speed

▼ Decrease speed

START

OK

STOP

Hint:

In this mode, a high-level signal must be applied at terminal 2 (DI1) as an enable signal for the DC1 variable

frequency drive.

Changes the operating direction if the motor is running

Hint:

Only if P-12 = 2

Changes the value being displayed: A, rpm, etc.

Stops the variable frequency drive

DC1…E1 Variable Frequency Drives 11/16 MN040022EN www.eaton.com 11

Loading...

Loading...