Instruction Leaflet IL01203001E

Effective April 2011

Supersedes IL01203001EH06 7/08

Installation Instructions for Series C F-Frame 310+

Electronic Circuit Breaker Types FDE, HFDE, FDCE

Contents

Description Page

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation

Manual Operation . . . . . . . . . . . . . . . . . . . . . . . . . 4

Inspection & Field Testing . . . . . . . . . . . . . . . . . . . 4

Trip Unit Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Neutral Current Sensor Installation . . . . . . . . . . . . 6

FDE Zone Interlocking System . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Instruction Leaflet IL01203001E

Effective April 2011

Installation Instructions for Series C F-Frame 310+

Electronic Circuit Breaker Types FDE, HFDE, FDCE

DWARNING

DO NOT ATTEMPT TO INSTALL, TEST, OR PERFORM MAINTENANCE ON

EQUIPMENT WHILE IT IS ENERGIZED. DEATH OR SEVERE INJURY AND/

OR SUBSTANTIAL PROPERTY DAMAGE CAN RESULT FROM CONTACT

WITH ENERGIZED EQUIPMENT. BEFORE INSPECTING THE CIRCUIT

BREAKER IN AN ELECTRICAL SYSTEM, MAKE SURE THE CIRCUIT BREAKER

IS SWITCHED TO THE OFF POSITION AND THAT THERE IS NO VOLTAGE

PRESENT WHERE WORK IS TO BE PERFORMED. ALWAYS FOLLOW

GENERALLY ACCEPTED SAFETY PROCEDURES.

EATON IS NOT LIABLE FOR THE MISAPPLICATON OR MISINSTALLATION

OF ITS PRODUCTS.

The user is cautioned to observe all recommendations, warnings

and cautions relating to the safety of personnel and equipment, as

well as all general and local health and safety laws, codes and procedures.

The recommendations and information contained herein are based

on Eaton experience and judgement, but should not be considered

to be all-inclusive or covering every application or circumstance

which may arise. If any questions arise, contact Eaton for further

information or instructions.

1. Introduction

The F-Frame electronic Circuit Breaker (Figure 1) is available in the

3-pole style with three rated currents (80A, 160A, 225A) and four

electronic tripping options. For single-phase ground fault applications, both the supply and return must be routed through the

Breaker. Throughout this document, the electronic circuit breaker

will be referred to as a breaker. The circuit breaker is equipped with

an electronic sensing and tripping mechanism which makes the

inverse time delay release independently of ambient temperature.

A thermal memory is incorporated which prevents power operation

immediately after an overload trip.

2. Installation

The installation procedure consists of inspecting and mounting the

breaker, connecting and torquing the line and load terminations, and

attaching terminal shield or barriers when supplied. To install the

breaker, perform the following steps.

NOTICE

THE BREAKERS ARE FACTORY SEALED. ACCESSORY INSTALLATION

SHOULD BE DONE BEFORE THE BREAKER IS MOUNTED AND CONNECTED.

Mounting hardware and unmounted terminations (where required)

are supplied in separate packages.

Make sure that the breaker is suitable for the installation by comparing nameplate data with system requirements. Inspect the breaker

for completeness and check for damage before mounting.

DWARNING

BEFORE MOUNTING THE BREAKER IN AN ELECTRICAL SYSTEM,

MAKE SURE THERE IS NO VOLTAGE PRESENT WHERE WORK IS TO BE

PERFORMED. THE VOLTAGES IN ENERGIZED EQUIPMENT CAN CAUSE

INJURY OR DEATH.

Depending on the equipment configuration, the breaker can be

mounted using different styles of hardware. The following steps

describe how to mount the breaker using standard hardware. When

special hardware is needed with the electrical operator, for example,

the instruction leaflet describing the accessory also describes the

special mounting arrangements.

NOTICE

BEFORE MOUNTING THE BREAKER, CHECK TO SEE IF THE TERMINATION

DEVICES SHOULD BE INSTALLED FIRST. SEE TERMINATION INSTRUCTIONS.

Figure 1. F-Frame 310 + Electronic Circuit Breaker.

The electronic options include with or without ground fault and

a linear of I2t response for the short delay time. The LS and LSG

(catalog suffixes 33 and 35) have an I2t response for the short delay

time function. The LSI and LSIG (catalog suffixes 32 and 36) have a

flat response for the short delay time function. The LSG and LSIG

include the ground fault function. The LSI and LSIG configurations

also have a zone interlock option which are specified with the 32ZG

and 36ZG catalog suffixes. These breakers are designed to comply

with Underwriters Laboratories, Inc. Standard UL-489 and Canadian

Standards Association CSA-22.2.

To mount the breaker, perform the following steps:

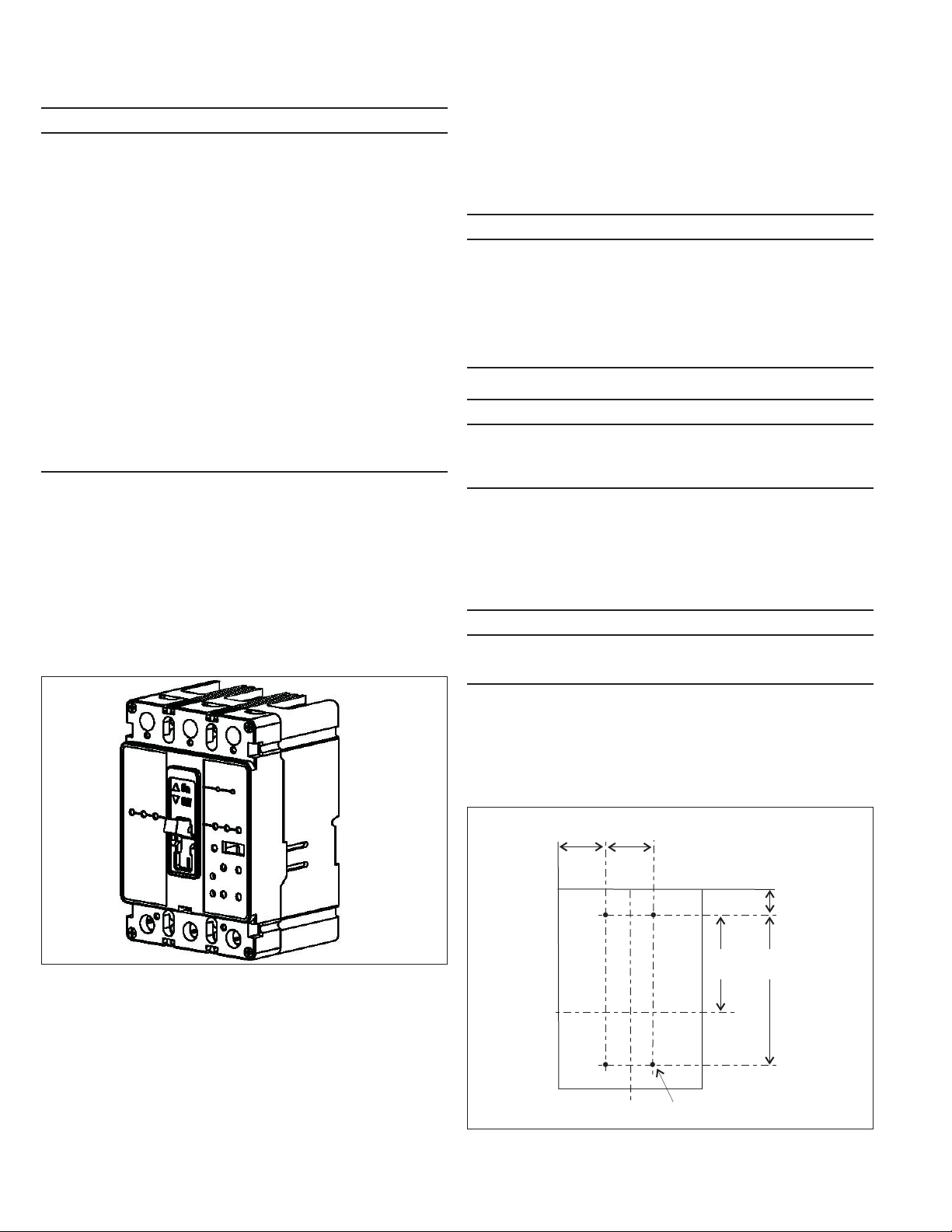

1. For individual mounting panels, make sure the mounting panel

is predrilled using bolt drilling plan (Figure 2). For panel board

mounting, only load end support mounting holes are required.

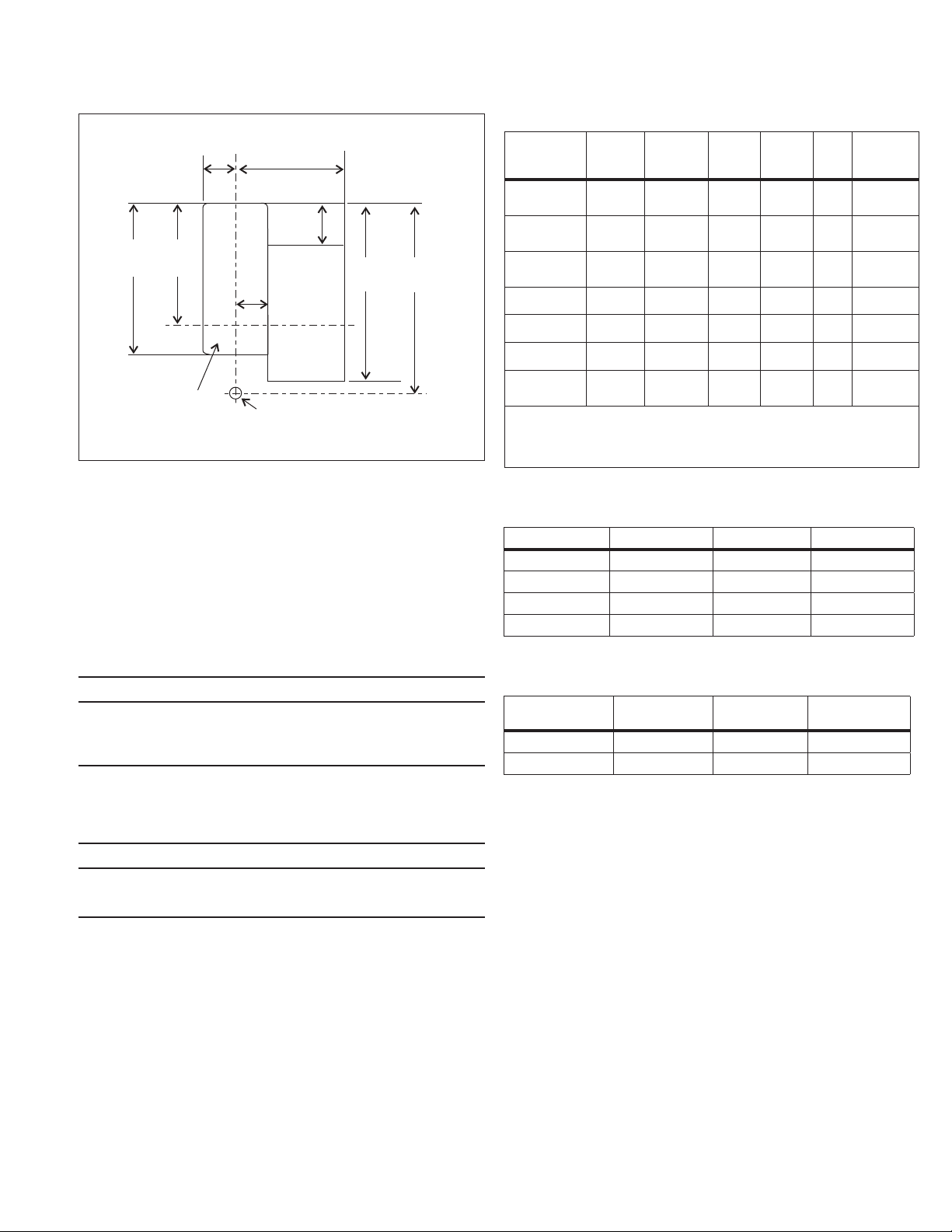

For deadfront cover application, make sure panel cover is cut out

to correct escutcheon dimensions (Figure 3).

1.375

(34,93)

Line

End

Breaker

Handle

Load

End

Figure 2. Breaker Mounting Bolt Drilling Plan.

1.375

(34,93)

1.375

(34,93)

2.875

(73,03)

164-.32 Tap Holes

(M4 x .07)

750

(19,05)

4.500

(11,43)

2

EATON CORPORATION www.eaton.com

Installation Instructions for Series C F-Frame 310+

Electronic Circuit Breaker Types FDE, HFDE, FDCE

Instruction Leaflet IL01203001E

Effective April 2011

.594

(15,09)

2.00

(50,98)

Line End

.80

(20,3)

2.906

(73,81)

2.313

(58,75)

3.40

(86,4)

3.40

(86,4)

3.64

(92,5)

Breaker

Handle

Load End

R250

(6,35)

ø

.188

(4,78)

Hole for access to Push-to-Trip

Figure 3. Breaker Escutcheon Dimensions.

2. If the breaker includes factory installed internal accessories,

make sure accessory wiring can be reached when the breaker is

mounted.

3. Position the breaker on the mounting surface.

4. Install mounting screws, washers and nuts. Tighten screws firmly, but do not exceed 28 pound-inches (3.16 N.m.)

If an optional terminal end cover is to be installed with the breaker

(usually line end only), it must be positioned before the cable is connected to terminals.

Table 1. Terminal Types.

Terminal

Catalog No.

3TA225FD * Aluminum 3/16

3TA225FDM * Aluminum 5mm

3TA225FDK * † Aluminum 5/16

3TA100FD * Aluminum Slotted #14-1/0 2.5-50 Cu/Al See Table 2.

3TA50FB * Aluminum Slotted #14-#4 2.5-16 Cu/Al See Table 2

3T100FB * Steel Slotted #14-1/0 2.5-50 Cu/Al See Table 2

3T150FB * Stainless

ote:N Terminal wire connectors are UL listed for standard wire size as

defined in UL 486A & UL 486B.

* Package of 3.

† Individual terminal identified as TA225FD1.

Terminal

Body

Material

Steel

Screw

Head Type

Socket Hex

Socket Hex

Socket Hex

Slotted #4-4/0 25-95 Cu

AWG

Wire

Range

#4-40 25-95 Cu/Al 120 (13.6)

#4-40 25-95 Cu/Al 120 (13.6)

#6-300 16-150 Cu/Al 275 (31)

Metric

Wire

Range

Wire

Type

only

Torque

Value lb.

in. (N-m)

See Table 2

Table 2. Terminal Torque Values of Slotted Head.

Metric Wire Range. Torque Value (N-m) AWG Wire Range Torque Value Lb in.

2.5-6 3.96 #14-10 35

10 4.52 #8 40

16-25 5.06 #6-4 45

35-95 5.65 #3-4/0 50

DCAUTION

WHEN ALUMINUM CONDUCTORS ARE USED, THE APPLICATION OF

A SUITABLE JOINT COMPOUND IS RECOMMENDED TO REDUCE THE

POSSIBILITY OF TERMINAL OVERHEATING. TERMINAL OVERHEATING CAN

CAUSE NUISANCE TRIPPING AND DAMAGE TO THE BREAKER.

After mounting the breaker, line and load terminals and accessory

leads should be connected (see accessory schematic diagram on

side of breaker).

NOTICE

IF TERMINAL SHIELD OR INTERPHASE BARRIERS ARE TO BE INSTALLED

ON THE BREAKER, INSTALL THEM AFTER THE TERMINALS ARE CONNECTED.

•

If required, install terminal shield on breaker cover with mounting

screws provided.

•

If required, install an interphase barrier by sliding barrier into dovetail grooves between terminals.

•

After the breaker is installed, check all mounting hardware and

terminal connecting hardware for correct torque loading. Torque

values for line/load terminals are provided in Tables 1, 2 and 3.

Table 3. Bolted Connections (Keeper Nut or End Cap).

Termination Catalog

No.

KPR1A/KPR1AM User Supplied 10-32/M5 35-(4.0)

KPEKxxx Slotted 10-32/M5 35-(4.0)

Screw Head Type) Nut Thread Size Torque Value Lb in.

(N-m)

EATON CORPORATION www.eaton.com

3

Loading...

Loading...